Page 1

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 7 A M

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

^ /

MODEL 23^

Inst^llatioiii Instructions

GAS FIRED WATER OR STEAM BOILER

A. G. A. APPROVED

note;: these

[HSTRUCTI ONS

MUSTPE LEFT

ON OR NEAR

THE BOILER.

The Model 234 is a low pressure, sectional, cast

iron water and steam boiler, approved by A.G.A. for

use with natural, manufactured and propane gases.

It is tested for a maximum working pressure of 30

psi on water and 15 psi on steam in accordance with

A.3.M.E. standards for cast iron boilers*

The boiler is available as a Type GW - Gravity,

Type PW - Circulation Pump, Type CW - Coil Circu

lation Pump, and Type S - Steam. All boilers are

factory assembled.

SERIES g

I

39234D3

10/5/64

Install in compliance with requirements of local

utility or other agency having jurisdiction.

GAS CONTROL OPTIONS

Control Type

D2

100% shutoff

24 volt

. Thermti'i:oupl'e'"P'ii'o''t

D4

Non 100% shutoff

24 volt

Bryant pilot

D5

100% shutoff

24 volt

Thermocouple pilot

D6

100% shutoff

Millivolt

Thermocouple pilot

Gas Type

Propane PWSiE

Nat&Mfd PW, GW,

Boiler Type

cw&s

NataaMfd PW, GW

CWQlS

Nat&Mfd GW&S Salf-'geh orating

Control Components

100% pilot shutoff valve

Thermocouple pilot

Trans fonner

Biyaiit ■disp'hT'SgÉK ■■■ '

gas valve

Bryant automatic pilot

Bryant diaphragm

gas valve

Gas pressure regulator

Transformer

100% pilot shutoff valve

Thermocouple pilot

Transformer

Bryant diaphragm

gas valve

thermocouple pilot

Diaphragm gas valve

Gas pressure regulator

DO NOT

remove!

Page 2

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 7

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

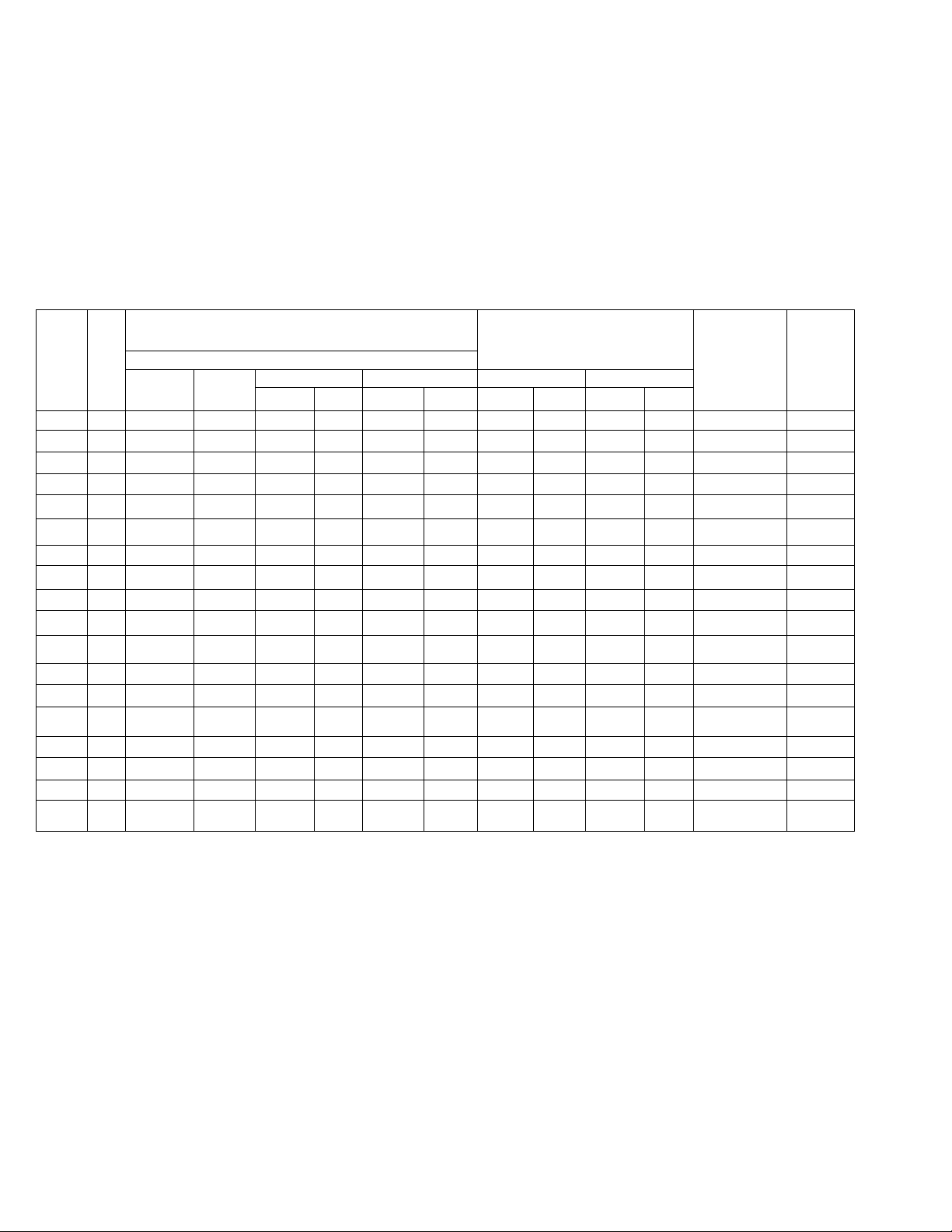

RATINGS AND CAPACITIES

P , 0 0 2

Boiler

Sixie

3

\ 4.

K ■

6

7

l7

5

4

...

5...

6

7

Gross Input BTUH

Type

Nat&MfdpTOpqne

, "i

90,000

PW

PW 125,000

160,000

P,W

;200;Gi3Q.

