Page 1

installdt^n, start-up and

service instructions

UNDER CEILING FAN COIL UNITS

619C

Sizes 024-048

2 to 4 Tons

CONTENTS

Page

SAFETY CONSIDERATIONS

INSTALLATION

I. Complete Pre-Installation Checks ..............................2

II. Select Location

III. Mount Unit

IV. Connect Refrigerant Piping

V. Connect Condensate Drain Line

VI. Make Electrical Connections

VII. Install Control................................................................8

VIII. Connections to Outdoor Unit.......................................9

START-UP..............................................................................9-12

I. After Extended Shutdown

II. Seasonal Changeovers

III. Adjusting Airflow

IV. Operating Mode Memory............................................11

V. Automatic Operation (Auto.) Mode

VI. Operating Fault Diagnosis.........................................11

VII. Operation of Microprocessor Control

CLEANING AND MAINTENANCE.......................................12,13

SERVICE..................................................................................14

TROUBLESHOOTING

NOTE: Detailed controls, service, and troubleshooting

......................................................................

.....................................................................

....................................................

.............................................................

.........................................

................................

.......................................

...........................................

................................................

........................................................

.......................

.....................

........................................................

14-17

1

1-9

3

3

3

5

8

9

9

11

11

11

information is in a separate manual, available from your

distributor.

Cancels: New

II 619C-24-1

7/1/92

INSTALLATION

The 619C under ceiling fan coil unit is installed with the 700C

outdoor condensing unit, or the 705C heat pump (Fig. 1). Re

fer to Table 1 to make sure the correct indoor unit is in

stalled with the correct outdoor unit.

Fig. 1 — 619C Under Ceiling Fan Coil Unit

Table 1 — System Combinations for Indoor

and Outdoor Units

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment can be

hazardous due to system pressure and electrical compo

nents. Only trained and qualified service personnel should

install or service air conditioning equipment.

Untrained personnel can perform basic maintenance, such as

cleaning and replacing filters. All other operations should be

performed by trained service personnel. When working on air

conditioning equipment, observe precautions in literature, tags,

and labels attached to unit.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for brazing operations. Have fire extin

guisher available. Read these instructions thoroughly. Con

sult local building codes and National Electrical Code (NEC)

for special installation requirements.

SPLIT

SYSTEM UNIT UNIT

Under Ceiling Cooling Only System

535BNC024 619CNX0240E0 700CNX024

535BNC036

535BNC048 619CNX0480E0

Under Ceiling Heat Pump System

635ANC024

635ANC036

635ANC048 619CNX0480W0 705CNX048000

INDOOR OUTDOOR

619CNX0360E0

619CNX0240W0

619CNX0360W0

700CNX036

700CNX048

705CNX024000

705CNX036000

Installation instructions for 619C fan coils are contained in

this manual. Refer to this manual for proper installation of

the complete system. Note that the 700C and 705C outdoor

units are shipped with installation and service instructions

for basic installation of the outdoor section.

Be sure the unit will be operated within the application guide

lines shown in Table 2. When installing the 700C or 705C

unit, it is important to note that for cooling operation when,,

the outside air temperature is below 55 F, it is necessary to

equip the outdoor unit with the low-ambient control

accessory.

Page 2

■À

To install this system you will need:

1 — 619C fan coil

1 — 700C or 705C outdoor unit

1 — Remote controller kit (included with 619C fan coil) —

note that kit normally includes 15-ft long wire cable;

however, cable length up to 200 ft can be ordered.

1 — Low Ambient Kit (if required for your application)

1 — Check-Flo-Rater™ Metering Device Kit (included with

619C fan coil)

1 — Fresh-Air Intake Kit (if required for your application)

1 — Condensate Pump Kit (if required for your application)

NOTE: Refrigerant pipe, drain pipe, wire, etc., are also re

quired to install system.

Be sure you have the required parts before beginning instal

lation. The 619C unit utilizes a microprocessor control sys

tem to deliver optimal levels of comfort and efficiency. Be sure

to follow these instructions carefully to obtain proper func

tioning of the unit.

Table 2 - Application Range

COOLING

Maximum

Indoor

95 F DB

71 F WB

Maximum

Indoor

80 F DB

71 F WB

LEGEND

DB — Dry Bulb

WB - Wet Bulb

'Unit may be equipped with a iow-ambient control that will allow

operation down to ~20 F

I. COMPLETE PRE-INSTALLATION CHECKS

A. Unpack Unit

Outdoor Indoor

125 F DB

HEATING

Outdoor Indoor

75 F DB

65 F WB

57 F WB

Minimum

Outdoor

67 F DB

Minimum

55 F DB -20 F DB

55 F DB*

Outdoor

Store unit in the original packaging until it is moved to the

final site for installation. When removing unit from carton,

lift unit by its 4 corners; DO NOT lift unit by its plastic parts.

B. Inspecf^hipmeiit

Upon receipt of shipment check unit for damage. Forward claim

papers directly to the transportation company. Manufac

turer is not responsible for damage incurred in transit.

Check all items; if any item is missing notify your distribu

tor. To prevent loss or damage, leave all parts in original pack

ages until installation.

C. Before Installation

Perform the following steps before installing indoor unit

(Fig. 2). Place the unit upside down on the floor, then:

1. Remove side panels by sliding forward, then away from

sides of unit.

2. Remove air filters from inlet grilles; then remove and

retain screws securing inlet grilles to indoor unit.

3. Remove inlet grilles from indoor unit by sliding

forward.

LOOSEN eOLTS AND SLIDE-

MOUNTING BRACKET THIS

DIRECTION—TO REMOVE

2 T/8

tSSJ

DISCHARGE AIR

SLIDE SIDE PANEL THIS

OIRECTION—TO REMOVE

PIPING JOINT

(LIQUID SIDE)

PIPING JOINT

(VAPOR SIDE)

REMOVABLE AIR FILTER

NOTE: Dimensions shown in brackets [ ] are in mm

Fig. 2 — Removal of Mounting Brackets

from Indoor Unit

'-DRAIN CONNECTION

[INLET AIR

PIPING KNOCKOUT

(RIGHT SIDE)

UNIT 619C

OPERATING WT (lb)

REFRIGERANT

FAN

Rpm

High

Med

Low

Nominal Cfm (High Speed)

COIL

Rows

Face Area (sq ft)

FIns/in.

