OPERATION MANUAL

YSTEM ICS115

-

MAINTENANCE

Translation of original operati o n manual (English)

Read carefully before use! Keep safe for later reference!

INDUCTIVE CHARGIN G S

- INDUCTIVE CHARGING SYSTEM ICS115

FOR INSTALLATION – OPERATION –

www.brusa.biz

BRUSA Elektronik AG

Neudorf 14

CH–9466 Sennwald

+41 81 758 19 00

IMPRINT

Title

O

Publisher

BRUSA

Neudorf 14

CH

T +41

F +41

www.brusa.biz

info@brusa.biz

Managing Director: Josef Brusa

Valid for

ICS115 (2017)

Edition

1

st

Number

07/2018

Date of Issue

15.02.2018

Online version

Can be found at www.brusa.biz

Copyright

©

The copyright of this document lies with BRUSA Elektronik AG. The content of this document must

not be passed on to third parties

Elektronik AG. All technical specifications, drawings and photos used are protected by copyright.

The violation of the copyrights represents a criminal offence!

Updates

Due to the technical further development of our products, we reserve the right to make

constructional changes. Any

through exchange of

the relevant pages or revision of the electronic data carrier.

Writing style

For reasons of better readability, the simultaneous use of feminine and masculine linguistic forms is

disp

Creator / Author

Pirmin Bader, Sina Kaufmann, Josef Olliges

2.0

24.02.2017

Sina Kaufmann

Redesign of the documentation

3.0

11.04.2017

Josef Olliges

Integration of review comments

6

30.10.2017

Josef Olliges

Review comments Zollner integrated, Update GPM-B4

PERATION MANUAL INDUCTIVE CHARGING SYSTEM ICS115

Elektronik AG

–9466 Sennwald

8175 819–00

8175 819–99

Edition

2017 – 2018 BRUSA Elektronik AG

– even in extracts – without the written authorization of BRUSA

changes will be notified in the individual manuals

ensed with. All personal designations are always applicable for both genders.

REVISION INDEX

REVISION DATE NAME CHANGE

1.0 07.02.2017 Pirmin Bader Technical documentation based on the B3 prototype stage

4 03.05.2017 Josef Olliges Integration of review comments BMW, notes from risk

analysis

5 18.07.2017 Josef Olliges Review comments Daimler, BMW integrated

2

Operation Manual

Inductive Charging System

ICS115

7 15.02.2018 Josef Olliges Review comments Approval

TABLE OF CONTENTS

1 List of Abbreviations ....................................................................................................................... 7

2 Foreword .......................................................................................................................................... 8

2.1 Content and Scope of this Manual .............................................................................................. 8

2.2 Requirements for handling the User Manual ............................................................................... 8

3 Identification of the Product ICS .................................................................................................... 9

3.1 Product Identification .................................................................................................................. 9

3.2 Explanation of the code for the product identification .................................................................. 9

3.3 Service- and Contact Data ....................................................................................................... 10

3.4 Scope of Supply ....................................................................................................................... 11

4 Product Description of the ICS ..................................................................................................... 12

4.1 Scope of Application ................................................................................................................. 12

4.1.1 User Description ................................................................................................................ 12

4.1.2 Health Hazards ................................................................................................................. 12

4.1.3 Proper Intended Use ......................................................................................................... 13

4.1.4 Proper Intended Application .............................................................................................. 13

4.1.5 Improper Use .................................................................................................................... 13

4.1.6 Delimitation ....................................................................................................................... 14

4.2 Functionality ............................................................................................................................. 14

4.2.1 Energy Efficiency .............................................................................................................. 15

4.3 Requirements of the ICS .......................................................................................................... 15

4.4 Emissions ................................................................................................................................. 15

4.5 Electromagnetic Compatibility .................................................................................................. 15

5 Safety and Warning Signs ............................................................................................................ 16

5.1 Symbols and their Meaning ...................................................................................................... 16

5.2 Safety Instructions and Danger Levels ..................................................................................... 17

5.3 Generally Applicable Safety Instructions .................................................................................. 19

5.3.1 Safety Instructions for Thermal Hazards ............................................................................ 19

Operation Manual

Inductive Charging System

ICS115

3

5.3.2 Safety Instructions for Electrical Hazards .......................................................................... 19

5.3.3 Safety Instructions for Handling and Operation ................................................................. 20

5.4 Safety Equipment / Power Limitations ...................................................................................... 22

5.4.1 Overvoltage Protection ...................................................................................................... 22

5.4.2 Mains Protection Input Current .......................................................................................... 22

5.4.3 Overcurrent Protection ...................................................................................................... 22

5.4.4 Thermal Overload Protection (Derating) ............................................................................ 23

5.4.5 HV Interlock....................................................................................................................... 23

5.4.6 Living Object Detection (LOD) ........................................................................................... 23

5.4.7 Foreign Object Detection (FOD) ........................................................................................ 24

5.4.8 Control of the Efficiency .................................................................................................... 24

5.4.9 Enabling the Positioning .................................................................................................... 25

5.4.10 Automatic Shutdown of the Charging Operation ............................................................ 25

5.5 Warnings .................................................................................................................................. 26

5.5.1 Warnings ........................................................................................................................... 26

6 Commissioning and Use of the ICS ............................................................................................. 27

6.1 Installation of the GPM and Commissioning ............................................................................. 27

7 Control and Operation .................................................................................................................. 30

7.1 Use of the CPM and the GPM .................................................................................................. 30

7.2 Use of the Charging Function of the ICS .................................................................................. 30

7.3 Displays and Signals ................................................................................................................ 31

7.3.1 LED Display ...................................................................................................................... 31

7.4 GPM Cooling System Fan ........................................................................................................ 34

7.5 Emergency Situations .............................................................................................................. 34

7.6 Troubleshooting by the User .................................................................................................... 35

8 Maintenance .................................................................................................................................. 36

8.1 Cleanliness............................................................................................................................... 37

8.1.1 Cleanliness of the CPM ..................................................................................................... 37

8.1.2 Cleanliness of the GPM ..................................................................................................... 37

8.2 Behavior after a vehicle accident .............................................................................................. 38

9 Deinstallation ................................................................................................................................. 38

10 Disposal ...................................................................................................................................... 38

10.1 Notes for Customer Service .................................................................................................. 38

Operation Manual

Inductive Charging System

4

ICS115

11 Legal Notices ............................................................................................................................. 39

11.1 Warranty ............................................................................................................................... 39

11.2 Company Names .................................................................................................................. 39

12 Annex A1 .................................................................................................................................... 40

12.1 Technical Specifications of the ICS ....................................................................................... 40

12.1.1 Emissions ...................................................................................................................... 40

12.1.2 Dimensions and Center of Gravity ................................................................................. 40

12.1.3 Dimensions CPM [m m] .................................................................................................... 1

12.1.4 Center of Gravity CPM [mm] .......................................................................................... 42

12.2 Technical Data ...................................................................................................................... 43

12.2.1 Conditions for Storage and Transport of the ICS ........................................................... 44

12.2.2 Conditions for Operation of the ICS ............................................................................... 44

12.2.3 Mechanical Data of the CPM ......................................................................................... 45

12.2.4 Mechanical Data of the GPM ......................................................................................... 45

12.3 Requirements on Specialist Personnel ................................................................................. 45

12.3.1 Specialist Requirements ................................................................................................ 45

12.3.2 Health-related Requirements ......................................................................................... 45

12.4 Information about Protective Equipment ............................................................................... 45

12.4.1 Protective Equipment during Transport and Storage ...................................................... 45

12.4.2 Protective Equipment during Installation ........................................................................ 46

12.4.3 Protective Equipment during Operation ......................................................................... 46

12.4.4 Protective Equipment during Disposal / Deinstallation ................................................... 46

12.5 Preparation of the ICS for Use .............................................................................................. 46

12.5.1 Installation Information ................................................................................................... 46

12.5.2 Placement of the GPM ................................................................................................... 46

12.5.3 Alignment of GPM to CPM ............................................................................................. 46

12.5.4 Optional Installation of the GPM with Mounting Rails ..................................................... 48

12.5.5 Line Connections CPM .................................................................................................. 50

12.5.6 Line Connections GPM .................................................................................................. 50

12.5.7 Planning the Assembly and Installation of the ICS ......................................................... 52

Planning the assembly and installation of the CPM, see Annex 12.7.4. ........................................... 52

12.5.8 Transport and Storage ................................................................................................... 52

12.6 Deinstallation of the GPM ..................................................................................................... 54

Operation Manual

Inductive Charging System

ICS115

5

12.6.1 Procedure for the Deinstallation of the GPM (Information for Customer Service): .......... 54

12.7 Vehicle Integration of the CPM ............................................................................................. 55

12.7.1 Installation Information ................................................................................................... 55

12.7.2 Mounting the CPM ......................................................................................................... 55

12.7.3 Line Connections CPM .................................................................................................. 56

12.7.4 Planning the Assembly and Installation of the CPM ....................................................... 60

12.7.5 Transport and Storage of the CPM ................................................................................ 60

12.7.6 Installation of the CPM ................................................................................................... 61

12.7.7 Deinstallation of the CPM .............................................................................................. 62

13 Annex A2 .................................................................................................................................... 64

13.1 Standards and Legal Requirements ...................................................................................... 64

13.2 DECLARATIONS OF CONFORMITY ................................................................................... 65

13.2.1 SIMPLIFIED EU-DECLARAT IO N OF CONFORMITY ICS115 ....................................... 65

13.2.2 SIMPLIFIED EU-DECLARAT IO N OF CONFORMITY ICS1-WLAN-ATWILC-MU-D ....... 65

14 Index ........................................................................................................................................... 66

15 Glossary ..................................................................................................................................... 68

Operation Manual

Inductive Charging System

6

ICS115

AC

Alternating Current

ICSP

ICS Primary (GPM)

B [T]

ICSS

C [F]

Electrical capacity C in Farad F

LOD

Living Object Detection

CAN

Controller Area Network

LV

Low Voltage

CPM

Car Pad Module

OEM

Original Equipment Manufacturer

DC

P [W]

EMC

ElectroMagnetic Compatibility

R [Ω]

Electrical Resistance in the unit Ohm Ω

f [Hz]

Frequency f in Hertz Hz

RCD

Residual Current Device

FW

Firmware

SSID

Service Set IDentifier

GPM

Ground Pad Module

SW

Software

HV

High Voltage

t [s]

Time t in second s

I [A]

T [°C]

ICS

Inductive Charging System (CPM+GPM)

U [V]

Electrical vo lta g e U in Vo lt V

1 List of Abbreviations

In the course of this manual sever al trade-specific abbr eviations are used. An overv iew as well as their meanings

can be found in the following table:

ABB. DESCRIPTION ABB. DESCRIPTION

FOD

Magnetic flux density B in Tesla T

Direct Current

Foreign Object Detection

Electrical Current Intensity I in Ampere A

s [m]

ICS Secondary (CPM)

Power P in Watt W

Distance s in Meter m

Temperature T in degrees Celsius °C

Operation Manual

Inductive Charging System

ICS115

7

The completeness

2 Foreword

Valued Customer!

