Page 1

Bryant

JiiTJpüA

Airconditioning

Indianapolis, IN

City of Industry. CA

HORIZONTAL RIGHT

FAN-COIL UNITS

fi l e

CO P Y

Model 517G Fan-Coil Units are packaged air handlers that are

specifically designed for horizontal right-hand discharge for

split-system applications—both conventional air conditioning and

heat pump.

These fan-coil units are available In nominal coil sizes 042, 048,

and 060. Fan-Coil units with electric heaters and the accessory

heat packages for field-installation into the fan-coil units without

heaters are available in sizes ranging from 7.5 to 30KW.

Model 517G

Sizes 042, 048,

&060

FEATURES

WRAPAROUND FULLY INSULATED CABINET—One-piece

heavy-duty steel construction helps eliminate casing noise. Fully

insulated interior provides both thermal and acoustic isolation.

The cabinet exterior is finished with an attractive silver sage

enamel.

SPECIAL DESIGN FEATURES—Designed for horizontal-right

mounting attitude. Refrigerant and condensate connections are

provided on the front of the fan-coil units for ease of installation.

Knockouts are provided for optional horizontal suspension,

using suspension rods. Separate access panels for the coil sec

tion and blower/control section on the cabinet front make these

units totally serviceable from the front. A third front access panel

provides easy access to the permanent-type air filter furnished

with each unit.

DIRECT-DRIVE MULTISPEED, PSC, BLOWER MOTORS have

been carefully selected to minimize energy consumption while

providing the airflow to meet the requirements of a wide variety

of applications. A blower speed-tap-changer simplifies speed

changes. Blower and motor assembly is resiliently mounted to

minimize vibration, and slides out for easy servicing.

COMPUTER-DESIGNED INDOOR COILS provide for optimum

heat transfer and cooling and/or heat pump heating efficiency.

Flare refrigerant connections enable quick leak-proof connec

tions, using our precharged refrigerant tubing sets. All coils have

a condensate drain pan with primary and secondary connec

tions, and a holding charge of R-22 refrigerant.

CHECK-FLO-RATER—All coils have a Check-Flo-Rater for effi

cient and dependable refrigerant metering, and to eliminate the

potential service requirements of other metering devices.

Located external to the unit, the Check-Flo-Rater is readily

accessible for piston changeout or maintenance. For added sys

tem reliability, all coils have a liquid-tube strainer to help maintain

clean, unrestricted operation.

ELECTRIC HEAT PACKAGES are available either as factoryinstalled in the heating/cooling fan-coil units or as a field-instalied

accessory for the fan-coil units. The application flexibility of

these heaters is increased with the availability of single- and

three-phase power supply options. The 10-, 15-, and 20-KW

single-phase heaters are available with or without circuit break

ers for internal circuit protection. Sequencer control is used for

incremental energizing and deenergizing of the heater elements.

Field-installation of a heater into a unit has been made extremely

easy—simply slide in the heater, secure with three screws, and

plug-in three leads for blower motor control.