Number of Circuits

CONNECTIONS

Suction (in.) Flare

Liquid (in.) Flare

Condensate Drain (in.)

LINE SIZES

Suction (in.)

Liquid (in.)

Condensate Drain

Table 3 — Physical Data

NX0240E0 NX0360E0 NX0480E0 NX0240W0

108 117 140

R-22, Check-Flo-Rater Control

1035 1310 1345

990 1160 1307

940 1010 1270

635 935 1300

4 4 4

2.189 2.625 3 069

149 149 14.9

4

%

%

%

%

% % % 3/e

3/4

4

3/4

3/a

3/4

3/4

3/4 3/4

-2-

8 4

3/4 3/a

3/a 3/a

3/4

%

110 119 142

1035

990

940

635

4

2 189 2.625

14.9 14.9

3/4 3/4

Va 3/4

3/4

NX0360W0 NX0480W0

1310 1345

1160 1307

1010

935

4 4

4

3/4

Ve 3/a

3/a 3/a

3/4

1270

1300

3.069

14.9

8

3/4

3/4

%

3/4

Page 3

II. SELECT LOCATION

Consult local building codes and NEC for special installation

requirements.

There are several ways the unit may be installed to different

types of ceiling construction. These instructions do not cover

all installation methods. As a typical installation, these in

structions focus primarily on mounting the unit to metal in

new construction. Plan your installation carefully before you

begin. Listed below are some guidelines that should be fol

lowed when determining location for the unit.

1. Place unit adjacent to an outside wall if fresh air is re

quired, ensuring that location allows for complete air

distribution.

2. Determine a convenient and accessible location to mount

the wired remote controller. Note that because the con

troller is not used to sense room conditions, it is not nec

essary to consider this factor when determining the

controller location.

The controller cable can be routed through walls and does

not need to be surface mounted. For additional informa

tion on remote controller, see separate controller kit in

stallation instructions.

3. Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit (Fig. 3).

4. Make sure the unit is easily accessible to electrical power.

5. Run refrigerant piping as directly as possible, avoiding

any unnecessary turns or bends.

6. Condensate piping can be directed through the inside

wall to an approved drain, or directed straight outside.

NOTE: The piping hole for condensate line must slope at a

minimum pitch of 1 in. per 10 ft to ensure proper drainage. If

proper pitch cannot be achieved, install accessory conden

sate pump at this time.

NOTE; The accessory condensate pump should be installed

before hanging the unit.

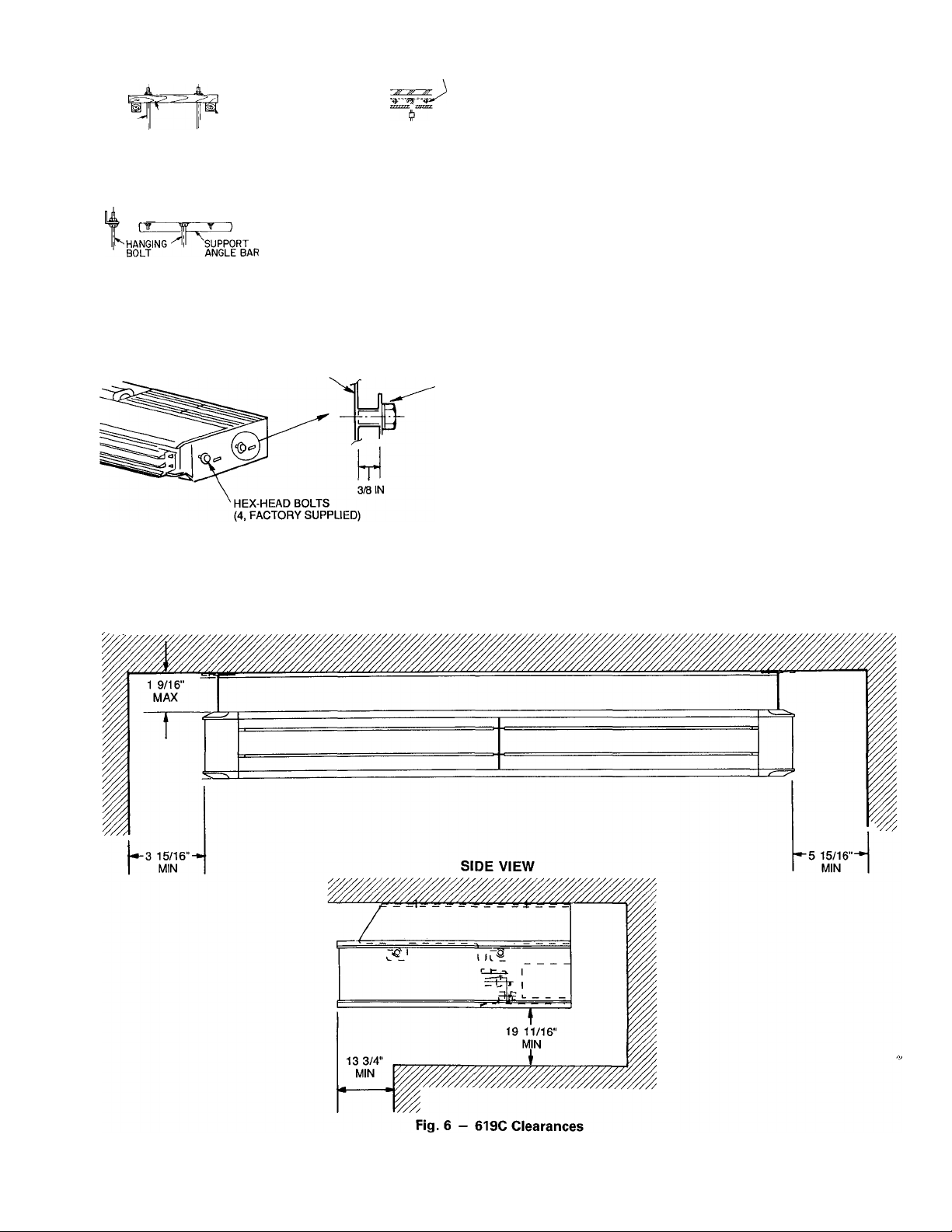

2. Determine installation position, paying particular at

tention to piping lengths and wiring connections, clear

ances, etc. See Fig. 3 for connection locations. Fig. 6 for

clearances, and Fig. 7 and 8 for bolt locations.

