installation, start-up and

service instructions

CEILING

SINGLE PACKAGE COOLING UNITS

PA C

™ HORIZONTAL INDOOR

Cancels: II 502A-24-1 II 502A-36-1

502A

Sizes 036-060

3 to 5 Tons

12/15/05

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

I. Step 1 — Receive and Inspect Unit . . . . . . . . . . . . . 1

II. Step 2 — Protect Unit from Damage . . . . . . . . . . . . 1

III. Step 3 — Provide Unit Support. . . . . . . . . . . . . . . . . 1

IV. Step 4 — Rig and Place Unit. . . . . . . . . . . . . . . . . . . 4

V. Step 5 — Make Piping Connections. . . . . . . . . . . . . 4

VI. Step 6 — Install Ductwork. . . . . . . . . . . . . . . . . . . . . 4

VII. Step 7 — Make Electrical Connections . . . . . . . . . . 4

VIII. Splitting Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

IX. Field Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . 5

X. Thermostat Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

XI. Step 8 — Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . 5

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7,8

SAFETY CONSIDERATIONS

Installing and servicing air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions such as cleaning c oils and filters an d replaci ng filters.

All other operations should be performed by trained service

personnel. When working on air-conditioning equipment,

observe precaution s in the lit erature and o n tags and labe ls

attached to unit.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire

extinguisher avail abl e.

WARNING: Before performing service or maintenance operations on unit, turn off main power switch

to unit. Electrical shock can ca use personal injury.

NOTE: Ensure voltage on unit agrees with voltage listed on

the unit rating plate.

GENERAL

The 502A036,048, and 060 units are single-package, indoor,

horizontally mounted air conditioners of 3, 4 and 5 tons

capacity, respectively.

These units can be mounted as factory-shipped singlepackage units or can be separated and mounted as a split

system. If unit is spl it, the co nden ser sec tio n c a n be m oun ted

horizontally.

All units are designed to be ducted on both the condenser

and evaporator sides. Centrifugal blowers are used to ensure

quiet air delivery to the conditioned space. Sound level

requirements should be determined before final unit installation site is chosen.

