Brother TU-878B Owner's Manual

BAS-6150

INSTRUCTION MANUAL

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

AUTOMATIC LOCKSTITCH POCKET WELT SEWER

Thank you very much for buying a BROTHER sewing machine. Before using your new machine,

please read the safety instructions below and explanations given in the instruction manual.

The nature of industrial sewing machine requires operators to be always exposed to the hazard

to themselves, because they have to work very close to moving parts such as the needle and

thread take-up lever. Prior to using, be sure to be well informed of instructions for safe and

correct operation of the machine by experts and/or instructors.

SAFETY INSTRUCTIONS

1 Safety indications and their meanings

This instruction manual and the indications & symbols labeled on the machine are provided to ensure safe

operation of this machine and to prevent hazards from an operator and/or other people. The meanings of these

indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

............ This symbol ( ) indicates what an operator must be careful of.

..............This symbol (

The instructions following this term indicate situations where

negligence of the instructions will almost certainly result in death

or severe injury.

The instructions following this term indicate situations where

negligence of the instructions to operation could cause hazards

to the material and body.

The picture inside the triangle indicates the nature of the caution that must be observed. (For

example, the symbol on the left means "beware of injury".)

) indicates what you must not do.

..............This symbol (

The picture inside the circle indicates what must be done. (For example, the symbol on the

left means "you must set the ground connection".)

) indicates what you must do.

BAS-6150

1

2 Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the

wall outlet before opening the face plate of the control box. Touching areas where high voltages are

presant can result in severe injury.

DANGER

CAUTION

Requirements for environment

Use the machine in an area free of the impact

from sources of strong electrical noise such

as high-frequency welders. Sources of strong

electrical noise may cause problems with

correct operation of the machine.

Any fluctuations in the power supply voltage

should be within ±10% of the rated voltage

for the machine. Voltage fluctuations greater

than this range may cause problems with

correct operation of the machine.

The power supply capacity should be greater

than the requirements for electrical consumption of the machine. Insufficient power supply capacity may cause problems with correct operation of the machine.

The air supply capacity should be greater

than the requirements for air consumption of

the machine. Insufficient air supply may

cause problems with correct operation of the

machine.

The ambient temperature during use should

be within the range from 5°C to 35°C Temperature lower or higher than this range may cause

problems with correct operation of the machine.

The relative humidity in operation should be

within the range from 45% to 85% and no dew

formation should occur in any device. Excessive

dry or humid environment and dew formation may

cause problems with correct operation of the machine.

Avoid exposure to direct sunlight in operation.

Exposure to direct sunlight may cause problems with correct operation of the machine.

When an electrical storm occurs, turn off the

power and plug off the power cord. Lightening may cause problems with correct operation of the machine.

Do not use the machine outdoors.

Installation

Machine installation should be carried out

only by a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical wiring.

The machine weighs 225kg. The installation

should be carried out by two persons or more.

Do not plug in the power cord before the installation is completed. Unintended press on

the foot switch may cause injury.

Be sure to connect ground. Insecure grounding may cause problems with correct operation and a serious electrical shock.

2

BAS-6150

Be sure to wear protective goggles and gloves

when handling lubricating oil or grease so that

no oil or grease gets into your eyes or onto your

skin. Do not eat or drink lubrication oil or grease

in order not to have vomiting or diarrhea. Keep

oil and grease out of the reach of children.

Install the machine well apart from sources

of strong electrical noise such as high-frequency welding equipment. Otherwise, incorrect machine operation may result.

Place the leveling sheet on the sound floor

and secure the machine with casters so that

it will not move.

CAUTION

Sewing

The machine should be operated only by

operators who have been trained for safety

operation.

Do not let children access to the machine.

The machine should not be used for any other

application than sewing.

Be sure to wear protective goggles when

operating the machine. Otherwise, a broken

needle may get in your eyes and cause injury.

Turn off the power on the following occasions. Otherwise, unintended press on the

foot switch may cause injury.

• When replacing a needle

• When not operating the machine and leaving it unattended

Do not operate the machine where an aerosol

product (air spray) is used or where oxygen is

being administered.

Attach all safety devices before using the

machine. Operation without safety device

may cause injury.

Do not touch any of the moving parts nor press

any objects against the machine in operation.

Any touch or press may cause damage to the

machine or injury to human body.

Do not put objects or a screwdriver in the

exhaustion outlet or inside the machine. Accidental touch on an area with high voltage

may cause electrical shock.

Do not damage, process, heat, and apply excessive force to the power cord or other wiring cords. Breakage of the power cord and

other wiring cords may cause fire or electric

shock.

Turn off the power switch when the control

unit is subject to water or chemicals. Continuous operation of the control unit subjected to water or chemicals may cause fire

or electrical shock.

Turn off the power switch when incorrect

operation and abnormal sound or smell are

noticed. Contact your Brother dealer or a

qualified technician.

Contact your Brother dealer or a qualified

technician when the machine is in trouble.

BAS-6150

3

Cleaning

Turn off the power switch before cleaning.

Unintended press on the foot switch may

cause injury.

Disconnect the air hoses from the air supply

and wait for the needle on the pressure gauge

to drop to "0" before carrying out inspection,

adjustment and repair of any parts which use

the pneumatic equipment.

Maintenance and inspection

Be sure to turn off the power switch when the

machine is raised. Unintended press on the

foot switch may cause injury.

Turn off the power switch and pull off the plug

by holding not of the cord but of the plug for

the following occasions. Otherwise, unintended press on the foot switch may cause

injury.

• maintenance, adjustment, and repairment

• replacement of consumable parts such as

the rotary hook, knife, lamp, etc

When adjustment has to be done with the

power switch and air supply on, pay enough

attention to safety. Detach the air tube of air

source and set the pointer of the pressure

gauge to [0] for inspection, adjustment, and

repair of air using devices.

Be sure to wear protective goggles and

gloves when handling lubricating oil or

grease so that no oil or grease gets into your

eyes or onto your skin. Do not eat or drink

lubrication oil or grease in order not to have

vomiting or diarrhea. Keep oil and grease out

of the reach of children.

If safety devices are once detached, re-attach

them to the original position. Make a check to

confirm that they are in proper function.

Loss and others due to remodeling the machine are excluded from the scope of warranty.

Do not put scissors, needles, threads, tools

on the table when the machine is set upright.

Falling down of them may cause damage to

the machine or injury to human body.

Ask your Brother dealer or a qualified technician for electrical maintenance and inspection.

4

BAS-6150

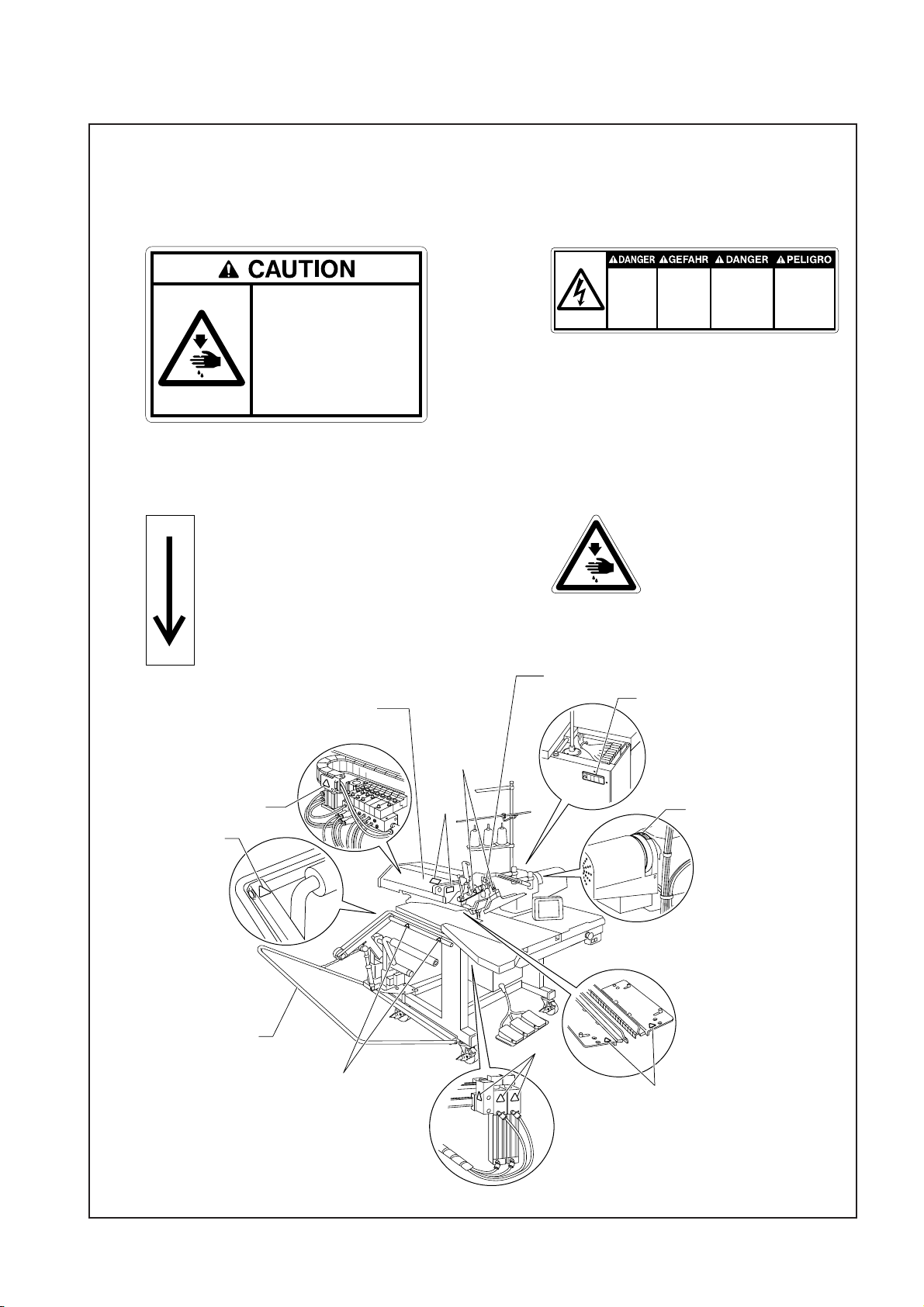

3 Warning labels

* The following labels appear on the machine.

Please follow instruction described on the labels when using the machine. If labels have been removed

or become illegible, contact your dealer.

12

Un voltaje inadecuado

puede provocar las

heridas.

Apagar el interruptor

principal y esperar 5

minutos antes de abrir

esta cubierta.

Moving parts

may cause injury.

Operate with safety devices.

Turn off main switch before

changing needle, cleaning

etc.

Safety devices: cover, take-up lever cover,

guard bar

Hazardous voltage

will cause injury.

Turn off main

switch and wait 5

minutes before

opening this cover.

Hochspannung

verletzungsgefahr!

Bitte schalten sie den

hauptschalter aus und

warten sie 5 minuten,

bevor sie diese

abdeckung ffnen.

Un voltage non adapt

provoque des blessures.

Eteindrel’interrupteur et

attendre 5 minutes

avantd’ ouvrir le capot

3

Direction of operation

4

Moving parts may

cause injury.

