Page 1

DESCRIPTION

Model 542F is a high-efficiency, single-package heat pump that

has an energy efficiency ratio (EER) of 8.5 and a coefficient of

performance (COP) of 3.0 at 47 F outdoor temperature rating

point.

The 542F has supply- and return-air openings on the bottom of

the unit and is designed primarily for rooftop installation on a

factory-supplied 14- or 24-in. high roof curb. The air ducts connect to the curb only; therefore, the curb and ductwork may be

installed before the unit arrives at the jobsite.

A 24-in. high factory-supplied adapter for horizontal supply/

return duct connections to an over-and-under duct configuration

is also available for grade level or rooftop installation.

‘‘Variable circuited’’ indoor and outdoor coils allow both coils to

operate with parallel circuits when they are performing as

evaporators, and with a series of circuits when they are performing as condensers.

STANDARD FEATURES

FACTORY-ASSEMBLED PACKAGE is a compact, fully self-

contained heating/cooling unit that is prewired, prepiped, and

precharged for minimum installation time and expense.

TWO RUGGED, SERVICEABLE, SEMI-HERMETIC COMPRESSORS provide two stages of heating and cooling. These

compressors are electrically and mechanically independent.

COMPRESSOR ISOLATION MOUNTING minimizes vibration

(noise) transmission to building.

TWO SUCTION-TUBE ACCUMULATORS protect compres-

sors against liquid slugging — permitting operation over wide

range of temperatures.

CRANKCASE HEATERS AND FILTER DRIERS are standard.

HIGH-AND LOW-PRESSURE SAFETY DEVICES are included

to prevent major component breakdown when abnormal refrigerant operating conditions occur.

INTERNAL AND EXTERNAL PROTECTION is provided

against compressor overload and overheat conditions.

HIGH-STATIC, BELT-DRIVEN BLOWER with an adjustable

motor pulley permits variable airflow rates. An optional motor

pulley adjusts the airflow range to meet most applications.

WEATHERIZEDCABINET of heavy-duty phosphated and zinccoated steel is standard. Baked-on finish is corrosion and fade

resistant.

VERTICAL CONDENSER AIR DISCHARGE prevents recirculation of hot condenser air and reduces the operating sound

level.

MANUAL OUTDOOR-AIR DAMPER (standard equipment on

units without optional economizer) provides up to 25% outdoor

air for ventilation.

SUPPLEMENTAL ELECTRIC HEATERS are available as accessory equipment for operation on 208, 230, and 460 v, and

are modular in design for easy installation.

SINGLE-POINT POWER CONNECTION is provided on units

with field-installed electric heaters. Only one power supply with

one disconnect switch is required.

PROTECTION AS REQUIRED BY NEC (National Electrical

Code) for fan motors is factory supplied.

TWO-IN. FILTERS are standard.

RIGGING HOLES are provided in unit base rails for a 4-point lift

to facilitate lifting and moving operations.

THERMALLY AND ACOUSTICALLY INSULATED air-handling

section provides quieter and more efficient operation.

FACTORY-INSTALLED OPTIONS

DESCRIPTION AND USAGE

Economizer — The economizer will allow a fixed percentage

(between 0 and 100%) outdoor ventilation air into the unit any

time the indoor fan is running.Adry-bulbchangeoverthermostat

allows up to 100% outdoor air whenever the temperature of the

outdoor air alone will adequately provide cooling. If the economizer alone cannot provide enough cooling, then simultaneous

economizer and compressor operation will provide the most

economical operation.

SUGGESTED USE:

• To allow a fixed percentage of outdoor air any time the indoor

fan is on, or operates in economizer mode if outdoor air can

provide cooling, but closes when the indoor fan is off to prevent cold backdrafts and wasted energy.

• To reduce energy usage. Use whenever the number of hours

of operation at below 55 F is significant.

• The damper may be used on either vertical or horizontal

applications.

Alternate Indoor-Fan Drive — Alternate drive allows operation

of the indoor fan at conditions outside the range of the standard

factory motor and drive combination.

SUGGESTED USE:

• When higher static/airflow is required to meet job conditions.

MODEL 542F

Bryant

Air Conditioning

COMMERCIAL ROOFTOP

PACKAGED HEAT PUMP

Model 542F

Size 180

15 Tons

Form No. PDS 542F.180.2B

Page 2

FIELD-INSTALLED ACCESSORY

DESCRIPTION AND USAGE

Roof Curbs (Vertical) — Full-perimeter galvanized steel sup-

port frame in 14- and 24-in. high designs provides wood nailer

to attach roof counter flashing. Insulated basepans in curb are

provided to prevent condensation. Ductwork attaches to rails

provided in the roof curb. A gasket is provided to form an airand watertight seal between unit and curb. The gasket meets

the standards of the NRCA (National Roofing Contractors’

Association).

SUGGESTED USE:

• Rooftop application for vertical discharge.

• Slab-mounted applications when elevation of the unit is

necessary.

Horizontal Adapters — The adapters are prefabricated, easily

field-assembled, and permit full perimeter mounting. Adapters

can be installed at the jobsite before unit is installed, eliminating

a major leak source.

SUGGESTED USE:

• Rooftop application for horizontal discharge.

• Rooftop applications for horizontal discharge on units where

high air delivery cfms are required.

Two-Position Damper — Package consists of a low-leak

damper assembly. The damper will allow either 0 or 25% outdoor air into the unit any time the evaporator fan is running.

When the evaporator fan is off, the damper will be closed.

SUGGESTED USE:

• Allows a fixed percentage of outdoor air any time the evaporator fan is on, but closes when the evaporator fan is off to

prevent cold backdrafts and wasted energy.

• The damper may be used on either vertical or horizontal airflow applications.

Thermostats and Subbases — Provide staged cooling and

heating, automatic (or manual) changeover, fan control, and indicator light.

SUGGESTED USE:

• To control unit operations.

Barometric Relief Package — This package is useful when it

is necessary to remove excess pressure from the conditioned

space.

NOTE: Optional economizer is required with this accessory.

Power Exhaust — This package is useful when it is necessary

to remove excess pressure from the conditioned space.

NOTE: Optional economizer is required with this accessory.

SUGGESTED USE:

• When the job requires the ability to relieve internal building

pressure and pressure losses through the return-air ductwork

are greater than 0.20 in. wg.

• When the job requires the ability to move large quantities

of air to relieve pressure in the conditioned space.

Head Pressure Control — Kit consists of an outdoor-air thermostat that permits adequate head pressure control during

cooling operation at low outdoor-ambient temperatures. Refer

to Trade Prices for more details.

SUGGESTED USE:

• When cooling at low-ambient outdoor temperatures is

desired.

