Page 1

User’s Guide

Page 2

http://www.boat-fuel-economy.com/evinrude-icommand-for-sale

Page 3

IMPORTANT: This User’s Guide outlines the functionality and usage of the I-Command™ Integrated Perfor-

mance System. Before using the I-Command Digital gauge, first read and understand ALL of the supplied

product literature, as well as the boat’s user’s guide and outboard’s operator’s guide. This User’s Guide

should be stored onboard for reference.

The photographs, illustrations, and display screens used in this Guide might not depict actual models, figures,

data fields, equipment, or software versions, but are intended as representative views for reference only. The

continuing accuracy of this Guide cannot be guaranteed.

† NMEA 2000 is a registered trademark of the National Marine Electronics Association or its subsidiaries.

The following trademarks are the property of Bombardier Recreational Products Inc. or its affiliates.

Evinrude

®

I-Command

Johnson

®

E-TEC

™

™

S.A.F.E.™ (Speed Adjusting Failsafe Electronics)

BRP US Inc. / Outboard Engines Division

After Sales Support

P.O. Box 597

Sturtevant, WI 53177

© 2008 BRP US Inc. All rights reserved.

TM, ® and the BRP logo are registered trademarks of Bombardier Recreational Products Inc. or its affiliates.

1

Page 4

About This Guide

IMPORTANT: Read this User’s Guide carefully before

using the I-Command Digital gauge. This User’s

Guide should be kept onboard at all times during

operation.

Need Assistance?

For any questions regarding the boat or outboard

operation, please refer to the boat’s user’s guide, or

outboard’s operator’s guide for support information.

For questions or problems regarding the I-Command

Digital gauge, contact your dealer.

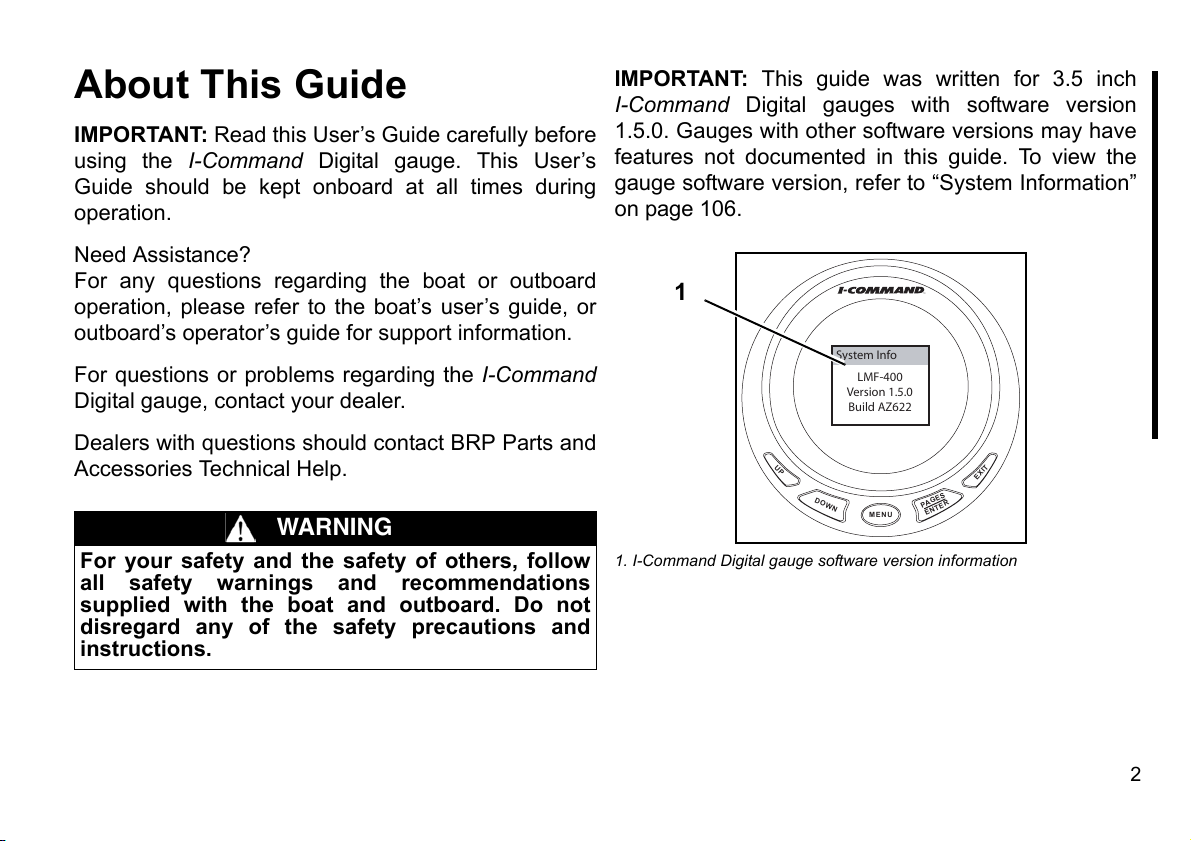

IMPORTANT: This guide was written for 3.5 inch

I-Command Digital gauges with software version

1.5.0. Gauges with other software versions may have

features not documented in this guide. To view the

gauge software version, refer to “System Information”

on page 106.

1

System Info

LMF-400

Version 1.5.0

Build AZ622

Dealers with questions should contact BRP Parts and

Accessories Technical Help.

WARNING

For your safety and the safety of others, follow

all safety warnings and recommendations

supplied with the boat and outboard. Do not

disregard any of the safety precautions and

instructions.

UP

DOWN

MENU

1. I-Command Digital gauge software version information

PA

ENTER

EXIT

GES

2

Page 5

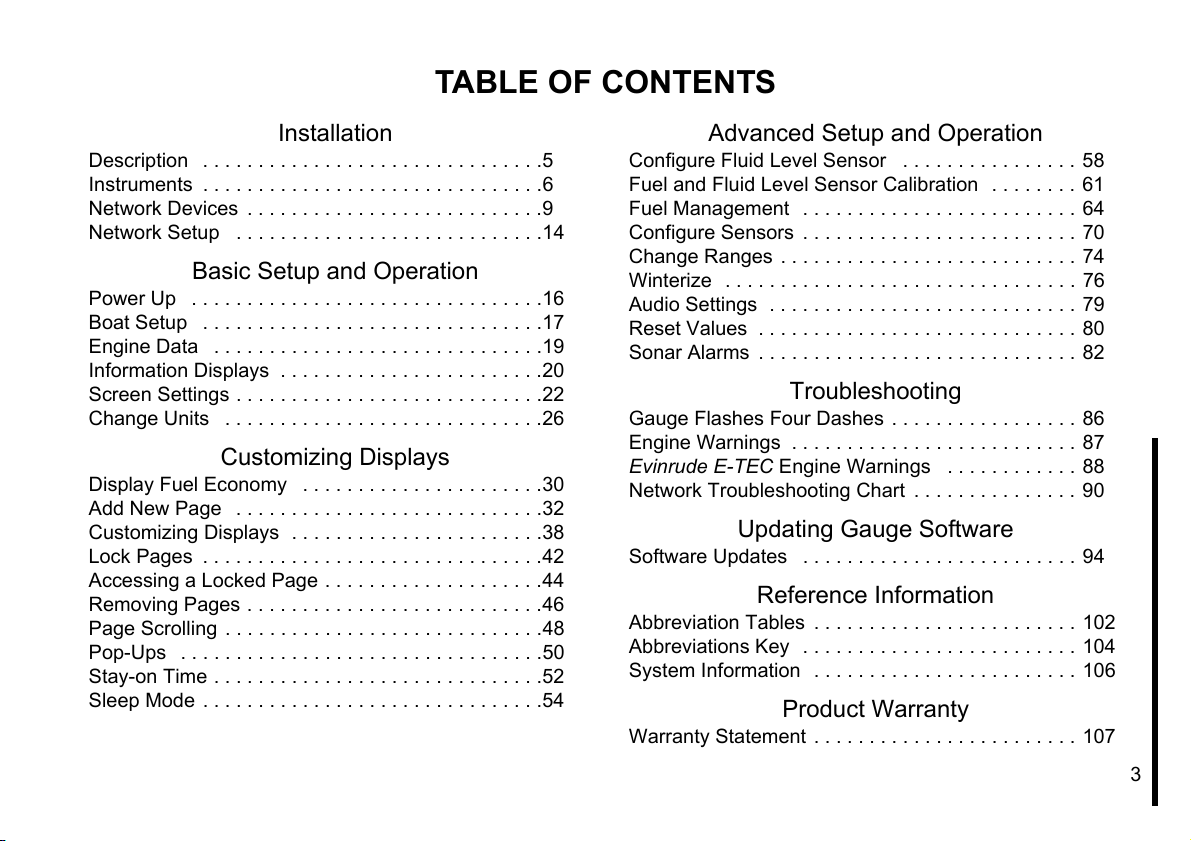

TABLE OF CONTENTS

Installation

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Network Devices . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Network Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Basic Setup and Operation

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Boat Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Engine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Information Displays . . . . . . . . . . . . . . . . . . . . . . . .20

Screen Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Change Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Customizing Displays

Display Fuel Economy . . . . . . . . . . . . . . . . . . . . . .30

Add New Page . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Customizing Displays . . . . . . . . . . . . . . . . . . . . . . .38

Lock Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Accessing a Locked Page . . . . . . . . . . . . . . . . . . . .44

Removing Pages . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Page Scrolling . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Pop-Ups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Stay-on Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Advanced Setup and Operation

Configure Fluid Level Sensor . . . . . . . . . . . . . . . . 58

Fuel and Fluid Level Sensor Calibration . . . . . . . . 61

Fuel Management . . . . . . . . . . . . . . . . . . . . . . . . . 64

Configure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . 70

Change Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Winterize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Audio Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Reset Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Sonar Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Troubleshooting

Gauge Flashes Four Dashes . . . . . . . . . . . . . . . . . 86

Engine Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Evinrude E-TEC Engine Warnings . . . . . . . . . . . . 88

Network Troubleshooting Chart . . . . . . . . . . . . . . . 90

Updating Gauge Software

Software Updates . . . . . . . . . . . . . . . . . . . . . . . . . 94

Reference Information

Abbreviation Tables . . . . . . . . . . . . . . . . . . . . . . . . 102

Abbreviations Key . . . . . . . . . . . . . . . . . . . . . . . . . 104

System Information . . . . . . . . . . . . . . . . . . . . . . . . 106

Product Warranty

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . 107

3

Page 6

Installation

4

Page 7

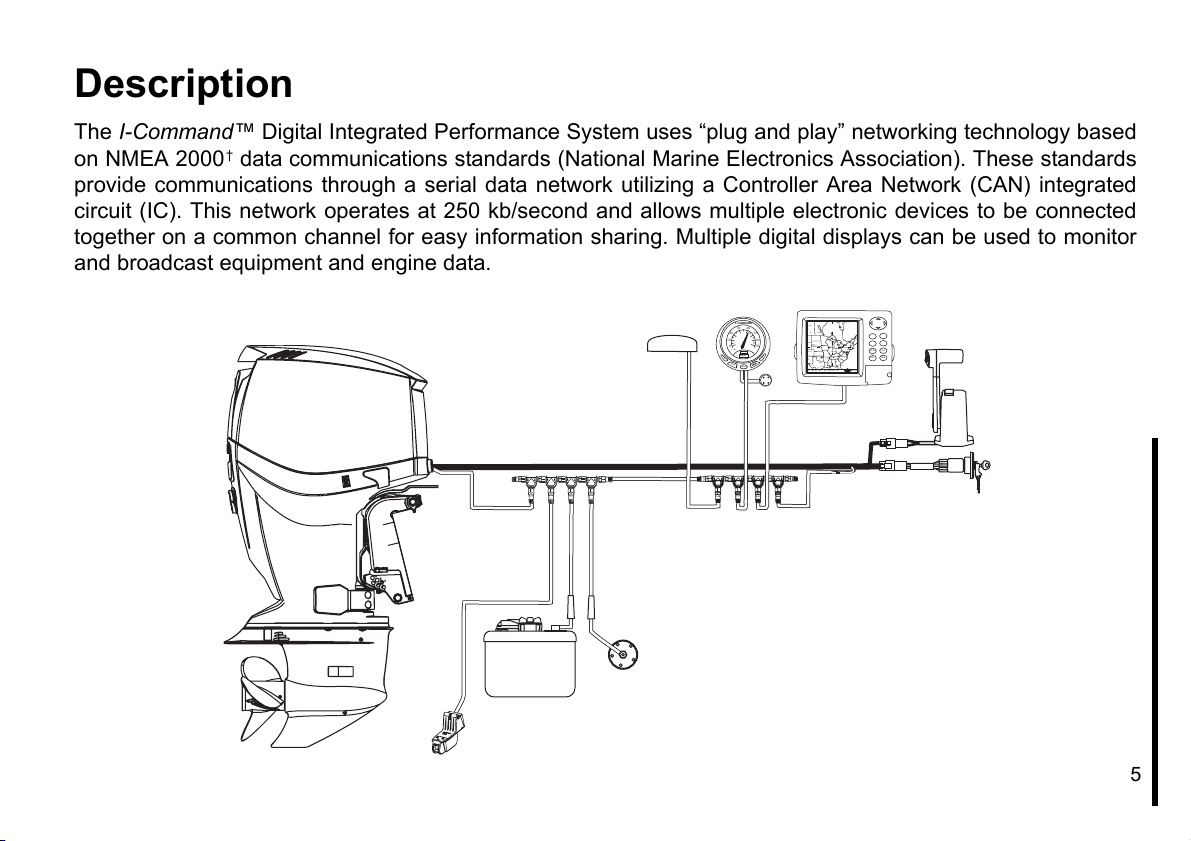

Description

The I-Command™ Digital Integrated Performance System uses “plug and play” networking technology based

on NMEA 2000† data communications standards (National Marine Electronics Association). These standards

provide communications through a serial data network utilizing a Controller Area Network (CAN) integrated

circuit (IC). This network operates at 250 kb/second and allows multiple electronic devices to be connected

together on a common channel for easy information sharing. Multiple digital displays can be used to monitor

and broadcast equipment and engine data.

20 50

10 60

0 70

x 100

U

P

D

OWN

30 40

RPM

4257

MENU

Canada

Winnipeg

Quebec

United

Toronto

States

Chicago

New York

MENU EXIT

Indianapolis

Denver

T

XI

E

S

GE

PasoPaso

R

PA

TE

N

E

N

Dallas

Houston

42°21,770’ W 87°49.7 15’

ENT PWR

Memphis

Jacksonville

2000 mi

5

Page 8

Instruments

Spacing of Instruments

The minimum distances between instruments on a panel should be as follows:

•3 13/16 (112 mm) center to center for 3 1/2 in. instruments

•3 1/4 in. (95.5 mm) center to center for 3 1/2 in. instruments to 2 in. instruments

•2 5/8 in. (77 mm) center to center for 2 in. instruments

Panel Thickness

Instruments can be mounted in panels up to 1 in. thick.

Hole Sizes

IMPORTANT: Check space behind panel to be sure adequate clearance for instruments exists before drilling

panel.

3 1/2 in. Multifunction Gauge

Cut 3 3/8 in. (99 mm) diameter hole in panel for 3 1/2 in. instruments.

Fastening to Panel

Insert instrument into panel hole. Install bracket and tighten nuts finger tight.

6

Page 9

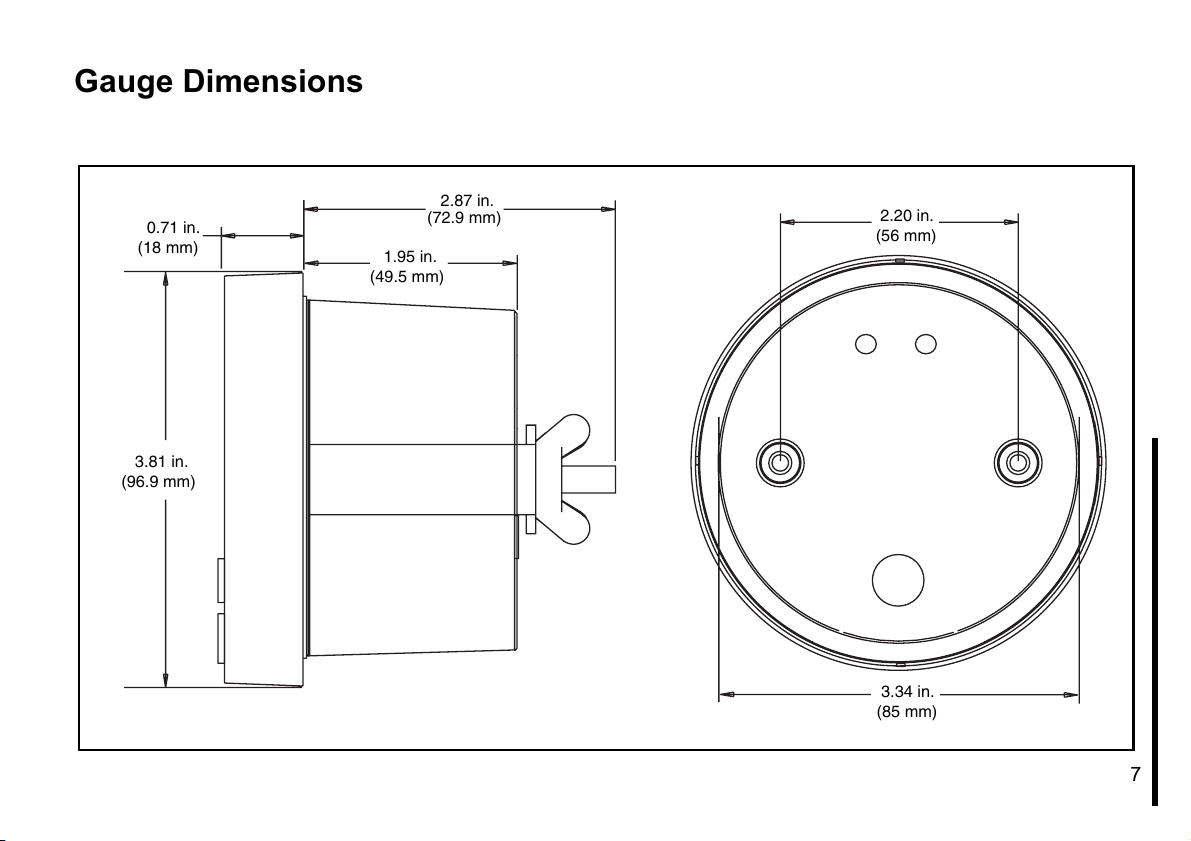

Gauge Dimensions

0.71 in.

