Bryant 619ENF, 619ENQ, 619ENF018, 619ENF024, 619ENF030 Installation, Start-up And Service Instructions Manual

...

installation, start-up and

619ENF

service instructions

FAN COIL UNITS

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

I. Step 1 — Complete Pre-Installation Checks . . . . . . 1

II. Step 2 — Mount Unit . . . . . . . . . . . . . . . . . . . . . . . . . 5

III. Step 3 — Complete Refrigerant Piping

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IV. Step 4 — Make Electrical Connections . . . . . . . . . . 8

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . .14,15

SAFETY CONSIDERATIONS

Installing and servicing air-conditioning equipment can be

hazardous due to system pressure and electrical components.

Only trained and qualified service personnel should install or

service air-conditioning equipment.

Untrained personnel can perform basic maintenance, such as

cleaning and replacing filters. All other operations should be

performed by trained service personnel. When working on air

conditioning equipment, observe safety precautions in literature, tags, and labels attached to unit.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for brazing operations. Have fire extinguisher available. Read these instructions thoroughly. Consult local building codes and the National Electrical Code

(NEC) for special installation requirements.

619ENQ

Sizes 018-036

Cancels: New II 619E-18-4

4/1/06

GENERAL

CAUTION: This system uses R-410A, which has

higher pressures than R-22 and other refrigerants. No

other refrigerant may be used in this system. All

equipment must be designed to handle R-410A refrigerant. If unsure about equipment, consult the equipment manufacturer.

These instructions cover the installation, start-up and service

of cooling only and heat pump duct-free systems.