Tale-up lever cover

Cover

4

4

1

4

2

1434S

3

Guard bar

4

4

BAS-6150

4

1432S

5

Contents

Chapter 1 Machine Preparation.............................................. 9

1. Specifications .......................................................................................... 10

2. Name of parts .......................................................................................... 11

3. Installation ............................................................................................... 12

3-1. How to carry the machine ..........................................................................12

3-2. How to install the machine ......................................................................... 12

3-3. Installation of the 3-pedal foot switch .........................................................13

3-4. Attachment of the cotton stand .................................................................. 13

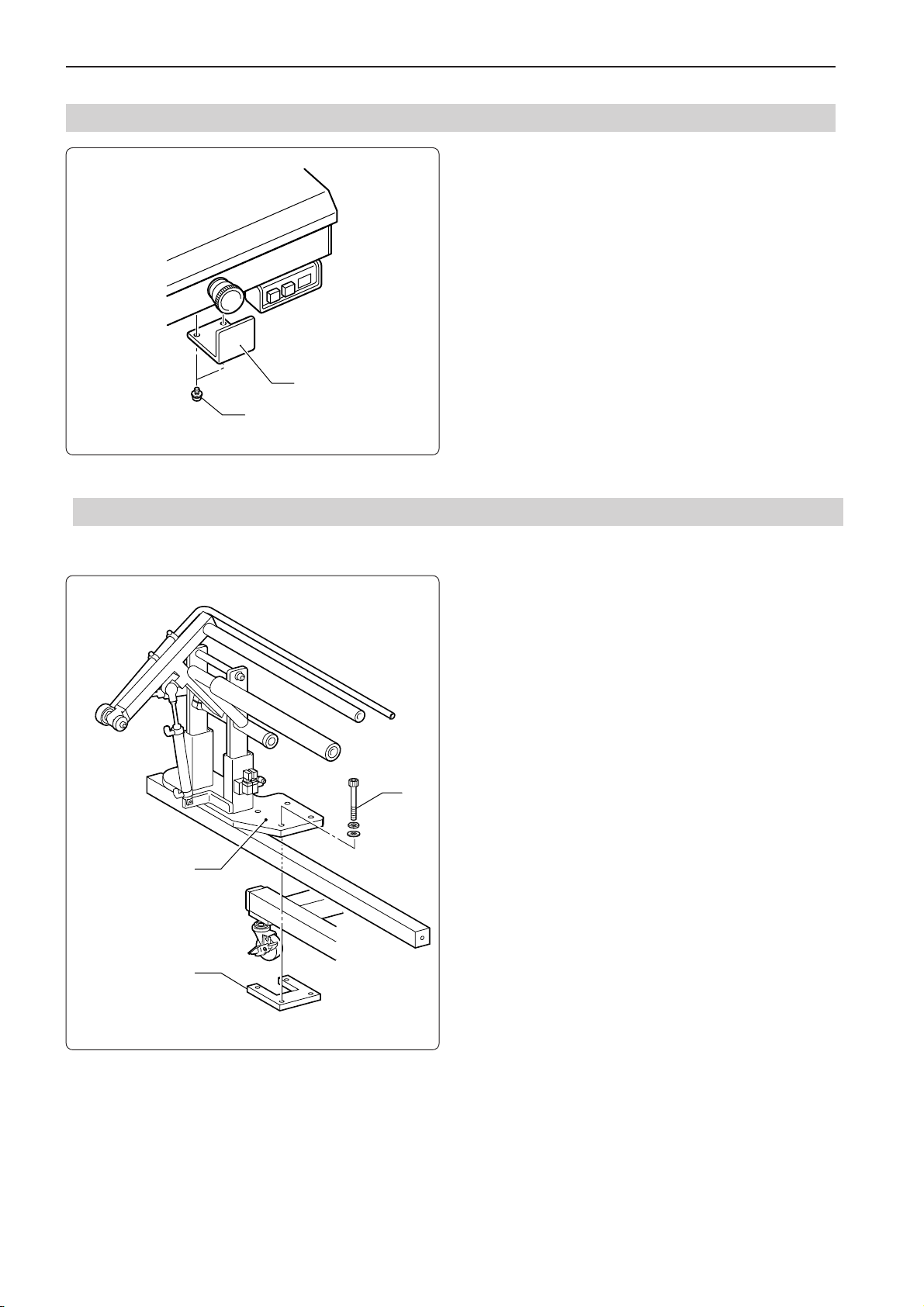

3-5. Detachment of the emergency stop switch cover.......................................14

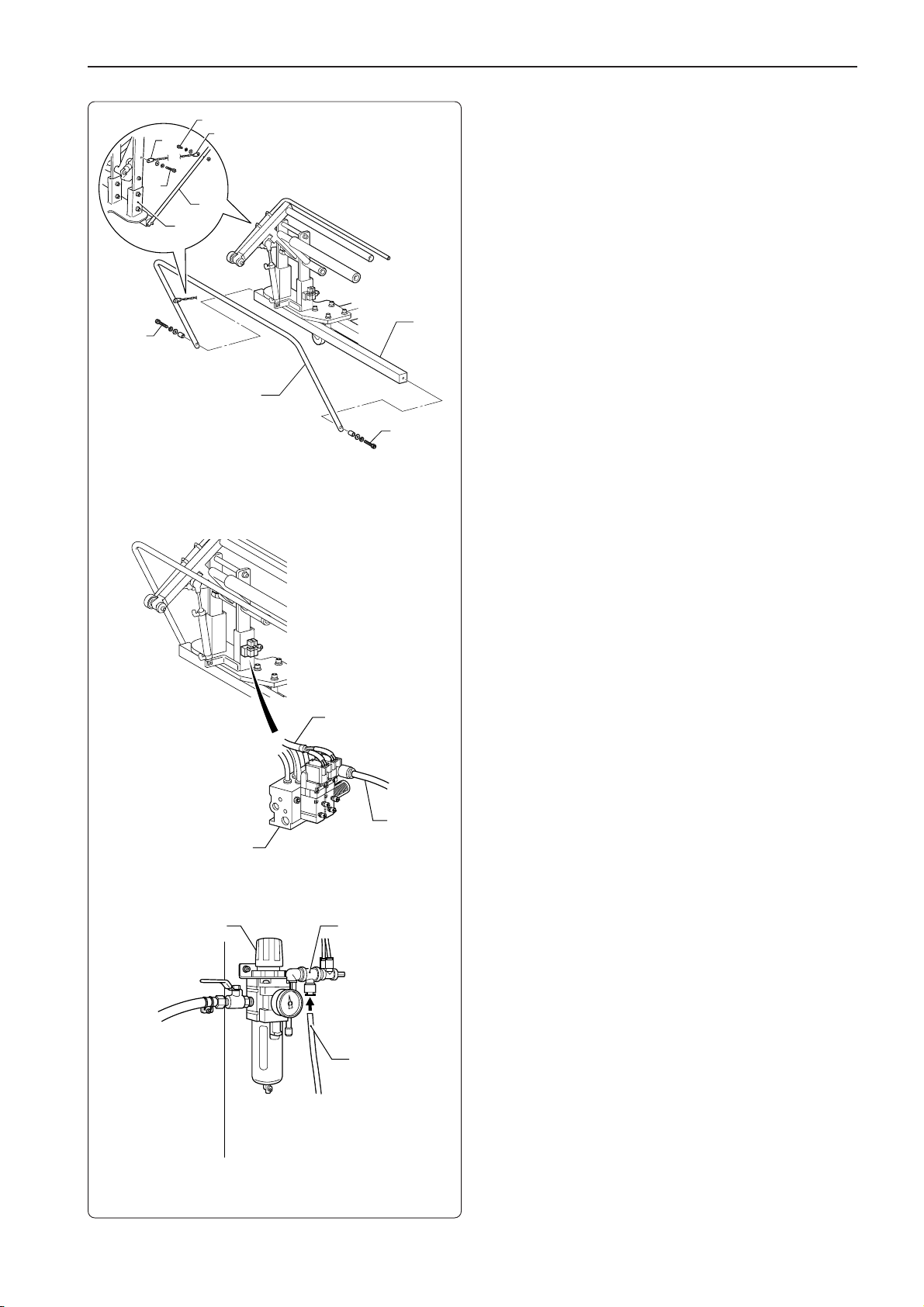

3-6. Attachment of the stacker (option) ............................................................. 14

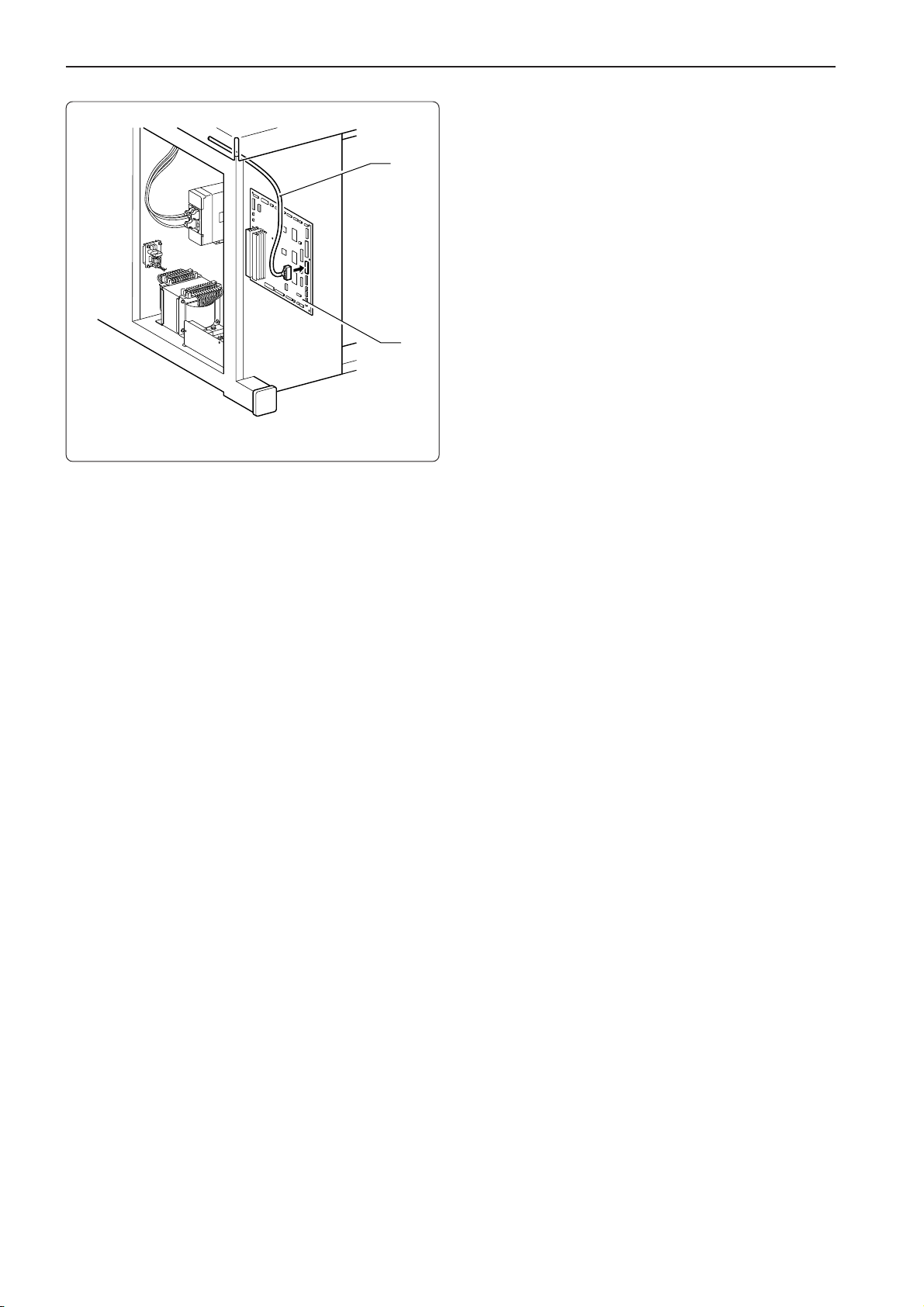

3-7. Air pressure setting .................................................................................... 17

