BRUSA Elektronik AG

Neudorf 14

CH-9466 Sennwald

+41 81 758 19 00

info@brusa.biz

www.brusa.biz

TECHNICAL DATA

AND STARTUP

Translation of the original German operating instructions.

DMC514 (ISU)

DMC524 (ISU)

DMC534 (ISU)

DMC544

2

Technical data

and startup

LEGAL NOTICE

Publisher

BRUSA Elektronik AG

Neudorf 14

CH-9466 Sennwald

T +41 81 758 19- 00

Fax: +41 81 758 19 - 99

www.brusa.biz

office@brusa.biz

Date of issue

11. October 2011

Copyright

© 2011

The content of this document may not be passed on to third parties without the written authorisation

of the company BRUSA Elektronik AG- not even in extracts. Any technical information, drawings and

photos used are copyrighted and failure to respect this constitutes a punishable offence!

Updates

In light of the further technical development of our products, we reserve the right for structural

changes. Any changes will be disclosed in the relevant manuals through the replacement of the

relevant pages and/or a revision of the electronic data storage device.

Writer / Author

Holger Schmidt

REVISION

DATE

NAME

CHANGE

rev11

04.06.2015

F. Müller

- chap. 9.5 add information about cable and terminal insert

rev12

30.09.2015

M. Voppichler

- chap. 8.3.5 “Pin 9 CNH, Pin 10 CNL (CAN-Bus, CANInterface)” deleted

- chap. 8.4 “LV current consumption” added

- Cooling system warnings added (chap. 8.7)

rev13

18.11.2015

M. Voppichler

- adjusted delivery content

- adjusted diameters of cooling water connections

rev14

29.04.2016

M. Voppichler

- adjusted delivery content

- Warning about terminal insert (chap. 9.5)

- Chap. 12 added

rev15

28.11.2016

A. Girod

- Chapter 14 Warranty new

rev16

02.05.2017

M. Cvorak

- Chapter 8.3, LV input voltage range

rev17

15.09.2017

M. Cvorak

- Chapter 4.3, DEL: LEMO-cable from “delivered content”

REVISIONS

3

Technical data

and startup

VALIDITY

TYPE

DMC514 (ISU) - Ser.No. > 1000

DMC524 (ISU) - Ser.No. > 1000

DMC534 (ISU) - Ser.No. > 1000

DMC544 - Ser.No. > 1000

This manual is valid only for the following devices:

Technical data

and startup

4

Table of contents

1 Foreword .............................................................................................................................. 7

2 List of abbreviations ........................................................................................................... 7

3 Safety and warning instructions ........................................................................................ 8

3.1 Symbols and their meaning ........................................................................................................ 8

3.2 Safety instructions and danger levels ......................................................................................... 9

3.3 Generally applicable safety measures ...................................................................................... 10

3.3.1 Safety instructions for cooling water systems .................................................................... 10

3.3.2 Safety instructions for mechanical systems ....................................................................... 10

3.3.3 Safety instructions for handling and operation ................................................................... 11

3.3.4 Safety instructions for electrical systems ........................................................................... 12

3.4 Safety installations / power limitations ...................................................................................... 13

3.4.1 Interlock ............................................................................................................................ 13

3.4.2 Short-circuit protection ...................................................................................................... 13

3.4.3 Automatic discharge of DC-link voltage ............................................................................. 14

3.4.4 Monitoring of HV voltage ................................................................................................... 14

3.4.5 Overload protection (derating) ........................................................................................... 14

3.4.6 Inverter safety unit (ISU).................................................................................................... 14

3.5 Safety measures for vehicle installation .................................................................................... 15

3.5.1 Principle of operation Interlock .......................................................................................... 15

3.6 Requirements for the start-up personnel .................................................................................. 16

4 General ............................................................................................................................... 17

4.1 Content and scope of this manual ............................................................................................ 17

4.2 Scope of the entire documentation ........................................................................................... 17

4.3 Delivered mechanical components ........................................................................................... 18

4.4 Optional delivery contents ........................................................................................................ 20

4.5 EU-guidelines ........................................................................................................................... 21

4.6 Contact information of the manufacturer ................................................................................... 21

5 Intended use of the device ............................................................................................... 22

5.1 Proper use................................................................................................................................ 22

5.2 Improper use / limits of the product .......................................................................................... 23

6 About this device............................................................................................................... 24

5

Technical data

and startup

6.1 Technical data .......................................................................................................................... 24

6.2 Type plate ................................................................................................................................ 26

6.3 Device warnings ....................................................................................................................... 27

6.4 Basic function ........................................................................................................................... 27

6.5 Covers ...................................................................................................................................... 28

6.6 Assembly information ............................................................................................................... 29

6.6.1 Installation position ............................................................................................................ 29

6.6.2 Fixing (as in example DMC524) ........................................................................................ 29

6.7 Example of use ........................................................................................................................ 30

6.8 Input and output values ............................................................................................................ 31

6.9 Block diagram output stage / power print .................................................................................. 32

6.10 Operating modes of the inverter ............................................................................................... 33

6.11 Regulatory approach and limitations ........................................................................................ 34

6.12 Error and warning messages .................................................................................................... 34

6.12.1 Error definition ................................................................................................................... 35

6.12.2 Warning message definition .............................................................................................. 35

7 Level of inverter efficiency ............................................................................................... 36

7.1 DMC514 measured with HSM1-10.18.04 at 400V (first quadrant) ............................................ 36

7.2 DMC524 measured with HSM1-6.17.12 at 400V (first quadrant) .............................................. 36

7.3 DMC534 measured with HSM1-10.18.13 at 400V (first quadrant) ............................................ 37

7.4 DMC544 measured with HSM1-10.18.13-W7 at 400V (first quadrant) ...................................... 37

8 Connections ....................................................................................................................... 38

8.1 Circuit connections ................................................................................................................... 38

8.2 Pin assignment motor sensor connection (device side) ............................................................ 39

8.3 Pin assignment of control connector (device side) .................................................................... 40

8.3.1 Pin 1 GND (ground terminal 31) ........................................................................................ 41

8.3.2 Pin 2 AUX (Wiring system terminal 30) .............................................................................. 41

8.3.3 Pin 3 EN (Enable, Power ON) ........................................................................................... 42

8.3.4 Pin 8 PG1, 14 PG2, 15 PG3 (Reserve ground, RS232 ground) ......................................... 42

8.3.5 Pin 11 TXD, Pin 12 RXD (RS232 interface) ....................................................................... 43

8.3.6 Pin 13 PRO (Enable firmware programming)..................................................................... 44

8.3.7 Pin 17 EXT AW1, Pin 18 EXT AW2 (External shut down path 1 + 2) ................................. 45

8.3.8 Pin 19 IL1, Pin 20 IL2 (Interlock 1 + 2) .............................................................................. 46

Technical data

and startup

6

8.4 LV current consumption............................................................................................................ 47

8.4.1 I

8.4.2 I

..................................................................................................................................... 48

Aux

+ IEn + I

Aux

Ext AW1

+ I

................................ ................................................................ .. 49

Ext AW2

8.5 Grounding screw ...................................................................................................................... 50

8.6 Cooling water connections ....................................................................................................... 51

8.7 Cooling circuit Information and Warnings ................................................................................. 52

8.7.1 Cooling water filter............................................................................................................. 52

9 Start-up ............................................................................................................................... 53

9.1 System requirements for PARAM-tool software ........................................................................ 54

9.2 Ventilate and check cooling system .......................................................................................... 54

9.3 Load motor parameter table onto inverter ................................ ................................................. 54

9.4 Build HV supply ........................................................................................................................ 55

10 Operation of the inverter through CVI ................................ .......................................... 59

10.1 Build connection between CVI and the inverter ........................................................................ 60

10.2 Disconnect the communication between CVI and the inverter / Switch off the inverter ............. 60

10.3 Fix CVI problems ...................................................................................................................... 61

11 Error correction .............................................................................................................. 62

12 Flooding in the device ................................................................................................... 62

13 Instructions for disposal ............................................................................................... 63

14 Warranty and guarantee ................................................................................................ 64

15 Index ................................................................................................................................ 65

7

Technical data

and startup

1 Foreword

ABBR.

