Page 1

installation, start-up and

service instructions

SPLIT SYSTEM

HEAT PUMP UNITS

Cancels: II 541A-120-1 II 541A-120-2

541A

Sizes 120,180

10 to 15 Tons

12/15/98

CONTENTS

Page

SAFETY CONSIDERATIONS ........................1

INSTALLATION ................................1-10

I. Step 1 — Complete Pre-Installation Checks .....1

II. Step 2 — Rig and Mount Unit .................1

III. Step 3 — Complete Refrigerant Piping

Connections ...............................2

IV. Step 4 — Complete Electrical Connections .....8

PRE-START-UP ................................10-12

START-UP ....................................12-14

SERVICE .....................................14,15

TROUBLESHOOTING ...........................16-19

START-UP CHECKLIST ....................CL-1, CL-2

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be

hazardous due to system pressures, electrical components and

location of equipment (roofs, elevated structures, etc.).

Only trained, qualified installers and servicemechanicsshould

install, start up, and service this equipment.

Untrained personnel can perform basic maintenance functions, such as cleaning coils and filters and replacing filters.

All other operations should be performed by trained service

personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Keep a quenching cloth and fire extinguisher handy.

• Use care in handling, rigging, and setting bulky

equipment.

WARNING:

to equipment is shut off before performing maintenance or service.

IMPORTANT: Follow unit location, height proximity, and piping requirements in this booklet carefully to enhance system

efficiency and to avoid system failure. Read entire booklet before starting installation.

I. STEP 1 — COMPLETE PRE-INSTALLATION CHECKS

A. Uncrate Unit

Remove unit packaging except for thetopskidassembly, which

should be left in place until after the unit is rigged into

position.

To prevent electric shock, be sure power

INSTALLATION

B. Inspect Shipment

File claim with shipping company if shipment is damaged or

incomplete.

C. Consider System Requirements

• Consult local building and electrical codes for special installation requirements.

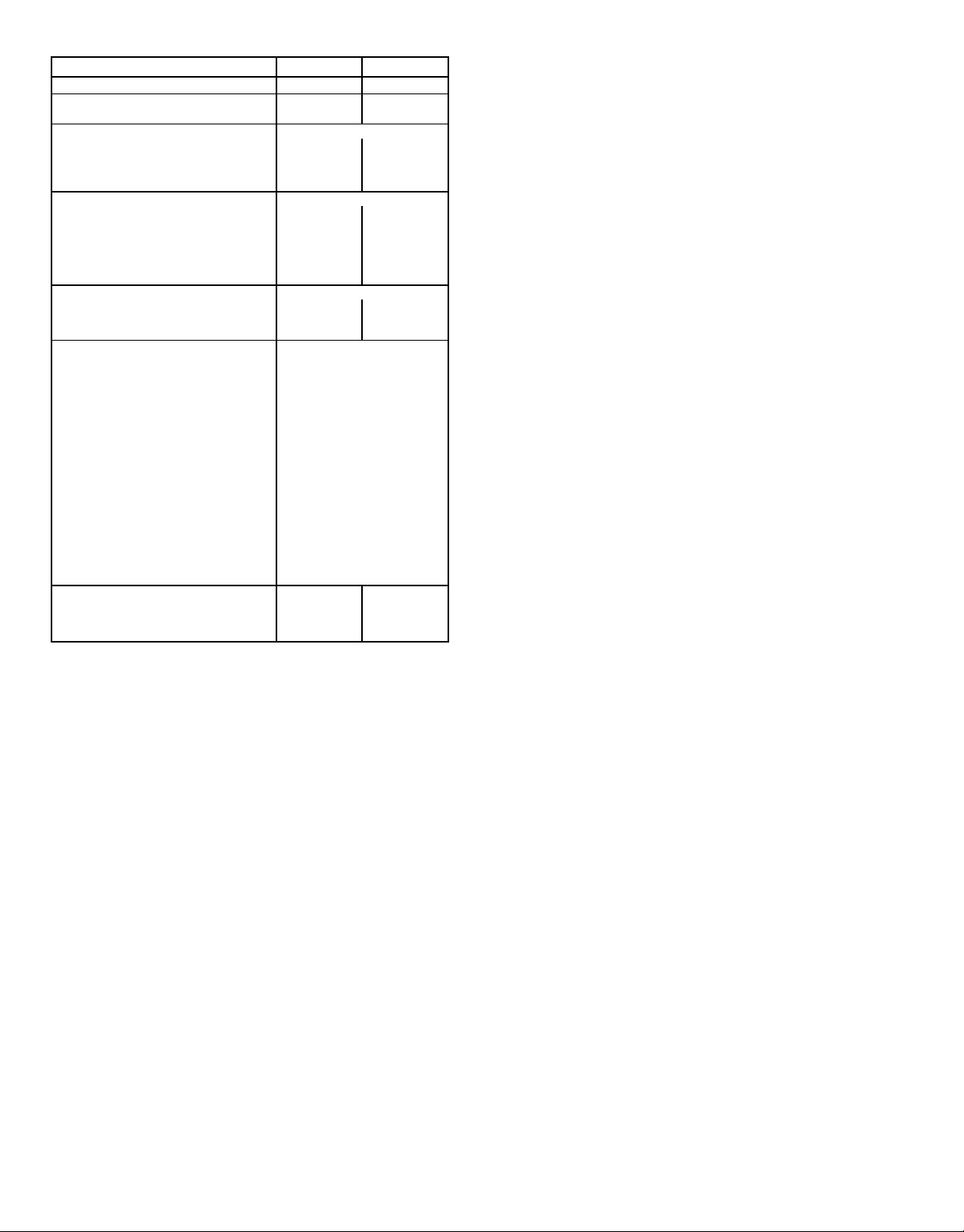

• Allow sufficient space for airflow clearance, wiring, refrigerant piping, and servicing unit. See Fig. 1 and 2.

• Ensure unit weight will be properly supported. See

Table 1.

• Unit may be mounted on a level pad directly on the base

channels or mounted on raised pads at support points. See

Fig. 3 and Table 2 for weight distribution based on recommended support points.

NOTE: If vibration isolators are required for a particular installation, use data in Table 2 to make proper selection.

• Accessory mounting legs (Part No. 309273-227) are recommended for elevation of unit for improved air circulation

and better condensate drainage. Legs also minimize interference from ice build-up, snow, leaves, and debris. See

Fig. 1.

II. STEP 2 — RIG AND MOUNT UNIT

CAUTION:

prior to rigging. Be careful rigging, handling, and installing unit. Improper unit location can cause system

malfunction and material damage. Inspect base rails for

any shipping damage and make sure they are fastened

securely to unit before rigging.

A. Rigging

Units are designed for overhead rigging only. For this purpose, the transverse base rails extend beyond sides of unit,

with holes provided in end plates to attach clevis for securing cables. Rig with top skid packaging assembly in place to

prevent unit damage by rigging cable. For coil face protection, place plywood sheets against the sides of unit, behind

cables. Run cables to a central suspension point so that the

angle from the horizontal is not less than 45 degrees. Raise

and set unit down carefully.

If it is necessary to roll unit into position, mount unit on fieldsupplied longitudinal rails using a minimum of 3 rollers.APPLY FORCE TO THE RAILS, NOT THE UNIT. If unit is to

be skidded into position, place it on a large pad and drag the

pad. DO NOT APPLY ANY FORCE TO THE UNIT.

Raise from above to lift unit from rails or pad when placing

unit in final position.

Be sure unit panels are securely in place

Page 2

Table 1 — Physical Data

UNIT 541A 120 180

OPERATING WEIGHT (lb) 750 803

REFRIGERANT R-22 R-22

Operating Charge (lb)* 30 37

COMPRESSOR Recip Hermetic; 1750 Rpm

Model No. 06DF824 06DF537

Cylinders 66

Oil (pts) 10 10

Crankcase Heater (Watts) 180 180

OUTDOOR AIR FANS Direct Drive — Axial Flow

Number 22

Speed (rpm) 1075 1075

Diameter (in.) 26 26

Motor Hp

Airflow (cfm) 11,000 11,000

kW (total) 1.46 1.46

OUTDOOR COIL Plate Fins; 15 Per Inch

Rows Deep 23

Face Area (sq ft) 29.2 29.2

Storage Capacity (lb)† 27.2 40.1

CONTROLS

High-Pressure Switch (HPS)

Cutout (psig) 400

Cut-in (psig) 300

Loss-of-Charge Switch

(Liquid Line)

Cutout (psig) 7 6 3

Cut-in (psig) 22 6 5

Head Pressure

(No. 2 Fan Cycling)**

Opens (psig) 160±10

Closes (psig) 255±10

Oil Pressure Switch (Differential)

Set Point (psig)

(Close on Rise) 9.5 6 1

(Open on Fall) 5

Defrost Pressure Switch (HPS2)

Opens (psig) 280 6 10

Closes (psig) 180 6 2

THERMOSTAT

Defrost Switch

Opens (F) 65 80

Closes (F) 27 27

*Approximate charge with 25 ft of interconnecting piping. Use

appropriate charging charts for actual charging of unit.

†Refrigerant storage capacity at 120 F condensing temperature with

condenser 80% full of liquid.

**Head pressure control on cooling cycle only.

1

⁄

2

1

⁄

2

B. Locate Unit

For service access and unrestricted airflow,provide2 ft clearance on each end of unit and 3 ft clearance on each side of

unit. Position unit so that there is unrestricted airflow above

unit.

NOTE: Before mounting unit, remove 4 holddown brackets

and release skid.

If conditions or local codes require unit to be fastened to

pad, use the mounting holes in the 4 unit mounting feet (see

Fig. 1).

C. Mount Unit

The unit may be mounted on a solid, level concrete pad, on

accessory mounting legs, or on field-supplied raised supports

at each mounting position. (Note that mounting hardware is

field supplied.)