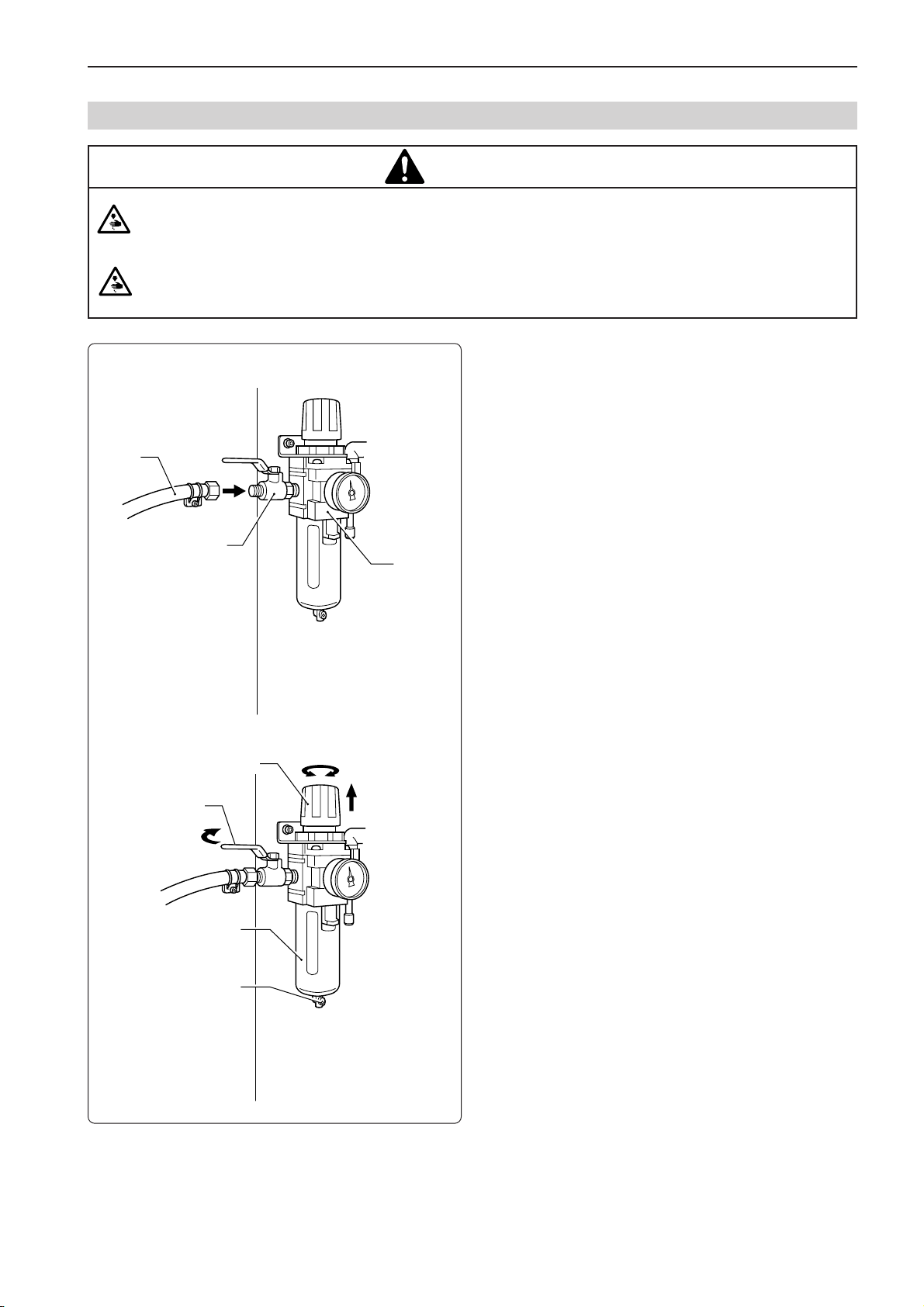

3-8. How to open the main plate .......................................................................18

4. Preparation for sewing............................................................................. 19

4-1. How to mount the needle ........................................................................... 19

4-2. How to dismount the bobbin or bobbin case ..............................................20

4-3. How to wind the lower thread ..................................................................... 21

4-4. How to thread the lower thread ..................................................................22

4-5. How to thread the upper thread .................................................................23

4-6. Adjusting the thread tension....................................................................... 23

4-7. Retention of upper and lower threads ........................................................24

4-8. Adjusting the thread tension spring ............................................................25

4-9. Initialization at the time of power ON .........................................................26

Chapter 2 Sewing flow.......................................................... 27

1. Outline of operation ................................................................................. 28

1-1. Description of the panel ............................................................................. 28

1-2. How to operate the 3-pedal switch .............................................................32

2. Preparation flow for sewing ..................................................................... 33

2-1. Turn on the power supply for the machine ................................................. 33

2-2. Test (step) operation................................................................................... 34

2-3. How to set the cloth .................................................................................... 35

2-4. How to adjust the marking light beam ........................................................37

3. Machine stop ........................................................................................... 38

3-1. How to stop the machine ............................................................................ 38

3-2. Machine stop reset ..................................................................................... 38

3-3. Post-process after the machine stop due to errors .................................... 38

6

BAS-6150

Chapter 3 Settings ................................................................ 39

1. Program operation ................................................................................... 40

1-1. Contents of the parameter .........................................................................40

1-2. Center knife and corner knife correction .................................................... 48

1-3. Cycle program ............................................................................................49

1-4. Counter operation ...................................................................................... 50

2. Program lock ........................................................................................... 51

3. How to set double and single welting ...................................................... 52

Chapter 4 Oiling.................................................................... 53

1. Oiling ....................................................................................................... 54

2. Oiling ....................................................................................................... 55

3. How to raise the head .............................................................................. 56

Chapter 5 Adjustment ........................................................... 57

1. Timing adjustment of needle and rotary hook ......................................... 58

2. Clearance adjustment between needle and rotary hook ................................ 59

3. Clearance adjustment between rotary hook and needle plate ................ 59

4. Clearance adjustment between rotary hook and bobbin case opener ........... 60

5. Height adjustment of carriage feed.......................................................... 60

6. Explanation of sensor amplifier ............................................................... 61

7. Adjustment of flap sensor (flap specifications) ........................................ 62

7-1. Before starting flap sewing .........................................................................62

7-2. How to set the detection sensitivity ............................................................63

8. Adjustment of the lower thread detection sensor (option) ........................65

8-1. How to wind the lower thread ..................................................................... 65

8-2. How to set the detection sensitivity ............................................................66

9. Adjustment of the upper thread breakage sensor (option) ...................... 67

Chapter 6 Knife replacement ................................................ 69

1. Corner knife ............................................................................................. 70

2. Upper thread trimming knife .................................................................... 71

3. Lower thread trimming fixed knife and movable knife .............................. 72

3-1. How to dismount the fixed and movable knife ............................................72

3-2. How to sharpen the fixed knife ...................................................................72

4. Center knife (Upper knife)......................................................................... 73

5. Center fixed knife..................................................................................... 74

5-1. How to dismount the fixed knife ................................................................. 74

5-2. Position adjustment of the center knife(upper knife) and fixed knife .......... 74

BAS-6150

7

Chapter 7 Environment setting ............................................. 75

1. Environment parameter setting ............................................................... 76

2. Machine test mode .................................................................................. 86

3. Foot switch timer setting .......................................................................... 87

4. Operation test for the stacker and roller .................................................. 88

5. Sensor check ........................................................................................... 89

5-1. Sensor switch .............................................................................................90

5-2. DIP switch .................................................................................................. 91

5-3. Voltage of 210 V and 55 V ..........................................................................91

5-4. Voltage of 30 V and 24 V ............................................................................91

6. ROM version display................................................................................. 92

Chapter 8 Dipswitch.............................................................. 93

DIP-SW A (Control panel) ........................................................................... 94

DIP-SW B (Main print circuit board) ............................................................ 94

DIP-SW C (Main print circuit board) ............................................................ 95

Chapter 9 Error code List ..................................................... 97

Error code List ............................................................................................. 98

Chapter 10 Troubleshooting................................................ 101

Reference table in trouble ......................................................................... 102

8

BAS-6150

Chapter 1 Machine Preparation

Chapter 1 Machine Preparation

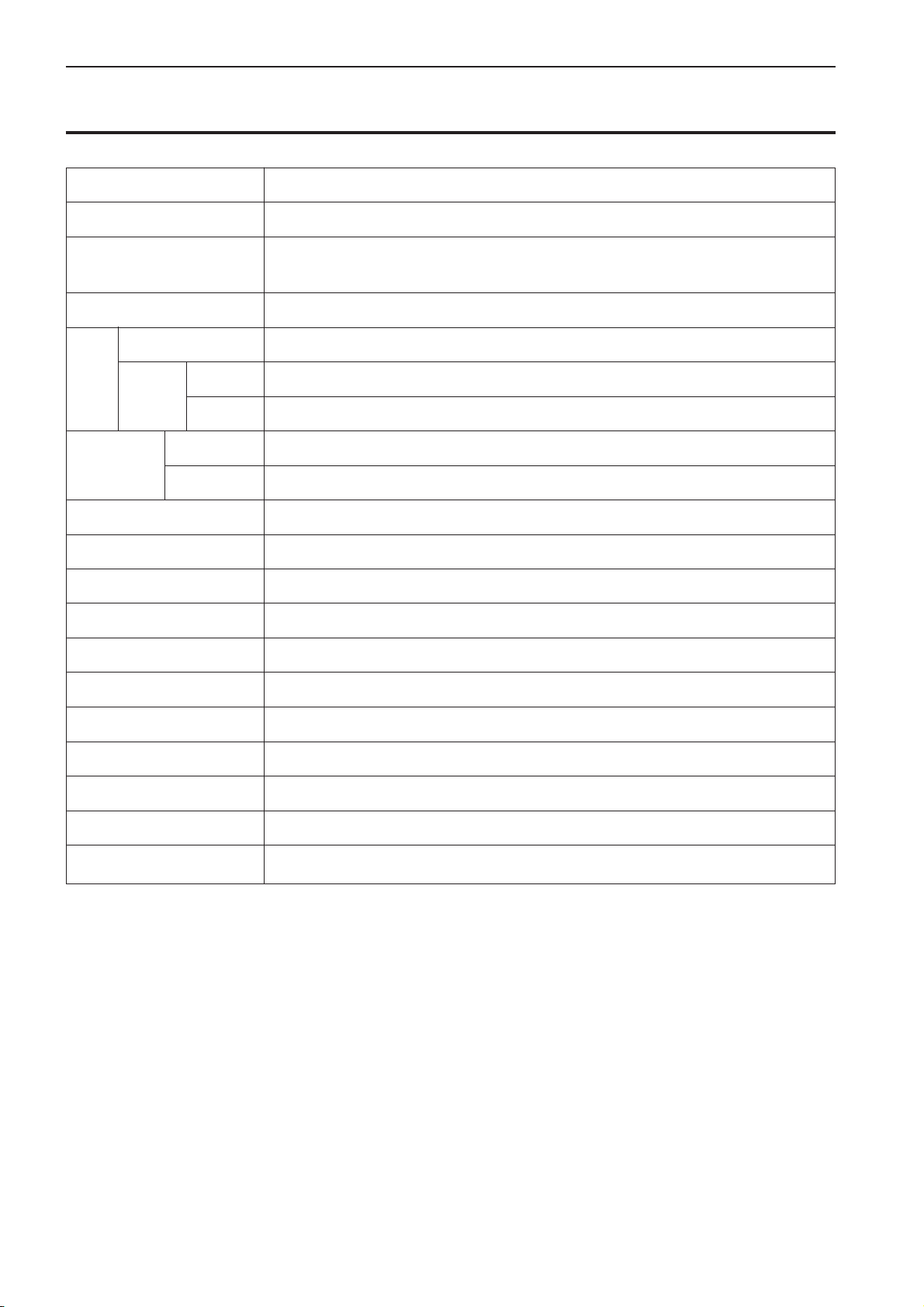

1. Specifications

Model 151-6150

Head 118-U73 (the machine with double needles and center knife)

Sewing speed

Welting Parallel double welting, parallel single welting (with flap, without flap)

Standard pitch Standard 2.4 mm (1.8 - 3.4mm)

Stitch

length

Back tack

pitch

Seam

length

Program number 10 (enable to copy)

Cycle program number 5 (4 prgrams/1 cycle, stacker movable in the middle)

Lower thread counter 0 - 999 (disable when remaining amount detection device in use)

Sensor check function Display of conditions of sensors, switches, etc

Needle gauge 8, 10, 12, 14, 16, 18, 20 mm (Standard: 12mm)

Needle to be used Mtx190#16 (#14 - #18)

Condense Standard 1mm (0.4 - 2.0mm)

V.N. back

tack

Minimum 30mm (center knife ON), 15mm (center knife OFF)

Maximum 220mm (standard), 250mm (option)

(3000, 2800, 2500, 2200, 2000, 1800, 1500, 1200, 1000, 800, 500, 200 rpm)

Maximum 3000rpm

Standard 1mm (0.8 - 3.4mm)

