Page 1

288BNV EVOLUTIONRV VARIABLE SPEED HEAT PUMP

189BNV EVOLUTION

R

V VARIABLE SPEED AIR CONDITIONER

WITH PURONr REFRIGERANT

Service Manual

TABLE OF CONTENTS

UNIT IDENTIFICATION 2.................................................................................

REFRIGERANT PIPING LENGTH LIMITATIONS 3...........................................................

LONG LINE APPLICATIONS 3.............................................................................

SAFETY CONSIDERATIONS 4.............................................................................

GENERAL INFORMATION 4..............................................................................

ELECTRICAL 5..........................................................................................

MAJOR COMPONENTS 5--7...............................................................................

AOC Board 5..........................................................................................

Inverter 5..............................................................................................

Variable Speed Compressor 5..............................................................................

Electronic Expansion Valve (EXP) 6.........................................................................

Outdoor Fan Motor 6.....................................................................................

Pressure Transducer (SPT) 6...............................................................................

Pressure Equalizer Valve (PEV) 6...........................................................................

Outdoor Coil Thermistor (OCT) 6...........................................................................

Suction Thermistor (OST) 7...............................................................................

Discharge Thermistor (ODT) 7.............................................................................

Crankcase Heater 7......................................................................................

Time--Delays 7.........................................................................................

COMMUNICATION AND STATUS FUNCTION LIGHTS 7.....................................................

CHECK CHARGE 9.......................................................................................

TROUBLESHOOTING 9--13................................................................................

Service Tool 14-- 31......................................................................................

System Communication Failure 14..........................................................................

Model Plug 14..........................................................................................

Status Codes 14.........................................................................................

Variable Speed Compressor Winding Resistance 14.............................................................

Fan Motor 15...........................................................................................

Control Fault 15........................................................................................

Brown Out Protection 15..................................................................................

230v Line (Power Disconnect) Detection 15...................................................................

Pressure Switch Protection 15..............................................................................

Suction Pressure Transducer (SPT) 15........................................................................

Temperature Thermistors 16...............................................................................

Fault Code Action Table 18................................................................................

Variable Speed Drive LED Location and Description 25..........................................................

Compressor Power Harness Assembly Replacement 26..........................................................

Inverter Assembly with Shield Gasket Installation 28............................................................

Compressor Replacement 31...............................................................................

WIRING DIAGRAMS 34-- 35.................................................................................

REFRIGERATION SYSTEM 36-- 40..........................................................................

Refrigerant 36..........................................................................................

Compressor Oil 36.......................................................................................

Servicing Systems on Roofs With Synthetic Materials 36.........................................................

Brazing 36.............................................................................................

Service Valves and Pump down 36..........................................................................

Liquid Line Filter Drier 39................................................................................

Suction Line Filter Drier 39................................................................................

Thermostatic Expansion Valve (TXV) 39.....................................................................

Accumulator 40.........................................................................................

REFRIGERATION SYSTEM REPAIR 40.....................................................................

PAGE

Page 2

UNIT IDENTIFICATION

The unit is identified using a 16 digit model number structure. It is recommended providing the complete 16 digit model number when

ordering replacement parts to insure receiving the correct parts.

MODEL NUMBER NOMENCLATURE -- HEAT PUMP

12 3 4 5 6 78910 11 12 14

N N N A A/N N N N N A/N A/N N A

28 8 B N V 0360 0 0 A

Product

Famil y

2=HP 8=

Tier SEER Major

Evolution

8 = 18 SEER B=Puron N= 208---230 --- 1

Series

Series

Voltage V ariations Cooling Capacity Open Open Open Series

or 208/230 ---1

V=Variable

Speed

0=Not

Defined

0=Not

Defined

0=Not

DefinedA=Original

Series

MODEL NUMBER NOMENCLATURE -- AIR CONDITIONER

12 3 4 5 6 78910 11 12 14

N N N A A/N N N N N A/N A/N N A

18 9 B N V 0360 0 0 A

Product

Famil y

1=AC 8=

Tier SEER Major

Evolution

9 = 19 SEER B=Puron N= 208---230 --- 1

Series

Series

Voltage V ariations Cooling Capacity Open Open Open Series

or 208/230 ---1

V=Variable

Speed

0=Not

Defined

0=Not

Defined

0=Not

DefinedA=Original

Series

SERIAL NUMBER NOMENCLATURE

Week of Manufacture

01 06

E

00001

Serial Number

Year of Manufacture

Manufacturing Site

E = Collierville TN

X = Monterrey Mexico

2

Page 3

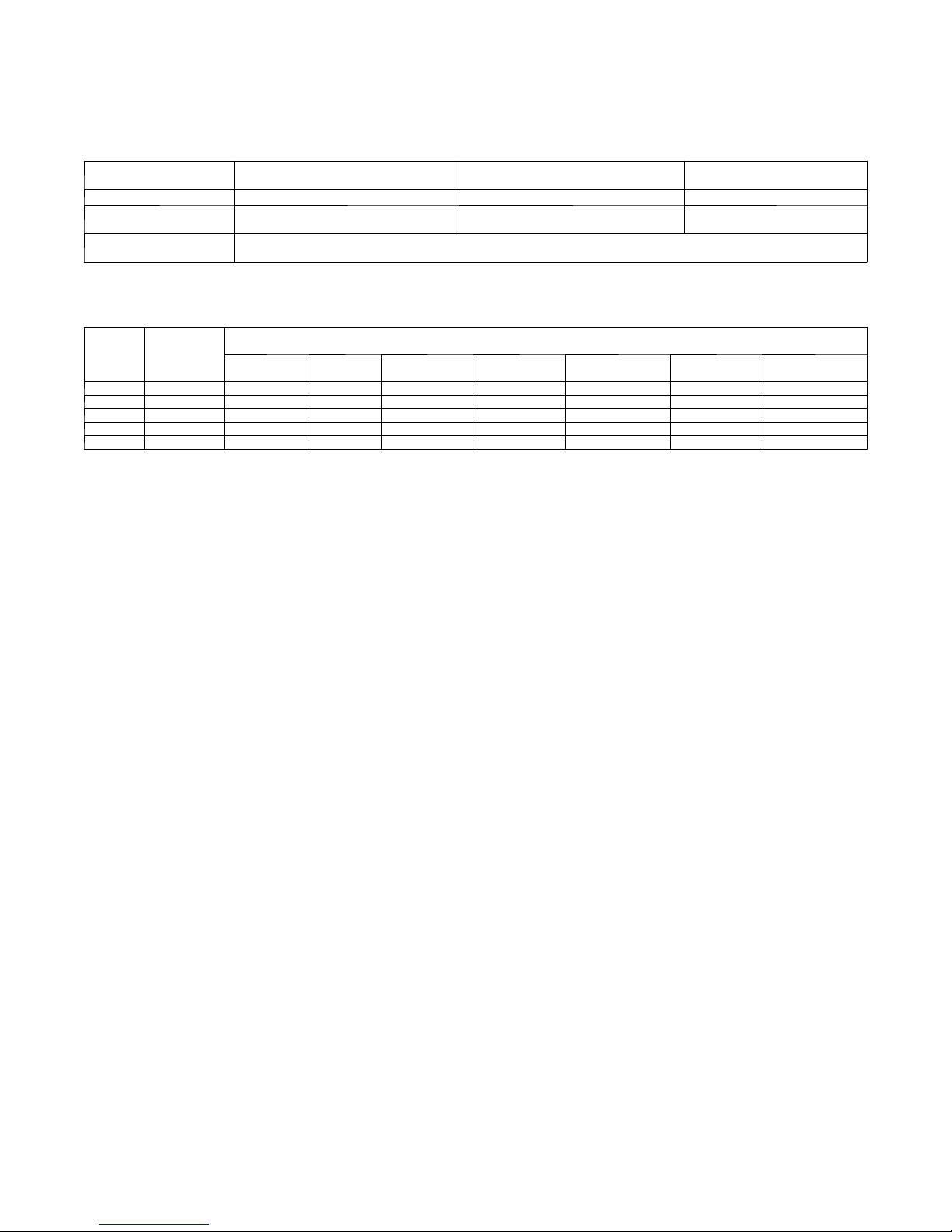

REFRIGERANT PIPING LENGTH LIMITATIONS

Maximum Line Lengths:

The maximum allowable total equivalent length varies depending on the vertical separation. See the tables below for allowable lengths

depending on whether the outdoor unit is on the same level, above or below the outdoor unit.

Maximum Line Lengths

MAXIMUM ACTUAL LENGTH

Units on equal level 100 (30.5) 100 (30.5) N/A

Outdoor unit ABOVE

indoor unit

Outdoor unit BELOW

indoor unit

{ Total equivalent length accounts for losses due to elbows or fitting. See the Long Line Guideline for details.

ft (m)

100 (30.5) 100 (30.5) 100 (30.5)

See Table ’Maximum Total Equivalent Length: Outdoor Unit BELOW Indoor Unit’

Maximum Total Equivalent Length{-- Outdoor Unit BELOW Indoor Unit

Liquid Line

Size

1 --- T o n 3/8 100* 100* 100* 100* 100* 100* 100*

2 --- T o n 3/8 100* 100* 100* 100* 100* 100* 100*

3 --- T o n 3/8 100* 100* 100* 100* 100* 100* 100*

4 --- T o n 3/8 100* 100* 100* 100* 100 100 --- --5 --- T o n 3/8 100* 100* 100* 100* 100 100 --- ---

* Maximum actual length not to exceed 100 ft (30.5 m)

{ Total equivalent length accounts for losses due to elbows or fitting.

--- --- = o u t s i d e a c c e p t a b l e r a n g e

Diameter

w/ TXV

0 --- 2 0

(0 --- 6.1)

21---30

(6.4 --- 9.1)

HP with Puronr Refrigerant --- Maximum Total Equivalent Length{

Vertical Separation ft (m) Outdoor unit BELOW indoor unit;

31---40

(9.4 --- 12.2)

MAXIMUM EQUIVALENT LENGTH{

41---50

(12.5 --- 15.2)

ft (m)

51---60

(15.5 --- 18.3)

MAXIMUM VERTICAL SEPARA-

61---70

(18.6 --- 21.3)

TION ft (m)

71---80

(21.6 --- 24.4)

LONG LINE APPLICATIONS

Unit is approved for up to 100 ft (30.5 m) equivalent length and vertical separations shown above with no additional accessories.

Longer line set applications are not permitted.