Time GuardT Device — Package consists of a control to be

field wired into the unit controls, and provides a 5-minute delay

in compressor operation between cooling cycles.

SUGGESTED USE:

• Prevents compressor short cycling when rapid compressor

cycles may be a problem.

Electric Heat Packages — Each package consists of one or

more heater modules. Each module slides into keyed mounting

slots in the fan discharge section.

SUGGESTED USE:

• To provide heat in the unit when required.

Economizer — See description listed under Factory-Installed

Options Description and Usage section on page 1.

Remote Control Panel — The remote control panel accessory

consists of a decorative, indoor, wall-mounted panel. The panel

contains: 2-stage heat/2-stage cool thermostat with auxiliary

changeover, a system switch with HEAT-COOL-AUTO.-OFF

settings, a fan switch with ON-AUTO. settings, indicator lights

for HEAT-COOL-FAN operation, and 3 unused indicator lights

for field use.

SUGGESTED USE:

• Whenever remote unit operation is desired.

Emergency Heat Package — The emergency heat package includes an emergency heat control box containing: emergency

heat relays, outdoor thermostat(s), and an emergency heat

thermostat subbase with a warning light.

SUGGESTED USE:

• As auxiliary heating system in the event mechanical heating

should be locked out.

CONTENTS

Page

Model Description .................................3

ARI Capacity Ratings ..............................3

Dimensional Drawings .............................4-6

Specifications ....................................7

Selection Procedure ...............................8

Gross Cooling Capacities ...........................9

Integrated Heating Capacities .......................9

Air Delivery .....................................10

Electric Resistance Heater Data .....................11

Electrical Data ...................................11

Operating Sequence ..............................12

Application Data .................................13

Typical Field Wiring .............................14,15

Typical Installation ................................15

Engineers’ Specification Guide ......................16

2

Page 3

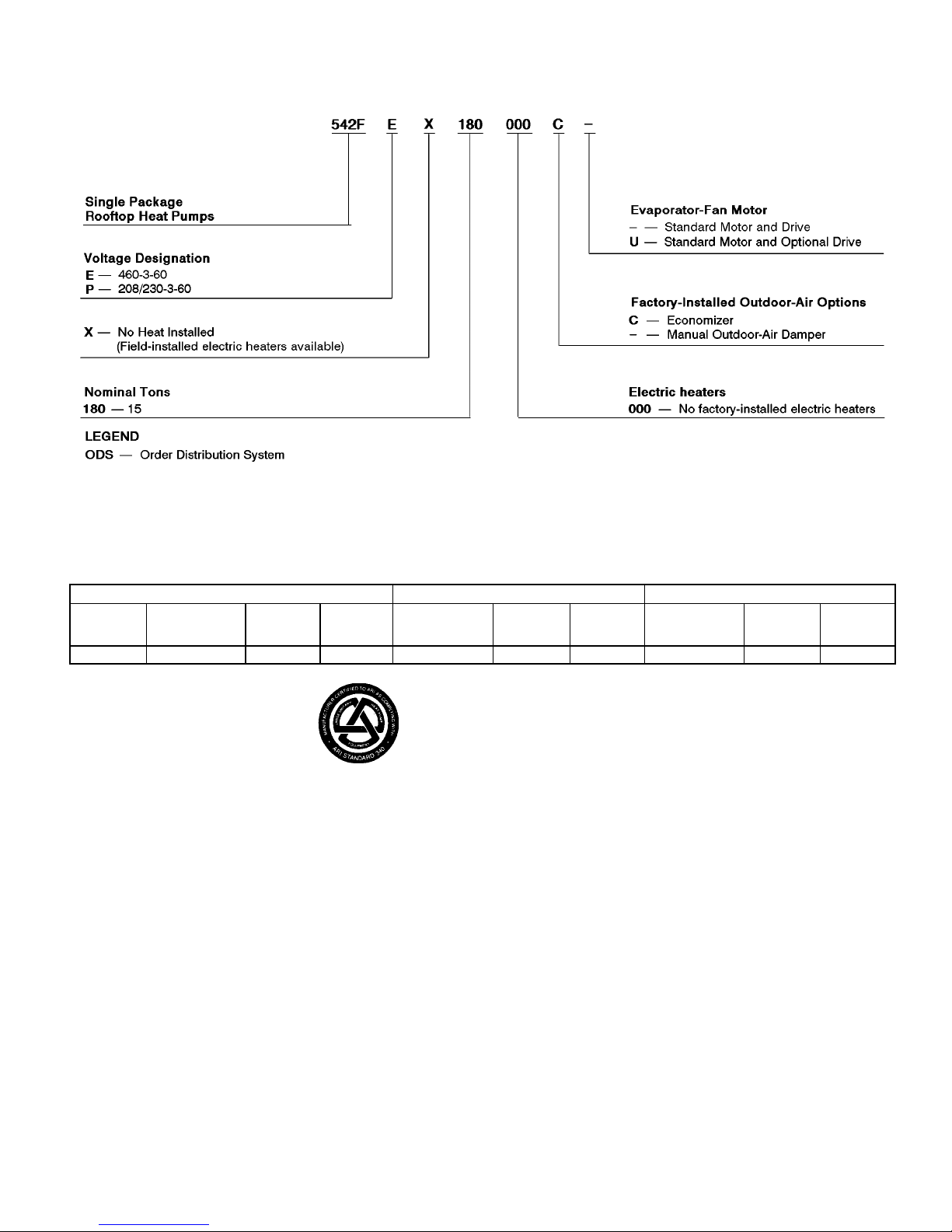

MODEL DESCRIPTION

ODS CATALOG ORDERING NUMBER NOMENCLATURE

ARI* CAPACITY RATINGS

COOLING HEATING-HIGH TEMP HEATING-LOW TEMP

Total

kW

Net

Capacity

(Btuh)

Cfm EER

Total

Capacity

(Btuh)

Total

kW

COP

Total

Capacity

(Btuh)

Total

kW

COP

21.0 162,000 6750 8.5 166,000 17.5 2.8 92,000 14.3 1.8

LEGEND

COP — Coefficient of Performance

db — Dry Bulb

EER — Energy Efficiency Ratio

ESP — External Static Pressure

kW — Kilowatts

wb — Wet Bulb

*Air Conditioning and Refrigeration Institute.

NOTE: 542F180 units are rated in accordance with ARI Standard 340.

Cooling ratings are net values, reflecting the effects of circulating fan

heat. Ratings are based on:

ESP: −.35 in. wg

Cooling Standard: 80 F db, 67 F wb indoor coil entering-air temperature and 95 F outdoor coil entering-air temperature.

High-Temp Heating Standard: 70 F db indoor coil entering-air temperature and 47 F db, 43 F wb outdoor coil entering-air temperature.

