Page 1

Installation Instructions

516

ELECTRIC DUCT HEATER PACKAGE

These instructions are to be used in con

junction with the basic instructions for the

Model 516 Fan Coil Unit. Section II of this

instruction describes the installation of the

electric duct heater package with other than

the Model 516 air handlers .

SECTION I

The electric duct heater is designed to be

used with the Models 18- and 24-516 Fan Coil

Units. Refer to Table I, Ratings and Capaci

ties, for sizes and power inputs. Refer also

to the Dimensional Drawing.

The package, as shipped from the factory,

contains heater coils, a rating plate, a

sequencing relay (for 11- through 14,4-KW

size units), automatic temperature control,

and a manual temperature control switch.

Each heater has both sides of the power line

broken by a main contactor and a backup

contactor, and has an open set of contacts for

fan control.

Before Starting Installation:

1. Check local codes and ordinances for ad

ditional requirements.

2. Check the incoming power supply to be

sure that the rated voltage, frequency, and

phase correspond to that stamped on the unit

ratirig plate.

3 . Check the building power supply to be sure

that it is sufficient to handle the additional

electrical load imposed by this equipment.

b Pliant

39516D3

5/1/69

I

if the heater is to be installed within 6 inches

downstream from the Fan Coil. Mount the

collar on the duct flanges of the Fan Coil so

that the opening for the duct heater is on the

same side of the Fan Coil as the coil con

nections and rating plate. Make certain that

the flange is at the bottom of the duct heater

opening. This will insure that the heater is

placed at the correct depth.

Now, place the heater into the collar and

attach it to the collar with four sheet metal

screws.

If the application does not provide adequate

space for the duct heater to be installed

6 inches from the Fan Coil, then the duct

heater must be installed 48 inches down

stream from the Fgyj-Coil Unit-.

Installing the Electric Duct Heater Package

The duct heater package is designed for zero

clearance from combustible material. There

must be a 7 -1 /2 inch clearance in front of the

control box cover.

A collar for mounting the duct heater is pro

vided with each Fan Coil Unit. Use this collar

To install the he,

from the Fan Co

hole in the side

heater into place

template, drill fo|.r_moun

the heater with

An air filter mi

airstream.

es .downstream

8 inch

de the

Ox as a

attach

crews.

