minispec

Temperature Unit TC3

●

User Manual

Version 003

Innovation with Integrity

AIC

Copyright © by Bruker Corporation

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form, or by any means without the prior consent of the

publisher. Product names used are trademarks or registered trademarks of their respective holders.

This manual was written by

Bruker BioSpin AIC

© October 26, 2015 Bruker Corporation

P/N: H148851

For further technical assistance for this product, please do not hesitate to contact your

nearest BRUKER dealer or contact us directly at:

Bruker Corporation

Am Silberstreifen

76287 Rheinstetten

Germany

Phone: + 49 721 5161 0

E-mail: minispec.SLS@bruker.com

Internet: www.bruker.com

Contents

Contents

1 About This Manual .............................................................................................................................5

1.1 Policy Statement ................................................................................................................. 5

1.2 Symbols and Conventions ..................................................................................................5

2 Introduction.........................................................................................................................................7

2.1 Overview .............................................................................................................................7

2.2 Features..............................................................................................................................8

2.3 Intended Use.......................................................................................................................8

3 Safety...................................................................................................................................................9

3.1 Safety Notices.....................................................................................................................9

3.1.1 Power Cord Set Requirements ...........................................................................................9

3.1.2 Power Cord Safety Maintenance ........................................................................................9

3.1.3 Mains Disconnect................................................................................................................9

3.1.4 Mechanical Hazards .........................................................................................................10

3.1.5 Thermal Hazards ..............................................................................................................11

3.1.6 Operating Environment ..................................................................................................... 11

3.1.7 Explanation of Caution and Warning Notices ...................................................................12

3.2 Electromagnetic Interference ............................................................................................ 13

3.3 Explanation of Regulatory Marks ...................................................................................... 14

4 Technical Data ..................................................................................................................................15

4.1 Environmental Characteristics ..........................................................................................15

4.2 Electrical Characteristics...................................................................................................15

4.3 Gas Connection ................................................................................................................16

4.4 Thermal Characteristics ....................................................................................................16

5 Transport, Packaging and Storage .................................................................................................19

6 Installation.........................................................................................................................................21

6.1 Site Selection .................................................................................................................... 21

6.2 Installing the Unit on the Base ..........................................................................................21

6.3 Connecting the Cables to the Sample Changer................................................................23

6.4 Connecting to a Power Source .........................................................................................24

6.5 Connecting the Nitrogen Supply .......................................................................................25

7 Operation...........................................................................................................................................27

7.1 Power-On..........................................................................................................................27

7.2 Power-Off..........................................................................................................................27

7.3 Controlling the Temperature .............................................................................................27

7.4 Understanding the LEDs...................................................................................................27

7.4.1 Power Indicator ................................................................................................................. 27

7.4.2 Zone Status Indicators ...................................................................................................... 27

8 Maintenance......................................................................................................................................29

8.1 Replacing the Fuse ........................................................................................................... 29

8.2 Replacing the Air Filter......................................................................................................30

H148851_3_003 3

Contents

8.3 Cleaning Instructions ........................................................................................................31

9 Dismantling and Disposal................................................................................................................33

9.1 Safety................................................................................................................................33

9.2 Dismantling .......................................................................................................................33

9.3 Disposal ............................................................................................................................34

10 Contact ..............................................................................................................................................35

List of Figures...................................................................................................................................37

List of Tables ....................................................................................................................................39

Index ..................................................................................................................................................41

4 H148851_3_003

1 About This Manual

Before starting any work, personnel must read the manual thoroughly and understand

its contents. Compliance with all specified safety and operating instructions, as well as local

work safety regulations, are vital to ensure safe operation.

The figures shown in this manual are designed to be general and informative and may not

represent the specific Bruker model, component or software/firmware version you are

working with. Options and accessories may or may not be illustrated in each figure.

1.1 Policy Statement

It is the policy of Bruker to improve products as new techniques and components become

available. Bruker reserves the right to change specifications at any time.

Every effort has been made to avoid errors in text and figure presentation in this publication.

In order to produce useful and appropriate documentation, we welcome your comments on

this publication. Support engineers are advised to regularly check with Bruker for updated

information.

Bruker is committed to providing customers with inventive, high quality products and services

that are environmentally sound.

About This Manual

1.2 Symbols and Conventions

Safety instructions in this manual are marked with symbols. The safety instructions are

introduced using indicative words which express the extent of the hazard.

In order to avoid accidents, personal injury or damage to property, always observe safety

instructions and proceed with care.

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

This is the consequence of not following the warning.

1. This is the safety condition.

u This is the safety instruction.

WARNING indicates a hazardous situation, which, if not avoided, could result

in death or serious injury.

This is the consequence of not following the warning.

1. This is the safety condition.

u This is the safety instruction.

DANGER

WARNING

H148851_3_003

5

About This Manual

CAUTION indicates a hazardous situation, which, if not avoided, may result in

minor or moderate injury or severe material or property damage.

This is the consequence of not following the warning.

1. This is the safety condition.

u This is the safety instruction.

NOTICE indicates a property damage message.

This is the consequence of not following the notice.

1. This is a safety condition.

u This is a safety instruction.

CAUTION

NOTICE

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS are used for control flow and shutdowns in the event

of an error or emergency.

This is the consequence of not following the safety instructions.

1. This is a safety condition.

u This is a safety instruction.

This symbol highlights useful tips and recommendations as well as

information designed to ensure efficient and smooth operation.

6 H148851_3_003

2 Introduction

2.1 Overview

The TC3 temperature unit, also called a dry bath, allows you to control the temperature of

samples in an ASX-7000-series sample changer. It heats or chills the samples under the

control of a host computer.

Introduction

Figure2.1: The TC3 Unit.

The temperature unit comes in three versions:

• 10 mm SFC version: The unit holds vials in three temperature-controlled zones. Each

zone holds 60 vials, with a maximum temperature of 100° C.

• 10 mm polymers version: The unit holds vials in one temperature-controlled zone. Each

zone holds 60 vials, with a maximum temperature of 110° C.

• 26 mm version: The unit holds vials in two temperature-controlled zones. Each zone

holds 24 vials, with a maximum temperature of 80° C.

A power cord and appropriate data cables are also provided.

H148851_3_003

7

Introduction

2.2 Features

Temperature Range

Three zones hold samples at 0° C to +100° C.

Sample Changer Compatibility

Use only with an ASX-7600 pick-and-place NMR sample changer.

Chemical Compatibility

Exposed surfaces are made of corrosion‑resistant stainless steel alloys or anodized

aluminum.

