Page 1

4-Way Multipoise

Induced Combustion

Gas Furnace

311AAV/311JAV

Sizes 045 thru 155

Series A

The Plus 80 311AAV/JAV Deluxe 4-Way Multipoise

Gas Furnace offers outstanding features in an 80%

AFUE furnace. Deluxe features include: third fan

relay for discrete continuous fan speed, the ability to

change continuous fan speeds from the thermostat,

dehumidify mode, standard Media Filter Cabinet, fault

code storage, and more. The Plus 80 is very quiet

thanks to a new combustion design that eliminates

noise, rather than just muffle or box it in. Applications

are easy with 4-way mulitpoise design, through-thefurnace downflow venting, 13 different venting options,

and a door designed for easy service access. An inner

blower door is provided for tighter sealing in sensitive

applications. The 311AAV/JAV furnace is approved for

P

LUS

80

E

n

e

r

g

y

E

ff

i

c

i

e

n

t

G

a

s

Fur

n

a

c

e

use with natural or propane gas, and the 311JAV is

approved for use in LowNOx Air Quality Management

Districts.

ama

A02180

CERTIFIED

REGISTERED

QUALITY SYSTEM

MEETS DOE RESIDENTIAL CONSERVATION

SERVICES PROGRAM STANDARDS.

Before purchasing this appliance, read important

energy cost and efficiency information available

from your retailer.

STANDARD FEATURES

.

Four-position furnace: upflow, horizontal right,

horizontal left, downflow

Thirteen different vent options

.

Noise elimination combustion system

.

Media Filter Cabinet included

.

Microprocessor based "smart" control

center

"Fan On PlusTM" Continuous Fan speed adjustable

from thermostat

Dehumidify mode

Adjustable heating air temperature rise

LED diagnostics and self test feature

Non-volatile fault code storage

.

Patented blocked vent safeguard to ensure

proper furnace venting

.

All models are Chimney Friendly when used

with accessory vent kit

.

Insulated blower compartment

Shorter unit height, only 331/3" tall

.

Heat pump compatible

.

Hot surface Ignition (HSI)

.

Residential installations eligible for

consumer financing through the Comfort

Credit Program

.

Twinning in Upflow, Downflow, and Horizontal

LIMITED WARRANTY

.

20-year warranty on "Super S

.

5-year parts warranty on all other components

TM

" heat exchanger

Form No. PDS 311A.45.2

Page 2

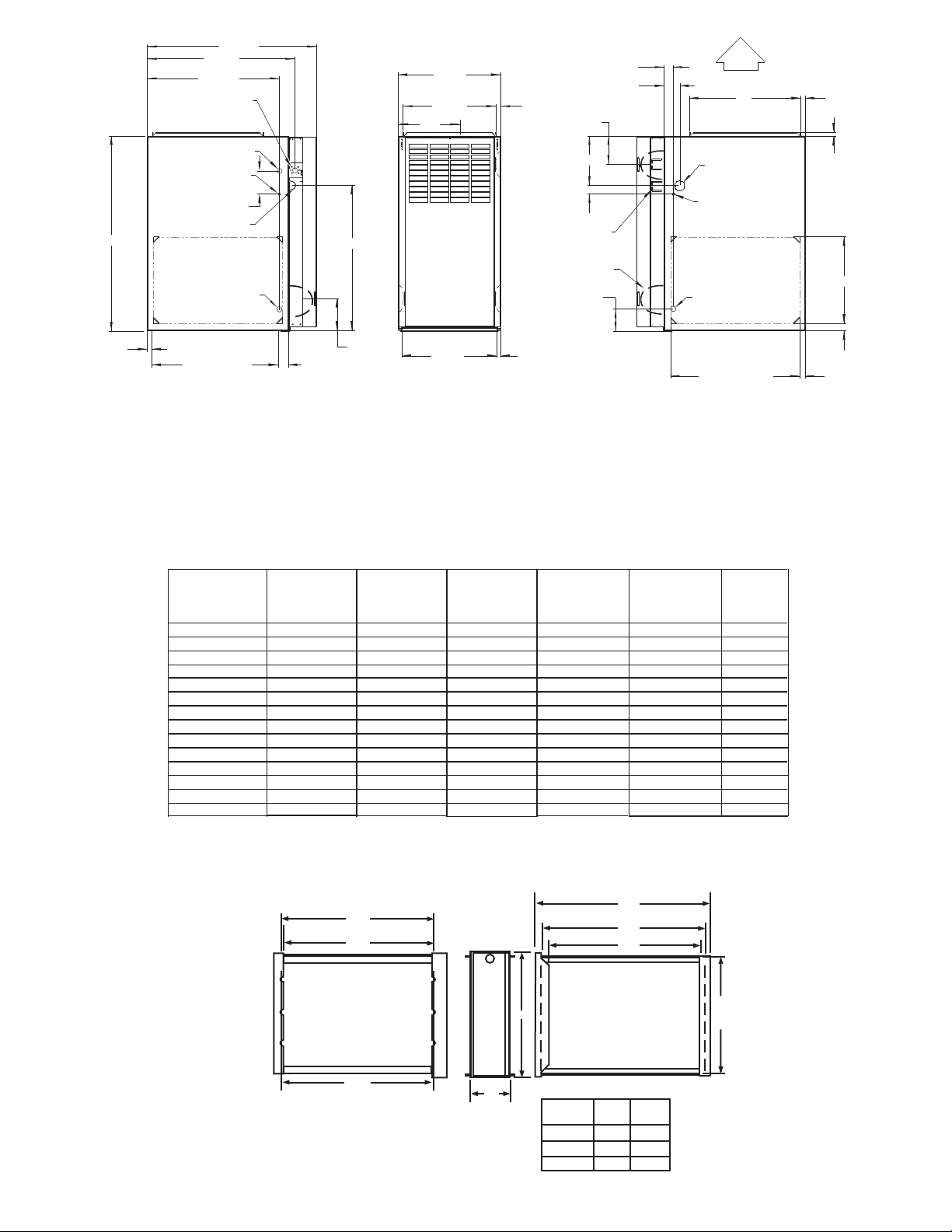

33-5/16"