(18 mm)

3.81 in.

(96.9 mm)

2.87 in.

(72.9 mm)

1.95 in.

(49.5 mm)

2.20 in.

(56 mm)

3.34 in.

(85 mm)

7

Page 10

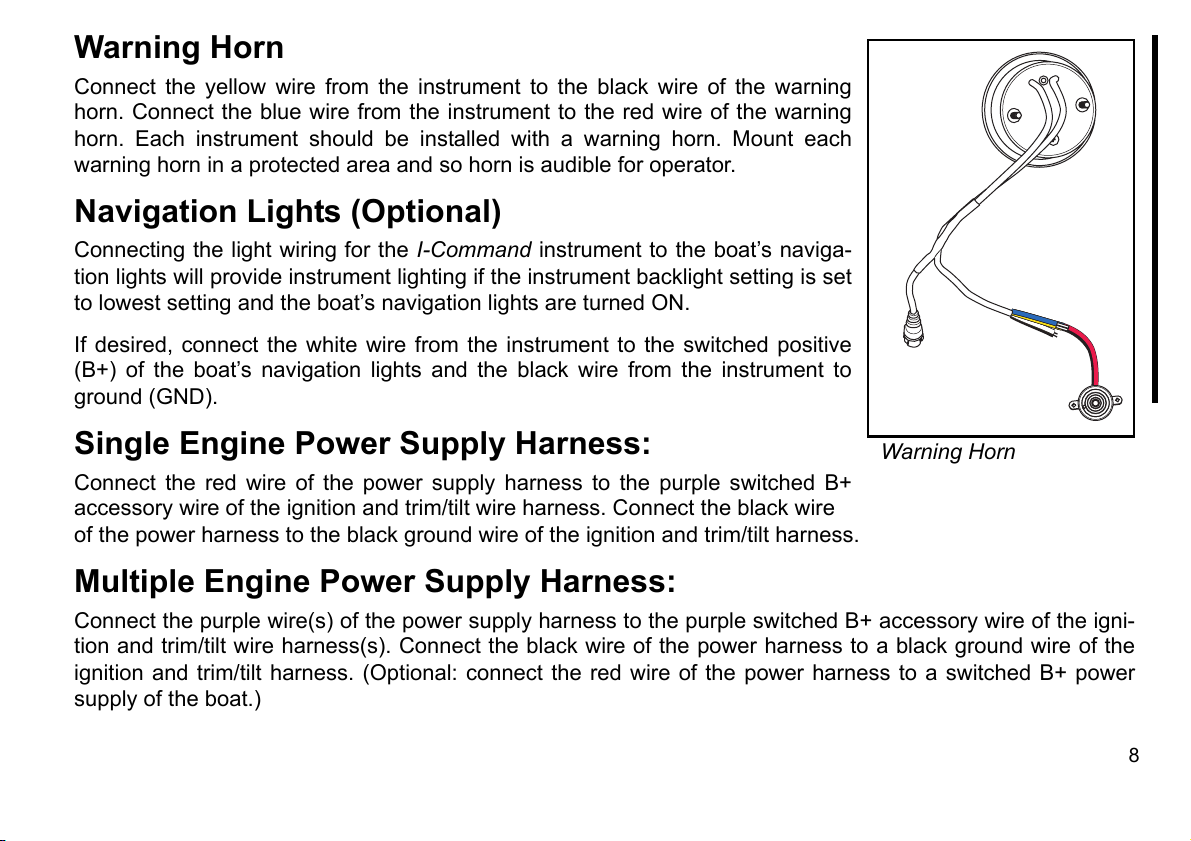

Warning Horn

Connect the yellow wire from the instrument to the black wire of the warning

horn. Connect the blue wire from the instrument to the red wire of the warning

horn. Each instrument should be installed with a warning horn. Mount each

warning horn in a protected area and so horn is audible for operator.

Navigation Lights (Optional)

Connecting the light wiring for the I-Command instrument to the boat’s naviga-

tion lights will provide instrument lighting if the instrument backlight setting is set

to lowest setting and the boat’s navigation lights are turned ON.

If desired, connect the white wire from the instrument to the switched positive

(B+) of the boat’s navigation lights and the black wire from the instrument to

ground (GND).

Single Engine Power Supply Harness:

Connect the red wire of the power supply harness to the purple switched B+

accessory wire of the ignition and trim/tilt wire harness. Connect the black wire

of the power harness to the black ground wire of the ignition and trim/tilt harness.

Warning Horn

Multiple Engine Power Supply Harness:

Connect the purple wire(s) of the power supply harness to the purple switched B+ accessory wire of the igni-

tion and trim/tilt wire harness(s). Connect the black wire of the power harness to a black ground wire of the

ignition and trim/tilt harness. (Optional: connect the red wire of the power harness to a switched B+ power

supply of the boat.)

8

Page 11

Network Devices

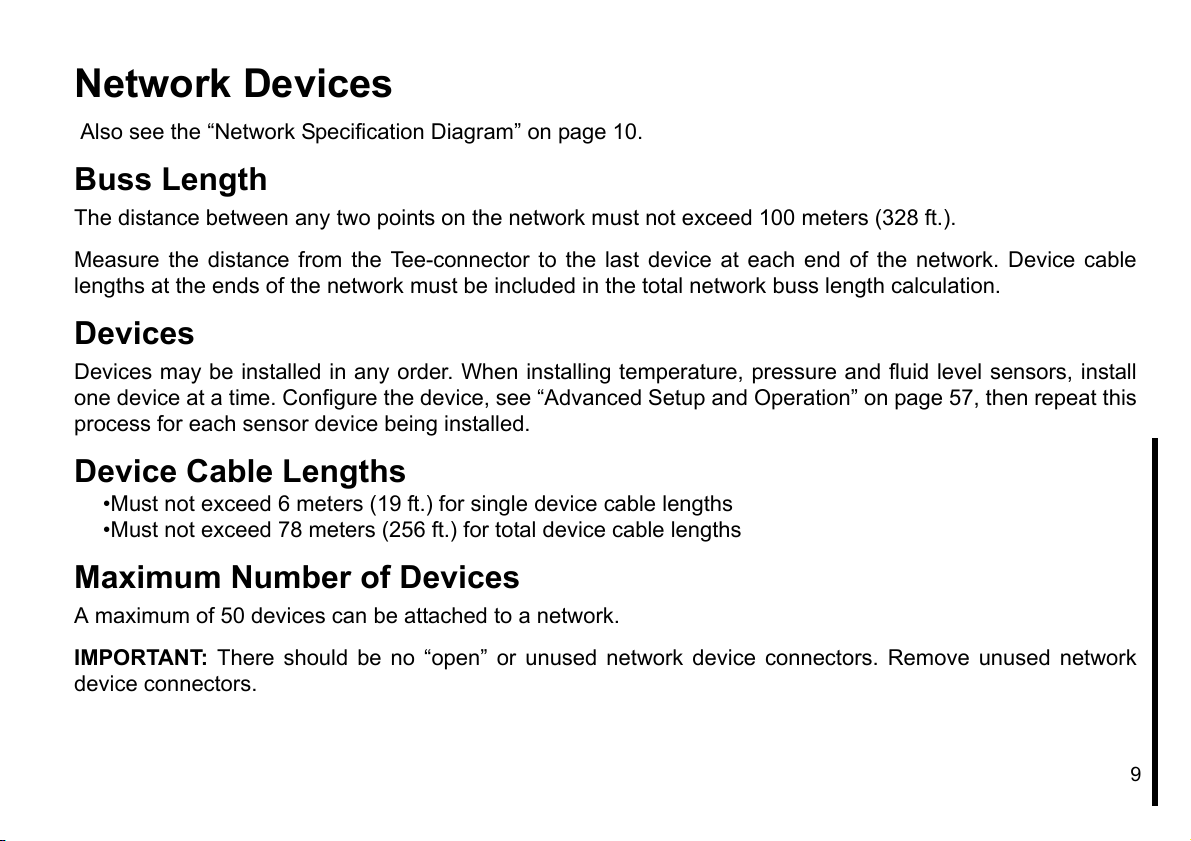

Also see the “Network Specification Diagram” on page 10.

Buss Length

The distance between any two points on the network must not exceed 100 meters (328 ft.).

Measure the distance from the Tee-connector to the last device at each end of the network. Device cable

lengths at the ends of the network must be included in the total network buss length calculation.

Devices

Devices may be installed in any order. When installing temperature, pressure and fluid level sensors, install

one device at a time. Configure the device, see “Advanced Setup and Operation” on page 57, then repeat this

process for each sensor device being installed.

Device Cable Lengths

•Must not exceed 6 meters (19 ft.) for single device cable lengths

•Must not exceed 78 meters (256 ft.) for total device cable lengths

Maximum Number of Devices

A maximum of 50 devices can be attached to a network.

IMPORTANT: There should be no “open” or unused network device connectors. Remove unused network

device connectors.

9

Page 12

Network Specification Diagram

Open Network

Connector

REMOVE

100M (328 ft.)

Terminator

6M (19 ft.)

maximum

P

G

NMEA

®

2000

Device

Device cables

R

E

V

I

E

C

E

R

S

Maximum Network

Buss Length

NMEA

®

2000

Device

Power supply

& Ground

connection

30 40

20 50

10 60

0 70

x 100

RPM

4257

UP

DOWN

MENU

NMEA

2000

Device

Terminator

6M (19 ft.)

maximum

EXIT

PAGES

ENTER

®

10

Page 13

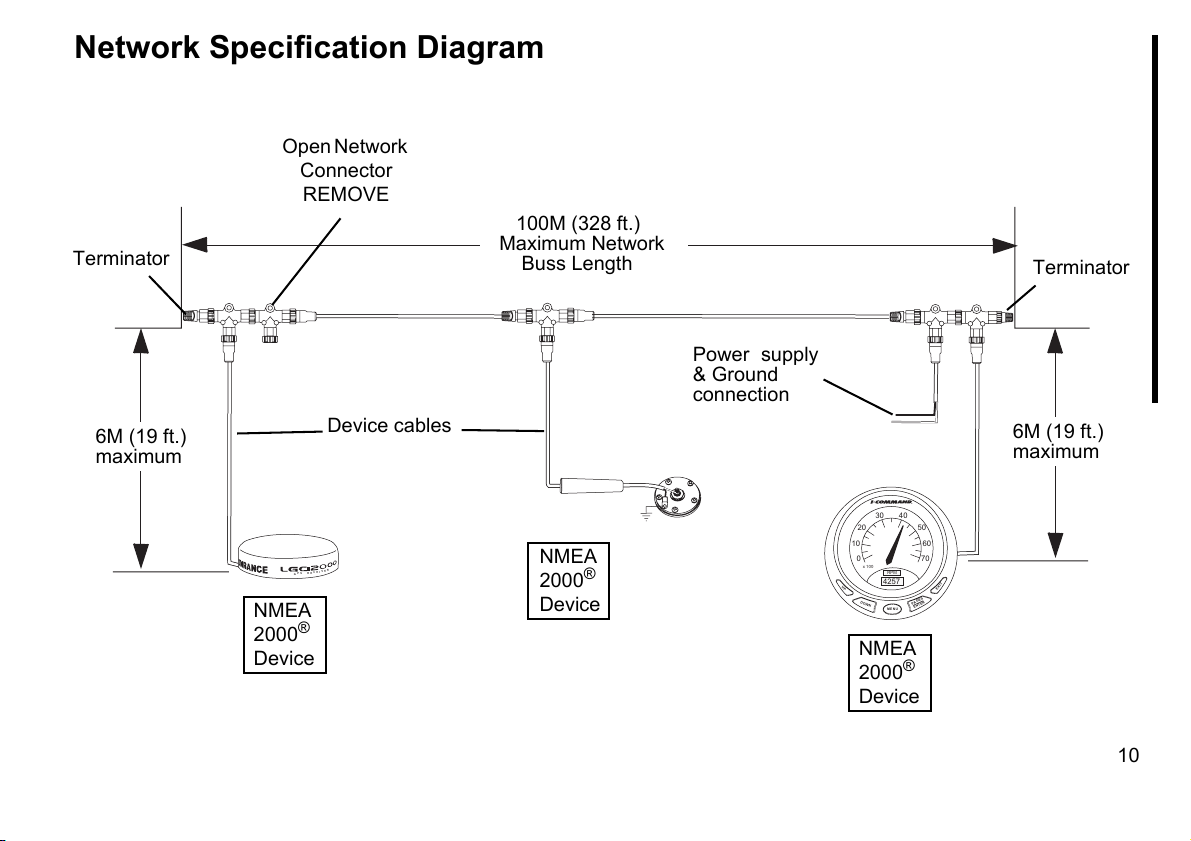

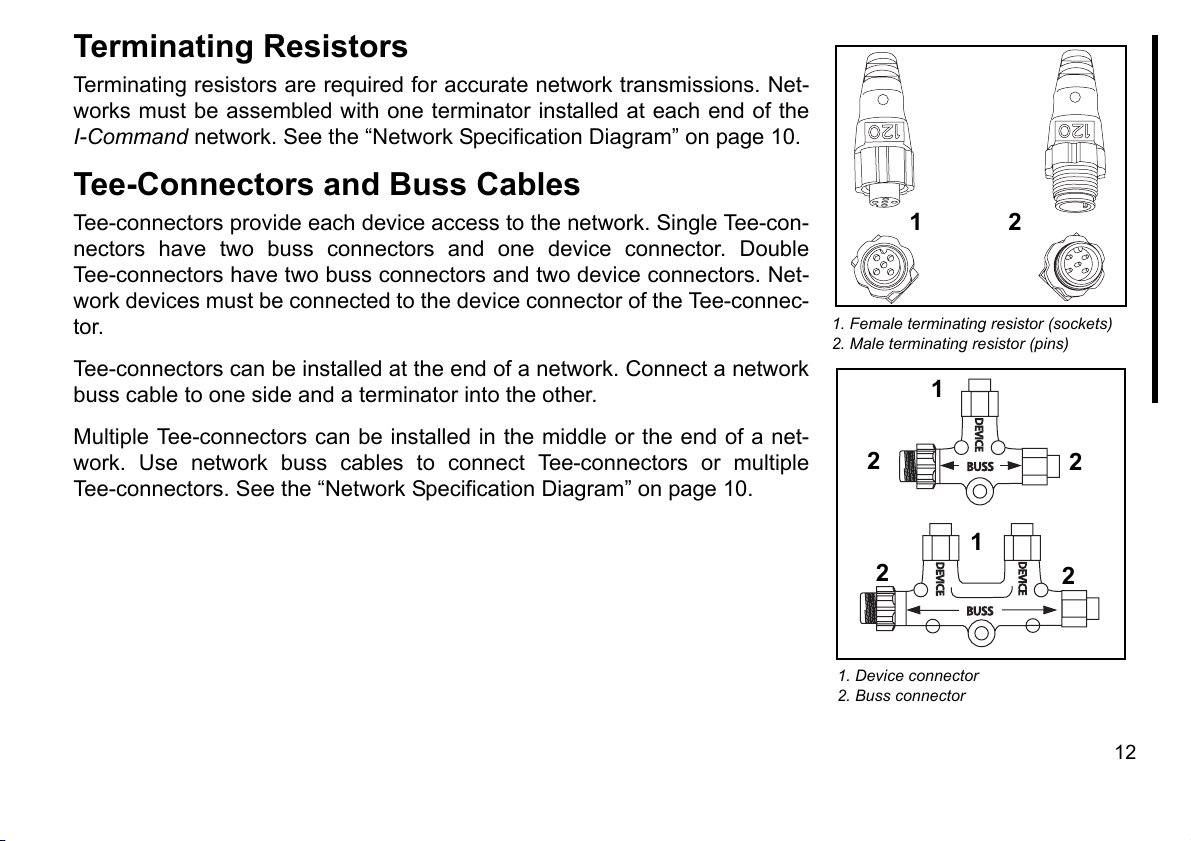

Device Net-style Connectors

I-Command and NMEA 2000 networks use DeviceNet Micro-C type connec-

tors. These connectors use 12 mm threaded locking rings and are water-

proof when assembled properly. All DeviceNet Micro-C connectors are

compatible with the I-Command red network connectors.

