Page 1

Date: 8-4-2010

Revision: 0

Form: 2396

Bryan Steam LLC

Installation and Operating Service Manual

Triple-Flex

High Efficiency Boilers

Page 2

Date: 8-4-2010

Revision: 0

Form: 2396

INSTALLATION AND OPERATION SERVICE MANUAL

Triple-Flex 150, 200, 250, & 300

E-mail:

High Efficiency Boilers

Bryan Steam LLC

783 North Chili Avenue * Peru, IN 46970

Phone 765.473.6651 • Fax 765.473.3074

inquiry@bryansteam.com Internet: www.bryanboilers.com

Page 3

Date: 8-4-2010

Revision: 0

Form: 2396

Table of Contents

Bryan Steam LLC ..............................................................................................................................i

Installation and Operating Service Manual........................................................................................i

Table of Contents ............................................................................................................................ iii

Tables ...............................................................................................................................................v

Figures..............................................................................................................................................v

Section 1 Installation Instructions– Triple-Flex High Efficiency Boilers........................................... 1

1.1 Boiler Foundation................................................................................................................... 2

1.2 Clearances............................................................................................................................. 2

1.2.1 Minimum Clearances to Combustible Surfaces............................................................... 2

1.3 Receiving The Boiler.............................................................................................................. 2

1.4 Boiler Connections................................................................................................................. 3

1.4.1 Flow Connection .............................................................................................................. 3

1.4.2 Safety Relief Valves......................................................................................................... 3

1.4.3 Expansion Tank Connections .......................................................................................... 3

1.4.4 Drain Connection ............................................................................................................. 3

1.4.5 Condensate Drain Connection......................................................................................... 3

1.4.6 Gas Supply Connection ................................................................................................... 3

1.4.7 Drip Leg............................................................................................................................ 3

1.4.8 Gas Piping Leak Test....................................................................................................... 3

1.4.9 Venting Of Gas Train Components.................................................................................. 4

1.5 Electrical Requirements......................................................................................................... 4

1.6 Combustion Air Supply .......................................................................................................... 4

1.6.1 Combustion Air Openings: ............................................................................................... 5

1.6.2 Louvers, Grilles, and Screens.......................................................................................... 5

1.7 Flue Gas Venting System ...................................................................................................... 6

1.7.1 Design & Installation ........................................................................................................ 6

1.7.2 Combustion Air and Venting Requirements for Canada.................................................. 7

1.7.3 Marking Of Gas Vents...................................................................................................... 8

1.8 Before Placing Boiler In Operation ........................................................................................ 8

1.8.1 Hydrostatic Test Of Boilers And System.......................................................................... 9

1.8.2 Test Of Gas Piping........................................................................................................... 9

Section 2 Start-Up and Operation Triple-Flex High Efficiency Boilers .......................................... 10

2.1 Boiler Assembly ................................................................................................................... 11

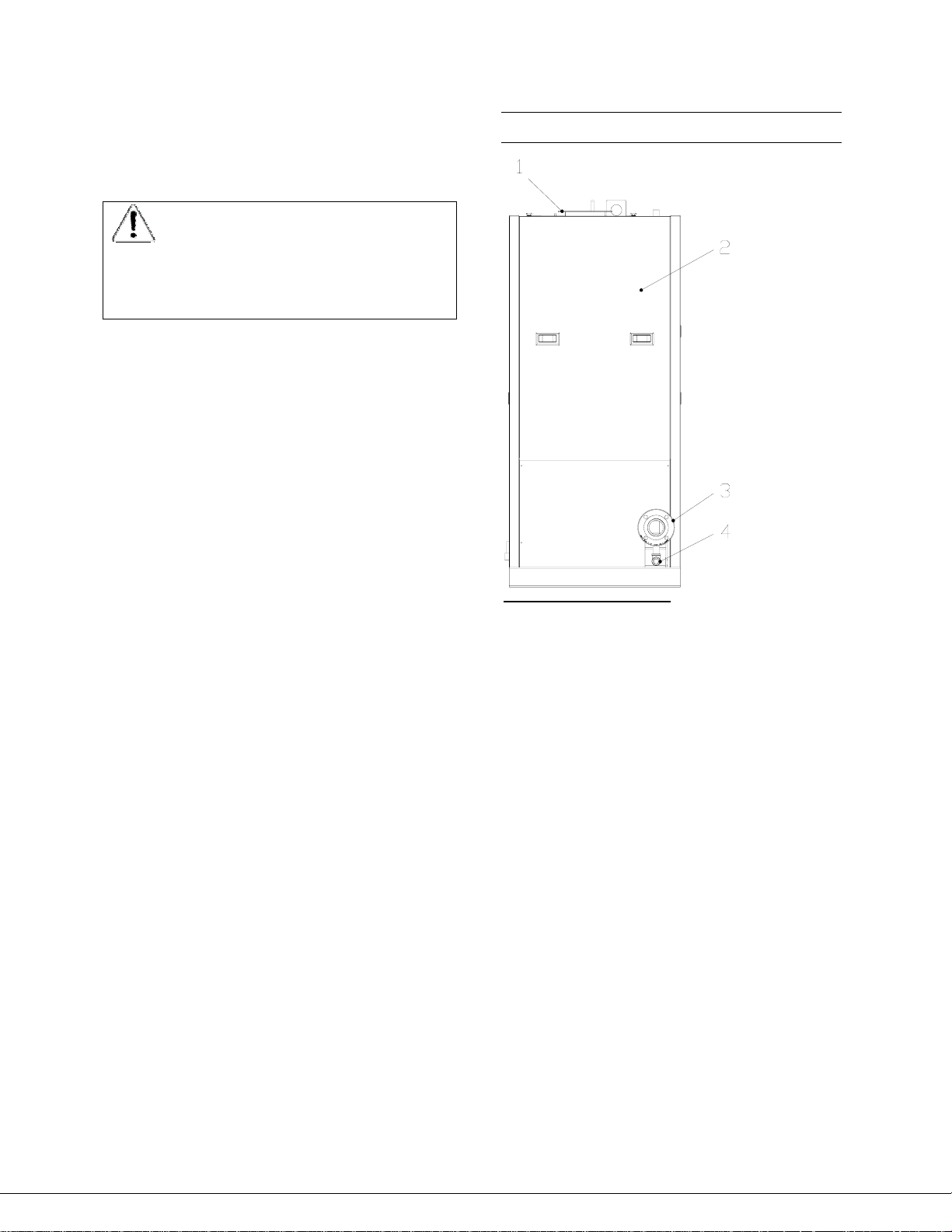

2.1.1 Triple-Flex Front View.................................................................................................... 11

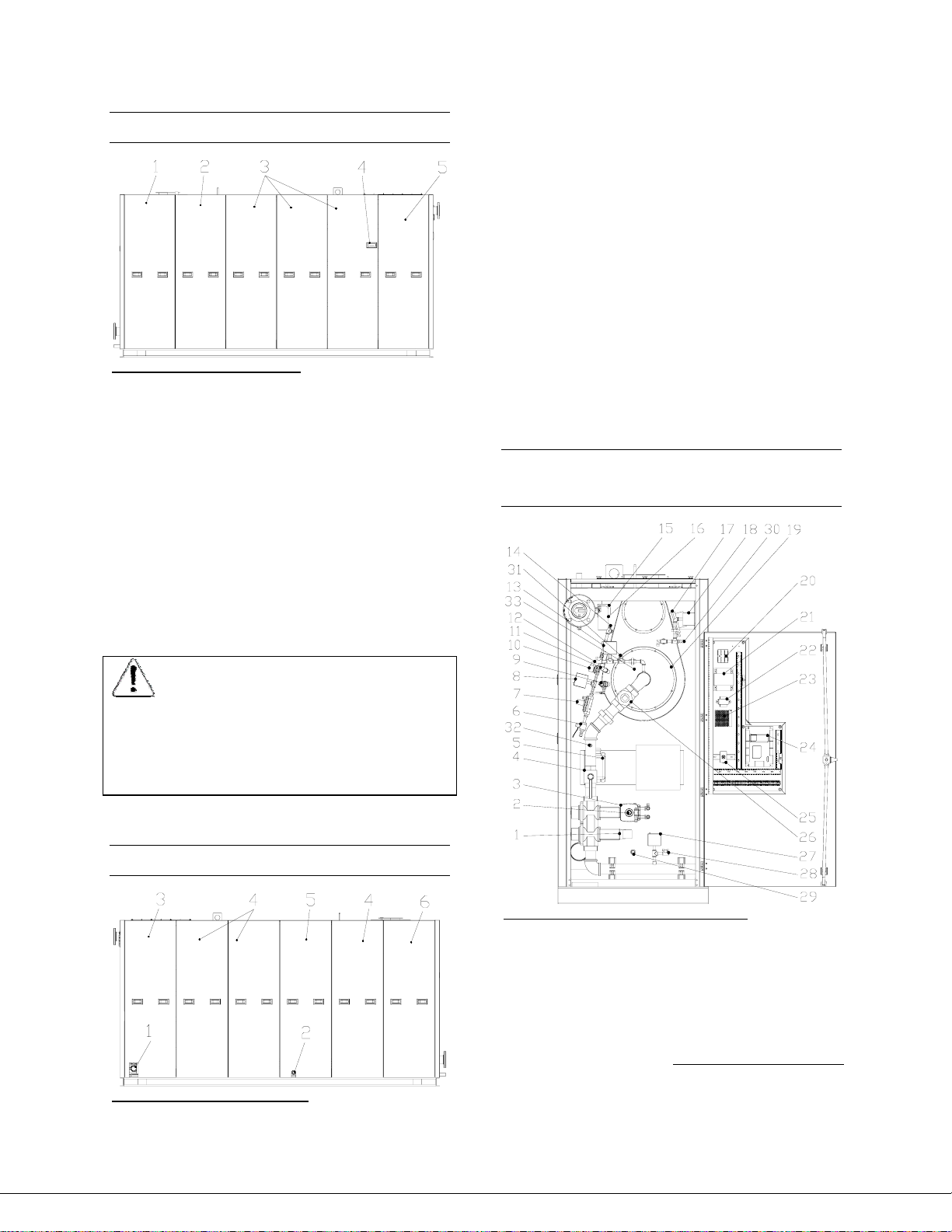

2.1.2 Triple-Flex Rear View .................................................................................................... 12

