Page 1

Form No. 6440

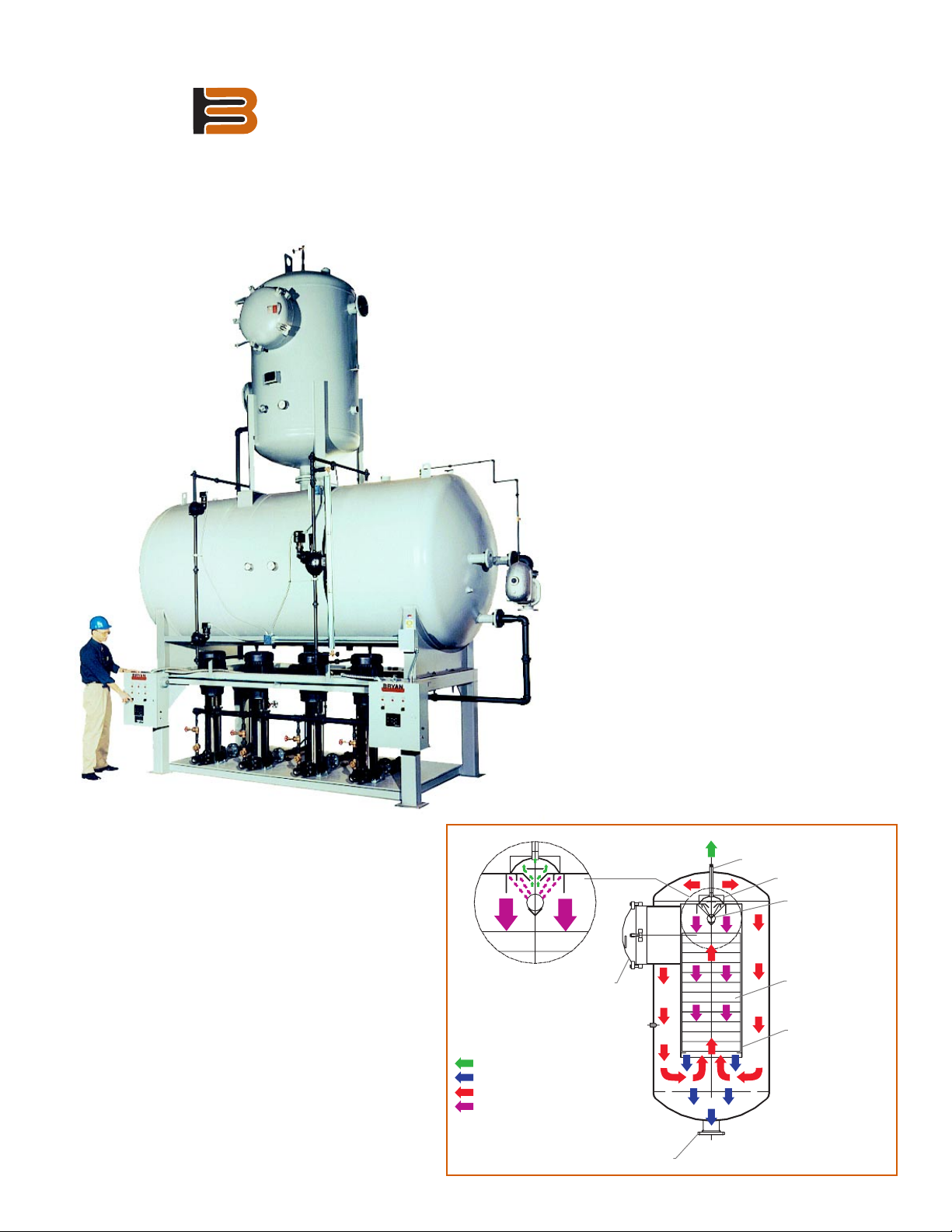

Non-Condensable Gases (O , Co )

22

Deaerated Water

Steam

Tray

Access

Door

Deaerator Outlet

to Storage Tank

Stainless Steel Vent Pipe

Vented to Atmosphere

Stainless Steel

Internal Vent Condenser

Stainless Steel

Spray Tube

Welded Stainless

Steel Trays

Stainless Steel

Tray Chamber

Condensate Return

and Water Make-up

TM

BRYAN STEAM

Separable Tank Tray Type Boiler Feedwater Deaerators

Capacities 70,000 to 300,000 PPH (2030 to 8695 BHP)