MEANING

ABBR.

MEANING

AUX

Wiring System Plus

Terminal 30

DMC

Digital Motor Controller

DMC5x4

DMC514 inverter, 524,534 and 544

IL1:

Interlock

EN

Device activation

Terminal 15

IL2:

Interlock

GND

Minus wiring System, vehicle ground

Terminal 31

ISU:

Inverter Safety Unit

High

High level (logic level)

Low

Low level (logic level)

HV

High voltage, DC-link voltage

(high voltage)

LV

Low voltage

HV+

High voltage plus (high voltage+)

LV+

Low voltage plus (low voltage+)

HV-

High voltage minus (high voltage-)

LV-

Low voltage minus (low voltage-)

Dear customer!

With the BRUSA inverter DMC5x4 you have received a very capable and versatile product. As this is a component

of high performance electronics, we require specialist knowledge in the dealing with as well as the operation of the

product!

Read the manual - particularly the chapter 3 Safety and warning instructions - carefully before you inverter

DMC5x4 or carry out any other work!

2 List of abbreviations

Throughout this manual, some specific technical abbreviations are used. You will find an overview as well as their

meaning in the following table:

Technical data

and startup

8

PROHIBITION SYMBOLS

SYMBOL

MEANING

SYMBOL

MEANING

General prohibition

Warning high voltage

Touching forbidden

Switching on forbidden

WARNING SYMBOLS

SYMBOL

MEANING

SYMBOL

MEANING

General hazard warning

Electromagnetic field warning

Potentially explosive warning

Battery hazard warning

Hot surface warning

High electrical voltage warning

High pressure warning / fluid spurting out

Fire hazard warning

MANDATORY SIGNS

SYMBOL

MEANING

SYMBOL

MEANING

Disconnect device from voltage

Disconnect device from mains

INFORMATION SIGNS

SYMBOL

MEANING

SYMBOL

MEANING

Important information on avoiding possible

damage to property

Important information

3 Safety and warning instructions

In this chapter you will find safety instructions which apply to this device. These refer to assembly, start-up and

running operation in the vehicle. Always read and observe these instructions in order to protect people's safety and

lives and to avoid damage to the device!

3.1 Symbols and their meaning

Throughout this manual, some specific technical abbreviations are used. You will find an overview as well as their

meaning in the following table:

9

Technical data

and startup

3.2 Safety instructions and danger levels

DANGER

This instruction warns against serious, irreversible risks of injury and in some cases death!

Avoid these dangers by observing these instructions!

WARNING

This instruction warns against serious, irreversible risks of injury!

Avoid these dangers by observing these instructions!

CAUTION

This instruction warns against serious, irreversible risks of injury!

Avoid these dangers by observing these instructions!

INSTRUCTION

This instruction warns against possible damages to property if the following instructions and work

procedures are not observed.

INFORMATION

This type of instruction discloses important information for the reader.

Technical data

and startup

10

WARNING

Spurting cooling fluid!

Skin burning hazard!

Check the tightness of the cooling water system, particularly the pipes, screw joints and pressure

tanks.

Resolve recognisable leakages immediately!

DANGER

Potential explosion area!

Danger to life!

Do not store any highly flammable materials or combustible fluids in the direct surroundings of the

device!

Sparks at the device connections can set these on fire and lead to explosions!

CAUTION

Hot surfaces!

Burn hazard!

The device produces high temperatures when in operation!

Handle the device with care and caution!

3.3 Generally applicable safety measures

The following safety measures have been developed based on the knowledge of the manufacturer. They are not

complete, they can be supplemented by place and/or country specific safety instructions and guidelines for

accident prevention!

The present safety instructions from the system integrator and/or distributor must therefore be supplemented by

specific country and local guidelines.

3.3.1 Safety instructions for cooling water systems

3.3.2 Safety instructions for mechanical systems

11

Technical data

and startup

3.3.3 Safety instructions for handling and operation

INSTRUCTION

A high cooling water temperature reduces the life span! So take ongoing care to ensure sufficient

cooling of the device!

Do not place the device in direct sunlight and in close proximity to heat sources!

Although if the device has high IP protection, you should avoid placing it in direct contact with water

(rain, spurting water) if possible!

Under no circumstances should you put a low-resistance connection between the HV contacts, the

housing contacts and the LV contacts! This will lead to malfunctions and furthermore to the

destruction of the device!

Prevent any penetration of fluids into the device (e.g. during assembly work)! The penetration of fluids

will lead to a short circuit and subsequent damage to the device!

Under no circumstances should you operate the device if liquid is leaking in anywhere, refer

immediately to the company BRUSA Elektronik AG!

Technical data

and startup

12

DANGER

High voltage!

Danger to life!

Under no circumstances should you touch the HV wires or HV connections without ensuring that

there is no voltage beforehand!

The device may only be connected by a qualified electrician!

Under no circumstances should you bypass or avoid security installations! Any malfunctions resulting

from this could have life threatening consequences!

Always use an insulation monitoring unit for ongoing monitoring of the galvanic isolation between HV

and LV circuits!

Before starting work with the device, the shut-down of the coupled motors must be ensured! Even

when the HV supply is switched off, a turning motor can still produce voltage!

INSTRUCTION

Under no circumstances should the device be opened without authorisation! The opening of the

device (housing sealed-up) leads directly to the forfeit of any guarantee and warranty rights!

INFORMATION

Adhere strictly to the following 5 safety rules when working on a HV grid:

Disconnect system from power.

Switch off the ignition

Remove service / maintenance plug and/or turn off main battery switch

Remove fuse

Ensure that system does not reconnect.

Keep ignition key safe to prevent unauthorised access.

Keep service / maintenance plug safe to prevent unauthorised access.

Use lockable cover cap to ensure that the main battery switch does not reconnect.

Check that it is not live with a suitable voltage tester (note voltage range!)

Ground and short-circuit the system.

Cover or seal-off adjacent live parts.

3.3.4 Safety instructions for electrical systems

13

Technical data

and startup

3.4 Safety installations / power limitations

INFORMATION

The pins IL1 and IL2 on the control connector must be connected and evaluated by the customer for

this.

1. Interlock switch

3.4.1 Interlock

The interlock switch (1) protects the operator from injuries from the HV connections. The interlock switch (1) is

automatically activated as soon as the service cap is opened.

3.4.2 Short-circuit protection

If a short-circuit of the power output stage is detected (e.g. short circuit of the motor phases) then the power output

stage is immediately deactivated. A corresponding error is detected over CAN. The error must be confirmed before

further operation.

Technical data

and startup

14

DANGER

High voltage!

Danger to life!

If the High voltage is present, the HV connections are live!

Under no circumstances should you touch the HV connections without ensuring that there is no

voltage beforehand!

In the case of additional connected capacities, consider a correspondingly longer discharge time!

INSTRUCTION

Continuous operation at the temperature limit will inevitably lead to a higher level of wear of the

components!

INFORMATION

In general, the customer or the integrator is responsible for the safety of the system, in which the

inverter is integrated. The device is set up for the use of an Inverter Safety Unit (ISU). This protective

function was developed in accordance with ISO26262 and can meet the criteria of ASIL-C.

The ISU is not a standard protective function and can be applied by BRUSA optionally.

You can find detailed information on the ISU on the attached sheet DMC_ISU.pdf

3.4.3 Automatic discharge of DC-link voltage

As soon as the voltage on the HV connections is switched off (manually or automatically), active discharge of DClink capacitors takes place in the inverter.

3.4.4 Monitoring of HV voltage

Integrated in the inverter is an overvoltage protective circuit, which deactivates the inverter immediately when the

HV voltage is too high (Error mode). A corresponding error is detected over CAN. The error must be confirmed

before further operation.

If the voltage of the HV input falls below the minimum voltage, the inverter is again deactivated (Error mode). A

corresponding error is detected over CAN. The error must be confirmed before further operation.