Weightdistribution (shown in Fig. 3 and Table 2) determines

the type of support required. Bolt unit securely to pad or supports after unit is in position and is level. Be sure to mount

unit level to ensure proper oil return to compressors. Mounting holes on unit can be used to secure unit to vibration isolators, if required.

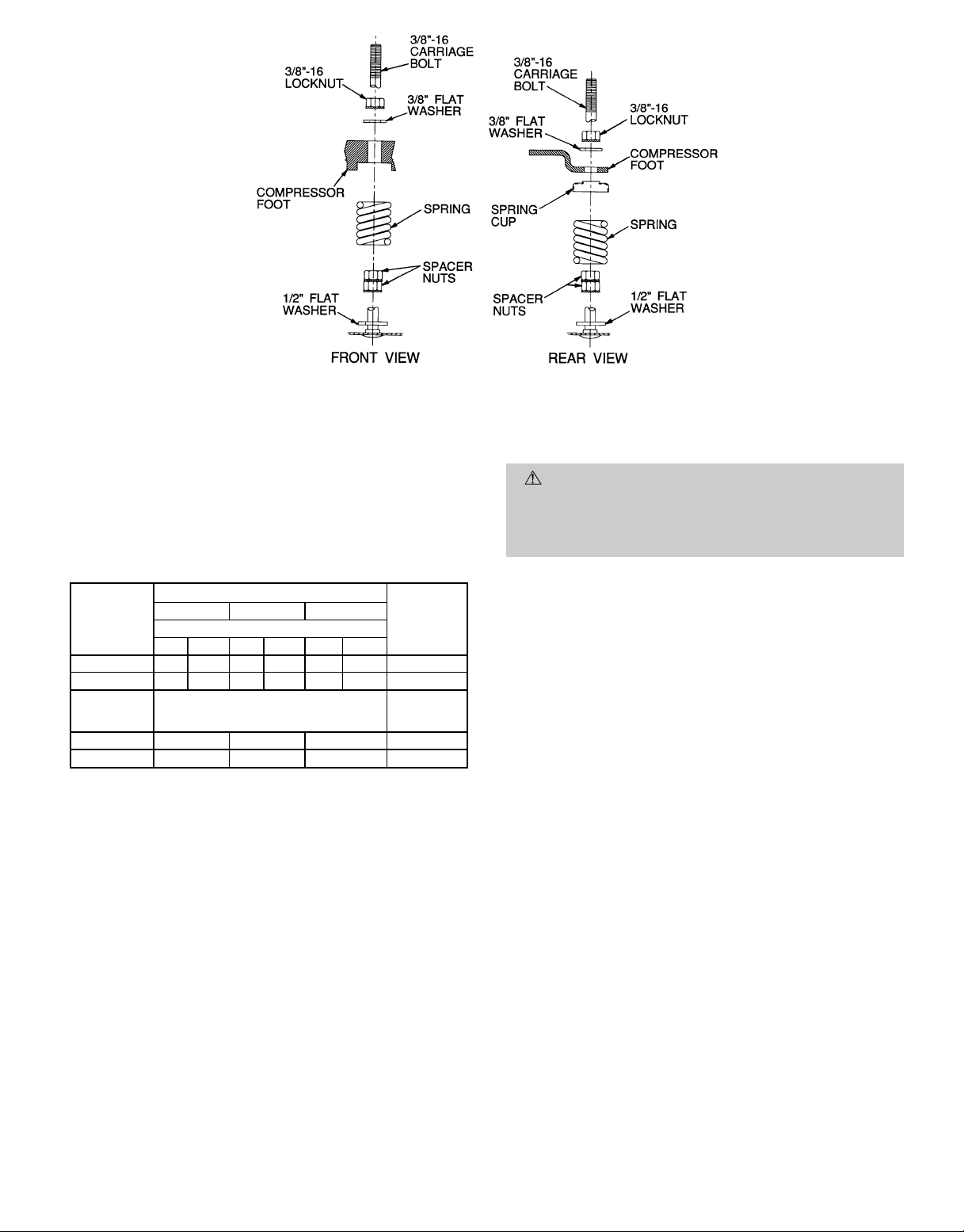

D. Compressor Mounting

As shipped, compressor is held down by 4 bolts. After unit is

installed, loosen each bolt using locknut shown in Fig. 4 un-

3

til flat washer (

⁄8in.) can be moved with finger pressure.

III. STEP 3 — COMPLETE REFRIGERANT PIPING

CONNECTIONS

Refrigerant lines must be carefully designed and constructed

to ensure equipment reliability and efficiency. Line length,

pressure drop, compressor oil return, and vertical separation

are several of the design criteria that must be evaluated. See

the following sections.

IMPORTANT: Piping must be properly sized and installed for

the system to operate efficiently.

A. Check Vertical Separation

If there is any vertical separation between the indoor and outdoor units, checkT able3 to ensure that the separation is within

allowable limits. Relocate equipment if necessary.

—2—

Page 3

Fig. 1 — Dimensions

—3—

Page 4

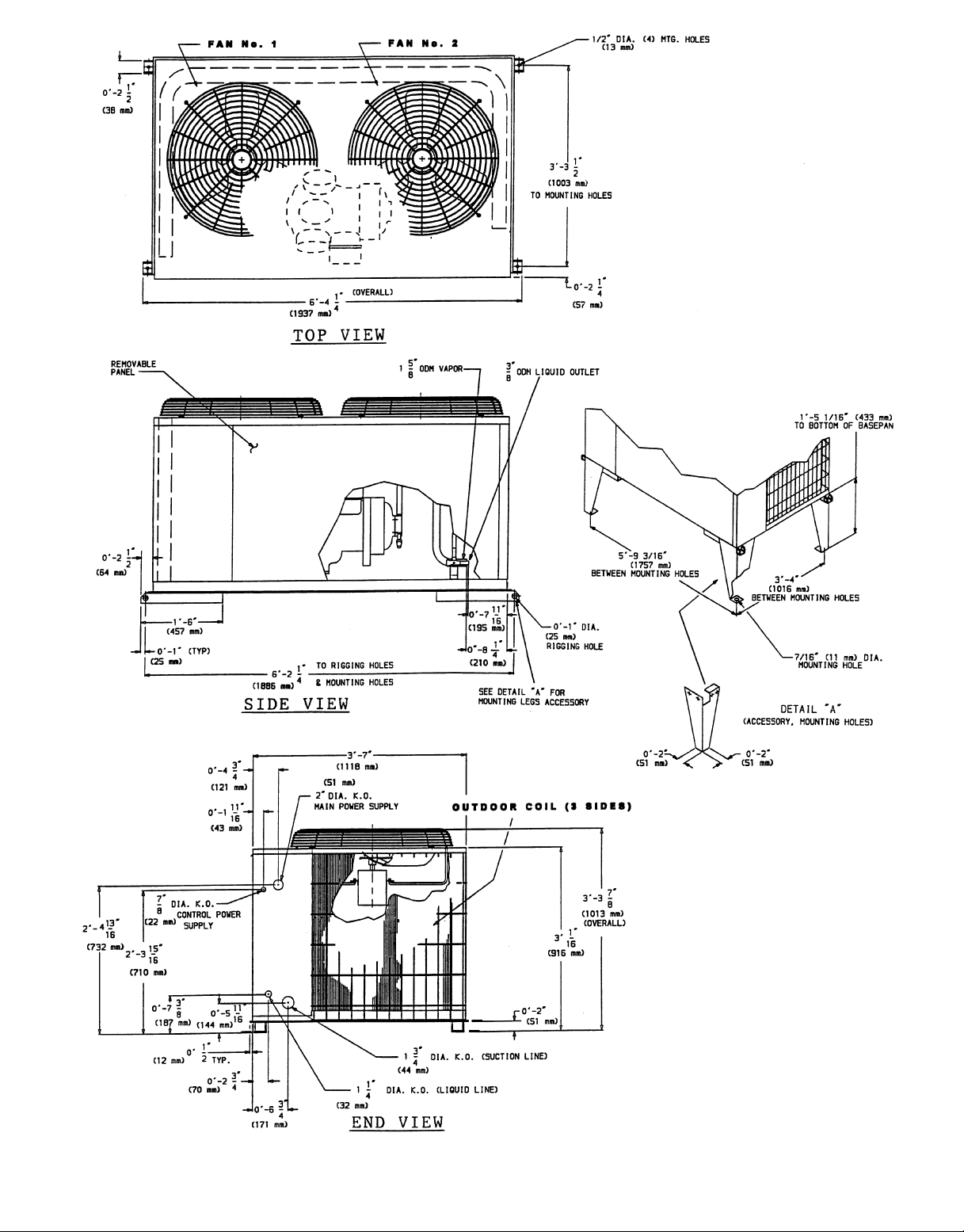

12 3 45 6 78 9101112

13

14

15

28

27

26

1—Defrost Board/Time GuardT II Control

2—Fuse

3—Fan No. 1

4—Signal-LOC™ Device

5—Outdoor-Fan Relay

6—Outdoor-Fan Contactor

7—Compressor Contactor

8—Fan Motor Capacitors

9—Circuit Breaker

10 — Fan No. 2

38 1/4"

2

LEGEND

11 — Power Terminal Block

12 — Control Terminal Block

13 — Compressor Lockout (CLO2 for

Crankcase Heater)

14 — Control Relay (CR3)

15 — Liquid Line Solenoid

16 — Control Relay (CR2)

17 — No Dump Relay (NDR)

18 — Oil Pressure Switch

19 — Fusible Plug (hidden)

Fig. 2 — Component Locations

4

26 11/16"

UNIT

541A

120 750 147 228 228 147

180 803 158 243 244 158

19202122232425

20 — High-Pressure Switch

21 — Compressor

22 — Capacity Control Solenoid

23 — Filter Drier

24 — Muffler

25 — Oil Solenoid

26 — Reversing Valve

27 — Accumulator

28 — Coil

Table2—Weight Distribution

WEIGHT — lb

Total

Operating

Weight

1234

Support Point

(Fig. 3)

16

17

18

541A120, 180

1

3

Fig.3—Weight Distribution

Table 3 — Maximum Vertical Separation*

OUTDOOR

UNIT

541A

INDOOR

UNIT

524A-H

Above Outdoor

DISTANCE — FT

Unit

Indoor Unit

Below Outdoor

Unit

120 120 50 50

180 180 80 80

*Vertical distance between indoor and outdoor units.

