180B (2 -- 5 Ton)

EVOLUTIONr 20 AIR CONDITIONER

WITH PURONr REFRIGERANT

Product Data

TM

the environmentally sound refrigerant

Bryant’s air conditioners with Puronr refrigerant provide a

collection of features unmatched by any other family of

equipment. The 180B has been designed utilizing Bryant’s

Puronr refrigerant. The environmentally sound refrigerant allows

consumers to make a responsible decision in the protection of the

earth’s ozone layer.

This product has been designed and manufactured to meet

Energy Starr criteria for energy efficiency when matched with

appropriate coil components. Refer to the combination ratings in

the Product Data for system combinations that meet Energy Starr

guidelines.

NOTE: Ratings contained in this document are subject to

change at any time. Always refer to the AHRI directory

(www.ahridirectory.org) for the most up--to--date ratings

information.

INDUSTRY LEADING

FEATURES / BENEFITS

Efficiency

14 -- 20 SEER / 11.6 -- 14.5 EER

S

S Microtube Technologyt refrigeration system

S Indoor air quality accessories available

Sound

Sound level as low as 66 dBA

S

S Electronic ECM ball bearing outdoor condenser fan

motor

S Compressor sound hood

S Forward--swept condenser fan blade

S Quiet mount split post compressor grommets

Comfort

System supports Evolutiont Control or standard

S

2--stage thermostat controls

Reliability

Puronr refrigerant -- environmentally sound, won’t

S

deplete the ozone layer and low lifetime service cost.

S Front--seating service valves

S 2--stage scroll compressor

S Internal pressure relief valve

S Internal thermal overload

S Low pressure switch

S High pressure switch

S Filter drier

S Crank case heater standard

S Balanced refrigeration system for maximum reliability

Durability

DuraGuard Plust protection package:

S Solid, Durable sheet metal construction

S Steel louver coil guard

S Baked--on, complete outer coverage, powder paint

Applications

S Long--line -- up to 250 feet (76.2 m) total equivalent

length, up to 200 feet (60.96 m) condenser above

evaporator, or up to 80 ft. (24.38 m) evaporator above

condenser (See Longline Guide for more information.)

MODEL NUMBER NOMENCLATURE

1234 5 678910111214

NNNAA/NNNNNA/NA/NNA

180B N A036000A

Product

Famil y

1=AC 8=

the environmentally sound refrigerant

180B

Tier SEER Major

0=21

Evolution

Series

SEER

Nominal

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

Series

Voltage Variation s Coolin g Capacity Open Open Open Minor

B=Puron N=

208--- 230--- 1

A=

Standard

0=Not

Defined0=Not

Defined

This product has been designed and manuf actured t o

meet En ergy St ar® criteria for energy efficiency when

matched with appropriate coil components. However,

proper refrigerant charge and proper air flow are critical

to achieve rated capacity and efficiency. Installation of

this product should f ollow all manufacturing refrigerant

charging and air flow instructions. Failure to confirm

proper charge an d air flow may reduce energy

efficiency and shorten equ ipment life.