-EiW <

PW‘ 240,000

•er

It:

w.^ .34b;ow^220,000:

GW‘ iso,oijp:^

..2Oi5;:OQ0'"

■-S

s 105,000

s 175;000 162,500

s 210,000

‘“Ip?!

^60,Mo

¡rSg'ifSSj

‘•'TGjoeb“

.......

............. ’

.440^000 .

85,000 72,000

n0;00:o 100,000’^^67?

ii5o,oao 128,000

I75:00a

220,000 1.92,QQQ:1280;

i ssiOdS-

i^ iTo:oGOi

h.50,Q0p; 128^000' 85:3

^75,000; 16.0,00.0

|!130,0QG; 110,400, 736

N60,000

|200,000 160,000?1067 ,

“ 65,000

97,500 84,000 350

130,000.

195,000 168,000 700

G,r05.5

Nqt^Mfd

BTUHSq.;Ft,

■■■ '#P';

853,

160,000

■1,00,^000^

l92;:O0f

128,0003

112,000 467 .

140,000 583

.;1067^

‘72,ooo;

- .48.0;: 68;ooo 453 54,000

667

1067 140,000' 933 120,000

128:0

853

56,000 234

A,G,A, RATINGS

Output

Propane

BTUH

6s,ooo:■ 453''- 54;00.0

.88,000.

l:20;000 800 96,0:o;o

140/bOO: 933 120,000

N76,000

8S;000 5S7 7'5,000

i;20;ooo, 800

176,000

104,000 695 82,800

128,0.0.0 853 96,000

160,000 1067 120,000

52,000 217 42,000

78,000 325 63,;0.0.0i

104,000..

130,000 543 105,000:

156,000 650 126,000

Sq. Ft/ BTUH Sq. Ft:

75/000'

587

144,000

ii/b

96,000

144,000

1173

..84,G0:O'

.433 .

Net Output

Nat&Mfd

360 ^ 51,000. 340 ’

500 66,000 440

640 90,0Q0

800 TQ5.0.D0700 9.3

960 132,000 880

360 51,000 340

500 66,000

640 90,000 600

800 105,000 700

960 132,000 88.0

552 78,000 520

640 96,000 640

800

175

253 58,500 242

„..350.. ...78,oo:o.325

‘ 4 38 97,000 405

525 117,000

Propane

BTUH Sq. Ft.

120,000 800

39,0.00

600

440

162

487

\

Boiler Water Approx.

