Brugg LMS 120 monitoring device

Operating and service instructions

Art.-Nr.: 1010368

Operating and service instructions | LMS 120 2

Contents

1.! Scope of delivery .............................................................................................................................................. 4!

2.! General ............................................................................................................................................................... 4!

2.1. System design ................................................................................................................................................. 4!

3.! Installation ......................................................................................................................................................... 5!

3.1. Mechanical installation ..................................................................................................................................... 5!

3.2. Electrical connection ........................................................................................................................................ 6!

4.! Operation ........................................................................................................................................................... 7!

4.1. Display and operating elements ...................................................................................................................... 7!

4.2. Operation menu ............................................................................................................................................... 8!

4.3. Quick parameter setting ................................................................................................................................... 9!

4.4. Enhanced parameter setting .......................................................................................................................... 10!

4.5. Alarm menu ................................................................................................................................................... 13!

4.6. Manual measurement .................................................................................................................................... 14!

4.7. Firmware update ............................................................................................................................................ 14!

5.! Maintenance .................................................................................................................................................... 15!

6.! Service ............................................................................................................................................................. 15!

6.1. System code .................................................................................................................................................. 15!

6.2. Fault record .................................................................................................................................................... 16!

Tab. 5 (Fault record)7.! Accessories ................................................................................................................... 16!

8.! Technical data ................................................................................................................................................. 17!

9.! Glossary, terms ............................................................................................................................................... 18!

10.! Notes ................................................................................................................................................................ 19!

Operating and service instructions | LMS 120 3

Safety notes

The following points must be observed for safety during connecting and operating the device. Read the notes

carefully before commissioning the device. The installer is responsible for any damage caused by improper use or

application of the device.

Mains

voltage

Operate the device only with the mains voltage intended (see 8. Technical data;

page 17). The device may only be connected to the mains once all connections

have been established. There is a risk of fire in the event of incorrect mains voltage.

Mains cable

It must be ensured that the mains cable is not damaged. Devices with damaged

mains cables must be disconnected from the mains (disconnect the mains plug)

and made secure before re-commissioning. There is a danger to life from electric

shock.

Earthing

The device must be earthed as required by regulations or connected to a suitable

potential equalisation. The DIN VDE 100 and the country-specific regulations must

be observed. There is a risk of excess voltage.

Place of

installation

Protect the device from humidity, dripping and spray water. Do not place any

objects on the device. Do not install the device near strong sources of heat. Do not

expose it to direct sunlight.

There is a risk of fire.

Cleaning

Disconnect the mains plug before cleaning the device. Use a dry cloth for cleaning

and clean the surface only. There is a danger to life from electric shock when

coming into contact with parts inside the device.

Connections

Incorrect wiring of the connections may result in faults or defective devices. The

manufacturer accepts no liability for accidents that are caused by incorrectly

installed or improperly maintained devices. The manufacturer accepts no liability

whatsoever if the system is incorrectly used or programmed in a way that is not

safe.

Ventilation

The heat created in the device is dispersed sufficiently. Do not install the device in a

cabinet with insufficient heat extraction or near sources of heat. (see 3.1.

Mechanical installation and 3.2. Electrical connection; from page 5). There is a risk

of fire.

Operation

Correct operation requires that the transparent front lid of the LMS 120 is closed to

ensure protection category IP65.

Repairs

Installation, modification, repairs or maintenance must be carried out in accordance

with the regulations of the manufacturer. Any disassembly and repair attempts

without the manufacturer’s approval result in the warranty claim becoming null and

void. Tampering with the device may put the electric safety of the device at risk.

The manufacturer is not liable for accidents of the user on the open device.

Electronic devices should not be disposed of with domestic waste. They must be disposed of in

accordance with the country-specific directives. Please discard this device at the intended collection

points for disposal when no longer in use. For discarded electric and electronic devices, Directive

2002/96/EC of 27 January 2003 applies in the European Union.

When conducting welding work on the district heating pipeline, the LMS 120 MUST be deactivated and

the measuring lines MUST be disconnected. Otherwise, the LMS 120 and other connected devices may

be damaged.