With the BRUSA Inducti ve Charging System Model ICS115 you h ave p urchased an induc tiv e charg ing s ystem with

the latest technolog y. Model ICS115 is an inductive chargi ng system of the 1

voltage battery, whic h is s ubs equentl y abbr eviated t o I CS. Sinc e it c oncerns hig h-performance electronic s de vices,

we expect particular caution whe n deal ing w ith it as well as when hand l ing it!

Read through this manual carefully – in particular the chapter entitled Safety and Warning Signs – before you

install the device or perform other work on it!

st

Generation for vehicles with high-

2.1 Content and Scope of this Manual

INFORMATION

In order to successfully commission the s ystem, you require this user manual.

and topicality is ensur ed with provision of the custom er package. Updates of individua l documents

are performed automatically and are visible in a history.

This documentation c onveys to th e reader an o verview of all the work steps required for the insta llation as well as

operation of the system and the safety measures necessary for this.

The specified operation- and safety instructions mus t be observed precisely, in order to continuousl y ensure the

function of the system.

The customer package contains the following registers:

Inductive charging system (ICS), consisting of Ground Pad Module (GPM) and Car Pad Module (CPM)

User manual

2.2 Requirements for handling the User Manual

The user manual must be read and understood by all persons who work with or use the ICS.

All safety instructions at the beginning of a cha pter are valid in equal m easure for all subsequent an d associated

subchapters following the chapter.

As user and also as custom er service of the ICS, familiari ze yourself with the user manual, so tha t you have fast

access to required information. Keep the user manual safe for later reference. Select an appropriate storage

location, so that the user manual is ready to hand and easy to find.

Operation Manual

8

Inductive Charging System

ICS115

ICSS115-U0-01X-Xxx (CPM, 2-HV-Connectors)

3 Identification of the Produc t ICS

3.1 Product Identification

This manual is valid exclusively for the devices listed in the following table:

ICS1 WITH THE FOLLOWING DEVICE DESIGNATIONS

ICSP11W-U0-01X-Xxx (GPM)

3.2 Explanation of the code for the product identification

The breakdown of the device designation for the complete system, the GPM and the CPM, is as follows:

GPM:

Operation Manual

Inductive Charging System

ICS115

9

Delivery

D, A, CH

BMW Customer Support

CPM:

3.3 Service- and Contact Data

TYPE OF INQUIRY COUNTRIES CONTACT DATA

Help and Support

Deinstallation and Disposal

D–80788 Munich

Germany

Tel: +49 89 1250-16000

kundenbetreuung@bmw.de

10

Operation Manual

Inductive Charging System

ICS115

QUANTITY

1

Ground Pad Module (GPM)

1

2

Car Pad Module (CPM)

1

3

Original Operation Manual

1

3.4 Scope of Supply

The following items are included in the scope of supply of the ICS system

DESCRIPTION

ILLUSTRATION

Operation Manual

Inductive Charging System

ICS115

11

Note:

The Car Pad Modules of th e possib le var iants f rom chapter

function with all Ground Pad Modu les

(GPM) of the ICS.

Risk of injury from electromagnetic field!

With inductive charging an electromagnetic field is generated under the vehicle.

Cardiac pacemakers and medical implants can be affected.

Do not reach underneath the vehicle or perform maintenance work during the charging process.

4 P roduct Description of the ICS

4.1 Scope of Application

The ICS consists of t wo separate devices. The Gr ound Pad Module (GPM) thereb y forms that part connected to

the power supply net work , which trans mits the en ergy to th e Car Pa d Module (CPM) int egrated i n the veh icle. T he

communication between GPM and CPM is automated and takes place via WLAN.

NOTE

3.1

4.1.1 User Description

The user group of the system ICS includ es a ll per sons who are able to operate a v ehic le. T he us er of the system is

responsible for the observance of and com pliance with the saf ety instructions conta ined in this user m anual. The

user is also respons ible, that persons in his environment, in particular all per sons who come int o contact with the

ICS, are knowledgeab le of and familiar with the safety instructions in this user manual. The user must indicate

possible hazards d ue to the IC S to o ther persons . H e m ust ther eb y ensure, that indi vidual, part icularl y enda ngere d

persons, e.g. children and disabled persons, have understood the safety instructions – or on the other hand

ensure, that access to the ICS is not possible for these persons.

All activities that concern the installation, commissioning and deinstallation / disposal of the ICS may only be

performed by specialist personnel. The specialist personnel or qualified electricians must satisfy the specialist

requirements specified in chapter 12.3.

4.1.2 Health Hazards

WARNING

12

Operation Manual

Inductive Charging System

ICS115

The electromagnetic radiat ion of the ICS remains within the legall y permitted limits. During the charg ing process,

the following groups of people are exposed to increased health risks in the vicinity of the ICS:

People with active medical implants (e.g. cardiac pacemakers, defibrillators)

People with passive medical implants (e.g. stents)

People with electric ally conductive forei gn objects in their bod ies (e.g. metallic splinter s from accidents / war

injuries)

4.1.3 Proper Intended Use

It is not permitted to use the products in any way other than the intended way described in section 4.1.4.

4.1.4 Proper Intended Application

The ICS is a system for the cordless transmission of energy and is designed to be integrated in an electric or hybrid

vehicle with high-volta ge battery. The pr oduct ICS is designed exc lusively for us e under consider ation of th e limits

specified in chapter 12.2.1 and 12.2.2.

With a planned use in areas other than those previou sly defined, the purchas er shall be obliged t o coordinate this

accordingly in advance with the manufacturer and obtain a written release for this.

4.1.5 Improper Use

All applications that ar e not included in the intend ed u se des cribed by the m anuf acturer in 4.1.4 are to be re garde d

as improper use.

The device must not be used, in particular

for charging vehicles that do not use the ICS as charging function

for charging accumulators / batteries of devices, that are also based on an inductive charging function, e.g.

electric toothbrushes, Smartphones

to replace the function of an induction hob, e.g. heating meals by using pots / bowls / grilling appliances

for drying objects (e.g. skiing equipment) or living things (e.g. pets)

for the use for functions other than the function of charging, e.g. as seating surface or for sports activities,

such as skateboarding.

The following areas must not be used as charging station, i.e. for the installation of the GPM:

public parking places and parking lots

Under consideration of the proper intended uses specified in chapter 4.1.4, limits have been defined for the

storage, transport and oper ation of the ICS pro duct, see chapter 12.2.1 and 12.2.2. T he product m ust not be used

outside these limits within the respective life phases. Modification of products.

It is not permitted to undertake modifications to the product and then continue to use the product.

Operation Manual

Inductive Charging System

ICS115

13

4.1.6 Delimitation

This operation manua l d es c ribes the s af e han dl ing with the Inductive Char g in g S ystem in all phases of lif e. BR U SA

Elektronik AG accepts no liability for the incomplete passing o n of information fr om this document, in p articular to

those persons from the target group defined in chapter 4.1.1 and any damage resulting therefrom.

4.2 Functionality

The ICS consists of two separate devices. T he Ground Pad Module (GPM) th ereby forms that part conne cted to

the power supply network , which transmits the energy to the Car Pad M odule (CPM) integrated in the vehic le by

means of magnetic induction. The communication between GPM and CPM is automated and takes place via

WLAN.

Basically the charging process takes place in these steps:

• The vehicle parks over the GPM with the help of the positioning function with optimal coverage between

GPM and CPM.

• The charging process is started automatically from the vehicle and also ended automatically.

• After the charging process the battery is charged according to the charging time and the charging

efficiency. The vehicle is read y to use.

Operation Manual

Inductive Charging System

14

ICS115

4.2.1 Energy Efficiency

The energy efficiency is generally dependent on the parking position of the vehicle over the GPM during the

charging process. Max imum efficiency is ac hieved when you park in the optimal positi on range. The efficienc y of

the charging process d epends, among other things, on the param eters of the drive battery (e.g. perf ormance and

charging cycle) of the vehicle in which the ICS is installed.

4.3 Requirements of the ICS

The CPM is maintena nce-fr ee and does not requir e an y supply m aterials, suc h as coolan t, lubrica nts, etc . For the

cooling of the GPM, a ir circulation is a pr erequisite, in particular during the chargin g process. Regular cle aning of

the fan intake duct and keeping the GPM clean extends the service life of the charging system, see chapter 8.1.2.

4.4 Emissions

The ICS has a fan whic h causes a noise level during operation. No ha zardous chemical s ubstances are emitted.