E

VENT

28-7/8"

25-1/4"

22-9/16"

JUNCTION BOX

LOCATION

7/8" DIA

ACCESSORY

1/2" DIA THERMOSTAT

WIRE ENTRY

3-15/16"

LEFT HAND GAS

ENTRY

7/8" DIA. ACCESSORY

24-7/8"

A

D

13/16"

F

JUNCTION BOX

LOCATION (TYP)

VENT OUTLET

5 PLACES (TYP)

1-9/16"

2-9/16"

4-13/16"

8-7/16"

1-7/16"

ALTERNATE

3-3/4"

AIRFLOW

19"

OUTLET

1-1/2" DIA.

RIGHT HAND

GAS ENTRY

1/2" DIA. THERMOSTAT

WIRE ENTRY

7/8" DIA. ACCESSORY

13/16"

11/16"

14-7/8"

11/16"

5-1/2"

NOTES:

21-5/8"

BOTTOM INLET

1. Two additional

1-11/16"

7

/8

-in. dia knockouts are located in the top plate.

2. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufacturer's recommendations for equivalent diameters.

3. Minimum return-air opening at furnace:

a. For 800 CFM-16-in. round or 14

b. For 1200 CFM-20-in. round or 14 x 19 -in. rectangle.

c. For 1600 CFM-22-in. round or 14 x 22 -in. rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data literature for specific

use of single side inlets. The use of both side inlets, a combination of 1 side and the bottom, or the

bottom only will ensure adequate return air openings for airflow requirements above 1800 CFM.

A

311AAV/311JAV

UNIT SIZE

024045

036045

024070

036070

048070

042090

21 19-3/8 19-1/2 13-5/16 4

048090

060090

036110

048110

066110

048135

24-1/2 22-7/8 23 15-1/16 4 (note 1)

066135

060155

(CABINET

WIDTH)

14-3/16 12-9/16 12-11/16 9-5/16 4

14-3/16 12-9/16 12-11/16 9-5/16 4

14-3/16 12-9/16 12-11/16 9-5/16 4

14-3/16 12-9/16 12-11/16 9-5/16 4

17-1/2 15-7/8 16-1/8 11-9/16 4

17-1/2 15-7/8 16-1/8 11-9/16 4

21 19-3/8 19-1/2 13-5/16 4

17-1/2 15-7/8 16-1/8 11-9/16 4

21 19-3/8 19-1/2 13-5/16 4

21 19-3/8 19-1/2 13-5/16 4

21 19-3/8 19-1/2 13-5/16 4 (note 1)

24-1/2 22-7/8 23 15-1/16 4 (note 1)

1) 135 and 155 size furnaces require five-inch

furnace and vent stack.

2) See Installation Instructions for complete

23 "

3

/

22

4"

E

1

/

x 12-in. rectangle.

2

1

1

/

/

2

1

1

/

/

2

D

(SUPPLY

WIDTH)

11/16"

2

16

F

(BOTTOM

RETURN

WIDTH)

(C.L. TOP &

BOTTOM

VENT OUTLET)

CONNECTION

SIZE

(see notes 1 & 2)

vents. Use a 4-5 inch vent adapter between

installation requirements.

25 "

3

/

23

4"

Opening with Flanges Bent

1

/

22

2"

Opening

22-1/16"

SIDE INLET

SHIPPING

WEIGHT

1-1/4"

1"

A02304

114

117

121

125

136

135

150

156

143

156

162

159

173

180

Furnace Side

1

/

23

8"

Centerline Screw Slots

-2-

B Opening

A

Duct Side

3

/

5

4"

Media/

Filter Cabinet

16" 17" 16"

20" 21" 20"

24" 25" 24"