Rotary hook Horizontal double hook

Power

Air pressure/air consumption

Weight 225kg

Dimensions W1,010mm x D1,350mm x H1,200mm

3 phase 200V,220V,380V,400V,415V, 600VA

0.49Mpa, 10l /min

10

BAS-6150

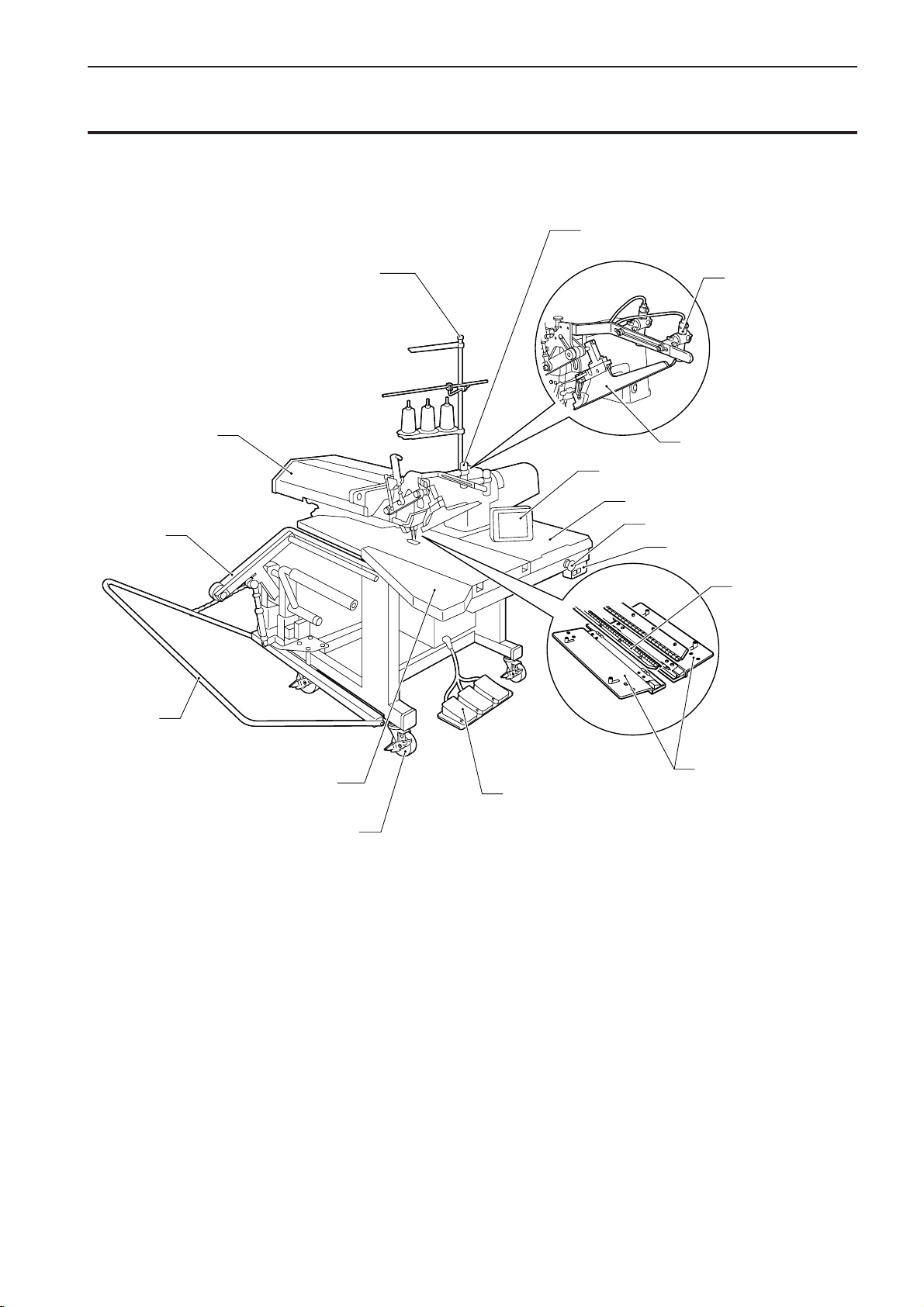

2. Name of parts

Chapter 1 Machine Preparation

Marking light

Stacker

(option)

Guard bar

(option)

Cover

Cotton stand

Marking light

Binder

Control panel

Table R

Emergency stop switch

Power switch

Flap clamp

Table L

Caster

Carriage feed

3-pedal switch

1435S

BAS-6150

11

Chapter 1 Machine Preparation

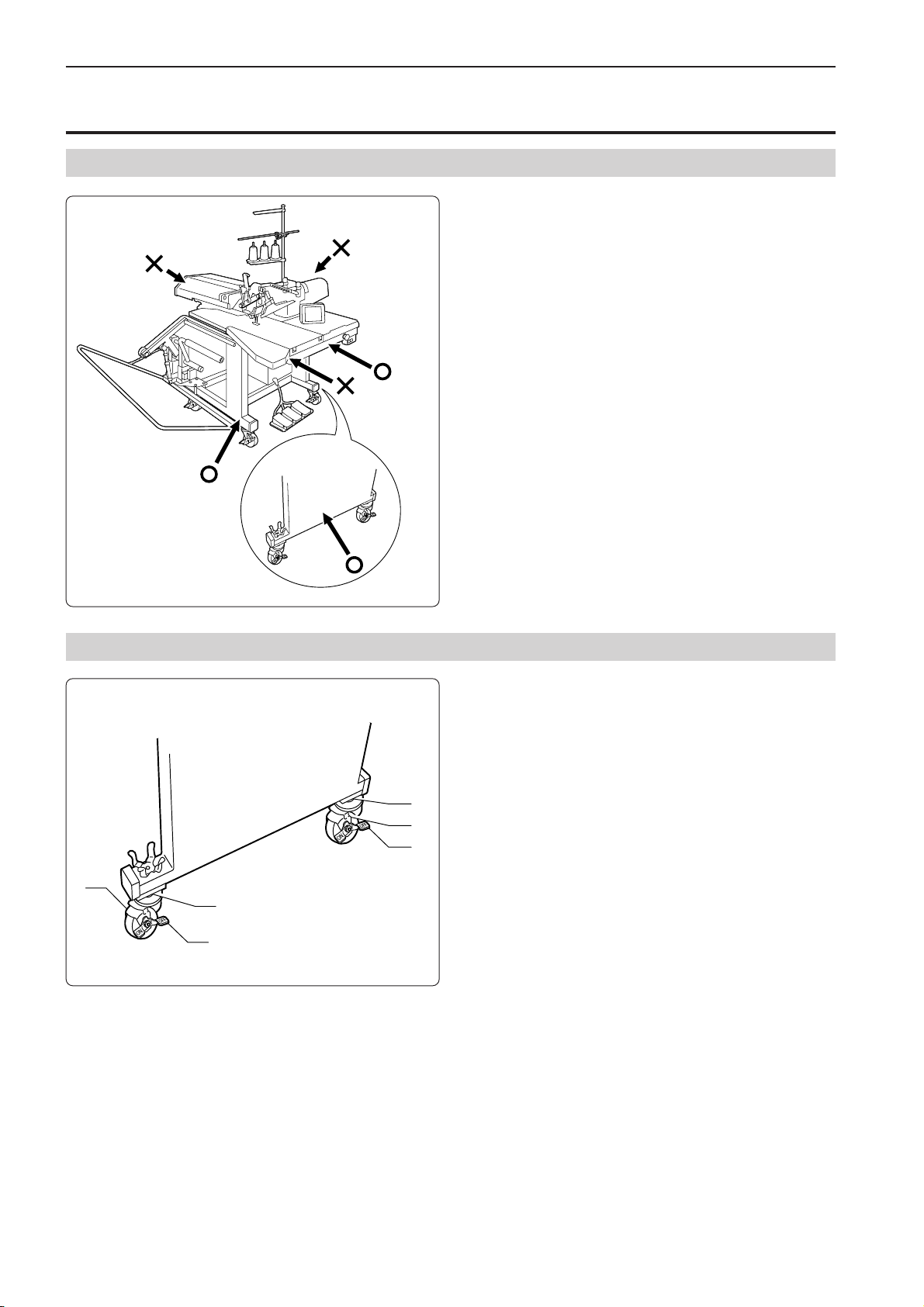

3. Installation

3-1. How to carry the machine

Lift up the main body (the frame) to carry the

machine.

(Note) Be sure not to hold and lift the table, equip-

ment, cover, sub-frame, etc. to lift the power

table.

3-2. How to install the machine

w

q

e

1436S

q

w

e

1437S

1. Loosen nut q and adjust the height of

caster w so that the power table be parallel

with the surface of the floor.

2. Descend lever e in order not to move the

main body and fix caster w.

Up lever e, then the main body can be movable.

(Note) If the floor is not solid enough, the machine

may become unstable. Lay something solid

like concrete plates and precede the installation steps.

12

BAS-6150

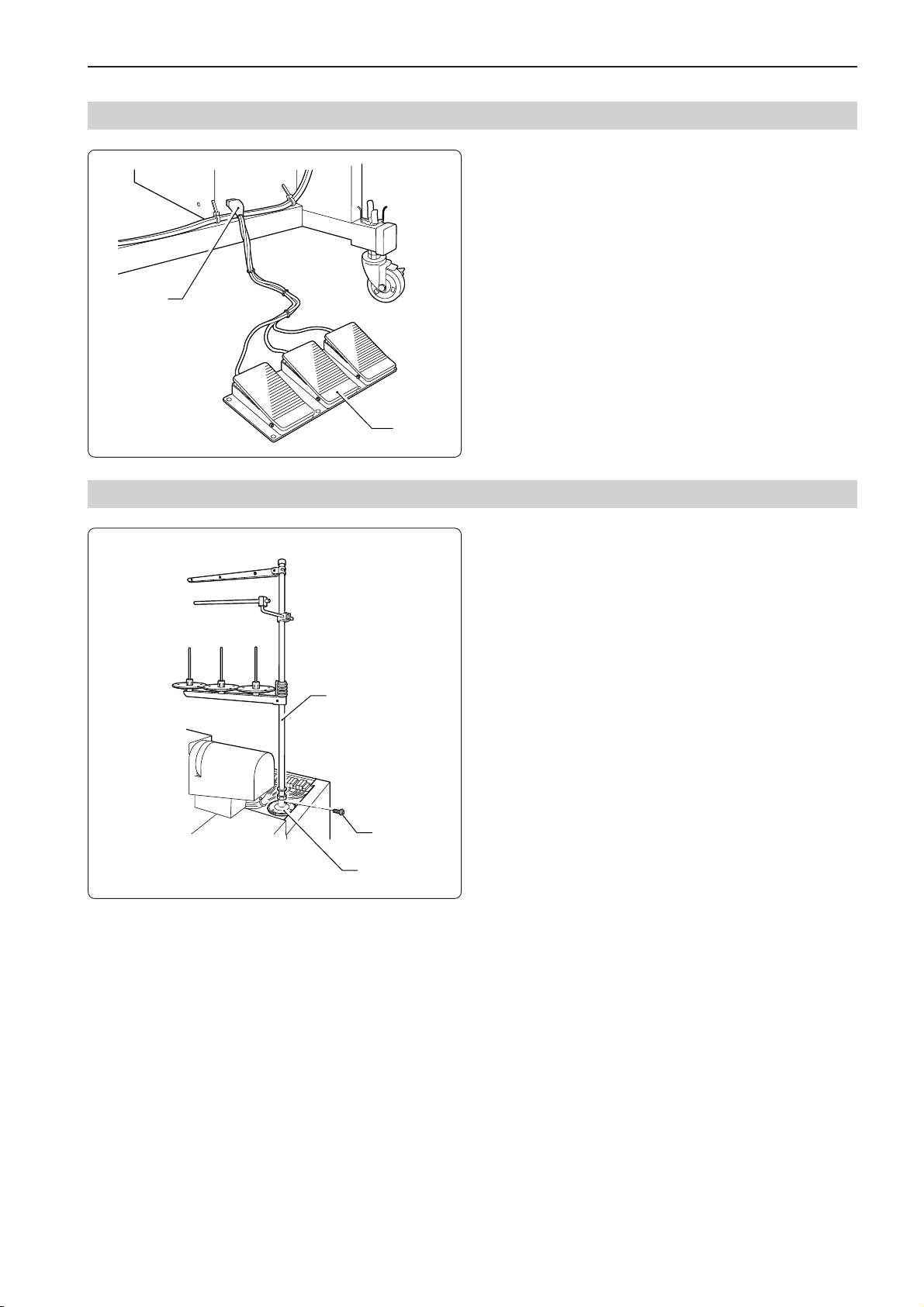

3-3. Installation of the 3-pedal foot switch

Plug connector w of 3-pedal foot switch q into

the connector on the front side.

w

q

1438S

3-4. Attachment of the cotton stand

Chapter 1 Machine Preparation

q

Put cotton stand q into bracket w and fix with

screw e.

e

w

1439S

BAS-6150

13

Chapter 1 Machine Preparation

3-5. Detachment of the emergency stop switch cover

Unscrew two tightening screws q and

detach emergency stop switch cover w.