Connectors with slighty different appearances supplied with I-Command or

NMEA 2000 devices should NOT affect network operation. Always check

pin and socket and locking ring configurations when installing connectors on

a network.

Use the I-Command Product Guide, P/N 764677, or a current Accessories

Parts Catalog (2008 or newer) to look up part numbers for I-Command net-

work connectors. See your dealer.

Connector Installation

Connectors have two configurations – Male (pins) and Female (sockets).

Lubricate all connector gaskets with Electrical Grease before assembly.

Connectors should assemble easily. Do not force connectors or locking

rings together.

I-Command Network Connectors

(DeviceNet-style Connectors)

If connectors do not match, an adapter cable may be available. See your

dealer.

DeviceNet Micro-C connectors offered by

other suppliers.

11

Page 14

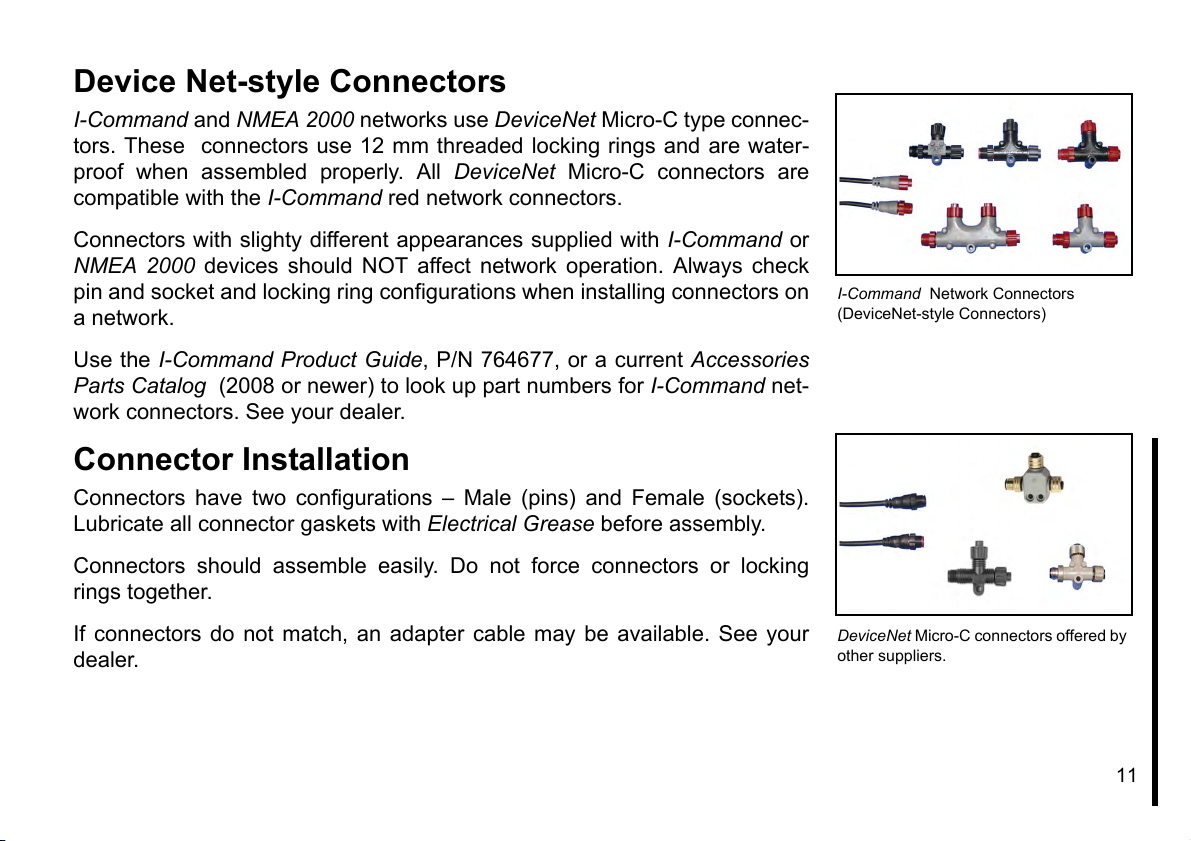

Terminating Resistors

BUSS

DEVICE

DEVICE

DEVICE

BUSS

Terminating resistors are required for accurate network transmissions. Net-

works must be assembled with one terminator installed at each end of the

I-Command network. See the “Network Specification Diagram” on page 10.

Tee-Connectors and Buss Cables

Tee-connectors provide each device access to the network. Single Tee-con-

nectors have two buss connectors and one device connector. Double

Tee-connectors have two buss connectors and two device connectors. Net-

work devices must be connected to the device connector of the Tee-connec-

tor.

Tee-connectors can be installed at the end of a network. Connect a network

buss cable to one side and a terminator into the other.

Multiple Tee-connectors can be installed in the middle or the end of a net-

work. Use network buss cables to connect Tee-connectors or multiple

Tee-connectors. See the “Network Specification Diagram” on page 10.

1

1. Female terminating resistor (sockets)

2. Male terminating resistor (pins)

2

1

2

2

1

2

1. Device connector

2. Buss connector

2

12

Page 15

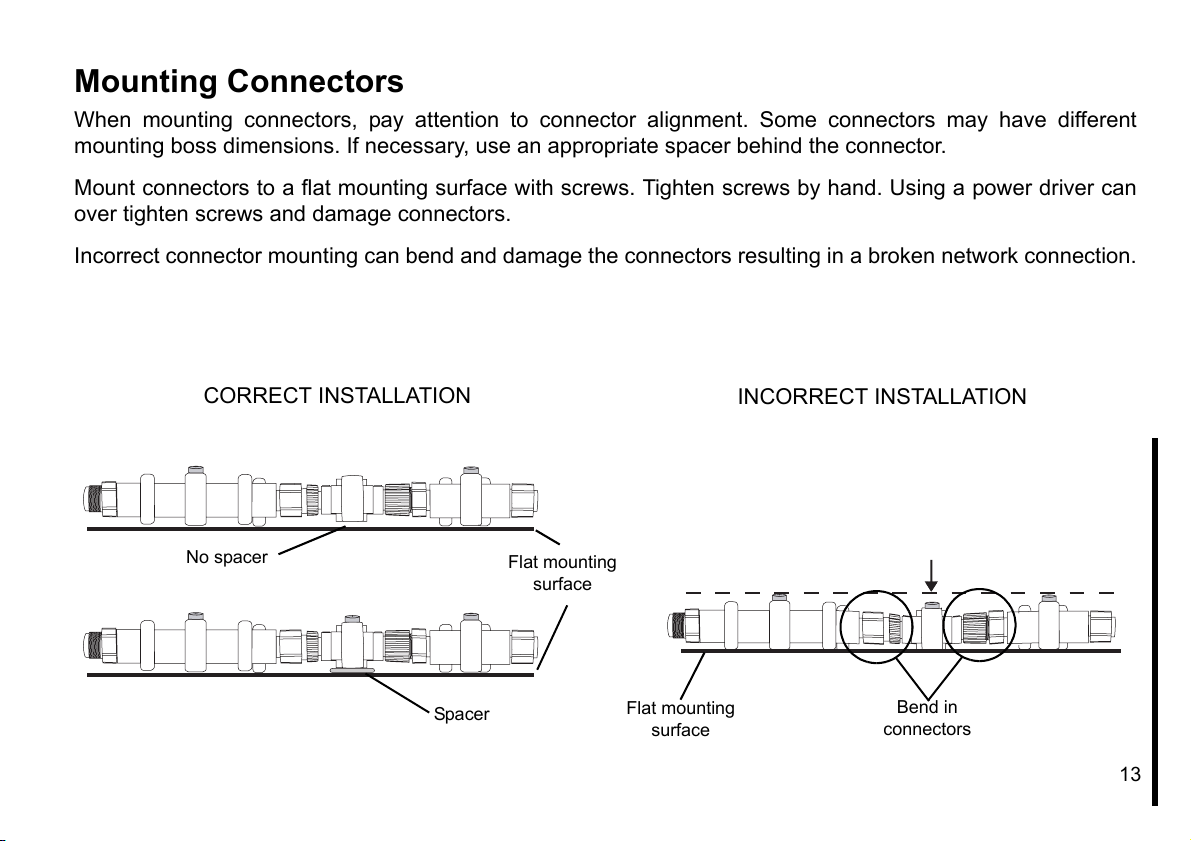

Mounting Connectors

When mounting connectors, pay attention to connector alignment. Some connectors may have different

mounting boss dimensions. If necessary, use an appropriate spacer behind the connector.

Mount connectors to a flat mounting surface with screws. Tighten screws by hand. Using a power driver can

over tighten screws and damage connectors.

Incorrect connector mounting can bend and damage the connectors resulting in a broken network connection.

CORRECT INSTALLATION

No spacer

Spacer

Flat mounting

surface

Flat mounting

surface

INCORRECT INSTALLATION

Bend in

connectors

13

Page 16

Network Setup

IMPORTANT: Set “ENGINE OPTIONS” on Evinrude E-TEC outboards

before power is applied to the I-Command Network.

Engine Options

Use Evinrude Diagnostics software to set “ENGINE OPTIONS”.

Settings include:

•Set multi engine identity (engine count and engine position)

•Calibrate trim sensor

•Water pressure transducer (ONLY if equipped with water pressure

transducer that is installed on engine block, P/N 5006214)

See your dealer if set “ENGINE OPTIONS” has not been completed.

Evinrude Diagnostics software, set engine

options

14

Page 17

Basic Setup and Operation

15

Page 18

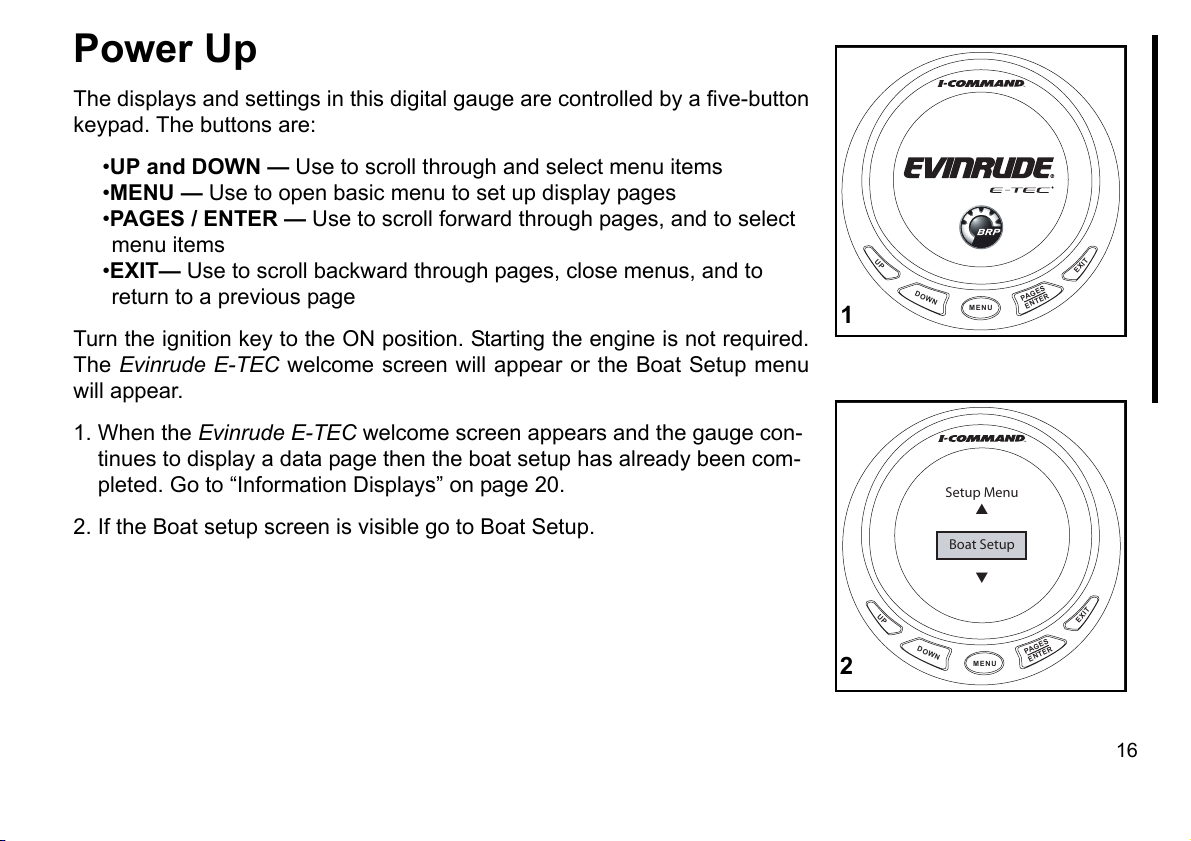

Power Up

The displays and settings in this digital gauge are controlled by a five-button

keypad. The buttons are:

•UP and DOWN — Use to scroll through and select menu items

•MENU — Use to open basic menu to set up display pages

•PAGES / ENTER — Use to scroll forward through pages, and to select

menu items

•EXIT— Use to scroll backward through pages, close menus, and to

return to a previous page

Turn the ignition key to the ON position. Starting the engine is not required.

The Evinrude E-TEC welcome screen will appear or the Boat Setup menu

will appear.

1. When the Evinrude E-TEC welcome screen appears and the gauge con-

tinues to display a data page then the boat setup has already been com-

pleted. Go to “Information Displays” on page 20.

2. If the Boat setup screen is visible go to Boat Setup.

UP

DOWN

DOWN

MENU

Setup Menu

Boat Setup

MENU

1

UP

2

PA

ENTER

PA

GES

GES

ENTER

EXIT

EXIT

16

Page 19

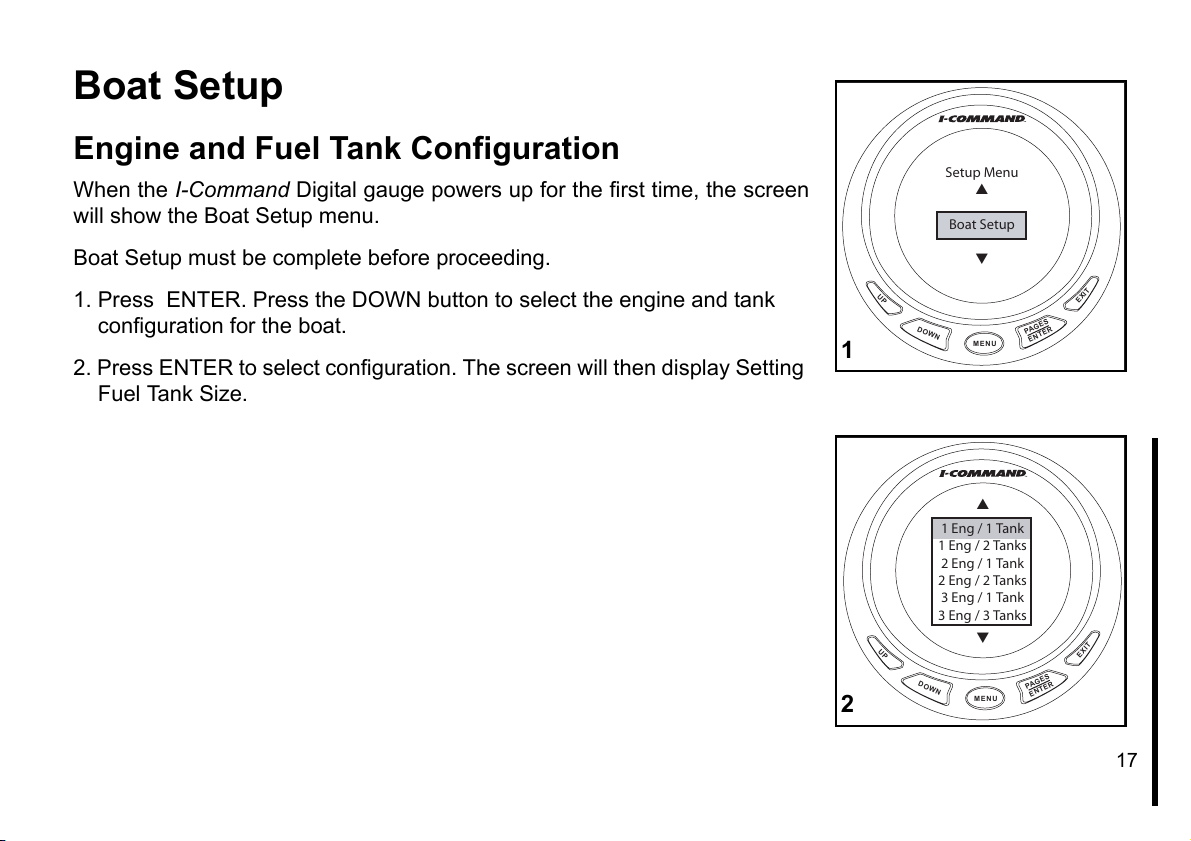

Boat Setup

Engine and Fuel Tank Configuration

When the I-Command Digital gauge powers up for the first time, the screen

will show the Boat Setup menu.