Performance Features

• Oxygen removal to .005 cc/l (7 PPB)

•CO2 removal to 0% measurable

• Reduce chemical costs

• Reduce boiler and system corrosion

• Pre-heat boiler feedwater

• Improve boiler efficiency

• Quick equipment payback, compared

to chemical oxygen removal

(5/00)

175,000 PPH

unit shown

The Bryan tray type deaerator is unsurpassed in

performance and reliability. These units are

ASME Code pressurized units, and are guaranteed to deliver deaerated water at a maximum

oxygen content of .005cc/l (7PPB) and zero

measurable CO2. All internal surfaces that

come in contact with undeaerated water are

constructed of type 304L stainless steel for long

life and low maintenance. Their long residence

time makes them readily adaptable to all

systems, even where wide load swings occur.

A complete line of boiler feedpump and

control packages is available making the Bryan

tray deaerator a completely packaged unit

ready for installation with the minimum amount

of field assembly.

Construction Features

• Constructed to ASME Section VIII,

Division I for 50 PSIG

• Hinged tray access door

• Standard 10 minutes deaerated water storage

• Easily accessible manway in storage tank

• All internal surfaces that contact

undeaerated water are constructed of type

304L stainless steel

• Internal direct contact vent condenser

for minimum steam loss

• Structural steel stand/pump platform

• 2-stage deaeration

• Available as completely packaged unit

including pumps and control panel

Page 2

TM

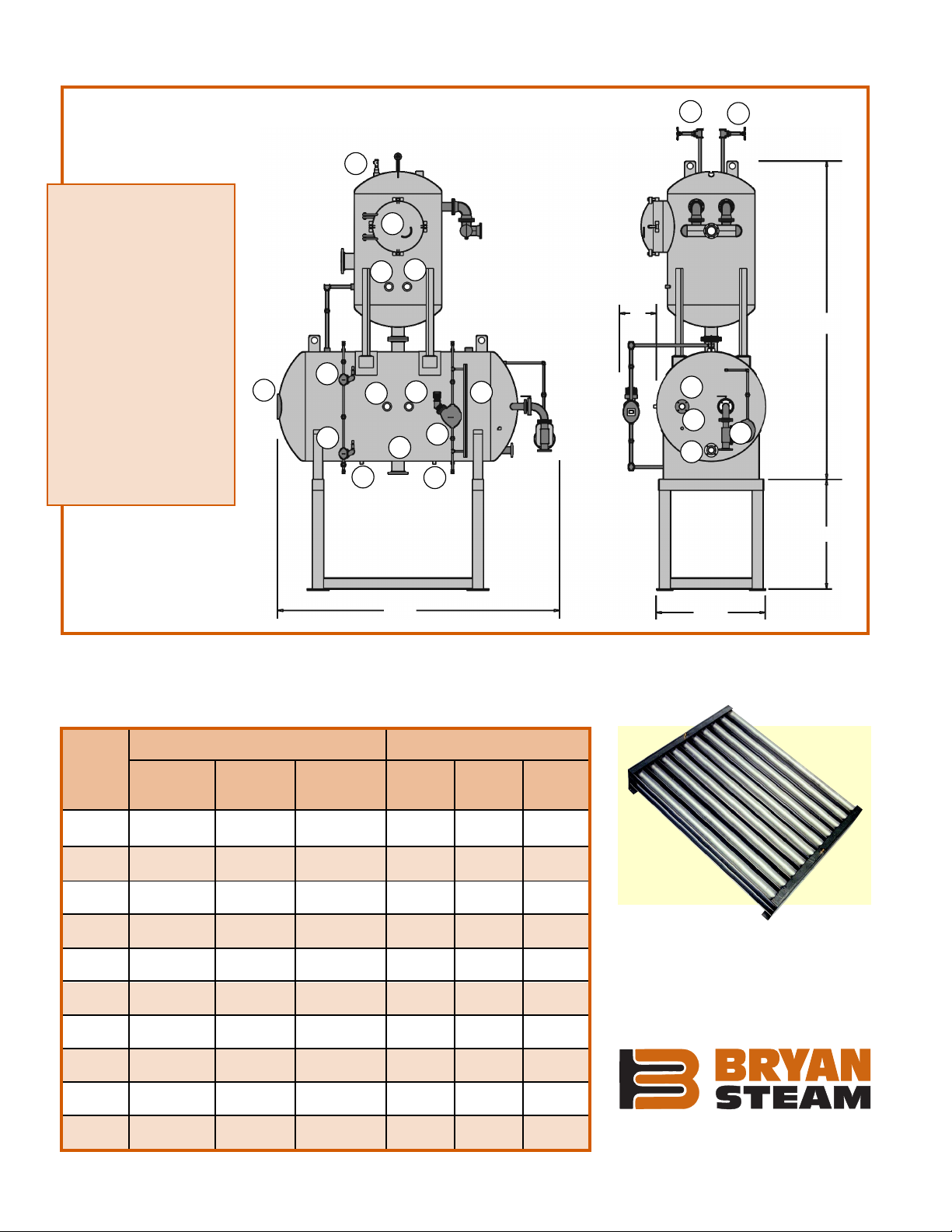

Bryan Separable Tank Tray Type Deaerators

1. High water level control

2. Low water level control

3. Make-up water control

4. Vacuum breaker

5. Temperature gauge

6. Pressure gauge

7. Overflow trap

8. Vent

9. Pump suction

10. Pump bypass

11. Chemical port

12. Drain

13. Sample port

14. High temperature

condensate return

15. Gauge glass