2.3 Intended Use

This equipment is designed for use in analytical laboratories performing chemical analysis of

samples.

8 H148851_3_003

3 Safety

Review this product and related documentation to familiarize with safety markings and

instructions before you operate the instrument.

3.1 Safety Notices

Injury Hazard

If the device is used in a manner not specified by the manufacturer, the protection provided

by the device may be impaired.

Safety

CAUTION

Repair or service that is not covered in this manual should only be performed by qualified

personnel.

3.1.1 Power Cord Set Requirements

The power cord set supplied with the device meets the requirements of the country where the

device was purchased. Power is supplied to the device through the included 24V power

supply.

3.1.2 Power Cord Safety Maintenance

The operator should check the condition of the power/signal supply cord. The device should

not be operated if the mains inlet is cracked or broken. Any obvious damage to the case

(from a drop or fall) should be checked by service personnel for loose or damaged parts.

Refer to the individual part lists, or contact Bruker, for approved replacement parts.

3.1.3 Mains Disconnect

The power switch on the rear panel is not the mains disconnect. Power mains disconnect is

accomplished by unplugging the power cord from the power supply or from the wall outlet.

Ensure the power cord is easily accessible and removable, in the event of an emergency

which requires immediate disconnection.

H148851_3_003

9

Safety

Fire and Shock Hazard

Incorrect installation or use of the power supply may result in a fire or shock hazard.

u Use only the provided power supply.

u The power supply must be plugged into an outlet which has a protective ground

connection.

u Ensure that the power cord is disconnected before removing any covers.

3.1.4 Mechanical Hazards

WARNING

Figure3.1: Bottom View with Filter Drawer Removed

WARNING

Laceration Hazard

If the unit power is left on, the spinning fan blade just above the filter may cause injury.

u Ensure the AC power is off before removing the filter.

WARNING

Lifting Hazard

Lifting without assistance may cause injury.

u Two people are required to lift the device.

u Lifting should be done with a person situated on either side of the device.

10 H148851_3_003

3.1.5 Thermal Hazards

Burn Hazard

Incorrect handling of vials or inserting fingers into any holes in the device may result in burn

injuries.

u Do not handle vials from heated zones until they have been given time to cool.

u Do not attempt to insert fingers into any holes in the device.

3.1.6 Operating Environment

Shock Hazard from Rain or Humidity

Device exposure to rain or humidity could result in a risk of fie or electrical shock.

u Do not expose the device to rain or humidity.

u Do not open the cabinet, all maintenance is to be performed by an authorized service

provider.

Safety

WARNING

WARNING

Protection provided by the device may be impaired if the device is used in a manner not

specified by the manufacturer.

WARNING

Shock Hazard from Liquids

Liquid coming in contact with electrical components may result in a serious injury through

shock.

u Do not allow any liquid to enter the device cabinet other than as intended through the

specified tubing, or come into contact with any electrical components.

u The device must be thoroughly dry before you reconnect power, or turn the device on.

WARNING

Explosion Hazard

Explosive atmospheres caused by flammable gases, mists or vapors or by combustible

dusts could result in an explosion.

u Prevent the release of dangerous substances, which can create explosive atmospheres.

u Prevent sources of ignition.

u Do not operate the device in an explosive atmosphere.

H148851_3_003

11

Safety

WARNING

Chemical Hazards

Incorrect use of chemicals used in and near the device may result in injury or property

damage.

u Learn about the chemicals which will be used in and near the device, and observe the

necessary precautions.

u Always use appropriate personal protective equipment, including protective eyewear.

3.1.7 Explanation of Caution and Warning Notices

Warning symbol marked on device.

• This symbol means “Attention! Refer to the

manual.

Crush Hazard / Pinch Point.

• Keep hands clear of moving parts. X, Y, Z axis

movement may crush hand.

Puncture Hazard – Moving parts can cause severe

injury.

• Do not put hand under the gripper assembly!

12 H148851_3_003

Lifting Hazard – Single person lift could cause injury.

• Use assistance when moving or lifting.

Table3.1: Explanation of Caution and Warning Notices

3.2 Electromagnetic Interference

Safety

FEDERAL COMMUNICATIONS COMMISSION (FCC) NOTICE

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a commercial installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. Operation of this equipment in a residential environment is likely to cause

harmful interference, in which case the user will be required to correct the interference at his

expense.

MODIFICATIONS

The FCC requires the user to be notified that any changes or modifications made to this

device that are not expressly approved by the manufacturer may void the user's authority to

operate the equipment.

CABLES

Connections to this device must be made with shielded cables with metallic RFI/EMI

connector hoods to maintain compliance with FCC Rules and Regulations.

CANADIAN NOTICE

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus as set out in the interference-causing equipment standard entitled "Digital

Apparatus" ICES-001 of the Department of Communications.

AVIS CANADIEN

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux

appareils numériques de Classe A prescrites dans la norme sur le matériel brouilleur:

"Appareils Numériques," NMB-001 édictée par le ministre des Communications.

H148851_3_003

13

Safety

3.3 Explanation of Regulatory Marks

The CE mark is a registered trademark of the European Community. This CE mark

shows that the product complies with all the relevant European Legal Directives.