Operating and service instructions | LMS 120 4

1. Scope of delivery

• LMS 120 monitoring device with pre-installed mains cable

• Plug connector - insert for alarm terminal

• Plug connector - inserts for monitoring channels 1 and 2 terminals

• Operating instructions

• Drilling template

2. General

The LMS 120 is suitable for monitoring two sensor wires in district heating pipelines. These may be executed in accordance with the

NORDIC or BRANDES system. The so-called SWISS system corresponds to the Nordic system with one isolated conductor.

The technical design allows monitoring of two different system types at the same time. As such, it is possible to connect one line with the

NORDIC system on measurement channel 1 and one line with the BRANDES system on measurement channel 2, for instance.

The system is based on measuring resistances between monitoring conductors and the metal medium pipe or the resistances of

measurement loops. All measured values can be read from the display.

(see 4.2. Operation menu; page 8)

2.1. System design

The LMS 120 has measurement channels operating free of potential to increase measurement precision and minimise the influence of

parasitic current measurements in the pipe.

Fig. 1 (System design)

Sensor

Return

Sensor

Return

Relay

Display

Keys

CPU

Measurement

module

1

Measurement

module

2

Pipe

Pipe

Operating and service instructions | LMS 120 5

The current status and the measurements can be read from the display. The 5 LEDs to the left of the display

provide a quick overview of the current device status.

Fig. 2 (View of device)

3. Installation

3.1. Mechanical installation

The mechanical installation of the LMS 120 monitoring device

can be carried out on an even dry wall (drilling template) or

alternatively in a control cabinet.

At the place of installation, the device must be protected

against humidity (formation of condensation), strong dust and

strong electromagnetic fields. The safety notes, protection

measures and notes stated in these operating instructions

must be observed (see Safety notes; page 3). The housing lid

must be removed for fastening.

The installation must be carried out with fasteners that are

suitable for the respective substrate.

Fig. 3 (Wall installation)

Display

LEDs

Alarm contact

Voltage 2 (12v)

Alarm menu key

Cursor keys

Alarm off key

Terminal - channel 2

Terminal - channel 1

Operating and service instructions | LMS 120 6

3.2. Electrical connection

3.2.1. Connection terminals

Terminal

Description

12V

+

-

12V +

12V -

Low voltage

(optional)

Alarm

NO

COM

NC

Make cont’t

Root

Break cont’t

External fault

message

Channel 1

S1

Pipe

S2

Sensor

Pipe

Return

conductor

Channel 1

Channel 2

S1

Pipe

S2

Sensor

Pipe

Return

conductor

Channel 2

Tab. 1 (Terminals)

Note:

The 12V terminal is reserved for a special

version of the LMS 120. It must not be used.

The Alarm terminal can be charged with an

ohmic load of up to 2A/ 30V.

Fig. 4 (Wiring diagram)

3.2.2. Earth connection

To ensure smooth operation, the earth contact (pipe) of every measurement circuit must be connected with the

associated pipeline. When replacing existing leakage measurement systems, it is mandatory to check whether an

effective earth connection to the relevant pipe exists. Each measurement channel requires its own connection with

the pipeline.

3.2.3. Power

Finally, the device plug has to be inserted into a socket. The LMS 120 can be operated with an alternating current

of 90…240 V AC.

3.2.4. Commissioning

After the mechanical and electrical installation, the LMS 120 parameters need to be set. The procedure is

described in Section 4.3. Quick parameter setting on page 9.

Operating and service instructions | LMS 120 7

4. Operation

The LMS 120 displays information in various menus in a clear manner. 7 keys, 5 status displays (LED) and one

clear text display are arranged on the front plate. The current measurement values can be called up and operating

data set with the keys. The status displays (LED) provide a quick overview of the status of the line connected.

All detailed information and the parameter setting menus are shown by the info display.

4.1. Display and operating elements

Description

Symbol

Description

Cursor keys:

Left / right in the menu

Up / down in the menu

Confirmation, OK

Alarm menu

Open alarm menu

Deactivate acoustic signalling

Deactivate acoustic signalling

Display operating voltage

LED blue in the event of voltage

Measurement display operating

LED flashing green during ongoing

measurement

Error display

LED red in the event of device fault

Limit/s exceeded display

LED red in the event of exceeded limit

Stored alarms display

LED orange in the event of stored alarms

Tab. 2 (Display and operation)

Operating and service instructions | LMS 120 8

4.2. Operation menu

Operation displays 1 to 4 provide a complete overview of the status of the monitoring loops and the device status.