3. Open knockout if right-side piping connections are re

quired (Fig. 9).

4. Cut the slit portion in rear of the side panel with a saw

or cutter knife. (Fig. 9).

If indoor unit accessory louver guard is to be installed, in

stall at this time and refer to installation instructions pack

aged with this accessory.

5. Mount hanging brackets on ceiling (Fig. 10) for either

concealed or exposed bolt hanging position.

6. Lift the unit into place, and fit the hex-head bolts on

sides of indoor unit into slit grooves of mounting brack

ets (Fig. 11). Ensure unit is mounted level to assure proper

drainage.

7. Tighten bolts securely.

IV. CONNECT REFRIGERANT PIPING

Fan coil units may be connected to condensing units using

field-supplied refrigerant grade piping. Refer to Table 3 for

the correct size piping. The length of refrigerant pipe de

pends on the unit placement and building structure; keep in

mind to run pipes as directly as possible. For piping require

ments over 50 ft of total run, or more than 25 ft of lift, con

sult the long line application guidelines available from your

distributor.

III. MOUNT UNIT

Refer to Fig. 6 for clearances and dimensions. Use mounting

template included inside box to locate mounting bolt holes,

piping holes, electrical connections, and accessory outdoorair intake, if used.

Select proper type of hardware from the guidelines below. See

Fig. 4.

Wooden Structure

Install hanging bolts on a square wooden piece placed over

beams.

Newly Built Concrete Slab

Install hanging bolts with inserts, embedded bolts, etc.

Metal Structure

Install hanging bolts utilizing an existing angle or by install

ing a new support angle.

Previously Built Concrete Slab

Install hanging bolts with expansion anchor.

A. To Mount Unit:

1. Remove mounting bracket and reinstall the 2 hex-head

bolts (factory supplied) into each side of indoor unit as

shown in Fig. 5. Allow approximately 3/8-in. space be

tween bolt head and unit.

Use the following instructions to connect piping.

1. Install insulation. Insulate all refrigerant lines on heat

pumps to prevent condensation. It is extremely impor

tant that all refrigerant lines and the Check-FloRater"' metering device be insulated on heat pumps. On

cooling only units, the liquid line may be left uninsu

lated. Use any acceptable heat resistant closed-cell foam

insulation (minimum 3/8-in. wall thickness). When in

sulating piping, cap ends and slide insulation over the

piping. Insulation can also be cut and placed over

piping.

2. Run liquid and gas refrigerant piping.

a. Run pipes as directly as possible, avoiding any un

necessary turns and bends.

b. Suspend refrigerant pipes so that the insulation is

not damaged and vibrations are not transmitted to

the structure.

c. Leave slack in the refrigerant pipe between the struc

ture and the unit to absorb vibrations.

d. Install flare connection on tubing to liquid line at fan

coil (Fig. 12). The correct piston size is shipped in ths

Check-Flo-Rater body with 619C units. If you have

any questions, use Table 4 to determine required pis

ton size for the system being installed. The arrow on

the metering device body must face away from the

indoor coil.

-3-

Page 4

f8J

9 15/16

f253J I

6 9/16

[167J

-2 II/J6

f69J

UNIT 619C

024

036

048

UNIT 619C

024

036

048

NOTESI

I. OÍMENS/ONS IN [ J ARE MÍLL/METERS.

DIRECT/ON OF AIR FLOW.

DIMENSIONS (in.)

571/2

70/4

E

B

53% evs

665/s

F G

—

—

201/4 371/2

A

5015/16 46

58'3/, 6

713/16

495/8

C

6V8 7%

7%

7%

6%

201/16

2315/16

FRONT VIEW

LOOSEN BOLTS AND SLIDE

MOUNTING BRACKET TH/S

D1RECT10N-»TO REMOVE

SIDE PANEL

D

DISCHARGE AIR

SLIDE SIDE PANEL THIS

DIRECT lON^o-TO REMOVE

PIPING JOINT

(LIQUID SIDE)

PIPING JOINT

REMOVABLE AIR FILTER

Fig. 3 — 619C Dimensional Drawing

-4-

(VAPOR SIDE)

DRAIN CONNECTION

INLET AIR

SIDE VIEW

PIPING KNOCKOUT

(RIGHT SIDE)

Page 5

(SLIDE INSERT)

HANGING I BRACE

BOLT

I WOODEN

WOODEN STRUCTURE

^HANGER BOLT

IL à

METAL STRUCTURE PREVIOUSLY

Fig. 5 - instaliing Hex-Head Mounting Boits

REAM (EDGE SHARP

“ INSERT)

NEWLY BUILT CONCRETE SLAB

Fig. 4 - 619C Unit-Mounting Methods

(Hardware is Fieid Suppiied)

INDOOR UNIT

in 619C Unit

(EMBEDDED BOLT

OF PIPING)

BUILT CONCRETE SLAB

REINFORCING

BAR«

"‘embedded

BOLT

^EXPANSION

ANCHOR

BOLT

e. On heat pump installations check for factory-installed

piston in service valve. If not already installed, in

stall piston in the metering device located in the ser

vice valve on the outdoor unit (Fig. 13). Make sure

Teflon seal on the piston faces toward the outdoor unit.

Use Table 4 to determine required piston size for the

system being installed.

f Refer to 700C and 705C installation, start-up and ser

vice instructions for additional information.

g. Install a liquid line filter drier near the outdoor unit.

On heat pump systems, a bi-flow filter drier must be

used.

3. Insulate and caulk wall openings to reduce air infiltra

tion and refrigerant pipe vibrations on structure.

4. Evacuate piping, if necessary. If either refrigerant pip

ing or the indoor coil is exposed to atmospheric condi

tions for longer than 5 minutes, it must be evacuated to

1000 microns to eliminate contamination and moisture

in the system.