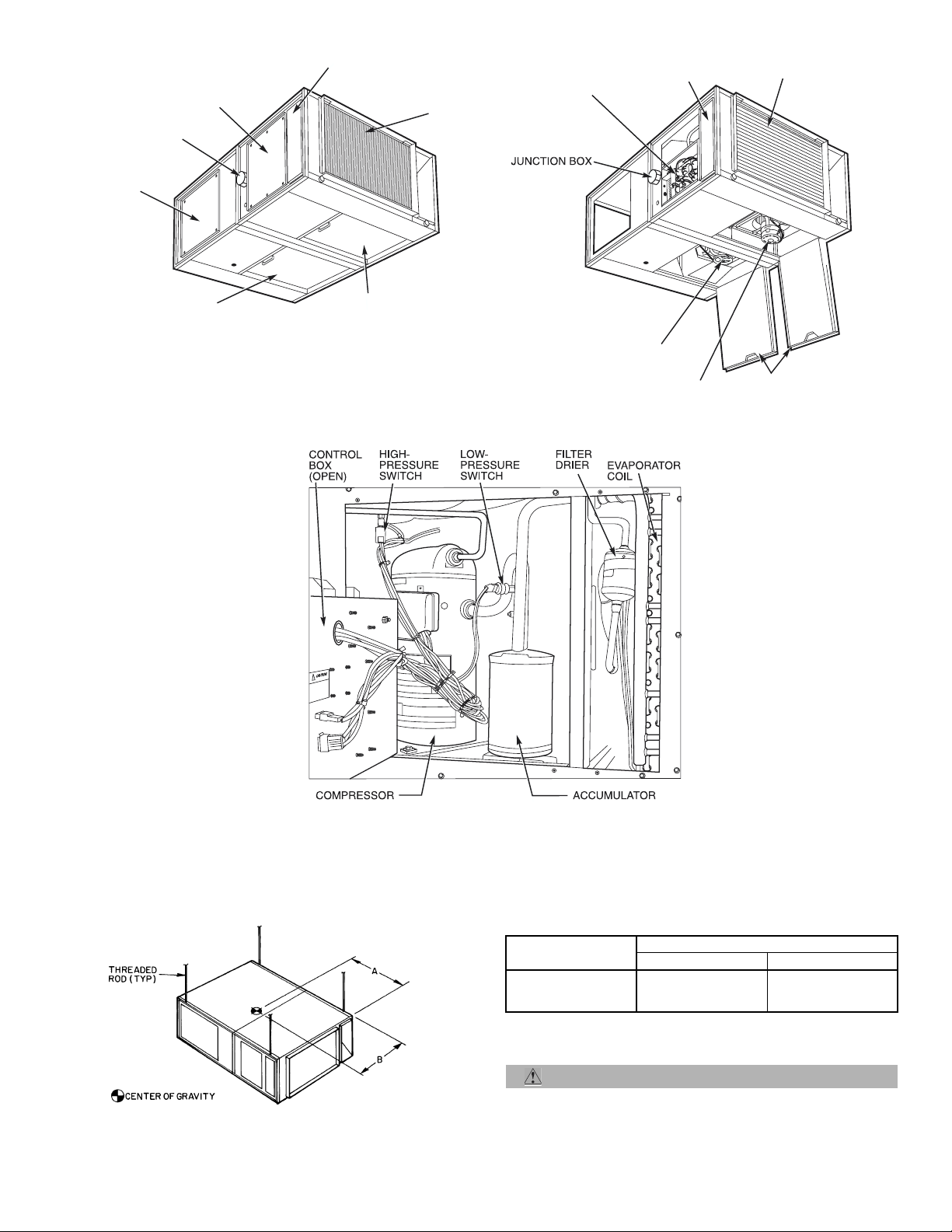

Unit servicing is relatively simple since access to the condenser and evaporator motors, blowers, belt, and pulley is

gained through removable swing do ors located on bottom of

unit. These d oo rs may al so b e u s ed fo r cl ea n ing o f co nde n ser

coils. Unit side panels provide access to control box and pressure switches.

Refrigeration cycle components (e.g., compressor, filter

drier, etc.) can be serviced upon removal of the base unit

from the space.

INSTALLATION

WARNING: Determine building alterations required

to run piping, wiring, and ductw ork. Follow dimensiona l

drawings carefully for ductwork, piping locations,

electrical wiring, and overall unit dimensions. Read all

installation instructions before starting installation.

The 502A units are intended f o r indoor instal lation only.

I. STEP 1 — RECEIVE AND INSPECT UNIT

Unpack and check unit against shipping order. Inspect carefully for concealed shipping damage. If unit is damaged or

incomplete, file claim with transportation company and

advise Bryant immediately.

II. STEP 2 — PROTECT UNIT FROM DAMAGE

To maintain warranty, unit must be protected against theft

and vandalism and stored indoors at all times.