14 H148851_3_003

4 Technical Data

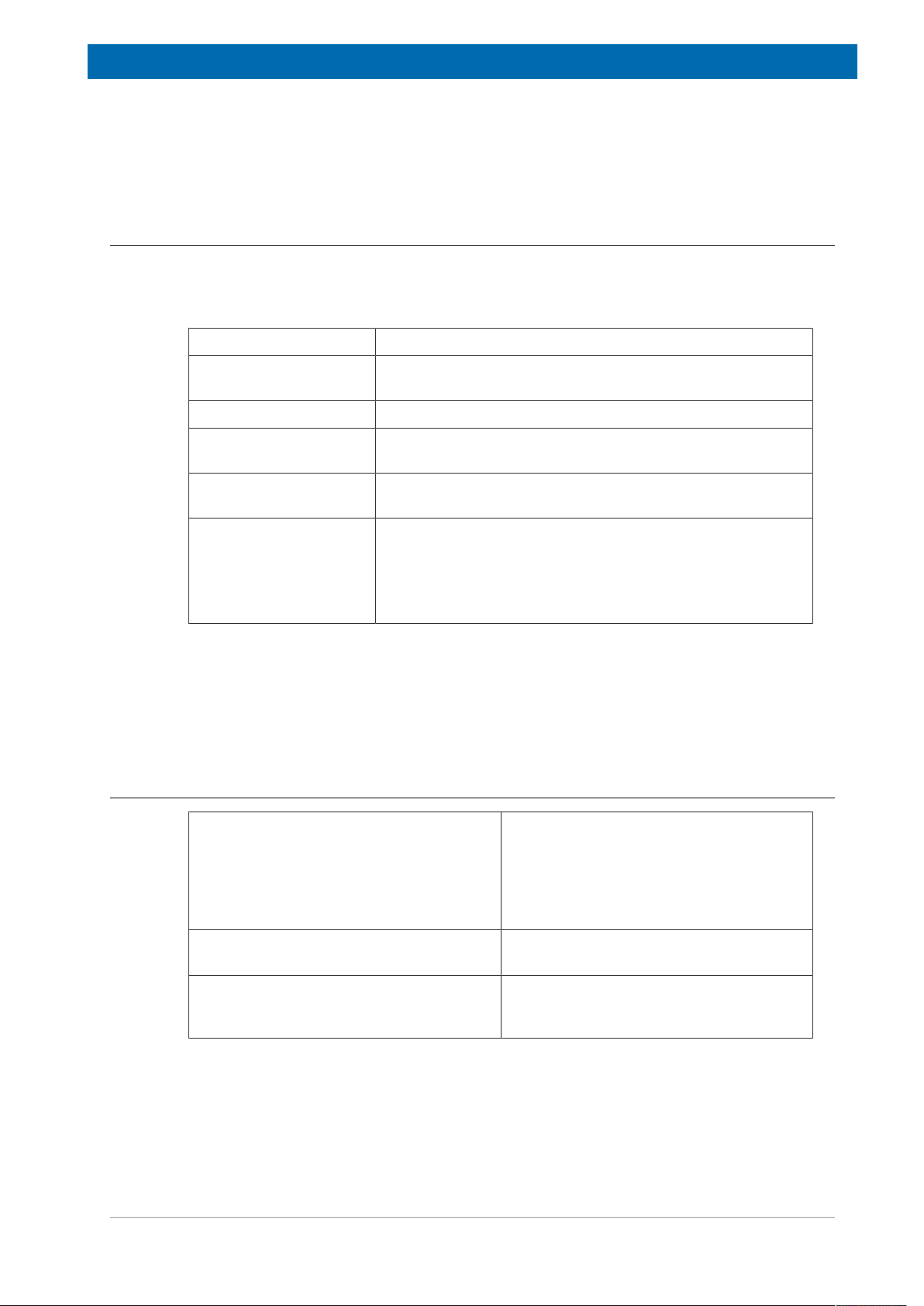

4.1 Environmental Characteristics

These environmental characteristics indicate the conditions for safe operation. Instrument

performance may depend on the ambient conditions.

Operating Temperature +5° C to +40° C (+41° F to +104° F)

Technical Data

Non-Operating

Temperature

Operating Altitude Up to 2,000 m (6,562 ft.)

Relative Humidity 0% to 80% non-condensing for temperatures up to 31° C,

Non-Operating Relative

Humidity

Pollution Degree Pollution degree 2.

Table4.1: Environmental Characteristics

For indoor use only.

Avoid sudden, extreme temperature changes which could cause condensation on circuit

boards in the device.

+0° C to +55° C (+32° to +131° F)

decreasing linearly to 50% at 40° C.

0% to 95% non-condensing.

Normally no pollution or only dry, non-conductive pollution

occurs. The pollution has no influence. Occasionally,

however, a temporary conductivity caused by condensation

may be expected.

4.2 Electrical Characteristics

Power Input:

RS232 RS-232 serial connection to the sample

RS485 TIA/EIA-485 (use only for connection to

Table4.2: Electrical Characteristics

H148851_3_003

AC voltage, frequency, and current

100-240 V ~, 50-60 Hz, 5 A maximum

Installation category: CAT II (line voltage in

appliance and to wall outlet)

changer (max ±12VDC, 8 mA)

another temperature unit, max ±8VDC, 200

µA)

15

Technical Data

4.3 Gas Connection

One fitting is provided for nitrogen purge gas. The nitrogen source must be regulated to a

pressure of no more than 35 kPa (5 psi, 0.35 bar). A typical gas flow of 0.5 liter/minute shall

apply.

4.4 Thermal Characteristics

Figure4.1: Thermal Characteristics of a 3-Zone 10 mm SFC Version

Zone Default Temperature Temperature Range

3 0° C 0° C to +66° C

2 65° C Ambient +5° C to +66° C

1 100° C Ambient +5° C to +100° C

16 H148851_3_003

Figure4.2: Thermal Characteristics of a 1-Zone 10 mm Polymers Version

Technical Data

Zone Default Range

1 Ambient +5° C to +110° C

Figure4.3: Thermal Characteristics of a 2-Zone 26 mm Version

H148851_3_003

Zone Temperature Range

2 Ambient +5° C to +80° C

1 Ambient + 5° C to +80° C

17

Technical Data

18 H148851_3_003

Transport, Packaging and Storage

5 Transport, Packaging and

Storage

WARNING

Lifting Hazard

Lifting without assistance may cause injury.

u Two people are required to lift the device.

u Lifting should be done with a person situated on either side of the device.

Inspect external packaging upon receipt for signs of shipping damage. Inspect all items

during unpacking and notify the carrier immediately of any concealed damage. Check for

kinked tubing.

If the system is shipped or removed from storage during cold weather, allow the packaged

equipment to equilibrate to room temperature before opening and exposing to warm, humid

air. It is usually sufficient to provide four to eight hours for this purpose.

CAUTION

Equipment Damage from Condensation

If condensation forms on or inside the unit, allow it to dry thoroughly before connecting it to a

power source and operating it. Failure to do so may cause equipment damage.

Remove the packing checklist from the shipping container, and check off items against it.

Leave accessories in the packing until you are ready to install them.

Note: Keep the factory packaging for use in case the product ever needs to be returned or

shipped to another location.

H148851_3_003

19

Transport, Packaging and Storage

20 H148851_3_003

6 Installation

6.1 Site Selection

Follow the guidelines in the sample changer Operator's Manual to choose a location for the

system. Keep in mind that:

• You will need to be able to access the back of the system to install cables and tubing.

• Place the sample changer within 1.2 meters of a power outlet.

• Allow at least 5 cm behind the power supply for cable egress, ventilation, and access to

the power switches. Always position the equipment so that it is easy to disconnect the

power cord.