V. CONNECT CONDENSATE DRAIN LINE

Observe all local sanitary codes when installing condensate

drains. Refer to Fig. 3 and 14 for drain hose connection from

indoor unit.

1. Use hard polyvinyl chloride (PVC) pipe material with

nominal ID of 3/4 in. to connect at drain line. Use pipe

insulation 1/4-in. thick, such as Armaflex insulation, on

exposed piping inside the conditioned space.

FRONT VIEW

-5-

Page 6

CONCEALED MOUNTING

HOLE FOR HANGING BOLT

4 -1/2" X 1" SLOTS

EXPOSED MOUNTING

HOLE FOR HANGING BOLT

4 -1/2” X 1" SLOTS

SIDE VIEW OF RIGHTSIDE PANEL

ri-|='C io

T

3 5/8"

IV" !

21

_____1______

i

1-

--------------

UNIT 619C

024

036

048

Fig. 7 — 619C Unit Hanging Dimensions

TOP

11 IN

REAR

NOTE: Dimensions are found in Fig. 7.

Fig. 8 — Mounting Template Included with 619C Unit

B

A

IQ

________

>1

DIMENSIONS (in.)

A

50'5/i6 46

58'3/i6 53%

718/16 66%

B CONCEALED MOUNT -

------

D EXPOSED MOUNT -

23 5/8”

oo

T

IT

r -................................1

1

1

---------------D-----------------

h

---------------A----------------

B C

D

6'/8

6'/8

7% 70V4

49Vb

57V2

POSITION OF

HANGING

BOLT

(3/8 IN DIA.

HOLE)

. FOLD

TEMPLATE

ON DOTTED

LINE

:«i' 1 u-fi

1

-

Fio. 9 — Removina Rear Knockout

If Right-Side Piping Connection is Used

1

rtrr 1

iliC - -------------

CUTTHESUT

PORTION IN REAR

OF PANEL WITH

A SAW OR CUTTER

KNIFE

2. To ensure regular flow of condensate water, the drain

pipe should be pitched toward an open drain or sump at

a downward slope of at least 1/4-in. per foot.

3. Secure drain pipe with nylon wire tie passing through

the knockout, as shown in Fig. 15.

4. Attach plate with screws under piping hole.

5. Attach drain pipe with nylon wire tie passing through

hole (Fig. 15).

NOTE: Do not fasten nylon wire ties tight enough to deform

the insulation, as this affects its performance.

6. Insulate condensate drain line(s). Insulate the conden

sate drain lines that are located in or above an occupied

area with a condensate proof material such as polyure

thane or neoprene.

7. Install an external trap at the end of the condensate line.

NOTE: Should your particular installation require one, a con

densate pump may be ordered as an accessory option.

Fig. 10 — Mounting Ceiling Brackets

Page 7

NOTE: Arrow on Check-Flo-Rater body points in free flow direction away

from the indoor coil

Fig. 12

Check-Flo-Rater™Metering Device in Liquid

Line (Bypass-Type Components)

UNDER CEILING INDOOR UNIT

Fig. 13 - Check-Flo-Rater Metering Device at Service

Valve (Bypass-Type Components)

Air Delivery Louvers

Air Filters

Remote Controller

Not Used

Drain Pipe

Interconnecting Tubing and Wire

Outdoor Condensing Unit

Outdoor Unit Disconnect Switch

Indoor Unit Disconnect Switch

Fig. 14 - Component Location (Typical Under Ceiling System)

OUTDOOR UNIT

-7-

Page 8

RIGHT-HAND EXIT

Fig. 15 — Routing Drain Piping

VI. MAKE ELECTRICAL CONNECTIONS

Be sure field wiring complies with local building codes and

NEC, and unit voltage is within limits shown in Table 5.

Contact local power company for correction of improper line

voltage.

NOTE: Use copper wire only between disconnect switch and

unit.

NOTE; Install branch circuit disconnect of adequate size to

handle unit starting current per NEC. Locate disconnect within

sight from and readily accessible from unit, per Section 440-14

of NEC. Some codes allow indoor unit to share disconnect with

outdoor unit if disconnect can be locked; check local code be

fore installing in this manner.

1. Route ground and power wires.

2. Route line power leads (see Fig. 16) from indoor discon

nect to the fan coil unit. Place wire through hole on the

control box (Fig. 17). Connect wire to high voltage ter

minal board (TB-1) and ground screw. When routing the

wire in the unit, use care to keep the wire away from

refrigerant and condensate piping and any sharp edges.

Units are factory wired for 230 V to 24-V transformer

operation. For 208 V to 24-V operation, interchange blue

(208 V) and red (230 V) wires. Cap unused wires with

wire nuts.

VII. INSTALL CONTROL

The 619C unit is equipped with a microprocessor control which

operates the system. This control is located in the control box

of the fan coil, with thermistors located in the fan coil inlet

and discharge, on the indoor coil, on the outdoor coil, and in

the outdoor-air inlet (heat pump systems only). The ther

mistors monitor system operation and control the operating

mode. To change settings or modes of operation, a wired re

mote controller is supplied.

The factory-preset DIP switches on the 619C control board

set the operation of the unit cooling only or for heat pump

operation. Be sure the switches are set correctly. See wiring

diagram on page 16 or 17, and also the control, service, and

troubleshooting guide (available from your distributor) for more

information.

A. Wired Remote Controller

The wired controller is directly connected to the unit by the

plug connection provided. Standard cable length is 15 ft, but

the cable can be any length up to 200 ft.

Determine where the best location is to mount the controller.

Since the controller is not used to sense the temperature of

the room, locate the controller in a convenient place that is

easily accessible to the user.

The cable can be surface mounted or may be run over ceil

ings and through walls. Follow local codes when installing

low voltage wires.

To install remote controller, see separate remote controller

installation instructions.