III. STEP 3 — PROVIDE UNIT SUPPORT

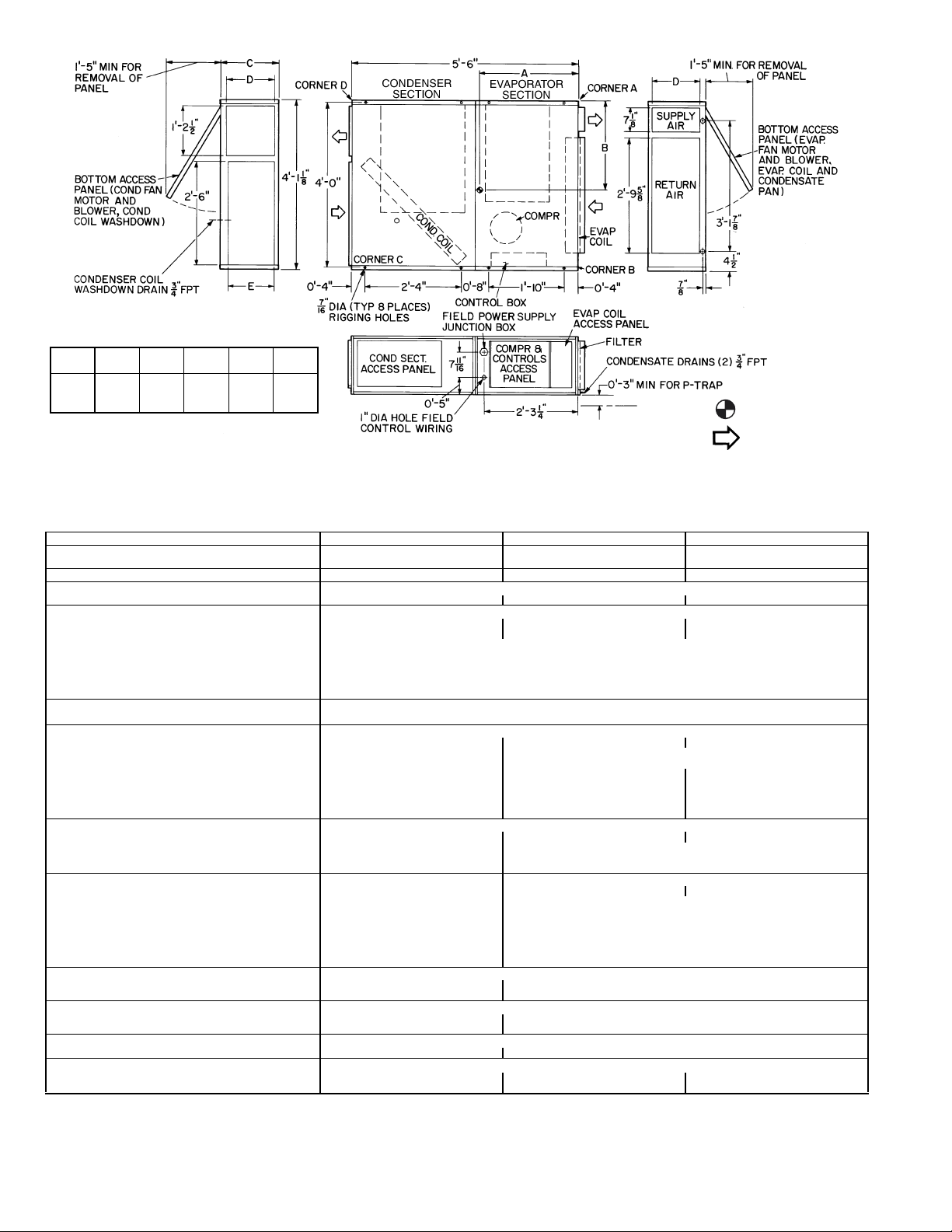

Refer to Fig. 1 and 2 for unit dimensions and component

locations. Refer to Table 1 for unit sizes and weights.

Each unit requires the following field-supplied items:

4 — threaded suspension rods (

minimum)

4—washers

4 — locknuts

Install the 4 field-supplied rods by suspending them from a

suitable ceiling support. Locate rods to mate with 4 outside

corner rigging holes shown in Fig. 1 and 3.

The ceiling and ceiling supports of existing buildings may

require reinforcements ; follow all applicable codes.

3

/8-in.-16 SAE Grade 1

DIMENSIONS (ft-in.)

UNIT

502A

036 2-4

048 2-5 2-3 1-11

060 2-43/42-23/41-115/81-77/81-77/

ABCDE

3

/42-2 1- 53/41-2 1-1

5

/81-87/81-77/

8

8

LEGEND

Center of Gravity

Direction of Airflow

Fig. 1 — Dimensions

Table 1 — Physical Data

UNIT 502A 036 048 060

OPERATING WEIGHT (lb)

Base Unit, Evap/Condenser Section 480, 206/274 580, 250/330 590, 254/336

SHIPPING WEIGHT (lb)* 590 690 700

REFRIGERANT TYPE R-22

Operating Charge (lb)† 5.5 8.0 7.6

COMPRESSOR — TYPE Scroll

Quantity...Model (1)...ZR34 (1)...ZR49 (1)...ZR57

Oil (oz) 42 48 54

HPS Setting (psig)

Cutout 426 ± 7

Reset 320 ± 20

LPS Setting (psig)

Cutout 27 ± 4

Reset 67 ± 7

CONDENSATE DRAIN CONNECTION

Size (in.)...Type

CONDENSER FAN Centrifugal — Belt Drive

Nominal Cfm 1350 2250 2450

Maximum Rpm 1100 1500

Blower Size (in.) 12 x 6 12 x 9

Pulley Pitch Diameter (in.)

Blower 5.0 6.0 6.0

Motor (Variable) 2.4-3.4 1.9-2.9 2.4-3.4

Motor Hp

Motor Rpm 1725 1725 1725

EVAPORATOR AIR FAN (Standard) Centrifugal — Direct Drive

Nominal Cfm 1200 1600 2000

Max Rpm 1150 1050

Blower Size (in.) 10 x 6 10 x 6

Motor Hp (Rpm)

EVAPORATOR AIR FAN (Optional)

Nominal Cfm 1600 2000

Max Rpm 1300

Blower Size (in.) 10 x 8

Motor Hp 1

Motor Rpm 1725

Pulley Pitch Diameter (in.)

Blower 4.2

Motor (Variable) 2.4-3.4

CONDENSER COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 40 x 16 40 x 22

Number of Rows...Fins/in. 4...17 4...13.6

EVAPORATOR COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 34 x 16 34 x 22

Number of Rows...Fins/in. 4...15 4...14.4

INDOOR-AIR FILTERS Factory-Supplied Cleanable Type

Number...Size (in.)

INTERCONNECTING TUBING SIZE (in.)**

Hot Gas

Liquid

HPS — High-Pressure Switch

LPS — Low-Pressure Switch

*Shipping weights include base unit plus packaging.

†If components are to be split, additional refrigerant will be needed. Refer to Fig. 5-7 for

charging charts.

LEGEND

3

/

4

1

/2 (1075)

Not

Available

1...14 x 34 x 1

1

/

2

3

/

8

**Use Type L copper only.

NOTE: If components are to be split, the maximum length of refrigerant tubing to be

used is 50 equivalent ft, assuming components will be installed in same horizontal plane.