Boat Setup must be complete before proceeding.

1. Press ENTER. Press the DOWN button to select the engine and tank

configuration for the boat.

2. Press ENTER to select configuration. The screen will then display Setting

Fuel Tank Size.

Setup Menu

Boat Setup

UP

DOWN

1 Eng / 1 Tank

1 Eng / 2 Tanks

2 Eng / 1 Tank

2 Eng / 2 Tanks

3 Eng / 1 Tank

3 Eng / 3 Tanks

DOWN

MENU

MENU

1

UP

2

PAGES

ENTER

PAGES

ENTER

EXIT

EXIT

17

Page 20

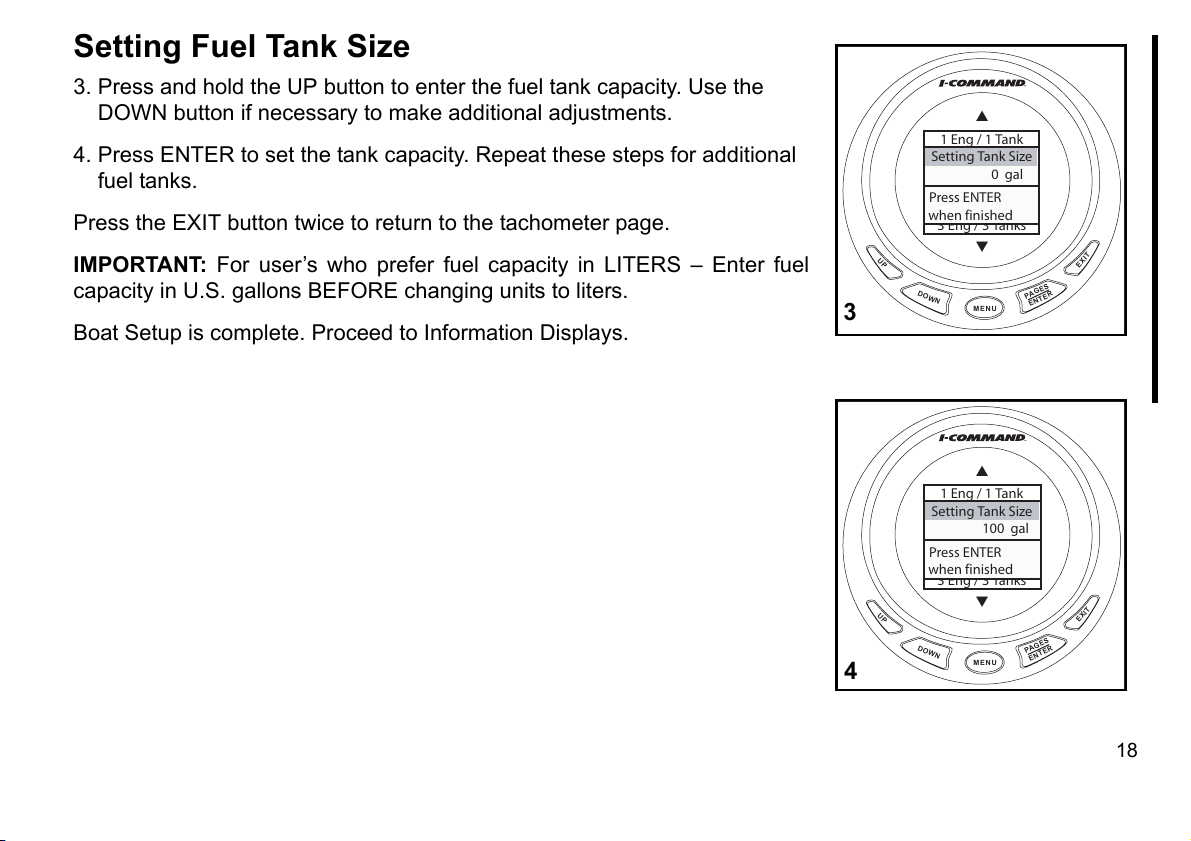

Setting Fuel Tank Size

3. Press and hold the UP button to enter the fuel tank capacity. Use the

DOWN button if necessary to make additional adjustments.

4. Press ENTER to set the tank capacity. Repeat these steps for additional

fuel tanks.

Press the EXIT button twice to return to the tachometer page.

IMPORTANT: For user’s who prefer fuel capacity in LITERS – Enter fuel

capacity in U.S. gallons BEFORE changing units to liters.

Boat Setup is complete. Proceed to Information Displays.

1 Eng / 1 Tank

1 Eng / 2 Tanks

Setting Tank Size

2 Eng / 1 Tank

0 gal

2 Eng / 2 Tanks

Press ENTER

3 Eng / 1 Tank

when finished

3 Eng / 3 Tanks

DOWN

MENU

PAGES

ENTER

EXIT

UP

3

1 Eng / 1 Tank

1 Eng / 2 Tanks

Setting Tank Size

2 Eng / 1 Tank

100 gal

2 Eng / 2 Tanks

Press ENTER

3 Eng / 1 Tank

when finished

3 Eng / 3 Tanks

DOWN

MENU

PAGES

ENTER

EXIT

UP

4

18

Page 21

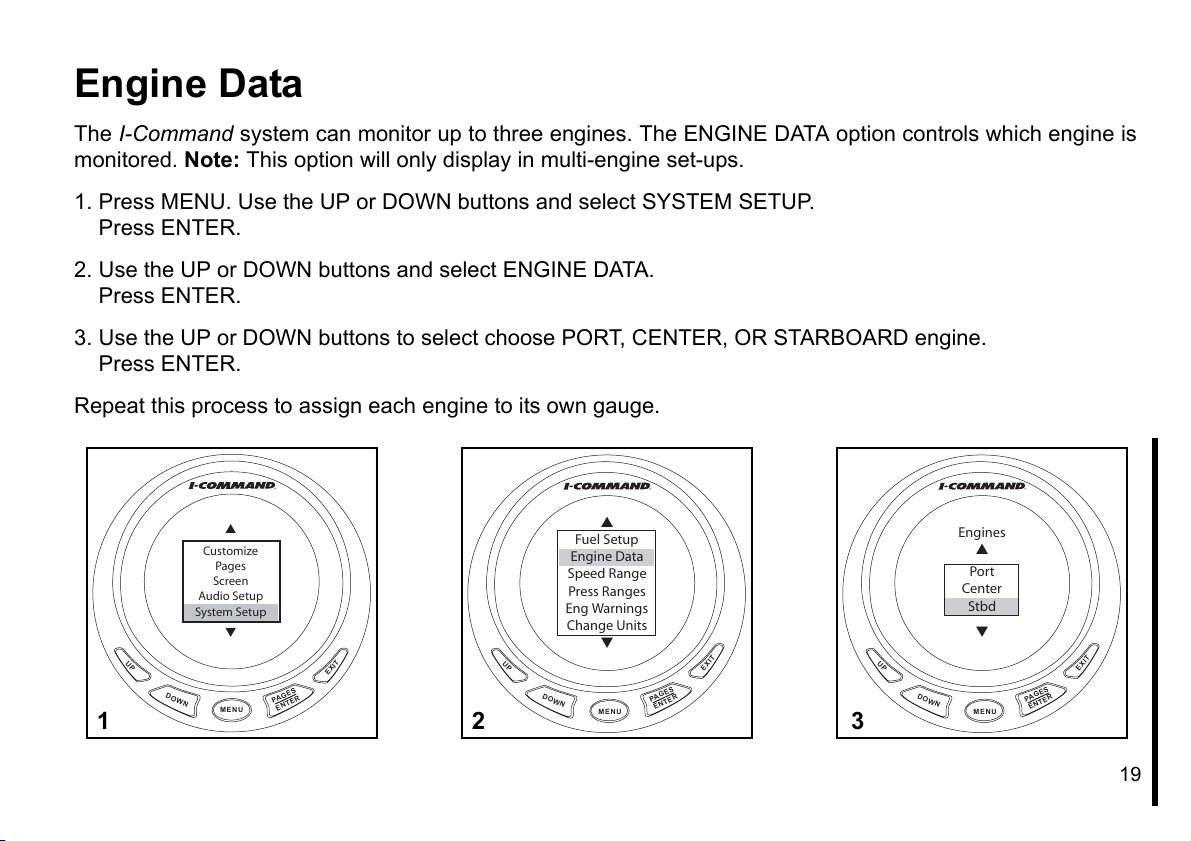

Engine Data

The I-Command system can monitor up to three engines. The ENGINE DATA option controls which engine is

monitored. Note: This option will only display in multi-engine set-ups.

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select ENGINE DATA.

Press ENTER.

3. Use the UP or DOWN buttons to select choose PORT, CENTER, OR STARBOARD engine.

Press ENTER.

Repeat this process to assign each engine to its own gauge.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

MENU

PA

ENTER

EXIT

ES

G

1

UP

2

Fuel Setup

Engine Data

Speed Range

Press Ranges

Eng Warnings

Change Units

DOWN

MENU

PA

ENTER

Engines

Port

Center

Stbd

EXIT

ES

G

UP

DOWN

3

MENU

PA

ENTER

EXIT

ES

G

19

Page 22

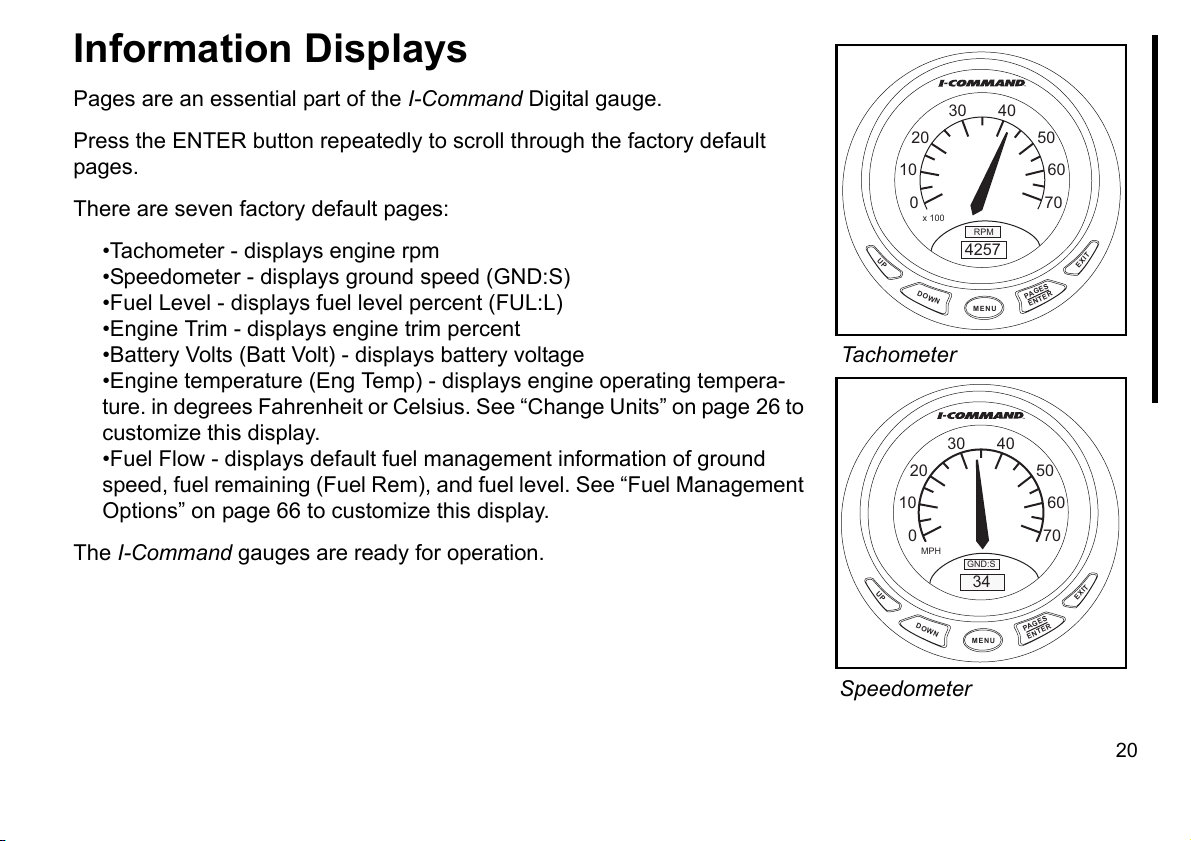

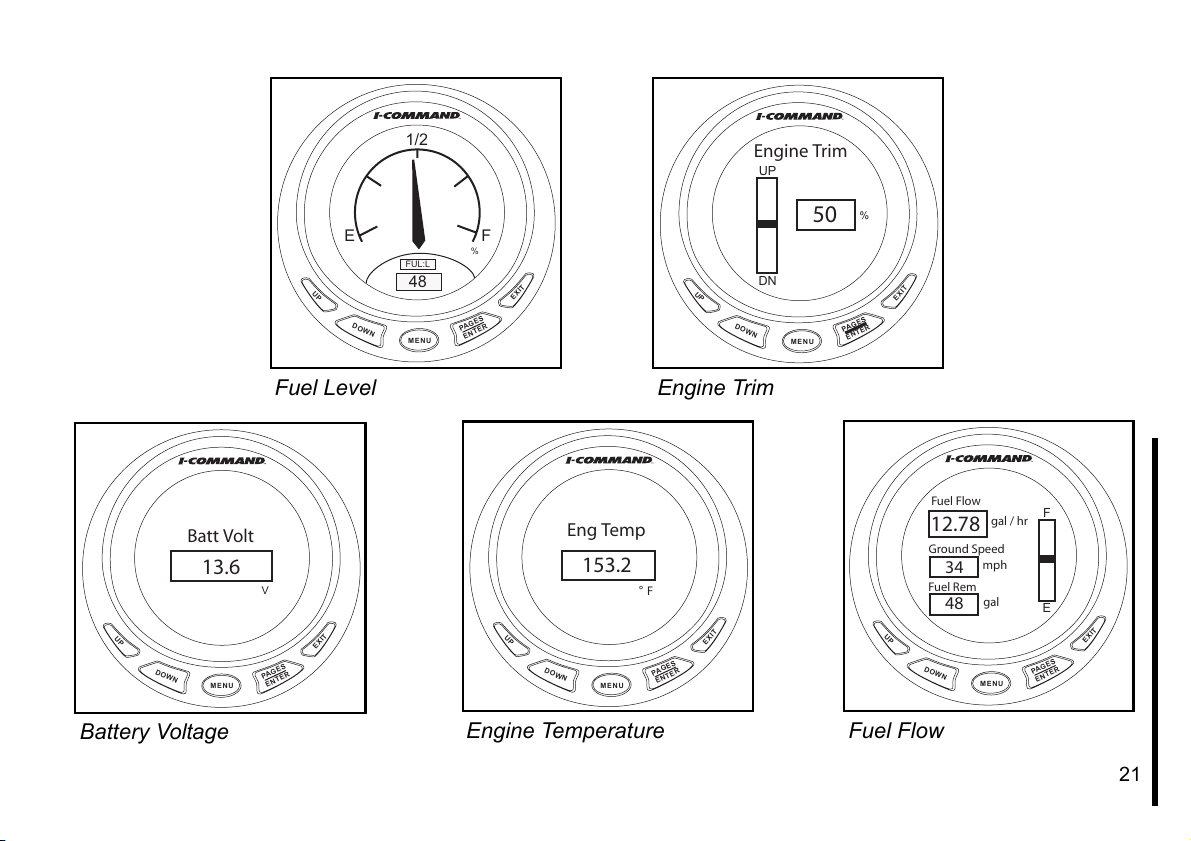

Information Displays

Pages are an essential part of the I-Command Digital gauge.

Press the ENTER button repeatedly to scroll through the factory default

pages.

There are seven factory default pages:

•Tachometer - displays engine rpm

•Speedometer - displays ground speed (GND:S)

•Fuel Level - displays fuel level percent (FUL:L)

•Engine Trim - displays engine trim percent

•Battery Volts (Batt Volt) - displays battery voltage

•Engine temperature (Eng Temp) - displays engine operating tempera-

ture. in degrees Fahrenheit or Celsius. See “Change Units” on page 26 to

customize this display.