Capacit.y in Sh ipping

Galfoas Weight

5.0 277

■ 340

8.0 403

478

IKO

5.0 257

6.5

BX

9.3 448

n.o 500

9.2 415

10.6 ~~4§6

12.2 544

—

-

—

535

318

383

259

318

383

448

500

39234D3

- 2

Page 3

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 7 A M U T C T E C H P U B

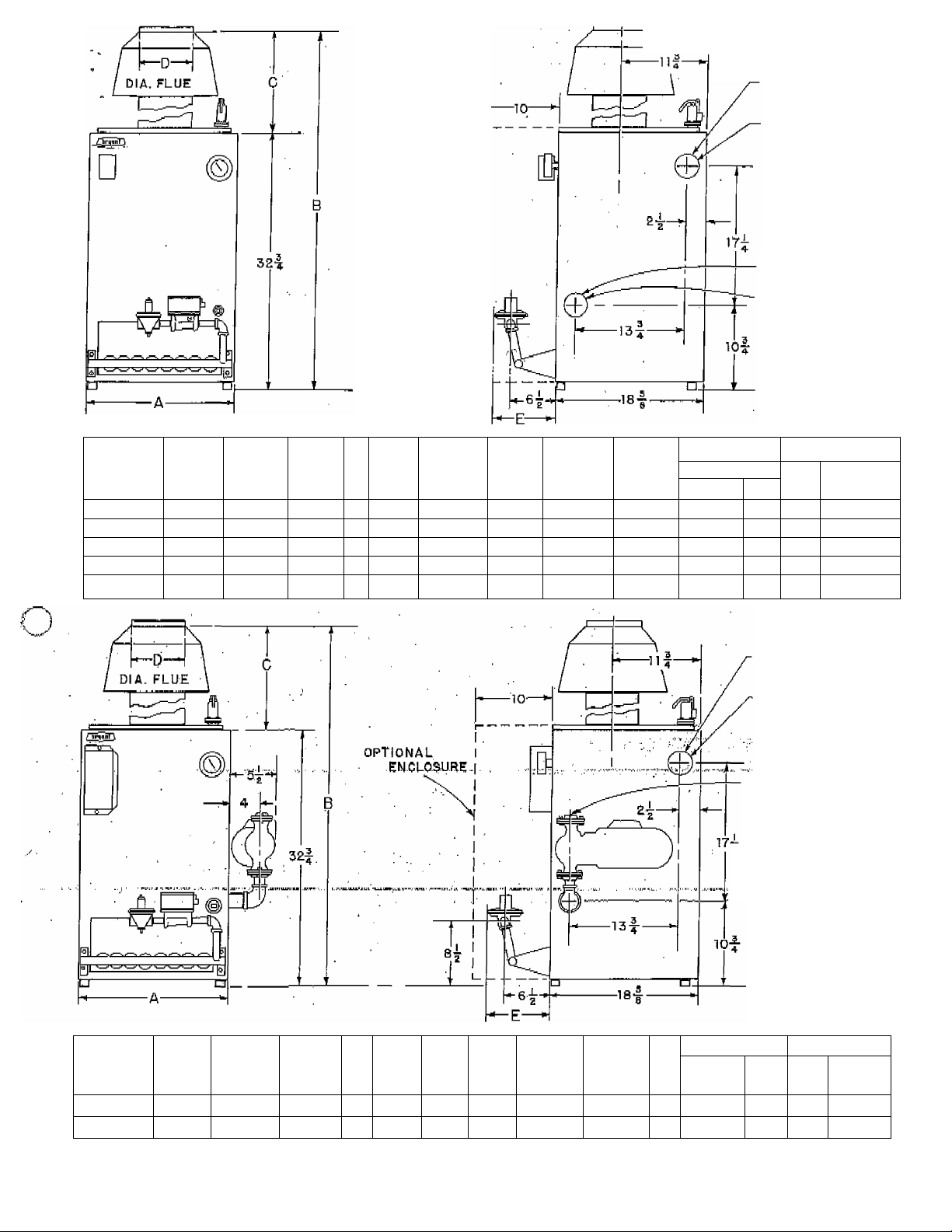

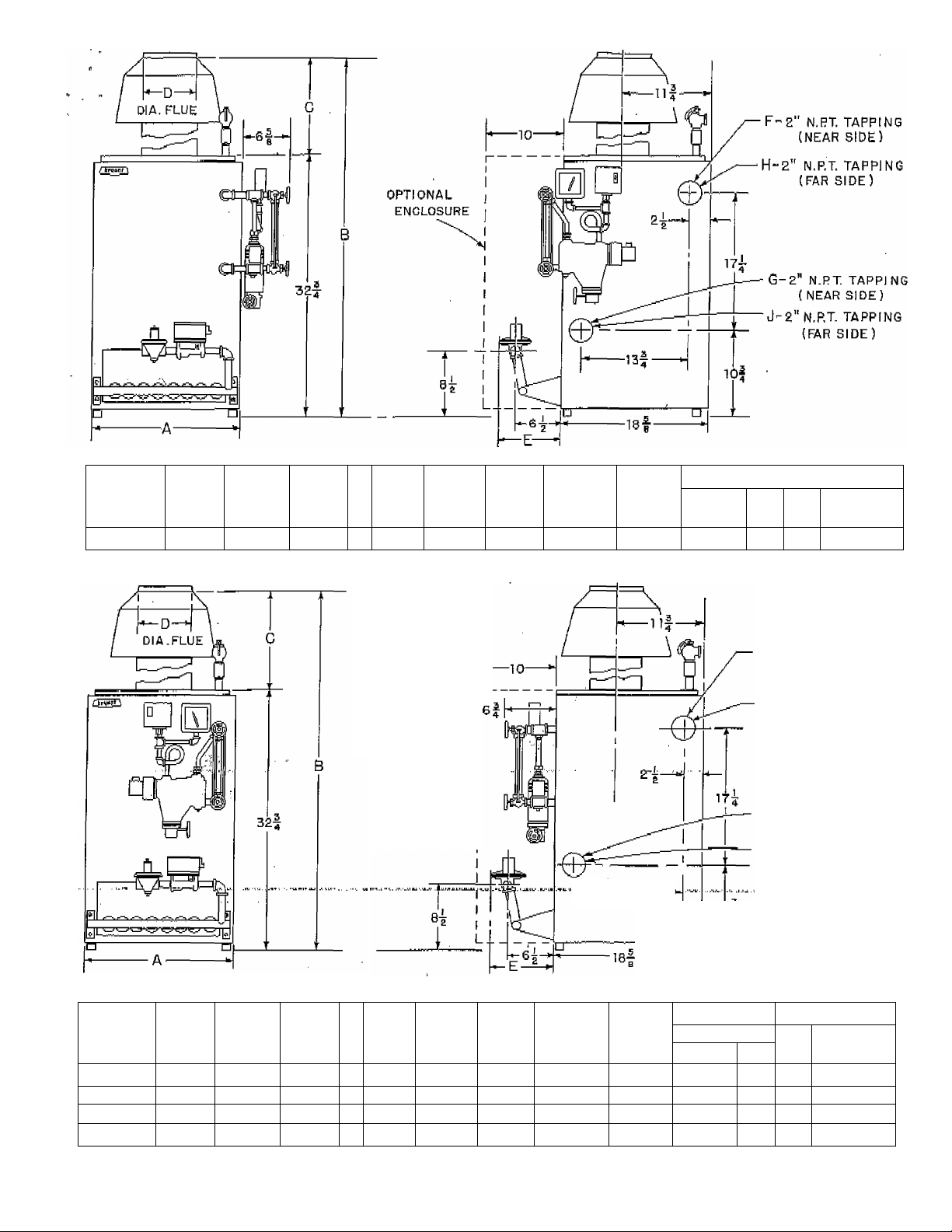

OPTIONAL

ENCLOSURE

F A X N o . 3 1 7 2 4 0 5 6 6 2

P . 0 0 3

F-‘£“ N,P.T, TAPPING

(NEAR SIDE)

H-a“N.PT TAPPING

(FAR SIDE)

G-£"N.P.T TAPPINQ

'(NEAR SIDE)

J- £"N.RT, TAPPING

( FAR SIDE)

r

Model

Size A

Type

234-3GW 9-3/4

234-4GW 12-5/8

234-5GW 15-1/2

234-6GW 18.3/8

234-7GW 21-1/4

-

B C

46-9/16 13-3/4 5

46-9/16 13-3/4 5

50-9/16

17-3/4 "6

53-5/16 20-1/2

53-5/16 20-1/2 7

D

E

8-5/8

8-5/8

8-5/8 plugged

7

8-3/S

8-3/S

F G

open open

}*

ft

jjf

tj ft

H

plugged plugged 1/2

M ft

open 1/2

ft y J

J9 J J ft i)