3.4.5 Overload protection (derating)

This security installation is the inverter's self-protection. If the inverter rises in temperature, this means a decrease

in power (derating) to protect the inverter from damage through overheating. The power will subsequently be

reduced until the temperature falls back to the target range.

The temperature measurement takes place in the high power switches and is set in the factory.

3.4.6 Inverter safety unit (ISU)

15

Technical data

and startup

3.5 Safety measures for vehicle installation

INFORMATION

This safety measure is a recommendation by the company BRUSA Elektronik AG and is understood

as a basic requirement for the safe operation of electric vehicles!

3.5.1 Principle of operation Interlock

The interlock switch (1) is closed if the corresponding interlock condition of each device is met (closed service

cover, plugged HV connections ...). The interlock evaluation of the PDU switches the 12V supply voltage (2) of the

HV contactors (4) in the battery if the interlock circuit is closed. The emergency stop switch (3) also interrupts the

12V supply voltage of the HV contactors (4). The second interlock (5) of the line insulation guard interrupts the

interlock circuit, if a fault in the HV- insulation is detected.

Technical data

and startup

16

3.6 Requirements for the start-up personnel

All courses of action described in this manual may only be carried out by a qualified electrician! Specialist staff is

defined as electricians who dispose of

professional training,

knowledge and experience in the field of electronics / electric mobility,

as well as knowledge of relevant requirements and dangers

which they can display in practice. Furthermore, they must be able to assess the work assigned to them

independently, detect possible dangers and establish necessary protection measures.

17

Technical data

and startup

4 General

INFORMATION

To start up the inverter successfully, you will need the entire documentation as well as different

software and firmware. With the provision of the customer package, it is ensured that they are

complete and up-to-date. The updating of specific documents is carried out automatically and can be

seen in the history.

4.1 Content and scope of this manual

The present documentation gives the reader an overview of all required working steps in the installation and

operation of the device and the safety measures necessary for these.

Furthermore, you can find technical information, usage information and a basic description of the inverter and its

specific components.

The operation and safety instructions given in the previous chapters must be strictly adhered to ensure the ongoing

optimum functioning of the inverter and to meet the guarantee requirements of BRUSA Elektronik AG.

All work sequences and illustrations are based on the DMC524 model and are applicable to all model versions

mentioned in this handbook. In the case of model-specific deviations, corresponding instructions are available.

4.2 Scope of the entire documentation

The customer package includes the following indexes:

Manual:

Contains all information fundamentally necessary for the installation and operation of the inverter.

Firmware / motor table:

Contains the necessary firmware, a motor specific motor parameter table and instructions for installation.

Tools:

Contains additional tools for the operation, parameter setting and maintenance of the inverter.

Debugging / calibration:

Contains additional specific documentation for further work on the inverter (e.g. error analysis, rotor offset

adjustment).

History:

Listing of all upgrades within the customer package with a specification of the affected documents or software /

firmware etc.

Technical data

and startup

18

INFORMATION

The components stated below are contained in the delivery and are necessary for the start-up! In the

case of possible missing parts, please refer to the manufacturing address given in chapter 4.6.

INFORMATION

For the DMC544, you can use the same cable lugs as for the DMC534. The diameter of 70mm2

cables fits without problems into 50mm2 cable lugs and is qualified by BRUSA Elektronik AG.

MEANING

PIECES

ILLUSTRATION

1.

DMC5x4 inverter

1

2.

M8 x 10 screws for the cable lugs

6

3.

M8 serrated lock washer for M8 x 10 screws

6

4.

Cable lugs (compression cable lugs)

for HV and motor cables

M8 x 25 mm2 without insulation (DCMC514)

VOGT AG type. 3575A

M8 x 35 mm2 without insulation (DCMC524)

VOGT AG type. 3584A

M8 x 50 mm2 without insulation (DCMC534 and DMC544)

VOGT AG type. 3590A

5

5.

Cable lug (compression cable lugs)

for grounding

M8 x 25 mm2 90° without insulation (DCMC514)

GLOMAR AG type. DIN-25-08-W

M8 x 35 mm2 90° without insulation (DCMC524)

GLOMAR AG type. DIN-35-08-W

M8 x 50 mm2 90° without insulation (DCMC534 and DMC544)

GLOMAR AG type. DIN-50-08-W

1

4.3 Delivered mechanical components

19

Technical data

and startup

MEANING

PIECES

ILLUSTRATION

6.

23 pole control connector with crimp terminals

AMPSEAL 770680-1

1

7.

SN/LP contacts

AMPSEAL 770854-1

for wire diameter: 0.5 mm

2

We recommend the use of the following

crimping tool: Tyco 58440-1

25

8.

Normaquick cooling water connection pieces 0° Norma PS3

2

9.

Software package

(For a listing see chapter 4.2 Scope of the entire documentation)

1

---

10.

Entire documentation

(For a listing see chapter 4.2 Scope of the entire documentation)

1

---

Technical data

and startup

20

INFORMATION

These accessories can be obtained optionally from BRUSA Elektronik AG.

MEANING

TYPE

ILLUSTRATION

1.

Special key for HV cable fitting

RAAA041

---

2.

Normaquick cooling water connection pieces 90° Norma PS3

MHAA776

1.

M18x1.5 D16 cooling water connection

MAAA366

1.

Rubber seal for M18x1.5 D16 cooling water connection

MAAA365

2.

Protective cap for M18x1.5 D16 cooling water connection

MHAA682

3.

Cable glands for 13 mm - 18 mm cable diameter

RAAA040

4.

Cable glands for 9 mm - 16 mm cable diameter

RKAA144

5.

14 pole Lemo connecting cable (inverter - motor) 2 m

11140

6.

14 pole Lemo connecting cable (inverter - motor) 4 m

11141

7.

Spare- CEQ 25 mm2

11471

---

8.

Spare- CEQ 35 mm2

11472

9.

Spare- CEQ 50 mm2

11473

10.

Conversion switch resolver to digital

MHAA745

---

4.4 Optional delivery contents

21

Technical data

and startup

4.5 EU-guidelines

BRUSA Elektronik AG

Neudorf 14

9466 Sennwald

Switzerland

Phone:

+41 81 758 19 - 00

Fax:

+41 81 758 19 - 99

Internet:

www.brusa.biz

E-mail:

support@brusa.biz

This manual has been produced under the application and in respect of Inverter DMC5x4 EG guidelines, national

regulations and harmonised standards (EN) which were valid at the time of production.

4.6 Contact information of the manufacturer

Technical data

and startup

22

INFORMATION

This equipment is a custom built evaluation kit destined for professionals to be used solely at

research and development facilities for such purposes.

5 Intended use of the device

5.1 Proper use

The BRUSA DMC5x4 inverter has been designed for the following uses. In the case of planned operations in other

sections, please contact the company BRUSA Elektronik AG beforehand at the manufacturers address as given in

chapter 4.6.

The DMC5x4 inverter is a universal inverter for the driving of different three phase motors, such as for example:

Induction Motor or Asynchronous Motor (ASM)

Permanently Excited Synchronous Motor (PSM)

Hybrid synchronous motor (HSM)

Internal Permanently Excited Synchronous Motor (IPM)

The BRUSA DMC5x4 inverter has generally been designed for integration into power trains. The inverter can also

be operated in generator mode. This can be done in combination with a range extender (combustion motor for

range extension). In this way, the inverter is inserted between a generator and a battery to convert the produced

electricity and store it in the battery.

23

Technical data

and startup

5.2 Improper use / limits of the product

The carrying out of applications which do not conform to the conditions and requirements stated in the technical

documents and datasheets of the manufacturer is viewed as improper use.

The following limit values are set for the operation of the DMC5x4 inverter. Operation out with the defined limits can

also lead to life-threatening situations!

The following limit values are set for the DMC5x4 inverter by the manufacturer and must be adhered to in all cases:

Max HV input voltage (operation): 450 V

Max HV input voltage (without damage): 520 V

Min temperature of surroundings: - 40°C

Max temperature of surroundings: + 85°C

Min coolant temperature: - 40°C

Max coolant temperature: + 65°C

Maximum pressure cooling water system: 1.0 bar

The three-phase output voltage given out from the frequency inverter cannot be used to drive a one-

phase motor!

