BROWNING MAXUS User Manual [fr]

browning.com

browning cAnADA: Browning Canada Sports Ltd/Lteé, St-Laurent, Quebec H4S 1W6

browning US: Morgan, Utah 84050-9326

browning inTL: Parc Industriel des Hauts-Sarts, B-4040 Herstal, Belgium

NEU0903.1/08121

AutoloAding shotgun | owner’s mAnuAl

fusil semi-AutomAtique | mAnuel du propriétAire

selbstlAdende flinte | benutzerhAndbuch

fucile AutomAtico | mAnuAle dell’utente

escopetA AutomáticA | mAnuAl de instrucciones

Important operating instructions for:

b ro w n i ng mA x U S™

A UT o L o AD i n g S h oT gU n S

E N

If you have any questions about your new firearm,

this owner’s manual or other Browning products,

contact:

Browning International S.A.

Parc Industriel des Hauts-Sarts

3ème Avenue, 25

B-4040 Herstal Belgium

www.browning-int.com

Please use the space below to record information

about your new firearm.

Model ___________________________________

Serial Number _____________________________

Purchased From ___________________________

Date of Purchase

c on T e n TS PA g e

You are Responsible for Firearms Safety ..............1

General Description and Operation .....................5

Nomenclature...........................................................5

Serial Number .......................................................... 5

Initial Cleaning ........................................................5

Operation of the “Safety” .......................................6

Assembly ...................................................................6

Disassembly ..............................................................7

Ammunition ............................................................8

Magazine Capacity ..................................................8

Three-Shot Adaptor (Plug) .................................... 8

Loading ...................................................................10

Firing ....................................................................... 11

Unloading ...............................................................12

Magazine Cut-Off..................................................12

Interchangeable Choke Tube System ..................13

Adjusting Length of Pull ......................................15

Adjusting Cast and Drop at Comb .....................15

Extra Barrels ...........................................................17

Cleaning and Maintenance Suggestions.............17

Removal of the Trigger Group.............................19

Removal of the Bolt Assembly............................. 20

Lubricating the Action Tube and Spring............21

Maintenance of Oil Finish Stocks .......................22

Models with Special Finishes ............................... 22

Service or Repair ...................................................23

n oT e S

T hA n K Y o U F o r c h oo S i n g A

b ro w n i ng mA x U S S h oT gU n .

The Maxus shotgun represents the most advanced gas-operated technology available in autoloading

shotguns. Maxus shotguns combine the best of traditional Browning craftsmanship with state-of-the-art

design and manufacturing. Every detail of the Maxus Hunter shotgun is engineered to provide you the

best in reliable operation and handling.

With a reasonable amount of care, your Maxus shotgun is designed

to give you many years of dependable, enjoyable service.

2

Y OU AR E R ES P ON SI B LE F OR FI R E A RM S S AF E TY

Failur e to Follow any oF the Following war nings cou ld result in serious inju ry or death.

As a gun owner, you accept a set of demanding responsibilities. How seriously you take these

responsibilities can be the difference between life and death.

There is no excuse for careless or abusive handling of any firearm. At all times handle this firearm and all

other firearms with intense respect for their power and potential danger.

Please read and understand all of the cautions, warnings, notices, proper handling procedures and

instructions outlined in this owner’s manual before using your new firearm.

1 always KeeP the M uZZle oF your FirearM Poi nted in a saFe direct ion even t hough you are

certain it is unloaded.

Never point any firearm at anything you do not intend to shoot.

Be extremely alert and aware of all persons and property within the range of your ammunition.

2 never rely totally on your FirearM’s Mechanical ˝saFety ” device. liKe any Mechanica l device,

a ˝saFety” can s oMet iMes Fail; i t can be jarred or ina dvertently ManiPulated into an unsaFe

condition.

The word ˝safety” describes a firearm’s trigger block mechanism, sear block mechanism, hammer

block mechanism or firing pin

block mechanism. Mechanical ˝safeties” are designed to place your firearm in a safer status, and no

guarantee can be made that the firearm will not fire even if the ˝safety” is in the on safe position.

Mechanical ˝safeties” merely aid safe gun handling and are no excuse for pointing your firearm’s

muzzle in an unsafe direction.

Remember, safe gun handling does not stop with your firearm’s mechanical ˝safety” devices, it starts

there. Always treat this firearm with the respect due a loaded, ready-to-fire firearm.

Some firearms do not have a mechanical ˝safety.” Many target firearms, lever-action firearms and

pistols do not have manual ˝safety” mechanisms. Therefore it is critical to read and understand the

owner’s manual for every firearm which explains the safe operation of the firearm.

While it is a good idea to test your firearm’s mechanical ˝safety” periodically for proper function,

never test the ˝safety” while your firearm is loaded or pointed in an unsafe direction.

3 whenever y ou handle any FirearM, or hand it to soMe one, always oPen the action

iMMediately and v isually checK the F irea rM’s chaM ber to MaK e certain that the Fire arM is

coMPletely unloaded.

Make certain the firearm does not inadvertently contain any ammunition. Always keep the chamber

empty and the ˝safety” in the on safe position unless shooting is imminent.

4 always wear ear a nd eye Protection when shooting.

Unprotected, repeated exposure to gunfire can cause hearing damage. Wear hearing protection

(shooting ear plugs or muffs) to guard against such damage.

Wear shooting glasses to protect your eyes from flying particles. Allow proper distance (eye relief)

between a scope and your eye when firing a scoped rifle, shotgun or pistol. Do not use unorthodox

shooting methods that could cause the rearward travel of the slide or bolt of a firearm to contact your

eyes, face or hands. Always keep a safe distance between the muzzle of your firearm and any persons

nearby, as muzzle blast, debris and ejecting shells could inflict serious injury.

Always wear eye protection when disassembling and cleaning any firearm to prevent the possibility of

springs, spring-tensioned parts, solvents or other agents from contacting your eyes.

5 KeeP all FirearMs unloaded during transPort, even when stored in a holster, gun case,

scabbard o r other container.

E N

6 droPPing o r jarring a loa ded FirearM can cause acc iden tal discharge.

11

This can occur even with the ˝safety” in the on safe position. Be extremely careful while hunting or

during any shooting activity to avoid dropping any firearm.

7 hunting Fr oM elevated surFaces such as tr eestands is dang erous.

E N

Doing so may increase the risk of mishandling a firearm. The following rules should always be

observed by you and those you hunt with. Always make certain that the stand being used is safe and

stable. Always make certain that your firearm is unloaded when it is being taken up and down from

the stand. Always make certain that your firearm is not dropped from the stand, or dropped while it

is being taken up or down from the stand. Remember, a loaded firearm may discharge when dropped,

even with the ˝safety” in the on safe position.

8 store your FirearM and aMMunition s eParately, well beyond the reach oF children.

Take prudent safeguards to ensure your firearm does not become available to untrained,

inexperienced or unwelcome hands. Store all firearms in secure, locked cases or a gun safe. Keep your

firearm unloaded when not in use.

9 beware oF barrel ob structions.

Mud, snow and an infinite variety of other objects may inadvertently lodge in a barrel bore. It only

takes a small obstruction to cause dangerously increased pressures that can damage your firearm and

cause serious injury to yourself and others.

beFore che cKing For a bar rel obstructi on, be certain y our FirearM is coMP letely unload ed,

there is not a live shell in the ch aMber and the ˝saFety” is in th e on s aFe Position.

After assuring yourself that the firearm is completely unloaded, open the breech or action and look

through the barrel to be sure it is clear of obstructions. If an obstruction is seen, no matter how small

it may be, clean the bore with a cleaning rod and patch.

10 be alert to the signs oF aMMuni tion MalF unction. iF you detect an oFF s ound or li ght

recoil whe n a sh ell is Fir ed, do not load anot her shell into the chaMber.

If your firearm fails to fire, keep the muzzle pointed in a safe direction for a minimum of 30 seconds.

Carefully open the action and remove the shell from the chamber. If the primer is indented, the

defective shell should be disposed of in a way that cannot cause harm. If the primer is not indented,

your firearm should be examined by a qualified gunsmith and the cause of the malfunction corrected

before further use. Glance down the barrel to make sure that no obstructions remain in the barrel.

Completely clear the barrel before loading and firing again. Failure to follow these instructions can

cause extensive damage to your firearm and possible serious injury to yourself and others.

11 never insert a shell oF the incorrect gauge into any FirearM.

The gauge of your firearm is marked on the barrel. Store all shells of different gauges in completely

separate and well-marked containers. Never store shells of mixed gauges in a common container or in

your pockets.

12 exaMine every shel l you Put in you r FirearM .

We assume no responsibility for the use of unsafe or improper firearm and ammunition combinations

or damage or injury caused by damaged ammunition. It is your responsibility to read and heed all

warnings in this owner’s manual and on ammunition boxes.

13 use only saaMi aPProved aMMunitio n.

The barrel and action of this firearm have been made with substantial safety margins beyond the

pressures developed by established American commercial loads. Nevertheless, we can assume no

liability for incidents which occur through the use of shells of nonstandard dimensions or which

develop pressures in excess of commercially available ammunition which has been loaded in

accordance with standards established by the Sporting Arms and Ammunition Manufacturers’

Institute (SAAMI).

14 MaKe sure o F adequate ventilation in the area that you discharge a FirearM . lead exPosure

can occur FroM d isch arging Fi rearMs in Poorly ve ntil ated areas, clea ning Fire arMs or

handling a MMunition.

2

Lead is a substance that has been known to cause birth defects, reproductive harm and other serious

injury. Wash hands thoroughly after exposure to ammunition or after cleaning a firearm.

15 do not snaP the Firing Pin on an eMPty chaM ber; the c haMb er May not b e eMPty!

Treat every firearm with the respect due a loaded firearm, even though you are certain the firearm is

unloaded.

16 KeeP your F inge rs away FroM the tr igger whi le loadin g and unlo adin g until shooting is

iMMinent.

17 be sure oF your target and bac KstoP, Particularly d uring low light Periods.

Know the range of your ammunition. Never shoot at water or hard objects.

18 always unload yo ur Firear M’s chaMber beFore crossing a Fenc e, cliMbi ng a tree, juMPing a

ditch or negotiating other obstacles.

Never place your firearm on or against a fence, tree, car or other similar object.

19 be deFensive and on guard against unsaFe g un handli ng around you and others.

Don’t be timid when it comes to firearms safety. If you observe other shooters violating any of these

safety precautions, politely suggest safer handling practices.

20 be certain y our FirearM is unlo aded beFo re cleani ng.

Because so many firearm accidents occur when a firearm is being cleaned, special and extreme care

should be taken to be sure your firearm is unloaded before disassembly, cleaning and reassembly.

Keep ammunition away from the cleaning location. Never test the mechanical function of any firearm

with live ammunition.

21 teach and s uPervise FirearMs saFety to all MeMbers oF your FaMily, esPecially to c hild ren

and non-sh ooters.

Closely supervise newcomers to the shooting sports. Encourage enrollment in hunting and shooting

safety courses.

22 never drinK alcoholic beverag es or taKe an y tyPe oF drugs beFore or during shoo ting.

Your vision, motor skills and judgment could be dangerously impaired, making your gun handling

unsafe to you and to others.

23 read and he ed all warnings in this o wner ’s Manual , on a MMun ition box es and with all

accessories that you i nstall on your FirearM.

It is your responsibility to secure the most up-to-date information on the safe handling procedures of

your Browning firearm. We assume no liability for incidents which occur when unsafe or improper

firearm accessories or ammunition combinations are used.

24 Practice Periodic Maintenance, avoid unauthoriZed servicing.

Your firearm is a mechanical device which will not last forever, and as such, is subject to wear and

requires periodic inspection, adjustment and service. Browning firearms should be serviced by a

Browning Recommended Service Facility. We assume no responsibility for injuries suffered or caused

by unauthorized servicing, alterations or modifications of Browning firearms.

25 we reserve the r ight to reFuse service on FirearMs that have been altered, a dded to or

substa ntia lly changed.

Removal of metal from the barrel, or modifications of the firing mechanism and/or operating parts,

may lead to a refusal of service on such firearms. We will charge you for parts and labor to return the

firearm to original specifications.

do not, under any circuMstances, alter the trigger, sa Fety or other Parts oF the Fi ring

MechanisM oF this or any other Fire arM. Fa ilure to obey t his warning M ay result in injury

or death to yourselF or o thers.

E N

B E CA RE F U L !

3

E N

4

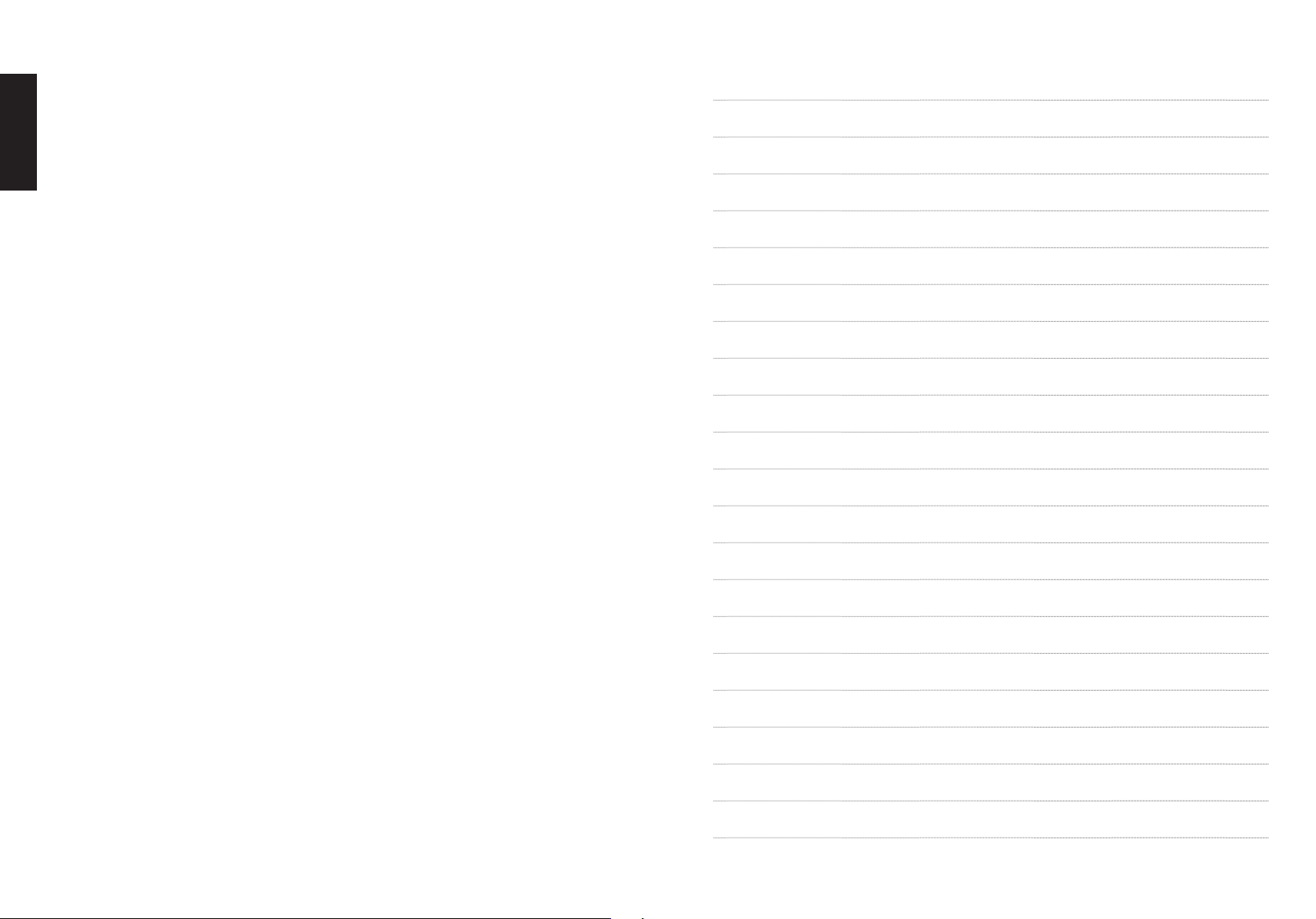

Fi gur e 1

Recoil Pad

Buttstock

˝Safety”

Trigger

Bolt Handle

Receiver

Forearm

Bolt Release Button

Front Sight Bead

Barrel

Rib

Muzzle

Speed Lock Lever

G EN E R A L

D ES C R I PT I O N A N D

O PE R A TI O N

The Browning Maxus is a gasoperated, autoloading shotgun

capable of quickly firing up to

five shells (with the three-shot

adaptor removed, using 2¾”

loads), one shell at a time, with

each successive pull of the

trigger. Upon firing, high-pressure gases from behind the shot charge pass through two ports in the barrel,

through the gas bracket and into the gas system, forcing it rearward. As the gas system moves rearward, it

forces the bolt to the rear, operating the action. As the bolt moves rearward, it cocks the hammer and

ejects the fired shell. After full rearward travel, the bolt returns forward, picks up a new shell from the

magazine and chambers it. After the last shell has been fired, the bolt locks to the rear facilitating fast

reloading.