A B

A02210

Page 3

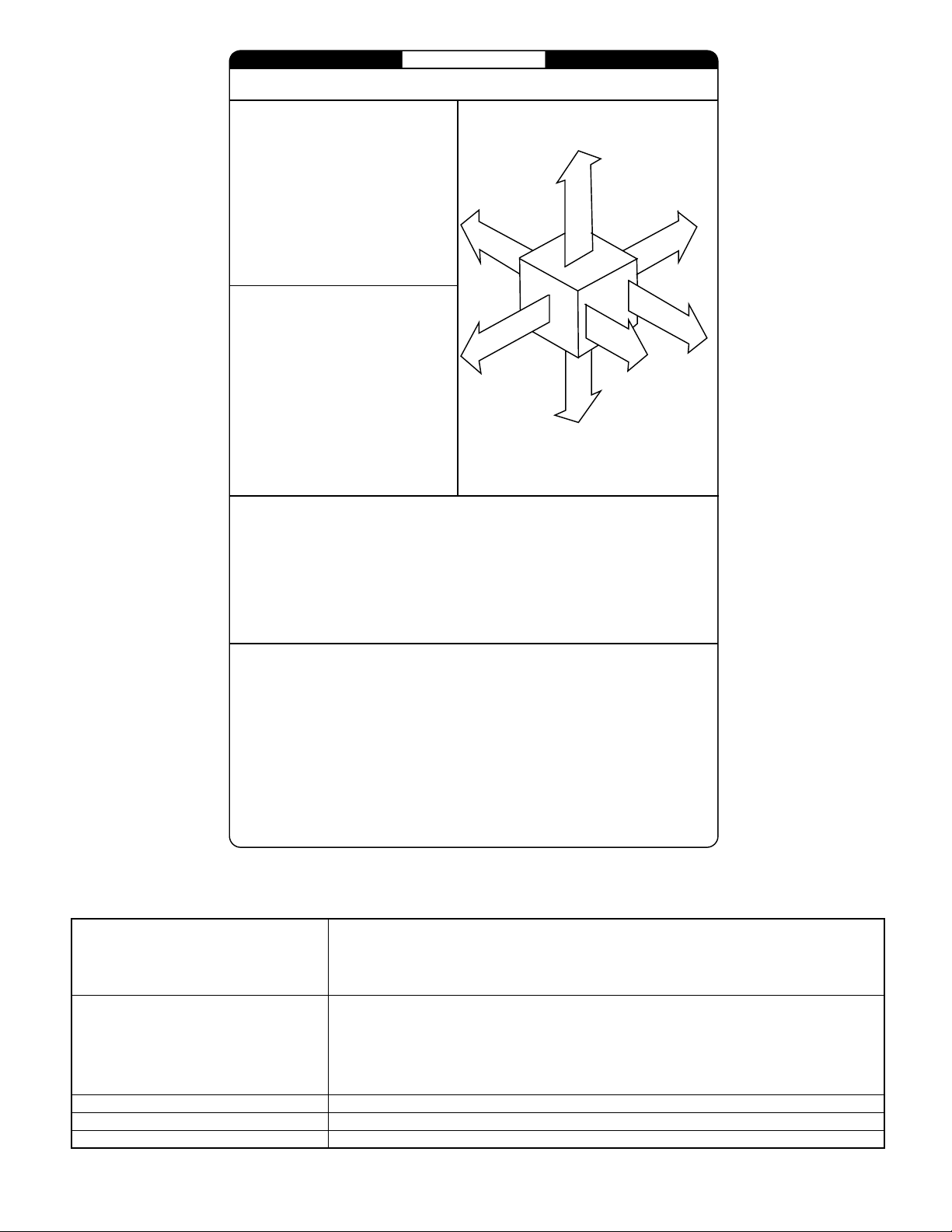

INSTALLATION

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

DISTANCE MINIMALE EN POUCES AUX CONSTRUCTIONS COMBUSTIBLES

This forced air furnace is equipped for use with

natural gas at altitudes 0-10,000 ft (0-3,050m).

An accessory kit, supplied by the

manufacturer,shall be used to convert to propane

gas use or may be required for some natural gas

applications.

This furnace is for indoor installation in a

building constructed on site.

This furnace may be installed on combustible

flooring in alcove or closet at minimum clearance

as indicated by the diagram from combustible

material .

This furnace may be used with a Type B-1 Vent

and may be vented in common with other gasfired appliances.

Cette fournaise à air pulsé est équipée

pour utilisation avec gaz naturel et altitudes

comprises entre 0-3,050m (0-10,000 pi).

Utiliser une trousse de conversion, fournie par

le fabricant, pour passer au gaz propane ou pour

certaines installations au gaz naturel.

Cette fournaise est prévue pour être

installée dans un bâtiment construit sur place.

Cette fournaise peut être installée sur

un plancher combustible dans une alcôve ou

dans un garde-robe en respectant le minimum

d'espace libre des matériaux combustibles, tel

qu'indiqué sur le diagramme..

Cette fournaise peut être util isée avec un

conduit d´évacuation de Type B-1 ou connectée

au conduit commun d´autres appareils à gaz..

This furnace is approved for UPFLOW, DOWNFLOW, and

HORIZONTAL install ations.

Cette fournaise est approuvée pour l´installation HORIZONTALE

et la circulation d´air VERS LE HAUT et VERS LE BAS.

1"

Clearance arrows

do not change with

furnace orientati on.

0"

B

A

A

C

R

K

R

I

È

R

E

E

D

I

S

É

T

Ô

C

0"

*

Vent Clearance to combustibles:

For Single Wall vents 6 inches (6 po).

For Type B-1 vent type 1 inch (1 po).

Dégagement de l´évent avec combustibles:

Pour conduit d´évacuation à paroi simple 6 po (6 inches).

Pour conduit d´évacuation de Type B-1 1 po (1 inch).

Les fléches de dégagement

ne changent pas avec

l´orientation de la fournaise.

TOP / PLE NUM

DESSUS / CHAMBRE D'AIR

E

C

E

A

S

N

I

A

R

U

N

F

R

U

T

FO

N

O

T

R

N

F

A

V

A

F

R

O

A

N

V

T

A

N

T

3"

DESSOUS

"

Clearance in inches

Dégagement (po).

BOTTOM

0

†

S

E

N

MIN

Ø

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

DOWNFLOW POSITIONS:

Installation on non-combustible floors only.

†

For Installation on combustible flooring only when installed on special base, Part No. KGASB0201ALL,

Coil Assembly, Part No. CD5 or CK5, or Coil Casing, Part No. KCAKC.

18 inches front clearance required for alcove.

Ø

Indicates supply or return sides when furnace is in the horizontal position. Line contact only permissible

*

between lines formed by intersections of the Top and two Sides of the furnace jacket, and building joists,

studs or framing.