6.2 Installing the Unit on the Base

WARNING

Installation

Lifting Hazard

Lifting without assistance may cause injury.

u Two people are required to lift the device.

u Lifting should be done with a person situated on either side of the device.

WARNING

Pinch/Puncture Hazard

Ensure the AC power is off before proceeding with installation. If the power is left on, motors

may move unexpectedly and cause injury.

H148851_3_003

21

Installation

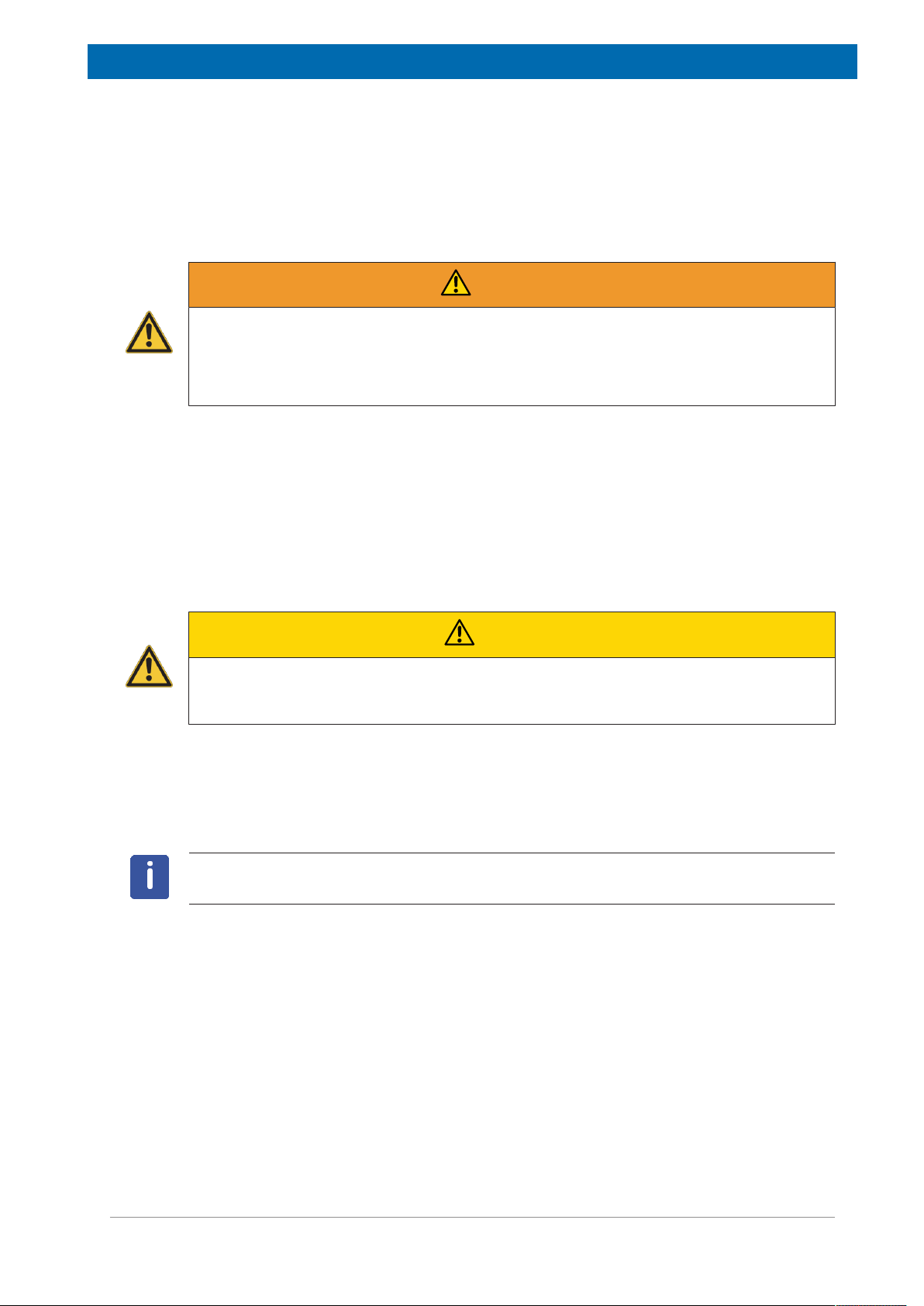

The temperature unit is positioned by means of two spring-loaded pins:

Figure6.1: Base of the Sample Changer

Figure6.2: Bottom of the Temperature Unit

• If using a version which is equipped with an air filter, remove the filter drawer from the

front of the temperature unit. This provides an additional lifting point.

With the help of an assistant, place each temperature unit on the base of the sample

changer slightly toward the front edge of the base.

• Keep the bottom of the temperature unit parallel to the base, so that the corners don't

gouge the finish on the base.

• Slide the temperature unit back until the pins engage the holes. You should hear or feel a

click.

22 H148851_3_003

Installation

Note: You can mount the temperature unit on a bench top or table using the optional table

adapter:

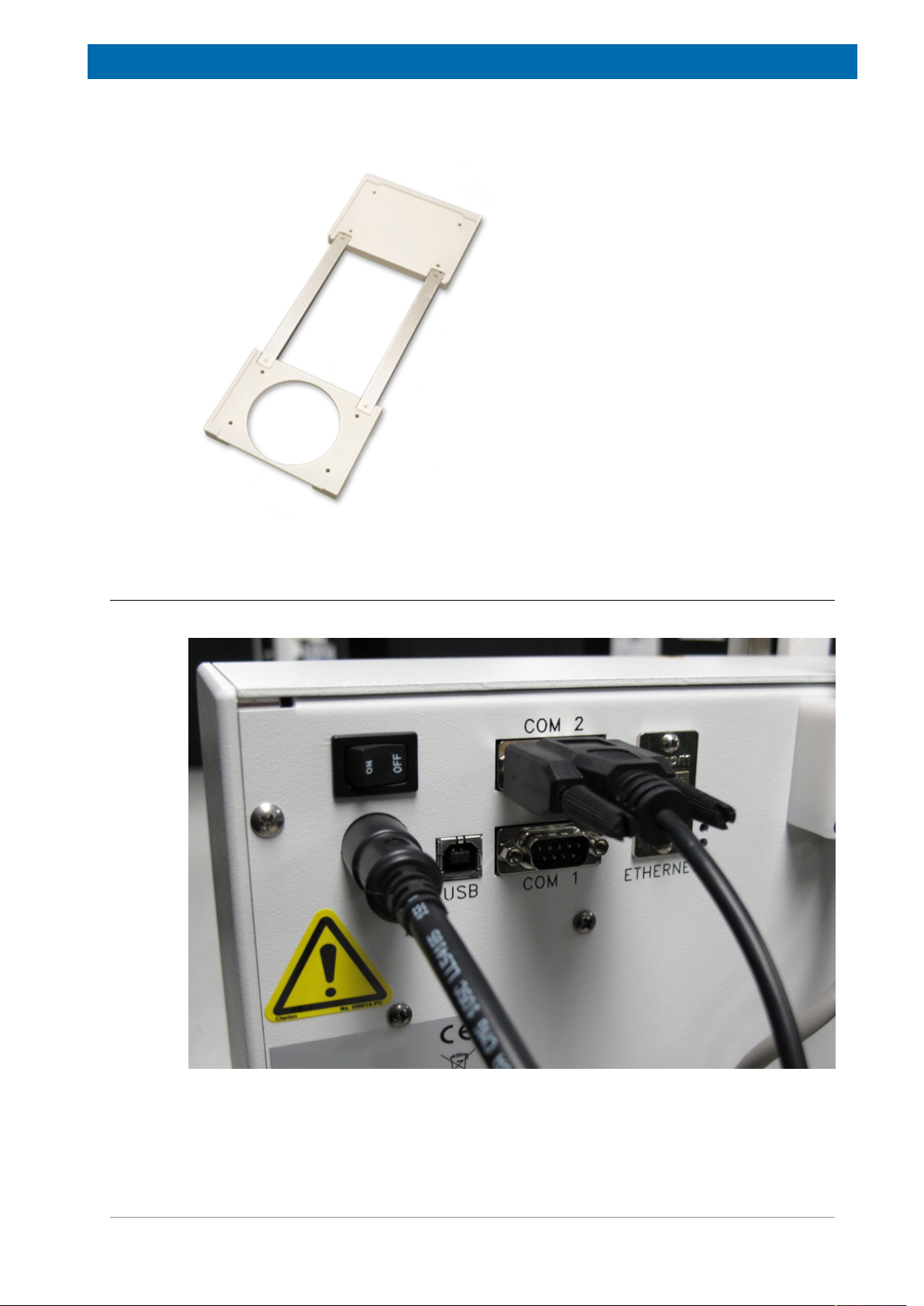

Figure6.3: Optional Table Adapter

6.3 Connecting the Cables to the Sample Changer

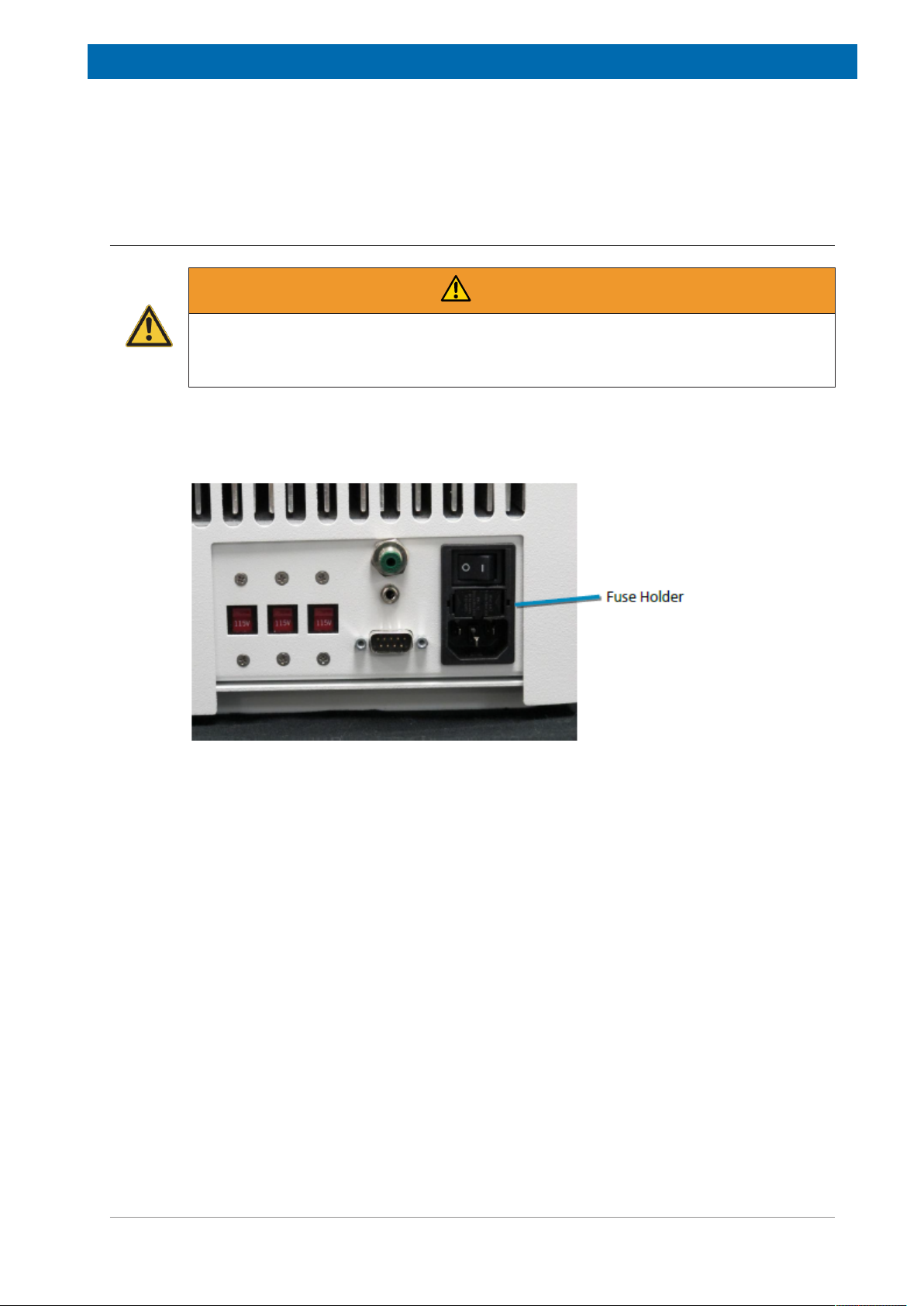

• Connect the 9-pin serial cable to the COM 2 port on the sample changer.

Figure6.4: Serial Cable Connected to the Back of the Sample Changer.