•Fuel Flow - displays default fuel management information of ground

speed, fuel remaining (Fuel Rem), and fuel level. See “Fuel Management

Options” on page 66 to customize this display.

The I-Command gauges are ready for operation.

20 50

10 60

0 70

x 100

UP

DOWN

Tachometer

20 50

10 60

0 70

MPH

UP

DOWN

30 40

RPM

4257

MENU

30 40

GND:S

34

MENU

PA

PA

GES

ENTER

GES

ENTER

EXIT

EXIT

Speedometer

20

Page 23

1/2

E F

FUL:L

UP

DOWN

48

MENU

PAGES

ENTER

Engine Trim

UP

%

DOWN

DN

MENU

EXIT

UP

50

PA

ENTER

%

EXIT

ES

G

Batt Volt

13.6

UP

DOWN

MENU

Battery Voltage

Fuel Level

V

EXIT

GES

PA

ENTER

Eng Temp

153.2

° F

UP

DOWN

MENU

Engine Temperature

Engine Trim

EXIT

GES

PA

ENTER

UP

DOWN

Fuel Flow

Fuel F low

12.78

Ground Speed

mph

34

Fuel R em

gal

48

MENU

gal / hr

PAGES

ENTER

F

E

EXIT

21

Page 24

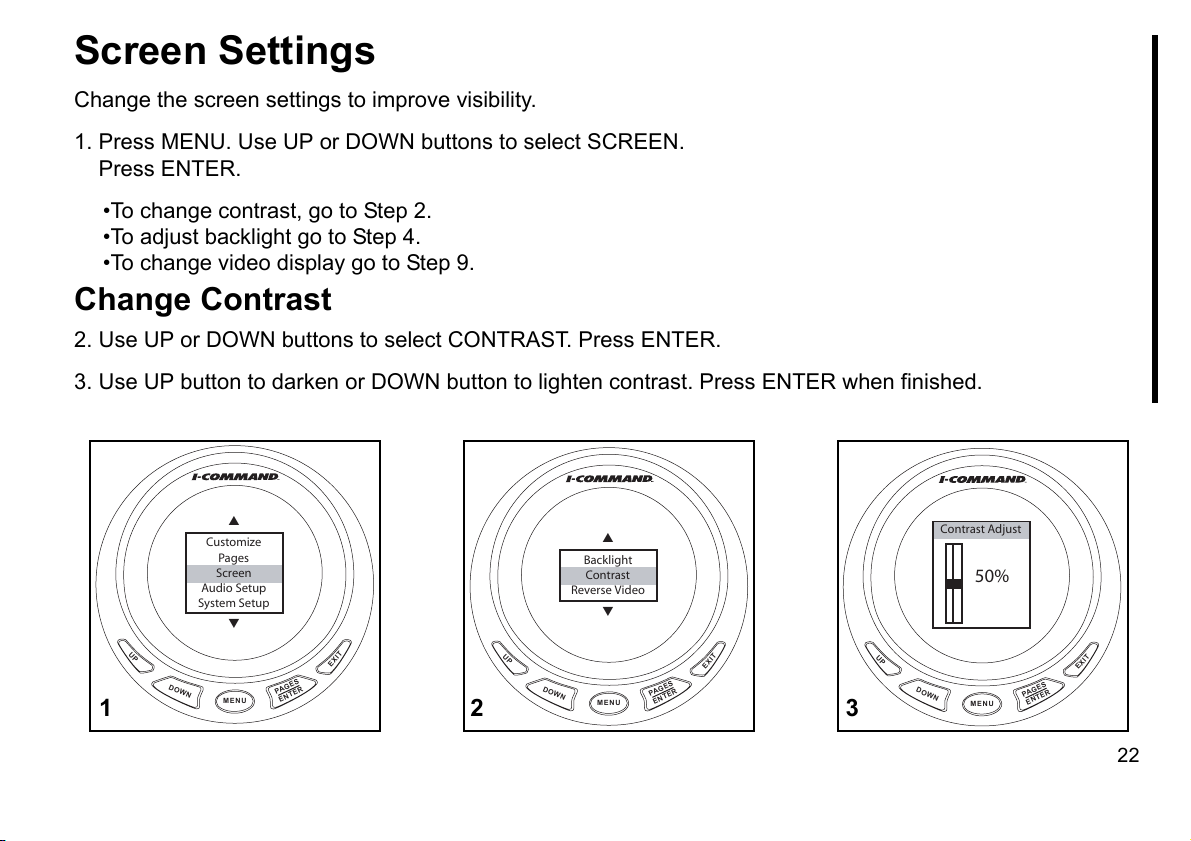

Screen Settings

Change the screen settings to improve visibility.

1. Press MENU. Use UP or DOWN buttons to select SCREEN.

Press ENTER.

•To change contrast, go to Step 2.

•To adjust backlight go to Step 4.

•To change video display go to Step 9.

Change Contrast

2. Use UP or DOWN buttons to select CONTRAST. Press ENTER.

3. Use UP button to darken or DOWN button to lighten contrast. Press ENTER when finished.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

ES

G

UP

2

Reverse Video

DOWN

Backlight

Contrast

MENU

PA

ENTER

EXIT

ES

G

UP

3

Contrast Adjust

DOWN

50%

MENU

PA

ENTER

EXIT

GES

22

Page 25

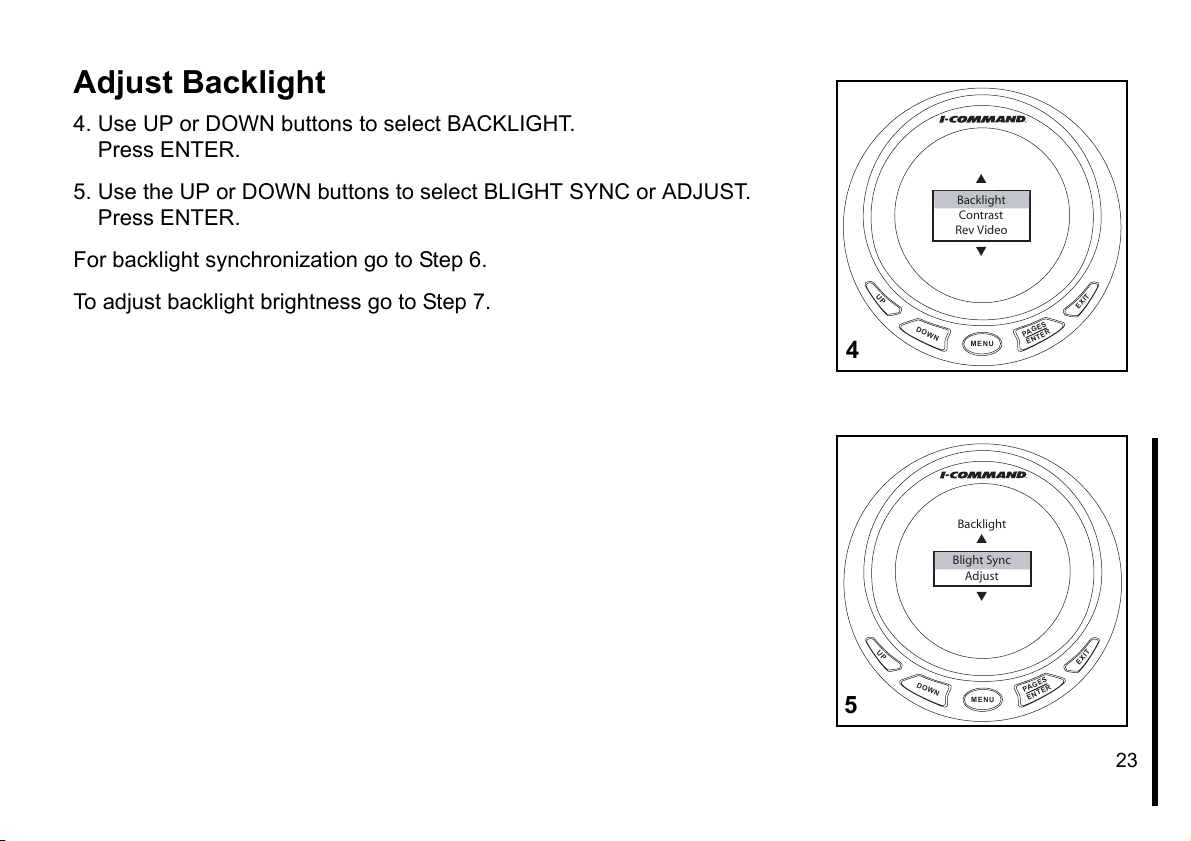

Adjust Backlight

4. Use UP or DOWN buttons to select BACKLIGHT.

Press ENTER.

5. Use the UP or DOWN buttons to select BLIGHT SYNC or ADJUST.

Press ENTER.

For backlight synchronization go to Step 6.

To adjust backlight brightness go to Step 7.

Backlight

Contrast

Rev Video

UP

DOWN

4

MENU

Backlight

Blight Sync

Adjust

PA

ENTER

EXIT

GES

UP

DOWN

5

MENU

PAGES

ENTER

EXIT

23

Page 26

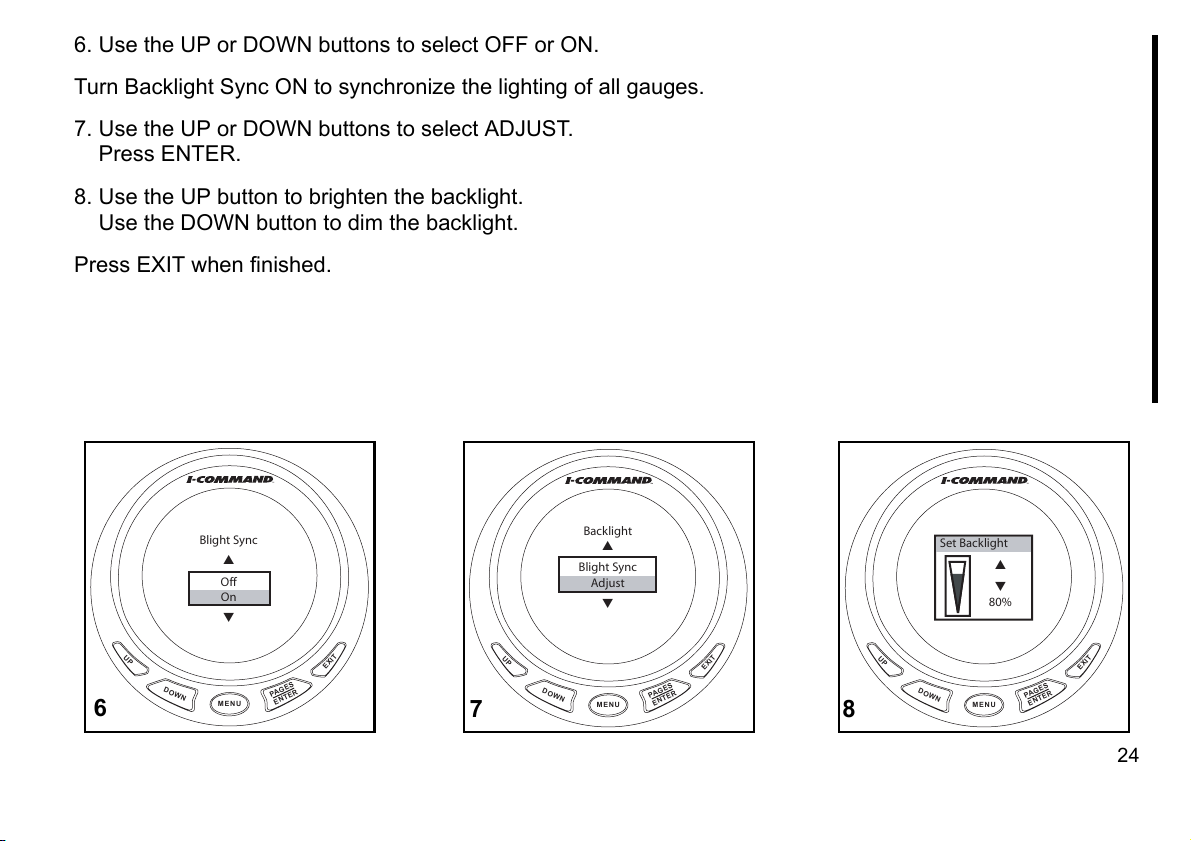

6. Use the UP or DOWN buttons to select OFF or ON.

Turn Backlight Sync ON to synchronize the lighting of all gauges.

7. Use the UP or DOWN buttons to select ADJUST.

Press ENTER.

8. Use the UP button to brighten the backlight.

Use the DOWN button to dim the backlight.

Press EXIT when finished.

DOWN

Backlight

Blight Sync

Adjust

MENU

PA

ENTER

Set Backlight

80%

EXIT

GES

UP

DOWN

8

MENU

PA

ENTER

EXIT

GES

Blight Sync

Off

On

UP

DOWN

6

MENU

PA

ENTER

EXIT

GES

UP

7

24

Page 27

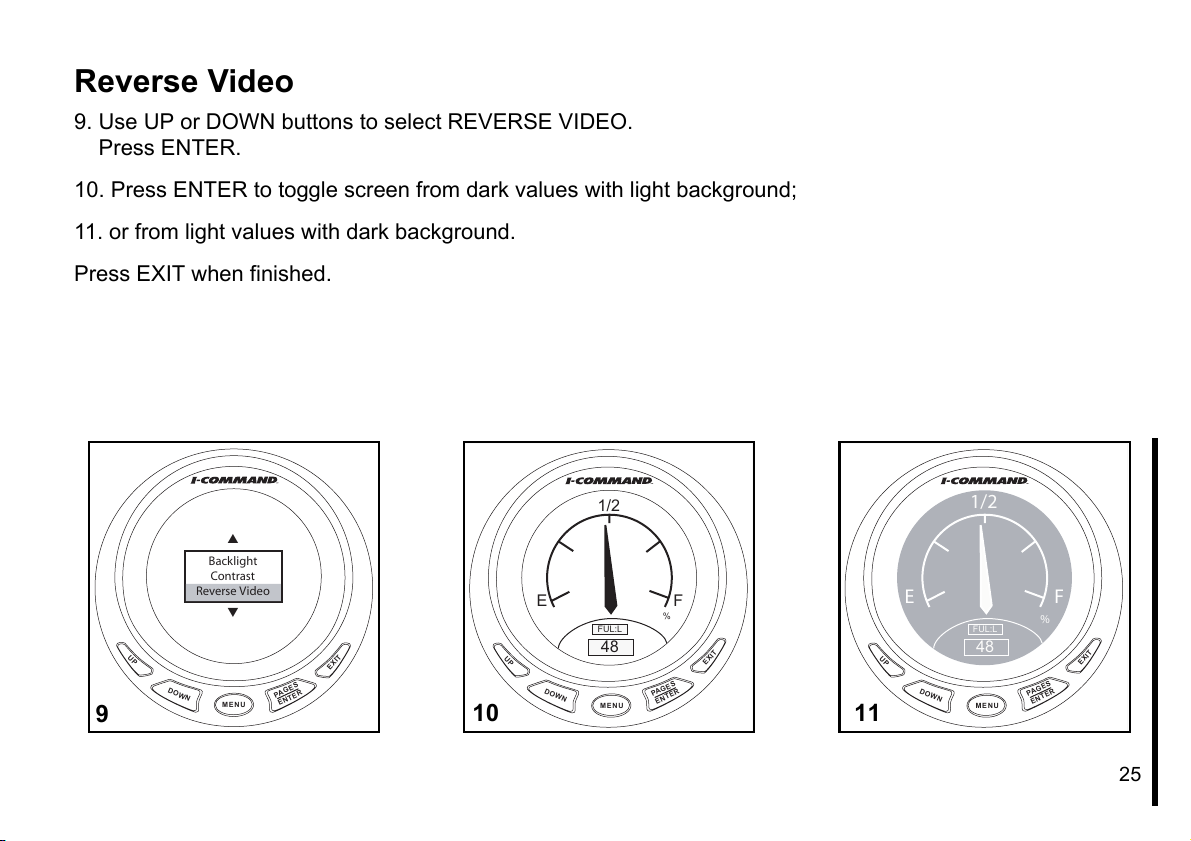

Reverse Video

9. Use UP or DOWN buttons to select REVERSE VIDEO.

Press ENTER.

10. Press ENTER to toggle screen from dark values with light background;

11. or from light values with dark background.

Press EXIT when finished.

