Page 1

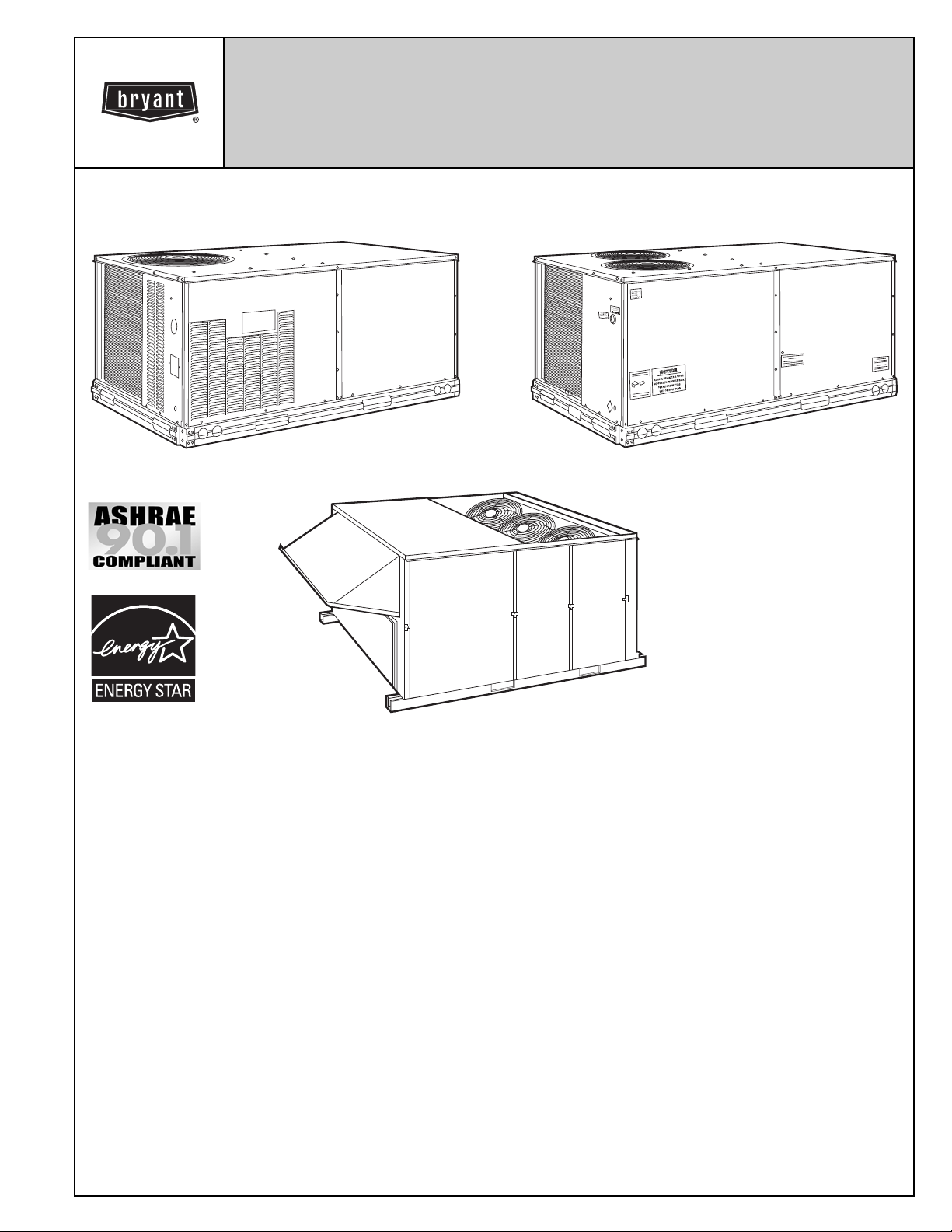

COMMERCIAL

548F036-072

549B036-072

549C024-060

548F090-120

549B090-120

542J150,180

50-1219

50-1304

50-1214

Models 542J, 548F, 549B, 549C

SINGLE P ACKAGE ROOFT OP

ST ANDARD AND HIGH EFFICIENCY

HEA T PUMP UNITS

Sizes 024-180

DuraPac and DuraPac Plus

2 to 15 Tons

Standard-Efficiency (548F), and High-Efficiency (549B, 549C,

542J) heat pump units offer:

• Pre-painted galvanized steel cabinet for long life and quality

appearance

• Commercial strength base rails with built-in rigging capability

• Convertible design for vertical or horizontal supply/return

• Non-corrosive, sloped condensate drain pan, meets

ASHRAE 62 (IAQ)

• Two-inch return-air filters

• A wide assortment of factory-installed options available,

including high-static drives that provide additional performance range

• Factory-installed optional gear driven EconoMi$erIV (vertical

return for sizes 024-120 only) for use with standard rooftop

unit controls (includes CO

• Factory-installed optional gear driven EconoMi$er2 (vertical

return only) for use with third party controls (includes 4 to

20 mA actuator for demand control ventilation)

• State-of-the-art defrost system

• Dependable 4-way valve operation

Heat Options

• Field-installed electric heat available

• Glycol hydronic coils

sensor control capability)

2

FEATURES/BENEFITS

Every compact one-piece unit arrives fully assembled,

charged, tested, and ready to run.

QUIET, EFFICIENT OPERATION AND DEPENDABLE PERFORMANCE — Compressors have vibration isolators for quiet

operation. Efficient fan and motor design permits operation at

low sound levels.

Unit sizes 090-180 offer lower utility costs through part-load

operation using 2 stages of cooling.

Quiet and efficient operation is provided by belt-driven indoor

fans (standard on all units over 5 tons). The belt-driven indoor

fan is equipped with variable-pitch pulleys which allow adjustment within the rpm ranges of the factory-supplied pulleys.

Increased operating efficiency is achieved through computerdesigned coils featuring staggered internally enhanced copper

tubes. Fins are ripple-edged for strength, lanced, and double

waved for higher heat transfer.

Form No. PDS548F-36-6

Page 2

TABLE OF CONTENTS

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Model Number Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . 4,5

ARI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,6

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

548F

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14,15

Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16,17

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 18,19

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-54

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-64

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . 65-67

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69-72

549B, 549C

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73-75

Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-78

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 79-80

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-118

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119-130

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . 131-133

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 135-139

542J

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 142-144

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146-152

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . 154-156

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 158-162

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163,164

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165-168

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

DURABLE, DEPENDABLE CONSTRUCTION — Designed for

durability in any climate, the weather-resistant cabinets are

constructed of galvanized steel and bonderized, and all exterior

panels are coated with a prepainted baked enamel finish. The

paint finish is non-chalking, and is capable of withstanding

ASTM (American Society for Testing and Materials) B117

500-hour Salt Spray Test. All internal cabinet panels are primed,

permitting longer life and a more attractive appearance for the

entire unit.

In addition, all size 024-120 units are designed with a sing le,

continuous top piece to eliminate any possible leaks. Totally

enclosed outdoor-fan motors and permanently lubricated bearings provide additional unit dependability.

Patented State-of-the-Art Chronotemp™ Defrost System

uses time and temperature to keep the outdoor coil frost-free for

economical, dependable operation. The Chronotemp defrost

board can be easily configured for defrost cycles eve ry 30, 50,

or 90 minutes.

Dependable 4-Way Valve Operation safely and efficiently

accomplishes cycle reversals, defrost, and normal operation.

EASY INST ALLATION AND CONVERSION

All Units are Shipped in the Vertical Duct Configuration for

fit-up to standard roof curbs. (3 different curb sizes fit unit sizes

024-072, 090-120, and 150,180 respectively.) The contractor

can order and install the roof curb early in the construction

stage, before decisions on size requirements are made.

All units feature a base rail design with forklift slots and rigging

holes for easier maneuvering. Durable packaging protects all

units during shipment and storage.

The units can be easily converted from a vertical to a horizontal

duct configuration by relocating the panels supplied with the

unit.

T o Convert 024-120 Units from vertical to horizontal discharge,

simply relocate 2 panels. The same basic unit can be used for a

variety of applications and can be quickly modified at the

jobsite.

To Convert Size 150 and 180 Units from vertical to horizontal

discharge, use the optional horizontal supply/return adapter

roof curb.

Convenient Duct Openings in the unit basepans permit sideby-side or concentric duct connections (see Application Data

section) without requiring internal unit modification (size

150,180 only).

NOTE: On units using horizontal supply and return, the accessory barometric relief or power exhaust MUST be installed on

the return ductwork.

Thru-the-bottom service connection capability comes standard

with the rooftop unit to allow power and control wiring to be

routed through the unit’s basepan, thereby minimizing roof penetrations (to prevent water leaks). Power and control connections are made on the same side of the unit to simplify

installation.

The Non-Corrosive Sloped Condensate Drain Pan permits

either an external horizontal side condensate drain (outside the

roof curb) or an internal vertical bottom drain (inside the roof

curb). Both options require an external, field-supplied P-trap.

Standard 2-in. Throwaway Filters are easily accessed

through a removable panel located above the air intake hood.

No tools are required to change unit filters.

All 024-120 Units are Designed With a Single, Continuous

Top Piece to eliminate leaking at the seams or gasketing.

Belt-Driven Indoor-Fan Motors allow maximum on-site flexi-

bility without changing motors or drives.

Field-Installed Accessory Electric heaters are available in a

wide range of capacities. An available single-point wiring kit

makes installation simple.

Low Voltage Wiring Connections are easily made due to the

large terminal board which is located for quick, convenient

access.

In addition, color-coded wires permit easy tracing and

diagnostics.

PROVEN COMPRESSOR RELIABILITY

Design techniques feature computer-programmed balance

between compressor, condenser , and evaporator. Bryant-specified

hermetic compressors are equipped with compressor overcurrent

and overtemperature protection to ensure dependability.

All units have a fixed orifice metering device which precisely

controls refrigerant flow, preventing slugging and flood-back,

while maintaining optimum unit performance. Refrigerant filter

driers are standard.

Standard Low Ambient Cooling Operation to 25 F; optional

head pressure control kit available for outdoor ambient con ditions to –20 F.

2

Page 3

INTEGRATED ECONOMIZERS AND OUTDOOR-AIR

DAMPERS

Available as options or accessories, economizers and manual

outdoor-air dampers introduce outdoor air which mixes with the

conditioned air, improving indoor-air quality and often reducing

energy consumption.

During a first stage call for cooling, if the outdoor-air temperature is below the economizer control changeover set point, the

mixed-air sensor modulates the economizer outdoor-air damper

open to take advantage of free cooling provided by the outside

air. When second-stage cooling is called for, the compressor is

energized in addition to the economizer. If the outdoor-air temperature is above the changeover set point, the first stage of

compression is activated and the economizer damper stays at

minimum position.

Accessory upgrade kits allow for control by differential dry-bulb

temperature (outdoor vs return), outdoor air enthalpy

changeover, or more precise differential enthalpy control.

Units can be equipped with different economizer options to

meet specific controls applications. The factory-installed or

field-installed EconoMi$erIV and EconoMi$er2 are available.

The EconoMi$erIV is used with the standard rooftop unit

controls and includes an industry standard, stand-alone, solidstate control. The control can be used with a CO

sensor for

2

DCV (demand control ventilation) operation. For direct digital

control (DDC) applications, the EconoMi$er2 can be operated

using a third party controller. The EconoMi$er2 includes 4 to

20 mA actuator capability for demand control ventilation

applications.

All economizers incorporate a parallel blade, gear driven

damper system for efficient air mixing and reliable control. In

addition, the standard damper actuator includes a spring return

to provide reliable closure on power loss. The economi zers for

sizes 024-120 are equipped with up to 100% barometric relief

capability for high outdoor airflow operations. Economizers for

unit sizes 024-120 are available, factory-installed, for vertical

return only. Economizers for unit sizes 150 and 180 are compatible for vertical or horizontal return. An optional field-installed

barometric relief package is available for 150 and 180 size

units.

In addition, single-stage power exhaust is available as a fieldinstalled accessory for EconoMi$erIV to help maintain proper

building pressure.

For units without economizer, year-round ventilation is

enhanced by a manual outdoor-air damper. On size 024-120

units, a 25% or 50% manual damper is available as a fieldinstalled accessory. Unit sizes 150 and 180 are equipped with a

manual 25% damper.

SERVICE OPTIONS

Servicing a rooftop unit has never been easier with the new

factory-installed service options for these rooftop units. These

options include the following:

• Hinged access panels (549B, 549C and 542J only) are provided for the filter/indoor-fan motor, compressors, indoor fan,

and control box areas. Quick access to major components is

accomplished by simply unlatching and swinging open the

various panels. Each hinged panel is permanently mounted to

the unit, thereby eliminating the concern of a dropped or windblown panel puncturing delicate roof materials. The

4 extended access panels are also equipped with ‘‘tie back’’

retaining devices to hold the door in the open position while

servicing the unit.

• An external, covered, 115-v Ground Fault Interrupt (GFI)

receptacle is provided as a convenient power source for drills,

lights, refrigerant recovery units, or other electrical service

tools. Simply connect the outlet to a field-supplied and properly fused branch circuit power supply.

• An integral non-fused disconnect switch within the rooftop unit

reduces installation time, labor and material costs. Safety is

assured by an interlock which prevents access to the control

box unless the switch is in the OFF position. In addition, the

externally mounted handle incorporates power lockout capability to further protect service personnel.

INDOOR-AIR QUALITY BEGINS WITH BRYANT ROOFTOPS

Sloped condensate pans minimize biological growth in rooftop

units in accordance with ASHRAE Standard 62. Two-inch filters

with optional dirty filter indicator switch provide for greater particle reduction in the return air. The face-split evaporator coils

improve the dehumidification capability of standard units, maximize building humidity control.

Optional proportional reacting CO

sensor is available with the

2

EconoMi$erIV outdoor air damper option/accessory to aid the

IAQ benefits.

3

Page 4

MODEL NUMBER NOMENCLATURE — 548F UNITS

Voltage Designation

E– 460-3-60

J– 208/230-1-60†

P– 208/230-3-60

T– 575-3-60

548F E X 090 000 AA

548F – Single-Package

Heat Pump

Unit

X–No Heat Installed.

(Field-installed electric heaters available.)

Factory-Installed Options*

Nominal Tons

036 – 3 090 – 7-1/2

048 – 4 120 – 10

060 – 5

072 – 6

Electric Heaters

000 – No factory-installed electric heaters

LEGEND

*Refer to Trade Price Sheets or contact your local representative for specific

information regarding which options are available on which units.

†Single-phase is only available on 036-060 size units.

NOTE: The example model number 548FEX090000AA designates a 71/2 ton

460-3-60 volt electric heat pump unit with factory-installed economizer.

ODS — Order Distribution System

Quality Assurance

Certified to ISO 9001:2000

a50-8038

LEGEND

*Available on 549C units only.

ODS — Order Distribution System

Quality Assurance

Certified to ISO 9001:2000

a50-8039

(ODS Model Number)

MODEL NUMBER NOMENCLATURE — 549B AND 549C UNITS

549B – Single-Packaged High-Efficiency

549C

Voltage Designation

E–460-3-60

J–208/230-1-60

P–208/230-3-60

X– No Heat Installed

Nominal Tons

024

036 – 3

048 – 4

060 – 5

072 – 6

090 – 7-1/2

102

120––

Heat Pump Unit

–

Single-Packaged High-Efficiency

Plus Heat Pump Unit

(Field-installed electric heaters available)

2*

–

8-1/2

10

(ODS Model Number)

549B E X 090 000 AA

Factory-Installed Options

See unit price pages for

factory-installed option codes

Electric Heaters

000 – No factory-installed electric heaters

4

Page 5

MODEL NUMBER NOMENCLATURE — 542J150,180 UNITS

Nominal Cooling Capacity

150 – 12 Tons

180 – 15 Tons

Factory-Installed Outdoor

Air Upgrade Options

C– Economizer

H– 25% Manual Damper

542J E X 150 000 AB H B

542J – High-Efficiency Rooftop Units

Electric Heat Pumps

Voltage Designation

E–460-3-60

P–T–208/230-3-60

575-3-60

Heat Type

X– No Heat Installed

Electric Heaters

000 – No Factory-Installed Electric Heaters

Accessory Field-Installed Electric Heaters

Available

Fan Drive Position

(Standard Motor)

B– Standard Low-Medium

Fan Drive Static Capability

D– Alternate High Fan

Drive Static Capability

Design Series Code

AB – Economizer Design Change

Quality Assurance

Certified to ISO 9001:2000

a50-8040

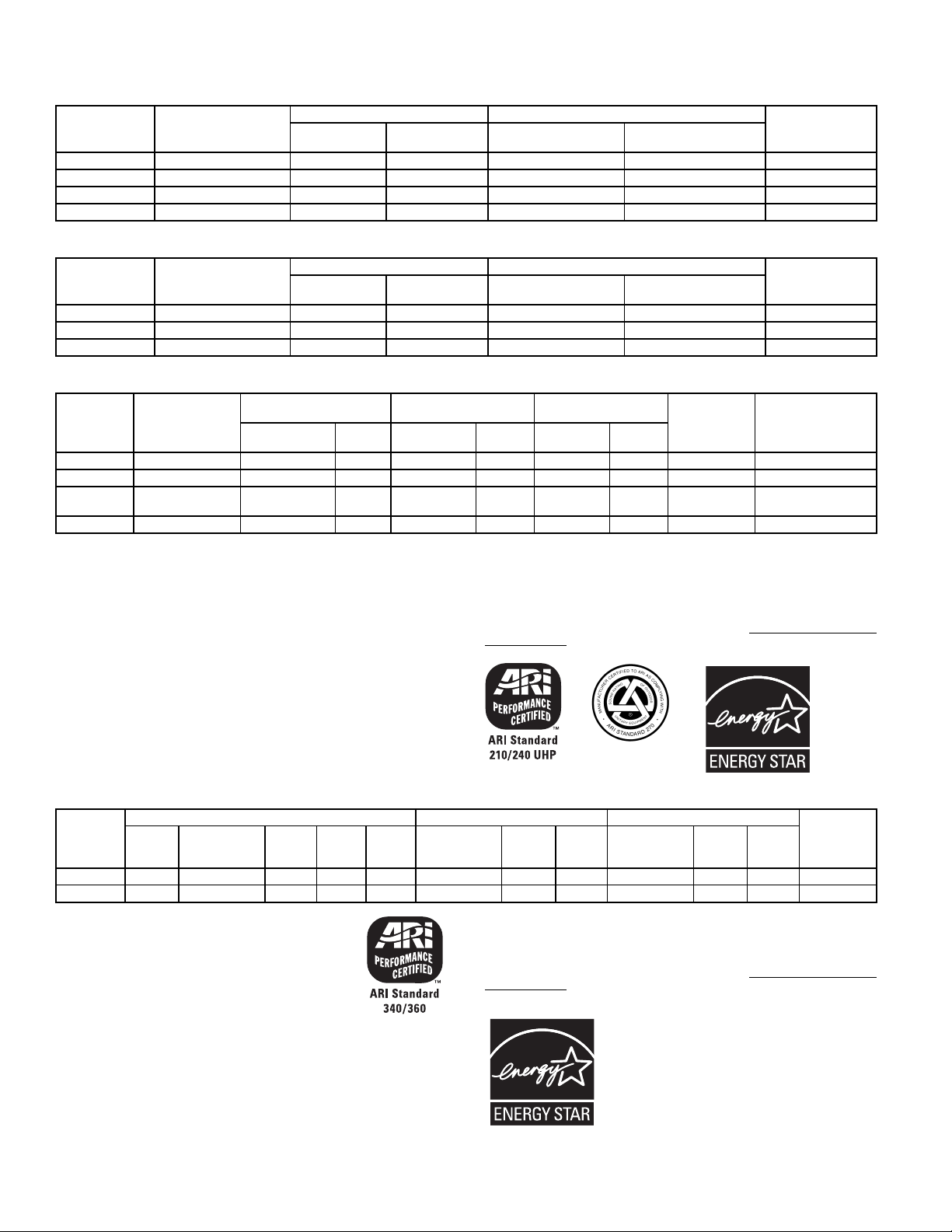

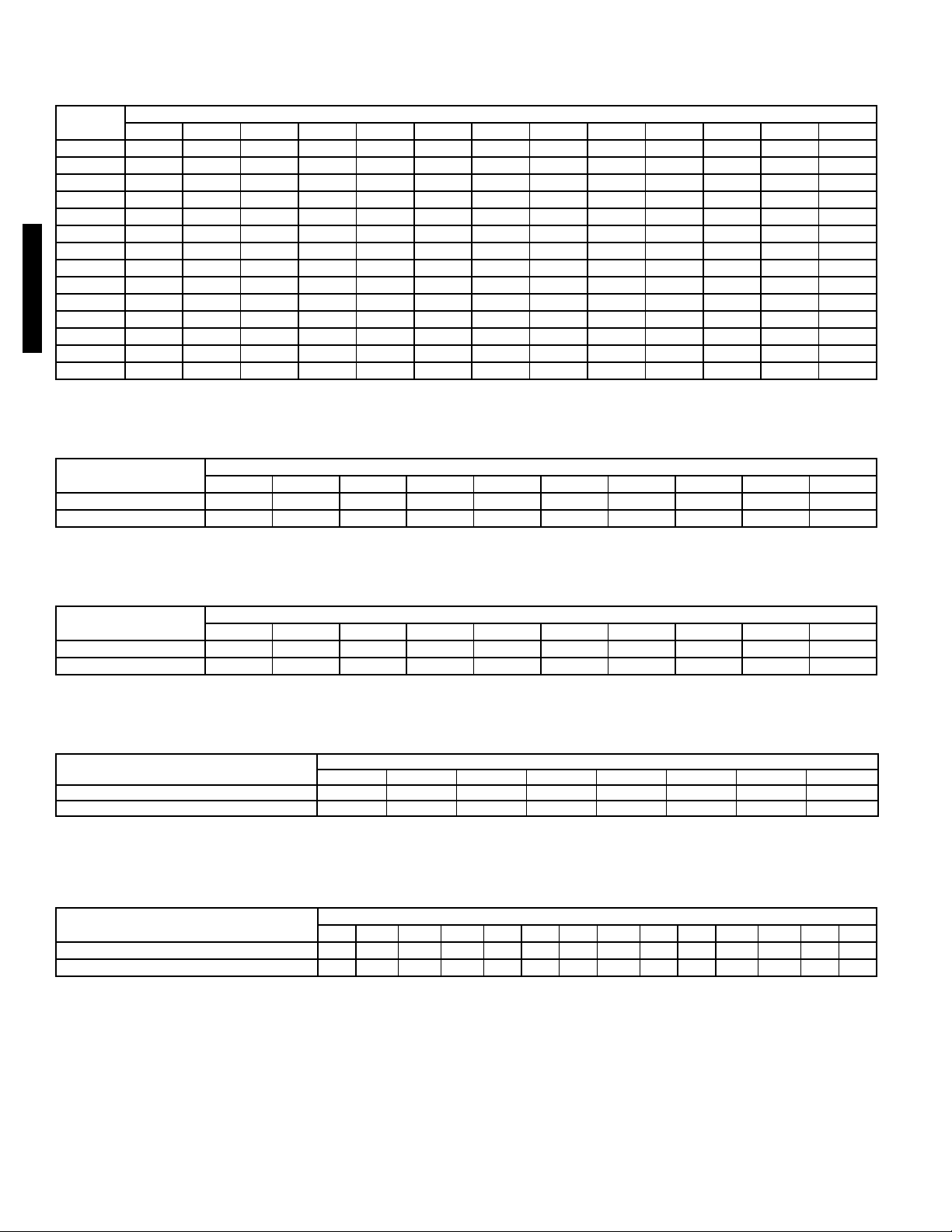

UNIT

548F

036 3 35,600 10.20 10.00 34,400 6.7 84

048 4 46,500 10.00 9.70 46,500 7.0 80

060 5 57,000 10.00 9.90 57,000 7.5 82

UNIT

548F

072 6 70,000 9.05 72,400 3.20 42,000 2.14 — 82

090 7

120 10 112,000 9.00 105,000 3.10 59,000 2.00 9.0 84

COP — Coefficient of Performance

db — dry bulb

EER — Energy Efficiency Ratio

HSPF — Heating Seasonal Performance Factor

IPLV — Integrated Part-Load Values

SEER — Seasonal Energy Efficiency Ratio

wb — wet bulb

*Air Conditioning and Refrigeration Institute.