Form No. PDS517G.42.1B

Page 2

¿OD FLARE--------3 LIQUID CONN

Vi

'32^

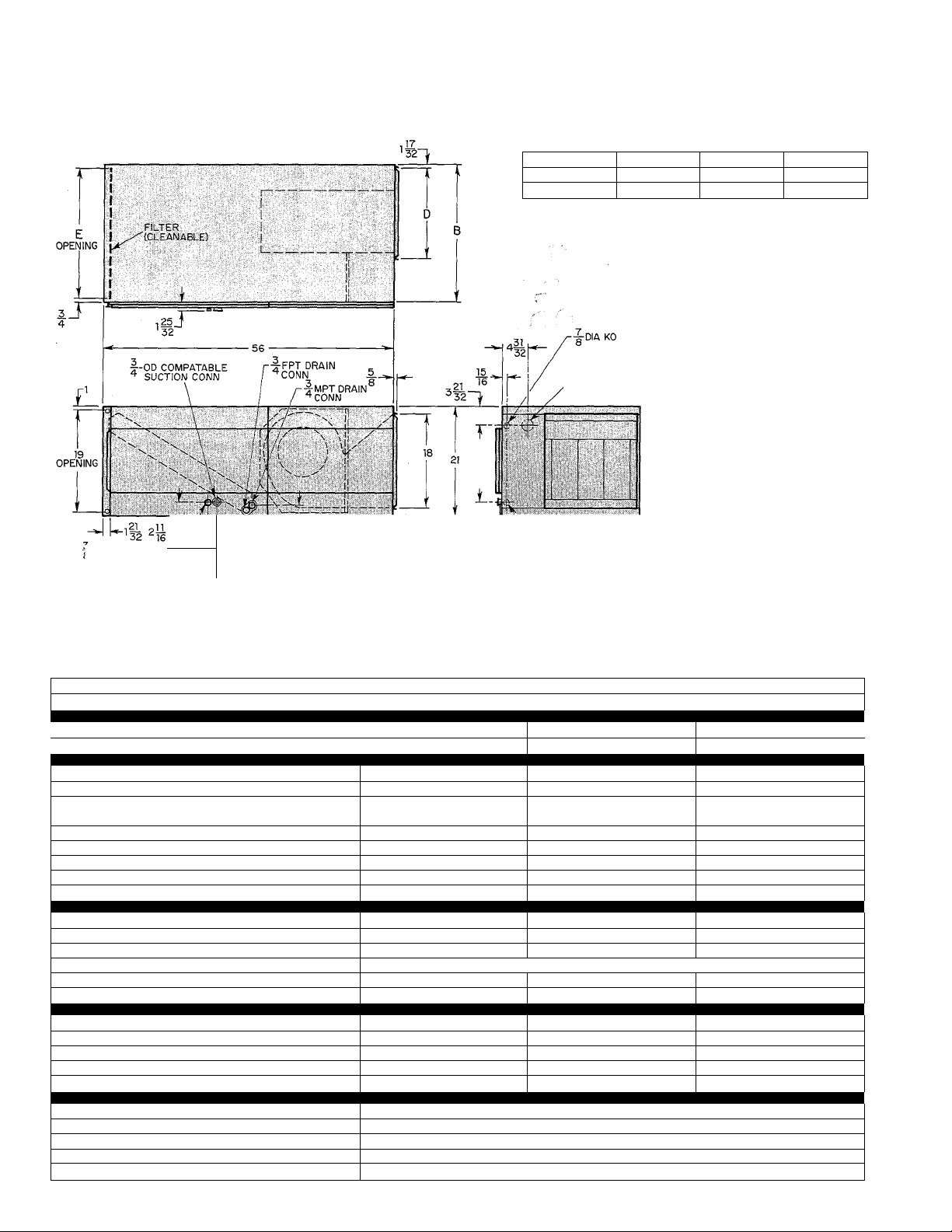

DIMENSIONAL DRAWING

517G Size B

042 22-3/4

048 & 060 26-7/16

(FIELD POWER-COOL)

^2 DIA KO

/ (FIELD POWER-HEAT)

I-Di A KO

S LOW-VOLTAGE

517G DIMENSIONS (Inches)

D E

13-13/16 21

17-9/32 24-1/2

Shipping Weights (lbs)

042

.......................................

048 .........................................185*

060 ........................................

*Add heater weights shown in

heater table to determine ap

proximate weights of fan-coil

units with heaters.

REQUIRED CLEARANCES

Recommended service clearance from front

of unit..........................................................21

Minimum clearance from combustible

materials:

Unit............................................................... 0

First 36 inches of uninsulated supply duct

A33202

when using heater

(Inches)

................................

175*

190*

36

SPECIFICATIONS—UNITS WITHOUT ELECTRIC HEATER

MODEL

SIZE

N042

I N048 1 N060

RATINGS & PERFORMANCE

Nominal Capacity (Btuh)*

Nominal Airflow (FWMin)t

42,000 48,000 60,000

1400

ELECTRICAL

Unit Voits—Phase (60 Hz)

Operating Voltage Range

208/230-1 208/230-1

187-253

Single-Circuit Operation

Rated Load Amps

Minimum Ampacity for Wire Sizing

Minimum Wire Size

Maximum Wire Length (Ft)

Maximum Fuse Size (Amps)

3.8

7.0

14

191/212

15

Control Transformer—24V (VA)

INDOOR COIL

Rows & Fins Per Inch

Height X Width (In.)

Face Area (Sq Ft)

R-22 Refrigerant Metering Device

•Piston ID Number

Condensate Drain Connection (Pri-Sec)

r Check-Flo-Rater |

3&13

32.5x19.4

4.4 5.1 5.1

76

3/4 MPT-3/4 FPT

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (in.)

Filter Size—Cleanable (in.)

Blower Motor HP

Blower Motor Speeds & Type

Rated Load Amps

10x9

20x21 x1

1/2

3 & DD(PSC)

3.8 4.8 5.6

OPTIONAL EQUIPMENT (P/N’S)

Liquid-Tube Swivel Ell (3/8)tt

Vapor-Tube Swivel Ell (3/4)tt

Single-Circuit Kit** 301820-4001

Electric Heat Package***

See Accessory Electric Heat Package Table

Control Package***

See notes on next page.

