Brother MFC4800, FAX2800 Service Manual

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODEL: FAX2800/MFC4800

© Copyright Brother 2001

All rights reserved.

No part of this publication may be reproduc ed in any

form or by any means without perm ission in writing

from the publisher.

Specifications are subject to change without notice.

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation,

and maintenance of the Brother facsimile equipment. It includes information required for field

troubleshooting and repair--disassembly, reassembly, and lubrication--so that service personnel

will be able to understand equipment function, to rapidly repair the equipment and order any

necessary spare parts.

To perform appropriate maintenance so that the facsimile equipment is always in best condition

for the customer, the service personnel must adequately understand and apply this manual.

This manual is made up of six chapters and appendices.

CHAPTER 1 GENERAL DESCRIPTION

CHAPTER 2 INSTALLATION

CHAPTER 3 THEORY OF OPERATION

CHAPTER 4 DISASSEMBLY/REASSEMBLY AND LUBRICATION

CHAPTER 5 MAINTENANCE MODE

CHAPTER 6 ERROR INDICATION AND TROUBLESHOOTING

Appendix 1. EEPROM Customizing Codes

Appendix 2. Firmware Switches (WSW)

Appendix 3. Circuit Diagrams

This manual describes the models and their versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

SAFETY INFORMATION

Laser Safety (110-120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health

and Safety Act of 1968. This means that the printer does not produce hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective housings and

external covers, the laser beam cannot escape from the machine during any phase of user

operation.

CDRH Regulations (110-120V Model only)

The Center for Device and Radiological Health (CDRH) of the US Food and Drug Administration

implemented regulations for laser products on August 2, 1976. These regulations apply to laser

products manufactured from August 1, 1976. Compliance is mandatory for products marketed in

the United States. The label shown below indicates compliance with the CDRH regulations and

must be attached to laser products marketed in the United States.

The label for Chinese products

MANUFACTURED: JUNE 2001 C

BROTHER CORP. (ASIA) LTD.

BROTHER BUJI NAN LING FACTORY

Gold Garden Industry, Nan Ling Village, Buji,

Rong Gang, Shenzhen, China.

This product complies with FDA radiation

performance standards, 21 CFR Subchapter J.

CHAPTER

GENERAL DESCRIPTION

1

CHAPTER 1 GENERAL DESCRIPTION

CONTENTS

1.1 EQUIPMENT OUTLINE ...................................................................................................1-1

1.1.1 External Appearance and Weight ........................................................................1-1

1.1.2 Components.........................................................................................................1-1

1.2 SPECIFICATIONS............................................................................................................1-2

1.1 EQUIPMENT OUTLINE

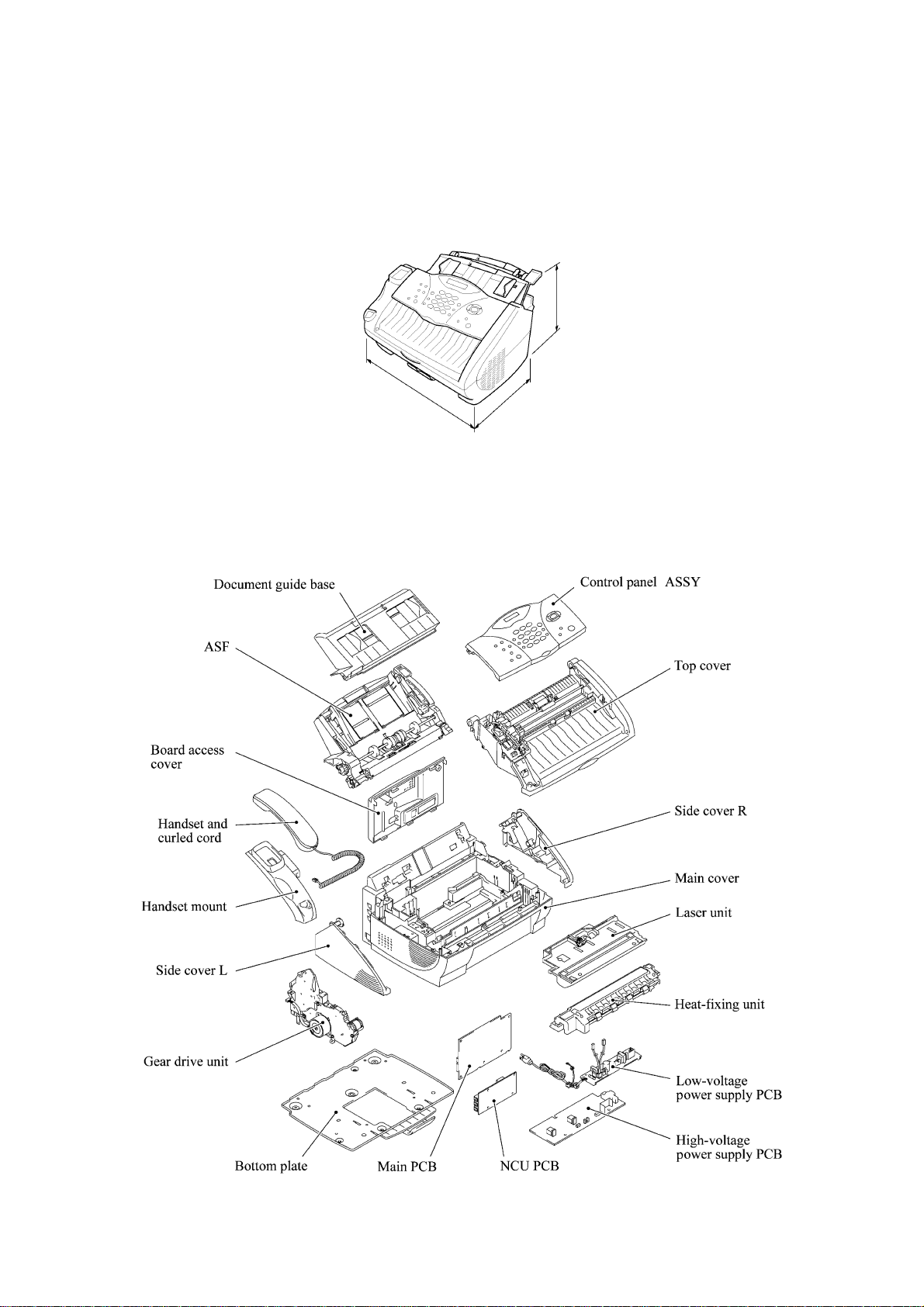

1.1.1 External Appearance and Weight

The figure below shows the equipment appearance and approximate dimensions.