• Connect the other end of the serial cable to the RS232 port on the unit.

H148851_3_003

23

Installation

Figure6.5: Serial Connector on the Unit.

• Connect the sample changer to the host computer as described in the sample changer

Operator's Manual.

• If using a TC3 and TC6 temperature unit together, connect the supplied RS-485 serial

cable between the two temperature units.

6.4 Connecting to a Power Source

• Turn the power switches on the sample changer and power supply OFF.

• Check the plug on the power cord to verify that it is of the correct type for your country.

Contact the manufacturer if you need a different power cord.

• Set the voltage selection switches to the correct voltage for your country (115VAC or

230VAC).

WARNING

Fire and Shock Hazard

Incorrect installation or use of the power supply may result in a fire or shock hazard.

u Use only the provided power supply.

u The power supply must be plugged into an outlet which has a protective ground

connection.

u Ensure that the power cord is disconnected before removing any covers.

• Locate the proper fuse for your voltage, then install the fuse in the fuse holder.

• Push the fuse holder in until it clicks into place.

• Plug the power cord into the back of the unit.

24 H148851_3_003

Installation

Figure6.6: Power Connections for the Unit

• Plug the power cord into a power outlet.

It is important to use the appropriate power cord for your country. See Power Cord Set

Requirements [}9].

6.5 Connecting the Nitrogen Supply

A source of low-pressure nitrogen may be connected for purging the unit. The nitrogen

displaces air within the unit to prevent condensation.

Use a regulator. The nitrogen source must supply a pressure of no more than 35 kPa (5 psi,

0.35 bar). A typical gas flow of 0.5 liter/minute shall apply.

Use as little nitrogen as is needed to prevent condensation.

If the pressure exceeds 35 kPa, the excess nitrogen will be vented and you will hear a hissing

sound.

Figure6.7: Nitrogen Connection for the Unit

H148851_3_003

25

Installation

26 H148851_3_003

7 Operation

7.1 Power-On

To turn the system on, first turn the temperature unit switch ON, then the sample changer.

7.2 Power-Off

To turn the system off, first turn the sample changer power switch OFF, then the temperature

unit.

In case of emergency, or before performing maintenance, remove the power cord from the

back of the temperature unit and from the sample changer.

7.3 Controlling the Temperature

The host computer sends commands to the sample changer, which then passes the

commands through to the power supply.

Operation

7.4 Understanding the LEDs

There are two kinds of LEDs on the temperature unit:

• A power indicator.

• Status indicators for each temperature control zone.

Figure7.1: LEDs (for 10 mm SFC version with 3 zones).

7.4.1 Power Indicator

Green: Lighted green when power is connected.

7.4.2 Zone Status Indicators

Red: Flashing indicates it is heating and in transition to a set point, solid indicates it is heating

and at a set point.

Blue: Flashing indicates it is chilling and in transition to a set point, solid indicates it is chilling

and at a set point.

H148851_3_003

27

Operation

28 H148851_3_003

8 Maintenance

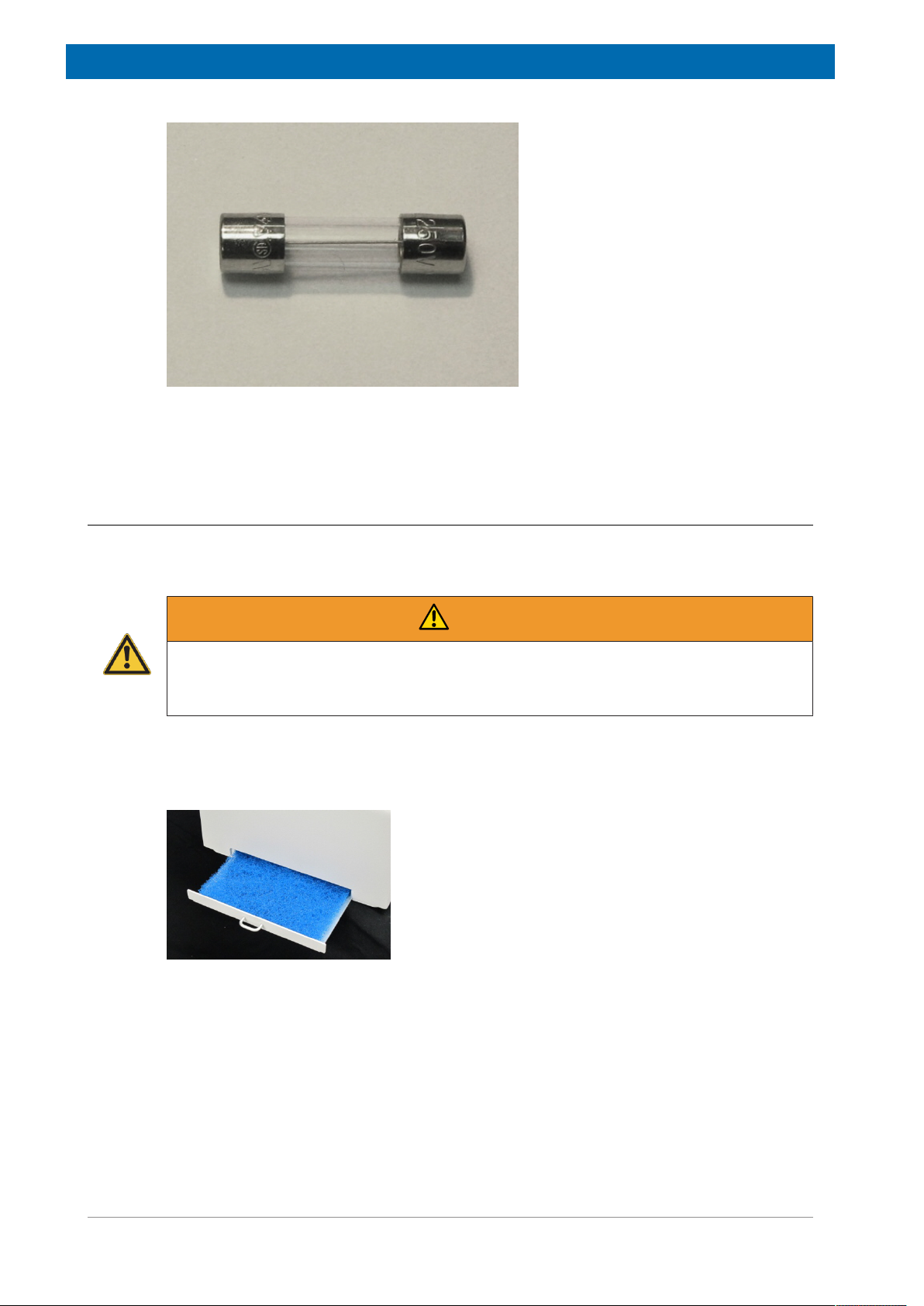

8.1 Replacing the Fuse

Fire and Shock Hazard

Using an incorrect fuse may cause fire or personal injury. .

u Replace the fuses only with a 10A 250V slow-blow 5x20 mm fuse (T10AL250V).