517G

1600 2000

187-253

4.8

7.0

14

152/158

15

***

3&13

32.5 X 22.8

82

3/4 MPT-3/4 FPT

10x9

20 X 25 x 1

1/2

3 & DD(PSC)

P651-1066

P651-1068

305971-464

208/230-1

187-253

5.6

7.0

14

130/144

15

4&14

32.5 X 22.8

93

3/4 MPT-3/4 FPT

11x9

20 X 25 X1

3/4 ■

3 & DD(PSC)

SSC-66

Page 3

SPECIFICATIONS—UNITS WITH ELECTRIC HEATER

MODEL

SIZE N042075 N042010 P042010 N042012

RATINGS & PERFORMANCE

Nominal Capacity (Btuh)^

Nominal Airflow (FP /Min)t

Electric Heating Output (KW)t

Electric Heating Capacity (MBtuh)t

42,000 42,000 42,000 42,000

1400 1400 1400 1400 1400 1400 1400 1400

7.5 10.0 10.0 12.0 15.0 15.0 18.0 20.0

19.2/23.5 25.6/31.3 25.6/31.3 30.8/37.6 38.5/47.0 38.5/47.0 46.1/56.4 51.3/62.7

ELECTRICAL

Unit Volts—Phase (60 Hz)

Operating Voltage Range

208/230-1

187-253 187-253 187-253

Internal Circuit Protections^ None

208/230-1 208/230-3 208/230-1 208/230-1

187-253 187-253 187-253 187-253 187-253

None iCBft

None

Fuses Fuses

Single-Circuit Operation

Rated Load Amps

Minimum Ampacity for Wire Sizing 40.8/44.5

30.8/33.8 39.8/43.8 24.6/26.8

52/57 33/35.75

Minimum Wire SizeH 8/8 6/6 8/8

Maximum Wire Length (Ft)B 95/96 115/115 146/148

Maximum Fuse Size (Amps)

45/45 60/60 35/40

47.2/51.8 57.8/63.8

61.25/67 74.5/82

6/4

97/154 79/125

70/70 80/90

Dual-Circuit Operation

Rated Load Amps LI & L2

L3&L4

—

32.7/35.8

—

14.5/16

Minimum Ampacity for Wire Sizing

LI &L2

L3&L4

Minimum Wire SizeH LI & L2

L3&L4

Maximum Wire Length (Ft)H L1 & L2

L3&L4

Maximum Fuse Size (Amps) LI & L2

L3&L4

— —

—

_

_

—

_

— —

_ _

— —

—

— —

—

43.1/47 52/57

18/20

8/6

12/12 10/10

89/141 115/115

80/80

45/50 60/60

20/20 25/25

Control Transformer—24V (VA) 60 60 60 60

INDOOR COIL

Rows & Fins Per Inch

Height X Width (In.)

Face Area (Sg Ft)

R-22 Refrigerant Metering Device

Piston ID Number

Condensate Drain Connection (Pri-Sec)

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.)

Filter Size—Cleanable (In.)

Blower Motor HP

Blower Motor Speeds & Type

Rated Load Amps

OPTIONAL EQUIPMENT (P/N’S)

Liguid-Tube Swivel Ell (3/8)TT

Vapor-Tube Swivel Ell (3/4)tt

Single-Circuit Kit^*

*See condensing unit or heat pump outdoor section PDS for cooling and/or heating capacity ratings with 517G Fan Coils.

tSee air delivery table in this PDS.

JKW values shown are nominal rated heater outputs at 240V and do not Include blower motor heat. Capacity values shown are calculated using KW

outputs at 208V/230V.

♦♦Single-phase 10-, 15-, or 20-KW electric heaters have the internal circuit protection options shown. Single-phase 12-, 15-, or 20-KW heaters are

wired for dual-circuit operation. The optionai single-circuit kit may be field-installed In units with a 12-, 15-, or 20-KW single-phase fused heater for

single-circuit operation.

ttCB = circuit breakers

ttUsed for right-angle refrigerant connections to the coil.

♦♦♦A 60-VA control transformer for units without factory-supplied heaters is supplied with the accessory electric heat package or control package. The

control package must be field-installed when a heater is not being used.

HWire sizes and lengths are based on copper conductor at 86 ° F (30 ° C) ambient temperature and ampacity shown in table. Insulation must be 90 ° C

on conductor used between the disconnect switch and the heater and at least 75 °C on the conductor used between the disconnect and the serv

ice panel. If other than copper conductor Is used, or if ambient temperature is above 86 ° F, determine wire size from ampacity shown and the Na

tional Electrical Code. Wire lengths shown are measured one way along the wire path between the disconnect and service panel for minimum 2%

voltage drop.