N OM E N C LA T U RE

In conventional firearm terminology the position and movement of firearm parts are described as they

occur with the firearm horizontal and in the normal firing position: i.e., the muzzle is forward or in front;

the buttstock is rearward or to the rear; the trigger is downward or underneath; the rib is upward or on

top. For general parts nomenclature, refer to Figure 1. For specific parts names related to disassembly,

refer to Figure 2.

S ER I A L N U MB E R

The serial number of your Maxus shotgun is found on the left side of the receiver, above the trigger guard.

Record this number in the space provided at the front of this owner’s manual for future reference.

I NI T I A L C LE A N I NG

NO TIC E! Pl ease taKe no te oF the Following inForMation beFore cleaning your FirearM.

C LE ANI N G PA RTS W IT H SPEC I AL FIN I SH ES

Be especially careful when cleaning firearms with camouflage, Dura-Touch® Armor Coating and other

special finishes. Always prevent these surfaces from coming in contact with cleaning solvents, barrel

scrubbers and other strong chemicals. It is preferable to clean these surfaces with a lightweight gun oil

containing no solvents, or with a damp cloth and mild dish soap (be sure to keep water out of the action).

When cleaning your firearm’s bore and action, protect the external finishes from any contact with

chemicals used. Also, avoid any contact between external finishes and other strong chemicals like those

found in DEET-containing insect repellents, sunscreens, etc. Damage to camouflage, Dura-Touch and

other finishes caused by chemicals is irreversible and not repairable.

Fi gur e 2

Barrel Extension

Recoil Pad

Bolt Handle

Trigger Group

Gas Bracket

Slide Link

Bolt

Bolt Slide

Receiver

Trigger Group Pins

Piston Sleeve Spring

Piston Sleeve

Barrel

Gas Piston

Magazine

Three-Shot A daptor

Forearm

C LE ANI N G

Various exposed metal parts of

your new firearm have been

coated at the factory with a

rust preventative compound.

Before assembling your

shotgun, clean the anti-rust

compound from the inside of

the barrel, receiver and the

action/chamber areas. A high-

quality lightweight gun oil is

ideal for removing this

compound, and for giving

E N

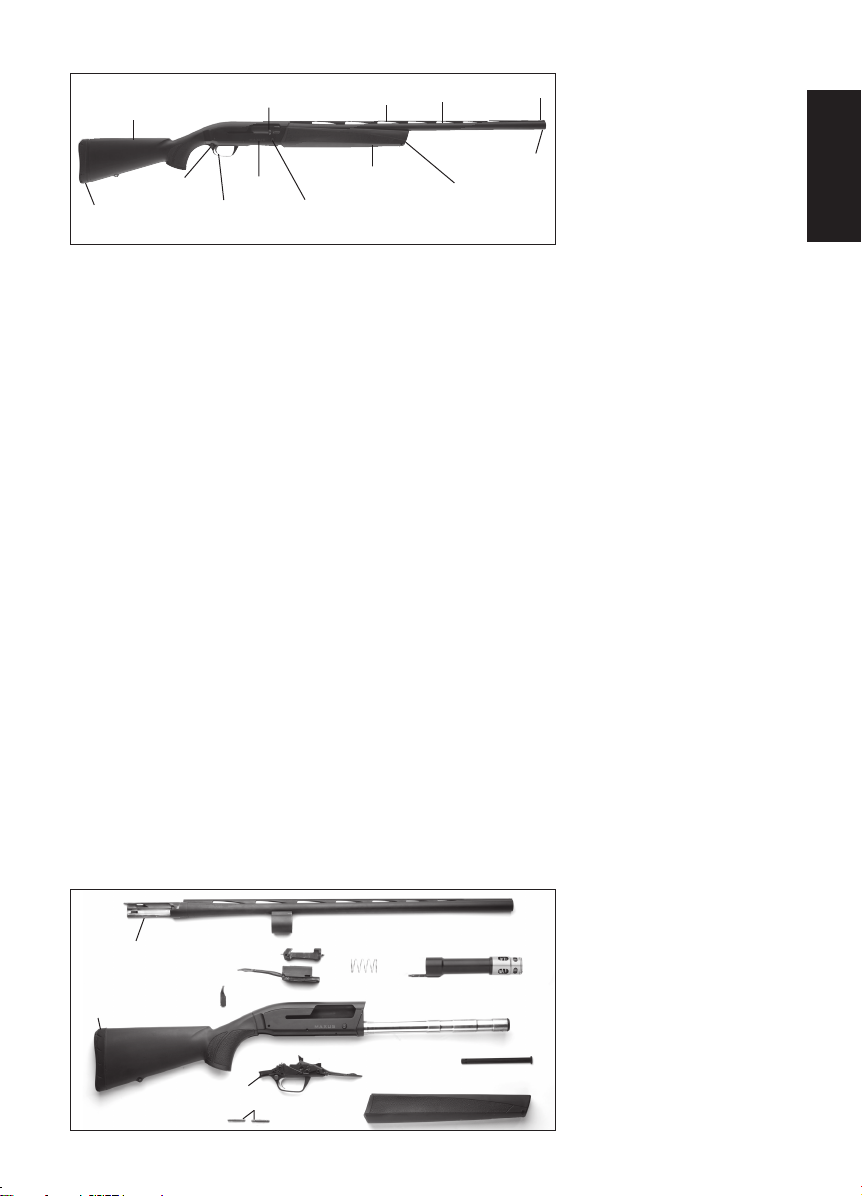

5

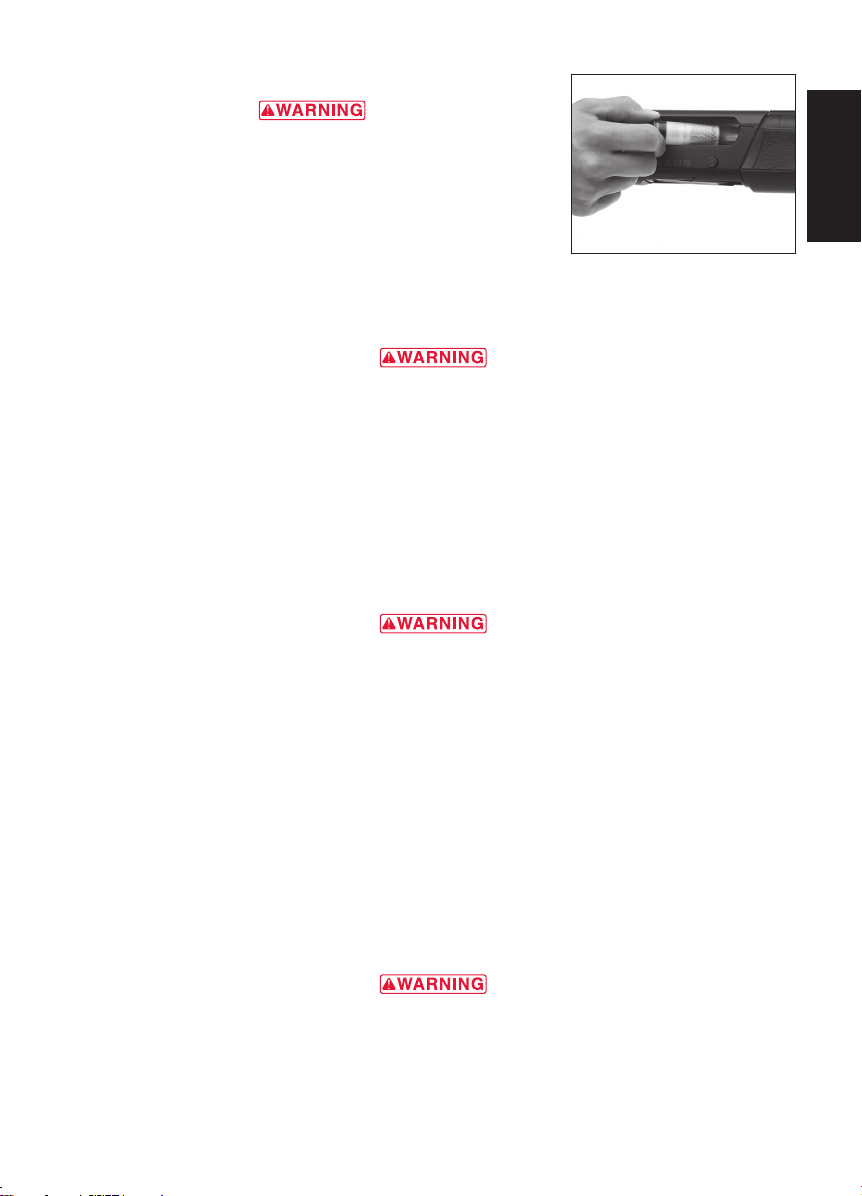

your new firearm its first lubrication. Place a drop of lightweight gun

oil on both sides of the inside of the receiver on the rails on which the

bolt slides (Figure 3). Clean the barrel using a cleaning rod and patch

as explained under ˝Cleaning and Maintenance Suggestions”.

E N

O PE R A TI O N O F TH E ˝ S A FE T Y ”

always KeeP the ˝ saFe ty” in the on sa Fe Positi on unless

shooting i s iMMinen t. always KeeP the MuZZle Pointed in a

saFe direction. Failure to Follow these warnings could

result in serious inj ury or death.

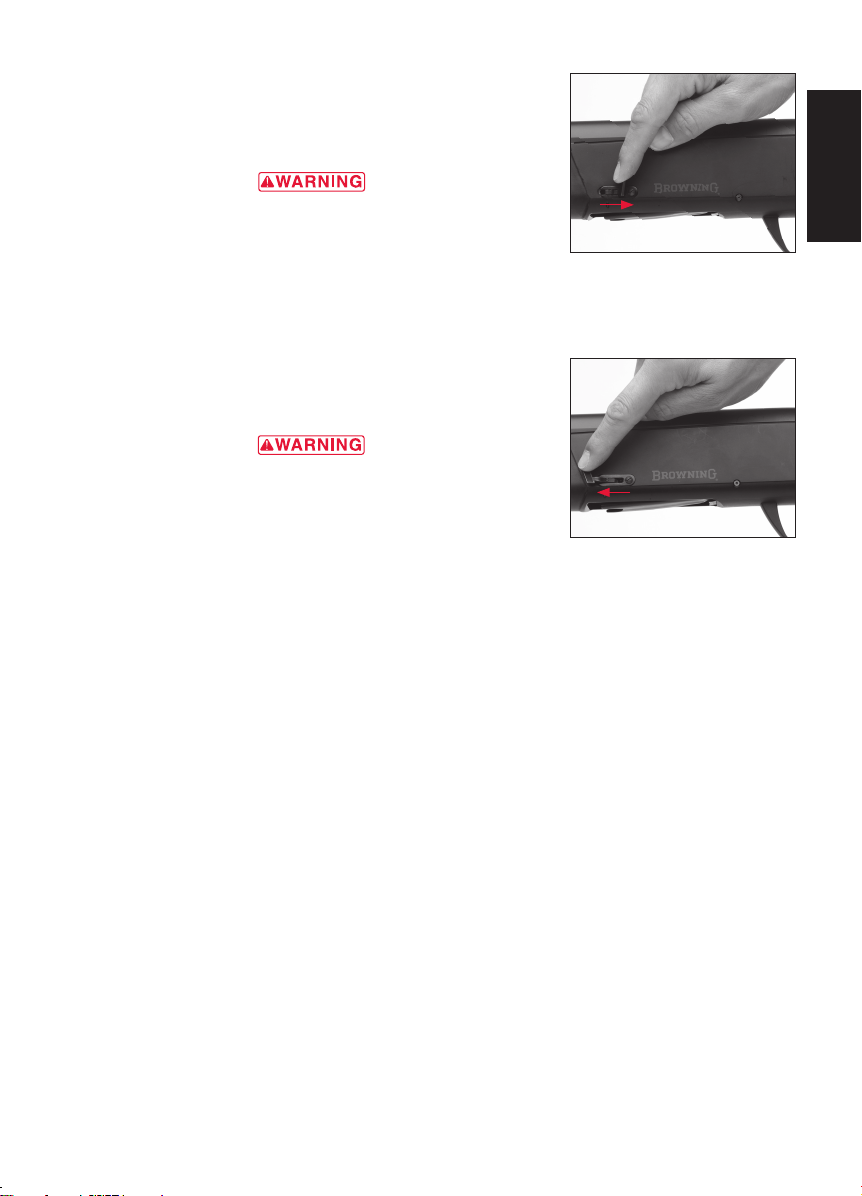

The ˝safety” is designed to prevent the trigger from being pulled when

in the on safe position. The ˝safety” is located at the rear of the trigger

guard (Figure 4). In the off safe position, a red warning band is visible

on the safety button on the left side of the trigger guard.

To place the firearm on safe, press the ˝safety” button to the right.

To move the ˝safety” to the off safe or fire position, press the safety

button to the left. This exposes the red warning band on the ˝safety”

button (Figure 5).

do not dePend on the red color alone to indi cate your

FirearM’s saFety status. tiM e, exPosu re to the eleMents, and

the abrasi ve action oF cl eani ng agents can e rase it. Failure to

Follow thi s warning could result in seri ous injury or death.

The ˝safety” can be reversed from right- to left-handed by a

qualified gunsmith. When installed, the left-handed ˝safety” will

have the ˝safety” button’s red warning band on the right side of

the trigger guard.

Fi gur e 3

Lightly lubricate the bolt rails inside

the receiver.

Fi gur e 4

The ˝safety” shown in the on safe position.

Fi gur e 5

A SS E M B LY

always KeeP the M uZZl e Pointed in a saFe direction. beFore

starting asseMbly Pr ocedures, visually insPect t he chaMbe r

to be a bsolutely certain t he Firear M is coMPletely unlo aded.

Place the ˝saFety” in the on saFe Positio n. Fail ure to Fol low

this warning could result in serious injury or death.

The ˝safety” shown in the off safe position.

The Maxus shotgun is delivered in the box with the barrel removed

and the forearm attached to the magazine tube. The Maxus features

the innovative Speed Lock forearm that makes removing the forearm for cleaning or taking down the

shotgun fast and easy.

1 Lock the bolt rearward by pulling the operating handle fully to the rear.

NO TIC E! ne ver allow the a ctio n to s laM closed by Pressing

the bolt release button without the b arrel ins talled.

iF the bolt is released Forward with the barrel reMoved , the oPer ating handle will striKe th e

receiver a nd cause daMage.

