Page 1

installation, operation,

and maintenance instructions

542E

Sizes 024 thru 06(f

PACKAGED HEAT PUMPS

NOTE: Installation must conform to the guidelines pre

sented in these unit Installation Instructions. Read and

become familiar with these instructions before starting in

stallation.

Models 542D and 542E Packaged Heat Pumps are fully selfcontained combination heating/cooling units designed for

outdoor installation. Model 542E may be installed either on

a rooftop or ground level slab. Model 542D is used in con

junction with an accessory roof mounting curb and incorpor

ates a down-discharge/return-air plenum as an integral part

of the unit.

These packaged heat pumps are factory-charged and sealed.

Installation is easy—simply connect condensate drain, air

ducts, high- and low-voltage wiring, and install a field-sup

plied air filter in the return-air ductwork (except for Model

542D which has factory-supplied high-capacity air filters) to

obtain heating during the heating season, cooling and

dehumidification during the cooling season, and filtering of

the conditioned space.

All units can be connected into existing duct systems that

are properly sized and designed to handle an airflow of 400 to

450 ft^lmin per each 12,000 Btuh of unit capacity.

Accessory UL-listed, field-installed, supplemental electric

heat packages are available in a variety of KW and voltage

options. These electric resistance heaters mount inside the

unit blower compartment.

Important-Read Before Installing

1. Check all local and other applicable codes for informa

tion concerning proximity to property lines, height

above roof, obstructions, or other special installation re

quirements.

2. Make certain that power supply available (volts, hertz,

and phase) corresponds to that specified on unit rating

plate.

3. Check electrical supply provided by utility to be sure

that service capacity is sufficient to handle load imposed

by unit being installed.

4. Refer to the 542D or 542E dimensional drawing for loca

tions of electrical inlets, condensate drain, duct connec

tions, and required clearances before setting unit in

place.

GENERAL

Models 542D and 542E Packaged Heat Pumps have been de

signed and tested in accordance with ARI Standard 240-77

and 270-75, and are UL-listed.

These instructions contain the following sections:

I. Moving and Setting Unit in Place

II. Condensate and Defrost Disposal

III. Duct Connections

IV. Electrical Connections

V. Preparing Unit for Startup

& 542D060

Cancels: New

Figure 1—Model 542E

Figure 2—Model 542D060 Mounted On

Accessory Roof Mounting Curb

VI. Refrigerant Leaks

VII. Startup and Adjustments

VIII. Sequence of Operation

IX. Care and Maintenance

I. MOVING AND SETTING UNIT IN PLACE

CAUTION: Pjvc ■aiition.' Mui.-iT hf lakcii 1o prevunl d.itnage

wlic-n nio\ing the unit. The unit intfrl remain in at) upright

position during all rigging and moving oper;ition.-!, lie .-iure

to |)j-olect the top and ■iide-! of the unit by using spreaders

when rigging the unit to be lifted. Model 5i2n mu.st be

rigged for lifting as .shown in Figure 7. Model .542E must he

rigged for lifting ;is shovsn in Figure

The unit must be installed level for proper condensate

drainage. Be sure that the ground level pad, field-fabricated

support, or accessory roof mounting curb is level before set

ting the unit in place.

When selecting an installation site, try to locate the unit on

the side opposite the prevailing wind to assure proper opera

tion of the defrost cycle and to avoid snow drifts that could

block the outdoor coil. Be sure that the unit is installed at least

6 inches above the highest probable snow level to prevent

blockage of the outdoor coil and assure proper drainage of

defrosted ice.

A. Rooftop Installation

When installing a Model 542D downflow unit or a Model

542E end-discharge unit with an accessory downflow

40542DP6-A

12/15/79

A79110

flplt

A79111

BDP Company, Division of Carrier Corp.

Page 2

Top of unit ...............................

Duct side of unit

Compressor access door access end

side

........

......................

............................. 30 Bottom of unit above

. CONTROL ACCESS DOOR^ 7

COMPRESSOR

ACCESS DOOR

Size

024 & 030

036

042, 048, & 060

48 Blower access door end..

12 End opposite blower

■ anticipated snow level.. ■6

A

60-3/16

60-3/16

68-3/16

542E REQUIRED CLEARANCE (Inches)

..30

.112

\ /-4oia r-i DIÁ

,MPT DRAIN

^CONNECTION

542E DIMENSIONS (Inches)

B

32-3/16 24-13/16 21

32-3/16

40-3/16 30-13/16 21

c D E F

24-13/16 21 13-3/4

HIGH-VOLTAGE

INLET WITH MULTIPLE.

KNOCKOUTS

11-1/2 13-5/16 54

16-3/8 17-5/16

13-5/16

i-E

.«

------------------

-SUPPLY-AIR

61-3/16 5-1/8 ' 7-1/2

A

ELECTRIC HEAT

HIGH-VOLTAGE INLET WITH

MULTIPLE KNOCKOUTS

G H

54

6-7/8 6-15/16

4-5/8

U-N"

“T

M

_L

J

6-15/16

A79071

Sizes K

024 & 030

036

042, 048, & 060

18-1/8 3

18-1/8 3

25

L

3-3/8 20-3/32

M N P

15-3/32

15-3/32 12-9/16

12-9/16 13 ,28-9/16

15-1/8 16-19/32 34-9/16 44-1/4 2

Figure 3--542E Dimensional Drawing

TABLE l-RATINGS, PERFORMANCE, & RECOMMENDED FILTER SIZES

MODEL

SIZE

SERIES A

Rated Heating Capacity® 47°F (Btuh)*

Total Power Consumption (Watts)*

COP*

Rated Heating Capacity® 17°F (Btuh)*

Total Power Consumption (Watts)*

COP*

Rated Cooling Capacity @ 95°F (Btuh)*

Total Power Consumption (Watts)*

EER

Rated Indoor Airflow (Ft3/Min)*

Rated External Static Pressure (In. wc)*

ARI Sound Rating Humbert

Recommended Minimum Filter Size (Sq ln.)t

Standard-Type

Cleanable- or High-Capacity-Type

* Rated in accordance with ARI Standard 240-77.

t

Rated in accordance with ARI Standard 270-75.

i Recommended field-supplied filter sizes shown are

**Two 20 X 20 X 2 high-capacity filters are furnished

with Model 542D060.

024

26,000

2850 3300 3850

2.7 2.7 2.7

14,000 16,000 18,000

2300 2650 3000 3650

1.8

25,500 30,000 35,000

3350

7.6

850

0.3

19

408 504 624

265

based on a velocity of 300 ft/min at the rated indoor airfow.

plenum, the accessory roof mounting curb must be installed

on and flashed into the roof before unit installation. The in

structions for installing the curb are packaged with the

curb.

CAUTION: Be sure that the roof will support the additional

weight. Refer to Figure 5 or 6 for weight information. On a

downflow installation with a-Model 542D or a Model 542E

with an accessory downflow plenum where the accessory roof

mounting curb is not being used, the field-fabricated support

must be level and must properly support the unit and downflow plenum.

When installing a Model 542E without an accessory down

flow plenum, place the unit on a level base that provides

proper support. On flat roofs, be sure that the unit is at least

R S T

7.5

37-1/8

542E

4700 5100 6300 6300

2.7 2.8 2.7 2.7

22,000 25,000 31,500 31,500

43,000 47,000 58,000 58,000

8.1

1550 1700 2000 2000

744

484

13 28-9/16 37-1/8 2 7/8 27-3/8

030 036 042 048 060

A A A

30,000 35,000 43,000 48,000 58,000

1.8 1.8 1.8 1,8 1.8

3800 4650 5300 6100

7.9

1050 1300

0.3 0.3 0.3 0.3 0.3

19 19 18 18 20 20

328 406

U

2

7/8 27-3/8

7/8 33-11/16

4150 5200 5200

7.7

816 960

530 624

V

542D

060

A A A

58,000

1.8

7700 7700

7.5 7.5

0.3

**

**

4 inches above the highest expected water level on the roof

to prevent flooding. Consult local codes for installation re

quirements.

NOTE: See Figure 10 for a typical rooftop installation. B. Ground-Level Installation

The unit must be placed on a solid level concrete pad that is

a minimum of 4 inches thick and that extends approximate

ly 2 inches beyond the casing on all four sides of the unit.

The unit does not need to be secured to the pad except when

required by local codes.

NOTE: See Figure 11 for a typical ground level installation. C. Clearances

The required minimum operating and service clearances are

-2-

Page 3

542D060 REQUIRED CLEARANCES (Inches)

Top of unit

Compressor access door End opposite blower

side

Side opposite compressor Bottom of unit above

access door

.......

.........................48 Blower access door end__30

........................................

..........................

30 accessend

12 anticipated snow level

.....