return

Page 2

TOP VIEW

SIDE VIEW

10

D

Electric Duct Heater Dimensional Drawing

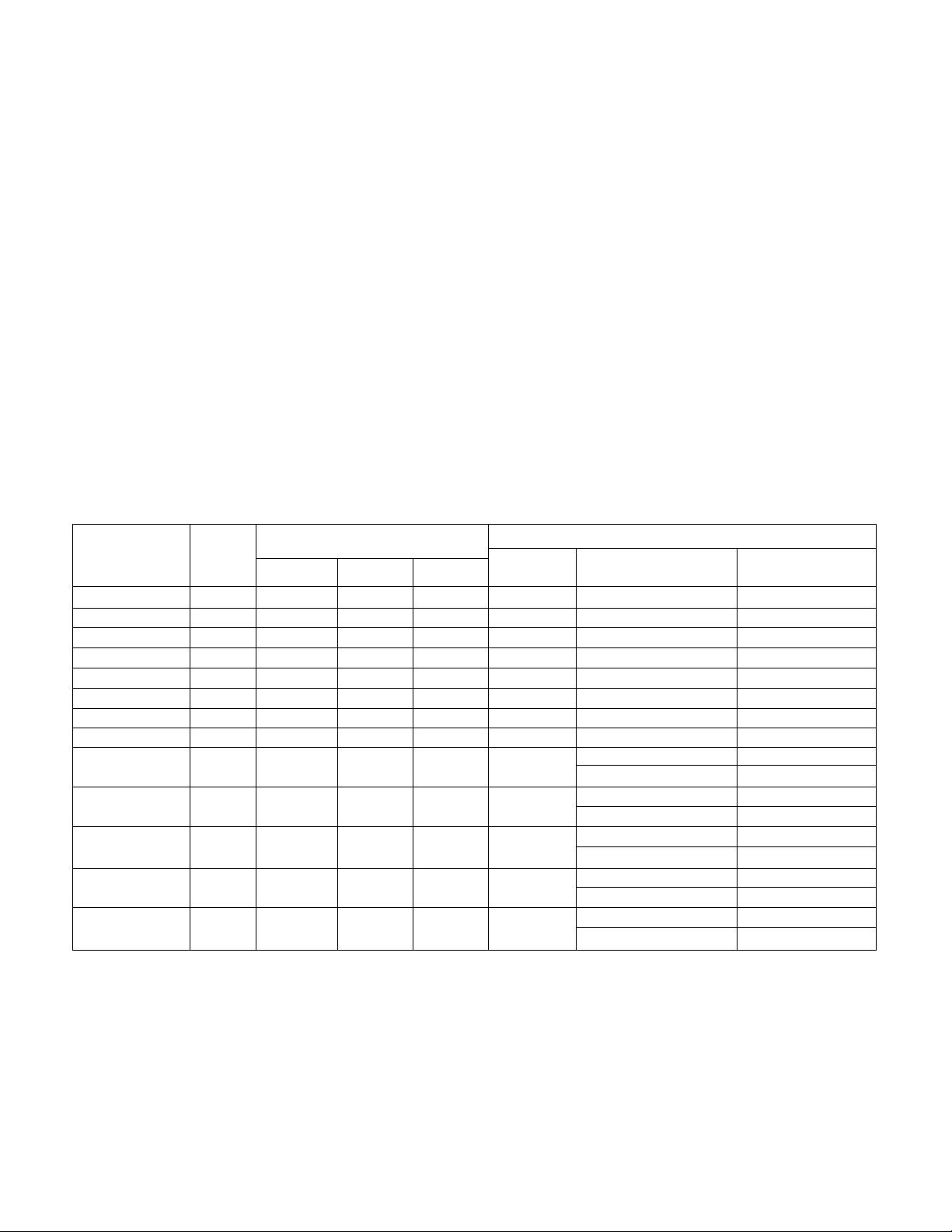

TABLE I - RATINGS AND CAPACITIES

Packoge

P/N

KW

Rating

208 V

65901D03 3

65901D04 4 10,254

65901D05 5

65901D06

65901D07

6

7 17,944 21,941

65901D08 8

65901D09

65901D010

65901D011

65901D012

9 23,071

.9.6

11

12

6590IDO13 13

6590IDO14 14

65901D015 14.4

12,817 15,672 17,065 1

15,381

20,508 25,076

24,610 30,091

28,199 34,479 37,543 2

30,762

33,326

35,889

36,915

* Rated at 240V, 60 cycle, single phase

** Includes blower motor and one heating element

* Capacity Btuh

7,690 9,403 10,239

230V 240V

12,538

18,807

13,652

20,478 1

No. of

Circuits

23,891 1

27,304

28,210

30,717

32,764

37,614

40,956

40,748 44,369

43,883

47,782 2

45,136 49,147 2

«i

o o

Field Wire Connections

Minimum Wire Size

AWG - 90° C - Copper

1

1

12

10

10

10 (2)40

8

1

1

1

8 (2) 50

6 (2) 60

6

10 ** (2) 30

10 (2) 40

2

2

10

8

10 ** (2) 30

8 (2) 50

10 ** (2) 30

8 (2) 50

10

8 - (2) 50

Max Fuse Size

Amps

(2) 20

(2) 20

(2) 30

(2) 50

(2) 60

** (2) 30

(2) 50

** (2) 30

39516D3

-2 -

Page 3

Limitations and Recommendations

1. The duct heaters should never be installed

from the bottom or the top of the duct - only

from the sides of the duct. The heaters must

always be installed on the discharge side of

the Fan Coil.

2. Only one duct heater may be used in any

one duct. If the capacity required exceeds the

output of one duct heater, select the total

number of heaters and proportion them in

separate runouts or separate ducts from the

plenum.