2.1.3 Triple-Flex Left Side View .............................................................................................. 13

2.1.4 Triple-Flex Right Side View............................................................................................ 13

2.1.5 Triple-Flex Behind the Cabinet Door.............................................................................. 13

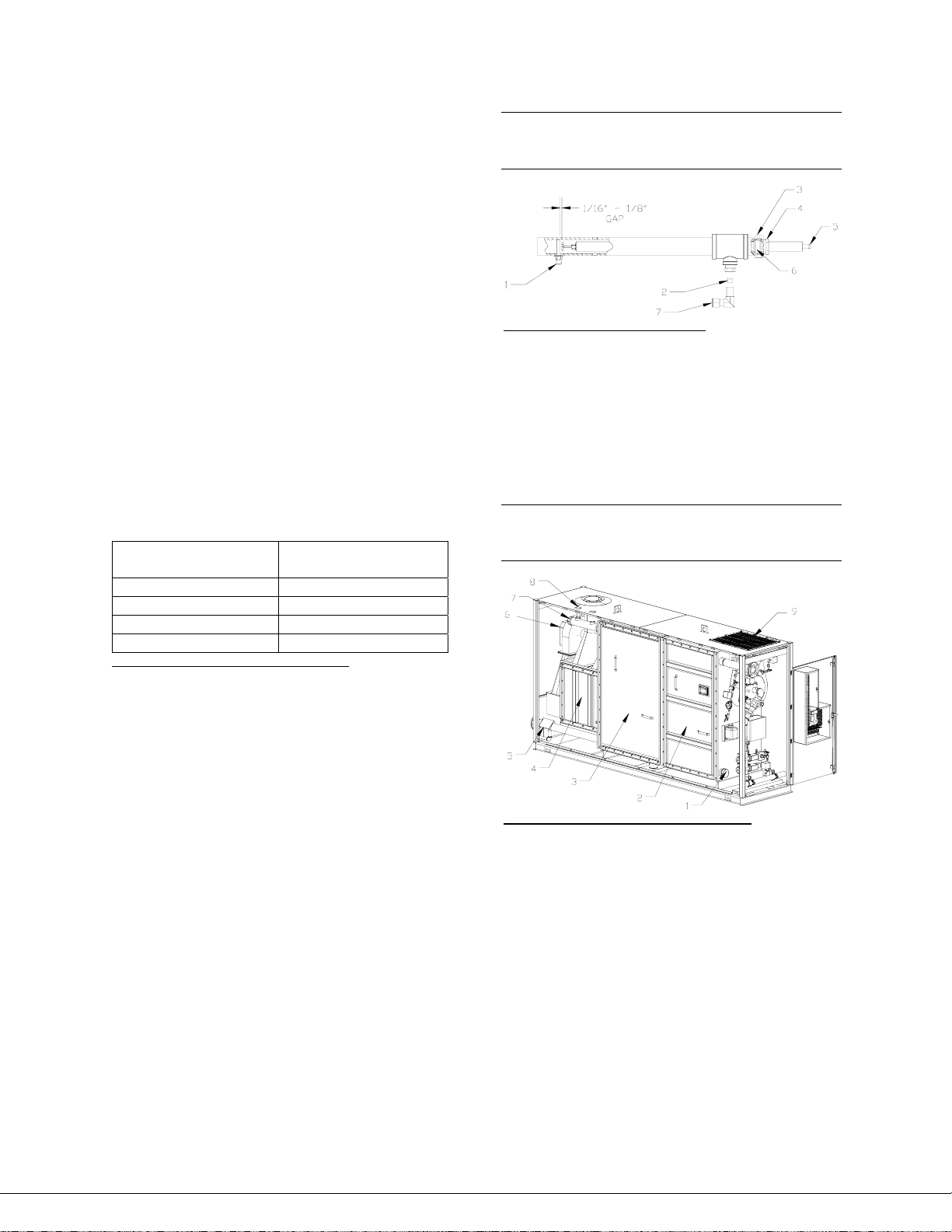

2.1.6 Pilot Spark Igniter Assembly .......................................................................................... 15

2.1.7 Triple-Flex Left Flue Collector View............................................................................... 15

2.1.8 Triple-Flex Right Flue Collector View............................................................................. 16

2.2 SOLA Hydronic Control System .......................................................................................... 16

2.2.1 Power-up Validation....................................................................................................... 16

2.2.2 Home Page .................................................................................................................... 16

2.2.3 Page Navigation............................................................................................................. 17

2.2.4 Keyboard........................................................................................................................ 17

2.2.5 Status Page.................................................................................................................... 18

2.2.6 Configuration Page ........................................................................................................ 18

2.2.7 Configuration Password................................................................................................. 19

2.2.8 Change Parameter Settings........................................................................................... 20

2.2.9 Safety Verification .......................................................................................................... 20

2.2.10 Fault/Alarm Handling ................................................................................................... 21

Page 4

Date: 8-4-2010

Revision: 0

Form: 2396

2.2.11 Operation Page............................................................................................................ 22

2.2.12 Annunciation Page....................................................................................................... 23

2.2.13 Modulation Configuration............................................................................................. 23

2.2.14 Firing Rate Control Page ............................................................................................. 23

2.2.15 Advanced Setup........................................................................................................... 24

2.2.16 System Time ................................................................................................................ 24

2.2.17 Calibrate Touch Screen ............................................................................................... 24

2.2.18 Reset / Reboot Display ................................................................................................ 25

2.2.19 Outdoor Reset.............................................................................................................. 25

2.2.20 Remote Setpoint (4 – 20 mA) ...................................................................................... 26

2.2.21 Central Heat Configuration .......................................................................................... 27

2.2.22 Sound Pressure Levels................................................................................................ 27

2.2.23 Modbus Communication .............................................................................................. 29

2.2.24 Alert Codes .................................................................................................................. 29

2.3 Boiler Commissioning .......................................................................................................... 35

2.3.1 Modulation...................................................................................................................... 35

2.3.2 Test Setup...................................................................................................................... 35

2.3.3 Pre Checks And Setup................................................................................................... 35

2.3.4 Dry Run .......................................................................................................................... 36

2.3.5 Pilot Adjustment ............................................................................................................. 36

2.3.6 Initial Light Off ................................................................................................................ 37

2.3.7 Adjusting Boiler Maximum Input .................................................................................... 37

2.3.8 Adjusting Boiler Minimum Input ..................................................................................... 37

2.3.9 Gas Meter Readings ...................................................................................................... 38

2.4 Troubleshooting ................................................................................................................... 39

Section 3 Care and Maintenance .................................................................................................. 50

3.1 Cleaning The Boiler And System – New Systems............................................................... 51

3.1.1 Pre-Boil Out Flushing Of System................................................................................... 51

3.1.2 Boil Out Procedure......................................................................................................... 51

3.1.3 Draining The System ..................................................................................................... 52

3.2 Replacement Boiler Installations: Protection Against Corrosion And Sediment.................. 52

3.3 Boiler Water Treatment........................................................................................................ 52

3.4 External “Fire-Side” Cleaning............................................................................................... 53

3.5 Suggested Maintenance Schedule ...................................................................................... 53

Section 4 Lead Lag........................................................................................................................ 55

4.1 General Description Of The Lead Lag Application .............................................................. 56

4.2 Lead Lag (Ll) Master General Operation............................................................................. 56

4.3 System Wiring Hookup ........................................................................................................ 58

4.4 Lead-Lag Operation............................................................................................................. 59

4.5 Slave Operation And Setup ................................................................................................. 60

4.6 Slave Parameters ................................................................................................................ 60

4.7 Ll Master Operation And Setup ........................................................................................... 61

4.7.1 Overall Control ............................................................................................................... 61

4.7.2 Periodic Data Polling messages .................................................................................... 62

4.7.3 Slave Status Manager.................................................................................................... 62

4.7.4 Master Active Service .................................................................................................... 65

4.7.5 Modulation Sensor ......................................................................................................... 65

4.7.6 Demand and Rate.......................................................................................................... 66

4.7.7 Rate Adjustment............................................................................................................. 67

4.7.8 Implementation............................................................................................................... 67

4.7.9 Rate Allocation............................................................................................................... 68

4.7.10 Burner Demand............................................................................................................ 70

4.7.11 Lead Drop-Stage On Error - LDSE: ............................................................................. 73

iv

Page 5

Date: 8-4-2010

Revision: 0

Form: 2396

Tables

Table 1 Minimum Clearance............................................................................................................ 2

Table 2 Electrical Requirements...................................................................................................... 4

Table 3 Boiler Draft.......................................................................................................................... 7

Table 4 Water Flow Switch Settings.............................................................................................. 14

Table 5 Gas Limiting Orifice Rough Settings ................................................................................ 15

Table 6 Sound Pressure Readings................................................................................................ 28

Table 7 Modbus Terminals............................................................................................................ 29

Table 8 Alert Codes....................................................................................................................... 29

Table 9 Approximate Boiler Settings ............................................................................................. 38

Table 10 Gas Pressure Correction................................................................................................ 38

Table 11 Gas Temperature Correction.......................................................................................... 38

Table 12 R7910A Lockout and Hold Codes .................................................................................. 39