3

Page 4

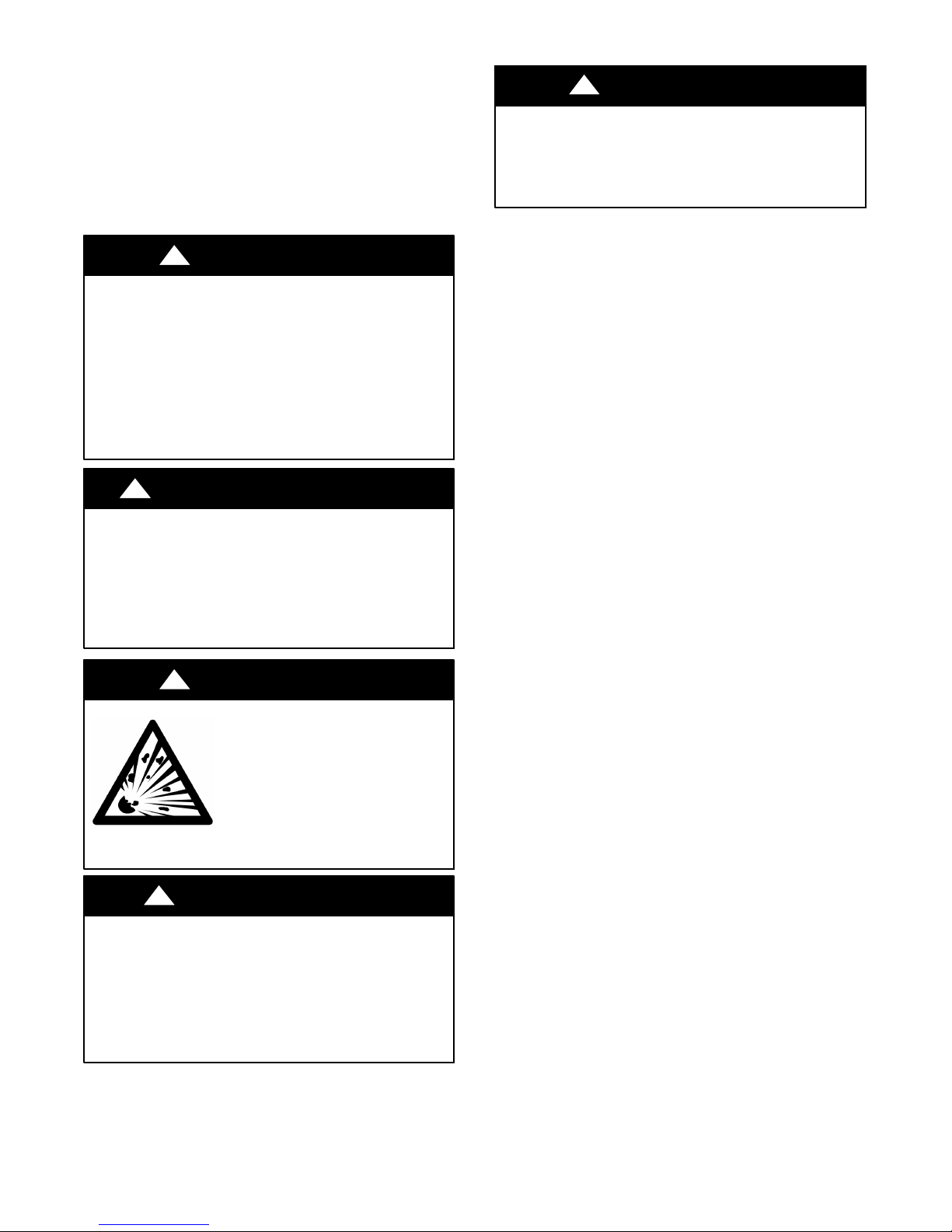

SAFETY CONSIDERATIONS

Installation, service, and repair of these units should be attempted

only by trained service technicians familiar with standard service

instruction and training material.

All equipment should be installed in accordance with accepted

practices and unit Installation Instructions, and in compliance with

all national and local codes. Power should be turned off when

servicing or repairing electrical components. Extreme caution

should be observed when troubleshooting electrical components

with power on. Observe all warning notices posted on equipment

and in instructions or manuals.

!

ELECTRICAL HAZARD -- HIGH VOLTAGE!

Failure to follow this warning could result in personal injury

or death.

Electrical components may hold charge. DO NOT remove

control box cover for 2 minutes after power has been

removed from unit.

PRIOR TO TOUCHING ELECTRICAL COMPONENTS:

Verify zero (0) voltage at inverter connections shown on

inverter cover.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

!

WARNING

WARNING

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when

handling parts.

Refrigeration systems contain refrigerant under pressure. Extreme

caution should be observed when handling refrigerants. Wear

safety glasses and gloves to prevent personal injury. During normal

system operations, some components are hot and can cause burns.

Rotating fan blades can cause personal injury. Appropriate safety

considerations are posted throughout this manual where potentially

dangerous techniques are addressed.

If you do not understand any of the warnings, contact your

product distributor for better interpretation of the warnings.

GENERAL INFORMATION

The 288BNV & 189BNV split system heat pump and air

conditioners features a new outdoor cabinet design that uses a

four--sided coil design to minimize the unit footprint and provide

the best heat exchange taking full advantage of the latest variable

speed technology.

The heart of the system is the variable speed rotary compressor

powered through the use of the variable speed drive (VSD) inverter

control. Through the use of Puron refrigerant, compact ECM

outdoor fan motor, VSD and variable speed scroll compressor,

along with the new outdoor cabinet, the unit achieves a Seasonal

Energy Efficiency Ratio (SEER) of up to 19 and up to 11 Heating

Seasonal Performance Factor (HSPF).

To ensure ultimate comfort, these units should be combined with

either the FE fan coil or Variable Speed Gas furnace controlled

with a two wire communication Evolutionr Connext Control

SYSTXBBITC01, SYSTXBBITW01 or SYSTXBBITN01 with

version 11 software or newer. Version 12 software or newer

required for model size 13. This combination will ensure

achievement of comfort with the convenience of fingertip trouble

shooting and diagnostic capability. These units can also use a

standard, 2--stage or single--stage thermostat, for limited

functionality. However, 1 --ton models will require the use of an

Evolution Control.

!

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could result in personal

injury or equipment damage.

Puronr (R--410A) systems operate at higher pressures than

standard R --22 systems. Do not use R--22 service equipment

or components on Puronr equipment. Ensure service

equipment is rated for Puronr.

WARNING

4

Page 5

ELECTRICAL

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Exercise extreme caution when working on any electrical

components. Shut off all power to system prior to

troubleshooting. Some troubleshooting techniques require

power to remain on. In these instances, exercise extreme

caution to avoid danger of electrical shock. ONLY TRAINED

SERVICE PERSONNEL SHOULD PERFORM

ELECTRICAL TROUBLESHOOTING.

Aluminum Wire

WARNING

MAJOR COMPONENTS

Application Operational Control Board (AOC)

!

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Aluminum wire may be used in the branch circuit (such as

the circuit between the main and unit disconnect), but only

copper wire may be used between the unit disconnect and the

unit.

Whenever aluminum wire is used in branch circuit wiring with this

unit, adhere to the following recommendations.

Connections must be made in accordance with the National

Electrical Code (NEC), using connectors approved for aluminum

wire. The connectors must be UL approved (marked Al/Cu with

the UL symbol) for the application and wire size. The wire size

selected must have a current capacity not less than that of the

copper wire specified, and must not create a voltage drop between

service panel and unit in excess of 2 of unit rated voltage. To

prepare wire before installing connector, all aluminum wire must

be “brush--scratched” and coated with a corrosion inhibitor such as

Pentrox A. When it is suspected that connection will be exposed to

moisture, it is very important to cover entire connection completely

to prevent an electrochemical action that will cause connection to

fail very quickly. Do not reduce effective size of wire, such as

cutting off strands so that wire will fit a connector. Proper size

connectors should be used. Check all factory and field electrical

connections for tightness. This should also be done after unit has

reached operating temperatures, especially if aluminum conductors

are used.

CAUTION

Unit Electrical Power

Power wires from the unit’s disconnect should be routed through

the power wiring hole provided at the bottom of the unit’s control

box.

Connect the ground wire to the ground connection in the control

box and connect the power wiring to the terminal block as shown

on the wiring and Installation Instructions supplied with the unit.

The unit does not require a contactor or outdoor unit transformer in

order to operate.

A13361

Fig. 1 – AOC (Application Operational Control) Board

The AOC board is located in the lower right hand side of inverter

tray. It’s functions include:

S Compressor speed control

S Outdoor fan motor control

S Reversing valve operation

S Defrost operation

S Crankcase heater operation

S Pressure switch monitoring

S Time Delays

S Pressure Transducer measurements

S PEV control (pressure equalizer valve)

S Temperature measurements

S EXV (Electronic Expansion Valve) operation control

S Inverter communication and control

Inverter

The inverter is located inside the control box. This is an air--cooled

device that communicates with the control board and drives the

compressor and fan motor to the demanded RPM. The inverter is

always powered with line voltage since no contactor is used. The

inverter changes the line voltage to DC volts and then recreates 3

phase sine waves that vary in frequency to drive the compressor

and fan motor at the desired RPM.

NOTE: The unit may be operated with an Evolution Connex

Control or a standard 2--stage HP thermostat. However, 1 --ton

models will require the use of an Evolution Control. Evolution

Connex Control will utilize 5 stages of heating and cooling, while

2--stage HP thermostat will only allow 2 discrete stages of heating

and cooling operation.

Variable Speed Compressor

This unit contains a variable speed rotary compressor that has a

wide operating range. It operates on a variable 3 phase sine wave

provided by the inverter. This compressor can only be operated by

the specific inverter supplied with the unit.

5

Page 6

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

and/or improper operation.

Do not attempt to apply line voltage directly to the

compressor. This will destroy the compressor.

Electronic Expansion Valve (EXV)

This unit uses an electronic expansion valve for refrigerant

metering in the heating mode. The control board drives the EXV to

its proper position based on the operating mode and conditions.

The Evolution Connex Control Service mode allows for manual

opening and closing of the EXV for troubleshooting and pump

down.

Outdoor Fan Motor

The compact ECM outdoor fan motor is a variable--speed brushless

DC (BLDC) motor that operates at speeds from 400 to 1050 RPM.

The motor is a 3--phase permanent magnet--type motor. Just like

the compressor, this motor speed is determined by the inverter

output frequency and amplitude.

Motor speed is controlled through the inverter board in the outdoor

unit and no electronic module is attached. Motor speed is slowed as

the building load decreases, maintaining the proper condensing

temperature for both cooling and dehumidification. As the building

load increases, the motor will increase speed until it is at maximum

speed at the maximum building load.

At unit start--up, there is a slight delay and thrust motion of the fan

motor/blade in the reverse direction, prior to ramping--up the fan

assembly.

Pressure Transducer (SPT)

A 5 VDC output low pressure transducer that provides a 0--5 VDC

data for interpretation by the control board for a 0 to 200 psig

range of pressure at the suction tube. This interpreted pressure data

is then intelligently used by the AOC control board for low

pressure cut--out, loss of charge management, compressor

protection, oil circulation management, lubrication management

and EXV control.

Pressure Equalizer Valve (PEV)

At the end of every compressor operation (after the 3.5 minute

Time Guard period), the equalizer valve opens for 150 seconds

plus an additional 15 seconds of protection before allowing the

compressor to start ramping up.

The PEV is located next to the suction and discharge of the

compressor. The function of this valve is to prevent the

compressor from starting with a high refrigerant pressure

differential, thus helping the reliability of the compressor.

NOTE: A hissing sound may be heard during the equalization

process. This is normal.