___

12

6

-FRESH AIR

INLET HOOD

l-MPT DRAIN

^CONNECTION

Figure 4—542D060 Dimensional Drawing

542E

Size

024

030

036

042

048

060

Shipping

Wt (lbs)

320 310 78 75 77 80

334 324 81 78 81 84

348 338 85 82 84 87

453 443

465 455 114 110 113

490 480 120 116 120 124

Operating

Wt (lbs)

Corner Wt (lbs)

A B

111 107

D

C

110 115

118

Figure 5—542E Corner Weights

shown in Figure 3 for Model 542E and Figure 4 for Model

542D.

CAUTION: Any air restriction at the outdoor air inlet tthe

entire surface of the outdoor coil) can be detrimental to com

pressor life.

The fan discharge is through the top of the unit. Do not

locate the unit under a complete overhead obstruction. Mini

mum clearance under a partial overhang (such as a normal

house roof overhang) is 48 inches.

Be sure that the unit is located so that water, ice, or snow

from an overhang or roof will not fall directly on the top of

the unit and damage it. Be sure that grass, shrubs, or other

plants do not interfere with the airflow into or out of the

unit.

II. CONDENSATE AND DEFROST DISPOSAL

NOTE: Condensate and defrost water disposal methods must

comply with local codes, restrictions, and practices.

Models 542D and 542E are designed to dispose of cooling

cycle condensate water through a 3/4-inch MPT plastic

HIGH-VOLTAGE INLET

A79072

Top View

Model 5420

A79116-A,

Shipping Wt (lbs) 703

Operating Wt (lbs)

Unit Corner Wts (lbs)

ROOF MOUNTING CURB P/N 304851-302

Shipping Wt (lbs) 120

Operating Wt (lbs)

Curb Corner Wt (lbs) A

Combined Operating Wt (lbs)

Curb Corner Wts with

Unit on Curb

UNIT-MODEL 542D060

A B

144

27.5 27.5 29 29

UNIT&CURB

A B

154 164

556

C D

134

138

113

B C D

669

C

181 170

140

D

Figure 6—542D060 Corner Weights

drain fitting. To prevent damage during the shipping and

moving of the unit, this fitting is shipped inside the unit

compressor compartment (secured with tape). Locate this

fitting and insert the nonthreaded end into the drain hose

located in the compressor compartment. See Figure 12.

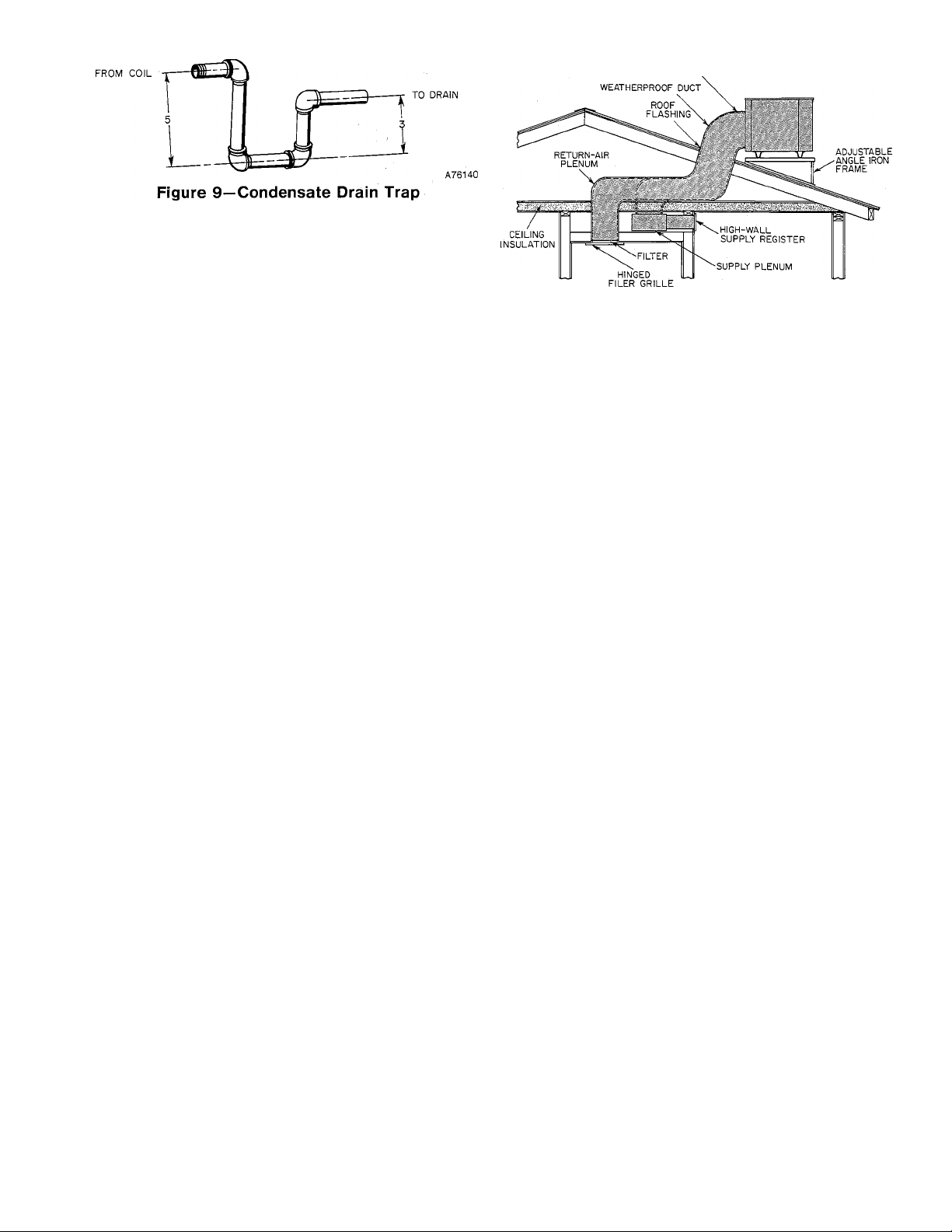

It is recommended that a 3-inch trap be installed in the

drain line to avoid improper drainage and to prevent leakage

of indoor air to the outdoors. See Figure 9. Make sure that

the outlet of the trap is at least 2 inches lower than the unit

drain pan connection to prevent the pan from overflowing.

-3-

Page 4

TABLE ll-ELECTRICAL DATA-MODEL 542E-SIZES 024 THRU 042

MODEL

SIZE

SERIES A A A

Unit Volts-Phase (60Hz)

Operating Voltage Range 197-253 197-253 197-253 187-253

Total Unit Amps

Max Branch Circuit Fuse Size (Amps) 30

Unit Ampacity for Wire Sizing 20.2 27.5 29.2

Minimum Wire Size (AWG)*

Maximum Wire Length (Ft)* 115 85 80 95

024

208-230-1

16.7

10

030 036

208-230-1

22.7

45

10

208-230-1

542E

208/230-3

23.9 14.8

45 25

10

17.8

12

042

A

230-1

207-253 187-253

28.7 21.0

50

34.9

8

112

208/230-3

40

25.2

10

107

TABLE MI-ELECTRICAL DATA-MODELS 542E048, 542D060, & 542E060

MODEL

SIZE

SERIES

Unit Volts—Phase (60Flz) 230-1

Operating Voltage Range 207-253

Total Unit Amps

Max Branch Circuit Fuse Size (Amps) 60

Unit Ampacity for Wire Sizing 38.9

Minimum Wire Size (AWG)* 8 10

Maximum Wire Length (Ft)* 101 100

*Only use copper wire for field connections to unit. Wire size is based on 60 or 75°C copper conductor at 86°F (30°C) ambient tempera

ture and ampacity shown in fable. If other than 60 or 75°C copper conductor is used, if ambient temperature is above 86°F, or if voltage

drop of wire exceeds 2% of unit rated voltage, determine wire size from ampacity shown and the National Electrical Code. Wire lengths

shown are measured one way along the wire path between unit and service panel for minimum voltage drop.

USE SPREADER BARS TO PROTECT UNIT

31.9

542E 542E

048 060

A A

208/230-3 460-3

187-253

22.4 10.9 40.9 26.1

45 20 60

27.1

414-506 207-253 187-253

13.2

14

181 123

USE SPREADER BARS TO PROTECT UNIT

230-1

49.8

6 8

542D & 542E

208/230-3

50

31.3

137

060

A

460-3

414-506

13.7

25

16.4

12

229

ONE INCH FROM PLENUM FOR

PROPER FIT ON CURB AND PLATFORM

CHAIN RETAINER FOR

PROPER BALANCE

Figure 7—542D060 Suggested Rigging

Prime the trap with water and check the condensate line for

leaks.

CAUTION; Do not undersize the condensate drain line.

During the heating defrost cycle, defrost water from the

melting ice on the outdoor coil flows through the slots in the

heat pump base directly below the outdoor coil. If a field-supplied drain pan is to be used to catch the defrost water, this

pan should be at least 2 inches high and extend at least 2 in

ches beyond the width and length of the unit.