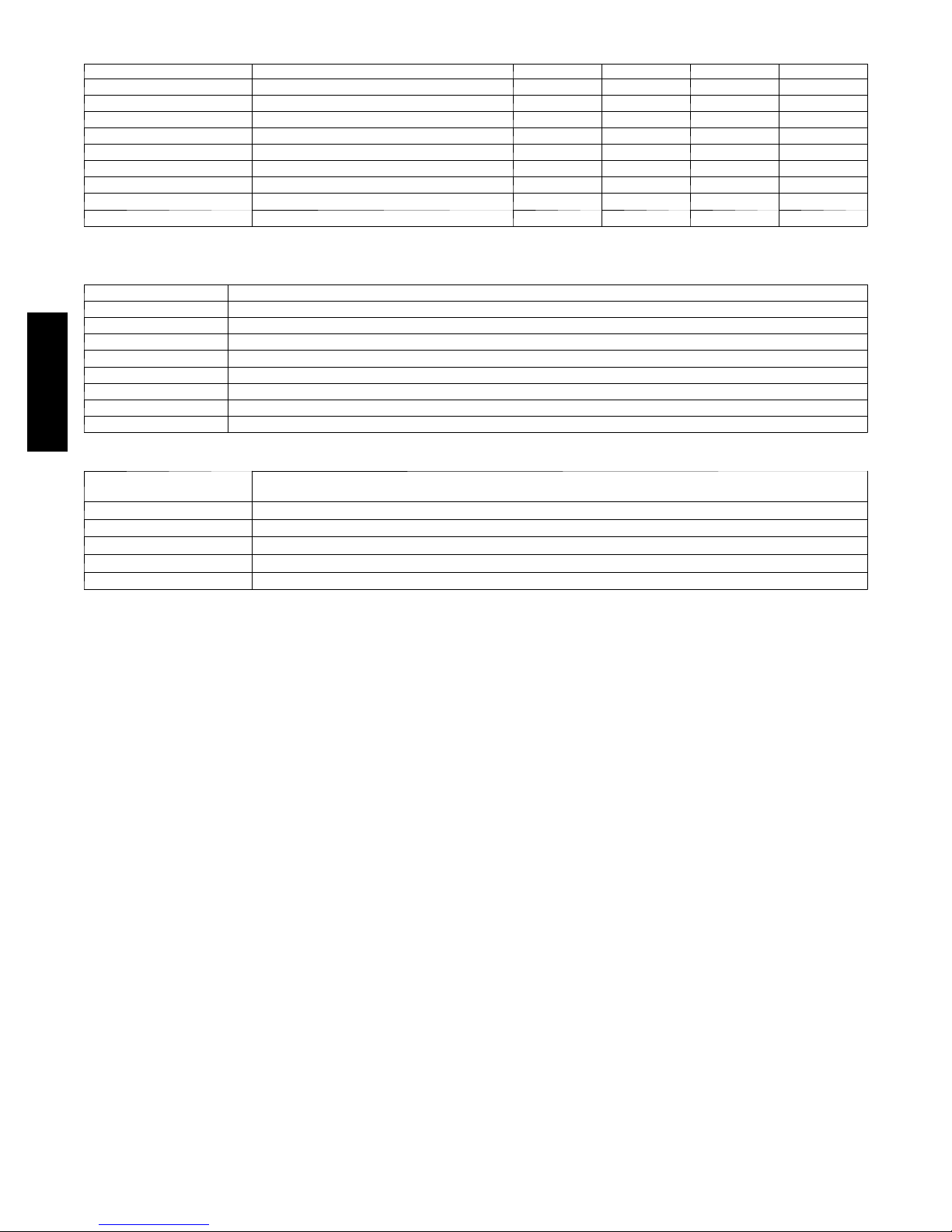

STANDARD FEATURES

MODEL

FEATURES

024---A 036--- B 048- -- A 060--- A

Puron Refrigerant X X X X

Maximum SEER Rating 21.0 20.0 17.7 16.7

2 --- Stage Scroll Compressor X X X X

Crankcase Heater w/Temperature Switch X X X X

Long line Capability X X X X

Low Ambient Capability to 0_F ( --- 1 7 .8_C) w/Evolution Control X X X X

Advanced Diagnostics with Evolution Control X X X X

Utility Interface Conn ection X X X X

Louvered Coil Guard X X X X

FieldInstalledFilterDrier X X X X

Fron t Seating Serv ice Valv es X X X X

Internal Pressure Relief Valve X X X X

Internal Thermal Overload X X X X

Long Line capability X X X X

Low Pressure Switch X X X X

High Pressure Switch X X X X

Sound Blanket X X X X

* With approved combinations

X=Standard

UNIT SIZE---SERIES

180BNA

0=

Not

Defined

Series

A=

Original

Series

2

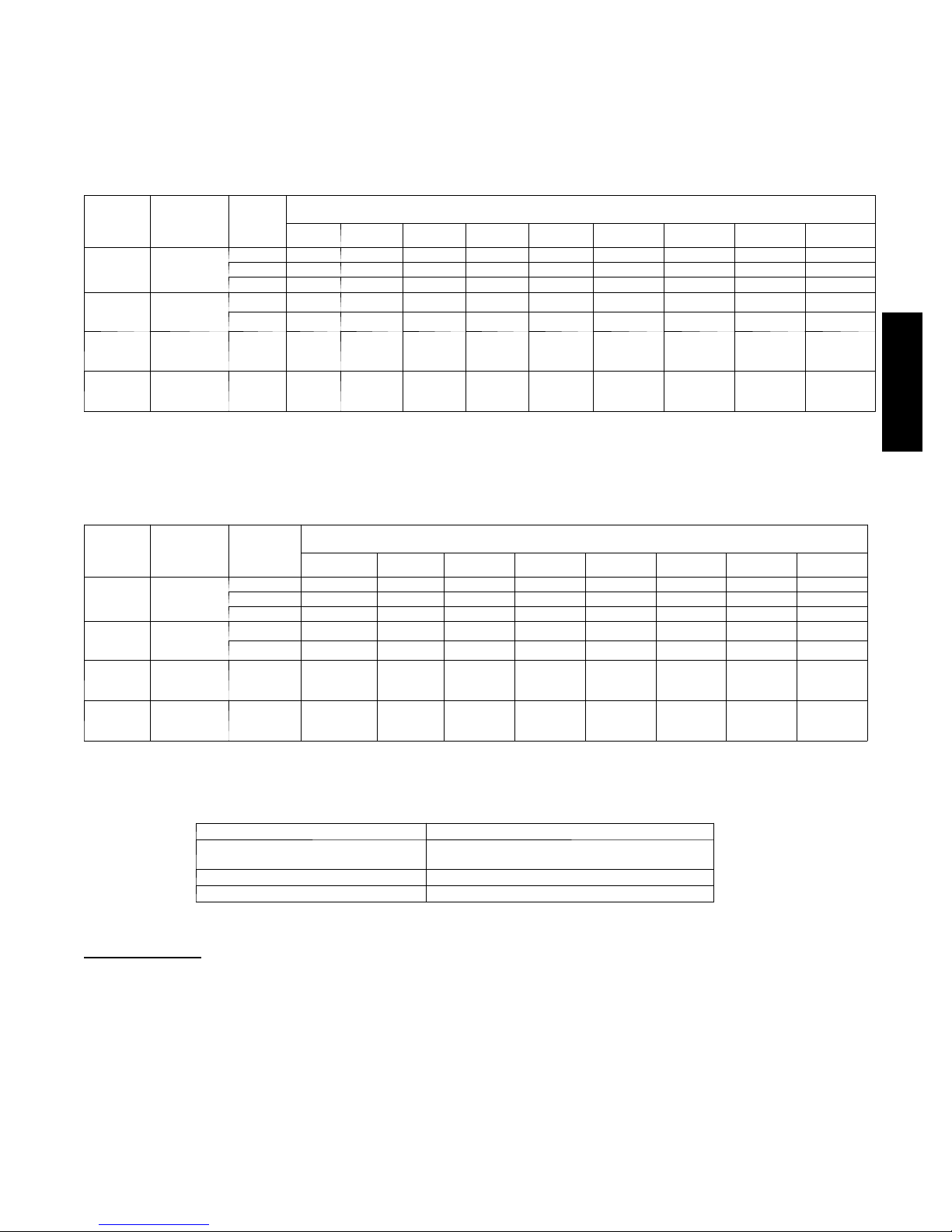

REFRIGERANT PIPING LENGTH LIMITATIONS

Liquid Line Sizing and Maximum Total Equivalent Lengths

The maximum allowable length of a residential split system depends on the liquid line diameter and vertical separation between indoor and

outdoor units.

See Table below for liquid line sizing and maximum lengths :

Maximum Total Equivalent Length

Outdoor Unit BELOW Indoor Unit

Liquid

Size

024

AC with

Puron

036

AC with

Puron

048

AC with

Puron

060

AC with

Puron

* Maximum actual length not to exceed 200 ft (61 m)

{ Total equivalent length accounts for losses due to elbows or fitting. See the Long Line Guideline for details.

--- --- = o u t s i d e a c c e p t ab l e r an g e

Size

024

AC with

Puron

036

AC with

Puron

048

AC with

Puron

060

AC with

Puron

* Maximum actual length not to exceed 200 ft (61 m)

{ Total equivalent length accounts for losses due to elbows or fitting. See the Long Line Guideline for details.

Liquid Line

Connection

3/8

3/8

3/8 3/8 250* 250* 250* 250* 250* 250* 230 160 --- ---