OUTDOOR UNIT

700CNX024

700CNX036

700CNX048

705CNX024

705CNX036

705CNX048

LEGEND

B - Chatleff

Table 4 — Required Piston Size for Check-Flo-Rater™ Metering Device

INDOOR UNIT

619CNX0240E0 55

619CNX0360E0

619CNX0480E0

619CNX0240WO 619CNX0360W0

619CNX0480W0

INDOOR PISTON

INDOOR PISTON TYPE

B

65

84

-

-

B

B

B

B

B

'Charge amount is determined with 25 ft. of iine

-8-

OUTDOOR

PISTON

- A

-

-

~ A -

-

-

OUTDOOR PISTON

TYPE

A

A

A -

A

REQUIRED SYSTEM

CHARGE * (lb)

68

6.8

too

-

Page 9

Table 5 — Electrical Data

OPERATIONAL

INDOOR UNIT

619CNX0240E0

619CNX0360E0 20 1.3 160 -

619CNX0480E0 3.7 1.0 396 —

619CNX0240W0 07 0.5 2092

619CNX0360W0 20 1.3

619CNX0480W0

FLA — Full Load Amps

HACR — Heating, Air Conditioning, Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps per NEC Section 430-24

NEC — National Electrical Code

208/230 VOLT

1-PHASE

CONNECTION

TO INDOOR

DISCONNECT

<

V-PH

208/230-1-60

LEGEND

VOLTAGE*

Max

187

Min

253

FAN

LRA FLA

07 0.5 92

37

WATTS

3160 3

1.0

‘Permissible limits of the voltage range at which unit will operate

satisfactorily.

4396 4

The following checks should be made before system start-up.

Refer to 700C or 705C installation, start-up and service in

structions for system start-up instructions and refrigerant

charging methods.

EQUIPMENT

GROUND

Fig. 16 — Line Power Connections

VIII. CONNECTIONS TO OUTDOOR UNIT

A. Cooling Only Systems

The following connections must be made to the 700C unit for

it to operate as a system with the indoor unit:

1. A thermistor connection cord with a lead length of 35 ft

is shipped with the 619C unit. Run the connection cord

from the condensing unit to the low-voltage terminal strip

on the control board of the fan coil unit. The stripped

end of the connection cord goes to the fan coil end. Use

1. Check condensate drainage system.

a. Remove grille and frame from the unit.

b. On the opposite side of the drain connection, insert a

water bottle up into the fan coil unit and fill drain

pan. Refer to Fig. 18. Water must flow regularly; if

not, check the pipe slope or inspect for any pipe

restrictions.

2. Make sure that all wiring connections are correct and

that they are tight.

3. Check that all barriers, covers, and panels are in place.

Ensure that the filters and return-air grilles have been

installed and that the discharge louvers are positioned

correctly.

care to route the wires so that they will not be dam

aged, and do not run them near power wires. Connect

the orange wires to terminals D1 and D2 on the control

board.

2. Route 2 wires of 18-gage thermostat cable between the

low-voltage terminal block of the fan coil and the 700C

I. AFTER EXTENDED SHUTDOWN

If the system has been turned off for more than 12 hours,

turn on the indoor and outdoor unit disconnect switches to

supply power to the system for 12 hours BEFORE starting

the system.

unit. Connect the wires Y to blue wire going to highpressure switch, and R to R on the low-voltage

transformer.

B. Heat Pump Systems

The following connections must be made to the 705C unit for

it to operate as a system with the indoor unit:

1. A thermistor cord with a lead length of 35 ft is shipped

with the 619C unit. Run this cable from the heat pump

to the low-voltage terminal strip on the control board on

the fan coil unit. Use care to route the wires so that they

will not be damaged, and do not run them near power

wires. Connect the orange wires to terminals D1 and D2

on the terminal strip, and the blue wires to terminals

A1 and A2 on the terminal strip.

2. Route 4 wires of 18-gage thermostat cable between the

II. SEASONAL CHANGEOVERS

When changing heat pump system from cooling to heating or

heating to cooling, or before starting cooling only system af

ter it has been out of use for the winter season, the following

steps must be performed.

BEFORE starting the system:

1. Inspect and clean the outdoor unit, particularly the coil.

2. Clean or replace the air filters in the indoor unit.

3. Clean the indoor unit drain pan and drain pipe, and re

move any obstructions.

4. Turn on indoor and outdoor unit disconnect switches to

supply power to the system 12 hours before starting the

system.

low-voltage terminal block of the fan coil and the 705C

unit low-voltage terminal block. Connect Y to Y, O to O,

G to G, and C to C with the wires.

ELECTRIC

HEATER

kW AT 240 V

-

2

START-UP

20

MAX FUSE OR

HACR TYPE

CKT BKR AMPS

MCA

1 0

1.8

11.5

17.9 35

22.9

15

15

15

20

40

-9-

Page 10

FRONT VIEW

<3>®<Z>(D(B)<3>

I IFM

®®<3>

®®CD

gMHiM5

¿b

QD<S><B>

Itili

i?iat

"T

'B

SIDE VIEW

ll

-POWER

LEADS

CONNECTION

ASM — Air Sweep Motor

ASR — Air Sweep Reiay

CB — Circuit Breaker

DAT — Discharge Air Temperature Thermistor

EQUIP GND — Equipment Ground

IDC — Indoor Coil Temperature Thermistor

IFM — Indoor Fan Motor

NEC — National Electrical Code

PCB — Printed Circuit Board

PL - Plug

RA — Return Air Temperature Thermistor

TB — Terminal Board

TRAN — Transformer

NOTES:

1 If any of the original wire furnished must be replaced, it must be replaced with type 90 C wire or its equivalent.

2 Wire in accordance with NEC and local codes

Fig. 17 — Control Circuit Connections

<Z>

Circuit Board Run

Terminal (Marked)

Terminal Block

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

-10-

Page 11

III. ADJUSTING AIRFLOW

A. Automatic Air Sweep

All units are equipped with an automatic air sweep feature

which automatically directs the airflow louvers up and down

to provide optimum room air circulation. If the auto sweep

feature is not desired, temporarily start the auto sweep us

ing the remote controller. When the louvers are in the de

sired position, turn the auto sweep off to hold them in that

position.

IV. OPERATING MODE MEMORY

After the system is turned off or after a power failure, the

system remains in the last operating mode selected. When

the system is turned back on, or when power is automati

cally restored, operation continues in the same operating mode

as when it shut down.

V. AUTOMATIC OPERATION (AUTO.) MODE

If Auto, mode is selected, the system automatically switches

over the Operating mode from heating to cooling, or from cool

ing to heating (heat pump system only) depending on the se

lected temperature.