Low-Temp Heating Standard: 70 F db indoor coil entering-air temperature and 17 F db, 15 F wb outdoor coil entering-air temperature.

3

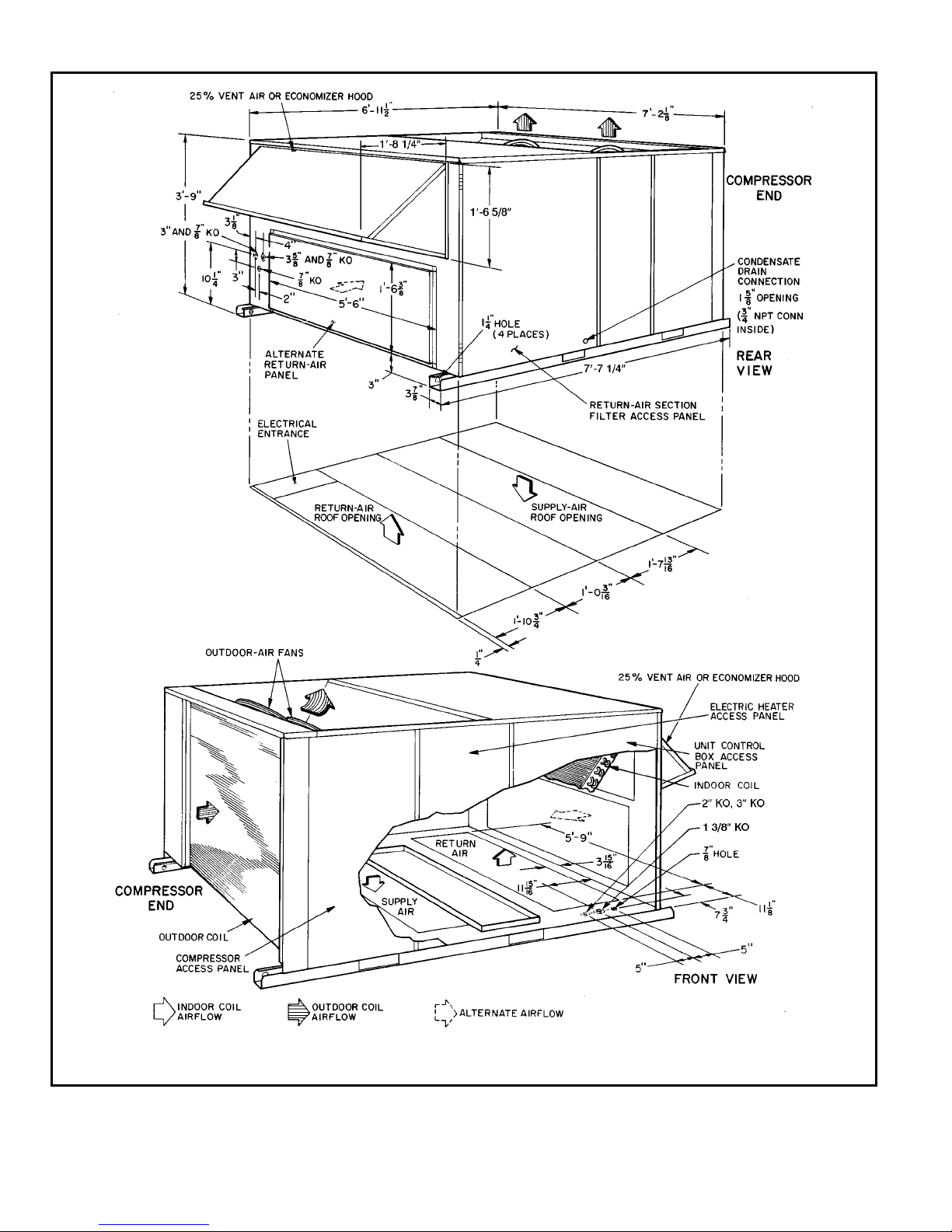

Page 4

DIMENSIONAL DRAWING — BASE UNIT

NOTE: Space required for service clearance and airflow: Allow 68-09 above the unit; 78-09 on filter access panel end; and 48-09 on

remaining sides of unit.