DÉGAGEMENT MINIMUM EN POUCES AVEC ÉLÉMENTS

DE CONSTRUCTION COMBUSTIBLES

POUR LA POSITION COURANT DESCENDANT:

Pour l ´installation sur plancher non combustible seulement.

†

Pour l´installation sur un plancher combustible seulement quand on utilise la base spéciale, pièce

o

n KGASB0201ALL, l´ensemble serpentin, pièce n CD5 ou CK5, ou l e carter de serpenti n, pièce

o

n KCAKC.

Dans une alcôve, on doit maintenir un dégagement à l´avant de 18 po (450 mm).

Ø

La position indiquée concerne le côté d´entrée ou de retour quand la fournaise est dans la

*

position horizontale.

Le contact n´est permis qu´entre les lignes formées par les intersections du dessus et des

deux côtés de la chemise de la fournaise et les solives, montant sous cadre de charpente.

o

327590-101 REV. B

0"

E

D

*

I

È

T

Ô

C

S

E

R

V

I

T

R

C

E

E

T

I

E

N

30"

MIN

CONTROLS-THERMOSTATS AND ZONING

Auto Changeover, oF/oC, 1-Stage Heat/1-Stage Cool - TSTATBBNAC01-B

Auto Changeover, oF/oC, 2-Stage Heat/1-Stage Cool - TSTATBBNHP01-B

THERMOSTAT- NON-PROGRAMMABLE

THERMOSTAT- PROGRAMMABLE

Auto Changeover, 7-Day Programmable, oF/oC, 1-Stage Heat/1-Stage Cool - TSTATBBPAC01-B

Auto Changeover, 7-Day Programmable, oF/oC, 2-Stage Heat/1-Stage Cool - TSTATBBPHP01-B

Auto Changeover, 7-Day Programmable, oF/oC, 2-Stage Heat/2-Stage Cool - TSTATBBP2S01-B

Thermidistat Control - Non-Programmable/Programmable Thermostat - TSTATBBPRH01-B *

with Humidity Control (For use in Dual Fuel, AC, HP, and 2S applications. Includes Outdoor Air

Auto Changeover, oF/oC, 2-Stage Heat/2-Stage Cool - TSTATBBN2S01-B

Air Conditioner, 1-Stage Heat/1-Stage Cool, Manual Changeover, oF/oC - TSTATBBBAC01

Heat Pump, 2-Stage Heat/1-Stage Cool, Manual Changeover, oF/oC - TSTATBBBHP01

Dual Fuel Thermostat, includes Outdoor Air Temperature Sensor - TSTATBBPDF01-B

in AC Mode, 3-Stage Heat/2-Stage Cool in HP Mode

in AC Mode, 3-Stage Heat/2-Stage Cool in HP Mode

Temperature Sensor.)

ZONING- 2-ZONE ZONEBB2KIT01-B, ZONEKIT2ZBDP

ZONING- 4-ZONE ZONEBB4KIT01-B

ZONING- 8-ZONE ZONEBB8KIT01-B

* Do not use in zoning heat pump applications.