The transmission of energy of the ICS as well as the positioning functionality are based on the principle of magnetic

induction. In addition WLAN is used for the communication between the two components CPM and GPM.

Associated with this are e missions due to electromagnet ic radiation. The charac teristic values of these em issions

are to be taken from Table 1: Emissions.

4.5 Electromagnetic Compatibility

The ICS system m eets the requirements on the electromagnetic e nvironmental compatibility without cons traints,

see No. 11 – 15, 22 in Table 3: Stan dards. Normall y no disturbances that unaccept ably impair the functio nality of

other electrical operating equipment are caused through the use of the ICS. Nevertheless, a disturbance of Comfort

Access Systems of adjacent vehicles cannot be excluded, since both systems are based on the use of WLAN.

Operation Manual

Inductive Charging System

ICS115

15

General prohibition

Attention high voltage

Switching prohibited

No access for people with cardiac

Warning of potentially explosive

Warning of dangers from batteries

Warning of non-ionizing radiation

Warning of the risk of fire

5 S a f e ty and Warning Signs

In this chapter you will fin d s afet y instruct ions that m us t be tak en int o cons iderat ion in a ll lif e phases of th e s ystem .

Read and observe thes e instructions witho ut fail, in order to saf eguard the safet y and the life of peop le as well as

avoid damage to the device!

5.1 Symbols and their Meaning

Various symbols are used throughout this manual. An overview as well as their meanings can be found in the

following tables:

PROHIBITORY SIGNS

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

Touching prohibited

pacemakers or implanted defibrillators.

WARNING SIGNS

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

General warning of a hazard point

environment

Warning of hot surface

Warning of magnetic field

Warning of electric shock

Warning of high electric voltage

Warning of hot surfaces

16

Operation Manual

Inductive Charging System

ICS115

MANDATORY SIGNS

Disconnect device

Disconnect device from the mains

Wear safety glasses

Wear protective gloves

Important information for the avoidance of

Important Information

This sign warns of serious, irreversible risks of injury with possible fatal consequences!

Avoid this danger by observing this notice!

This sign warns of a serious, but reversi b le risk of injury!

Avoid this danger by observing this notice!

This sign warns of a minor risk of injury!

Avoid this danger by observing this notice!

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

INFORMATION SIGNS

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

possible material damage

5.2 Safety Instructions and Danger Levels

DANGER

WARNING

CAUTION

NOTICE

This notice warns of possib le material damage, if the following instructions and work sequences are

not observed.

Operation Manual

Inductive Charging System

ICS115

17

This type of notice is used to communicate important information for the reader.

INFORMATION

18

Operation Manual

Inductive Charging System

ICS115

Explosive Environment!

Do not store

devices! The generation of sparks at the device connections can ignite these materials and lead to an

explosion!

Hot Surfaces!

The devices

with caution!

High Voltage!

Do not touch HV

beforehand!

The device may only be connected by a qualified electrician!

Do not bridge or bypass safety equipment under any circumstances! Resulting malfunctions can have

life

Overheating the cable!

Mains connection cables must not be operated coiled up. In the coiled up state the cable can ignite

due to a build

5.3 Generally Applicable Safety Instructions

5.3.1 Safety Instructions for Thermal Hazards

DANGER

Danger to life!

any highly flammable substances or combustible liquids in the immediate vicinity of the

CAUTION

Risk of burning!

generate high temperatures during operation! Therefore always touch them carefully and

5.3.2 Safety Instructions for Electrical Hazards

Danger to life!

-lines or HV-connections under any circumstances without ensuring zero voltage

-threatening consequences!

Risk of fire!

DANGER

CAUTION

-up of heat! Therefore basically uncoil the mains connection cable completely!

Operation Manual

Inductive Charging System

ICS115

19

Basically observe the following 5 safety rules when working on the HV network:

Completely de

Secure system against

switch against restarting with lockable cover cap.

Establish zero voltage with suitab le volta

Ground and short

Cover or cordon off adjacent live parts.

Danger of electric shock!

In the operating state the ICS is subjected to high voltages and currents. If the device is damaged it is

possible, that live components are exposed. People can come into contact with these components.

It is therefore absolutely imperative to operate the

which monitors exclusively the function of the GPM.

Heating of foreign objects during the indu ctive transmission of energy!

Electrically conducting objects inside the charging magnetic field can heat up considerably, and under

certain circumstances can lead to damage / ignition of other materials. Therefore during the charging

process

GPM Magnetic Field!

No person must connect a GPM to the power supply without knowing the safety

A GPM may only be connected to the power supply, when all persons who are

are aware of the potential dangers.

INFORMATION

-energize the system.

Switch off the ignition

Pull out service- / maintenance plug or switch off main battery switch

Remove fuse

restarting.

Keep ignition key secured against unauthorized access.

Keep service- / maintenance plug secured against unauthorized access or secure main battery

ge tester (observe voltage range!)

-circuit system.

5.3.3 Safety Instructions for Handling and Operation

DANGER

GPM via a separate residual current device (RCD),

WARNING

Risk of fire!

there must be no objects between CPM and GPM.

WARNING

Danger for living beings and objects!

- and warning signs.

working near the GPM

20

Inductive Charging System

Operation Manual

ICS115

Strong magnetic field (non-ionizing radiation)!

Effect on living beings!

During

the limits for long

In order to exclude acute effects, such as muscle

damage, no

charging

In addition, jewelry (rings, wristwatches, etc.) can heat up considerably and become damaged or lead

to burns.

People with a cardiac pacemaker, implanted defibrillator or other implants should keep away from the

vicinity of the system during the charging

Keep animals away from the system during operation.

Damage to the HV-Battery:

Damage to the devices:

the charging process there is a strong magnetic field between CPM and GPM, which exceeds

process.

-term exposure of living beings.

body parts may get into and around the space between the GPM and CPM during the

DANGER

- and nerve stimulation, as well as conseque nti al

process.

NOTICE

Make sure, that the voltage ranges of the device and the HV-battery are identical!

Use only technically suitable and high-quality cabling! In case of uncertainties, please contact

BRUSA Elektronik AG beforehand at the manufacturer address specified in chapter 3.3.

NOTICE

Regularly check the GPM for defects and report defects or damage to your customer service.

A visibly damaged GPM must be replaced, in order to exclude the risk of injury. Do not touch

an obviously damaged GPM under any circumstances

Check generally when connecting the GPM, that the mains voltage is in the permissible range

(see chapter 4.2.1)!

Do not establish a low-resistance connection between the HV contacts, the housing- as well

as the LV-contacts under any circumstances! This leads to malfunctions and ultimately to the

destruction of the device!

The components of the ICS must not be opened under any circumstances!

Do not install and operate the GPM in the immediate vicinity of heat sources!

A high ambient temperature reduces the service life! Therefore continuously ensure for

sufficient cooling of the device!

Prevent any penetration of liquids in the device (e.g. during installation work)! The penetration

of liquids leads to a short circuit and subsequently to damage of the device!

If any liquid has entered, do not start the device again under any circumstances and contact

your customer service!

Operation Manual

Inductive Charging System

ICS115

21

Danger for persons due to strong magnetic field (non-ionizing radiation)!

5.4 Safety Equipment / Power Limitations

The charging system has several safety functions in order to avoid personal injur y and material damage during

commissioning, operation and maintenance of the system. Essentially these are

• Monitoring of the electrical limits

• Monitoring the operating temperatures

• Foreign object detection

• Living object detection

• Monitoring the efficiency

• Positioning only with connected HV-battery

DANGER

During the charging process it is not permitted under any circumstances to move/shift the GPM.

5.4.1 Overvoltage Protection

An overvoltage protec tion is integra ted in th e GPM, whic h continuous ly protec ts the device f rom overload dam age.

Overvoltages in the mains are detected by the fast sensor system and lead to the shutdown of the device.

An overvoltage protec tio n i s als o int egrat ed at the output side. B y m eans of the fas t s ensor system, overvoltages at

the HV-battery side (e.g. load shed ding or -fluctuations) are detected and lead to the shutdown of the charging

device.

5.4.2 Mains Protection Input Current

In the GPM the phase and the neu tral conductor are each protected b y a 25 A device fuse, in order to pr otect the

device and the electrical installations from damage due to overcurrent. If these fuses are defective, then the

relevant device must be sent back to the manufacturer (see manufacturer address in chapter 3.3 )! Contact

customer service.

5.4.3 Overcurrent Protection

NOTICE

It is prescribed to insert suitable overcurrent protection between CPM and HV-battery of the vehicle!

22

Operation Manual

Inductive Charging System

ICS115

An overcurrent protec tion is integrat ed in the CPM, which contin uously protects the chargin g device from overload

damage. Overcurr ents are detect ed by the f ast sensor system and, depending on the streng th, are either reduced

or lead to the shutdown of the charging process.

5.4.4 Thermal Overload Protection (Derating)

This safety equipment is s elf-protection of the system. If an internal component of the GPM or the C PM reaches a

defined temperature thr eshold, this causes a reduct ion of the charging capacit y (Derating), in order to protect the

component and consequently the device from damage due to overheating. As a result the capacity is reduced

proportional to the tem perature incre ase, in order to k eep the temper ature in the target range. The GP M regulates

the fan according to the temperature and ensures for additional cooling of the GPM.

The CPM and the GPM notif y their respective Derati ng-Status in the CAN, as well as the capacity reduct ion as

percentage. W hen the CPM goes into dera ting, the GPM reduces t he transmission power. If the measures tak en

above do not achieve the desired success, this leads to a shutdown of the charging system.

If the temperature is increased due to external effects independent of the charging system and the energy

transmission proces s, then the function of the seco ndary systems can also only b e used to a limited degree or

cease their function temporarily. This concerns the systems Positioning, WLAN, CAN and Diagnostic Function.