—4—

Page 5

Fig. 4 — Compressor Mounting

B. Refrigerant Line Design and Sizing

Consider the length of the piping required between the outdoor and indoor units. The maximum allowable line length is

100 ft. Select proper liquid and vapor line sizes from Table 4.

Contact your local representative if assistance is required for

design details and proper piping practices.

Table 4 — Piping Selection and Refrigerant

Charge Data

OUTDOOR

UNIT

541A

120

180

120 30 38 46 48

180 37 45 59 62

LEGEND

L—Liquid Line

V—Vapor Line

*Approximately 4 elbows assumed in determining pipe sizes.

†Maximum length of interconnecting piping is 100 ft.

**Approximate system charge is for estimating only. It includes charge

requirements for one outdoor unit, matching indoor coil, and interconnecting piping. See Preliminary Charge section on page 10.

NOTE: If there is a vertical separation between indoor and outdoor units,

see Table 3. Double vapor line riser may be required.

LENGTH 0F PIPING — FT*

0-25 25-60 60-100†

Line Size (in. OD)

LVLVLV

5

⁄811⁄

5

⁄813⁄

Approximate System Charge

5

8

⁄813⁄

3

8

⁄415⁄

lb**

8

8

5

⁄815⁄

3

⁄415⁄

8

8

MAXIMUM

LIQUID

LINE OD

(in.)

5

⁄

8

3

⁄

4

Maximum

Charge —

lb

Carefully evaluate any vapor risers at minimum load conditions to ensure proper compressor oil return. If the indoor

unit is above the outdoor unit, the riser will function as a hot

gas riser.If the outdoor unit is above the indoor unit, the riser

is a suction riser. Design and construct a double riser if necessary. Contact your local representative if assistance is

required.

C. Liquid Line Piping Procedure

Pipe the system liquid line as follows:

WARNING:

Unit is pressurized with a holding charge

of refrigerant. Recover R-22 holding charge before removing runaround liquid piping loop. Failure to recover holding charge before removing piping loop could

result in equipment damage and severe injury.

1. Open service valves in sequence:

a. Discharge service valve on compressor.

b. Suction service valve on compressor.

c. Liquid line valve.

2. Remove

1

⁄4-in. flare cap from liquid valve Schrader port.

3. Attach refrigerant recovery device and recover holding

charge.

4. Remove runaround loop.

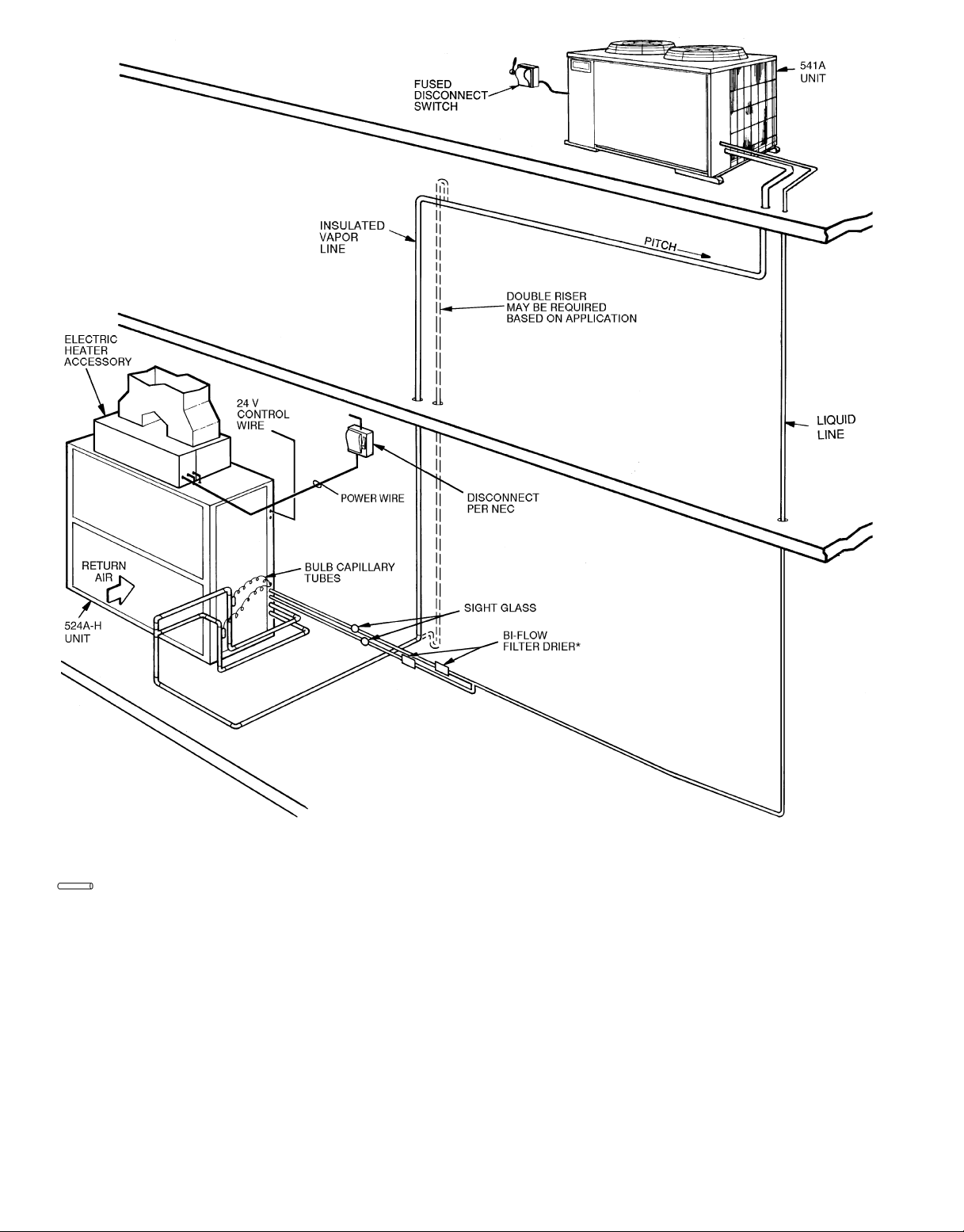

5. Connect system liquid line from liquid connection of outdoor (541A) unit to indoor unit liquid line connections.

See Fig. 5 for typical piping and wiring. Select proper

field-supplied bi-flow filter driers and install in the liquid line. See Fig. 6. Install a field-supplied liquid moisture indicator between the filter drier(s) and the liquid

connections on the indoor (524A-H) unit. Braze or silver

alloy solder all connections. Pass nitrogen or other inert

gas through piping while making connections to prevent formation of copper oxide. (Copper oxides are extremely active under high temperature and pressure.

Failure to prevent collection of copper oxides may result in system component failures.)

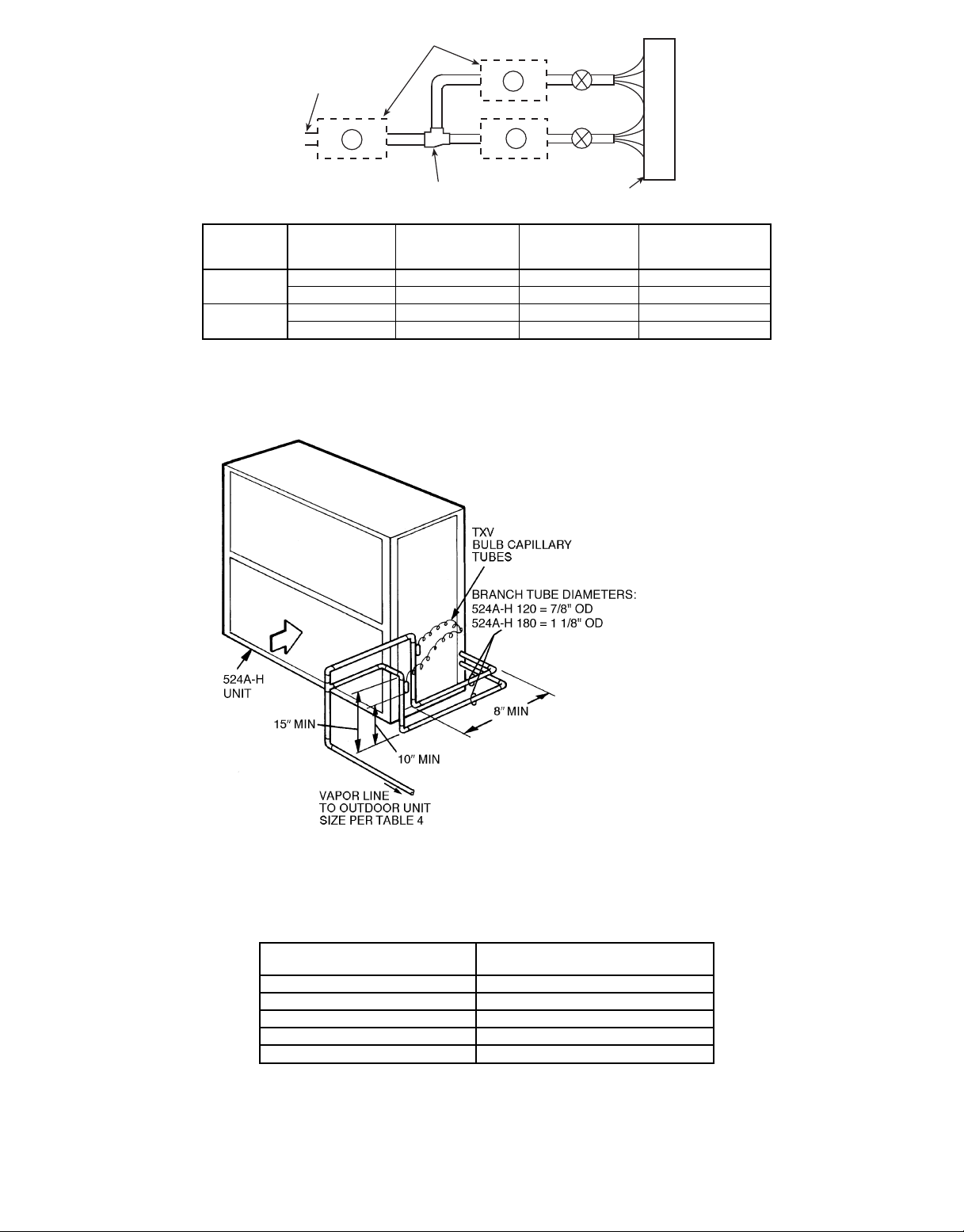

D. Vapor Line Piping Procedure

Connect system vapor line to the vapor line stub on the outdoor unit and the vapor stubs on the indoor unit. At the indoor unit, construct vapor piping branches as shown in Fig. 7

for good mixing of the refrigerant leaving the indoor coil during cooling. This will ensure proper TXV (thermostatic expansion valve) bulb sensing.

