Bryant 549B Series Installation, Start-up And Service Instructions Manual

installation, start-up

and service instructions

SINGLE PACKAGE ROOFTOP

HIGH-EFFICIENCY HEAT PUMP UNITS

IMPORTANT — READ BEFORE INSTALLING

1. Read and become familiar with these installation instructions before installing this unit (Fig. 1).

2. Be sure the installation conforms to all applicable local

and national codes.

3. These instructionscontainimportant information for the

proper maintenance and repair of this equipment.

Retain these instructions for future use.

549B

Sizes 090,120

71⁄2and 10 Tons

Cancels: New II 549B-90-1

7/15/95

CONTENTS

Page

SAFETY CONSIDERATIONS ........................1

INSTALLATION .................................1-16

I. Locate the Unit .............................3

II. Unit Duct Connections ......................3

III. Rig and Place Unit ..........................3

IV. Field Connections ..........................6

PRE-START-UP ................................16,17

START-UP ....................................17-24

I. Compressor Rotation .......................17

II. Heating Section Start-Up and Adjustments

For Units With Accessory Electric Heat .......17

III. Cooling Section Start-Up and Adjustments ....18

IV. Indoor Airflow and Airflow Adjustments .......19

CARE AND MAINTENANCE .......................25

I. Air Filter ..................................25

SERVICE .....................................25-27

I. Cleaning .................................25

II. Lubrication ...............................26

III. Outdoor-Fan Adjustment ....................26

IV. Economizer Adjustment ....................26

V. Refrigerant Charge .........................26

VI. Replacement Parts .........................27

TROUBLESHOOTING ...........................28-30

START-UP CHECKLIST ..........................CL-1

Fig.1—Typical Unit

WARNING:

nance operations on unit, turn off main power switch

to unit. Electrical shock could cause personal injury.

1. The power supply (volts, hertz, and phase) must correspond to that specified on unit rating plate.

2. The electrical supply provided by the utility must be sufficient to handle unit load.

3. Refer to Locate the Unit section on page 3 and Fig. 2 for

locations of electrical inlets, condensate drain, duct connections, and required clearances before setting unit in

place.

4. This installation must conform with local building codes

and with NEC (National Electrical Code) or NFPA

(National Fire Protection Association) 54 TIA-54-1.

Refer to provincial and local plumbing or wastewater codes

and other applicable local codes.

5. Approved for outdoor installation on wood flooring or on

class A, B, or C roof covering materials.

Before performing service or mainte-

SAFETY CONSIDERATIONS

Recognize safety information. This is the safety-alert symbol

( ). When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal

injury.

Understand the signal words — DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol. Danger identifies the most serious hazards which will

result in severe personal injury or death. Warning indicates

a situation that could result in personal injury. Caution is

used to identify unsafe practices which would result in minor

personal injury or product and property damage.

INSTALLATION

Unit is shipped in the vertical airflow configuration (see

Fig. 1). To convert to horizontal discharge, remove side duct

opening covers. Using the same screws, install covers with

insulation-side down (facing outside) on the unit over vertical duct openings. Seals around duct openings must

be tight.

All units can be connected into existing duct systems that are

properly sized and designed to handle an airflow of 300 to

500 cfm per each 12,000 Btuh of rated cooling capacity.

UNIT

549B

STANDARD

UNIT

WEIGHT

CORNER

WEIGHT

(A)

CORNER

WEIGHT

(B)

CORNER

WEIGHT

(C)

CORNER

WEIGHT

(D)

Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg ft-in. mm ft-in. mm ft-in. mm

090 870 395 195 90 183 83 237 108 252 114 28-0

120 1000 454 231 105 214 97 269 122 286 130 28-10

NOTES:

CONNECTION SIZES

3

A 1

B 2

C 1

D

E

⁄89 Dia. [35] Field Power Supply Hole

1

⁄29 Dia. [64] Power Supply Knock-Out

3

⁄49 Dia. [44] Charging Port Hole

7

⁄89 Dia. [22] Field Control Wiring Hole

3

⁄49-14 NPT Condensate Drain

F 29 Dia. [51] Power Supply Knock-Out

1. Dimensions in [ ] are in millimeters.

2. Center of Gravity.

3. Direction of airflow.

4. Ductwork to be attached to accessory roof curb only.

5. Minimum clearance (local codes or jurisdiction may prevail):

a. Bottom to combustible surfaces (when not using curb) 0 in., on horizon-

tal discharge units with electric heat, 1 in. clearance to ductwork for 1 ft.

b. Outdoor coil, for proper airflow, 36 in. one side, 12 in. the other. The

side getting the greater clearance is optional.

c. Overhead, 60 in. to assure proper outdoor fan operation.

d. Between units, control box side, 42 in. per NEC (National Electrical Code).

e. Between unit and ungrounded surfaces, control box side, 36 in. per NEC.

f. Between unit and block or concrete walls and other grounded surfaces,

control box side, 42 in. per NEC.

g. Horizontal supply and return end, 0 inches.

6. With the exception of the clearance for the outdoor coil and combustible

surfaces as stated in notes 5a, b, and c, a removable fence or barricade

requires no clearance.

7. Units may be installed on combustible floors made from wood or Class A,

B, or C roof covering material.

8. The vertical center of gravity is 18-7

from the bottom of the base rail.

‘‘H’’ ‘‘J’’ ‘‘K’’

7

⁄89 632 38-55⁄169 1050 28-911⁄169 856

7

⁄89 885 48-15⁄169 1253 38-03⁄89 924

1

⁄29 [495] for 090, 28-69 [610] for 120 up

These holes req’d for use with accessory packages —

CRBTMPWR001A00 (

THREADED

CONDUIT SIZE

*Select either

BOTTOM POWER CHART

1

⁄29,3⁄49) or CRBTMPWR002A00 (1⁄29,11⁄49)

WIRE

1

⁄2( 24V

3

⁄4( Power* 11⁄89 [28.4]

1

⁄4( Power* 13⁄49 [44.4]

1

3

⁄49 or 11⁄49 for power, depending on wire size.

USE

REQ’D HOLE

SIZES (MAX.)

7

⁄89 [22.2]

Fig. 2 — Base Unit Dimensions

—2—

NOTE: When installing any accessory item, see the manufacturer’s installation instructions packaged with the accessory. A qualified installer or agency must use only factoryauthorized kits or accessories when modifying this unit.