(H)

243 mm

9.6"

(W)

395 mm

15.6"

(including handset)

Weight: Machine proper Approx. 7.5 kg

Machine (incl. drum unit & toner cartridge) Approx. 8.7 kg

In package Approx. 11 kg

1.1.2 Components

The equipment consists of the following major components:

(D)

359 mm

14.1"

1-1

1.2 SPECIFICATIONS

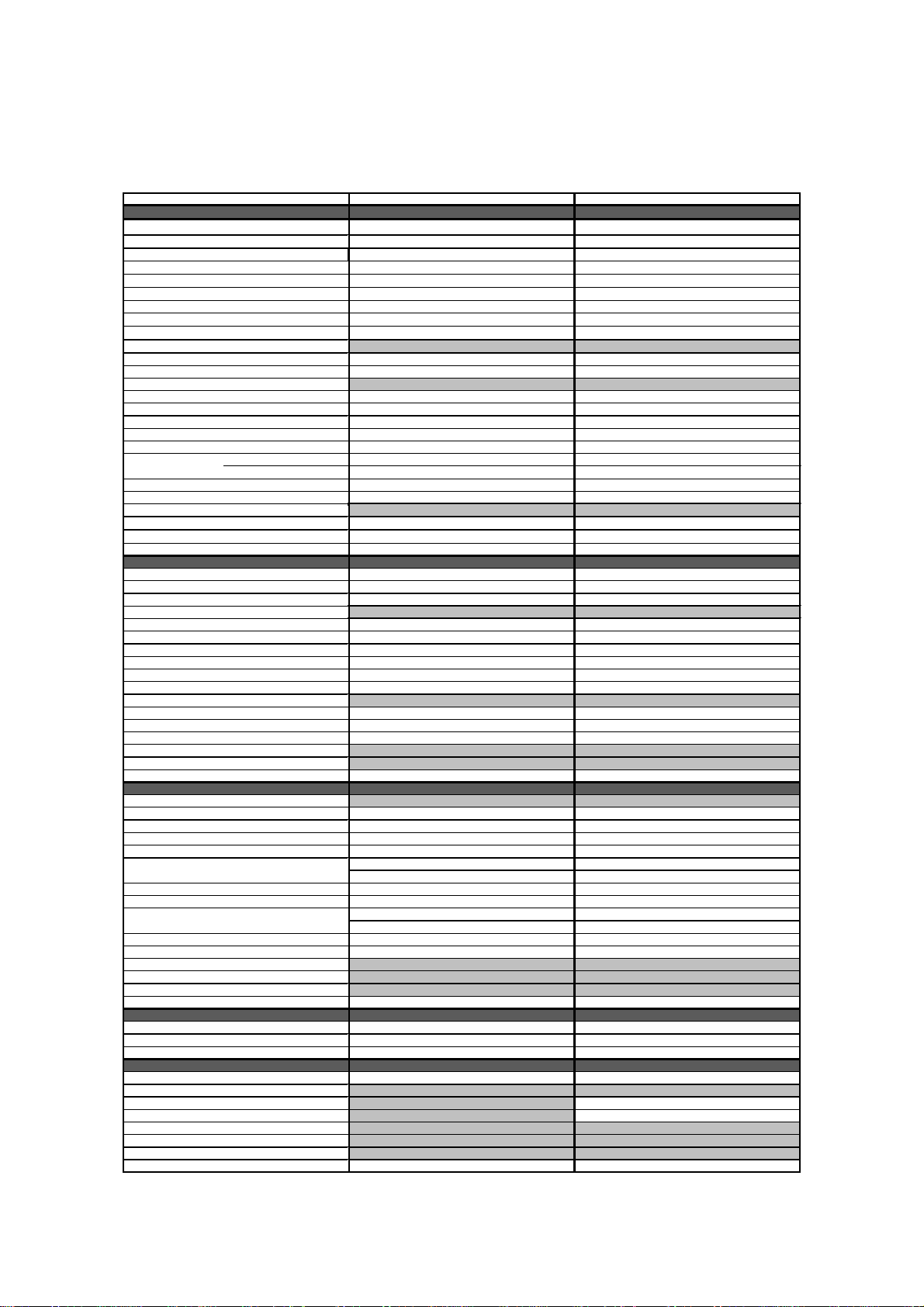

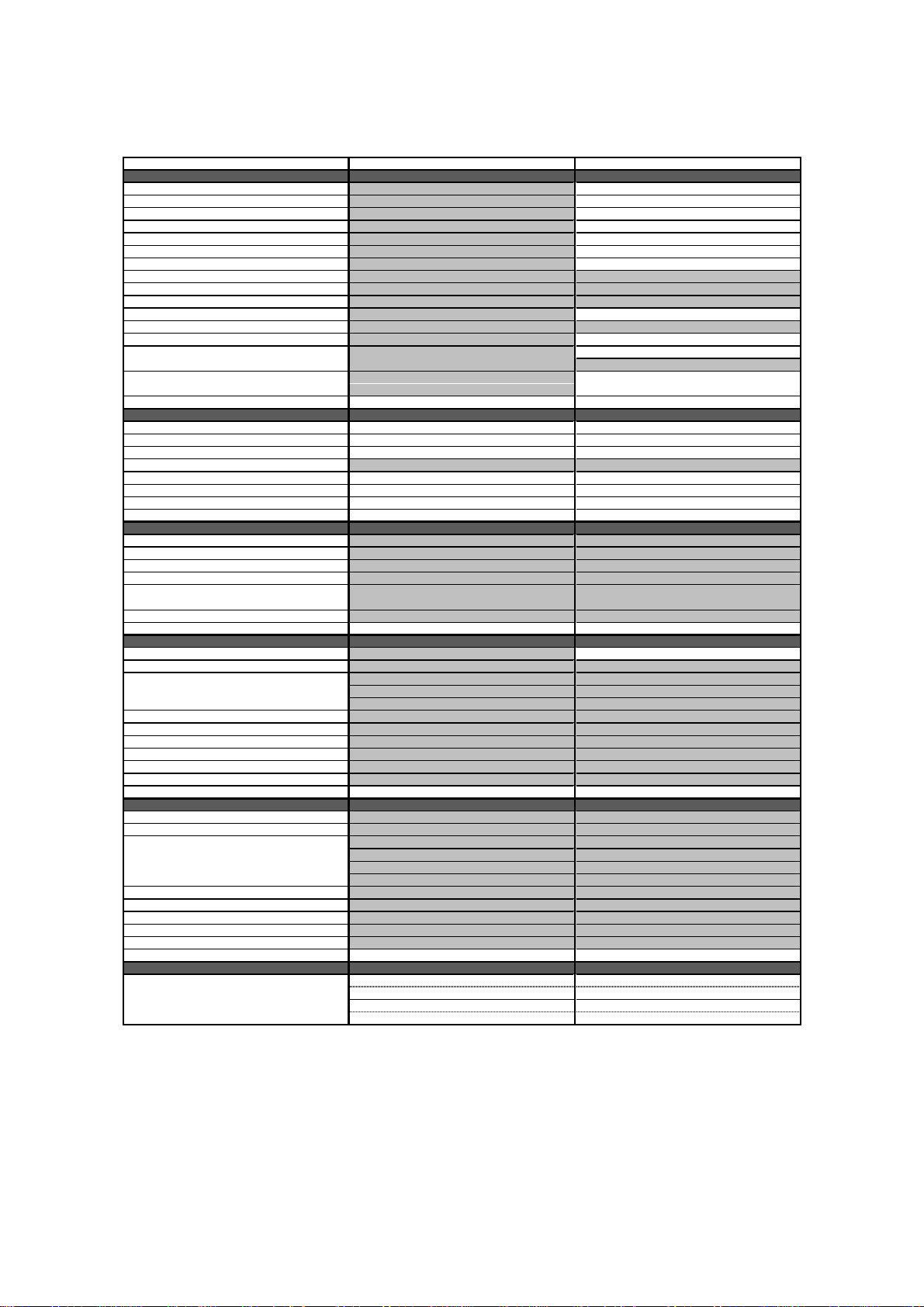

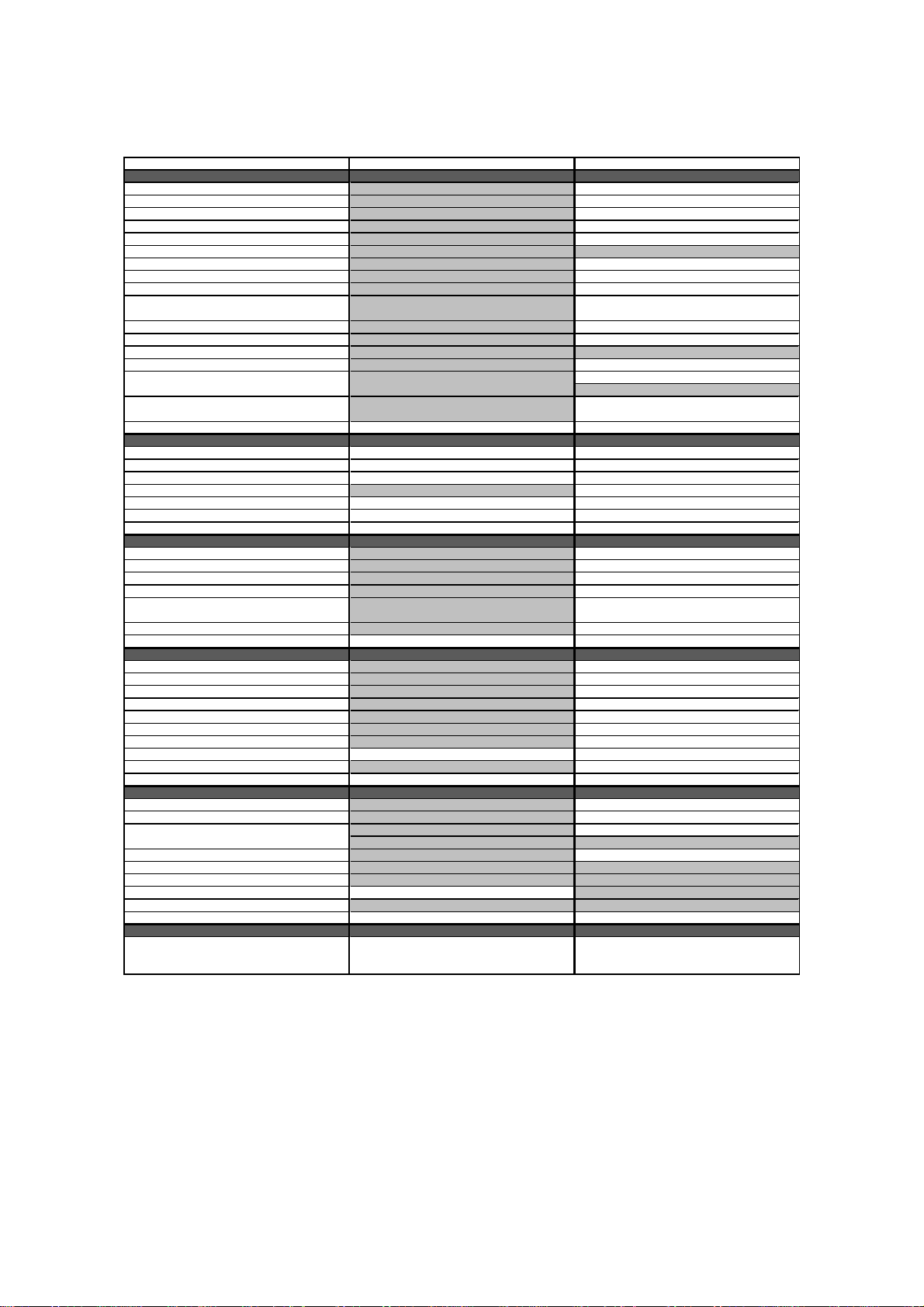

FAX2800 (FAX2850)/FAX2900 (1/2)

Model Name

GENERAL

Print Engine Laser (YL4) Laser (YL4)

Modem Speed(bps) 14,400(Fax) 14,400(Fax)

Transmission Speed(sec.) 6(Brother#1,MMR) 6(Brother#1,MMR)

ITU-T Group G3 G3

Coding Method MH/MR/MMR MH/MR/MMR

Input/Output Width 5.8"-8.5"/3.5"-8.5" 5.8"-8.5"/3.5"-8.5"

Input/Output Length 5"-14"/5"-14" 5"-14"/5"-14"

ADF(pages) up to 20 up to 20

LCD Size 16 Characters 16 Characters x 1 Line

LCD Backlight No No

Backup Clock Yes (1 hour) Yes (1 hour)

Memory Capacity (physical) 2MB (RAM) 4MB (RAM)

Optional Mem ory N/A N/A

Dimensions w/ Carton (WxDxH) 519mm x 454 mm x 375 mm 519mm x 454 mm x 375 mm

Dimensions w/o Carton (WxDxH) 395mm x 359mm x 243mm 395mm x 359mm x 243mm

Weight w/ Carton 11 Kg 11 Kg

Weight w/o Carton 7.5 K g 7.5 Kg

Color Gray 1495 Gray 1495

Operating Environment Temperature 5 - 32.5 degrees Centigrade 5 - 32.5 degrees Centigrade

Humidity 20 - 80 % 20 - 80 %

Power Source 120 VAC, 50/60Hz 120 VAC, 50/60Hz

Power Consumption (Sleep/Standby/Peak) 10W/ 70W/ 940W or less 10W/ 70W/ 940W or les s