Where vapor line is exposed to outdoor air, line must be insulated. See Table 5 for insulation requirements.

—5—

Page 6

LEGEND

NEC — National Electrical Code

TXV — Thermostatic Expansion Valve

*Field supplied.

Piping

NOTES:

1. All piping must follow standard refrigerant piping techniques.

2. All wiring must comply with applicable local and national codes.

3. Wiring and piping shown are general points-of-connection guides

only and are not intended for, or to include, all details for a specific installation.

4. Filter driers must be bi-flow type suited for heat pump duty.

5. Internal factory-supplied TXVs and check valves not shown.

Fig.5—Typical System Piping and Wiring

—6—

Page 7

BI-FLOW FILTER DRIER

LIQUID LINE

TXV

A

B

REDUCING TEE

UNIT

541A

120

180

LIQUID

LINE

SIZE (in.)

1

⁄

2

5

⁄

8

1

⁄

2

5

⁄

8

LEGEND

TXV — Thermostatic Expansion Valve

Fig. 6 — Recommended Filter Driers and Installation Locations

A

INDOOR COIL

PART NO.

QUANTITY

REQUIRED

FIGURE

REFERENCE

P504-8084S 2 A

P504-8165S 1 B

P504-8084S 2 A

P504-8085S 2 A

LEGEND

TXV — Thermostatic Expansion Valve

Fig.7—Vapor Line Branch Piping Details

Table 5 — Insulation for Vapor Line Exposed to Outdoor Conditions

LENGTH OF EXPOSED

VAPOR LINE*

ft in.

10

25

35

50

*Recommended vapor line insulation for piping exposed to outdoor conditions to

prevent loss of heating during heating cycle. When vapor line goes through interior spaces, insulation should be selected to prevent condensation on cooling cycle.

Heating capacity should be reduced 1000 Btuh if over 35 ft of vapor line with

3

⁄4in. insulation is exposed to outdoor conditions.

†Closed cell foam insulation with a thermal conductivity of:

0.28 Btu • in/ft2•h•°F.

INSULATION THICKNESS†

3

⁄

8

1

⁄

2

3

⁄

4

3

⁄

4

—7—

Page 8

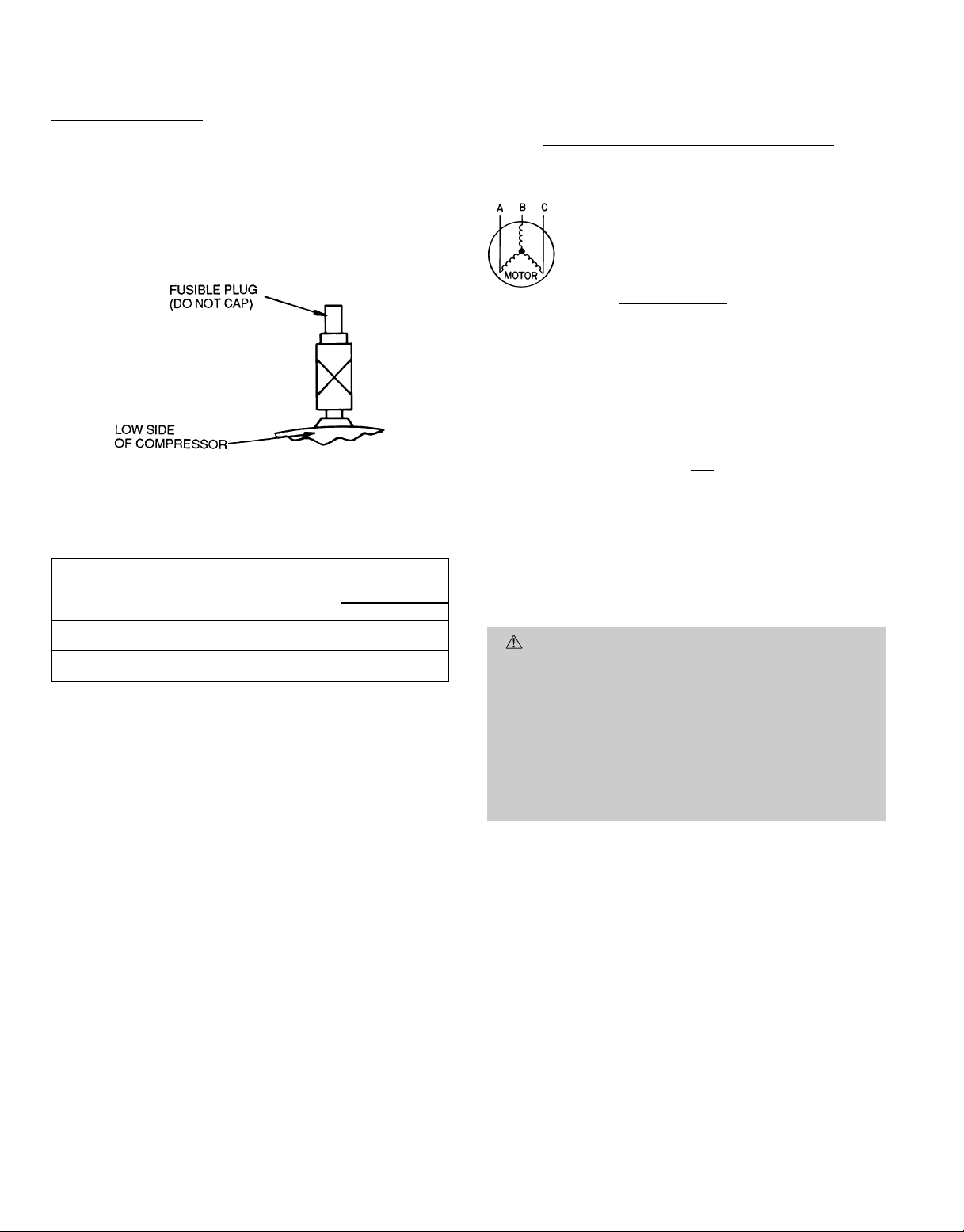

E. Provide Safety Relief

A fusible plug is located on the compressor crankcase

(Fig. 8). Do not cap this plug. If local code requires additional

safety devices, install as directed.

Head Pressure Control

Fan cycling for head pressure control is a standard offering

but is functional on the cooling cycle only. Number 2 fan cycles

as a function of liquid pressure. Fan cycling pressure switch

cycles the fan off at 160 ± 10 psig as pressure decreases and

cycles back on at 255 ± 10 psig. Switch is automatically bypassed in heating cycle. Table 6 shows minimum outdoor ambient air temperature for full cooling capacity.

C. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply

voltage is greater than 2%. Use the following formula to determine the percentage of voltage imbalance:

% Voltage Imbalance:

= 100 x

max voltage deviation from average voltage

average voltage

EXAMPLE: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Fig. 8 — Location of Fusible Plug

Table 6 — Minimum Outdoor Air

Operating Temperature

UNIT

541A

120

180

*Applies to Cooling mode of operation only.

%

COMPRESSOR

CAPACITY

100 90 35

67 80 45

100 90 23

67 80 36

OUTDOOR COIL

TEMP — F

MINIMUM

OUTDOOR

TEMP — F*

Standard Unit

IV. STEP 4 — COMPLETE ELECTRICAL CONNECTIONS

A. Power Supply

Electrical characteristics of available power supply must agree

with nameplate rating. Supply voltage must be within tolerances shown in Table 7. Phase unbalance must not exceed

2%. Operation of unit on improper supply voltage or with ex-

cessive phase imbalance constitutes abuse and is not covered

by warranty.

Per local code requirements, provide an adequate fused disconnect switch within sight of unit and out of reach of children. Provision for locking switch open (off) is advisable to

prevent power from being turned on while unit is being serviced. The disconnect switch, fuses, and field wiring must comply with local requirements. Refer to Table 7 for electrical

data. Route power wiring through entrance in right-hand corner post of unit. The power terminal block is sized to handle

either copper or aluminum wires. Unit must be grounded. Affix crankcase heater warning sticker to unit disconnect switch.

B. Power Wiring

All power wiring must comply with applicable local requirements. Install a field-supplied branch circuit disconnect switch

that can be locked off or open. Run power wires from disconnect switch through unit power opening and connect to terminal block inside the unit control box. See Fig. 9.

Average Voltage =

452 + 464 + 455

3

= 457 v

Determine maximum deviation from average voltage:

(AB) 457 − 452 = 5 v

(BC) 464 − 457 = 7 v

(AC) 457 − 455 = 2 v

Maximum deviation is 7 v. Determine percentage of voltage

imbalance:

% Voltage Imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is

below the maximum allowable of 2%.