I. LOCATE THE UNIT

A. Clearance

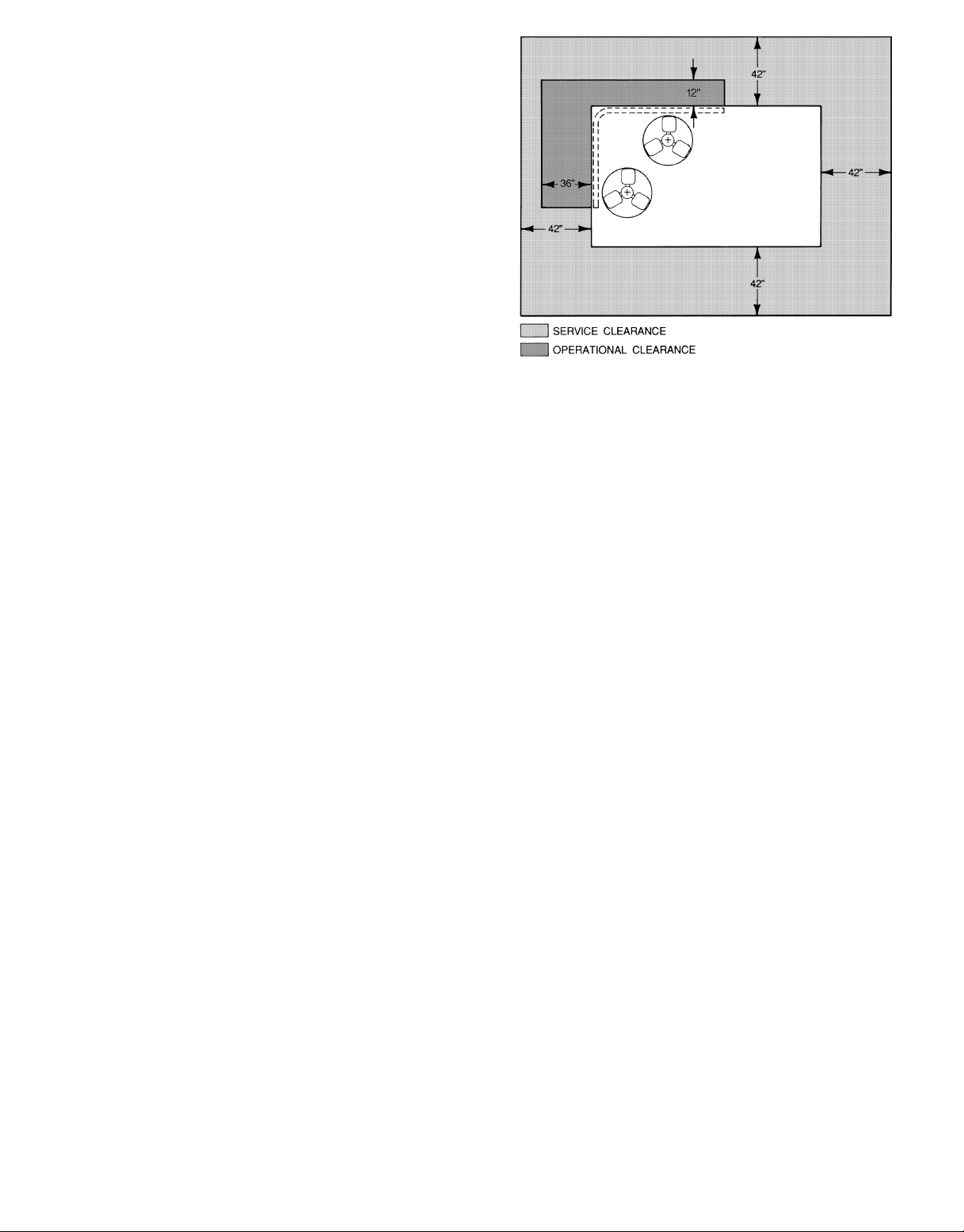

Maintain clearance around and above unit to provide minimum distance from combustible materials, proper airflow ,and

service access. See Fig. 2 and 3.

Minimum clearance to combustibles (when not using curb) is

0 in. on vertical discharge units and 1 in. on horizontal discharge units.

Minimum clearance to block walls or any other grounded surface is 42 in. on all sides.

Minimum clearance of 42 in. should be provided between units

on side with control box. Between unit and ungrounded surfaces, control box side, clearance is 36 inches.

Minimum clearance around outdoor coil is 12 in. one side and

36 in. the other side (side getting greater clearance is

optional).

Overhead minimum clearance is 60 in.

Do not install unit in an indoor location. Do not locate unit

air inlets near exhaust vents or other sources of contaminated air.

Although unit is weatherproof, guard against water from higher

level runoff and overhangs.

Slab mounted units should be at least 4 in. above the highest

expected water, flood, and runoff levels. Do not use the unit if

it has been under water.