-3-

*

*

Page 4

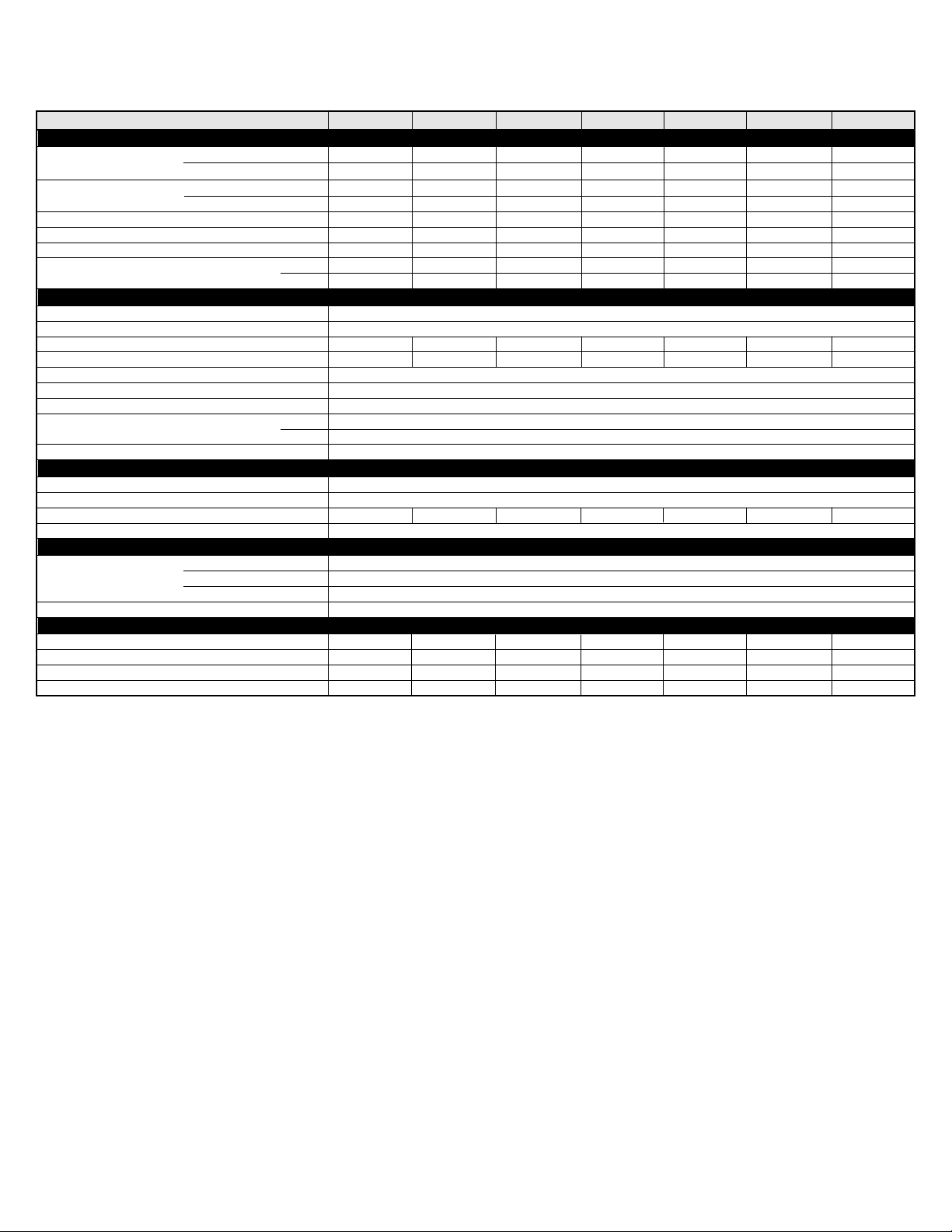

SPECIFICATIONS

UNIT SIZE

RATINGS AND PERFORMANCE

Input Btuh

Nonweatherized ICS

Output Capacity (Btuh)

Nonweatherized ICS

AFUE

Certified Temperature Rise Range oF

Certified External Static Pressure Heat/Cool

Airflow CFM ‡

ELECTRICAL

Unit Volts-Hertz-Phase 115-60-1

Operating Voltage Range Min-Max 104-127

Maximum Unit Amps

Maximum Wire Length (Measured 1 Way in Ft)

Minimum Wire Size 14

Maximum Fuse or Ckt Bkr Size (Amps)** 15

Transformer (24v) 40va

External Control Heating 12va

Power Available Cooling 35va

Air Conditioning Blower Relay Standard

CONTROLS

Limit Control SPST

Heating Blower Control Solid-State Time Operation

Burners (Monoport)

Gas Connection Size 1/2-in. NPT

GAS CONTROLS

Gas Valve (Redundant)

Ignition Device Hot Surface

BLOWER DATA

Direct-Drive Motor HP (PSC)

Motor Full Load Amps

RPM (Nominal)-Speeds

Blower Wheel Diameter x Width (In.)

* Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 ft, reduce ratings 4 percent for each 1000 ft above sea level. Refer to National

*

311JAV Upflow; all 311AAV

311JAVDownflow/Horizontal

†

311JAV Upflow; all 311AAV

311JAVDownflow/Horizontal

†

Heating

Cooling

Min Inlet Pressure (In. wc) 4.5 (Natural Gas)

Max Inlet Pressure (In. wc) 13.6 (Natural Gas)

Fuel Gas Code Table F4 or furnace Installation Instructions. In Canada, derate the unit 10 percent for elevations 2000 ft to 4500 ft above sea level.

024045

44,000

42,000

35,000

34,000

80.0

30-60

0.10/0.50

920

845

5.6

47

2

1/5

2.9

1075-3

10 x 6

036045

44,000

42,000

36,000

34,000

80.0

20-50

0.10/0.50

1250

1160

7.0

39

2

1/3

5.2

1075-4

10 x 6

024070

66,000

63,000

53,000

51,000

80.0

40-70

0.12/0.50

720

900

5.0

52

3

1/5

2.9

1075-4

10 x 6

036070

66,000

63,000

54,000

51,000

80.0

30-60

0.12/0.50

1195

1200

6.7

40

3

White Rodgers

1/3

5.2

1075-4

10 x 6

048070

66,000

63,000

53,000

51,000

80.0

25-55

0.12/0.50

1450

1530

9.4

29

3

1/2

5.2

1075-4

11 x 8

042090

88,000

84,000

71,000

68,000

80.0

40-70

0.15/0.50

1375

1385

8.1

34

4

1/3

5.2

1075-4

10 x 8

048090

88,000

84,000

71,000

68,000

80.0

30-60

0.15/0.50

1505

1720

9.8

28

1/2

7.9

1075-4

10 x 10

** Time-delay type is recommended.

†

Capacity in accordance with U.S. Government DOE test procedures.

‡

Airflow shown is for bottom only return-air supply for the as-shipped speed tap. For air delivery above 1800 CFM, see Air Delivery table for other options. A filter

is required for each return-

ICS-Isolated Combustion System

N/A-Not Applicable

air supply. An airflow reduction of up to 7% may occur when using the factory-specified 4-5/16-inch wide, high efficiency media filter.

4

-4-

Page 5

SPECIFICATIONS

UNIT SIZE

RATINGS AND PERFORMANCE

Input Btuh

Nonweatherized ICS

Output Capacity (Btuh)

Nonweatherized ICS

AFUE

Certified Temperature Rise Range oF

Certified External Static Pressure Heat/Cool

Airflow CFM ‡

ELECTRICAL

Unit Volts-Hertz-Phase 115-60-1

Operating Voltage Range Min-Max 104-127

Maximum Unit Amps

Maximum Wire Length (Measured 1 Way in Ft)

Minimum Wire Size 14

Maximum Fuse or Ckt Bkr Size (Amps)** 15

Transformer (24v) 40va

External Control Heating 12va

Power Available Cooling 35va

Air Conditioning Blower Relay Standard

CONTROLS

Limit Control SPST

Heating Blower Control Solid-State Time Operation

Burners (Monoport)

Gas Connection Size 1/2-in. NPT

GAS CONTROLS

Gas Valve (Redundant)

Ignition Device Hot Surface

BLOWER DATA

Direct-Drive Motor HP (PSC)

Motor Full Load Amps

RPM (Nominal)-Speeds

Blower Wheel Diameter x Width (In.)

* Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 ft, reduce ratings 4 percent for each 1000 ft above sea level. Refer to National

Fuel Gas Code Table F4 or furnace Installation Instructions. In Canada, derate the unit 10 percent for elevations 2000 ft to 4500 ft above sea level.

*

311JAV Upflow; all 311AAV

311JAVDownflow/Horizontal

†

311JAV Upflow; all 311AAV

311JAVDownflow/Horizontal

†

Heating

Cooling

Min Inlet Pressure (In. wc) 4.5 (Natural Gas)

Max Inlet Pressure (In. wc) 13.6 (Natural Gas)

060090

88,000

84,000

71,000

68,000

80.0

25-55

0.15/0.50

1990

2025

13.6

32

12

20

4

3/4

11.1

1075-4

11 x 11

036110

110,000

105,000

89,000

85,000

80.0

50-80

0.20/0.50

1335

1355

8.1

34

5

1/3

5.2

1075-4

10 x 8

048110

110,000

105,000

89,000

85,000

80.0

40-70

0.20/0.50

1515

1680

10.0

28

5

1/2

7.9

1075-4

10 x 10

066110

110,000

105,000

89,000

85,000

80.0

30-60

0.20/0.80

1900

2220

13.6

32

12

20

5

White Rodgers

3/4

11.1

1075-4

11 x 11

048135

132,000

126,000

107,000

102,000

80.0

50-80

0.20/0.50

1525

1710

10.0

28

14

15

6

1/2

7.9

1075-4

10 x10

066135

132,000

126,000

107,000

102,000

80.0

40-70

0.20/0.50

1850

2110

14.4

30

6

3/4

11.1

1075-4

11 x 11

060155

154,000

147,000

125,000

119,000

80.0

45-75

0.20/0.50

1790

2230

15.0

12

20

3/4

11.1

1075-4

11 x 11

** Time-delay type is recommended.

†

Capacity in accordance with U.S. Government DOE test procedures.

‡

Airflow shown is for bottom only return-air supply for the as-shipped speed tap. For air delivery above 1800 CFM, see Air Delivery table for other options. A filter

is required for each return-

ICS-Isolated Combustion System

N/A-Not Applicable

air supply. An airflow reduction of up to 7% may occur when using the factory-specified 4-5/16-inch wide, high efficiency media filter.

29

7

-5-

Page 6

SEE NOTES: 1,2,4,7,8,9

UPFLOW

A02058

SEE NOTES: 1,2,3,4,7,8,9

UPFLOW

A02059

SEE NOTES: 1,2,4,5,7,8,9

DOWNFLOW

A02061

SEE NOTES:1,2,3,4,5,7,8,9

DOWNFLOW

A02060

SEE NOTES: 1,2,3,4,5,7,8,9

DOWNFLOW

A02063

SEE NOTES: 1,2,4,5,6,7,8,9

DOWNFLOW

Venting Notes

1. For common vent, vent connector sizing and vent material: United States, latest edition of the National Fuel

Gas Code (NFGC), ANSI Z223.1/NFPA 54. In Canada, latest edition of the National Standards of Canada,

Natural Gas and Propane Installation Code (NSCNGPIC), CSA B149.1-00.

2. Immediately increase to 5-inch vent connector outside furnace casing when 5-inch vent connector required,

refer to Note 1.

3. Side outlet vent for upflow and downflow installations must use Type B vent immediately after exiting the

furnace, except when KGAVG0101DFG is used in downflow position.

4. Type B vent where required, refer to Note 1.

5. 4" single wall vent must be used inside furnace casing and the KGAVG0101DFG Downflow Vent Guard Kit.

6. Accessory Downflow Vent Guard Kit, KGAVG0101DFG required in downflow installations with bottom vent

configuration.

7. Chimney Adapter Kit required for exterior masonry chimney applications. Refer to Chimney Adapter Kit,

KGACA02014FC and KGACA02015FC for sizing and complete application details.

8. Secure vent connector to furnace elbow with (2) corrosion-resistant sheet metal screws, space approximately

o

apart.

180

9. Secure all other single wall vent connector joints with (3) corrosion-resistant screws spaced approximately

o

apart. Secure Type B vent connectors per vent connector manufacturer's recommendations.

120

A02062

-6-

Page 7

SEE NOTES: 1,2,4,5,7,8,9

HORIZONTAL RIGHT

A02068

SEE NOTES: 1,2,4,7,8,9

HORIZONTAL RIGHT

SEE NOTES: 1,2,4,5,7,8,9

HORIZONTAL RIGHT

A02070

A02069

SEE NOTES: 1,2,4,7,8,9

HORIZONTAL LEFT

SEE NOTES: 1,2,4,5,7,8,9

HORIZONTAL LEFT

A02066

A02064

SEE NOTES: 1,2,4,5,7,8,9

HORIZONTAL LEFT

SEE NOTES: 1,2,4,5,7,8,9

HORIZONTAL LEFT

A02065

A02067

-7-

Page 8

FACTORY-AUTHORIZED DEALER-INSTALLED ACCESSORIES

DESCRIPTION PART NO.