INSTALLATION

I. STEP 1 — COMPLETE PRE-INSTALLATION CHECKS

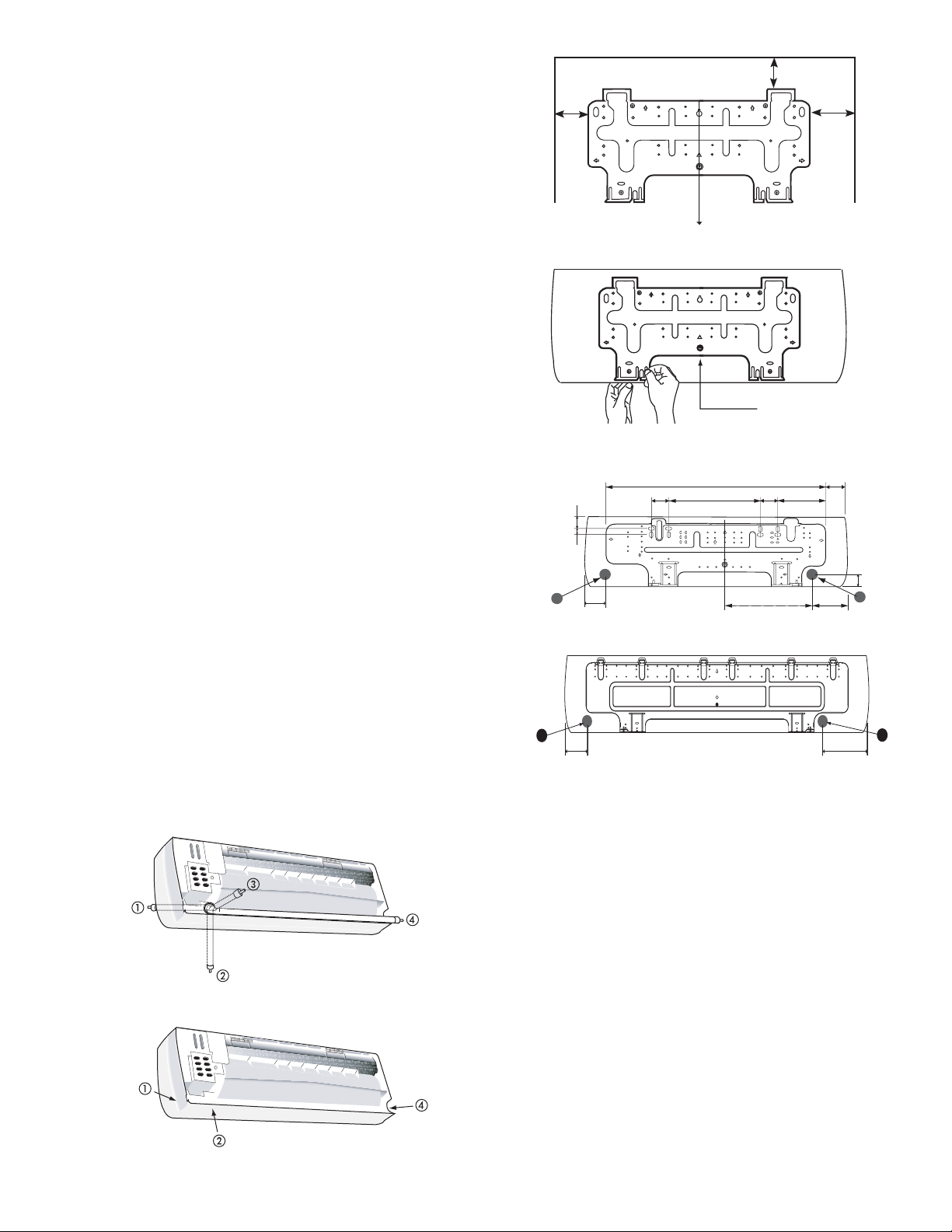

A. Unpack Units (See Fig. 1)

Move the unit to final location. Remove unit from carton,

being careful not to damage service valves and grilles. See

Table 1A for installation materials included in shipment and

see Table 1B for field supplied materials needed to complete

the installation.

B. Inspect Shipment

File a claim with the shipping company if shipment is damaged or incomplete. Check the unit nameplate to ensure unit

matches the job requirements.

C. Consider System Requirements

Consult local building codes and NEC for special installation

requirements. Use only designated indoor units with outdoor

units. See Tables 2 and 3.

WAR NING : Before installing or servicing system,

always turn off main power to system. There may be

more than one disconnect switch. Turn off accessory

heater power if applicable. Electrical shock can cause

serious personal injury.