IMPORTANT: Contact your local electric utility company

immediately if the supply voltage phase imbalance is more

than 2%.

WARNING:

Unit cabinet must have an uninterrupted,

unbroken electrical ground to minimize the possibility

of personal injury if an electrical fault should occur.This

ground may consist of electrical wire connected to unit

ground lug in control compartment, or conduit approved for electrical ground when installed in accordance with NEC (National Electrical Code), ANSI/

NFPA(AmericanNational Standards Institute/National

Fire Protection Association), and local electrical codes.

Failure to follow this warning could result in the

installer being liable for personal injury of others.

IMPORTANT: Operation of unit on improper power supply voltage or with excessive phase imbalance constitutes abuse and

is not covered by Bryant warranty.

D. General Wiring Notes

1. A crankcase heater is wired in the control circuit so it is

always operable as long as power supply disconnect is

on, even if any safety device is open or unit stop/start

switch is off.

2. The power-circuit field supply disconnect should never

be open except when unit is being serviced or is to

be down for a prolonged period. When operation is

resumed, crankcase heater should be energized for 24 hours

before start-up. If system is to be shut down for a prolonged period, it is recommended that the suction and

discharge valves be closed to prevent an excessive

accumulation of refrigerant in the compressor oil.

3. Terminalsfor field power supply are suitable for copper,

copper-clad aluminum, or aluminum conductors.

—8—

Page 9

TERMINAL BOARD (TB1) IN

UNIT CONTROL BOX

21

22

23

EQUIP GND

11

12

13

LEGEND

CAP — Capacitor

EQUIP — Equipment

GND — Ground

NEC — National Electrical Code

Field Wiring

Factory Wiring

Fig. 9 — Main Power Supply Wiring

Table 7 — Electrical Data (3 Ph/60 Hz)

UNIT COMPRESSOR FAN MOTORS (Single-Phase)

541A

120

180

FLA — Full Load Amps (fan motors)

ICF — Maximum Instantaneous Current Flow during start-up

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps per NEC Section 430-24

MOCP — Maximum Overcurrent Protection (fuse only)

RLA — Rated Load Amps (compressor)

Model

501 208-230 187 253 62.5 178 100 43.6 170

601 460 414 528 29.1 81 40 20.0 77 2.3 1.9

501 208-230 187 253 87.5 274 125 63.6 266

601 460 414 528 40.7 124 60 29.3 120 2.3 1.9

Name-

plate

(LRA of compressor plus total FLA of fan motors)

Volts

Supplied*

MCA ICF

Min Max 12

LEGEND

DISCONNECT PER NEC

OR LOCAL CODE

MOCP

(Amps)

Fuse Only

RLA LRA

Total

Fans

2

2

*Units are suitable for use on electrical systems where voltage supplied

to the unit terminals is not below or above the listed limits.

NOTES:

1. MCA and MOCP values are calculated in accordance with NEC

(National Electric Code), Article 440.

2. Motor RLA and FLA values are established in accordance with

UL (Underwriters’ Laboratories) Standard 1995.

FLA (ea)

Fan No.

4.3 3.7

4.3 3.7

—9—

Page 10

E. Control Circuit Wiring

Unit internal control circuit voltage is 24 volts. See Table 8

for recommended thermostats. Connect thermostat assembly

and other accessories as shown in unit label diagram and

Fig. 10. Refer to installation instructions shipped with indoor unit. See Fig. 11 for field-supplied airflow switch wiring

if airflow switch is used. The control wiring entrance is located on right corner post of 541A unit. See Fig. 1. Wiring

connects to a terminal block located at extreme right of control box.

Transformers no. 1 and 2 are wired for a 230-v unit. If a 208/

230-v unit is to be run with a 208-v power supply, the transformers must be rewired as follows:

1. Remove cap from red (208 v) wire.

2. Remove cap from orange (230 v) spliced wire.

3. Replace orange wire with red wire.

4. Recap both wires.

IMPORTANT: BE CERTAIN UNUSED WIRES ARE CAPPED.

Failure to do so may damage the transformer.

Route thermostat cable or equivalent single leads of no. 18 AWG

(American Wire Gage) colored wire from subbase terminals

through conduit in unit to low-voltage connections as shown

on unit wiring diagram and Fig. 10.

NOTE: For wire runs up to 50 ft, use no. 18 AWG insulated

wire (35 C minimum). For 51 to 75 ft, use no. 16 AWG insulated wire (35 C minimum). For over 75 ft, use no. 14 AWG

insulated wire (35 C minimum).All wire larger than no. 18AWG

cannot be directly connected to the thermostat and will require a junction box and a splice at the thermostat.

F. Electric Resistance Crankcase Heater

The crankcase heater is inserted into the compressor crankcase. The crankcase heater is operated from the normally closed

contacts of the control relay (CR1) and is automatically

energized when compressor stops. This heater keeps crankcase warm to prevent oil dilution by refrigerant, ensures good

lubrication, and minimizes loss of oil during start-up.

G. Airflow Switch

Bryant recommends an indoor airflow switch (field supplied)

be installed and interlocked with the outdoor unit. This prevents the outdoor unit from operating if indoor airflow fails

(broken fan belt, etc.). Operation of the compressor in vacuum

can damage bearing surfaces. Install indoor airflow switch in

a convenient location at the indoor supply air duct and wire

per Fig. 11.

PRE-START-UP

IMPORTANT: Before beginning Pre-Start-Up or Start-Up, re-

view Start-Up Checklist at the back of this book. The checklist assures proper start-up of the system and provides a record

of unit condition, application requirements, system information, and operation at initial start-up.

CAUTION:

system, even momentarily,until the following steps have

been completed. Compressor damage may result.

I. SYSTEM CHECK

1. Check all air handler and other equipment auxiliary

components. If unit has field-installed accessories, be

sure all are properly installed and correctly wired. If

used, airflow switch must be properly installed. See

Fig. 11.

Do not attempt to start the heat pump

2. Backseat (open) compressor suction and discharge valves.

Now close valves one turn to allow refrigerant pressure to reach test gages.

3. Open liquid line service valve.

4. Check tightness of all electrical connections.

5. Compressor oil level should be visible in sight glass.

Adjust the oil level as required. No oil should be

removed unless the crankcase heater has been energized for at least 24 hours. See Start-Up section, Preliminary Oil Charge on page 12.

6. Be sure unit is properly leak checked, dehydrated, and

charged. See Preliminary Charge, this page.

7. Electrical power source must agree with nameplate

rating.

8. Crankcase heater must be firmly locked into compres-

sor crankcase. Be sure crankcase is warm (heater must

be on for 24 hours before starting compressor).

9. Be sure compressor floats freely on the mounting springs

and that upper flat washers can be moved with finger pressure. See Compressor Mounting, page 2, and

Fig. 4 for loosening compressor bolts.

II. LEAK TEST AND DEHYDRATION

Leak test the entire refrigerant system using soap bubbles

and/or an electronic leak detector. Evacuate and dehydrate

entire refrigerant system by use of methods described in

GTAC II, Module 4, System Dehydration.

III. TURN ON CRANKCASE HEATER

Turnon crankcase heater for 24 hours before starting the unit

to be sure all refrigerant is out of the oil. To energize crankcase heater, perform the following steps:

1. Set the space thermostat system switch to OFF, or adjust the temperature so there is no demand for cooling.

2. Close the field disconnect.

3. Leave the compressor circuit breaker off. The crankcase

heater is now energized.

IV. PRELIMINARY CHARGE

Refer to GTAC II, Module 5, Charging, Recovery, Recycling,

and Reclamation for charging methods and procedures. Charge

with R-22 by the liquid charging method (through liquid service valve) on the high side. See approximate refrigerant charge

in Table 4. Charge according to the values in the Charging

Chart, Fig. 12 and 13, page 14.

V. THERMOSTAT ANTICIPATOR ADJUSTMENT

A. Heating/Cooling Thermostat (HH621606)

The thermostat has an adjustable heat anticipator for both

first- and second-stage heating circuits.

B. Settings

Set adjustment lever for first-stage anticipator at 0.79 (lefthand side). Set adjustment lever for second-stage anticipator

(right-hand side) at 0.42.

C. Outdoor Thermostat

Refer to 524A-H accessory heater installation instructions for

details of this thermostat (if used).

—10—

Page 11

Table 8 — Recommended Thermostat

THERMOSTAT NO. HH621606 (°F)

SUBBASE NO. HH93AZ174*

Type Standard

Display — °F

2 Cooling Stages X

2 Heating Stages X

Auto Changeover X

Fan Switch X*

Emergency Heat X

*Subbase has ON-AUTO fan switch. Use emergency heat relay part no. HN65DZ026.

Fig. 10 — Field Wiring Diagram, 541A120 or 180 System with

Standard Thermostat and Electric Heat

—11—

LEGEND

EQUIP — Equipment

GND — Ground

HC — Heater Contactor

IFC — Indoor Fan Contactor

IFM — Indoor Fan Motor

NEC — National Electrical Code

TB — Terminal Block

Page 12

LEGEND

AFS — Airflow Switch (Sail Switch)

DB — Defrost Board

HR — Heat Relay

NOTES:

1. LocateYEL wire between on DB and terminal 5 of HR and cut.

2. Splice airflow switch (AFS) (field supplied) contact wires (field pro-

Factory Wiring

Field Wiring

Y

vided) to two ends of cut YEL wire as depicted.

Fig. 11 — Field Wiring for Airflow Switch —

541A120,180/524A-H

START-UP

Compressor crankcase heater must be on for 24 hours

before start-up. To energize the crankcase heater,set the space

thermostat above the ambient temperature so there is no

demand for cooling. Close the field disconnect. Leave the compressor circuit breaker off/open. The crankcase heater is now

energized.