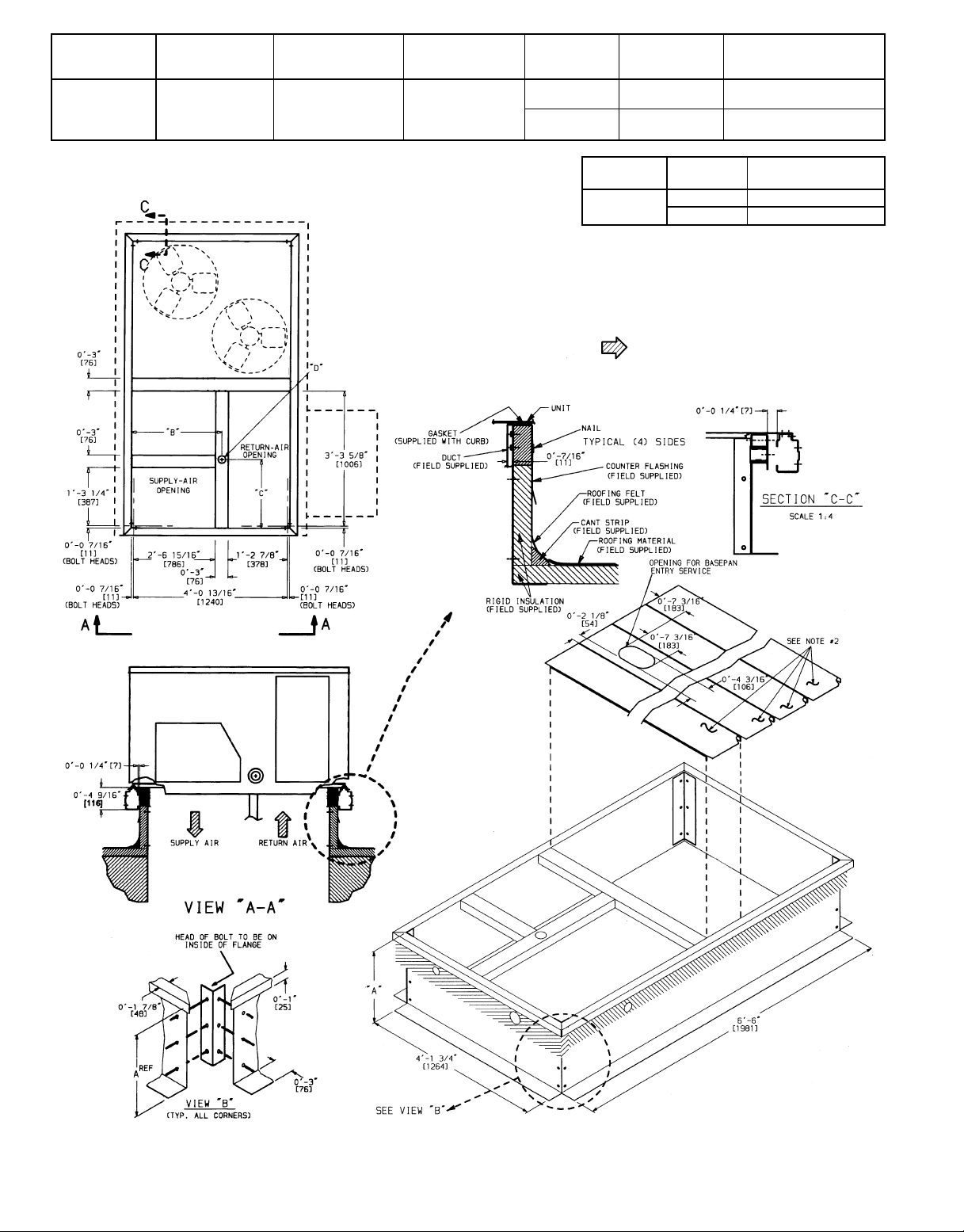

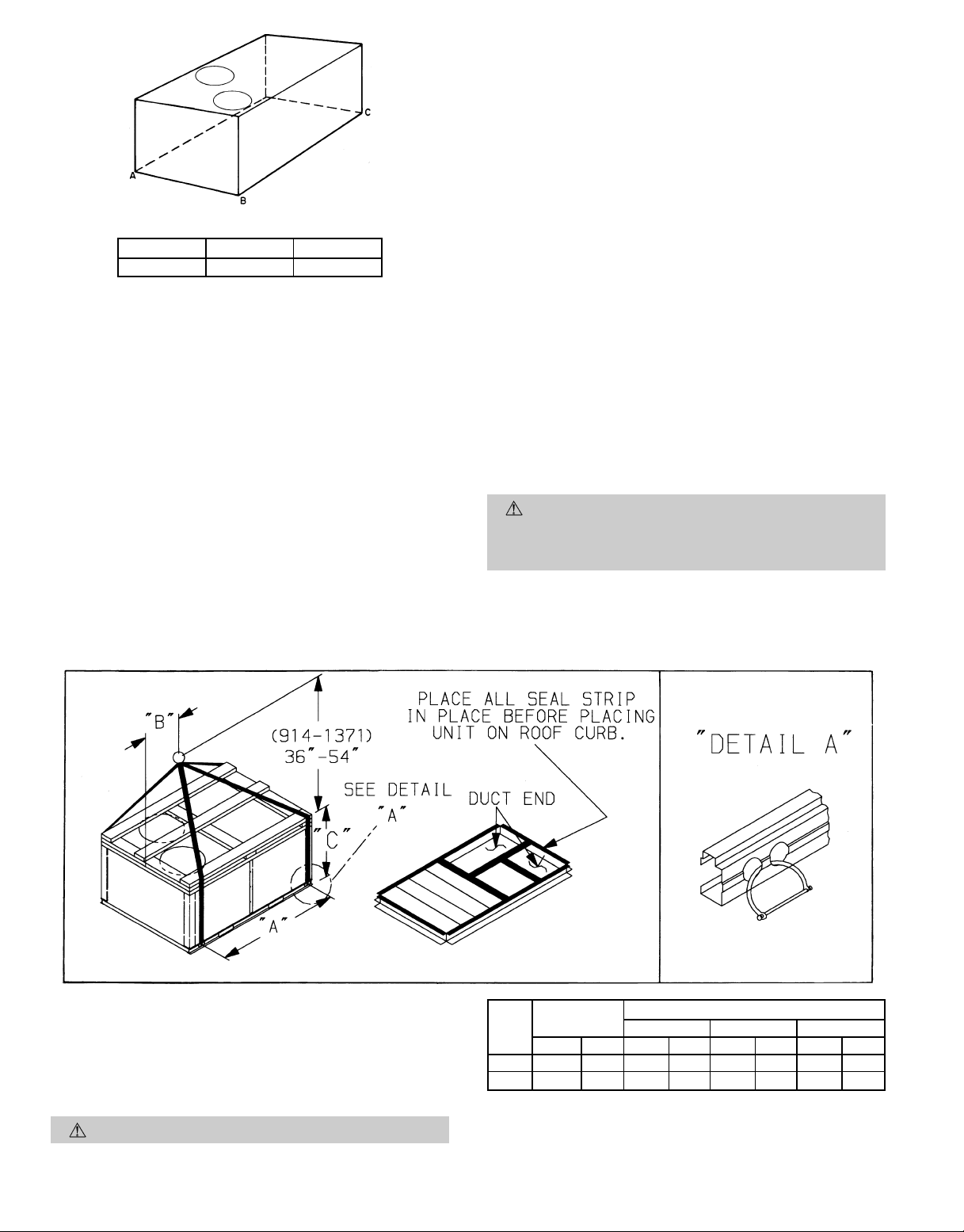

B. Roof Curb Mount

Assemble and install accessory roof curb in accordance with

instructions shipped with curb. See Fig. 4. Install insulation,

cant strips, roofing felt, and counter flashing as shown. Duct-

work must be attached to curb. If electric or control power is

to be routed through the basepan, attach the accessory thruthe-bottom connections to the basepan in accordance with the

accessory installation instructions. Accessory electric connections must be installed before unit is in place on roof curb.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for water integrity. Install gasket with the roof curb

as shown in Fig. 4. Improperly applied gasket can also result

in air leaks and poor unit performance.

Curb should be level. Unit leveling tolerances are shown in

Fig. 5. This is necessary for unit drain to function

properly.

C. Slab Mount (Horizontal Units Only)

Provide a level concrete slab that extends a minimum of

6 in. beyond unit cabinet. Install a gravel apron in front of

outdoor-coil air inlet to prevent grass and foliage from obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if

required.

II. UNIT DUCT CONNECTIONS

On vertical units, secure all ducts to roof curb and building

structure. Do not connect ductwork to unit. On horizontal units,

duct flanges should be attached to horizontal openings and

all ductwork should be secured to flanges.

Fig. 3 — Service and Operational Clearances

Insulate and weatherproof all external ductwork, joints, and

roof openings with counter flashing and mastic in accordance

with applicable codes.

Ducts passing through an unconditioned space must be insulated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should

be ducted through the roof deck to comply with applicable

fire codes.

A minimum clearance to combustibles is not required

around ductwork on vertical discharge units. On horizontal

discharge units, a minimum clearance of 1 in. is required

for the first 12 in. of ductwork. Cabinet return-air static

shall not exceed –0.35 in. wg with Varislide™ economizer

−0.20 in. wg with PARABLADE economizer, or –0.45 in. wg

without economizer.

NOTE: Connection must be made to roof curb before unit is

set in place.

III. RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

transportation agency. Keep unit upright and do not drop.

Spreader bars are not required if top crating is left on unit.

Rollers may be used to move unit across a roof. Level by using unit frame as a reference. See Table 1 and Fig. 6 for additional information. Operating weight is shown in Fig. 6.

Lifting holes are provided in base rails as shown in Fig. 6.

Refer to rigging instructions on unit.

A properly positioned unit will have the following clearances

between unit and roof curb:

and base rails on each side and front of unit; 1

1

⁄4-in. clearance between roof curb

5

⁄32-in. clearance between roof curb and rear of unit. See Fig. 4, Views

A-A and C-C.

After unit is in position, remove polyethylene shipping wrapper and rigging skid.