Technical data

and startup

24

HV AND LV POWER SUPPLY

DMC514

DMC524

DMC534

DMC544

UNIT

Min. Input voltage at terminal 15 (connect inverter)

6 6 6 6 V

Min. Input voltage at terminal 15 (automatic disconnection of the

inverter)

2 2 2 2 V

Min. HV input voltage for operation

(Software disconnection)

120

120

120

120

V

Min. HV input voltage for operation

130

130

130

130

V

Min. HV input voltage for full electrical output (V

DCmin

)

200

200

200

200

V

Max. HV input voltage (operation) (V

DCmax

)

450

450

450

450

V

HV input voltage software disconnection

460

460

460

460

V

HV input voltage hardware disconnection

480

480

480

480

V

Max. HV input voltage of device (without damage):

520

520

520

520

V

Max. protective fuse1)

150

300

450

600

A

X capacity (for HV pre-charging)

200

380

560

740

uF

Y capacity (for dimensioning of insulation monitoring unit)

98 + 98

128 + 128

158 + 158

188 + 188

nF

THREE PHASE OUTPUT U, V, W (R, S, T)

DMC514

DMC524

DMC534

DMC544

UNIT

RMS current duration (I

ACcont

)

112

225

337

450

A

Periodic cycle with max. current 30 sec 100%, 90 sec 50%

150

300

450

600

A

Continuous output (VDC=75%V

DCmax

, IAC=I

ACcont

, cosφ=0.9)1 (P

ACcont

) *1

39

79

118

160

kW

Max. output (VDC=75%V

DCmax

, IAC=I

ACmax

, cosφ=0.9)1 (P

ACmax

) *1

52

105

157

212

kW

PWM frequency (symmetric modulation) (f

PWM

)

24

24

24

24

kHz

Efficiency (VDC=75%V

DCmax

, PAC=P

ACcont

, cosφ=0.9)

*1

0.97

0.97

0.97

0.97

---

*1: 100% AC Sine Modulation, Phase-to-Phase AC Voltage amplitude = VDC

MECHANICS AND EQUIPMENT

DMC514

DMC524

DMC534

DMC544

UNIT

Height

88

88

88

88

mm

Width

240

240

240

240

mm

Length (without cable lugs and connections)

250

360

470

580

mm

Length (with cable lugs and connections)

276

386

496

606

mm

Weight (with cooling water)

6.5

9.5

12.5

15.5

kg

IP protection

IP67

IP67

IP67

IP67

---

CONNECTIONS

DMC514

DMC524

DMC534

DMC544

UNIT

HV+, HV- high voltage: 2 M8 cable lugs, recommended cable

diameter

25

35

50

70

mm2

Phases U, V, W: 3 M8 cable lugs, recommended cable diameter

25

35

50

70

mm2

23 pole AMP, wire diameter

0.5

0.5

0.5

0.5

mm2

Motor sensor connector, number of contacts

14

14

14

14

---

6 About this device

6.1 Technical data

1: semiconductor fuse for DC / e.g. fuse type FWH 500V from Bussmann

25

Technical data

and startup

THERMAL

DMC514

DMC524

DMC534

DMC544

UNIT

Amount of coolant in device

0.3

0.6

0.9

1.2

l

Flow rate

6-10

6-10

6-10

6-10

l/min

External diameter of cooling water connection pieces

18

18

18

18

mm

Minimum coolant temperature at inlet

- 40

- 40

- 40

- 40

°C

Maximum coolant temperature at inlet

+ 65

+ 65

+ 65

+ 65

°C

Coolant pressure drop @ 6l/min, T

coolant

= 25°C

(with a water to glycol mixture ratio of 50 / 50)

70

120

150

180

mbar

Maximum pressure of the coolant

1 1 1 1 bar

Maximum particle size in the coolant

0.2

0.2

0.2

0.2

mm

Ambient temperature range for storage

- 40 to

+ 85

- 40 to

+ 85

- 40 to

+ 85

- 40 to

+ 85

°C

Ambient temperature range in operation

- 40 to

+ 85

- 40 to

+ 85

- 40 to

+ 85

- 40 to

+ 85

°C

INSTRUCTION

The mixing ratio of glycol and water must be at least 50% / 50%. Apart from that, the inverter will

fail at low temperatures.

WARNING

When the abovementioned points based on the cooling are not complied, the inverter will fail!

Technical data

and startup

26

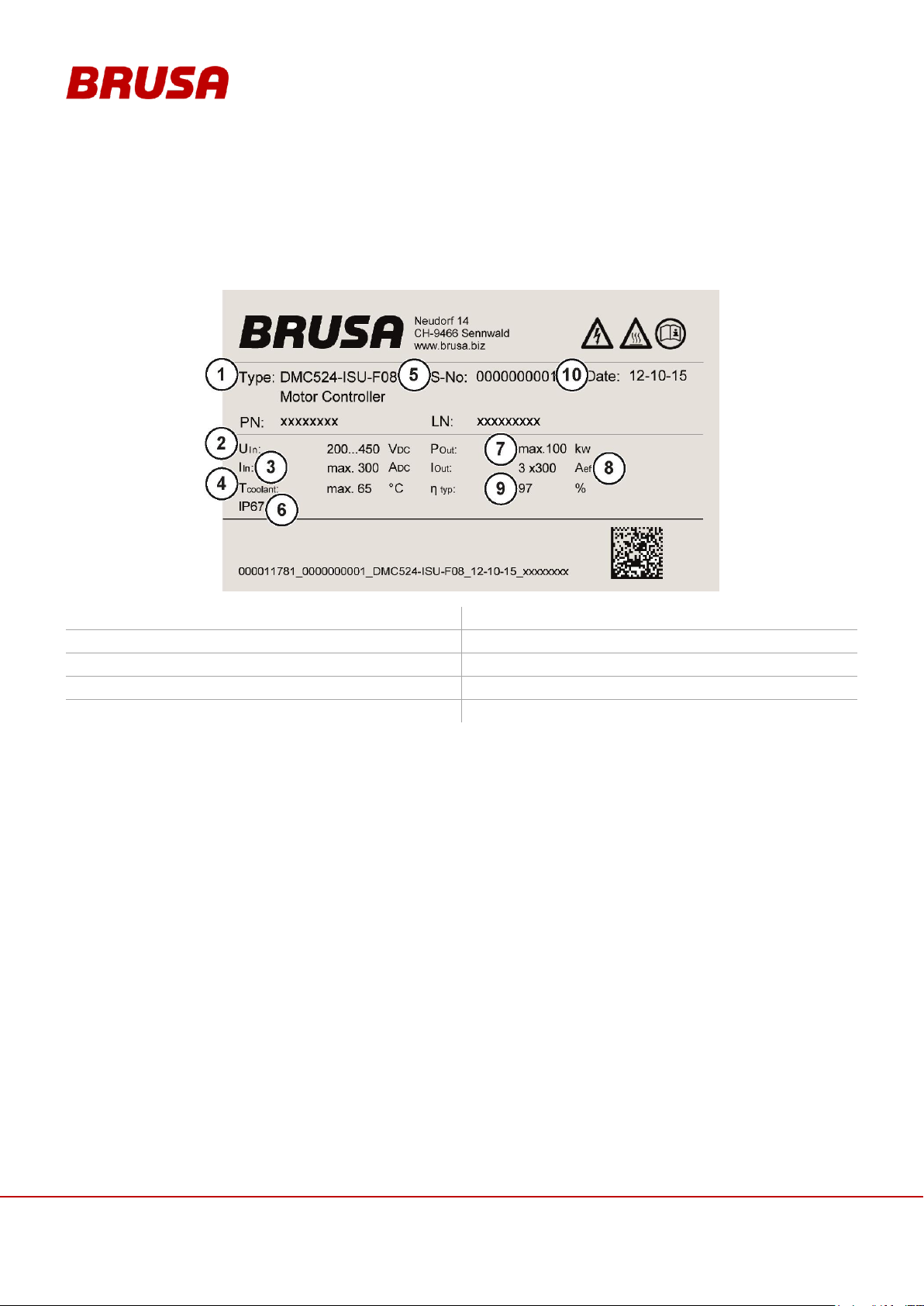

1. Classification

2. Operating voltage (section)

3. Maximum input current

4. Maximum coolant temperature at inlet

5. Serial number

6. IP protection category

7. Max. power

8. Maximum phase currents (U, V, W)

9. Level of efficiency

10. Date of manufacture

6.2 Type plate

The type plate is on the back of the device and contains the following information:

27

Technical data

and startup

6.3 Device warnings

Warning signs are installed on the device to warn the operator of possible dangers. Should one of these warning

signs fail or become illegible due to wear and tear, it must be immediately renewed! To get an original label, please

refer to BRUSA support at the manufacturing address given in chapter 4.6!