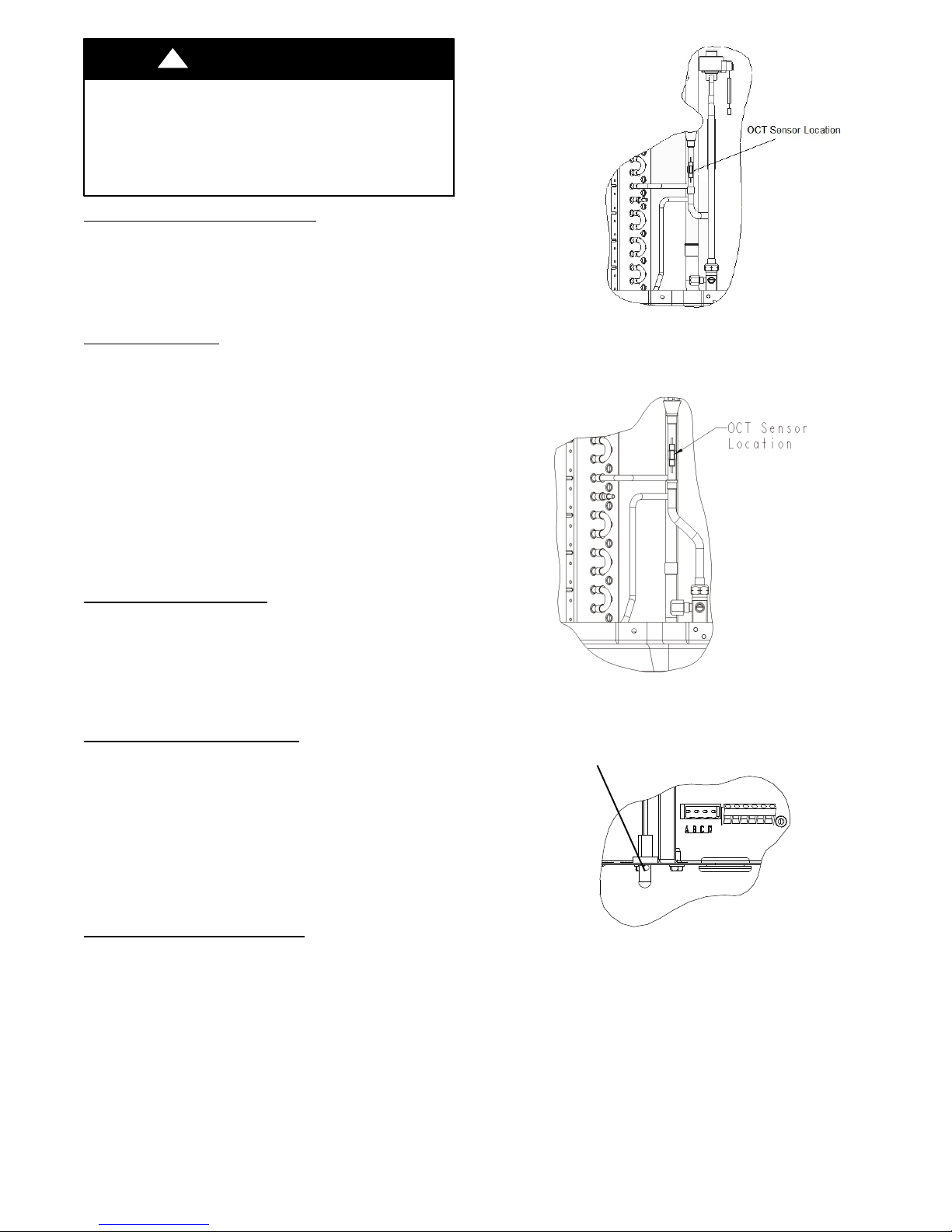

Outdoor Coil Thermistor (OCT)

The outdoor coil thermistor is a 10Kohm resistor used for multiple

system operations. It provides the coil/liquid line temperature to

the heat pump board and user interface. Low ambient operation,

defrost initiation, defrost termination and assistance with OAT

temperature measurement of some of the functions (see Fig.4) .

The sensor must be securely mounted to the tube connecting the

EXV and distributor. See Fig. 2 and Fig. 3 for proper placement.

See Table 5 for proper resistances.

A14302

Fig. 2 – HP Outdoor Coil Thermistor (OCT) Attachment

Fig. 3 – AC Outdoor Coil Thermistor (OCT) Attachment

OAT Thermistor must be locked in place with

spherical nib end f acing towards the f ront of

the control box

Fig. 4 – OAT Thermistor Location (Bottom of Control Box)

(On Distributor Tube)

A14328

(On Distributor Tube)

A11142

6

Page 7

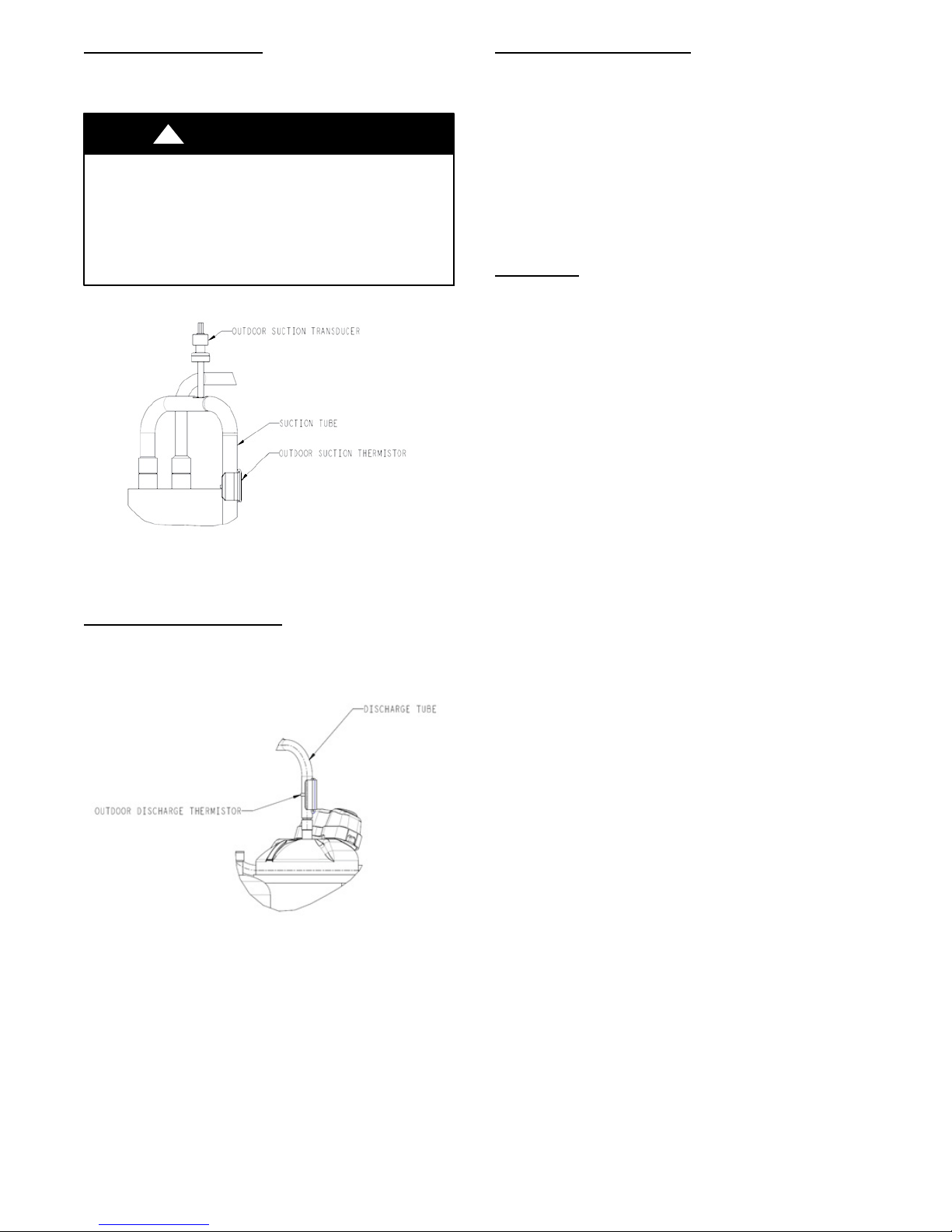

Suction Thermistor (OST)

Suction Thermistor is used for assisting in EXV control and must

be secured on the suction tube and aligned longitudinally to the

vertical surface of the tube axis (see Fig. 5).

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

In order to minimize the ambient influence, make sure the

thermistor curved surface hugs the pipe surface and is

secured tight using the wire tie fished through the original

slot insulating polymer body.

CAUTION

Crankcase Heater Operation

This unit has an internal crankcase heater that will be energized

during the off cycle and is intelligently demanded by the system to

prevent the compressor from being the coldest part of the system

thus enhancing the reliability. The crankcase heater will function

as needed any time the outdoor unit is powered. The indoor unit

and UI do not need to be installed for the crankcase heater to

operate properly.

The compressor windings will occasionally be energized during

the OFF cycle (depending on the length of the OFF cycle) to start

the stator heat operation, thus maintaining a sump temperature that

is essential for compressor reliability. The compressor will not run

during this process.

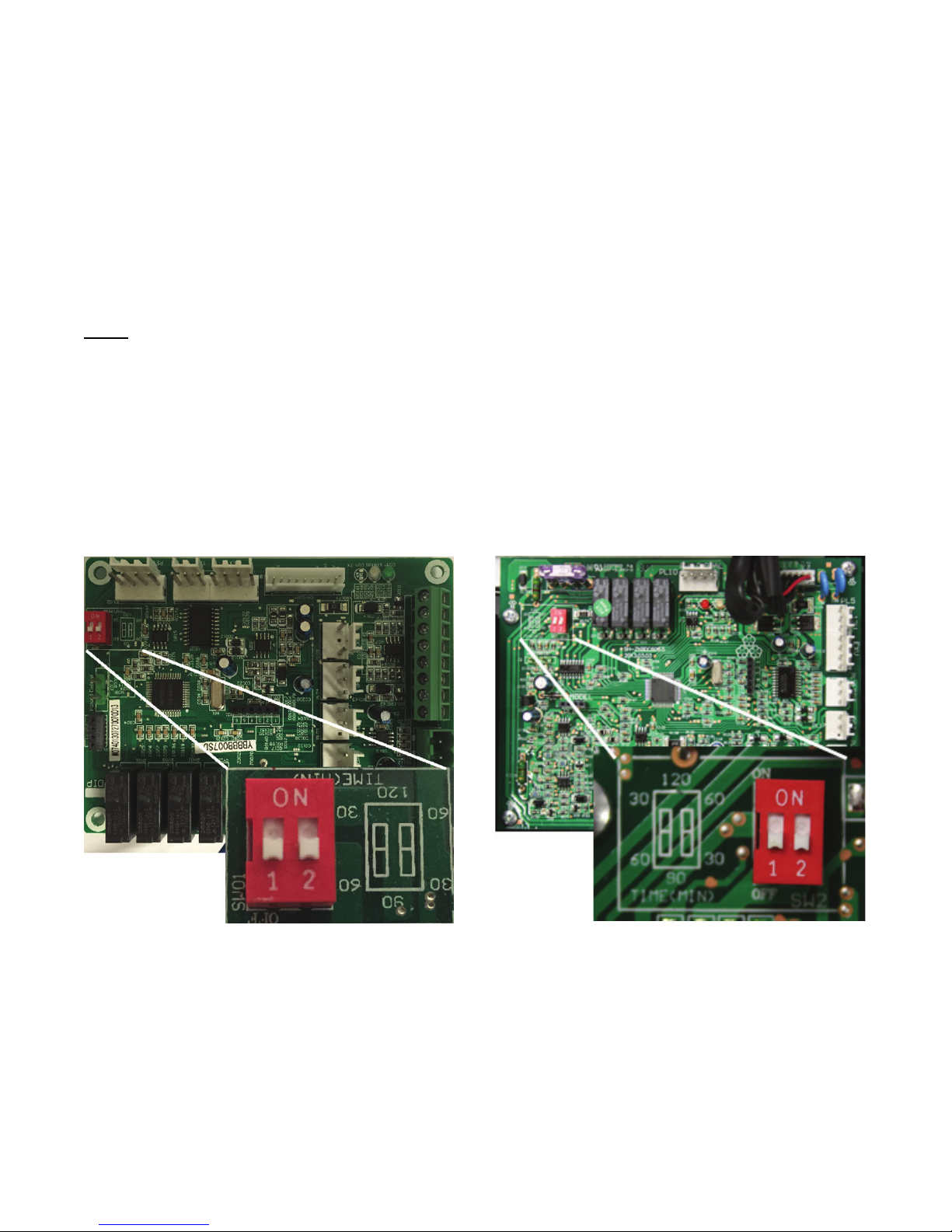

Time Delays

The unit time delays include:

S 3.5 minute time delay after last cycle, initial power up, return

from brown--out condition. To bypass this feature, momentarily

short and release Forced Defrost pins.