5170

N042015 P042015 P042018

42,000

42,000 42,000 42,000

208/230-3

CBtr

6/4

39.8/43.8

18/20

None

_

35.0/38.5 41.4/45.4

—

46/50.4

_

— 160/161

— 50/60 60/60 100/110 —

6/6 6/6 3/2

_ _

_

_

22.5/25

6/6

102/102

60

3&13

32.5x19.4

4.4

Check-Flo-Rater

76

3/4 MPT-3/4 FPT

10x9

20 X 21 X1

1/2

3 & DD(PSC)

3.8

P651-1066

P651-1068

—

— — 6/6

—

—

—

—

60 60

- 1 - 1 - 1 301820-4001 1 - 1 - 1 301820-4001

N042020

208/230-3 208/230-1

None Fuses

75.8/83.8

54/59 97/107

136/137

120/152 —

39.8/43.8

-

_

—

—

—

—

—

—

36/40

52/57

45/50

8/6

115/115

81/126

60/60

45/50

60

CBtt

_

—

—

CERTIFICATION APPLIES ONLY WHEN

USED WITH PROPER COMPONENTS

AS USTED WITH ARI

SSC-67

Page 4

SPECIFICATIONS—UNITS WITH ELECTRIC HEATER

MODEL

SIZE

1 RATINGS & PERFORMANCE

Nominal Capacity (Btuh)»

Nominal Airflow (Fts/Min)t 1600

Electric Heating Output (KW)t

Electric Heating Capacity (MBtuh)t

1 ELECTRICAL

Unit Voits—Phase (60 Hz)

Operating Voltage Range

Internal Circuit Protection»»

N048075 IN048010

48,000

48,000

1600

7.5 10.0

19.2/23.5

25.6/31.3

208/230-1 208/230-1

187-253 187-253

None

None 1 CBtt

P048010 N048012 N048015 P048015 P048018

48,000 48,000

1600 1600 1600 1600 1600

10.0 12.0

25.6/31.3

208/230-3 208/230-1 208/230-1

187-253

None Fuses

Single-Circuit Operation

Rated Load Amps

Minimum Ampacity for Wire Sizing

Minimum Wire Size»»»

Maximum Wire Length (Ft)»»»

Maximum Fuse Size (Amps)

31.8/34.8

40.8/44.5

8/8

92/93

45/45

40.8/44.8

52/57

6/6

112/113

60/60

25.6/27.6 48.2/52.8

33/35.75 61.25/67

8/8 6/4

140/144 95/151 78/123

35/40 70/70

Dual-Circuit Operation

Rated Load Amps LI & L2

L3&L4

—

— —

Minimum Ampacity for Wire Sizing

LI &L2

Minimum Wire Size»»» LI. & L2

L3 & L4

L3&L4 - -

Maximum Wire Length (Ft)»»» LI & L2

L3&L4

Maximum Fuse Size (Amps) LI & L2 —

L3&L4

Control Transformer—24V (VA)

— —

—

—

—

— — —

—

— —

—

60 60

-

—

—

_

—

60 60

INDOOR COIL

Rows & Fins Per Inch

Height X Width (In.)

Face Area (Sg Ft)

R-22 Refrigerant Metering Device

Piston ID Number

Condensate Drain Connection (Pri-Sec)

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.)

Filter Size—Cleanable (In.)

Blower Motor HP

Blower Motor Speeds & Type

Rated Load Amps

OPTIONAL EQUIPMENT (P/N’S)

Liguid-Tube Swivel Ell (3/8)tt

Vapor-Tube Swivel Ell (3/4)tt

Single-Circuit Kit»»

1 1 i 301820-4001 \ = 1

»See condensing unit or heat pump outdoor section PDS for cooiing and/or heating capaoity ratings with 517G Fan Coils.

fSee air delivery table in this PDS.

tKW values shown are nominal rated heater outputs at 240V and do not include blower motor heat. Capacity values shown are calculated using KW

outputs at 208V/230V.

»»Single-phase 10-, 15-, or 20-KW electric heaters have the internal circuit protection options shown. Single-phase 12-, 15-, or 20-KW heaters are

wired for dual-oirouit operation. The optional single-circuit kit may be field-installed in units with a 12-, 15-, or 20-KW single-phase fused heater for

single-circuit operation.

ttCB = circuit breakers.

ttUsed for right-angle refrigerant connections to the coil.

»»»Wire sizes and lengths are based on copper conductor at 86 ° F (30 ° C) ambient temperature and ampacity shown in table. Insulation must be 90 ° C

on conductor used between the disconnect switch and the heater and at least 75 “ C on the conductor used between the disconnect and the serv

ice panel. If other than copper oonductor is used, or is ambient temperature is above 86 °F, determine wire size from ampacity shown and the Na

tional Electrical Code. Wire lengths shown are measured one way along the wire path between the disoonnect and service panel for minimum 2%

voltage drop.