6.4 Basic function

The DMC5x4 inverter is a universal inverter which can be used to drive different three phase motors.

The power output stage of the DMC5x4 is based on the most capable, resonant SoftSwing® topology which was

developed and patented by BRUSA Elektronik AG. SoftSwing® topology achieves minimal switching losses and

excellent EMC features which are above average. Through this, the use of applications with motor frequencies of

up to 2 kHz is possible. With its very compact and easy assembly method, the DMC5x4 inverter is suitable for

practically any application.

To drive a motor, the corresponding motor parameter table is necessary. This must be tailored to the specific motor

by BRUSA who will also set the parameters!

Technical data

and startup

28

6.5 Covers

INFORMATION

Only the covers mentioned in this chapter may be removed by the customer!

Torque for M4 x 08 screws: 2.5 Nm

1. Service lid

2. M4 x 08 screws (8 pieces)

29

Technical data

and startup

6.6 Assembly information

INFORMATION

Recommended screw types:

Cylinder screw ISO 4762 - M6 x 30 - 8.8

or

Hexagon screw ISO 4017 - M6 x 30 - 8.8

Torque for M6 x 30 screws: 10 Nm +/-0.5

1. Screw fixing points (4 pieces)

6.6.1 Installation position

Even if the device has high IP protection, install it well above the fording depth of the vehicle. Ensure for the

installation positioning that the connection side is tilted downwards. This prevents water accumulation on the cable

sealing which could result in water leaking into the housing.

6.6.2 Fixing (as in example DMC524)

Technical data

and startup

30

6.7 Example of use

31

Technical data

and startup

6.8 Input and output values

TRQrq,

TRQact

Requested and current torque

Iz min, Iz

max

Min. and max. high voltage current (DC)

SPDrq,

SPDact

Requested and current speed

Uz act

Current high voltage

Uz min, Uz

max

Min. and max. high voltage (DC)

IAC act, Iz

act

High voltage actual current phases and

actual current

Technical data

and startup

32

6.9 Block diagram output stage / power print

33

Technical data

and startup

6.10 Operating modes of the inverter

1.

Start / Power up:

This mode can be viewed as standby state. The requirements for this are:

Terminal 30 connected (12 V is engaged)

Connect terminal 15 (activation of the ignition key)

2.

Standby:

The activation of this mode takes place automatically after the start-up process (after activation of Start mode

/ Power up).

For detailed information see also the descriptions of Pin 2 and Pin 3

(see chapter 8.3.2 Pin 2 AUX (Wiring system terminal 30) and chapter 8.3.3 Pin 3 EN (Enable, Power ON)).

3.

Ready:

As soon as a voltage is present at the HV inputs, the inverter switches to this mode automatically. For this it

is required that the inverter is in standby mode.

From this mode, the inverter can drive the motor through CAN-enable.

Technical data

and startup

34

4.

Speed mode:

In this mode, the main controller is the speed regulator. The entry of the speed takes place over CAN. The

negative or positive torque can be reduced at the same time. The inverter continuously attempts to follow the

given speed (in respect of the limited torque value).

It is always possible that the desired operating point cannot be reached through a limitation elsewhere (e.g.

motor temperature, HV battery voltage etc.). Under some circumstances this can also lead to a complete

deactivation (Error Mode).

5.

Torque mode:

In this mode, the main controller is the torque regulator. Setting of the torque value takes place over CAN.

The inverter can be limited in its power with the following limitations:

Too high motor temperature

Too high inverter temperature

Too high / too low DC voltage

DC and AC Current

Power

INFORMATION

If no limitation is active, the motor will attempt to reach the entered value immediately! If there is no

load on the drive side, the motor accelerates until it reached the maximum speed!

6.

Error mode:

If an error occurs, the inverter switches to this mode. Errors which have occurred can be confirmed with the

command DMC_ClrError over CAN, see DMC5_ISU_CAN_Spec.HTML

If the error remains, the cause must be found and dealt with, see DMC5_ErrorsAndWarnings.pdf

6.11 Regulatory approach and limitations

Detailed information on the regulatory approach and possible limitations can be found in the manual

DMC5_ControlConcept.pdf

6.12 Error and warning messages

Error and warning messages are generally produced over CAN and have different effects on the function of the

inverter.

For a targeted diagnosis, an event log can be read out through the provided software PARAM-Tool.

You can find detailed information in the manual PARAM_Manual.pdf

35

Technical data

and startup

6.12.1 Error definition

Errors invariably lead to shut down the inverter (Error mode). The resuming of operation is not taken place here

automatically.

Errors must always be cleared with the command DMC_ClrError. This can take place alternatively through a

hardware reset. You will find further information in the manual DMC5_ControlConcept.pdf.

You will find a list of possible error and warning messages along with their description in the manual

errors_and_warnings.pdf

The statuses of each error are periodically updated in CAN messages.

6.12.2 Warning message definition

Warning messages do not cause shut down of the inverter. They can however in many cases lead to a reduction in

output. The statuses of each warning message are periodically updated in CAN messages.

Technical data

and startup

36

DMC514

Torque [Nm]

Speed [rpm]

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

1000

77.39

79.95

84.24

86.43

87.75

88.65

89.30

89.78

90.13

90.35 2000

80.93

87.80

90.47

91.90

92.79

93.38

93.88

94.15

94.11

94.21 3000

90.18

93.43

94.56

95.12

95.40

95.53

95.57

95.54

95.48

95.38 4000

90.27

93.15

94.75

95.50

95.96

96.22

96.40

96.52

96.57

96.56 5000

90.44

94.36

95.69

96.27

96.62

96.90

97.05

97.07

96.85

6000

92.00

95.11

96.86

97.36

97.56

97.66

97.33

97.30

97.25

7000

93.06

95.84

96.99

97.43

97.63

97.21

97.10

8000

93.75

96.10

96.87

97.28

97.20

97.10 9000

94.24

96.30

96.95

97.16

97.15

10000

94.60

96.45

97.01

97.15 11000

94.87

96.61

97.13

97.05

12000

96.44

97.26

97.30

DMC524

Torque [Nm]

Speed [rpm]

10

20

30

40

50

60

70

80

100

120

140

160

180

200

220

1000

74.32

82.62

86.02

87.79

88.80

89.47

89.93

90.25

90.65

90.81

90.83

90.80

90.62

90.40

90.14

2000

84.56

89.84

91.91

92.94

93.54

93.95

94.22

94.41

94.65

94.74

94.72

94.65

94.52

94.36

94.18

3000

88.77

92.68

94.19

94.95

95.39

95.70

95.88

96.01

96.18

96.23

96.20

96.13

96.04

95.89

95.73

4000

91.05

94.28

95.52

96.13

96.47

96.69

96.84

96.92

97.04

97.06

97.04

96.95

96.84

96.71

96.57

5000

92.64

95.36

96.38

96.90

97.17

97.36

97.48

97.54

97.55

97.49

97.35

97.12

96.88

96.90

96.98

6000

93.85

96.18

97.06

97.42

97.60

97.68

97.71

97.70

97.60

97.41

97.04

96.91

96.93

96.94

7000

94.77

96.74

97.33

97.61

97.72

97.75

97.74

97.71

97.50

97.01

96.94

96.95

8000

95.51

97.01

97.49

97.68

97.76

97.78

97.76

97.64

97.21

97.11

97.13

9000

95.84

97.18

97.61

97.78

97.82

97.82

97.72

97.54

97.23

97.26

97.11

10000

95.87

97.11

97.67

97.82

97.88

97.79

97.60

97.26

97.23

97.22

11000

95.91

97.26

97.69

97.81

97.83

97.69

97.48

97.26

12000

95.96

97.35

97.74

97.87

97.82

7 Level of inverter efficiency

7.1 DMC514 measured with HSM1-10.18.04 at 400V (first quadrant)

*The efficiency map is only valid for the inverter

7.2 DMC524 measured with HSM1-6.17.12 at 400V (first quadrant)

*The efficiency map is only valid for the inverter

37

Technical data

and startup

7.3 DMC534 measured with HSM1-10.18.13 at 400V (first quadrant)

DMC534

Torque [Nm]