Figures

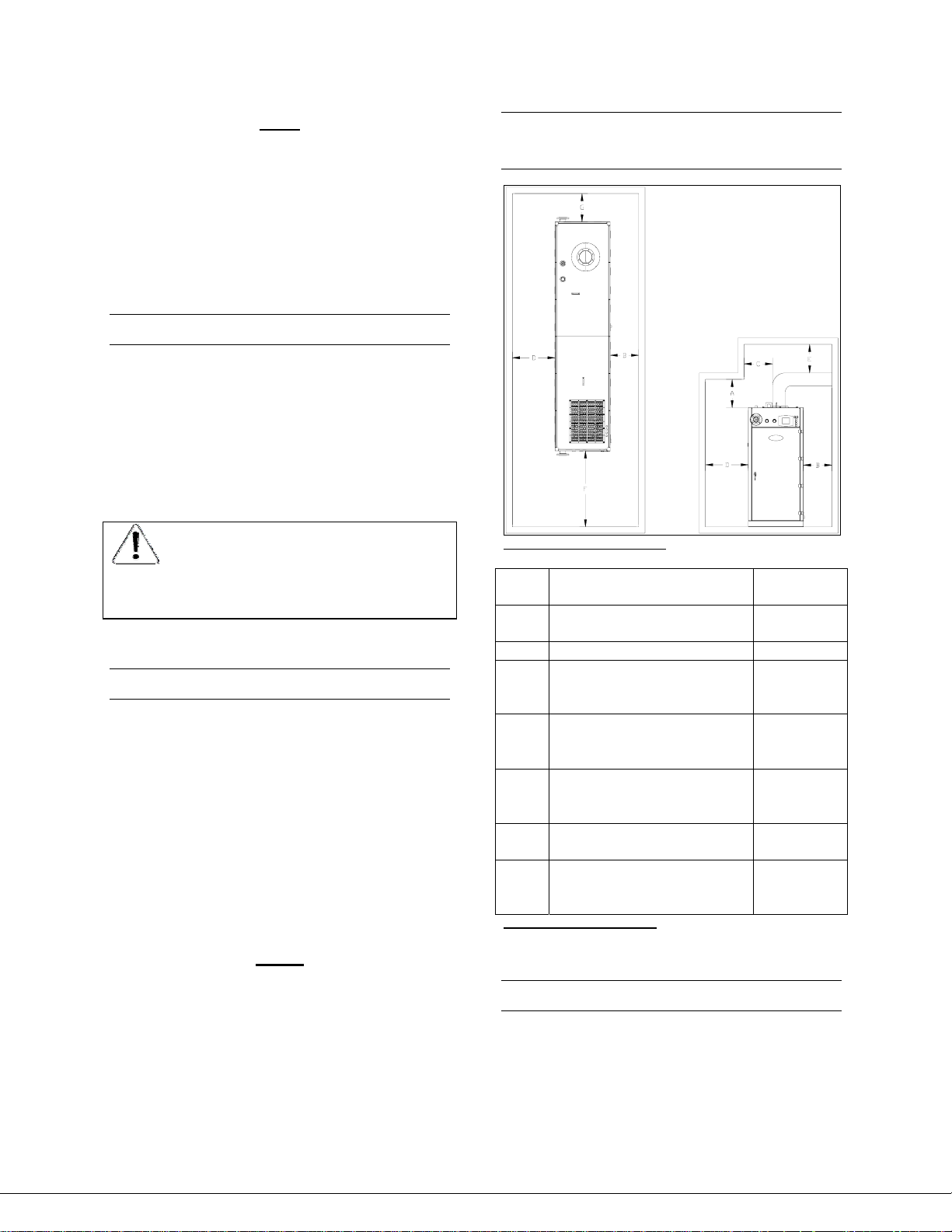

Figure 1 Minimum Clearances......................................................................................................... 2

Figure 2 Main Gas Inlet Connection................................................................................................ 4

Figure 3 Triple-Flex Front View ..................................................................................................... 11

Figure 4 Triple-Flex Rear View...................................................................................................... 12

Figure 5 Triple-Flex Left Side View ............................................................................................... 13

Figure 6 Triple-Flex Right Side View............................................................................................. 13

Figure 7 Triple-Flex Behind the Cabinet Door............................................................................... 13

Figure 8 Air Flow Switch................................................................................................................ 14

Figure 9 Pilot Spark Igniter Assembly ........................................................................................... 15

Figure 10 Triple-Flex Left Flue Collector View .............................................................................. 15

Figure 11 Triple-Flex Right Flue Collector View............................................................................ 16

Figure 12 Home Page ................................................................................................................... 16

Figure 13 Keyboard ....................................................................................................................... 17

Figure 14 Status Page................................................................................................................... 18

Figure 15 Configuration Menu Page.............................................................................................. 18

Figure 16 Sample Configuration Page .......................................................................................... 19

Figure 17 Change Parameter Dialog............................................................................................. 20

Figure 18 Safety Parameter Verification ....................................................................................... 20

Figure 19 Safety Parameter User Confirmation ............................................................................ 21

Figure 20 Safety Parameter Reset................................................................................................ 21

Figure 21 Home Page Lockout...................................................................................................... 22

Figure 22 Status Page Lockout ..................................................................................................... 22

Figure 23 History Dialog ................................................................................................................ 22

Figure 24 Lockout History Page .................................................................................................... 22

Figure 25 Operation Page ............................................................................................................. 22

Figure 26 Annunciation Page ........................................................................................................ 23

Figure 27 Modulation Configuration .............................................................................................. 23

Figure 28 Firing Rate Control Page............................................................................................... 23

Figure 29 Advanced Setup ............................................................................................................ 24

Figure 30 System Time ................................................................................................................. 24

Figure 31 Display Diagnostics....................................................................................................... 24

Figure 32 Reset / Reboot Display.................................................................................................. 25

Figure 33 Outdoor Reset............................................................................................................... 25

Figure 34 Outdoor Reset Curve .................................................................................................... 26

v

Page 6

Date: 8-4-2010

Revision: 0

Form: 2396

Figure 35 Outdoor Reset Sensor Configuration............................................................................ 26

Figure 36 Air / Gas Ratio Tappings ............................................................................................... 35

Figure 37 LL / Multi-Boiler Field Wiring ......................................................................................... 58

vi

Page 7

Date: 8-4-2010

Revision: 0

Form: 2396

Section 1 Installation Instructions–

Triple-Flex High Efficiency Boilers

1

Page 8

Date: 8-4-2010

Revision: 0

Form: 2396

Note:

Please read and save for future reference the

entire instruction manual before attempting

installation of or starting the unit. Insurance and

local or state regulatory codes may contain

additional or more stringent requirements than

those contained in this manual. Installation must

conform to these codes and any other authority

having jurisdiction. This instruction manual shall

be posted and maintained in a legible condition.

1.2.1 MINIMUM CLEARANCES TO

COMBUSTIBLE SURFACES

1.1 BOILER FOUNDATION

Before uncrating, the boiler location should be

prepared. The boiler should set upon a good

level concrete floor. If the boiler is not level or

the floor is not in good condition, a concrete

foundation should be built, the dimensions being

larger than the outside dimensions of the boiler

base. A 4” high housekeeping pad is

suggested.

WARNING:

Do not install boiler on combustible

flooring.

1.2 CLEARANCES

See Table 1 for minimum clearances to walls,

ceilings, or obstructions. The clearances in

Table 1 are intended as a general

recommendation only. Local codes must be

applied to specific installations and the minimum

clearances established accordingly. Provisions

must also be made for service, accessibility and

clearance for piping and electrical connections.

Do not obstruct combustion air and ventilation

openings with piping or any other construction.

All boilers must be installed in a space that is

large compared to the boiler.

NOTE:

These boilers should be installed in a room that

is large compared to the size of the boiler. They

are not intended for alcove installation and are

suitable for installation on non-combustible

flooring only. Adhere to all applicable local

codes regarding boiler installation and

clearances.

Figure 1 Minimum Clearances

DIM. Description

A

B Right Side 18”

C

D

E

F

G

Table 1 Minimum Clearance

Clearance Above Top of

Boiler

From Chimney or Vent

Collector Measured

Horizontally

Left Side – Tube Access

Side On Standard

Construction

From Chimney or Vent

Collector Measured

Vertically

Front of Boiler – Gas Train

& Control Panel End

Rear of Boiler Opposite

Gas Train & Control Panel

End

Triple-Flex

150 - 300

18”

18”

27”

18”

48”

18”

1.3 RECEIVING THE BOILER

The boiler is shipped from the factory with (4)

shipping feet/legs bolted to the skids. These are

provided to facilitate unloading/moving with a

forklift. Lifting lugs are also provided to enable

over-head lifting. The shipping feet/legs MUST

2

Page 9

Date: 8-4-2010

Revision: 0

Form: 2396

BE REMOVED after the boiler is set in-place on

its concrete foundation before any

piping/electrical connections are made. It is

recommended that the plastic protective cover

be left on as long as possible to reduce finish

damage from the installation.

1.4 BOILER CONNECTIONS

Do not run any pipes along the tube access

panel side of the boiler. Maintain clearances as

shown on the dimensional drawing for servicing

of the boiler tubes. Provide at least 48" from the

front of the boiler, unless a larger dimension is

indicated on the dimensional. All piping should

be designed and installed to avoid any loadings

on the boiler connections or piping.

1.4.1 FLOW CONNECTION

The system supply and return flow connections

are shown on Figure 3 and Figure 4

respectively. A gate valve should be installed on

the boiler outlet and inlet lines. This allows the

boiler to be isolated from the heating system for

draining and servicing.

1.4.5 CONDENSATE DRAIN

CONNECTION

A 1” MPT connection is provided to drain the

condensed products of combustion from a trap

located beneath the boiler. This must be run to

a drain using stainless steel or PVC piping. The

condensate temperature should never exceed

o

212

F and the pH of the condensate should

never be greater than 3.5. NO VALVE is to be

installed in this line from the boiler to point of

discharge.

1.4.6 GAS SUPPLY CONNECTION

The installation must conform completely to the

requirements of the authority having jurisdiction,

or in the absence of such, requirements shall

conform in the U.S. to the current National Fuel

Gas Code, ANSI Z223.1-1984, or in Canada to

the current Natural gas and propane installation

code (CAN/CSA B149.1-05), and applicable

regional regulations for the class; which should

be followed carefully in all cases. Authorities

having jurisdiction should be consulted before

installations are made.

1.4.2 SAFETY RELIEF VALVES

Safety relief valve(s) are shipped loose.

Connections are provided in the top of the boiler

for the safety relief valve(s). The safety relief

valve discharge piping must be the same size as

the safety relief valve discharge opening and run

to a point of safe discharge. Avoid overtightening as this can distort valve seats. All

piping from the safety relief valve(s) must be

independently supported with no weight carried

by the valve.

1.4.3 EXPANSION TANK

CONNECTIONS

Connection(s) to an expansion tank are to be

provided by others in the system piping separate

from the boiler.