Attach the emergency stop switch cover to protect the emergency stop switch. Keep the emergency stop switch cover with

good care.

N

N

O

O

F

F

F

F

O

O

w

q

1440S

3-6. Attachment of the stacker (option)

■ How to attach

e

w

1. Set tap plate q at the bottom and the

stacker base w at the top of the leg. Fix

them with four bolts e respectively.

14

q

1441S

BAS-6150

Chapter 1 Machine Preparation

r

u

o

i

t

u

o

2. Attach guard t to guard base y with bolts

r at right and left ends.

3. Attach chain o to stacker i and guard t

with bolt u.

y

t

r

1442S

4. Connect air hose !1 from manifold !0 on

the stacker to plumber module !3 of

regulator !2.

!2

!4

!1

!0

1443S

!3

!1

1444S

BAS-6150

15

Chapter 1 Machine Preparation

5. Connect bar stacker harness !4 to P20 on

main circuit board !5 in the control box.

!4

!5

1445S

16

BAS-6150

3-7. Air pressure setting

When adjustment has to be done with the power switch and air pressure on, pay enough attention to

safety.

Detach the air tube of air source and set the pointer of the pressure gauge to [0] for inspection,

adjustment, and repair of devices using air.

q

Chapter 1 Machine Preparation

CAUTION

1. Joint rubber hose q to union e of air unit

w.

u

e

t

y

r

w

1446S

2. Turn handle r while pulling up it to set air

pressure to 0.49 Mpa.

3. When water is noticed in bottle t, drain

water by pressing the button of the drain

cock y.

(Note) When bulb u is opened, pay due attention to

movement of the stacker bar.

1447S

BAS-6150

17

Chapter 1 Machine Preparation

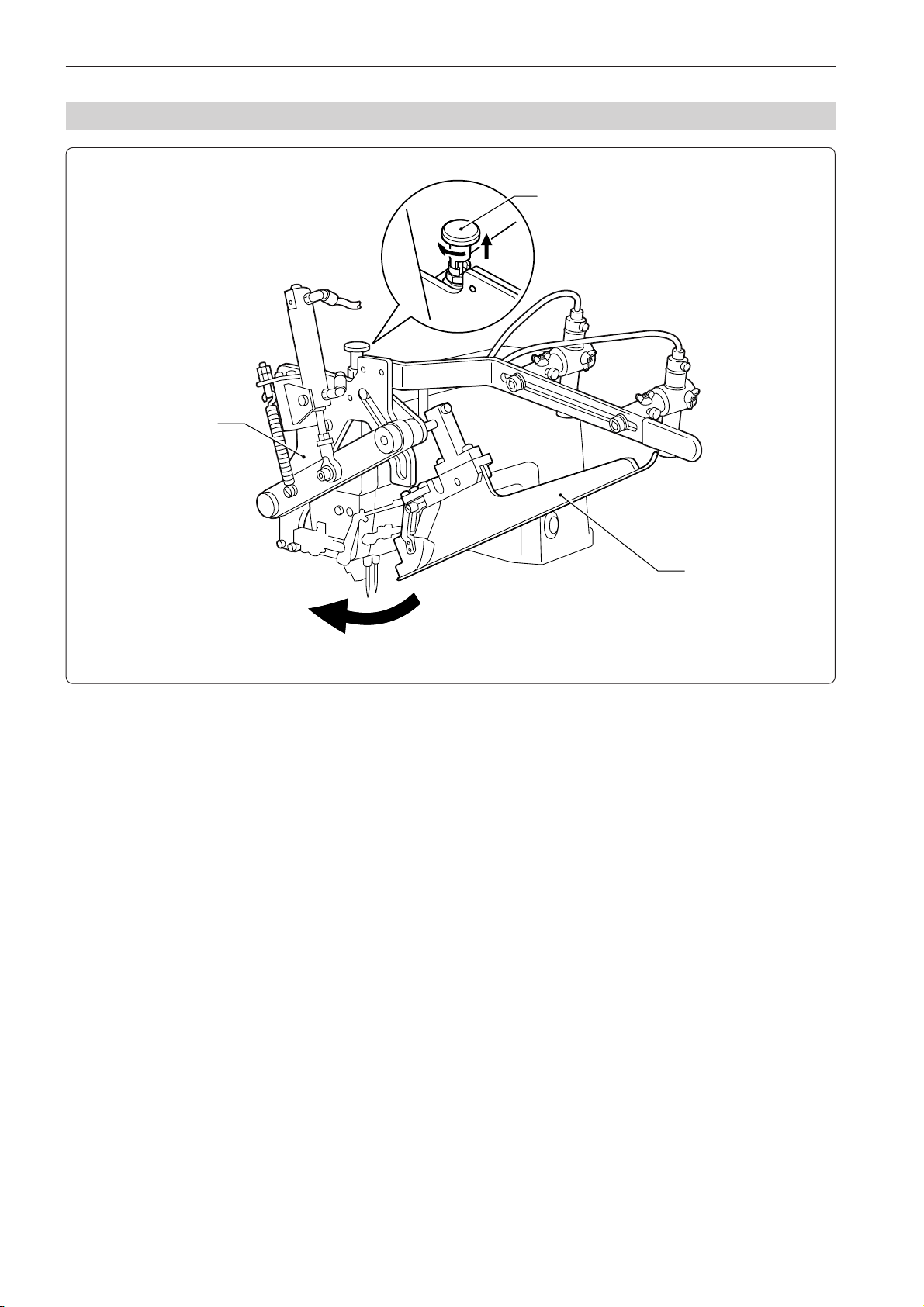

3-8. How to open the main plate

w

q

e

Pull up plunger q and lock it, and then open main plate w.

(Note) Open or close main plate w with binder e held up by hand not to touch the needle when the binder e is in

down position. ( Binder e goes down when the power or air supply is OFF.)

1448S

18

BAS-6150

4. Preparation for sewing

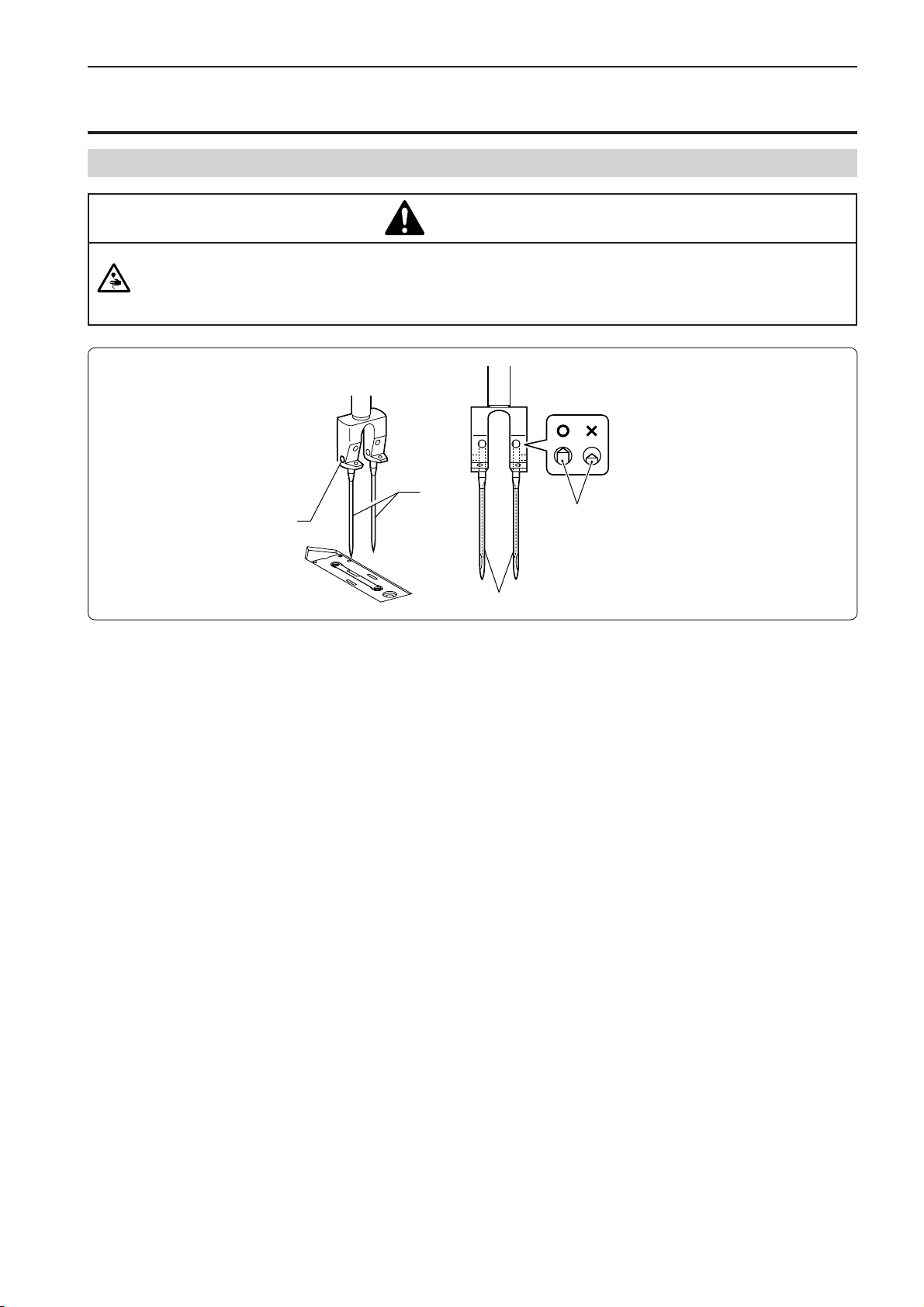

4-1. How to mount the needle

CAUTION

Turn off the power switch when needles are mounted. Otherwise, unintended press on the foot switch

may cause injury.

w

q

Chapter 1 Machine Preparation

w

Long groove

1. Rotate the pulley to lift the needle to the highest point.

2. Pull up the plunger and lock it, and then open the main plate. (Refer to "3-8. How to open the main

plate")

3. Loosen set screw q.

4. Thrust needles w up straight with their long grooves facing to the inside and fasten up set

screw q.