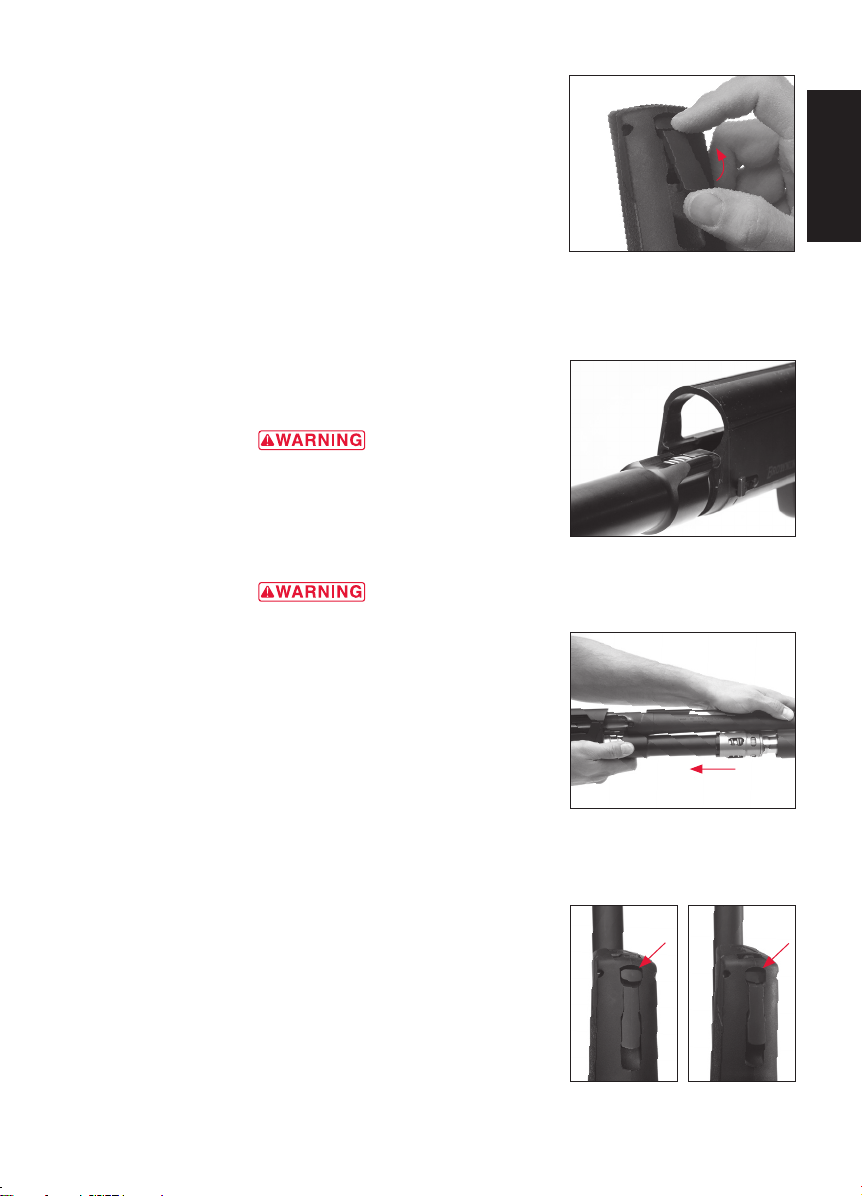

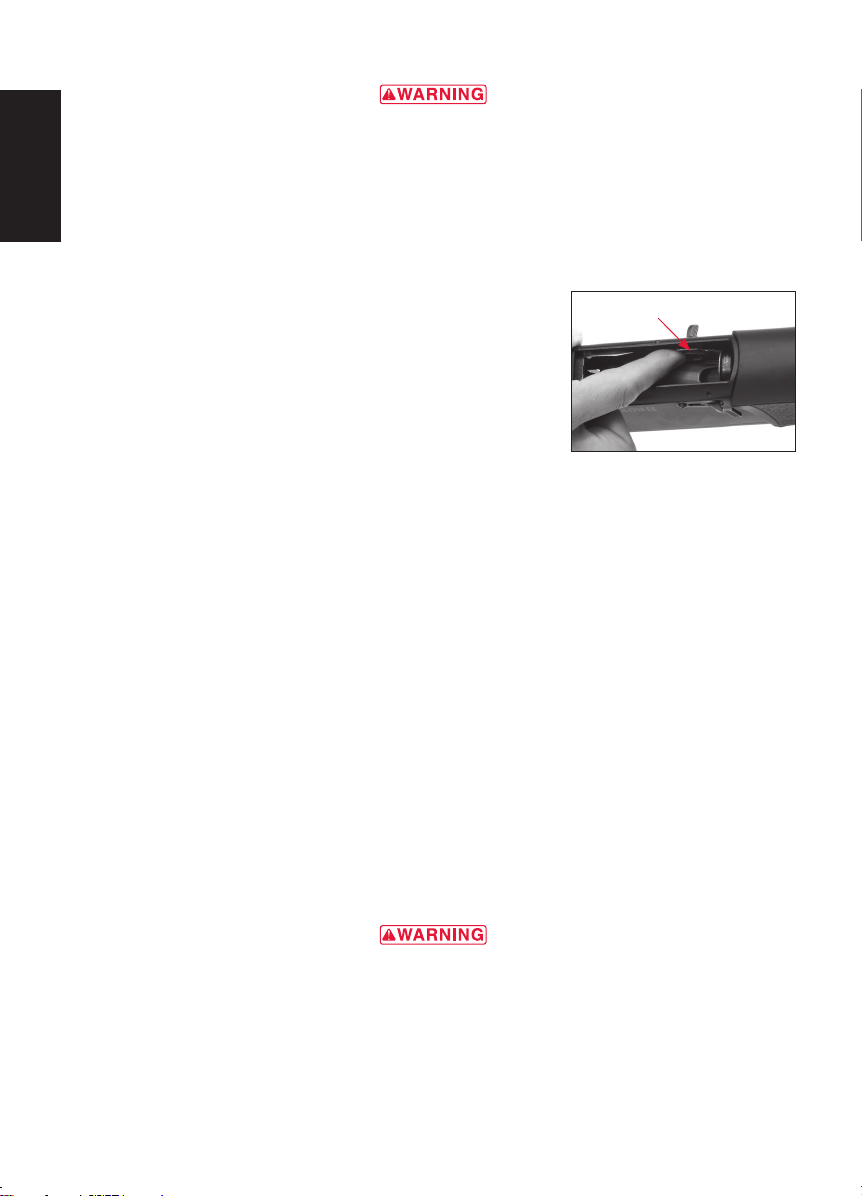

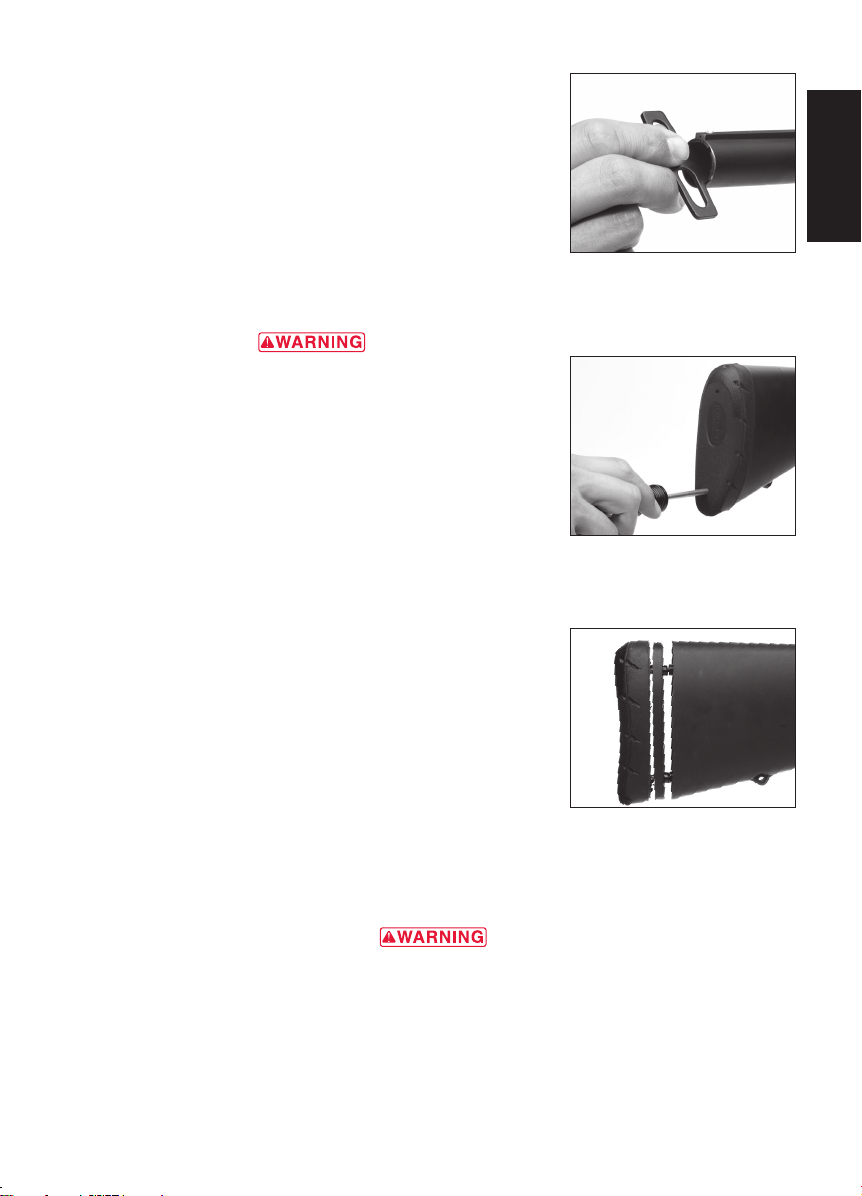

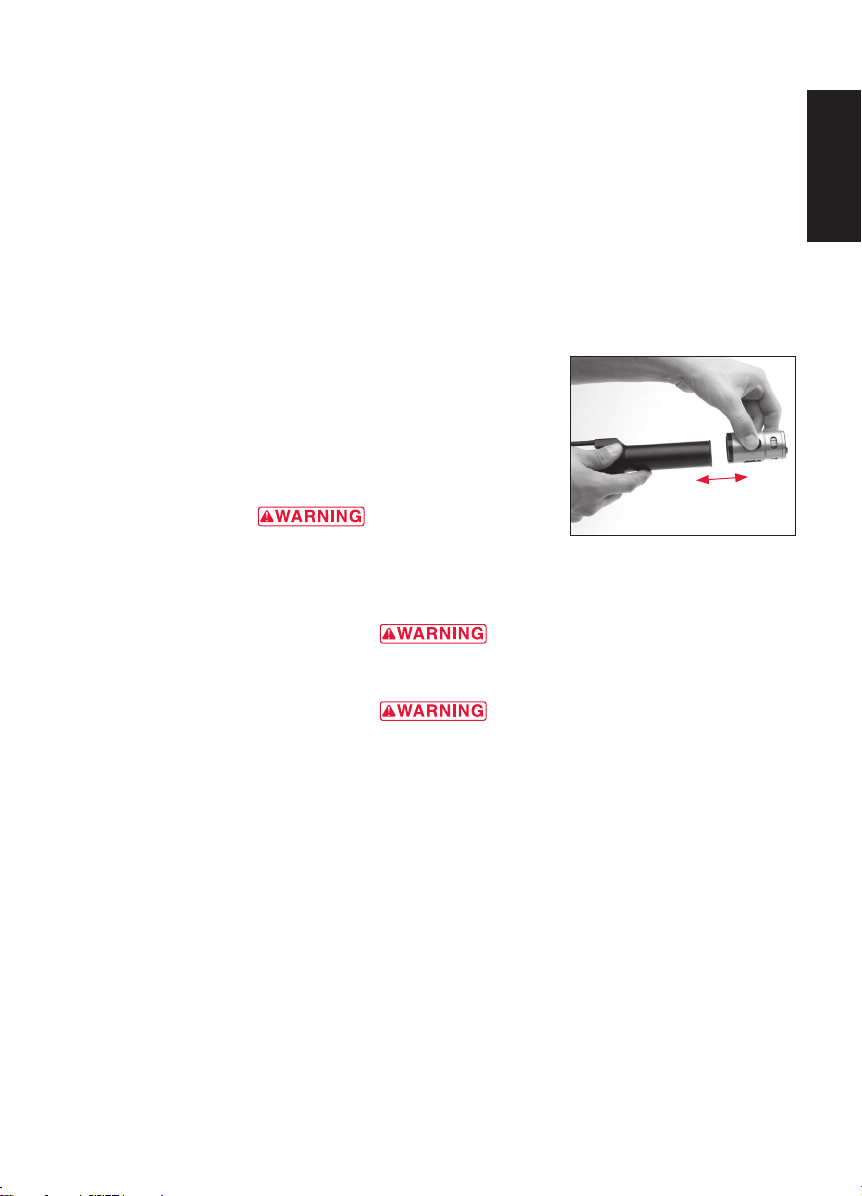

2 Remove the forearm from the magazine tube by pressing and holding the release button while lifting

the Speed Lock lever (Figure 6). Slide the forearm forward and off the magazine tube.

NO TIC E! do not s quee Ze hard on the oPen rear end oF a w ood ForearM. too Mu ch Pressu re

6

could caus e the wood to sPlit.

3 The gas system remains in place and does not need to be removed

except for cleaning. If the gas system has been removed, reinstall it

as explained below. Otherwise, proceed to step 5.

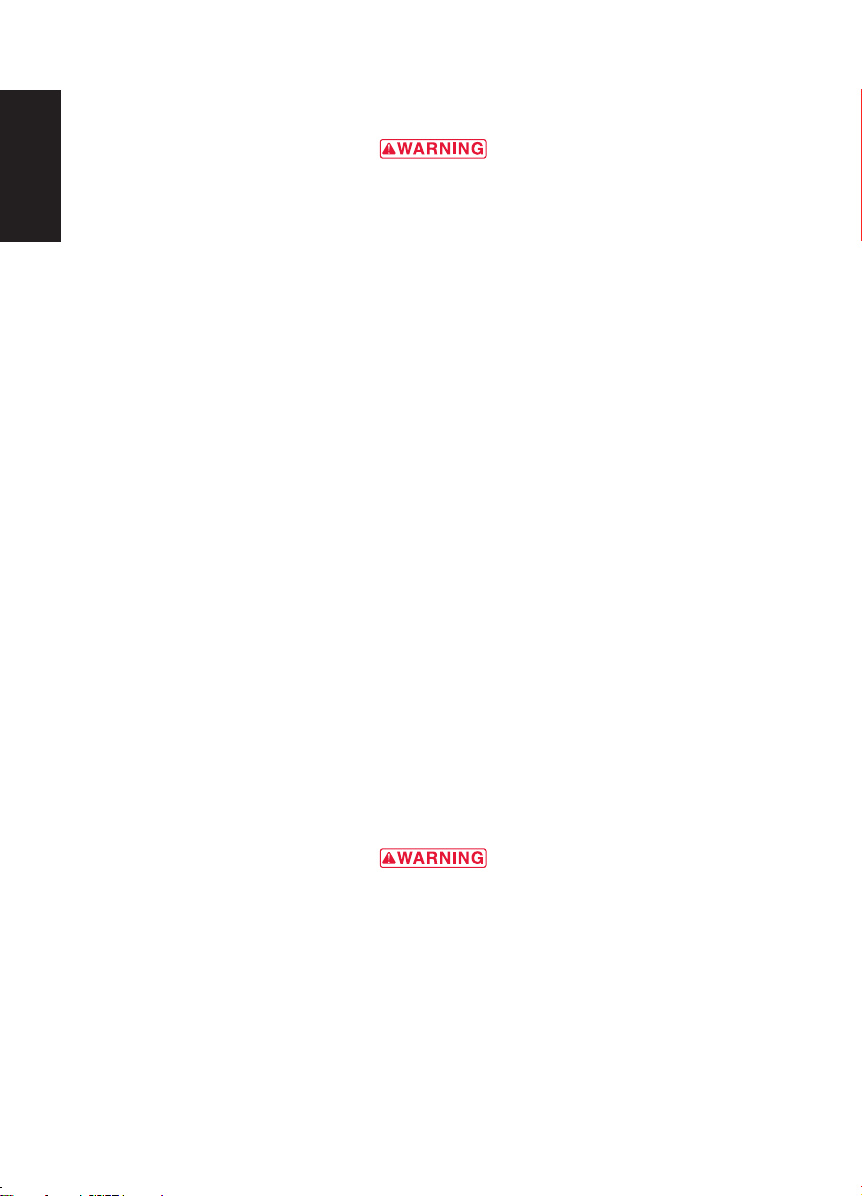

4 Slide the gas system (push rod end first) onto the magazine tube.

Align the push rod with the slot in the left side of the receiver.