—3—

UNIT SIZE

549B

090,120 28-8

‘‘B’’ ‘‘C’’

7

⁄169 [827] 18-1015⁄169 [583] 13⁄49 [45]

‘‘D’’ALT

DRAIN HOLE

POWER CONTROL

3

⁄49 NPT

1

1

⁄49 NPT

1

⁄29 NPT

1

⁄29 NPT

CONNECTOR

ACCESSORY

PACKAGE

CRBTMPWR00A100

(Thru-the-Bottom)

CRBTMPWR00A200

(Thru-the-Bottom)

UNIT SIZE

549B

090,120

NOTES:

1. Roof curb accessory is shipped unassembled.

2. Insulated panels.

3. Dimensions in [ ] are in millimeters.

4. Roof curb: galvanized steel.

5. Attach ductwork to curb (flanges of duct rest on curb).

6. Service clearance 4 ft on each side.

‘‘A’’

18-29 [356] CRRFCURB003A00

28-09 [610] CRRFCURB004A00

ROOF CURB

ACCESSORY

7. Direction of airflow.

Fig. 4 — Roof Curb Details

—4—

Table 1 — Specifications

UNIT 549B 090 120

1

⁄

1

⁄4...1100

7

⁄

8

2

Acutrol™ Feed Device

Acutrol Feed Device

1...16 x 25 x 1

NOMINAL CAPACITY (tons) 7

OPERATING WEIGHT (lb)

Unit 870 1000

With Varislide™ Economizer 914 1044

With PARABLADE Economizer 932 1062

Roof Curb 143 143

COMPRESSOR Scroll

Quantity 22

Oil (oz) (each compressor) 57 57

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1 5-3 9-11

Circuit 2 5-8 9-11

OUTDOOR FAN Propeller Type

Quantity...Diameter (in.) 2...22 2...22

Nominal Cfm 6500 7000

Motor Hp...Rpm

Watts Input (Total) 650 650

OUTDOOR COIL

Rows...Fins/in. 2...17 2...17

Total Face Area (sq ft) 20.5 25.1

INDOOR FAN Centrifugal Type, Belt Drive

Size (in.) 1...15 x 15 1...15 x 15

Nominal Cfm 3000 4000

Maximum Continuous Bhp 2.90 4.20

Motor Frame 56 56

Fan Rpm Range 725-925 860-1080

Motor Bearing Type Ball Ball

Maximum Fan Rpm 2100 2100

Motor Pulley Pitch Diameter A/B (in.) 3.4/4.4 4.0/5.0

Nominal Motor Shaft Diameter (in.)

Fan Pulley Pitch Diameter (in.) 8.0 8.0

Belt — Quantity...Type...Length (in.) 1...A...51 1...A...51

Pulley Center Line Distance (in.) 16.75-19.25 15.85-17.50

Speed Change per Full Turn of 50 45

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full Turns 55

From Closed Position

Factory Setting — Full Turns Open 55

Factory Speed Setting (rpm) 725 860

Fan Shaft Diameter at Pulley (in.) 11

High-Efficiency Enhanced Copper Tubes, Lanced Aluminum Fins

INDOOR COIL High Efficiency Enhanced Copper Tubes, Aluminum Double-Wavy Fins,

Rows...Fins/in. 3...15 4...15

Total Face Area (sq ft) 8.9 11.1

HIGH-PRESSURE SWITCH (psig)

Standard Compressor Internal Relief 450±50

Cutout 428

Reset (Auto.) 320

LOSS-OF-CHARGE/LOW-PRESSURE

SWITCH (Liquid Line) (psig)

Cutout 7±3

Reset (Auto.) 22±7

FREEZE-PROTECTION THERMOSTAT

Opens (F) 30±5

Closes (F) 45±5

OUTDOOR-AIR INLET SCREENS Cleanable

Quantity...Size (in.) 1...20 x 25 x 1

RETURN-AIR FILTERS Throwaway

Quantity...Size (in.) 4...16 x 20 x 2 4...20 x 20 x 2

10

1

⁄4...1100

7

⁄

8

LEGEND

Bhp — Brake Horsepower

—5—

MAXIMUM ALLOWABLEDIFFERENCE (in.)

