285B

EVOLUTIONR15 HEAT PUMP

WITH PURONr REFRIGERANT

1--1/2 TO 5 TONS

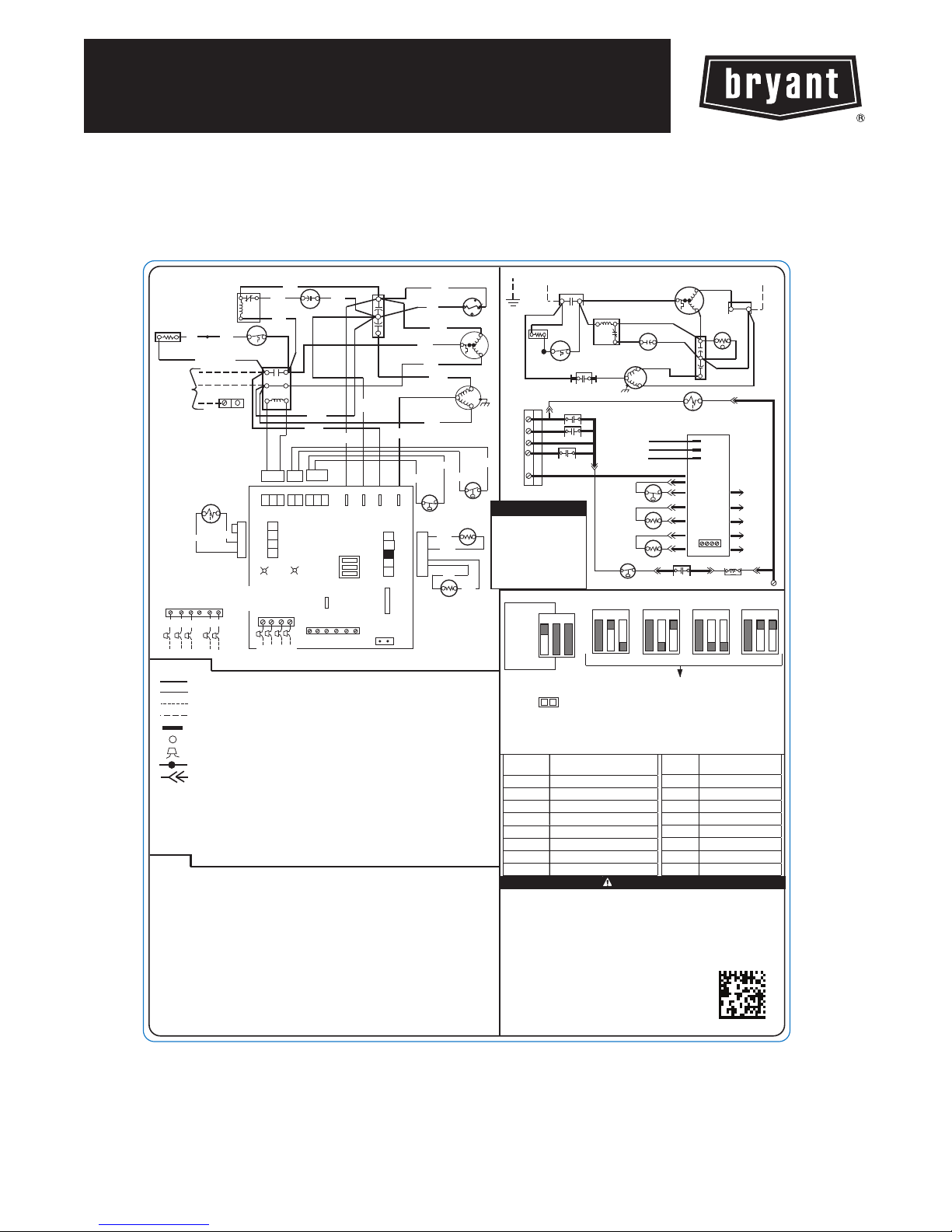

Wiring Diagram

CONNECTION DIAGRAM

BRN

1

2

5

BLK

BLK

*CHS

CONT

11

23

C

YEL / BLU

PL4

CC

13

HP

C

PL1

RVS

COMM

AS PROVIDED

SEE NOTE #12

B

A

YEL

GRN

TO INDOOR UNIT

BLU

21

23

C

BRN / YEL

4

3

2

STATUS

C

WHT

D

RED

*SC

PL3

HPS

12

VIO

1

RC

YEL

YEL

PL2

LPS

2

UTIL

YLSW2

* MAY BE FACTORY OR FIELD INSTALLED

*SR

(NOTE #8)

BLK

or

BLK

RED

*C

H

RED or BLK

L1

208/230 1Ø

L2

POWER

SUPPLY

NON-COMMUNICATING

LEGEND

AUXR

CAP

*CH

*CHS

COMP

NOTES:

1. Compressor and fan motor furnished with inherent thermal protection.

2. To be wired in accordance with national electric code (N.E.C.) And local codes.

3. N.E.C. Class 2, 24 V circuit, min. 40 VA required, 60VA on units installed with LLS.

4. Use copper conductors only from disconnect to units suitable for at least 75ºC (167ºF).

5. Must use thermostat and sub-base as stated in pre-sale literature.

6. If indoor section has a transformer with a grounded secondary, connect the Grounded

side to "C" on the circuit board.

7. If any of the original wire, as supplied, must be replaced, use the same or

Equivalent wire.