5.4.5 HV Interlock

The Interlock is a saf ety loop in the vehic le, which monitors the drive compone nts. On the CPM the HV -side plug

connections can be m onitored with this. The wiring of the Interlock-Pins is not func tionally relevant for the CPM,

however to guarantee the safety we definitely recommend using an interlock system!

5.4.6 Living Object Detection (LOD)

Operation Manual

Inductive Charging System

ICS115

DANGER

23

Danger for persons due to magnetic field (non-ionizing radiation)!

Danger for persons due to magnetic field (non-ionizing radiation)!

Danger for persons due to magnetic field (non-ionizing radiation)!

This function does not replace the attention of the user, to keep away from the charging station

during the charging process!

It can happen, that bod y parts or living beings are n ot detected by the LOD f unction and as a res ult

the protection from electromagnetic hazards is restricted!

The LOD function ensures, that body parts of people or animals are detected in the space between GPM and CPM.

This safety function protects people or animals from the dangers of the strong electromagnetic field, with the

charging process stopping when a living object is detected. It depends on the vehicle integration, whether the

charging process is resumed automatically as soon as the living object is no longer detected by the GPM.

5.4.7 Foreign Object Detection (FOD)

DANGER

This function does not replace the duty of the user, to keep the charging station free of foreign

objects!

It is possible, that cer tain foreign objects are not detected by the FOD functio n and as a result the

protection from thermal dangers is restricted!

The FOD function ensures, that there are no electr ical l y conduc t ing f orei gn obj ec t s on the GPM during the charging

process. Electrically conducting objects are relevant, as they can experience heating through electromagnetic

induction in the e lectromagnetic f ield. This function st ops the charging process when a foreign object is detected.

This safety function prevents a heating up of electrically conductive foreign objects during the charging process and

consequently reduces thermal dangers, such as e.g. fire or hot surfaces.

This function must be initialized during commissioning and after mains failures, see 7.3.1.2. In rare cases this

initializing can also be necessary during normal operation, see 7.3.1.2.

5.4.8 Control of the Efficiency

DANGER

This function does not replace the duty of the user, to keep the GPM free of foreign objects!

It is possible, that certain foreign objects are not detected due to the function of the Efficiency Control

and as a result the protection from thermal dangers is restricted!

If the efficiency falls below a certain limit value, e.g. due to the vehicle rolling away during charging, then the

charging process is shut down. As a r esult it is ens ured, that no energ y is transm itted to the system environment.

This safety function also pr events the he ating of electr ically conduc tive foreig n objects during the charging pr ocess

and thus reduces thermal dangers, such as e.g. fire or hot surfaces.

24

Operation Manual

Inductive Charging System

ICS115

5.4.9 Enabling the Positioning

With this safety function it is ensured, that no electrical voltage is present on the HV-outputs of the CPM (see

chapter 12.7.3), if the connections are not connected. Vice versa, voltage can only be present on the HVconnections of the CPM, if they are connected with a voltage source of 170 V (e.g. through connection to the

vehicle drive battery). This prevents people getting an electric shock by touching the connections.

5.4.10 Automatic Shutdown of the Charging Operation

With the occurrence of one of the following conditions, the ICS terminates the charging operation:

Detection of a foreign object (FOD) during charging

Detection of a living object (LOD) during charging

Overvoltage on the CPM HVDC-connector (> 450 V or greater than the specified maximum value)

Undervoltage on the CPM HVDC-connector (< 170 V)

Separation of the Interlock circuit

Missing CAN commanding to the CPM

Failure of the 12 V supply of the CPM

Short circuit on HVDC

Failure of the mains voltage

Voltage jumps on HVDC

Voltage drop AC-mains supply

Fault of the WLAN-connection

Overtemperature of the CPM (> 120°C)

Overtemperature of the GPM (> 85°C)

Load Dump (load shedding)

Charging capacity < 500 W

Mains failure (no independent restart of the energy transmission when the mains supply returns)

Communication failure between GPM and CPM

Communication failure bet ween CP M and veh icle-CAN (Vehicle-CAN, VCAN)

With a change of position of the CPM until the device is no longer physically able to transmit energy