A-B B-C A-C

0.5 1.0 1.0

Fig. 5 — Unit Leveling Tolerances

IV. FIELD CONNECTIONS

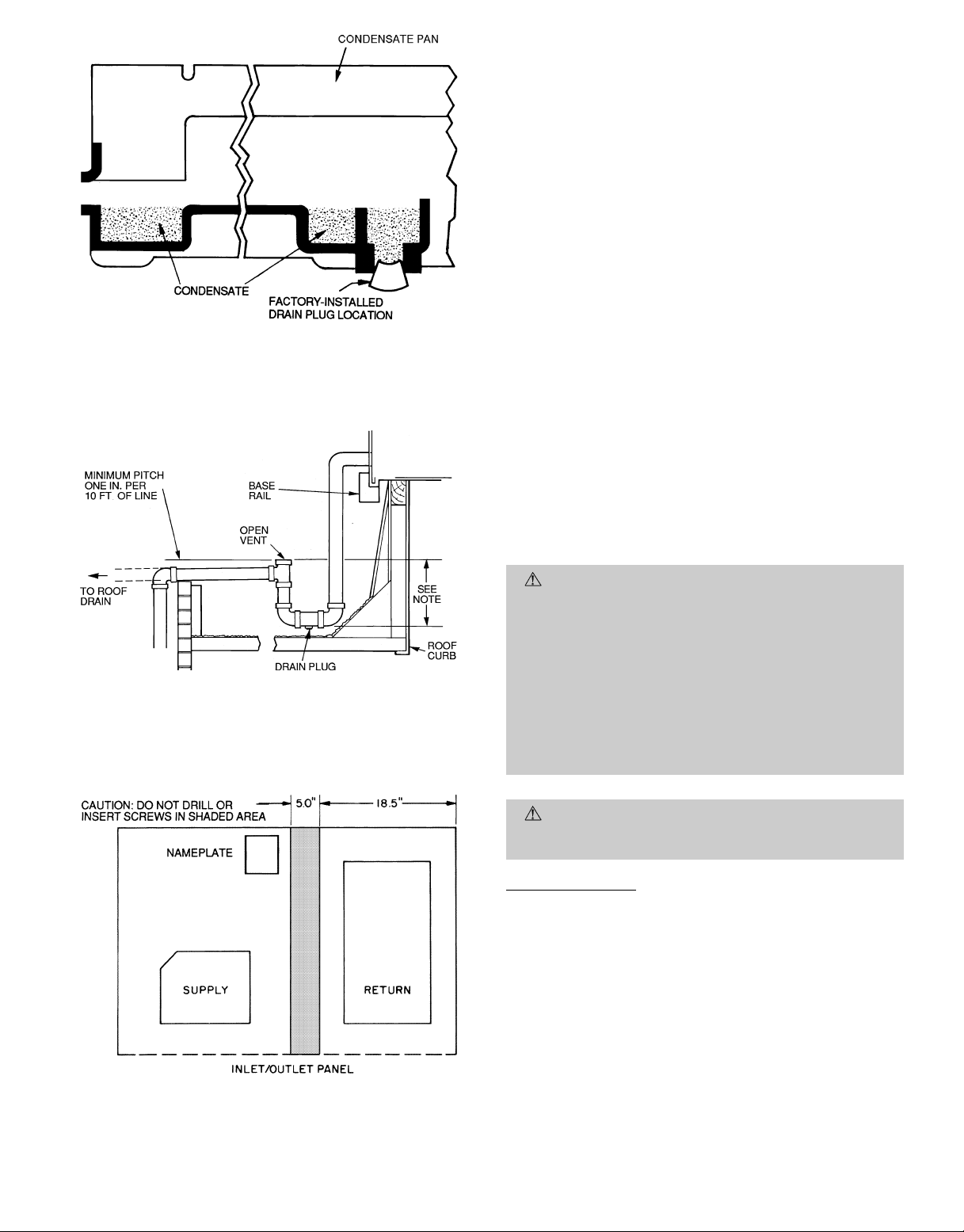

A. External Trap Condensate Drain

The unit’s

3

⁄4-in. condensate drain connections are located

at the bottom and end of the unit. Unit discharge connections do not determine the use of drain connections; either

drain connection can be used with vertical or horizontal

applications.

When using the standard end drain connection, make sure

the plug in the alternate bottom connection is tight before

installing the unit.

To use the bottom drain connection for a roof curb installation, relocate the factory-installed plug from the bottom

connection to the end connection. See Fig. 7. The piping for

the condensate drain and external trap can be completed

after the unit is in place.

All units must have an external trap for condensate drainage. Install a trap at least 4-in. deep and protect against freezeup. See Fig. 8. If drain line is installed downstream from the

external trap, pitch the line away from the unit at 1 in. per

10 ft of run. Do not use a pipe size smaller than the unit

connection.

B. Field Duct Connections

NOTE: The design and installation of the duct system must

be in accordance with NFPA standards for the installation of

nonresidence-type air conditioning and ventilating systems,

NFPA No. 90A, or residence-type, NFPA No. 90B, and/or

local codes and ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Remove appropriate panels from unit to obtain either

horizontal or vertical discharge. If units are installed in

horizontal discharge applications, remove vertical discharge duct covers, save screws, and install covers on

vertical duct openings.

2. Select and size ductwork, supply-air registers, and returnair grilles according to ASHRAE (American Society

of Heating, Refrigeration and Air Conditioning Engineers) recommendations.

CAUTION:

When drilling the duct system fastening

holes into the side of the unit for duct flanges, use extreme care not to puncture the coil or coil tubes. See

Fig. 9.

NOTES:

1. Dimension in ( ) is in millimeters.

2. Hook rigging shackles through holes in base rail, as shown in detail

9A.9 Holes in base rails are centered around the unit center of gravity. Use wooden top skid when rigging to prevent rigging straps from

damaging unit.

3. Unit weights do not include economizer. See Table 1 for economizer

weights.

CAUTION: All panels must be in place when rigging.

Fig. 6 — Rigging Details

—6—

OPERATING

UNIT

549B

090 870 395 87.38 2219 40.25 1022 41.31 1050

120 1000 454 87.38 2219 40.25 1022 49.31 1253

WEIGHT

lb kg in. mm in. mm in. mm

(A((B((C(

DIMENSIONS

NOTE: Drain plug is shown in factory-installed position.

Fig. 7 — Condensate Drain Pan

3. Use flexible transition between rigid ductwork and unit

to prevent transmission of vibration. The transition may

be screwed or bolted to duct flanges. Use suitable gaskets to ensure weather- and airtight seal.

4. When horizontal return is used, install external fieldsupplied air filters in return-air ductwork where they

are easily accessible for service. Recommended filter sizes

are shown in Table 1.

5. For horizontal applications, be sure ductwork does not

cover nameplate.

6. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed.Avoidabrupt

duct size increases or decreases.

7. Adequately insulate and weatherproof all ductwork

located outdoors. Insulate ducts passing through unconditioned space, and use vapor barrier in accordance with

latest issue of SMACNA (Sheet Metal and Air Conditioning Contractors National Association) and ACCA

(Air Conditioning Contractors of America) minimum

installation standards for heating and air conditioning

systems. Secure all ducts to building structure.

A minimum clearance to combustibles is not required

around ductwork on vertical discharge units. On horizontal discharge units, a minimum clearance of 1 in. is

required for the first 12 in. of ductwork.

8. Flash, weatherproof, and vibration isolate all openings

in building structure in accordance with local codes and

good building practices.

NOTE: Trap should be deep enough to offset maximum unit static diffrence. A 4-in. trap is recommended.

Fig. 8 — External Trap Condensate Drain

Fig. 9 — Location of Coil Area

Not to be Drilled

C. Electrical Connections

WARNING:

The unit cabinet must have an uninterrupted, unbroken, electrical ground to minimize the

possibility of personal injury if an electrical fault should

occur. This ground may consist of electrical wire connected to the unit ground lug in the control compartment, or conduit approved for electrical ground when

installed in accordance with NEC ANSI (American

National Standards Institute)/NFPA70-1990(inCanada,

Canadian Electrical Code CSA [Canadian Standards

Association] C22.1) and local electrical codes. Failure

to adhere to this warning could result in personal

injury.

CAUTION:

Failure to obey the following precautions could result in damage to the unit being

installed:

Field Power Supply

1. Make all electrical connections in accordance with NEC

ANSI/NFPA 70-1990 and local electrical codes governing such wiring. In Canada, all electrical connections must be in accordance with CSA Standard C22.1

Canadian Electrical Code Part One and applicable local

codes. Refer to unit wiring diagram.

2. A unit disconnect switch is required within sight

from the unit. The disconnect switch may be mounted

on the unit corner post (see Fig. 2). When mounting disconnect switch, be sure the unit rating plate is not

obstructed.

NOTE: A factory-installed disconnect switch is available.

—7—

3. Use only copper or copper-clad conductor for connections between field-supplied electrical disconnect switch

and unit. The use of aluminum wire is not recommended. Maximum wire size is no. 2 AWG (American

Wire Gage) on units with heat(up to 34 kW). The maximum wire size is no. 2/0 AWG on units with heat (over

34 kW).

4. Units with accessory electric heat must also have the

correct single point box kit to meet UL (Underwriters’

Laboratories) requirements. Refer to installation instructions shipped with the accessory for more details.

5. Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (also

see Tables 2A and 2B). On 3-phase units, voltages between phases must be balanced within 2% and the current within 10%. Use the formula shown in Tables 2A

and 2B, Note 2 to determine the percent voltage imbalance. Operation on improper line voltage or excessive

phase imbalance constitutes abuse and may cause damage to electrical components. Such operation would invalidate any applicable warranty.

6. Insulate low-voltage wires for highest voltage contained within conduit when low-voltage control wires are

run in same conduit as high-voltage wires. Install conduit through side panel openings. For units without accessory electric heat, install conduit between disconnect

and control box.

7. Do not damage internal components when drilling through

any panel to mount electrical hardware, conduit, etc.