After the heater has been on for 24 hours, the unit can be

started. If no time has elapsed since the preliminary charge

step was completed, it is unnecessary to wait the 24-hour

period.

NOTE: Use only approved compressor oil. Approved sources

are:

Petroleum Specialties Inc. ..................Cryol 150A

Texaco, Inc. ...........................Capella WF-32

Witco Chemical Co. .......................Suniso 3GS

Do not use oil that has been drained out, or oil that has been

exposed to atmosphere.

B. Remove Oil

1

Pump down compressor to 2 psig. Loosen the

⁄4-in. pipe plug

at the compressor base and allow the oil to seep out past the

threads of the plug. Retighten plug when level is correct.

NOTE: The crankcase is slightly pressurized. Do not

remove the plug, or the entire oil charge will be lost.

Small amounts of oil can be removed through the oil pump

discharge connection while the compressor is running.

III. START UNIT

Close the field disconnect and set the space thermostats above

ambient temperature so that there is no demand for cooling.

Only the crankcase heaters will be energized.

Next, close the compressor circuit breakers. Place thermostat selector switch at COOL and set space set point below

ambient temperature so that a call for cooling is ensured. If

compressor does not start, set thermostat lower.

NOTE: Do not use circuit breaker to start and stop the compressor except in an emergency.

CAUTION:

Never charge liquid into the low-pressure

side of system. Do not overcharge. During charging or

removal of refrigerant, be sure indoor-fan system is

operating.

I. PRELIMINARY CHECKS

1. Ensure that compressor service valves are backseated.

2. Verify that the compressor floats freely on its mounting

springs.

3. Check that electric power supply agrees with unit nameplate data.

4. Verify that compressor crankcase heater is securely in

place.

5. Check that compressor crankcase heater has been on at

least 24 hours.

6. Check to see if compressor oil level is visible in the sight

glass. If oil level adjustment is required, see the following Preliminary Oil Charge section.

7. Recheck for leaks using same procedure as previously

outlined in Pre-Start-Up section, Leak Test and Dehydration, page 10.

8. If any leaks are detected, evacuate and dehydrate as previously outlined in Pre-Start-Up section, Leak Test and

Dehydration, page 10.

II. PRELIMINARY OIL CHARGE

The compressor is factory charged with oil (see Table1). When

oil is checked at start-up, it may be necessary to add or remove oil to bring it to the proper level. One recommended oil

level adjustment method is as follows:

A. Add Oil

Close suction service valve and pump down crankcase to

2 psig. Wait a few minutes and repeat until pressure remains steady at 2 psig. Remove oil fill plug above the sight

glass, add oil through plug hole, and replace plug. Run compressor for 20 minutes and check oil level.

IV. ADJUST REFRIGERANT CHARGE

NOTE: The remaining start-up procedures and all refriger-

ant charge modifications should be done only under supervision of a qualified refrigeration mechanic.

Withall fans operating, and compressor operating fully loaded,

adjust the refrigerant charge in accordance with the unit charging charts located on the inside of the control box doors and

in Fig. 12 and 13.

CAUTION:

Charge unit on cooling cycle only. If unit

is charged on heating cycle, overcharging may occur.

1. Be sure to use Refrigerant-22.

2. Regulate refrigerant drum valve to maintain suction pressure at 80 psig while charging. Charge with vapor only,

at suction side of unit.

NOTE: Do not depend on sight glass when charging unit. Use

charging chart.

Allow system to operate for 20 minutes. Take temperature

and pressure readings at liquid line service valve and check

values with the charging chart.

Plot point on charging chart. If point is above curve, add charge.

If point is below curve, reduce charge until point falls on line.

Record the final refrigerant charge.

If the sight glass is cloudy, check refrigerant charge again.

Ensure all fans are operating. Also ensure maximum allowable liquid lift has not been exceeded. If charged per chart

and if the sight glass is still cloudy, check for a plugged filter

drier or a partially closed solenoid valve. Replace or repair,

as needed.

—12—

Page 13

V. CHECK HEATING CYCLE OPERATION

Place thermostat selector switch at HEATand reset the space

set point above ambient temperature so that a call for heating is ensured. Compressor will start within 5 minutes. Observe system operation.

VI. CHECK COMPRESSOR OIL LEVEL

After adjusting the refrigerant charge, allow the system to

run fully loaded for 20 minutes. Running oil level should be

within view in the crankcase sight glass. Stop the compressor at the field power supply disconnect and check the crankcase oil level. Add oil only if necessary to bring the oil into

view in the sight glass. If oil is added, run the system for an

additional 10 minutes, then stop and check oil level. If the

level remains low, check the piping system for proper design

for oil return; also check the system for leaks.

If the initial check shows too much oil (too high in the sight

glass) remove oil to proper level. See Preliminary Oil Charge,

page 12, for proper procedure for adding and removing oil.

When the above checks are complete, repeat the procedure

with the unit operating at minimum load conditions.

Unload the compressor by disconnecting the field-control

circuit lead at TB2 .

Reconnect the field-control circuit lead when checks are

complete.

VII. FINAL CHECKS

Ensure all safety controls are operating, control panel covers

are on, and the service panels are in place.

VIII. SEQUENCE OF OPERATION

A. Heating

Place thermostat selector at HEAT and set temperature selector above room ambient.

B. Cooling

Place thermostat selector at COOL and set temperature selector below room ambient.

When thermostat calls for unit operation (either heating or

cooling), the indoor-fan motor starts immediately.The outdoorfan motors and compressor start within 3 seconds to 5 minutes depending on when unit was last shut off by thermostat,

because unit contains a Time Guardt circuit. When firststage cooling is required, thermostat (TC1) closes, causing the

heat pump to start with an unloaded compressor. When TC2

closes, demanding additional cooling, the compressor loads

to full load operation.

During heating, compressor is always fully loaded. When TH1

demands first-stage heating, the heat pump starts within

3 seconds to 5 minutes depending on when unit was last

shut off by thermostat, because unit contains a Time Guard

circuit. (The defrost board has speed terminals to shorten this

cycle.) When TH2 of the thermostat closes, auxiliary heat supply (electric strip heat) is energized in 1 or 2 stages depending on number of stages available and whether outdoor thermostats are closed.

Defrost is achieved by reversal from heating to cooling cycle

and deenergization of outdoor-fan motors, allowing hot refrigerant gas to defrost outdoor coil. Defrost is achieved with

a timer set to initiate defrost every 30, 50 or 90 minutes (factory set at 30 minutes).

Defrost is initiated when refrigerant temperature leaving the

outdoor coil is measured below 27 F, (typically when the outdoor ambient temperature is below 45 F as sensed by the defrost thermostat [DFT]).

Y2

Defrost is terminated when: The refrigerant temperature rises

to 65 F (80 F for 541A180) at the DFT location on the liquid

line; or the refrigerant pressure rises to 280 psig at the HPS2

location on the liquid line; or the defrost timer completes the

10-minute cycle.

Malfunction

The high-pressure switch, loss-of-charge switch, oil pressure

safety switch, and compressor overtemperature safety are located in a Signal-LOC™ circuit that prevents heat pump operation if these safety devices are activated. A light at the

thermostat energizes when Signal-LOC circuit is affected.The

lockout system can be reset by adjusting the thermostat to

open the contacts (down for Heating mode, up for Cooling mode),

deenergizing the Signal-LOC circuitry. Compressor overcurrent protection is achieved with a circuit breaker which requires manual resetting at the outdoor unit control box.

The unit is equipped with an oil pressure safety switch that

protects the compressor if oil pressure does not develop on

start-up or is lost during operation. The oil pressure switch

is of the manual reset type and therefore must be reset at

the outdoor unit. DO NOT RESET MORE THAN ONCE.

If oil pressure switch trips, determine cause and correct. DO

NOT JUMPER OIL PRESSURE SAFETY SWITCH.

To reset the oil pressure switch:

1. Disconnect power to the unit.

2. Press the RESET button on the oil pressure switch.

3. Reconnect power to the unit.

Unit is equipped with a no-dump reversing valve circuit. When

unit is in Cooling mode, reversing valve remains in cooling

position until a call for heating is requested by thermostat.

When unit is in Heating mode, reversing valve remains in

heating position until there is a call for cooling.

The crankcase heater is in a lockout circuit. If crankcase heater

is defective, compressor is locked off. Heat pump remains off

until corrective action is taken. The lockout circuit cannot be

reactivated by adjusting the thermostat. To reset the crankcase heater lockout, disconnect and then reconnect power to

unit.

C. Liquid Line Solenoid

To minimize refrigerant migration to the compressor during

the heat pump OFF cycle, the unit features a bi-flow liquid

line solenoid valve. The valve opens when the compressor is

energized, and closes when the compressor is deenergized. This

feature reduces compressor flooded starts, significantly increasing compressor life.

D. Accumulator

The unit accumulator controls the rate of liquid refrigerant

to the compressor during heat pump operation. The accumulator features a unique method for returning oil to the compressor.The oil return mechanism is external to the accumulator. The mixture of oil and refrigerant is metered to the

compressor by a brass orifice which is removable and cleanable. The oil return mechanism also contains a solenoid valve

that opens when the compressor is ON and closes when the

compressor is OFF. This keeps the liquid refrigerant stored

in the accumulator from draining to the compressor during

the heat pump OFF cycle, which further protects the compressor against flooded starts.

—13—

Page 14

Fig. 12 — Cooling Cycle Charging Chart,

541A120

shutdown is caused by manual reset devices (including OPS

[oil pressure switch] and compressor circuit breaker protection). To restart the unit when IP, HPS, or LCS has tripped

(after device has reset automatically), open and then close the

thermostat contacts. Opening and then closing thermostat contacts interrupts and restores 24-v power to the compressor

lockout (CLO), which resets the circuit.

It is necessary to manually reset the compressor circuit breaker

and OPS at the unit if either of these safeties should shut

down the unit.

IMPORTANT: If OPS trips, it must be reset first before mak-

ing and breaking the thermostat contacts to reset CLO. If this

procedure is not followed, the CLO cannot reset.