(Figure 7). Make sure the gas system spring is properly positioned.

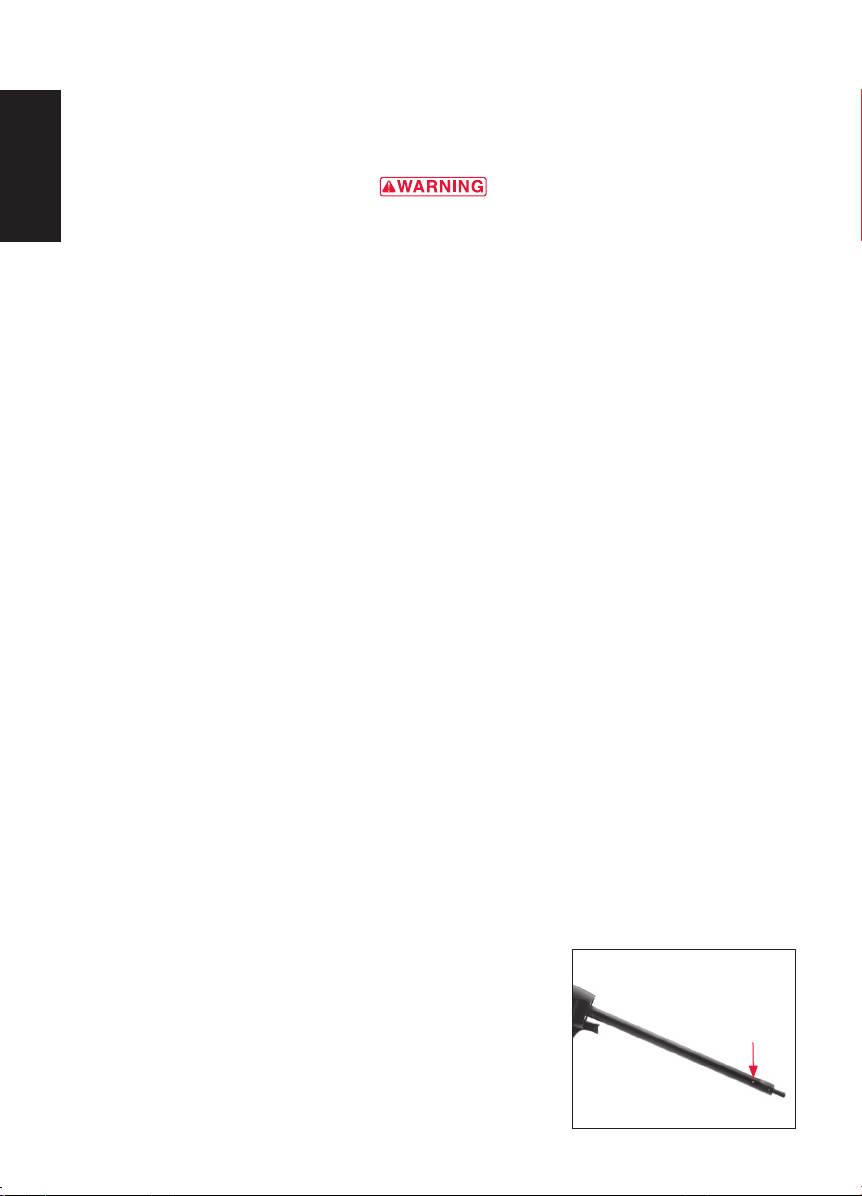

5 Align the barrel extension with the top of the receiver and place

the gas bracket over the magazine tube (Figure 8). The barrel

extension should slip solidly into the receiver. Make sure

the push rod moves freely in its slot in the receiver.

6 Replace the forearm by sliding it onto the magazine tube and over

the gas bracket so it seats securely. Make sure the Speed Lock lever

is fully closed. It may be necessary to push rearward on the

forearm slightly to ensure the forearm is locked in place. When the

forearm is in place and the Speed Lock lever is fully locked, the

release button is flush with the surface of the forearm (Figure 9).

always ensure the ForearM is Ful ly locKed and the sPeed locK

lever rele ase button is Flush with the su rFace o F the Fore arM.

Failur e to Follow this war ning coul d result in seri ous injury,

death or daMage to your FirearM.

D IS A S S EM B L Y

Fi gur e 6

Press and hold the release button while lifting

the Speed Lock lever.

Fi gur e 7

Align the push rod with the slot in the receiver.

E N

always KeeP the M uZZl e Pointed in a saFe direction. beFore

starting disasseMbly Procedu res, oPen the action and visu ally

insPect th e chaMber to be absolutely certain the FirearM is

coMPletely unloaded. Place the ˝sa Fety ” in t he on saFe

Position. Failure to F ollo w this wa rning cou ld result in

serious in jury or d eath.

1 Lock the bolt rearward by pulling the operating handle fully to

the rear.

NO TIC E! ne ver allow the a ctio n to s laM closed by Pressing th e

bolt r elea se button without the barrel installed. iF the bolt i s

released F orward with the b arre l reMoved , the oPer ating

handle wil l striKe the re ceiv er and cause daM age.

2 Remove the forearm as explained previously.

NO TIC E! do not s quee Ze hard on the oPen rear end oF a w ood

ForearM. t oo Much Pressure could cause the woo d to s Plit.

3 For cleaning, remove the barrel and gas system by sliding

them forward and off the magazine tube. See ˝Cleaning and

Maintenance Suggestions” for cleaning procedures.

For storage, remove the barrel and reinstall the forearm over the

magazine tube. You will then have two compact units: the barrel,

and the action with stock and forearm.

NO TIC E! aF ter the barrel has been r eMoved, l eave th e bolt

in the rearward Position. do not Press the bolt release

Fi gur e 8

Slide the barrel and piston over the magazine

tube and the barrel extension into the receiver.

Fi gur e 9

Ensure the forearm is secured co rrectly, wi th

the button flush with the forear m, as shown in

the picture on the left.

7

button. iF the b olt is released Forward with the barrel reMoved, the oPerating ha ndle will

striKe the receiver , causing daMage.

A MM U N I TI O N

E N

use only sh ells oF the correct g auge and l ength. the gauge and leng th oF the chaMber is

inscribed on the side oF the barrel. d o not use aMMunitio n other than what i s inscrib ed

on the side oF the barr el. exaMine every shel l you Put in you r shotgun . Failu re to Foll ow

this warning could result in serious injury or death and cause daMage to your shot gun.

use shells oF th e correct length. do not use 3” or 3½” shells in a barrel wi th a 2¾” chaMber ,

or 3½” shells in a barrel with a 3” chaMber.

high Pressures. Failure to Foll ow this warning cou ld result in ser ious inju ry or death and

cause daMa ge to your shot gun.

do not Put a 16 or 20 gauge sh ell in a 12 gaug e shotgun . do n ot Put a 28 gauge shell in a 20

gauge shotgun. do not Put a .410 bore shell in a 28 gauge shotgun. never Put Metallic

cartridges oF any K ind in a shotgun. sPeciFi cally, never P ut center Fire riFle or Pistol

cartridges in a sho tgun chaMbered For .410 b ore. Fa ilure to Follow this warning could

result in serious inj ury or death and cause daMa ge to your shot gun.

The most certain way to bulge or rupture a shotgun barrel is to load a smaller gauge shell into a larger

gauge chamber. The smaller gauge shell will not fall completely through the barrel; its rim is caught by

the front of a larger gauge chamber or at the larger gauge’s choke. Your shotgun will misfire (with the

chamber appearing to be empty). It is then possible to load the correct gauge shell behind the smaller

gauge shell. If the shotgun is then fired, the result will be a so-called ˝12-16, 12-20, 20-28 or 28-.410

burst” which can cause extensive damage to your shotgun and possible serious injury to you and others.

We can assume no responsibility for incidents which occur through the use of shells of nonstandard

dimension or those developing pressures in excess of SAAMI (Sporting Arms and Ammunition

Manufacturers’ Institute) established standards.

Maxus 12 gauge, 3” chamber models will shoot all 12 gauge, 2¾” and 3”, 1 oz. and heavier factory lead

and steel field loads. Maxus 12 gauge, 3½” chamber models will shoot all 1 oz. and heavier factory lead

and steel 12 gauge, 2¾”, 3” and 3½” field loads.

doing so can result in a builduP o F dangerously

M AG A Z I NE CA PA CI T Y

With the magazine three-shot adapter (plug) removed, Maxus 3” shotguns will hold four 2¾” or three 3”

shells in the magazine. Maxus 3½” shotguns will hold four 2¾” shells, or three 3” or 3½” shells in the

magazine.

T HR E E - SH O T A D A PT ER (P L UG )

always KeeP the M uZZl e Pointed in a saFe direction. beFore re Movi ng or installing the threeshot adaPtor, coMPletely unload the sh otgu n. oPen the action an d visually insPect

the chaMbe r, Feed MechanisM and MagaZine to be absolute ly certain the FirearM is coM Pletely

unloaded. Place the ˝saFety” in the on sa Fe Positi on. Failure to Follow t his warning could

result in serious inj ury or death.

wear eye Protection when reMo ving or installing the thre e-shot ad aPto r to P reve nt sPring s,

sPring-loaded Parts, solvents or other ag ents FroM contac ting your eyes, resultin g in i njury.

The Maxus is delivered with the magazine three-shot adapter (plug) installed in the magazine, limiting

magazine capacity to two shells in compliance with federal migratory bird regulations. If you do not wish

to be limited to three shots, when it is not required by law, you can remove (or reinstall) the three-shot

adapter as follows:

8

R EM OVI N G THE T HR EE-SH O T ADAP T OR (PLU G )

Fi gur e 10

1 Lock the bolt rearward by pulling the operating handle fully

to the rear.

NO TIC E! ne ver allow the a ctio n to s laM closed by Pressing th e

bolt r elea se button without the barrel installed. iF the bolt

is release d Forward with the barr el reMoved, the oPerating

handle wil l striKe the re ceiv er and cause daM age.