DOWN

1/2

FUL:L

48

MENU

PA

ENTER

%

EXIT

ES

G

1/2

Backlight

Contrast

Reverse Video

UP

DOWN

9

MENU

PA

ENTER

EXIT

ES

G

10

E F

FUL:L

DOWN

48

MENU

UP

PA

%

ES

G

ENTER

EXIT

E F

UP

11

25

Page 28

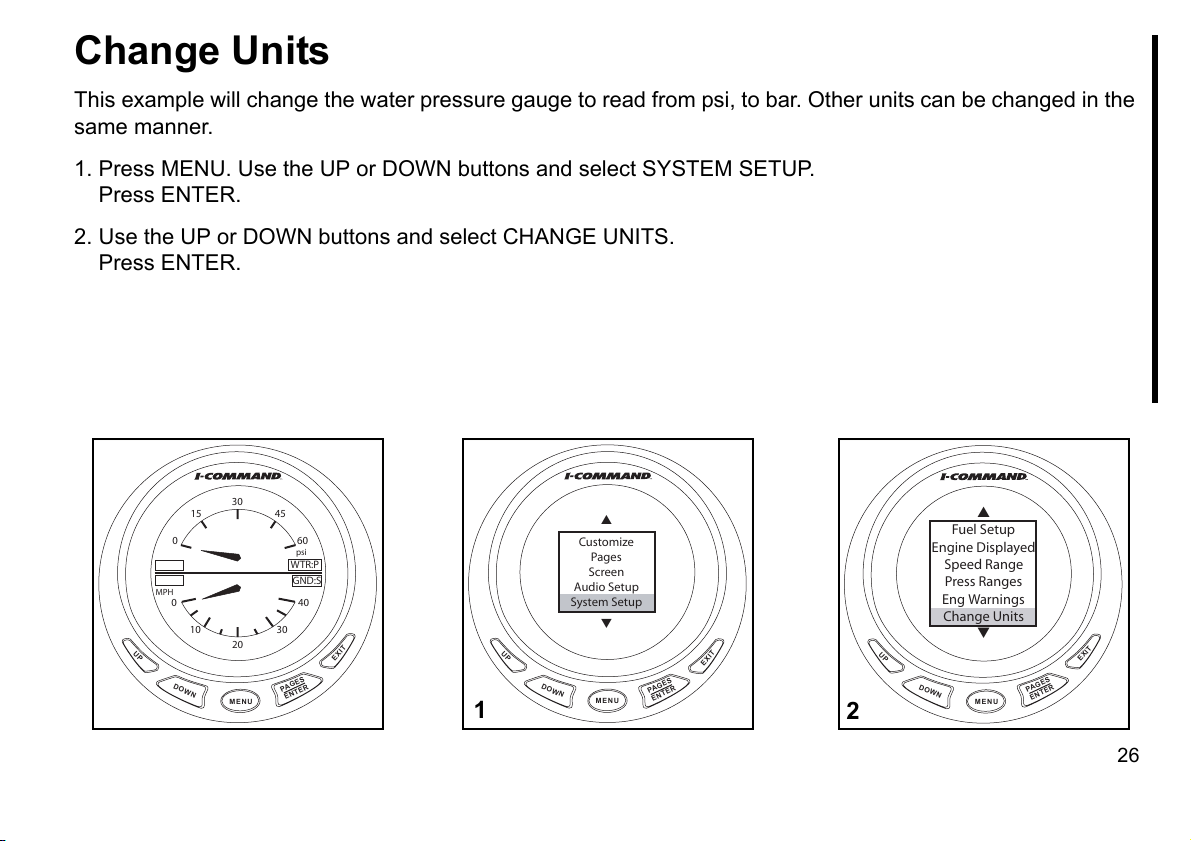

Change Units

This example will change the water pressure gauge to read from psi, to bar. Other units can be changed in the

same manner.

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select CHANGE UNITS.

Press ENTER.

30

15 45

0 60

MPH

0 40

10 30

UP

DOWN

20

MENU

PA

ENTER

psi

WTR:P

GND:S

GES

EXIT

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

UP

2

Fuel Setup

Engine Displayed

Speed Range

Press Ranges

Eng Warnings

Change Units

DOWN

MENU

PAGES

ENTER

EXIT

26

Page 29

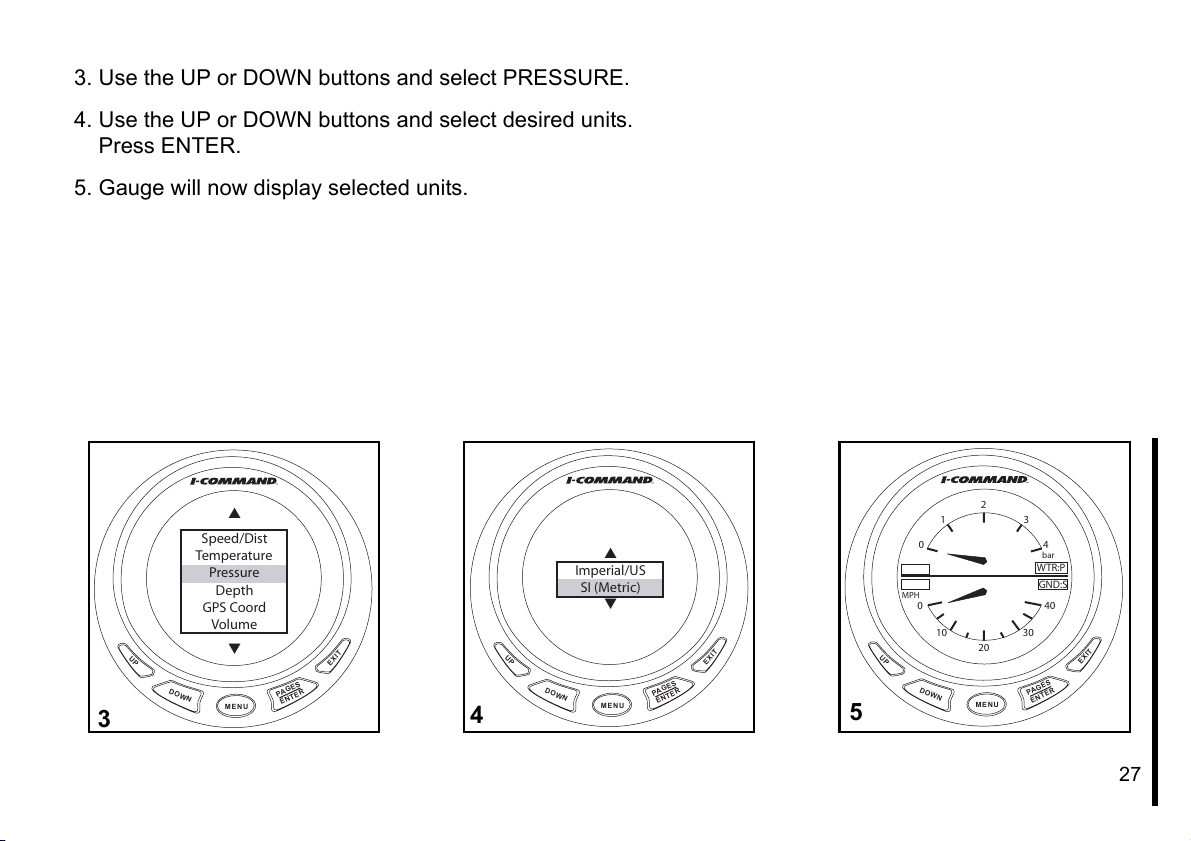

3. Use the UP or DOWN buttons and select PRESSURE.

4. Use the UP or DOWN buttons and select desired units.

Press ENTER.

5. Gauge will now display selected units.

Speed/Dist

Temperature

Pressure

Depth

GPS Coord

Volume

DOWN

MENU

PA

ENTER

EXIT

GES

UP

3

UP

4

DOWN

Imperial/US

SI (Metric)

MENU

PA

ENTER

EXIT

ES

G

5

0 4

MPH

0 40

UP

DOWN

2

1 3

10 30

20

MENU

WTR:P

PAGES

ENTER

bar

GND:S

EXIT

27

Page 30

Setup Notes

28

Page 31

Customizing Displays

29

Page 32

Display Fuel Economy

1. Press the ENTER button repeatedly to scroll to the Fuel Flow page.

The center data box is Ground Speed.

2. Press MENU.

Use the UP or DOWN buttons to select CUSTOMIZE.

Press ENTER.

Fuel F low

12.78

Ground Speed

34

Fuel R em

48

UP

DOWN

DOWN

MENU

Customize

Pages

Screen

Audio Setup

System Setup

MENU

1

UP

2

gal / hr

mph

gal

PAGES

ENTER

PA

ENTER

F

E

EXIT

EXIT

GES

30

Page 33

3. Use UP or DOWN buttons to select CENTER DATA.

Press ENTER.

4. Press UP or DOWN button to select FUEL ECONOMY.

Press ENTER.

5. Press EXIT twice to return to fuel manager page.

Fuel Economy (MPG) is now activated.

UP

Fuel F low

12.78

Fuel Economy

3.56

Fuel R em

48

DOWN

mpg

gal

MENU

gal / hr

PA

ENTER

F

E

EXIT

GES

Top Data

Center Data

Bottom Data

UP

DOWN

3

MENU

PAGES

ENTER

EXIT

UP

DOWN

4

Fuel Flow

Fuel Economy

F Consumption

Fuel Remaining

MENU

PA

ENTER

EXIT

GES

5

31

Page 34

Add New Page

Page displays can be presented in analog or digital format as single, dual, or

quad displays.

In addition to analog or digital gauge displays, seven other pages can be

added. They are:

•Trim Tabs - requires sending unit

•GPS Position - requires GPS module

•Rudder - requires sending unit

•Clock - requires GPS module

•Fuel Manager (labeled as Fuel Flow, also a default page)

•Engine Trim (also a default page)

•Engine Diagnostics

•Synchronizer – displays RPM for up to three engines, allowing users to

synchronize the engines for smoother performance.

Note: Only supported in multi-engine setups.

This example will add an Engine Diagnostics page.

1. Press MENU.

Use UP or DOWN buttons to select PAGES.

Press ENTER.

2. Press ENTER to select ADD PAGE.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

Add Page

Remove Page

Page Scrolling

Popups Setup

DOWN

MENU

MENU

1

UP

2

GES

PA

ENTER

PA

ENTER

EXIT

EXIT

ES

G

32

Page 35

3. Use the UP or DOWN buttons to select Diagnostics.

Press ENTER.

4. Press ENTER again to confirm.

5. The Engine Diagnostic page will now display.

Trim Tabs

GPS Position

Rudder

Clock

Engine Trim

Diagnostics

DOWN

MENU

PAGES

ENTER

EXIT

UP

4

UP

3

Trim Tabs

Adding Page

GPS Position

Press ENTER

Rudder

to Add

Clock

Diagnostics

Engine Trim

Diagnostics

DOWN

MENU

Eng Diagnostics

Engine OK

PAGES

ENTER

EXIT

UP

DOWN

5

MENU

PAGES

ENTER

EXIT

33

Page 36

Add Analog Page

Analog page displays allow the following data combinations:

•Alt Voltage •GPS Speed

(speed over ground)

•Atmospheric Pressure •Paddle Wheel Speed (speed over water)

•Battery Voltage •Pitot Speed

•Engine Temp •Tachometer

•Fluid Level •Temperature

•Fuel Pressure •Engine Water Pressure

•Engine Oil Pressure •Engine Boost Pressure

•Transmission Oil Pressure

This example adds a dual analog gauge display. Single analog or quad ana-

log displays may be added by selecting those options.

1. Press MENU.

Use UP or DOWN buttons to select PAGES.

Press ENTER.

2. Press ENTER to select ADD PAGE.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

Add Page

Remove Page

Page Scrolling

Popups Setup

DOWN

MENU

MENU

1

UP

2

PAGES

ENTER

PA

ENTER

EXIT

EXIT

ES

G

34

Page 37

3. Press UP button to select DUAL ANALOG.

Press ENTER.

4. Press ENTER again to confirm.

The Dual Analog gauge will now display.

To change the items displayed on any single, dual or quad analog gauge,

see “Customizing Displays” on page 38.

Single Analog

Dual Analog

Quad Analog

Single Digital

Dual Digital

Quad Digital

UP

3

E F

%

MPH

0 40

UP

DOWN

4

DOWN

MENU

1/2

10 30

20

MENU

PAGES

ENTER

PAGES

ENTER

EXIT

FUL:L

GND:S

EXIT

35

Page 38

Add Digital Page

Digital page displays allow the following data combinations:

•Alt Voltage •Fuel Remaining

•Atmospheric Pressure •GPS Speed (speed over ground)

•Battery Voltage •Paddle Wheel Speed (speed over water)

•Depth •Pitot Speed

•Engine Temperature •Tachometer

•Fuel Economy •Temperature

•Fuel Flow •Total Engine Hours

•Fuel Range •Throttle Percentage

•Fuel Consumption •Engine Water Pressure

•Fuel Used •Engine Oil Pressure

•Trip Fuel Used •Fuel Pressure

•Seasonal Fuel Used •Engine Boost Pressure

•Transmission Oil Pressure •Time

This example adds a quad digital gauge display. Single analog or dual digital

displays may be added by selecting those options.

1. Press MENU.

Use UP or DOWN buttons to select PAGES.

Press ENTER.

2. Press ENTER to select ADD PAGE.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

Add Page

Remove Page

Page Scrolling

Popups Setup

DOWN

MENU

MENU

1

UP

2

PAGES

ENTER

PA

ENTER

EXIT

EXIT

ES

G

36

Page 39

3. Use UP or DOWN buttons to select QUAD DIGITAL.

Press ENTER.

4. Press ENTER again to confirm.

The Quad Digital gauge will now display.

To change the items displayed on any single, dual or quad digital gauge, see

“Customizing Displays” on page 38.

Single Analog

Dual Analog

Quad Analog

Single Digital

Dual Digital

Quad Digital

DOWN

MENU

RPM

Throttle Pct

Eng Hrs

Time

MENU

PA

%

Hrs

PAGES

ENTER

GES

ENTER

EXIT

EXIT

UP

3

UP

DOWN

4

37

Page 40

Customizing Displays

Changing Display Defaults

When adding pages, each single, dual or quad page has a default display. Use the CUSTOMIZE menu to

change which items are displayed on a page.

1. Press ENTER multiple times to scroll to page to customize.

Press MENU.

2. Use UP or DOWN buttons to select CUSTOMIZE.

Press ENTER.

3. Use UP or DOWN buttons to select GAUGE (if analog), or DATA BOX (if digital).

Press ENTER.

1/2

E F

%

MPH

0 40

10 30

DOWN

20

MENU

UP

1

PA

ENTER

FUL:L

GND:S

ES

G

EXIT

UP

2

DOWN

Customize

Pages

Screen

Audio Setup

System Setup

MENU

PA

ENTER

Top Gauge

Bottom Gauge

EXIT

GES

UP

DOWN

3

MENU

PA

ENTER

EXIT

GES

38

Page 41

4. Use UP or DOWN buttons to select desired display item.

Press ENTER.

5. Press EXIT once to return to Step 3 and change remaining items.

Press EXIT multiple times to return to display.

Display change will now appear.

Alt Voltage

Batt Voltage

Engine Temp

Eng Water Press

Fuel Pressure

UP

DOWN

4

MPH

UP

MENU

10 20

0 30

0 40

10 30

20

DOWN

MENU

PAGES

ENTER

WTR:P

G

PA

ENTER

EXIT

psi

GND:S

EXIT

ES

5

39

Page 42

Configure Time Display

1. Press MENU.

Use UP or DOWN buttons to select SYSTEM SETUP.

Press ENTER.

2. Use UP or DOWN buttons to select TIME CONFIG.

Press ENTER.

3. Use UP or DOWN buttons to select:

HOUR FORMAT, go to Step 4.

SHOW SECONDS, go to Step 5.

TIME ZONE go to Step 6.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

2

Sonar Alarms

Eng/Tank Cfg

Time Config

Reset Values

Lock Pages

NMEA Info

UP

DOWN

MENU

PAGES

ENTER

EXIT

Time

Hour Format

Show Seconds

Time Zone

UP

DOWN

3

MENU

PAGES

ENTER

EXIT

40

Page 43

4. Use UP or DOWN buttons to select 12 or 24 hour display option.

Press ENTER.

5. Use UP or DOWN buttons to select YES or NO.

Press ENTER.

6. Use UP or DOWN buttons to select Time Zone.

Press ENTER.

7. Press EXIT multiple times to return to time display.

DOWN

GMT -3

GMT -2

GMT -1

GMT

GMT +1

GMT +2

MENU

PAGES

ENTER

EXIT

Show Seconds

No

Yes

UP

DOWN

5

MENU

PAGES

ENTER

EXIT

UP

6

Hour Format

24 hrs

12 hrs

UP

DOWN

4

MENU

Time

PAGES

ENTER

EXIT

13 : 35 : 47

pm

UP

DOWN

7

MENU

PA

ENTER

EXIT

GES

41

Page 44

Lock Pages

Viewing Pass Code

This feature prevents unauthorized users from changing select gauge settings. If you have the PASS CODE,

skip to step 4.

1. Press MENU. Use UP or DOWN buttons to select SYSTEM SETUP. Press ENTER.

2. Select NMEA INFO and press ENTER.

3. The PASS CODE is the last four digits of the SERIAL NUMBER.

For easy reference, write gauge serial number here: ______________

Press EXIT to return to the MENU.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

UP

DOWN

2

Sonar Alarms

Eng/Tank Cfg

Time Config

Reset Values

Lock Pages

NMEA Info

MENU

PAGES

ENTER

EXIT

NMEA Info

Address: 10

Instance: 0

Serial Number:

6 5 4 3 2 1

NMEA Ver: 1.2.0

Bus Volt: 12.8

UP

DOWN

3

MENU

PA

ENTER

EXIT

GES

42

Page 45

Lock Pages

4. Use the UP or DOWN buttons to select LOCK PAGES.

Press ENTER.