‘

J

Ggs In et Size

Nat Mfd Propane

D4&D5 D6 D5 D2

1/2

ITT™

1/2

1/2 3/4

1/2

3/4

3/4 3/4

3/4 3/4

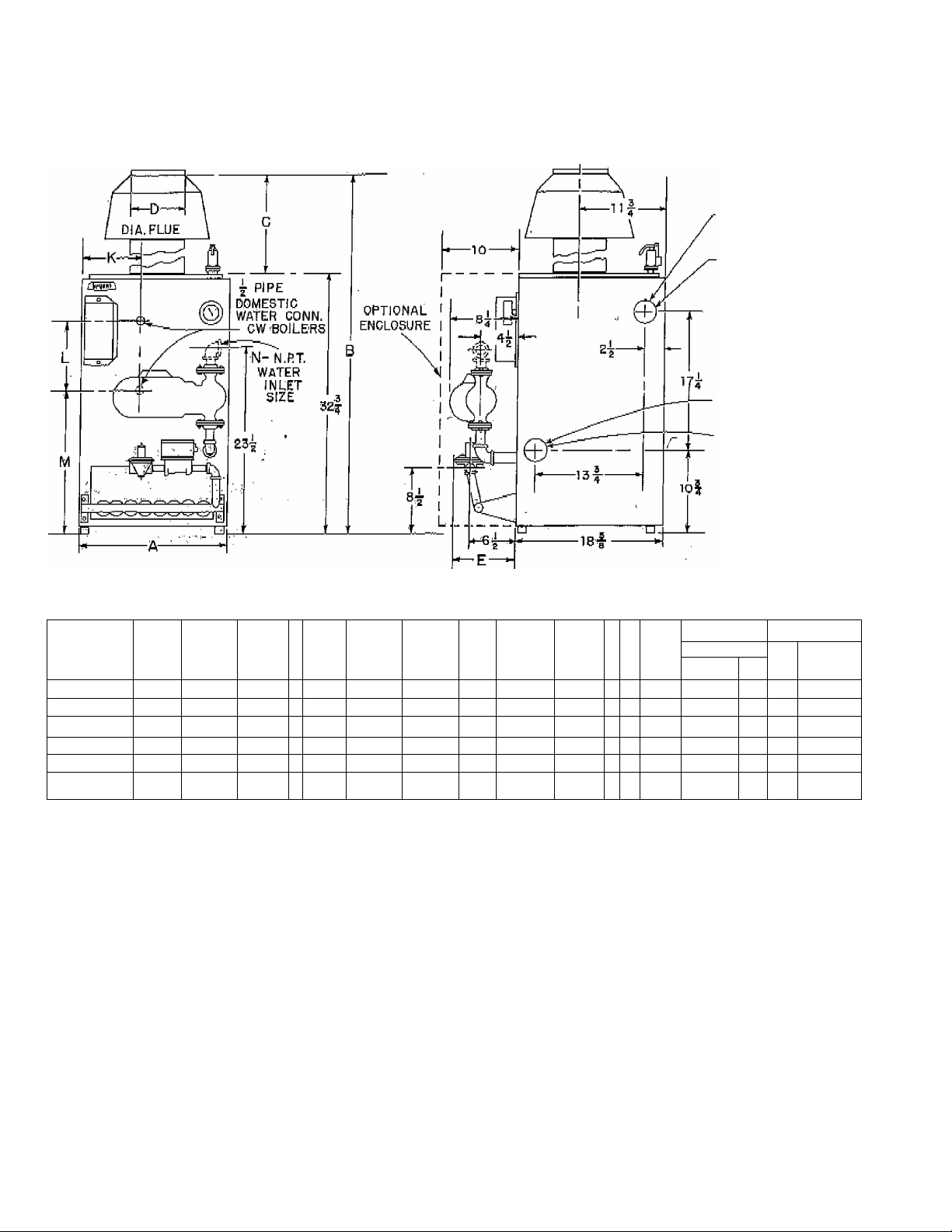

F- E" N.RT TAPPING

N-N.PT WATER INLET

^ G- £" N.RT. TAPPING

1/2

3/4

-■

—

-

um

-

(NEAR S1D,E)

H-£"N,RT. TAPPING

(FARSi-P^.).

SIZE.

(NEAR SIZE)

tapping'''

(FAR SIDE)

Model

Size&

A

Type

234-3PW

' 9-3/4 46-9/16 13-3/4 5

234-4PW r 12-5/8

B C 0

46-9/16 13-3/4 5

*

E

8-5/8

8-5/8

F G H

open open

li ft

J N Nat

D4&D5

plugged plugged 1 1/2

y y

1 1/2 1/2

Gas In

et Size

Mfd

D6

D5

1/2 1/2 1/2

3/4 1/2

39234D3

Fropgne

D2

Page 4

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 8

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

■)

F“e"N,RI TAPPING

(NEAR SIDE )

H“ Z" N,RT TAPPING

(FAR SIDE)

G- 2" N.PT TAPPING

(NEAR SIDE)

J- £" N*RT. TAPPING

(FAR SIDE)

Modd

Size & A

B C D E F G H J

Type

23.4-5PW

15-1/2

50-9/16

234-6PW 18-3/8 53-5/16

17-3/4 6 8-5/8

20-1/2 7 8-3/8

234-7PW 21-1/4 53-5/16 20-1/2 7

234-4CW 15-1/2 50-9/16

..

:234i'5CW.18-3/8,

'234^6CW 2l-i/'4-

53-5/16 20-1/2 7 8-3/8

17-3/4 6 8-5/8

20-1/2, 7 S-.5/8

plugged plugged

8-3/8

plugged —

f7 /7

open

IJ if tt ¡7

J J

J V

tt 97 77 7 7

rr If I f r 1

Gg 9 In et Size

K L M N Nqt MM

D4&D5 D6 DS D2

- -

i-1/4 1/2 1/2 3/4 1/2 .