†Applies only to units with capacity of 60,000 Btuh or less.

**The IPLV applies only to 2-stage cooling heat pump units.

NOTES:

1. Rated in accordance with ARI Standards 210/240-95 and 270-95.

2. Ratings are net values, reflecting the effects of circulating fan heat.

3. ALL the 548F036-060 units are in compliance with ASHRAE 90.1

2001 Energy Standard for minimum SEER and EER requirements.

Refer to state and local codes or visit the following website:

http://solstice.crest.org/efficiency/bcap

with this standard pertains to a given geographical area of the United

States.

NOMINAL

TONS

NOMINAL

TONS

1

/

2

LEGEND

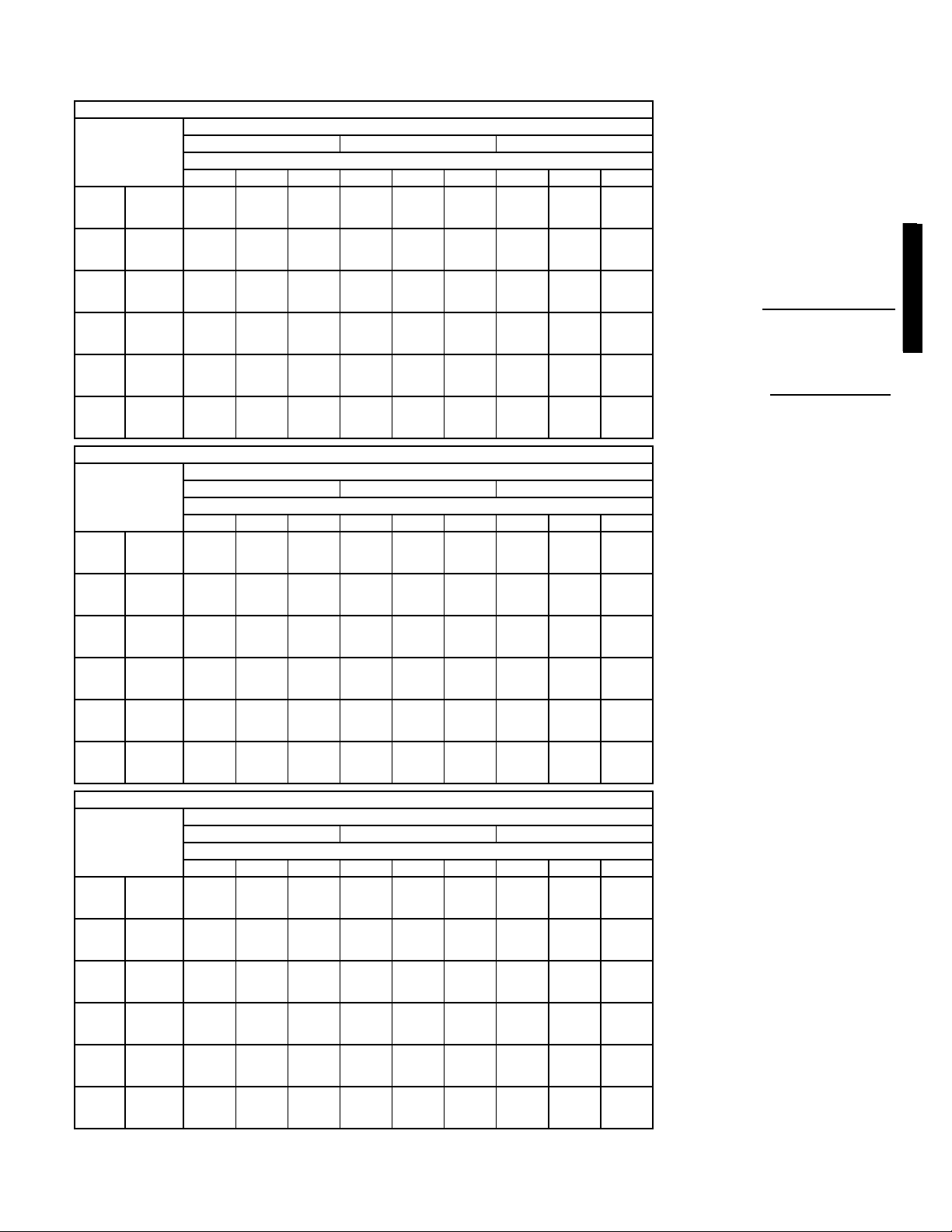

ARI* CAPACITY RATINGS

548F036-060

COOLING

Net Capacity

(Btuh)

Belt

Drive

SEER†

Direct

Drive

548F072-120

COOLING

Net Capacity

(Btuh)

86,000 9.00 78,000 3.00 39,000 1.80 9.3 86

EER

HEATING

(High)

Capacity

(Btuh)

COP

4. Ratings are based on:

Capacity

(Btuh)

to determine if compliance

Cooling Standard: 80 F db, 67 F wb indoor entering-air temperature

and 95 F db air entering outdoor unit.

IPLV Standard: 80 F db, 67 F wb indoor entering-air temperature and

80 F db outdoor entering-air temperature.

High-Temp Heating St andard: 70 F db indoor entering-air temperature

and 47 F db, 43 F wb outdoor entering-air temperature.

Low-Temp Heating Standard: 70 F db indoor entering-air temperature

and 17 F db, 15 F wb outdoor entering-air temperature.

5

HEATING

(High Temp)

Capacity

(Btuh)

HEATING

(Low)

HSPF

IPLV**

COP

SOUND

RATING

(decibels)

SOUND

RATING

(decibels)

Page 6

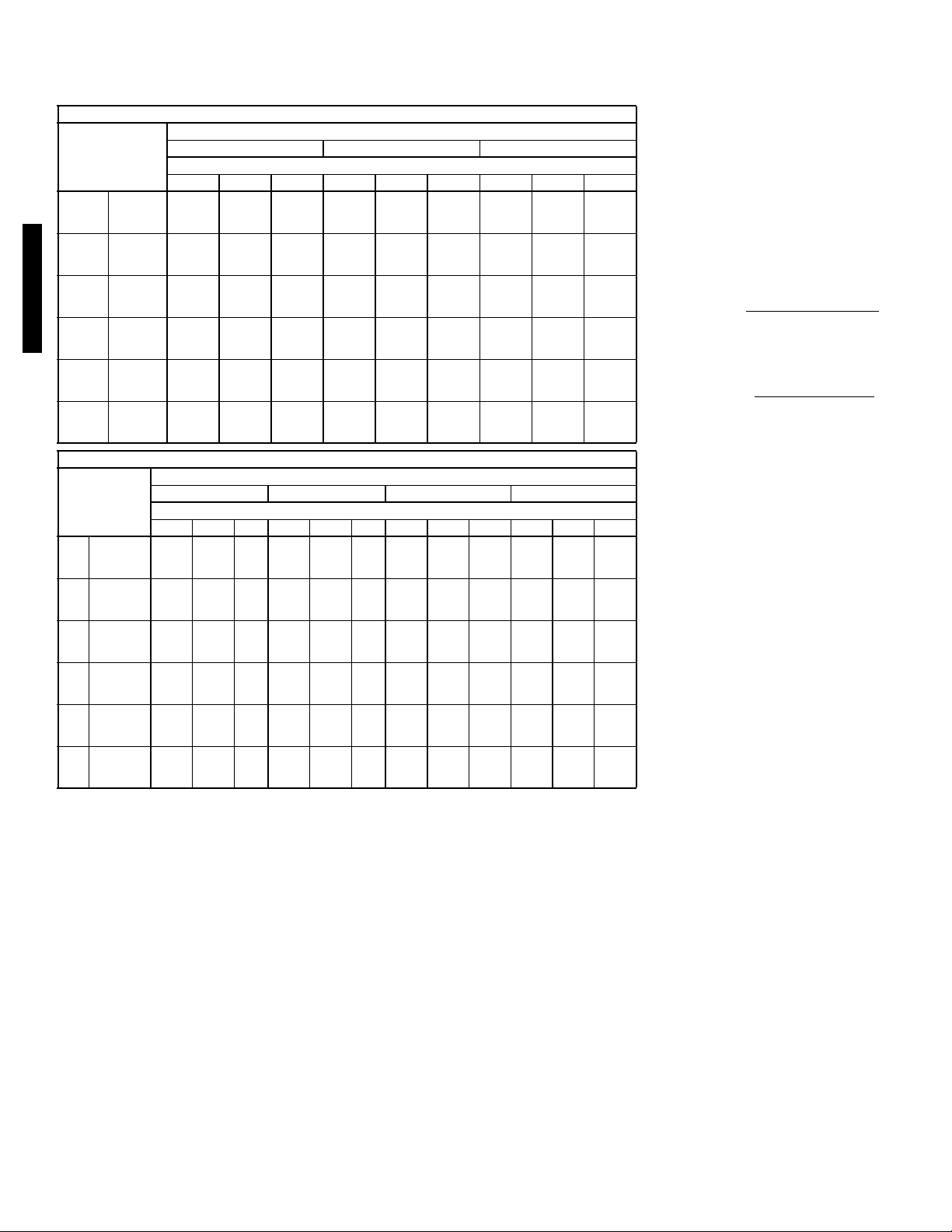

ARI* CAP ACITY RATINGS (cont)

549C024-060

UNIT

549C

NOMINAL

TONS

Net Cap.

COOLING HEATING (High Temp)

(Btuh)

SEER†

Cap.

(Btuh)

HSPF†

024 2 24,000 14.0 23,600 8.10 76

036 3 37,000 14.0 36,000 8.10 76

048 4 46,000 14.0 46,000 8.00 76

060 5 58,500 14.0 58,000 8.00 80

549B036-060

UNIT

549B

NOMINAL

TONS

Net Cap.

036 3 35,600 13.1 34,800 7.7 76

048 4 45,000 13.0 45,000 7.8 76

060 5 58,000 13.0 55,000 7.7 80

COOLING HEATING (High Temp)

(Btuh)

SEER†

Cap.

(Btuh)

HSPF†

549B072-120

UNIT

549B

NOMINAL

TONS

COOLING

Net Cap.

(Btuh)

EER

HEATING

Cap.

(Btuh)

(High)

COP

072 6 71,000 10.5 69,000 3.4 37,000 2.2 80 —

090 7

102 8

1

/

2

1

/

2

88,000 10.3 85,000 3.3 48,000 2.2 82 10.5

98,000 10.3 96,000 3.3 52,000 2.2 110

120 10 116,000 10.3 103,000 3.3 64,000 2.2 84 10.4

LEGEND

Cap. — Net Capacity (Btuh)

COP — Coefficient of Performance

EER — Energy Efficiency Ratio

HSPF — Heating Seasonal Performance Factor

IPLV — Integrated Part-Load Values

SEER — Seasonal Energy Efficiency Ratio

*Air Conditioning and Refrigeration Institute.

†Applies only to units with capacity of 60,000 Btuh or less.

NOTE: Rated in accordance with ARI Standard 210/240-94 and 270-

95. Ratings are net values, reflecting effects of circulating fan heat.

Supplementary electric heat is not included. Ratings based on:

Cooling Standard: 80 F db (dry bulb), 67 F wb (wet bulb) indoor entering-air temperature and 95 F db outdoor entering-air temperature.

IPLV Standard: 80 F db, 67 F wb indoor entering-air temperature and

80 F db outdoor entering-air temperature.

High-Temp Heating Standard: 70 F db indoor entering-air te mpe ratu re

and 47 F db, 43 F wb outdoor entering-air temperature.

Low-Temp Heating Standard: 70 F db indoor entering-air temperature

and 17 F db, 15 F wb outdoor entering-air temperature.

ALL the 549B units are in compliance with ASHRAE 90.1 2001 Energy

Standard for minimum SEER and EER requirement s. Refer to state and

local codes or visit the following website: http://solstice.crest.org/

efficiency/bcap to determine if compliance with this standard pertains to

a given geographical area of the United States.

HEATING

Cap.

(Btuh)

(Low)

COP

SOUND

RATING

(decibels)

SOUND

RATING

(decibels)

SOUND

RATING

(decibels)

IPLV

12.7 (100%)

10.4 ( 50%)

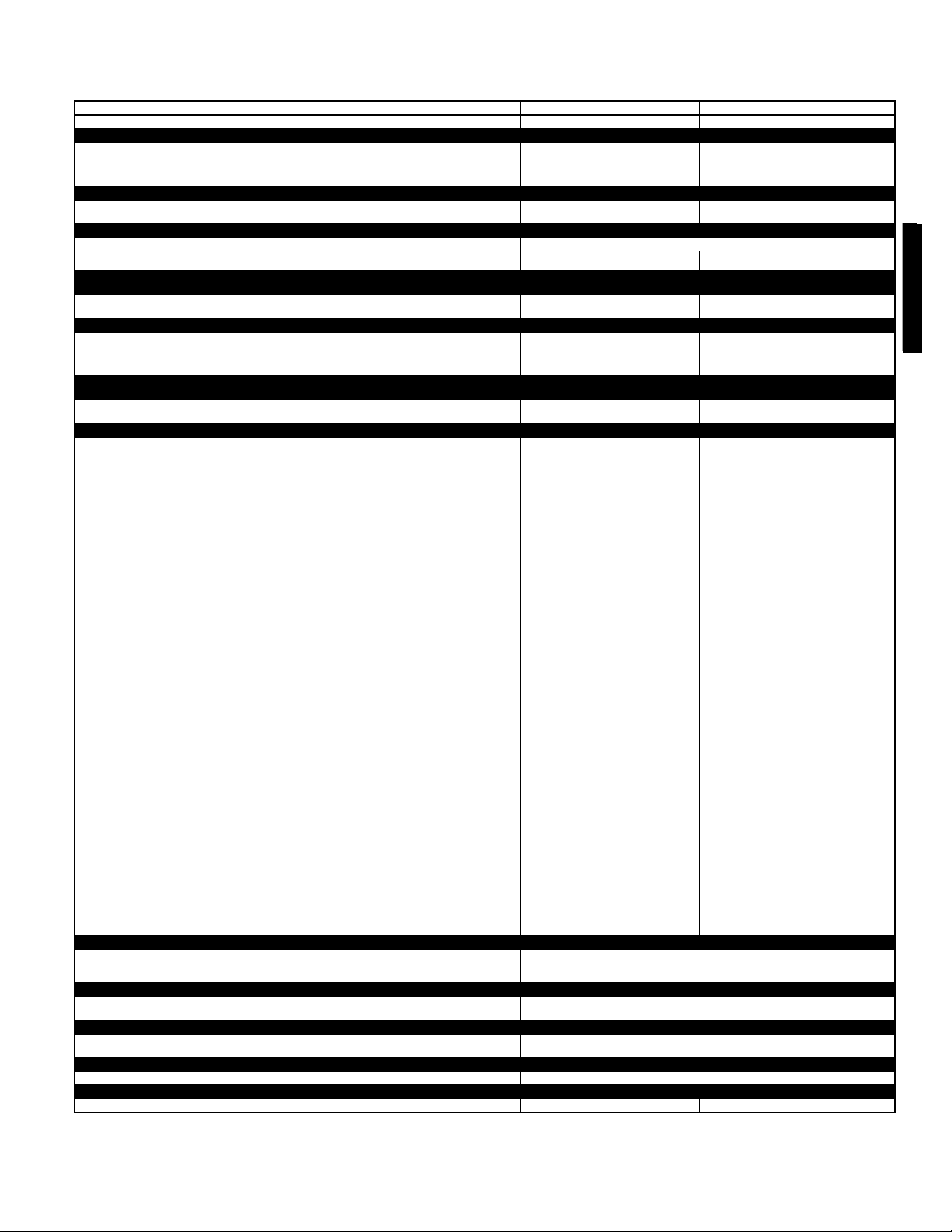

542J150,180 UNITS

UNIT

542J

Total

kW

150 14.3 140,000 4500 12.4 9.8 136,000 12.4 3.2 72,000 10.0 2.1 87

180 18.5 172,000 5200 9.7 9.3 172,000 15.3 3.3 90,000 12.5 2.2 88

LEGEND

COP — Coefficient of Performance

db — Dry Bulb

EER — Energy Efficiency Ratio

ESP — External Static Pressure

IPLV — Integrated Part-Load Value

wb — Wet Bulb

*Air-Conditioning and Refrigeration Institute.

NOTE: 50HJQ units are rated in accordance with ARI Standard 340-93.

Cooling ratings are net values, reflecting the effects of circulating fan

heat. Ratings are based on:

ESP: –.35 in. wg

Cooling Standard: 80 F db, 67 wb indoor coil entering-air temperature

and 95 F outdoor entering-air temperature.

High-Temp Heating Standard: 70 F db indoor coil entering-air temperature and 47 F db, 43 F wb outdoor coil entering-air temperature.

Low-Temp Heating Standard: 70 F db indoor coil entering-air temperature and 17 F db, 15 F wb outdoor coil entering-air temperature.

COOLING HEATING-HIGH TEMP HEATING-LOW TEMP

Net

Capacity

(Btuh)

Cfm IPLV EER

Total

Capacity

(Btuh)

Total

kW

IPLV Standard: 80 F db, 67 F wb indoor entering-air temperature and

80 F db outdoor entering-air temperature.

ALL the 542J units are in compliance with ASHRAE 90.1 2001 Energy

Standard for minimum SEER and EER requirement s. Refer to state and

local codes or visit the following website: http://solstice.crest.org/

efficiency/bcap to determine if compliance with this standard pertains to

a given geographical area of the United States.