On/Off Switch No No

Starter Toner Yes (1,000 pages) Yes (1,000 pages)

Warm Up Time Approx. 12 sec Approx. 12 sec

TELEPHONE

Handset Yes Yes

One-Touch D ia l 8 8

Speed Dial 100 120

Speaker Phone N/A N/A

Chain Dialing Yes Yes

Caller ID Yes Yes

Call Waiti n g Caller ID Yes Yes

Distinct ive Rin ging Yes Yes

Call Manage Yes Yes

Hold/Mute Key Yes Yes

Power Failure Dialing N/A N/A

Speaker Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Ring Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Handset Volume Yes (2 steps + OFF + Amplify) Yes (2 steps + OFF + Amplify)

PBX Feature N/A N/A

Transfer Method No No

FAX

Internet FAX N/A N/A

Easy Receive/Fax Detect Yes Yes

Fax/Tel Switch Yes Yes

Enhanced Remote Activate Yes Yes

Scan Speed (sec./page, A4:Standard) Approx. 3.5 Approx. 3.5

Memory Transmission (Brother#1 Chart) 90 Pages(MMR/Standard Resolution) 220 Pages(MMR/Standard Resolution)

(ITU-T Chart) 80 Pages(MM R/Stan da rd Re solution ) 240 Pages(MM R /Stand a rd Re solution)

Broadcasting Yes (158 locations) Yes (178 locations)

Auto Reduct ion Yes Yes

Out-of-Paper Reception (Brother #1 Chart) 90 Pages(MMR/Standard Resolution) 220 Pages(MMR/Standard Resolution)

(ITU-T Chart) 80 Pages(MMR/Standard Resolution) 240 Pages(MMR/Standard Resolution)

ECM(Error Correction Mode) Yes Yes

Group Dial Yes (6) Yes (6)

Color FAX (Document Send/Receive) No / No No / No

Color FAX (Memory Send/Receive) No / No No / No

Memory Backup No Yes

LIST/REPORT

Activity Report/Journal Report Yes (up to 200) Yes (up to 200)

Transmission Verification Report Yes Yes

INTERFACE

External TAD Interface Yes Yes

Host Interface (Ser ial) No No

Host Interface (IEEE1284) No Yes

Host Interface (USB) No Yes

LAN Interface No No

Acceptable Media Card Slot

Analog Video Port

FAX2800 (FAX2850) FAX2900

N/A N/A

N/A N/A

1-2

FAX2800 (FAX2850)/FAX2900 (2/2)

Model Name

PRINTER

Color/Mono - Mono

Engine Type - Laser (YL4)

Resolution(dpi) - 600x600

Speed(ppm) - up to 10

Paper Capacity(sheets) - 200

Output Paper Capacity(sheets) - 50

Standard Print Language - Windows GDI

Emulation -No

Resident Fonts - No

Fonts Disk Based - No

Paper Handling Size - LTR, LGL, A4, B5, A5, EXE

Manual Feed Slot - N/A

Other Paper Type - OHP, Envelopes, Organizer

Sheet Weight (Paper Cassette) - 64-105 g/m2 (17 - 28 lb)

(Manual Slot) Printer Driver - Win95/98/98SE/Me/2000Professional/

COPY

Color/Mono Mono Mono

Speed(ppm) up to 10 up to 10

Multi Copy(Sta ck) Yes Yes

Multi Copy(Sort) No No

Reduction/Enlargement(%) 50 to 200 in 1% increments 50 to 200 in 1% increments

Resolution(dpi) 200 x 300 200 x 300

First Copy Out Time (From Ready Mode) Approx. 13 sec. Approx. 13 sec.

SCANNER No No

Color/Mono - Resolution(Optical : dpi) - Resolution(I n t . : d pi) - Gray Scale - TWAIN Compliant & Operating System - -

PCI Scanner (Parallel/Serial) - -

BUNDLED SOFTWARE (For Windows)

Printer Driver No Available download from Web

TWAIN No No

Viewer No No

PC Fax No No

Remote Setup No No

PC Diagnostics

Others

BUNDLED SOFTWARE (For iMAC)

Printer Driver No No

TWAIN No No

Viewer No No

PC Fax No No

Remote Setup No No

PC Diagnostics

Others --

ACCESSORY

Life / Yield Toner Starter (N/A) 1,000 pages 1,000 pages

Supply (TN-250) 2200 pages 2200 pages

Drum (DR-250) 20,000 pages: Continuous Printing 20,000 pages: Continuous Printing