S At the end of every compressor ON cycle, there will be 150

seconds of PEV open period for pressure equalization followed

by 15 seconds of PEV Off period before the next compressor

ON cycle. This delay cannot be bypassed as it helps compressor

reliability.

S 15 second delay at termination of defrost before the auxiliary

heat is de--energized.

S See Table 6 for other delay information.

S 10 minute sump warm--up delay. This delay is at the beginning

of each high voltage power up.

A14023

Fig. 5 – Suction Thermistor (OST) Attachment

(On Suction Tube)

Discharge Thermistor (ODT)

Discharge Thermistor is used for protection against over

temperature of the compressor. The ODT is located on the

compressor discharge stub--out (see Fig. 6).

A14024

Fig. 6 – Discharge Thermistor (ODT)

7

Page 8

COMMUNICATION AND STATUS FUNCTION LIGHTS

Evolution Connex Control, Green Communications (COMM)

Light

A green LED (COMM light) on the outdoor board (see Fig. 7 and

8) indicates successful communication with the other system

products. The green LED will remain OFF until communication is

established. Once a valid command is received, the green LED will

turn ON continuously. If no communication is received within 2

minutes, the LED will be turned OFF until the next valid

communication. The green LED will be turned off when using a

standard 2--stage non--communicating heat pump thermostat.

Amber Status Light

Amber colored STATUS light indicates operation and error status.

See Table 6 for definitions.

S Two minute time delay to return to standby operation from last

valid communication.

Defrost

This user interface (UI) offers 4 possible defrost interval times: 30,

60 and 90 minutes, or AUTO. The default is AUTO.

Defrost interval times: 30, 60, and 90 minutes or AUTO are

selected by the Evolution Connex Control User Interface if using

UI. The 90 minute selection will default to 60 minutes at ambient

below 37 degrees. The UI setting will supersede the dip switch

settings on the control board if not the same.

If using non--communicating thermostat, defrost intervals are set

using dip switches on outdoor control board (see Fig. 7 and 8).

AUTO defrosts adjusts the defrost interval time based on the last

defrost time as follows:

S When defrost time <5 minutes, the next defrost interval=90

minutes. (outdoor temperature above 37_F)

S When defrost time 5--7 minutes, the next defrost interval=60

minutes.

S When defrost time >7 minutes, the next defrost interval=30

minutes.

The control board accumulates compressor run time. As the

accumulated run time approaches the selected defrost interval time,

the control board monitors the coil temperature sensor for a defrost

demand. If a defrost demand exists, a defrost cycle will be initiated

at the end of the selected time interval. A defrost demand exists

when the coil temperature is at or below 32_F(0_C) for 4 minutes

during the interval. If the coil temperature does not reach 32_F

(0_C) within the interval, the interval timer will be reset and start

over.

S Upon initial power up the first defrost interval is defaulted to 30

minutes. Remaining intervals are at selected times.

S Defrost is only allowed to occur below 50_F(10_C) outdoor

ambient temperature.

The defrost cycle is terminated as described below.

S When O AT is > 25_F(+3.89_C), defrost terminates if outdoor

coil temperature (OCT) > 60_F (+15.6_C). And a minimum of

one (1) minute defrost length.

S When OAT ≦ 25_F(+3.89_C), defrost will terminate if OCT is

>45_F(+4.4_C) and a minimum of 2 minutes defrost length.

S Or 10 minutes has passed.

At the defrost termination, the outdoor fan will turn on 10 seconds

before the reversing valve switching.

NOTE: Compressor speed during defrost will go to defrost speed.

Fig. 7 – AOC Control Board for 1 and 2 Ton

A150034

Fig. 8 – AOC Control Board for 3, 4 and 5 Ton

A14021

8

Page 9

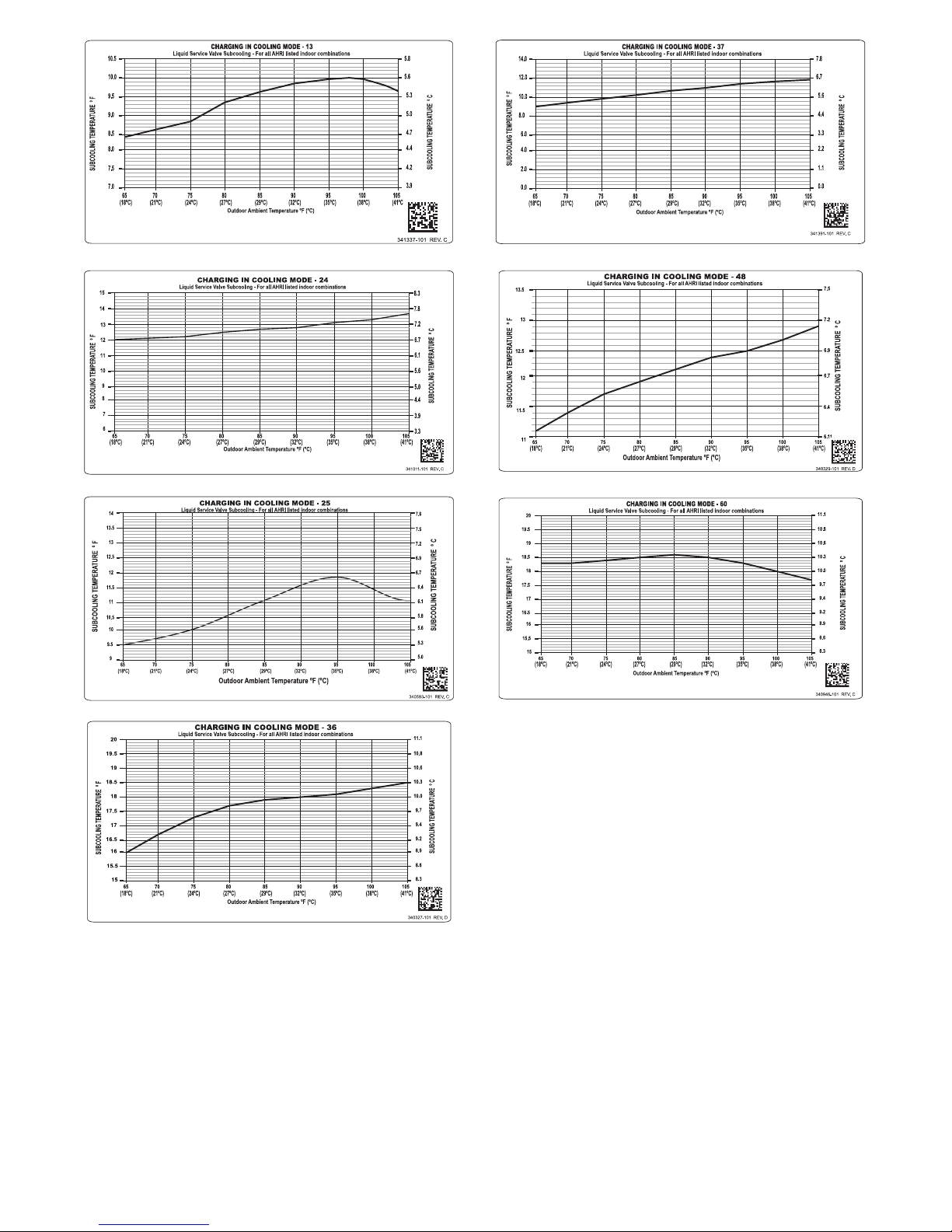

CHECK CHARGE

Charge in CHARGING mode (communicating only)

Unit is factory charged for 15ft (4.57 m) of lineset. If any

refrigerant charge adjustment is required due to the user inputted

line set length, the UI will calculate and display the target

subcooling and the amount of additional charge to be added.

Therefore, the UI is your source of information for charging the

system correctly. Refrigerant charge adjustment amount for adding

or removing 0.6 oz/ft (17.74 g/m) of 3/8 liquid line above or below

15ft (4.57 m) respectively. Perform a final charge check only when

in cooling and OD is between 65_F(18_C) and 100_F(38_C).

The use of a commercial charge metering device (restrictor) such as

Imperial liquid low side charger model 535--C or Watsco

ChargeFaster model CH200 is recommended when adding

refrigerant to an operating system. This prevents potential damage

of liquid slugging of the compressor and allows the subcooling to

stabilize quicker.

Charging using the subcooling method optimizes charge volume

and is preferred if possible. If the outdoor temperature is between

65_F -- 100_F (18.3_C -- 37.8_C) and indoor temperature is 70_F

-- 8 0 _F (21.1_C -- 26.7_C), the option to further adjust charge

using “service valve subcool” will be available in the “charging

mode selection” screen. If temperatures are outside of range, this

option will be greyed out and not selectable. Inaccurate charging

may result in nuisance fault codes.

Initial start--up can be performed using calculated charge only and

once conditions are within range, the ”Service Valve Subcool”

option will become selectable.

Once start is selected the system will operate in a preset mode until

“done” is selected. Wait for required stabilization time then check

subcooling at service valve.

Adjust charge as required to meet target service valve subcooling

shown on screen --3/+0 degree. If any adjustment is necessary, add

or remove the charge slowly (no greater than .5 lb per minute) and

allow system to operate for 25 minutes to stabilize, before

declaring a properly charged system.

Fig. 11 – Stabilization Time

A14575

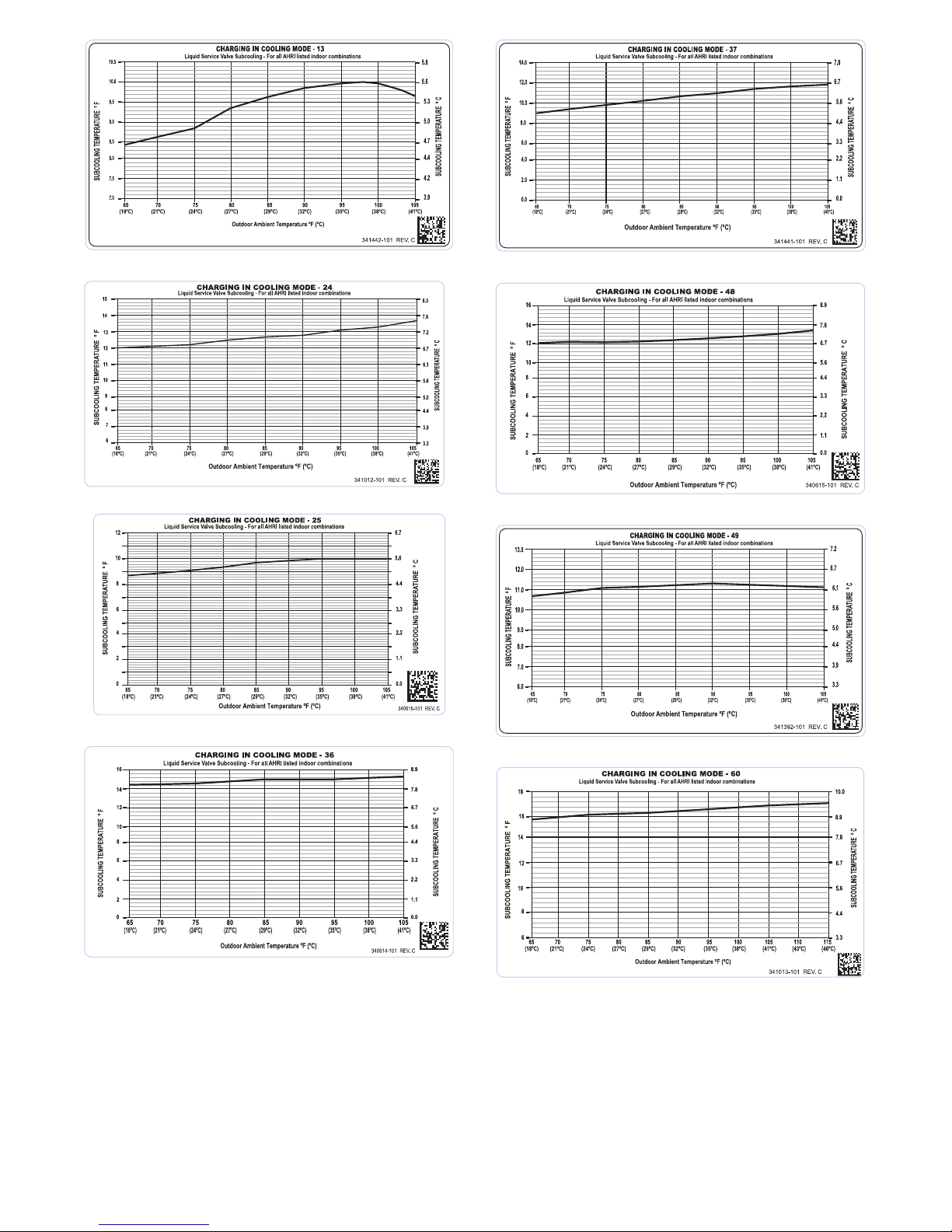

Charging Non--Communicating Systems

Charging Procedure: Force system to operate in high stage

cooling by creating a large differential between room temperature

and set point on thermostat. Use multi-- meter to verify that 24

VAC is present between C, Y1 /Y2 terminals at outdoor unit.