COP

Total

Capacity

(Btuh)

Total

kW

COP

6

SOUND

RATING

(decibels)

Page 7

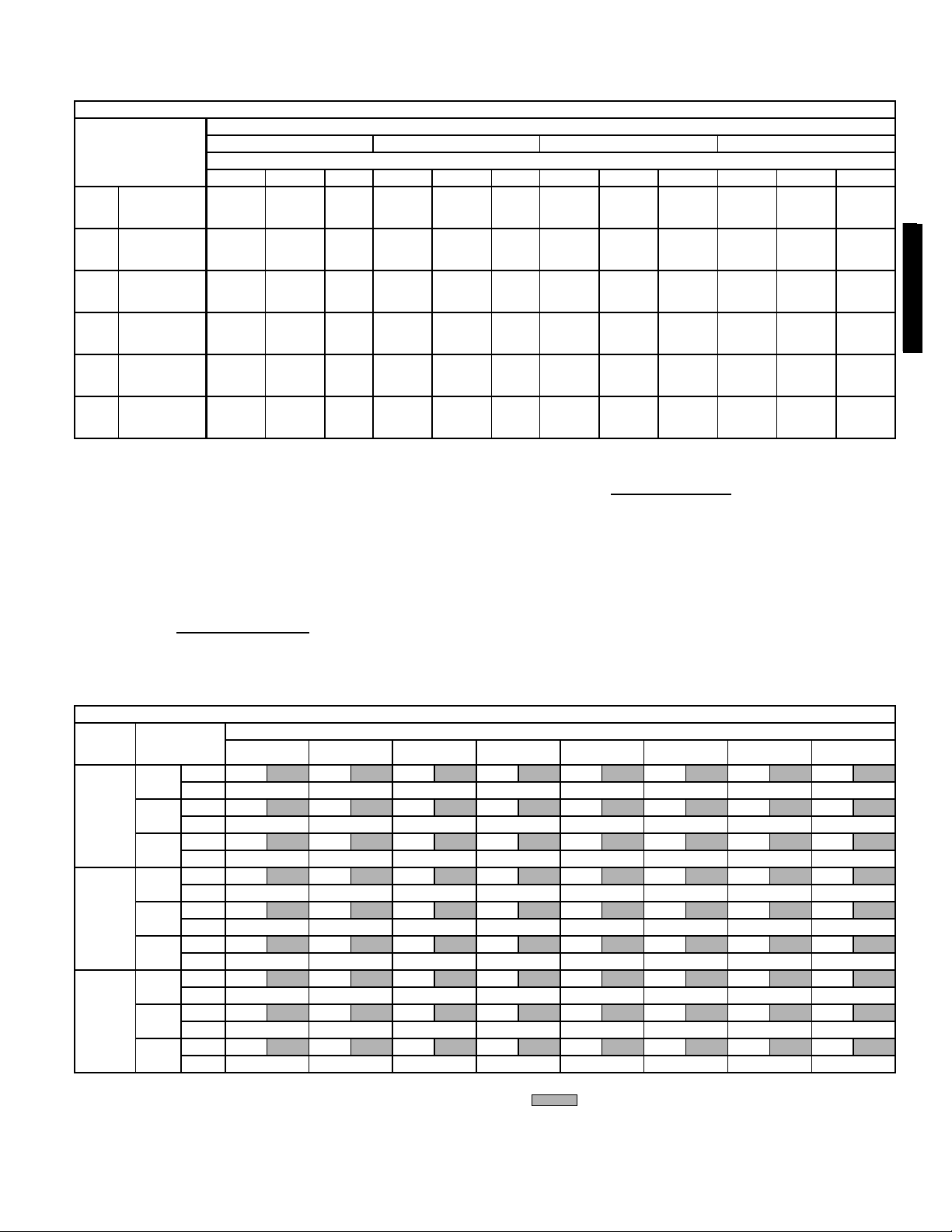

OPTIONS AND ACCESSORIES

548F036-120

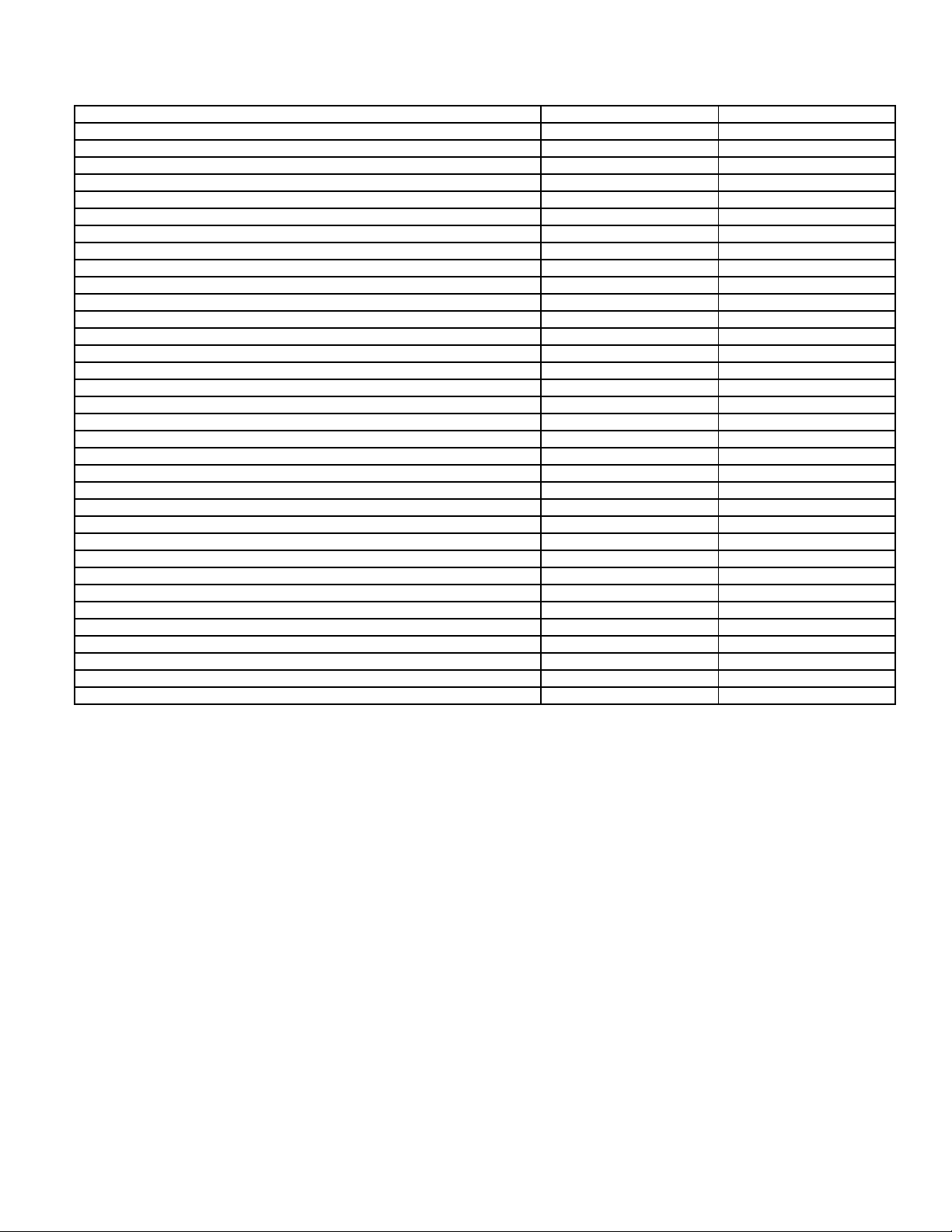

ITEM OPTION* ACCESSORY†

100% Open Two-Position Damper X

25% Open Two-Position Damper X

Alternate Motors and Drives XX

Convenience Outlet (Load Side) X

Copper Fins Indoor and Outdoor Coil X

Copper Fins Outdoor Coil X

E-Coat Outdoor Coil (Aluminum) X

E-Coat Outdoor Coil (Copper) X

EconoMi$erIV with Controller XX

EconoMi$er2 (without Controller) XX

Electric Heat X

Electronic Programmable Thermostat X

Emergency Heat Package X

Enthalpy or Differential Enthalpy Sensor X

Fan/Filter Status X

High-Static Motor and Drive X

Hinged Panel Kit for Economizer X

Indoor Air Quality (CO

Louvered Hail Guard X

Manual Outdoor-Air Damper (50% or 100%) X

Motormaster® I, II Head Pressure Control (Low Ambient Kit) X

Outdoor Air Enthalpy Sensor X

Outdoor Air/Return Air Temperature Sensor X

Outdoor Coil Grille X

Outdoor Coil Hail Guard Assembly X

Power Exhaust with Barometric Relief X

Pre-coat Aluminum Fins on Outdoor Coil X

Return Air Enthalpy Sensor X

Return Air Temperature Sensor X

Roof Curbs (Vertical and Horizontal Discharge) X

Thermostats and Subbases X

Thru-the-Bottom Utility Connections X

Time Guard II Control Circuit (Compressor Cycle Delay) X

Unit-Mounted Non-Fused Disconnect X

*Factory-installed.

†Field-installed.

NOTES:

1. Refer to unit guide specifications, price pages, or contact your

local representative for accessory and option package information.

2. Some options may increase product lead times.

) Sensor X

2

7

Page 8

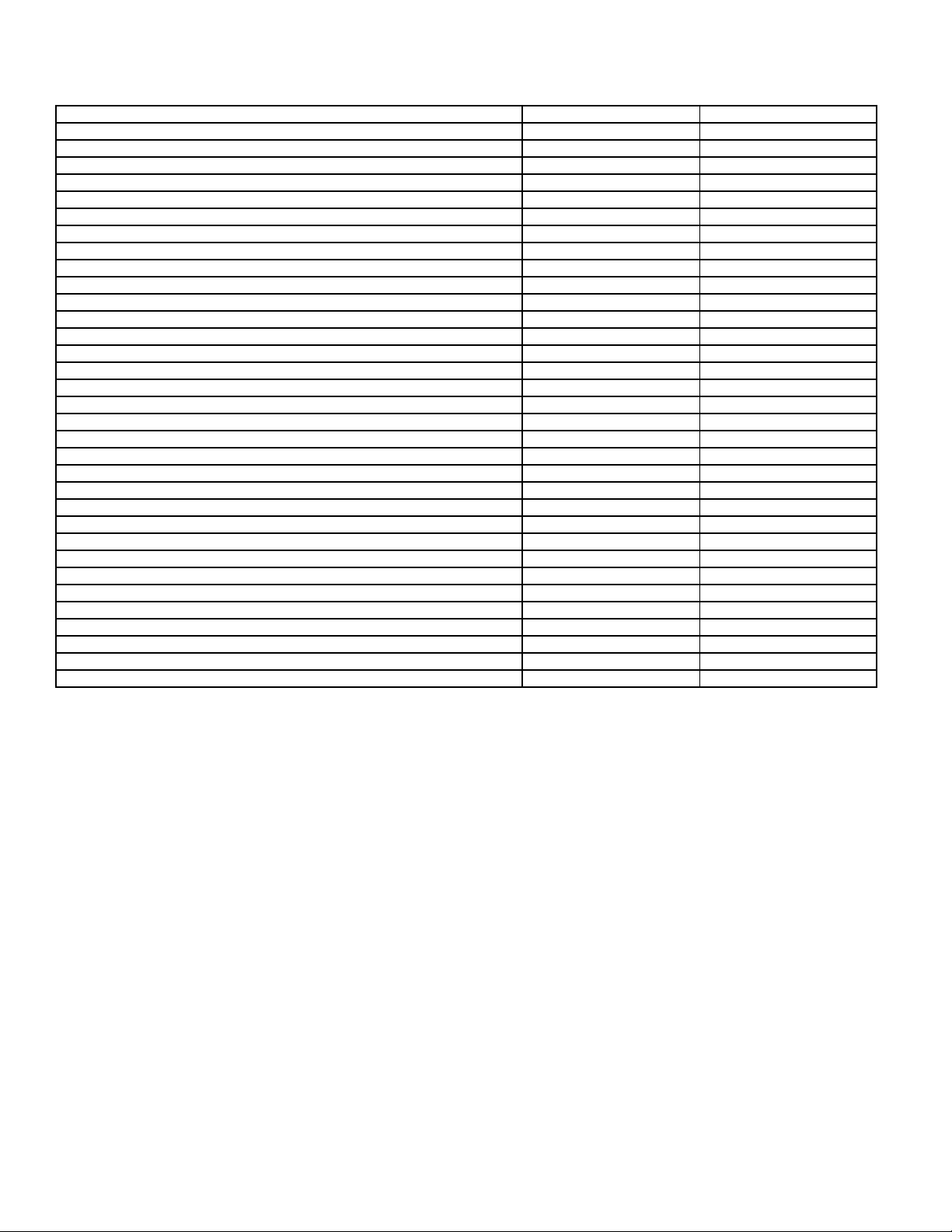

OPTIONS AND ACCESSORIES (cont)

549B036-120, 549C024-060

ITEM OPTION* ACCESSORY†

100% Open Two-Position Damper X

25% Open Two-Position Damper X

Alternate Motors and Drives XX

Convenience Outlet (Load Side) X

Copper Fins Indoor and Outdoor Coil X

Copper Fins Outdoor Coil X

E-Coat Outdoor Coil (Aluminum) X

E-Coat Outdoor Coil (Copper) X

EconoMi$erIV with Controller XX

EconoMi$er2 (without Controller) XX

Electric Heat X

Electronic Programmable Thermostat X

Emergency Heat Package X

Fan/Filter Status X

Hinged Access Panels X

Hinged Panel Kit for Economizer X

Indoor Air Quality (CO

Louvered Hail Guard X

Manual Outdoor-Air Damper X

Motormaster® I, II Head Pressure Control (Low Ambient Kit) X

Outdoor Air Enthalpy Sensor X

Outdoor Coil Grille X

Outdoor Coil Hail Guard Assembly X

Outdoor Air/Return Air Temperature Sensor X

Power Exhaust with Barometric Relief X

Pre-coat Aluminum Fins on Outdoor Coil X

Return Air Enthalpy Sensor X

Return Air Temperature Sensor X

Roof Curbs (Vertical and Horizontal Discharge) X

Thermostats and Subbases X

Thru-the-Bottom Utility Connections X

Time Guard II Control Circuit (Compressor Cycle Delay) X

Unit-Mounted Non-Fused Disconnect X

*Factory-installed.

†Field-installed.

NOTES:

1. Refer to unit guide specifications, price pages, or contact your

local representative for accessory and option package information.

2. Some options may increase product lead times.

) Sensor X

2

8

Page 9

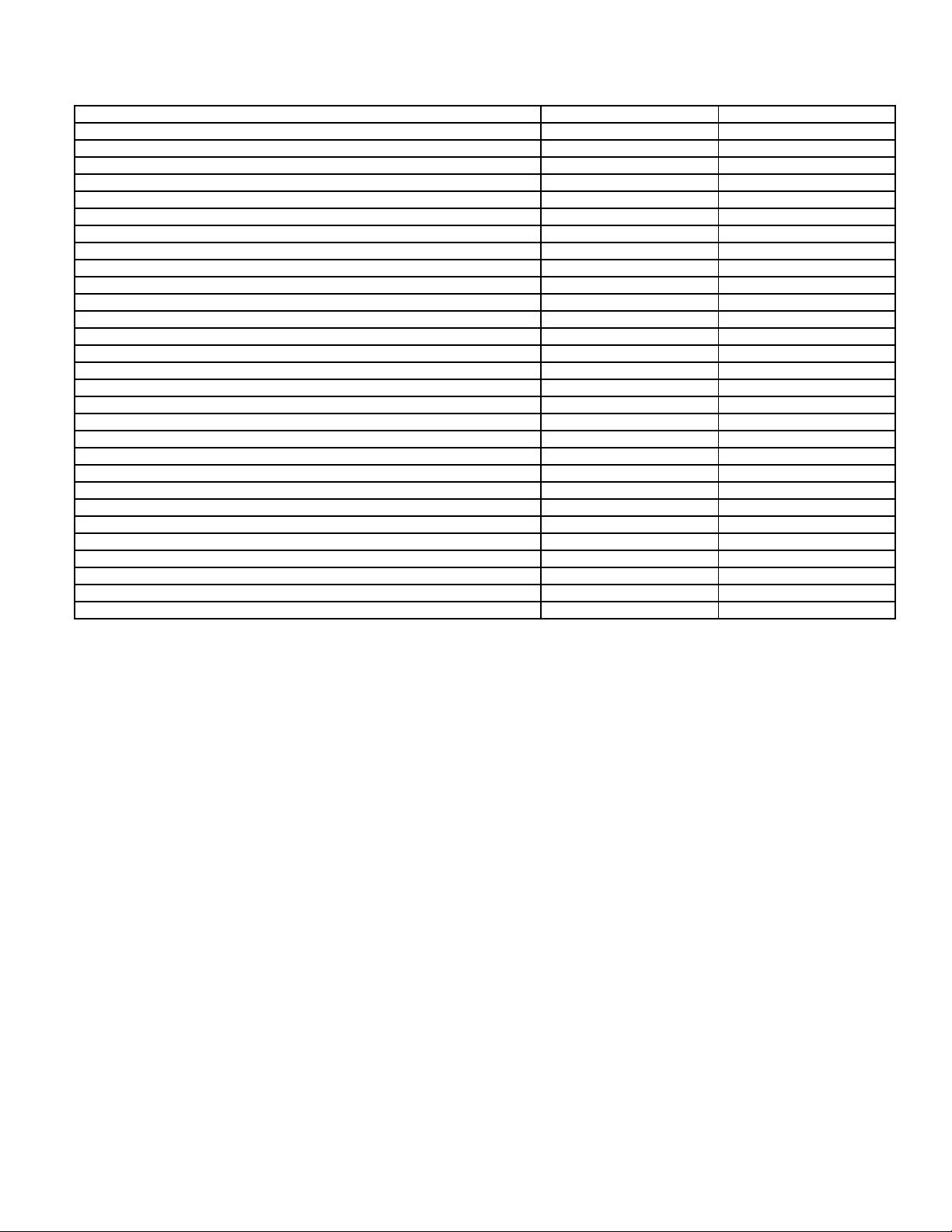

OPTIONS AND ACCESSORIES (cont)

542J150,180

ITEM OPTION* ACCESSORY†

25% Open Two-Position Damper X

Alternate Motors and Drives XX

Barometric Relief Damper (Not for use with horizontal roof curb) X

Convenience Outlet (Load Side) X

Copper Fins Indoor and Outdoor Coil X

Copper Fins Outdoor Coil X

E-Coat Outdoor Coil (Aluminum) X

E-Coat Outdoor Coil (Copper) X

EconoMi$erIV with Controller XX

EconoMi$er2 (without Controller) X

Electric Heat X

Electronic Programmable Thermostat X

Emergency Heat Package X

Fan/Filter Status X

Hinged Access Panels X

Horizontal Adapter Curb X

Hydronic Glycol Coil X

Indoor Air Quality (CO

Manual Outdoor-Air Damper X

Motormaster® V Head Pressure Control (Low Ambient Kit) X

Outdoor Air Enthalpy Sensor X

Power Exhaust without Barometric Relief X

Pre-coat Aluminum Fins on Outdoor Coil X

Return Air Enthalpy Sensor X

Return Air Temperature Sensor X

Roof Curbs (Vertical and Horizontal Discharge) X

Thermostats and Subbases X

Time Guard II Control Circuit (Compressor Cycle Delay) X

Winter Start Time Delay X

*Factory-installed.

†Field-installed.

NOTES:

1. Refer to unit price pages or contact your local representative for

accessory and option package information.

2. Some options may increase product lead times.

) Sensor X

2

9

Page 10

OPTIONS AND ACCESSORIES (cont)

Roof Curbs (Horizontal and Vertical) permit installation and

securing of ductwork to curb prior to mounting unit on the curb.

Both 14-in. and 24-in. roof curbs are available as field-installed

accessories.

EconoMi$erIV is available as a factory-installed option in

vertical supply/return configuration only for unit sizes 036-120.

Vertical or horizontal configuration is available for unit sizes 150

and 180. (EconoMi$erIV is available as a field-installed accessory for horizontal and/or vertical supply return configurations.)

The EconoMi$erIV is provided with an industry standard,

standalone, solid-state controller that is easy to configure and

troubleshoot. The EconoMi$erIV is compatible with non-DDC

applications. EconoMi$erIV is equipped with a barometric relief

damper capable of relieving up to 100% return air. Dry bulb

outdoor-air temperature sensor is provided as standard. The

return air sensor, indoor enthalpy sensor, and outdoor enthalpy

sensor are provided as field-installed accessories to provide

enthalpy control, differential enthalpy control, and differential

dry bulb temperature control.

EconoMi$er2 is available as a factory-installed option in vertical supply/return configuration only. (EconoMi$er2 is available

as a field-installed accessory for horizontal and/or vertical

supply return configurations.) The EconoMi$er2 is provided

without a controller for use with field-installed third-party controls. EconoMi$er2 is equipped with a barometric relief damper

capable of relieving up to 100% return air. Dry bulb outdoor-air

temperature sensor is provided as standard. The enthalpy,

differential temperature (adjustable), and differential enthalpy

control are provided as field-installed accessories. The

EconoMi$er2 is capable of control from a 4 to 20 mA signal

through optional 4 to 20 mA design without microprocessor

control (required for third party control interface).

Manual Outdoor-Air Damper accessory can be preset to

admit up to 50% outdoor air for year round ventilation.

Tw o- Po s it i on Da m pe r package is available as an accessory.

Both 25% or 100% outdoor air dampers are available.

Head Pressure Control (Motormaster) accessory package

maintains condensing temperature between 90 F and 110 F at

outdoor ambient temperatures down to –20 F by condenser-fan

speed modulation or condenser-fan cycling and wind baffles.

Electric Resistance Heaters are UL listed and available to

match heating requirements. Single point kits available for each

heater when required. Heaters are field-installed accessories.

Unit-Mounted, Non-Fused Disconnect Switch provides unit

power shutoff. The switch is accessible from outside the unit

and provides power off lockout capability and is available as

factory-installed option .

Convenience Outlet is factory-installed and internally mounted

with easily accessible 115-v female receptacle.

Compressor Cycle Delay (Time Guard II) prevents unit from

restarting for minimum of 5 minutes after shutdown.

Thru-the-Bottom Utility Connectors permit electrical connections to be brought to the unit through the basepan. Connectors

are a field-installed accessory.

Fan/Filter Status Switch accessory provides status of indoor

(evaporator) fan (ON/ OFF) or filter (CLEAN/DIRTY).

Power Exhaust accessory will provide system exhaust of up to

100% of return air (vertical only). The power exhaust is a fieldinstalled accessory (separate vertical and horizontal design).

Ultra-Violet Germicidal Lamps eliminate odor causing mold

and fungus that may develop in the wet area of the evaporator

section of the unit. The high output, low temperature germicidal

lamps are field installed in the evaporator section of the un it,

aimed at the evaporator coil and condensate pan.

Hinged Panel Option provides hinged access panels for the filter, compressor, evaporator fan, and control box areas. Filter

hinged panels permit tool-less entry for changing filters. Each

hinged panel is permanently attached to the rooftop unit and is

a factory-installed option.

Emergency Heat Control Package accessory activates auxiliary heat when necessary if mechanical heating is locked out.