NOTE: Betvieen the cooling cycle and the heating cycle there

is a neutral zone of approximately 2° F above and 2° F below

the selected temperature when only the fan is operating. This

neutral zone lasts for a minimum of 10 minutes.

VI. OPERATING FAULT DIAGNOSIS

The system includes an automatic diagnosis feature which is

activated under difficult or unacceptable operating condi

tions. If such conditions occur, the system stops automati

cally, the operating fault signal appears on the liquid crystal

display (LCD) of the remote controller, and an analysis of the

system operating conditions is initiated. The system will then

be restarted automatically, as soon as normal conditions have

been restored, or it will remain off. If the system does not

start again, the temperature indicator on the LCD display

alternates between the selected temperature value and an er

ror code. See separate controls, service, and troubleshooting

guide to troubleshoot the problem.

VII. OPERATION OF MICROPROCESSOR CONTROL

This system is controlled by a microprocessor control de

signed to give optimum levels of comfort and operating effi

ciency. The control is located in the 619C unit. To operate

the unit, a remote controller is required. This control may be

wired directly to the unit and mounted on the wall up to

200 ft away from the unit.

See separate owner’s manual for remote controller operation

instructions. More detailed operating sequence and timing are

located in the controls, service, and troubleshooting guide. Both

manuals are available from your distributor.

There are 7 operating modes (including the OFF mode) for

cooling only systems and 11 operating modes (including the

OFF mode) for heat pump systems. The following operation

should be expected in each mode.

• OFF Mode — When the unit is in the OFF mode, all func

tions (compressor, outdoor fan, indoor fan, electric heat, and

air sweep) are off, except the reversing valve, which will

stay energized if the unit was last operated in the COOL

ING mode.

• AIR CIRCULATION Mode (Fan Operation Only) - When

AIR CIRCULATION mode is selected, the indoor fan will

operate continuously in the selected speed (high, medium,

low, or auto). If the AUTO, mode is selected, the indoor fan

will operate at high speed. The compressor, outdoor fan,

and electric heat are off The reversing valve will remain

in the last operating mode. The air sweep motor will oper

ate if selected.

• COOLING Mode — When the COOLING mode is selected,

the indoor fan will operate continuously at the selected speed

if the speed is high, medium, or low. If the indoor fan is in

auto., the fan will change operating speeds depending on

the room temperature. The electric heat will be off and re

versing valve will be on. The compressor cannot run for 3

minutes from the time the system starts up or for 3 min

utes from the time it last operated. When the temperature

of the room is 2° F above the selected temperature, the com

pressor and outdoor fan will operate until the room tem

perature is equal to the selected temperature. If the room

temperature is 4° F or more above the selected tempera

ture, the indoor fan will run at high speed. When the room

temperature is between

2° F and 4° F above the selected

temperature, the indoor fan will operate at medium speed.

When the room temperature is 2° F below the selected tem

perature, the indoor fan will operate at low speed.

When the room temperature is equal to the selected tem

perature, the compressor and outdoor fan shut off. The in

door fan, if in auto, operation, operates for one minute af

ter the compressor shuts off. The fan remains off for 3

minutes, then operates for one minute at low speed. The

indoor fan repeats this process until cooling is again

required.

• MAXIMUM DEHUMIDIFICATION Mode - When the DE

HUMIDIFICATION mode is selected, the indoor fan will

operate continuously at the selected speed if the speed is

high, medium, or low. If the indoor fan is in auto, opera

tion, the fan will change operating speeds depending on the

room temperature. The electric heat will be off and revers

ing valve will be on. The compressor cannot run for 3 min

utes from the time the system starts up or for 3 minutes

from the time it last operated.

Initial Operation — When the mode is first selected, or if

the indoor fan has been off for more than one minute, the

fan will operate at low speed for 30 seconds. Then, if the

room temperature is above the selected temperature, the

unit will operate for 16 minutes, and the compressor and

outdoor fan will operate. The indoor fan will operate as in

the cooling mode. After 16 minutes of operation, the unit

switches to normal operation.

If the room temperature is below the selected tempera

ture, the unit will operate for 8 minutes, and the compres

sor and outdoor fan will operate for 3 minutes. The indoor

fan will operate in low speed, and one minute after the com

pressor stops the indoor fan stops. After remaining off for

3 minutes, the indoor fan starts in low speed for one minute,

then switches to normal operation.

-11-

Page 12

Normal Operation — When the temperature of the room is

6° P above the selected temperature, the compressor and

outdoor fan will operate for 8 minutes. The indoor fan will

operate in low speed. If the room temperature is above the

selected temperature, but not by more than 6° F, the com

pressor and outdoor fan operate for 4 minutes. The indoor

fan will run at low speed and will stop 30 seconds after the

compressor stops. After 3 minutes, the indoor fan runs at

low speed for 30 seconds. The normal dehumidification op

eration is repeated for the new room temperature.

When the room temperature is within 4° F below the se

lected temperature, the system operates for 8 minutes. The

compressor and outdoor fan operate for 3V2 minutes. The

indoor fan will operate at low speed and will stop 30 sec

onds after the compressor stops. After 3 minutes, the in

door fan starts in low speed for one minute. The normal

dehumidification operation is repeated for the new room

temperature.

If the room temperature is 4° F below the selected temper

ature, the compressor, outdoor fan, and indoor fan remain

off. After 3 minutes, the indoor fan operates at low speed

for one minute. This is repeated until 8 minutes have elapsed.

The normal dehumidification operation is repeated for the

new room temperature.

HEAT PUMP Heating Mode (Heat Pump Systems Only)

— When the HEAT PUMP mode is selected, the indoor fan

will operate continuously at the selected speed if the speed

is high, medium, or low. If the indoor fan is in auto oper

ation, the fan will change operating speeds depending on

the room temperature. The electric heat is off and the re

versing valve will be on. The compressor cannot run for 3

minutes from the time the system starts up or for 3 min

utes from the time it last operated. When the temperature

of the room is 8° F below the selected temperature, the unit

will operate in HEAT PUMP mode until the temperature

is 2° F above the selected temperature. If the temperature

of the room is between 2° F and 8° F below the selected

temperature, the unit operates in HEAT PUMP mode un

til the selected temperature is reached.