Formats (Import) - Formats (Export) - -

Pop Up Menu

OCR No No

Formats (Import) - Formats (Export) - -

Pop Up Menu No No

OCR No No

FAX2800 (FAX2850) FAX2900

N/A

-NT4.0WS

No No

No No

--

No No

8,000 pages:1 page/job 8,000 pages:1 page/job

1-3

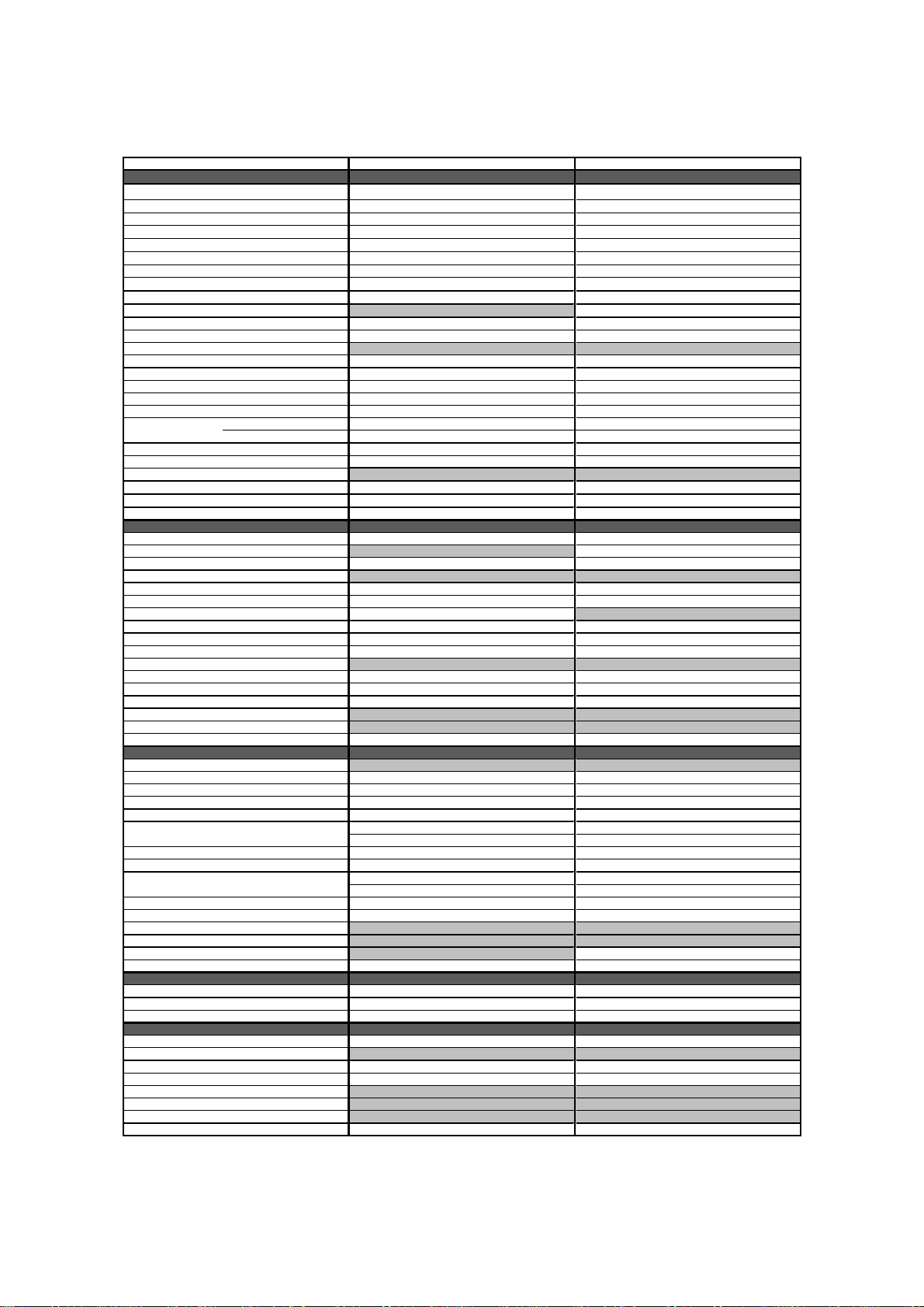

MFC4800/FAX3800 (1/2)

Model Name

GENERAL

Print Engine Laser (YL4) Laser (YL4)

Modem Speed(bps) 14,400(Fax) 33,600(Fax)

Transmis sion Speed(sec.) 6(Brother#1,MMR) 2(Brother#1,JBIG)

ITU-T Group G3 Supper G3

Coding Method MH/MR/MMR MH/MR/MMR/JBIG

Input/Output Width 5.8"-8.5"/3.5"-8.5" 5.8"-8.5"/3.5"-8.5"

Input/Output Length 5"-14"/5"-14" 5"-14"/5"-14"

ADF(pages) up to 20 up to 20

LCD Size 16 Characters x 1 Line 16 Characters x 1 Line

LCD Backlight No Yes

Backup Clock Yes (1 hour) Yes (1 hour)

Memory Capacity (physical) 2MB (RAM) 8MB (RAM)

Optional Memory N/A N/A

Dimensions w/ Ca rto n (Wx D xH) 5 19 mm x 454 mm x 375 mm 519mm x 454 mm x 37 5 mm

Dimensions w/o Carton (WxDxH) 395mm x 359mm x 243mm 395mm x 359mm x 243mm

Weight w/ Carton 11 Kg 11 Kg

Weight w/o Carton 7.5 Kg 7.5 Kg

Color Gray 1495 Gray 1495

Operating Environ me nt Temperature 5 - 32.5 degrees Centigra de 5 - 32.5 degrees Centigrade

Humidity 20 - 80 % 20 - 80 %

Power Source 120 VAC, 50/60Hz 120 VAC, 50/60Hz

Power Consumption (Sleep/Standby/Peak) 10W/ 70W/ 940W or less 10W/ 70W/ 940W or less

On/Off Switch No No

Starter Toner Yes (1,0 00 pa ge s) Yes (1,000 pa ges)

Warm Up Time Approx. 12 sec Approx. 12 sec

TELEPHONE

Handset Yes Yes

One-Touch Dial No 8

Speed Dial 100 120

Speaker Phone N/A N/A

Chain Dialing Yes Yes

Caller ID Yes Yes

Call Waiting Caller ID Yes N/A

Distinctive Ringing Yes Yes

Call Manage Yes Yes

Hold/Mute Key Yes Yes

Power Failure Dialin g N/A N/A

Speaker Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Ring Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Handset Volume Yes (2 steps + OFF + Amplify) Yes (2 steps + OFF + Amplify)

PBX Feature N/A N/A

Transfer Method No No

FAX

Internet FAX N/A N/A

Easy Receive/Fax Detect Yes Yes

Fax/Tel Switch Yes Yes

Enhanced Remote Activate Yes Yes

Scan Speed (sec./page, A4:Standard) Approx. 3.5 Approx. 3.5

Memory Transmission (Brother#1 Chart) 90 Pages(MMR/Standard Resolution) 600 Pages(MMR/Standard Resolution)

(ITU-T Chart) 80 Pages(MMR/Standar d Resolution) 400 Pages(MMR/Standard Reso lution)

Broadcasting Yes (150 locations) Yes (178 locations)

Auto Reduction Yes Yes

Out-of-Paper Reception (Brother #1 Chart) 90 Pages(MMR/Standard Resolution) 600 Pages(MMR/Standard Resolution)

(ITU-T Chart) 80 Pages(MMR/Standard Resolution) 400 Pages(MMR/Standard Resolution)

ECM(Error Correction Mode) Yes Yes

Group Dial Yes (6) Yes (6)

Color FAX (Document Send/Receive) No / No No / No

Color FAX (Mem or y S en d/R ece ive) No / No No / No

Memory Backup No Yes

LIST/REPORT

Activity Report/ Journal Report Yes (up to 200) Yes (up to 200)

Transmission Verification Report Yes Yes

INTERFACE

External TA D Interf a c e Yes Yes

Host Interface (Serial ) No No

Host Interface (IEEE1284) Yes Yes

Host Interface (USB) Yes Yes

LAN In terface No No

Acceptable Media Card Slot

Analog Video Port

MFC4800 FAX3800

N/A N/A

N/A N/A

1-4

MFC4800/FAX3800 (2/2)

Model Name

PRINTER

Color/Mono Mono Mono

Engine Type Laser (YL4) Laser (YL4)

Resolution(dpi) 600x600 600x600

Speed(ppm) up to 10 up to 10

Paper Capacity(sheets) 200 200

Output Pape r Capacity(sheets) 50 50

Standard Print Language Windows GDI Windows GDI

Emulation No No

Resident Fonts No No

Fonts Disk Based Yes No

Paper Handling Size LTR, LGL, A4, B5, A5, EXE LTR, LGL, A4, B5, A5, EXE

Manual Feed Slot

Other Paper Type OHP, Envelopes, Organizer OHP, Envelopes, Organizer

Sheet Weight (Paper Cassette) 64-105 g/m2 (17 - 28 lb) 64-105 g/m2 (17 - 28 lb)

(Manual Slot) N/A N/A

Printer Driver Win95/ 98/98SE/Me/2000Professional/ Win95/98/98SE/Me/2000Professional/

COPY

Color/Mono Mono Mono

Speed(ppm) up to 10 up to 10

Multi Copy(Stack) Yes Yes

Multi Copy(Sort) No No

Reduction/Enlargement(%) 50 - - 200 in 1% increments 50 -- 200 in 1% inc rements

Resolution(dpi) 200 x 300 200 x 300

First Copy Out Time (From Ready Mode) Approx. 13 s ec. Approx. 13 sec.