If the installation requires draining the condensate and/or

defrost away from the unit, connect a minimum of 7/8-inch

OD copper tubing, 3/4-inch galvanized pipe, or 7/8-inch

plastic pipe. The drainage lines should pitch downward at a

slope of at least 1 inch in every 10 feet of horizontal run.

Both condensate and defrost water can be drained directly

onto the roof in rooftop installations where permitted or

onto a gravel apron in ground-level installations. When a

gravel apron is being used, it should extend at least 24 in

ches around the mounting pad to ensure proper drainage.

III. DUCT CONNECTIONS

Flanges are provided on the 542E supply- and return-air

A79148

Figure 8—542E Suggested Rigging

openings on the side of the unit. See Figure 3 for connection

sizes and locations. See Figures 10 and 11 for illustrations of

typical installations.

Flanges are provided on the 542D supply- and return-air

openings on the bottom of the unit. See Figure 4 for connec

tion sizes and locations.

NOTE: The minimum installation requirements of the duct

system must be in accordance with the standards of the Na

tional Fire Protection Association for installation of air con

ditioning and ventilating systems of other than residence

type, NFPA No. 90; or residence type, NFPA No. 90B; and/or

local codes and ordinances.

CAUTION: When the duct system fastening holes are being

drilled into the 542E side instead of the unit duct flanges

provided, use care to avoid puncturing the coil tubes.

The following criteria must be followed when selecting, siz

ing, and installing ductwork:

1. When electric heater is installed, a minimum clearance

of one inch to combustible materials must be main

tained for the first 36 inches of duct.

2. It is recommended that flexible connectors be used be-

-4-

Page 5

tween the ductwork and unit to prevent transmission of

vibration. The duct system can be screwed or bolted to

the unit duct flanges. Suitable gaskets should be used to

insure an airtight seal. When a supplemental electric

resistance heater is being used, use fireproof material

for the connector between the ductwork and unit sup

ply-air duct flange. If flexible duct (which is not heat re

sistant) is being used, use a sheet metal duct sleeve in

side the flexible duct for at least the first 36 inches of

duct.

3. An external field-supplied air filter must be installed in

the 542E return-air ductwork. Recommended filter sizes

are shown in Table I. Filters should be installed where

they are easily accessible for service.

NOTE: Model 542D has factory-supplied high-capacity air

filters. High-capacity air filters are also factory-supplied

when the accessory plenum, horizontal economizer, or highcapacity filter rack is being used with Model 542E.

4. Avoid abrupt duct size increases of decreases.

5. Size all ductwork for required heat pump airflow.

6. Adequately insulate and weatherproof all ductwork

located outdoors. Ducts passing thru an unconditioned

space must be insulated and covered with a vapor bar

rier in accordance with the latest issue of SMACNA and

NESCA minimum installation standards for heating

and air conditioning systems.

7. Secure all ducts to the building structure.

8. All openings in the building structure must be properly

flashed, weatherproofed, and vibration-isolated in ac

cordance with local codes and good building practices.

IV. ELECTRICAL CONNECTIONS

WARNING: Tlit- iiiiit l aliinet have.-in uninrerrupted or

unbroken electrical ground to mininii/o por.ional injury if aii

electrical fault should occur. This may consist of elec.rical

wire connected to the unit ground lug in the control com

partment, or conduit approved for electrical ground when in

stalled in accordance with the National Electrical Code and

local electrical codes. A failure to follow this warning can re

sult, in the installer being liable for the personal injury .of

others. ■ , ■ ,

CAUTiON: A failure to follow these precautions could result

in danaage to the. unit being installed:

1. All electrical connections must be made in accordance

with the National Electrical Code and local electrical

codes governing such wiring.

2. Copper conductor is the only type of wire that is to be

connected between the field-supplied electrical discon

nect switch and the unit. DO NOT USE ALUMINUM

WIRE.

3. High-voltage power to the unit must be within the

operating voltage range indicated on the unit rating

plate. On 3-phase units, phases must be balanced within

2%. Consult the local power company for correction of

improper voltage and/or phase balance.

4. When the low-voltage control wires are run in the same

conduit as the high-voltage wires, the low-voltage wires

must be insulated for the highest voltage contained

within the conduit.

ACOUSTIC a INSULATION

DUCT LINER

Figure 10—542E Typical Rooftop

Installation on Pitched Roof

5. When drilling thru any panel to mount electrical hard

ware, conduit, etc; ensure that the drill does not damage

internal components.

6. If aluminum ,conductors are used between the electrical

service panel (power source) and the field-supplied

electrical disconnect switch, the wire gauge selected

must have a current capacity that is not less than the

; copper wire specified and must not create a; voltage drop

in excess of 2% of the unit rated voltage.

A. High-Voltage Connections

A separate electrical line with a field-supplied, waterproof,

fused disconnect, switch mounted at, or within sight of, the

unit must be used for this installation. Refer to the unit rat

ing plate for maximum fuse size and minimum amps

(ampacity) for wire sizing. Tables II and III show recom

mended wire sizes and lengths based on rating plate data.

NOTE: The field-supplied fused disconnect may be mounted

over the unit high-voltage inlet hole directly on the control

corner panel adjacent to the blower access panel. See Figure

3 or 4. Be sure that the disconnect box does not interfere

with the removal of the blower access panel. When mount

ing the disconnect box, align the knockout in the box with

the unit high-voltage inlet hole. Route the wiring from the

disconnect box thru the aligned holes. This connection must

be watertight to prevent water from entering the control

box.

Proceed as follows to complete the high-voltage connections

to the unit:

1. Run high-voltage power leads from fused disconnect

thru high-voltage inlet hole in control corner panel. See

Figure 3 or 4.

2. Connect ground lead to chassis ground connection, and

connect high-voltage power leads to unit high-voltage

pitgail leads. Single-phase units have two black pigtail

leads. Three-phase units have two black and one red pig

tail lead. See Figure 12, Figure 13, and unit wiring

label. Use a suitable wire splice connector or wirenut to

make each high-voltage connection. Tape each com

pleted connection.

B. Low-Voltage Connections

Recommended heat pump room thermostats for heat pump

operation with or without supplemental electric heaters are

P/N 34427DP115 (subbase included) for automatic system

changeover and P/N34427DP118 (subbase included) for

manual system changeover. These thermostats have an

emergency heat (EM. HT.) switch and red indicator light.

Heat pump room thermostat P/N 34427DP87 (subbase in

cluded) can be used for heat pump operation without supple

mental electric heaters. This thermostat provides for

manual system changeover and does not have an emergency

heat switch.

-5-

Page 6

LOW-PRESSURE

SERVICE FITTING

ACCUMULATOR

ACCUMULATOR

FUSIBLE

PLUG

DEFROST

THERMOSTAT

METERING

DEVICE

Figure 11—542E Typical Ground Level Installation

Into Crawl Space

DUAL CAPACITOR

REVERSING VALVE

ASSEMBLY .

HIGH-PRESSURE

SERVICE FITTING

(COMPRESSOR a

FAN MOTOR)

BLOWER MOTOR

RELAY

------

.Si LOW-VOLTAGE

-

--------- \ TERMINAL

A79242

BLOWER MOTOR

CAPACITOR

DEFROST

RELAY

DEFROST

TIMER

TRANSFORMER

\ BOARD

LOW-VOLTAGE

INLET HOLE

CHASSIS

GROUND

CONNECTION

LOW-PRESSURE SWITCH

INDOOR COIL DRAIN PAN

I MPT PLASTIC DRAIN FITTING

^(SHIPPED TAPED INSIDE

COMPRESSOR COMPARTMENT)

Figure 12—Partial Side View With Compressor & Control

Access Panels Removed (Model 542E036, 208V-230V—1)

QUICK-START PTC

THERMISTOR

COMPRESSOR

HIGH-VOLTAGE

PIGTAIL LEADS

FIELD SPLICE

FIELD-SUPPLIED

FUSED DISCONNECT

SWITCH

Figure 13—Field High-Voltage Connections

-6-

A79244

HIGHVOLTAGE

PIGTAIL

LEADS

A79243

Page 7

Figure 14—Field Low-Voltage Connections Using Room

Thermostat P/N 34427DP115or P/N 34427DP118

HEAT PUMP

LOW-VOLTAGE

TERMINAL

BOARD

Figure 15—Field Low-Voltage Connections Using Room Thermostat P/N 34427DP87

Mount the room thermostat on an inside wall in the space to

be conditioned. The thermostat should be approximately 4 or

5 feet above the floor and located where it will not be sub

jected to either a cooling or heating source, or direct ex

posure to sunlight.

Use No. 18 AWG “color-coded” insulated wires to make the

low-voltage connections between the thermostat and the

unit. If the thermostat is located more than 100 feet from

the unit as measured along the low-voltage wires, use No. 16

AWG wire.