Factory charge amount is shown on unit rating plate for high stage.

Target subcooling chart is provided on back of control box door

see Fig. 12 -- 26 for example. To properly check or adjust charge,

condition must be favorable for subcooling charging. Favorable

conditions exists when outdoor temperature is between 65_F

(18_C) and 100_F(38_C), and the indoor temperature is between

70_F(21_C) and 80_F(27_C). Follow the procedure below:

Unit is factory charged for 15ft (4.57 m) of lineset. Adjust charge

by adding or removing 0.6 oz/ft (17.7 g/m) of 3/8 liquid line above

or below 15ft (4.57 m) respectively.

For standard refrigerant line lengths (80ft/24.4 m or less), allow

system to operate in cooling mode at least 25 minutes. If conditions

are favorable, check system charge by subcooling method. If any

adjustment is necessary, adjust charge slowly and allow system to

operate for 25 minutes to stabilize before declaring a properly

charged system.

If the indoor temperature is below 70°F (21.11°C), or the outdoor

temperature is not in the favorable range, adjust charge for line set

length above or below 15ft (4.57 m) and indoor fan coil /furnace

coil per Table 1 and 2. Charge level should then be appropriate for

the system to achieve rated capacity. The charge level should then

be checked at another time when the both indoor and outdoor

temperatures are in a more favorable range.

NOTE: If the line length is beyond 80ft (24.38 m) or greater than

20ft (6.10 m) vertical separation see Long line guideline for special

charging requirement.

Fig. 9 – Adjusting Charge Using Service Valve Subcool

Fig. 10 – Service Valve Subcool Target Value

A14573

A14574

9

Page 10

Table 1—Required Charge Adjustment for Indoor Coil Model -- HP

Furnace or Fan Coil Model Number

13 24B 25 36 37 48 60

CNPV*18** --- / / / / / /

CAP**18** --- / / / / / /

CNP**24 --- / / / / / /

CNPV*19** --- / / / / / /

CAP**24 --- / / / / / /

CSPH*24 --- / / / / / /

CSPH* 30** / / / / / / /

F(E,V)4(A,B,C)NF002 +0.19 --- --- --- --- / /

CAP**30 / --- / / / / /

CNP**30 / --- / / / / /

CNP**36 / --- --- --- --- / /

F(E,V)4(A,B,C)N(B,F)003 / --- --- --- --- / /

CAP**36 / --- --- --- --- / /

CNP**42 / +.50 --- --- +.75 / /

CAP**42 / +.50 --- --- +.75 / /

CSPH*36 / / --- --- +.75 / /

CSPH* 42** / / +.75 +.7 5 +.75 / /

CNP**31* * / / +.75 +.75 +.75 / /

CNP**48 / / +.75 +.75 +.75 --- /

CSPH* 48** / / +.75 +.7 5 +1.00 --- /

CNP**37 / / / / / / /

CNP**43 / / / / / / /

CAP**48 / / / +.75 +1.00 --- /

CNP**60 / / / / +1.00 --- ---

CSPH*60 / / / / +1 .00 --- ---

F(E,V)4(A,B,C)N(B,F)005 / / +.75 +.75 +1.00 --- /

F(E,V)4(A,B,C)NB006 / / / / +1.00 +2.2 +1.00

CAP**60 / / / / / +2.2 +1.00

CNP**61 / / / / / / /

/ = Comb. not allowed

--- = No charge adjust for ID

Outdoor Model Size

Table 2—Required Charge Adjustment for Indoor Coil Model -- AC

Furnace or Fan Coil Model Number

CNPV*18** ---

CAP**18** ---

13 24B 25 36 37 48 49 60

/ / / / / / /

/ / / / / / /

CNP**24 --- --- ---

CNPV*19** ---

/ / / / / / /

CAP**24 --- --- ---

CSPH*24 --- --- ---

CSPH* 30**

/

--- ---

F(E,V)4(A,B,C)NF002 +0.19 --- --- ---

CAP**30

CNP**30

CNP**36

F(E,V)4(A,B,C)N(B,F)003

CAP**36

CNP**42

CAP**42

CSPH*36

CSPH* 42**

CNP**31* *

CNP**48

CSPH* 48**

CNP**37

CNP**43

CAP**48

CNP**60

CSPH*60

F(E,V)4(A,B,C)N(B,F)005

F(E,V)4(A,B,C)NB006

CAP**60

CNP**61

/ = Comb. not allowed

--- = No charge adjust for ID

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / /

/ / / /

/ / / /

/

/ / /

/ / / / /

/ / / / /

--- ---

--- ---

--- --- --- ---

--- --- --- ---

--- +.50 --- ---

+.50 +.50 --- +.75

+.50 +.50 --- +.75

+.50 +.50 --- +.75

+.50 +.50 +.75 +.75

+.50 +1.25 +.75 +.75

+.50 +1.25 +.75 +.75 --- ---

+.625 +1.25 +.75 +1.00 --- ---

+.625 +1.25 +.75 +1.00 --- ---

+.625 +1.25 +.75 +1.00 --- ---

+.625 +1.25 +.75 +1.00 --- +0.125

Outdoor Model Size

/ / / / /

/ / / / /

/ / / / /

/ / / / /

/ / / /

/ / / / /

/ / / / /

/ / /

/ / /

/ / /

/ / /

/ / /

/ / /

/ / /

/ / /

+.75 +1.00 --- ---

+1.00 --- +0.125 ---

+1.00 --- +0.125 ---

+.75 +1.00 +1.5 +.625 +1.00

+1.5 +.625 +1.00

+1.5 +.625 +1.00

/

/

/

/

/

/

10

Page 11

Fig. 12 – Charging in Cooling Mode 288BNV013

Fig. 16 – Charging in Cooling Mode 288BNV037

Fig. 13 – Charging in Cooling Mode 288BNV024

Fig. 14 – Charging in Cooling Mode 288BNV025

Fig. 15 – Charging in Cooling Mode 288BNV036

Fig. 17 – Charging in Cooling Mode 288BNV048

Fig. 18 – Charging in Cooling Mode 288BNV060

11

Page 12

Fig. 19 – Charging in Cooling Mode 189BNV013

Fig. 23 – Charging in Cooling Mode 189BNV037

Fig. 20 – Charging in Cooling Mode 189BNV024B

Fig. 21 – Charging in Cooling Mode 189BNV025

Fig. 24 – Charging in Cooling Mode 189BNV048

Fig. 25 – Charging in Cooling Mode 189BNV049

Fig. 22 – Charging in Cooling Mode 189BNV036

Fig. 26 – Charging in Cooling Mode 189BNV060

12

Page 13

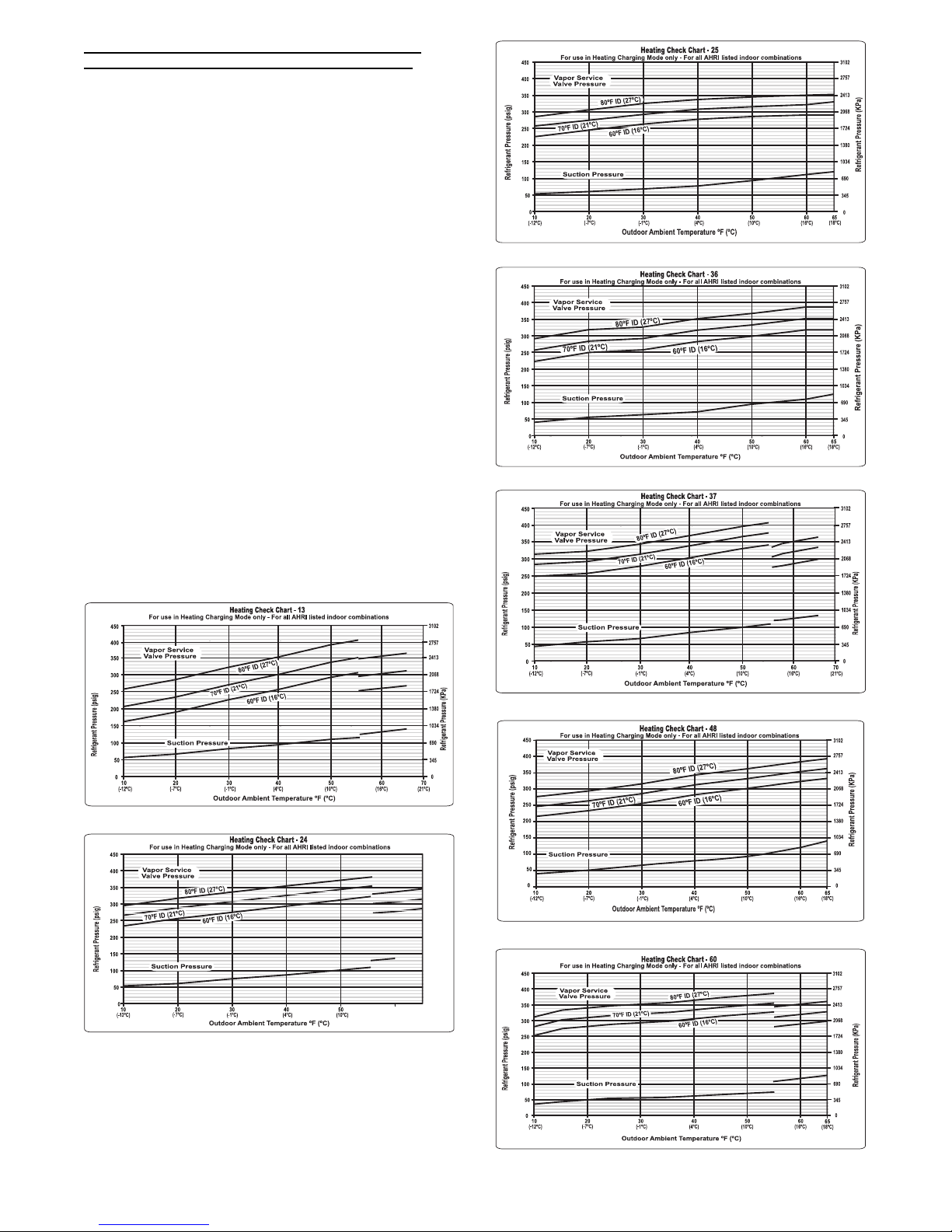

Heating Check Chart Procedure (See Fig.27 -- 33)

(Communicating / Non--communicating Systems)

In heating mode, the required charging method is by weigh--in. On

new installations or complete recharge, refer to the unit 0 and

indoor fan coil / furnace coil per Table 1 for additional charge

needed. Refrigerant charge adjustment amount for adding or

removing 0.6 oz/ft (17.74 g/m) of 3/8 liquid line above or below

15ft (4.57 m) respectively.