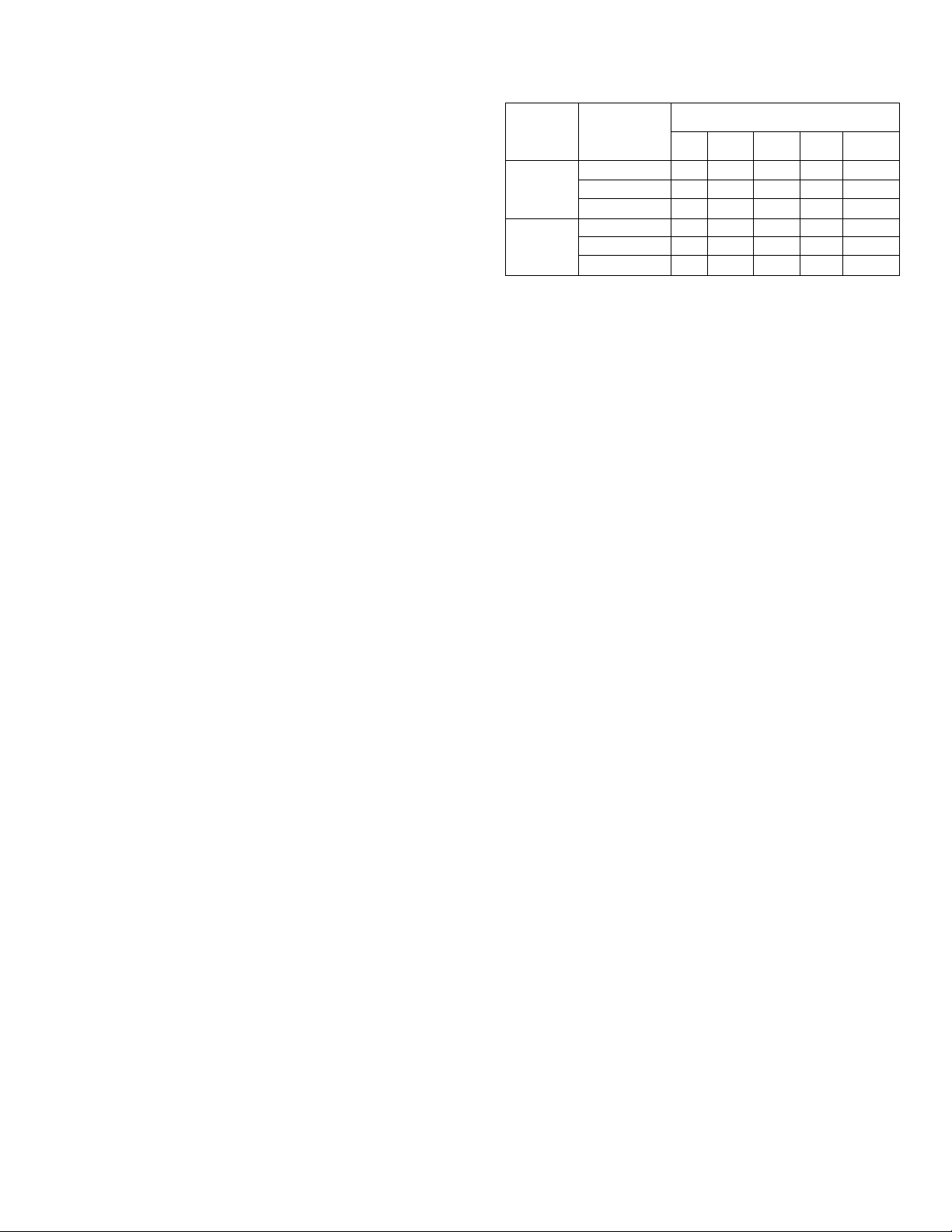

Table II - Air Delivery at Indicated Static Pressure

(Dry Coil, Less Filter)

Evaporator

Model

18-516

24-516

* Static pressure - inches w.c.

Motor

Speed Tap

High 930 920

Medium

Low

High 955

Medium

Low

*0.0

705

605

695

615 605

*0.1 *0.2 *0.3

CFM

890

905

700 690

600 590

940 915

690 680 670

675 650

580

880

600 580

*0.4

860

550

830

680

555

3. Install the duct heater at least 18 inches

away from any canvas duct connector. If the

heater must be located closer, replace the

canvas connector with an asbestos connector.

4 . The control enclosures of the duct heaters

must be completely accessible and so located

as to provide ventilation at all times.

5. The air duct should be installed in ac cordance with the standards of the National

Board of Fire Underwriters for the Instal

lation of Air Conditioning and Ventilating

Systems of other than Resident Type (pamphlet

no. 90A), and Resident-Type Warm Air Heat

ing and Air Conditioning Systems (pamphlet

no. 90B).

6. Each duct heater should be provided with

a fan relay. The heater and fan motor are to

be wired so that the duct heater cannot oper

ate unless the fan is on. Always hook the fan

interlock to the high-voltage side of the

system. Never use a fan delay with the

electric duct heater.

7. The coil of the secondary contactor

(general-purpose, continuous duty rated at

6000 cycles) must be wired in series with the

manual reset limit control (TMR).

NOTE; Observe at least one complete heating

cycle before leaving the installation.

Electrical Connections

Make all electrical connections in accordance

with the National Electric Code and any local

codes or ordinances that may apply.

Provide power supply (or supplies; 11- throu^

14.4-KW heaters will have two power sup

plies) for the heating capacity of the unit

being installed in accordance with Table I Ratings and Capacities. Power supply con

nections are made at the high-voltage termi

nals with wire suitable for at least 90° C

(194°F). It is good practice to ground casing

parts and to check factory wiring connections,

to be sure none were loosened in transit or

installation. Refer to Figures 5, 6, and 7 for

field wiring diagrams.