10

Page 11

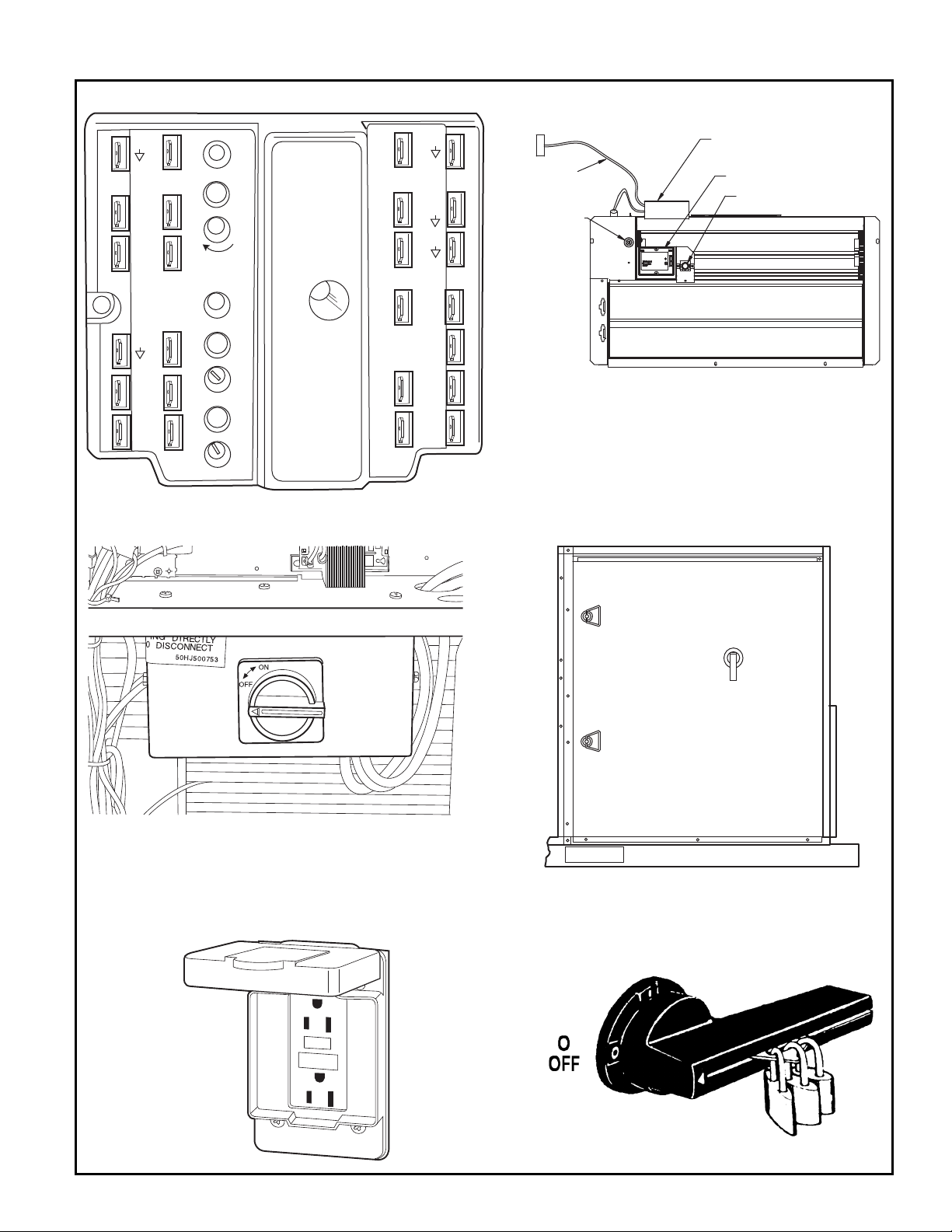

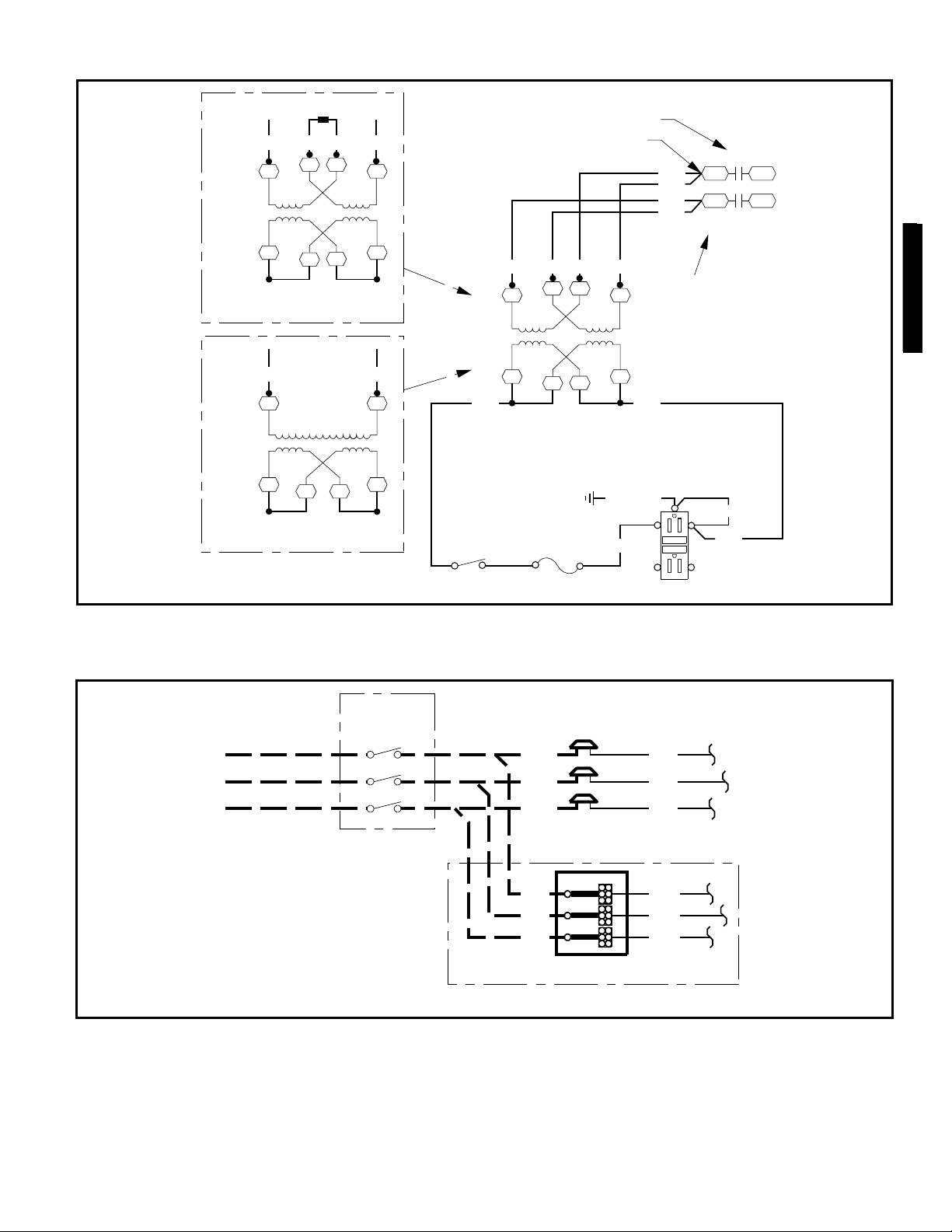

TR1

24 Vac

COM

TR

24

Vac

HOT

12

3

4

5

EF

EF1

+

_

P1

T1

P

T

N

EXH

2V 10V

EXH

Set

Set

2V 10V

2V 10V

DCV

DCV

Free

Cool

B

C

A

D

SO+

SR+

SR

SO

AQ1

AQ

DCV

Min

Pos

Open

Max

N1

ECONOMI$ERIV CONTROL

GEAR-DRIVEN ECONOMI$ERIV COMPONENT PARTS

(3 to 6 Ton Unit Shown)

UNIT-MOUNTED DISCONNECT (Sizes 150,180)

UNIT-MOUNTED DISCONNECT (Sizes 024-120)

CONVENIENCE OUTLET

a50-7750

a50-8041

50-1247

50-1246

a48-4181

a48-7445

OPTIONS AND ACCESSORIES (cont)

WIRING

HARNESS

ACTUATOR

ECONOMI$ERIV

CONTROLLER

OUTSIDE AIR

TEMPERATURE SENSOR

LOW AMBIENT

SENSOR

11

Page 12

OPTIONS AND ACCESSORIES (cont)

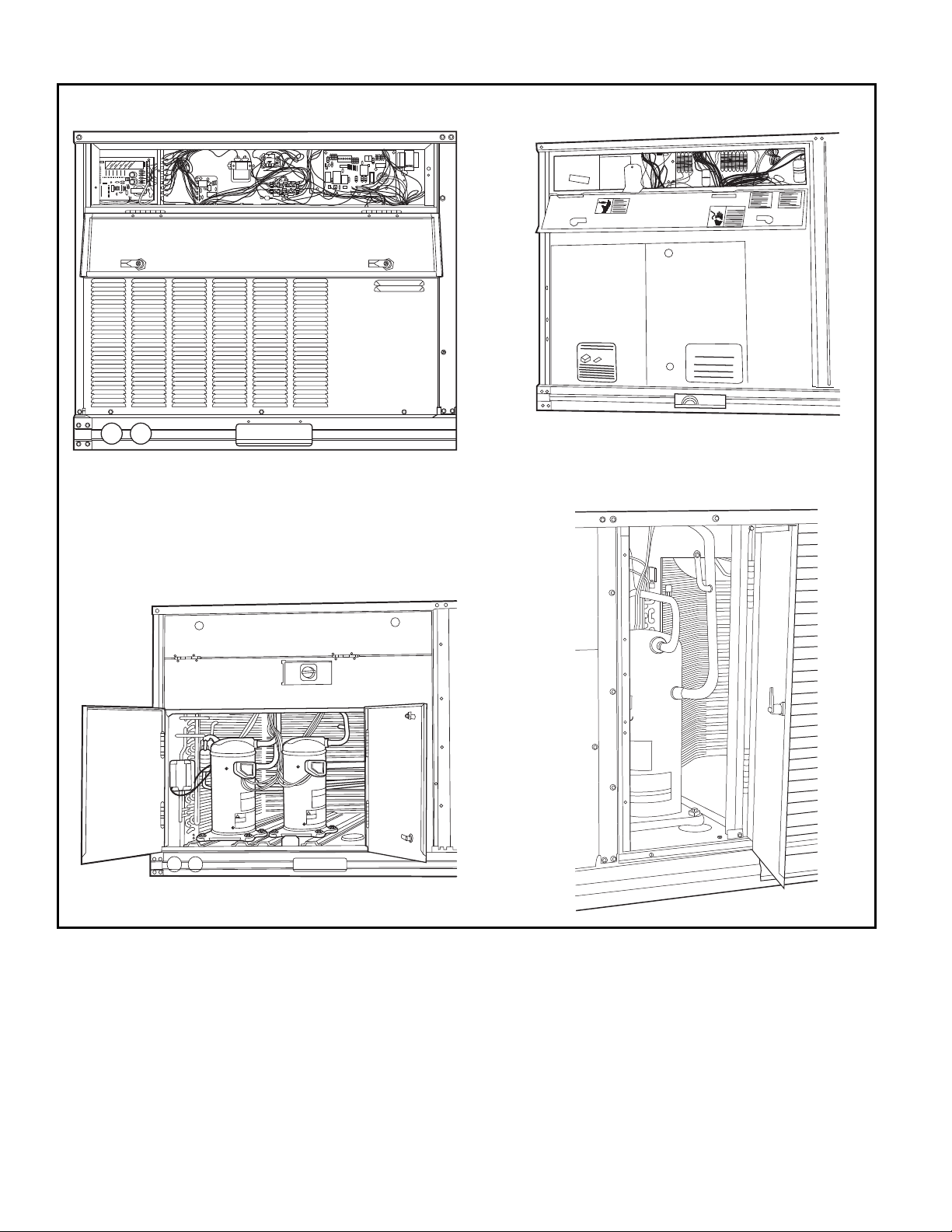

CONTROL BOX HINGED PANEL OPTION,

549B036-072 UNITS SHOWN

CONTROL BOX HINGED PANEL OPTION,

549B090-120 UNITS SHOWN

COMPRESSOR HINGED PANEL OPTION,

549B090-120 UNITS SHOWN

COMPRESSOR HINGED PANEL OPTION,

549B036-060 UNITS SHOWN

NOTE: Hinged access panels are not available on 548F units.

a50-8042

50-1298

50-1288

50-1289

12

Page 13

OPTIONS AND ACCESSORIES (cont)

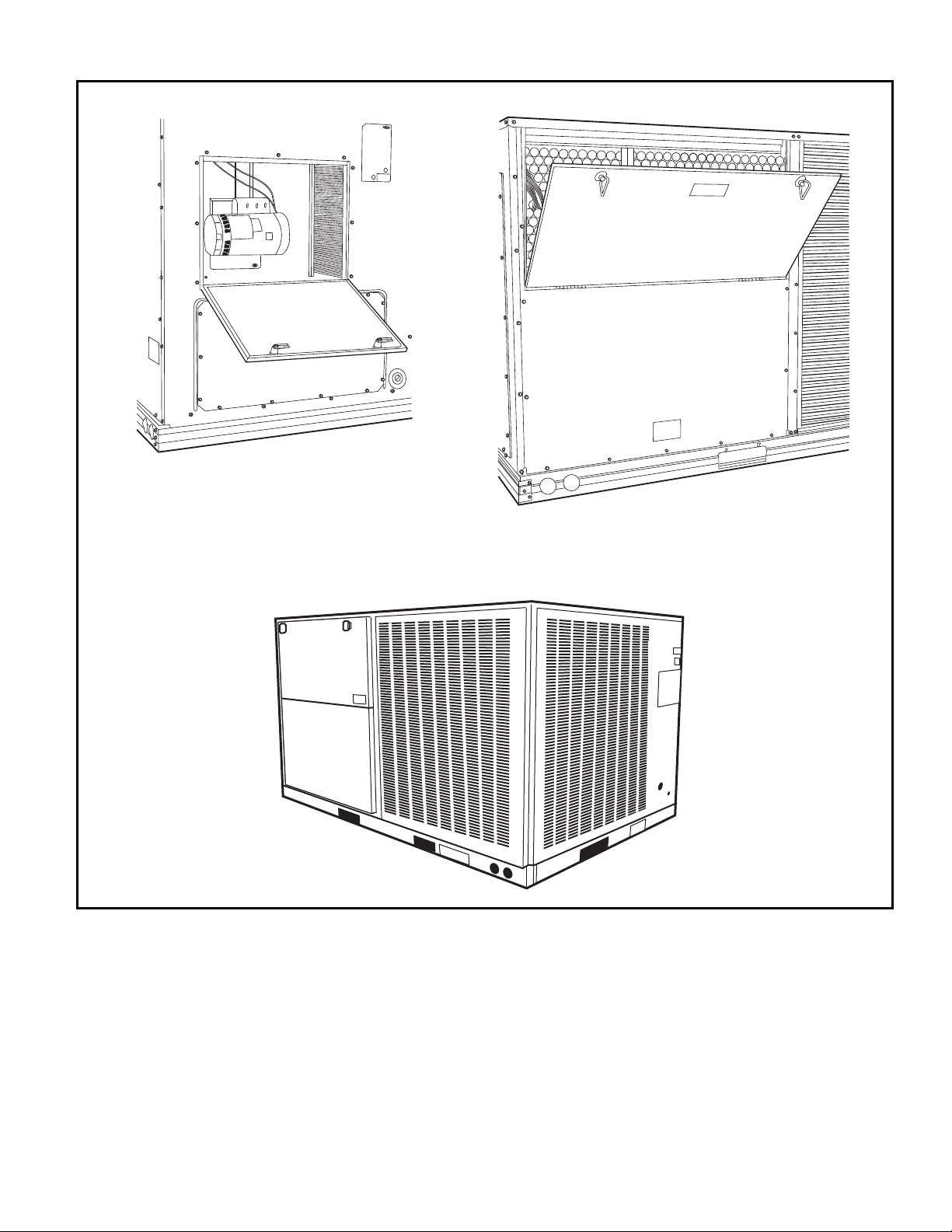

EVAPORATOR-FAN HINGED PANEL OPTION

FILTER HINGED PANEL OPTION

NOTE: Hinged access panels are not available on 548F units.

LOUVERED HAIL GUARD OPTON

(024-120 only)

50-1290

a50-8043

a50-8059

13

Page 14

PHYSICAL DATA

548F

548F036-072

UNIT SIZE 548F 036 048 060 072

NOMINAL CAPACITY (tons) 3456

OPERATING WEIGHT (lb)

Unit 500 520 550 590

Economizer

EconoMi$erIV or EconoMi$er2 50 50 50 50

Roof Curb* 115 115 115 115

COMPRESSOR Hermetic

Quantity 1111

Oil (oz) 45 54 50 54

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1 5-1 6-0 8-0 11-2

Circuit 2 ————

OUTDOOR COIL

Rows...Fins/in. 1...17 1...17 2...17 2...17

Total Face Area (sq ft) 10.31 14.58 12.25 16.53

3

/8-in. OD Enhanced Copper Tubes, Aluminum Lanced Fins, Fixed Orifice Metering Device

OUTDOOR FAN Propeller Type

Nominal Cfm 4000 4000 4000 4000

Quantity...Diameter (in.) 1...22.0 1...22.0 1...22.0 1...22.0

Motor Hp...Rpm

Watts Input (Total) 325 325 325 325

INDOOR COIL

Rows...Fins/in. 2...15 2...15 3...15 3...15

Total Face Area (sq ft) 4.2 4.2 5.5 5.5

1

/4...1100

3

/8-in. OD Enhanced Copper Tubes, Aluminum Double-Wavy Fins, Fixed Orifice Metering Device

1

/4...1100

1

/4...1100

1

/4...1100

INDOOR FAN Centrifugal Type

Quantity...Size (in.) Std 1...10 x 10 1...10 x 10 1...11 x 10 1...10 x 10

Type Drive Std Direct Direct Direct Belt

Nominal Cfm 1200 1600 2000 2400

Maximum Continuous Bhp Std .34 .75 1.20 2.40

Motor Frame Size Std 48 48 48 56

Nominal Rpm High/Low Std 860/800 1075/970 1075/970 —

Fan Rpm Range Std — — — 1070-1460

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 2100 2100 2100 2100

Motor Pulley Pitch Diameter Min/Max (in.) Std — — — 2.8/3.8

Nominal Motor Shaft Diameter (in.) Std

Fan Pulley Pitch Diameter (in.) Std ———4.5

Belt, Quantity...Type...Length (in.) Std — — — 1...A...40

Pulley Center Line Distance (in.) Std — — — 14.7-15.5

Speed Change per Full Turn of

Movable Pulley Flange (rpm) Std

Movable Pulley Maximum Full Turns

From Closed Position Std

Factory Setting Std ——— 3

Factory Speed Setting (rpm) Std — — — 1225

Fan Shaft Diameter at Pulley (in.)

Alt 1...10 x 10 1...10 x 10 1...10 x 10 —

High-Static 1...10 x 10 1...10 x 10 1...10 x 10 1...10 x 10

Alt Belt Belt Belt —

High-Static Belt Belt Belt Belt

Alt 1.00 1.00 1.30/2.40† —

High-Static 2.40 2.40 2.90 2.90

Alt 48 48 56 —

High-Static 56 56 56 56

Alt 1620 1620 1725 —

High-Static 1725 1725 1725 1725

Alt 760-1000 770-1175 878-1192 —

High-Static 1075-1455 1075-1455 1300-1685 1300-1685

Alt 1.9/2.9 1.9/2.9 2.4/3.4 —

High-Static 2.8/3.8 2.8/3.8 3.4/4.4 3.4/4.4

Alt

High-Static

Alt 4.5 4.0 4.5 —

High-Static 4.5 4.5 4.5 4.5

Alt 1...A...34 1...A...34 1...A...39 —

High-Static 1...A...39 1...A...39 1...A...40 1...A...40

Alt 10.0-12.4 10.0-12.4 14.7-15.5 —

High-Static 10.0-12.4 10.0-12.4 14.7-15.5 14.7-15.5

1

/

2

1

/

2

5

/

8

1

/

2

1

/

2

5

/

8

1

/

2

5

/

8

5

/

8

5

/

8

—

5

/

8

———80

Alt 48 70 80 —

High-Static 65 65 60 60

——— 5

Alt 556—

High-Static 6655

Alt 333—

High-Static 3

Alt 856 932 1035 —

High-Static 1233 1233 1416 1416

1

/

2

5

/

8

31/

2

5

/

8

31/

2

5

/

8

31/

2

5

/

8

HIGH-PRESSURE SWITCH (psig)

Standard Compressor Internal Relief (Differential) 450 ± 50

Cutout 428

Reset (Auto.) 320

LOSS-OF-CHARGE SWITCH (psig)

Cutout 7 ± 3

Reset (Auto.) 22 ± 7

FREEZE-PROTECTION THERMOSTAT (F)

Opens 30 ± 5

Closes 45 ± 5

OUTDOOR-AIR INLET SCREENS Cleanable. Quantity and size depend on options selected.

RETURN-AIR FILTERS Throwaway

Quantity...Size (in.) 2...16 x 25 x 2

LEGEND

Bhp — Brake Horsepower

*Weight of 14-in. roof curb.

†Single phase/three phase.

NOTE: The 548F units have a loss-of-charge switch located in the liquid line.

14

Page 15

548F

PHYSICAL DATA

548F090-120

NOMINAL CAPACITY (tons) 7

UNIT SIZE 548F 090 120

OPERATING WEIGHT (lb)

Unit 940 1015

Economizer

EconoMi$erIV or EconoMi$er2 75 75

Roof Curb* 143 143

COMPRESSOR (Hermetic) Reciprocating Scroll

Quantity 22

Oil (oz) 45 ea 54 ea

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1 5-14 7-14

Circuit 2 5-13 8- 3

OUTDOOR COIL

Rows...Fins/in. 1...17 2...17

Total Face Area (sq ft) 20.50 18.30

OUTDOOR FAN Propeller Type

Nominal Cfm 6500 6500

Quantity...Diameter (in.) 2...22 2...22

Motor Hp...Rpm

Watts Input (Total) 500 500

INDOOR COIL

Rows...Fins/in. 3...15 3...15

Total Face Area (sq ft) 8.0 11.1

3

INDOOR FAN Centrifugal Type

Quantity...Size (in.) Std 1...15 x 15 1...15 x 15

Type Drive Std Belt Belt

Nominal Cfm 3000 4000

Maximum Continuous Bhp Std 2.40 2.40

Motor Frame Size Std 56 56

Nominal Rpm Std ——

Fan Rpm Range Std 590- 840 685- 935

Motor Bearing Type Ball Ball

Maximum Allowable Rpm 2100 2100

Motor Pulley Pitch Diameter Min/Max (in.) Std 2.4/3.4 2.8/3.8

Nominal Motor Shaft Diameter (in.) Std

Fan Pulley Pitch Diameter (in.) Std 7.0 7.0

Belt, Quantity...Type...Length (in.) Std 1...A...53 1...A...49

Pulley Center Line Distance (in.) Std 16.75-19.25 15.85-17.50

Speed Change per Full Turn of

Moveable Pulley Flange (rpm)

Moveable Pulley Maximum Full Turns

From Closed Position

Factory Setting Std 55

Factory Speed Setting (rpm) Std 590 685

Fan Shaft Diameter at Pulley (in.) 11

Alt 1...15 x 15 1...15 x 15

High-Static 1...15 x 15 1...15 x 15

Alt Belt Belt

High-Static Belt Belt

Alt 2.40 2.90

High-Static 3.70 5.25

Alt 56 56

High-Static 56 56

Alt ——

High-Static 1725 1725

Alt 685- 935 835-1085

High-Static 860-1080 830-1130

Alt 2.8/3.8 3.4/4.4

High-Static 4.0/5.0 2.8/3.8

Alt

High-Static

Alt 7.0 7.0

High-Static 8.0 5.8

Alt 1...A...49 1...A...51

High-Static 1...A...65 1...BX...48

Alt 16.75-19.25 15.85-17.50

High-Static 16.75-19.25 15.85-17.50

Std 50 50

Alt 50 50

High-Static 60 60

Std 55

Alt 55

High-Static 56

Alt 55

High-Static 55

Alt 685 835

High-Static 860 887

HIGH-PRESSURE SWITCH (psig)

Standard Compressor Internal Relief (Differential) 450 ± 50

Cutout 428

Reset (Auto.) 320

LOSS-OF-CHARGE (LOW-PRESSURE) SWITCH (psig)

Cutout 7 ± 3

Reset (Auto.) 22 ± 5

FREEZE PROTECTION THERMOSTAT (F)

Opens 30 ± 5

Closes 45 ± 5

OUTDOOR-AIR INLET SCREENS Cleanable.