2 Remove the forearm as explained previously.

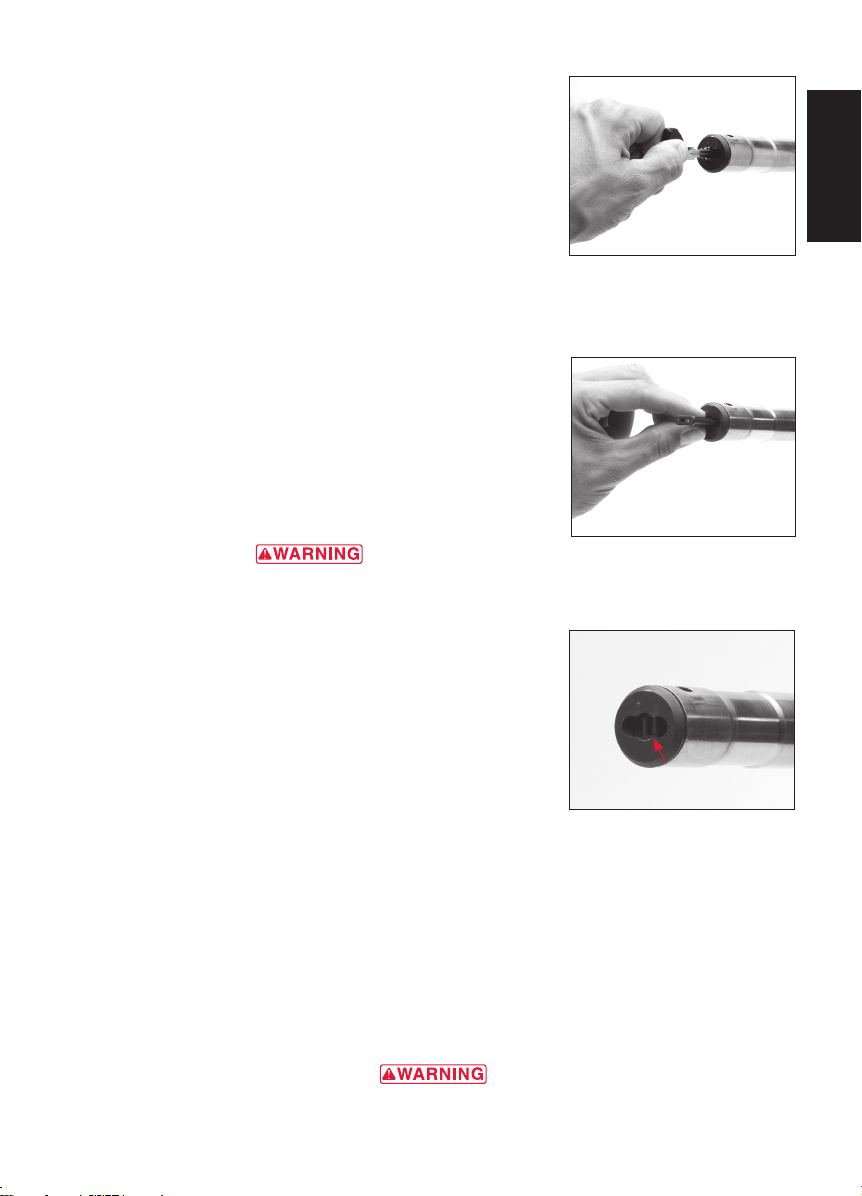

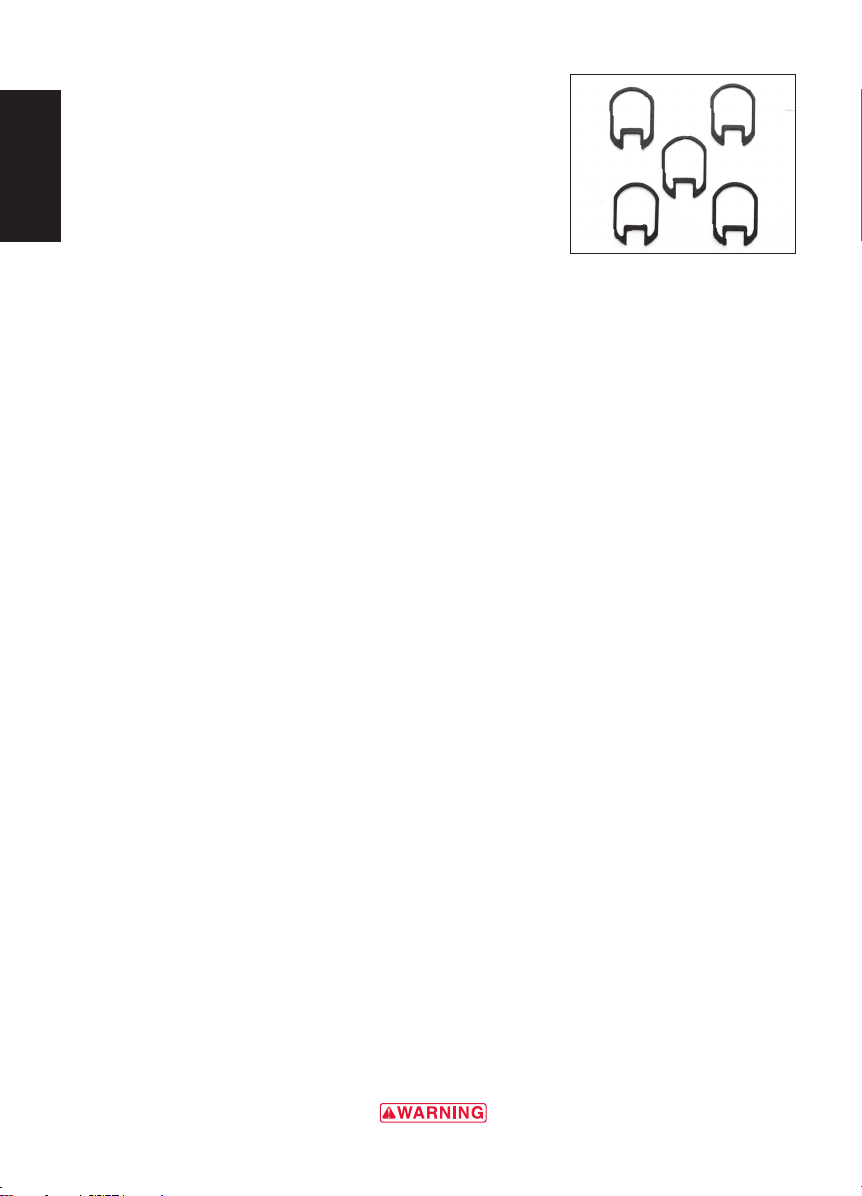

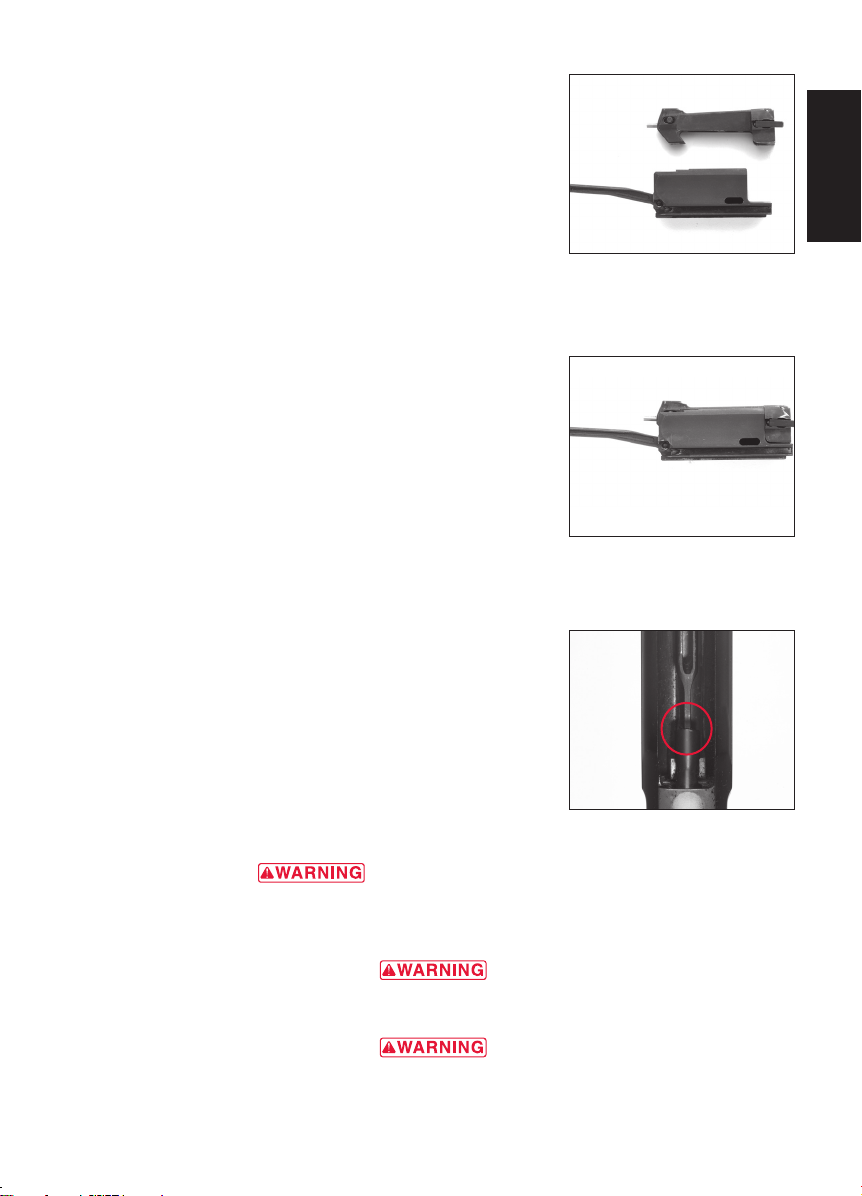

3 The Maxus features the unique TurnKey Magazine Plug which

is quickly and easily removed by inserting a key or standard

screwdriver into the slot in the end of the magazine tube. To

remove the three-shot magazine adaptor, press inward and turn

the key or flat-blade screwdriver a quarter-turn to align the threeshot adaptor with the slot in the end of the magazine (Figure 10).

Use a key or small screwdriver to press in

on the three-shot adaptor, then rotate a

quarter-turn.

Fi gur e 11

This unlocks the three-shot adaptor, allowing it to be removed.

4 If the barrel is on the shotgun, hold it to prevent it from falling

out of the receiver while pointing the magazine tube down to

allow the three-shot adaptor (plug) to fall out of the end of the

magazine tube. Grasp and remove it (Figure 11).

5 Reinstall the forearm as explained previously. When the forearm

is in place and the Speed Lock lever is fully locked, the release

button is flush with the surface of the forearm (Figure 8).

Remove the three-shot adaptor.

always ensure the ForearM is Ful ly locKed and the sPeed locK

lever rele ase button is Flush with the su rFace o F the Fore arM.

Failur e to Follow this war ning coul d result in seri ous injury,

Fi gur e 12

death or daMage to your FirearM.

I NS TA LLI N G THE T HR EE-SH O T ADAP T OR (PLU G )

If you need to install the magazine three-shot adaptor (plug) to

limit your shotgun magazine to three shells, again perform the

following operation:

1 Lock the bolt rearward by pulling the operating handle fully to the

rear.

NO TIC E! ne ver allow the a ctio n to s laM closed by Pressing th e

bolt r elea se button without the barrel installed. iF the bolt i s

The three-shot adaptor shown secured in the

magazine tube.

released F orward with

the barrel reMoved, the o Perating handle will s triK e the receiver and cause daMa ge.

2 Remove the forearm as explained previously.

3 Insert the magazine three-shot adapter into the slot in the end of the magazine tube.

4 Insert a key or flat-blade screwdriver into the slot in the end of the magazine tube. Press inward and

turn the key or screwdriver a quarter-turn to secure the three-shot adaptor in the magazine (Figure

12).

5 Reinstall the forearm as explained previously. When the forearm is in place and the Speed Lock lever

is fully locked, the release button is flush with the surface of the forearm (Figure 9).

E N

always ensure the ForearM is Ful ly locKed and the sPeed locK leve r release button is Flush

with the surFace oF the ForearM. Failur e to F ollow thi s wa rning cou ld result in ser ious

9

injury, death or daMage to your Fire arM.

Fi gur e 13

L OA D I N G

E N

when loading your shotgun always Kee P the MuZZ le Pointe d

in a sa Fe direct ion, always Pla ce the ˝saFety” in th e on saFe

Position a nd KeeP your Fingers away FroM the trigger.

Failur e to Follow thes e wa rnings co uld result in se rious

injury or death.

do not carry your shotgun with a shell in the chaMber to

avoid accidental discharge. when Firi ng is no longer

iMMinent, M aKe sure t he ˝saFet y” is in the on saFe Position and

unload the chaMber. Failur e to F ollow the se warnings could

result in serious inj ury or death.

always taKe care when loading the MagaZine. the edges oF the carrier a re sharP and May

cause inju ry to Fin gers or da Mage to gl oves.

S PE ED L OA DING

1 If shooting is imminent, lock the bolt open and insert a shell into the magazine (Figure 13). The shell

will be automatically cycled from the magazine to the chamber.

KeeP your Fingers clear oF the ejection Port when l oading

the shotgu n using the sPeed loa ding Procedur e. Failure t o Follow this warni ng could result

in injury.

2 If desired, load the magazine to full capacity by inserting a shell of proper gauge and length through

the loading port at the bottom of the receiver up into the magazine, using your thumb to position it

fully forward in the magazine tube. Make sure the rim of the shell engages the shell stop and is held

fully inside the magazine tube. It will make an audible click when fully inserted.

Insert the shell into the bottom of the receiver

and push it fully forward into the magazine.

the shotgu n is n ow ready to Fire by si MPly Moving th e ˝saFety ” to t he oFF saFe Posi tion and

Pulling th e trigger .

L OA DIN G T HE MAG A ZI NE

1 Pull the operating handle to the rear until the bolt locks in the open position. Visually inspect the

chamber, feed mechanism and magazine to make sure they are unloaded and clear of any

obstructions.

2 Close the bolt by pressing the bolt release button.

3 Insert a shell of the proper gauge and length through the loading port at the bottom of the receiver up

into the magazine, using your thumb to position it fully forward in the magazine tube (Figure 13).

Make certain the rim of the shell engages the shell stop and is held fully inside the magazine tube. It

will make an audible click when fully inserted.

4 If desired, continue loading the magazine until it is full.

L OA DIN G T HE CHA M BE R MA N UA LLY FR O M THE M AG AZINE

1 With the bolt closed, depress the carrier with the front of the shell and, using your thumb, push the

shell into the magazine until the shell is held in place by the shell stop.

2 If desired, continue to load the magazine, as explained above, to full capacity.

3 If shooting is imminent, a shell can now be moved from the magazine to the chamber by pulling back

fully on the operating handle and releasing it forward. A shell will be fed automatically from the

10

magazine to the chamber as the bolt closes. Another shell can then

Fi gur e 14

be inserted into the magazine to load to full capacity.

the shotgu n is n ow ready to Fire by si MPly Moving th e ˝saFety ”

to the oFF saFe P osition a nd Pullin g the trig ger.

L OA DIN G T HE CHA M BE R TH R OU GH T HE EJ ECTI O N PORT

1 Pull the operating handle to the rear until the bolt locks in the

open position. Visually inspect the chamber, feed mechanism and

magazine to make sure they are clear of any obstructions.

2 If shooting is imminent, insert a shell of the proper gauge and

Insert a shell through the ejection port into

the breech.

length through the ejection port into the open breech (Figure 14).

3 Press the bolt release button to deliver the shell into the chamber.

KeeP your Fingers clear oF the ejection Port whenever closing the action wi th the bolt release

button. Failure to Fol low this warn ing could result in injury.

the shotgu n is n ow ready to Fire by si MPly Moving th e ˝saFety ” to t he oFF saFe Posi tion and

Pulling th e trigger .

4 With a shell in the chamber, you may load the magazine to full capacity. To load the magazine, insert a

shell of proper gauge and length through the loading port at the bottom of the receiver up into the

magazine, using your thumb to position it fully forward in the magazine tube. Make sure the rim of

the shell engages the shell stop and is held fully inside the magazine tube. It will make an audible click

when fully inserted.

F IR I N G

E N

never load a she ll into the chaM ber or Pla ce the ˝saFety” in the oFF saFe Position unless

shooting i s iMMinen t. always KeeP the MuZZle Pointed in a s aFe direction . Failu re to Foll ow

these warning s could result in ser ious inju ry o r death.

1 Place the ˝safety” in the on safe position.

2 Load a shell into the chamber as explained previously.

3 With a shell in the chamber, you need only move the ˝safety” to the off safe position to fire the

shotgun.

4 When ready to fire, move the ˝safety” into the off safe position, take aim and squeeze the trigger.

After a shell is fired, the gas system operates the bolt, ejects the fired shell and picks up a loaded shell

from the magazine and automatically chambers it. You may continue to fire the shotgun until the

magazine is empty by pulling the trigger to fire each shell. After the last shell is fired, the breech of the

shotgun remains open, with the bolt locked to the rear. This allows convenient and fast reloading.

If you are done shooting, leave the bolt locked to the rear, with the breech in the open position so that you

may visually inspect the chamber, bore, carrier and magazine to be sure they contain no shells.

aFter Firi ng, or when sho otin g is n o longer iMMinent, iM Mediately Place the ˝saFety” in the on

saFe Position. Failure to Follow thes e wa rnings co uld result in se rious inj ury or de ath.

even with the bo lt locK ed oPen aFter shooting, do not assuMe the shot gun is unl oaded.

always insPect the chaMber, barrel, Feed Mech anisM and MagaZine to be certain the shot gun is

coMPletely unloaded. Fail ure to Fol low these warnings cou ld result in ser ious inju ry o r

death.

11

U NL O A D IN G

when unloading your shotgun always Plac e the ˝saF ety” in th e on s aFe Position. KeeP the

E N

MuZZle Poi nted in a saFe direct ion and yo ur Finger s away FroM the trig ger. Failure to Follow

these warning s could result in ser ious inju ry o r death.

always insPect the chaMber, barrel, Feed Mech anisM and MagaZine careFully aFter unl oading

to be s ure all li ve shells are c lear ed FroM the FirearM.

S PE ED U NL OADI N G

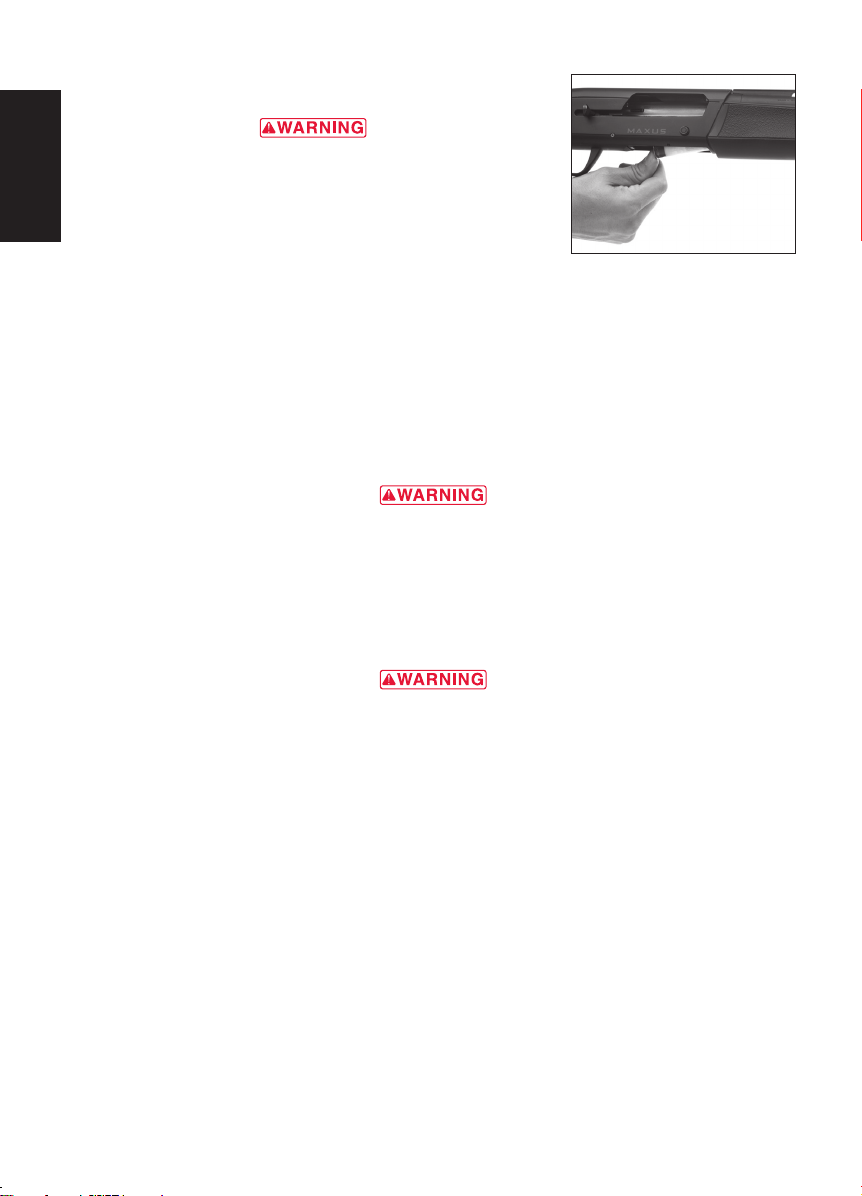

1 With the ˝safety” in the on safe position, turn the shotgun over so

the trigger guard is facing up, then push the carrier down with

your finger as far as it will go.