5. Use the UP or DOWN buttons to change the active digit.

Use the MENU button to select the next digit.

Press ENTER to submit PASS CODE.

6. Use the UP or DOWN buttons to scroll through the list. Press the MENU button to view the next list.

Press ENTER to select page(s) to be locked. An "x" will appear in the box when a page is selected.

Press EXIT when selection is complete.

Sonar Alarms

Eng/Tank Cfg

Time Config

Reset Values

Lock Pages

NMEA Info

DOWN

MENU

PA

ENTER

EXIT

GES

UP

5

UP

4

Eng/Tank Cfg

Time Config

Enter Pass-Code

Reset Values

Lock Pages

0 0 0 0

NMEA Info

System Info

DOWN

MENU

UP

6

PA

ENTER

EXIT

ES

G

Eng/Tank Cfg

Locked Pages

Time Config

Customize

Reset Values

Pages

Lock Pages

x Fuel Setup

Eng/Tank Setup

NMEA Info

MENU key for more

System Info

DOWN

MENU

PA

ENTER

EXIT

ES

G

43

Page 46

Accessing a Locked Page

Locking pages prevents an unauthorized user from changing select gauge settings.

1. Press MENU.

Use UP or DOWN buttons to select SYSTEM SETUP.

2. Select desired page and press ENTER.

3. Enter the gauge PASS CODE.

Use the UP or DOWN buttons to change the active digit.

Use the MENU button to select the next digit.

Press ENTER to submit PASS CODE.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

13

MENU

PA

ENTER

EXIT

GES

UP

DOWN

2

Fuel Setup

Speed Range

Press Ranges

Eng Warnings

Change Units

Bus Devices

MENU

PA

ES

G

ENTER

EXIT

UP

Fuel Setup

Speed Range

Press Ranges

Enter Pass-Code

Eng Warnings

0 0 0 0

Change Units

Bus Devices

DOWN

MENU

EXIT

PAGES

ENTER

44

Page 47

4. An incorrect entry will result in an INVALID PASS CODE message.

Press ENTER to start over.

5. Correct entry of pass code allows access to pages.

Use UP or DOWN buttons to select desired items and make changes.

6. When finished, press ENTER to return to gauge display.

DOWN

1/2

FUL:L

100

MENU

PAGES

ENTER

%

EXIT

Fuel Setup

Speed Range

Press Ranges

Pass-Code

Eng Warnings

Invalid

Change Units

Bus Devices

DOWN

MENU

PAGES

ENTER

EXIT

UP

4

UP

5

Refill Tank

Partial Fill

Eco Speed Src

Fuel Rem Src

Rst Trip Fuel

Rst Seasonal

DOWN

MENU

E F

UP

6

PA

ENTER

EXIT

GES

45

Page 48

Removing Pages

1. Press the ENTER button repeatedly to scroll to the page to be removed.

Press MENU.

2. Use UP or DOWN buttons to select PAGES.

Press ENTER.

20 70

x10

DOWN

DOWN

10 35

0 0

20 70

10 35

0 0

MENU

Customize

Pages

Screen

Audio Setup

System Setup

MENU

PAGES

ENTER

PAGES

ENTER

Volts

ALR:VBATT:V

WTR:P

EXIT

EXIT

Volts

WTR: T

°F psi

UP

1

UP

2

46

Page 49

3. Use UP or DOWN buttons to select REMOVE PAGE.

Press ENTER.

4. A confirmation message will appear.

Press ENTER to remove page.

The display will return to the next page.

Add Page

Remove Page

Page Scrolling

Popups Setup

UP

DOWN

3

UP

4

MENU

Removing Page

Press ENTER

to Remove

current Page

DOWN

MENU

PA

ENTER

PA

ENTER

EXIT

GES

EXIT

GES

47

Page 50

Page Scrolling

Pages can be viewed by manual or automatic scrolling.

Manual

To scroll through pages manually, use the ENTER and EXIT buttons to view

pages.

Automatic

To scroll through pages automatically, a viewing interval must be selected.

1. Press MENU.

Use the UP or DOWN buttons to select PAGES.

Press ENTER.

2. Use the UP or DOWN buttons, select PAGE SCROLLING.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PAGES

ENTER

EXIT

Add Page

Remove Page

Page Scrolling

Popups Setup

UP

DOWN

2

MENU

PAGES

ENTER

EXIT

48

Page 51

3. Use the UP or DOWN buttons to select SET TIME.

Press ENTER.

4. Use the UP or DOWN buttons to set time.

Select an interval between one and sixty seconds.

Press ENTER to set automatic scrolling interval.

Note: To turn off automatic page scrolling, repeat the first two steps. When

the Page Scrolling menu appears, select OFF. Then press ENTER.

Page Scrolling

Off

Set Time

UP

DOWN

3

MENU

Set Time

Add Page

Remove Page

5 sec

Page Scrolling

Press ENTER

Popups Setup

when finished

PA

ENTER

EXIT

GES

UP

DOWN

4

MENU

PAGES

ENTER

EXIT

49

Page 52

Pop-Ups

The Pop-Up feature alerts users when changes occur in a monitored cate-

gory (RPM, Engine Trim, Trim Tabs or Rudder). Pop-ups appear when a

user-specified incremental measurement is met. When an increment

changes, the main page for the category will pop up on the main display for

a preset duration. See “Stay-on Time” on page 52 to set the pop-up dura-

tion.

Setting a Pop-Up

This example illustrates setting the RPM Pop-Up. Engine trim, trim tabs and

rudder can be set up similarly.

1. Press MENU.

Use UP or DOWN buttons to select PAGES.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

MENU

PAGES

ENTER

EXIT

1

2. Use the UP or DOWN button to select POPUPS SETUP.

Press ENTER.

Add Page

Remove Page

Page Scrolling

Popups Setup

UP

DOWN

2

MENU

PAGES

ENTER

EXIT

50

Page 53

3. Use the UP or DOWN button to select RPM.

Press ENTER.

4. Use the UP or DOWN button to select OFF to turn off the RPM pop-up, or select SET THRESHOLD.

Press ENTER.

5. The threshold for RPM ranges from 50 to 3,000 RPM. Set the desired RPM value that activates the pop-up

by using the UP or DOWN buttons.

Press ENTER when finished.

RPM

Engine Trim

Trim Tabs

Rudder

Stay On Time

UP

DOWN

MENU

PAGES

ENTER

EXIT

3

UP

4

Set Threshold

DOWN

RPM

Off

MENU

Set Threshold

Add Page

Remove Page

100 rpm

Page Scrolling

Press ENTER

Popups Setup

when finished

UP

DOWN

5

MENU

PA

ENTER

EXIT

GES

PAGES

ENTER

EXIT

51

Page 54

Stay-on Time

1. Press MENU.

Use UP or DOWN buttons to select PAGES.

Press ENTER.

2. Use the UP or DOWN button to select POPUPS SETUP.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PAGES

ENTER

EXIT

Add Page

Remove Page

Page Scrolling

Popups Setup

UP

DOWN

2

MENU

PAGES

ENTER

EXIT

52

Page 55

3. Use the UP or DOWN buttons to select STAY-ON TIME.

Press ENTER.

4. The stay-on time ranges between two and fifteen seconds. Set the

desired stay-on time using the UP or DOWN buttons.

Press ENTER when finished.

Note: The stay-on time selected applies to all monitored categories.

RPM

Engine Trim

Trim Tabs

Rudder

Stay On Time

UP

DOWN

3

MENU

Set Time

Add Page

Remove Page

5 sec

Page Scrolling

Press ENTER

Popups Setup

when finished

PAGES

ENTER

EXIT

UP

DOWN

4

MENU

PAGES

ENTER

EXIT

53

Page 56

Sleep Mode

Sleep mode allows the I-Command gauge to enter a power-save status to

keep from overdrawing the boat power source.

1. Press MENU.

Use Up or DOWN buttons to select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN button to select SLEEP.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

Engine Warnings

Change Units

Bus Devices

Sleep Mode

Sonar Alarms

Eng/Tank Cfg

DOWN

MENU

PAGES

ENTER

EXIT

UP

2

54

Page 57

3. Use the UP or DOWN buttons to select ON or OFF.

Press ENTER. Guage will return to last display.

Sleep Mode

Off

On

UP

DOWN

3

MENU

PA

ENTER

EXIT

ES

G

12

11 1

10 2

9 3

8 4

7 5

UP

DOWN

6

MENU

PAGES

ENTER

EXIT

55

Page 58

Customizing Notes

56

Page 59

Advanced Setup and Operation

57

Page 60

Configure Fluid Level Sensor

This example illustrates Fluid Level Sensor Configuration for the second of two fuel tanks. Fluid level sensors

for other fluid tanks will configure similarly.

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select BUS DEVICES

Press ENTER.

3. The gauge will search for devices.

DOWN

Eng Warnings

Change Units

Bus Devices

Sleep Mode

Sonar Alarms

Eng/Tank Cfg

MENU

PA

ENTER

EXIT

GES

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

12

MENU

PA

ENTER

EXIT

GES

UP

Eng Warnings

Message

Change Units

Bus Devices

Searching

Sleep Mode

Bus

Sonar Alarms

Devices...

Eng/Tank Cfg

DOWN

MENU

PA

ENTER

EXIT

GES

UP

3

58

Page 61

4. Use the UP or DOWN buttons and select UNCFG F LEV.

Press ENTER.

5. Press ENTER to configure Fluid Level Sensor.

6. Use the UP or DOWN buttons to select FUEL.

Press ENTER.

Water Temp

Fuel Tank 1

UnCfg F Lev

Water Press

Oil Tank

Storage Device

DOWN

MENU

PAGES

ENTER

EXIT

UP

5

UP

4

Water Temp

Configuring

Fuel Tank 1

UnCfg F Lev

Press ENTER

Water Press

to Configure

Oil Tank

Fluid Lev Snsr

Storage Device

DOWN

MENU

EXIT

GES

PA

ENTER

UP

DOWN

6

Oil

Black Water

Fuel

Fresh Water

Waste Water

Live Well

MENU

PA

ENTER

EXIT

GES

59

Page 62

7. Use the UP or DOWN buttons and select the tank.

Press ENTER.

8. The gauge will change the tank setting and return to the BUS DEVICES

list.

Proceed to “Fuel and Fluid Level Sensor Calibration” on page 61.

Select Tank

Tank 1

Tank 2

UP

DOWN

7

UP

MENU

Select Tank

Message

Tank 1

Changing

Tank 2

Device

Settings

DOWN

MENU

PA

PA

GES

ENTER

GES

ENTER

EXIT

EXIT

8

60

Page 63

Fuel and Fluid Level Sensor Calibration

Fluid level sensors use the tank sending unit to calculate remaining fuel, oil,

water etc. Calculation is based on sending unit accuracy, capacity entered

during setup, and liquid level in the tank. Use the FIVE POINT calibration to

achieve best accuracy.

•Two-Point calibrates EMPTY and FULL levels.

•Three-Point calibrates EMPTY, 50% and FULL levels.

•Five-Point calibrates EMPTY, 25%, 50%, 75% and FULL levels.

WARNING

Running out of fuel could cause the operator of the boat to have

diminished or no control of the vessel, presenting a risk of personal

injury to the operator, passengers, and people who are nearby.

This example illustrates a 2-Point Calibration. Follow the on-screen prompts

if a Three or Five-Point Calibration is desired.

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select BUS DEVICES

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

DOWN

MENU

Eng Warnings

Change Units

Bus Devices

Sleep Mode

Sonar Alarms

Eng/Tank Cfg

MENU

1

UP

2

PA

ENTER

PA

ENTER

EXIT

GES

EXIT

GES

61

Page 64

3. The gauge will search for devices.

4. Use the UP or DOWN buttons to select the device to be calibrated.

Press ENTER.

5. Use the UP or DOWN buttons and select CALIBRATE.

Press ENTER.

6. Use the UP or DOWN buttons to select the number of points for the cali-

bration.

Press ENTER.

Eng Warnings

Message

Change Units

Bus Devices

Searching

Sleep Mode

Bus

Sonar Alarms

Devices...

Eng/Tank Cfg

DOWN

MENU

PA

ENTER

EXIT

GES

UP

3

Water Temp

Fuel Tank 1

Fuel Tank 2

Water Press

Oil Tank

Storage Device

DOWN

MENU

PAGES

ENTER

EXIT

UP

UP

DOWN

54

Level Wrng

UnConfigure

ReConfigure

Calibrate

Reset Cal

Reset Values

MENU

GES

PA

ENTER

EXIT

Num of Points

2

3

5

UP

DOWN

6

MENU

PA

ENTER

EXIT

GES

62

Page 65

7. Select EMPTY LEVEL.

Press ENTER.

8. Be sure the tank is EMPTY.

Press ENTER.

9. Select FULL LEVEL.

Press ENTER.

10. Fill the tank.

Press ENTER.

Empty Level

Full L evel

UP

DOWN

7

MENU

PA

ENTER

EXIT

ES

G

Calibrating

Empty Level

Set Tank to

Full L evel

Full L evel

Press ENTER

DOWN

MENU

EXIT

GES

PA

ENTER

DOWN

Empty Level

Full L evel

MENU

PA

ENTER

EXIT

GES

UP

Calibrating

Empty Level

Set Tank to

Full L evel

Empty Level

Press ENTER

UP

DOWN

8

MENU

PA

GES

ENTER

EXIT

UP

910

63

Page 66

Fuel Management

Select Fuel Remaining Source

Perform the following procedure on each gauge. The default setting is FLUID LEV SNSR.

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select FUEL SETUP.

Press ENTER.

3. Use the UP or DOWN buttons and select FUEL REM SRC.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

ES

G

UP

DOWN

2

Fuel Setup

Engine Displayed

Speed Range

Press Ranges

Eng Warnings

Change Units

MENU

PA

GES

ENTER

EXIT

UP

3

Refill Tank

Partial Fill

Eco Speed Src

Fuel Rem Src

Rst Trip Fuel

Rst Seasonal

DOWN

MENU

EXIT

PAGES

ENTER

64

Page 67

Use the UP or DOWN buttons to make selection. Review the following to

determine which choice will work best in your application.

FLUID LEV SNSR (Fluid Level Sensor) -

4. Fluid level sensor requires installation of a fuel tank level converter which

uses the fuel tank sending unit to calculate remaining fuel. Calculation is

based on sending unit accuracy, capacity entered during setup, and fuel

consumed from tank. Use the FIVE POINT calibration (see “Fuel and

Fluid Level Sensor Calibration” on page 61) to achieve the best accuracy.

ENG/FFLOW (Engine Fuel Flow) -

5. Engine fuel flow requires installation of memory module kit. Uses Out-

board’s EMM software to calculate fuel consumption. Total fuel use is cal-

culated based on EMM fuel tables and subtracted from fuel tank capacity

entered during setup.

A GPS antenna and memory module kit must be installed to track seasonal

fuel, trip fuel, fuel range, and economy.

IMPORTANT: Fuel flow data from the EMM is required. User must enter

amount of fuel added at each fill up (see “Refill Tank” on page 67) or perform

the “Partial Fill” procedure (see “Partial Fill” on page 67). A GPS antenna

must be installed for fuel management features to be functional.

Eng/Fflow

Fluid Lev Snsr

UP

DOWN

Eng/Fflow

Fluid Lev Snsr

DOWN

MENU

MENU

4

UP

5

PAGES

ENTER

PAGES

ENTER

EXIT

EXIT

65

Page 68

Fuel Management Options

Use the following steps to access fuel management options.

1.Press MENU.

Use UP or DOWN buttons to Select SYSTEM SETUP.

Press ENTER.

2. Use UP or DOWN buttons to select FUEL SETUP.

Press ENTER.

3. Use the UP or DOWN buttons to select REFILL TANK or PARTIAL FILL.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

ES

G

UP

2

Fuel Setup

Engine Displayed

Speed Range

Press Ranges

Eng Warnings

Change Units

DOWN

MENU

PA

ENTER

Refill Tank

Parti al Fill

Eco Speed Src

Fuel Rem Src

Rst Trip Fuel

Rst Seasonal

EXIT

ES

G

UP

DOWN

3

MENU

PA

ENTER

EXIT

GES

66

Page 69

Refill Tank

1. Choose the Refill Tank option to recalibrate the fuel tank level after it has

been filled to full capacity.

Press the ENTER button after fuel tank has been filled.

Note: Only supported when the memory module is used as the fuel remain-

ing source.

Partial Fill

2. Choose the Partial Fill option to maintain the accuracy of the level by

allowing users to input fuel added to the tank.

Use the UP button to enter the quantity of fuel added to the fuel tank.

Use the UP or DOWN button to make adjustments.