Malfunction in the device

Operation Manual

Inductive Charging System

ICS115

25

5.5 Warnings

5.5.1 Warnings

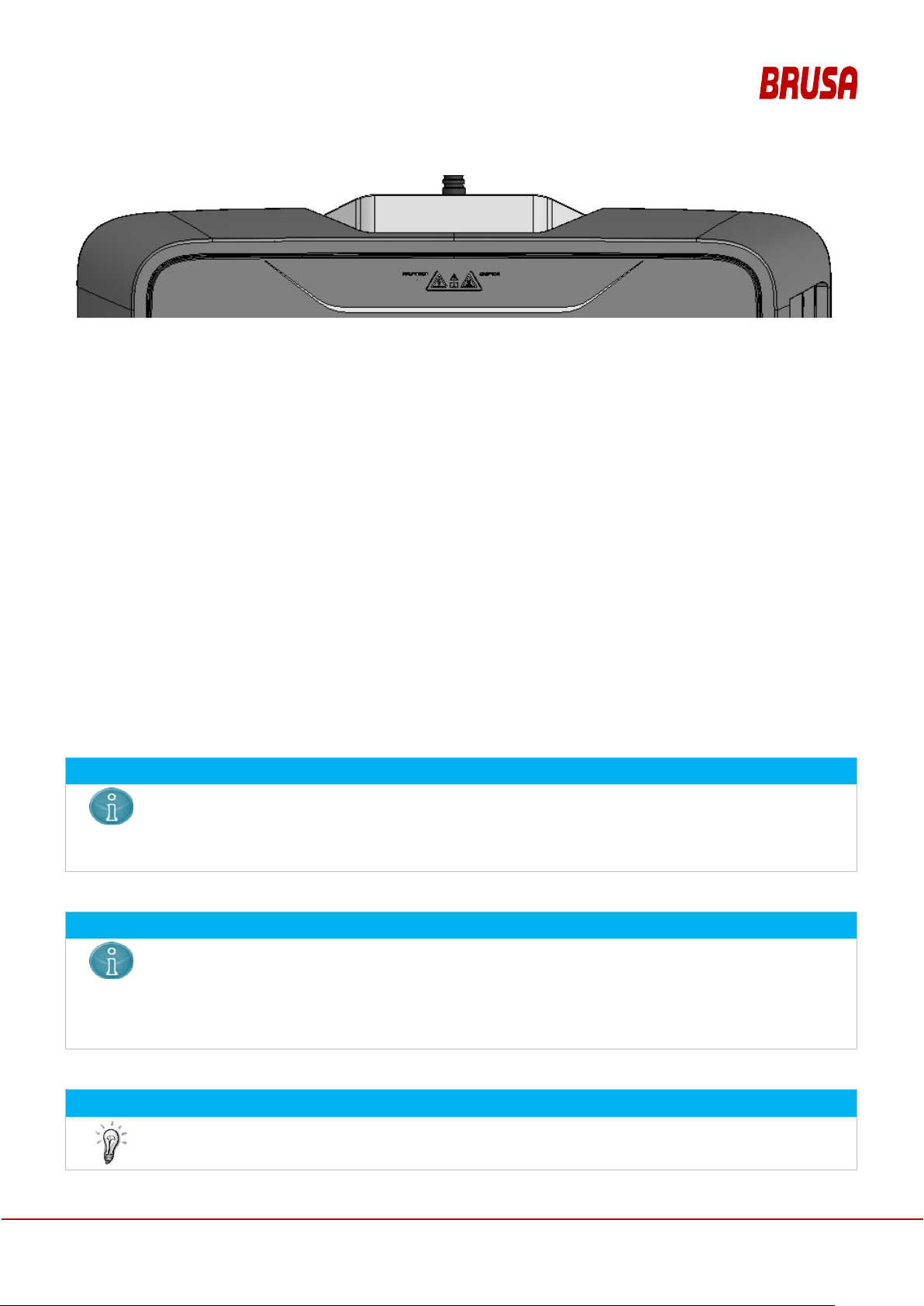

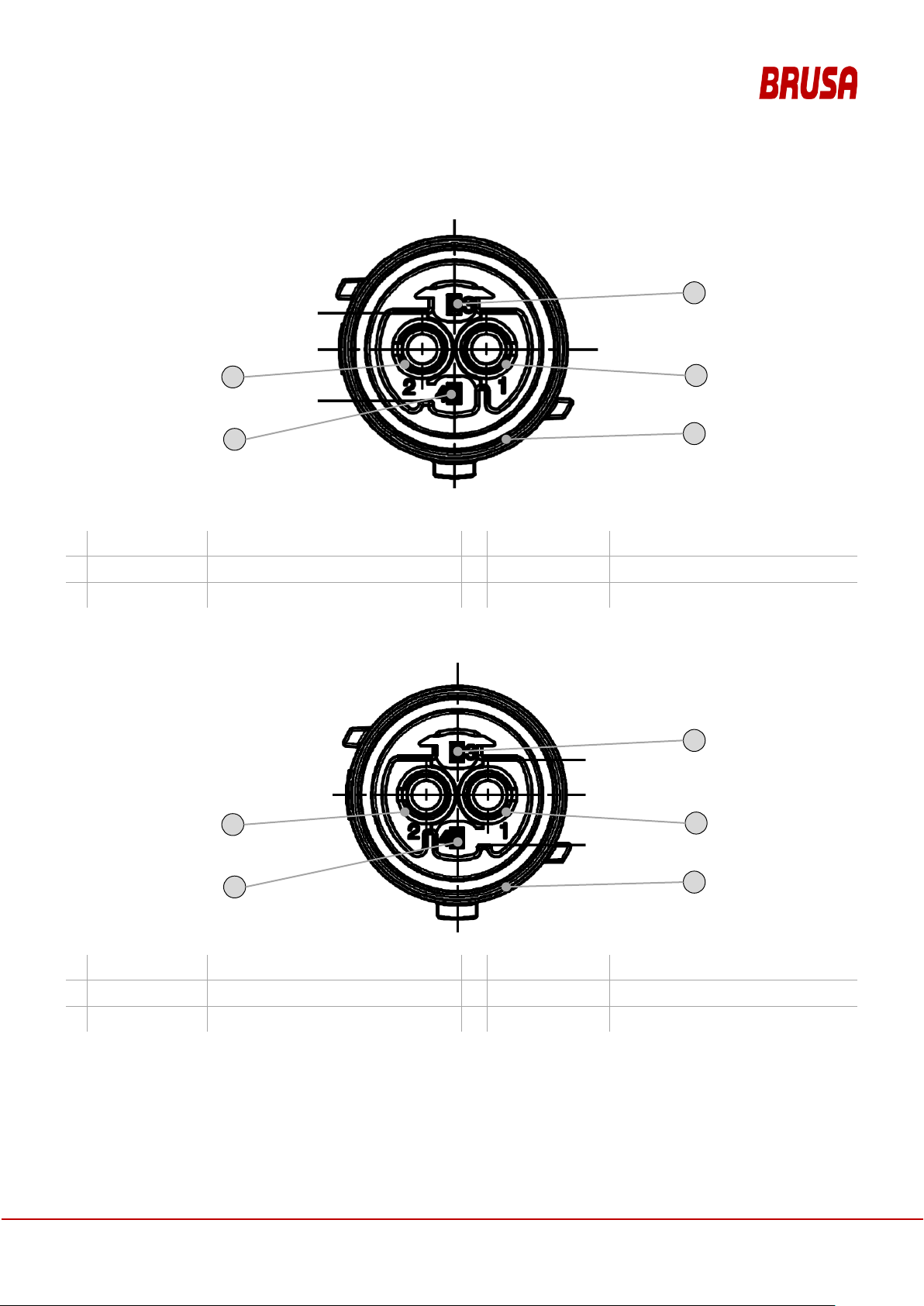

Warning signs are attach ed to the devices, which warn the operator of possible dangers. On the GPM there are

warning notices and a ratin g plate on the underside. In addition, encl osed in the GPM ser vice flap there is a rating

plate as well as inform ation about which types of cables are suitable for the co nnection of the power suppl y and

which temperature res istance is required for these cables. If one of these warning signs is missing or no longer

legible due to wear, it must be renewed immediately! To obtain an original label, please contact your customer

service!

Figure 1: Warning notice (colored) on GPM underside (left) and CPM (right)

26

Operation Manual

Inductive Charging System

ICS115

The installation of the GP M may only be carried out by a qualif ied electrician. In particu lar, country-

The GPM must be installed flat and level on the floor. A sinking of the GPM into the floor is not

Visually inspect the packaging material and in particular the GPM itself for damage before

Figure 2: Warning notice (black/white) on GPM top side

6 Com m issioning and Use of the ICS

The commissioning of the ICS assumes, that there is a suitable electrical connection available. The CPM is

mounted on the vehicle. T he GPM is insta lled b y the ser vice of the v ehicle m anufac turer at the i nstal lation lo cation .

The steps necessar y for this are des cribed in the anne x. Af ter the inst allation of the GPM it is c omm issioned b y the

service and thereby its functionality is explained.

6.1 Installation of the GPM and Commissioning

The installation of the CPM is the respo nsibilit y of the veh icle m anufactur er or his s ervice, see c hapter 12.7.6. The

installation of the G PM may only be carried o ut b y a q ualified electrician. T he commissioning s hou ld be u nd er taken

together with the user, in order to familiarize him with the functio n of the ICS, in particular with the LED flashing

patterns.

NOTICE

specific regulations f or electr ical lines an d instal lations ar e to be obs erved. For Am erica the Nationa l

Electrical Code NF PA 70 is to be com plied with, and in Cana da the Canadian E lectrical Code CSA

C22.1.

NOTICE

permitted. Protect the m ains connection cable with suitabl e floor mounted ducting resistant to overrolling. Due to its over all height, the GPM repr esents a tripping ha zard. Therefore do not insta ll the

GPM on footpaths or routes that you use frequently.

Ensure for sufficient lighting during installation, operation and deinstallation.

INFORMATION

installation. Ever y GPM undergo es a stric t quality- and func tion control before deli very. Howev er we

Operation Manual

Inductive Charging System

ICS115

27

have no influence on the long transport routes in some cases and the loading activities of our

Mains Voltage!

During installation of the GPM there exists a danger to life from electric shock, if the connection

For the installation you require:

Access to the circuit breakers with 16 A fuse and residual

During planning please no te, that the

GPM is monitored by a separate

residual current device. No other

device may be operated in parallel on the

supply line protected by the residual current

device.

nformation for the tra nsport

of the GPM in chapter

Observe the information for the

installation of the GPM in chapter

(Position to the CPM,

Requirements of the vehicle manufacturer,

Request of the user).

Connect the cable with the GPM.

Ensure safe and secure laying of the cable from the power

Avoid posing a tripping hazard due to

Use resources such as floor-mounted

ducting or similar to avoid tripping

products.

DANGER

sequence is not observed!

Make sure before commencing work, that the power connection is voltage-free!

Make sure, that ther e is an overcurrent protection device and a residual current dev ice (Type A) in

the connected current circ uit of the GPM! T he residual current dev ice may only monitor the f unction

of the GPM.

Check the residual curr ent dev ice by pressing the test butto n! Do not perform t he ins tal lat ion, if thes e

electrical safeguards are missing or are not functional!

Follow the prescribed work sequence without fail!

Do not act recklessly or impetuously under any circumstances!

WORK STEP ILLUSTRATION / OTHER INFO

current device (RCD) Type A

- Customary local mains cable of sufficient length with at least 1.5

- Floor-mounted ducting res istant against being run over for the

- GPM

Bring the GPM to the required des tination. Separate t he GPM from

the rest of the packaging material.

Determine the position of the GPM by applying the conditions for

the installation.

2

mm

line cross-section

protection of the mains cable.

Observe the i

12.5.8.2.

12.5.7.1

connection to the GPM.

protruding cable.

28

hazards.

Inductive Charging System

Operation Manual

ICS115

WORK STEP ILLUSTRATION / OTHER INFO

Make sure, that there are no foreign objects in the charging area.

Switch the power supply for the GPM on and check the residual

availability of the user for

instruction in the use of the device and the

dangers that can emanate from the ICS.

Initialize the foreign-/living object detection:

it again after 10sec. If there is no vehicle in the vicinity which is

The GPM now sends WLAN signals to vehicles in the reception

If the vehicle with functional CPM is in the transmit range of the

installed GPM, then the vehicle must be m ade known to the GPM.

practice this takes place as follows

In the vehicle display a list of all GPMs in the reception

Position the vehicle o ver the GPM, so that the CPM and GPM are

optimally overlaid. If the vehicle sends a request for charging and if

the request is success ful, then you see that on t he GPM b y the LED

flashing pattern, see

The preconditions for t he start of the c har ging

process are OEM

Wait a few minutes while t he vehicle charg es. Then place a sui table

foreign object (metallic, app rox .

GPM

and the LED on the GPM should flash, see

. After removing

the inserted object the charging process should be resumed, see

7.3.1.5

Remove the vehicle from the area in which char gin g is poss ible. T he

status of the GPM should c hange to the status CONNECTED, see

7.3.1.4

the GPM, or the GPM s witches to the status NO T CONNECTED, if

the vehicle should not have any W LAN rec eption fr om the GPM, s ee

7.3.1.3

Connect the cable with the power connection.

On the GPM the LED should not l ight up, in other words OF F, see

7.3.1.1.

current device. If the GPM is supplied with mains voltage, then as

next step the LED signals the initialization of the foreign-/living

object detection, see

Place an approx. 5cm large m etallic objec t on the GP M and rem ove

suitable for the ICS chargin g s ystem, then t he GPM fla shes with t he

appropriate pattern

range, but is not yet connected with any vehicle.

1.

range of the CPM is displayed.

2. The required GPM is selected

3. The password for the selected GPM is entered.

Once this step is suc cessfull y concluded, then th e LED of the GPM

flashes with the pattern CONNECTED, see 7.3.1.4

7.3.1.2.

7.3.1.3

In

:

Note the

7.3.1.5.

5cm diameter) in the space between

and CPM. The charging process should then be interrupted

7.3.1.7

.

, insofar as the vehi cle is still sensed in the transmit range of

Operation Manual

Inductive Charging System

ICS115

-specific.

29

The ICS has onl y one LED display, which signa ls important states of the GPM. Obs erve all safety

instructions and warnings in the user manual without fail!

Scrutinize the instructions of the positioning display in your vehicle!

Physical Limits. Within the octagon described above, energy is transmitted with a high level of

Take into consideration the properties and parameters of the CPM and GPM, if you have

modifications carried out on the vehicle or perform them yourself!

Please note, that material damage to the vehicle or ICS is possible, if modifications to the vehicle

(t

7 Cont rol and Operation

NOTICE

7.1 Use of the CPM and the GPM

The charging process between GPM and C PM functions autom atically and does not nee d to be controlled. Used

on its own, the CPM exec utes no function; without the pres ence of the CPM the GPM merely onl y detects foreign

objects and otherwise does not execute any function when used on its own.

7.2 Use of the Charging Function of the ICS

Observe the warnings in 5.3.3 Safety Instructions for Handling and Operation

NOTICE

It is possible, that strict compliance with the positioning leads to m aterial damage to the vehicle! A

faulty positioning display or incorrect position of the GPM, e.g. due to the GPM shifting on the

ground, can lead to damage to your vehicle during the parking process!