A grommeted low-voltage inlet hole has been provided in the

control panel adjacent to the control access panel. See

Figure 3 or 4. Run the low-voltage thermostat leads thru the

inlet hole and to the low-voltage terminal board. See Figure

12. Complete the low-voltage thermostat connections as

shown in Figure 14 or 15, depending on which recommended

room thermostat is being used.

C. Heat Anticipator Settings

The recommended room thermostats have a fixed heat antic

ipator for heat pump heating. When using an accessory

electric heater to provide supplemental heat and emergency

heat capability for the system, see the Installation Instruc

tions packaged with the heater for setting the adjustable

second-stage heat anticipator.

V. PREPARING UNIT FOR STARTUP

WARNING/DANGER: A failure to Inllow the-e in.struclion.'

could roiult in seiiou.-< person;.I injury:

1. Follow recognized safety practice.- and wear protective

goggles when checking or .servicing the refrigerant

2. Do not oper.ali' the compres.=or or pro\ ide any electric

power to thi- unil unles.s compre-.'or tormin.il co\ or i.- in

place and secured.

0. Do not rerno\e the compres.-or terminal cu\er iinli! all

electrical source- lia\e been di.sronnected.

1. If a rcl'ngeranl leak is su.-pi'Cted ,iround the com)!re.--or

terminals, relie\e all pres-utv from the -v-tem before

touching or di-ttirliing anything inside the tciminal

■7). .Sy-tem contani.- ml :ind r efri.ger.int under pre.-.-tire. De

not use a torch to remove any component To remote a

component, wear protective goggles and [U'oceed as fol-

a. Shut oil electrical power to unit.

li. Reliete all pressure from sy-tem.

c. (7ut component connectin.g tubing with tubing ciit-

ti'i- and remove component from unit.

d. When nece.ssary. un.-weat remaining tubing -tubs

carefully. Oil may ignite when exposed to torch

ÎiisilïiïiSilSijîliSîiiïiiliillS^^

Proceed as follows to prepare the unit for initial startup:

1. Read and follow instructions on all WARNING, CAU

TION, and INFORMATION labels attached to the unit;

for example, blower rotation labels etc.

2. Visually inspect for oil at all refrigerant tubing connec

tions and on unit base. Detecting oil generally indicates

a refrigerant leak. Leak-test all refrigerant tubing con

nections, using electronic leak detector, halide torch, or

liquid-soap solution. If refrigerant leak is detected, see

Section VI, “Refrigerant Leaks,” in these instructions.

-7-

Page 8

3. Make certain all field and factory wiring connections

have been completed and are tight.

4. Inspect all supply ducts and grilles to be sure they are

open.

5. Check for correct position of outdoor fan blade in fan

orifice. Blades should clear fan motor by no more than

1/4 inch.

6. Check to be sure air filters are in proper place.

7. Fill condensate drain pan with water to assure proper

drainage.

8. Make certain all tools and miscellaneous loose parts

have been removed.

9. If coil fins have been damaged during shipping and han

dling, carefully straighten fins with a fin comb.

10. Replace all access panels. Unit is now ready for initial

startup.

VI. REFRIGERANT LEAKS

In rare instances when the factory refrigerant charge has

been lost because of a shipping damage leak, or when a re

frigerant leak has been found, proceed as follows:

1. Locate leak and ensure that refrigerant system

prressure has been relieved.

2. Repair leak following accepted practices.

3. Add a small charge of R-22 refrigerant to system and

leak-test unit.

4. If additional leaks are not found, evacuate refrigerant

system.

5. Charge unit with R-22 refrigerant to exact amount

shown on unit rating plate, using volumetric charging

cylinder or accurate scale.

NOTE: It is recommended that a filter-drier be installed

whenever the system has been open for repair. If a filterdrier has been installed, be sure to add enough extra R-22 to

compensate for the internal volume of the filter-drier.

VII. STARTUP AND ADJUSTMENTS

CAUTION: Ho nm lu'iiperanv .-.afct\ di'\ue.s wln-n oiu-nii

ing the unit. Do not operate the compressor until electric

power has been applied to the heat pump for a minimum of 4

hours to ensure that the off-cycle crankcase heater has sufii-

cii.-Miiy uyrnii.'d I hi’ l.■ll[llV"'^■'■.мll■ oil t(.i fit-e niosi of ilu- ac

cumulated refrigerant.

A. Checking Unit Operation

The heat pump should be started and checked for proper

operation as follows:

1. Set room thermostat SYSTEM switch to OFF position.

Observe that indoor blower motor starts when FAN

switch is placed in ON position and shuts down when

FAN switch is placed in AUTO position.

Proceed as follows to evaluate the system performance and

refrigerant charge level:

2. Place SYSTEM switch in COOL position and FAN

switch in AUTO position. Set thermostat temperature

setting to “call” for cooling. Compressor, outdoor fan,

and indoor blower motors should start. Observe that

unit shuts down when thermostat temperature setting

is satisfied. Wait 5 minutes for pressues to equalize.

3. Place SYSTEM switch in HEAT position and leave FAN

switch in AUTO position. Increase room thermostat

temperature setting gradually unitl thermostat “calls”

for heat. Compressor, outdoor fan, and indoor blower mo

tor should start. If supplemental electric heater is being

used in the system, increase room thermostat tempera

ture setting an additional 6 degrees. The supplemental

electric heater should energize. Set thermostat setting

below room temperature and observe that heater

deenergizes and that heat pump shuts down.

4. If supplemental electric heater is being used in the sys

tem, leave FAN switch in AUTO position, SYSTEM

switch in HEAT position, and move emergency heat

switch from NORM, position to EM. HT. position. Set

room thermostat temperature setting above room tem

perature. Observe that all supplemental electric heat is

energized, that indoor blower motor starts, and that

emergency heat indicator bulb lights. When thermostat

temperature setting is satisfied, observe that heater

deenergizes and that blower motor stops; however,

indicator light should remain on as long as emergency

heat switch is in EM. HT. position.

5. If autochangeover thermostat P/N 34427DP115 is

being used, place both SYSTEM and FAN switches in

AUTO position. Observe that heat pump operates in

heating mode when thermostat temperature selector is

set above room temperature, and operates in cooling

mode when selector is set below room temperature.

B. Checking and Adjusting Refrigerant Charge

The refrigerant system has been fully charged with R-22 re

frigerant, tested, and factory-sealed. The factory charge is

the correct charge for optimum performance for most in

stallations; however, this charge may require a slight

adjustment for some installations to assure full rated per

formance.

An operating pressure/temperature tag (also see Tables IV

and V) is fastened inside the unit compressor compartment.

This tag is provided so that the refrigerant charge can be

evaluated by checking operating pressures and tempera

tures. This method of checking is sufficiently accurate to

determine the adequacy of the refrigerant charge in the sys

tem when the conditions and system components are nor

mal; however, it does not solve or fix system abnormalities.

The evaluation indicates whether the refrigerant charge

needs a slight increase or decrease to establish the correct

operating pressures for the system at the time of checking.

The level of refrigerant operating charge determines how

efficiently and economically the unit will operate. An over

charged or undercharged unit will lead to insufficient heat

ing and cooling mode capacity, high operating costs, and the

possibility of premature compressor failure.

When checking the refrigerant using the temperature/pressure evaluation method, adhere to the following criteria:

1. Check refrigerant charge in cooling mode when outdoor

temperature is above 65°F.

2. Check refrigerant charge in heating mode when outdoor

temperature is below 65°F.

3. For best results, do not operate unit continuously for

more than 10 minutes if for any reason charge must be

checked in opposite mode above or below 65°F.

1. Remove caps from low- and high-pressure service fit

tings. See Figure 12.

2. Attach low- and high-side pressure gauge hoses to lowand high-pressure service fittings, respectively. Hoses

must have valve core depressors. Gauges should be cali

brated for accuracy.

3. Set room thermostat below room temperature to start

cooling operation or above room temperature to start

heating operation, depending on outdoor temperature.

Allow unit to operate until conditions stabilize and pres

sures level out.

4. Determine and record these conditions:

a. Low- and high-side pressure.

b. Dry-bulb temperature of inlet air at outdoor coil.

c. Temperature of inlet air at return-air grille—wet

bulb if operating in cooling mode or dry bulb if

operating in heating mode.