—

—

-

7-1/2' 9 18 1-1/4

7-1/2. 9 18T-1/4

— 1-1/4

M/2 3/4 3/4:

-

[ li2

1/2

1/2

3/4 3/4 1/2

3/4:

3/4

1/2

1/2

3/4

10-3/8 9 18 1-1/2 1/2 3/4 3/4

Propane

i/2

-

-

muDZ

-4^

Page 5

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 8 A M

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

P . 0 0 5

O

Model

SizeSt

Type

234-3S

A

B C

9-3/4 46^9/16

13-3/4

E F

P

5 8-5/8 open

OPTIONAL r

ENCLOSURE

G H

open

plugged

J

plugged

Nat

D4&D5

1/2

Gas Inlet Size

Mfd

Propane

Mfd

D5

D2

1/2 1/2 1/2

F- 2”N.RT. TAPPING

(NEAR SIDE)

N.RT* TAPPING

( FAR SIDE )

G“ 2" N,RT TAPPING

(NEAR SIDE)

J- 2" N. P.T, TAPPING

(FARSiDE)

Model

Size

A

B C

D

E F

G H

J

Type D4&D5

234-4S

234-5S

234-6S

234-7 S

12-S/S

15-1/2

18-3/S

21-1/4

46-9/16 13-3/4

50-9/16

17-3/4

S3-5/16 20-1/2

53-5/16

20-1/2

S-5/S Open

5

6 S-5/3 plugged

,8-3/S

7

7 8-3/8

r r

tt

- 5^

open

plugged

ff

7 7 j i

}t

open

9 J

plugged

i J

1 r

1/2

1/2

1/2

3/4

Gas In

at Size

Nat

Mfd D5 D3

1/2 3/4

"1/2 3/4

3/4 3/4'

3/4 3/4 1/2

Mfd

Propane

1/2

1/2

1/2

39234P3

Page 6

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 8

UTC TECH PUB

ni

N o , 3 1 7 2 4 0 5 6 6 2

P . 0 0 6

LOCATING THE UNIT

Consult local building codes or ordinances that may

apply.

1. The boiler should be installed on a level founda

tion. Metal shims may be used to level if required.

Locate boiler near gas vent or chimney.

2. Combustible Floors - When the boiler is installed

on a combustible floor it is necessary to ¡nsulote

the floor» Bryqnt supplies, as optional equipment, □

combustible floor installation kit. This kit contains

a rectangular plate of galvanized steel with □

matching piece of insulating material. Fasten the

insulation end steel plate to the combustible floor

and place the boiler on fop of the steel plate.

3. Maintain at least 6" from combustible material

on ail sides.

4. Leave enough room for service access. Consult

local approval agency; some require □ minimum of

24" for service access.

5. When unit is installed in a small room, or a build

ing of roiatiyely air-tight'construction, provide air

for combustion and ventilat'iou. This air must be

supplied through two openings of equal area; one

located above the draft diverter relief opening and

the other near the floor. The total free area of each

opening should be equal to 1 square inch for each

1,000 BTU/Hr. of boiler input. There should be a

minimum of 100 square inches for each opening. If

ait openings are directly to outdoors, the minimum

free area should be 1 square .inch per 2,000 BTU per

hour or input rating, or in accordance with Z21.301959 or latest edition of ^'American Standards .for

Inst^Uatiqii of Gas Appliances and Gas Pfpipg/'

2. Flue pipe must slope upward from boiler to chim.- '

ney. Minimum slope is 1/4 inch upward per linear*

foot of flue pipe,

3. Run pipe as directly as possible with a minimum

number of turns.

4. Do not connect into chimney serving an open fire

place,

5. End of flue pipe must be flush with inner face of

chimney liner.

6. Rigidly support pipe with hangers and straps.

7. Chimneys should extend at least two feet above

any object within a radius of 15 feet.

8. All flue pipe extended through the roof should be

equipped with a hood.

9. The boiler may.be installed with either a galvan

ized Type C vent or a listed . Type B yent, at the

option of the installer. Where a Type C flue or vent

connector is used, it shall have a clearance of 6"

between its surface and any combustible material.

If a Type B flue or vent connector is used, clear

ance from its surface to any combustible material

shall be in accordance with its listing. Consult

local codes to insure correctness.

10. Where two or more appliances Vent into a com

mon flue, the area of the common flue should at

least equal the area of the largest flue or yent con

nector plus 50% of the areas of the additional flues

or vent connectors.

GAS SUPPLY LINE

6- Advise owner of necessity for keeping air pas

sages to the boiler area free of obstructions. This

clearance is necessaiy so that combustion air can

enter freely into the combustion chamber. It is also

necessary to provide adequate ventilating air.

FLUE CONNECTIONS

Make sure draft hood furnished with boiler is instal

led without modifications. The following is standard

practice for installing the flue pipe. In addition,

consult local codes and gas company requirements.

1. Flue pipe must be of the same si^re as the outlet

collar on the draft hood.

39234D3

Comply with applicable codes and regulations.

It is good practice to run a separate gas line direct

ly to the gas meter for supplying central heating

boilers. This line should be at least as large as the

-manual "gas shut-off-supplied.. If . the calculated pres^

sure drop exceeds 0.3 inches water, the line should

be run at least one size larger than the usual gas

shut-off. In no case should the drop exceed 0.3

inches water.

The pipe should be. supported with adequate straps

or pipe hangers. Provide a drip leg at the bottom of

the supply riser. Drip leg may extend down to floor

to help support the weight of the gas. supply line.

Install a ground joint union between the riser or

drip leg and the boiler controls. .

Joint compound (pipe dope) which is resistani to the

action of liquefied petroleum gases should be ap-

.6-

Page 7

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 8

UTC TECH PUB

_plied sparingly and only to the male threads of the

Joints. Consult local supplier for type of compound

to he used.

The manual gas shut-off valve should be approxi

mately 5 feet above the floor. Install the valve so

that the 1/8 " tapping used to connect the pilot gas

supply line is located on the inlet (supply) side*

Noter For LP Gas installations the main manual

shut-off valve is an integral part of the 100% shut

off safety control mounted on the manifold with the

electric gas control valve.

Where a pilot gas filter is required by local regula

tions, place filter between manual gas shut-off

valve and pilot valve. See Figure T.