Use the Defrost CHECKOUT mode to remove ice or frost from

coil, if present, prior to checking the heating pressures.

To use the Heating Check Chart, the user interface (UI) must be in

Refrigerant Charging mode selected from the Installation and

Service screen. The Charging Mode Selection screen will show

selections for Weigh-- In Charge Method or Heating Check Charge

Method. Select Heating Check Charge Method. The Heating

Check Charge method will only be displayed if the conditions are

right for checking the charge in heating mode. When Heating

Check Charge Method is selected, the system will operate by

running in stage 5 with appropriate outdoor fan speed and indoor

airflow. Upon completion of a countdown period for system

stabilization, check refrigerant pressures for the appropriate

ambient temperatures shown in Fig. 27 through 33 based the OD

unit size.

To use the Heating Check Chart in non--communicating systems,

operate system at Y1+Y2–high stage. These charts indicate

whether a correct relationship exists between system operating

pressure and air temperature entering indoor and outdoor units. If

pressure and temperature do not match on chart, system refrigerant

charge may not be correct. DO NOT USE CHART TO ADJUST

REFRIGERANT CHARGE.

NOTE: High pressure is at vapor service valve. Add 12 psig if

high pressure is taken from liquid service valve.

NOTE: When charging is necessary during heating season, charge

must be weighed in accordance with unit rating plate,

(

±17.74 g/m). of 3/8--in. liquid--line above or below 15 ft (4.57

m), respectively.

±0.6 oz./ft

Fig. 29 – Heating Pressure Check Chart 288BNV025

Fig. 30 – Heating Pressure Check Chart 288BNV036

Fig. 27 – Heating Pressure Check Chart 288BNV013

Fig. 28 – Heating Pressure Check Chart 288BNV024

Fig. 31 – Heating Pressure Check Chart 288BNV037

Fig. 32 – Heating Pressure Check Chart 288BNV048

Fig. 33 – Heating Pressure Check Chart 288BNV060

13

Page 14

Service Tool

TROUBLESHOOTING

Table 3—Factory Supplied Model Plug Information

288BNV

13 HK70EZ029 11K 220K

24B HK70EZ009 5.1K 91K

25 HK70EZ001 5.1K 11K

36 HK70EZ002 5.1K 18K

37 HK70EZ026 11K 120K

48 HK70EZ003 5.1K 24K

60 HK70EZ004 5.1K 33K

MODEL PLUG

NUMBER

P i n s 1 --- 4 Pins 2 ---3

Fig. 34 – Service Tool Connection

A150062

When working on the outdoor unit of a split system, the technician

would usually need to repeatedly walk between the indoor wall

control and the unit outside. To save time, the communicating

controls offer a service tool feature.

By wiring the service tool into the AOC board and powering it

with an external adapter, the technician can have a wall control

capable of running the system right at the outdoor unit.

To use a service tool, connect the A and B communication bus

wires from this second communicating control to the terminals

marked A and B on the terminal strip located in the bottom left

corner of the AOC board (see Fig. 34). But instead of connecting

the wires on the service tool to the terminals marked C and D,

connect the C and D wires from the service tool to the 24V and C

on ST1 as shown in Fig. 34.

When the service tool is connected and powered up, the

communicating controls inside the home will ”go to sleep” and let

the service tool take control of the system. In this manner, the

service technician can run the diagnostic checkouts right at the

outdoor unit using the service tool.

After the checkouts are completed and it is no longer necessary to

use the service tool, remove it from the communicating controls

and the indoor communicating controls will regain control in about

two minutes.

Systems Communication Failure

If communication is lost with the User Interface (UI), the control

will flash the appropriate fault code (see Table 6). Check the wiring

to the User Interface and the indoor and outdoor units and power.

Model Plug

Each control board contains a model plug. The correct model plug

must be installed for the system to operate properly (see Table 3).

The model plug is used to identify the type and size of unit to the

control.

On new units, the model and serial numbers are inputted into the

AOC board’s memory at the factory. If a model plug is lost or

missing at initial installation, the unit will operate according to the

information input at the factory and the appropriate error code will

flash temporarily. An RCD replacement AOC board contains no

model and serial information. If the factory control board fails, the

model plug must be transferred from the original board to the

replacement board for the unit to operate.

When installing heat pump with older fan coils, a model plug

change may be required.

NOTE: The model plug takes priority over factory model

information input at the factory. If the model plug is removed after

initial power up, the unit will operate according to the last valid

model plug installed, and flash the appropriate fault code

temporarily.

189BNV

13 HK70EZ028 11K 180K

24B HK70EZ010 5.1K 120K

25 HK70EZ011 5.1K 150K

36 HK70EZ012 5.1K 180K

37 HK70EZ025 11K 91K

48 HK70EZ013 5.1K 220K

49 HK70EZ027 11K 150K

60 HK70EZ014 5.1K 270K

MODEL PLUG

NUMBER

P i n s 1 --- 4 Pins 2 ---3

Status Codes

!

ATTENTION

Unit may occasionally become unresponsive due to certain

combinations of previous fault codes. There may not be

anything wrong with the unit or components. The unit may

require a high voltage power cycling for at least 2 minutes or

longer to clear the condition. If the condition persists, conduct

further troubleshooting per Service Manual.

Table 6 shows the status codes flashed by the amber status light.

Most system problems can be diagnosed by reading the status code

as flashed by the amber status light on the control board.

The codes are flashed by a series of short and long flashes of the

status light. The short flashes indicate the first digit in the status

code, followed by long flashes indicating the second digit of the

error code.

The short flash is 0.25 seconds ON and the long flash is 1.0 second

ON. Time between flashes is 0.25 seconds. Time between short

flash and first long flash is 1.0 second. Time between code

repeating is 2.5 seconds with LED OFF.

Codes are easily read from user interface (UI)

EXAMPLE:

3 short flashes followed by 2 long flashes indicates a 32 code.

Table 6 shows this to be low pressure switch open.

Variable Speed Compressor Winding Resistance

This compressor operates with 3--phase variable frequency PWM

variable voltage. For troubleshooting certain fault codes related to

compressor resistances, follow these steps:

1. Disconnect compressor power leads from the inverter MOC

terminals, U (YEL), V (RED), and W (BLK).

2. Measure the resistance between YEL to RED, YEL to BLK,

and RED to BLK and compare to Table 4 values. Each

resistance set should be equal.

3. Measure the resistance to ground for each lead.

4. If the resistances check out, reconnect power leads to

appropriate terminal.

5. If the resistances appear to be abnormal, it will be necessary

to measure the resistance at the compressor fusite terminals.

6. During the removal of the compressor fusite cap, do not remove the RTV sealant. Remove the harness plug, measure

the resistances, and compare to Table 4.

7. Special care will need to be taken with the replacement of

the compressor fusite cap. Make sure the two holes in the

compressor fusite terminal box are still full of RTV sealant

before the cap is reinstalled. The factory RTV can be reused

14

Page 15

as long as none of it has been removed during the cap

removal.

8. Reinstall compressor sound blanket making sure discharge

thermistor and compressor power harness are routed as they

were from the factory

Table 4—Variable Speed Compressor Resistance

(winding resistance at 70_F 20_F)

WINDING

Between

terminals

Between

terminal &

ground

!

MODEL 288BNV / 189BNV (OHMs)

13, 24B 25 36 37, 48 49, 60

1.13 .59 .59 .37 .24

>1 mega

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

and/or improper operation.

Do not use Meggar for measuring the winding resistance.

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

and/or improper operation.

To maintain water integrity of the compressor fusite terminal

box, the two holes in outer ring need to be full of RTV sealant.

Fan Motor

If verification of proper operation is required for the fan motor

used in this unit, follow these steps:

1. Disconnect fan motor connector from control board.

2. Measure resistance between any 2 of the 3 leads present.

3. Compare measurement to values below

Fan Motor Resistance

Unit Size Resistance (Ohms)

13, 24B 21.2

25, 36, 37, 48, 49 (AC), 60 11.1

Control Fault

If the outdoor unit control board has failed, the control will flash

the appropriate fault code (see Table 6). The control board should

be replaced.

Brown--Out Protection

If the line voltage is less than 187V for at least 4 seconds, the

Compressor and OD fan goes to 0 rpm. Compressor and fan

operation are not allowed until voltage is a minimum of 190V. The

control will flash the appropriate fault code (see Table 6).

230V Line (Power Disconnect) Detection

The control board senses the presence of absence of 230V through

inverter feedback. Voltage should present at all times when system

is in service regardless if system is running or standby. If there is

no 230V at the inverter when the indoor unit is powered with a

cooling or heating demand, the appropriate fault code is displayed

on UI (communicating only – see Fig. 38). If system is configured

with conventional heat pump thermostat (non--communicating), no

fault code will be displayed on AOC board, nor will any status

LEDs be lit. Use multimeter to check for the presence of 230V in

this situation.

High Pressure Switch Protection

The outdoor unit is equipped with a high pressure switch. If the

control senses the opening of a high pressure switch (open 600+/--5

psig, close 470+/--10 psig @77_F), it will respond as follows:

1. Display the appropriate fault code (see Table. 6).

2. After a 6 minute delay, if there is a call for cooling or heating and HPS is reset, the PEV opens for 150 seconds to

equalize system pressures. The compressor and fan will then

ramp to the next lower stage of operation until demand is

satisfied. The staging down and resetting to the highest

stage will end after 2 hours of accumulated operation without further HPS trips.

3. A system malfunction will occur after repeated HPS faults

and the stages have reached the lowest level. This could

take five consecutive HPS trips if the first occurred in stage

5demandor1HPStripifinstage1demand.

4. In the event of a high--pressure switch trip or high--pressure

lockout, check the refrigerant charge, outdoor fan operation,

and outdoor coil (in cooling) for airflow restrictions, or indoor airflow in heating.

Low Pressure Protection

The outdoor unit is equipped with low pressure transducer. If the

control senses a low pressure per the table below, it will respond as

follows:

Cooling

Low

Pressure

3 minute

operation

<= 33 >43 <= 15 <= 33 >35

Cool

mode

resume

operation

begins

Low

Pressure

(No Operation)

Heating Low

Pressure

5 minute

operation

Heat

mode

resume

operation

begins

1. Display the appropriate error code on the status LED (see

Tab le 6).

2. If a demand persists after the 6--minute delay and the

pressure has reached the operation level, then resume

operation. Reset the 6 minute timer, clear the displayed

error code and communicate cleared error to the User

Interface. Status LED reverts to operation code display.

3. If a demand persists after the 6--minute delay but the

pressure has not recovered, turn off the ODF. If the pressure

recovers any time after the 6 minute delay, then resume

operation. Reset the 6 minute timer, clear the displayed

error code and communicate cleared error to the User

Interface. Status LED reverts to operation code display.

4. If a pressure drops below the NO-- operation level three (3)

consecutive times, then lock out operation for 4 hours and

flash the appropriate error code and communicate lockout

status to the User Interface. The trip counter will reset to

zero if 15 minutes of successful operation occurs before the

rd

3

trip is recorded. Record the low pressure lockout in the

historical data.

5. In the event of a low pressure trip or low pressure lockout,

check the refrigerant charge and indoor airflow (cooling)

and outdoor fan operation and outdoor coil in heating.

Suction Pressure Transducer (SPT)

If the accuracy of the transducer is questioned, the technician can

check it while it is attached to the AOC board. Connect a gage

manifold to the suction valve gage port fitting.