If components are not to be installed in same horizontal plane, contact your Bryant representative for more information.

3

/4...FPT

11

3

/4 (1050)

Centrifugal Belt Drive

1

/

2

1...21 x 34 x 1

1

/

2

3

/

8

1

/

2

1

/

2

3

/

8

—2—

CONTROL BOX ACCESS PANEL,

COMPRESSOR, LOW-PRESSURE AND

HIGH-PRESSURE SWITCHES AND

SERVICE PORT CONNECTION

ACCESS

JUNCTION BOX

CONDENSER

SIDE ACCESS

PANEL

FILTER DRIER AND

CAPILLARY TUBE ACCESS

FILTER

CONTROL BOX

FILTER

DRIER

UNIT WITH FILTER

REMOVED

CONDENSER MOTOR

AND BLOWER ACCESS-ALSO

PROVIDES ACCESS FOR

CLEANING CONDENSER COIL

EVAPORATOR MOTOR

AND BLOWER ACCESS-ALSO

PROVIDES ACCESS FOR

CLEANING EVAPORATOR

CONDENSER MOTOR AND

BLOWER ASSEMBLY

EVAPORATOR MOTOR

ACCESS DOORS

Fig. 2 — Component Locations

UNIT 502A

036 28.8 26.0

048 29.0 27.0

060 28.8 26.8

NOTE: Fasten threaded rods through holes in end frames as shown.

Use 2 rods on each side of unit for a total of 4.

CAUTION: All panels must be in place when rigging.

Fig. 3 — Rigging Details

—3—

CENTER OF GRAVITY

DIMENSIONS (in.)

AB

IV. STEP 4 — RIG AND PLACE UNIT

Move and store unit in horizontal position. Provide space

around unit for service, filter access, ductwork, and overhead

clearance as indicated in Fig. 1.

Using suitable hydraulic lift source, raise unit up to meet

bottom of the 4 threaded rods suspended from ceiling. Center

unit so that the 4 threaded rods can be easily i nserted into

the factory-drilled holes at each end. Refer to Fig. 3 for rigging details.

Apply washers and locknuts on ends of each of the 4 rods.

Tighten locknuts sufficiently so that unit weight is sup-

ported entirely by the 4 rods. Level unit within the space by

adjusting locknuts.

IMPORTANT: Unit must be level to operate properly.

NOTE: Th e 2 factory-drilled holes in the middle of th e unit

can be used for support if a split system application is

desired. If re q uir e d, a v ibration isola tor pack ag e acce s so ry is

available for use to minimize vibration that may be transmitted to building structure.

NOTE: For split systems, 8 suspension rods are required.

Refer to Splitting Systems section.

V. STEP 5 — MAKE PIPING CONNECTIONS

3

Two

/4-in. pipe thread condensate drain connections are provided below the evaporator coil. One 3/4-in. pipe thread connection is provided for condenser coil washdown. One of the

evaporator drains is plugged at the factory; plug must be

removed when making field connections. The condenser

washdown pan is plugged at the factory. This drain is to be

used only when condense r co il i s be ing c l ea ned; plug must be

replaced when cleaning is completed.

VI. STEP 6 — INSTALL DUCTWORK

Use flexible ductwork to attach duct to unit and to help control transmission of vibrations to building structures. Attach

ductwork to the return and supply ends of both coils.

If unit is located with condenser close to outside of building,

install a field-supplied rainhood. Hood intake dimensions

should be same as condenser return-air dimensi ons. In addition, install a tr iple-layer bird s cre en over rainhood in take t o

eliminate possibility of insects, birds, water, or debris from

entering unit. Ensure hood and/or louvers are installed correctly to avoid condenser air recirculation.

VII. STEP 7 — MAKE ELECTRICAL CONNECTIONS

Provide and install a safety discon nect switch i n accordance

with National Electric Code (NEC) and all local codes.

Connect power wiring to junction box located on unit side

near control box access panel. All wiring must comply

with NEC and all local code re qui re me nt s.

Operating voltage to compressor must be within voltage

range as indicated on unit nameplate. Voltages between

phases must be balanced within 2% and current must be

balanced within 10%. Contact local power company for

correction of improper voltage or phase imbalance. Unit

failure as a result of operation on improper line voltage or

excessive phase imbalance constitutes abuse and may cause

damage to electrical components. Such operation would

invalidate any applicable Bryant warranty.

Refer to unit nameplate and Table 2 for fuse sizes and wire

amperages for all units.

VIII. SPLITTING SYSTEMS

The 502A roomtop units may be split into 2 sections, if

desired, with condensing section mounted remotely either

horizontally or vertically. If sections are installed in same

horizontal plane they may be separated by up to 50 equivalent ft of tubing. Use type L copper or better.