Speed [rpm]

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

1000

78.57

84.89

87.29

88.49

89.13

89.48

89.64

89.68

89.64

89.53

89.38

89.17

88.91

88.64

88.35

2000

86.66

90.93

92.46

93.23

93.62

93.82

93.90

93.90

93.84

93.72

93.57

93.38

93.15

92.90

92.71

3000

90.18

93.43

94.56

95.12

95.40

95.53

95.57

95.54

95.48

95.38

95.27

95.10

94.90

94.68

94.47

4000

92.36

94.88

95.78

96.19

96.38

96.46

96.48

96.46

96.40

96.38

96.26

96.13

95.96

95.79

95.65

5000

93.04

95.33

96.15

96.53

96.69

96.76

96.78

96.76

96.75

96.67

96.56

96.43

96.26

96.07

6000

94.49

96.37

96.97

97.22

97.31

97.31

97.23

97.09

96.91

96.65

96.29

95.91 7000

95.28

96.85

97.30

97.43

97.42

97.34

97.16

96.91

96.52

95.95 8000

95.82

97.15

97.43

97.45

97.41

97.23

96.95

96.28 9000

96.24

97.26

97.46

97.45

97.32

97.03

96.32

10000

96.41

97.32

97.44

97.39

97.14

11000

96.50

97.31

97.44

97.31

12000

96.54

97.34

97.37

97.19

DMC544

Torque [Nm]

Speed [rpm]

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

1000

80.32

80.97

82.74

84.38

85.16

85.72

85.98

86.03

85.95

85.76

85.53

85.19

84.75

84.23

82.79

2000

83.27

88.46

90.49

91.51

92.04

92.35

92.49

92.54

92.52

92.44

92.33

92.17

92.00

91.77

91.51

3000

86.23

90.61

92.25

93.07

93.51

93.72

93.84

93.85

93.80

93.70

93.57

93.40

93.20

92.94

92.72

4000

89.18

92.75

94.00

94.62

94.97

95.09

95.18

95.16

95.07

94.96

94.80

94.62

94.40

94.11

5000

90.77

94.11

95.07

95.60

95.83

95.94

95.95

95.87

95.78

95.65

95.49

95.29

95.05

94.81

6000

91.79

94.71

95.68

96.17

96.40

96.47

96.46

96.41

96.32

96.19

96.03

95.86

95.62

95.36

7000

92.53

95.35

96.23

96.61

96.76

96.78

96.74

96.67

96.52

96.29

96.02

95.54 8000

92.96

95.68

96.47

96.81

96.92

96.90

96.81

96.64

96.36

96.02

95.36

9000

94.19

96.19

96.85

97.07

97.06

96.94

96.72

96.41

95.74

10000

95.09

96.71

97.09

97.11

96.98

96.70

95.98

11000

95.52

96.84

97.09

97.04

96.82

96.71 11500

95.64

96.84

97.09

97.02

96.85

12000

95.79

96.88

97.11

97.00

96.79

*The efficiency map is only valid for the inverter

7.4 DMC544 measured with HSM1-10.18.13-W7 at 400V (first quadrant)

*The efficiency map is only valid for the inverter

Technical data

and startup

38

INFORMATION

For connections 1 - 5 the following specifications are recommended:

Shielded, insulated automotive cable (e.g. Huber & Suhner).

Cable lug without insulation for each M8 cross section (e.g. Vogt AG).

Torque for cable lug (M8 x 10): 15 Nm.

1.

High voltage- (HV-)

2.

High voltage+ (HV+)

3.

Motor phase U

4.

Motor phase V

5.

Motor phase W

6.

Control connector

(Chapter 8.3 Pin assignment of control connector)

7.

Motor sensor connection

(14 pole low voltage)

(Chapter 8.2 Pin assignment motor sensor

connection)

8.

Grounding screw

(Chapter 8.5 Grounding screw)

9.

Cooling water outlet

(Chapter 8.6 Cooling water connections)

10.

Cooling water inlet

(Chapter 8.6 Cooling water connections)

8 Connections

8.1 Circuit connections

39

Technical data

and startup

8.2 Pin assignment motor sensor connection (device side)

INFORMATION

The pin assignment of the motor sensor connection is BRUSA specific and deviates from the

standard pin assignment standards of the cable manufacturer!

1.

POS3

6 bit absolute position bit 3

2.

POS4

6 bit absolute position bit 4

3.

POS5

6 bit absolute position bit 6

4.

GND-NTC

Ground NTC / PTC

5.

NTC

Motor temperature sensor

6.

PTC

Motor overheat switch-off

7.

VCC-GEB

Motor sensor- supply voltage 6 VDC

8.

POS0

6 bit absolute position bit 0

9.

POS1

6 bit absolute position bit 1

10.

POS2

6 bit absolute position bit 2

11.

GND

Ground

12.

MOTB

Motor B (incremental)

13.

MOTA

Motor A (incremental)

14.

UPD

Position update data

15.

–––

Centering groove

Technical data

and startup

40

1.

GND*

Ground (Minus wiring system,

terminal 31, input range 6 – 32V)

2.

AUX*

+12 V (Plus wiring system,

terminal 30, input range 6 – 32V)

3.

EN*

Enable (Power ON, terminal 15, input

range 6 – 32V)

4.

DO0

Reserve

5.

DO1

Reserve

6.

DO2

Reserve

7.

DO3

Reserve

8.

PG1

Ground reserve

9.

CNL*

CAN low

10.

CNH*

CAN high

11.

TXD**

RS232 Transmit (9 pole D-Sub pin 2)

12.

RXD**

RS232 Receive (9 pole D-Sub pin 3)

13.

PRO**

Enable firmware download

14.

PG2

Ground reserve

15.

PG3**

RS232 ground (9 pole D-Sub: pin 5)

16.

DI0

Reserve

17.

Ext. AW1*

External shut down path 1

(Plus wiring system, terminal 30,

input range 6 – 32V)

18.

Ext. AW2*

External shut down path 2

(Plus wiring system, terminal 30

Input range 6 – 32V)

19.

IL1*

Interlock signal loop

20.

IL2*

Interlock signal loop

21.

AI1

Reserve

22.

AI2

Reserve

23.

AI3

Reserve

* = The connections must be wired for normal operation!

** = Programming of the inverter is necessary!

8.3 Pin assignment of control connector (device side)

41

Technical data

and startup

8.3.1 Pin 1 GND (ground terminal 31)

INFORMATION

If DMC5x4 control signals are connected with other vehicle components, then the connection to the

vehicle's ground must take place at this pin.

Internal wiring

1MΩ

24μF

Pin 1 GND

Housing

48V

Direct ground connection of the inverter's control electronics.

The signal ground is connected with the inverter housing through a few components. These components serve for

self protection and constitute a defined connection.

INFORMATION

Aside from the HV inputs, this 12 V inlet is also necessary for the functioning of the inverter!