Fig. 1 — 619ENF,ENQ Units

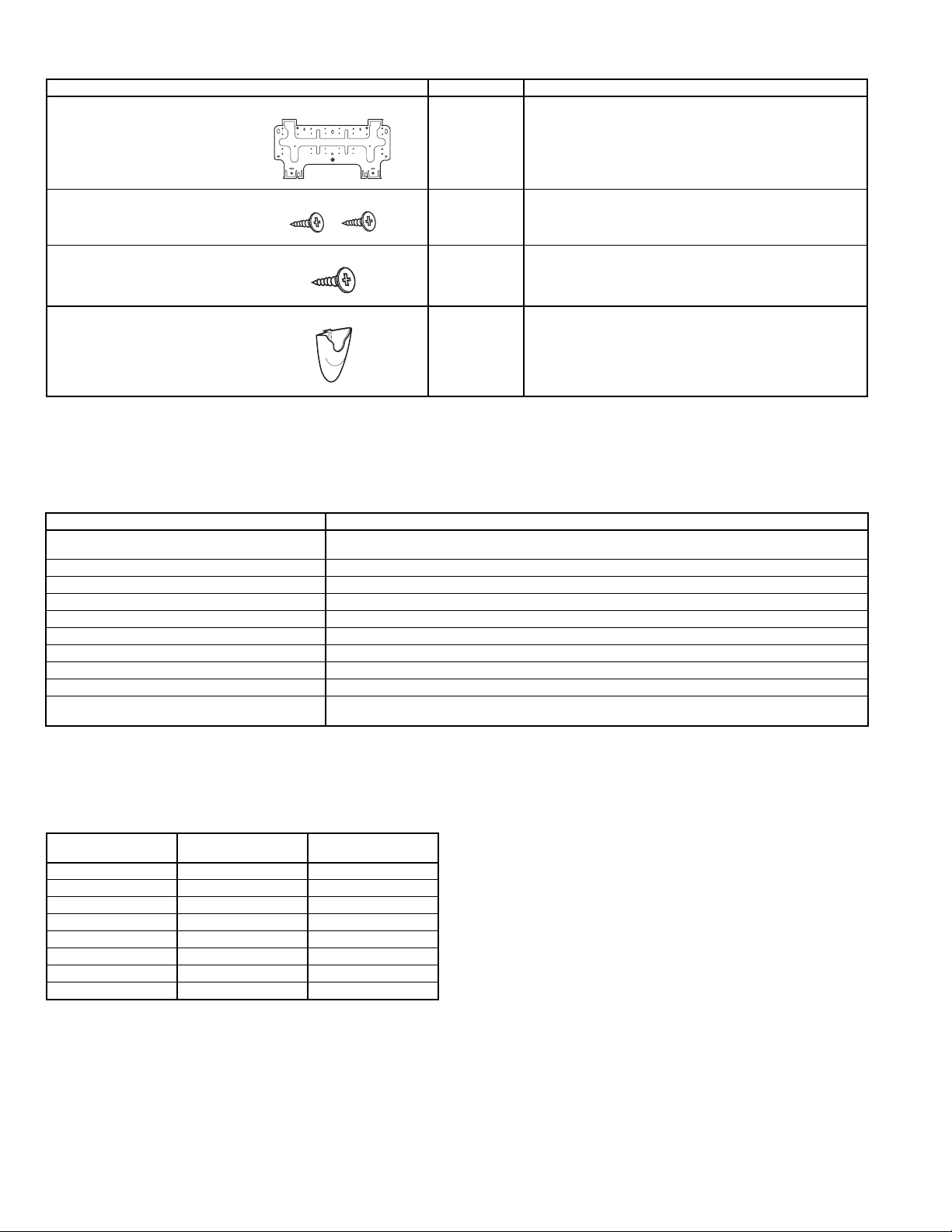

Table 1A — Installation Materials — Included In Shipment

DESCRIPTION QTY USAGE

Wall Hanging Bracket 1 For indoor unit installation.

Screws, 4xL10 2 For affixing unit and hanging bracket.

Screws, 5xL25 5/14*

Wireless Remote Control

Mounting Bracket

*619ENF01824, 619ENQ018,024: 5

619ENF,ENQ030,036: 14

Table 1B — Installation Materials — Field-Supplied

NAME SPECIFICATIONS

Connection Pipe (nominal capacity)

Wall Sleeve —

Wall Cap —

Finishing Tape PVC Film

Fastening Tape —

Pipe Insulation —

Drain Hose

Sealer Putty —

Power Supply Cable AWG 14 or higher

Electrical Connecting Cable Between

Indoor and Outdoor Unit

LEGEND

AWG — American Wire Gage

NEC — National Electrical Code

Liquid line:

Mixed Phase line:

5

/8 in. (619ENF01824 and 619ENQ018,024) 3/4 in. (619ENF,ENQ030,036)

Cable Type: AWG 14 synthetic rubber insulation with Neoprene coating, according to NEC codes.

3

/8 in. (619ENF,ENQ018-036)

5

/8 in. (619ENF01824 and 619ENQ018,024), 3/4 in. (619ENF,ENQ030,036)

For wall hanging bracket installation.

For wireless remote control mounting bracket installation.