8. Install power lines to terminal connections as shown in

Fig. 10.

9. For units with accessory electric heat, refer to accessory

installation instructions for wiring the accessory.

During operation, voltage to compressor terminals must be

within range indicated on unit nameplate (see Tables 2A and

2B). On 3-phase units, voltages between phases must bebalanced within 2%, and the current within 10%. Use the formula shown in Tables 2A and 2B, Note 2 to determine the

percentage of voltage imbalance. Operation on improper line

voltage or excessive phase imbalance constitutes abuse and

may cause damage to electrical components. Such operation

would invalidate any applicable warranty.

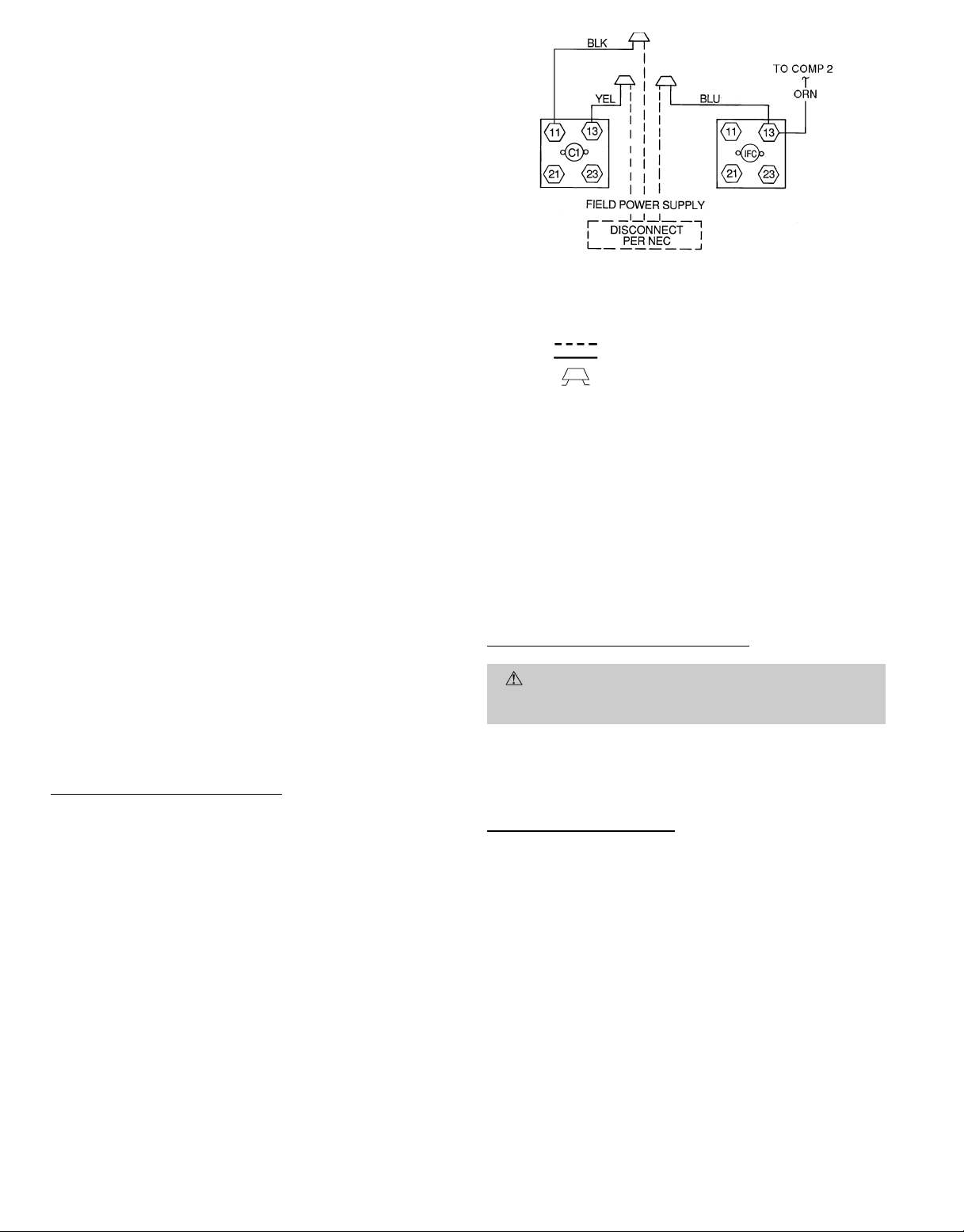

High-Voltage Connections (Fig. 10)

The unit must have a separate electrical service with a field-

supplied, waterproof fused disconnect switch mounted at, or

within sight from, the unit. Refer to the unit rating plate for

maximum fuse/circuit breaker size and minimum circuit amps

(ampacity) for wire sizing. Be sure disconnect switch does not

obstruct unit rating plate. A factory-installed disconnect is

available.

The field-supplied disconnect switch box may be mounted on

the unit over the high-voltage inlet holein the control corner

panel.

Proceed as follows to complete the high-voltage connections

to the unit:

1. Connect ground lead to chassis ground connection when

using separate ground wire.

LEGEND

C—Contactor

COMP — Compressor

IFC — Indoor Fan Contactor

NEC — National Electrical Code

Field Wiring

Factory Wiring

Splice Connection (Factory-Supplied)

Fig. 10 — Power Wiring Connections

2. Pigtails are provided for field power connection. Use

factory-supplied splices or UL-approved copper/aluminum

connector .Install conduit connectors in side panel power

supply knockout openings indicated in Fig. 2. Route power

lines through connector to unit control box.

NOTE: If accessory thru-the-bottom power connections are

used, refer to the accessory installation instructions for information on power wiring. Refer to Fig. 2 for drilling holes

in basepan.

Special Procedures for 208-V Operation

DANGER: Make sure that the power supply to the

unit is switched off before making any wiring changes.

Electrical shock can cause personal injury or death.

For operation on 208 v, disconnect the black wire from the

230-v orange wire on the transformer and connect it to the

200-v red wire from the transformer. Insulate the end of the

orange wire.

Control Voltage Connections

Install a factory-approved room thermostat. See Table 3,

page 11.Locate the thermostat on an inside wall in the space

to be conditioned where it will not be subjected to either a

cooling or heating source or direct exposure to sunlight. Mount

the thermostat 4 to 5 ft above the floor.

NOTE: For wire runs up to 50 ft, use no. 18 AWG insulated

wire (35 C minimum). For 51 to 75 ft, use no. 16 AWG insulated wire (35 C minimum). For 76 to 155 ft, use no. 14 AWG

insulated wire (35 C minimum). All wire larger than no. 18

AWG cannot be connected directly tothe thermostat and will

require a junction box and splice at the thermostat.