At the AOC board, with the wire harness receptacle exposing a

portion of the three pins on the AOC board, a DC voltmeter can

read the DC voltage between ground and supply (input) terminal.

Ensure that the input voltage is 5 VDC. Next, read the DC voltage

across the ground and output terminal. Record the output voltage.

The suction pressure that the pressure transducer is reading can be

calculated by taking the output voltage and subtracting 0.5 from it

then taking that difference and multiplying it by 50. Pressure

(psig) = 50.0 x (DCV out -- 0.5). For example, if the measured

voltage is 3.0 VDC: 50 X (3.0 -- 0.5) -- 50 X 2.5 = 125 psig. See

Fig. 35.

15

Page 16

0

1

2

3

4

5

6

0 25 50 75 100 125 150 175 200 225

Output Voltage (V)

Pressure - Sealed Gauge (psi)

Fig. 35 – Suction Pressure Transducer (SPT)

0

50

100

150

200

250

300

350

400

450

020406080100120

RESISTANCE (KOHMS)

TEMPERATURE (°°F)

50K THERMISTOR

A12035

Output Funtion Graph

Temperature Thermistors

Thermistors are electronic devices which sense temperature. As the

temperature increases, the resistance decreases. 10Kohm

thermistors are used to sense outdoor air temperature (OAT), coil

temperature (OCT) and the suction line temperature (OST) located

between the reversing valve and the accumulator. A 50Kohm

thermistor is used to sense discharge temperature (ODT).

Refer to Table 5 and Fig. 36 and 37 for resistance values versus

temperature.

Table 5—10K/50Kohm Resistance Values vs Temperature

10Kohm

TEMPERATURE RESISTANCE (ohms)

25.0 (77.0) 10.0 + / --- 2.3%

0.0 (32.0) 32.6 + / --- 3.2%

-28.0 (-18.4) 85.5 + / --- 3.4%

125.0 (257.0) 1.7 + / --- 1.6%

75.0 (167.0) 7.40 + / --- 2.0%

25.0 (77.0) 50.0 + / --- 2.3%

_C(_F)

50Kohm

THERMISTOR CURVE

90

80

70

60

50

40

30

20

RESISTANCE (KOHMS)

10

0

0 20 40 60 80 100 120

Fig. 36 – 10K Thermistor Resistance Versus Temperature

TEMPERATURE (DEG. F)

A91431

Check to ensure thermistors are mounted properly (See Fig. 2,

3, 4, 5 and 6).

Thermistor Sensor Comparison

The control continuously monitors and compares the outdoor air

temperature sensor and outdoor coil temperature sensor to ensure

proper operating conditions. The comparison is:

S In cooling if the outdoor air sensor indicates 10_F( 5.6_C)

warmer than the coil sensor (or) the outdoor air sensor indicates

25_F( 15_C) cooler than the coil sensor, the sensors are out

of range.

S In heating if the outdoor air sensor indicates 35_F( 19.4_C)

warmer than the coil sensor (or) the outdoor air sensor indicates

10_F( 5.6_C) cooler than the coil sensor, the sensors are out

of range.

If the sensors are out of range, the control will flash the appropriate

fault code as shown in Table 6.

Failed Thermistor Default Operation

Factory defaults have been provided in the event of failure of

outdoor air thermistor (OAT) and/or outdoor coil thermistor

(OCT).

If the OAT sensor should fail, defrost will be initiated based on coil

temperature and time.

If the OCT sensor should fail, defrost will occur at each time

interval during heating operation, but will terminate after 2

minutes.

If there is a thermistor out-- of--range error, defrost will occur at

each time interval during heating operation, but will terminate after

2 minutes.

Count the number of short and long flashes to determine the

appropriate flash code. Fig. 38 and Table 6 gives possible causes

and actions related to each error.

Maximum Power Mode -- Inverter Over

The outdoor unit is equipped with inverter temperature sensing. If

the inverter senses a temperature above the high threshold limit it

will respond as follows:

1. Display the local fault code only on the AOC Status LED.

2. The system will continue to run but attempt to mitigate by

speed reduction.

3. When the system demand is satisfied, the unit will shut

down.

4. If the fault is still active on the AOC Status LED, the ODF

will continue to run at 500 RPM until the inverter

temperature falls below the threshold.

5. The compressor will not restart if the fault is still active.

Temperature

Fig. 37 – 50K Thermistor Resistance Versus Temperature

If the outdoor air or coil thermistor should fail, the control will

flash the appropriate fault code (see Table 6).

IMPORTANT: The outdoor air thermistor, coil thermistor and

suction thermistor should be factory mounted in the final locations.

A14022

16

Page 17

Fig. 38 – Fault Code Label

17

Page 18

Table 6—Fault Code Actions

Flash

Code

ON, no flash Standby

1, pause Variable Capacity

1 (2 sec ON), longer pause

(1 second OFF)

25

31 Local

32 Local

33 Local

46 Local BROWNOUT EVENT 6 Minutes Both low line voltages if persistent contact power provider

48

49 Local

53 Fault

54 Fault

Ty p e Amber LED Description

Variable Capacity

(Range Cutback)

System Mal-

function

System

Malfunction

INVALID MODEL

PLUG/INVERTER SIZE

HIGH PRESSURE SWITCH

(stage/speed down for each

occurrence, elevates to fault

code 84 when it occurs while

running on the lowest stage)

(elevates to fault code 83 after

LOST INVERTER COMMUNI-

(Occurs aftr 2 minutes of no

communications between AOC

(Elevates to fault code 48 after

3 consecutive failures within 20

minute or 20 minutes continu-

LOST INVERTER COMMUNI-

(Elevated from fault code 33 af-

COMPRESSOR OVER CUR-

(Elevates to fault code 95 after

SUCTION TEMP SENSOR

OPEN

LOW PRESSURE TRIP

3 occurrences)

CATIONS

and MOC)

ous loss of connection)

CATIONS

ter 3 occurrences)

RENT FAULT

5 occurrences)

OUTDOOR AIR TEMP

SENSOR FAULT

FAULT

Reset

Time

NA Both

6 Minutes

(then re-

duced

stage oper-

ation)

6 Minutes Both Low Pressure Event

NA Both

NA Both

6 Minutes Both Refer to fault code 95 Refer to fault code 95

NA Both

NA Both

Mode Possible Causes Actions

Wrong Model Plug In-

stalled

Damaged Model Plug

Missing model plug on

service board

Damaged AOC control Replace AOC control

Incorrect Model Plug

with Inverter Size

Both High Pressure Event

Loose or disconnected

harness (Hardness between AOC (PL20) and

MOC)

Radio or Electrical noise

Possible damage to in-

verter

Loose or disconnected

harness (Hardness between AOC (PL20) and

MOC)

Radio or Electrical noise

Possible damage to in-

verter

Sensor Harness not

connected to AOC con-

Suction Thermistor not

properly attached or in

trol

Broken or loose har-

ness wire

Broken or Damaged

Sensor

Hardware damage to

AOC control

Sensor Harness not

connected to AOC

control

Broken or loose

harness wire

wrong location

Broken or Damaged

Sensor

Hardware damage to

AOC control

Verify correct model plug installed

Check model plug for corrosion or breakage;

Replace plug or inverter with correct size (If

model plug is for 2 Ton but Inverter is 3 Ton,

System will self-mitigate by reducing the stage,

persistent conditions will lead to lockout (refer

to Error Code 84). 2 hours of accumulated

operation without further fault will reset fault

System will self-mitigate, persistent conditions

will lead to lockout (refer to Error Code 83) 2

hours of accumulated operation without further

System will try to self-mitigate with repeated

System will try to self-mitigate with repeated

Ensure plug is connected to AOC control

Check harness for continuity; see resistance

chart to check resistance at given temperature

Check harness for continuity; see resistance

chart to check resistance at given temperature

Ensure plug is connected to AOC control

Check harness for continuity; see resistance

chart to check resistance at given temperature

Ensure Sensor is properly attached to the ac-

Check harness for continuity; see resistance

chart to check resistance at given temperature

replace if necessary

Re-install original model plug

fault code 25 will be shown)

reduced stage operation.

fault will reset fault counter

Verify good harness connection

start attempts

change out the Inverter drive

Verify good harness connection

start attempts

change out the Inverter drive

Replace AOC control

cumulator entry-tube

Replace AOC control

18

Page 19

Flash

Code

55 Fault COIL TEMP SENSOR FAULT NA Both

56 Local

57 Fault

59 Local

61 Local

62 Local

63 Local

65 Local

66 Local

67 Local STATOR HEATER FAULT 6 Minutes Both

68 Event

69

71 Local

System Mal-

function

Amber LED DescriptionTy p e

OAT-OCT THERMISTOR OUT

INTERNAL FAULT (elevates to

OF RANGE

SUCTION PRESSURE

SENSOR FAULT

DISCHARGE TEMP OUT OF

RANGE EVENT

(elevates to fault code 74 after

5 occurrences)

FAN INVERTER FAULT

(elevates to fault code 76 after

5 occurrences)

FAN INVERTER TEMP HIGH

(elevates to fault code 85 after

3 occurrences)

FAN INVERTER CURRENT

(elevates to fault code 86 after

DC VOLTS LOW - SPEED

OUTDOOR FAN DROPPED

10 MIN STAGE 2 WARMUP

INVERTER/COMPRESSOR

this fault code after 5 occur-

COMPRESSOR DROPPED

FAULT

5 occurrences)

LIMITING

OUT

DELAY

rences of itself)

OUT

Reset

Time

NA

NA Both

15 Minutes Both See fault 74 Same actions for 74

6 Minutes Both OFMfailedtostart

NA Both See fault 85 Same actions for 85

6 Minutes Both See fault 86 Same actions for 86

NA Both

6 Minutes Both

10 Minutes Both

15 Minutes Both

6 Minutes Both

ActionsPossible CausesMode

Sensor Harness not

connected to AOC

control

Broken or loose

harness wire

Coil Thermistor not

properly attached or in

wrong location

Broken or Damaged

Sensor

Hardware damage to

AOC control

Coil Thermistor not

properly attached or in

wrong location

Outdoor Ambient Tem-

Both

perature sensor improp-

erly installed (sensor

body may be in contact

with sheet metal)

Heating when cooling is

Cool

demanded

Sensor Harness not

connected to AOC

control

Broken or loose

harness wire

Electrical short

destroyed Transducer

electronics

Heat damage during

brazing

Fan motor misalignment System will attempt to run again

See Fault 76 Same actions for 76

Low supply line voltage

(< 197 VAC)

Loose wire in control

box area

Inverter internal

damage

MOC is reporting that

OFM isn't running

There is a demand for

stator heat but MOC

doesn't detect it

High voltage power cy-

Phase imbalance/com-

cle

pressor or inverter-

miswire

Flooded start Troubleshoot EXV & TXV

Incorrect refrigerant

charge

Inverter damage Replace inverter

Compressor damage Replace compressor

MOC is reporting that

compressor isn't

running

Ensure plug is connected to AOC control

Check harness for continuity; see resistance

chart to check resistance at given temperature

Ensure Sensor is properly clipped to the dis-

Check harness for continuity; see resistance

chart to check resistance at given temperature

Ensure Sensor is properly clipped to the dis-

Check wiring between AOC and reversing

Ensure plug is connected to AOC control

Compare transducer reading to gauge reading

at service valve (see transducer measurement

chart); Check system for electrical shorts and

Compare transducer reading to gauge reading

at service valve (see transducer measurement

Troubleshoot outdoor fan motor & blade and

Check supply voltage to ODU; if low contact

Loose wire: check for loose wire in ODU

Troubleshoot outdoor fan motor and make

Check compressor winding resistance or mis-

wire of compressor leads at terminals U,V,W

Check compressor winding resistance or mis-

wire of compressor leads at terminals U,V,W

Check compressor winding resistance or mis-

wire of compressor leads at terminals U,V,W

tributor entry-tube

Replace AOC control

tributor entry-tube

Properly install OAT sensor

Check fuse on AOC control

troubleshoot reversing valve

Inspect outdoor coil for obstructions

Check harness

correct; replace transducer

chart); replace transducer

make sure they are working

utility provider

Replace Inverter

sure it is working

No action

Check refrigerant amount

valve

19

Page 20

Flash

Code

72 Local

74

75 Local

76

77 Local

79 Local

82

System

Malfunction

System

Malfunction

System Mal-

function

Amber LED DescriptionTy p e

SUCTION OVER TEMPERA-

TURE EVENT

(elevates to fault code 82 after

3 occurrences)

DISCHARGE TEMP OUT OF

RANGE LOCKOUT

(Elevated from fault code 59 af-

ter 5 occurrences)

MAXIMUM POWER MODE -

(Temporary RPM reduction or

FAN INVERTER LOCKOUT

(Elevated from fault code 61

MAXIMUM POWER MODE -

(Temporary RPM reduction or

COMPRESSOR/INVERTER

(Elevates to fault code 88 after

(Elevated from fault code 72 af-

TEMP

stage lowering will result.)

after 5 occurrences)

COMP CURRENT

stage lowering will result.