-8-

Page 9

TABLE IV-HEATING PERFORMANCE PRESSURES

Air Temp at

Indoor Coil

Inlet l°F DB|

Pressure

Designation

(Psig)

60 50 40

65 High Side 250 229 209 190 172 155 140 127 238 218 201

Low Side

69 59

70 High Side 268 243 220

Low Side 70 60 50 42 34

75

High Side 280 256 233 211 190 172 155

Low Side

71 61 51

5426024

Air Temperature at Outdoor Coil F°0B Air Temperature at Outdoor Coil °F0B Air Temperature at Outdoor Coil °FDB

30 20 10 0

49 41 33 25 18 14

199 180 162 147 134

26 19 15

-to

60 50 40

251

266 246 226

140

71

72 61 51

43 35 27 20 16 73 62

50 41 32

60

211 195 179

231

52 43

542E030 542E036

30 20 10 0 -10 60 50 40 30

184 169 155 144 134 232

24

18 13

165 153 142

42 33 25 19 14 65

207 190 176 162 151 261

34

26 20

15 66

214

198 183 170

64 52 46 38

247 230 213

53 47 39 31

225

243

54 48 40 32 26

198 184 171 161 152

209 195 182 171 162

20 10 0 -10

158 149 142

31 25 18 13

25 19 13

19

14

Air Temp at

Indoor Coil

Inlet (°F OBI

65

Pressure

Designation

High Side

Low Side

70 High Side

Low Side 72 63 51

75

High Side 283 266 243 218 194 180 166

Low Side

(PsigI

60 50 40 30 20 10 0

254 234

71 62

250 230

268

73 64

542E042 542E04B

Air Temperature at Outdoor Coil °FDB Air Temperature at Outdoor Coil °FDB

216 193 171 159 148 136 262 237 214 193

50 42 32

24

205 183 169 156 144 278 251 226

43 33

25

52 44 34 26 19 14 66 58

TABLE V-COOLING PERFORMANCE PRESSURES

Air Temp at

Indo or Coil

Inle t (°FWB I

Air Temp at

indo or Coil

Inle t l°F WB I

Pressure

Des ignatio n

55 High S ide 157 174 190

50 High S ide 162 179 195 212 228

65 High Side 168 185 200 216 232 247

70

75 High S ide 175 192 209 227 242 260 278 294 315 336 164

55 High Side 165 179

60 High Side 169

65

70

75

IPsi gi

Low Side 58 59

Low Side

Low Side

High Side

Low Side 77 78 79

Low Side 84 85

Pressure

Des ignatio n

Low Side

Low Side 64 66

High Side 173 187

Low Side 68

High Side 177 191

Low Side 72

High Side 181 196

Low Side

173 191

IPsi gi

75 B O B5 90 95 10 0 10 5

65 70

60 61 62 63 64 66

64 65 66 67 68 69 70 71 73

70 71 72 73 75 76 77 78 79 80 67

206 223 239

86 87 88

70 7 5 80 85 90

65

192 206 222

60 62 63

183 196 210 226

67 69 70 72

201 215 231 246 263 280 298

69 71 73

205 220 235 251 268 285 303

73 75

210 225 240 256 273 290 3 08

76 77 79 81

542 E02 4

Air T em p a t Ou tdo or C oil i°F D BI

207 224 240 258 276 293 313

244 261 279 296 315

264

270 288 304 324

253

80

81 82 83

91 93 94 95

90

542 E04 2 542 E04 8

Air T em p a t Ou tdo or C oil (°F O B)

65 67 68 70 72

77

95 1 00 1 05 11 0

237 254 270 289 308 178 192 207 224 238 255 272 291 308 330 176 189 202

241 258 275 293 312

74 75 77 79 65 66 67 69 70 72 74 76 78 80 63 65 66 67 68 70

74

78 79 81 83 69 70 71 73 74 76 78 80 82 8 4 67 69 70

76

80 82 83 85 87 73 74 '75 77 78 80 82

78

82 84 86 87 89 91

67

298 317

282

84 86 87

74 75 61 62 63 65 66 68 70 72 74

5420060 S 542E060

Air Temperature at Outdoor Coil °FDB)

-10

18 14

60 50 40

64

56 48 40 33

20 10 0 -10

30

174

144 134 268

158

26

19

204 184 166 154 146

18 14

153

65 57 49 41

290 266 242

34 27

20 13

220 201 184 169 158 298 268

50 42 35 28 21

542 E03 0 54ZE036

110

65 70 75 60 85 9 0 95 100 10 5 1 10 65 70 7 5 8 0 85 90 95 100 105 110

150 166 181 196 212 226 246 264

68

60 62 63 65 67 69

153 169 185 200 216 230 250 268

74

63 65 66 68 70 72 75 77 79 81 69 ' 71 72

157 173

160 177 192 208 224 240 259 277 295 315 192 207 223 239 255 273 290 308 326 346

70

180 196 212 2 28 244 264 282 300 320 196 212 228

74

65

70 7 5 80 85 9 0

183 197

317 188 203

322 193 208

327 198 214

77

Air T em p a t Ou tdo or C oil i°FD BI Air T em p a t Ou tdo or C oil l°FD BI

282 302 182 196

71

73 75 77 67 69 70 72 74 75 76 78 79 8 1

286 306 185 199

204 220 235 255 273

188

69 70 72 74 76 79 81 83 85 71 73

74

72

76 78 80 83

76 78 80 82

Air T em p a t Ou tdo or C oil l°F D BI Air Te mp at O utd oor Co il l°FDB |

212 229 243 260 277 296 314 335 180 193

235 249 266 283 302 320

218

240 254 271 288 307 326 345 191 205 219 234 250 266 283

223

229 246

78 80 81 8 3

84 87

260 277 294 312 332 350 198 212

84 86 88 90 92 76 77 79 80 82

291 311 188 203

85 87

89 91 93 79

95

100 10 5 110 6 5 70

84

86 88

60 50

13 66

284 252

67 57

14

68 58

74

89

59 61 62 63 65 67 68 70

76

340 185 198

71

40 30 20

210 186 166 151 142 136

238

47 39 32

56

224 198 178

48 40

238 212

49

211 227 242 259 276 294 312 332

215 231 246 263 280 298 316 336

74

219 235 251 268 285 303 321 341

74

76 78

77 79 81 83 84 86 88 89

76

244

81 83 84 86 88 89 91 93 95

75 6 0 B5 90 95 100 105 11 0

217 233

207

222

212 227 242 259 275 292 310 329

71 72 74 75 76 78 80

74 75 77 79 80 81 83

73

227 242 258 274 292 310 328 346

32 25 19 13

190 174 162 156

41 33 25 20

77

76

79 80 82

80

81 83

260 278 296

542 006 0 8 542E060

266 283 300 320

249

237 254 270 287 305

71

84

85

10

0 -10

24

19 13

164 154 146

14

83

85 86

314

332 352

72 74

324

75 77

73

301 319 338

85

87

89 91

5. Evaluate system performance and refrigerant charge

level by comparing recorded readings with unit operat

ing pressure/temperature tag.

6. When necessary, make slight adjustment to refrigerant

charge. If a substantial adjustment is indicated, deter

mine abnormal condition in system that is causing inac

curate readings, such as insufficient airflow across

either or both coils.

CAUTION: If it i.-^ dcri-rrniin-d thaï ihe problem i' ai; o\cr

charged or undercharged unit’when operating in the heat

ing mode, the refrigerant system should be evacuated and

recharged by adding the exact amount of R-22 refrigerant as

shown on the unit rating plate. A volumetric charging

cvliiuler or ac'. uraie .•fcoie should be u.~ed. \V her. operating in

the cooling mode, the operatiiig pre.ssiin' tempierature tag

may be used to adjust the charge.

C. Indoor Airflow & Airflow Adjustments

Model 542D and 542E units are equipped with direct-drive

-9-

blower motors. All motors have a high- and low-speed con

nection except for 460-V motors which have only a high

speed connection.

The system airflow for all units (except 460-V) can be

changed, when necessary, by changing the blower motor

speed connection from the factory setting to the unused

speed connection. The factory setting is indicated on the

unit wiring label.

CAUTION: The recommended airflow is 400 to 450 ftVmin

per each 12,000 Btuh of unit capacity. Inadequate airJlmv

can cause unsatisfactory operation and performance. Cer

tain unit./heater combinations can only be used with high

speed blower operation. See electric heater information

Table VI shows the air delivery performance of all units at

various external static pressures. Determine the airflow for

the system being installed as follows:

1. Start unit and measure static pressure in duct system at

unit.

Page 10

TABLE VI-AIR DELIVERY (FtVMin) AT INDICATED EXTERNAL STATIC PRESSURE & VOLTAGE*

Blower

Model

542E024 Low

542E030 Low

■ 542E036

542E042 Low 208

542E048

542E060 Low

542D060 Low

*Air delivery values shown for Model 542D060 are with factory-supplied air filter and plenum. Air delivery values shown for all sizes of

Model 542E are without air filter.

t Heating airflow values are with a dry coil. Cooling airflow values are with a wet coil.