16. Manway access opening

17. Tray access door

16

STEAM

INLET

8

8

4

17

6

5

CONDENSATE/

MAKE-UP

WATER INLET

20"

REF

C

1

6

5

15

10

11

2

13

3

9

14

12

7

48" *

A

*Note: Stand height varies depending upon pump specifications and job conditions.

Dimensions are for reference only and may change without notice. Consult factory for certified dimensions.

B

Specifications

Capacity

Model

DTA-70

DTA-80

DTA-90

DTA-100

DTA-125

DTA-150

DTA-175

DTA-200

DTA-250

DTA-300

* Not including the stand.

©2000 Bryan Steam LLC 50-2517A

Pounds/hr Boiler hp

(kg/h) (kW)

70,000 2,029 1,400

(31,752) (19,911) (5,299)

80,000 2,319 1,600

(36,288) (22,756) (6,056)

90,000 2,609 1,800

(40,824) (25,600) (6,813)

100,000 2,899 2,000

(45,360) (28,445) (7,570)

125,000 3,623 2,500

(56,700) (36,556) (9,463)

150,000 4,348 3,000

(68,040) (42,667) (11,355)

175,000 5,072 3,500

(79,380) (49,779) (13,248)

200,000 5,797 4,000

(90,720) (56,890) (15,140)

250,000 7,246 5,000

(113,400) (71,112) (18,925)

300,000 8,695 6,000

(136,080) (85,335) (22,710)

Storage A B C

in gallons Overall Overall Overall

(liters) length width height

176 (447) 60 (152) 180 (457)

194 (493) 60 (152) 184 (467)

190 (483) 66 (168) 173 (439)

200 (508) 66 (168) 177 (450)

187 (475) 72 (183) 203 (516)

217 (551) 72 (183) 207 (526)

247 (627) 72 (183) 211 (536)

228 (579) 84 (213) 220 (559)

274 (696) 84 (213) 239 (607)

249 (632) 96 (244) 244 (622)

Dimensions

in inches (cm)

*

The tray assemblies in the Bryan tray deaerators are constructed of type 304L stainless

steel. Trays are welded construction and are

engineered to offer maximum residence time.

This ensures complete deaeration even during wide load swings.

Bryan Steam LLC — Leaders Since 1916

783 N. Chili Ave., Peru, Indiana 46970 U.S.A.

Phone:765-473-6651 • Internet:www.bryanboilers.com

Fax: 765-473-3074 • E-mail: bryanboilers@iquest.net

Loading...

Loading...