1 For wireless remote control installation.

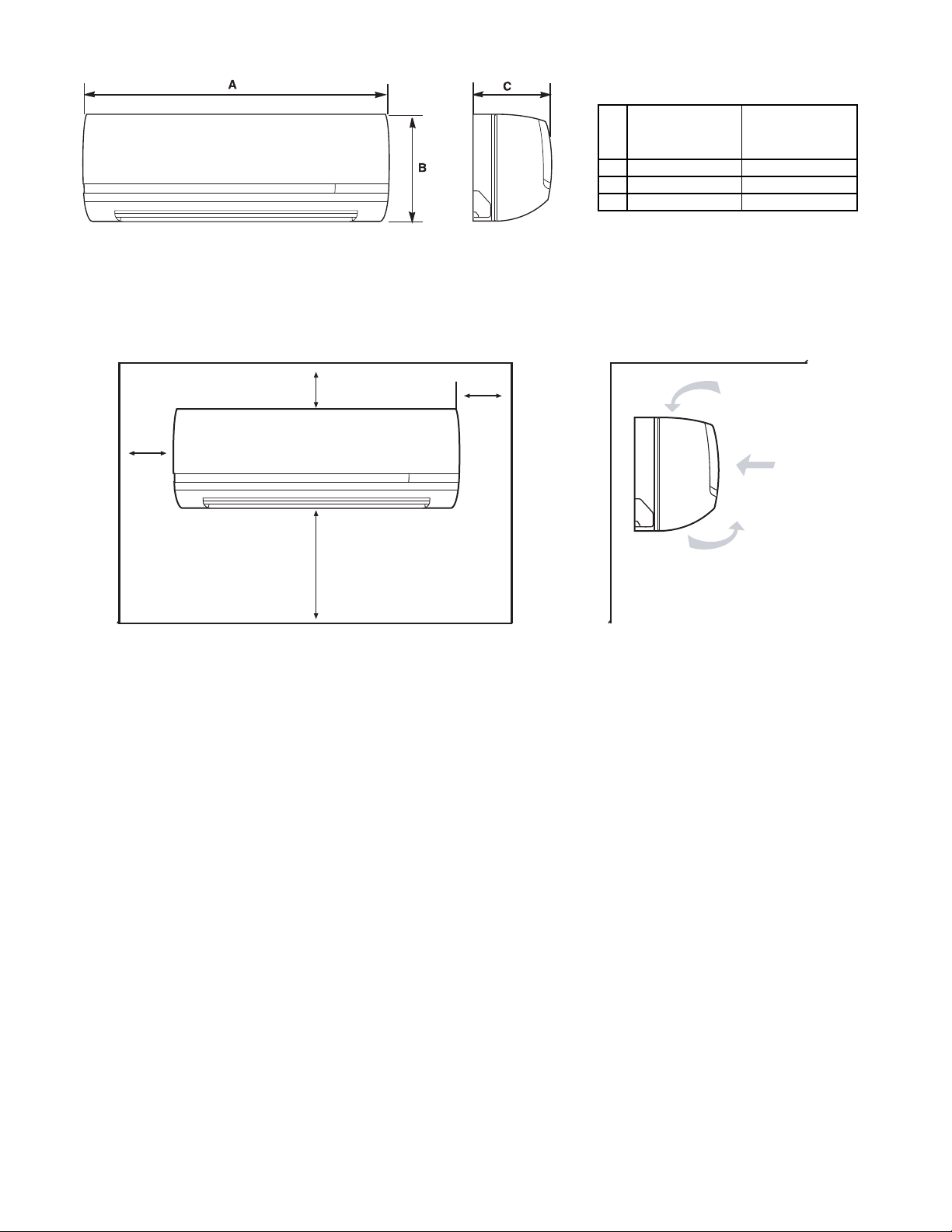

Table 2 — Matching Indoor Units to Outdoor Units See Fig. 2 for unit dimensions. Allow sufficient space for air-

OUTDOOR UNIT

538ENF018 Cooling Only 619ENF01824

538ENF024 Cooling Only 619ENF01824

538ENF030 Cooling Only 619ENF030

538ENF036 Cooling Only 619ENF036

538QNF018 Heat Pump 619ENQ018

538QNF024 Heat Pump 619ENQ024

538QNF030 Heat Pump 619ENQ030

538QNF036 Heat Pump 619ENQ036

COOLING ONLY OR

HEAT PUMP

INDOOR UNIT

flow clearance, wiring, refrigerant piping, and servicing

units. See Fig. 3.

Avoid mounting the unit in areas that are:

• exposed to direct sunlight

• too close to heat sources

• too close to humid conditions

• located in an area with oily ambient conditions.