2 Shells are retained in the magazine by the shell stop, which catches

the rim of the shell base. Locate the shell stop inside the receiver

on the right side of the loading port (visually to the left side when

looking down into the loading port).

3 Push inward on the shell stop with your index finger (Figure 15)

to release a shell from the magazine. As the shell stop is pressed in,

the shell will be forced out of the magazine under spring pressure.

Catch the shell in your hand as it comes out.

4 Press the stop again to release the next shell. Continue to do this

until the magazine is empty. Be careful not to pinch your finger.

5 With the ˝safety” still in the on safe position, pull rearward on the bolt handle to eject the shell from

the chamber. The bolt will lock rearward when the action is cycled with an empty magazine.

6 Using your index finger, feel the opening of the magazine to make sure there are no shells that have

not been fed from the magazine and ejected. Visually inspect the chamber, feed mechanism and

magazine to assure there are no shells remaining.

U NL OAD I NG BY C YC LING T HE AC TIO N

1 With the ˝safety” in the on safe position, grasp the bolt handle and cycle the action until all shells are

transferred from the magazine to the chamber and then ejected. Take care to avoid damaging shells.

Avoid letting them fall to the ground.

2 When the last shell in the magazine has been cycled through the chamber and out the ejection port,

the bolt will lock rearward. The bolt will lock rearward when cycled with an empty magazine.

3 Using your index finger, feel the opening of the magazine to make sure there are no shells that have

not been fed from the magazine and ejected. Visually inspect the chamber, feed mechanism and

magazine to assure there are no shells remaining.

Fi gur e 15

Push inward on the shell stop to unload

the magazine.

M AG A Z I NE CU T- OF F

when unloading your shotgun always Plac e the ˝saF ety” in th e on s aFe Position. KeeP the

MuZZle Poi nted in a saFe direct ion and yo ur Finger s away FroM the trig ger. Failure to Follow

these warning s could result in ser ious inju ry o r death.

The Magazine Cut-Off allows you to unload a shell from the chamber without cycling a shell from the

magazine. With this feature you can quickly and easily load a heavier or lighter shell into the chamber

should the need arise. To change loads in the chamber using the Magazine Cut-Off, perform the

following operation:

1 Pull the Magazine Cut-Off lever to the rear to engage the magazine cut-off and block the magazine

12

(Figure 16). With the lever to the rear, shells are locked in the

magazine. Additionally, shells cannot be loaded into the magazine

with the lever to the rear.

2 Pull the bolt handle fully rearward to eject the shell in the chamber.

3 Load a shell through the ejection port.

Fi gur e 16

the shotgu n is n ow ready to Fire by si MPly Moving th e ˝saFety ”

to the oFF saFe P osition a nd Pullin g the trig ger.

4 The shotgun may now be fired and will fire only the shell in the

chamber.

Pull the Magazine Cut-Off rearward to block

the magazine.

5 To disengage the Magazine Cut-Off, place the ˝safety” in the on

safe position, then push the Magazine Cut-Off lever fully forward

(Figure 17). If the action is open, shells will immediately feed from

Fi gur e 17

the magazine. If the action is closed, a shell can be loaded into the

chamber from the magazine.

I NT E R C HA N G E AB L E CH O KE TU BE SY S T EM

never atteMPt to reMove or install a choKe tube in a loaded

FirearM. w henever r eMoving o r insta lling a choKe tu be in a

shotgun, a lways KeeP the MuZZle Pointed in a saFe di rection.

coMPletely unload t he shotgun. oPen the acti on and visually

insPect th e chaMber , Feed MechanisM and Maga Zine to be

absolutely certain t he Firear M is c oMPl etely unloade d.

always Place the ˝saF ety” in the on saFe Position and KeeP

your Fingers away FroM the tr igger. Failure to Follow these warn ings coul d result in serious

injury or death.

do not Fire this shotgun without the corr ect choKe tube installed. PerManen t daMage May

result to the threads inside the barr el.

use only th e aPProPr iate gauge a nd tyPe oF choKe tubes, MarKed invector- Plus or stan dard

invector, dePending on your shotgu n.

invector-Plus choK e tubes are For use on ly in br owning shotguns with bacK-bored barrels,

and are not interchangeable wi th standard inve ctor choK e tubes. do not use in vect or-Plus

tubes in barrels threaded For s tandard invector tubes.

standa rd invector tubes are For use on ly in br owning sh otguns, a nd are not interchangeable

with invector-Plus choKe tub es. do not use standar d invector tubes in barrels thr eaded For

invector-Plus tube s.

do not use browning standard inv ector or invector- Plus choKe tubes in any sh otgun bar rels

not suPPli ed by browning. do not use any other choK ing device in a ny shotgu n barrels

suPPlied b y brownin g.

Failur e to Follow thes e wa rnings May caus e injury or deat h and caus e daMage to your

shotgun.

All Maxus shotgun barrels are threaded to accept the Invector-Plus™ choke system. Standard Invector™ and

Invector-Plus tubes are not interchangeable. Confirm the choke system of your shotgun by looking on the

right side of the barrel where the specifications are inscribed, where the choke markings are normally

located.

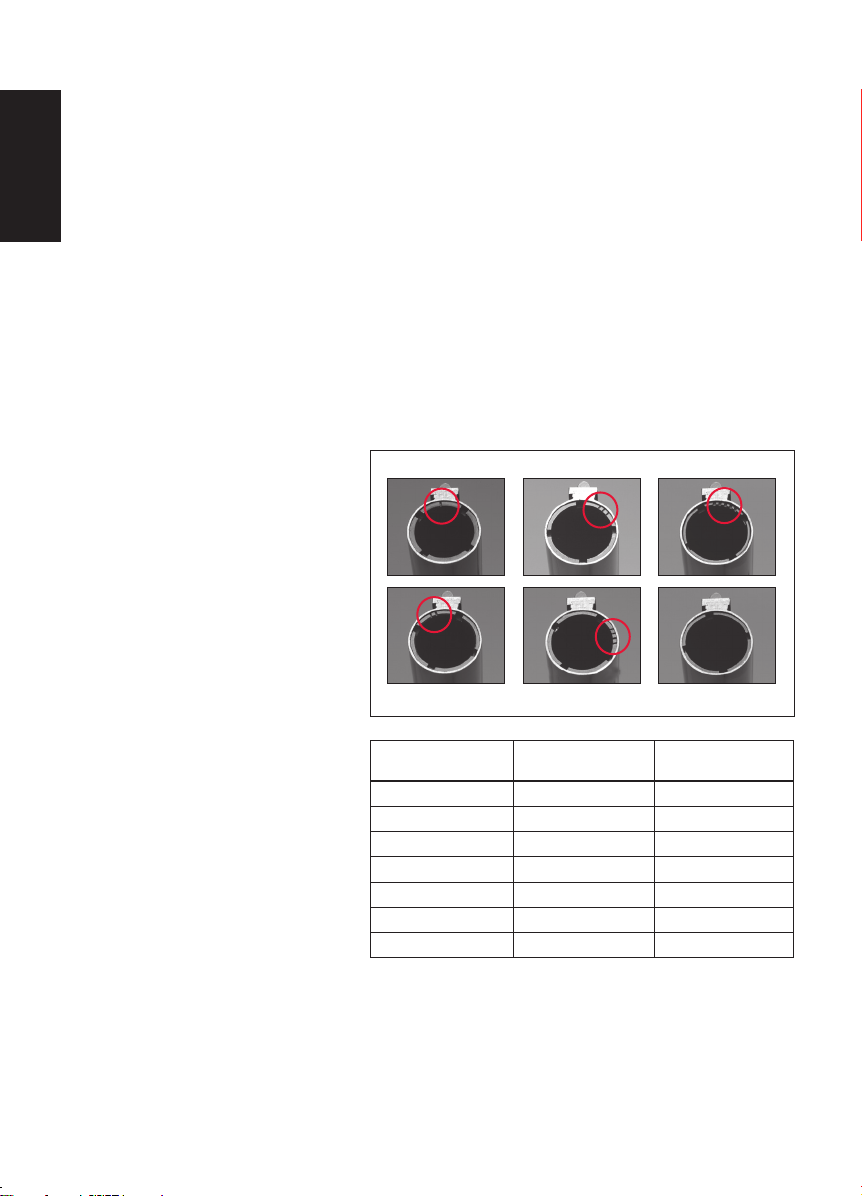

The constriction of each choke tube is indicated twice on the choke tube: on the side of the tube, and

indicated with a ˝notch” code on the top rim of the tube. The included universal choke tube wrench is

Push the Magazine Cut-Off forward to unblock

the magazine.

E N

13

used to remove and install choke tubes.

Invector choke tubes are compatible with factory ammunition that has been loaded in compliance with

SAAMI specifications, including magnum lead and steel shot loads, sabots and shotgun slug loads.

E N

Replacement and additional tubes and wrenches are available from your Browning dealer, or by

contacting the Browning Customer Service Department.

C HO KE T UB E SELE C TI ON

To help you choose the correct choke tube for each hunting and shooting situation, all Browning Invector

choke tubes are inscribed on the side with the patterns they produce with both lead and steel shot. Each

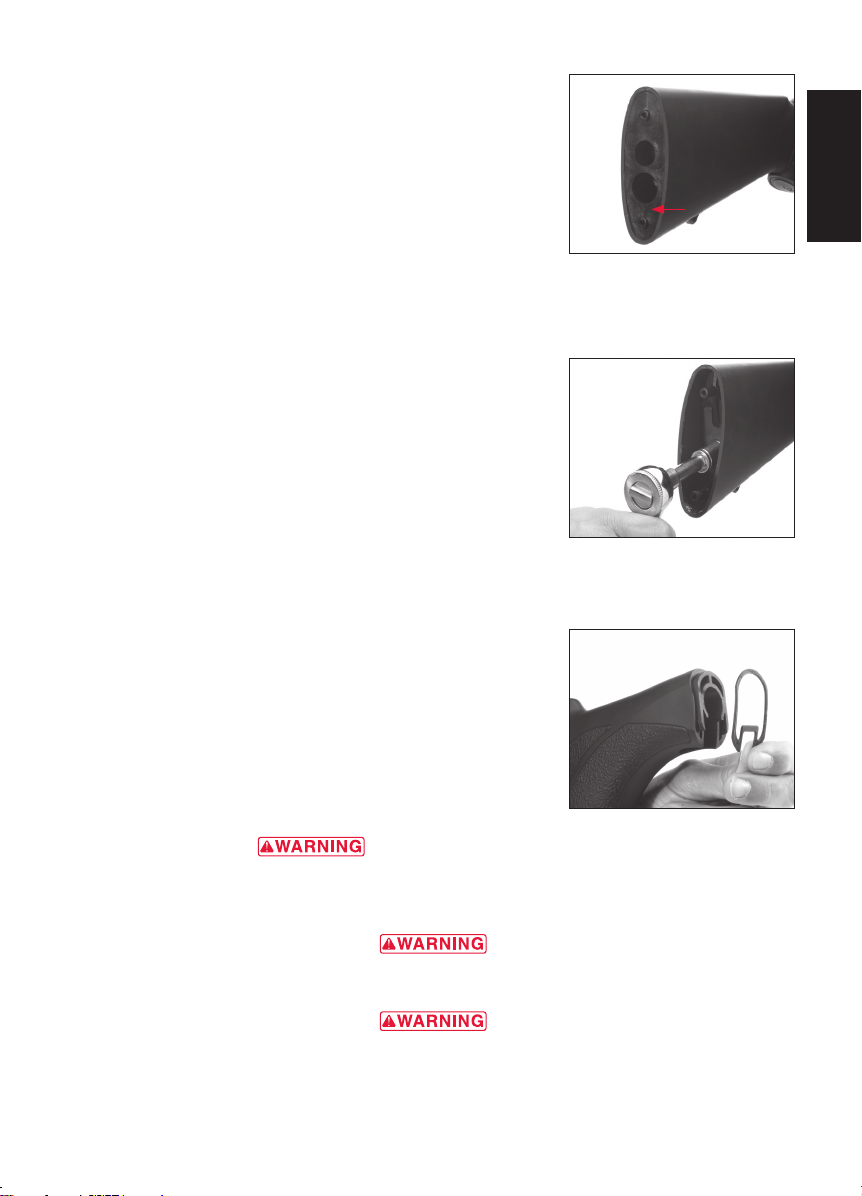

Invector tube also has notches in the top rim of the tube (Figure 18). These notches are a code

to allow you to determine the choke designation while the tube is installed. Rim notches refer specifically

to lead shot. You will need to use the charts to cross-reference from lead to steel, and determine the

appropriate tube for your ammunition and hunting/shooting situation.

Several choke tubes are supplied with your shotgun. The choke tubes listed are also available as

accessories. Remember, Standard Invector and Invector-Plus tubes are not interchangeable. Invector-Plus

tubes are for Browning shotguns with back-bored barrels only. Before removing or installing tubes, or

reading the rim notch code, make

sure your shotgun is completely

unloaded.

C HO KE T UB E REMO VA L

Fi gur e 18

O NE NO T C H

T HRE E N O TC H E S

F IVE N O T CH E S

1 Place the ˝safety” in the on safe

position. Always make sure the

shotgun is completely unloaded.

Always keep the muzzle pointed in a

safe direction.

2 Use the choke tube wrench to loosen

the tube, turning it counterclockwise

(Figure 19). Finger-twist the tube the

rest of the way out of the barrel.

C HO KE T UB E INST AL L AT IO N

T WO NO T C HE S

F OUR N O T CH E S

N O NO T C HE S

1 Place the ˝safety” in the on safe

position. Always make sure the

shotgun is completely unloaded.

Always keep the muzzle pointed in a

safe direction.

2 Before installing a tube, check the

internal choke tube threads in the

muzzle, as well as the threads on the

choke tube to be sure they are clean.

Lightly oil the threads with a highquality, lightweight gun oil.

3 Using your fingers, screw the

appropriate tube into the muzzle of

the barrel, tapered end first, notched

end outward. When it is finger-tight,

use the choke tube wrench to firmly

seat the tube.

NO TIC E! th e choKe tube should b e

Periodically checKed to assure that

*

**

1

R IM

N OTC HE S

e x t e nd e d * * x - F u ll t u r K e y * *

i F u l l *

i i i M P. M o d i Fi e d

i i i M o d i Fi e d

i i i i iM P . cy l i n d e r M o d i Fi e d

i i i i i s K e e t i M P. c y l i nd e r

n o n o tc h e s c y l i nd e r c y l i nd e r

Not for use with steel shot. Using an over-tight choke constriction with

steel shot will result in an ineffective ˝blown” pattern.

Extra Full Special, extended with ports. Do not use with steel shot.

When more than one choke designation is listed for a given steel shot

pattern, use the more open choke listed for high velocity, larger shot size

steel loads.