NOTE: Shaded portions of this table fall below 350 ft^/min per 12,000 Btuh of rated cooling

airflows below this point. Dashes are used in those areas of the table that fall beyond

Motor

Speed

High

High

Low 208 Heating

High

High

Low

High

High

High

Opera

ting

Voltage

208

230

208 Heating

230

208 Heating

230 Heating 1070 1050 1025

208 Heating

230

230 Heating

208 Heating

230 Heating 1850

230

208 Heating

230

208 Heating

230 Heating

208 Heating

230 Heating

460 Heating

208

230 Heating

208 Heating

230 Heating

460 Heating

208 Heating

230

208 Heating 2270

230 Heating

460 Heating

Applica-

tiont

Heating 880

Cooling 850

Heating

Cooling

Cooling 985 940 890

Heating 1070

Cooling

Cooling 980 945 910

Cooling

Cooling

Heating

Cooling 1245 1225 1200

Cooling

Cooling 1400 1350

Cooling

Cooling

Heating 1400

Cooling

Heating 1655

Cooling

Cooling

Heating

Cooling

Cooling

Cooling

Cooling

Cooling

Cooling

Heating

Cooling

Cooling

Cooling

Cooling

Cooling

Cooling

Heating

Cooling 2085

Cooling 2190

Cooling 2395

Cooling 2165

0.0

965 925 880

940 900 855

1015 970 920

1040 1000 955

995 965 930

1055 1030 1005

1165 1145 1125

1150 1130 1105

1260 1245 1225

1280 1235 1185

1225 1185 1140

1485 1435

1685 1630 1575

1565 1510

1670 1615

1370 1330

1615 1565

1895

1825 1770

2125

2030 1970

1690

1650 1595

1905

1860

2005 1955

1955

2270 2195

2180

2070 2000

2000 1930

1860 1850

1840 1830

2250

2180 2135

2355 2315

2285 2240

2700 2625

2550 2475

2290 2260

2240 2205

1840 1825

1820 1800

2160

2550

2225

0.1 0.2 0.3

835 790

810 770

1030 985

1785 1720

1360

1610

1840

■ 2065

1635

1855 1800

1810

1905

2110

2205

2110

2030

2225

2135

2465

2315

2185 2140 2090

2115

External Static Pressure—Inches wc

/i 740 690

725,';'

835

810

870

840

940

910

890

865

995

970

1095

1075

1200

1170

1135 1080

1380 1325

1300

1455

1560

1315

1280

1560 1505

1510

1780

1710

2005 1935 1860

1905

1575 1510 1440

1535

1755 1690

1900

1850 1790

2120

2040 1960

1925

1855 1775 1690

1840

1820

2160 2110

2085

2270 2220 2165

2190

2550

2395 2315

2225

2165 2115 2065

1805

1765

2050 1990 1915

1970

2170 2105 2035

2075

2380 2285 2180

2225 2120 2010

2065 2000 1915

1095

1250 1190

1510 1440

1395 1325

1650 1575

1495 1425

....

1265 1205

1230 1165

1450 1380

1715

1645 1570

1835 1760

1475 1405

1740 1675

1845 1780

2040 1955

1845 1760

1825 1805

1800 1765

2030 1970

2135 2075

2465 2380

2185 2140

1770 1710

1705 1600

1900 1815 1700

2005

0.4

; . 675;

780 : 720

755 700 635

815 , 750 ' ; : 685

785 ; 730 ,S65 '

885

855

845

820

960.

930

1065

1035

1165

1135

1040

1265

1435

1645

1625

1725

1880

2050

2220 2120

1920

2025

capacity. Indoor coil icing may occur at

the capability of the indoor blower motor.

f

0.5

■ 630 ; 565

'.615

830 '.765.; :■ : : 680

800 735

785 705

760 680

915

880 800

1020 955 845 ,

980 900

1125

1080

1020

985

1200

1125

1360

1250 1160

1490

1345 1250

1130

1085 955 —

1360

1,305 1205

1570

1490 1395

1775

1675 1575

1360 1270

1325

1600 1510

1545

1705 1625

1650

1870

1785

1665

1595

1770

1705

1990

1900

2105

2005

2285

2090

2000

1585

— —

1830

1950

1800

2055

1860

1940

1770

0.6

: 550 :

:655„'" "■ 5.75'"‘i

840 730

1065 970

1005

955

920

1115 1025

1050

1275

1395

1015

1270 1140

1480 1365

1685 1570

1230

1445

1560

1765 1650

1685

1560 1425

1490

1710

1600 —

1915

1815 1700

2035

1920

2175 2055

2005

2025

1915

-

1695 —

...

1815

—

1905 -

—

1790 —

—

0.7

470 :

465 :

560 ; :

605

585 ;;

660

590 '

560

680

770

875

875

850

970

1160

1045

1280

1100

1050

1270

1440

1140

1100

1370

1290

1510

1430

1570 ,

1355

1575

1830

1950

1800

1860

1940

1770

—

—

■

—

—

—

-10-

Page 11

2. Refer to Table Vl and determine airflow at static pres

sure measured.

When an accessory electric heater is being used, the system

airflow can also be determined by measuring the tempera

ture rise through the unit and using the following formula:

AIRFLOW (fts/min) = i X Y

where,

KW = Heater nominal KW at 240 or 480V

TR = Measured température rise

Y =

200V

2195 2374

NOTE: Value Y varies with the operating voltage at the heater.

Interpolate to determine the value of Y for voltages not

shown.

D. Unit Controls and Safety Devices

208V 220V

440V 460V

2655 2902

230V

240V

480V

3160

1. High-Pressue Relief VaZue—This valve, which is located

in the compressor, opens when the pressure differential

between the low and high side becomes excessive.

2. Compressor Internal Overload—Hhis overload, which is

located in the compressor, interrupts power to the com

pressor when the current and internal temperature

become excessive. It automatically resets when the

internal motor temperature drops to a safe level. It may

require up to 60 minutes or longer for this overload to

reset; therefore, if an internal overload is suspected of

being open, disconnect the electrical power to the unit

and check the circuit thru the overload with an ohmmeter or continuity tester.

3. Low-Pressure Switch—This switch with automatic reset

interrupts the compressor control circuit when the re

frigerant high-side pressure becomes too low. It protects

the compressor from damage attributable to loss of the

refrigerant charge.

4. Time/Temperature Defrost System—The defrost control

system consists of a defrost timer, a defrost thermostat

switch, and a defrost relay. The system initiates defrost

cycle operation every 90 minutes if a coil icing condition

exists. See the defrost cycle sequence of operation in

Section VIII.

5. Crankcase Heater—This device prevents overdilution of

compressor oil with refrigerant during shutdown

periods, thereby extending the life of the compressor.

See the crankcase heater sequence of operation in Sec

tion VIII.

6. Compressor Quick-Start Componenis—These components

are used with all single-phase units to improve com

pressor starting characteristics.

7. Outdoor Fan Thermostat—This control, which is

featured on all 3-phase units, maintains the proper cool

ing mode condensing temperature by switching the

outdoor fan motor to high- or low-speed operation. Lowspeed fan operation permits low-ambient cooling opera

tion down to 40°F outdoor temperature.

Vili. SEQUENCE OF OPERATION

Do not leave the installation until the heat pump has been

observed throughout one or two complete cycles. The in

staller should make certain during this time that all compo

nents are operating in correct sequence.

The sequences of operation described in this section pertain

to all 208/230-volt, 3-phase units; however, the sequence of

operation of single-phase and 460-volt units is Very similar.

Refer to the line-to-line wiring diagram in Figure 16.

NOTE: Although the actual unit wiring may vary slightly

from that shown in Figure 16, the sequence of operation will

not be affected. The sequences of operation described in this

section pertain to a typical system using room thermostat

P/N 34427DP115 or P/N 34427DP118 for system control,

and using an accessory electric resistance heater for supple

mental heat.

NOTE: The indoor blower motor will operate continuously,

regardless of the room thermostat SYSTEM switch position,

when the FAN switch is in the ON position. The ON position

of the FAN switch keeps the circuit through blower relay

coil 2A closed and the coil energized. When the FAN switch

, is in the AUTO position, the blower operates only when the

system is started by the room thermostat demand for heat

ing or cooling.

A. Crankcase Heater Operation

Compressor crankcase heater llA is connected across nor

mally open compressor contractor 2D contacts between 13

and 23. When electric power is supplied to the heat pump,

and the unit is not operating in either the heating or cooling

mode, a completed circuit between power legs LI and L3 per

mits current to flow through one leg of compressor motor 3F

windings and through crankcase heater 11 A. The high

electrical resistance of the crankcase heater causes the

heater to heat up, while the compressor motor windings

serve only as a means of completing the circuit between LI

and L3.

When the heat pump receives a “call” for either heating or

cooling, normally open compressor contactor 2D contacts be

tween 13 and 23 are closed. (See heating and cooling

sequences of operation in this section.) Electric current,

which always follows the path of least resistance, now flows

through the closed contacts and through both compressor

motor 3F and outdoor fan motor 3D1. The crankcase heater,

which offers a much higher electrical resistance than the

two motors, receives virtually no electrical current as long

as the contactor is energized.