4

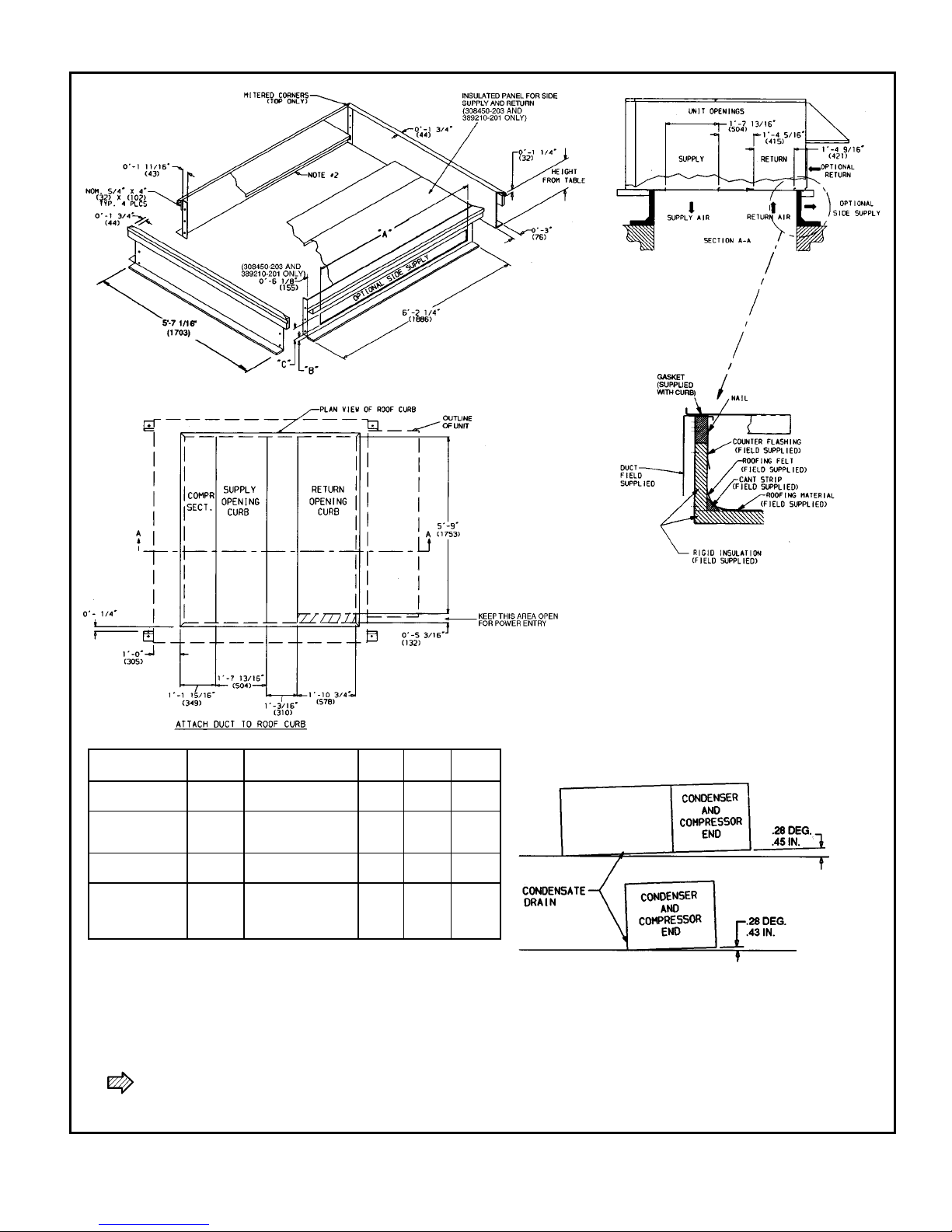

Page 5

DIMENSIONAL DRAWING — HORIZONTAL AND VERTICAL ROOF CURBS AND HORIZONTAL ADAPTER

ACCESSORY

PACKAGE NO.

CURB

HEIGHT

DESCRIPTION ‘‘A’’ ‘‘B’’ ‘‘C’’

308450-201

18-29

(305)

Standard Curb —

149 High

———

308450-202

28-09

(610)

Standard Curb

for Units Requiring

High Installation

———

308450-203

28-09

(610)

Horizontal

Roof Curb

58-69

(1676)

08-2

1

⁄

2

9

(64)

18-69

(457)

389210-201

18-119

(584)

Pre-Assembled,

High-Static

Horizontal

Adapter

68-29

(1880)

08-6

1

⁄

4

9

(159)

18-25⁄

8

9

(371)

LEGEND

COMP SECT. — Compressor Section

NOTES:

1. Roof curb accessory is shipped unassembled.

2. Insulated panels,

1

⁄2-in. thick neoprene-coated,

2 lb density.

3. Dimensions in ( ) are in millimeters.

4. Direction of airflow.

5. Roof curb: 18 gage steel.

6. Attach all ductwork to roof curb.

NOTE: To prevent the hazard of stagnant water build-up in the

drain pan of the indoor-air section, unit can only be pitched as

shown.

5

Page 6

DIMENSIONAL DRAWING — HORIZONTAL ADAPTER INSTALLATION

NOTE: 389210-201 is a fully factory preassembled horizontal

adapter which includes an insulated high static regain transition duct

and substantially improves fan static performance.

6

Page 7

SPECIFICATIONS

UNIT 542F 180 (15 TON)

OPERATING WT (lb)

Unit 1760

with Economizer 1870

Roof Curb 200

COMPRESSOR Semi Hermetic, 4 Cyl

Quantity...Type 2...06D

Oil (oz) 112 ea

Capacity Steps 0, 50, 100

REFRIGERANT (Capillary Control) R-22

Charge (lb) Sys 1*, Sys 2 16.8, 16.8

OUTDOOR COIL Copper Tube, Aluminum Plate Fins

Rows 3

Fins/in. 13.6

Total Face Area (sq ft) 22.2

OUTDOOR-AIR FAN Propeller Type, Direct Drive

Nominal Cfm 12,000

Quantity...Diameter (in.) 2...26

Motor Hp (1100 Rpm)...kW Input 1...2.2

INDOOR COIL Copper Tube, Aluminum Plate Fins

Total Face Area (sq ft) 18.3

Rows...Fins/in. 3...14.4

INDOOR-AIR FAN Centrifugal, Adjustable Belt Drive

Quantity...Size (in.) 2...10 x 10

Nominal Cfm 6000

Rpm Range Std 916-1186

Alt 1158-1428

Max Allowable Rpm 1550

Fan Pulley Pitch Diameter (in.) 6.4

Motor Pulley Pitch Diameter (in.) Std 3.4-4.4

Alt 4.3-5.3

Motor Frame Size Std 56

Alt —

Belt, Quantity...Type Std 1...A44

Alt 1...B45

Speed Change per Full Turn of 54

Moveable Pulley Flange (Rpm)

Moveable Pulley Maximum Full

5

Turns from Closed Position

Factory Setting — Full Turns Open 5

Factory Speed Setting (Rpm) Std 916

Alt 1158

Motor (1750 Rpm), Hp...Max Watts 3...3500

HIGH-PRESSURE SWITCH

Cutout (psig) 426

Reset (psig) 320

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH

(Liquid Line)

Cutout (psig) 7

Reset (psig) 22

INDOOR-AIR FILTERS, Type 10% Efficient — Throwaway Fiberglass

Quantity...Size (in.) 4...20 x 20 x 2

4...16 x 20 x 2

*System 1 consists of upper portion of outdoor coil and lower portion of indoor coil, and System 2 consists of the upper

portion of the indoor coil and the lower portion of the outdoor coil.

7

Page 8

SELECTION PROCEDURE (with example)

I DETERMINE COOLING AND HEATING REQUIRE-

MENTS AT DESIGN CONDITIONS:

Given:

Required Cooling Capacity (TC) .........172,000 Btuh

Sensible Heat Capacity (SHC) ..........133,000 Btuh

Required Heating Capacity .............170,000 Btuh

Outdoor Entering-Air Temperature ..............95F

Indoor Entering-Air Temperature

(Cooling) .............80Fentering dry bulb (edb)

67 F entering wet bulb (ewb)

Outdoor Coil Entering Air Temperature (Heating) ...0°F

Indoor-Air Winter Design Temperature ...........70F

Evaporator Air Quantity ...................6000 cfm

External Static Pressure (ESP) ...........0.75 in. wg

Electrical Characteristics (V-Ph-Hz) ..........230-3-60

II SELECT UNIT BASED ON REQUIRED COOLING

CAPACITY:

Enter Gross Cooling Capacities table on page 9 at outdoor

entering-air temperature of 95 F, indoor air entering at

6000 cfm and 67 F ewb. The 542F unit will provide a total

cooling capacity of 185,400 Btuh and a sensible heat capacity of 146,700 Btuh.

For indoor-air temperature other than 80 F edb, calculate

sensible heat capacity correction, as required, using the

formula found in Note 3 following the cooling capacities

table.

NOTE: Unit ratings are gross capacities and do not include

the effect of indoor-fan motor heat. To calculate net capacities, see Step V.