SCANNER Yes No

Color/Mono Mono Resolution(Optical : dpi) 200x400 Resolution(Int. : dpi) 1,200x1,200 Gray Scale 256 TWAIN Compliant & Operating System Win95/98/98SE/Me/NT4.0/20 00Profess inal -

PCI Scanner (Parallel/Serial)

BUNDLED SOFTWARE (For Windows)

Printer Driver Yes Available download fr om Web

TWAIN Yes No

Viewer Yes No

PC Fax Yes (TX only) No

Remote Setup Yes No

PC Diagnostics

Others

BUNDLED SOFTWARE (For iMAC)

Printer Driver Yes No

TWAIN Yes No

Viewer Yes No

PC Fax Yes No

Remote Setup No No

PC Diagnostics

Others --

ACCESSORY

Life / Yield Toner Starter (N/A) 1,000 pages 1,000 pages

Supply (TN-250) 2200 pages 2200 pages

Drum (DR-250) 20,000 pages: Continuous Printing 20,000 pages: Continuous Printing

Formats (Import) TIFF/BMP/PCX/DCX/BTF/BTX/MAX Formats (Export) TIFF/BMP/MAX -

Pop Up Menu Yes

OCR Yes No

Auto E-mail Printing(Win 95/98/Me only) -

Formats (Import) TIFF/BMP/PCX/DCX/BTF/BTX/MAX Formats (Export) TIFF/BMP/MAX -

Pop Up Menu No No

OCR Yes No

MFC4800 FAX3800

N/A N/A

NT4.0WS MacOS 8.5-9.1 NT4.0WS

MacOS 8.6-9.1

Parallel/USB -

No

No No

No No

8,000 pages:1 page/job 8,000 pages:1 page/job

1-5

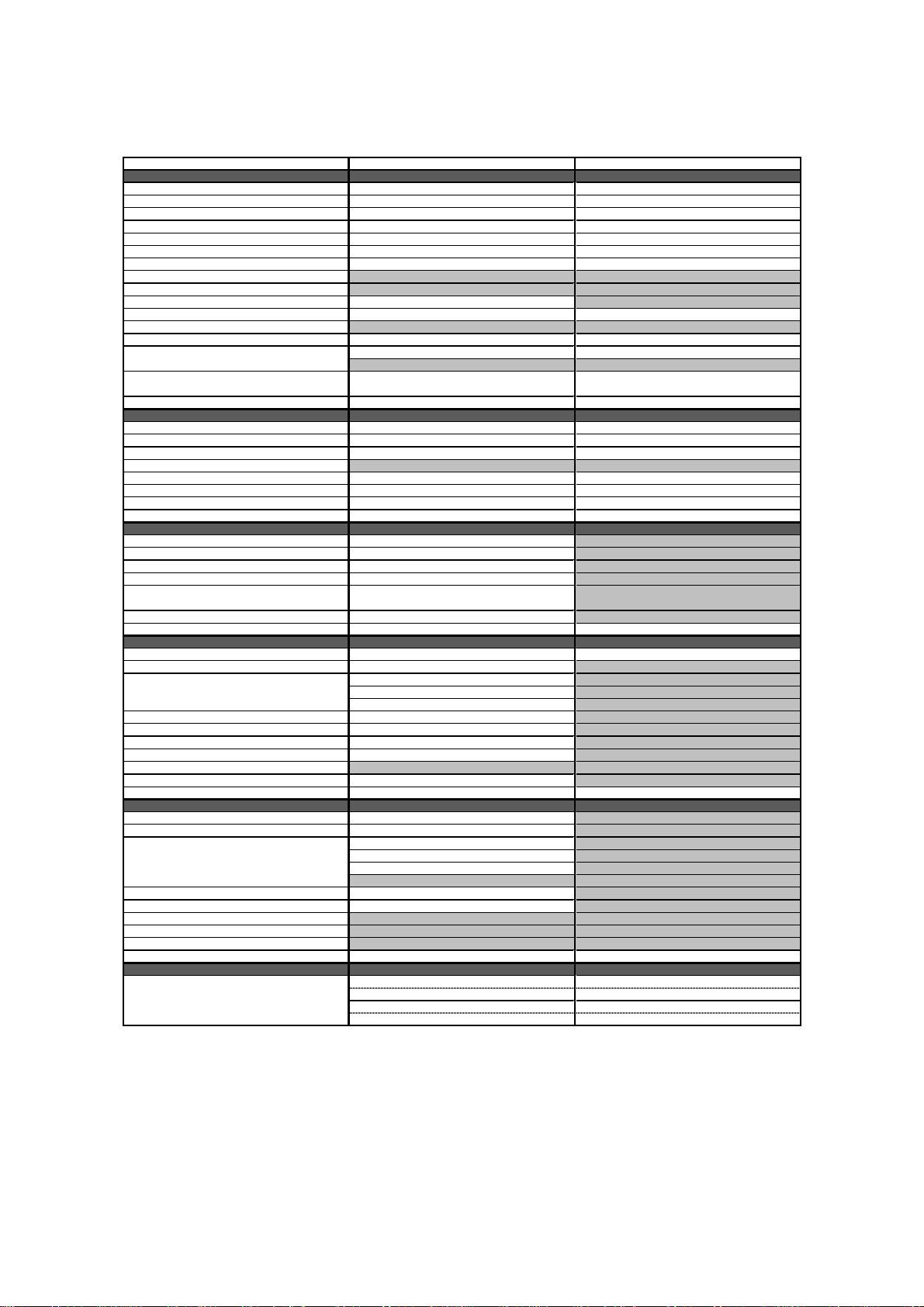

FAX-8070P/MFC-9070 (1/2)

Model Name

GENERAL

Print Engine Laser (YL4) Laser (YL4)

Modem Spee d(bps) 14,400(Fa x) 14,400(Fax)

Transmission Speed(sec.) Approx.6 (Brother#1,MMR) Approx.6(Brother#1,MMR)

ITU-T Group G3 G3

Coding Method MH/MR/MMR MH/MR/MMR

Input/Output Wi dth 5.8"-8.5"/3.5"-8.5" 5.8"-8.5"/3.5"-8.5"