F AX M o . 3 1 7 24 0 5 6 62 P .0 0 7

BOILER WITH REFRIGERATION SYSTEM

VALVES A a В - OPEN FOR HEATING; CLOse FOR COOLING

VALVES C a □ - CLOSE FOR HEATING; OPEN FOR COOLING

When the boiler is used in connection with a refri

geration system it must be installed so that the

chilled medium is piped in parallel with the heating

boiler with appropriate valves to prevent the chilled

medium from entering the heating boiler. An example

of such piping is shown above.

FILTER

PILOT GAS VALVE

Figure 1

ELECTRICAL CONNECTIONS

All electrical connections are to be made in accord

ance with the National Electric Code and local

codes governing such wiring. Field connections are

to be made in accordance with the wiring label

attached to the boiler. These labels are reproduced

in this manual.

When the boiler is connected to heating coils lo

cated in air handling units where they may be ex

posed to refrigerated air circulation, The boiler

piping system must be equipped with flow control

valves or other automatic means to prevent gravity

circulation of the boiler water during^^^^'^^^t^

CAUTIOM, - Note: It is recommended that a relief

valve be installed between valve ,A and the boiler

or valve B and the boiler. This relief valve should

preferobty be on the boiler itself. The relief valve

will protect the boiler from expansion pressures

during the-cooling'seasoni-^ - - ■ -

...

...

- 7 ■

39234D3

Page 8

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 8

STÁRT-.UP AND ADJUSTMENT

Check to be sure that all connections have been

made. Before attempting any operation, fill the

system with water. Never light a burner under an

empty boiler. After filling system with water, bleed

all air from the radiators. Add water and bleed

again. Repeat as necessary until system is free of

air. Open all valves on water supply and- return

lines.

Light the pilot using procedure outlined on the

lighting instruction plate attached to unit However,

when lighting the pilot for the first time, perform the

following additional steps:

1. If the gas supply line, was not purged prior to

connecting the boilet it will be full of air; Since

it would take a long time to.went this ,air thipugh the

small pilot port, it is ,recóMffiended-th^P pilot

supply line be disconnected at the pilot shut-off

valve and the supply line be allowed to purge until

the odoi of gas Is 'dëtected- -;Never:purge ^^Çias- l ines

into the combustion chamber: Itniiiëdiatèly upon

detection of gas odor^ :rëcOnneCt the pilot supply

tube* Allow 5 minutes tO-élápsfe and light the pilot

in accordance with the instructions on the lighting

plate.

2. The pilot Дате should be soft blue' in color.

a. For natural gas controls (D4), this flame should

be of sufficient length to provide good impingment

on the unimetal of the Bryant pilot. Flame should

extend upward between the carry-over ports of the

two adjacent burners. Pilot ñame should not touch

boiler section.

'b.tFof -Dâ and ;D€iUghs'controls, the ñame should

Buïfounid the tip of the thermocouple element of the

piidf and extend downward to include 3/8” to 1/2”

of' the thermocouple. The ñame must never come in

contact with any other part of the thermocouple or

■its lea'd''Wire.“"'The"ña'm6'^li'es'"un'de'r-th'ff“tarr'y-over ^

ports of the burners and merges with the carry-over

flames. Pilot flame should not touch boiler section.

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2 P . 0 0 8

Light main burners using the procedure outlined on

the metal lighting instruction plate attached, to the

unit.

Adjust gas rate for natural and manufactured gases.

Input should be checked at the meter to make sure

that it corresponds with that shown on the rating

plate attached to the unit.

L Remove 1/8” plug in manifold downstream from

the gas valve and connect manometer to observe

manifold pressure.

2. Set thermostat to call for heat. Be sure that all

other gas using appliances are turned off during

this period of adjustment.

3. Observe manifold pressure. It should be adjusted

to read ,3” w.c. * 0.3" w.q. Adjustment of the pres,sure.^ is accomplished by means of the adjusting

isctew on |he ,gas pressure regulator. (This screw is

concealed under the regulator sealing cap.) Turn

screw clockwise to increase pressure and counter-

blbckwise td decrease pressure.

4. Determine input as follows:

a. Count number of seconds required for one com

plete revolution of dial on the test meter (utility gas

meter).

b. Divide 3,600 by the number of seconds counted

in Item ^a' above.

c. Multiply results of 'b' above by the number of

cubic feet per revolution of the test dial. This gives

cubic feet per hour of gas flow.

d. Multiply results of Item 'c* above by the heat

value of the gas in BTU. (Consult local utility for

this value). This gives the total measured input in

BTU/Hr.

Example:

’"Size of 'test'MeterdiaT-5 icUt'-ft, ■ ■■''■'■ ■ “ ■ .....

Seconds to complete one-revolution -185 seconds

Heating value of gas used-1050 BTU/cu. ft.

.

3. If the pilot flame does not have the appearance

described above, it may be adjusted by means of

the manual pilot shut-off valve (B valve).

a. The valve is equipped with an adjustable screw.

Turn the handle to the full open position and remove

the screw cap to expose the adjustable screw. Turn

adjusting screw until flame has the desired appear

ance.

b- Replace screw cap.

39234D3

Proceed with calculation as follows:

□ . 185 seconds to. complete one revolution

b. 3,600 .divided ’by 185 = 19.5 (approximately)

c. 19.5 X 5 = 97.5 cu. ft./hr. gas flow

d. 97.5 X 1« = 102,375

Small changes in input can be made by changing the

manifold pressure as previously described. However,

the manifold pressure should not vary more than 0.3"

w,c. from the rated pressure of 3” w.c.

Page 9

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 9 A M U T C T E C H P U B

F A X N o . 3 1 7 2 4 0 5 6 6 2

P , 0 0 9

J'urthex change in gas xate can be accomplished if

necessary by changing the fiired orifice to the burners*

Propane Gas: Propane gas units axe not equipped

with gas pressure regulators. Burner orifices are

sized to give the rated input at a manifold pressure

of 11" w.c. The only check for rated input is the

manifold.pressure.