III SELECT ELECTRIC HEAT:

Enter the Integrated Heating Capacities table on page 9 at

6000 cfm. At 70 F return air and 0° F air entering outdoor

coil, the integrated heating capacity is 67,000 Btuh. (Deductions for outdoor-coil frost and defrosting have already

been made. No correction is required.)

The required heating capacity is 170,000 Btuh. Therefore,

103,000 Btuh (170,000 – 67,000 Btuh) additional electric

heat is required.

Determine additional electric heat capacity in kW.

103,000 Btuh

= 30.2 kW of heat required.

3413 Btuh/kW

Enter the Electric Resistance Heater Data table on page 11

for 542F at 230-3-60. The 31.0-kW heater at 230 v most

closely satisfies the heating required.

31.0 kW x 3413 Btuh/kW = 105,800 Btuh

Total unit heating capacity at 0° F is 172,800 Btuh

(105,800 + 67,000).

IV DETERMINE FAN SPEED AND POWER REQUIRE-

MENTS AT DESIGN CONDITIONS:

Before entering the Air Delivery table calculate the total

static pressure required based on unit components. From

the given and the Pressure Drop tables, find:

External static pressure 0.75 in. wg

Economizer 0.07 in. wg

Electric heat 0.09 in. wg

Total static pressure 0.91 in. wg

Enter the Air Delivery table on page 10. At 6000 cfm, the

standard motor with alternate drive will deliver up to

1.40 in. wg static pressure and 3.82 brake horsepower

(bhp). This will adequately handle job requirements.

V DETERMINE NET CAPACITIES:

Capacities are gross and do not include the effect of

indoor-fan motor (IFM) heat.

Determine net cooling capacity as follows:

Convert bhp to Watts using the formula found in the note

following the Air Delivery table on page 10.

For example:

746 x Bhp

Watts =

Motor Efficiency

746 x 3.82

Watts =

.81

Watts = 3518

Net capacity = Gross capacity – IFM heat

= 185,400 Btuh – (3518 Watts

x 3.413 Btuh/Watts)

= 185,400 Btuh – 12,007 Btuh

= 173,393 Btuh

Net sensible capacity = 146,700 Btuh – 12,007 Btuh

= 134,693 Btuh

Determine net heating capacity as follows:

Net capacity = Gross capacity + IFM heat

+ Electric heat capacity

= 67,000 Btuh + 12,007 Btuh

+ 105,800 Btuh

= 184,807 Btuh

8

Page 9

GROSS COOLING CAPACITIES

UNIT 542F180

Indoor Air

Outdoor Air (F)

85 95 105 115

Cfm BF

Ewb

(F)

Capacity

MBtuh

Compr

kW

Capacity

MBtuh

Compr

kW

Capacity

MBtuh

Compr

kW

Capacity

MBtuh

Compr

kW

Total Sensible Total Sensible Total Sensible Total Sensible

5500 .07

62 176.1 169.7 13.9 167.2 165.4 14.9 158.0 157.9 16.0 148.4 148.4 17.7

67 191.4 142.6 14.6 182.7 139.9 15.6 171.4 130.1 16.6 159.0 130.8 17.7

72 207.1 111.2 15.3 199.8 109.4 16.4 189.3 106.0 17.6 176.9 102.0 18.6

6000 .08

62 180.0 176.8 14.0 171.4 161.9 14.9 162.5 162.5 16.1 152.7 152.7 17.3

67 194.3 148.9 14.6 185.4 146.7 15.6 173.9 143.0 16.6 161.5 137.4 17.7

72 209.7 115.2 15.2 202.3 113.3 16.4 191.6 110.2 17.5 179.0 106.3 18.6

7000 .09

62 186.3 184.6 13.8 178.3 178.3 14.8 169.1 169.1 16.0 158.9 158.9 17.2

67 198.4 158.6 14.3 189.4 156.6 15.4 178.0 153.1 16.4 165.4 147.5 17.5

72 213.3 121.3 15.0 205.9 119.7 16.2 195.2 117.0 17.3 182.6 113.2 18.4

LEGEND

BF — Bypass Factor

Edb — Entering Dry Bulb

Ewb — Entering Wet Bulb

kW — Compressor Power Input

SHC — Sensible Capacity

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formula may be used:

sensible capacity (Btuh)

t

ldb=tedb

−

1.10 x cfm

t

lwb

= Wet-Bulb temperature corresponding to enthalpy of air

leaving indoor coil (h

lwb

)

total capacity (Btuh)

h

lwb=hewb

−

4.5 x cfm

Where: h

ewb

= Enthalpy of air entering indoor coil.

3. The SHC is based on 80 F edb temperature of air entering indoor

coil.

Below 80 F edb, subtract (correction factor x cfm) from SHC.

Above 80 F edb, add (correction factor x cfm) to SHC.

BF

ENTERING AIR DRY-BULB TEMP (F)

79 78 77 76 75

Under 75

Over 85

81 82 83 84 85

Correction Factor

.03 1.06 2.11 3.17 4.33 5.28

use formula

shown below

.10 .98 1.96 2.94 3.92 4.91

.15 .93 1.85 2.78 3.71 4.63

.20 .87 1.74 2.62 3.49 4.36

Interpolation is permissible. Do not extrapolate.

Correction Factor = 1.10 x (1 − BF) x (edb − 80).

INTEGRATED HEATING CAPACITIES

OUTDOOR-

AIR TEMP

(F db at

70% RH)

INTEGRATED

CAPACITY

(MBtuh)*

TOTAL POWER

INPUT (kW)

INTEGRATED

CAPACITY

(MBtuh)*

TOTAL POWER

INPUT (kW)

INTEGRATED

CAPACITY

(MBtuh)*

TOTAL POWER

INPUT (kW)

Indoor-Air Temp (F edb) Indoor-Air Temp (F edb) Indoor-Air Temp (F edb)

55 70 80 55 70 80 55 70 80 55 70 80 55 70 80 55 70 80

Indoor Airflow (cfm) Indoor Airflow (cfm) Indoor Airflow (cfm)

5500 6000 7000

60 218 208 198 18.5 19.6 20.2 221 210 200 18.5 19.5 20.1 230 219 208 19.6 19.6 20.2

50 189 180 171 16.9 17.8 18.3 192 183 174 17.0 17.9 18.4 201 191 181 17.2 18.1 18.6

40 163 155 147 15.5 16.3 16.8 165 157 149 15.8 16.6 17.1 174 166 158 16.1 16.9 17.4

30 121 115 109 14.5 15.3 15.8 122 116 110 14.7 15.5 16.0 129 123 117 15.0 15.8 16.3

20 105 100 95 13.7 14.4 14.8 107 102 97 14.1 14.8 15.2 114 109 104 14.4 15.2 15.7

10 89 85 81 12.7 13.4 13.8 91 87 83 13.3 14.0 14.4 99 94 89 13.8 14.5 14.9

0 69 66 63 11.5 12.1 12.5 70 67 64 11.7 12.3 12.7 80 76 72 12.0 12.6 13.0

−10 51 49 47 10.4 10.9 11.2 53 50 48 10.5 11.1 11.4 61 58 55 10.9 11.5 11.8

−20 44 42 40 9.2 9.7 10.0 46 44 42 9.4 9.9 10.2 54 51 48 9.9 10.4 10.7

LEGEND

ARI — Air Conditioning and Refrigeration Institute

Edb — Entering Dry Bulb

kW — Total Unit Power Input — Includes compressors, outdoor-fan

motors, and indoor-fan motor. Indoor-fan motor heat based

on unit operating at cfm shown and external static pressures

(ESP) of 0.35.