Two fuses are located in the power supply, just above the power cord connector.

Maintenance

WARNING

Figure8.1: Fuse Holder for the TC3

• Disconnect the power cord.

• Inspect all of the equipment which is plugged into the power supply for moisture or other

conditions which might pose a hazard and cause the new fuse to blow.

• Using your fingernails or a small, flat-blade screwdriver, squeeze the ends of the fuse

holder.

• Pull the fuse holder out.

• Replace the blown fuse with a new one of the same size, type, and rating.

H148851_3_003

29

Maintenance

Figure8.2: Fuse

• Press the fuse holder back in until it clicks into place.

• Plug the power cord back in.

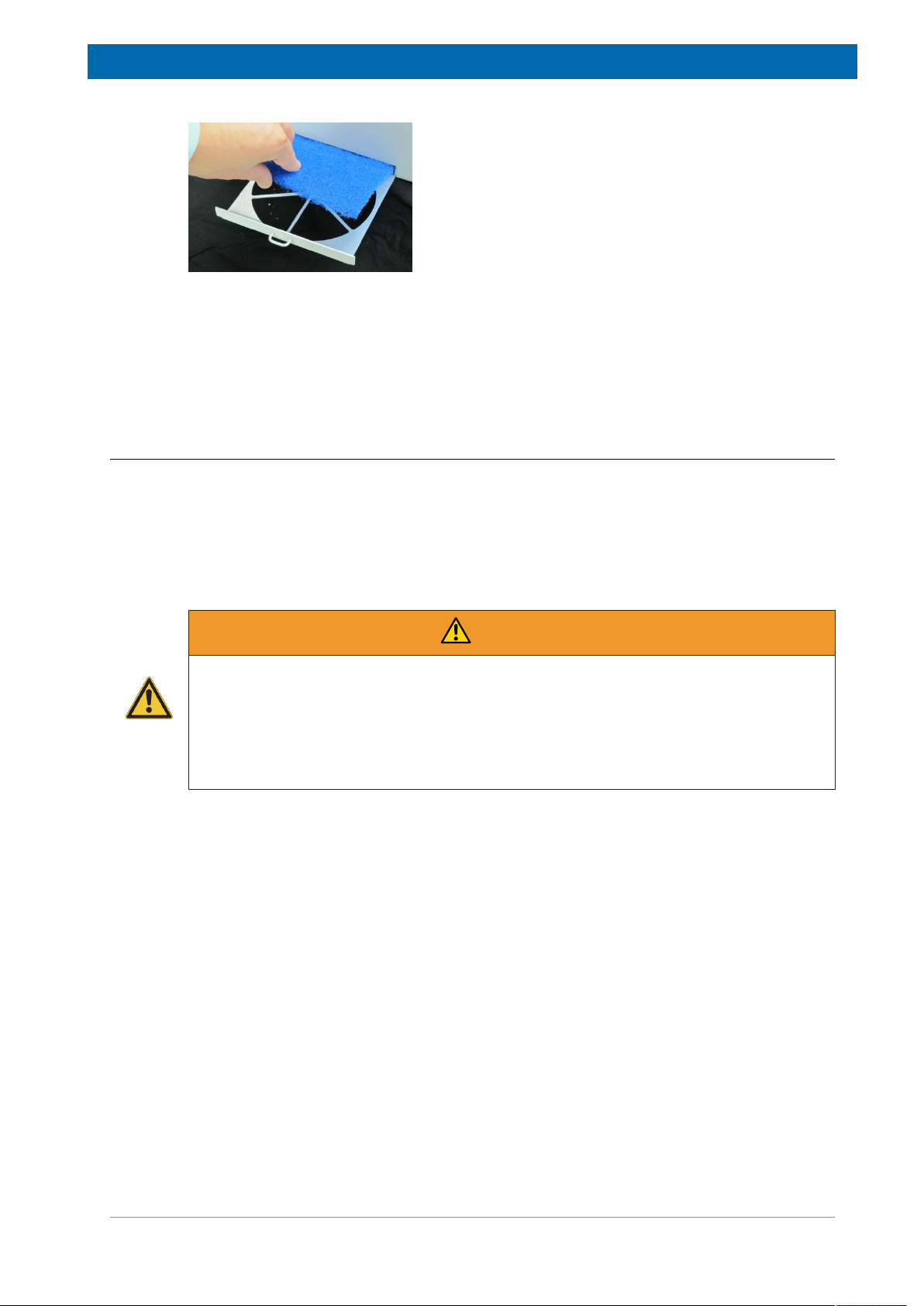

8.2 Replacing the Air Filter

The 3-zone 10 mm SFC version of the TC3 includes a user-replaceable air filter. Contact

Bruker for information on replacement filters.

WARNING

Laceration Hazard

If the unit power is left on, the spinning fan blade just above the filter may cause injury.

u Ensure the AC power is off before removing the filter.

• Turn the power switch off.

• Pull the filter drawer open.

Figure8.3: Opening the Filter Drawer

• Remove the old filter. If necessary, use your fingers to pull it out of the opening.

30 H148851_3_003

Figure8.4: Removing and Installing the Filter

• Install the new filter.

• Close the filter drawer.

• Turn the power back on.

8.3 Cleaning Instructions

To clean the exterior surfaces of the device, complete the following steps:

• Shut down and unplug the device.

• Wipe the exterior surfaces only using a towel dampened with a lab‑grade cleaning agent.

• Repeat the previous step, using a towel dampened with clear water.

• Dry the device exterior using a dry towel.

Maintenance

WARNING

Shock Hazard from Liquids

Liquid coming in contact with electrical components may result in a serious injury through

shock.

u Do not allow any liquid to enter the device cabinet other than as intended through the

specified tubing, or come into contact with any electrical components.

u The device must be thoroughly dry before you reconnect power, or turn the device on.