3/8 3/8 250* 250* 250* 225* 190 150 110 --- --- --- ---

Liquid Line

Connection

3/8

3/8

3/8 3/8 250* 250* 250* 250* 250* 250* 250* 250*

3/8 3/8 250* 250* 250* 250* 250* 250* 250* 250*

Line

Diam.

w/TXV

1/4 75 75 75 50 50 --- --- --- --- --- --- --- ---

5/16 250* 250* 250* 250* 250* 225* 175 125 100

3/8 250* 250* 250* 250* 250* 250* 250* 250* 250*

5/16 175 150 150 100 100 100 75 --- --- --- ---

3/8 250* 250* 250* 250* 250* 250* 250* 250* 250*

Liquid

Diam.

w/TXV

(0--- 1.5)

Line

1/4 100 125 175 200 225* 250* 250* 250*

5/16 250* 250* 250* 250* 250* 250* 250* 250*

3/8 250* 250* 250* 250* 250* 250* 250* 250*

5/16 225* 250* 250* 250* 250* 250* 250* 250*

3/8 250* 250* 250* 250* 250* 250* 250* 250*

AC with Puron Refrigerant Maximum Total Equivalent Length{: Outdoor unit BELOW Indoor

0 --- 5

6 --- 1 0

(1.8--- 3.0)

11--- 20

(3.4--- 6.1)

Maximum Total Equivalent Length

Outdoor Unit ABOVE IndoorUnit

AC with Puron Refrigerant Maximum Total Equivalent Length{: Outdoor unit ABOVE Indoor

25

(7.6)

26--- 50

(7.9--- 15.2)

{

for Cooling Only Systems with Puronr Refrigerant:

Vertical Separation ft (m)

21--- 30

(6.4--- 9.1)

51--- 75

(15.5--- 22.9)

31--- 40

(9.4--- 12.2)

Vertical Separation ft (m)

76--- 100

(23.2--- 30.5)

41--- 50

(12.5--- 15.2)

101--- 125

(30.8--- 38.1)

51--- 60

(15.5--- 18.3)

126--- 150

(38.4--- 45.7)

61--- 70

(18.6--- 21.3)

151--- 175

(46.0--- 53.3)

71--- 80

(21.6--- 24.4)

176--- 200

(53.6--- 61.0)

180B

Liquid Line Size Puron Charge oz/ft (g/m)

3/8

5/16 0.40 (11.83)

1/4 0.27 (7.98)

Units are factory charged for 15 ft (4.6 m) of 3/8” liquid line. The factory charge for 3/8” lineset 9 oz.(266.16 g). When using other length

or diameter liquid lines, charge adjustments are required per the chart above.

Charging

Formula:

[(Lineset oz/ft x total length) – (factory charge for lineset)] = charge adjustment

Example 1: System has 15 ft of line set using existing 1/4“ liquid line. What charge adjustment is required?