P AT T ER N WIT H

L EAD S H O T

P AT T ER N WIT H

S TEE L S H OT

14

F u l l

F u l l

1

1

it is t ight and FirMly seated. beFore c hecKing, Foll ow all

choKe tube reMoval and instal lation saFety guidelines

Previously outlined.

A DJ U S T IN G L E N G TH OF P UL L

The buttstock can be adjusted for length of pull by adding or

removing spacers (available separately) to the rear of the stock. Each

spacer extends length of pull ¼” and a maximum of three spacers can

be added with the screws provided to extend length of pull ¾”. With

longer screws (not provided), more than three spacers can be added to

further extend length of pull.

Spacers can be ordered through your Browning dealer or by calling

our Customer Service Department.

beFore Per ForMing a djustMent Procedures, Place the ˝ saFe ty”

in the on saFe Position. oPen the acti on and MaKe certain yo ur

shotgun is coMPlete ly unloaded. Kee P the MuZZ le Pointe d in a

saFe direction. Failure to Follow these warnings could r esult

in serious injury o r death .

I NS TA LLI N G A SPA CER

1 Use a #2 cross tip or Phillips screwdriver to remove the recoil pad

at the end of the buttstock (Figure 20). Place a small amount of

petroleum jelly on the screw access slits on the top and bottom of

the rear of the buttstock to prevent damaging the recoil pad. Insert

the screwdriver into each of the two access holes. Make certain the

tip of the screwdriver engages the head of the screw. Turn the

screw counterclockwise until the screw is completely loose from

the stock. When both screws are free, remove the recoil pad.

2 Add or subtract spacers to fit your firearm to your specifications

(Figure 21). After making an adjustment hold the shotgun to your

shoulder to determine if the new length feels comfortable.

Remember to always keep the muzzle pointed in a safe direction,

with the ˝safety” in the on safe position and make certain the

shotgun is completely unloaded.

3 When you are satisfied with the length of pull, start the screws

through the pad and spacer(s) into the holes in the stock.

4 Attach the recoil pad to the stock using the screwdriver. Turn the

screws clockwise to tighten. Do not overtighten the screws.

Fi gur e 19

Use the choke tube wrench to change

choke tubes.

Fi gur e 20

Insert a screwdriver into the holes in the

recoil pad.

Fi gur e 21

Install or remove stock spacers to achieve

correct length of pull.

E N

A DJ U S T IN G C A S T A N D D R OP AT C OM B

beFore Per ForMing a djustMent Procedures, Place the ˝ saFe ty” in the on saFe Pos ition. oP en the

action and MaKe certain yo ur shotgu n is coMPletely unlo aded. Kee P the MuZZ le Pointe d in a

saFe direction. Failure to Follow these warnings could r esult in seriou s injury or deat h.

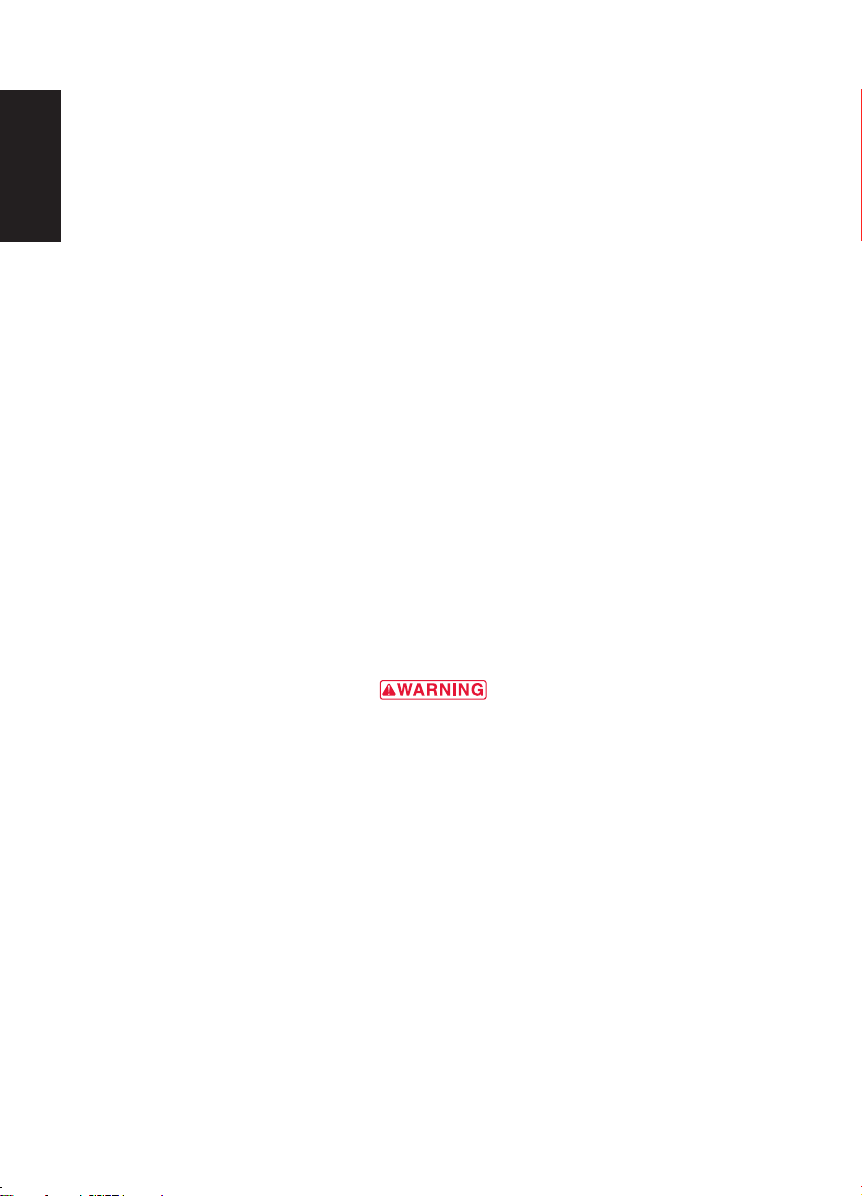

Six shims are included with your new shotgun (Figure 22). The shims fit between the buttstock and

receiver, allowing customized adjustments to the comb and heel. Each shim is labeled/stamped for a

specific amount of adjustment. The neutral shim, No. 2, is already installed on your shotgun.

Drop at comb is defined as the place on the comb that your cheek rests when taking aim. If drop at comb

is correct, your eye naturally falls in line with the sight. Shims marked 1, 2 and 3 do not give any cast on

15

or off. The stock remains straight. They only adjust drop at comb.

Fi gur e 22

These shims with their respective stamps are further clarified here:

1

E N

• Shim 1 raises the comb approximately

approximately

1

/

8”.

/

16”, and the heel

• Shim 2 is neutral. This shim is already installed on the firearm.

1

• Shim 3 lowers the comb approximately

approximately

1

/

8”.

/

16”, and the heel

Cast is the offset of the buttstock from the longitudinal center line of

the firearm. Some right-handed shooters like the stock to angle away

(cast off) from their face, making their line of sight more directly in

Cast and drop adjustment shims. Shim 2 comes

on your shotgun and is not show n.

line with the barrel. Angling the stock to the left for left-handed

shooters is ˝cast on.” Shims marked 1R1L, 2R2L, and 3R3L, will all

adjust drop at comb the same amount as shims 1, 2 and 3, and will also adjust the cast right or left

approximately

1

/

8”. You will notice that the two opposing edges of these spacers are different in thickness.

For right-handed shooters, install shims between the receiver and the stock with the R facing the end of

the buttstock, so its thicker side is on the left side. This casts the stock slightly to the right, away from the

face of a right-handed shooter. If you turn the shim around so the L is facing the end of the buttstock,

and it will cast the stock to the left. These shims with their respective stamps are further clarified below:

• Shim 1R1L raises the comb approximately

cast on or cast off approximately

1

/

8”.

1

/

16”, and the heel approximately

1

/

8” and will adjust the

• Shim 2R2L adds the same amount of cast to the stock as shim 1R1L with neutral drop like shim 2.

• Shim 3R3L adds the same amount of cast to the stock as shims 1R1L and 2R2L, and lowers the comb

approximately

I NS TA LLI N G A SHIM

1

/

16” and the heel approximately

1

/

8”.

1 Make sure your shotgun is completely unloaded and the ˝safety” is in the on safe position.

2 Use a #2 cross tip or Phillips screwdriver to remove the recoil pad at the end of the buttstock (Figure

20). Place a small amount of petroleum jelly on the screw access slits on the top and bottom of the

rear of the buttstock to prevent damaging the recoil pad.

Insert the screwdriver into each of the two access holes. Make certain the tip of the screwdriver

engages the head of the screw. Turn the screw counterclockwise until the screw is completely loose

from the stock. When both screws are free, remove the recoil pad.

3 Remove the stock insert to access the stock bolt nut (Figure 23).

4 Use a ½” socket wrench to remove the two stock bolt nuts and stock bolt washer. (Figure 24).

5 Completely remove the buttstock from the receiver, along with the existing shim, and install the shim

you have selected (Figure 25). Make certain you have the proper shim installed and in position before

reattaching the buttstock and recoil pad.

6 When you are satisfied with the fit, reattach the buttstock to the receiver with the washer and the

nuts.

7 Snug the nuts down with the socket wrench, do not overtighten.

8 Reinstall the stock insert.

9 Reinstall the recoil pad with care, so as not to scratch or mar the finish of the stock.

E XT R A B A R RE L S

16

beFore ins talling an a ccessory bar rel on you r shotgun , read

the Follow ing guidelines to ensure the barrel/shotgun

coMbination is saFe. Place t he ˝saFet y” in the on saFe Position .

oPen the action and MaKe c ertain you r shotgun is coMPletely

unloaded. KeeP the MuZZle Pointed i n a sa Fe direct ion. Failure

to Follow these warnings cou ld result in ser ious inju ry

or death.

The versatility of your new shotgun can be extended with an extra

barrel. Maxus shotgun barrels are interchangeable within a given

gauge and chamber length. No special fitting is required. However,

some important restrictions must be observed:

• Never use a barrel with a 3½” chamber on a shotgun designed for

barrels with a 3” chamber.

• Never use a barrel with a 3” chamber on a shotgun designed for

barrels with a 3½” chamber.

• Never use any other barrel from any other manufacturer on your

shotgun. Some other brands may seem similar, but the barrels are

not interchangeable.

• Never use a barrel from any other Browning shotgun.

C LE A N I NG AN D M AI N TE NA N CE S UG G E S TI O N S

NO TIC E! Pl ease taKe no te oF the Following inForMation beFore

cleaning y our FirearM.

C LE ANI N G PA RTS W IT H SPEC I AL FIN I SH ES

Be especially careful when cleaning firearms with camouflage,

Dura-Touch

prevent these surfaces from coming in contact with cleaning solvents,

barrel scrubbers and other strong chemicals. It is preferable to clean

these surfaces with a lightweight gun oil containing no solvents or

with a damp cloth and mild dish soap (be sure to keep water out of

the action). When cleaning your firearm’s bore and action, protect the

external finishes from any contact with chemicals used. Also avoid

any contact between external finishes and other strong chemicals like

those found in DEET-containing insect repellents, sunscreens, etc.

Damage to camouflage, Dura-Touch and other finishes caused by

chemicals is irreversible and not repairable.

®

Armor Coating and other special finishes. Always

Fi gur e 23

E N

Remove the stock insert.

Fi gur e 24

Use a socket wrench to remove t he stock bolt.

Fi gur e 25

Install the shim between the sto ck and receiver.

beFore Per ForMing c leaning P rocedures, Place the ˝sa Fety ” in t he on saFe Position . oPen the

action and MaKe certain yo ur shotgu n is coMPletely unlo aded. Kee P the MuZZ le Pointe d in a

saFe direction. Failure to Follow these warnings could r esult in seriou s injury or deat h.

wear eye Protection when disa sseMbling and clea ning your shotgun to Prevent sPrings,

sPring-loaded Parts, solvents or other ag ents FroM contac ting your eyes, resultin g in i njury.

KeeP all aMMunition away FroM the clea ning area. never tes t the Mechanical Function oF y our

shotgun wi th live aMMunition. Failure to Follow thes e wa rnings co uld result in se rious

injury or death.

C LE ANI N G THE B AR REL

17

Your Maxus shotgun will function better and more reliably over a longer period of time if it is properly

maintained and kept clean.

You should clean your shotgun after every day of shooting, and more often if it becomes excessively dirty.

At a minimum the barrel should be cleaned and the action wiped clean and oiled after every day of

E N

shooting. The gas system should require only occasional cleaning.

Normal maintenance can be accomplished with the barrel still attached to the receiver (oiling and wiping

down). More careful cleaning requires removal of the barrel from the receiver (cleaning the barrel) and

the removal of the gas system components. A complete cleaning requires removal of the bolt and trigger

group.

If a malfunction occurs, perform a thorough cleaning to see if it solves the problem before seeking the

services of a Browning Recommended Service Center.

1 Place the ˝safety” in the on safe position. Open the action and inspect the chamber and magazine to

make certain they do not contain any shells. Keep the muzzle pointed in a safe direction.

2 Remove the forearm and barrel as explained under ˝Disassembly”.

3 Using a shotgun cleaning rod with tip and patch large enough for a snug fit in the bore, insert the rod

and a lightly oiled patch in the breech end of the barrel and run back and forth through the bore

several times. Remove and wipe the choke tube, threads and barrel threads with a nylon brush and

lightly oil.

Alternately, the Browning Barrel Weasel

sure to follow all instructions when using any product to clean your firearm.

4 Inspect the bore from both ends for leading and plastic residue that often remain in the bores from

the shot cups in modern shells. Leading and plastic residue will appear as longitudinal streaks and are

usually more predominant near the muzzle and just forward of the chamber. A normal amount of

either is common and not serious.

5 If leading or plastic residue seems excessive you can remove it by brushing the bore with a brass

brush. Soak the brush or spray the bore with a powder solvent first. Scrub until clean. To prevent

bristles from breaking off, push the brush fully through the barrel each time before pulling it back

through.

™

makes cleaning the bore of your firearm fast and easy. Be

Most solve nts are highly FlaM Mable. we ar eye Protection and Practice aPProPriate saF ety

Measures w hen worKing with solvent s to avoid serious injury.

6 After all leading and plastic residues have been removed, run a clean, dry patch through the bore.

Follow this with a final, lightly oiled patch.

7 Reassemble the shotgun and wipe all exposed metal surfaces with an oiled cloth making sure to wipe

away all finger marks where moisture could accumulate.

8 Inspect the barrel and chamber to be certain no patches have inadvertently been left in them. Remove

any that remain.

9 Lightly oil your firearm at the points described under ˝Periodic Oiling”. Regular, light oiling is

extremely important to the durability and reliable operation of your shotgun.

10 The wood surfaces can also be wiped with a quality, lightweight gun oil or they can be polished with

any quality furniture wax (but not both).

C LE ANI N G THE G AS SY STEM

1 Remove the gas system from the magazine tube as explained in ˝Disassembly”.

2 To simplify cleaning the gas system, separate the gas piston from the piston sleeve by pulling them

apart (Figure 26).

3 Spray the magazine tube, gas piston and piston sleeve with gun solvent and brush them thoroughly

18

with a nylon brush to remove any deposits. It will be easier to remove the piston sleeve spring to clean

the interior of the piston sleeve. Spray the inside of the gas piston. A green Scotch-Brite

®

kitchen scrub

pad works best for removal of heavy carbon fouling on the tube and inside the gas piston. Do not

remove the spring inside of the piston. Never use a steel brush on any of the gas components.

4 Complete the cleaning of the gas system by applying a very light film of oil to all parts for protection

and lubrication. Reassemble the gas system by snapping the piston sleeve into the gas piston.