H148851_3_003

31

Maintenance

32 H148851_3_003

Dismantling and Disposal

9 Dismantling and Disposal

Following the end of its operational life, the device must be dismantled and disposed of in

accordance with the environmental regulations.

Installation, initial commissioning, retrofitting, repairs, adjustments or dismantling of the

device must only be carried out by Bruker Service or personnel authorized by Bruker.

Damage due to servicing that is not authorized by Bruker is not covered by your warranty.

9.1 Safety

WARNING

Danger of injury from electrical shock!

A life threatening shock may result when the housing is open during operation.

u Only qualified personnel should open the housing.

u Disconnect the device from the electrical power supply before opening the device. Use

a voltmeter to verify that the device is not under power!

u Be sure that the power supply cannot be reconnected without notice.

WARNING

Danger of injury due to improper dismantling!

Stored residual energy, angular components, points and edges on and in the device or on

the tools needed can cause injuries.

u Ensure sufficient space before starting work.

u Handle exposed, sharp-edged components with care.

u Dismantle the components properly.

u Secure components so that they cannot fall down or topple over.

u Consult the manufacturer if in doubt.

9.2 Dismantling

Before starting dismantling:

1. Shut down the device and secure to prevent restarting.

2. Disconnect the power supply from the device; discharge stored residual energy.

3. Remove consumables, auxiliary materials and other processing materials and dispose of

in accordance with the environmental regulations.

4. Clean assemblies and parts properly and dismantle in compliance with applicable local

occupational safety and environmental protection regulations.

H148851_3_003

33

Dismantling and Disposal

9.3 Disposal

After the lifespan of the product, Bruker takes responsibility for disassembly and disposal in

accordance with the European Directive WEEE 2012/19/EC. Bruker BioSpin will take back

the components free of charge upon request by the customer. If the customer wants to

arrange disposal on their own, then this must be stated when the product is ordered.

European Waste Electrical and Electronic Equipment Directive (WEEE 2012/19/EC)

Do not dispose in domestic household waste.

The affixed label indicates that it is prohibited to discard this electrical/electronic product in

domestic household waste, in compliance with the European Waste Electrical and Electronic

Equipment Directive (WEEE 2012/19/EC).

For instructions on how to return end-of-life equipment, producer-supplied electrical

accessories or auxiliary items for proper disposal contact the supplier or importer. If the

supplier cannot be reached, contact the manufacturer.

NOTICE

Danger to the environment from incorrect handling of pollutants!

Incorrect handling of pollutants, particularly incorrect waste disposal, may cause serious

damage to the environment.

u Always observe local environmental regulations regarding handling and disposal of

pollutants.

u Take the appropriate actions immediately if pollutants escape accidentally into the

environment. If in doubt, inform the responsible municipal authorities about the damage

and ask about the appropriate actions to be taken.

34 H148851_3_003

10 Contact

Manufacturer:

Bruker BioSpin GmbH

Am Silberstreifen

D-76287 Rheinstetten

Germany

Helpdesk Europe: (+49) 721-5161-6155

Helpdesk USA: (+1) 978-667-9580

Contact

E-Mail:

http://www.bruker.com

WEEE DE43181702

Bruker BioSpin Hotlines

Contact our Bruker BioSpin service centers.

Bruker BioSpin provides dedicated hotlines and service centers, so that our specialists can

respond as quickly as possible to all your service requests, applications questions, software

or technical needs.

Please select the service center or hotline you wish to contact from our list available at:

http://www.bruker.com/service/information-communication/helpdesk/magnetic-

resonance.html

minispec.SLS@bruker.com

H148851_3_003

35

Contact

36 H148851_3_003

List of Figures

List of Figures

Figure 2.1: The TC3 Unit. ............................................................................................................... 7

Figure 3.1: Bottom View with Filter Drawer Removed .................................................................... 10

Figure 4.1: Thermal Characteristics of a 3-Zone 10 mm SFC Version ........................................... 16

Figure 4.2: Thermal Characteristics of a 1-Zone 10 mm Polymers Version ................................... 17

Figure 4.3: Thermal Characteristics of a 2-Zone 26 mm Version ................................................... 17

Figure 6.1: Base of the Sample Changer........................................................................................ 22

Figure 6.2: Bottom of the Temperature Unit ................................................................................... 22

Figure 6.3: Optional Table Adapter................................................................................................. 23

Figure 6.4: Serial Cable Connected to the Back of the Sample Changer....................................... 23

Figure 6.5: Serial Connector on the Unit......................................................................................... 24

Figure 6.6: Power Connections for the Unit .................................................................................... 25

Figure 6.7: Nitrogen Connection for the Unit .................................................................................. 25

Figure 7.1: LEDs (for 10 mm SFC version with 3 zones)................................................................ 27

Figure 8.1: Fuse Holder for the TC3 ............................................................................................... 29

Figure 8.2: Fuse.............................................................................................................................. 30

Figure 8.3: Opening the Filter Drawer............................................................................................. 30

Figure 8.4: Removing and Installing the Filter ................................................................................ 31

H148851_3_003 37

List of Figures

38 H148851_3_003

List of Tables

List of Tables

Table 3.1: Explanation of Caution and Warning Notices .................................................................... 12

Table 4.1: Environmental Characteristics ........................................................................................... 15

Table 4.2: Electrical Characteristics.................................................................................................... 15

H148851_3_003 39

List of Tables

40 H148851_3_003

Index

Index

P

pollution degree................................................15

power cord..........................................................9

A

Air filter .............................................................30

avis Canadien...................................................13

C

cleaning ............................................................31

condensation

humidity .......................................................19

D

Disassembly .....................................................34

disposal ............................................................34

E

Electrical characteristics...................................15

F

FCC notice .......................................................13

Filter..................................................................30

Fuse ...........................................................24, 29

R

Regulatory notices..............................................9

S

Safety information ..............................................9

T

Table adapter ...................................................23

Temperature

Operating.....................................................15

Temperature range...........................................16

Tubing

kinks ............................................................19

V

Voltage selection ..............................................24

W

WEEE notice ....................................................34

H

Humidity ...............................................11, 15, 19

I

ICES 001 ..........................................................13

intended use.......................................................8

interference ......................................................13

L

Lamps

LEDs............................................................27

LEDs.................................................................27

lifting instructions..................................10, 19, 21

M

mains disconnect................................................9

N

Nitrogen supply ................................................25

H148851_3_003

41

Index

42 H148851_3_003

H148851_3_003 43

Bruker Corporation

●

info@bruker.com

www.bruker.com

Order No: H148851

Loading...

Loading...