CHECK CONTROLS

Bryant Gas Control Valve: If not already checked

when .iighting the main burner, check" thè proper

opexa'Lon pof This valve. Move the thermòstaf to a

call for diedi position. Observe there-Iwiil^ jAbe an

approxitnetfe 30 'second delay for the vaTye; ip 'ppen.

Move the the mio stai to a satisfied position;, again,

the 30 second -delay before the'.val ve iQlphes,.T' .^^^^

Automatic Pilot'; Check 'the Vìithe

automatic pilot as fòliows;

1. Set the room thermostat bh tail'fpi heaf-

2. After burners have ignited, close the pilot gas

cock.

3. After pilot gas cock is closed, the gas valve will

close in approximately 1 minute. After the pilot gas

is shut off the monometal cools and returns to the

open position. This breaks the circuit to the gas

valve closing the gas valve.

The thermocouple transforms heat energy from the

pilot flame into electrical energy. The current thus

generated is sufficient to operate the 100% shut-off

valve. The Bryant Diaphragm Gas Control Valve is

powered externally from the transformer, and oper

ates independently of the shut-off valve. When there

is a pilot flame, the current generated from the ther

mocouple holds thè 100% shut-off valve in the open

position and the gas control valve controls the flow

of gas. Should the pilot go out, there will be no cur

rent generated fay the thermocouple and the 100%

shut-off valve will close and no gas can flow to the

pilot.

If the pilot should go out, the electrical circuit to

the main gas valve will be broken and gas cannot

flow through the diaphragm valve. '

BRYANT AUTOMATIC PILOT (D4)

The pilot assembly includes a normally open switch

wired in series with the Bryant diaphragm gas con

trol -valve. The switch is at the free end of . the

monometal element assembled so that the fixed end

is positioned at the pilot flame. Heat applied to the

fixed end of the monometal element causes the free

end to move. This closes the switch and completes

the electrical circuit to the control valve. The cir

cuit will close within one minute. It will remain

PILOTS WITH THERMOCOUPLE ELEMENT

The D2 andTÌS gas :x-on|rolV.Mye;p^

with thermocouple elements., , vi

The pilot flame should surround the tip of -the ther

mocouple. It should also extend downward to include

3/8 VTq 1/2." Ql.th§.Th??Lmpcoub^i^^^^ -Th£ flame mu St

not come in contact with any other part of. the ther

mocouple.

- 9 -

^' closed aS long as there is iiori^al pilot flame. .While,

closedTbe ^bbilei tS riiidef tiie difieCf aj^Miiatic con

trol of the ioo^ ojpetating con

trol as long as the ;main gas manual shutpif vATve is

open. If the pilot .ilanie' g^ reason^ the

monometal element will cool and the free end will

move back to its original position. This breaks the

electric circuit and the Bryant diaphragm gas con

trol valve will close. This shuts off the gas supply

to the main burner.

39234D3

Page 10

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 9 A M

GAS PRESSURE REGULATOR

The gas pressure regulator, provided with all units

except those using LP Gas, is of the adjustable

spring loaded type. It functions to give a constant

gas pressure to the burners during all main line gas

pressure fluctuations. This regulator is factory

adjusted to produce 3" manifold pressure.

D6 CONTROLS - SELF-GENERATING

The D6-Control system consists of a powerpile ther

mocouple, a Q314 Pilot Head and a self-generating

thermocouple and a combination valve.

The powerpile thermocouple transforms the heat

energy of the pilot flame into electrical energy

which operates the controls.

Should the pilot flame not be positioned correctly

on the powerpile thermocouple or the pilot flame be

out, there will be no heat energy, hence no electrical

energy-can be generdtedj

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

HIGH TEMPERATURE LIMIT

(Wafer Boilers Only)

The high temperature limit switch is a normally

closed switch which opens on temperature rise.

This limit has a cut-out set at 240F and an adjust

able range from 180^ F to 240 ^. F. .When the water

temperature reaches the cut-out setting the circuit

to the gas valve is broken and the gas valve closes.

39234D3

10 -

Page 11

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 1 9 A M

PRESSURE LIMIT CONTROL

'This control will shnt off the gas supply to the bur

ners in the event that the steam pressure in the

boiler reaches the *'cut-out” setting. It will also

permit gas flow to the burners when the steam pres

sure drops to the “cuHn"* setting. The range be

tween these two settings is called the *'differen

tial”. The cut-out pressure is equal to the cut-in

pressure setting plus the differential.

LOW WATER CUT-OFF

(Steam Boilers Only)

This control operates to shut off the gas supply to

the burner in the event that the water line in the

boiler drops to a low level. It also permits ga^ flow *

to the burners when sufficient water is ^dded to the

boiler, either by opening a water valve manually or

be an electric water feeder.

UTC TECH PUB

(St0am Boilers Only)

^NOT TO BE MADE BEFORE HERE.

F A K N o , 3 1 7 2 4 0 5 6 6 2

ftlbUCTI IN PIPE SIZE

P . 0 1

£" PIPE

' 'Re'coinmefi'dSd''

8t*am heoder

proportions for

175, 210.

Racomm ended

steam Heoder

proportions for

70, 105, 140.

Under no circum-

otoncofi should the

risers he reduced

in six* before the

first horizontal

run.

Under no circtitn-

stances should tl

risers be reducec

in size before th<

first horizontal

run.

- 11 -

39234D3

Page 12

SE P / 02 /2 0 08 / TU E 08 : 20 AM UT C TECH PUB

FAX No, 317 240 5662

P. 012

CLEANING STEAM BOILERS

Caution: The boiler should not be left unattended

during the cleqn-out process.

1, Skimming off Impurities

Some of the impurities in the boiler water will float

on the water .and must be skimmed off. Run a tem

porary connection from the skimmer tee.