The inverter is generally ready for operation when the following requirements are met:

Voltage is applied at the HV inlet (> V

DCmin

)

Voltage is applied at pin 2 (terminal 30)

Pin 17 and pin 18 are active,

see chapt. 8.3.7 Pin 17 EXT AW1, Pin 18 EXT AW2 (External shut down path 1 + 2)

Pin 1 (terminal 31) is connected

No error messages present

Internal wiring

1.3uF

Pin 2

AUX

100uH

1.5A

5V/uP

36V

ISU

+15V if HV present

Internal

Supply

20uF

Pin 3 EN

The internal 5 V supply is generated with this pin and offers the following possibilities:

CAN communication

Microprocessor programming (firmware)

Voltage measurement

As soon as HV is applied, LV is released:

If HV voltage = 0 V, LV is loaded with </= 150 mA

8.3.2 Pin 2 AUX (Wiring system terminal 30)

Technical data

and startup

42

If HV voltage > 100 V, the wiring system is loaded with </= 30 mA.

INFORMATION

To program new firmware, pin 3 must be high!

Internal wiring

95nF

Pin 3

EN

48V

47uF

+5V

4,7K

4,7K

100n

5V6

KL30

10K

KL15

INT

ISU

FLT

If voltage is applied at pin 2 and pin 3 = high, this effects the start-up of the controller. Communication with the

inverter is thereby enabled. If additional HV voltage is applied, this effects the activation of Ready mode.

The internal device logic is only fed if pin 3 = high. This is also the case if HV+ and HV- are already applied in high

voltage. Pin 3 has the function of terminal 15.

INFORMATION

The additional ground connections are intended to simplify the external wiring.

Internal wiring

470pF

Pin 8 PG1

Pin 14 PG2

Pin 15 PG3

750mA

The pins 8, 14 and 15 are each connected with pin 1 GND via a reversible fuse (PTC) and are thereby protected.

The following allocation is recommended:

Pin 8: Reserve

Pin 14: CAN-GND

Pin 15: 9 pole D-Sub: Pin 5

8.3.3 Pin 3 EN (Enable, Power ON)

8.3.4 Pin 8 PG1, 14 PG2, 15 PG3 (Reserve ground, RS232 ground)

43

Technical data

and startup

8.3.5 Pin 11 TXD, Pin 12 RXD (RS232 interface)

INFORMATION

This interface is NOT intended for general use! It is designed for firmware updates. Should you have

questions regarding this, refer to BRUSA support at the manufacturing address given in chapter 4.6.

Internal wiring

47pF

Pin 12

RXD

33V

47pF

Pin 11

TXD

33V

RS232-

Transceiver

200Ω

200Ω

470pF

470pF

The RS232 port enables a direct, serial connection between the inverter and a PC. You will find the configurations

for this in the manual SW-FW -SHC3_Firmware_download.pdf

In this document you will find all information regarding programming and the settings necessary for it.

The firmware for the microprocessor can be downloaded over this interface (provided by BRUSA). Pin 13 PRO

must be high for this.

Technical data

and startup

44

INSTRUCTION

The programming of the wrong firmware can lead to the damage of the inverter!

The programming may only be carried out after consultation with the company BRUSA Elektronik

AG!

INFORMATION

This pin is only activated for the programming of a new firmware (Pin PRO = high). Pin 3 EN must

also be high for this.

In normal operation, this pin may not be wired or it must be directly connected with terminal 31. An

open circuit can lead to a reset of the inverter!

Internal wiring

47nF

Pin 13

PRO

10uF

Schmitt

Trigger

22kΩ

5VSupply

Enable

22kΩ

1,0V

3,3V

48V

As soon as Pin 13 PRO is high, the following processes are triggered:

The inverter is stopped (reset) if it is in operation.

The programming can now be carried out via the serial interface.

8.3.6 Pin 13 PRO (Enable firmware programming)

45

Technical data

and startup

8.3.7 Pin 17 EXT AW1, Pin 18 EXT AW2 (External shut down path 1 + 2)

INFORMATION

These pins must be active for the basic functioning of the inverter.

This function is also intended as an additional safety installation. The shutdown takes place

redundantly through this at the output stage drivers (see illustration).

If this function is not used, both pins must be connected with terminal 30!

Internal wiring

470pF

Pin 17 EXT AW1

Pin 18 EXT AW2

20uF

Schmitt

Trigger

100kΩ

5VSupply

Enable

160kΩ

1,0V

3,3V

48V

15kΩ

To enable the output stage, pin 3 EN must also be high.

The both different circuits enable a redundant, direct switching off of the output stages.

The output stage can be released through higher-level control via these pins.

ISU

Upper

Lower

Pin 18 EXT.AW2

Pin 17 EXT.AW1

Pin 17 EXT.AW1

Pin 18 EXT.AW2

Lower

driver

Signal

Upper

driver

Signal

&

&

Powerstage released

driver

stage

driver

stage

Technical data

and startup

46

DANGER

High voltage!

Danger to life!

The bypassing or short-circuiting of safety installations can result in fatal dangers through high

voltage!

The interlock is a security installation and under no circumstances can it be disabled or bypassed!

INFORMATION

This function must be implemented by the customer by connecting and assessing both pins (pin 19

IL1 and Pin 20 IL2)!

The interlock switch is automatically activated as soon as the service cap is opened.

As a result, the high voltage connections will be forced to disconnect immediately! See chapter

3.4.1 Interlock.

Internal wiring

Pin 20 IL2

Pin 19 IL1

Switch opened if service

lid is open

Max switching voltage = 32 V

Max switching current = 30 mA

8.3.8 Pin 19 IL1, Pin 20 IL2 (Interlock 1 + 2)

47

Technical data

and startup

V

A A A

A

I

I

I

DMC5x4

HV-Supply

I

8.4 LV current consumption

Test setup

In the following tables you can see the LV current consumption of the control connector.

The currents were measured as follows:

Technical data

and startup

48

I

Aux

[µA] without HV

I

Aux

[µA] @ 300V

I

Aux

[µA] @ 400V

0

10

20

30

40

50

60

6 8 10 12 14 16 18 20 22 24 26 28 30 32

Strom [uA]

Spannung [V]

I_Aux [uA]

0

10

20

30

40

50

60

6 8 10 12 14 16 18 20 22 24 26 28 30 32

Strom [uA]

Spannung [V]

I_Aux [uA]

0

10

20

30

40

50

60

6 8 10 12 14 16 18 20 22 24 26 28 30 32

Strom [uA]

Spannung [V]

I_Aux [uA]

8.4.1 I

Aux

49

Technical data

and startup

I

Aux

+ IEn + I

Ext AW1

+ I

Ext AW2

without HV

I

Aux

+ IEn + I

Ext AW1

+ I

Ext AW2

@ 300V

I

Aux

+ IEn + I

Ext AW1

+ I

Ext AW2

@ 400V

0

20

40

60

80

100

120

140

160

6 8 10 12 14 16 18 20 22 24 26 28 30 32

Current [mA]

Voltage [V]

I_Aux [mA]

I_En [mA]

I_Ext AW1 [mA]

I_Ext AW2 [mA]

Total Current [mA]

0

10

20

30

40

50

60

70

6 8 10 12 14 16 18 20 22 24 26 28 30 32

Current [mA]

Voltage [V]

I_Aux [mA]

I_En [mA]

I_Ext AW1 [mA]

I_Ext AW2 [mA]

Total Current [mA]

0

10

20

30

40

50

60

70

6 8 10 12 14 16 18 20 22 24 26 28 30 32

Current [mA]

Voltage [V]

I_Aux [mA]

I_En [mA]

I_Ext AW1 [mA]

I_Ext AW2 [mA]

Total Current [mA]

8.4.2 I

+ IEn + I

Aux

Ext AW1

+ I

Ext AW2

Technical data

and startup

50

WARNING

Sparking!

Fire hazard!

A loose ground circuit can lead to sparking and subsequent fires!

Ensure that the ground connection is connected correctly!

INFORMATION

The grounding screw (1) must be connected with the ground of the vehicle and/or testing bay. We

generally recommend a direct connection to the motor.

The cable diameter of the ground cable must correspond to the dimensions of the HV wiring.

Torque grounding screw (1) M8 x 10 = 15 Nm

8.5 Grounding screw

51

Technical data

and startup

8.6 Cooling water connections

INFORMATION

The cooling water hose gets attached to the Normaquick terminals (1) and (2). Optionaly, you can

order normal cooling water connections for hose clamps, see chapter 4.4 Optional delivery contents.