P ER IOD I C OILI N G

The metal parts of a firearm should receive a light film of oil after

the firearm has been exposed to weather or handling.

Occasionally, a drop of lightweight gun oil may be placed inside the receiver on the rails on which the bolt

slides (Figure 3), and on the surface of the magazine tube, where the gas piston slides.

This reduces friction for smooth operation.

If the firearm has been exposed to excessive dust, dirt, mud or water,

Fi gur e 26

the principal working parts including the gas system, should be wiped

clean and lubricated with a light film of quality, lightweight gun oil.

NO TICE! do not Place large quantities oF oil into the action.

excess oil will run bacK into the wood oF the stocK soFtening

the wood, with consequential loosening oF the stocK.

R EM O V AL OF TH E T RI G G ER GR O U P

E N

beFore reM oving the trigger grouP, Place the ˝saFety” in the

on saFe Position. oPen the acti on and MaKe certain yo ur

shotgun is coMPlete ly unloaded. Kee P the MuZZ le Pointe d in a

saFe direction. Failure to Follow these warnings could r esult in seriou s injury or deat h.

wear eye Protection when disa sseMbling and clea ning your shotgun to Prevent sPrings,

sPring-loaded Parts, solvents or other ag ents FroM contac ting your eyes, resultin g in i njury.

KeeP all aMMunition away FroM the clea ning area. never tes t the Mechanical Function oF y our

shotgun wi th live aMMunition. Failure to Follow thes e wa rnings co uld result in se rious

injury or death.

Separate the gas system component s to

simplify cleaning.

The Lightning Trigger and bolt can be removed if the action becomes excessively dirty or wet. If this

occurs, disassemble the action for a complete cleaning as explained in the following sections. The trigger

group and bolt assembly of your Maxus shotgun are designed to be removed in the field, without special

tools.

Disassembly of the action involves the removal of the bolt assembly and the trigger group. Disassembly

beyond this point should only be performed by a qualified gunsmith.

R EM OVI N G THE T RI GGER G RO UP

1 Place the bolt in the forward position by holding the operating handle and depressing the bolt release

button.

NO TIC E! ne ver allow the a ctio n to s laM closed by Pressing th e bolt release button without t he

barrel ins talled. iF t he bolt is r elea sed Forward with the barrel reMoved, the oPerating

handle wil l striKe the re ceiv er and cause daM age.

2 Use a punch or similar object to push inward on the trigger guard pins, taking care not to scratch the

receiver (Figure 27). Trigger group pins may be removed from either side of the receiver. Push the

19

trigger group pins through the receiver. Pull on them from the

opposite side to remove them.

3 Grasp the trigger guard and pull it up and out of the receiver

E N

(Figure 28).

4 Perform any cleaning of the parts and receiver cavity as necessary.

We suggest cleaning the trigger group with a quality aerosol gun

solvent. Allow it to dry and then very lightly oil the moving parts.

NO TIC E! do not d isasseMble the trigger g rouP beyond

this Point.

R EI NST AL L AT IO N OF TH E TR IGG E R GROU P

1 Make sure the bolt is in the forward position.

2 Insert the trigger group into the receiver. Align the holes in the

trigger group with the holes on each side of the receiver.

3 Reinsert the trigger guard pins and gently tap them into place

with a plastic or wooden mallet, again using caution not to

scratch the receiver.

R EM O V AL OF TH E B OL T A S SE M B LY

beFore reM oving the bolt asseMbly, Plac e the ˝saF ety” in the on

saFe Position. oPen the a ctio n and MaKe certain your shotgun

is coMPlet ely unloaded. KeeP the MuZZle Pointed in a saFe

direction. Failu re to Foll ow these warnings coul d result in

serious in jury or d eath.

wear eye Protection when disa sseMbling and clea ning your

shotgun to Prevent sPrings, sPring-lo aded Parts, solvents or

other agen ts FroM contacting your eye s, resulting in injury.

Fi gur e 27

Push the trigger group pins thro ugh

the receiver.

Fi gur e 28

Lift the trigger group from the receiver.

Fi gur e 29

KeeP all aMMunition away FroM the clea ning area. never

test the Mechanical Function oF your shotgun with live

aMMunition. Fail ure to Fol low these warnings could result

in serious injury o r death .

1 Remove the barrel, gas piston, piston sleeve and piston sleeve

spring as explained previously.

2 Prior to removing the bolt assembly, it is preferred to first remove

the trigger group, as explained previously.

3 Carefully place the bolt in the forward position by holding back on

the operating handle and depressing the bolt release button.

NO TIC E! ne ver allow the a ctio n to s laM closed by Pressing th e

bolt r elea se button without the barrel installed. iF the bolt i s

released F orward with the b arre l reMoved , the oPer ating

handle wil l striKe the re ceiv er and cause daM age.

4 Remove the operating handle by pulling the operating handle

outward (Figure 29).

5 Slide the bolt assembly forward and out of the receiver (Figure 30).

20

Pull outward to remove the bolt handle.

Fi gur e 30

Slide the bolt forward and out of the receiver.

6 The bolt and bolt slide can now be separated for cleaning (Figure

31). Perform cleaning of the bolt and receiver cavity as necessary.

NO TIC E! do not d isasseMble the bolt asse Mbly beyond th is

Point.

R EI NST AL L IN G TH E B OLT AS SEM B LY

1 Reassemble the bolt and bolt slide (Figure 32).

2 Place a few drops of oil in the grooves in the bolt to lubricate

the bolt slide rails (Figure 3).

3 Align the rails on the bolt slide with the grooves in the receiver.

Press the bolt release button and slide the bolt assembly into the

receiver, bolt slide link end first.

4 Ensure the bolt slide link fits into the socket in the recoil spring

follower (Figure 33).

5 Replace the operating handle by inserting it in its slot in the bolt.

6 Open and close the action several times to make sure the bolt slide

link and recoil spring follower are properly engaged.

NO TIC E! ne ver allow the a ctio n to s laM closed by Pressing th e

bolt r elea se button without having the ba rrel installed.

daMage wil l result to the receiver and oP erating handle.

C LE ANI N G THE A CT ION

1 When the action becomes excessively dirty, remove the trigger

group and bolt assemblies from the receiver as explained under

˝Removal of the Trigger Group” and ˝Removal of the Bolt

Assembly”. Clean with a gun solvent as necessary, using a nylon

brush to loosen any caked-on grime.

Wipe the receiver cavity clean. Lightly oil the cavity and wipe it

dry. No further disassembly is required for cleaning.

2 Reassemble the trigger group, bolt assembly, gas system and the

barrel to the receiver as explained previously. Then wipe all

exposed metal surfaces with an oiled cloth, making sure to wipe

clean all finger marks where moisture could accumulate.

3 The barrel and action should be inspected thoroughly to be certain

no cleaning patches have been inadvertently left in them.

L UB R I C AT I N G T HE AC TI O N T U BE AN D S PR I NG

Fi gur e 31

The bolt and bolt slide can be separated

for cleaning.

Fi gur e 32

The bolt shown assembled.

Fi gur e 33

Guide the bolt slide link into its socket in the

recoil spring follower.

E N

beFore lub ricating the action tube an d sPring, Place the ˝saFety” in the on sa Fe Position. oPen

the action and M aKe certain your shotgun i s coMPlet ely unloaded. KeeP the MuZZle Pointed in

a saFe direction. Fail ure to Fol low these warnings cou ld result in ser ious inju ry or death.

wear eye Protection when disa sseMbling and lubr icating your shotgun t o Prevent sPrings,

sPring-loaded Parts, solvents or other ag ents FroM contac ting your eyes, resultin g in i njury.

KeeP all aMMunition away FroM the clea ning area. never tes t the Mechanical Function oF y our

shotgun wi th live aMMunition. Failure to Follow thes e wa rnings co uld result in se rious

injury or death.

21

If you frequently use your shotgun in inclement weather conditions, oiling the action tube and spring will

aid in maintaining the performance and reliability of your firearm.

1 Remove the recoil pad and buttstock as explained previously.

E N

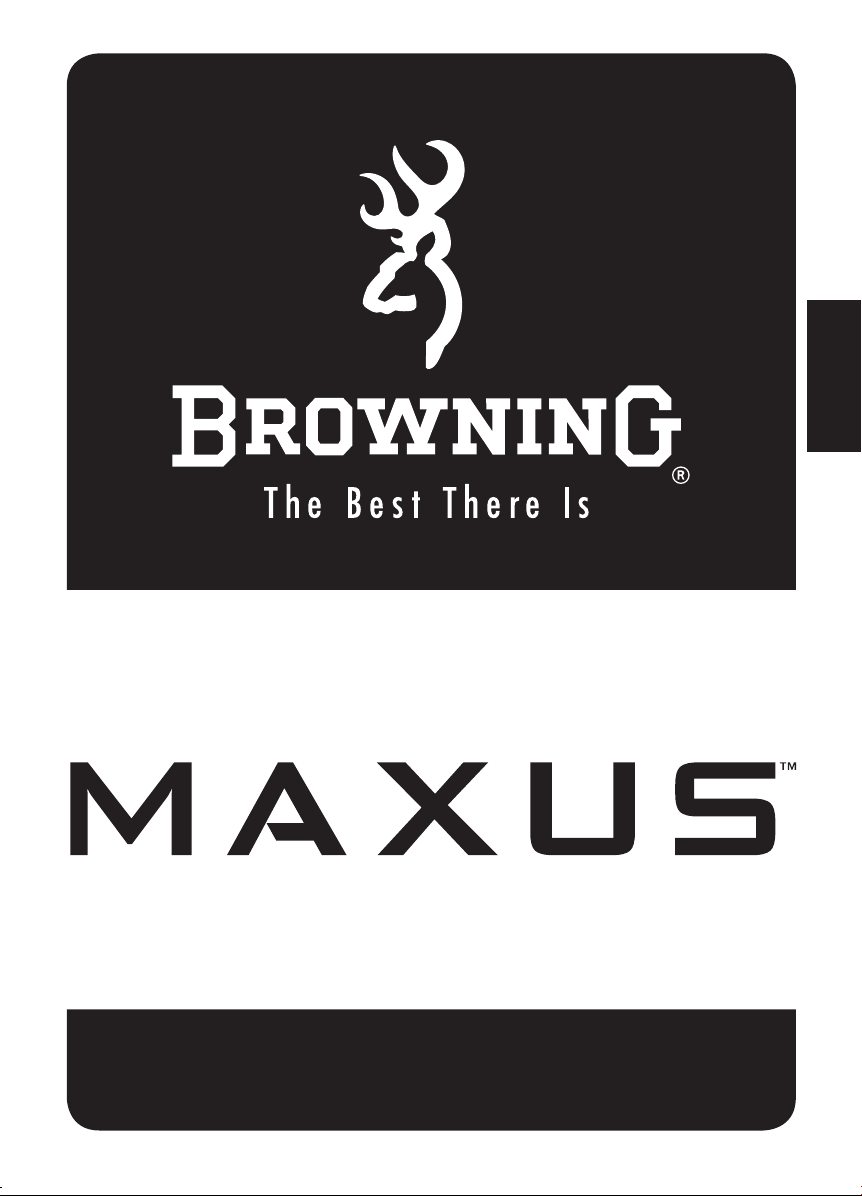

2 Place a few drops of high-quality lightweight gun oil in the opening in the rear of the action tube

(Figure 34).

do not atteMPt to r eMov e the acti on sPring FroM the action tube. the acti on tube is easily

daMaged an d the acti on sPring is un der sPring tension. Failure to Follow this warning could

result in serious inj ury or daMage your shot gun.

3 Hold the shotgun with the muzzle down. Rotate the shotgun and cycle the action using the bolt

handle to operate the action several times to evenly disperse the oil on the spring and inside the

action tube.

NO TIC E! do not u se excess ive lubricant. using too Much lubricant can i nterFere with the

Functioning oF your shotgun. do not sPray solvent inside the a ctio n tube.

4 Carefully rest the shotgun vertically on a rag with the action tube down to allow any excess oil to

drain out of the action tube. Wipe away any excess oil.

5 Lightly lubricate the external surface of the action tube.

6 Install the buttstock and recoil pad as explained previously.

NO TIC E! do not taKe your FirearM’s action aPart beyond what is exPlained in this owner’s

Manual. th is is a sPecial iZed , Finely F itted Mec hani sM; any atteMPt to dis asseMble the inner

MechanisM May Mar it For liFe. it is unnecessary, and May do daM age to the inner MechanisM

to disasse Mble it For routine c lean ing and oiling. oF course , MisFortune s (such as droPPing

your FirearM in water) req uire aPPr oPriate atten tion, and in su ch circuMstances we

recoMMend you iMMediately taKe yo ur Firear M to a qualiFied gunsMith .

M AI N T E NA N C E O F O I L F I NI S H S T O CK S

Keeping the oil-finished wood surface on your firearm looking its best requires only a small amount of

maintenance. When the surface becomes spotted or dull, the affected area(s) can be treated using rubbing

alcohol on a soft, lint free cloth and allowed to dry. A small amount of a linseed oil-based finish, such as

®

Watco

Danish Oil Finish, Deft® Danish Oil Finish, or Formby’s® Tung Oil Finish should then be applied to

the surface of the wood with a soft, lint free cloth according to the manufacturer’s instructions. To treat

the checkering, a small amount of oil-based finish can be applied and then distributed evenly using a

toothbrush or other soft bristled brush.

M OD E L S W I TH SP EC I AL F IN I S H ES

As with any firearm, the only way to preserve its pristine condition and collector appeal is to never

handle or fire it, which in turn would deprive you of much of the enjoyment that comes with owning a

fine Browning firearm.

While special finishes such as engraving and gold plating greatly

enhance the aesthetic appeal of your shotgun, please be aware that

Fi gur e 34

they are no more durable, and in some cases may even be slightly less

durable than more common firearm finishes.

As you use your shotgun, you can expect special finishes to wear in

much the same manner as any other firearm finish. These marks are

the honest product of the hours spent enjoying your firearm and each

scuff and scratch will probably have a good story to go along with it.

S ER VI CE OR RE PA I R

22

Place a few drops of oil in the opening in the

action tube.

If your firearm should require service or repairs, we suggest you first contact a local recommended

Browning Firearms Service Center.

To locate a service center visit www.browning-int.com, contact our Customer Service Department or your

Browning firearms dealer for the address of the Service Center nearest you.

Parts listings, Firearm Service Center lists, service procedures, service/repair form and general product

information are also found on the internet at: www.browning-int.com. For technical questions about your

firearm or service, contact:

Browning International S.A.

Parc Industriel des Hauts-Sarts

3ème Avenue, 25

B-4040 Herstal Belgium

Fax +32(0)4 240 52 12

www.browning-int.com

When returning your firearm for servicing, you must do the following:

1 Be sure it is completely unloaded.

2 Remove the scope or other optics.

3 Package it securely in a cardboard container.

4 Enclose the service/repair form available at www.browning-int.com or a letter that clearly describes

the trouble experienced, the ammunition used and the repairs desired. Also include your name and a

daytime phone number where you can be reached.

5 If convenient, send a copy of the service/repair form or letter to us separately.

6 Never return ammunition with your firearm. It is against postal and most commerce regulations.

E N

23

E N

24

F R

browning Maxus™

Fusils seMi-autoMatiques

25

Instructions de fonctionnement importantes pour :

BRO W NING MAXUS

™

FUS I LS S E MI-AU T OMAT IQUES

Si vous souhaitez poser des questions à propos de votre

nouvelle arme à feu, de ce manuel du propriétaire ou

d’autres produits Browning, contactez :

Browning International S.A.

Parc Industriel des Hauts-Sarts

3ème Avenue, 25

B-4040 Herstal Belgium

Fax +32(0)4 240 52 12

www.browning-int.com

F R

Veuillez utiliser l’espace ci-dessous pour enregistrer les

renseignements de votre nouvelle arme à feu.

Modèle __________________________________