Condensing section must be located in same plane as, or

above, evaporator section to maintain the liquid refrigerant

seal at the expansion device. This permits expansion device

to feed liqu id ref rige rant to ev apor ator coil p rop erly. To split

sections (some of the following steps may be eliminated

depending on particular application):

1. Disconnect all electrical power to unit and tag

disconnect.

2. Remove 4 bolts connecting the 2 sections.

3. Remove top panels from each section.

4. Recove r the refrigerant from the system using both

the high and low-pressure ports.

5. Cut refrigerant piping in the evaporator section just

inside the partition between the 2 sections.

Table 2 — Electrical Data

UNIT

502A

036

048

048*

060

060*

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

V-P H

(60 Hz)

208/230-3 187 254 10.2 77.0 .50 3.20 .75 3.93 19.9 25

460-3 414 508 4.3 37.0 .50 1.50 .75 1.97 8.8 15

208/230-3 187 254 13.5 99.0 .75 4.00 1.0 3.93 24.8 35

460-3 414 508 7.4 49.5 .75 2.15 1.0 1.97 13.4 15

575-3 518 632 5.8 40.0 .75 1.40 1.0 1.45 10.1 15

208/230-3 187 254 13.5 99.0 1.5 5.60 1.0 3.93 26.4 35

460-3 414 508 7.4 49.5 1.5 2.80 1.0 1.97 14.0 20

208/230-3 187 254 17.3 123.0 .75 4.00 1.5 4.82 30.4 45

460-3 414 508 9.0 62.0 .75 2.15 1.5 2.41 15.8 25

575-3 518 632 7.1 50.0 .75 1.40 1.5 1.90 12.2 20

208/230-3 187 254 17.3 123.0 1.5 5.60 1.5 4.82 32.0 40

460-3 414 508 9.0 62.0 1.5 2.80 1.5 2.41 16.5 25

VOLTAGE RANGE COMPRESSOR

Min Max RLA LRA Hp FLA Hp FLA

LEGEND *Optional evaporator-fan motor nameplate data.

—4—

FAN MOTORS POWER SUPPLY

Evaporator Condenser

Min Ckt

Amps

MOCP

Amps

6. Unsweat the cut portions of the refrigerant piping in

evaporator sect ion at the closest bell joint. The bell

joints are used to connect field-supplied refrigerant

piping to evaporator section. Cut and braze a length

of tubing to extend refrigerant piping outside the

evaporator section.

7. Cut condenser-fan motor wiring at the partitions separating co ndenser and evaporator sections.

8. In the condenser section, install a junction box adjacent to the D-shaped grommet.

9. Install evaporator and condensing sections in desired

locations. Refer to Steps 10-12 below.

10. Use appropriate length of no. 16 American Wire Gage

4

(AWG) (minimum),

/64-in. insulated copper wire to

reconnect cut condenser-fan motor wi res. Make connections in junction boxes installed in earlier steps.

Follow all applicable electrical codes.

11. Use sufficient length of refrigerant piping to reconnect piping cut in previous step. Liquid line tubing is

3

/8-in. OD copper tubing, and hot gas line is 1/2-in. OD

copper tubing.

12. Replace top panels on eac h sect io n.

13. Evacuate refrigerant system to 500 microns.

14. Recharge unit with R-22 refrigerant following

Charging Charts (p age 8) in these instruction s. Use

refrigerant charge as indicated on unit.

NOTE: National Electric Code (NEC) disconnects are

required at each section if units are not installed within line

of sight of each other.

After splitting sections, additional refrigerant must be added

to system to ensure proper refrigerant charge. The amount of

refrigerant to be added depends on length of tubing added to

system and opera ting tem perature s of syst em. Allo w unit to

operate at least 10 minutes before adjusting refrigerant

charge.

Since standa rd roomt op u nit has negl igib le li ne lo sses, spli tting the system can increase line loss and decrease system

capacity.

IX. FIELD CONTROL WIRING

Install a Bryant-approved thermostat assembly accessory

according to i n stallation instruct i on s p r ovid e d by t he r mo st at

manufacturer. Locate thermostat assembly on a solid wall in

the conditioned space away from drafts to sense average

room temperature.

Using thermostat cable or equivalent single leads of no. 18

AWG colored wire, route cable or wire from the subbase terminals, up and through connector on unit side (below power

lead junctio n box) a nd conn ect to low-volt age ter minal block

inside the control box.

X. THERMOSTAT WIRE

Use 18 gage for 0 to 50 ft long wires and 16 gage for 51 to

75-ft wire lengths.

XI. STEP 8 — FAN SPEED

Adjust condenser fan speed and evaporator fan s pee d to m ee t

job requirements. Enter the condenser and evaporator sections through the hinged access panels on the bottom of

units (see Fig. 2). S ee Service section of this docum ent for

general service procedures.

A. Evaporator-Fan Motors

Standard evaporator fans are direct-driven designs. Size 036

units have single-speed motors and require no adjustment.