1449S

BAS-6150

19

Chapter 1 Machine Preparation

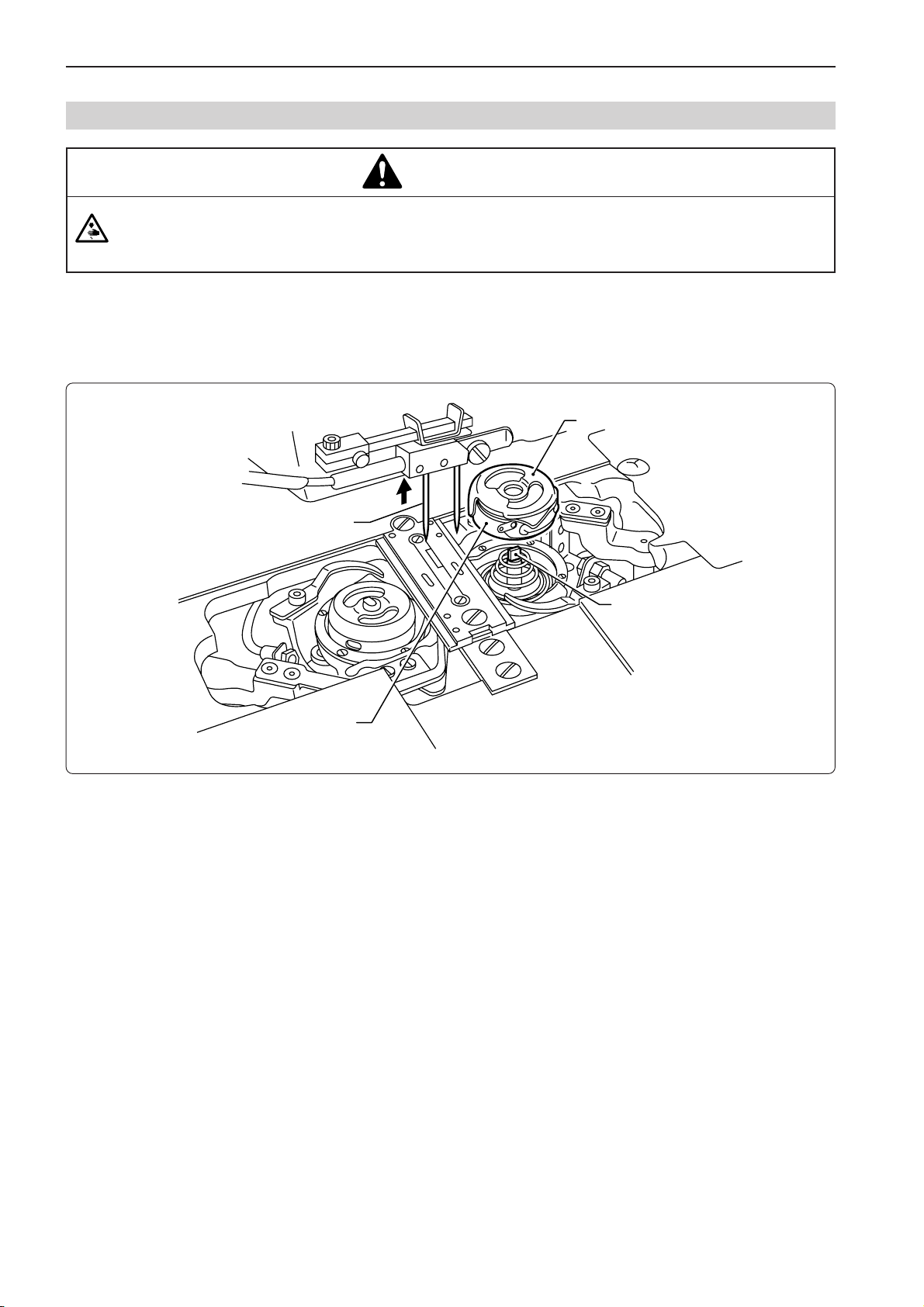

4-2. How to dismount the bobbin or bobbin case

CAUTION

Turn off the power switch when the bobbin or bobbin case is dismounted. Otherwise, unintended

press on the foot switch may cause injury.

Proceed to following steps at the occurrence of the lower thread breakage after an error is reset

by pressing the reset switch. After finishing with the steps, proceed to the next steps in

accordance with “4-3. How to wind the lower thread” and “4-4. How to thread the lower thread”.

e

q

w

r

1. Rotate the pulley to lift needle q to the highest point.

2. Open the slide plate.

3. Dismount bobbin case e and bobbin r after pulling up rotary hook hold w.

1450S

20

BAS-6150

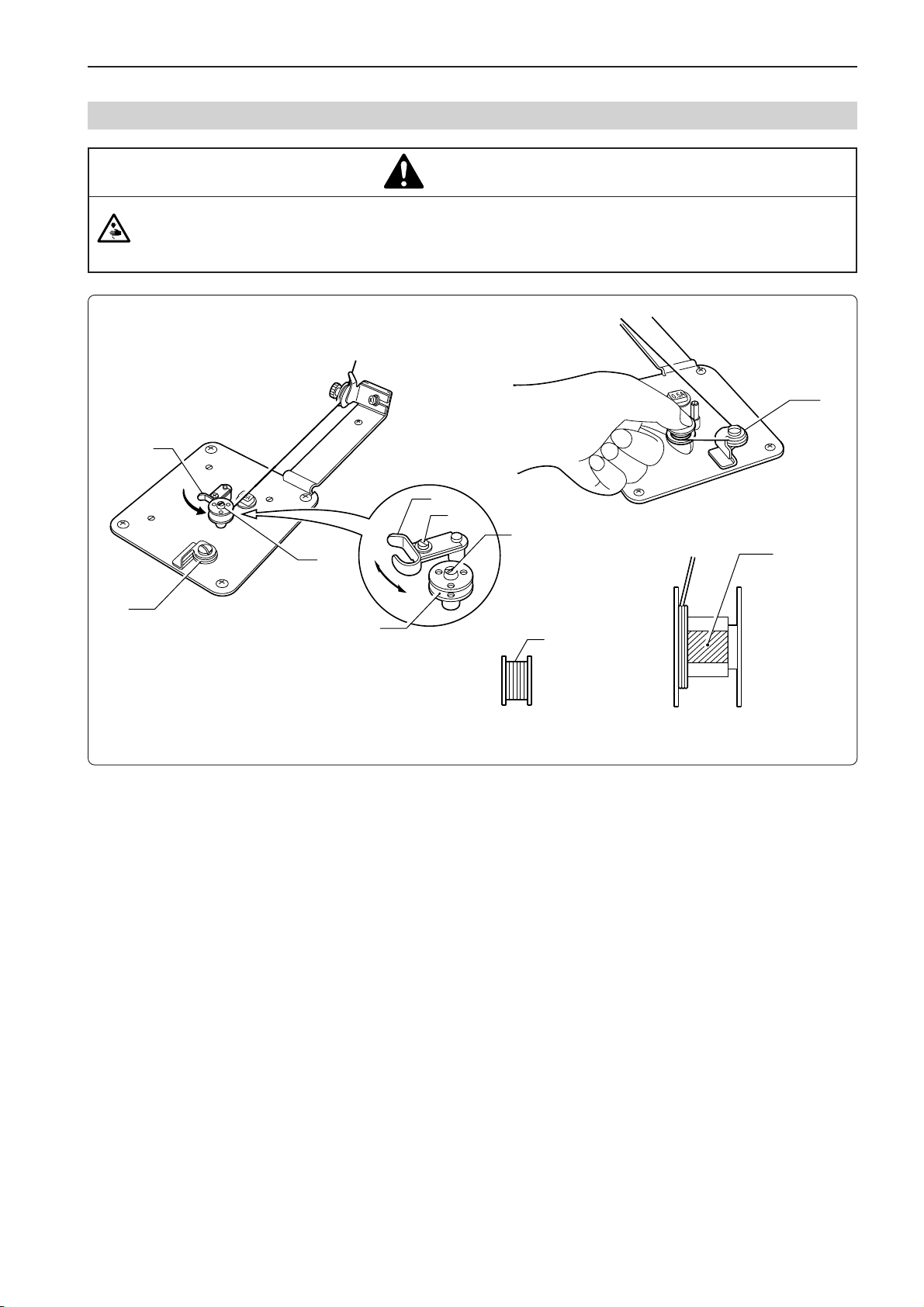

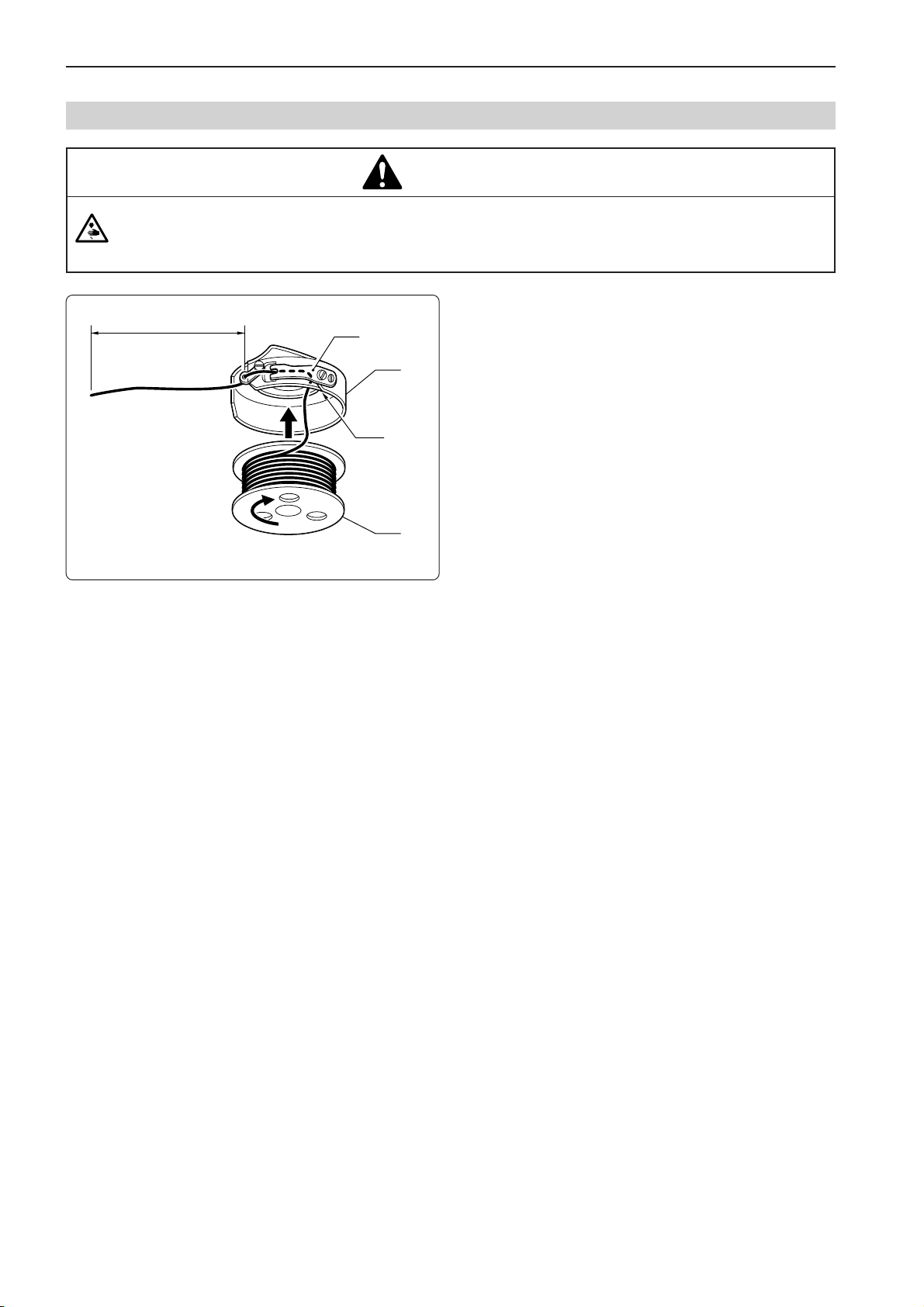

4-3. How to wind the lower thread

Be sure not to touch moving parts nor push them with objects while winding threads.

Otherwise, any touch or push may cause damage to the machine or injury to human body.

e

Chapter 1 Machine Preparation

CAUTION

t

1452S

Mirror

t

w

q

e

r

1451S

w

80%

Thread winding

amount

Lower thread remaining amount

1454S 1453S

detection bobbin (option)

1. Turn on the power switch.

2. Thrust empty bobbin q into shaft w.

3. Thread the end of thread through the cotton stand as illustrated and wind up the end of the

thread onto bobbin q several times.

4. Move lever e to the arrow pointed direction.

The automatic switch sets shaft w to rotate and start winding threads.

5. When thread rolling is over, lever e returns to original position and thread roll axis w stops.

6. Loosen set screw r and move lever e to right and left for adjustment of thread winding

amount of bobbin q.

7. Detach bobbin q from shaft w. Cut the thread while winding the middle part of thread onto

thread nipper t.

At the next winding of the thread, pick up the end of the thread from thread nipper t and roll it onto bobbin q.

(Note) • The winding amount of thread should be less than 80 % of full roll.

• If threads are wound onto the lower thread remaining amount detection bobbin (option), start winding

from the end of bobbin because a mirror is placed on the center of the bobbin.

BAS-6150

21

Chapter 1 Machine Preparation

4-4. How to thread the lower thread

CAUTION

Turn off the power switch when the bobbin is to be attached. Otherwise, unintended press on the foot

switch may cause injury.

50mm

r

q

e

1. Cover bobbin w with bobbin case q.

2. Let the thread through slit e and go

through under timing spring r.

3. Pull out the thread by approx. 50 mm from

the thread hole at the end of spring r.