The individual displays can be selected with the following keys:

Fig. 5 (Operation

menu)

Operation display 1:

In this view, the type, channel number and the status of the monitoring loops are displayed.

Possible displays are:

System type NORDIC, BRANDES, SWISS, OFF

Channel 1, 2

Status OK, Alarm Loop, Alarm Iso., Alarm I&L

Operation display 2:

The values of the last measurement are displayed here.

Explanation:

I: Isolation value (measure of dampness of thermal

isolation)

L: Loop resistance (monitoring loop verification)

Operation display 3:

This display is only needed for service purposes. The data must be entered into the record of the fault report. (see

6. Service; page 15)

Operation display 4:

The serial number and device version are displayed here. The data must be entered into the record of the fault

report. (see 6. Service; page 15)

Operation display 1

Operation display 2

Operation display 3

Operation display 4

or

Operating and service instructions | LMS 120 9

4.3. Quick parameter setting

The quick parameter setting function applies practical values for all parameters depending on the monitoring

system. This procedure is sufficient to commission the LMS 100 in full.

System defaults:

Nordic

Brandes

Swiss

Device defaults

Standard

Isolation limit

Measure cycle

1 h

Loop limit

200 Ω

6.0 kΩ

200 Ω

Horn

On

Tolerance

- - -

Tab. 3 (Default values)