—2—

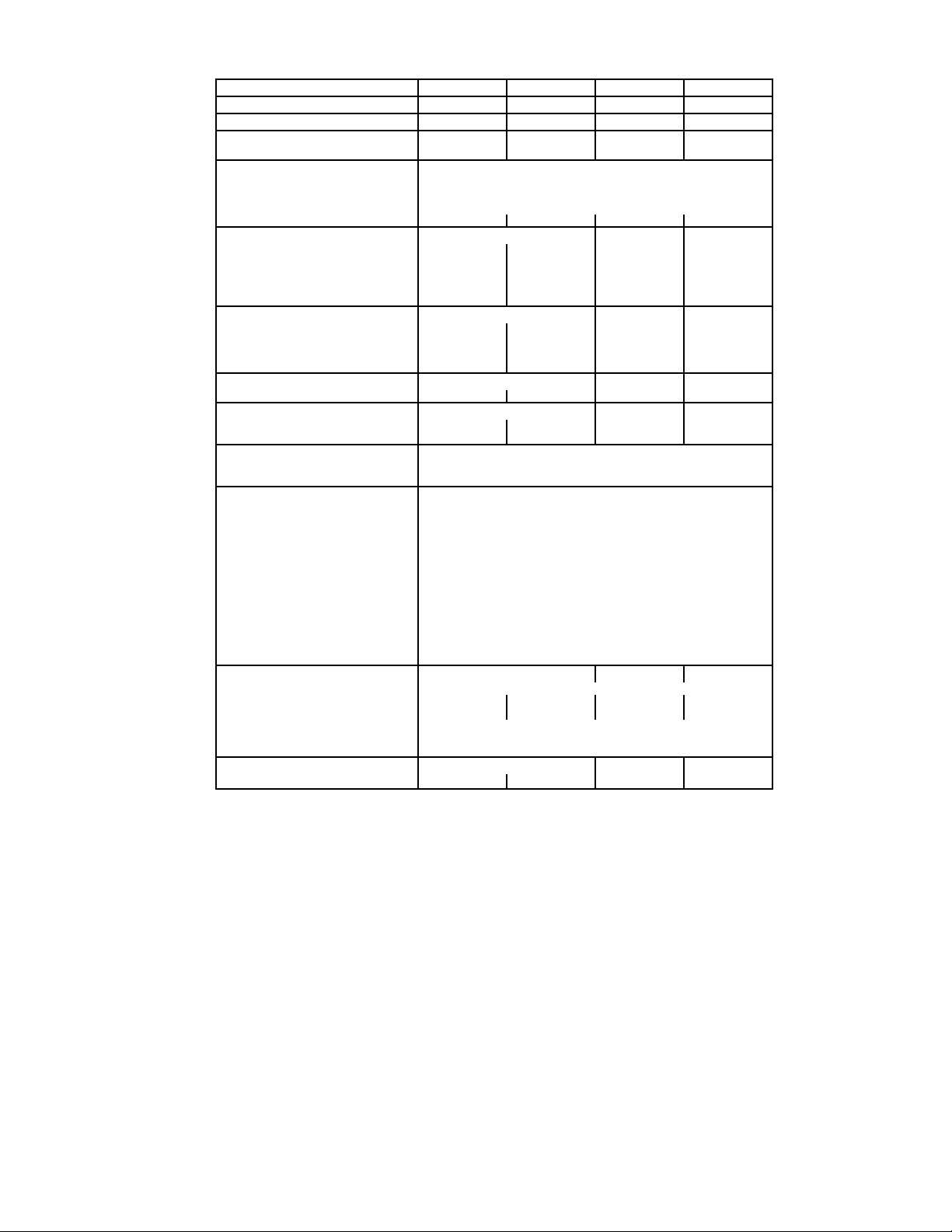

Table 3 — Indoor Unit Physical Data

SYSTEM SIZE 018 024 030 036

NOMINAL CAPACITY (Btuh) 18,000 24,000 30,000 36,000

OPERATING WEIGHT (lb) 31 31 51 51

MOISTURE REMOVAL RATE

(Pints/hr) (619ENF/ENQ)

REFRIGERANT

Type R-410A

Control Device (Cooling) Accurator Piston at Outdoor Unit

Control Device (Heating) Accurator Piston at Outdoor Unit

System Charge Required (lb)* 6.0 6.3 7.4 10.5

INDOOR FAN

Rpm/Cfm (High) 1335/645 1335/645 1030/730 1200/900

Rpm/Cfm (Med) 1120/525 1120/525 930/630 1050/750

Rpm/Cfm (Low) 1000/460 1000/460 830/530 900/600

Motor Watts 64 64 74 74

Blowers Quantity...Size 1...4.0 x 33.7 1...4.0 x 33.7 2...4.2 x 23.5 2...4.2 x 23.5

INDOOR COIL

Face Area (sq ft) 3.0 3.0 4.9 4.9

No. Rows 2222

FPI (619ENF/ENQ) 16/16 16/20 18/18 18/18

Circuits 5599

FILTERS

Quantity...Size (in.) 2...12.5 x 16.1 2...12.5 x 16.1 3...17.3 x 16.1 3...17.3 x 16.1

AIR SWEEP

Horizontal Manual Manual Automatic Automatic

Vertical Automatic Automatic Automatic Automatic

OPERATING LIMITS

Heating (Min/Max) —/81 F db

Cooling (Min/Max) 59 F wb, 70 F db/74 F wb, 90 F db

CONTROLS Integrated Microprocessor

Remote Controller Options Wireless, CRC

Diagnostics Ye s

Defrost Method Demand Defrost

Timer Mode Ye s

Warm Start Feature Ye s

Test Mode Ye s

Freeze Protection Ye s

Dehumidification Mode Ye s

Fan Mode Yes

Auto Changeover Ye s

Auto Restart Ye s

Control Voltage 24v

System Voltage 208/230

REFRIGERANT LINES

Connection Type Flare

Mixed Phase Line (in.) OD

Vapor Line (in.) OD

Max Length (ft) 200

Max Lift (Fan coil above) (ft) 60

Max Drop (Fan coil below) (ft) 60

CONDENSATE DRAIN

Size (in.)