—8—

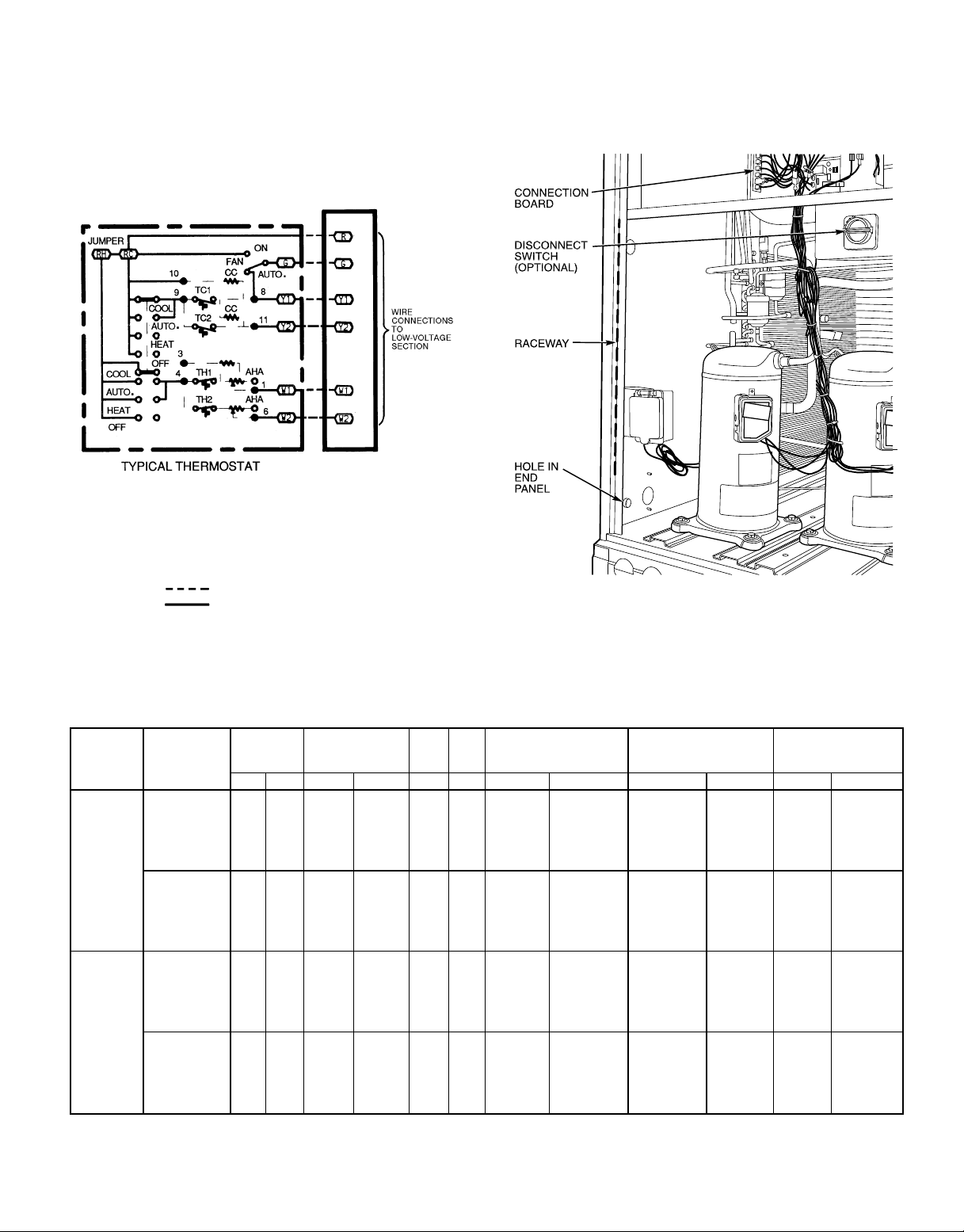

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals to low-voltage connections on

unit (shown in Fig. 11) as described in Steps 1 through 4

below.

1. If unit is mounted on roof curb and accessory thru-thebottom service connections are used, route wire through

basepan.

2. Pass control wires through the hole provided on unit (see

connection D in Connection Sizes table in Fig. 2).

LEGEND

AHA — Adjustable Heat Anticipator

CC — Cooling Compensator

RC — 24 V Cooling

RH — 24 V Heating

TC — Thermostat-Cooling

TH — Thermostat-Heating

Field Wiring

Factory Wiring

Fig. 11 — Low-Voltage Connections With or

Without Economizer

3. Feed wire through the raceway built into the corner post

to the 24-v barrier located on the left side of the control

box. See Fig. 12. The raceway provides the ULrequired

clearance between the high- and low-voltage wiring.

4. Connect thermostat wires to screw terminals of lowvoltage connector (see Fig. 11).

Fig. 12 — Field Control Wiring Raceway

UNIT

549B

090

1

(7

⁄2Tons)

120

(10 Tons)