Conversion formula: Btuh = kW x 3413

*Includes effect of defrost and indoor-fan motor heat at ARI conditions.

9

Page 10

AIR DELIVERY

CFM

EXTERNAL STATIC PRESSURE (in. wg)

0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

5500 923 1.88 1002 2.13 1075 2.35 1143 2.58 1208 2.80 1271 3.01 1334 3.24 1394 3.49

6000 993 2.36 1066 2.63 1135 2.88 1200 3.12 1260 3.36 1320 3.59 1378 3.82 — —

6500 1064 2.92 1131 3.21 1197 3.48 1259 3.74 1318 4.00 ——————

7000 1136 3.55 1199 3.86 ————————————

LEGEND

Bhp — Brake horsepower

NOTES:

1. — Alternate drive required.

2.

indicates maximum capability of standard drive.

3. Maximum allowable fan speed is 1550 rpm.

4. Fan performance is based on wet coil and clean 2-in. filters. Casing

losses have been deducted.

5. Electric heater pressure drop must be accounted for in fan rpm and

bhp section (see Static Pressure Losses table on page 11).

6. Minimum cfm for units with electric resistance heat: 5650 cfm.

Converting Bhp to Watts:

Bhp x 746

Watts input =

Motor Efficiency

Approximate Motor Efficiency: .81

AIR DELIVERY USING ACCESSORY POWER EXHAUST

HORIZONTAL SUPPLY/RETURN FAN PERFORMANCE

WITH 389210-201 HIGH STATIC REGAIN ADAPTER

NOTE: The 389210-201 high static regain adapter accessory may

be used to provide horizontal supply/return.

NOTE: The 389210-201 horizontal supply/return adapter accessory

improves 542F180 fan performance by increasing external static

pressure by amount shown above.

10

Page 11

INDOOR FAN DRIVE DATA

TYPE

FAN RPM

Turns Open

012345

Std 1186 1132 1079 1029 970 916

Alt 1428 1374 1321 1267 1213 1158

ELECTRIC RESISTANCE HEATER DATA

HEATER kW*

HEATING

STAGES

% HEAT

PER STAGE

MAXIMUM

STAGES†

Unit Voltages

208 230 460

26 31 32 2 50/50 2

42 52 55 2 33/67 3

56 69 80 2 50/50 4

*Field-installed accessory only.

†Maximum number of stages using accessory outdoor-air thermostats.

NOTE: Heater kW is based on heater voltage of 240 v or 480 v. If power

distribution voltage to unit varies from rated heater voltage, heater kW

will vary accordingly.

STATIC PRESSURE LOSSES* (in. wg)

ACCESSORY/FIOP

UNIT

VOLTAGE

kW

CFM

3500 4000 4500 5000 5500 6000 6500 7000

Electric

Heaters

208/230-3-60

26/31 .04 .05 .06 .07 .08 .09 .11 .12

42/52 .05 .06 .07 .08 .10 .12 .14 .16

56/69 .06 .07 .08 .10 .12 .15 .17 .20

460-3-60

32 .04 .05 .06 .07 .08 .09 .11 .12

55 .05 .06 .07 .08 .10 .12 .14 .16

80 .06 .07 .08 .10 .12 .15 .17 .20

Economizer All — .02 .03 .04 .05 .06 .07 .08 .09

FIOP — Factory-Installed Option

*Static pressure losses must be added to external static pressure before entering Air Delivery table.

ELECTRICAL DATA

V-PH-HZ

VOLTAGE

RANGE

COMPRESSOR

(each)

OUTDOOR

FAN

MOTOR

INDOOR

FAN

MOTOR

ELECTRIC

HEAT

POWER SUPPLY*

Min Max RLA LRA Qty FLA Hp FLA kW† FLA MCA MOCP

208/230-3-60 187 254 31.3 137 2 7.7 3.0 10.5

— — 97/ 97 125/125

26/31 72/ 82 186/199 200/200

42/52 117/135 243/231 250/250

56/69 156/180 252/276 300/300

460-3-60 414 508 15.7 62 2 3.3 3.0 4.8

— — 47 60

32 39 96 100

55 66 113 125

80 96 143 150

LEGEND

FLA — Full Load Amps

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

*Fuse only.

†Heater capacity (kW) is based on heater voltage of 240 v or 480 v. If

power distribution voltage to unit varies from rated heater voltage,

heater kW will vary accordingly. Heaters are field-installed only.

11

Page 12

OPERATING SEQUENCE

BASE UNIT OPERATING SEQUENCE

Cooling, Units Without Economizer — With unit main power

on, set thermostat at COOL position and desired room temperature. Set fan switch at AUTO. (on demand) or ON (continuous)

position.

On a rise in room temperature, cooling contact no. 1 in the thermostat closes, energizing compressor no. 1 contactor on all

units. Compressor no. 1, indoor-fan motors, and outdoor-fan

motors start. Compressor no. 1 cycles on demand of thermostat

to satisfy room conditions.

With an additional rise in room temperature, cooling contact

no. 2 in the thermostat closes, energizing compressor contactor

no. 2. Compressor no. 2 starts. Compressor no. 2 cycles on demand of the thermostat to satisfy room conditions.

Heating, Units Without Economizer — Turn power on and set

thermostat at HEAT position and desired temperature. Set fan

at AUTO. (on demand) or ON (continuous) position.

On a drop in room temperature, heating contact no. 1 in the

thermostat closes, energizing compressor contactor no. 1 and

reversing valve, and starting compressor no. 1. Indoor blower

contactors and outdoor-fan contactors energize at the same

time for heat pump cycle.

When thermostat second-stage heating contacts close, compressor contactor no. 2 energizes and compressor no. 2 starts.