LEGEND

CRC — Carrier Room Controller

db — dry bulb

FPI — Fins Per Inch

wb — wet bulb

*Factory charge is based on 25 ft of interconnecting line.

5.4/5.2 7.9/7.9 8.8/9.2 13.0/12.8

3

/

8

5

/

8

5

/8 OD, 7/16 ID

3

/

8

5

/

8

5

/8 OD, 7/16 ID3/4 OD, 5/9 ID3/4 OD, 5/9 ID

3

/

8

3

/

4

3

/

8

3

/

4

—3—

619ENF,ENQ

Fig. 2 — Unit Dimensions

619ENF01824

619ENQ018,024

DIMENSIONS

(in.)

619ENF,ENQ

030, 036

DIMENSIONS

(in.)

A 42.5 57.5

B 11.6 13.4

C 7.9 9.5

4 in.

min.

4 in.

min.

80 in.

min.

8 in.

min.

619ENF,ENQ UNITS

Fig. 3 — Unit Clearances

—4—

II. STEP 2 — MOUNT UNIT

Before mounting the 619ENF,ENQ unit on the wall with a

wall hanging bracket, consider how the unit will be

connected to the refrigerant piping. The indoor unit can be

connected in four ways. Refer to Fig. 4 for connection options.

When the piping is connected to points 1, 2 or 4, remove the

knockout either at the side or at the bottom of the unit.

The indoor units are mounted on the wall with a wall hanging bracket. Position the wall hanging bracket so that it is

flush with the wall. See Fig. 5 for service clearances. See

Fig. 6 for wall bracket dimensions.

Complete the following when installing the wall hanging

bracket:

1. Before installing the wall hanging bracket to the wall

remove it from the indoor unit by pushing at the indicated pressure points at the bottom of the unit.

2. Install the wall hanging bracket in a location that is

strong enough to withstand the weight of the unit.

3. Install the wall hanging bracket so that it is level.

Use a plumb line if necessary.

NOTE: Be sure that the wall hanging bracket is level. If the

wall hanging bracket is not level water will leak from the

indoor unit.

4. Fasten the wall hanging bracket to the wall with 4 or

more screw anchors through the holes near the outer

edge of the bracket.

5. Install the wall hanging bracket flush to the wall,

and ensure the bracket does not move.

6. If the unit is removed from the wall hanging bracket

after installing it on to the wall, remove it by pushing up

on the indicated marks at the bottom of the unit body.

III. STEP 3 — COMPLETE REFRIGERANT PIPING

CONNECTIONS

When running the piping for indoor units the piping can be connected as rear piping or side or bottom piping. Refer to Fig. 4.

A. Rear Piping

Route the piping behind the indoor unit so that the piping is

concealed by the unit. For rear piping installation drill a

1

/2 in. diameter hole in the wall at point A or B in Fig. 6. Drill

2

the hole at a slope so that the outside end is lower (

1

/2 in.) than the inside end to ensure optimal drainage. Refer

1

/4 in. to

to Fig. 7. Pass the pipe through the hole.

Fig. 4 — Indoor Unit Piping Configurations

5 in. min.

12 in.

min.

Plumb line

Remove Screw

Fig. 5 — Installing the Wall Bracket

2.1"

1"

2"

A

A

2"

35.4"

2.8"

619ENF01824, 619ENQ018,024

619ENF, ENQ030,036

14.9"

2.8"

13.8

18 in.

min.

3.5"

7.7"

2.1"

B

5.1

"

"

B

5.1"

Fig. 6 — Wall Bracket Dimensions

B. Side or Bottom Piping

Remove the knockout in the unit and pass the piping

through the wall. The pipe should slope downward and away

from the unit to ensure optimal drainage.

C. Routing the Drain Hose and Refrigerant Piping

The drain hose and drain cap are assembled as shown in

Fig. 8 in the factory. To do right-side (1), right-bottom (2) or

right-back (3) piping in Fig. 4 draw the drain hose to rightside piping direction. (It is not always necessary to exchange

the location of drain hose and drain cap.)

1. Tie together the refrigerant piping, the drain hose,

and the electrical connection wire.

2. Route the refrigerant piping in the required direction, and bend carefully avoiding pipe deformation.

3. Bind the drain hose and the electrical connection

wire together with fastening tape.

4. The drain hose should be at the bottom. See Fig. 9

and 10.

5. For left-hand piping, fit the pipes and the wiring into

the recess at the back of the unit.

—5—

Loading...

Loading...