024045

036045

024070

036070

048070

042090

048090

060090

036110

048110

066110

048135

066135

060155

EZ Flex Media Filter with end

caps - 16 i n. (9 pack)

EZ Flex Media Filter with end

caps - 20 i n. (9 pack)

EZ Flex Media Filter with end

caps - 24 i n. (6 pack)

Replacement EZ Flex Filter - 16

in. (10 pack)

Replacement EZ Flex Filter - 20

in. (10 pack)

Replacement EZ Flex Filter - 24

in. (10 pack)

Unframed filter, one inch - 16x25 KGAWF1301UFR

Unframed filter, one inch 20x25

Unframed filter, one inch 24x25

Twinning Kit KGATW0601HSI x x x x x x x x x x x x x x

Combustible Floor Base (not

required when evaporator coil

case is used)

Downflow Vent Guard (not

required when vent is routed

through cabinet)

Vent Extension Kit (may be used

when vent is routed through

cabinet in downflow)

Chimney Adapter Kit - 4 i nch

vent

Chimney Adapter Kit - 5 i nch

vent

Natural-to-Propane Gas

Conversion Kit (Single Kit)

Propane-to-Natural Gas

Conversion Kit (Single Kit)

EXPXXUNV0016

EXPXXUNV0020

EXPXXUNV0024

EXPXXFIL0016

EXPXXFIL0020

EXPXXFIL0024

KGAWF1306UFR (6-pack)

KGAWF1401UFR

KGAWF1406UFR (6 pack)

KGAWF1501UFR

KGAWF1506UFR (6 pack)

KGASB0201ALL

KGAVG0101DFG

KGAVE0101DNH

KGACA02014FC

KGACA02015FC

KGANP2901ALL

*

KGAPN2301ALL

x x x x x x x

x x x x x x x

x x x x x x

x

x x x x x x x x x x x x x x

x x x x x x x x x x x x x x

x x x x

x

x x x x x x x x x x x

x x x x x x x x x x x x x x

x x x x x x x x x x x x x x

x x x x x

x x

x x x x x

x x

s s s s s s s

x x x x x

xx

x x x x x x x x x

x x x

Gas Orifice Kit (Qty 50) Size 42 KGAHA0150N42

Gas Orifice Kit (Qty 50) Size 43 KGAHA0250N43

Gas Orifice Kit (Qty 50) Size 44 KGAHA0350N44

Gas Orifice Kit (Qty 50) Size 45 KGAHA0450N45

Gas Orifice Kit (Qty 50) Size 46 KGAHA0550N46

Gas Orifice Kit (Qty 50) Size 47 KGAHA1550N47

Gas Orifice Kit (Qty 50) Size 48 KGAHA1650N48

See Installation Instructions for model,

altitude, and heat value usages.

Gas Orifice Kit (Qty 50) Size 54 KGAHA0650P54

Gas Orifice Kit (Qty 50) Size 55 KGAHA0750P55

Gas Orifice Kit (Qty 50) Size 56 KGAHA0850P56

Gas Orifice Kit (Qty 50) 1.25 mm KGAHA5750125

Gas Orifice Kit (Qty 50) 1.30 mm KGAHA5750130

* Factory-authorized and field installed. Gas conversion kits are A.G.A./C.G.A. recognized.

s

16x25 filters suitable for side return on all furnace sizes.

-8-

Page 9

AIR DELIVERY-CFM (With Filter)*

UNIT SIZE

024045

036045

024070

036070

048070

042090

048090

060090

036110

048110

* A filter is required for each return-air supply. Airflow performance includes 1" washable filter media such as contained in factory-authorized accessory filter rack.

To determine airflow performance without this filter, assume an additional .1 available external static pressure.

-Indicates unstable operating conditions.

RETURN-AIR

SUPPLY

Bottom

or

Side(s) Med-Low

Bottom

or

Side(s)

Bottom

or

Side(s)

Bottom

or

Side(s)

Bottom

or

Side(s)

Bottom

or

Side(s)

Bottom

or

Side(s)

Bottom

Only

Both Sides or

1 Side & Bottom

1 Side Only

Bottom

or

Side(s)

Bottom

or

Side(s)

SPEED

High

Med-High

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

0.1 0.2

1085

920

820

1440

1360

1250

1085 1055

1030

835

725

1425

1320

1200

1040

1805

1630

1460

1275

1650

1515

1385

1205

2060

1790

1505

1225

2405

2225

2020

1810

2530

2285

1995

1770

2475

2260

1950

1730

1625

1510

1360

1195

2035

1745

1530

1270 1265

1035

875

775

1375

1300

1210

1010

815

700

1375

1280

1175

1030

1740

1585

1420

1250

1600

1485

1360

1180

1985

1765

1505

1225 1220

2310

2155

1955

1765 1715 1645

2450

2215

1945

1740

2395

2190

1910

1695

1575

1470

1335

1180

1965

1710

1515

0.3 0.4

1305

1240

1160

1035 990 945 885

1320

1240

1145

1010

1670

1530

1385

1225 1195

1535

1440

1320

1160

1915

1715

1480

2220

2080

1880

2365

2150

1900

1700

2300

2110

1855

1650 1600

1515

1415

1295

1155

1880

1650

1470

1235 1195

EXTERNAL STATIC PRESSURE (In. wc)