RETURN-AIR FILTERS Throwaway

Quantity...Size (in.) 4...16 x 20 x 2 4...20 x 20 x 2

LEGEND

Bhp — Brake Horsepower

*Weight of 14-in. roof curb.

1

/

2

3

/8-in. OD Enhanced Copper Tubes, Aluminum Lanced Fins,

1

/4...1100

/8-in. OD Enhanced Copper Tubes, Aluminum Double-Wavy Fins,

Fixed Orifice Metering Device

Fixed Orifice Metering Device

5

/

8

5

/

8

7

/

8

10

1

/4...1100

5

7

7

/

8

/

8

/

8

Screen quantity and size vary based on options selected.

15

Page 16

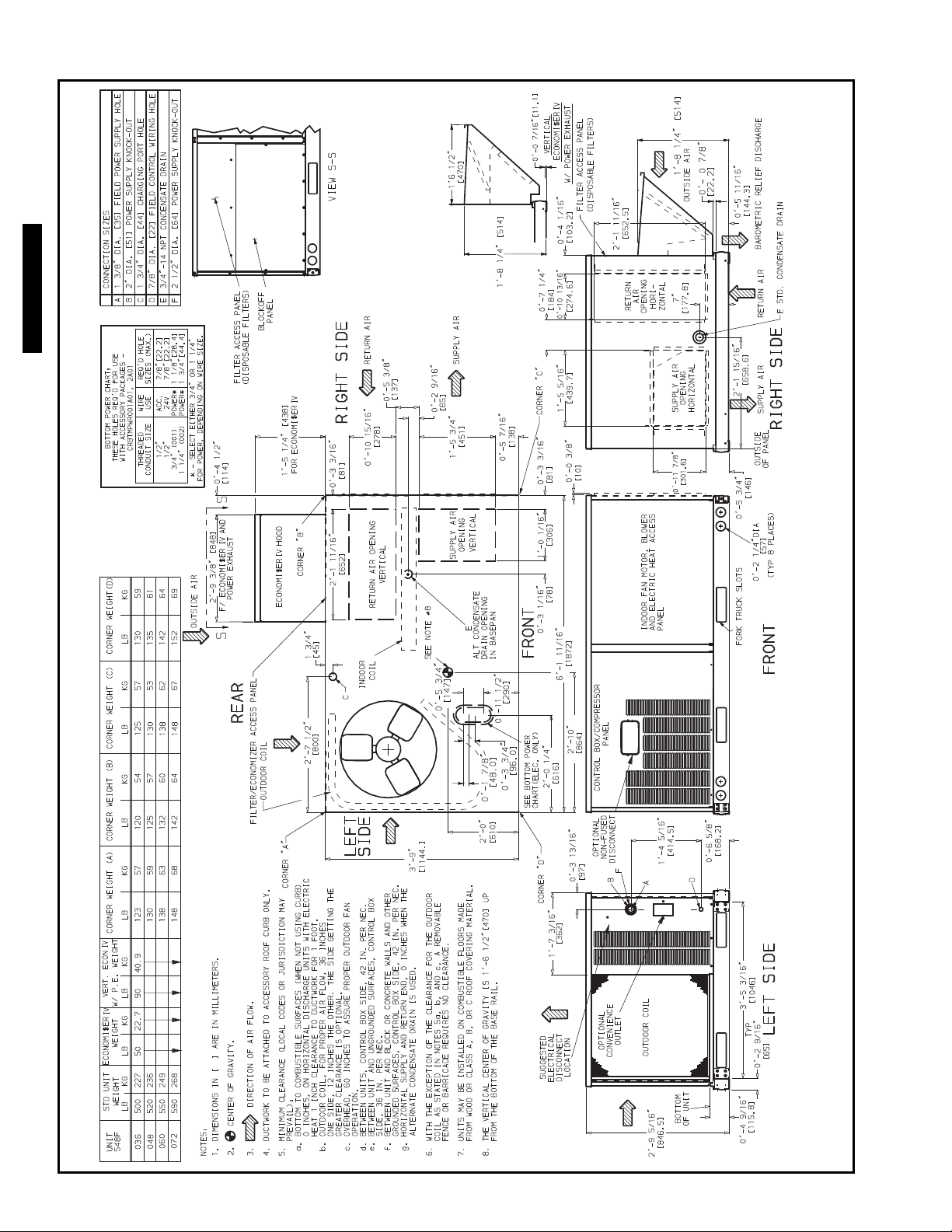

BASE UNIT DIMENSIONS

548F036-072

a50-8044

548F

16

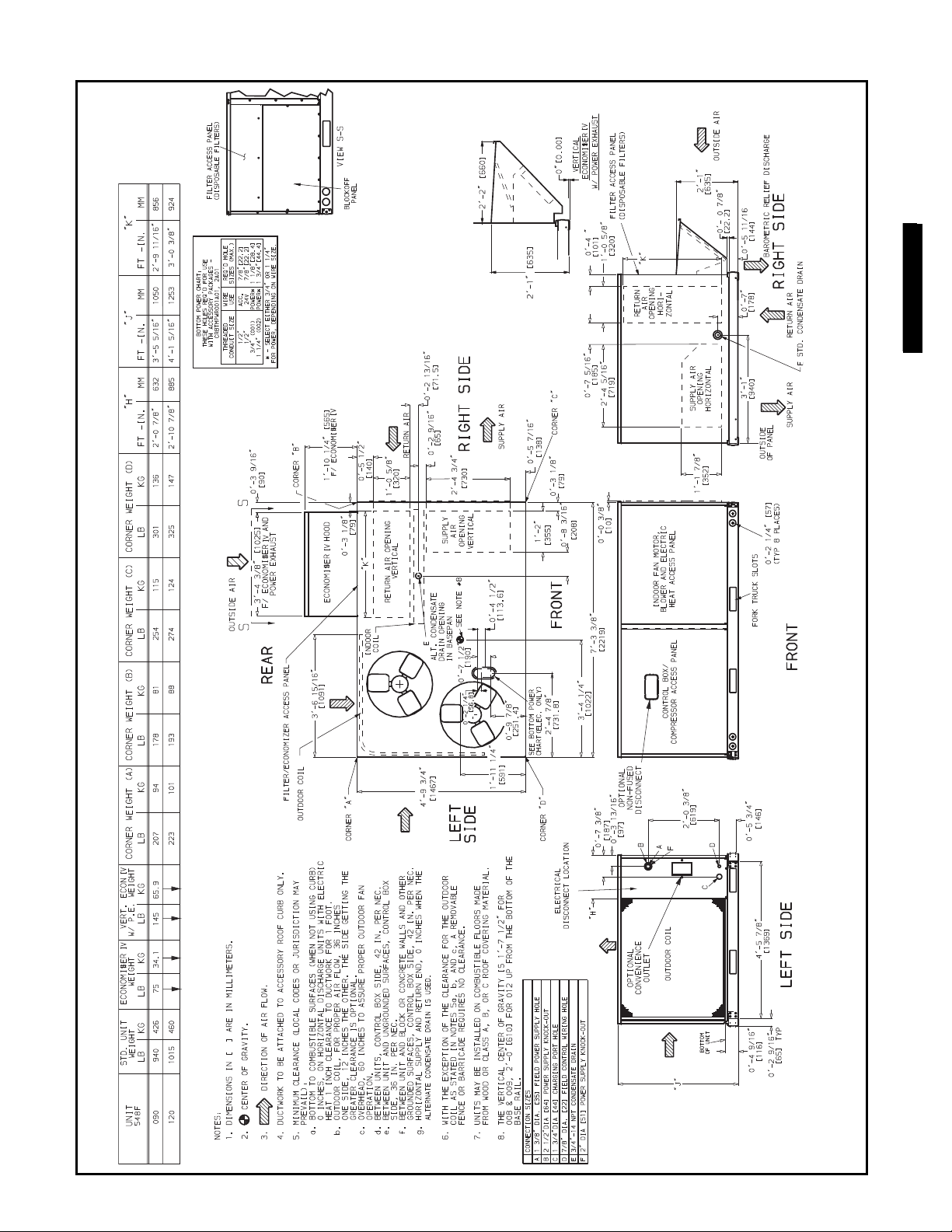

Page 17

BASE UNIT DIMENSIONS (cont)

548F090,120

a50-8045

548F

17

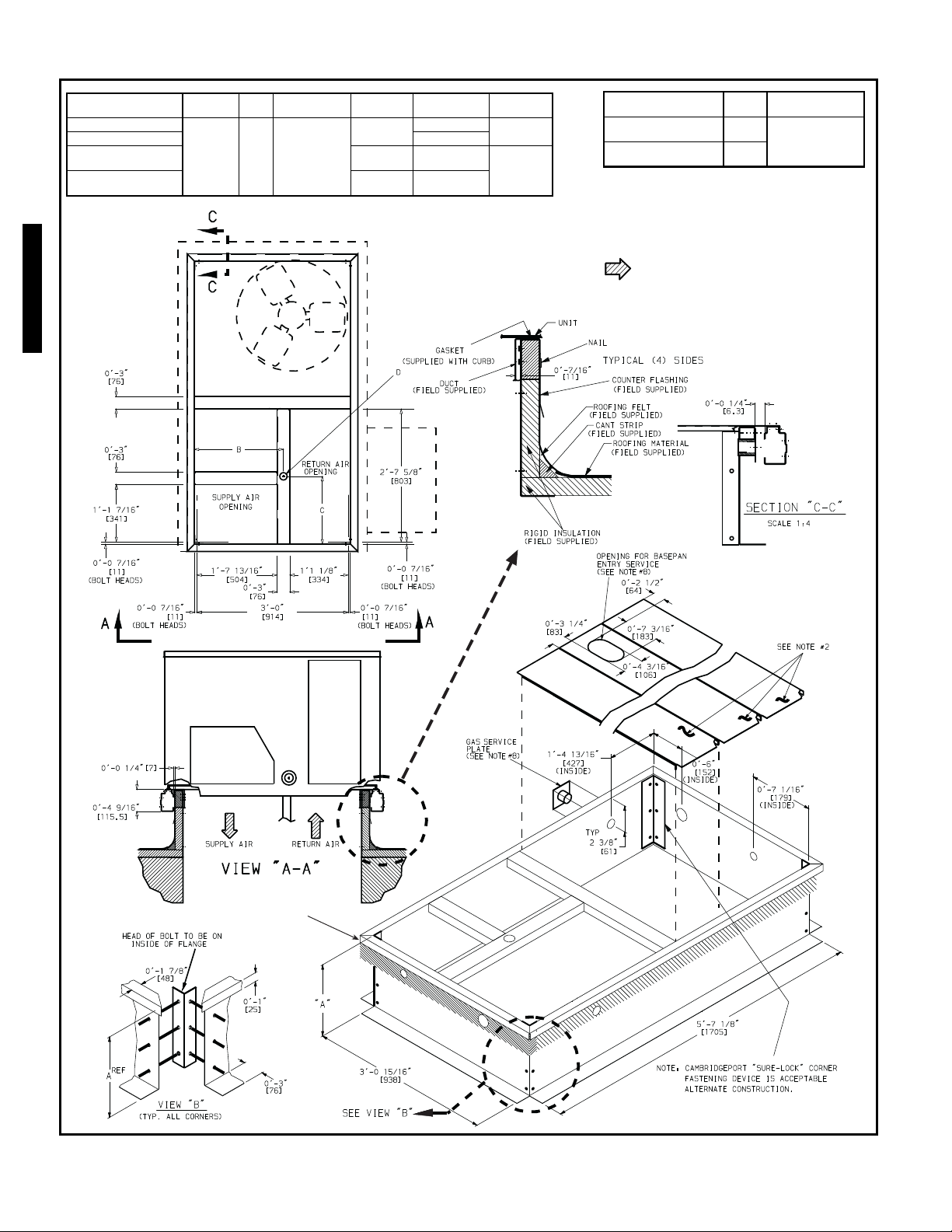

Page 18

ACCESSORY DIMENSIONS

TO ENSURE AIRTIGHT CONNECTION.

PLACE UNIT AS CLOSE TO THIS

END AS POSSIBLE

TO ENSURE AIRTIGHT CONNECTION.

PLACE UNIT AS CLOSE TO THIS

END AS POSSIBLE

ROOF CURB

ACCESSORY

A UNIT SIZE

CRRFCURB001A00

1′-2″

[356]

548F036-072

CRRFCURB002A00

2′-0″

[610]

NOTES:

1. Roof curb accessory is shipped disassembled.

2. In su late d panels.

3. Dimensions in [ ] are in millimeters.

4. Roof curb: galvanized steel.

5. Attach ductwork to curb (flanges of duct rest on curb).

6. Service clearance: 4 ft on each side.

7. Direction of airflow.

8. Connector packages CRBTMPWR001A00 and

002A00 are for thru-the-curb type gas. Packages

CRBTMPWR003A00 and 004A00 are for thru-thebottom type gas connections.

CONNECTOR

PKG. ACCY.

BC

D ALT

DRAIN HOLE

GAS POWER CONTROL

CRBTMPWR001A00

1′-9

11

/

16

″

[551]

1′-4″

[406]

13/

4

″

[44.5]

3

/

4

″

[19] NPT

3

/4″ [19] NPT

1

/

2

″

[12.7]

CRBTMPWR002A00 1

1

/4″ [31.7]

CRBTMPWR003A00

1

/

2

″

[12.7] NPT

3

/4″ [19] NPT

1

/

2

″

[12.7]

CRBTMPWR004A00

3

/

4

″

[19] NPT

11/4″ [31.7]

548F036-072

a48-5374

548F

18

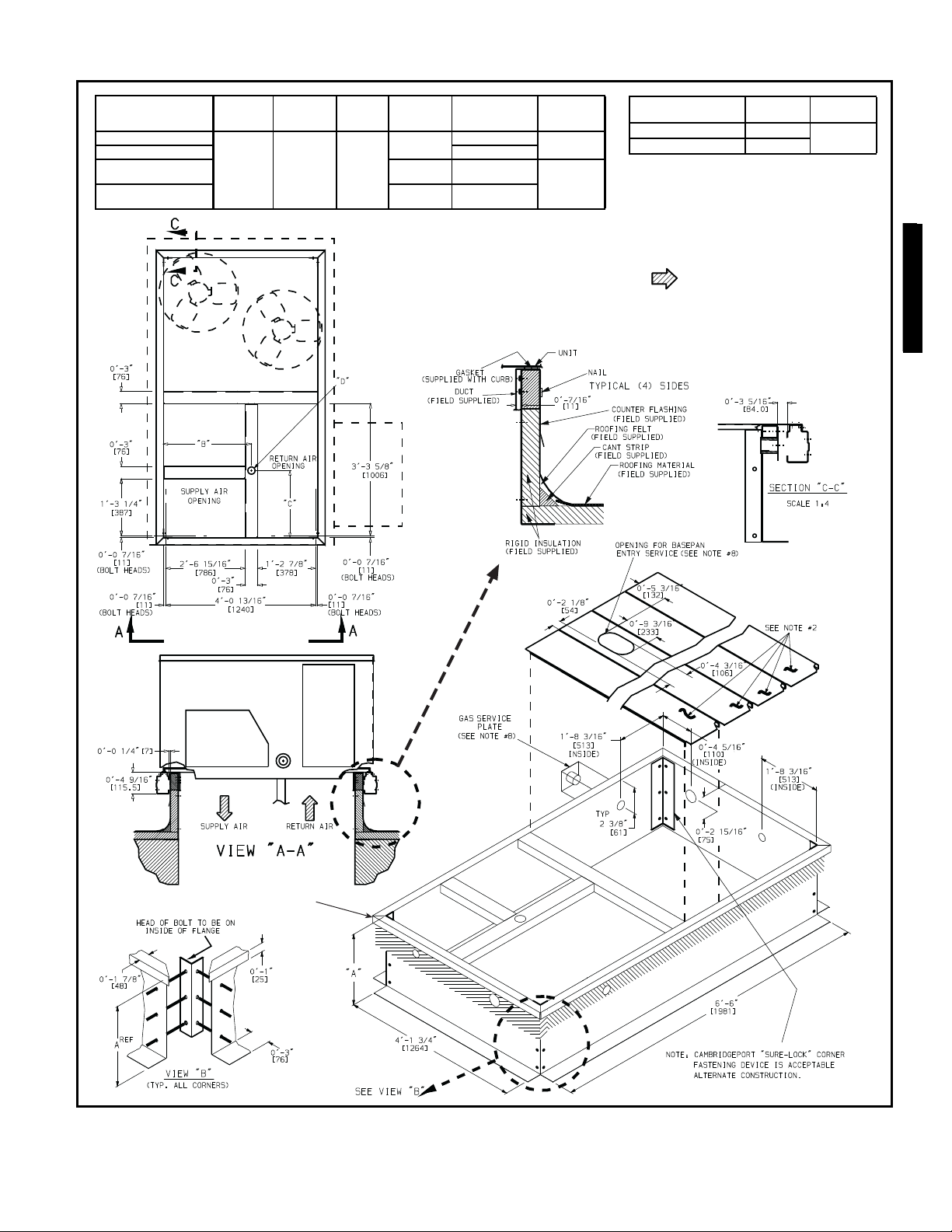

Page 19

ACCESSORY DIMENSIONS (cont)

TO ENSURE AN AIRTIGHT CONNECTION,

PLACE UNIT ON CURB AS CLOSE TO

DUCT END AS POSSIBLE.

TO ENSURE AN AIRTIGHT CONNECTION,

PLACE UNIT ON CURB AS CLOSE TO

DUCT END AS POSSIBLE.

CONNECTOR

PKG. ACCY.

BC

D ALT

DRAIN

HOLE

GAS POWER CONTROL

CRBTMPWR001A00

2′-87/

16

″

[827]

1′-1015/

16

″

[583]

13/

4

″

[44.5]

3

/

4

″

[19] NPT

3

/4″ [19] NPT

1

/

2

″

[12.7] NPT

CRBTMPWR002A00 1

1

/4″ [31.7]

CRBTMPWR003A00

1

/

2

″

[12.7] NPT

3

/4″ [19] NPT

1

/

2

″

[12.7] NPT

CRBTMPWR004A00

3

/

4

″

[19] NPT

11/4″ [31.7]

NOTES:

1. Roof curb accessory is shipped disassembled.

2. Insulated panels: 1-in. thick polyurethane foam,

1

3

/4 lb density.

3. Dimensions in [ ] are in millimeters.

4. Roof curb: 16-gage steel.

5. Attach ductwork to curb (flanges of duct rest on

curb).

6. Service clearance 4 ft on each side.

7. Direction of airflow.

8. Connector packages CRBTMPWR001A00 and

2A00 are for thru-the-curb gas type. Packages

CRBTMPWR003A00 and 4A00 are for thruthe-bottom type gas connections.

ROOF CURB

ACCESSORY

“A”

UNIT SIZE

548F

CRRFCURB003A00 1′-2″ [356]

090,120

CRRFCURB004A00 2′-0″ [610]

548F090,120

a50-6162

548F

19

Page 20

SELECTION PROCEDURE (WITH 548F048 EXAMPLE)

548F

I DETERMINE COOLING AND HEATING LOADS AT

DESIGN CONDITIONS.

Given:

Required Cooling Capacity (TC). . . . . . . . . . . 38,000 Btuh

Sensible Heat Capacity (SHC) . . . . . . . . . . . . 24,000 Btuh

Required Heating Capacity. . . . . . . . . . . . . . . 35,000 Btuh

Outdoor Entering-Air Temperature db. . . . . . . . . . . . . 95 F

Outdoor-Air Winter Design Temperature . . . . . . . . . . 0° F

Indoor-Air Winter Design Temperature. . . . . . . . . . . . 70 F

Indoor-Air

Temperature . . . . . . . . .80 F edb (entering air, dry bulb)

67 F ewb (entering air, wet bulb)

Indoor-Air Quantity . . . . . . . . . . . . . . . . . . . . . . . 1600 cfm

External Static Pressure. . . . . . . . . . . . . . . . . . 0.45 in. wg

Electrical Characteristics (V-Ph-Hz) . . . . . . . . . . 230-3-60

II SELECT UNIT BASED ON REQUIRED COOLING

CAPACITY.

Enter Cooling Capacities table at outdoor entering temperature of 95 F, indoor air entering at 1600 cfm and

67 F ewb. The 548F048 unit will provide a total cooling

capacity of 49,900 Btuh and a sensible heat capacity of

33,900 Btuh.

For indoor-air temperature other than 80 F edb, calculate

sensible heat capacity correction, as required, using the

formula found in Note 3 following the cooling capacities

tables.

NOTE: Unit ratings are gross capacities and do not

include the effect of indoor-fan motor heat. To calculate

net capacities, see Step V.

III SELECT ELECTRIC HEAT.

Enter the Instantaneous and Integrated Heating Ratings

table at 1600 cfm. At 70 F return indoor air and 0° F air

entering outdoor coil, the integrated heating capacity is

18,000 Btuh. (Select integrated heating capacity value

since deductions for outdoor-coil frost and defrosting have

already been made. No correction is required.)

The required heating capacity is 35,000 Btuh. Therefore,

17,000 Btuh (35,000 – 18,000) additional electric heat is

required.

Determine additional electric heat capacity in kW.

Enter the Electric Heating Capacities table (page 52) for

548F048 at 208/230, 3 phase. The 6.5-kW heater at 240 v

most closely satisfies the heating required. To calculate

kW at 230 v, use the Multiplication Factors table.

6.5 kW x .92 = 5.98 kW

6.5 kW x .92 x 3413 = 20,410 Btuh

Total unit heating capacity is 38,410 Btuh (18,000 +

20,410).

IV DETERMINE FAN SPEED AND POWER REQUIRE-

MENTS AT DESIGN CONDITIONS.

Before entering Fan Performance tables, calculate the

total static pressure required based on unit components.

From the given and the Pressure Drop tables, find:

External static pressure .45 in. wg

EconoMi$erIV .07 in. wg

Electric heat .09 in. wg

Total static pressure .61 in. wg

Enter the Fan Performance table for 548F048 vertical discharge. At 1600 cfm and 230-v high speed, the standard

motor will deliver 0.76 in. wg static pressure, 723 watts,

and 0.64 brake horsepower (bhp). This will adequately

handle job requirements.

V DETERMINE NET CAPACITIES.

Capacities are gross and do not include the effect of

indoor-fan motor (IFM) heat.