Thermostat Connection

The electric duct heater and Model 516 Fan

Coil Unit are designed for use with a 24-V

heat-cool thermostat, Bryant Model 883 .

Connect the thermostat and the low-voltage

terminal block on the side of the Fan Coil in

accordance with field wiring diagrams Figures 5, 6, and 7. Set the thermostat

heating anticipator at 0.8 amps .

- 3 -

39516D3

Page 4

Start-up, Adjustment.and Checkout

1. Turn on the electrical supply,

2 . Set the thermostat to call for heat.

3. The sequence of operation for 3 - through

9.6 -KW duct heaters is as follows:

A. When the thermostat calls for heating,

the primary contactor closes. See

Figures 1 and 2 .

B. The fan and heating elements are

energized at the same time.

4. Unit shutdown is as follows:

A. As the thermostat is satisfied, the

primary contactor coil is de-energized.

B. The fan and heating elements are de

energized at the same time .

5. The sequence of operation for 11- through

14.4-KW duct heaters is as follows:

A. When the thermostat calls for heating,

the sequencer is energized. See Figure

3.

B. The fan is energized at the same time.

C . The heating elements are energized in

rapid succession.

6. Unit shutdown is as follows:

A. As the thermostat is satisfied, the

sequencer is de-energized.

B. The heating elements are de-energized

in rapid succession.

C . The blower motor is in operation until

the last heating element is de-ener

gized .

1. The amount of supplementary heat required

may be expressed in terms of KW as follows:

KW required

BTU Heat Loss

3413

2. If the air handling equipment is expressed

in CFM's, then a direct cross-reference can

be made by comparing the temperature of the

air (as it enters the duct heater) to the KW

rating on the chart at the rated CFM. See

Figure 4.

A. Draw a line horizontally from the inlet

air temperature to the KW (BTU) re

quired,

B. From this point of intersection on the

KW line, draw a line down vertically to

establish the CFM. See Table II for the

CFM at a given static pressure.

C. The CFM should never be lower than

the CFM as determined from the chart.

In cases where this is not true, then

the CFM must be increased or the KW

required must be reduced.

3 . In cases where the air handling equipment

is expressed in FPM, convert to CFM by

multiplying the FPM by the duct area.

Example:

Air Velocity = 1000 FPM

Duct Size = 8 X 20 in. = 160 sq in.

Duct Area = - 1.11 sq ft

144

Airflow = 1000 FPM X 1 .11 sq ft = 1110 CFM

Check the control circuit operation. Be sure

that the thermostat turns the unit on and off

when heating contacts are closed, then

opened. Be sure that the thermostat fan

switch (if there is one) turns the blower on

and off when switch is turned on, then off.

Replace all control box covers and outer

cabinet panels.

Minimum Air Velocities

The minimum airflow is directly related to

the inlet air temperature. Consideration must

be given to both the airflow across the heater

and the inlet temperature.

39516D3

SECTION II

If the electric duct heater package is used

with an air handler other than our Model 516

Fan Coil Unit:

1. All previous instructions, limitations, and

recommendations apply to this type of instal

lation .

2 . The duct heater must be mounted 48 inches

downstream from the air handler. It cannot

be mounted 6 inches downstream as on the

Model 516 Fan Coil Unit.

• 4 -

Page 5

1. Transformer

2. Blower motor

3. R2 Contactor

Figure 1 - Wiring Diagram for 3-, 4-, & 5-KW Electric Duct Heater

4. Rl Contactor

5. Cooling fan relay

6. Manual reset limit switch

7. Automatic reset limit switch

8. Heater

1. Transformer

2. Blower motor

3. Contactor R3

4. Heaters

5. Contactor R2

6. Contactor Rl

7. Cooling fan relay

8. Manual reset limit switch

9. Automatic reset limit switch

Figure 2 - Wiring Diagram for 6-, 7-, 8-, 9-, & 9.6-KW Electric Duct Heater

- 5 -

• 39516D3

Page 6

1. Transformer

2« Blower motor

3. Contactor R1

4. Heaters

5. Sequencing relay

6. Contactor R2

7. Cooling fan relay

8. Manual reset limit switch

9. Automatic reset limit switch

Figure 3 - Wiring Diagram ior 11-, 12-, 13-, 14-, & 14.4-KW Electric Duct Heater

39516D3

- 6 .

Page 7

co

Ф

(л

м

Ol

ö

со

Page 8

ю

сл

н*

о\

Ö

00

Page 9

0

VJ

3

(О

2

Q*

<Û

•Ч

O

Э

r

0

a.

2L

01

Os

K>

CO

\o

en

H»

<J\

Ö

00

m

0

n

O

c

O

Loading...

Loading...