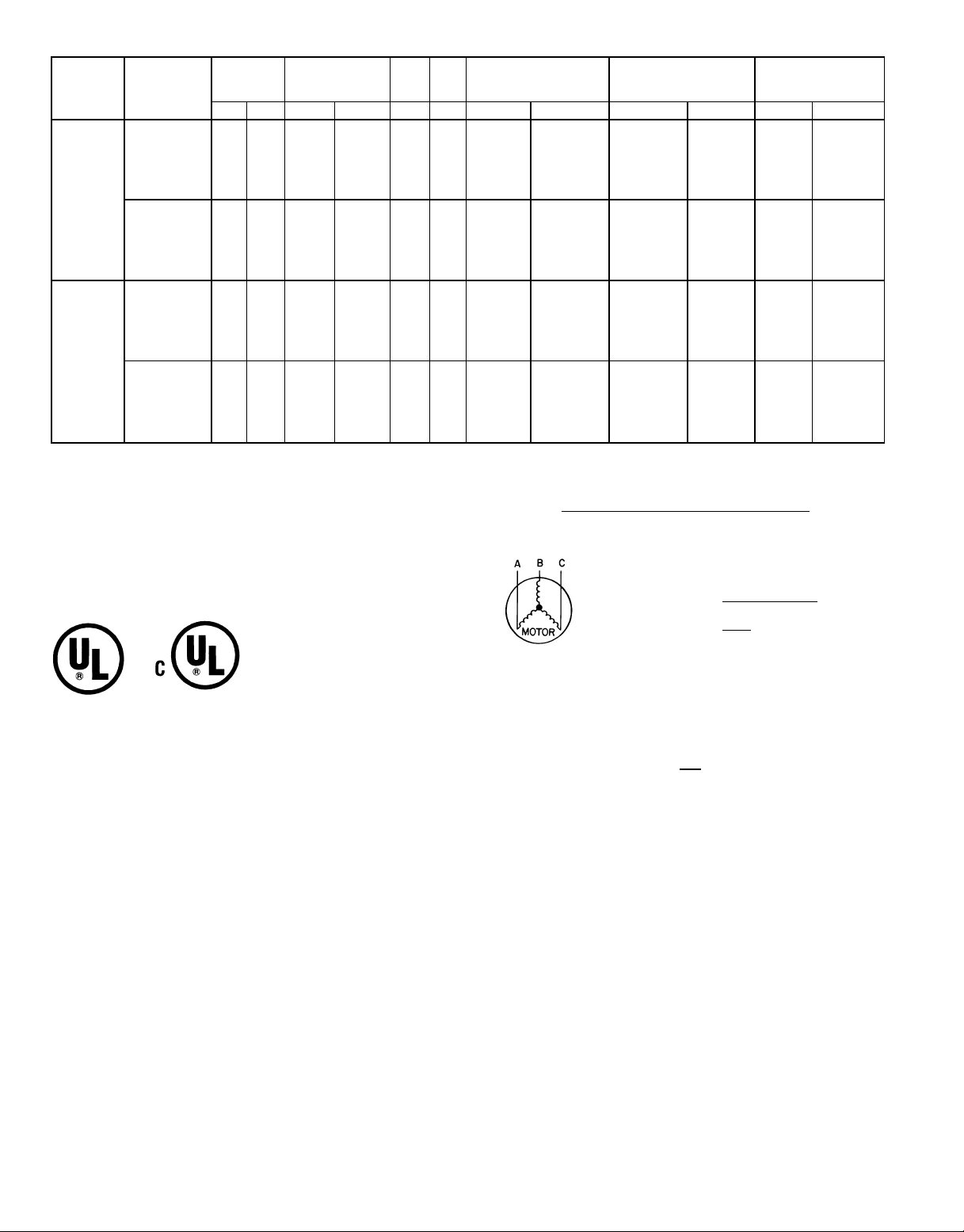

Table 2A — Electrical Data (Units Without Electrical Convenience Outlet)

NOMINAL

VOLTAGE

(V-Ph-Hz)

208/230-3-60 187 254 12.4 88.0 1.4 7.5

460-3-60 414 508 6.4 44.0 0.7 3.4

208/230-3-60 187 254 19.3 123.0 1.4 10.6

460-3-60 414 508 10.0 62.0 0.7 4.8

VOLTAGE

RANGE

Min Max RLA LRA FLA FLA kW† FLA MCA MOCP FLA LRA

COMPRESSOR OFM IFM ELECTRIC HEAT* POWER SUPPLY

—/—

7.8/10.4

12.0/16.0

18.6/24.8

24.0/32.0

31.8/42.4

—

13.9

16.5

27.8

33.0

41.7

—/—

7.8/10.4

12.0/16.0

24.0/32.0

31.8/42.4

37.6/50.0

—

16.5

27.8

33.0

41.7

50.0

—/—

21.7/ 25.0

33.3/ 38.5

51.6/ 59.7

66.6/ 77.0

88.3/102.0

—

16.7

19.8

33.4

39.7

50.2

—/—

21.7/ 25.0

33.3/ 38.5

66.6/ 77.0

88.3/102.0

104.4/120.3

—

19.8

33.4

39.7

50.2

60.1

38.2/ 38.2

65.3/ 69.5

79.8/ 86.3

102.7/112.8

121.5/134.5

148.6/165.7

19.2

40.1

44.0

61.0

68.8

82.0

56.8/ 56.8

84.0/ 88.1

98.5/105.0

140.1/153.1

167.2/184.3

187.3/177.1

28.7

53.3

70.5

78.3

91.5

88.8

40/ 40**

70/ 70

80/ 90

110/125

125/150

150/175

20**

45**

45**

70

70

90

60/ 60**

90/ 90

100/110

150/175

175/200

200/200

30**

60**

80

80

100

100

MINIMUM UNIT

DISCONNECT

SIZE

40/ 40

65/ 69

79/ 85

100/109

117/129

142/158

60/ 60

85/ 89

98/104

136/148

161/177

180/198

20

39

43

59

66

78

30

53

69

76

88

99

242/242

264/267

275/281††

294/302††

309/319††

330/344††

337/337

358/362††

370/375††

403/414††

425/439††

441/457††

121

138

141

155

161

171

170

189

203

209

220††

230††

—9—

Table 2B — Electrical Data (Units With Electrical Convenience Outlet)

UNIT

549B

NOMINAL

VOLTAGE

(V-Ph-Hz)

VOLTAGE

RANGE

COMPRESSOR OFM IFM ELECTRIC HEAT* POWER SUPPLY

Min Max RLA LRA FLA FLA kW† FLA MCA MOCP FLA LRA

208/230-3-60 187 254 12.4 88.0 1.4 7.5

009

1

(7

⁄2Tons)

460-3-60 414 508 6.4 44.0 0.7 3.4

208/230-3-60 187 254 19.3 123.0 1.4 10.6

120

(10 Tons)

460-3-60 414 508 10.0 62.0 0.7 4.8

LEGEND AND NOTES TO TABLES 2A AND 2B

LEGEND

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Heater capacity (kW) is based on heater voltage of 208 v, 240 v,

or 480 v. If power distribution voltage to unit varies from rated heater

voltage, heater kW will vary accordingly.

**Fuse or HACR circuit breaker.

††Factory-installed disconnect is not available for these units when elec-

tric heat package is installed.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load and equipment (refer to NEC Articles 430 and 440), the

overcurrent protective device for the unit shall be fuse or HACR breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is

greater than 2%.

age of voltage imbalance.

Use the following formula to determine the percent-

MINIMUM UNIT

DISCONNECT

SIZE

—/—

7.8/10.4

12.0/16.0

18.6/24.8

24.0/32.0

31.8/42.4

—

13.9

16.5

27.8

33.0

41.7

—/—

7.8/10.4

12.0/16.0

24.0/32.0

31.8/42.4

37.6/50.0

—

16.5

27.8

33.0

41.7

50.0

—/—

21.7/ 25.0

33.3/ 38.5

51.6/ 59.7

66.6/ 77.0

88.3/102.0

—

16.7

19.8

33.4

39.7

50.2

—/—

21.7/ 25.0

33.3/ 38.5

66.6/ 77.0

88.3/102.0

104.4/120.3

—

19.8

33.4

39.7

50.2

60.1

43.0/ 43.0

70.1/ 74.3

84.6/ 91.1

107.5/117.6

126.3/139.3

153.4/170.5

21.4

42.3

46.1

63.1

71.0

84.1

61.6/ 61.6

88.8/ 92.9

103.3/109.6

144.9/157.9

172.0/189.1

192.1/181.9

30.9

55.6

72.6

80.5

93.6

91.0

45/ 45**

80/ 80

90/100

110/125

150/150

175/175

25**

45**

50**

70

80

90

70/ 70

90/100

110/110

150/175

175/200

200/200

35**

60**

80

90

100

100

46/ 46

71/ 75

84/ 90

105/115

122/134

147/163

23

42

46

61

68

80

65/ 65

90/ 94

104/110

142/154

167/183

185/204

33

55

71

78

90

102

247/247

269/272

280/285††

298/307††

313/324††

335/349††

123

140

143

157

163

174

341/341

363/366††

375/380††

408/418††

430/443††

446/462††

172

191

205

211

222††

232††

% Voltage Imbalance

= 100 x

max voltage deviation from average voltage

average voltage

EXAMPLE: Supply voltage is 460-3-60

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

452 + 464 + 455

1371

=

3

3

= 457

Determine maximum deviation from average voltage:

(AB) 457 – 452=5v

(BC) 464 – 457=7v

(AC) 457 – 455=2v

Maximum deviation is 7 v.

Determine percentage of voltage imbalance:

% Voltage imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%

contact your local electric utility company immediately.

—10—

Loading...

Loading...