1.4.4 DRAIN CONNECTION

A drain valve must be installed on the boiler

drain connection, the same pipe size as this

connection, to allow draining of the boiler.

1.4.7 DRIP LEG

A drip leg, or sediment trap, must be installed in

the gas supply line. See Fig. 1.5A. The gas line

must be connected to a supply main at least as

large as the gas train connection at the boiler.

This connection should be made with a union so

that the boiler gas train components and burner

may be easily removed for service.

1.4.8 GAS PIPING LEAK TEST

Leaks shall be checked using a soap and water

solution.

After completion of the gas-piping hookup, the

installation must be checked for leaks. All joints

up to the main motorized gas valve shall be

checked. A pressure gauge shall be installed

down stream of the main motorized gas valve

and up stream of the manual gas shutoff valve in

the closed position to ensure the main motorized

valves are not leaking by. During

commissioning, the remainder of the gas train

joints down stream of the main motorized gas

3

Page 10

Date: 8-4-2010

Revision: 0

Form: 2396

valve shall be tested for leaks.

1.4.9 VENTING OF GAS TRAIN

COMPONENTS

Model TF300/250 TF200/150

200 V – 240 V / 60 Hz / 3 Ph

Blower Motor

KW (HP)

Full Load

Amps

1

3 (4.02) N/A

15.6 N/A

Service Fuse (3) 20 Amp N/A

400 V – 480V / 60 Hz / 3 Ph

Blower Motor

KW (HP)

Full Load

Amps

1

N/A N/A

N/A N/A

Service Fuse N/A N/A

200 V – 240 V / 60 Hz / 1 Ph

Blower Motor

KW (HP)

Full Load

Amps

1

N/A 1.05 (1.41)

N/A 6

Service Fuse N/A (2) 7 Amp

Table 2 Electrical Requirements

Equipment Grounding

The boiler must be grounded in accordance with

the current American National Standard

Electrical Code, ANSI/NFPA #70.

Figure 2 Main Gas Inlet Connection

Normally open vent valves (when supplied) These valves must be piped to outdoors using

pipe no smaller than that of the valve.

1.6 COMBUSTION AIR SUPPLY

Gas pressure switches – All gas pressure

switches provided are of the VENTLESS type

and do not require venting to atmosphere.

Gas pilot pressure regulator – A vent limiter for

the pilot pressure regulator is provided

eliminating the need to run a vent line to

atmosphere.

NOTE:

Do not use Teflon tape for threaded joints in gas

piping.

Combustion Air:

For proper combustion it is necessary to provide

the boiler room with appropriate openings for

fresh air supply. Temporary air intakes such as

windows and doors should be avoided since

they may be closed. In addition to air needed

for combustion, sufficient air must be supplied

for ventilation as well as other air consuming

equipment that may be present in the boiler

room. Often when personnel are working in the

boiler room, combustion air openings are closed

1.5 ELECTRICAL REQUIREMENTS

due to the temperature of the outside air. THIS

MUST BE AVOIDED AT ALL COSTS!

Provisions should be made to heat the outside

WARNING:

All electrical connections must

conform to the National Electrical

Code and to all other applicable State

and Local Codes. See boiler wiring

diagram and equipment list for specific

combustion air, if necessary, for personnel

comfort.

Positive means for supplying an ample amount

of outside air, allowing for the complete

combustion of the gas, must be provided.

Movable combustion air dampers, automatic or

manually adjustable, must be electrically

voltage requirements.

1

Full load Amps include blower and control

circuit.

4

Page 11

Date: 8-4-2010

Revision: 0

Form: 2396

interlocked with the boiler to prevent boiler

operation if the dampers are closed.

Combustion air openings must never be blocked

or obstructed in any manner.

The boiler room must be at a positive or neutral

pressure relative to the outdoors. A negative in

the boiler room will result in downdraft problems

and incomplete combustion due to the lack of

air.

WARNING!

Failure to provide an adequate air

supply will result in boiler damage and

hazardous conditions in the building

(fire and asphyxiation hazard as well

as equipment damage).

One Permanent Opening Method

One opening commencing within 12” of the top

of the room shall be provided. The opening

shall be directly to the outside or shall be ducted

to the outside with a horizontal or vertical duct.

The opening or duct shall have a minimum free

area of:

2

/ 3000 BTU /hour of the total input ratting of

1 in

all appliances (boilers) in the room.

Not less than the sum of the areas of all

connectors in the room. A “vent connector” is

defined as the pipe or duct that connects a fuel

burning appliance to a vent or chimney.

Additional area must be provided for other air

consuming equipment in the room.

vent

Mechanical Air Supply Systems

1.6.1 COMBUSTION AIR OPENINGS:

The design of combustion air openings MUST

comply with local and/or State codes or the

authority having jurisdiction. As a minimum,

combustion air openings to the boiler room shall

be provided as follows:

Note:

Combustion air provided solely from an indoor

source is discouraged. No dimension for a

round or rectangular opening shall be less than

3”.

Two Permanent Opening Method

One opening starting within 12” of the top of the

boiler room and one starting within 12” of the

bottom of the boiler room shall be provided. The

openings shall be open directly to the outside or

ducted directly to the outside.

When directly open to the outside or ducted to

the outside by

duct shall have a minimum fee open area of 1

2

in

per 4000 BTU total input rating of the

boiler(s) in the room.

If ducted to the outside through

ducts, each opening or duct shall have a

minimum free area of 1 in2 per 2000 BTU total

input rating of the boiler(s) in the room.

vertical ducts, each opening or

horizontal

The combustion air supply may be provided by a

mechanical air supply system. If utilized, the

combustion air must be provided from the

outside at a minimum rate of 0.35 ft

every 1000 Btu/hr. input for all appliances

located in the space.

If exhaust fans are utilized, additional air shall be

provided to replace the exhausted air.

Each boiler and other appliance must be

interlocked to prevent operation when the

mechanical air supply system is not in operation.

If the combustion air is provided by a buildings

mechanical ventilation system, the system shall

be sized to provide the specified combustion air

in addition to the ventilation air requirements.

3

/min. for

1.6.2 LOUVERS, GRILLES, AND

SCREENS

Louvers and Grilles:

The required size of openings for combustion,

ventilation, and dilution air shall e based on the

net free area of each opening. Where the free

area through a design of louver, grille, or screen

is know, it shall be used in calculating the size

opening required to provide the free area

5

Page 12

Date: 8-4-2010

Revision: 0

Form: 2396

specified. Where the louver and grille design

and free area are not know, it shall be assumed

that wood louvers have a 25 percent free area,

and met louvers and grilles have 75 percent free

area. Non-motorized louvers and grilles shall be

fixed in the open position.

Screens

Minimum Screen Mesh Size:

Screens shall not be smaller than 1/4 “ mesh.

BOCA, National Mechanical Code

WARNING:

Do not locate air intakes where

petroleum distillates, CFC’s,

detergents, volatile vapors or any

other chemicals are present. Severe

boiler corrosion and failure will result.

Motorized Louvers:

Motorized louvers shall be interlocked with the

appliance so they are proven in the full open

position prior to main burner ignition and during

main burner operation. Means shall be provided

to prevent the main burner from igniting should

the louver fail to opening during burner startup

and to shut down the main burner if the louver

close during burner operation.

Combustion Air Ducts

Combustion air ducts shall comply with the

following:

Ducts shall be constructed of galvanized steel or

a material having equivalent corrosion

resistance, strength and rigidity.

Ducts shall terminate in an unobstructed space,

allowing free movement of combustion air to the

appliances.

Ducts shall serve a single space.

Ducts shall not serve both upper and lower

combustion air openings where both such

openings are used. The separation between

ducts serving the upper and lower combustion

air openings shall be maintained to the source of

combustion air.

Ducts shall not be screened where terminating

in an attic space.

Horizontal upper combustion air ducts shall not

slope downward toward the source of

combustion air.

For informational purposes, there are several

codes that address the amount of air and/or size

of the opening(s) in walls for combustion air.

NFPA 54, National Fuel Gas Code (ANSI

Z223.1)

ASME CSD-1, Controls and Safety Devices for

Automatically Fired Boilers

ASME Section VI, Recommended Rules for

Care and Operation of Heating Boilers

1.7 FLUE GAS VENTING SYSTEM

Triple-Flex boilers are Category IV appliances

that vent with a positive exhaust vent pressure

and with a temperature that is likely to cause

condensation. Any venting system used with

the Triple-Flex boiler must comply with the

requirements for Special Gas Vents per UL

Category Code (CCN) DGSH, which are UL

Listed per UL 1738 or UL Category Code

DGSH7, which are cUL Listed (Canada) per UL

1738.

WARNING:

The Triple-Flex boiler is NOT certified

for use with other types of venting

excepting Special Gas Vents. Use of

any other types of venting may cause

vent failure resulting in serious injury

or death.

1.7.1 DESIGN & INSTALLATION

A qualified venting professional experienced in

venting system designs should design the boiler

vent system. The vent size must be NO LESS

THAN 8” IN DIAMETER and sized such that the

pressure drop between the boiler and the point

of discharge does not exceed 0.20” WC. While

the vent must be UL Listed Special Gas Vent

per Category Code DGSH or DGSH7 for

Canada, Bryan Steam, LLC recommends the

use of venting components fabricated from

AL29-4C® material. The vent installation must

be in strict compliance with the vent

manufacturers requirements. Clearances to

combustible materials and supporting

requirements, per the vent manufacturers

installation instructions, must be maintained.

6

Page 13

Date: 8-4-2010

Revision: 0

Form: 2396

Horizontal sections of the flue vent system must

be pitched back towards the boiler at ¼ inch per

foot to avoid condensate pooling and allow for

proper drainage. Venting may be horizontal,

through the wall installation or vertical, through

the roof installation. The vent system, including

An existing masonry chimney may be utilized

PROVIDING that the existing chimney is lined

with Special Gas Vent material(s), primarily

AL29-4C®. There are venting manufacturers

that have these products available.

Note:

terminus, must be sized in accordance with the

flue gas flow(s) and pressure drop(s) per

Flue Gas

Flow,

Boiler Model

TF-150 452 330

TF-200 603 441

TF-250 753 550

TF-300 904 661

Table 3 Boiler Draft

ACFM

@40%X

SA

200

o

F

Comb Air

Req.