X. CAUSES OF COMPLETE UNIT SHUTDOWN:

• interruption of supplied power

• open compressor overtemperature protection (IP)

• compressor electrical overload protection (CB)

• open high-pressure or loss-of-charge safety switches

• open oil pressure switch

• open crankcase heater lockout (CLO2)

• open control circuit fuse (FU1 or FU2)

SERVICE

I. COMPRESSOR REMOVAL

See Table 1 for compressor information and Fig. 2 for component location. Follow safety codes and wear safety glasses

and work gloves.

1. Shut off power to unit. Remove unit access panel (front

of unit).

2. Recover refrigerant from system using refrigerant

recovery methods described in Training booklet GTAC

II, Module 5, and in accordance with local and national standards.

3. Disconnect compressor wiring at compressor terminal

box.

4. Remove bolts from suction and discharge service valves.

5. Remove 2 bolts and 2 screws from compressor mounting plate.

Fig. 13 — Cooling Cycle Charging Chart,

541A180

E. Oil Charge (Table 1)

Allow unit to run for about 20 minutes. Stop unit and check

compressor oil level. Add oil only if necessary to bring oil into

view in sight glass. Refer to Preliminary Oil Charge section

on page 12. Use only approved compressor oil.

F. Check Operation

Ensure operation of all safety controls. Replace all service panels. Be sure that control panel cover is closed tightly.

IX. RESTART

Manual reset of the 24-v control circuit is necessary if unit

shutdown is caused by automatic reset devices (including IP

[internal compressor overcurrent protection], HPS [highpressure switch], and LCS [loss-of-charge switch]) or if

—14—

CAUTION:

compressor may cause higher levels of vibration when

unit is restored to service.

6. Remove crankcase heater from compressor base.

7. Remove compressor from unit.

8. Remove compressor holddown bolts and lift compressor off mounting plate.

9. Clean system. Add new liquid line filter drier.

10. Install new compressor on compressor mounting plate

and position in unit. Connect suction and discharge lines

to compressor.Secure mounting plate with compressor

to unit. Ensure that compressor holddown bolts are in

place. Connect wiring. Install crankcase heater.

11. Evacuate and recharge unit.

12. Restore unit power.

Excessive movement of copper lines at

Page 15

II. CRANKCASE HEATER

The crankcase heater prevents refrigerant migration and compressor oil dilution during shutdown when compressor is not

operating.

Close both compressor service valves when crankcase heater

is deenergized for more than 6 hours.

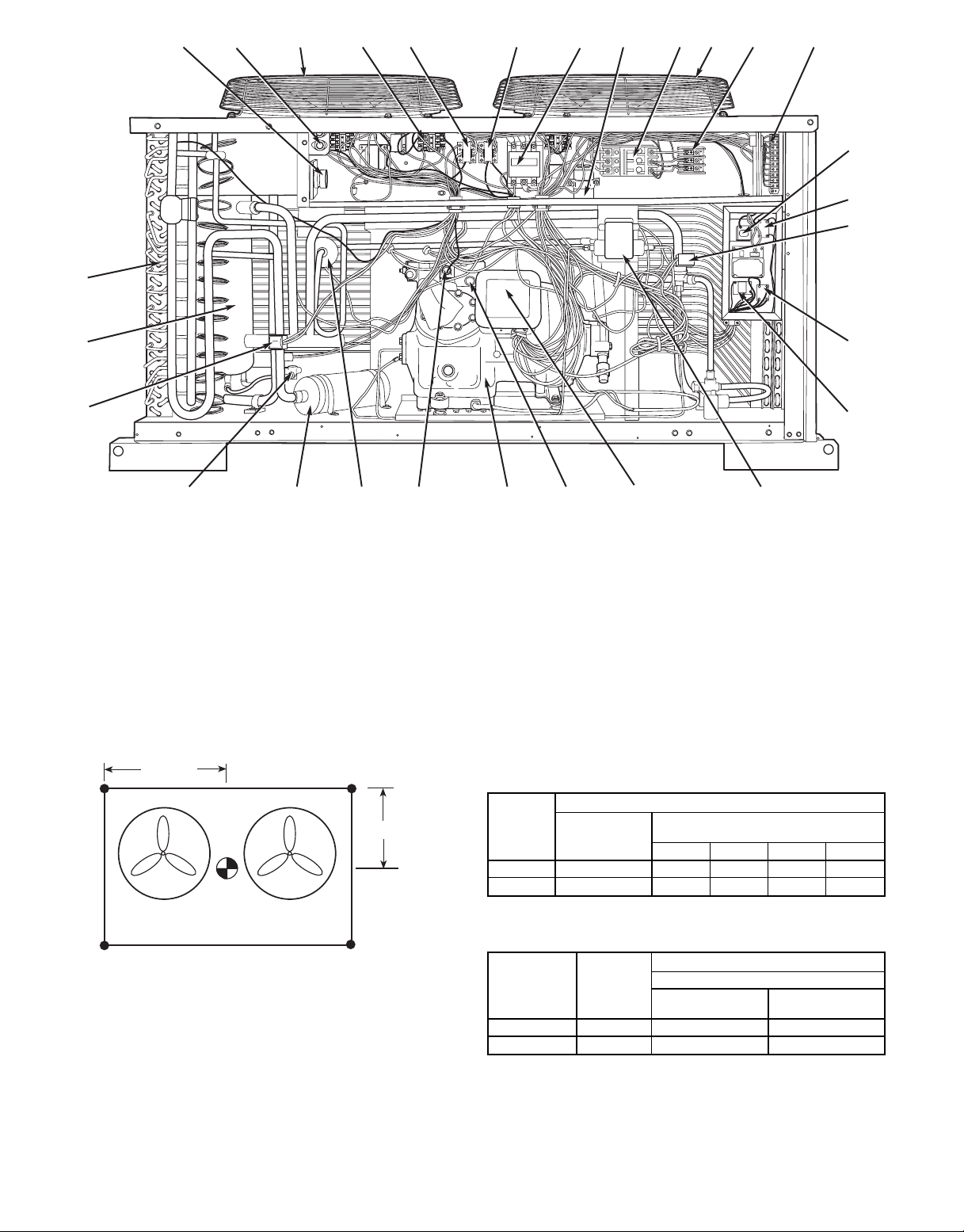

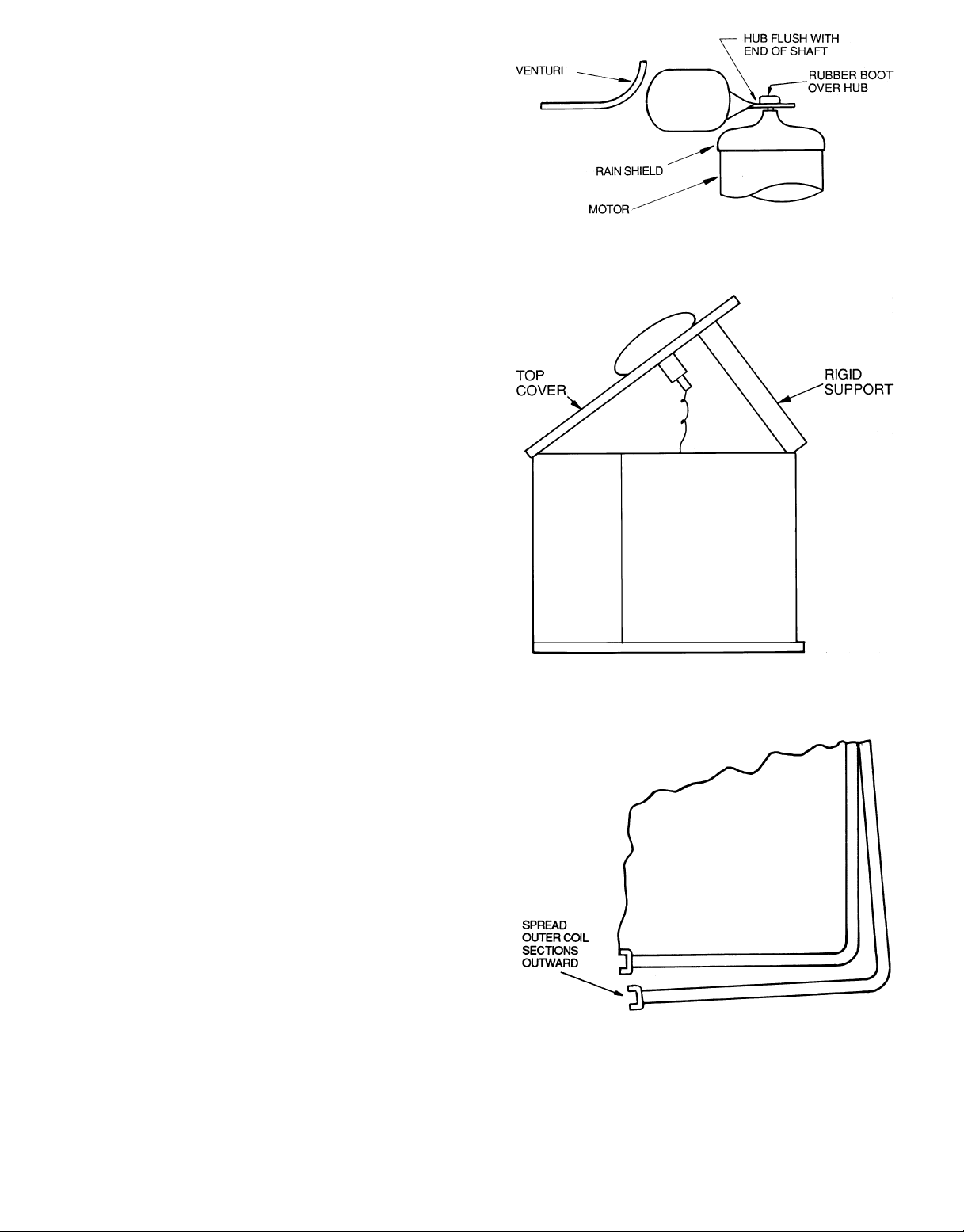

III. OUTDOOR UNIT FANS

Each fan is supported by a formed-wire mount bolted to the

fan deck and covered with a wire guard. The exposed end of

the motor shaft is covered with a rubber boot. In case a fan

motor must be repaired or replaced, be sure the rubber boot

is put back on when the fan is reinstalled and be sure the fan

guard is in place before starting the unit. Figure 14 shows

the proper position of the mounted fan.