Press ENTER when finished.

Note: Only supported when the memory module is used as the fuel remain-

ing source.

Refill Tank

Refill Tank

Parti al Fill

Eco Speed Src

Press ENTER

Fuel Rem Src

after refilling

Rst Trip Fuel

the fuel tank

Rst Seasonal

DOWN

Refill Tank

Adding Fuel

Parti al Fill

Eco Speed Src

0.00 gal

Fuel Rem Src

Press ENTER

Rst Trip Fuel

when finished

Rst Seasonal

DOWN

MENU

MENU

EXIT

GES

PA

ENTER

EXIT

GES

PA

ENTER

UP

1

UP

2

67

Page 70

Economy Speed Source

1. The Economy Speed Source option allows selection of the speed mea-

surement source.

Notes:

•Water Speed (Paddle Wheel) is best suited for low speeds.

•Pitot Speed will work best at high speeds.

•Ground Speed (GPS) works well at both high and low speeds.

Use the UP or DOWN buttons to select the desired option.

Press ENTER when finished.

Eco Speed Src

Water Speed

Pitot Speed

Ground Speed

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

68

Page 71

Reset Trip Fuel

1. The Reset Trip Fuel option resets a trip fuel usage total.

Press ENTER to reset the seasonal fuel total to zero.

Reset Seasonal Fuel

2. Fuel usage can be tracked for trips and even entire seasons. The reset

seasonal option allows a reset of the total seasonal fuel usage.

Press ENTER again to reset the seasonal fuel total to zero.

Note: For multi-engine applications, select the appropriate engine to reset,

or select A

LL ENGINES to simultaneously reset all engines.

Refill Tank

Rst Trip Fuel

Parti al Fill

Eco Speed Src

Press ENTER

Fuel Rem Src

to reset

Rst Trip Fuel

Trip Fuel

Rst Seasonal

DOWN

DOWN

MENU

Refill Tank

Rst Seasonal

Parti al Fill

Eco Speed Src

Press ENTER

Fuel Rem Src

to reset

Rst Trip Fuel

Seasonal Fuel

Rst Seasonal

MENU

PA

ENTER

PA

ENTER

EXIT

GES

EXIT

GES

UP

1

UP

2

69

Page 72

Configure Sensors

Temperature Sensor

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select BUS DEVICES.

Press ENTER.

3. The gauge will search for devices.

DOWN

Eng Warnings

Change Units

Bus Devices

Sleep Mode

Sonar Alarms

Eng/Tank Cfg

MENU

PA

ENTER

Eng Warnings

Message

Change Units

Bus Devices

Searching

Sleep Mode

Bus

Sonar Alarms

Devices...

Eng/Tank Cfg

EXIT

GES

UP

DOWN

3

MENU

PA

GES

ENTER

EXIT

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

UP

2

70

Page 73

4. Use the UP or DOWN buttons and select UNCFG TEMP.

Press ENTER.

5. Press ENTER to configure Temperature Sensor.

6. Use the UP or DOWN buttons to make selection.

Press ENTER.

7. The gauge will change the device setting and return to the BUS DEVICES

list.

Press EXIT three times to return to gauge display.

Water Temp

Fuel Tank 1

UnCfg Temp

Water Press

Oil Tank

Storage Device

DOWN

MENU

PA

ENTER

EXIT

GES

UP

4

DOWN

Water Temp

Outside Temp

Inside Temp

Engine Room

Live Well

Bait Well

MENU

PAGES

ENTER

EXIT

Water Temp

Message

Outside Temp

Changing

Inside Temp

Device

Engine Room

Settings

Live Well

Bait Well

DOWN

MENU

PA

ENTER

EXIT

GES

UP

7

Water Temp

Configuring

Fuel Tank 1

UnCfg F Lev

Press ENTER

Water Press

to Configure

Oil Tank

Temp Sensor

Storage Device

UP

DOWN

5

MENU

PA

ENTER

EXIT

ES

G

UP

6

71

Page 74

Configure Pressure Sensor

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select BUS DEVICES.

Press ENTER.

3. The gauge will search for devices.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

ES

G

UP

DOWN

2

Eng Warnings

Change Units

Bus Devices

Sleep Mode

Sonar Alarms

Eng/Tank Cfg

MENU

PA

ENTER

Eng Warnings

Message

Change Units

Bus Devices

Searching

Sleep Mode

Bus

Sonar Alarms

Devices...

Eng/Tank Cfg

EXIT

GES

UP

DOWN

3

MENU

PA

ENTER

EXIT

GES

72

Page 75

4. Use the UP or DOWN buttons and select UNCFG PRESS.

Press ENTER.

5. Press ENTER to configure Pressure Sensor.

6. Use the UP or DOWN buttons to make selection.

Press ENTER.

7. The gauge will change the device setting and return to the BUS DEVICES

list.

Press EXIT three times to return to gauge display.

Water Temp

Configuring

Fuel Tank 1

UnCfg F Lev

Press ENTER

Water Press

to Configure

Oil Tank

Press Sensor

Storage Device

DOWN

MENU

PA

G

ENTER

EXIT

ES

UP

6

UP

Fuel Pressure

Trns Oil Press

Pitot Speed

Eng Bst Press

Eng Oil Press

Eng Water Press

DOWN

MENU

EXIT

GES

PA

ENTER

Water Temp

Fuel Tank 1

UnCfg Press

Water Press

Oil Tank

Storage Device

UP

4

UP

75

DOWN

MENU

Fuel Pressure

Message

Outside Temp

Changing

Inside Temp

Device

Engine Room

Settings

Live Well

Eng Water Press

DOWN

MENU

EXIT

GES

PA

ENTER

EXIT

GES

PA

ENTER

73

Page 76

Change Ranges

This example will change the water pressure gauge to read from 0 – 60 psi, to 0 – 30 psi. Speed ranges and

other pressure ranges can be changed in the same manner.

1. Press the ENTER button repeatedly to scroll to the page to be chnaged.

2. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

3. Use the UP or DOWN buttons and select PRESS RANGES.

Press ENTER.

30

15 45

0 60

MPH

0 40

10 30

DOWN

20

MENU

UP

1

WTR:P

PAGES

ENTER

psi

GND:S

EXIT

UP

2

DOWN

Customize

Pages

Screen

Audio Setup

System Setup

MENU

PA

ENTER

EXIT

ES

G

UP

3

Fuel Setup

Engine Displayed

Speed Range

Press Ranges

Eng Warnings

Change Units

DOWN

MENU

PA

ENTER

EXIT

GES

74

Page 77

4. Use the UP or DOWN buttons and select ENG WATER PRESS.

Press ENTER.

5. Use the UP or DOWN buttons and select desired pressure range.

Press ENTER.

6. Gauge will now display selected range.

Eng Water Press

Eng Oil Press

Fuel Press

Eng Bst Press

Trans Oil Press

DOWN

MENU

PAGES

ENTER

EXIT

UP

4

UP

5

DOWN

0-15 psi

0-30 psi

0-60 psi

0-80 psi

0-100 psi

MENU

PA

ENTER

EXIT

GES

UP

6

10 20

0 30

%

MPH

0 40

10 30

20

DOWN

MENU

WTR:P

PAGES

ENTER

psi

GND:S

EXIT

75

Page 78

Winterize

I-Command digital gauges (with software version 1.4.0 or higher) provide a winterize feature for 2008 or

newer V4 and V6 models only.

Engine must be running to use this option. Refer to Outboard Operator's Guide for complete procedure and

Safety Precautions.

1. Press MENU. Use the UP or DOWN buttons and select SYSTEM SETUP.

Press ENTER.

2. Use the UP or DOWN buttons and select BUS DEVICES.

Press ENTER.

3. The gauge will search for devices.

DOWN

Eng Warnings

Change Units

Bus Devices

Sleep Mode

Sonar Alarms

Eng/Tank Cfg

MENU

PA

ENTER

Eng Warnings

Message

Change Units

Bus Devices

Searching

Sleep Mode

Bus

Sonar Alarms

Devices...

Eng/Tank Cfg

EXIT

GES

UP

DOWN

3

MENU

PA

ENTER

EXIT

GES

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

UP

2

76

Page 79

4. Use the UP or DOWN buttons and select engine to winterize.

Press ENTER.

5. The gauge will display WINTERIZE menu.

Press ENTER.

6. Press ENTER again.

Water Temp

Fuel Tank 1

Evinrude Port

Evinrude Center

Evinrude Stbd

Storage Device

DOWN

MENU

PA

GES

ENTER

EXIT

UP

4

UP

DOWN

Winterize

MENU

PA

ENTER

GES

EXIT

Winterization

Press ENTER

Winterize

to Start

the Process

UP

DOWN

MENU

PAGES

ENTER

EXIT

65

77

Page 80

7. The gauge will display WINTERIZATION message.

8. When prompted, engage NEUTRAL only button on throttle and

advance THROTTLE ONLY to at least 50%.

9. Gauge will display WINTERIZATION IN PROGRESS message.

10. Gauge will display WINTERIZATION IS COMPLETE message.

Winterization

Receiving Data

Winterize

to Start

the Process

Press EXIT to return to BUS DEVICES menu.

Repeat steps 4 through 10 for other engines (multi-engines set up only).

Winterization

Advance

Winterize

Throttle

to 50%

UP

DOWN

8

MENU

PA

ENTER

EXIT

GES

UP

9

Winterization

Winterization

Winterize

in Progress

DOWN

MENU

EXIT

GES

PA

ENTER

7

10

UP

DOWN

MENU

Winterization

Winterization

Winterize

is Complete

UP

DOWN

MENU

PA

ENTER

PA

ENTER

EXIT

GES

EXIT

GES

78

Page 81

Audio Settings

The I-Command Digital gauge will emit audible sounds during operation. The key sounds can be turned OFF

or ON.

1. Press MENU.

Use the UP or DOWN buttons to select AUDIO SETUP.

Press ENTER.

2. Use the UP or DOWN buttons to select KEY SOUNDS.

Press ENTER.

3. Use the UP or DOWN buttons to select ON or OFF setting.

Press ENTER when finished.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

MENU

PA

ENTER

EXIT

ES

G

1

UP

2

DOWN

Key Sounds

MENU

PA

ENTER

EXIT

GES

UP

3

DOWN

Key Sounds

Off

On

MENU

PA

ENTER

EXIT

GES

79

Page 82

Reset Values

RESET VALUES will not clear Engine/Tank configuration or the sensor set-

tings that were previously calibrated or configured.

1. Press MENU.

Use UP or DOWN buttons to select SYSTEM SETUP.

Press ENTER.

2. Use UP or DOWN buttons to select RESET VALUES.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

Sonar Alarms

Eng/Tank Cfg

Time Config

Reset Values

Lock Pages

NMEA Info

DOWN

MENU

PAGES

ENTER

EXIT

UP

2

80

Page 83

3. Use UP or DOWN buttons to select PAGES, SETTINGS or ALL.

Press ENTER.

Select PAGES to reset the seven factory default pages.

Select SETTINGS to reset Fuel Remaining Source, Fuel Economy Speed

Source, Keypad Sounds, Sleep Mode, Fluid Level Warnings and Sonar

Alarms.

Select ALL to reset both.

4. A confirmation message will appear.

Press ENTER to continue.

Sel Option

Pages

Settings

All

UP

DOWN

3

MENU

PAGES

ENTER

EXIT

Sel Option

Resetting Values

Press ENTER

to reset

All values

UP

DOWN

4

MENU

PA

ENTER

EXIT

GES

81

Page 84

Sonar Alarms

Sonar alarms are available to aid in avoiding underwater objects or shallow

operating conditions. A transducer or triducer is required for sonar alarm

functionality.

This example will set the shallow sonar alarm.

1. Press MENU.

Use UP or DOWN buttons to select SYSTEM SETUP.

Press ENTER.

2. Use UP or DOWN buttons to select SONAR ALARMS.

Press ENTER.

Customize

Pages

Screen

Audio Setup

System Setup

UP

DOWN

1

MENU

PA

ENTER

EXIT

GES

Change Units

Bus Devices

Sleep Mode

Sonar Alarms

Eng/Tank Cfg

Time Config

DOWN

MENU

PAGES

ENTER

EXIT

UP

2

82

Page 85

3. Use UP or DOWN buttons to select SHALLOW (or DEEP) alarm.

Press ENTER.

4. Use UP or DOWN buttons to select SET DEPTH (or OFF).

5. Use UP button to set depth. Use UP or DOWN buttons to make adjustments.

Press ENTER to save selection.

To set DEEP alarm, press EXIT one and go to Step 3.

To turn sonar alarms OFF, press EXIT and go to Step 4.

Press EXIT four times, when finished.

DOWN

Shallow

Off

Set Depth

MENU

PA

ENTER

Shallow

Set Depth

4

Off

ft

Set Depth

Press ENTER

when finished

EXIT

GES

UP

DOWN

5

MENU

PA

ENTER

EXIT

ES

G

Sonar Alarms

Shallow

Deep

UP

DOWN

MENU

PA

ENTER

EXIT

GES

3

UP

4

83

Page 86

Advanced Setup Notes

84

Page 87

Troubleshooting

85

Page 88

Gauge Flashes Four Dashes

DEVICE

BUSS

1. If the I-Command digital display flashes four dashes (– – – –) it indicates

the gauge is not receiving signal from one or more devices.

2. A Network Test Kit, P/N 765023 is available to assist in troubleshooting

network problems. If desired, order the tester kit through your dealer.

Troubleshoot network problems using process of elimination.

•Make sure devices are configured. See “Advanced Setup and Opera-

tion” on page 57.

•If multiple displays are flashing, check common items such as cables

and tees.

•Remove components from the network one at a time to isolate which

one may have failed.

•Look for damaged parts. Check connectors for corrosion.

•Swap known good components (sensor, cables or tees) to isolate the

faulty component.

•Reconnect the good component to the network and the remove the next

one in line.

•Continue this process for each device, cable or tee connector on the

network until the faulty part is found.

Note: Once components are reconnected, if the digital display continues to

flash, turn power to the network OFF and back ON to reset the gauge(s).

Volts

13.6 56.2

WTR: T

°F psi

x10

UP

DOWN

1

2

N2K Bus

Tester

+

+

-

+

H

L

L

BUSS

20 70

10 35

0 0

20 70

10 35

0 0

MENU

L

-

-

S

H

H

+

+

DEVICE

PAGES

ENTER

Volts

ALR:VBATT:V

WTR:P

– – – –– – – –

EXIT

86

Page 89

Engine Warnings

The I-Command gauges monitor engine conditions and display warnings in the event of a malfunction. Refer

to the outboard Operator’s Guide if any engine warnings are displayed.

WARNING MESSAGE

DISPLAYED

A “Check Engine” condition may be activated when a critical engine con-

dition occurs, or when a service is required:

Check Engine

Over Temperature

Low Oil Level A low oil level has been detected in the oil tank. Fill tank.

Low System Voltage A low voltage condition has been detected. See your dealer.

Rev Limit Exceeded The RPM limit has been exceeded. Reduce throttle.

Throttle Position Sensor A throttle position sensor fault has been detected. See your dealer.

Power Reduction EMM has activated S.A.F.E.

Neutral Start Protection Attempt to start engine while in gear. Shift to neutral.

Engine Shutting Down EMM has activated engine shutdown.

· A “Critical” condition will activate S.A.F.E. (RPM reduction) - Seek assis-

tance to return to safe harbor immediately and see your dealer.

· A minor service issue will NOT activate S.A.F.E. - See your dealer as

soon as practical.

Engine or EMM above temperature range. Check cooling water to water

intakes.

POSSIBLE CAUSE / PROCEDURE

87

Page 90

Evinrude E-TEC Engine Warnings

The I-Command gauges monitor engine conditions and display warnings in the event of a malfunction. The

following table lists warnings that are specific to Evinrude E-TEC models. Refer to the outboard Operator’s

Guide if any engine warnings are displayed.

WARNING MESSAGE DISPLAYED POSSIBLE CAUSE / PROCEDURE

Throttle position sensor fault detected

Sensor malfunction see dealer

Analog 5V supply overload detected

Exhaust pressure circuit fault detected

RPM reductn activated see dealer

System Voltage below expected range

System Voltage above expected range

Winterization Mode activated Auto-winterization routine activated

Overheat RPM reductn activated see manual EMM temperature above expected range

Low battery voltage see manual Battery voltage below expected range

Engine shutdown, EMM above max temperature

Overheat Eng Shutdwn see manual

Engine shutdown, engine above max temperature

No Oil Shutdwn see manual Engine shutdown, excessive no oil fault

No Oil RPM reductn check oil Oil solenoid open circuit

Water in Fuel, service soon Water in fuel detected

88

Page 91

WARNING MESSAGE DISPLAYED POSSIBLE CAUSE / PROCEDURE

No Oil RPM reductn see dealer Oil pressure pulses in manifold not detected

No Oil RPM reductn see dealer Oil system prime failure

Sensor malfunction service soon

Engine temperature sensor, Air temperature sensor, Oil

pressure circuit or Water pressure circuit fault detected