Formula: (.27 oz/ft x 15ft) – (9 oz) = (-4.95) oz.

Net result is to remove 4.95 oz of refrigerant from the system

Example 2: System has 45 ft of existing 5/16” liquid line. What is the charge adjustment?

Formula: (.40 oz/ft. x 45ft) – (9 oz.) = 9 oz.

Net result is to add 9 oz of refrigerant to the system

REFRIGERANT CHARGE ADJUSTMENTS

0.60 (17.74)

(Factory charge for lineset = 9 oz / 266.16 g)

3

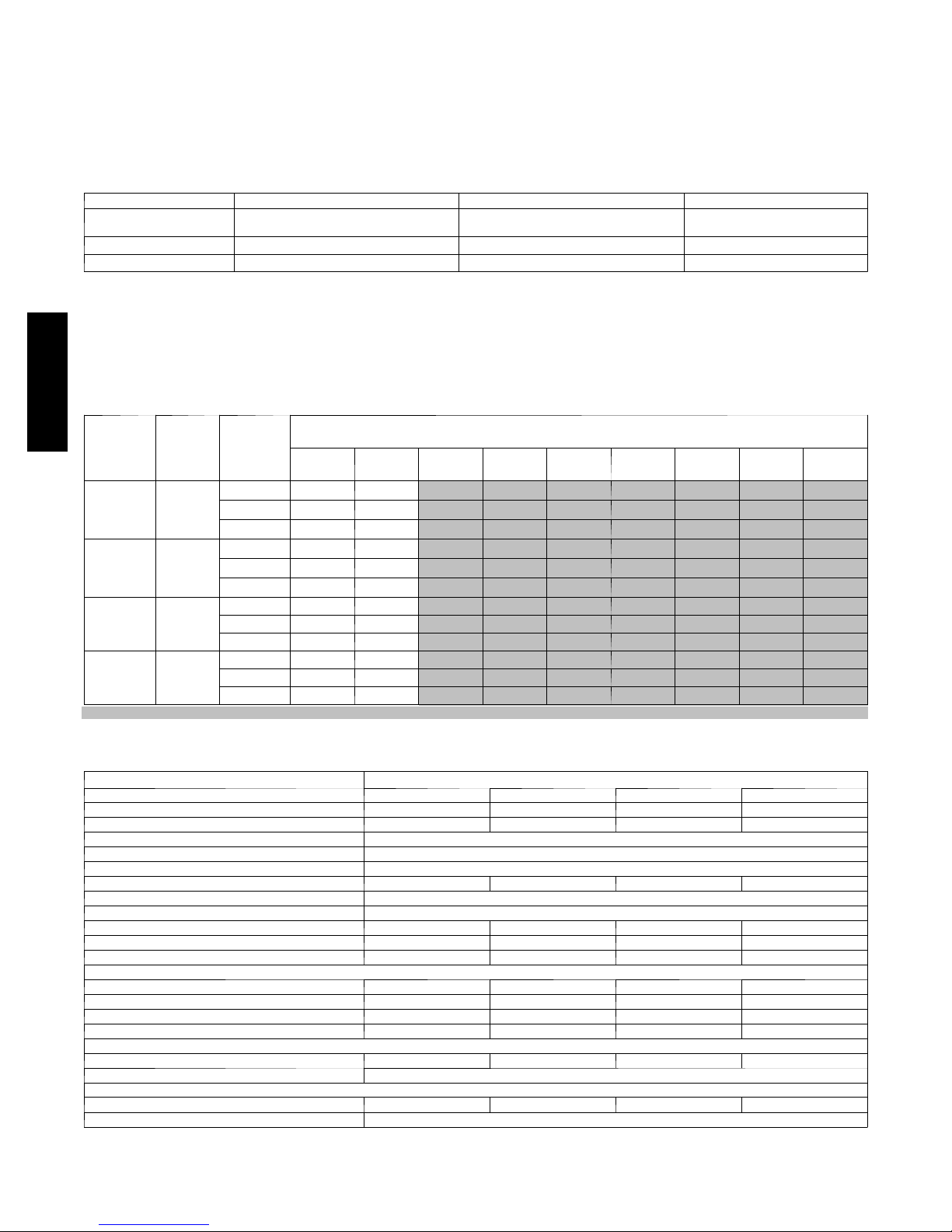

LONG LINE APPLICATIONS

An application is considered Long Line, when the refrigerant level in the system requires the use of accessories to maintain acceptable

refrigerant management for systems reliability. See Accessory Usage Guideline table for required accessories. Defining a system as long line

depends on the liquid line diameter, actual length of the tubing, and vertical separation between the indoor and outdoor units.

For Air Conditioner systems, the chart below shows when an application is considered Long Line.