4. Put bobbin case q and bobbin w into the

rotary hook.

w

1455S

22

BAS-6150

Chapter 1 Machine Preparation

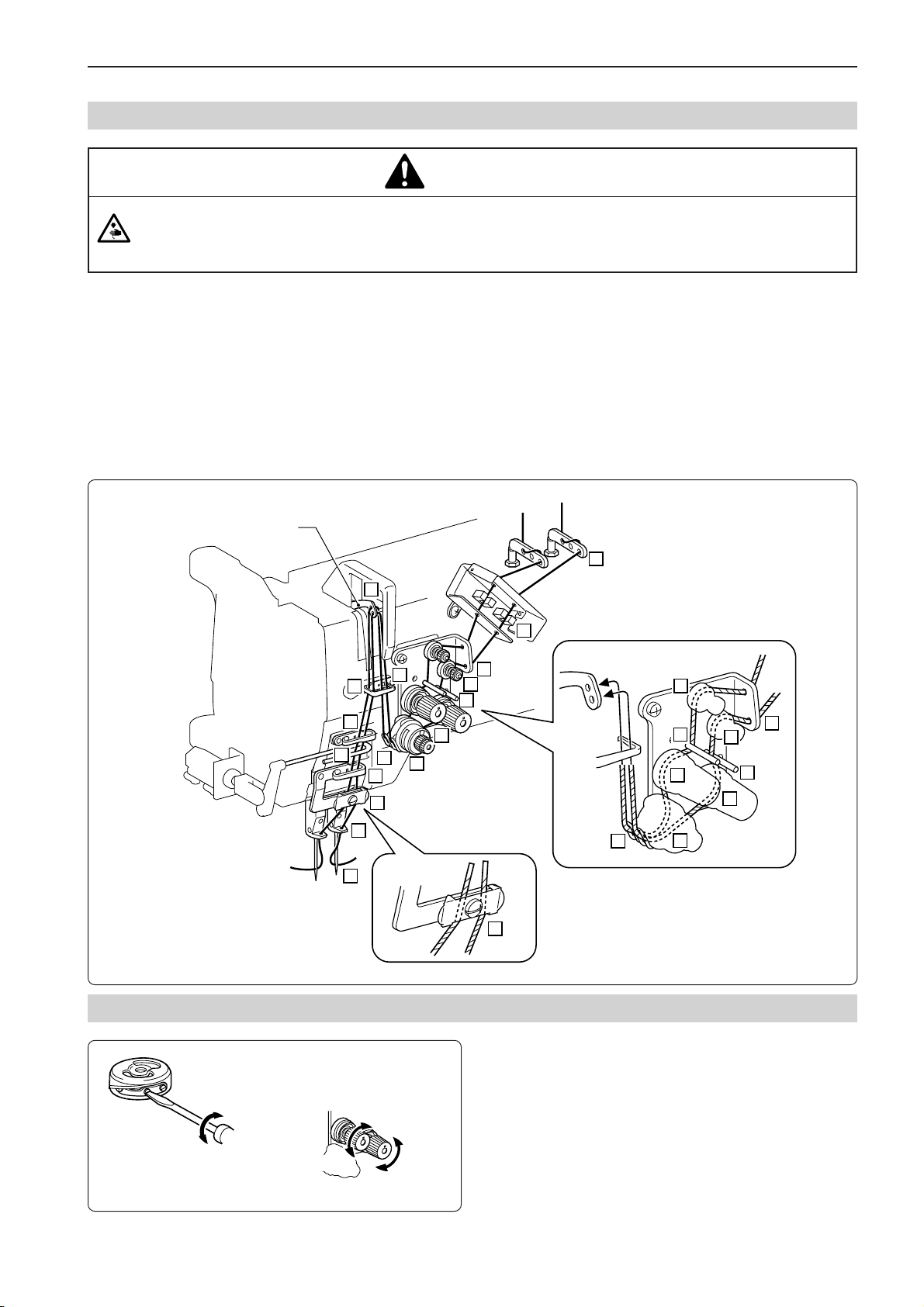

4-5. How to thread the upper thread

CAUTION

Turn off the power switch for threading the upper thread. Otherwise, unintended press on the foot

switch may cause injury.

Proceed to the following steps at the occurrence of upper thread breakage after the error is reset

by pressing the reset switch.

1. Lift up the plunger and lock it, and then open the main plate.

2. Rotate the pulley to set the thread take-up q at the highest position and start threading from

the tread take-up on the left.

Threading at the highest position is for easy threading and good prevention of the thread come-off at sewing start up.

*The upper thread breakage

detection sensor is an option.

q

11

11

12

12

13

13

17

• Push the thread into a needle hole

inside to outside.

• Pull out the end of thread by about

50mm.

1

10

9

9

8

8

7

14

14

15

16

3

4

5

6

6

15

*

Be sure to pass the thread through

2

2

between timing plates.

4

4

5

5

6

8

7

3

4

4

5

6

1456S

4-6. Adjusting the thread tension

Weaker

Stronger

1630S

Weaker

Stronger

Weaker

Stronger

1631S

After the lower thread tension has been

adjusted, adjust the upper thread tension.

BAS-6150

23

Chapter 1 Machine Preparation

4-7. Retention of upper and lower threads

1. Press the "FEED" key q to move the

q

e

w

carriage feed to the feed position.

y

50mm

r

t

u

1457S

1458S

2. Open the slide plate.

3. Cover the bobbin with the bobbin case.

Place them into the rotary hook, leaving the

end of the thread t out about 50 mm and

pull down the nipper.

Pull up each lower thread through a thread

hole and press "BBN. THREAD CUT" key

w to retain the threads.

(Note) Pay enough attention not to touch center knife

y.

4. Close the slide plate.

5. By pressing down the "NDL. THREAD CUT"

key e, place two upper threads u onto

upper thread trimmer knife i.

24

i

6. By releasing the "NDL. THREAD CUT" key

e, revert the upper thread trimmer knife.

7. Press the "FEED" key q to move the

carriage feed to the standby position.

* When the setting for the memory switch 3 (environment

parameter No.63) is set to ON, press the "ENTER" key r

with the "FEED" key q being pressed.

1459S

BAS-6150

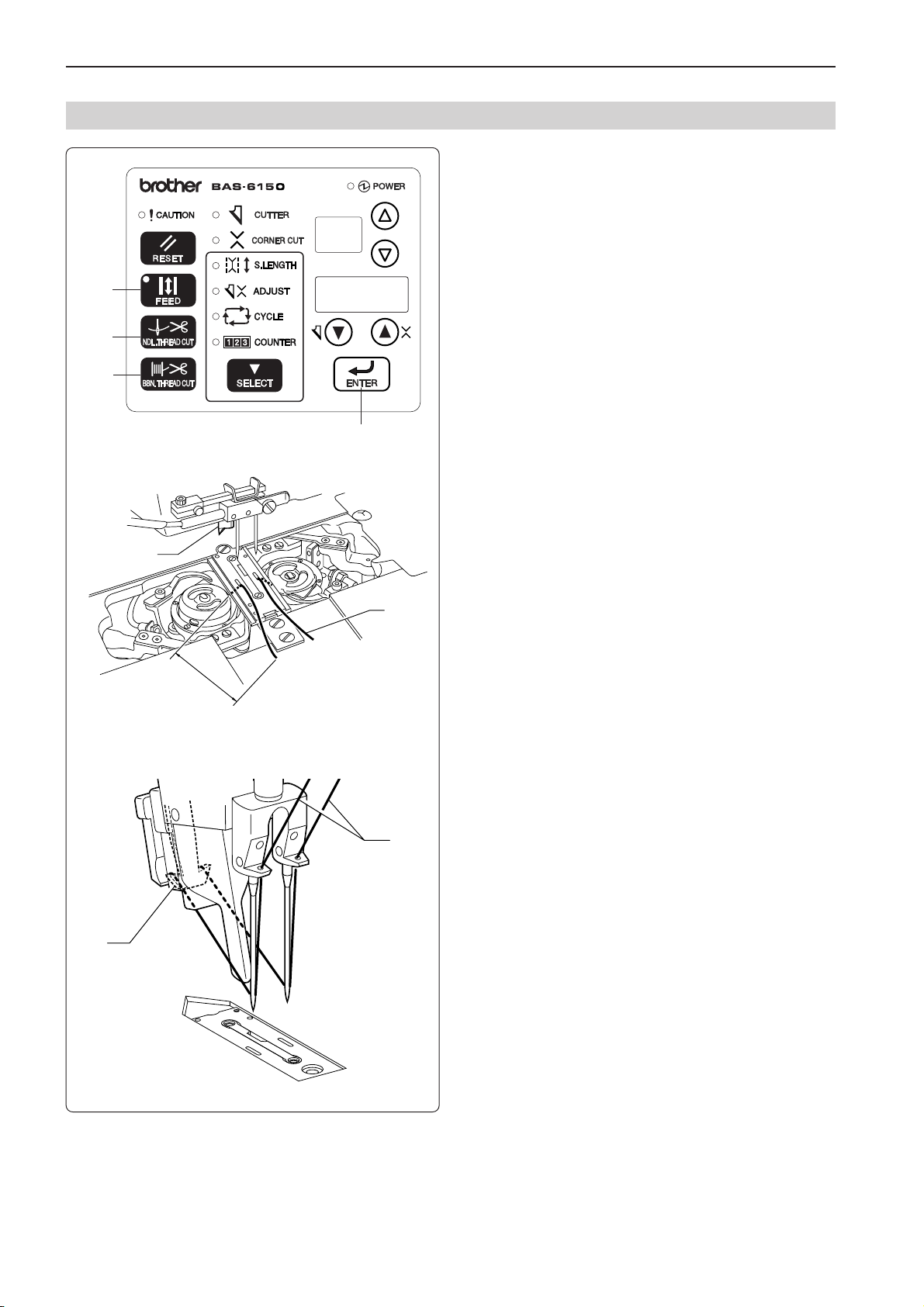

4-8. Adjusting the thread tension spring

4-8-1. Operating range of thread take-up spring

Chapter 1 Machine Preparation

The standard operating range for thread takeup spring L q and thread take-up spring R w

is 5-10mm for both springs.

5-10mm

q

w

Less

More

1632S 1633S

4-8-2. Thread take-up spring tension

0.15-0.35N

q

<L >

q

w

1634S

<R >w

i

w

o

q

t

y

Weaker

u

y

Stronger

Stronger

Weaker

r

e

1635S

1. Loosen the left and right screws e, and

then turn the left and right thread take-up

spring stoppers r to adjust the operating

range.

2. Tighten the screws e.

The standard tension for thread take-up spring

L q and thread take-up spring R w is 0.15-

0.35N for both springs.

<Thread take-up spring L q>

1. Open the face plate.

2. Loosen the screw t.

3. Loosen the knob y, and then turn the

thread tension stud u to adjust the tension.

4. Tighten the screw t, and then tighten the

knob y.

<Thread take-up spring R w>

1. Loosen the set screw i.

2. Loosen the knob y, and then turn the

adjustment knob o to adjust the tension.

3. Tighten the screw i, and then tighten the

knob y.

4-8-3. Thread take-up spring operation timing

qw

!1

!0

1636S

!1

!0

Earlier

Later

y

1637S

The standard operation timing for thread takeup spring L q and thread take-up spring R w

is the middle position within the operating

range of the thread take-up spring guide !0.

1. Loosen the set screw !1.

2. Loosen the knob y, and then turn the left

and right thread take-up spring guides !0

to adjust the tension.

3. Tighten the screw !1, and then tighten the

knob y.

BAS-6150

25

Chapter 1 Machine Preparation

4-9. Initialization at the time of power ON

q

e

w

1457S

Initialization of the unit memory can be performed by pressing a certain key when the power

supply switch is turned ON.

4-9-1. Initialization of programs

Initialization is performed for memories listed below:

All programs

All cycle programs

Production counter

Lower thread counter

1. While holding down "RESET" key q and "ENTER" key w, turn on the power switch. The start

switch is not pressed.

* Hold the DIP switch B-7 and B-8 to be ON to initialize the [Environment parameter]. (Refer to Chapter 8 Dip switch.)

2. The gauge (needle gauge) setting screen appears. Select the gauge size (needle gauge) by

pressing

key.

3. Initialization is performed as for the memory by pressing "ENTER" key w.

4-9-2. Initialization of the counter

When you turn on the power switch while holding down "RESET" key q and "SELECT" key

e, both counters for the lower thread and the production will be reset to 0.