With the boiler empty and cool, slowly begin to add

After water has' entered boiler-never beforeturn main gas burners and adjust flame at main

manual shut-off valve so that the water being added

is kept just below boiling point. Avoid boiling and

turbulenceGradually raise hot .Water level to tee being careful

not to raise it above the opening in the tee. Skim

until there is no trace of impurities. Repeat process

if necessary.

Water may be checked to make sure it is free from

oil by drawing off a sample at the skimming tee. If

the sample its reasonably free from oil, it will *not

froth when ^boiled on a stoye. This test does not

indicate the amount'of sedment which may lay in

the bottom of the boiler. It is therefore necessary

that the iboiler ;be further cleaned by 'blowing down'. ,

Sal Soda (washing soda) is sometimes usOd for ex

ceptionally dirty boilers buf its Use requires'e?i-

treme caution. The boiler can be seriously harmed

if the soda is not thoroughly washed out or at least

sufficiently so that the water does riot ekceed the

pH value of 7 to 8. Soda is difficult to ;remo,ve and

requires a lengthy process of repeatedly Hushing

the boiler to assure complete removal. t/

If spjla is insisted ripon it is recommended that a

solution of one pound dissolved in a pail of hot

water, be prepared for each ten gallons of boiler

water. (Check water capacity of boiler). Pour the

solution in any convenient opening at, or above the

flow tapping. Fill boiler to flow tapping and adjust

fire manually to maintain simmering for live or six

hours. Increase fire to build up five pounds pressure

and blow down boiler. '

Blow down boiler again as in Step 2, then flush con

tinuously until it is certain-that boiler is free of the

soda. After the boiler has ‘been thoroughly cleaned,

add fresh, clear water to the proper level in the

heating system. If the degree of acidity or alkalinity

of the water must be adjusted, it is recommended

that the water be mildly alkaline, not exceeding a

pH value of 7 to 8.

).

2. “Blowing Down" Boiler

Before blowing down the boiler, fill if to the water

line. Light burners and allow five pounds of steam

pressure to build up. Run a temporary connection

from one of the drain valyes to a .nearby sewer.

...

Cotih.ect .to a .drain ^v^lve oh ihe oppp the

boiler from the feed water inlet, if possible. Shut

off the gas burners, open drain valve and blow down

entire contents of boiler.

Allow boiler to thoroughly cool and slowly refill to

water line. Repeat Step 2 as many times as required

' until blow'off water is 'clear.

3. Using Cleaning Compound

.................

.

..........

If an exceptional amount of dirt or sludge seems to

be present in the boiler, a boiler cleaning compound

made by a reputable manufacturer may be used ac

cording to the instructions of the manufacturer of

the compound. When any type of cleaning compound

is used, care must be taken to thoroughly flush all

traces of the compound out of the boiler.

..

.

39234D3

12

Page 13

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 2 0

^Flye Pqssqgei: FJue passages between sections

should be examined yearly and cleaned as required.

Boiler Controls: Check all boiler controls for proper

operation at the start of each heating season. If

boiler is operated year-roundj check controls at

least every six months.

Note: The hand of the TemperaturerAltitude Gauge

should be pre-set by the installer to indicate the

vertical distance between the gauge and the expan

sion tank on open systems. On closed systems, pre-

set the hand to agree with system pressure when

cold. This will normally be about 12 psi. The oper

ating pressure hand should approximately agree

with this setting when the boiler is properly filled.

UTC TECH PUB

CARE AND MAINTENANCE

1 . 8 1 7 2 4 0 5 6 6 2

7 0 1 8

Draining Boiler:

ing seasons. In

Do not drain boiler between heot-

fact, the boiler should never be

drained, flushed, or boiled out unless it is abso

lutely necessary. See special instructions ior blow

ing down steam boilers on start up' when "required.

Leakage; Make certain that there is no leakage in

the system at any time.

Flue Connections; Inspect the flue connection to

the chimney annually to make sure it is in good

condition and has not become obstructed.

CLEANING THE BOILER

1. Remove manifold enclosure and burner access

door.

2. Remove burners and pilot.

3. 'Remove' draft hood" and“Vent“piper' ■ """

4. Loosen top panel and swing aside-

5. Remove flue collector,

6. Use flexible handled wire brush to clean pas

sageways. Remove scrapings from bottom of

boiler.

7. Re-assemble.

Swing Top Panel Aside

- 13 -

Use of Flexible Handled Brush

39234D3

Page 14

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 2 0

UTC TECH PUB

F A X N o . 8 1 7 2 4 0 5 6 6 2

§

3

E

s 'e

I -

l E

3

ìt о ilk-

o C J

J

^ $ ß

2 2

g (A tn

eoo

о о о

с f“ f“

'Ч- Ю fN

а .û а

^ Ï

“Hi

4}

i

....

)

3

E

№

e

S

m

d

39234D3

U-

Page 15

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 2 0

U T C T E C H P U B

F A X H o . 3 1 7 2 4 0 5 6 6 2

WATER BOILER WIRING

P . 0 1 5

ROOM THERMOSTAT .55 AMP.

HEAT ANTICIPATOR.

LIMIT

L

|0. ■

SUGGESTED

MANUAL

SWITCH

4___22_^ „

3 : 1

TRANS.

I PR! J

HOrl ;«6R0UND

LOW VOLTAGE

LINE VOLTAGE

RELAY

CIRCULATOR

j' 1

BRYANT

yALVE;,:-

vh, [¡/.'li..

PILOT OR

PILOT RELAY

n

D4 not, mM, non 1005S shutoff

D5 not, mfd, 100% shutoff

Forced circulation with water coil

15-

D2 proparift, jpri% shutoff

D4 not, mfd, no« 100% shutoff

D5 not, mfd; 1Q0% shutoff

Forced circuì dtion

39234D3

Page 16

S E P / 0 2 / 2 0 0 8 / T U E 0 8 : 2 0

UTC TECH PUB

WATER BOILER WIRING

F A X N o , 3 1 7 2 4 0 5 6 6 2

P .

, ^

%

39234D3

- 16

Loading...

Loading...