AC WITH PURONr REFRIGERANT LONG LINE DESCRIPTION ft (m)

Beyond these lengths, long line accessories are required

Liquid Line Size Units On Same Level Outdoor Below Indoor Outdoor Above Indoor

1/4

5/16 120 (36.6) 50 (15.2) vertical or 120 (36.6) total 120 (36.6)

3/8 80 (24.4) 35 (10.7) vertical or 80 24.4) total 80 (24.4)

Note: SeeLongLineGuidelinefordetails

No accessories needed within allowed

lengths

No accessories needed within allowed

lengths

175 (53.3)

VAPOR LINE SIZING AND COOLING CAPACITY LOSS

Acceptable vapor line diameters provide adequate oil return to the compressor while avoiding excessive capacity loss. The suction line

diameters shown in the chart below are acceptable for AC systems with Puron refrigerant:

180B

Nominal

Size (Btuh)

2 --- St a g e

Puron

2 --- St a g e

Puron

2 --- St a g e

Puron

2 --- St a g e

Puron

Applications in this area may be long line and may have height restrictions. See the Residential Piping and Long Line Guideline.

— Applications in this area are not recommended due to insufficient oil return

Vapor Line Sizing and Cooling Capacity Losses — Puronr Refrigerant 2--Stage Air Conditioner Applications

Unit

024

AC

036

AC

048

AC

060

AC

Maximum

Liquid

Line

Diameters

(In. OD)

3/8

3/8

3/8

3/8

Vapo r Line

Diameters

(In.) OD

5/8 0 1 1 2 3 3 4 4 5

3/4 0 0 0 0 1 1 1 1 1

7/8 0 0 0 0 1 1 1 1 1

5/8 1 2 4 5 6 7 9 10 11

3/4 0 0 1 1 2 2 3 3 4

7/8 0 0 0 0 1 1 1 1 2

3/4 1 2 2 3 4 5 6 7 7

7/8 0 1 1 2 2 2 3 3 3

1 --- 1/8 0 0 — — — — — — —

3/4 1 2 4 5 6 7 9 10 11

7/8 0 1 2 2 3 4 4 5 5

1 --- 1/8 0 0 0 1 1 1 1 1 1

26---50

(7.9--- 15.2)

51---80

(15.5--- 24.4)

81---100

(24.7--- 30.5)

Cooling Capacity Loss (%)

Total Equivalent Line Length ft. (m)

101---125

(30.8--- 38.1)

126---150

(38.4--- 45.7)

151---175

(46.0--- 50.3)

176---200

(53.6--- 60.0)

201---225

(61.3--- 68.6)

PHYSICAL DATA

Model 180BNA

Unit Size -- - Series 024---A 036--- B 048---A 060--- A

Operating Weight lb (kg) 323 (147) 324 (147) 325 ( 147) 350 (159)

Shipping Weight lb (kg) 368 (167) 368 (167) 370 ( 168) 394 (179)

Compressor Ty pe 2 --- Stage S c r o l l

REFRIGERANT Puronr (R --- 410A)

Control TXV (Puronr Hard Shutoff)

Charge lb (kg) 14.21 (6.67) 14.36 (6.51) 14.45 (6.55) 14.83 (6.73)

COND FAN Propeller Type, Direct Drive

Air Discharge Vertical

Air Qty (CFM) 3000 / 3637 3124 / 3700 3703 / 4304 4209 / 4668

Motor HP 1/5 1/5 1/5 1/5

Motor RPM 628 / 752 582 / 669 659 / 765 742 / 828

COND COIL

Face Area (Sq ft) 30.18 30.18 30.18 30.18

Fins per In. 20 20 20 20

Rows 2 2 2 2

Circuits 9 9 9 9

VALVECONNECT.(In.ID)

Vapor 7/8 7/8 7/8 7/ 8

Liquid 3/8

REFRIGERANT TUBES (In. OD)

Rated Vapor* 7/8 7/8 1 --- 1/8 1 --- 1/8

Liquid 3/8

*Units are rated with 25 ft (7.6 m) of lineset length. See Vapor Line Sizing and Cooling Capacity Loss table when using other sizes and lengths of lineset.

226---250

(68.9--- 76.2)