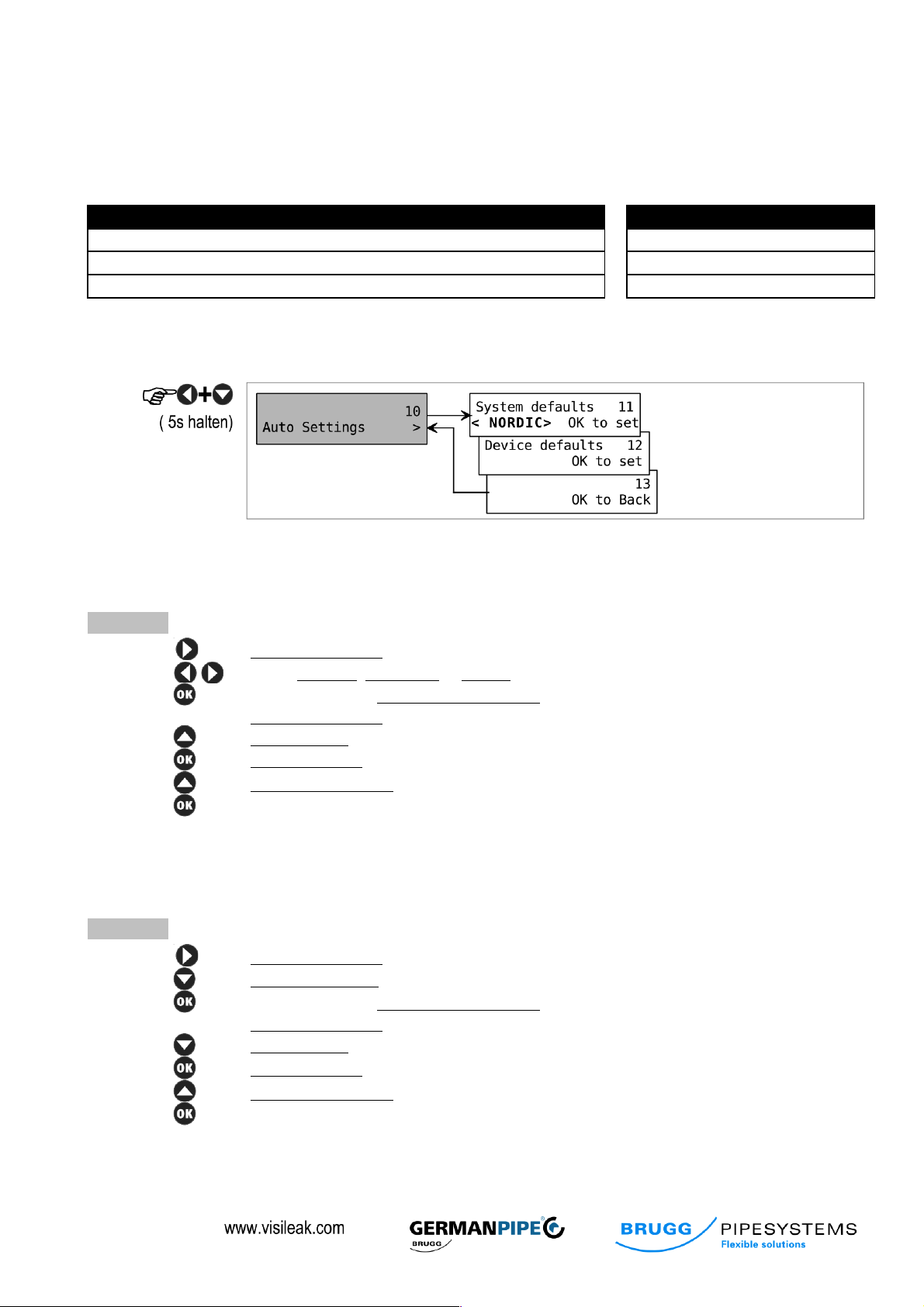

4.3.1. Activating the service menu

To adopt these values, the service menu has to be activated as follows:

Fig. 6 (Auto settings)

4.3.2. Setting NORDIC, BRANDES or SWISS

After activating the service menu (see 4.3.1.), perform the following steps.

Procedure:

1. System Defaults 11 is displayed

2. Select NORDIC, BRANDES or SWISS

3. Confirm selection, Setting channel defaults is displayed briefly, then again

System Defaults 11

4. OK to Back 13 is displayed

5. Auto Settings 10 is displayed

6. OK to Save & Exit 90 is displayed

7. Operation display 1 appears

4.3.3. Setting device to default

After activating the service menu (see 4.3.1.), perform the following steps.

Procedure:

1. System Defaults 11 is displayed

2. Device Defaults 12 is displayed

3. Confirm selection, Setting channel defaults is displayed briefly, then again

System Defaults 12

4. OK to Back 13 is displayed

5. Auto Settings 10 is displayed

6. OK to Save & Exit 90 is displayed

7. Operation display 1 appears

Operating and service instructions | LMS 120 10

4.4. Enhanced parameter setting

All parameters to be monitored can be defined individually in this menu. This procedure should be chosen when

the default values described under Section 4.3. Quick parameter setting on page 9 are not suitable or when the

limits should be or have to be modified. This multi-step menu is arranged on two levels where the desired settings

can be made with the cursor keys (7).

To enter the Configuration menu, please press the following key combination:

Fig. 7 (Settings)

Use the keys for navigation and selection and the key to confirm.

Level 1 menu

Level 2 menu

Settings

(hold down

Operating and service instructions | LMS 120 11

4.4.1. Auto settings

Menu item 11 sets default values depending on the type of monitoring system. Under menu item 12, the device

parameters are reset to factory settings. An overview of the default values can be found in Table 3 on page 9.

4.4.2. Channel settings

The type of the monitoring system is selected in menu items 21 and 31. Following this selection the limits for

isolation and loop monitoring are limited to sensible levels.

Isolation alarm - menu 22/ 32

The limit for triggering an alarm can be set with the keys. If the

measurement for the isolation resistance falls below the limit, the LMS 120

switches to alarm.

Possible settings:

NORDIC/ SWISS/ BRANDES: 10 kΩ … 20 MΩ

Loop alarm - menu 23/ 33

The limit for triggering an alarm can be set with the keys. If the

measurement for the loop resistance exceeds the limit, the LMS 120 switches

to alarm.

Possible settings:

NORDIC/ SWISS: 200Ω, 300Ω, 500Ω

BRANDES: 1 kΩ … 19 kΩ

Tolerance alarm - menu 24/ 34

The tolerance for triggering an alarm can be set with the keys. It is

selected in percent of the limit for the loop resistance.

If the measurement for the loop resistance exceeds or falls below the range,

the LMS 120 switches to alarm.

Possible settings:

NORDIC/ SWISS: not available

BRANDES: above limit, 10% ... 50%

When above limit, only the top limit has effect, which is determined by menus 23 and 33.