Input/Output Length 5"-14"/5"-14" 5"-14"/5"-14"

ADF(pages) up to 20 up to 20

LCD Size 16 Characters x 1 line 16 Characters x 1 l ine

LCD Backlight Yes Yes

On-Screen Programming Yes Yes

Backup Clock Yes (9 hours) Yes (9 hours)

Memory Capacity(physical) 2 MB(RAM) 8 MB(RAM)

Memory Backup Yes ( Max. 4 days ) Yes ( Max. 4 days )

Optional Memory N/A N/A

Dimensions w/ Carton (WxDxH) 519mm x 454 mm x 375 mm 519mm x 454 mm x 375 mm

Dimensions w/o Carton (WxDxH) 395mm x 359mm x 243mm 395mm x 359mm x 243mm

Weight w/ Carton 11 Kg 11 Kg

Weigh t w/o Carton 7.5 Kg 7.5 Kg

Color Gray 1495 Gray 1495

Operating Environment Temperature 5 - 32.5 degrees Ce ntigrade 5 - 32.5 degrees Centigrade

Humidity 20 - 80 % 20 - 80 %

Power Source 220-240 VAC, 50/60Hz 220-240 VAC, 50/60Hz

Power Consumption (Sleep/Standby/Peak) 10W/70W/940W or less 10W/70W/940W or less

On/Off Switch No No

Starter Toner No No

TELEPHONE

Handset No No

One-Touch Dial 8 locatio ns No

Speed Dial 100 100

Speaker Phone N/A N/A

Chain Dialing Yes Yes

Caller ID N/A N/A

Call Waiting Caller ID N/A N/A

Disti nc ti v e Ri n gi n g Yes(UK, DEN on ly ) Yes(UK, DEN only)

Hold/Mute Key N/A N/A

Power Failure Dialing N/A N/A

Speaker Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Ring Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Handset Volume N/A N/A

PBX Feature Yes Yes

Transfer Method Flash/Earth for UK/Netherlands Flash/Earth for UK/Netherlands

FAX

Internet FAX N/A N/A

Easy Receive/Fax Detect Yes Yes

Fax/Tel Switch Yes Yes

Enhanced Remote Activate Yes Yes

Quick-Scan(Memory transmission) Yes as default , Approx.3.5 sec./page (A4 standard) Yes as default, Approx.3.5 sec./page (A4 standard)

Memory Transmission (Brother#1 Chart) 90 Pages(MMR/Standard Resolution) 500 Pages(MMR/Standard Resolution)

(ITU-T Chart) 80 Pages(MMR/Standard Resolution) 400 Pages(MMR/Standard Resolution)

Broadcasting Yes (158 locations) Yes (150 locations)

Manual Broadcasting

Auto Reduction Yes Yes

Out-of-Paper Reception (Broth er #1 Chart) 90 Pages(MMR /Standard R esolution ) 500 Pages(MMR/Standard Resolution )

(ITU-T Chart) 80 Pages(MMR/Standard Resolution) 400 Pages(MMR/Standard Resolution)

ECM(Error Correction Mode) Yes Yes

Color FAX (Document Send/Receive) N o / No No / No

Color FAX (Memory Send/Receive) No / No No / No

LIST/REPORT

Activity Report/Journal Report Yes (up to 200) Yes (up to 200)

Transmission Verification Report Yes Yes

INTERFACE

External TAD Interface Yes Yes

Host Interface (Serial) No No

Host Interface (IEEE1284) No Yes

Host Interface (USB) No Yes

LAN Interface No No

Accepta ble Media Card Slot

Analog Video Port

FAX-8070P MFC-9070

Yes(50 locations ) Yes ( 50 locations )

N/A N/A

N/A N/A

1-6

FAX-8070P/MFC-9070 (2/2)

Model Name

PRINTER

Color/Mono - Mono

Engine Type - Laser (YL4)

Resolution(dpi) - 600x600

Speed(ppm) - up to 10

Paper Capacity(sheets) - 200

Additional Paper Capacity(she ets) - No

Output Paper Capacity(sheets) - 50

Standard Print Language - Windows GDI

Emulation - Yes(PCL5e)

Resident Fonts Fonts Disk Based - Yes

Paper Handling Size - LTR, LGL, A4, B5, A5, EXE

Manual Feed Slot - N/A

Other Paper Type - OHP, Envelopes, Organizer

Sheet Weight (Paper Cassette) - 64-105 g/m2 (17 - 28 lb)

(Manual Slot) - N/A

Printer Dr iver - Win95/ 98/98SE/Me,

COPY

Color/Mono Mono Mono

Speed(ppm) up to 10 up to 10

Mult i Copy(Stack) Yes Yes

Multi Copy(Sort) No Yes

Reduction/Enlargement(%) 50 to 200 in 1% increments 50 to 200 in 1% increments

Resolution(dpi) 200 x 300 200 x 300

SCANNER

Color/Mono - Mono

Resolution(Optical : dpi) - 200x400

Resolution(Int. : dpi) - 1,200x1,200

Gray Scale - 256

TWAIN Compliant & Operating System - Win95/98/98SE/Me,

PCI Scanner (Parallel/Serial)

BUNDLED SOFTWARE (For Windows)

Printer Driver No Yes

TWAIN No Yes

Viewer No Yes

Pop Up Menu

OCR No Yes

PC Fax No Yes

Remote Setup No

PC Diagnostics Yes Yes

Others

BUNDLED SOFTWARE (For iMAC)

Printer Driv e r

TWAIN No Yes

Viewer

Pop Up Menu

OCR

PC Fax No No

Remote Setup

PC Diagnostics

Others

ACCESSORY

Life / Yield TN-8000(Toner) (2,200 pages w/5% coverage ) TN-8000(Toner) (2,200 pages w/5% coverage )

DR-8000 ( Drum ) (20,000 pages: Continuous Printing) DR-8000 ( Drum ) (20,000 pages: Continuous Printing)

DR-8000( Drum ) (8,000 pages:1 page/job) DR-8000( Drum ) (8,000 pages:1 page/job)

FAX-8070P MFC-9070

Yes(Bitmap font: LetterGothic16.66, OCR-A, OCR-B,

- WinNT4.0WS/2000Professional

- Parallel/USB

No

- Auto E-mail Printing(Win 95/98/Me only)

No Yes

No Yes

No

No Yes

No No

Yes No

-No

Scaleable font; 49 fonts )

WinNT4.0WS/2000Professional

Yes

Yes

No

1-7

CHAPTER

INSTALLATION

2

CHAPTER 2 INSTALLATION

CONTENTS

2.1 INSTALLING THE UPDATE DATA TO THE FACSIMILE MACHINE.............................2-1

2.2 SETTING ID CODES TO FACSIMILE MACHINES CONNECTED TO A SINGLE

PC VIA USB.....................................................................................................................2-3

2.1 INSTALLING THE UPDATE DATA TO THE

r

FACSIMILE MACHINE

If the program version is updated or the main PCB is replaced, then install the update program

onto the flash ROM of the main PCB.