4

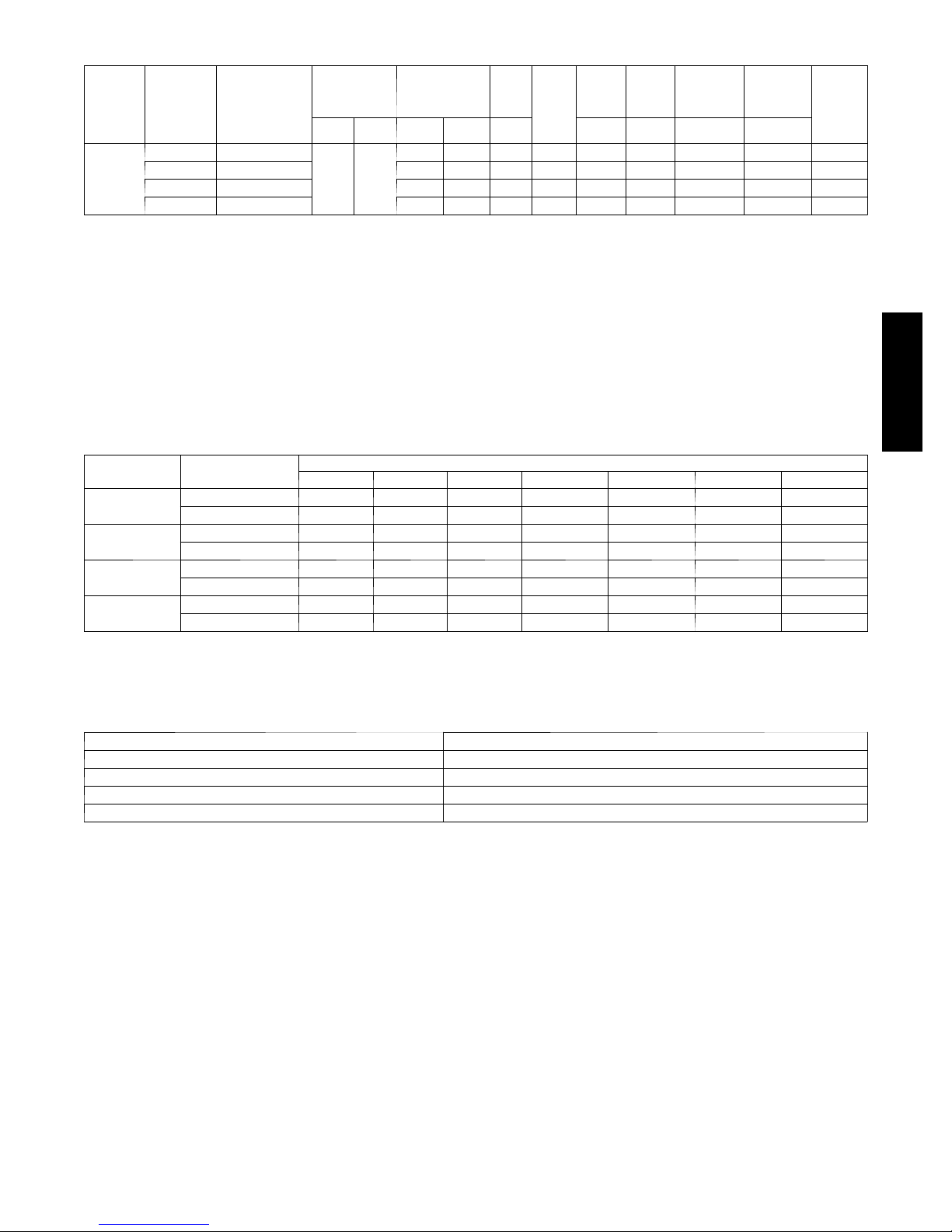

ELECTRICAL DATA

UNIT

MODEL

180BNA

* Permissible limits of the voltage range at which the unit will operate satisfactorily

{ If wire is applied at ambient greater than 30_C, consult table 310 --- 16 of the NEC (NFPA 70) . The ampacity of non---metallic--- sheathed cable (NM), trade

name ROMEX, shall be that of 60_C conditions, per the NEC (NFPA 70) Article 336--- 26. If other th a n u ncoated ( no---plated), 60 or 75_C insulation, copper

wire (solid wire for 10 AWG or smaller, stranded wire for larger than 10 AWG) is u sed, consult applicable tables of the NEC (NFPA 70).

} Length shown is as measured one way along wire path between unit and service panel for voltage drop not to exceed 2%.

* * T i m e --- D e l a y f u s e .

FLA --- Ful l L o a d A m ps

LRA --- L o c k e d R o t or A mps

MCA --- Minimum Circuit Amps

RLA ---RatedLoadAmps

NOTE: Control circuit is 24---V on all units and requires external power source. Copper wire must be used from service disconnect to unit.

Complies with 2010 requirements of ASHRAE Standards 90.1

S I Z E ---

SERIES

024---A 208/230---1---60

036---B 208/230--- 1--- 60 82.0 16.70 1.7 22.6 12.00 12.00 65 (16.8) 53 (16.2) 35

048---A 208/230---1---60 96.0 21.20 1.9 28.4 10.00 10.00 70 (21.3) 67 (20.4) 40

060---A 208/230---1---60 118.0 23.00 1.9 30.7 8.00 10.00 101 (30.8) 62 (18.9) 50

All motors/compressors contain internal overload protection.

V --- P H --- H z

OPER

VOLTS*

MAX MIN LRA RLA FLA 60°C 75°C 60°C 75°C

253 197

COMPR FA N

MCA

52.0 10.30 1.4 14.3 14.00 14.00 55 (16.8) 52 (15.9) 20

MIN

WIRE

SIZE{

MIN

WIRE

SIZE{

MAX

LENGTH

ft (m)}

MAX

LENGTH

ft (m)}

MAX

FUSE*

*or

CKT

BRK

AMPS

A--WEIGHTED SOUND POWER (dBA)

UNIT SIZE

180BNA024 ---A

180BNA036 ---B

180BNA048 ---A

180BNA060 ---A

NOTE: Tested in accordance with AHRI Standard 270---08. (Not listed with AHRI).