26

BAS-6150

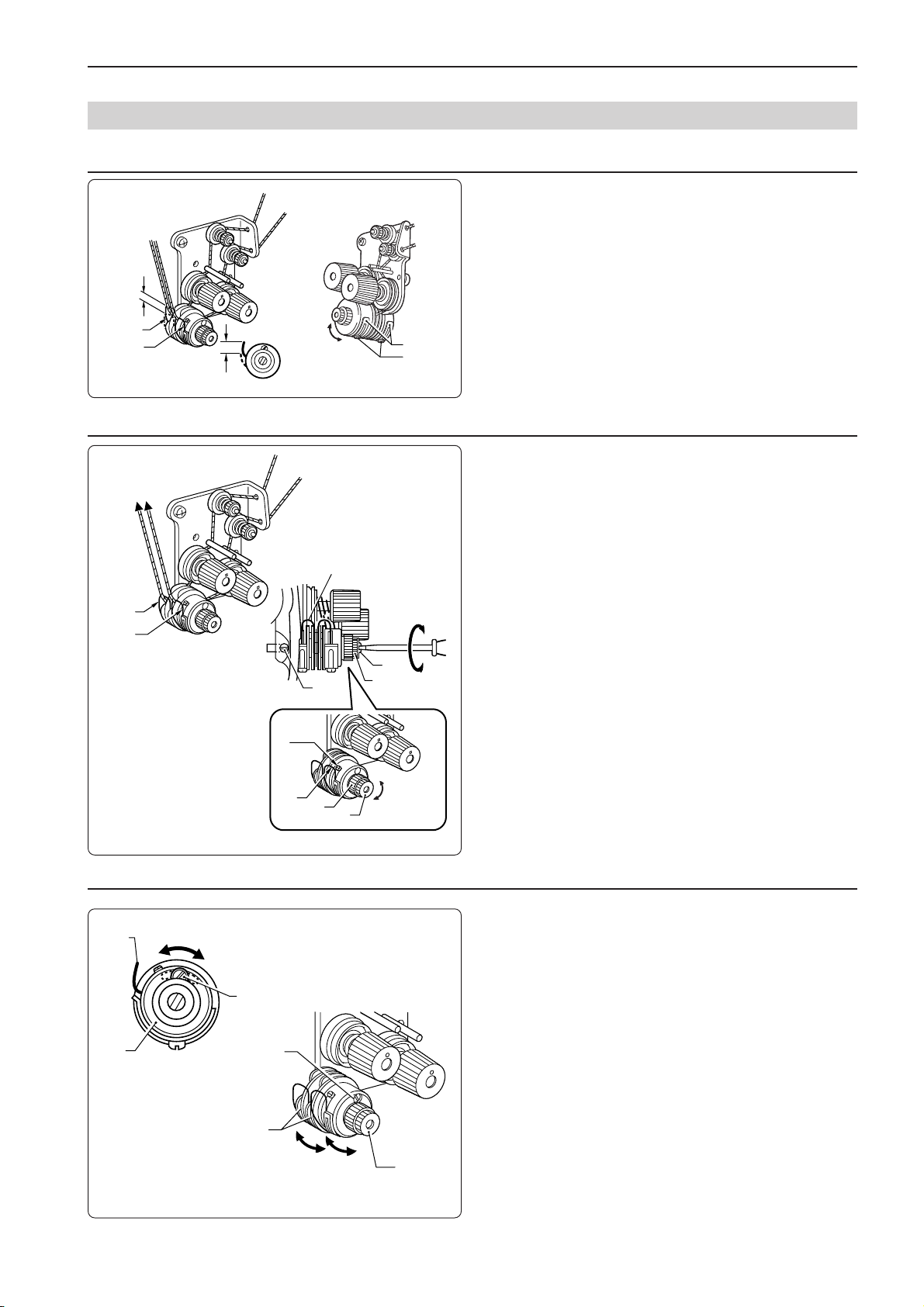

Chapter 2 Sewing flow

Chapter 2 Sewing flow

1. Outline of operation

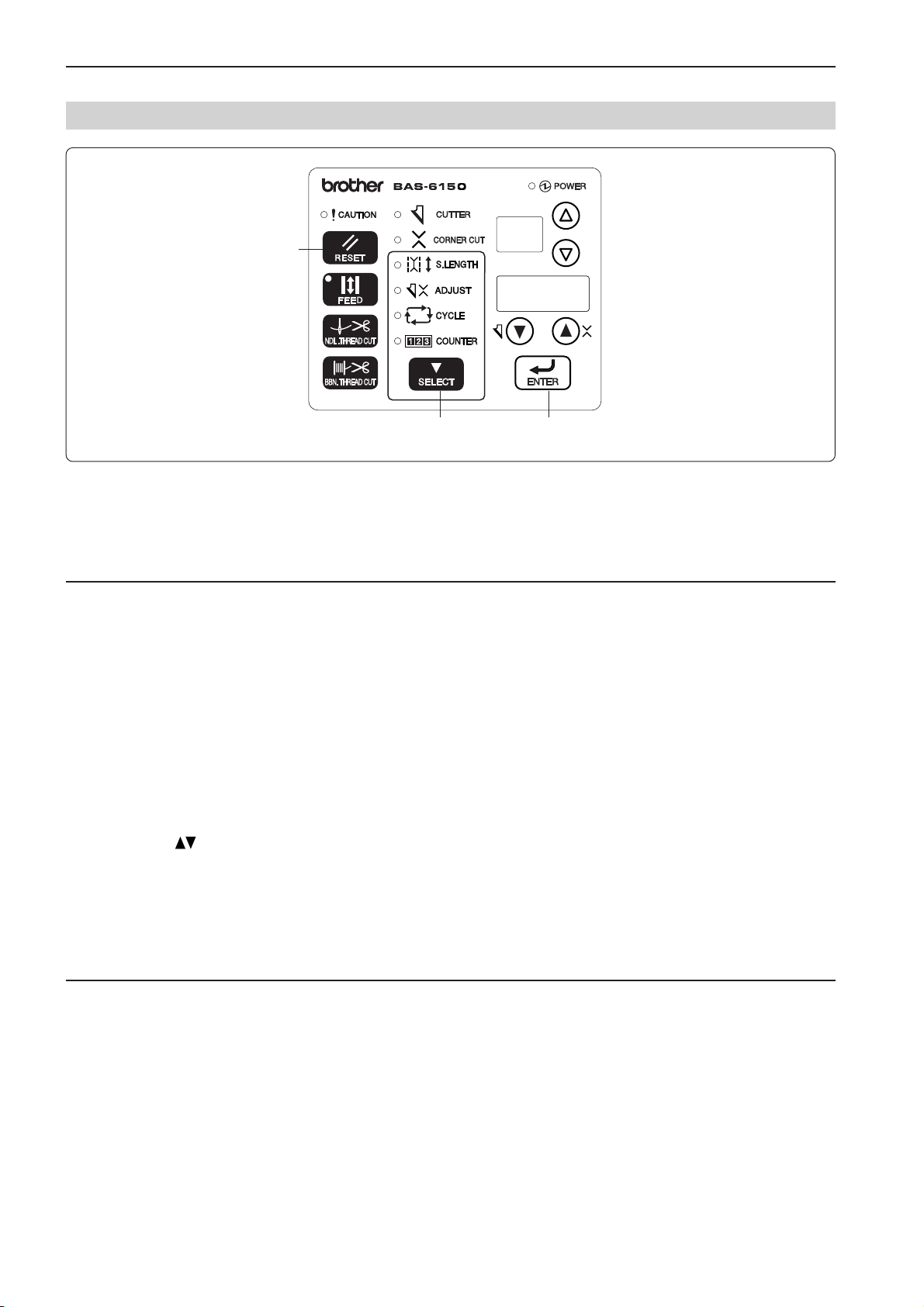

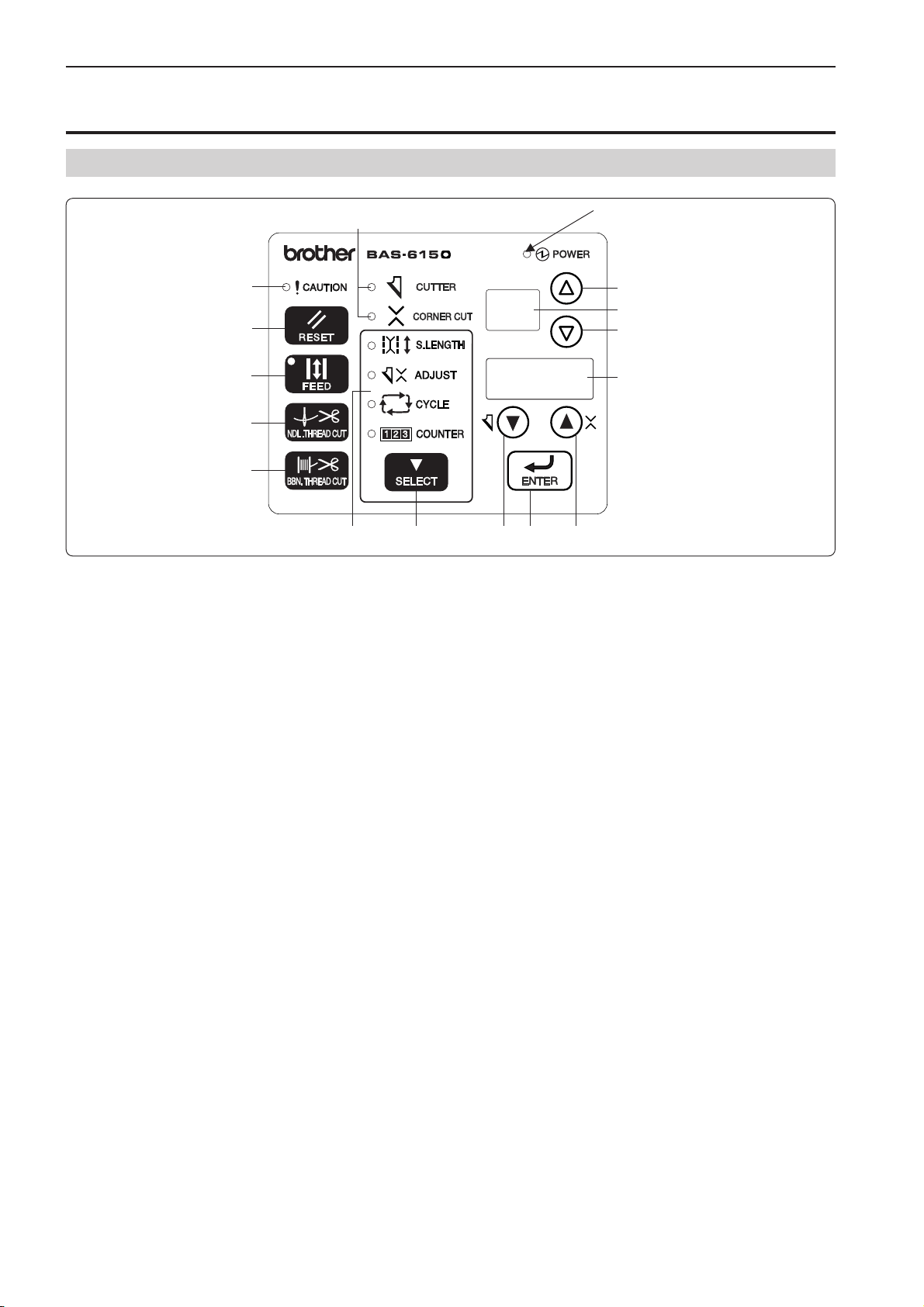

1-1. Description of the panel

The lamp turns on when the power

supply switch is set to ON.

u

!0

u

!1

!4

q

w

e

r

!2

t

y io!3

q "RESET"

Press the "RESET" key when an error is displayed or the machine stops due to a trouble. The

error is released when the cause for the trouble is solved. If pressed while the lower thread

counter ([COUNTER] LED is ON) is displayed, the production counter appears.

1457S

w "FEED"

Press the "FEED" key to move the carriage feed forward and backward. If pressed when the

carriage feed is placed at other positions than the feed position, the carriage feed moves to

the feed position. If pressed when the carriage feed is placed at the feed position, it moves to

the standby position. When the carriage feed is placed at the feed position, LED blinks.

* When the setting for the memory switch 3 (environment parameter No.63) is set to ON,

press the "ENTER" key y with the "FEED" key w being pressed.

e "NDL THREAD CUT" (upper thread cut)

The upper knife comes out only while the key is pressed and trims the upper thread as it

retracts when the key is released when the carriage feed is at the feed position.

r "BBN.THREAD CUT" (lower(bobbin) thread cut)

The lower knife comes out only while the key is pressed and trims the lower thread as it

retracts when the key is released when the carriage feed is at the feed position

t "SELECT"

Menu display !3 is changed. If pressed while the production counter is displayed, the

production counter is set to 0.

y "ENTER"

Contents of the displayed menu are set to be configurable.

28

BAS-6150

Loading...

Loading...