B. Cooling Operation

With the room thermostat SYSTEM switch in COOL posi

tion and the FAN switch in AUTO position, the cooling

sequence of operation is as follows:

When the room temperature rises to within 2 degrees of the

room thermostat temperature setting, the thermostat cool

ing operation bulb “makes” and thermostat terminal R is

connected to thermostat terminal 0. This completed circuit

through the thermostat completes the circuit through unit

terminal 0. Reversing valve solenoid coil 5B and outdoor fan

relay coil 2C are now connected across the 24-volt secondary

of unit transformer IB.

Energized solenoid coil 5B switches the reversing valve from

the normal heating mode position to the cooling mode posi

tion. Energized outdoor fan relay coil 2C closes its set of nor

mally open contacts between 1 and 3, and opens its set of

normally closed contacts between 1 and 2, permitting twospeed outdoor fan motor 3D1 to operate on either high- or

low-speed depending on the outdoor ambient temperature.

NOTE: When the contacts of outdoor fan relay coil 2C are in

their normal heating mode positions as shown in Figure 16,

fan motor 3D1 operates on high speed, regardless of the out

door ambient temperature.

The heat pump is now in a “standby” condition and ready to

operate in the cooling mode when the room thermostat

“calls” for cooling.

When the room temperature rises slightly above the ther

mostat temperature setting, the thermostat cooling bulb

“makes” and thermostat terminal R is automatically con

nected to thermostat terminals G and Y. These completed

circuits through the thermostat connect indoor blower relay

coil 2A (through unit terminal G) and compressor contactor

coil 2D (through unit terminal Y) across the 24-volt sec

-11-

Page 12

ondary of unit transformer IB.

Energized indoor blower relay coil 2A closes its set of nor

mally open contacts between 1 and 3, completing the circuit

through indoor blower motor 3D2, and the motor starts.

Energized compressor contactor coil 2D closes its normally

open contacts between 13 and 23, and 11 and 21, completing

the circuit through compressor motor 3F and outdoor fan

motor 3D1. Both motors start instantly. The current flow

through outdoor fan motor 3D1 also flows through fan

switching thermostat 7K which maintains the optimum

cooling mode condensing temperature by switching the fan

motor to high- or low-speed operation, depending on the out

door ambient temperature.

The heat pump is now operating in the cooling mode. The

energized reversing valve is directing the high-temperature,

high-pressure discharge gas to the outdoor coil where the

heat is transferred to the outdoor air.

All three energized motors will continue to run and the cool

ing cycle will remain “on” until the room temperature falls

slightly below the room thermostat temperature setting.

When this point is reached, the thermostat cooling bulb will

tilt and break the circuit between thermostat R to terminals

G and Y. These open circuits deenergize indoor blower relay

coil 2A and compressor contactor coil 2D. All closed contacts

return to their normally open position and all three motors

stop.

The heat pump has now returned to a “standby” condition,

awaiting another “call” for cooling by the room thermostat.

If the room temperature should continue to fall, the ther

mostat cooling operation bulb will tilt and break the circuit

between thermostat terminals R and 0. This open circuit

deenergizes reversing valve solenoid coil 5B and outdoor fan

realy coil 2C. The fan relay contacts open and the reversing

valve switches to the normal heating mode position.

Except for the crankcase heater, all heat pump components

are now deenergized. When the room temperature rises

again and reaches the room thermostat control points, the

cooling sequence will start again. If the room temperature

continues to drop, the heat pump will remain “olT’ and the

heating mode will not start until the room thermostat SYS

TEM switch is moved to the HEAT position (either HEAT or

AUTO when using autochangeover thermostat P/N

34427DP115).

C. Heating Operation

With the room thermostat SYSTEM switch in HEAT posi

tion and the FAN switch in AUTO position, the heating

sequence of operation is as follows:

When the room temperature drops slightly below the ther

mostat temperature setting, the thermostat first-stage heat

ing bulb “makes” and thermostat terminal R is connected to

thermostat terminals G and Y. These completed circuits

through the thermostat connect indoor blower relay coil 2A

(through unit terminal G) and compressor contactor coil 2D

(through unit terminal Y) across the 24-volt secondary of

unit transformer IB.

Energized indoor blower relay coil 2A closes its set of nor

mally open contacts between 1 and 3, completing the circuit

through indoor blower motor 3D2, and the motor starts.

Energized compressor contactor coil 2D closes its normally

open contacts between 13 and 23, and 11 and 21, completing

the circuit through compressor motor 3F and outdoor fan

motor 3D1. Both motors start instantly. Outdoor fan motor

3D1 will operate on high speed regardless of the outdoor

temperature because outdoor fan relay contacts 2C are in

their normal heating mode positions as shown in Figure 16.

In these normal positions, the line-voltage circuit to fan mo

tor 3D1 is always to the high-speed motor windings, regard

less of the switching action of fan switching thermostat 7K.

The heat pump is now operating in the heating mode. The

nonenergized reversing valve is in the normal heating mode

position and the high-temperature, high-pressure discharge

gas is being directed to the indoor coil, where the heat is

transferred to the indoor air.

All three energized motors will continue to run and the heat

ing cycle will remain “on” until the room temperature rises

slightly above the room thermostat temperature setting. If

the outdoor temperature has dropped to the point where the

heating capacity of the heat pump cannot maintain the

desired indoor room temperature, the second-stage heating

bulb will “make” when the indoor temperature continues to

drop to a point slightly below the room thermostat factory

differential setting. Thermostat terminal R is automatically

connected to thermostat terminals W1 and W2. These com

pleted circuits through the thermostat connect the relay coil

(or coils if using a two- or three-bank heater) of the supple

mental electric heater across the 24-V secondary of heat

pump transformer IB. The electric heater energizes to pro

vide supplemental electric heat to the system.

NOTE: See the Installation Instructions packaged with the

electric heater for a more comprehensive description of the

electric heater sequence of operation.

When the room temperature rises slightly above the room

thermostat second-stage heat setting, the second-stage

heating bulb will tilt and break the circuit between ther

mostat terminal R to terminals W1 and W2. The supplemen

tal electric heat deenergizes. When the room temperature

continues to rise to a point slightly above the room ther

mostat temperature setting, the first-stage heating bulb

will tilt and break the circuit between thermostat terminal

R to terminals G and Y. These open circuits deenergize

indoor blower relay coil 2A and compressor contactor coil

2D. All closed contacts return to their normally open posi

tion and all three motors stop.

The heat pump has now returned to a “standby” condition

awaiting another “call” for heating by the room thermostat.

Except for the crankcase heater, all heat pump components

are now deenergized. If the room temperature continues to

rise, the heat pump will remain “off” and the cooling mode

will not start until the room thermostat SYSTEM switch is

moved to the COOL position (either COOL or AUTO when

using autochangeover thermostat P/N 34427DP115).

D. Defrost Cycle

The defrost control circuit consists of defrost timer 3M,

defrost thermostat switch 7M, and defrost relay 2P. The

defrost timer is factory-set for 90-minute intervals of

elapsed running time, which results in optimum heating

mode efficiency for most installations; however, the adjusta

ble cam can be reset for a 30-minute interval when abnormal

climatic conditions dictate. The conditions include such

things as excessive outdoor humidity at low outdoor temper

atures.

CAUTION; The factory-set 90-minute interval should never

be adjusted unless the unit does not completely defrost after

the 10-rainute time-terminated defrost cycle.

With the heat pump operating in the heating mode, the

defrost cycle sequence of operation is as follows:

Defrost thermostat 7M switches to the closed position when

the outdoor coil refrigerant temperature drops to approx

imately 30°F. When defrost timer 3M completes 90 minutes

of elapsed running time, a coil in the timer energizes and the

normally open timer contacts between 3 and 4 for approx

imately 10 seconds. (The normally closed timer contacts be

tween 3 and 5 do not open at this time, as explained later.) If

defrost thermostat switch 7M has not switched close, the

normally open timer contacts return to the open position and

the heat pump continues to operate in the heating mode.

-12-

Page 13

LEGEND

1B-Transformer

2A-lndoor Blower Relay SPST (N.O.)

2C-Outdoor Fan Relay SPOT

2D-Compressor Contactor DPST (N.O.)

2P-Defrost Relay TPDT

3D1-Outdoor Fan Motor

3D2-lndoor Blower Motor

3F-Compressor

3M-Defrost Timer

4A1-Fan Motor Capacitor

4A2-Blower Motor Capacitor

5B-Reversing Valve Solenoid

7K-Fan Switching Thermostat

SPOT

7M-Defrost Thermostat

Switch (N.O.)

7P-Low-Pressure Switch

SPST (N.O.)