SCFM

@40%XS

o

F

A60

Note:

NFPA 54-2009 (ANSI Z223.1-2009) paragraph

12.7.3.3 states, “The sizing of gas vents for

Category II, Category III, and Category IV

Appliances shall be in accordance with the

appliance manufacturers instructions.”

Table 3.

Permissible

∆P Thru

Venting

0.2” WC

(Max)

0.2” WC

(Max)

0.2” WC

(Max)

0.2” WC

(Max)

1.7.2 COMBUSTION AIR AND VENTING

REQUIREMENTS FOR CANADA

Canadian Standard CAN/CSA-B149.1-05,

Natural gas and propane installation code

specifies venting systems and air supply for

appliances in Section 8. Paragraph 8.1.4 states

“Air supply shall be provided in accordance with

Clause 8.4 when either an appliance or a

combination of appliances has a total input

exceeding 400,000 Btuh”. Air supply is defined

as combustion air, excess air, flue gas dilution

air, primary air, secondary air, and ventilation

air. The air supply requirements below are a

summation of Clause 8.4 specific to the TripleFlex boiler.

Air Supply Requirements per CAN/CSAB149.1-05 for Appliances having an input

exceeding 400 MBH.

Ventilation Air: an opening for ventilation air at

the highest point that opens to the outdoors shall

provide Ventilation of the space. The cross

sectional area of this opening shall be at least

WARNING:

Do not use a barometric damper with

this boiler. This is a positive pressure

system. The use of a barometric

damper may cause flue gases to leak

into the boiler room.

The boiler vent must not be connected to any

portion of another vent system without

consulting the vent manufacturer. The boiler

shall not be connected to any part of a vent

system serving a Category I or Category II

appliance, nor shall a Category I or Category II

appliance be connected to the vent system

serving this boiler. Improper connection of

venting systems may result in leakage of flue

gases into building spaces.

10% of the area required for combustion air, but

in no case shall the cross-sectional area be less

that 10 in

2

(6500mm2).

Combustion Air: For combustion air where the

air supply is provided by natural airflow from

outdoors, in addition to the opening for

ventilation air, there shall be permanent opening

having a total cross-sectional free area of not

less than 1 in

2

for each 30,000 BTU/hr. (70 mm2

for each kW) of the total rated input of the

boiler(s). The location of the opening(s) shall

not interfere with the openings for ventilation air.

Please refer to CAN/CSA-B149.1-05, Para.

8.4.4, for combustion air openings if there are

natural draft, fan assisted or power draft

assisted equipment in the space.

When an air supply duct is used to supply

combustion air, it’s discharge opening shall be

located where there is no possibility of cold air

affecting steam or water lines or other

temperature sensitive equipment.

7

Page 14

Date: 8-4-2010

Revision: 0

Form: 2396

Combustion Air Supply Dampers, Louvers,

and Grilles

The free area of the combustion air supply

opening shall be calculated by subtracting the

blockage area of all fixed louvers, grilles or

screens from the gross area of the opening.

Openings in a fixed louver, grille, or screen shall

have no dimension smaller than ¼” (6 mm).

No manually operated damper or manually

operated adjustable louvers are permitted.

A motorized damper or louvers shall be

interlocked so the burner(s) cannot operate

unless the damper or louver is in the fully open

position.

Mechanical Combustion Air Supply

When combustion air is supplied by mechanical

means, an airflow sensing device shall be

installed and wired into the safety limit circuit of

the primary safety control to shut off the gas in

the even a an air supply failure.

Appliance Venting per CAN/CSA-B149.105

Paragraph 8.9 of CAN/CSA-B149.1-05 addresses

“Appliance Venting”. Paragraphs 8.9 through 8.31

address many facets of flue gas vents, many of which

do not apply to the Triple-Flex boiler, which is a

Category IV listed appliance requiring the use of

special venting systems as previously described.

NOTE:

Please note that the information provided in this

manual relative to the Canadian Standard is not

meant to be all-inclusive. Reading the entire

Standard is strongly suggested. The final

approval of all system designs must be

acceptable to the authority having jurisdiction.

• Venting for Category IV appliances shall

be as specified or furnished by the

manufacturer of the listed appliance.

The Triple-Flex boiler is a Category IV

appliance requiring the use of special

vent that is certified.

Vent Sizing

1.7.3 MARKING OF GAS VENTS

Where solid and liquid fuels are used, gas vents,

must be plainly and permanently identified by a

label. The label should read, "This gas vent is

for appliances that burn gas only. Do not

connect to incinerators or solid or liquid fuel

burning appliances."

This label must be attached to the wall or ceiling

at a point near where the gas vent connector

enters the wall, ceiling or chimney.

The authority having jurisdiction must determine

whether their area constitutes such a locality.

Solid Fuel Appliance Vents

Gas appliances shall not be vented to a vent or

a chimney that serves a solid-fuel burning

appliance.

shaft used for return air, hot air,

ventilating air, or combustion air.

• An appliance that operates at a positive

vent pressure shall not be connected to

a venting system serving any other

appliance. The Triple-Flex boiler

operates at a positive vent pressure.

• A factory-built chimney used for venting

an appliance shall be certified.

• A vent or chimney serving a single

appliance shall provide effecting venting

and shall be sized so that it’s effective

area is not less than that of the flue

outlet diameter of the boiler and in

accordance with engineering venting

tables acceptable to the authority having

jurisdiction.

• A vent or chimney serving more than

one appliance shall provide effective

venting and shall be sized in

accordance with good engineering

practice, such as by the use of

engineering venting tables acceptable to

the authority having jurisdiction.

• A special venting system shall be

installed in accordance with the terms of

it’s listing and the vent manufacturers

certified installation manual.

1.8 BEFORE PLACING BOILER IN

OPERATION

• A flue gas vent or a vent connector shall

not be installed in either a duct or a

8

Page 15

Date: 8-4-2010

Revision: 0

Form: 2396

1.8.1 HYDROSTATIC TEST OF

BOILERS AND SYSTEM

After completing the boiler and burner

installation, the boiler connections, fittings,

attachments and adjacent piping must be

inspected for leaks by filling the unit with water.

The pressure should be gradually increased to a

pressure just below the setting of boiler safety

relief valve(s).

Remove the boiler tube access panels (see

dimensional drawing in the boiler manual).

Inspect the tube to header joints to be certain

that all tube fittings are sealed. This is

necessary because, although the boiler is

hydrostatically tested at the factory, minor leaks

in fittings and at attachments can develop from

shipping vibration or from installation

procedures. It is often necessary to retighten

such fittings after installation and after the boiler

has been operated for some time. Replace tube

access panels before proceeding to start boiler.

1.8.2 TEST OF GAS PIPING

Reference the gas system test under paragraph

Gas Supply Connection, in this manual.

9

Page 16

Date: 8-4-2010

Revision: 0

Form: 2396

Section 2 Start-Up and Operation

Triple-Flex High Efficiency Boilers

10

Page 17

Date: 8-4-2010

Revision: 0

Form: 2396

WARNING:

Improper servicing and start-up of this

equipment may create a potential

hazard to equipment, operators, or

persons in the building.

Only fully trained and qualified

personnel should do servicing and

start-up.

WARNING:

Before disconnecting or opening any

fuel line, cleaning or replacing parts of

any kind take the following

precautions.

Turn OFF the main fuel shutoff valves,

including the pilot gas cock if

applicable.

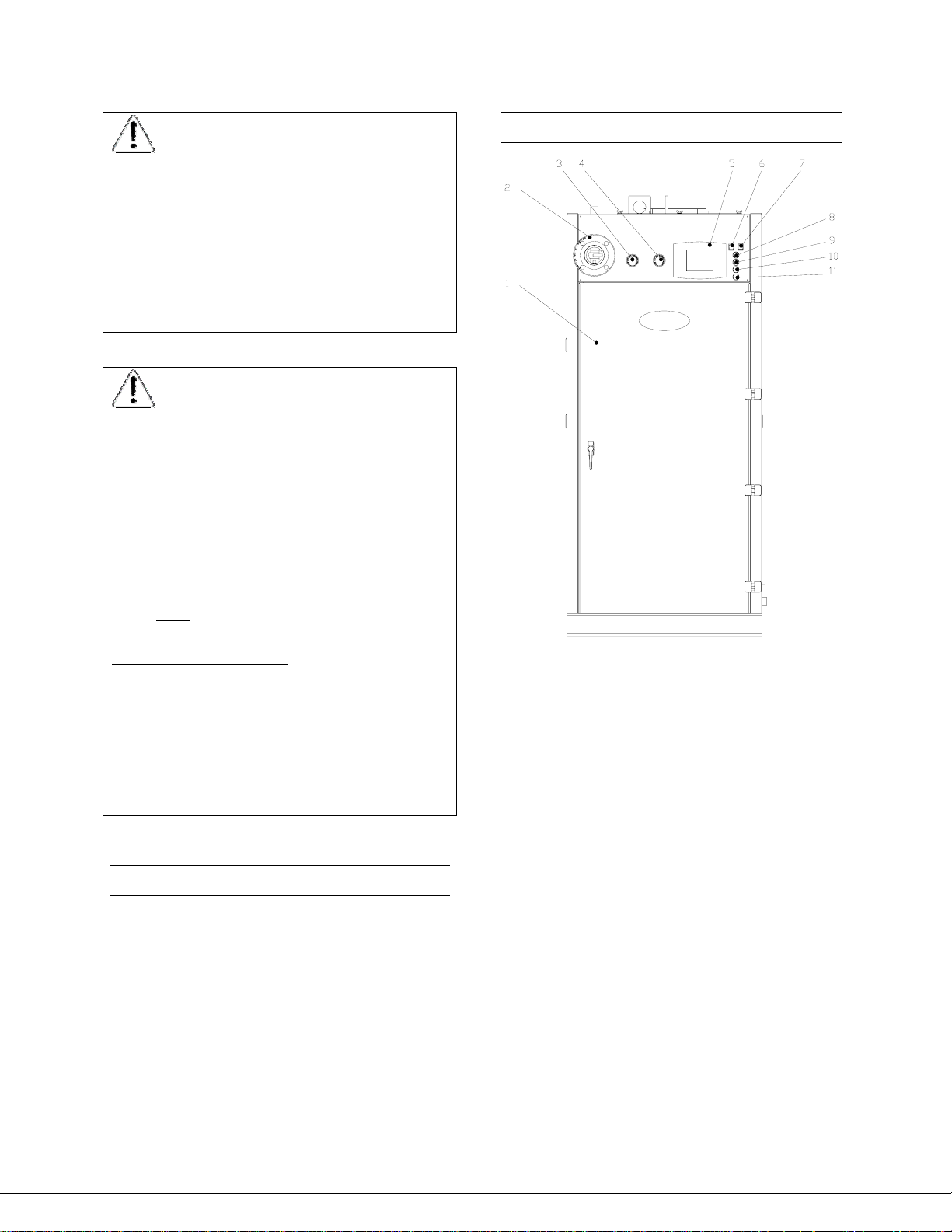

2.1.1 TRIPLE-FLEX FRONT VIEW

Turn OFF all of the electrical

disconnects to the burner, boiler and

any other equipment or systems

electrically interlocked with the burner

or boiler.