517G

48,000

15.0

30.8/37.6

38.5/47.0 38.5/47.0 46.1/56.4

187-253 187-253

Fuses

58.8/64.8

74.5/82

6/4

80/90

33.7/36.8 40.8/44.8

14.5/16

18/20

43.1/47 52/57

18/20

22.5/25

8/6 6/6

12/12 10/10

87/137

112/113

80/80 102/102

45/50

20/20

60/60

25/25

60 60 60

3&13

32.5x22.8

5.1

Check-Flo-Rater

82

3/4 MPT-3/4 FPT

10x9

20 X 25 X1

1/2

3 & DD(PSC)

4.8

P651-1066

P651-1068

48,000 , -48,000

15.0 18.0

208/230-3 208/230-3

187-253 187-253

CBtt

None None

36.0/39.5 42.4/46.4

46/50.4

_

—

156/157 132/134

—

50/60 60/60

6/6 6/6

54/59

—

— —

— —

_

—

— —

■ —

—

—

SSC-68

Page 5

SPECIFICATIONS—UNITS WITH ELECTRIC HEATER

I

MODEL

SIZE

1 RATINGS & PERFORMANCE

Nominal Capacity (Btuh)*

Nominal Airflow (FF/Min)t 1600 1600 1600

Electric Heating Output (KW)t 20.0 25.0 30.0

Electric Heating Capacity (MBtuh)f: 51.3/62.7 64.1/78.4

1 ELECTRICAL ^

Unit Volts-Phase (60 Hz) 208/230-1 208/230-3 1 208/230-1 ■ 208/230-3 1 208/230-1B 208/230-1 208/230-1

Operating Voltage Range

Internal Circuit Protection** Fuses

Single-Circuit Operation

Rated Load Amps 76.8/84.8

Minimum Ampacity for Wire Sizing 97/107

Minimum Wire Size*** 3/2

Maximum Wire Length (Ft)*** 119/151 — 156/157 154/194 167/168

Maximum Fuse Size (Amps) 100/110

Dual-Circuit Operation

Rated Load Amps L1 & L2

Minimum Ampacity for Wire Sizing

Minimum Wire Size*** L1 & L2

Maximum Wire Length (Ft)*** Lt &L2

Maximum Fuse Size (Amps) L1 & L2 60/60

Control Transformer—24V (VA) 60 60 60 60

INDOOR COIL .

Rows & Fins Per Inch 3&.13

Height X Width (In.) 32.5 x22.8

Face Area (Sq Ft) 5.1 5.1

R-22 Refrigerant Metering Device Check-Flo-Rater

Piston ID Number 82 88

Condensate Drain Connection (Pri-Sec) 3/4 MPT-3/4 FPT

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.) 10x9 11x9

Filter Size—Cleanable (In.) 20x25 x1

Blower Motor HP 1/2

Blower Motor Speeds & Type 3 & DD(PSC)

Rated Load Amps 4.8

OPTIONAL EQUIPMENT (P/N’S) I

Liquid-Tube Swivel Ell (3/8)tt P651-1066

Vapor-Tube Swivel Ell (3/4)t1: P651-1068

Single-Circuit Kit**

L3&L4

L1 & L2 52/57

L3&L4

L3&L4

L3&L4

L3&L4

H048020

48,000 48,000 48,000

187-253 187-253 187-253 187-253 187-253

CBtt

_

-

—

—

40.8/44.8

36/40

P0480Z5H P048030I

Fuses Fuses None

56.8/62.5 94.8/104.8 67.2/74.1 112.8/124.8 32.6/35.6 41.6/45.6 26.4/28.6

72/79.1 119.5/132 85/93.6 142/157 40.8/44.5

4/4 1/0 3/3 0/00

80/80 125/150 90/100 150/175

_ _ _

_

_ _ _

45/50

6/6

8/6

112/113

81/126

45/50

301802-4001 1 1 =

-

- - - — - . 8/6

-

- -

_

- - - ■ - — 45/50

- - - — 20/20

*See condensing unit or heat pump section PDS for cooling and/or heating capacity ratings with 517G Fan Coils.

tSee air delivery table in this PDS.

$KW values shown are nominal rated heater outputs at 240V and do not include blower motor heat. Capacity values shown are calculated using KW

outputs at 208V/230V.

**Single-phase 10-, 15-, or 20-KW electric heaters have the internal circuit protection options shown. Single-phase 12-, 15-, or 20-KW heaters are

wired for dual-circuit operation. The optional single-circuit kit may be field-installed in units with a 12-, 15-, or 20-KW single-phase fused heater for

single-circuit operation.

ttCB = circuit breakers.

ttUsed for right-angle refrigerant connections to the coil.

***Wire sizes and lengths are based on copper conductor at 86 ° F (30 ° C) ambient temperature and ampacity shown in table. Insulation must be 90 ° C

on conductor used between the disconnect switch and thé heater and at least 75 °C on the conductor used between the disconnect and the serv

ice panel. If other than copper conductor is used, or if ambient temperature is above 86 ° F, determine wire size for ampacity shown and the National

Electric Code. Wire lengths shown are measured one way along the wire path between the disconnect and service panel for minimum 2%

voltage drop.

■Units with 25- and 30-KW electric heaters are wired for 3-phase operation. These units are field-convertible for single-phase operation by moving

two factory high-voltage wires.