IV. LUBRICATION

A. Fan Motors

Fan motors have permanently sealed bearings. No further lubrication is required.

B. Compressor

Compressor has its own oil supply. Loss of oil due to a leak in

the system should be the only reason for adding oil after the

system has been in operation. See Start-Up, Preliminary Oil

Charge.

Fig. 14 — Outdoor Unit Fan

V. CLEANING COILS

The coils can be cleaned with a vacuum cleaner, washed out

with low velocity water, blown out with compressed air, or

brushed (do not use wire brush). Fan motors are dripproof

but not waterproof. Do not use acid cleaners.

Clean coil annually or as required by location or outdoor air

conditions. Inspect coil monthly and clean as required. Fins

are not continuous through coil sections. Dirt and debris may

pass through first section, become trapped between the 2 rows

of fins (541A120) or 3 rows of fins (541A180), and restrict condenser airflow. Use a flashlight to determine if dirt or debris

has collected between coil sections.

Clean coils as follows:

1. Turn off unit power.

2. Remove screws holding rear corner posts and top cover

in place. Pivot top cover up 12 to 18 in. and support with

a board or other adequate rigid support. See Fig. 15.

3. Remove clips securing tube sheets together at the returnbend end of the coil. Carefully spread the ends of

the coil rows apart by moving the outer sections. See

Fig. 16.

4. Using a water hose or other suitable equipment, flush

down between the sections of coil to remove dirt and

debris.

5. Clean the remaining surfaces in the normal manner.

6. Reposition outer coil sections. Reinstall clips which secure tube sheets, and replace top cover and rear corner

posts.

7. Restore unit power.

Fig. 15 — Pivot and Support Top Cover

Fig. 16 — Coil Cleaning (541A120 Shown)

—15—

Page 16

—16—

TROUBLESHOOTING CHART — HEATING CYCLE

LEGEND

CCH — Crankcase Heater

N.C. — Normally Closed

NOTE: See Fig. 17 for diagram showing

heating cycle operation.

Page 17

—17—

TROUBLESHOOTING CHART — COOLING CYCLE

LEGEND

CCH — Crankcase Heater

TXV — Thermostatic Expansion Valve

NOTE: See Fig. 18 for diagram showing cooling cycle operation.

Page 18

1. Hotgas from compressor flows through the reversing (4-way) valve

and is directed to the indoor coil header.At the header refrigerant

is directed to the indoor coil where it is condensed and subcooled

and then exits through the indoor coil check valve to the liquid

line. (The TXVs stop the refrigerant flow during the heating cycle.)

2. The refrigerant then feeds the outdoor coil by way of filter-drier, a

distribution manifold, and then through capillary tubes on each

circuit.

LEGEND

TXV — Thermostatic Expansion Valve

NOTES:

1. Check valves are designated ‘‘A’’ through ‘‘D.’’

2. Illustrations are typical and do not portray exact coil circuiting.

3. Check valve positions: open, closed.

Fig. 17 — Typical Heat Pump Heating Operation Schematic

(541A120 Shown)

3. Eachcircuit evaporates the refrigerant and all the circuits are combined in the outdoor header (with some of the circuits flowing through

the check valve ‘‘A’’).

4. The refrigerant then flows through the reversing (4-way) valve,

accumulator and back to the compressor.

—18—

Page 19

1. Hotgas from compressor flows through the reversing (4-way) valve

and is directed to the outdoor coil header.At the outdoor coil it is

condensed and subcooled through converging circuits.

2. Checkvalve ‘‘A’’ directs all hot gas flow into circuits in bottom face

of outdoor coil. Refrigerant condenses in these circuits and then

exits into an intermediary collection header.

3. Refrigerant is directed from intermediary header to circuits in

upper face where further condensing is accomplished.

4. Refrigerant exits upper coil section into the top half of the vapor

header (above check valve ‘‘A’’) and is then redirected to a final

(subcooling) pass in center of coil face (120) or exits header via

outlet tube (180).

LEGEND

TXV — Thermostatic Expansion Valve

NOTES:

1. Check valves are designated ‘‘A’’ through ‘‘D.’’

2. Illustrations are typical and do not portray exact coil circuiting.

3. Check valve positions: open, closed.

Fig. 18 — Typical Heat Pump Cooling Operation Schematic

(541A120 Shown)

5. Refrigerant leaves the outdoor coil by way of check valve ‘‘B’’ to

the liquid line.

6. The refrigerant then flows through the filter drier and feeds the

indoor coil by way of the TXV and feeder valves.

7. Each circuit evaporates the refrigerant and the circuits are combined in the indoor coil header.

8. The refrigerant then flows through the reversing (4-way) valve,

accumulator and back to the compressor.

—19—

Page 20

Page 21

Page 22

Copyright 1998 Bryant Heating & Cooling Systems CATALOG NO. 5354-100

Page 23

START-UP CHECKLIST

A. Preliminary Information

OUTDOOR UNIT: MODEL NO.

INDOOR UNIT: MODEL NO.

ADDITIONAL ACCESSORIES

SERIAL NO.:

SERIAL NO.:

B. Pre-Start-Up

OUTDOOR UNIT

IS THERE ANY SHIPPING DAMAGE? (Y/N)

IF SO, WHERE:

WILL THIS DAMAGE PREVENT UNIT START-UP? (Y/N)

CHECK POWER SUPPLY. DOES IT AGREE WITH UNIT? (Y/N)

HAS THE GROUND WIRE BEEN CONNECTED? (Y/N)

HAS THE CIRCUIT PROTECTION BEEN SIZED AND INSTALLED PROPERLY? (Y/N)

ARE THE POWER WIRES TO THE UNIT SIZED AND INSTALLED PROPERLY? (Y/N)

HAVE COMPRESSOR HOLDDOWN BOLTS BEEN LOOSENED (Snubber washers are snug, but not tight)?

(Y/N)

CONTROLS

ARE THERMOSTAT AND INDOOR FAN CONTROL WIRING

CONNECTIONS MADE AND CHECKED? (Y/N)

ARE ALL WIRING TERMINALS (including main power supply) TIGHT? (Y/N)

HAS CRANKCASE HEATER BEEN ENERGIZED FOR 24 HOURS? (Y/N)

INDOOR UNIT

HAS WATER BEEN PLACED IN DRAIN PAN TO CONFIRM PROPER DRAINAGE? (Y/N)

ARE PROPER AIR FILTERS IN PLACE? (Y/N)

HAVE FAN AND MOTOR PULLEYS BEEN CHECKED FOR PROPER ALIGNMENT? (Y/N)

DO THE FAN BELTS HAVE PROPER TENSION? (Y/N)

HAS CORRECT FAN ROTATION BEEN CONFIRMED? (Y/N)

PIPING

HAVE LEAK CHECKS BEEN MADE AT COMPRESSOR, OUTDOOR UNIT, INDOOR UNIT,

TXVs (Thermostatic Expansion Valves), SOLENOID VALVES, FILTER DRIERS, AND FUSIBLE

PLUGS WITH A LEAK DETECTOR? (Y/N)

LOCATE, REPAIR, AND REPORT ANY LEAKS.

HAVE ALL COMPRESSOR SERVICE VALVES BEEN FULLY OPENED (BACKSEATED)? (Y/N)

HAS LIQUID LINE SERVICE VALVE BEEN OPENED? (Y/N)

IS THE OIL LEVEL IN COMPRESSOR CRANKCASE VISIBLE IN THE COMPRESSOR SIGHT GLASS?

(Y/N)

CHECK VOLTAGE IMBALANCE

LINE-TO-LINE VOLTS: AB

(AB + AC + BC)/3 = AVERAGE VOLTAGE =

MAXIMUM DEVIATION FROM AVERAGE VOLTAGE =

VOLTAGE IMBALANCE = 100 X (MAX DEVIATION)/(AVERAGE VOLTAGE) =

IF OVER 2% VOLTAGE IMBALANCE, DO NOT ATTEMPT TO START SYSTEM!

CALL LOCAL POWER COMPANY FOR ASSISTANCE.

VAC VBC V

V

V

CL-1

%

Page 24

C. Start-Up

CHECK INDOOR FAN SPEED AND RECORD.

CHECK OUTDOOR FAN SPEED AND RECORD.

AFTER AT LEAST 10 MINUTES RUNNING TIME, RECORD THE FOLLOWING MEASUREMENTS:

COOLING HEATING

OIL PRESSURE

SUCTION PRESSURE

SUCTION LINE TEMP

DISCHARGE PRESSURE

DISCHARGE LINE TEMP

ENTERING OUTDOOR AIR TEMP

LEAVING OUTDOOR AIR TEMP

INDOOR ENTERING-AIR DB (dry bulb) TEMP

INDOOR ENTERING-AIR WB (wet bulb) TEMP

INDOOR LEAVING-AIR DB TEMP

INDOOR LEAVING-AIR WB TEMP

COMPRESSOR AMPS (L1/L2/L3) / / / /

CHECK THE COMPRESSOR OIL LEVEL SIGHT GLASSES; ARE THE SIGHT GLASSES SHOWING

OIL LEVEL IN VIEW? (Y/N)

NOTES:

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

Copyright 1998 Bryant Heating & Cooling Systems CATALOG NO. 5354-100

CL-2

----------------------------------------------------------------------------------------

Loading...

Loading...