Therefore always obser ve the signals of the park ing assistance of your veh icle! Give these signals

precedence over the positioning signals of the ICS!

NOTICE

efficiency. Outside the octagon limitations in the charging performance are to be reckoned with:

- Reduced efficiency

- Reduced transmission power

- Reduced charging voltage range

- Increased charging time

NOTICE

uning, lowering the vehicle) are undertaken.

Inductive Charging System

30

Operation Manual

ICS115

WORK STEP ILLUSTRATION / OTHER INFO

1

Observe the instructions for keeping the GPM clean in

2

Position the CPM above the GPM or position

your vehicle with the help of the positioning

On the GPM the LED should flash with the

pattern according to

Observe the instructions. Avoid dam age to your veh i c le

3

Start the charging process by following the

instructions on the user interface of your

If the charging process does not start, follow the

off

on

Make sure, that the GPM is free of objects.

function.

7.3.1.4.

vehicle. On the GPM the L ED should f lash with

the pattern according to

7.3.1.5.

7.3 Displays and Signals

chapter 8.1.2.

due to positioning malfunctions.

troubleshooting instructions in chapter 7.6 or contact

customer service.

7.3.1 LED Display

On the service flap of the GPM there is an LED, which indicates the operating status and error states.

7.3.1.1 Status: Off

The GPM is without power or defective. After unpacking the GPM, the LEDs are off. Likewise after installation

before the circuit break er has been switched on. If the LEDs remain off after the GPM is work ing, then there is a

defect. In this cas e, ch eck that neither the c ircuit br eak er nor the r esidua l curr ent device inter rupt the p ower s uppl y

to the GPM.

Figure 3: Flashing pattern in status Off

7.3.1.2 Status: Initialization Foreign-/Living Object D etection

For safety reasons during running operation, the GPM monitors that there are no living or foreign objects between

GPM and CPM. For this safety function a re-initialization may be necessary. In the status Initialization Foreign/Living Object Detection, charging the vehicle is not possible, because the GPM can no longer safely evaluate,

whether an object is present or not.

If the GPM requires an initialization of the foreign-/living object detection, you recognize this by this flashing pattern:

Operation Manual

Inductive Charging System

ICS115

31

off

on

0,25s

0,25s

0,25s

0,25s

0,25s 4s

off

on

2s

0,1s

0,1s

2s

off

on

Figure 4: Flashing pattern in status Initialization Foreign-/Living Object Detection

In practice this initialization is carried out by making sure that there is no object lying on the GPM surface. Then

place an approx. 5cm large piece of metal (e.g. 5cm large steel disk, beverage can, etc.) on the GPM and remove

it again after 6-9sec. The initialization of the foreign-/living object detection is possibly required

• after the GPM is switched on or after a mains failure,

• during the operation

7.3.1.3 Status: Not Connected

The GPM is in this status, when the power supply for the GPM has been switched on, the initialization of the

foreign-/living object detection has already been performed, but there is not yet any vehicle nearby, which is

suitable for charging with the GPM.

Figure 5: Flashing pattern in status Not Connected

7.3.1.4 Status: Connected

If a suitable vehicle ( with CPM) is c onfigured f or charging with the GPM an d if this vehicle is near the GPM, then a

WLAN connection is estab lished between CPM and GPM. The c harging process is controlled autom atically from

the vehicle via this WLAN connection.

Figure 6: Flashing pattern in status Connected

32

Operation Manual

Inductive Charging System

ICS115

7.3.1.5 Status: Charging / Energy Transmission

off

on

2,5s

2,5s2,5s

2,5s

2,5s 2,5s

off

on

0,25s

0,25s 0,25s

0,25s

0,25s

0,25s 0,25s

0,25s

0,25s

0,25s 0,25s

0,25s

0,25s

off

on

0,25s

0,25s

0,25s

4s

If the vehicle (with C PM) is in the optimal park ing position , then the ch arging proc ess is started a utomaticall y. The

energy transmission from GPM to the vehicle is signaled by means of LED with this flashing pattern.

Figure 7: Flashing pattern in status Charging / Energy Transmission

7.3.1.6 Status: General Error

With an error the LED flas hes with this pattern. Atte mpt to rectif y the error as described in 7.6 Troubl eshooting by

the User.

Figure 8: Flashing pattern in status General Error

7.3.1.7 Status: Foreign Object Detected

If a foreign object is detected during char g ing, the n th e c hargi ng pr oc ess is inter r upte d f or safety reasons. The LED

signals this with this pat tern. In this case chec k the GPM and m ake s ure, that the GPM is free of f oreign obj ects of

any kind.

Figure 9: Flashing pattern in status Foreign Object Detected

Operation Manual

Inductive Charging System

ICS115

33

off

on

0,25s

0,25s

0,25s

0,25s

0,25s

0,25s 0,25s 4s

Development of smoke or fire in

the charging environment

1.

2. Remove yourself and if neces sary other persons immediately from the source

of the fire and from the surroundings! Do not use the vehicle in the charging

station for this!

3.

4.

5.

Feeling of numbness in the

extremities

1.

2.

3.

Feeling unwell

1.

2.

3.

If a foreign object is det ected incorrec tly, although the GPM surfac e is free, then a reset of the G PM is necess ary,

i.e. the GPM mus t be disconnected from the power supply until the LED goes out. After switching the GPM on

again, a renewed initializat ion of the FOD is possibly necessar y, see 7.3.1.2 Stat us: Initialization Foreign-/Living

Object Detection.

7.3.1.8 Status: Cooling Fan Blocked

The GPM is reliant on a sufficient circulation of air, in particular during the charging process. If the fan duct is

clogged, and the fan is bl ock ed, then you recog nize thi s on the L ED with th is pat t ern. In th is case pl ease che ck the

cooling duct and clean it as required.

Figure 10: Flashing pattern in status Fan Blocked

7.4 GPM Cooling System Fan

Noise can be caused by the cooling function of the fan. The device is protected f rom overheating by an internal

function. Please treat the fan with care and observe the instructions f or cleaning, see section 8.1 Cleanliness. In

particular clean the fan intake duct regularly. Do not use any high-pressure cleaner, such as e.g. Kärcher!

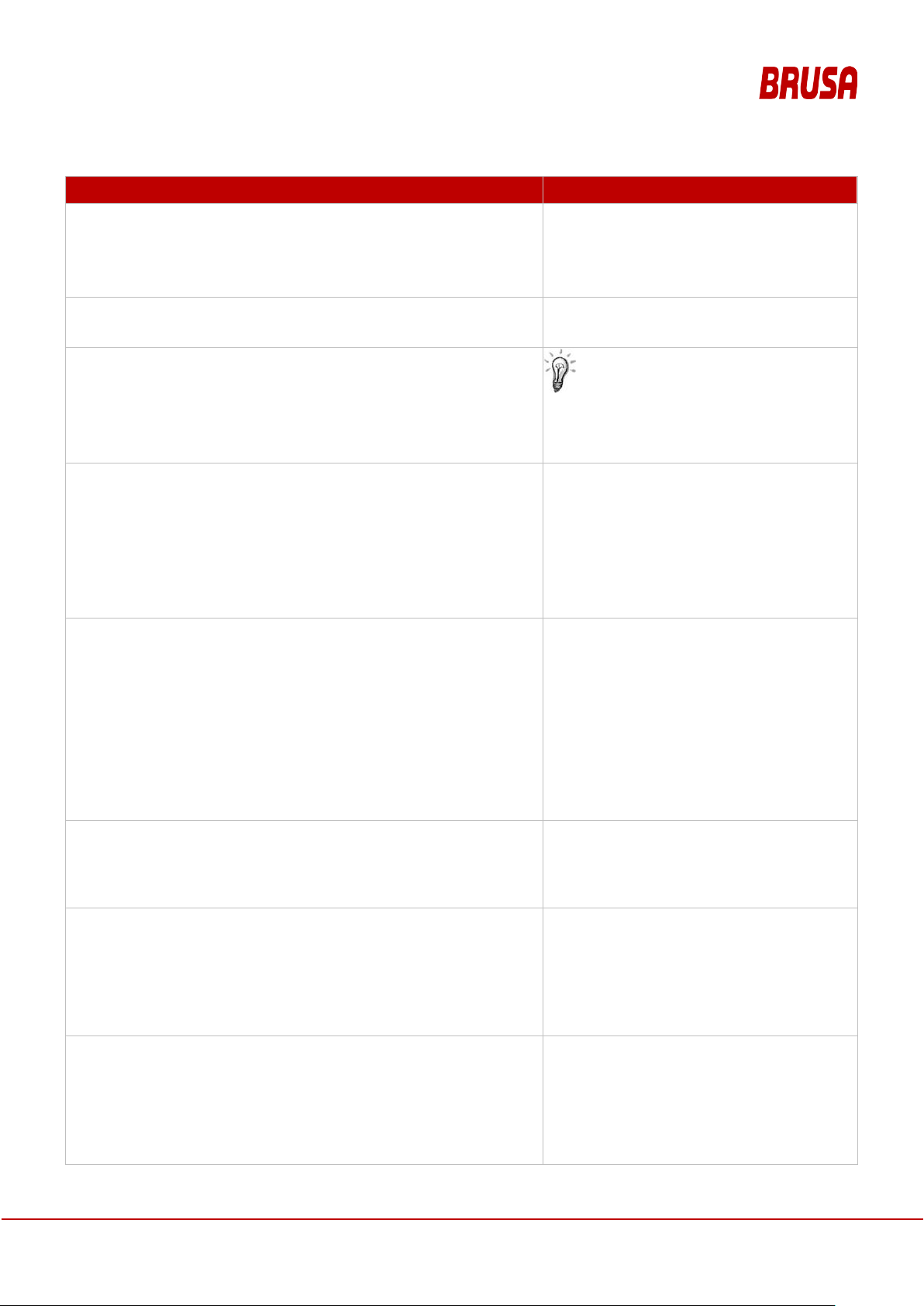

7.5 Emergency Situations

With the occurrence of emergenc y situatio ns, f ollow the c orres ponding s ituatio n descr iptions in th e table be lo w and

comply with the associated instruc tio ns!