The Normaquick connections have an inner diameter of 11 mm.

Cooling water inlet (1)

Cooling water outlet (2)

Technical data

and startup

52

INFORMATION

For correct operation, the following points have to be considered:

The mixing ratio of the coolant has to be at least 50% water and 50% glycol. Otherwise the

inverter will be destroyed at low temperatures!

The flow rate has to be between 6 l/min and 10 l/min!

If the particle size is over 0.2mm, the liquid pins get clogged!

The water pump must be active, even if the motor isn’t running when the inverter PWM is

active. The reason is, that the inverter also could clock when the vehicle is standing!

WARNING

When the abovementioned points based on the cooling getting ignored, the inverter will fail!

INSTRUCTION

For a proper cooling, please ensure the max. permissible particle size in the cooling water.

The max. allowable particle size in the cooling water is 0.2mm.

If this cannot be guaranteed, a water filter should be installed at the coolant inlet.

8.7 Cooling circuit Information and Warnings

8.7.1 Cooling water filter

53

Technical data

and startup

9 Start-up

DANGER

High voltage!

Danger to life!

While connecting the HV wiring, fatal injuries can occur if the HV wiring is live!

So check that the HV battery is not live before start-up!

INFORMATION

In this chapter, you will be lead step-by-step through each stage of the start-up. The given procedure

must absolutely be adhered to!

PROCEDURE STEP

ILLUSTRATION / OTHER INFORMATION

1.

Have the necessary additional documentation and

the required additional equipment ready.

see chapter 4.2 Scope of the entire documentation

2.

Install the provided software.

This step is only necessary if the inverter is not

integrated into a customer-provided CAN network

and/or no customer specific software is used for this.

3.

Integrate the device mechanically into the specified

position.

Use the screws and torques stated,

see chapter 6.6.2 Fixing (as in example DMC524)

4.

Ensure that the HV battery is not active.

---

5.

Build the interlock circuit and check the functioning.

see chapt. 8.3.8 Pin 19 IL1, Pin 20 IL2 (Interlock 1 + 2)

6.

If it is not already done, build all the connections at

the inverter.

see chapter 8 Connections

7.

Close the service cap.

see chapter 6.5 Covers

The interlock switch is activated.

8.

Ventilate and check the cooling system.

see chapter 9.2 Ventilate and check cooling system

9.

Connect the motor with inverter over the motor

sensor cable.

---

10.

Build the 12V supply.

---

11.

Establish communication between the PARAM_Tool

and the inverter.

see manual Param operation.pdf

12.

Parameters can now be set for the inverter with the

applied software (e.g. PARAM_Tool from BRUSA).

see manual Param operation.pdf

13.

If it is not already done, load the motor parameter

table onto the inverter.

see chapter 9.3 Load motor parameter table onto

inverter

14.

Build the HV supply.

see chapter 9.4 Build HV supply

15.

If it has not already been done, carry out rotor offset

adjustment.

see manual DMC5_RotorOffest_adjustment.pdf

16.

The inverter is now ready for operation and can be

operated though CVI.

see chapter 10 Operation of the inverter through CVI

Technical data

and startup

54

INSTRUCTION

Air pockets in the cooling passage along with generally insufficient cooling of the inverter lead to

increased wear!

Ensure that the cooling circuit is fault-free.

PROCEDURE STEP

ILLUSTRATION / OTHER INFORMATION

1.

Switch on the cooling circuit.

–––

2.

Leave the cooling circuit on for around 30 s.

To avoid the overheating of the device, flow must be

ensured as soon as the inverter is switched on via

CAN enable!

3.

Switch off the cooling circuit.

–––

4.

Check the cooling water level.

–––

9.1 System requirements for PARAM-tool software

Windows XP / Vista / WIN7 (32Bit /64Bit)

Serial port RS232 (firmware download)

9.2 Ventilate and check cooling system

9.3 Load motor parameter table onto inverter

To ensure the smooth driving of the motor, motor parameter tables corresponding to BRUSA motors are also

provided. These must be installed on the inverter using the PARAM-Tool software.

If using other brands of motor, the corresponding tables must be invoiced for and developed by BRUSA Elektronik

AG!

You will find instructions for installation and settings in the manual PARAM_Manual.pdf

55

Technical data

and startup

9.4 Build HV supply

INFORMATION

Before the HV connections are switched via a contactor, a pre-loading of the high voltage must take

place. The device specific X capacity values can be found in the technical data, see chapt.

6.1 Technical data

1.

Close the pre-charging contactor (1).

2.

Close the main contactor (3).

3.

Check that current U1 = U2. If so,

4.

Close the main contactor (2).

5.

Open the pre-charging contactor (1).

Technical data

and startup

56

INSTRUCTION

You must absolutely make sure that the individual strands of the shielding braid (4) do not jut out

again under any circumstances! Once in the integrated state, this will lead to damage of the sealing

lip and subsequently to the leaking of water into the housing! So cut all strands which stick out more!

PROCEDURE STEP

ILLUSTRATION / OTHER INFORMATION

1.

Insulate 25 mm of the HV cable (1).

Ensure that you do not damage the shielding

braid underneath it!

2.

Shorten the shielding braid (1) by 15 mm.

The cable-side shielding braid (2) must be a

length of around 10 mm.

9.5 Build HV-lines

The building of the HV wiring must be carried out in accordance with the following instructions. Here it is important

that no strands are damaged and that none stick out at the sides on the assembled cable. So check that the screw

connections are correct for each completed cable and that the cable lug is fixed properly (pull test).

For the HV connections we recommend:

A shielded, insulated automotive cable (e.g. Huber & Suhner).

A cable lug (for type see chapter 4.3 Delivered mechanical components)

To assemble the cable lug, using the appropriate crimping tool is absolutely necessary!

57

Technical data

and startup

PROCEDURE STEP

ILLUSTRATION / OTHER INFORMATION

3.

Lead the HV cable (1) through the union nut (2).

Lead the HV cable (1) through the terminal insert (3).

4.

Place the terminal insert (1) with the front edge flush

with the cable insulation (2).

5.

Put the shielding braid (1) over the terminal

insert (2).

During this, the shielding braid (1) may overlap the

O-Ring (3) by a maximum of 2 mm.

Fix the terminal insert (2) in position on the HV

cable, eg. with electrical tape (4).

Technical data

and startup

58

PROCEDURE STEP

ILLUSTRATION / OTHER INFORMATION

6.

Insulate 16 mm of the HV cable (1).

7.

Assemble the cable lug (1) at the end of the cable.

No strands should stick out at the sides!

The crimping must be hexagonal. Ensure that

the crimping has no deformations at the sides

because this will make later installations in the

BMS housing difficult!

8.

Check the secure positioning of the cable lug

manually.

---

9.

Assemble a shrinkage tube (1) on the cable lug (2).

The assembly of a shrinkage tube (1) is

absolutely necessary because otherwise

contacting can result in the BMS housing!

INSTRUCTION

During the layout of the cable take care that

the first part of the cable is at least 5cm

straight before it will be bend to a radius.

WARNING

If you have to reassembly the cable you have to use a new terminal insert. Otherwise it can cause a

leakage.

The terminal inserts can be ordered from BRUSA Elektronik AG or directly from hummel.com.

5cm

59

Technical data

and startup

10 Operation of the inverter through CVI

INFORMATION

The chapter is only relevant if you are working with the supplied CVI software CANAP_DMC5 !

1.

Activation of the CAN communication

2.

Deactivation of the CAN communication

3.

Torque

4.

Speed (number of revolutions)

5.

Error messages

6.

Warning messages

7.

Limitations

8.

Stop button (deactivate motor)

9.

CAN connection status

10.

Generator DC-current limitation value

11.

Motor DC-current limitation value

12.

Generator DC-voltage limitation value

13.

Motor DC-voltage limitation value

14.

Display of different actual values

15.

Command enable = switch output stage on/off

Clear error latch = confirm error message