11A-Crankcase Heater

When normally open defrost timer contacts between 3 and 4

close for their 10-second interval and defrost thermostat

switch 7M has switched close, the defrost control circuit is

completed and defrost relay coil 2P is energized.

Energized defrost relay coil 2P switches all of its contacts

and each of the following events occur simultaneously:

1. Normally open defrost relay contacts between 7 and 9

close before defrost timer 3M contacts between 3 and 4

complete their 10-second interval. The defrost control

circuit is maintained and defrost relay coil 2P remains

energized.

2. Normally closed defrost relay contacts between 7 amd 8

open and the circuit through outdoor fan motor 3D 1 is

broken. The motor stops running.

3. Normally open defrost relay contacts between 1 and 3

close, completing the circuit to reversing valve solenoid

5B. The reversing valve switches from the normal heat

ing mode position to the cooling mode position and the

hot discharge gas is directed to the outdoor coil to melt

the frost on the coil.

4. Normally open defrost relay contacts between 4 and 6

close. Unit terminal R is now connected to unit terminal

W1 and the first bank of supplemental electric heat is

automatically energized. Terminals W1 and W2 of the

room thermostat are internally connected; therefore,

any additional banks of supplemental electric heat are

also automatically energized.

The system is now heating the conditioned space with the

supplemental heaters while the outdoor coil is defrosting.

When the outdoor coil refrigerant temperature rises to ap

proximately 67°F, defrost thermostat 7M switches to the

open position to terminate the defrost cycle; however, if the

defrost thermostat 7M has not terminated the defrost cycle

within a 10-minute interval, normally closed timer 3M con

tacts between 3 and 5 automatically open and terminate the

defrost cycle.

When the defrost cycle is terminated by either the defrost

thermostat or the timer contacts, defrost relay 2P is

deenergized. Outdoor fan motor 3D1 restarts and reversing

valve solenoid 5B is deenergized. The reversing valve

switches to the normal heating mode position. The supple

mental electric heaters are deenergized if the room ther

mostat is not “calling” for second-stage heating.

The system has now returned to normal heating mode opera

tion. After 90 minutes of elapsed running time, defrost timer

3M will automatically make another check to determine if

the outdoor coil requires defrosting.

E. Emergency Heat Operation

When there is a heat pump compressor malfunction or other

malfunction in normal heat pump heating operation, it is

desirable to deactivate the compressor control circuit and to

remove the compressor from the heating system while con

tinuing to supply the conditioned space with heat. Room

thermostats P/N 34427DP115 and P/N 34427DP118, which

have an emergency heat switch, are used to deactivate the

compressor and are used in conjunction with the accessory

supplemental electric heater to continue supplying heat. See

the Installation Instructions packaged with the electric

heaters for the emergency heat sequence of operation.

F. Automatic Changeover Operation

When autochangeover thermostat P/N 34427DP115 is being

used, the switching from heating to cooling to heating, is au

tomatically controlled by the room thermostat when the

SYSTEM switch is in the AUTO position.

To prevent unwanted cycling between heating and cooling

mode operation, the heating and cooling temperature selec

tion levers provide for a 4°F minimum temperature setting

differential. For most installations, this differential will

probably be set closer to 10°F to comply with recommended

guidelines for energy conservation.

With both the SYSTEM and FAN switches in the AUTO

position, the heat pump will start operation in the heating

mode when the room temperature drops to the thermostat

heating temperature setting, or will start operation in the

cooling mode when the room temperature rises to the ther

mostat cooling temperature setting.

-13-

Page 14

IX. CARE AND MAINTENANCE

WARNING: A failure to follow these instructions could re-

: suit in serious personal injury:

1. Disconnect all electrical power to system before per

forming any maintenance or service on the unit.

2. Because of possible personal injury or damage to the

equipment, maintenance and/or service should be per

formed by qualified persons only.

3. As with any mechanical equipment, personal injury can

, result from sharp edges, etc.; therefore, be very careful

; \ when removing panels and parts.

ft; 4. Never place anything combustible on, ;in contact with,

eft:' or near the unit.

...

■ ftft

To ensure continuing high performance, and to minimize

possible equipment failure, it is essential that periodic main

tenance be performed on this equipment. Consult your local

Dealer as to the proper frequency of maintenance and the

availability of a maintenance contact.

The ability to perform maintenance on this equipment re

quires certain mechanical skills and tools. If you do not

possess these, contact your Dealer for maintenance.

The minimum maintenance that should be performed on

this equipment is as follows:

1. Inspect air filter after each month of system operation.

Clean or replace as required.

2. Inspect coils, drain pan, and condensate drain before

each heating and cooling season for cleanliness. Clean

as necessary.

3. Inspect blower motor and wheel for cleanliness and

lubrication each heating and cooling season. Clean and

lubricate as necessary.

4. Inspect all electrical connections for tightness and con

trols for proper operation each heating and cooling

season. Service as necessary.

A. Air Filter

CAUTION: I).. not operate the unit without having a suita

ble air filter in place in the return-air duct system. Alwaysreplace filter w'ith same size and type.

Air filters should be inspected at least once each month and

replaced (disposable-type) or cleaned (cleanable-type) at

least twice during each heating and cooling season or when

ever the filter becomes clogged with dust and lint.

Filters are not supplied as an integral part of the 542E. The

field-supplied air filter may be either disposable or cleanable.

Contact your Dealer if you cannot determine the location or

type of air filter in your system.

Model 542D units have two factory-supplied disposable

filters located in the down-discharge plenum section of the

unit. The access door on the return-air inlet side of the

plenum must be removed to gain access to the filters. See

Figure 4. When clogged with dirt or lint, these filters should

be replaced with the same size and type.

B. Lubrication

The outdoor fan motor and indoor blower are prelubricated

for 2 years of heavy duty or 5 years of normal duty. When

lubrication is necessary, call your Dealer for service.

C. Indoor and Outdoor Coils

WARNING: Be sure all electrical power to the system is '

turned OFF before cleaning coils.

The unit top cover must be removed to gain access to the

coils. The outdoor fan motor, leads must be disconnected in

the unit control box before lifting the cover, and reconnected

in accordance with the unit wiring label after replacing the

top cover.

The coils are easily cleaned when they are dry; therefore,

they should be inspected and cleaned before each cooling

season, and inspected periodically during the year.

If the coils are coated with dirt or lint, they should be

vacuumed with a vacuum cleaner soft brush attachment. Be

careful not to bend the fins. If the coils are coated with oil or

grease, they can be cleaned with a mild detergent and water

solution. Rinse coils with clear water, using a garden hose.

Be careful not to splash water on motors, insulation, wiring,

or filters. For best results, spray outdoor fins from inside to

outside the unit. On units with an outer and inner outdoor

coil, be sure to clean between coils. Be sure to flush all dirt

and debris from the unit base, from the condensate drain pan

located under the indoor coil, and from the condensate drain

line.

D. Condensate Drain

The drain pan and condensate drain should be checked at the

same time the coils are checked. Clean the pan and drain pan

and condensate drain by removing all foreign matter from

the pan. Flush pan and drain tube with clear water. Be care

ful not to splash water on insulation, motor, wiring, or air

filter. If the drain tube is restricted, it can generally be

cleared with high-pressure water. If this does not work, try a

“plumber’s snake’’ or similar probe device.

E. Indoor Blower

WARNING: Be eiiro all elei'l rical power to t lie unit ii ruri ied

off hefore servicing the blower.

The blower should be inspected at least once each year. Re

move caked-on dirt from the blower wheel and housing with

a brush; remove grease with a mild solvent. Make sure the

blower is centered in the blower housing. Be careful not to

disturb balance weights.

F. Outdoor Fan

WARNING: Be m ire all electrical power to the unit is ofl

lieforc S('f\ icing the fan. Do not poke slicks, screwdriver.-, or

any other object into revolving fan blades—severe bodily in

jury may result.

The fan should be kept free of all obstructions to ensure

proper operation. Do not set articles on top of unit that could

possibly interfere with the airflow of the fan.

Each year the fan blades should be inspected for cracks or

bends. The blades should clear the motor by no more than 1/4

inch. If the blade assembly has slipped down the motor shaft,

adjust the fan position on the motor shaft by loosening the

setscrew (s) and moving the blade assembly up. Be sure the

setscrew (s) is on the flat of the motor shaft before tight

ening.

G. Electrical Controls and Wiring

WARNING; Be sure all electrical power to the unit and the

heaters (if used) is turned off.

NOTE: When an accessory supplemental electrical heater is

being used in the system, there may be a separate electrical

supply to the heater.

With power disconnected to the unit, check all electrical

connections for tightness. Tighten all screws on connections.

If any smoky or burned connections are noticed, disassemble

the connections, clean all parts, strip the wire, and reassem

ble properly and securely. Electrical controls are difficult to

check without proper instrumentation; therefore, reconnect