Example;

Loop limit: 4.0 kΩ

Tolerance: 10%

Bottom limit: 3.6 kΩ

Top limit: 4.4 kΩ

If the measurement falls below 4.4 kΩ or if it falls below 3.6 kΩ, the LMS 120 switches to alarm.

Operating and service instructions | LMS 120 12

4.4.3. Device settings

Devices settings are settings that relate to the general functions of the LMS 120. The menu structure is displayed in

Fig. 7 on page 10.

Measure cycle - menu 41

The measure cycle of the fully automatic measurement is set here. In the event of an alarm message, the duration

of the fault can be assessed by multiplying the measure cycle with the number of errors saved. (see 4.5. Alarm

menu; page 13)

Example;

Measure cycle: 6 h

Error number: (092)

Fault since: 92 x 6 h = 552 h = 23 days

Possible settings: 2min, … , 30min, 1h, … 24h

Buzzer - menu 42

The LMS 120 issues an acoustic signal in the event of faults in the monitoring system. This signal can be

deactivated.

Possible settings: On, Off

Self-test - menu 43

The LMS 120 conducts a self-test after every start. If it is suspected that the LMS 120 is not working correctly, a

manual self-test should be started. To this end, the key in the Self-test menu has to be pressed.

The following message is shown in the display after successfully completing the self-test.

Operating and service instructions | LMS 120 13

4.5. Alarm menu

The LMS 120 has a non-volatile alarm log (the errors are not lost from the alarm log in the event of a power cut).

Fault messages can therefore be identified even if they are no longer current during the device inspection. To enter

the Alarm menu, please press the Alarm menu key (6).

Browse the menu with Fig.8 (Alarm menu)

Alarm menu 01 and Alarm menu 03:

The status and the number of faults of the sensor loop are shown in this display.

Possible displays are:

No Alarms

Active Alarms

Old Alarms

Alarm menu 02 and Alarm menu 04:

The status and the number of faults of the isolation resistance are shown in this display.

Possible displays are:

No Alarms

Active Alarms

Old Alarms

Alarm menu 05:

is used to clear the alarm log and to set all counters to 000.

Alarm menu 06:

is used to exit the alarm menu.

When active errors are displayed, it is possible to estimate how long the error has already been pending with the

use of the cycle set in the measure cycle and the number of stored errors. In the event of a fault message, please

fill in and send the record (see 6.2. Fault record; page 16) to the e-mail address alarm@visileak.com. The fault

message can also be sent online at www.visileak.com.

Alarm log channel 1 - loop

Alarm log channel 1 - isolation

Alarm log channel 2 - loop

Alarm log channel 2 - isolation

Clear alarm log

Exit alarm log

Operating and service instructions | LMS 120 14

4.6. Manual measurement

Regardless of the periodic, automatic measurements, a manual measurement can also be triggered where

required. This is helpful during the installation or after a modification of the system (e.g. grid expansion). Press the

following key to activate the manual measurement:

(hold down for 5 sec)

The measurement starts as soon as the LED starts to flash. At the end of the process, the LED

goes out and operation menu 1 is displayed.

4.7. Firmware update

New functions can be incorporated by updating the

software of the LMS 120. An appropriately prepared

micro SD card is required for this purpose.

Procedure:

1. Disconnect the LMS 120 from the mains

2. Insert micro SD card

3. Connect the LMS 120 with the mains

4. Wait until operation menu 1 appears

Fig. 1 (Firmware update)

Operating and service instructions | LMS 120 15

5. Maintenance

The LMS 120 is a maintenance-free monitoring device and does not need periodic maintenance or inspection. As

part of a district heating maintenance programme inspections should be carried out at least once a month.

The and displays indicate any errors. If one of these displays lights up, the

measurement values should be inspected.

The record from Section 6.2. Fault record on page 16 should be used for a service report.

6. Service

In the operation menu, display 3 provides coded information on the setting and measurement values of the LMS

120 (see 4.2. Operation menu; page 8). It offers the service technician a quick overview and is helpful for finding

errors. It is used for the error report.