517G

I N060075 I N060010 I P060010 I N060012

60,000 60,000

2000 2000

76.9/86.0 19.2/23.5 25.6/31.3

163/205

7.5 10.0 10.0

None ICBtt

52/57

8/8 6/6 8/8

90/91 110/111 .136/139 93/149

45/45 60/60 35/40

_

- - - 14.5/16

_

_

_

- -

— — - 18/20

- - - 12/12

_

- - 85/135

60 60 60

Check-Flo-Rater

3/4 MPT-3/4 FPT

3 & DD(PSC)

60,000

2000 2000

25.6/31.3 30.8/37.6

208/230-3 208/230-1

187-253

None Fuses

33/35.75 61.25/67

_

_

_

4&12

32.5 x22.8

20x25x1

3/4

5.6

P651-1066

P651-1068

T 1 1 = |301820-4001

60,000

12.0

187-253

49.0/53.6

6/4

70/70

34.5/37.6

43.1/47

80/80

Page 6

SPECIFICATIONS-UNITS WITH ELECTRIC HEATER

I MODEL

SIZE

RATINGS & PERFORMANCE

Nominal Capacity (Btuh)*

Nominal Airflow (Ft^/Min)t

Electric Heating Output (KW)t

Electric Heating Capacity (MBtuh)f:

ELECTRICAL ■■■' '

Unit Volts—Phase (60 Hz)

Operating Voltage Range

Internal Circuit Protection**

Single-Circuit Operation

Rated Load Amps

Minimum Ampacity for Wire Sizing

Minimum Wire Size***

Maximum Wire Length (Ft)***

Maximum Fuse Size (Amps)

Dual-Circuit Operation

Rated Load Amps L1 & L2

L3&L4 18/20

N060015 I PD60015 I P060D18'

60,000 60,000 60,000

2000 2000 2000 2000

15.0 15.0 18.0 20.0

38.5/47.0 38.5/47.0 46.1/56.4

208/230-1 208/230-3

187-253 187-253

Fuses

CBtt

59.6/65.6

74.5/82

6/4

77/122

80/90

36.8/40.3

-

46/50.4

-

__

152/154 130/132 118/149

—

41.6/45.6

None

6/6 6/6

50/60

208/230-3

187-253

None

43.2/47.2

54/59

60/60

_ _

- -

51.3/62.7 64.1/78.4

208/230-1

Fuses

77.6/85.6

97/107

3/2

100/110 -

41.6/45.6

Minimum Ampacity for Wire Sizing

Minimum Wire Size*** LI & L2

Maximum Wire Length (Ft)*** LI & L2

Maximum Fuse Size (Amps) L1 & L2

Control Transformer—24V (VA)

INDOORCOIL

LI &L2 52/57

L3&L4 22.5/25

6/6

L3&L4 10/10

110/111

L3&L4 102/102

60/60

L3&L4 25/25

60

_

- -

- -

- -

- -

- -

-

60

-

110/111 - -

-

60

Rows & Fins Per Inch

Height X Width (In.)

Face Area (Sq Ft)

R-22 Refrigerant Metering Device

Piston ID Number

Condensate Drain Connection (Pri-Sec)

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.)

Filter Size—Cleanable (In.)

Blower Motor HP

Blower Motor Speeds & Type

Rated Load Amps

OPTIONAL EQUIPMENT (P/N’S)

Liquid-Tube Swivel Ell (3IS)tt

Vapor-Tube Swivel Ell (3/4)tt

Single-Circuit Kit**

301820-4001 1 = 1 = 1 301820-4001 ] = |

*See condensing unit or heat pump outdoor section PDS for cooiing and/or heating capacity ratings with 517G Fan Coils.

tSee air delivery table in this PDS.

tKW values shown are nominal rated heater outputs at 240V and do not include blower motor heat. Capacity values shown are calculated using KW

outputs at 208V/230V.

♦♦Single-phase 10-, 15-, 20-KW electric heaters have the internal circuit protection options shown. Single-phase 12-, 15-, or 20-KW heaters are

wired for dual-circuit operation. The optional single-circuit kit may be field-installed in units with a 12-, 15-, or 20-KW single-phase fused heater for

single-circuit operation.

tfCB = circuit breakers.

ttUsed for right-angle refrigerant connections to the coil.

♦♦♦Wire sizes and lengths are based on copper conductor at 86 ° F (30 ° C) ambient temperature.and ampacity shown in table. Insulation must be 90 ° C

on conductor used between the disconnect switch and the heater and at least 75 °C on the conductor used between the disconnect and the serv

ice panel. If other than copper conductor is used, or if ambient temperature is above 86° F, determine wire size from ampacity shown and the Na

tional Electrical Code. Wire lengths shown are measured one way along the wire path between the disconnect and service panel for minimum 2%

voltage drop.

■Units with 25- and 30-KW electric heaters are wired for 3-phase operation. These units are field-convertible for single-phase operation by moving

two factory high-voltage wires.