All cover plates, enclosures, and

guards must be in place at all times

except during maintenance and

servicing.

2.1 BOILER ASSEMBLY

The Triple-Flex boiler is a fully integrated

assembly consisting of a Metal Fiber Pre-Mix

Burner Head and the necessary fittings, valves,

and safety devices. The boiler equipment list

provided in the boiler manual lists the

components supplied for the boiler assembly.

Refer to the boiler dimensional for location

dimensions. A description of the major

components follows. For additional information

refer to the manufactures literature provided in

the boiler manual.

Figure 3 Triple-Flex Front View

1. The boiler cabinet door provides easy

access to boiler and burner components.

This door should remain closed during

normal operation to ensure proper flow of air

around the boiler flue collector.

2. The boiler supply water connection provides

heated water to the system. This

connection is a standard ANSI 150# class 3”

flange.

3. The boiler water pressure gauge is 2”

diameter and will have a range not less than

1-1/2 nor more than 3-1/2 times the

pressure setting of the boiler safety relief

valve.

4. The boiler water temperature gauge is 2”

diameter and is located so that it will indicate

the boiler water temperature at the supply

water connection of the boiler.

5. The boiler touch panel display provides a

human interface for controlling the boiler.

Controlling the boiler with the touch panel

display will be explained in section 2.2.

6. The boiler on / off switch will turn on or off

the 120 volt ac control voltage for every

electrically connected device. This includes

11

Page 18

Date: 8-4-2010

Revision: 0

Form: 2396

the touch panel display. There is a soft

switch (paragraph 2.2.11) provided with the

2.1.2 TRIPLE-FLEX REAR VIEW

SOLA hydronic control that will put the boiler

into standby for an indefinite period of time.

WARNING:

The boiler on / off switch will not turn

off the 3 phase high voltage power to

the motor.

7. The boiler lockout reset button is a push

button used to reset the hydronic control

after a boiler failure.

8. The power on light will be white in color and

indicates that there is 120 volts ac being

supplied to electrically connected devices.

9. The enabled light will be green in color and

indicates that the boiler is enabled. Enabled

is a state in which the boiler is allowed to

operate within the boiler’s predefined

parameters.

10. The fuel on light will be amber in color and

indicates that the boiler is firing and

producing heated water.

11. The boiler lockout light will be red in color

and indicates that the boiler has failed. The

SOLA control will have additional

information displayed on the touch panel

display. These failures will be explained in

section 2.3.9.

Figure 4 Triple-Flex Rear View

1. The flue gas vent is 8” diameter and

exhausts products of combustion. Refer to

section 1.7 for installation details.

2. The rear jacket access panel provides

access to the combustion air blower for

servicing.

3. The boiler return water connection receives

cooled water from the system. This

connection is a standard ANSI 150# class 3”

flange.

4. The drain connection is 1” NPT and provides

a means for draining water from the boiler.

For installation details refer to paragraph

1.4.4.

12

Page 19

Date: 8-4-2010

Revision: 0

Form: 2396

2.1.3 TRIPLE-FLEX LEFT SIDE VIEW

1. Main gas inlet connection. This connection

is a 2” male national pipe thread.

2. Condensate Drain Connection. This

connection is a 1” male national pipe thread.

For installation details refer to paragraph

1.4.5.

3. This jacket access panel will permit access

to the majority of the boiler devices.

4. These jacket access panels will permit

access to the flue collector. There is no

practical reason for the removal of these

panels.

5. This jacket access panel will permit access

Figure 5 Triple-Flex Left Side View

1. This jacket access panel will permit access

to the primary air-to-air exchanger.

2. This jacket access panel will permit access

to the condensate trap. The condensate

trap is provided with a ½” NPT plugged

connection for cleanout purposes.

6. This jacket access panel will permit access

to the primary air-to-air exchanger.

to the primary air-to-air exchanger and the

boiler convection tube access panels.

3. These jacket access panels will permit

access to the convection and furnace tube

2.1.5 TRIPLE-FLEX BEHIND THE

CABINET DOOR

access.

4. Flame observation port. This port provides

visual access to observe the pilot and main

flame during operation and service.

5. This jacket access panel will permit access

to the majority of the boiler devices.

WARNING:

The flame observation port will

become very hot during normal

operation. Burn injuries can occur if

come in contact with the skin.

2.1.4 TRIPLE-FLEX RIGHT SIDE VIEW

Figure 6 Triple-Flex Right Side View

Figure 7 Triple-Flex Behind the Cabinet Door

1. Auxiliary gas shutoff valve actuator.

2. Low fire displacement adjustment that can

be adjusted by removing the cap and

rotating the slotted screw clockwise to

increase gas flow and counter-clockwise to

decrease gas flow.

Fig. 2.1.2 Triple-Flex Rear View

13

Page 20

Date: 8-4-2010

Revision: 0

Form: 2396

NOTE:

The low fire displacement final adjustment

should be made at low fire only.

3. Main gas pressure regulating and shutoff

valve actuator. The pressure regulating

actuator provides slow opening fast closing

safety shutoff and air/gas ratio control. The

actuator controls the pressure difference

across the gas limiting orifice valve (Figure 7

item 26) as a function of the pressure

difference across the furnace section so that

the air to gas ratio remains constant

irrespective of air volume changes. There is

no need for an upstream constant pressure

regulator when the supply gas pressure

does not exceed 56 inches of water column.

A minimum of 14 inches of water column

must be supplied at the gas inlet connection

(Figure 6 item 1). The supply pressure can

be measured at the test port (Figure 7 item

28).

NOTE:

The supply pressure is not static. The supply

pressure is at the maximum full flow of gas

through the burner.

4. Manual main gas shutoff valve.

5. Pilot ignition transformer.

6. Manual pilot gas shutoff valve.

7. Pilot gas pressure regulator. This regulator

provides a constant gas pressure to the pilot

when the solenoid valve is energized. The

pressure can be adjusted by removing the

cap and adjusting the slotted screw

clockwise to increase the pressure and

counter-clockwise to decrease the pressure.

The pilot gas supply is taken upstream of

the main gas cock so the pilot may be

lighted and adjusted with the main gas cock

closed.

8. Low pilot gas pressure switch (Manual

Reset)

9. Pilot spark igniter assembly. For further

detail see Figure 9.

10. Pilot gas solenoid valve.

11. Flame scanner.

12. Main gas manifold pressure test port (1/4”

NPT).

13. Main high gas pressure switch (Manual

Reset). This switch should be set 1” of

water column above the maximum gas

manifold pressure.

14. Pilot gas pressure test port (1/4” NPT). This

port is also used to record the furnace

pressure.

15. Boiler water flow switch. The boiler water

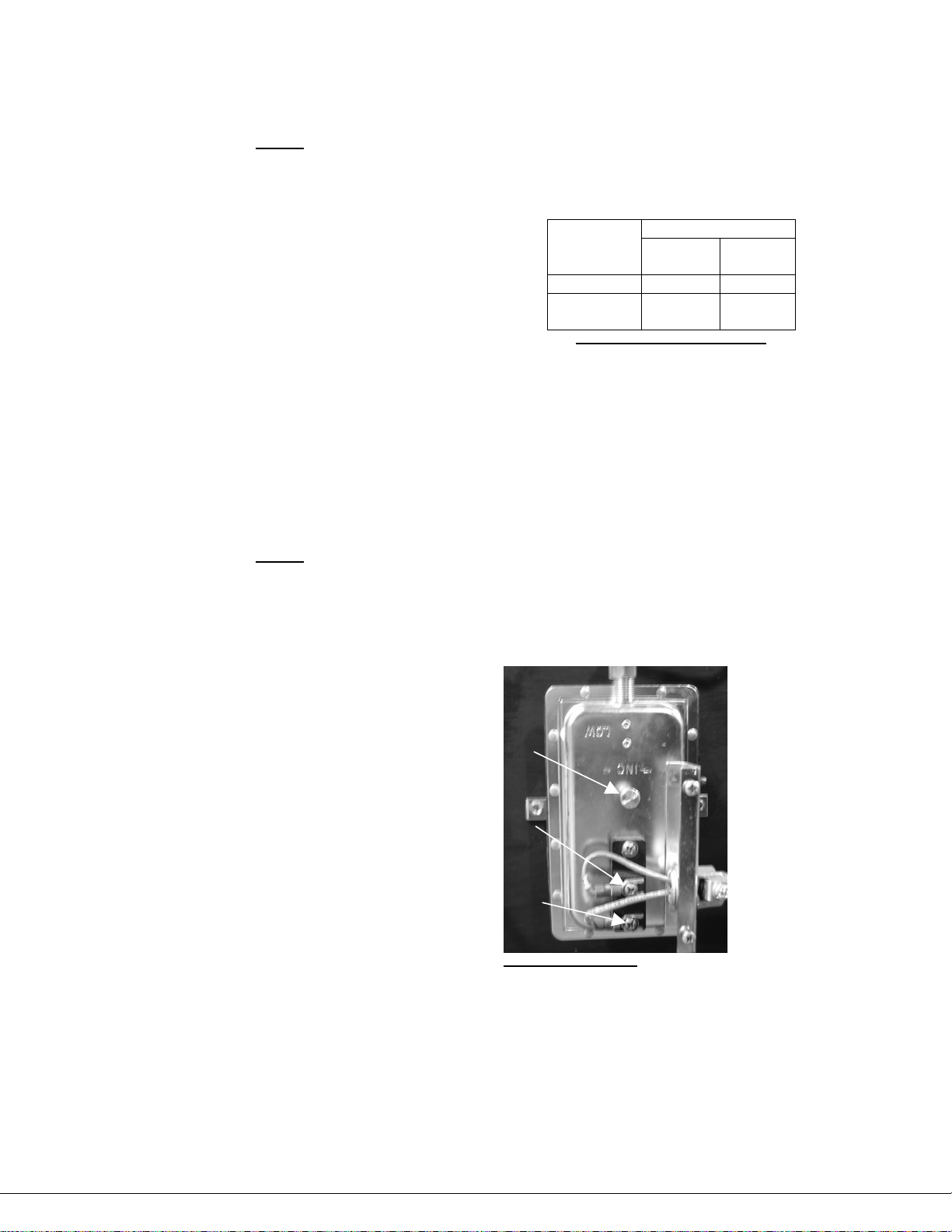

flow switch is adjustable within the

parameters listed in the table.