6.1. System code

N 1 1 0 0 5 0 0 1 7 4 1 2 0 0 2 0 0 1 - B 2 1 2 0 0 0 0 9 9 9 9 9 0 6 0 0 9 3

5

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

17

18

19

20

System / channel

Channel 1=on, 0=off

Isolation limit

[kΩ]

Isolation measurement

[kΩ]

Loop limit display x 100 = limit in

[Ω]

Loop measurement display x 100

= limit in

[Ω]

Tolerance / x 10 = limit in

[%]

Tab. 4 (System code)

Operating and service instructions | LMS 120 16

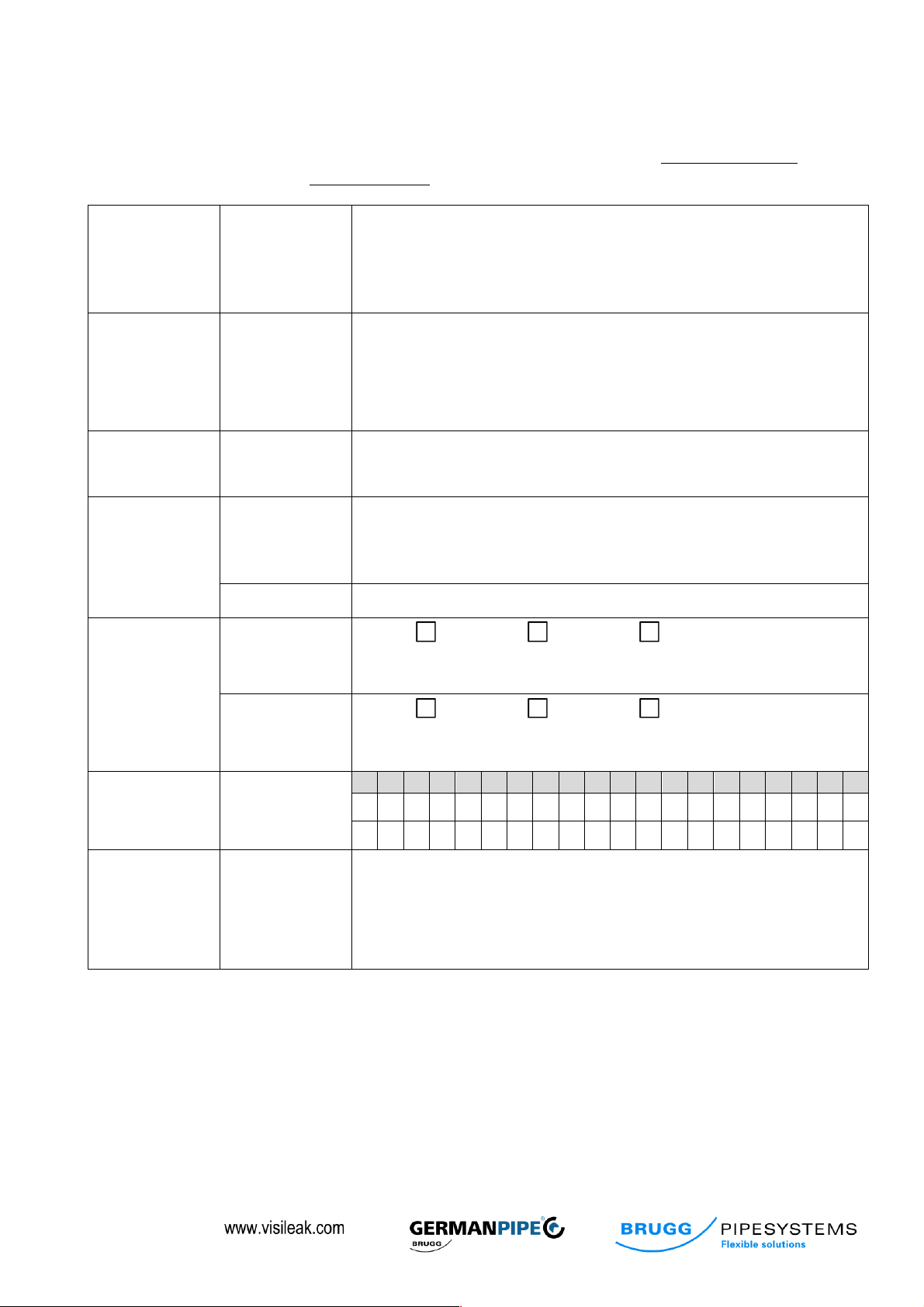

6.2. Fault record

In the event of a fault, please fill in the fault record and send it to the e-mail address alarm@visileak.com. The fault

report can also be sent online at www.visileak.com.