Units have a built-in electric resistance heat lockout through the

defrost thermostat. Above 40 F (approximate) outdoor temperature, electric resistance heat is locked out and second-stage

heat is from compressor no. 2. Below 40 F (approximate) ambient temperature, when the thermostat first-stage heating contacts close, compressor contacts no. 1 and no. 2 energize

sequentially through a time delay. Both compressors (no. 1 and

no. 2) are brought on to satisfy heating requirements.

On a further drop in room temperature (outdoor ambient below

40 F), the thermostat second-stage heating contacts close, energizing the electric resistance heat contactor and starting

second-stage heat. Electric heaters with 2 or more contactors

can have outdoor thermostats wired into the control circuit for

additional staging.

Automatic Changeover — When the system selection switch

is set at AUTO. position, unit automatically changes from heat

operation to cooling operation when the temperature of the conditioned space rises to cooling lever setting. When the temperature of the conditioned space falls to heating lever setting, unit

automatically changes from cooling to heating operation (with a

3 F deadband in between).

Continuous Air Circulation — Turn unit power on. Set system

control at OFF position. Set fan switch at ON position. The

indoor-fan contactor is energized through the thermostat switch

and the indoor fan runs continuously.

Defrost Cycle — The defrost thermostat on the outdoor coil activates a defrost timer which energizes electric resistance heaters and deenergizes reversing valve relays and outdoor-fan

motors. When the defrost thermostat is satisfied or when

10 minutes have elapsed, reversing valve solenoids energize

and electric heaters deenergize. The defrost timer will energize

the electric heaters every 90 minutes, if necessary.

The defrost thermostat, in conjunction with a time-delay relay,

prevents electric heat operation above an ambient temperature

of approximately 40 F (depending on coil frost conditions). If defrost thermostat closes, time-delay relay energizes, closing

compressor contactor no. 2. Both compressors now operate

from W1, and W2 controls electric heat.

Cooling, Units With Economizer

Outdoor Air Enthalpy Above Set Point — Indoor and outdoor

fans and compressors energize when there is a call for cooling.

The economizer damper moves to VENT position.

Outdoor Air Enthalpy Below Set Point — Indoor fan starts and

economizer damper opens fully on a first-stage call for cooling.

Compressor remains off.

Compressor is energized and mechanical cooling integrates

with economizer cooling upon a second stage call for cooling.

Economizer damper modulates when mixed-air temperature is

below mixed-air thermostat setting.

A freeze protection thermostat is located on the indoor coil. It

detects ice build-up and turns off the compressor, thus allowing

the coil to clear. Once ice melts, the compressor can be

reenergized.

Heating, Units With Economizer — Outdoor-air damper stays

at VENT position while indoor-air fan runs.

NOTE: If fan switch is at ON position, and room thermostat is

satisfied, damper goes to ventilation position.

Cycle-LOC™ Protection — If unit operation is interrupted by

an open high-pressure switch, low-pressure switch, indoor-coil

freezestat, or by compressor internal line-break device (overcurrent or overtemperature), and compressor is calling for either

cooling or heating, Cycle-LOC simultaneously locks out unit and

lights a warning light on the thermostat. Restart the unit by

manually turning room thermostat to OFF and then ON position.

If any of the protective devices opens again, the unit continues

to lock out until corrective action is taken.

NOTE: If the unit fails to operate due to compressor overcurrent

condition, restart by manually resetting circuit breakers at the

unit. Restart cannot be accomplished at room thermostat.

ACCESSORY OPERATING SEQUENCES

Emergency Heat — If compressor is inoperative due to a

tripped safety device (high-pressure, low-pressure, indoor-coil

freezestat, overcurrent, or overtemperature), Cycle-LOC™

locks out compressor and lights a warning light on the room

thermostat. When switch is on (thermostat is moved to the EM

HT position), compressor circuit and outdoor thermostats are

bypassed, and second stage of thermostat energizes indoor

blower and electric resistance heaters.

Time GuardT Control Circuit — The accessory Time Guard

control circuit provides a 5-minute delay of compressor restart

after desired space temperature has been attained and room

thermostat has shut down the compressor.Assuming that compressor has been off for at least 5 minutes due to room thermostat action, Time Guard control circuit sequence is as follows:

With fan selector switch at AUTO. position and a call for cooling

from the room thermostat, indoor blowers start immediately;

outdoor-air fans and compressor start 15 seconds later. When

room thermostat is satisfied, compressor shuts off. The Time

Guard control circuit timer motor then runs for 4 minutes and

45 seconds, at which point its internal switches reset so normal

sequence can begin again.

The base unit contains, as standard equipment, a factoryinstalled Cycle-LOC compressor protection device. If overload

protector causes the compressor to shut off, compressor

remains locked out until control circuit is manually reset. Reset

manually by moving system selector lever on room thermostat

to OFF position momentarily and then returning it to cooling position. After a standard 5-minute Time Guard control circuit delay, the compressor can restart.

12

Page 13

APPLICATION DATA

1. Ductwork must be attached to the curb on all units. Interior

installation may proceed before unit is set in place on roof.

Field-fabricated concentric ductwork may be connected as

shown below.

2. Factory-and field-installed electric heat allows single power

entry to unit for both heating and cooling. Values shown for

minimum circuit amps (MCA) and maximum overcurrent

protection (MOCP) in the Electrical Data table on page 11

apply to factory- or field-installed heaters.

3. Indoor coil is draw-thru configuration. Condensate trap

(minimum 4 in. deep) must be field-installed prior to start-up

on cooling cycle. Install plug in condensate drain on opposite side of unit from trap.

4. When return-air ductwork systems are used, return horizontal static pressures should be limited to 0.4 in. wg.

5. Cfm and other values indicated throughout this literature illustrate the operating range of the equipment. Operation

outside these limits is not recommended.

6. When use is required with emergency heat, in addition to

accessory emergency-heat components, field-supplied

emergency heat switch (DPST toggle switch) must be

used. Emergency heat subbase cannot be used with the remote control panel.

7. Units are designed to operate at outdoor temperatures

down to 40 F. At temperatures below 40 F, accessory head

pressure control device will permit operation at outdoor

temperatures as low as −20 F.

8. All roof curb and adapter installations must be counterflashed to prevent water leakage.

9. Selectunit based on cooling only.Donot select heat pumps

on heating capacity. Add auxiliary resistance heat if

required.

10. Electric power may be brought to unit within curb perimeter

through fittings provided in basepan. Provide power supply

in accordance with local codes. Branch circuit protection to

unit must be provided by fuses no larger than MOCP shown

in Electrical Data table on page 11.

11. The 24-v control wiring to thermostat is NEC (National Electrical Code) Class II.

OPTIONS AND ACCESSORIES

ITEM OPTION* ACCESSORY†

Alternate Drive X

Integrated Economizer XX

Electric Heater X

Emergency Heat Package X

Roof Curb (Vertical and Horizontal) X

Horizontal Adapter X

Remote Control Panel X

Thermostats and Subbases X

Time GuardT Control Device X

Power Exhaust X

Two-Position Damper X

Barometric Relief Damper X

Head Pressure Control X

*Factory Installed.