Mode Of Operation

Settings

Minimum 30 gpm 12 gpm

Maximum 52.1

Table 4 Water Flow Switch Settings

16. Low Water Cutoff (Manual Reset Probe

Type).

17. Combustion air-flow switch. An airflow

switch is provided to prove that air is being

provided to the burners before main flame

can be established. The airflow switch can

be adjusted by turning the screw (Figure 8

item A) clockwise to increase the pressure

setting and counter-clockwise to decrease

the pressure setting. The switch will open

on pressure drop. When the blower is

running there should be continuity between

the common and the normally open contacts

(Figure 8 item B and C). When the blower is

interrupted the switch should open and

cause a safety shutdown.

Switch

Closed

gpm

Switch

Open

46.1

gpm

A

B

C

Figure 8 Air Flow Switch

18. High burner air pressure switch manual

reset. This switch will trip when the air

pressure in the burner rises above the setpoint, indicating that the burner has become

plugged with dust or other foreign matter.

19. Gas and air mixer assembly.

20. Main 3-phase power connection and fuse

14

Page 21

Date: 8-4-2010

Revision: 0

Form: 2396

block.

21. Control circuit transformer.

22. 24 volt ac transformer.

2.1.6 PILOT SPARK IGNITER

ASSEMBLY

23. 12 volt dc power supply.

24. SOLA hydronic and flame supervision

control.

25. Repeat cycle timer. This timer will ensure

that a forced shut down and pre-start safety

check is performed at least once in a 24

hour period. This timer has been

incorporated into the SOLA control for newer

boilers.

26. Gas limiting orifice valve. This valve is used

to increase or decrease the gas / air ratio for

combustion. Adjustments are made by

removing the cap and using a flathead

screwdriver. Clockwise rotation will increase

the flue outlet % O2 levels and counterclockwise will decrease the flue outlet % O2

level. Starting point adjustments are listed

in the table. This vale is factory set and the

Figure 9 Pilot Spark Igniter Assembly

1. Spark grounding screw.

2. Pilot igniter gas orifice (#49 Drill)

3. Shell body ¾”.

4. Gland nut.

5. Igniter electrode.

6. Brass bushing.

7. Gas inlet fitting.

number of turns out is written in black

adjacent to the adjustment cap.

Boiler Model

Turns Out From

Bottom

2.1.7 TRIPLE-FLEX LEFT FLUE

COLLECTOR VIEW

TF300 8-1/2 to 9

TF250 8-1/2 to 9

TF200 6-1/2 to 7

TF150 6-1/2 to 7

Table 5 Gas Limiting Orifice Rough Settings

27. Main low gas pressure switch (Manual

Reset). This switch should be set 2 – 3

inches of water column below the minimum

required supply gas pressure.

28. Supply gas pressure test port (1/4” NPT).

29. (-) Air pressure sensing line connection.

30. (+) Air pressure sensing line connection.

31. (-) Gas pressure sensing line connection.

32. (+) Gas pressure sensing line connection.

33. Burner internal temperature fuse. This fuse

senses the internal burner temperature and

will open at a temperature greater than

o

F.

425

Figure 10 Triple-Flex Left Flue Collector View

1. 3” Lower drum cleanout and inspection

opening.

2. Furnace tube access panel.

3. Convection tube access panel.

4. Primary air-to-air exchanger access cover.

5. ASME name-plate stamping.

6. Combustion air blower.

7. 3” Upper drum cleanout and inspection.

8. ASME Safety relief valve.

9. Air filter 20” x 25”. This filter is a polyester

coated fiberglass. The frame is made of

fiberboard and has two tin-plated steel grills

(one bonded to each side) as well as sealed

corners to prevent dust leakage. Filters are

marked with size and airflow direction.

15

Page 22

Date: 8-4-2010

Revision: 0

Form: 2396

Actual length and width are 3⁄8” less than

trade size shown. Filters meet UL Class 2

flame retardance requirements. Maximum

temperature is 180° F.

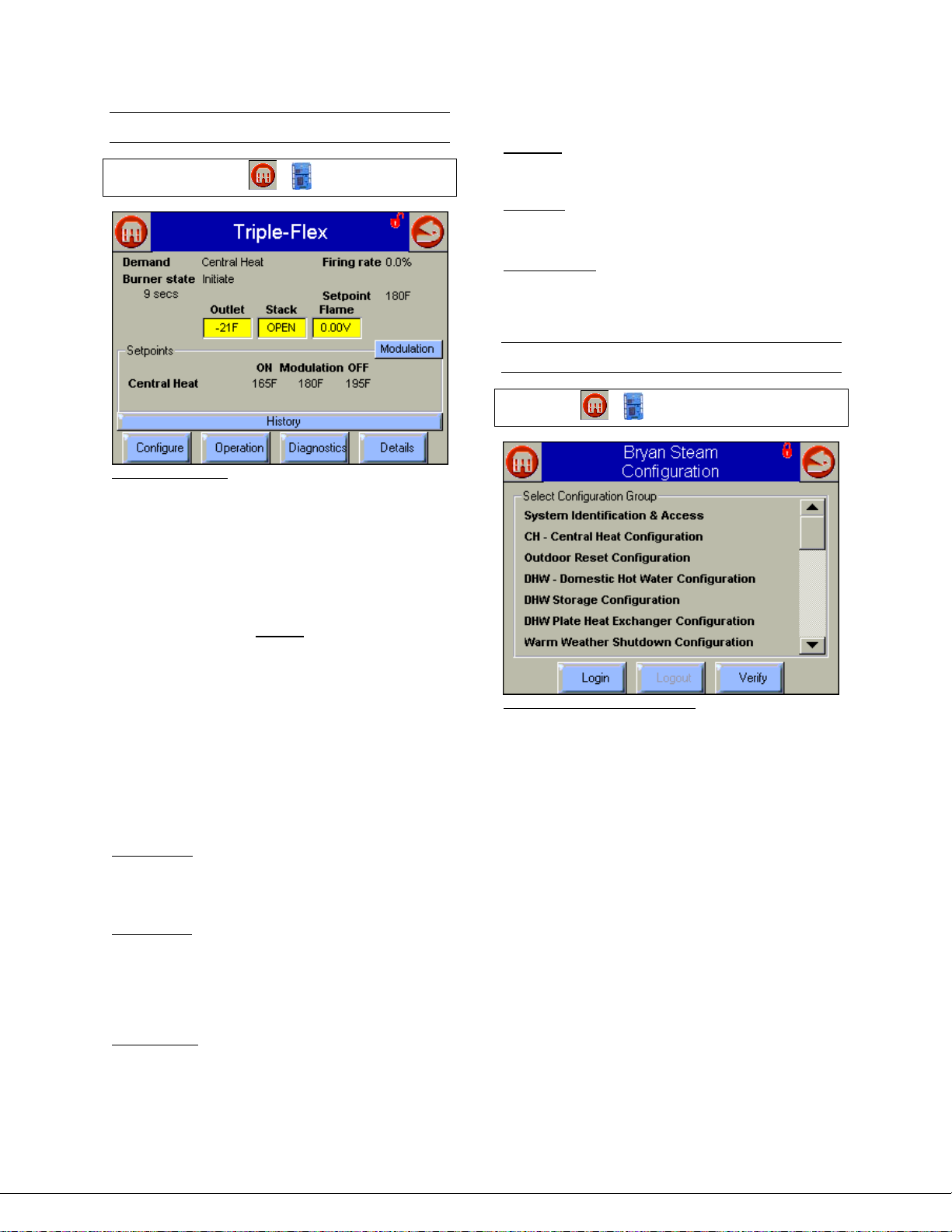

2.2.2 HOME PAGE

Make sure a screen similar to Figure 12 appears

after the system is completely powered up. The

directional map shown before each page

description in this manual will start with this

2.1.8 TRIPLE-FLEX RIGHT FLUE

COLLECTOR VIEW

symbol

you to the home page.

. Pressing this symbol will return

Figure 11 Triple-Flex Right Flue Collector View

1. High primary air-to-air exchanger pressure.

This switch will trip when the air pressure in

the primary air-to-air exchanger rises above

the set-point, indicating that the primary airto-air exchanger has become plugged with

dust or other foreign matter.

2. Condensate trap cleanout. This connection

is ½” NPT.

3. Condensate trap. The condensate trap is

welded and fixed into place.

4. Flue vent temperature sensor.

2.2 SOLA HYDRONIC CONTROL

SYSTEM

The Triple-Flex is equipped with a Honeywell

SOLA control system (Figure 3 item 5). This

section will explain navigation, configuration,

history, and diagnostics.

2.2.1 POWER-UP VALIDATION

Flip the power button, (Figure 3 item 6), to the

on position. After a few seconds the Home page

will appear and the POWER LED will be blinking

when the device is properly powered. Select the

Setup button to adjust the contrast as desired.