Sizes 048 and 060 units use two-speed fan motors. Refer to

Table 3 for standard evaporator fan performance. The evaporator fan motor factory speed select ion is shown on the label

diagram affixed to base unit. If other than factory speed setting is desired, refer to label diagram for motor reconnection.

Optional evaporator fan drives (for unit sizes 048 and 060)

are belt-drive designs. Refer to Table 4 for optional evaporator fan performance. Adjust the motor pulley setting as

required to provide the project design evaporator airflow

rate. Pulley setting must limit the airflow rate to maximum

of 2250 cfm.

See Service sectio n for instructions on che cking motor shaft

and fan shaft alignment, pulley alignment and belt tension.

B. Condenser-Fan Motors

Condenser-fan motors are belt driven. Fan speed must be

adjusted to maintain condenser airflow at the flow rate

specified in Table 1. Refer to Table 5 for condenser fan performance data. See Note 6 for factory drive pulley settings.

Adjust the motor pulley setting as required to provide design

condenser airflow through the si te’s cond enser duct system.

Table 3 — Evaporator-Fan Performance

UNIT SIZE — 502A

AIRFLOW

(cfm)

900 .69 .44 — — — —

1000 .57 .46 — — — —

1100 .42 .49 1.10 .45 1.11 .52

1200 .23 .52 1.01 .49 1.045 .55

1300 — — .90 .51 .97 .57

1400 — — .79 .55 .88 .59

1500 — — .67 .58 .78 .62

1600 — — .54 .61 .67 .64

1700 — — .39 .64 .53 .67

1800 — — .22 .67 .52 .70

1900 — — .03 .70 .40 .74

2000 —— —— .28 .78

ESP — External Static Pressure (in. wg)

kW — Total Fan Motor Power Input (kilowatts)

*Standard direct drive indoor-fan motor (IFM). For optional belt drive

IFM performance, see following table.

NOTES:

1. Above fan performance is based on wet coil and deducted casing

losses, and clean factory-installed permanent cleanable filter.

2. Evaporator fans are direct drive (except sizes 048, 060 indoor-fan

motor option).

3. Interpolation is permissible, do not extrapolate.

036 048* 060*

ESP

LEGEND

Fan

kW

ESP

Fan

kW

ESP

Fan

kW

Table 4 — Optional Belt-Drive

Evaporator-Fan Performance

AIRFLOW

(cfm)

1800 ————

1850 ————

1900 ————

1950 .81 1.03 — —

2000 .72 1.05 — —

2050 .63 1.07 — —

2100 .55 1.08 1.02 1.17

2150 .47 1.11 .93 1.21

2200 .42 1.14 .84 1.24

2250 .34 1.17 .75 1.27

NOTE: Pulley setting must be adjusted to limit cfm to 2250 cfm

maximum

condensate problems.

. Unit operation beyond that limit may result in blow-off and

ESP Fan kW ESP Fan kW

UNIT SIZE — 502A

048 060

—5—

Table 5 — Condenser-Fan Performance

UNIT

502A

036

048

060

kW — Total Fan Motor Power Input (kilowatts)

NOTES:

1. Above fan performance is based upon coil and deducted casing losses only.

2. External static pressure (ESP) is measured in inches water gage (in. wg).

AIRFLOW

(cfm)

1650 2 .84————————————

1600 — — 2 .82——————————

1550 — ——— 2 .80————————

1500 3 .72 — — — — 2 .78 1 .84 — — — —

1450 4 .63 3 .70 — — — — 2 .76 1 .83 — —

1400 — — 4 .61 3 .68 — — — — — — 1 .81

1350 5 .51 — — — — 3 .67 — — 2 .73 — —

1300 — — 5 .50 4 .57 — — 3 .65 — — 2 .71

2700 2 .90————————————

2600 — — 2 .87——————————

2550 3 .81————————————

2450 — — 3 .77 2 .83 1 .89 — — — — — —

2350 — ————— 2 .801 .86————

2300 4 .68 — — 3 .74 — — — — 0 .90 — —

2200 — — 4 .66 — — — — 2 .77 1 .82 0 .86

3100 31.34————————————

3000 — — 31.32——————————

2900 — ————— 21.39——————

2850 4 1.11 — — 3 1.24 — — — — — — — —

2750 — — 4 1.07 — — — — 2 1.32 — — — —

2700 — ————— 31.17——————

2650 — ——————————— 11.37

2600 5 .95 — — 4 1.01 — — — — 2 1.26 — —

2550 — ——————— 31.12————

2500 — — 5 .92——————————

2450 — — — — — — 4 .97 — — — — 2 1.21

2400 — — — — 5 .90 — — — — 3 1.08 — —

LEGEND

0.0 0.1 0.2 0.3 0.4 0.5 0.6

Turns kW Turns kW Turns kW Turns kW Turns kW Turns kW Turns kW

EXTERNAL STATIC PRESSURE (in. wg)

3. Interpolation is permissible. Do not extrapolate.

4. Minimum one turn open of motor pulley is required on unit sizes 036 and 060.

5. Number of turns open applies to field setting of motor pulley.

6. Factory setting as follows: 036, 4 turns open; 048, 2 turns open; 060, 5 turns

open.