FAULT

5 occurrences)

SUCTION OVER TEMP

LOCKOUT

ter 3 occurrences)

Reset

Time

15 Minutes Both See fault 82 Same actions for 82

Sensor Harness not

Both

2 Hours

Cool High Load conditions Over charge: Check system charge

Heat

Heat

NA Both

2 Hours Both

NA Both

6 Minutes Both

Both

4 Hours

Cool Uninsulated vapor line Insulate the vapor line

Cool Indoor TXV operation Troubleshoot TXV

Heat Outdoor EXV operation Troubleshoot EXV

Both Reversing valve bypass troubleshoot reversing valve

connected to AOC

control

Broken or loose

harness wire

Broken or Damaged

Sensor

Hardware damage to

AOC control

Indoor Unit Airflow too

low or off

Outdoor Unit Airflow too

low or off

Reversing Valve By-

pass or Reversing

Valve not energized

Low Charge or Loss of

Charge at low ambient

heating conditions

Expansion Device

Restriction

Outdoor Airflow too low

or off

Blocked Inverter Heat

Exchanger (fins)

Application violates

guideline

Fan blade bent/out of

balance

Fan blade restricted

Fan motor wiring

Fan motor Replace outdoor fan motor

Inverter damage Replace inverter

Compressor is operat-

ing outside the allowed

operational envelope

Incorrect refrigerant

charge

Outdoor Airflow too low

or off

Incoming power supply

voltage

Loose or incorrect wire

connections

Compressor fails to

start

Incorrect refrigerant

charge

Ensure plug is connected to AOC control

Check harness for continuity; see resistance

chart to check resistance at given temperature

Check harness for continuity; see resistance

chart to check resistance at given temperature

Troubleshoot indoor fan motor and make sure

Troubleshoot outdoor fan motor and make

Reversing Valve stuck halfway

Check harness and connectors

Undercharged or No charge: check charge

Heating: Trouble shoot EXV (coil, harnesses);

Power Cycle system, is EXV moving on power

Check ODU coil for clogging (ice or debris)

and clean if necessary; Troubleshoot ODU fan

motor and make sure it is working

Check Inverter fins for debris and clean if nec-

Consult Application Guideline for compliance

Check outdoor fan blade clearance

Check outdoor fan motor connectors and har-

Inverter will reduce speed to a lower stage

Check ODU coil for clogging (ice or debris)

and clean if necessary; Troubleshoot ODU fan

motor and make sure it is working

Check voltage versus unit rating plate for

Check incoming power leads and leads to the

System will try to self-mitigate with repeated

ActionsPossible CausesMode

Replace AOC control

it is working

sure it is working

Ensure AOC fuse is good

24 VDC in cooling mode

Trouble shoot the TXV

up (audible)

essary

Check outdoor fan blade

Check for ice build up

Check for ice build up

ness

Check refrigerant amount

allowable range

compressor plug

start attempts

Check refrigerant amount

20

Page 21

Flash

Code

83

Ty p e Amber LED Description

LOW PRESSURE LOCKOUT

System

Malfunction

FOR 4 HOURS

(Elevated from fault code 32 af-

ter 3 occurrences)

Reset

Time

4 Hours

Mode Possible Causes Actions

Cooling in Low Ambient

region (55 °F and be-

low) with "Low Ambient

Cool

Cool

Cool

Cool Undercharged System

Cool

Cool

Cool

Cool

Heat Troubleshoot EXV (see guide below)

Heat

Heat

Heat

Heat Undercharged System

Heat

Both

Both

Cooling Control" dis-

abled

Outside Normal Operating Range (e.g. improper load calculation, sys-

tem match issue, out-

side cooling range etc.)

Service Valve left

closed (Liquid or Vapor)

Indoor Airflow too low or

Restriction in Filter Drier

plus Long Line Applica-

Restriction in Circuits or

Outside Normal Operating Range (e.g. improper load calculation, sys-

side heating range etc.)

closed (Liquid Service

Outdoor Airflow too low

Restriction in Filter Drier

plus filter drier on Out-

Expansion Device Re-

off

tion and filter drier on

Indoor Unit

Restriction due to de-

bris

Tubing

tem match issue, out-

Service Valve left

Valve)

or off

Restriction due to de-

bris

door Unit

striction

Enable "Low Ambient Cooling" via user inter-

Consult Application Guidelines

Ensure Service Valves are open

Check system subcooling to determine charge

status, if low add charge using Charging Mode

(follow proper charging procedures)

Check Indoor for clogging (ice or debris) and

clean or de-ice if necessary; Troubleshoot In-

door fan motor and make sure it is working;

follow Indoor Airflow troubleshooting instruction

Clean System (refer to application guideline)

Clean System (refer to application guideline)

Check kinks and straighten or replace circuits

Consult Application Guidelines

Ensure Liquid Service Valve is open

Check Outdoor for clogging (ice or debris) and

clean or de-ice if necessary; Troubleshoot

Outdoor fan motor and make sure it is working;

follow Outdoor Airflow troubleshooting instruc-

Check charge in cooling (if in Cooling Charge

Mode Ambient Range), if low add charge using

Charging Mode (follow proper charging proce-

dures); if outside cooling charge mode range,

pull out charge, weigh in using heating charge

Clean System (refer to application guideline)

Clean System (refer to application guideline)

If short lineset (less than 15 ft.) Troubleshoot

TXV (see guide below); replace if necessary

face

and replace filter drier

and replace filter drier

tion

mode

and replace filter drier

and replace filter drier

21

Page 22

Flash

Code

84

85

86

System Mal-

function

System

Malfunction

System

Malfunction

Amber LED DescriptionTy p e

HIGH PRESSURE LOCKOUT

FOR 4 HOURS

(Elevated from fault code 31

when the stage (speed) can no

longer be lowered)

FAN INVERTER TEMP LOCK-

(Elevated from fault code 62 af-

FAN INVERTER CURRENT

(Elevated from fault code 63 af-

OUT

ter 3 occurrences)

LOCKOUT

ter 5 occurrences)

Reset

Time

Both

Both

Both

Both

Cool

Cool Overcharged System

Heat

Both

Both

4 Hours

15 minutes

5 minutes Both

Both

Cool

Cool

Cool

Both Faulty Pressure Switch

Heat

Heat

Heat

Both

Heat Overcharged System

Heat

Both

Both Inverter damage Replace inverter

ActionsPossible CausesMode

Outside Normal Operating Range (e.g. improper load calculation, sys-

tem match issue, outside cooling range, outside heating range etc.)

Service Valve left

closed (Liquid or Vapor)

Loose High Pressure

Switch harness leads

Pressure Switch dis-

connected from ODU

Control Board

Outdoor Airflow too low

or off

Indoor Airflow too low or

charge when charging

Restriction in EXV plus

leading to Overcharge

when charging in Cool-

Non-condensable lead-

Restriction in Filter Drier

plus Long Line Applica-

Restriction in EXV plus

Restriction in Circuits or

Heat pump application:

Electric Heater stuck on

pump application: Fur-

Restriction in Filter Drier

plus Long Line Applica-

Expansion Device Re-

Reversing Valve Stuck

Unusual loading of the

Improper airflow across

Sudden supply voltage

Sudden load change on

off

Restriction due to de-

bris leading to Over-

Long Line Application

ing mode

ingtohighload

tion and filter drier on

Outdoor Unit

Overcharge

Tubing

Electric Heater plus

Furnace plus Heat

nace stuck on

tion and filter drier on

Indoor Unit

striction

in Cooling

fan

inverter heat sink

change

fan/motor

Inverter damage Replace inverter

Consult Application Guidelines

Ensure Service Valves are open

Check HPS harness

Check HPS connection on ODU control

Check Outdoor Coil for clogging (ice or debris)

and clean or de-ice if necessary; Troubleshoot

Outdoor fan motor and make sure it is working;

follow Outdoor Airflow troubleshooting instruc-

Check system charge using Cooling Charging

Mode (follow proper charging procedures)

Check Indoor for clogging (ice or debris) and

clean or de-ice if necessary; Troubleshoot In-

door fan motor and make sure it is working;

follow Indoor Airflow troubleshooting instruction

Clean System (refer to application guideline)

Clean System (refer to application guideline)

Clean System (refer to application guideline)

Check kinks and straighten or replace circuits

Check Discharge pressure with gauge, if less

than 600 +/- 20 psig and switch is open (measure resistance) then replace pressure switch

If User Interface is not requesting Electric Heat

check for heater relays, if on troubleshoot

If not in Defrost and Furnace is running same

time as heat pump, troubleshoot Furnace

Clean System (refer to application guideline)

Check charge in cooling (if in Cooling Charge

Mode Ambient Range), if low add charge using

Charging Mode (follow proper charging proce-

dures); if out side cooling charge mode range,

pull out charge, weigh in using heating charge

Troubleshoot outdoor fan motor & blade and

Check for fan outlet blockage due to snow/ice

Troubleshoot outdoor fan motor & blade and

make sure they are working. Check harness

and replace filter drier

If long line, troubleshoot EXV

and replace filter drier

and replace filter drier

troubleshoot EXV

Electric Heater

and replace filter drier

Troubleshoot TXV

Troubleshoot EXV

mode

troubleshoot reversing valve

make sure they are working

Inspect outdoor coil for obstructions

Investigate incoming voltage

and connectors

tion

etc.

22

Page 23

Flash

)

Code

88

91 Local

92 Local

93 Local

94 Local

95

96

97

98 Local

99

System Mal-

function

System

Malfunction

System

Malfunction

System

Malfunction

System

Malfunction

Amber LED DescriptionTy p e

COMPRESSOR / INVERTER

(Elevated from fault code 79 af-

INVERTER VDC-OUT UNDER

(Elevated from fault code 49 af-

(Elevated from fault code 92 af-

VDC OVER VOLTAGE LOCK-

(Elevated from fault code 91 af-

LOCKOUT

ter 5 occurrences)

INVERTER VDC-OUT OVER

VOLTAGE EVENT

(Elevates to fault code 97

after 5 occurrences)

VOLTAGE EVENT (Elevates

to fault code 96 after 5 occur-

230VAC UNDER VOLTAGE

COMPRESSOR OVER CUR-

(Event will cause stage down

and when stage is at lowest

level, will elevate to fault code

HIGH TORQUE LOCKOUT

(Elevated from fault code 98

rences)

EVENT

230VAC OVER VOLTAGE

EVENT

RENT LOCKOUT

ter 5 occurrences)

VDC UNDER VOLTAGE