Determine net cooling capacity as follows:

Net capacity = Total capacity – IFM heat

= 49,900 Btuh – (723 Watts x 3.413

Btuh/Watts)

= 49,900 Btuh – 2468 Btuh

= 47,432

Net sensible capacity = 33,900 Btuh – 2468 Btuh

= 31,432 Btuh

Integrated heating capacity is maximum (instantaneous)

capacity less the effect of frost on the outdoor coil and the

heat required to defrost it. Therefore, net capacity is equal

to 38,410 Btuh, the total heating capacity determined in

Step III.

17,000 Btuh

3413 Btuh/kW

= 5.0 kW of heat required.

20

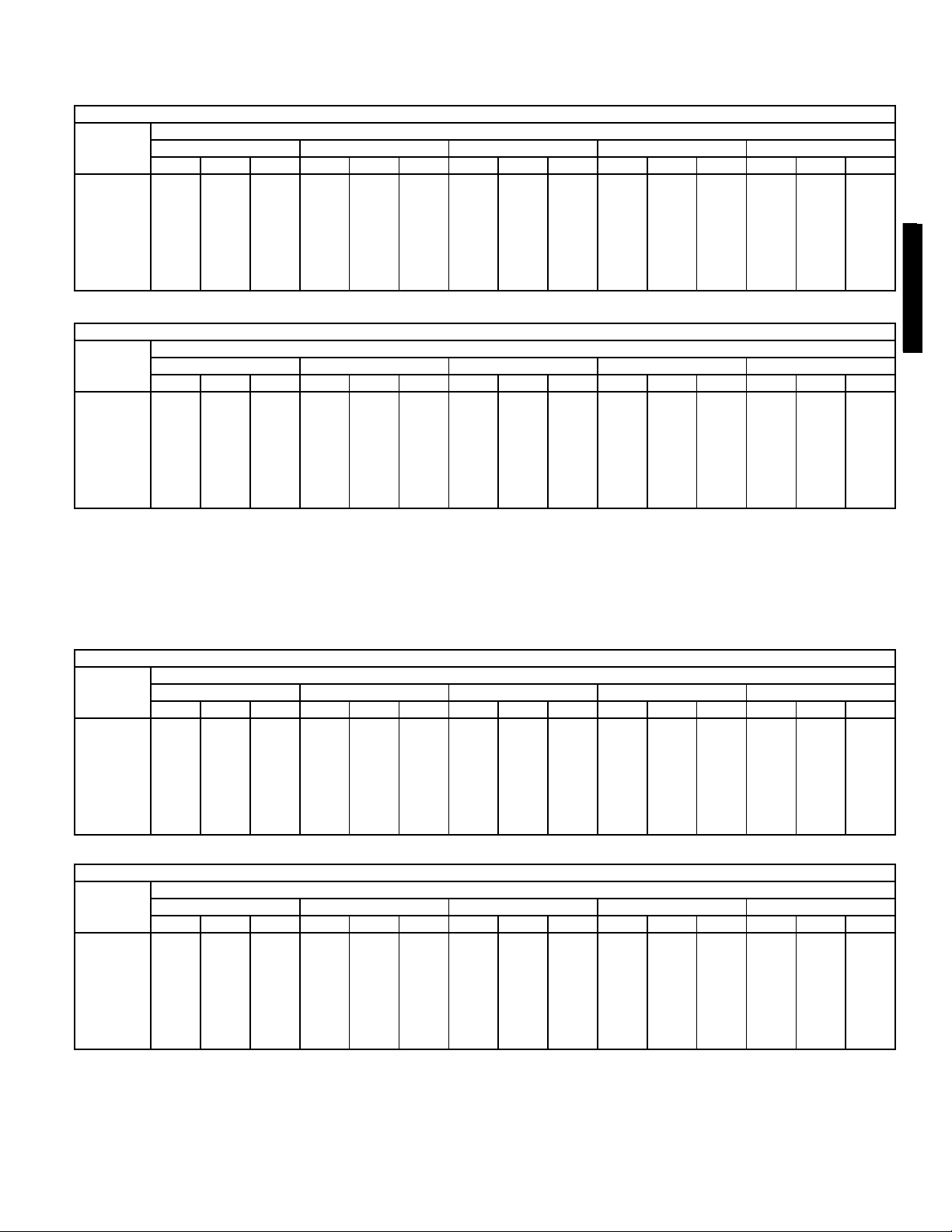

Page 21

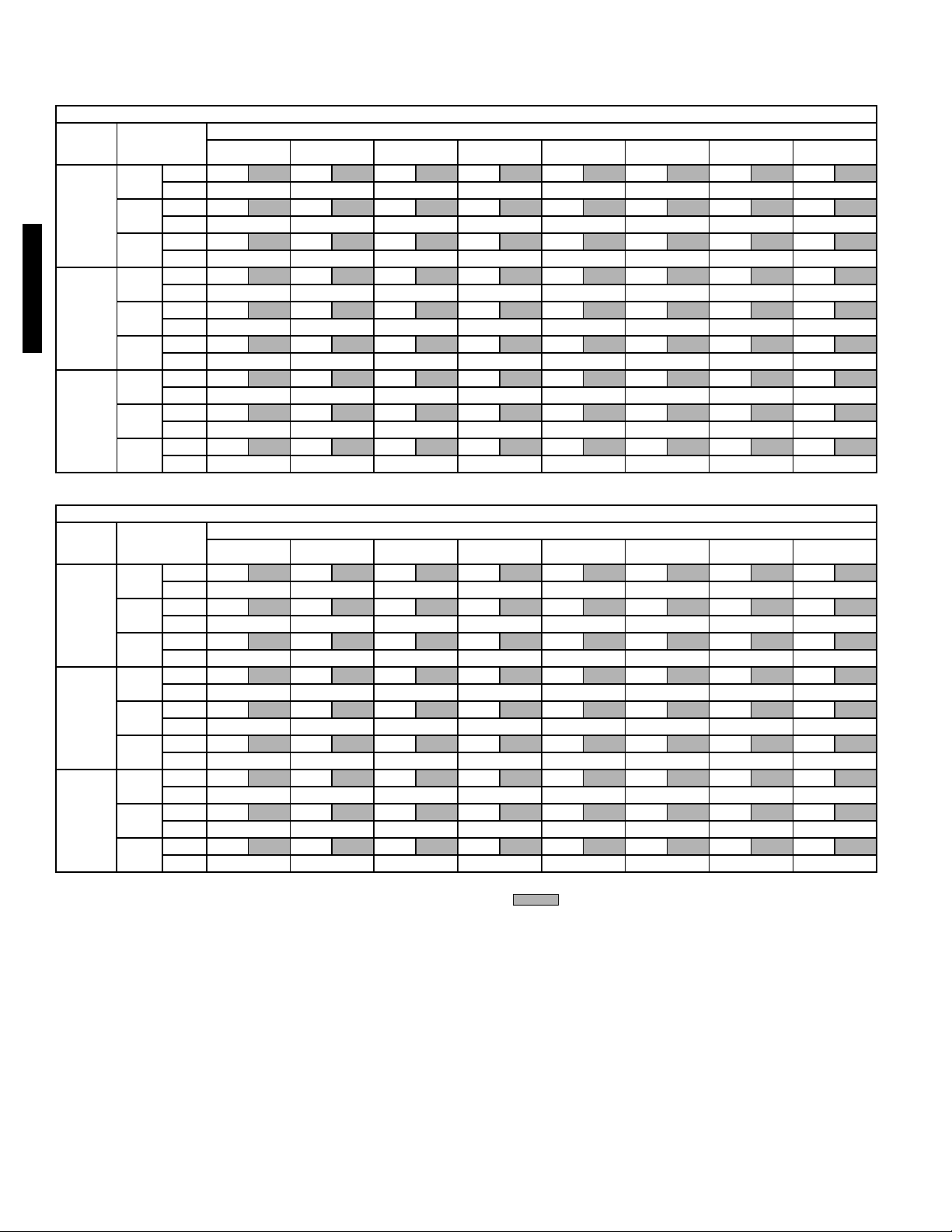

548F

548F036 (3 TONS)

Temp (F)

Outdoor

Entering Air

(Edb)

TC 42.4 39.9 36.5 43.0 41.2 38.7 45.1 42.8 40.3

75

SHC 16.7 22.0 26.8 17.5 24.2 30.9 19.3 26.9 34.1

kW 2.77 2.71 2.62 2.78 2.74 2.68 2.85 2.79 2.73

TC 41.5 38.4 34.8 43.3 40.4 37.0 44.0 41.7 38.7

85

SHC 16.6 21.6 26.2 18.2 24.6 30.3 19.3 27.2 33.7

kW 3.01 2.92 2.80 3.07 2.98 2.88 3.09 3.03 2.94

TC 40.0 36.3 33.0 42.3 38.5 35.2 43.4 40.0 36.7

95

SHC 16.2 20.9 25.7 18.2 24.2 29.8 19.7 27.2 32.7

kW 3.24 3.10 2.99 3.32 3.19 3.07 3.36 3.24 3.13

105

115

125

TC 38.4 34.7 31.0 40.0 36.7 33.1 41.2 37.7 35.2

SHC 15.7 20.5 24.8 17.5 23.9 28.8 19.3 26.6 31.7

kW 3.47 3.32 3.16 3.53 3.41 3.26 3.58 3.44 3.35

TC 36.1 32.5 28.9 38.1 34.3 31.1 39.3 35.5 33.2

SHC 15.1 19.8 23.9 17.2 23.2 27.8 19.1 26.2 30.2

kW 3.66 3.50 3.32 3.76 3.59 3.44 3.81 3.65 3.54

TC 34.2 30.5 26.8 35.9 32.0 29.3 36.8 33.0 31.3

SHC 14.6 19.2 22.9 16.7 22.6 26.3 18.5 25.5 28.4

kW 3.88 3.68 3.49 3.97 3.77 3.62 4.02 3.83 3.74

548F048 (4 TONS)

Temp (F)

Outdoor

Entering Air

(Edb)

TC 55.5 51.9 47.4 56.9 54.6 50.3 59.3 56.5 52.1

75

SHC 24.5 31.2 37.4 26.0 35.2 43.4 28.4 39.0 47.6

kW 3.80 3.70 3.55 3.84 3.79 3.66 3.93 3.86 3.71

TC 53.4 49.7 45.3 56.3 52.6 47.8 57.5 54.1 49.8

85

SHC 23.8 30.4 36.7 26.3 34.9 42.6 28.3 38.6 46.9

kW 4.10 3.99 3.84 4.23 4.11 3.94 4.27 4.16 4.01

TC 52.0 47.4 43.0 53.7 49.9 45.5 54.5 51.6 47.4

95

SHC 23.4 29.6 35.8 25.5 33.9 41.6 27.3 38.2 45.2

kW 4.47 4.28 4.11 4.53 4.39 4.23 4.56 4.48 4.29

105

TC 49.3 45.0 40.6 51.8 47.2 43.0 52.6 48.7 45.4

SHC 22.5 28.8 34.7 25.3 33.0 40.3 27.1 37.1 43.3

kW 4.77 4.59 4.39 4.90 4.68 4.52 4.92 4.76 4.63

115

TC 46.6 42.4 38.0 48.8 44.6 40.6 50.2 45.8 43.2

SHC 21.7 27.9 33.6 24.3 32.4 38.7 26.8 36.1 41.2

kW 5.08 4.90 4.66 5.21 5.01 4.81 5.29 5.06 4.96

125

TC 44.0 39.6 35.4 45.6 41.6 38.3 47.0 42.9 40.9

SHC 20.9 26.9 32.4 23.3 31.6 36.5 25.9 35.6 39.0

kW 5.45 5.21 4.96 5.51 5.34 5.14 5.60 5.41 5.30

548F060 (5 TONS)

Temp (F)

Outdoor

Entering Air

(Edb)

TC 69.3 64.5 59.3 70.8 67.9 62.8 72.9 69.3 65.4

75

SHC 30.9 39.2 47.4 33.1 44.9 55.4 35.8 49.4 61.4

kW 4.28 4.15 4.03 4.32 4.25 4.12 4.38 4.29 4.19

TC 67.7 62.4 56.8 69.1 65.7 60.2 71.1 67.7 63.2

85

SHC 30.4 38.6 46.5 32.8 44.6 54.4 35.8 50.0 59.8

kW 4.76 4.61 4.49 4.79 4.72 4.56 4.86 4.78 4.65

TC 65.2 59.8 54.4 67.7 62.9 57.6 69.1 64.8 60.7

95

SHC 29.6 37.6 45.5 32.8 43.6 53.2 35.6 49.3 57.7

kW 5.27 5.10 4.97 5.35 5.20 5.07 5.39 5.27 5.14

105

TC 62.3 57.2 51.8 65.1 59.6 54.9 66.8 61.7 58.3

SHC 28.6 33.8 44.4 32.1 42.6 51.6 35.4 48.2 55.5

kW 5.79 5.66 5.50 5.90 5.73 5.61 5.97 5.79 5.68

115

TC 59.7 54.2 49.0 61.7 57.0 52.5 63.2 58.4 55.8

SHC 27.6 35.8 43.2 31.1 41.9 49.6 34.3 47.0 53.2

kW 6.37 6.24 6.06 6.47 6.34 6.20 6.53 6.36 6.31

125

TC 56.5 51.0 46.0 58.2 53.5 49.8 59.4 55.1 53.0

SHC 26.8 34.7 41.9 30.0 40.8 47.3 33.0 46.5 50.5

kW 7.03 6.87 6.65 7.07 6.96 6.82 7.13 7.03 6.96

PERFORMANCE DATA — 548F

COOLING CAPACITIES

Indoor Entering Air — Cfm/BF

900/0.10 1200/0.15 1500/0.21

Indoor Entering Air — Ewb (F)

72 67 62 72 67 62 72 67 62

Indoor Entering Air — Cfm/BF

1200/0.11 1600/0.15 2000/0.22

Indoor Entering Air — Ewb (F)

72 67 62 72 67 62 72 67 62

Indoor Entering Air — Cfm/BF

1500/0.05 2000/0.08 2500/0.14

Indoor Entering Air — Ewb (F)

72 67 62 72 67 62 72 67 62

LEGEND

BF — Bypass Factor

Edb — Entering Dry-Bulb

Ewb — Entering Wet-Bulb

kW — Compressor Motor Power Input

Ldb — Leaving Dry-Bulb

Lwb — Leaving Wet-Bulb

SHC — Sensible Heat Capacity

TC — Total Capacity (1000 Btuh) Gross

NOTES:

(1000 Btuh) Gross

1. Direct interpolation is permissib le. Do

not extrapolate.

2. The following formulas may be used:

t

ldb=tedb

t

= Wet-bulb temperature corre-

lwb

h

= h

lwb

Where: h

ing evaporator coil

3. The SHC is based on 80 F edb temperature of air entering indoor coil.

Below 80 F edb, subtract (corr factor

x cfm) from SHC.

Above 80 F edb, add (corr factor x

sensible capacity (Btuh)

–

sponding to enthalpy of air

leaving indoor coil (h

–

ewb

ewb

1.10 x cfm

)

lwb

total capacity (Btuh)

4.5 x cfm

= Enthalpy of air enter-

cfm) to SHC.

21

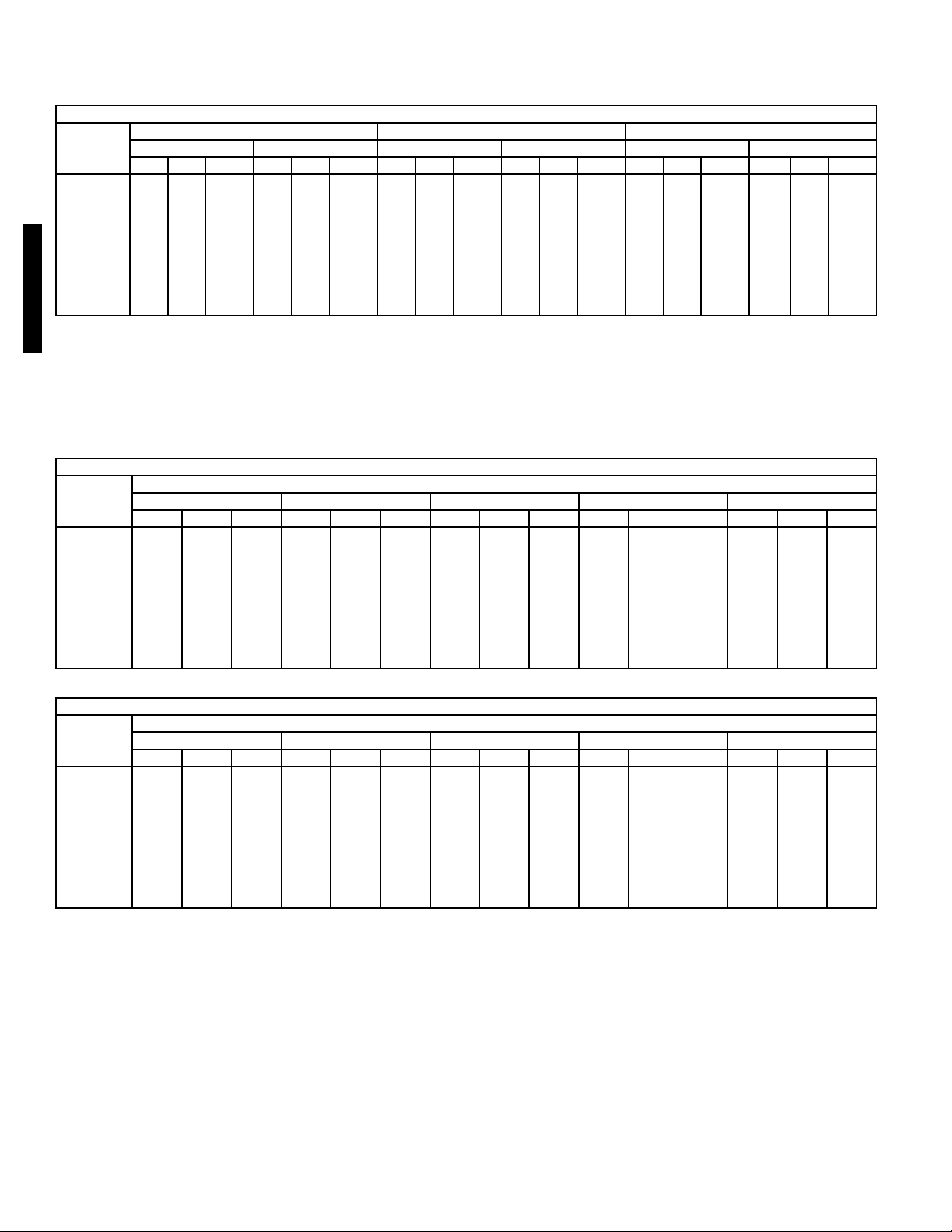

Page 22

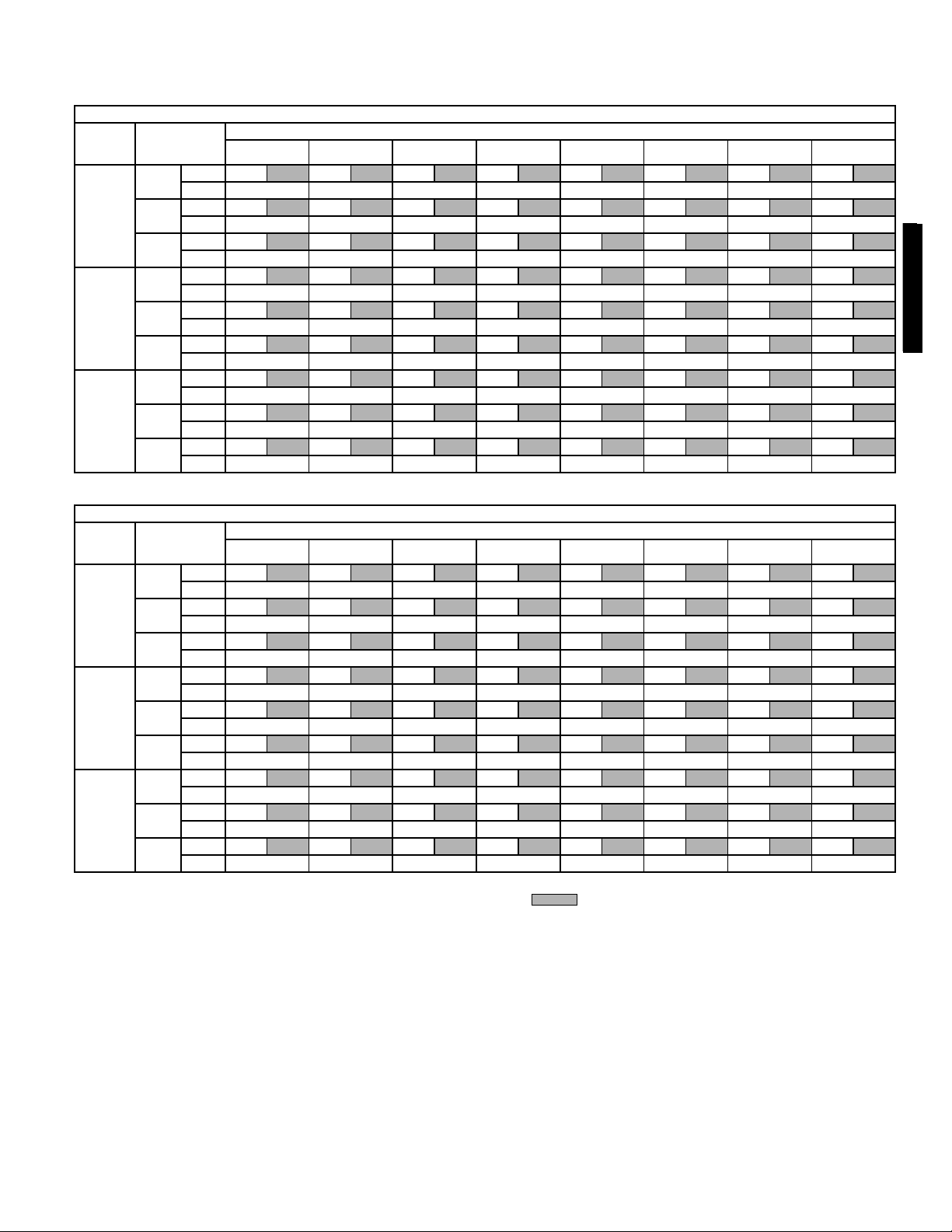

PERFORMANCE DATA — 548F (cont)

548F

COOLING CAPACITIES (cont)

548F072 (6 TONS)

Temp (F)

Outdoor

Entering Air

(Edb)