Customer:

Company

Name

Address

Country

Telephone

Building/

property:

Name

Address

Note:

Error:

Description

Error since:

Measured

values

Loop 1

Type: Nordic Brandes Swiss

Isolation:............................. Loop: :..............................

Loop 2

Type: Nordic Brandes Swiss

Isolation:............................. Loop: :..............................

Service code:

See 4.2.

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

17

18

19

20

Date:

Signature:

Tab. 5 (Fault record)

Operating and service instructions | LMS 120 17

7. Accessories

Item name

Item number

Description

LMS 120 DE

21000076

LMS 120 with mains plug for Germany

LMS 120 CH

LMS 120 with mains plug for Switzerland

Socket AD2

21000083

Socket for LMS 120

Monitoring end piece

21000081

Loop end plug

Tab. 6

(Accessories)

8. Technical data

Requirements for voltage supply

Voltage

100 – 240 VAC

Power consumption

max. 100 mA

Max. power consumption on

activation

6 A

Output

6 W

Housing specification:

Dimensions (width x height x depth)

182 x 180 x 90 mm

Installation

Wall instillation, control cabinet installation, screws

Materials and colour

Housing: Polystyrene, grey (similar to RAL 7035)

Lid: Polycarbonate, transparent

Protection category

IP 65 in accordance with EN 60529

Weight (excl. packaging)

1.1 kg

Measurement inputs specification:

Wire standards / measurement

wires

Nordic, 2 copper blank

Brandes, NiCr 5,7 Ω/m copper isolated

Swiss, copper blank – copper isolated

Potential separation

Yes

Alarm output specification

Type of the alarm output:

Relay

Max. contact voltage:

30 VDC

Max. switching current:

2 A

Min. switching current:

1 mA (at 10 mVDC)

Ambient conditions

Ambient temperature

0 to + 50° C

Transport and storage temperature

-20 to + 60° C

Humidity:

< 90 %, not condensing

Tests and certificates

EC Declaration of Conformity

Yes

Conformity standards

EN 61000-6-2 (2006-05-01)

EN 61000-6-4 (01/11/2007)

Operating and service instructions | LMS 120 18

Tab. 7 (Technical

data)

9. Glossary, terms

Device display

Meaning

Device display

Meaning

above Limit

above limit

Measure

Messung

Active alarm

aktuelle Alarmmeldung

Measure Cycle

Measure cycle

Alarm

Alarmmeldung

No

kein

Alarm Iso

Alarm Isolationsfehler

Off

Aus

Alarm Loop

Alarm Schleifenfehler

On

On

Alarm I&L

Alarm Isolations- und

Schleifenfehler

Pass

durchgeführt

Auto

Automatisch

Pipe

Rohr

Back

zurück

Power

Netzspannung

Buzzer

Signalhupe

Save

sichern

Channel

Kanal

Self Test

Selbsttest

Clear Alarms

Lösche Alarme

Setting

Einstellung

Default

Grundeinstellung

Stored Alarm

gespeicherte

Alarmmeldung

Device

Gerät

System

System

Error

Gerätefehler

Tolerance

Toleranz

Exit

Ausgang, Verlassen

wait

warten

Isolation

Isolation

Tab. 8 (terms)

Log

Speicher

Loop

Schleife

- Subject to technical changes. –

Operating and service instructions | LMS 120 19

10. Notes

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

....................................................................................................................................................................................

2013-11-01 Rev.D

Brugg Rohrsystem AG

Industriestrasse 39

CH-5314 Kleindöttingen

phone +41 (56) 268 78 78

fax +41 (56) 268 78 79

www.pipesystems.com

BRUGG Rohrsysteme GmbH

Adolf-Oesterheld-Straße 31

D-31515 Wunstorf

phone +49 (5031) 170-0

fax +49 (5031) 170-170

www.brugg.de

GERMAN PIPE

Industrie- und Fernwärmetechnik GmbH

Darrweg 43

D-99734 Nordhausen

phone +49 (36 31) 46 26 7 - 0

fax +49 (36 31) 46 26 7 - 79

www.german-pipe.de

Loading...

Loading...