In the HEAT PUMP mode, the compressor and outdoor fan

will operate until the room temperature has reached the

temperature indicated above. The indoor fan will remain

off until the discharge temperature of the fan coil is 86 F.

The fan will then operate in low speed until the discharge

temperature is 98 F. Then the fan will operate at high speed

if the room temperature is 4° F or more below the selected

temperature. The indoor fan will run at medium speed when

the room temperature is between 2° F and

4° F below the

selected temperature. The indoor fan will operate at low

speed if the room temperature is within 2° F of the se

lected temperature. When the heating demand is satisfied,

the compressor and outdoor fan will stop and the indoor

fan will operate until the discharge air temperature is

77 F. The fan will turn off for 3 minutes, then turn on for

one minute — this will be repeated until heating is again

required.

' MAXIMUM HEATING Mode (Heat Pump Systems Only)

— This mode of operation is the same as the HEAT PUMP

heating mode, except that electric heat is used to assist the

heat pump.

• ELECTRIC HEATING Mode (Heat Pump Systems Only)

— The indoor fan operation is the same as the HEAT PUMP

mode, except that electric resistance heating only is used.

• AUTOMATIC OPERATION Mode - AUTOMATIC OPER

ATION mode runs the system in cooling or heating at 2° F

above the selectéd temperature for cooling and 2° F below

the selected temperature for heating. In the temperature

range between heating and cooling, only the fan will oper

ate. A minimum of 10 minutes is required between a change

from heating to cooling or from cooling to heating.

• DEMAND DEFROST Mode (Heat Pump Systems only) —

This unit uses a demand defrost system to remove frost

from the outdoor coil during heating operation. The indoor

fan and outdoor fan are shut off during defrost. For com

plete description of defrost operation, see the controls, ser

vice and troubleshooting guide sections of the duct-free

systems manual, available from your distributor.

• SLEEP Mode — The SLEEP mode timer will turn the unit

off when the timer reaches zero minutes. During the first

IV2 hours from the time the SLEEP mode timer starts, the

room temperature is set back from the selected tempera

ture a total of 4 F in cooling and 6 F in heating.

• AWAKE Mode — The awake timer will turn the unit on

when the timer reaches zero minutes. The unit will start

in the same mode and at the same selected temperature as

when the system shut off.

NOTE: The system can be programmed for the sleep mode

or the awake mode, but it cannot be programmed for both of

these modes simultaneously.

CLEANING AND MAINTENANCE

For proper system operation we recommend that the clean

ing and maintenance operations in Table 6 be performed.

I. LUBRICATION

The indoor-fan motor, automatic air sweep motor, and the

outdoor fan motor are factory lubricated and require no

oiling.

-12-

Page 13

II. TO REMOVE AND CLEAN OR REPLACE AIR FILTERS

(FIG. 21)

A. To Remove Air Filters

Remove filters by pulling them straight out.

B. To Clean or Replace Filters

Filters can be vacuumed, or washed in warm water. See

Fig. 19. Shake filter to remove any excess water, and replace

by sliding filter behind grille until filter snaps in place.

NOTE: After cleaning, be sure to press the Filter Reset but

ton on the mode selection panel of the remote controller.

If the filter has begun to break down or is torn, it needs to be

replaced. Replacement filters are available through your

distributor.

A. REMOVE FILTERS

III. TO CLEAN INDOOR UNIT BOTTOM PANEL

If the bottom panel of the unit becomes dirty or smudged,

wipe the outside of the panel with a soft dry cloth. Use a mild

liquid detergent and wipe off carefully with a dry cloth.

IV. TO CLEAN INDOOR COIL

To clean the coil, remove indoor unit bottom panel and con

densate pan, and then vacuum the coil fins, using care not to

bend or damage fins.

V. TO CLEAN OUTDOOR COIL

To clean the outdoor coil:

1. Remove any dirt or obstruction from discharge opening.

2. Use a garden hose to spray water on the coil. Debris that

collects between coil fins inhibits heat transfer — direct

the water spray between coil fins to flush out debris.

VI. TO CLEAN CONDENSATE DRAIN PIPE AND PAN

Clean drain pipe quarterly and drain pan at the start of each

cooling season. Check the flow by pouring water into the drain

pipe.

A. To Clean or Replace Drain Pan

1. Place a plastic sheet on the floor to catch any water that

may spill from drain pan.

INTAKE

GRILLE B WASH FILTERS,

OR

2. Remove the air intake and distribution assembly.

3. Remove the condensate water in the drain pan by let

ting water drain into a 3-gallon bucket.

4. Remove the 4 screws holding the drain pan.

5. Carefully hold the drain pan to remove it from the

assembly.

C. VACUUM FILTERS

Fig. 19 — Cleaning Filters

Table 6 — Cleaning and Maintenance Schedule

TASK MONTHLY

INDOOR UNIT

Clean Air Filters

Clean Drain Pipe X

Clean Condensate Drain Pan

Clean Indoor Unit Front Panel

OUTDOOR UNIT

Clean the Fins From Outside

Open the Unit and Clean Fins Inside

Remove Dust From Eiectricai Parts

Check Eiectricai Connections are Tight

Ciean Outdoor Fan X

Check that Outdoor Fan Assembiy is Tight

Clean Condensate Drain Pan

NOTE: Maintenance procedures for the outdoor unit are in the 700C and 705C instaiiation instructions

X

QUARTERLY YEARLY

X

X

X

X

X

X

X

X

-13-

Page 14

1

SERVICE

NOTE: Refer to the control, service and troubleshooting guide

sections of the duct-free systems manual for a complete de

scription of the control system and for detailed service and

troubleshooting procedures. This manual is available from your

distributor.

TROUBLESHOOTING

I. DIAGNOSTIC CODES

This unit is equipped with a microprocessor control which con

tinuously monitors the operation of the unit. If an opera

tional fault is detected, a fault code appears on the LCD dis

play of the remote controller. A red LED indicator light, located

on the control board in the control box of the indoor unit, will

emit a flash code which can be used to troubleshoot a system

problem. The control will continue to monitor the unit and, if

thè conditions which cause the fault are cleared, the unit will

return to normal operation. If the fault code is present for 5

cycles of the unit, the unit will be locked out and the alarm

code will be displayed alternately with the temperature on

the remote controller LCD display.