Figure 12 Home Page

On multi-boiler applications, each boiler in the

hydronic system is represented on the Home

page by an icon and name. Pressing the boiler

icon allows the user to zoom in on that boiler

and see specific details about it. These details

are provided on a new page, which can include

additional buttons that display additional detail

and operation information, which itself leads to

other pages. The pages are traversed in a tree

structure method. The boiler icon button will

appear in one of four colors indicating the boiler

status.

• Blue: Normal operation

• Red:

• Gray:

• Gray and crossed out: Hydronic control

communication error (disconnected or powered

off)

Up to 8 boilers can be displayed on the System

Home page.

The name of each boiler is displayed next to the

boiler icon. When Lead Lag is enabled, the

system header temperature and firing rate are

displayed for each boiler. When the burner is in

standby or not firing the firing rate is not

displayed.

Lockout condition

Standby mode (burner switch off)

16

Page 23

Date: 8-4-2010

Revision: 0

Form: 2396

NOTE:

The boiler name may be cut off on the Home

page when all boilers are present for the

hydronic system.

The Home page also includes a System

Analysis button that allows the user to view

status information on a system-wide (that is,

multiple boiler) basis. The user can choose

which status information to compare from the

boilers in the system. Pressing the Setup button

on the Home page displays miscellaneous

display setup and diagnostic functions.

2.2.4 KEYBOARD

2.2.3 P

The System Display, (Figure 3 item 5), presents

information and options in a paged manner.

Pages are displayed in a tree structure in which

the user navigates up and down to arrive at the

desired function. The page descriptions are

provided below so that you can understand the

purpose of each and view the selections,

parameters, and information that are available or

required on each. Most pages have a Home

button

and a Back button in the top-right corner of the

screen. The Home button returns the user to the

Home page and terminates any operation in

progress. The Back button

to the previous page. Two other icons may be

noticed near the boiler name. A bell

displayed if the system is in lockout that reset

will be required. A padlock

screens that a password is needed to change

the parameter. An unlocked padlock

indicates the password has been entered to

change the parameter (either the installer or

OEM), depending on the security level entered.

AGE NAVIGATION

in the top-left corner of the screen

returns the user

will be

will be shown on

Figure 13 Keyboard

Some pages request user entry of characters.

When this type of input is required, a keyboard

page appears, as shown in Figure 13.

The text box at the top of the screen displays the

current (or default) setting of the user input. The

user can add to this text, clear it, or change it.

The Shift key on the left side of the screen shifts

between upper- and lowercase characters.

Pressing the Shift key toggles the keyboard from

one mode to the other (continuous pressing of

the Shift button is not required). The OK button

should be pressed when the user is done

entering the text input. The Cancel button on the

bottom of the screen allows the user to ignore

any text changes that have been made and

keep the original text value. Pressing the OK or

Cancel buttons returns the user to the page

displayed prior to the keyboard page.

17

Page 24

Date: 8-4-2010

Revision: 0

Form: 2396

2.2.5 STATUS PAGE

►

Figure 14 Status Page

The status page (Figure 14) is displayed when a

boiler is selected on the Home page. The status

page displays the current condition of the boiler

and displays some of the more important

configuration settings. The boiler name is

displayed in the title bar of the status page.

NOTE:

When the boiler has no name defined, the

display will use the Modbus address to identify

the boiler.

The standard status page displayed for the

Triple-flex boiler contains summary status

information as shown in Figure 14. Any status

information not applicable for the installation is

blanked out on the screen. Buttons on this

screen include:

Configure:

Used to configure the R7910 (see “Configuration

Page” 2.2.6 page 18 for more details).

Operation:

Used to perform daily/frequent functions with the

R7910, such as setpoint adjustment, etc. (See

“Operation Page” 2.2.11 page 22 for more

details.)

Diagnostic:

Used to view R7910 diagnostic information.

Details:

Used to view boiler detail status information.

History:

Used to view R7910 history.

Modulation:

Used to toggle between two different status

displays: modulation, and setpoints.

2.2.6 CONFIGURATION PAGE

► ►CONFIGURE

Figure 15 Configuration Menu Page

The configuration page allows the user to view

and set parameters that define how the boiler

functions in the hydronic heating system.

Configuration parameters for any boiler

connected in the Global Modbus™ network can

be accessed from the display. Press the boiler’s

button on the Home page to acess the Status

page. Pressing the Configure button on the

status page starts a configuration session. The

configuration page contains a menu of

parameters grouped into functional areas that

the user selects for configuration (see Figure

15).

No specific order for configuring the boiler is

required. All parameters are enabled for editing,

though some may not be applicable (e.g., a

configuration parameter may disable a boiler

feature). Selecting a parameter group from the

menu displays parameters exclusively

18

Page 25

Date: 8-4-2010

Revision: 0

Form: 2396

applicable for the functional group on the page

(Figure 16).

for a parameter that has a lower access level

than the access level achieved by an earlier

password entry for any configuration group (as

long as the user stays in the configuration

pages). The user only needs to enter a

password once until a parameter that has a

higher access level is selected.

The user enters the password from a keyboard

as shown in Figure 13. After the password is

entered, select the OK button. The Cancel

button aborts the password login.

WARNING:

Figure 16 Sample Configuration Page

These parameters can be edited, and when the

user is finished, control returns back to the

configuration menu page. Each parameter is

displayed in its group. If there are more

parameters than will fit on the screen, a vertical

scroll bar allows the user to scroll up and down

to view all parameters. The parameter name is

displayed on the left and the current setting is

displayed in the text box on the right.

2.2.7 CONFIGURATION PASSWORD

Any user can view the configuration parameters

(default mode). No access-level password is

required to view the parameters. A valid

configuration password for the parameter’s level

must be entered before the parameter can be

changed. The password need only be entered

once while the user remains on the configuration

pages. Leaving the configuration pages ends

the scope of the password entry. The user is

notified that a new password is needed upon the

first attempt to change a parameter (or until a

password is entered successfully). The user can

continue viewing the configuration parameters

regardless of whether a password is entered

successfully.

The boiler also maintains a password timeout

that limits the scope of the password entry.

Once a password is successfully entered the

boiler starts an internal timer that expires after

10 minutes of inactivity. After the timer expires,

the user is required to re-enter a password

before a parameter can be changed. The user

is not required to enter a configuration password

Explosion Hazard.

Improper configuration can cause fuel

buildup and explosion. Improper user

operation may result in PROPERTY

LOSS, PHYSICAL INJURY or DEATH.

Changing parameters, must be

attempted by only experienced and/or

licensed burner / boiler operators and

mechanics.

Three levels of write access to boiler parameters

are permitted. Each access level has defined

rights when interfacing with configuration and

status parameters in the Boiler.

• End user: The lowest access rights (no

password login). The end user can, in most

cases, only read or view boiler parameters. In

some instances the end user can change boiler

parameters, e.g., change the CH, central heat,

setpoint.

• Installer: The next highest level. The installer

can read all boiler parameters and change most

boiler parameters. This access level is used to

customize the boiler for a particular installation.

The default installer password is ‘

bryan’.

• OEM: The highest access level. The OEM can

read and change all R7910 parameters, as well

as change sensor limits and burner control

safety parameters

.

Different passwords exist in the boiler for each

access level. The end user level requires no

password, but the installer and OEM levels have

unique passwords defined for them. The display

19

Page 26

Date: 8-4-2010

Revision: 0

Form: 2396

validates all password entry attempts with the

boiler, but doesn’t conduct the validation itself.

The boiler has sole responsibility to accept a

password entry.

The display gets information from each boiler

about the access level settings for the status

and configuration parameters.

The installer and OEM passwords can be

changed in the boiler after logging in with the

current password. When the password is

changed at the S7999B1026 it is saved in the

R7910 and effective for all future logins.

NOTE:

Each boiler in a multi-boiler configuration has its

own set of installer and OEM passwords. To

avoid user confusion the passwords should be

changed to the same setting in all the boilers,

but there is no requirement to do so.

There are two classes of parameters.

Non-Safety: Non-safety parameters can be

changed without placing the boiler in a

dangerous state. These parameters typically do

not require a password to modify.

Safety: Safety parameters can be viewed the

same way non-safety parameters can be

viewed. If the user makes no attempt to change

a safety parameter, the user isn’t required to

enter safety verification mode.

Safety parameters are grouped into blocks that

include only safety parameters, not a mixture of

safety data and non-safety data. All parameters

within the safety group undergo a verification

process, (see paragraph 2.2.9 Safety

Verification). A safety parameter group is

identified on the display to indicate when the

configuration parameters are safety-related.

2.2.9 SAFETY VERIFICATION

2.2.8 CHANGE PARAMETER SETTINGS

Figure 17 Change Parameter Dialog

Change parameter settings by selecting the

parameter on the page. A dialog box displays

for the parameter with controls allowing the user

to change the value (Figure 17).

After changing the setting to a new value, press

the OK button. Pressing the Cancel button

leaves the parameter unchanged.

The changed setting is reflected on the screen

and sent to the boiler when the OK button is

pressed.

► ► CONFIGURE ►VERIFY

Figure 18 Safety Parameter Verification

For safety configuration parameters, safety

verification is required to commit the changes.

All safety configuration parameters in the group

should have the same access level. If this

condition isn’t so, the user is asked to enter

another password when a higher access level is

needed.

Each safety parameter group is verified one at a

time until all have been verified (Figure 18).

20

Page 27

Date: 8-4-2010

Revision: 0

Form: 2396

A verification step is required for each safety

parameter block that is changed. The verification

steps do not have to be completed immediately;

the user can traverse between parameter

groups before the verifications are done. If the

user is logged in with the appropriate password

After all safety parameter blocks have been

confirmed, the user is asked to press and hold

the reset button, (Figure 3 item 7), on the boiler

to complete the safety configuration session

(Figure 20).

and has changed a safety configuration

parameter, a verify button is enabled that allows

the user to conduct verification sessions.

If the user terminates the safety configuration

session after it has started, the boiler is left in an

un-configured (boiler will not operate) state.

The user can terminate the session by pressing

the Menu button or by attempting to leave the

Verification page with the Home or Back buttons

(top-left and -right screen corners, respectively).