SITUATION INSTRUCTIONS

Keep calm!

Fetch help. Call the fire department!

Keep other people away from the source of the fire!

Visit a doctor in order to exclude smoke poisoning!

Keep calm!

34

Remove yourself immediately from the charging environment!

Visit a doctor.

Keep calm!

Remove yourself immediately from the environment of the charging station!

Visit a doctor.

Operation Manual

Inductive Charging System

ICS115

7.6 Troubleshooting by the User

It is not possible t o position the

vehicle for a charging operation.

1.

whether your vehicle is switched on. The po sitio ning functi on onl y works

when readiness to drive is established. In addition the confirmation of your

consent for the charging operation is required via the interface of the vehicle.

2.

has shifted. If so, bring it bac k to that position, that

was determined in chapter

3.

r this, establish

whether the power suppl y for the GPM has been inter rupted by electrical safety

devices. If so, re-establish the power supply for the GPM, by switching on the

electrical safety device.

4. Check, whether the WLAN connection between CPM and

If necessary repeat the positioning process.

5

The charging operation is

aborted again immediately after

the start.

1. Check, whether the GP M is free of foreign objects. If necessary clear it, takin g

into consideration the information specified in chapter

2.

heck, whether the charging function has been and can be interrupted by

people or animals. If necessary, prevent the access to the charging station.

3. Check, whether the GPM can be supplied with power. For this, establish

whether the power suppl y for the GPM has been inter rupted by electrical safety

devices. If so, re-establish the power supply for the GPM, by switching on the

electrical safety device.

4. Check, whether the dif ference in height betwee n GPM and CPM has cha nged

in an inadmissible wa y, e.g. due to a gre at deal of snow on th e car tires or o n the

ground, on which the GPM is installed.

5.

For the following errors, limited troubleshooting can be undertaken by the user. The troubleshooting is to be

undertaken as described in this chapter. The user is forbidden to undertake further troubleshooting that goes

beyond the troubleshoot ing specified in this chapter. In the follo wing, situations are des cribed as can occur durin g

the operation. The tr oubleshooting is to be un dertaken and perform ed in the given order for ex actly that situation

description that applies to the current situation.

SITUATION TROUBLESHOOTING

Check,

Check , whether the GPM

12.5.1.

Check, whether the GPM can be supplied with power. Fo

GPM is faulty.

. If the error still occurs, contact customer service.

8.1.2.

C

If the error still occurs, contact customer service.

Operation Manual

Inductive Charging System

ICS115

35

The vehicle (the drive battery) is

not completely charged.

1.

complete charge of the battery was

sufficient. (Is the charging process resumed when you resume the charging

function?)

2. Check, whether the GPM and its immediate environment is free of foreign

objects. If necessar y clear it, tak ing into consideratio n the information specifie d in

chapter

. Perhaps the charging operation could not be completed in the

charging time provided due to the presence of

3. Check, whether the charging function has been and can be interrupted by

people or animals. If necessary, prevent the access to the charging station.

Perhaps the charging proc ess was stopped by a person or animal and theref ore

could not

4.

The vehicle (the drive battery) is

not completely charged,

although the charging operation

was indicated as completed.

1.

vehicle (e.g. radio, light, navigation?) were

switched on, so that after charging up, the drive battery was discharged again.

2.

The ICS System can no longer

be used / it is switched off.

1.

her the GPM can be supplied with power. For this, establish

whether the power suppl y for the GPM has been interrupted by electrical safet y

devices. If so, re-establish the power supply for the GPM, by switching on the

electrical safety device.

2.

Never perform maintenance measures during operation of the ICS!

During

the limits for long

In order to exclude acute effects, such as muscle

damage, no

charging

In addition, jewelry (rings, wristwatches, etc.) can heat up considerably and become damaged or lead

to burns.

People with a cardiac pacemaker

system during the charging

Keep animals away from the system during operation.

SITUATION TROUBLESHOOTING

Check, whether th e charging time for the

8.1.2

foreign objects.

be completed in the charging time provided.

If the error still occurs, contact customer service.

Check, whether consumers in the

If the error still occurs, contact customer service.

Check, whet

Contact customer service

8 Maintenance

DANGER

Strong magnetic field (non-ionizing radiation)!

Influence on electrically conductive obj ects!

36

the charging process there is a strong magnetic field between CPM and GPM, which exceeds

-term exposure of living beings.

- and nerve stimulation, as well as conseque nti al

body parts may get into and around the space between the GPM and CPM during the

process.

or implanted defibrillator should keep away from the vicinity of the

process.

Inductive Charging System

Operation Manual

ICS115

NOTICE

Apart from the cleaning in chapter 8.1.2 all maintenance measures may only be performed by

For the CPM regu lar c leaning by th e user is not i ntend ed and als o not perm itted. Non-obs ervanc e of

Do not perform cleaning during and imme d iately after the charging process!

Keep the GPM clean and remove objects in its close proximity, which would lie under the vehicle

during the charging process. In particular no cables may be routed over the GPM. During the

specialists!

Contact customer service to have measures carr ied out for the maintenance of the ICS! This way

you avoid material damage to the ICS or the loss of the warranty.

The ICS system consists of the components CPM and GPM. In the fram ework of the guarantee it is pos sible to

have these two com ponen ts ins pecte d b y specia lists, if failure s ymptom s ar e evident. C ont act cus tom er ser vice f or

this. The contact details can be found in chapter 3.3.

Consumables or individual replacement parts are not required or provided f or the CPM or the GPM of the IC S

system.

If a warranty case occurs , the respective components are to be rep laced exclusively by specialists . In particular,

renewed work for the installation of the components is also to be carried out by specialists. If individual components

have to be replaced, the de scr iptions for the pr eparat ion of the I CS for us e or for d einsta llation in ch apter

are to be observed for the removal of the old components and the installation of the new components.

6 resp. 9

8.1 Cleanliness

8.1.1 Cleanliness of the CPM

this notice can result in damage to the CPM.

8.1.2 Cleanliness of the GPM

charging process, objects in the charging area may have heated up. Touching these objects can lead

to injuries due to burning.

Deviation from recommended measures for cleaning can result in damage to the GPM.

NOTICE

CAUTION

NOTICE

During use the GPM must be kept c lean. It is recommended to keep the GPM clean by means of the following

measures:

Operation Manual

Inductive Charging System

ICS115

37

Manual clearing of the GPM surroundings

Sweeping off the GPM

Moist wiping of the GPM with a mild cleaning agent

Cleaning the fan intake duct

In particular the following measures should not be applied to keep the GPM clean:

High-pressure cleaner, e.g. Kärcher

(strong) chemical cleaning agent

Road sweeper

Snow plough

8.2 Behavior after a vehicle accident

After an accident with t he vehicle in which the C PM is installed, the CPM m ust be inspected for functionality by a

specialist.

9 Deinstallation

NOTICE

Measures for the deinstallation and disposal may only be performed by specialists!

Contact customer s ervice to have measures performed for the maintenance of t h e ICS! This way you

avoid material damage or dangers for nature and the environment!

The deinstallation of the GPM is described in chapter 12.7.7.

10 Disposal

The disposal of the IC S is carried out by custom er service after the deinstal lation of the system from the vehicle

(CPM) or from the charging station (GPM).

10.1 Notes for Customer Service

A basic prerequisite for the reuse and the recycling of used electronic devices is the correct disposal.

According to the EU-Direct ive 2012/19/ EU, since 24

together with the household waste, but m ust be collected and gat hered separately by a s pecialist company. The

disposal by a specialist com pany contributes significantl y towards avoiding dangers for people and nat ure. In the

case of disposal we therefore recommend that you contact a recognized specialist waste management company.

th

March 200 6 electrical dev ices may no longer be d isposed of

Operation Manual

Inductive Charging System

38

ICS115

11 Legal Notices

11.1 Warranty

For damage that occurs during proper intended use and despite observance of the safety instructions in this

document, BRUSA provides a warranty for the ICS. The warranty is in accordance with the provisions in our

currently valid General Terms and Conditions, which can be viewed at www.brusa.biz/support/agb.html

No warranty is provided for damage that can be traced back to improper use or non-observance of the safety

instructions.

11.2 Company Names

The company names mention ed in this operation manual are used exc lusively for identification and are ther efore

mentioned without consideration of a possibly existing patent- or trademark protection:

BMW

Daimler

.