975

830

730

980

790

675

915

770

680

1240

1175

1100

945

760

645

1265

1205

1105

985

1600

1470

1325

1465

1380

1260

1120

1820

1645

1440

1195

2130

1995

1805

2270

2075

1840

1645

2200

2035

1795

1445

1355

1250

1115 1065

1790

1560

1400

1160

1115

1040

1200

1140

1050

1530

1405

1280

1155

1385

1300

1195

1065

1720

1560

1375

1155

2025

1895

1730

1565

2165

1985

1770

1575

2090

1940

1730

1535 1470

1355

1285

1180

1680

1450

1310

1130

0.5

845

710

620

900

720

600

945

0.6

770

640

555

1070

1040

965

845

675

555

1125

1075

990

895

1445

1330

1220

1105 1050

1285

1220

1120

1005

1610

1470

1300

1085

1920

1785

1630

1480

2065

1890

1685

1505

1985

1845

1650 1555

1260

1185

1100

980 860 740

1495

1340

1215

1055

0.7

675

555

470

975

950

885

810

775

610

475

1035

995

920

845

1360

1255

1155

1175

1115

1025

925 810

1490

1345

1190

985

1790

1675

1535

1390

1940

1780

1600

1415

1865

1735

1385

1165

1070

985

1365

1205

1095

970 875

1340

0.8

565

440

360

870

850

790

715

680

490

390

940

905

840

765

1280

1170

1080

980

1055

990

915

1195

1045

870

1660

1565

1420

1280 1145

1805

1660

1480

1325

1730

1620

1445

1285 1165 1000

990

890

810

1215

1090

990

0.9

390

250

190

730

725

670

595

490

375

300

830

790

725

655

1180

1080

995

910

895

830

710

630

1135

1010

890

735

1530

1420

1275

1670

1525

1350

1190

1585

1475

1310 1150

785

725

670

605

1075

955

830

720

1.0

195

---

560

575

520

435

335

265

---

655

620

555

505

1075

990

910

835

645

600

565

510

925

820

740

620

1350

1260

1135

1005

1505

1360

1180

1040

1425

1325

595

530

475

410

875

750

670

600

---

-9-

Page 10

AIR DELIVERY-CFM (With Filter)*

UNIT SIZE

066110

048135

066135

060155

* A filter is required for each return-air supply. Airflow performance includes 1" washable filter media such as contained in factory-authorized accessory filter rack.

To determine airflow performance without this filter, assume an additional .1 available external static pressure.

-Indicates unstable operating conditions.

RETURN-AIR

SUPPLY

Bottom

Only

Both Sides or

1 Side & Bottom

1 Side Only

Bottom

or

Side(s)

Bottom

Only

Both Sides or

1 Side & Bottom

1 Side Only

Bottom

Only

Both Sides or

1 Side & Bottom

1 Side Only

SPEED

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

High

Med-High

0.1 0.2

2530

2230

1920

1640

--2235

1920

1640

2540

2125

1790

1515 1535

2090

1790

1545

1325 1320

2485

2195

1880

1640 1635 1615 1585

---

2180

1880

1640 1635

--2135

1880

1640

2465

2115

1800

1570 1565

---

2155

--2140

2470

2205

1900

1650

--2200

1900

1650

2495

2120

1795

2010

1755

1525

2400

2150

1850

---

2145

1850

---

2085

1850

1620

2430

2105

1790

---

2135

---

2095

0.3 0.4

2400

2165

1880

1635 1610 1575

2415

2155

1880

1635 1610 1575

2430

2105

1790

1535

1930

1705

1500

1295

2310

2090

1820

2385

2060

1820

1615

2245

2035

1820

1580

2375

2075

1770

1550

2375

2095

2260

2040

EXTERNAL STATIC PRESSURE (In. wc)

0.5

2320

2110

1845

2350

2100

1845

2355

2060

1765

1522

1835

1640

1450

1265 1210 1150

2215

2000

1780

2305

2010

1780

1585

2155

1975

1780

1540

2305

2030

1735

1525

2285

2040

2180

1975

2220

2035

1795

2250

2040

1795

2265

2010

1720

1490

1710

1550

1380

2110

1920

1715

1530

2195

1945

1715

1530

2055

1895

1715 1635 1540 1415 1290 1160

1485

2230

1980

1695

1495 1445

2200

1975

2085

1890

0.6

2115

1950

1730

1520 1455

2145

1955

1730

1520 1455 1375 1285

2175

1940

1650 1585

1445

1590

1465

1315

2000

1825

1635

1465

2085

1865

1635

1465

1940

1795

1410

2110

1910

1640

2105

1895

1975

1810

0.7

2000

1855

1650

2015

1850

1650

2065

1840

1390

1470

1360

1215

995

1880

1720

1540

1370

1960

1765

1540

1370

1825

1685

1330

2000

1830

1570

1370

1995

1790

1865

1705

0.8

1865

1740

1555

1375

1875

1740

1555

1935

1730

1500

1315

1335

1210

1005

865 745

1725

1565

1415

1255

1825

1660

1415

1255

1695

1565

1220

1865

1725

1465

1270

1870

1685

1740

1595

0.9

1730

1615

1460

1285

1715

1595

1460

1785

1615

1390 1280

1225

1025

945

855

1535

1405

1290

1150 1040

1670

1515

1290

1150

1555

1445

1080

1725

1590

1345

1175 1070

1730

1550

1605

1480

1.0

1590

1485

1340

1170

1560

1470

1340

1170

1650

1485

1120

835

785

670

540

1355

1255

1160

1465

1325

1160

1040

1385

1265

1545

1425

1225

1570

1400

1455

1325

960

-10-

Page 11

-11-

Page 12

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: 311A.45.1

© 2003 Bryant Heating & Cooling Systems, 7310 W. Morris St. Indpls., IN 46231 PRINTED IN U.S.A. Catalog No. 5231-102 02-03

Loading...

Loading...