If the LED indicator light continuously flashes on for one sec

ond, then off for one second, the control is functioning prop

erly and no fault is present. A fast flashing LED indicates

that a fault has been detected. Table 7 lists the number of

quick flashes and the associated fault. If the system does not

operate, the remote controller does not display a fault code,

and the LED indicator does not flash, either the power to the

control board is off, or the control board has failed.

Table 7 — System Fault Codes

FAULT

CODE*

E2

E3

E4

E5

E6

E7

E8

E11

E12

‘The fault code is alternately displayed with the temperature on the re

mote controller LCD display

tHeat pump systems only

II. TEST MODES

NO. OF

FLASHES

2

3

4

5

6

7

8

11

12

SYSTEM FAULT

Outdoor Coll Thermistor

Outdoor Air Thermistort

Room Air Thermistor

Indoor Coil Thermistor

Discharge Air Thermistor

Compressor Malfunction

Reversing Valve Malfunctlonf

Electric Heat Malfunction

Outdoor Coil Temperature

The remote controller allows troubleshooting of the system

by running a series of test modes. These tests may be man

ually initiated with the remote controller to test the system

operation:

• Fan Only Test

• Cooling Mode Test

• Dehumidification Test

• Heat Pump Heating Test

• Emergency Heat Test

See separate controls, service, and troubleshooting guide for

additional details on operating test modes.

III. SYSTEM TESTS

System tests listed below are performed continuously by the

microprocessor. If a fault is indicated, then the system al

lows only limited operation until the problem is resolved. If

the problem resolves itself, then the code is cleared and op

eration resumes.

A. Indoor Coil High-Temperature Protection (Heat Pump Sys

tems Only)

If indoor coil temperature is greater than or equal to 145 F

but less than 165 F for one minute or more, the system shuts

down.

B. Outdoor Coil High-Temperature Protection (Cooling or

Dehumidification Mode Only)

If outdoor coil temperature is greater than or equal to 145 F

but less than 165 F for one minute or more, the system shuts

down.

C. Indoor Coil Freeze Protection (Cooling or Dehumidifica

tion Mode Only)

If indoor coil temperature is less than or equal to 28 F but

more than —13 F for 4 minutes and the compressor has run

for 24 continuous minutes, the system shuts down.

D. Thermistor Tests

Each thermistor is tested for high limit out of range (shorted

condition) and low limit out of range (open condition). If the

thermistor is out of range, the fault status indicator comes

on and the LED flashes the appropriate fault code.

E. Compressor Failure

If the System is in COOLING or DEHUMIDIFICATION Mode

— After 2 minutes of operation, if the temperature of the in

door coil is not 2° F less than at the time the call for cool

ing started, then a compressor failure is indicated on the re

mote controller LCD display.

If the System is in HEAT PUMP HEATING Mode - After 2

minutes of operation, if the temperature indicated by the out

door thermistor is not 2° F less than at the time the call for

heating started, then a compressor failure is indicated.

F. Reversing Valve Failure

If the System is in COOLING or DEHUMIDIFICATION Mode

— After 4 minutes of operation, if the temperature at the in

door coil is 2° F more than at the time the call for heating

started, then a reversing valve failure is indicated.

If the System is in HEAT PUMP HEATING Mode — After 4

minutes of operation, if the temperature indicated by tbe in

door coil is not 2° F less than at the time the call for heat

ing started, then a reversing valve failure is indicated.

G. Electric Heater Failure

If, 4 minutes after the heater is energized, the discharge-air

temperature is not 2° F above the return-air temperature, an

electric heater failure is indicated.

H. Filter Dirty Indicator

Indicator (on remote controller LCD display) turns on after

250 hours of indoor fan operation.

-14-

Page 15

NOTES FOR FIG. 20 AND 21

1. Compressor and fan motor are thermally protected.

2. Wire in accordance with National Electrical Code (NEC)

and local codes. If any of the original wire must be re

placed, it must be replaced with type 90 C wire or its

equivalent.

LEGEND FOR FIG. 20 AND 21

ASM

ASR

C

CAP

CB

CH

COMP

DATTH

DTS

EQUIP

GND

FL

HPS

HR

HTR

HTT

_

Air Sweep Motor

—

Air Sweep Reiay

_

Compressor Contactor LPS

—

Capacitor

—

Circuit Breaker

—

Crankcase Heater

—

Compressor

—

Discharge Air Thermistor

—

Discharge Temperature Sensor

—

Equipment Ground

—

Fuse Link

—

High-Pressure Switch

—

Heater Relay

—

Heater

Heater Temperature Thermostat

IDC TH

IFM

OATTH

OCTTH

OFM

OFR

PCB

PL

RA TH

RVS Reversing Valve Solenoid

SC

SR

TB

TDR

TRAN —

3. Use minimum of 60 C wiring for field power wiring.

4. Thermostat is internal to unit. Unit must be controlled

with wired or infrared wireless remote controller.

5. Use copper conductors only.

_

Indoor-Coil Thermistor

—

Indoor-Fan Motor

—

Low-Pressure Switch

—

Outdoor Air Thermistor

—

Outdoor Coil Thermistor

—

Outdoor Fan Motor

Outdoor Fan Relay

—

Printed Circuit Board

—

Plug

—

Return Air Thermistor

—

Start Capacitor

Start Relay

—

Terminal Block

--

Time-Delay Relay

Transformer

<Z>

o

•

1 >■ 1

Circuit Board Run

Terminal Marked

Terminal Unmarked

Splice

Terminal Block

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

-15-

Page 16

Oi

-OPN-

-ft£D-

-UHT-

-BLK-

WIREO

REMOTE

I

Fig. 20 — Typical System Wiring Schematic; Heat Pump Systems

Page 17

I

J

K-0^0-BLK*-BH>^^

- - - - - - -- - - -- - -- - - -•- - - - - - - -

-O-

O j .

LPS

-C0O

Fig. 21 - Typical System Wiring Schematic; Cooling Only Systems

J

Loading...

Loading...