START-UP

I. UNIT PREPARATION

Make sure unit has been install ed in ac corda nce with ins tallation instructions and applicable codes.

II. COMPRESSOR MOUNTING

Compressors are internally spring mounted. Do not loosen or

remove compressor holddown bolts.

III. INTERNAL WIRING

Check all electrical connections in unit control boxes and

tighten as required. Be sure wires are not in contact with

sharp edges or refrigerant tubing.

IV. REFRIGERANT SERVICE VALVES

Each unit system has 3 Schrader-type service ports, one on

the suction line, one on the compressor discharge line, and

one for low-ambient damper kit. Be sure that caps on the

ports are tight. One Schrader-type valve is located under

both the high-pressure switch and low-pressure switch.

V. COMPRESSOR ROTATION

It is important to be certain compressor is rotating in the

proper direction. To determine whether or not compressor is

rotating in the proper direction:

1. Connec t service gages to suctio n and discharge pressure fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pressure does not rise to normal levels:

1. Note that the co ndenser fan may also be rotating in

the wrong direction.

2. Turn off power to the unit and tag disconnect.

3. Reverse any two of the unit power leads.

4. Reapply power to the unit; remove tag. Energize

compressor.

5. Verify correct refrigerant pressures.

The suction and discharge pressure levels should move to

their normal start-up levels.

NOTE: When the compre ssor is rotating in the wrong direction, the unit will sound louder than normal and will not

provide cooling.

VI. FAN ROTATION

Check fan rotation to ensure progression in proper direction.

VII. COOLING

To start unit, turn on main power supply. Set system selector

switch at COOL position and fan switch at AUTO. position.

Adjust thermostat to a setting below room temperature.

Compressor, condenser and evaporator motors start on closure of contactors.

A. To Shut Off Unit

Set system selector switch at OFF position or reset thermostat at a position above room temperature. Units are

equipped with Cycle-LOC™ protective device.

Cycle-LOC™ device prevents an automatic restart of a unit’s

compressor that has been shut down due to a safety device

trip. The Cycle-LOC device may cause an indicator light on

the thermostat subbase to illuminate upon a safety trip (if

the thermostat i ncludes this feature).

Be sure to check reason for safety trip befor e resetting the

Cycle-LOC device. Compressor restart is accomplished by

manual reset at the thermostat by first turning the selector

switch to OFF and then back to ON position.

—6—

SERVICE

WARNING: Electrical shock can cause personal

injury. Open al l remote discon nects and tag before servicing this equipment.

IMPORTANT: If repai rs t o refrig era nt cycle com pone nt s (e.g.,

compressor, filter drier, etc.) are requir ed, recover all refri gerant from the system by using bo th high- pressure a nd lowpressure ports, then remove base unit from the space.

I. COMPONENT LOCATION AND ACCESS

Refer to Fig. 2 for component locations and access panel locations. If a suspended ceiling has been installed beneath the

unit, the hinged access panels may not open fully. Remove

the panels at the hinged sides to provide full access.

II. FILTERS

Filters are clean abl e an d s hou l d b e ins pecte d a n d cle ane d at

regular intervals monthly or as conditions require. Filters

can be washed with wate r or v acuum ed as ne eded. They are

located in front of the evaporator coil and may be removed by

sliding them horizontally out to edge of unit. See Fig. 1 and

2. No tools are required for installation or removal of filters.

III. CONDENSER COIL

The condenser coil is accessible through the bottom access

door marked condenser secti on, o r thro ugh side a cce ss pan el

on condenser section, or through side access panel on condenser section. Use a stiff brush when cleaning coil. Be careful not to bend aluminum fins.

Connect the condenser washdown pan drain connection

3

(

/4-in. FPT) to the building drain using a 3/4-in. MPT hose.

Entering through unit bottom condenser access door, use a

water hose or other suit able equipm ent to f lush ou t dirt an d

wash do wn co il. Be careful not to force water spillage out of

condenser washdown pan.

IV. EVAPORATOR COIL

The evaporator coil is accessible for cleaning through the

bottom access door marked “Evaporato r Section.” When necessary, wash co il with a commercial cleane r (Oakite 164) or

dishwasher detergent using a pressurized spray canister.

Flush coil from return -air duct side and tak e care not to get

water in ductwork or unit insulation.

V. CONDENSATE DRAIN

Clean and empty drain pan at least once a year to prevent

sludge build-up.