†Field Installed.

Concentric Duct Air Distribution

NOTE: Do not drill in this area, damage to basepan may result in

water leak.

Concentric Duct Details

Shaded area indicates block-off panels.

NOTE: Dimensions A, A8 and B, B8 are obtained from field-

supplied ceiling diffuser.

13

Page 14

TYPICAL FIELD WIRING

14

Page 15

LEGEND FOR TYPICAL FIELD WIRING

TYPICAL INSTALLATION

AHA — Adjustable Heat Anticipator

BKR W/AT — Breaks With Amp Turns

C—Contactor

CB — Circuit Breaker

CC — Cooling Compensator

CLO — Cooling Lockout

CLS — Cooling Lockout Switch

CR — Control Relay

CT — Current Transformer

DFR — Defrost Relay

DM — Damper Motor

DR — Damper Relay

EC — Enthalpy Control

FPT — Freeze Protection Thermostat

HC — Heater Contactor

HPS — High-Pressure Switch

HR — Heater Relay

IFC — Indoor Fan Contactor

IP — Internal Protector

L—Light

LOR — Lockout Relay

LPS — Low-Pressure Switch

MAT — Mixed Air Thermostat

PL — Plug Assembly

PRI — Primary

RVR — Reversing Valve Relay

SW — Switch

TB — Terminal Block

TC — Thermostat, Cooling

TH — Thermostat, Heating

TRAN — Transformer

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Splice (Marked)

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory Wiring or Optional Wiring

Accessory

To indicate common potential only;

Not to represent wiring.

NEC — National Electrical Code

15

Page 16

ENGINEER’S SPECIFICATION GUIDE

GENERAL: Furnish and install a self-contained, air-to-air electric heat pump rooftop unit with supply- and return-air connections off the bottom of the unit, mounted on a full perimeter,fieldassembled roof curb. The rooftop unit shall be completely

factory-assembled and tested, and shall include compressors,

indoor coil, outdoor coil, fans and motors, interconnecting wiring, prewired control panel, filters, and other necessary components mounted in a corrosion-resistant all-weather cabinet. Unit

shall be shipped fully charged with oil and R-22 refrigerant.

COOLING CAPACITY: Total net cooling capacity of the unit

shall be Btuh or greater, and sensible capacity shall be

Btuh or greater at conditions of ft3/min evaporator entering air of 67 F wet bulb, 80 F dry bulb, and condenser

entering air temperature of 95 F dry bulb. Equipment must have

an EER of 8.5 or higher at this condition.

HEATING CAPACITY: Total heating capacity shall be

Btuh or greater (integrated rating) when rated at

F dry bulb outdoor ambient with ft3/min and

F air entering indoor (heating) coil. The equipment must

have a minimum heating COP of 3.0 at 47 F dry bulb outdoor

ambient (high temp) and 2.1 at 17 F dry bulb outdoor ambient

(low temp). Supplemental heat of kW shall be provided

to satisfy heat loss at winter design conditions. The coefficient of

performance (COP) must be 2.9 or better at 47 F.

CABINET: The cabinet shall be constructed of heavy-gage zinccoated galvanized steel with baked enamel finish. This finish

shall exceed the U.S. Army Corps of Engineers standards without peeling, cracking, or rusting beyond

1

⁄8in. on a scratch mark

when subjected to 5% salt spray solution at 95 F for 1000 hours.

The cabinet shall be constructed such that one-piece top is

used for the entire indoor air-handling section to ensure watertightness. Two-in. replaceable filters mounted internally shall be

supplied.

COMPRESSORS: Compressors shall be of the serviceable,

semi-hermetic type, with crankcase heaters and suitable vibration isolators. A separate refrigerant circuit shall be provided for

each compressor. An automatic resetting circuit shall be provided to prevent rapid compressor cycling.

OUTDOOR SECTION: The outdoor coil shall be constructed of

aluminum plate fins mechanically bonded to seamless copper

tubes. Outdoor fans shall be direct-driven, slow-speed propeller

type for quiet operation and shall be mounted for vertical discharge. The outdoor motors shall be protected as required by

NEC and be supplied with rainshields.

INDOOR SECTION: Indoor coil shall be constructed of aluminum plate fins mechanically bonded to seamless copper tubes.

Indoor blower shall be of centrifugal type, forward curved. The

blower shall be belt-driven by means of an adjustable pitch pulley, permitting a variation of airflow by means of blower speed

adjustment. Blower motor shall be electrically protected as required by NEC. Blower motor shall be mounted on the adjustable base, allowing for proper alignment and tension. The steel

shaft shall rotate in prelubricated bearings.

CONTROL CIRCUIT: The unit control panel shall be prewired in

the unit casing furnished with a 24-v control transformer, highand low-pressure switches, compressor, outdoor and indoor fan

motor contactors, as well as other protective devices. The defrost circuit shall be time and temperature initiated. A

90-minute timer shall energize the defrost cycle only if the coil

temperature indicates a frost condition. Defrost shall terminate

after 10 minutes of operation, or when a satisfactory coil temperature is achieved to minimize defrost operating time.

APPROVALS:The unit shall be ETL tested and certified. All wiring shall be in accordance with NEC, and units shall meet

ASHRAE Standard 62. The unit shall be rated in accordance

with ARI Standard 340. Units shall be designed to conform to

NRCAstandards. Insulation and adhesive shall meet NFPA90A

requirements for flame spread and smoke generation.

OPTIONS: Factory-installed integrated economizer shall include all hardware and controls to provide cooling using outdoor

air alone, or in conjunction with mechanical cooling. Dampers

shall be low leakage type, not to exceed 2% leakage at

1.0 in. wg pressure differential. Economizer shall be capable of

introducing up to 100% outdoor air and shall be equipped with a

gravity relief damper. Economizer controls shall be dry-bulb

type.

On all units where the factory-installed economizer is not chosen, the factory-installed manual outdoor-air damper shall be included. In addition, a factory-installed alternate indoor-fan drive

is available.

ACCESSORIES: Field-installed accessories shall include:

Economizer, vertical and horizontal roof curbs (14 or 24 in.),

horizontal adapter, two-position damper, Time GuardT short

cycle circuit protection, thermostats and subbases, electric

heaters, barometric relief damper, power exhaust, emergency

heat, remote control panel, and head pressure control device.

Bryant

Air Conditioning

Copyright 1995 Carrier Corporation

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED INACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Printed in U.S.A. 5/95 CATALOG NO. BY-3254-205

Loading...

Loading...