TC 81.1 77.6 72.1 84.0 80.3 75.2 84.2 81.1 77.8

75

SHC 36.2 46.9 57.0 39.1 52.4 65.4 40.8 56.2 72.2

kW 5.16 5.11 5.01 5.23 5.16 5.06 5.23 5.17 5.11

TC 80.7 75.8 70.0 83.9 79.3 73.4 84.1 80.8 76.2

85

SHC 36.1 46.5 56.4 39.7 52.9 65.2 41.6 58.3 71.9

kW 5.83 5.74 5.65 5.90 5.81 5.69 5.90 5.84 5.76

TC 79.3 73.0 67.3 82.0 76.7 70.8 83.0 79.1 73.5

95

SHC 35.8 45.4 55.3 39.3 52.3 64.3 42.2 58.9 69.7

kW 6.54 6.37 6.28 6.60 6.47 6.37 6.62 6.55 6.40

105

TC 76.0 70.6 64.3 79.6 73.4 67.9 80.7 75.5 71.3

SHC 34.6 44.8 54.1 38.8 51.2 62.9 42.0 57.6 67.8

1800/0.10 2400/0.13 3000/0.19

72 67 62 72 67 62 72 67 62

kW 7.21 7.12 6.94 7.34 7.15 7.06 7.36 7.22 7.14

115

TC 72.7 67.5 61.1 75.8 70.6 64.7 77.9 71.8 68.5

SHC 33.6 43.7 52.7 37.6 50.7 60.9 41.5 56.4 65.2

kW 7.95 7.86 7.63 8.06 7.95 7.77 8.14 7.94 7.90

125

TC 70.1 63.9 57.6 71.8 66.9 61.6 73.5 68.6 65.4

SHC 32.9 42.4 51.2 36.4 49.5 58.4 40.2 56.1 62.3

kW 8.82 8.62 8.37 8.83 8.73 8.54 8.89 8.79 8.69

548F090 (71/2 TONS)

Temp (F)

Outdoor

Entering Air

(Edb)

TC 109.8 101.4 92.2 116.2 107.0 98.0 117.6 108.8 100.2 118.8 110.4 102.4

75

SHC 44.2 57.4 69.4 49.6 66.0 82.0 51.8 69.8 87.0 54.0 74.0 92.0

2250/0.04 3000/0.06 3200/0.08 3750/0.11

72 67 62 72 67 62 72 67 62 72 67 62

kW 6.66 6.44 6.18 6.86 6.60 6.36 6.92 6.66 6.42 6.94 6.70 6.48

TC 105.2 96.4 87.0 111.4 102.2 92.6 113.0 104.0 95.0 114.6 105.8 97.6

85

SHC 42.8 55.6 67.6 48.4 65.0 80.0 50.8 69.0 84.4 53.4 73.8 88.8

kW 7.20 6.94 6.64 7.42 7.14 6.82 7.48 7.20 6.90 7.54 7.28 7.00

TC 100.6 91.0 82.0 105.6 96.2 87.4 107.2 98.0 89.8 108.6 99.6 92.8

95

SHC 41.6 54.0 65.8 47.0 63.2 77.8 49.4 67.4 81.4 52.0 72.2 84.6

kW 7.78 7.42 7.08 7.96 7.62 7.30 8.00 7.70 7.40 8.06 7.76 7.50

TC 94.8 85.4 76.8 99.8 90.2 82.2 101.4 91.6 85.0 103.2 93.2 88.0

105

SHC 40.0 52.2 63.8 45.6 61.6 74.6 48.2 65.8 77.6 51.2 70.4 80.4

kW 8.26 7.88 7.50 8.48 8.10 7.76 8.56 8.18 7.88 8.64 8.24 8.02

TC 88.8 79.9 71.4 93.4 84.0 77.6 94.8 85.4 80.0 96.0 86.6 83.0

115

SHC 38.4 50.4 61.6 44.2 59.8 70.6 46.6 64.0 73.2 49.4 68.6 75.8

kW 8.76 8.32 7.90 8.98 8.54 8.22 9.04 8.62 8.36 9.10 8.70 8.50

TC 82.6 73.8 65.8 86.6 77.4 74.4 88.0 78.8 75.0 89.2 80.0 77.6

125

SHC 36.8 48.6 59.2 42.2 57.8 66.2 45.2 62.0 68.6 48.2 66.6 71.0

kW 9.20 8.74 8.30 9.44 8.96 8.68 9.52 9.02 8.82 9.60 9.12 8.98

Indoor Entering Air — Cfm/BF

Indoor Entering Air — Ewb (F)

Indoor Entering Air — Cfm/BF

Indoor Entering Air — Ewb (F)

LEGEND

BF — Bypass Factor

Edb — Entering Dry-Bulb

Ewb — Entering Wet-Bulb

kW — Compressor Motor Power Input

Ldb — Leaving Dry-Bulb

Lwb — Leaving Wet-Bulb

SHC — Sensible Heat Capacity

TC — Total Capacity (1000 Btuh) Gross

NOTES:

(1000 Btuh) Gross

1. Direct interpola tion is permissible. Do

not extrapolate.

2. The following formulas may be used:

t

ldb=tedb

t

= Wet-bulb temperature corre-

lwb

h

= h

lwb

Where: h

ing evaporator coil

3. The SHC is based on 80 F edb temperature of air entering indoor coil.

Below 80 F edb, subtract (corr factor

x cfm) from SHC.

Above 80 F edb, add (corr factor x

sensible capacity (Btuh)

–

sponding to enthalpy of air

leaving indoor coil (h

–

ewb

ewb

1.10 x cfm

)

lwb

total capacity (Btuh)

4.5 x cfm

= Enthalpy of air enter-

cfm) to SHC.

22

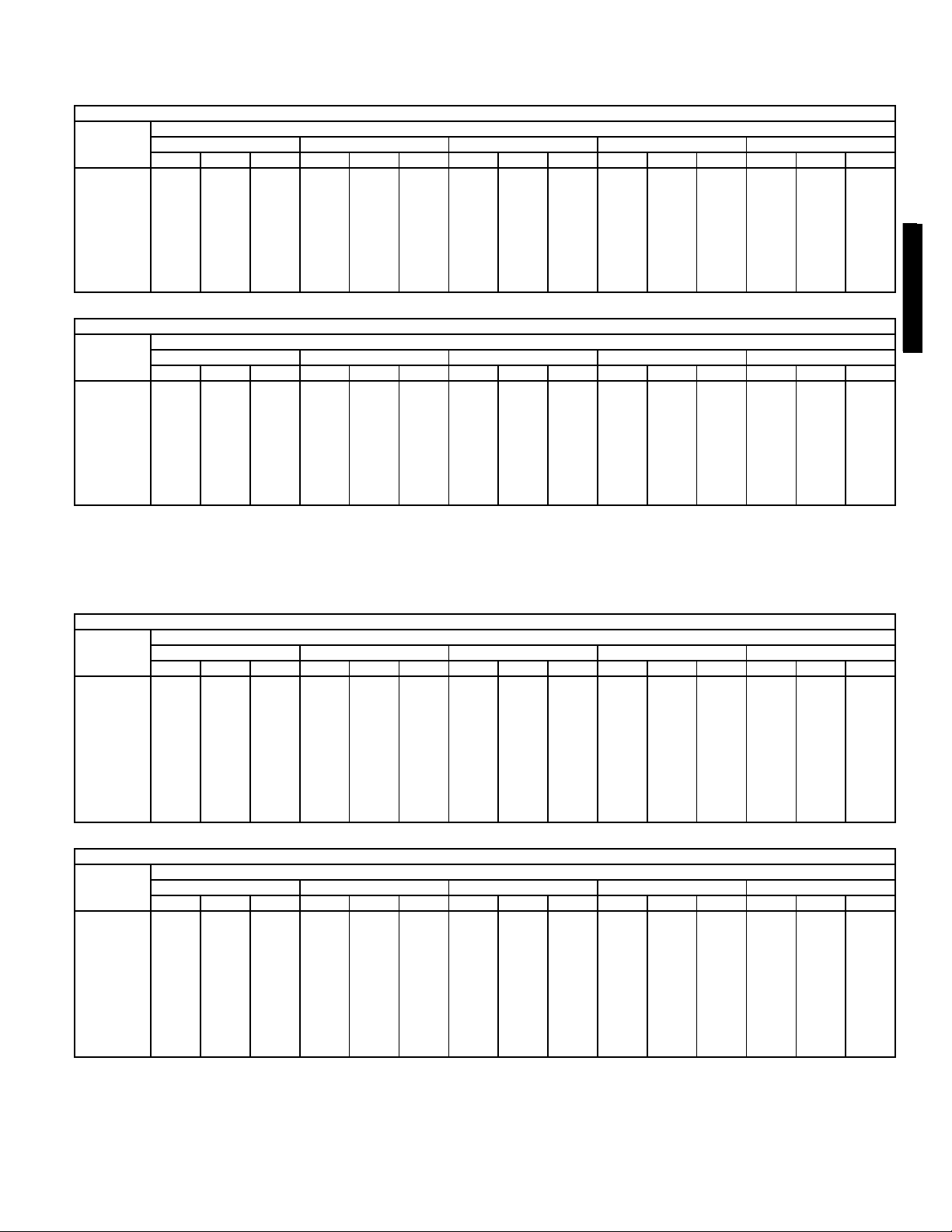

Page 23

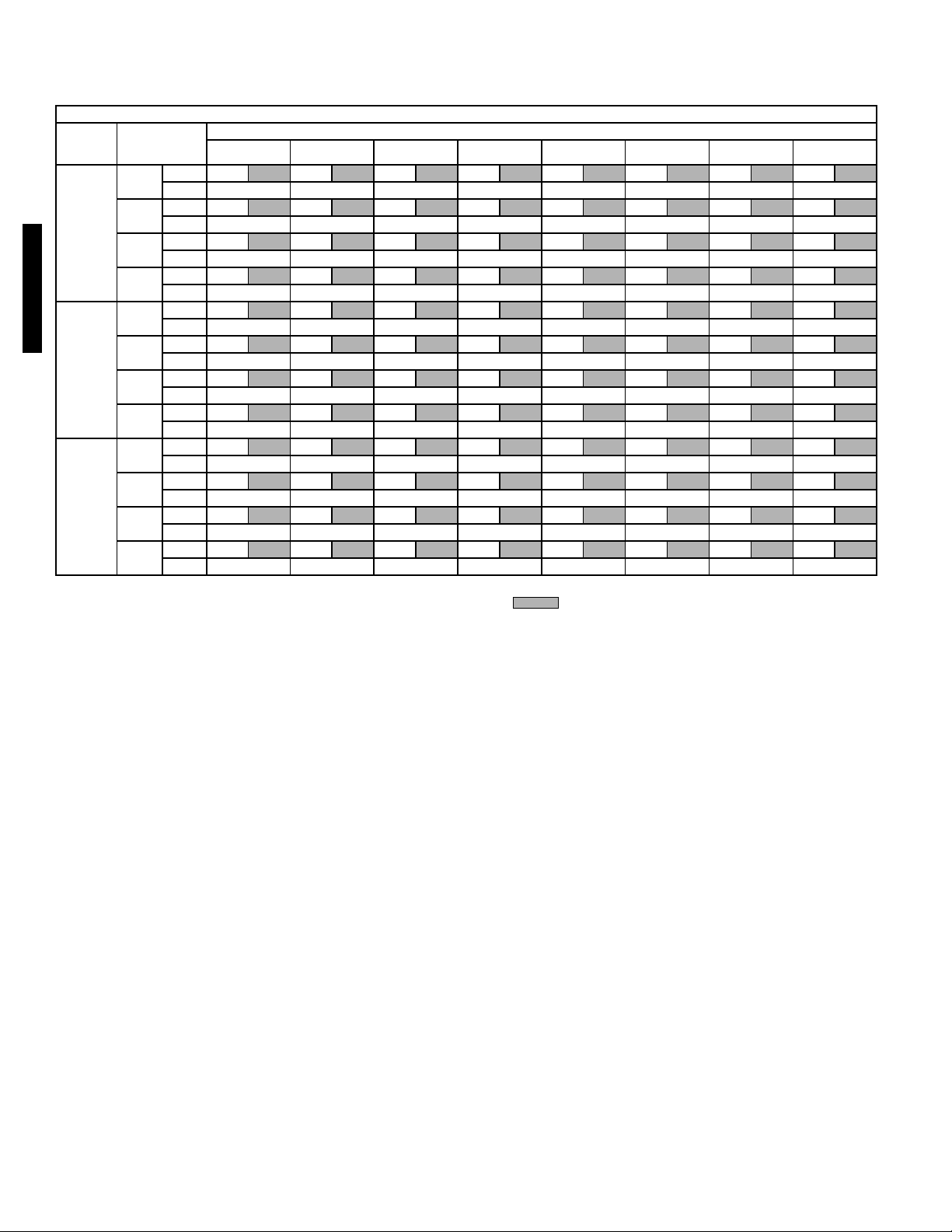

PERFORMANCE DATA — 548F (cont)

548F

548F120 (10 TONS)

Temp (F)

Outdoor

Entering Air

(Edb)

75

85

95

105

115

125

TC 127.4 120.4 110.6 134.2 126.2 116.2 135.6 127.4 117.8 137.0 129.0 120.6

SHC 60.0 76.4 91.0 66.2 86.0 104.4 67.8 89.0 108.8 70.2 93.4 115.6

kW 8.30 8.18 7.88 8.54 8.34 8.04 8.60 8.36 8.10 8.64 8.38 8.20

TC 124.6 116.2 106.4 131.0 122.0 112.4 132.4 123.6 114.0 133.8 126.0 116.4

SHC 59.2 74.6 89.4 65.4 84.8 103.6 67.4 88.4 107.4 70.0 94.2 112.8

kW 9.24 9.04 8.74 9.50 9.24 8.98 9.54 9.28 9.02 9.60 9.36 9.08

TC 121.8 112.0 102.2 126.2 117.4 107.4 127.8 119.0 109.4 130.0 121.2 112.6

SHC 58.4 73.2 87.4 63.8 83.4 101.0 66.0 87.2 104.8 69.6 93.4 110.2

kW 10.34 10.04 9.66 10.46 10.18 9.90 10.52 10.26 9.96 10.62 10.36 10.08

TC 116.9 107.2 97.6 122.4 112.4 102.8 123.6 113.8 105.0 124.6 115.6 108.4

SHC 56.6 71.4 85.4 63.0 82.0 98.4 65.0 85.8 101.8 67.8 91.4 106.2

kW 11.38 11.08 10.66 11.64 11.28 10.90 11.68 11.32 11.00 11.68 11.38 11.16

TC 112.0 102.0 92.8 116.6 107.0 98.0 118.0 108.2 100.2 120.0 110.0 103.8

SHC 55.0 69.6 83.2 61.2 80.2 95.2 63.6 84.2 98.0 67.4 90.2 101.8

kW 12.58 12.18 11.74 12.78 11.42 12.00 12.84 12.48 12.12 12.96 12.56 12.30

TC 106.4 96.8 87.8 110.4 101.2 93.6 111.6 102.2 95.8 113.6 103.8 99.0

SHC 53.2 67.4 80.8 59.2 78.4 91.4 61.4 82.2 94.0 65.4 88.0 97.2

kW 13.84 13.36 12.90 13.96 13.62 13.22 14.02 13.68 13.34 14.14 13.76 13.54

LEGEND

BF — Bypass Factor

Edb — Entering Dry-Bulb

Ewb — Entering Wet-Bulb

kW — Compressor Motor Power Input

Ldb — Leaving Dry-Bulb

Lwb — Leaving Wet-Bulb

SHC — Sensible Heat Capacity (1000 Btuh) Gross

TC — Total Capacity (1000 Btuh) Gross

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

t

ldb=tedb

sensible capacity (Btuh)

–

1.10 x cfm

2800/0.11 3750/0.16 4100/0.18 4700/0.21

72 67 62 72 67 62 72 67 62 72 67 62

COOLING CAPACITIES (cont)

Indoor Entering Air — Cfm/BF

Indoor Entering Air — Ewb (F)

t

= Wet-bulb temperature corresponding to enthalpy of air leav-

lwb

ing indoor coil (h

h

= h

lwb

Where: h

3. The SHC is based on 80 F edb temperature of air entering indoor

coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC.

)

lwb

total capacity (Btuh)

–

ewb

ewb

4.5 x cfm

= Enthalpy of air entering evaporator coil

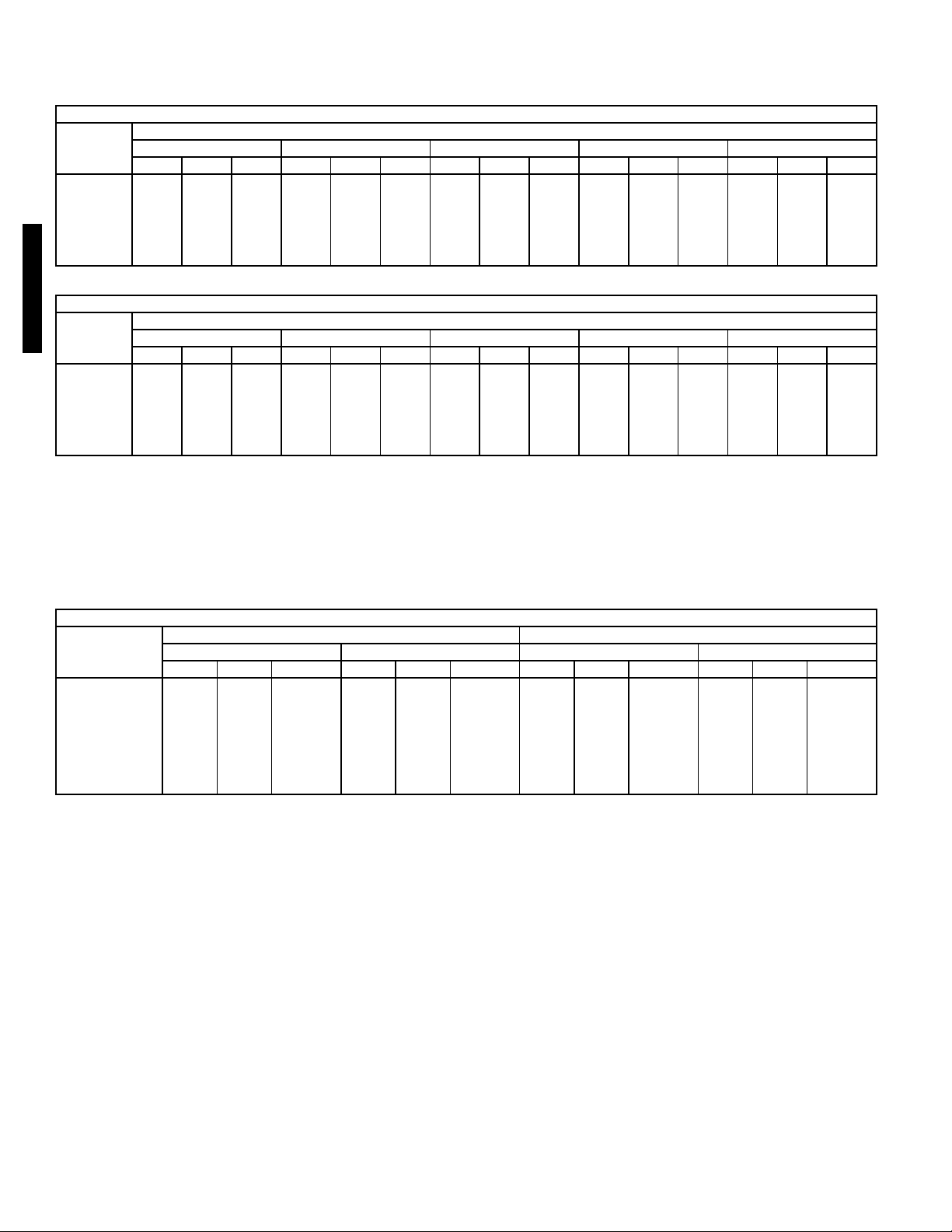

INSTANTANEOUS AND INTEGRATED HEATING RATINGS

548F036

Return

Air

(F db)

55

70

80

LEGEND NOTES:

Cap. — Heating Capacity (1000 Btuh) (includes indoor-fan motor heat)

db — dry bulb

kW — Total Power Input (includes compressor motor power input,

Cfm

(Standard

Air)

900

1200

1500

900

1200

1500

900

1200

1500

Cap. 15.4

kW 2.25 2.44 2.57 2.86 3.10 3.29 3.38 3.64

Cap. 15.9

kW 2.24 2.40 2.54 2.80 3.02 3.15 3.21 3.35

Cap. 16.2

kW 2.23 2.38 2.52 2.76 2.94 3.03 3.08 3.17

Cap. 13.2

kW 2.29 2.50 2.67 2.98 3.24 3.45 3.55 3.91

Cap. 13.7

kW 2.28 2.49 2.62 2.93 3.17 3.36 3.45 3.72

Cap. 14.0

kW 2.27 2.47 2.60 2.89 3.12 3.30 3.38 3.54

Cap. 11.5

kW 2.30 2.54 2.71 3.04 3.32 3.55 3.65 4.03

Cap. 12.0

kW 2.30 2.52 2.69 2.99 3.26 3.47 3.56 3.91

Cap. 12.3

kW 2.29 2.51 2.68 2.97 3.22 3.41 3.50 3.70

0 10173040475060

13.1 19.2 17.6 21.7 19.8 27.4 24.0 31.9 31.9 35.3 35.3 36.9 36.9 41.4 41.4

13.5 19.4 17.8 22.5 20.5 28.3 24.8 32.9 32.9 35.8 35.8 37.0 37.0 40.1 40.1

13.8 19.8 18.2 22.9 20.9 28.8 25.2 33.1 33.1 35.3 35.3 36.5 36.5 38.6 38.6

11.2 17.1 15.7 20.0 18.2 25.4 22.2 29.8 29.8 33.2 33.2 34.7 34.7 40.1 40.1

11.6 17.7 16.3 20.3 18.5 26.3 23.1 30.8 30.8 34.4 34.4 36.0 36.0 40.9 40.9

11.9 18.1 16.6 20.7 18.9 26.9 23.6 31.6 31.6 35.1 35.1 36.9 36.9 40.2 40.2

9.8 15.5 14.2 18.4 16.8 23.7 20.8 28.1 28.1 31.7 31.7 33.2 33.2 38.5 38.5

10.2 16.2 14.8 19.2 17.5 24.7 21.6 29.3 29.3 33.0 33.0 34.5 34.5 40.2 40.2

10.5 16.6 15.2 19.7 18.0 25.4 22.3 30.1 30.1 33.7 33.7 35.3 35.3 39.2 39.2

outdoor-fan motor input, and indoor-fan motor input)

Air Temperature Entering Outdoor Coil (F)

1. indicates integrated ratings.