517Б

N060020 P060025I

60,000 60,000

2000

25.0

208/230-3 1 208/230-1 ■

187-253

CBtt

_

187-253

Fuses

57.6/63.3

72/79.1

4/4 1/0

-

154/155

80/80

_

36/40

52/57

45/50

6/6 8/6

81/126

60/60

45/50

60 60

4&12

32.5 X 22.8

5.1

Check-Flo-Rater

88

3/4 MPT-3/4 FPT

11x9

20x25 x1

3/4

3 & DD (PSC)

5.6

P651-1066

P651-1068

-

_

_

- -

-

- -

- -

208/230-3 1 208/230-1 ■

95.6/105.6

68.0/74.9. 113.6/125.6

119.5/132 85/93.6

3/3

153/192 165/166

125/150 90/100

Р060030И

60,000

2000

30,0

76.9/86.0

187-253

Fuses

142/157

0/00 ■

161/203

150/175

_

-

_

-

-

-

60

SSC-70

Page 7

517E

Size

042

(Without Heater)

042

(With Heater)

048

(Without Heater)

048

(With Heater)

060

(Without Heater)

060

(With Heater)

AIR DELIVERY (Ft^/Min) AT INDICATED EXTERNAL STATIC PRESSURE (With Filter)

Motor

Speed

Coil

Tap

High

Dry 1760 1700 1625

Wet

Medium

Dry 1615 1545

Wet

Low Dry

Wet

High Dry

Wet

Medium

Dry 1565 1505

Wet

Low Dry

Wet

High Dry

Wet 1950

Medium Dry

Wet

Low Dry 1710

Wet

High Dry 1970

Wet

Medium

Dry 1830 1770

Wet 1750

Low Dry

Wet 1620

High

Dry 2315

Wet

Medium Dry

Wet

Low Dry

Wet 1860

High

Dry 2265

Wet

Medium

Dry

Wet

Low

Dry 1875

Wet

-

0.1 0.2

External Static Pressure

0.3 0.4 0.5 0.6

1690 1625 1545

1490 1415

1545 1495

1435 1385

1395

1350

1700 1635

1625 1565

1435

1340

1300 1235

1560

1485

1450 1385

1510 1450

1410 1360

1370

1325

2075 1995

1870

1900 1830

1810 1745

1665

1660 1615

1905

1875 1800

1390

1315

1270 1205

1910 1830

1795 1725

1765

1685

1615 1565

1565

1825

1740

1705

1670 1625

1690

1575

2280

2250

2215

2125 2080

2065

2025

1900 1870

1830

2230

2210 2170

2070 2035

2025 1985

1630

1580 1525

1525

2240 2200

2165 2140

2040

1990 1945

1840

1800 1760

2190 2145

2130

1995 1955

1945 1910

1850 1820

1850 1815

1780

—Inches wc

1535 1450 1350

1455 1355 1260

1345 1255 1150

1365 1275 1185

1280 1210 1135 1035

1165 1080

1475

1415

1395 1290 —

1320 1200

1305 1215

1320

1250

1235 1150

1180

1135

1745

1645

1700

1615

1625

1540

1510

1515

1755

1660

1635

1560

1450

1675

1580

1560

1485

1470

1470

1390

2155

2095 2045

1995

1950

1900

1805

1770

1730

2100

2085

2045

1915 1870

1865

1785

1750

1750

1715

0.7

1225

—

—

—

—

—

—

1100

—

— —

1655 1550

1555 1455

1545 1450

1455

—

1450 1370

1385

—

1580 1490

1490

1485

1400

1405

—

2115

1400

—

—

—

_

2065

1990

1905

1850

1850

1790

1730 1690

1680

2060

2000

1650

2010

1950

1820

1820

1710

1675

1765

1665

1625

OPTIONAL FIELD-INSTALLED ELECTRIC HEAT PACKAGES*

Heater

Capacity

(MBtuh)**

208V 230V

19.2

25.6

25.6 31.3

25.6

30.8

38.5

38.5 47.0

38.5

46.1 56.4

51.3

23.5

31.3

31.3

37.6

47.0 Fuses

47.0

62.7 Fuses

62.7

Heater

P/N

305971-451

305971-452

305971-453

305971-470

305971-471

305971-472

305971-473

305971-474

305971-475

305971-476

305971-477

305971-478tt

305971-479tt

517E

Sizes

Used

Witht

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

042, 048, 060

048, 060

048, 060

Heater

Volts-

Phase

(60 Hz)t

208/230-1

208/230-1

208/230-1 10

208/230-3

208/230-1 12

208/230-1 15

208/230-1

208/230-3

208/230-3

208/230-1

208/230-1

208/230-3

208/230-3

Total

7.5 7.5

Nominal Heater KW

@ 240V**

KW/Stage

1st 2nd

—

10 10

10 6.66 3.33

15

15 10 5

18

20 10 10

20 10

25

30 10

10

8 4

10 5

10 5

12

8.33 8.33

—

—

6

10

10 10 76.9 86.0

3rd

—

—

_

—

—

—

—

—

— 51.3

—

8.33 64.1 78.4

♦Refer to the appropriate unit/factory-installed heater combinations in the specifications tabies in this PDS for the eiectrical appiication data for these

heat packages.

fAli heat packages are used with Modei 517G Fan Units.