STANDARD

RATING (dBA)

* 6 9 --- l ow s t a g e 46.5 52.5 59.0 65.0 54.5 53.0 47.5

7 1 --- hig h s t a g e 48.5 54.5 63.0 59.5 58.0 58.5 54.5

* 6 9 --- l ow s t a g e 49.0 53.5 61.5 63.0 56.5 53.5 49.5

7 2 --- hig h s t a g e 49.5 55.5 67.0 63.5 57.5 53.0 56.0

* 6 6 --- l ow s t a g e 47.5 56.0 61.5 59.0 56.0 52.5 50.0

7 1 --- hig h s t a g e 48.5 59.0 66.0 64.5 58.5 57.0 54.5

* 6 9 --- l ow s t a g e 50.5 59.0 63.0 62.5 58.5 58.0 55.0

7 2 --- hig h s t a g e 53.5 60.5 65.0 67.0 60.0 58.5 54.5

125 250 500 1000 2000 4000 8000

TYPICAL OCTAVE BAND SPECTRUM (dBA, without tone adjustment)

180B

CHARGING SUBCOOLING (TXV--TYPE EXPANSION DEVICE)

UNIT SIZE --- SERIES

180BNA024 ---A

180BNA036 ---B

180BNA048 ---A

180BNA060 ---A

REQUIRED SUBCOOLING _F(_C)

9 (5.0) HIGH STAGE

12 (6.7) HIGH STAGE

14 (7.8) HIGH STAGE

16 (8.9) HIGH STAGE

5

ACCESSORIES

KIT NUMBER KIT NAME 024---A 036 --- B 048---A 060- -- A

KSAHS2301AAA HARD START KIT X

KSAHS2401AAA HARD START KIT X

KSAHS2501AAA HARD START KIT X

KSAHS2601AAA HARD START KIT X

KSASF0101AAA SUPPORT FEET X X X X

KSATX0201PUR TXV X

KSATX0301PUR TXV X

KSATX0401PUR TXV X

KSATX0501PUR TXV X

x = Accessory

CONTROLS

CONTROL DESCRIPTION

SYSTXBBUID01 --- D Evolution Control Deluxe 7 ---Day Programmable (Wall --- mounted system control.)

SYSTXBBUIZ01 ---D Evolution Control Deluxe Zoning 7 ---Day Programmable (Wall--- mounted control for a multi--- zone system.)

SYSTXBB4ZC01 Evolution 4--- Zone Damper Control Module (Wall---mounted control for a four---zone system.)

SYSTXBBSMS01 Evolution Smart Sensor (Optional wall control used to monitor temperature and/or fan control in an individual zone.)

SYSTXBBRRS01 E volution Remote Room Sensor (Monitors temperature in an individual zone.)

SYSTXBBRWF01 Evolution System Access Module (Hardware for wireless access an d control via phone or internet.)

180B

SYSTXBBNIM01 Evolution Network Interface Module (Connects Heat Recovery and Energy Recovery Ventilators on non--- zoning applications.)

SYSTXBBLBPU01 --- C Decorative Back Plate for Evolution Control (Decorative wall plate.)

THERMOSTATS

THERMOSTAT / SUBBASE

PKG.