2. Integrated capacity is maximum (instantaneous) capacity less the

effect of frost on the outdoor coil and the heat required to defrost it.

23

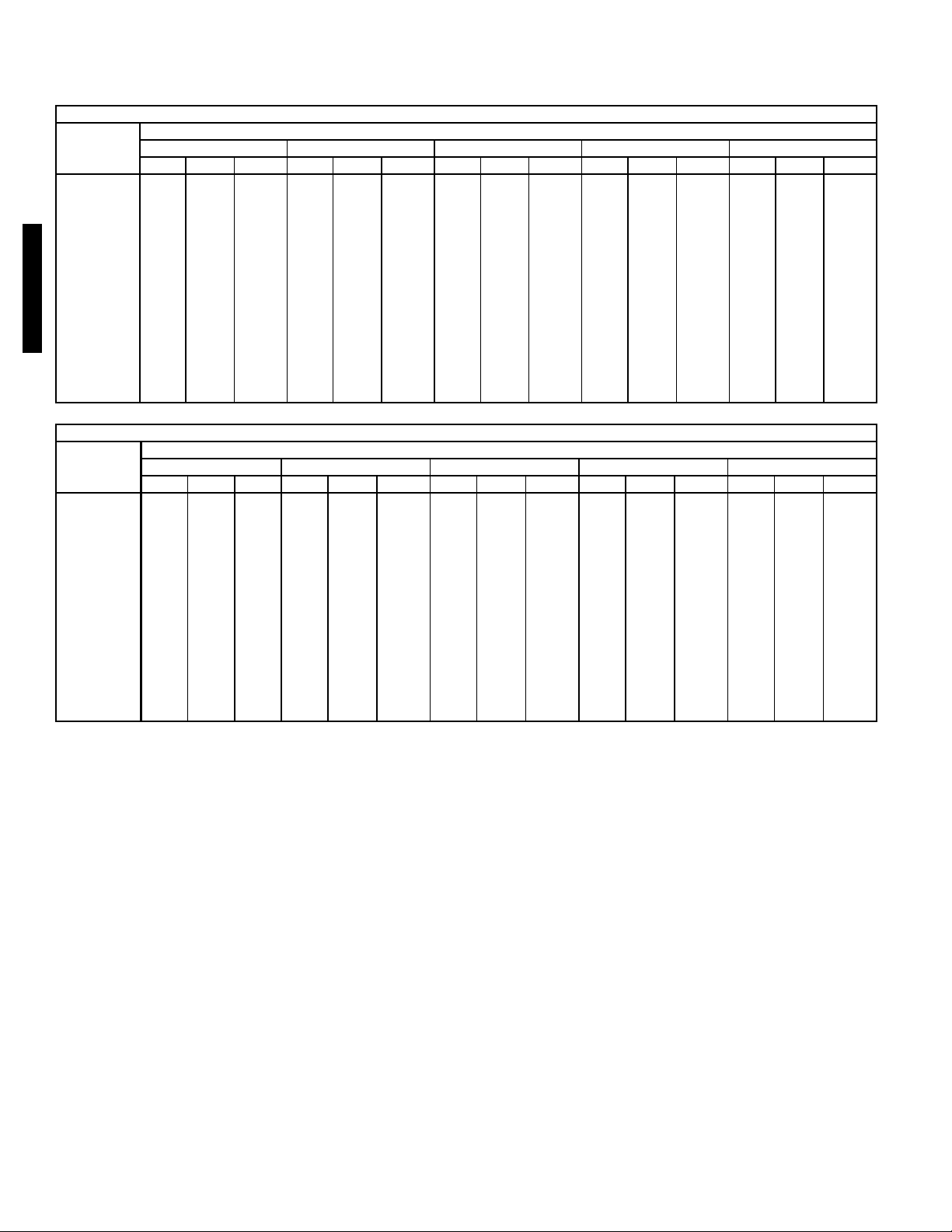

Page 24

548F048

548F

Return

Air

(F db)

55

70

80

PERFORMANCE DATA — 548F (cont)

INSTANTANEOUS AND INTEGRATED HEATING RATINGS (cont)

Cfm

(Standard

Air)

Cap. 22.7

1200

kW 2.91 3.14 3.35 3.77 4.12 4.40 4.54 5.04

Cap. 23.1

1600

kW 2.87 3.09 3.28 3.66 3.97 4.23 4.34 4.80

Cap. 23.4

2000

kW 2.85 3.05 3.23 3.59 3.88 4.11 4.23 4.65

Cap. 20.6

1200

kW 3.00 3.33 3.52 4.01 4.39 4.71 4.85 5.40

Cap. 21.2

1600

kW 2.99 3.25 3.47 3.90 4.25 4.54 4.67 5.15

Cap. 21.6

2000

kW 2.97 3.22 3.43 3.84 4.16 4.42 4.55 5.00

Cap. 18.6

1200

kW 3.01 3.40 3.62 4.15 4.56 4.90 5.06 5.63

Cap. 19.4

1600

kW 3.01 3.37 3.58 4.06 4.43 4.74 4.88 5.39

Cap. 19.8

2000

kW 3.01 3.35 3.54 4.00 4.35 4.63 4.76 5.24

0 10173040475060

19.3 26.6 24.4 30.2 27.6 37.4 32.7 43.1 43.1 47.6 47.6 49.8 49.8 57.2 57.2

19.7 27.2 25.0 30.8 28.1 38.2 33.5 44.1 44.1 48.9 48.9 51.1 51.1 59.0 59.0

19.9 27.4 25.2 31.2 28.4 38.7 33.9 44.8 44.8 49.7 49.7 52.0 52.0 60.2 60.2

17.5 25.5 23.4 28.4 25.9 35.6 31.2 41.0 41.0 45.5 45.5 47.5 47.5 54.9 54.9

18.0 25.6 23.5 29.1 26.6 36.3 31.8 42.1 42.1 46.8 46.8 48.9 48.9 56.5 56.5

18.3 25.9 23.8 29.5 26.9 36.9 32.3 42.8 42.8 47.5 47.5 49.7 49.7 57.6 57.6

15.8 23.9 21.9 27.1 24.7 34.2 29.9 39.7 39.7 44.1 44.1 46.1 46.1 53.2 53.2

16.4 24.7 22.6 27.8 25.4 35.1 30.8 40.7 40.7 45.3 45.3 47.3 47.3 54.9 54.9

16.8 25.1 23.1 28.2 25.7 35.7 31.3 41.5 41.5 46.0 46.0 48.2 48.2 55.8 55.8

Air Temperature Entering Outdoor Coil (F)

548F060

Return

Air

(F db)

55

70

80

LEGEND NOTES:

Cap. — Heating Capacity (1000 Btuh) (includes indoor-fan motor heat)

db — dry bulb

kW — Total Power Input (includes compressor motor power input,

Cfm

(Standard

Air)

Cap. 29.7

1500

kW 3.96 4.14 4.30 4.62 4.90 5.14 5.25 5.67

Cap. 29.8

2000

kW 3.83 3.98 4.12 4.38 4.63 4.82 4.91 5.25

Cap. 29.8

2500

kW 3.76 3.89 4.01 4.26 4.47 4.63 4.72 4.99

Cap. 28.7

1500

kW 4.43 4.66 4.84 5.21 5.53 5.79 5.91 6.39

Cap. 29.0

2000

kW 4.30 4.48 4.63 4.94 5.20 5.41 5.52 5.91

Cap. 29.2

2500

kW 4.22 4.38 4.51 4.78 5.01 5.21 5.30 5.63

Cap. 28.1

1500

kW 4.77 5.03 5.23 5.64 5.99 6.27 6.41 6.92

Cap. 28.4

2000

kW 4.63 4.84 5.01 5.34 5.63 5.86 5.97 6.39

Cap. 28.6

2500

kW 4.55 4.73 4.88 5.17 5.42 5.62 5.72 6.09

outdoor-fan motor input, and indoor-fan motor input)

0 10173040475060

25.2 34.5 31.7 38.4 35.0 46.0 40.3 52.4 52.4 57.2 57.2 59.6 59.6 67.9 67.9

25.4 34.7 31.8 38.6 35.2 46.3 40.6 52.9 52.9 57.7 57.7 60.1 60.1 68.7 68.7

25.4 34.8 31.9 38.7 35.3 46.6 40.8 53.1 53.1 58.0 58.0 60.4 60.4 68.4 68.4

24.4 33.8 31.0 37.8 34.4 45.4 39.8 51.5 51.5 56.2 56.2 58.4 58.4 66.5 66.5

24.7 34.0 31.2 38.0 34.7 45.7 40.1 51.9 51.9 56.7 56.7 59.0 59.0 67.4 67.4

24.8 34.2 31.4 38.2 34.8 45.8 40.2 52.2 52.2 57.1 57.1 59.4 59.4 67.9 67.9

23.8 33.1 30.4 37.2 33.9 44.9 39.3 51.0 51.0 55.6 55.6 57.8 57.8 65.7 65.7

24.2 33.5 30.7 37.6 34.2 45.3 39.7 51.4 51.4 56.1 56.1 58.3 58.3 66.5 66.5

24.3 33.7 30.9 37.7 34.4 45.5 39.8 51.6 51.6 56.4 56.4 58.7 58.7 67.0 67.0

Air Temperature Entering Outdoor Coil (F)

1. indicates integrated ratings.

2. Integrated capacity is maximum (instantaneous) capacity less the

effect of frost on the outdoor coil and the heat required to defrost it.

24

Page 25

548F072

548F

Return

Air

(F db)

55

70

80

Cfm

(Standard

Air)

1800

2400

3000

1800

2400

3000

1800

2400

3000

PERFORMANCE DATA — 548F (cont)

INSTANTANEOUS AND INTEGRATED HEATING RATINGS (cont)

Air Temperature Entering Outdoor Coil (F)

0 10173040475060

Cap. 37.8

kW 4.72 4.97 5.16 5.58 5.96 6.25 6.40 6.95

Cap. 37.9

kW 4.55 4.76 4.92 5.28 5.57 5.81 5.93 6.38

Cap. 38.0

kW 4.46 4.64 4.78 5.09 5.35 5.56 5.67 6.07

Cap. 37.3

kW 5.32 5.61 5.84 6.33 6.75 7.10 7.27 7.91

Cap. 37.5

kW 5.13 5.38 5.57 5.97 6.32 6.61 6.74 7.25

Cap. 37.6

kW 5.03 5.25 5.41 5.76 6.08 6.32 6.44 6.89

Cap. 36.8

kW 5.75 6.09 6.34 6.88 7.35 7.72 7.90 8.58

Cap. 37.0

kW 5.55 5.83 6.04 6.49 6.87 7.18 7.33 7.89

Cap. 37.1

kW 5.44 5.68 5.87 6.26 6.60 6.88 7.01 7.49

32.2 43.9 40.3 48.3 44.1 58.0 50.8 66.2 66.2 72.3 72.3 75.2 75.2 86.0 86.0

32.2 44.0 40.4 48.5 44.2 58.4 51.2 66.6 66.6 72.8 72.8 75.9 75.9 87.0 87.0

32.3 44.0 40.4 48.5 44.3 58.5 51.3 66.9 66.9 73.1 73.1 76.2 76.2 87.5 87.5

31.7 43.6 40.0 48.1 43.9 57.5 50.4 65.2 65.2 71.1 71.1 74.0 74.0 84.6 84.6

31.9 43.8 40.2 48.2 43.9 57.7 50.5 65.6 65.6 71.8 71.8 74.7 74.7 85.4 85.4

32.0 43.9 40.3 48.3 44.0 57.8 50.7 66.0 66.0 72.1 72.1 75.0 75.0 86.0 86.0

31.3 43.1 39.6 47.9 43.7 57.1 50.1 64.8 64.8 70.5 70.5 73.4 73.4 83.6 83.6

31.4 43.4 39.8 48.0 43.8 57.4 50.3 65.1 65.1 71.1 71.1 73.9 73.9 84.5 84.5

31.5 43.5 39.9 48.1 43.9 57.5 50.4 65.3 65.3 71.5 71.5 74.4 74.4 85.0 85.0

548F090

Return

Air

(F db)

55

70

80

LEGEND NOTES:

Cap. — Heating Capacity (1000 Btuh) (includes indoor-fan motor heat)

db — dry bulb

kW — Total Power Input (includes compressor motor power input,

Cfm

(Standard

Air)

2000

2600

3200

2000

2600

3200

2000

2600

3200

outdoor-fan motor input, and indoor-fan motor input)

Cap. 36.6

kW 5.24 5.64 5.94 6.58 7.08 7.50 7.68 8.32

Cap. 37.6

kW 5.18 5.56 5.82 6.40 6.84 7.20 7.36 7.78

Cap. 38.2

kW 5.16 5.50 5.74 6.28 6.70 7.02 7.12 7.40

Cap. 32.4

kW 5.42 5.90 6.22 6.92 7.48 7.94 8.16 8.90

Cap. 33.4

kW 5.38 5.82 6.12 6.76 7.28 7.68 7.86 8.48

Cap. 34.2

kW 5.36 5.76 6.06 6.66 7.14 7.50 7.68 8.16

Cap. 29.2

kW 5.52 6.02 6.40 7.12 7.72 8.22 8.44 9.24

Cap. 30.2

kW 5.48 5.96 6.30 6.98 7.54 7.98 8.18 8.88

Cap. 31.0

kW 5.46 5.92 6.24 6.90 7.42 7.82 8.00 8.58

0 10173040475060

31.2 44.0 40.4 49.8 45.4 61.4 53.8 70.4 70.4 77.4 77.4 80.6 80.6 91.8 91.8

32.0 45.2 41.4 51.2 46.6 63.0 55.2 72.4 72.4 79.6 79.6 83.0 83.0 92.4 92.4

32.4 45.8 42.0 51.8 47.2 63.8 55.8 73.6 73.6 81.0 81.0 83.8 83.8 91.2 91.2

27.6 40.4 37.2 46.0 41.8 57.8 50.6 66.8 66.8 73.6 73.6 76.6 76.6 87.8 87.8

28.4 41.8 38.2 47.4 43.2 59.6 52.2 68.8 68.8 75.8 75.8 79.0 79.0 90.4 90.4

29.0 42.2 38.6 48.4 44.0 60.6 53.0 70.0 70.0 77.2 77.2 80.6 80.6 91.0 91.0

24.8 37.4 34.4 43.4 39.6 54.8 48.0 64.0 64.0 70.8 70.8 73.8 73.8 84.8 84.8

25.8 38.8 35.6 44.6 40.6 56.8 49.8 66.2 66.2 73.2 73.2 76.4 76.4 87.8 87.8

26.4 39.6 36.4 45.4 41.4 58.0 50.8 67.4 67.4 74.6 74.6 78.0 78.0 89.0 89.0

Air Temperature Entering Outdoor Coil (F)

1. indicates integrated ratings.

2. Integrated capacity is maximum (instantaneous) capacity less the

effect of frost on the outdoor coil and the heat required to defrost it.

25

Page 26

PERFORMANCE DATA — 548F (cont)

548F

INSTANTANEOUS AND INTEGRATED HEATING RATINGS (cont)

548F120

Return

Air

(F db)

55

70

80

LEGEND NOTES:

Cap. — Heating Capacity (1000 Btuh) (includes indoor-fan motor heat)

db — dry bulb

kW — Total Power Input (includes compressor motor power input,

Cfm

(Standard

Air)

Cap. 52.2

2650

kW 7.20 7.58 7.86 8.46 9.00 9.42 9.62 10.38

Cap. 52.7

3500

kW 6.98 7.30 7.52 8.02 8.46 8.80 8.96 9.62

Cap. 53.2

4100

kW 6.88 7.16 7.38 7.82 8.22 8.54 8.68 9.28

Cap. 53.2

4400

kW 6.84 7.12 7.32 7.74 8.14 8.44 8.58 9.14

Cap. 49.8

2650

kW 8.08 8.50 8.86 9.56 10.14 10.62 10.86 11.72

Cap. 50.6

3500

kW 7.86 8.20 8.50 9.04 9.52 9.92 10.10 10.80

Cap. 51.0

4100

kW 7.74 8.06 8.32 8.82 9.26 9.62 9.78 10.40

Cap. 51.0

4400

kW 7.70 8.02 8.26 8.74 9.16 9.50 9.66 10.26

Cap. 47.6

2650

kW 8.72 9.20 9.56 10.36 11.00 11.52 11.76 12.70

Cap. 48.6

3500

kW 8.48 8.88 9.18 9.82 10.34 10.74 10.96 11.70

Cap. 49.0

4100

kW 8.36 8.72 9.02 9.58 10.04 10.42 10.60 11.28

Cap. 49.2

4400

kW 8.32 8.66 8.94 9.48 9.92 10.28 10.46 11.10

outdoor-fan motor input, and indoor-fan motor input)

0 10173040475060

44.4 62.2 57.0 69.6 63.4 84.2 73.8 96.0 96.0 104.6 104.6 108.8 108.8 123.6 123.6

44.8 62.8 57.6 70.2 64.0 85.0 74.4 96.8 96.8 105.8 105.8 109.8 109.8 125.4 125.4

45.2 63.0 58.0 70.4 64.2 85.2 74.8 97.2 97.2 105.8 105.8 110.2 110.2 126.0 126.0

45.2 63.2 58.0 70.6 64.4 85.4 74.8 97.4 97.4 106.0 106.0 110.4 110.4 126.4 126.4

42.2 59.2 54.4 67.0 61.2 82.0 72.0 94.0 94.0 102.6 102.6 106.8 106.8 121.2 121.2

43.0 60.2 55.2 63.2 62.2 83.2 72.8 95.2 95.2 103.8 103.8 108.0 108.0 122.8 122.8

43.2 60.6 55.6 68.6 62.6 83.6 73.2 95.6 95.6 104.2 104.2 108.4 108.4 123.4 123.4

43.4 60.8 55.8 68.8 62.6 83.8 73.4 95.8 95.8 104.4 104.4 108.6 108.6 123.8 123.8

40.6 57.6 52.8 64.6 58.8 80.2 70.4 92.0 92.0 101.0 101.0 105.2 105.2 119.8 119.8

41.4 58.6 53.8 66.0 60.2 81.6 71.4 93.6 93.6 102.4 102.4 106.6 106.6 121.2 121.2

41.8 58.6 53.8 66.6 60.8 82.0 71.8 94.2 94.2 103.0 103.0 107.2 107.2 121.8 121.8

41.8 58.8 54.0 66.8 61.0 82.2 72.2 94.4 94.4 103.2 103.2 107.4 107.4 122.2 122.2

Air Temperature Entering Outdoor Coil (F)

1. indicates integrated ratings.

2. Integrated capacity is maximum (instantaneous) capacity less the

effect of frost on the outdoor coil and the heat required to defrost it.

26

Page 27

PERFORMANCE DATA — 548F (cont)

548F

FAN PERFORMANCE — VERTICAL DISCHARGE UNITS

548F036 (3 TONS) — STANDARD MOTOR (DIRECT DRIVE)

Airflow

(Cfm)

900 0.67 0.21 253 0.68 0.23 277 0.69 0.26 307 0.69 0.31 363

1000 0.60 0.23 270 0.61 0.25 292 0.61 0.27 321 0.63 0.32 374

1100 0.55 0.24 287 0.56 0.26 307 0.57 0.28 335 0.58 0.33 385

1200 0.51 0.26 304 0.51 0.27 323 0.52 0.29 349 0.53 0.34 397

1300 0.45 0.27 321 0.46 0.29 338 0.46 0.31 364 0.47 0.34 408

1400 0.38 0.29 338 0.41 0.30 354 0.43 0.32 378 — — —

1500 0.34 0.30 355 0.36 0.31 369 0.38 0.33 392 — — —

Bhp — Brake Horsepower Input to Fan

ESP — External Static Pressure (in. wg)

Watts — Input Watts to Motor

548F036 (3 TONS) — ALTERNATE MOTOR AND DRIVE*

Airflow

(Cfm)

900 643 0.15 152 768 0.22 222 870 0.30 296 958 0.37 373 1037 0.46 454

1000 683 0.19 191 804 0.27 268 904 0.35 348 991 0.43 430 1069 0.52 517

1100 725 0.24 237 842 0.32 321 939 0.41 407 1025 0.50 496 1102 0.59 588

1200 767 0.29 291 880 0.38 382 976 0.48 474 1060 0.57 570 1136 0.67 668

1300 811 0.35 352 920 0.45 451 1013 0.55 550 1095 0.66 652 1170 0.76 756

1400 855 0.43 423 960 0.53 529 1051 0.64 636 1132 0.75 744 1205 0.86 855

1500 900 0.51 504 1002 0.62 617 1090 0.74 731 1169 0.85 846 1242 0.97 963

ESP Bhp Watts ESP Bhp Watts ESP Bhp Watts ESP Bhp Watts

LEGEND See General Fan Performance notes below.

Rpm Bhp Watts Rpm Bhp Watts Rpm Bhp Watts Rpm Bhp Watts Rpm Bhp Watts

208 v 230, 460, 575 v 208 v 230, 460, 575 v

0.2 0.4 0.6 0.8 1.0

Low Speed High Speed

External Static Pressure (in. wg)

548F036 (3 TONS) — ALTERNATE MOTOR AND DRIVE* (cont)

Airflow

(Cfm)

900 1110 0.54 538 1177 0.63 627 1239 0.72 718 1298 0.82 813 1355 0.92 911

1000 1141 0.61 607 1207 0.70 700 1269 0.80 796 1328 0.90 895 1384 1.00 998

1100 1173 0.69 683 1238 0.79 781 1300 0.89 883 1358 0.99 987 ———

1200 1205 0.77 768 1270 0.88 872 1332 0.98 979 ——————

1300 1239 0.87 863 1303 0.98 972 —————————

1400 1273 0.97 967 ————————————

1500 ———————————————

LEGEND

Bhp — Brake Horsepower Input to Fan

Watts — Input Watts to Motor

*Motor drive range: 760 to 1000 rpm. All other rpms require a field-

supplied drive.

Rpm Bhp Watts Rpm Bhp Watts Rpm Bhp Watts Rpm Bhp Watts Rpm Bhp Watts

1.2 1.4 1.6 1.8 2.0

External Static Pressure (in. wg)

See General Fan Performance notes below.

NOTES:

1. Boldface indicates field-supplied drive is required.

2. Maximum continuous bhp is 1.00.

GENERAL FAN PERFORMANCE NOTES