8. Check all electrical connections inside control box for tightness.

9. Do not attempt to operate unit until service valves have been opened.

10. Symbols are electrical representation only.

11. When start relay and start capacitor are installed, start thermistor is not used.

12. For communicating control only.

13. In case of non-communicating Indoor system, disconnect factory provided wires

from A, B, C, and D terminals. Using factory provided wires connect to R, C, Y, W2,

and O terminals as required by Installation Instructions. Connect field 24V wires to

factory provided wires, cap or remove unused factory provided wires.

EQUIP GND

RVS

ORG

ORG

OPTIONAL

CONTROL

SEE NOTE #13

RC

CB

BY MANUFACTURER

LS

W2

O

Y

FACTORY POWER WIRING

FACTORY CONTROL WIRING

FIELD CONTROL WIRING

FIELD POWER WIRING

CONDUCTOR ON CIRCUIT BOARD

COMPONENT CONNECTION

FIELD SPLICE

JUNCTION

PLUG RECEPTACLE

AUXILLARY HEAT RELAY

CAPACITOR (DUAL RUN)

CIRCUIT BOARD

CRANKCASE HEATER

CRANKCASE HEATER SWITCH

COMPRESSOR

BLU

VS

DEFROST

TIME

QUIET

SHIFT

CAP

H

C

F

YEL

BLK

YEL/PNK

VR L1 ODF

1

OCT

2

3

OAT

4

5

P1

FORCED

DEFROST

O

CONT

*HPS

LLSR

ODFR

RVSR

CB

CONTACTOR

DEFROST THERMOSTAT

DFT

DEFROST RELAY AND CIRCUITRY

DR

HIGH PRESSURE SWITCH

LOW PRESSURE SWITCH

*LPS

LIQUID LINE SOLENOID RELAY

OUTDOOR AIR THERMISTOR

OAT

OUTDOOR COIL THERMISTOR

OCT

OUTDOOR FAN RELAY

OUTDOOR FAN

ODF

REVERSING VALVE SOLENOID

RVS

REVERSING VALVE SOLENOID

RELAY START CAPACITOR

*SC

START RELAY

*SR

START THERMISTOR

*ST

YEL

BLU

BLK

YEL

BRN

YEL

YEL/PNK

* LPS

PL5

SCHEMATIC DIAGRAM (LADDER FORM)

BLU

*ST

t

+

S

C

R

COMP

ODF

BLU/PNK

BLU/PNK

* HPS

OCT

BRN

BRN

BLK

BLK

OAT

L1

CONT

21

GND

11

* CH

O

W2

R

LS

Y

* CHS

LLSR

L1

RVSR

AUXR

ODFR

ODF

* SR

2

5

1

NOTE

* HPS

DIP SWITCH SETTINGS

OFF

(DEFAULT)

123

QUIET

SHFT

ON

SPEED

UP

1) MOMENTARILY SHORT PINS AND RELEASE TO BYPASS COMPRESSOR OFF DELAY.

2) SHORT FOR 5+ SEC. AND RELEASE FOR FORCED DEFROST.

3) PERMANENT SHORT WILL BE IGNORED.

DEFROST WILL TERMINATE IN 30 SEC. IF DFT OPEN.

DEFROST WILL TERMINATE NORMALLY IF DFT IS CLOSED.

FLASH

CODE

On, No Flash Standby

1, Pause Normal Operation

16 System Communications Failure

31 High Pressure Switch

32 Low Pressure Switch

45 Control Fault

46 Brown out (24V)

53 Outside Temp Sensor

1. Compressor damage may occur if system is over charged.

2. This unit is factory charged with R-410A in accordance with the amount shown

on the rating plate. The charge is adequate for most systems using matched

coils and tubing not over 15 feet long. Check refrigerant charge for maximum

efficiency. See Product Data Literature for required Indoor air Flow Rates and

for use of line lengths over 15 feet.

3. Relieve pressure and recover all refrigerant before system repair or final

disposal. Use all service ports and open all flow-control devices, including

solenoid valves.

4. Never vent refrigerant to atmosphere. Use approved

recovery equipment.

30 M IN UT ES

123

30

JUMPERED TEST PINS (USE METAL OBJECT), FIELD SPEED-UP CYCLE

FAULT DEFINITION

EQUIP

THIS DEFROST CONTROL

BOARD CONTAINS A FIVE

MINUTE SHORT CYCLE

PROTECTOR. A FIVE

MINUTE DELAY WILL

OCCUR BETWEEN

COMPRESSOR OFF/ON

CYCLES.

COMP

R

C

*SC

ODF

RVS

L1

VS

VR

LPS

OAT

OCT

CB

K4

60 M IN UT ES

123 123 123

60

OR

FIELD SELECTABLE OPTIONS FOR TIME PERIOD

BETWEEN DEFROST CYCLES (MINUTES)

CAUTION

OR OR

FLASH

CODE

55 Coil Temp Sensor

56 Thermistor Range Error

72 Thermal Cutout

73 Contactor Shorted

74 No 230V at Compressor

82 Thermal lockout

83 Low pressure lockout

84 High pressure lockout

CONT

S

23

CAP

+t°

H

* ST

C

F

C

L

O

G

OUTPUT

I

C

INPUT

SEE NOTE #12

C

B

A

D

CONT

(D EFAU LT )

90 M INUT ES

90

FAULT DEFINITION

ODFR

RVSR

AUXR

LLSR

K4

120 MINUTES

L2

23

C

120

339109-101 REV. A

Fig. 1 – Wiring Diagram — Model size 1.5 -- 5 tons, 208/230--1

EBryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231 Edition Date: 09/12

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without i ncurring obligations.

Catalog No. WD285B--- 01

Replaces: New

2

Loading...

Loading...