Operation Manual

Inductive Charging System

ICS115

39

12 Annex A1

12.1 Technical Specifications of the ICS

12.1.1 Emissions

Table 1: Emissions

PARAMETER CHARACTERISTIC VALUE UNIT

Max. magnetic flux density between GPM and CPM 7*10-3 T

Magnetic flux density of the GPM at vehicle limitation 4.6*10-6 T

WLAN-Signal

- Frequency

- Max. t ransmit power 19 dBm

Positioning signal

- Frequency s

- Max. radiated magnetic field strength at 125 kHz

2.4

79 mW

125

17.5

GHz

kHz

dBµA/m

12.1.2 Dimensions and Center of Gravity

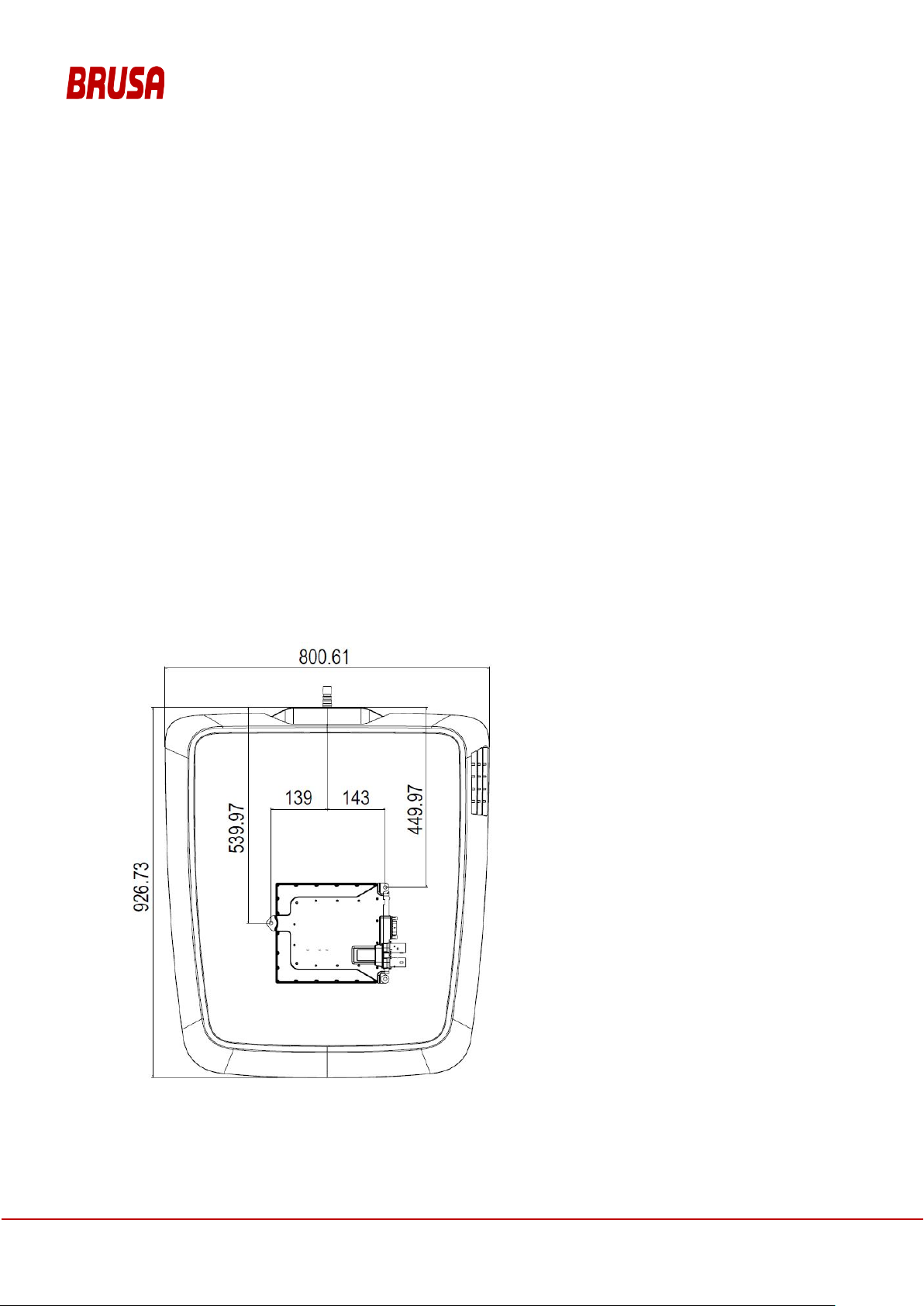

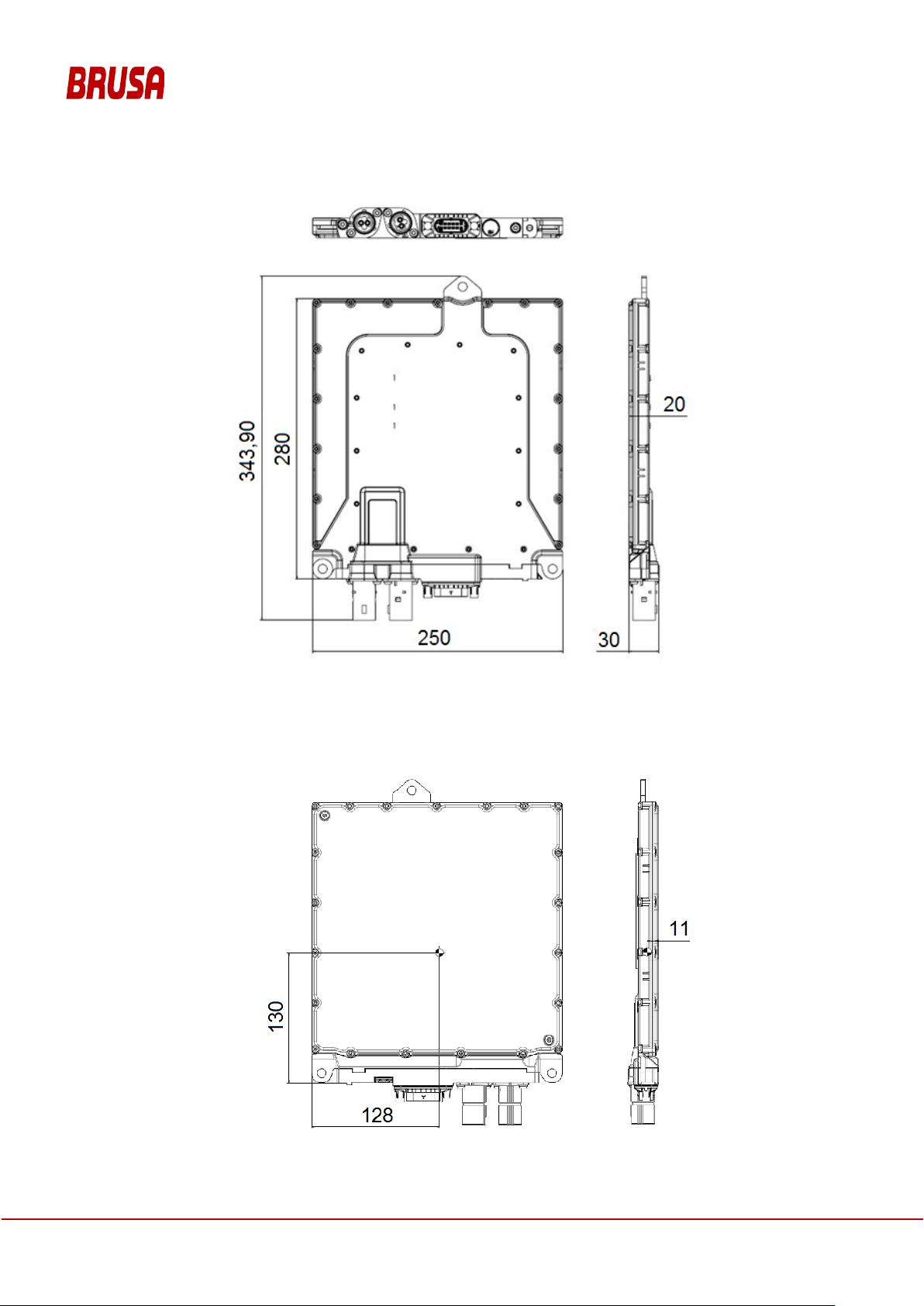

12.1.2.1 Dimensions GPM [mm]

Operation Manual

Inductive Charging System

40

ICS115

Intake duct

fan

Figure 11: Center of gravity of GPM with fan intake duct

Service flap

12.1.2.2 Center of Gravity GPM [mm]

12.1.3 Dimensions CPM [ mm]

with mains

cable

connection

Operation Manual

Inductive Charging System

ICS115

41

12.1.4 Center of Gravity CPM [mm]

Operation Manual

Inductive Charging System

42

ICS115

12.2 Technical Data

BASIC DATA ICS VALUE UNIT

Total weight approx. 52 kg

Rated input voltage (single-phase L1/N) 200 – 240 VAC

Rated input voltage (two-phase L1/L2) 100 – 120 VAC

Rated input frequency 50 – 60 Hz

Maximum input current 16 A

Max. input power 3600 W

Charging voltage 200 – 440 VDC

Max. c hargi ng current 12 ADC

Charging capacity 500 – 3200 W

Energy transmission frequency 81.38 – 90 kHz

Duration of a charging process Dependent on type of vehicle

Transmission frequency WLAN (ISM Band) 2.412 – 2.462 GHz

Max. t ransmit power WLAN 100 mW

Transmission frequency positioning 125 kHz

LV-wiring system CPM 9 – 16 VDC

LV-wiring system max. voltage CPM ( devi ce destruction) 27 VDC

IP protection class IP6K9K, IP65 Insulation class acc. EN 61140 Protection class I -

rms

BASIC MECHANICAL DATA MIN MAX UNIT

Height above ground GPM 0 0 mm

Height above ground CPM 100 160 mm

Operation Manual

Inductive Charging System

ICS115

43

Maximum offset GPM to CPM in travel direction (x-direction) -75 75 mm

Maximum offset GPM to CPM transverse to travel direction (y-direction) -150 150 mm

Above specified applies, if 0 |x| + |y| < 175 mm mm

This inductive charging system also functions outside these specified system limits, but with restricted efficiency and restricted transmission

power.

VEHICLE-CAN CPM ICS UNIT

CAN 2.0B --- --CAN Baud rate 500 (default) kBd

CAN input capacity 47 pF

CAN High – Low input resistance 36 kΩ

Startup time / charging readiness (until CAN-communication) 3 s

Sample Point 81 %

BTL Cycles 16 --SJW 3 ---

12.2.1 Conditions for Storage and Transport of the ICS

ICS UNIT