T 6 --- P R H 01 --- A Programmable Thermidistat

T 6 --- N R H 01 --- A Non --- programmable Thermidistat

T 6 --- PA C 0 1 Preferred Series Programmable AC Stat

T 6 --- N A C 01 Preferred Series Non---programmable AC Stat

TSTATXXSEN01--- B Outdoor Air Temperature Sensor

DESCRIPTION

6

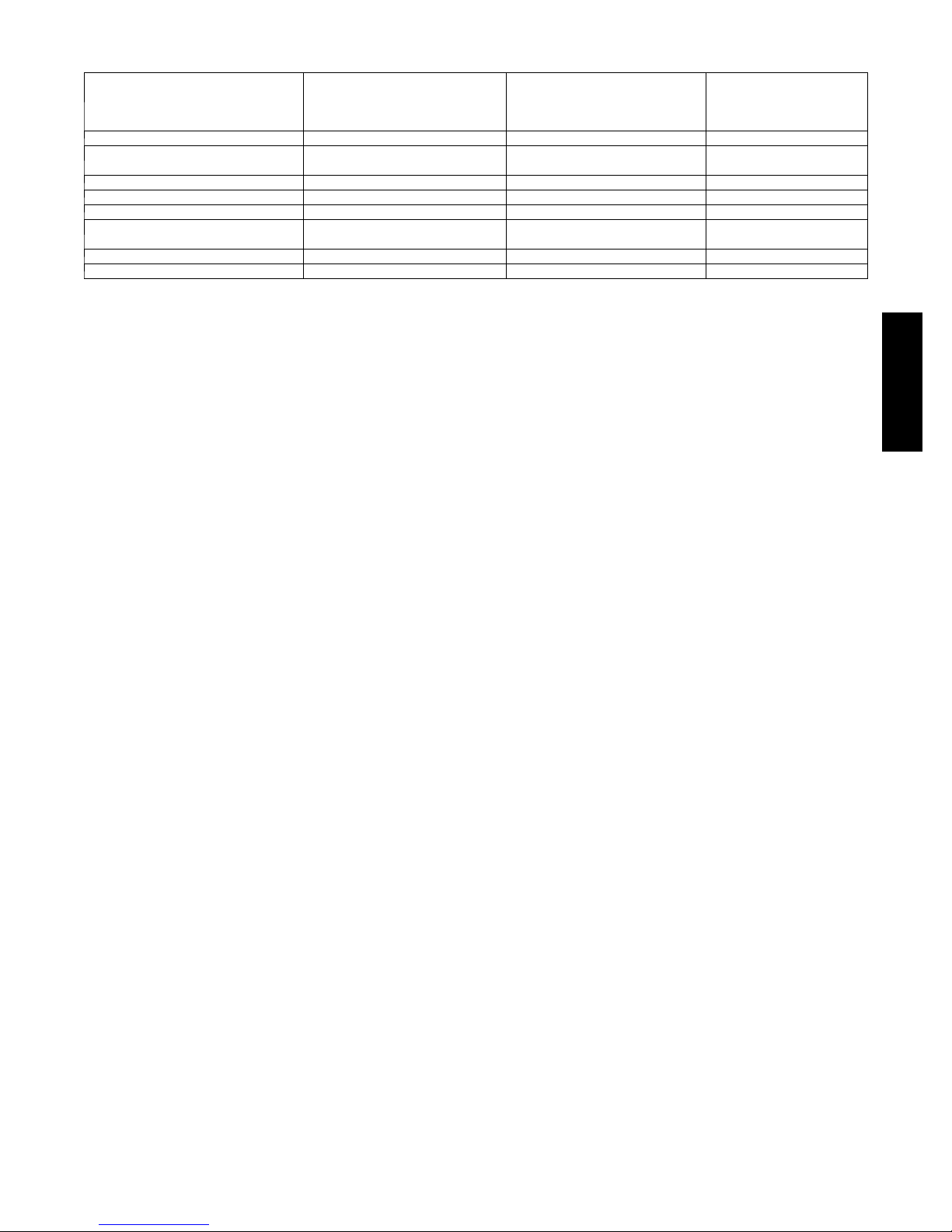

ACCESSORY USAGE GUIDELINE

REQUIRED FOR

ACCESSORY

Compressor Start Assist Kit No Ye s No

Crankcase Heater

Evaporator Freeze Protection Standard with Evolution Control No No

Liquid--- Line Solenoid Valve No No No

Low--- Ambient Control Standard with Evolution Control No No

Puron Refrigerant Balance Port Hard---

* For tubing set lengths between 80 and 200 ft. (24.38 and 60.96 m) horizontal or 35 ft. (10.7 m) vertical differential (total equivalent len gth), refer to the Long

Line Guideline—Air Conditioners and Heat Pumps using Puron® Refrigerant.

{ Required on all indoor units. Standard on all new Puron refrigerant fan coils and furnace coils.

ShutOff TXV

Support Feet Recommended No Recommended

Winter Start Control Standard with Evolution Control No No

L O W --- A M B I E N T C O O L I N G

APPLICATIONS

(Below 55°F/12.8_C)

Ye s

(standard on some units)

Ye s{

REQUIRED FOR LONG LINE

APPLICATIONS*

Ye s

(standard on some units)

Ye s{

REQUIRED FOR SEA COAST

APPLICATIONS

(Within 2 miles/3.22 km)

No

Ye s{

Accessory Description and Usage (Listed Alphabetically)

1. Compressor Start Assist -- Capacitor and Relay

Start capacitor and relay gives a ”hard” boost to compressor

motor at each start up.

Usage Guideline:

Required for reciprocating compressors in the

following applications:

Long line

Hard shut off expansion valve on indoor coil

Liquid line solenoid on indoor coil

Required for single--phase scroll compressors in the

following applications:

Long line

Suggested for all compressors in areas with a history of

low voltage problems.

2. Crankcase Heater

An electric resistance heater which mounts to the base of the

compressor to keep the lubricant warm during off cycles.

Improves compressor lubrication on restart and minimizes the

chance of liquid slugging.

Usage Guideline:

Required in low ambient cooling applications.

Required in long line applications.

Suggested in all commercial applications.

3. Outdoor Air Temperature Sensor

Designed for use with Bryant Thermostats listed in this

publication. This device enables the thermostat to display the

outdoor temperature. This device also

is required to enable special thermostat features such as auxiliary

heat lock out.

Usage Guideline:

Suggested for all Bryant thermostats listed in this

publication.

4. Support Feet

Four stick--on plastic feet that raise the unit 4 in. (101.6 mm)

above the mounting pad. This allows sand, dirt, and other debris

to be flushed from the unit base, minimizing corrosion.

Usage Guideline:

Suggested in the following applications:

Coastal installations.

Windy areas or where debris is normally circulating.

Rooftop installations.

For improved sound ratings.

5. Thermostatic Expansion Valve (TXV)

A modulating flow--control valve which meters refrigerant liquid

flow rate into the evaporator in response to the superheat of the

refrigerant gas leaving the evaporator.

Kit includes valve, adapter tubes, and external equalizer tube.

Hard shut off types are available.

NOTE: When using a hard shut off TXV with single phase

reciprocating compressors, a Compressor Start Assist Capacitor

and Relay is required.

Usage Guideline:

Required to achieve AHRI ratings in certain equipment

combinations. Refer to combination ratings.

Hard shut off TXV or LLS required in air conditioner

long line applications.

Required for use on all zoning systems.

180B

7

Loading...

Loading...