^Operating voitage range is 187—253V.

**KW vaiues shown are nominai rated heater outputs at 240V. Capacity vaiues shown are caicuiated using nominai KW outputs.

ttThese heaters are fieid-convertibie for singie-phase operation by moving two factory high-voltage wires.

ttThese heaters are factory-supplied for dual-circuit operation. Optional single-circuit kit P/N 301820-4001 is available to provide for single-circuit

operation.

SSC-71

Internal

Circuit

Supply

Protection

Provided

None

None

Ckt Brkr

None

Fuses

Ckt Brkr

None

None

Ckt Brkr Dual

Fuses

Fuses

Options

Circuit

Single

Single

Single

Single

Duaitt

Dualtt

Dual

Single

Single

Duaitt

Single

Single

Approx

Ship.

Wt

(lbs)

13

13

14

14

15

15

15

15

15

17

17

20

20

Page 8

BRYANT RECOMMENDED ROOM THERMOSTATS & SUBBASES

I

Application

Single-Stage Electric Heating-Only

P/N

♦P271-2161

♦P271-2162

♦P271-2171

♦P271-2121

♦P271-2121

P271-2781

Two-Stage Electric Heating-Only

Single-Stage Cooling-Only

P271-2782

♦P271-2161

♦P271-2162

♦P271-2161

♦P271-2162

♦P271-2171

P271-2781 0.1-1.2

Single-Stage Electric Heating

& Cooling

♦P271-2161

♦P271-2162

♦P271-2171

Manual Changeover

Autochangeover

P271-2781

P271-2781

Two-Stage Eleotric Heating &

Single-Stage Cooling

Manual Changeover

P271-2782 0.1-1.2

Autochangeover P271-2782

Heat Pump Heating & Cooling

Without Electric Heater

Manual Changeover

Autochangeover

P271-3773

♦P271-3454 0.15-0.7t

♦P271-3453

Heat Pump Heating & Cooling

With Electric Heater

Manual Changeover

Autochangeover

♦P271-3454

♦P271-3453 0.15-0.7*

♦These thermostats have a Bryant logo—all others have a Honeywell logo,

tField-supplied relay P/N P283-1203 must be installed as shown in unit Instaiiation Instructions to energize the indoor blower during electric heat

ing operation.

JThe heat pump heating mode anticipator is fixed. Range shown is for adjustable electric heater second-stage heating anticipator.

♦♦These thermostats also have an emergency heat switch and indicator light.

Thermostat

Heat

Anticipator

Range

0.18-1.0

P/N

System Switch Fan Switch

(Included) (No Switch) (No Switch)

Subbase

0.5-1.5

0.1-1.2

0.15-1.2

0.15-1.2

0.1-1.2

0.1-1.2

0.18-1.0

P271-1821 (No Switch) AUTO-ON

P271-1884 OFF-AUTO AUTO-ON

P271-1885

HEAT-OFF-COOL AUTO-ON

(Included) (No Switch)

0.5-1.5

0.18-1.0

P271-1861

AUTO-OFF AUTO-ON

0.5-1.5

0.1-1.2 P271-1874 COOL-OFF AUTO-ON

P271-1884 OFF-AUTO

0.18-1.0

P271-1811

HEAT-OFF-COOL AUTO-ON

0.5-1.5

0.1-1.2

P271-1873

HEAT-OFF-COOL

0.1-1.2 P271-1885 HEAT-OFF-COOL AUTO-ON

0.1-1.2 P271-1882*

HEAT-AUTO-COOL-OFF

P271-1885 HEAT-OFF-COOL

0.1-1.2 P271-1882* HEAT-AUTO-COOL-OFF

(Fixed) (Included)

HEAT-OFF-COOL

(Included) HEAT-OFF-COOL^*

0.15-0.7i (Included)

0.15-0.7* (Included)

(Included)

HEAT-AUTO-COOL-OFF^*

HEAT-OFF-COOL*^

HEAT-AUTO-COOL-OFF^^ AUTO-ON

(No Switch)

AUTO-ON

AUTO-ON

AUTO-ON

AUTO-ON

AUTO-ON

AUTO-ON

AUTO-ON

AUTO-ON

AUTO-ON

Bryant

Air Conditioning

BDP Company

Intjianapolis, IN

City of Industry. CA

SSC-72

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

PRINTED IN U.S.A. 10-83

Loading...

Loading...