VI. LUBRICATION

Lubrication of the condenser and evaporator motors is not

necessary since both are equipped with p ermanently lubricated bearings. Do not oil.

VII. MOTOR SPEED ADJUSTMENT

Direct-drive evaporator motors require no adjustment.

VIII. CONDENSER MOTOR

All 502A036-060 units contain belt-driven adjustable-pulley

condenser fan systems. All 502A048 unit fan motors are

shipped with adjustable pulley 2 turns open and 502A060

units are shipped at 5 turns open, and can be adjusted to

increase fan speed. The 502A03 6 u nit fan m otors ar e shi pped

with adjustable pulley at 4 turns open.

IX. BLOWER WHEEL SERVICING

In-space servicing is recommended for the evaporator and

condenser blowers. Both are removed by loosening and

removing the 4 screws that hold them in place. In both cases,

the entire ass embly is then moved outside of the b ase unit.

Once outside, the blower wheel and condenser shaft bearings

and/or evaporator motor can be serviced.

X. BELT-DRIVE FAN ADJUSTMENTS

Follow these instructions for adjusting motor pulley pitch

setting (to change fan speed), for aligning motor shafts and

pulleys, and for adj usting belt tension on all belt-drive fan

systems.

To change the fan speed:

1. Shut off unit power supply, tag disconnect(s).

2. Loosen belt by loosening fan motor mounting bolts.

3. Loose movable flange setscrew (see Fig. 4).

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed.

Increasing fa n speed inc reases lo ad on fan m otor. Do

not exceed maximum speed specified in Table 1.

Observe maximum evaporator flow rate limits per

note on Table 4.

5. Set movable flange at nearest keyway of pulley hub

and tighten setscrew.

6. Tighten fan motor mounting bolts.

To align fan and motor shafts, loosen motor from mounting

and reposition as necessary. To align fan and motor pulleys,

loosen fan pulle y setscrew s on fan sh aft and sli de fan pul ley

along shaft until straightedge check confirms alignment (see

Fig. 4). Tighten setscrews. Check all motor mounting bolts.

To adjust belt tension:

1. Loosen fan motor mounting bolts.

2. Slide motor away from fan shaft for proper belt ten-

1

sion (

/2-in. deflection with 8 to 10 lb of force) and

tighten motor mounting bolts.

XI. BLOWER BELT ADJUSTMENT

Inspect blower b elt for wear, proper belt tension, a nd pulley

alignment as conditions require or at the beginning of each

heating and air conditioning season. Refer to Step 8 — Fan

Speed on page 5 for adjustment and alignment procedures.

XII. CONTROL BOX SIDE ACCESS PANEL

The control box side access pa nel is held i n place wi th

1

/4-in.

self-retaining fasteners. When these fasteners are pulled,

the access panel can be t urned around 180 degre es so that i ts

metal lip w ill line up wit h the metal lip on bottom of uni t.

This enables the access panel cover to hang down, exposing

the base unit wiring diagram and enabling the service person to work more freely.

Fig. 4 — Evaporator-Fan Pulley Adjustment

—7—

XIII. REFRIGERANT CHARGE

Amount of refrigerant charge is listed on unit nameplate

(also refer to Table 1).

Unit panels must be in place when unit is operating during

charging procedure. Unit must operate for at least 10 minutes before adjusting charge.

A. No Charge

Use standard evacuating techniques. After evacuating system, weigh in the speci fied amount of refrig erant. (Refer to

Table 1.)

B. Low Charge Cooling

Using Cooling Charging Charts, Fig. 5-7, vary refrigerant

until the conditions of the appropriate chart are met. Note

the charging charts a re different from type normall y used.

Charts are based on charging the units to the correct supe rheat for the var ious op erating c onditio ns. Accurate pr essure

gage and temperature sensin g device are required. Connec t

the pressure gage to the service port on the suction line.

Mount the temperature sensing device on the suction line

and insulate it so that surrounding ambient temperature

does not affect the reading. Indoor-air cfm must be within

the normal operating range of the unit.

B. To Use Cooling Chart

Take the am bient temp eratu re and re ad th e sucti on press ure

gage. Refer to appropriate chart to determin e what suction

temperature should be. If suction temperature is high, add

refrigerant. If suction temp erature is low, carefully recove r

some of the charge. Recheck the suction pressure as charge

is adjusted.

Example: (Fig. 5)

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . .85 F

Suction Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 70 psig

Suction Temperature should be . . . . . . . . . . . . . . . . .47 F

(Suction Temperature may vary ± 5 F.)

Fig. 6 — Charging Chart —502A048

Fig. 7 — Charging Chart — 502A060

Fig. 5 — Charging Chart — 502A036

Copyright 2005 Bryant Heating & Cooling Systems Printed in U.S.A. CATALOG NO. 04-53502001-01

Loading...

Loading...