The program installation requires a PC/AT-compatible computer (which is capable of running MSDOS or its compatible OS).

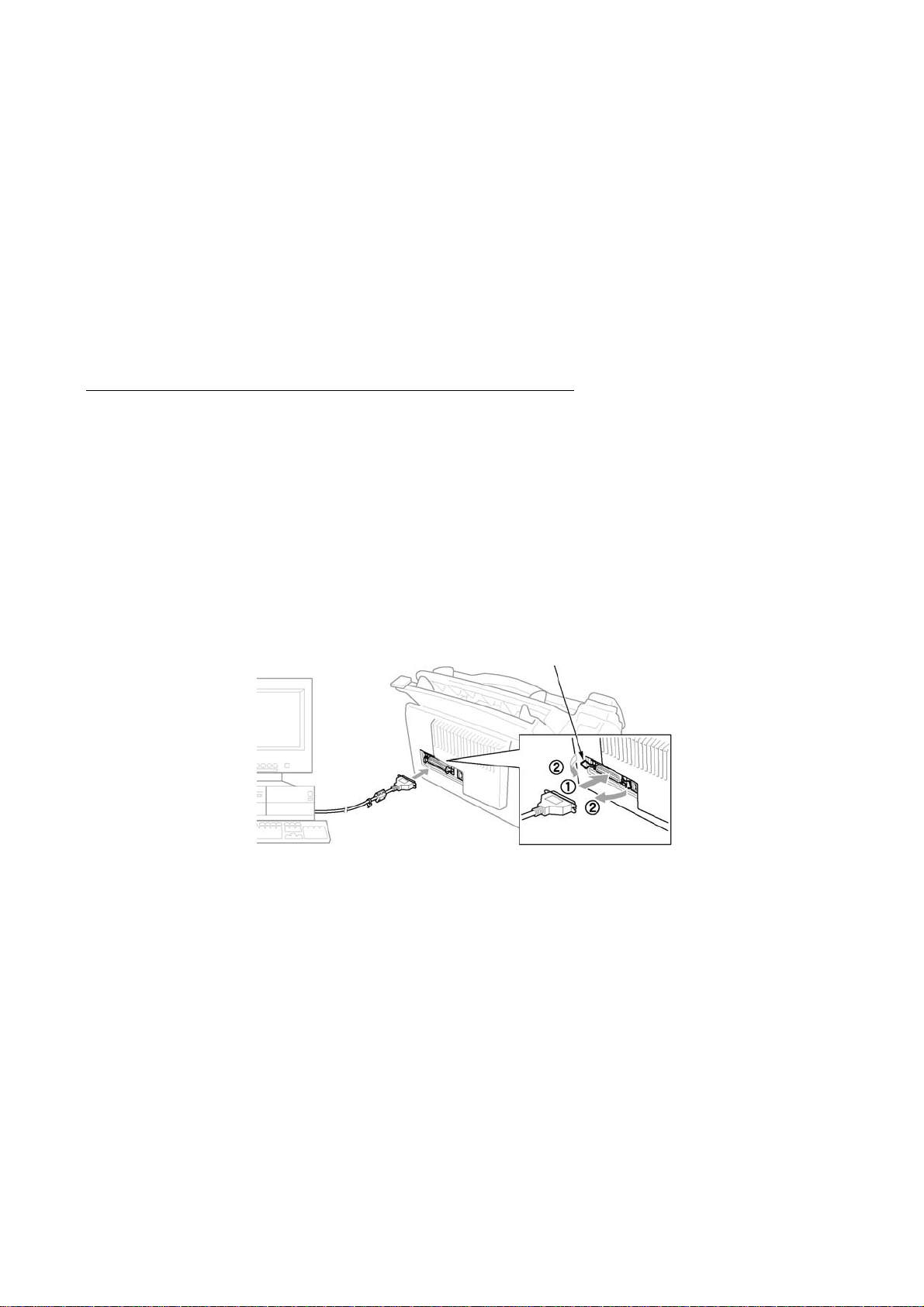

Connecting the facsimile machine to your computer

(1) Make sure that your computer is turned off.

(2) Make sure that the machine's power cord is unplugged from a wall socket.

(3) Connect the parallel interface cable to the parallel port on the back of the machine and secure

it with the lock wires.

(4) Connect the other end of the interface cable to the printer port of your computer and secure it

with the two screws.

(5) Plug the machine's power cord into a wall socket.

(6) Turn on your computer.

Host compute

Lock wires

Parallel interface

cable

2-1

Installing the update data onto the flash ROM of the facsimile machine

NOTE: The following is an installation procedure example on a PC that is running Windows 95/98.

(1) Copy the update data and transfer utility onto the desired directory of the hard disk.

e.g., C:\UPDATE

(2) Click the Start button, point to Programs, and then click MS-DOS Prompt to open an MS-DOS

window.

(3) Type the drive letter where the update data and transfer utility are located. In the above

example, type C:\ from the command line and press the ENTER key.

Then type CD UPDATE and press the ENTER key.

(4) Check that your computer is connected with the facsimile machine correctly.

(5) To start the transfer utility transmitting the update data to the flash ROM of the facsimile

machine, type the following:

ICEN filename /b

Then press the ENTER key.

During downloading, the machine beeps intermittently.

Upon completion of the downloading, the machine beeps continuously.

NOTE: If the facsimile machine cannot return to the standby state af ter completion of downloading,

turn the power off and on.

2-2

2.2 SETTING ID CODES TO FACSIMILE MACHINES CONNECTED TO A SINGLE PC VIA USB

Function

Brother facsimile machines are assigned ID codes (character strings) at the factory. If you replace

the main PCB of the machine, the machine will lose its assigned ID code so that it will not be

identified by the connected PC.

To connect those machines to a PC via USB, you need to assign ID codes (character strings) to

those individual machines according to the procedure given here. For models covered by this

manual, set serial numbers given to individual machines as ID codes.

Connecting each of facsimile machines to your PC

(1) Make sure that your PC is turned off.

(2) Make sure that the machine's power cord is unplugged from a wall socket.

(3) Connect the interface cable to the parallel interface port on the back of the facsimile machine

and secure it with the lock wires.

(4) Connect the other end of the interface cable to the printer port of your PC and secure it with

the two screws.

(5) Plug the machine's power cord into a wall socket.

(6) Turn on your PC.

Operating Procedure

(1) On your PC, run the ID setting utility. Follow the instructions shown on the PC's screen and

enter the 9-digit serial number (e.g., G01012345) printed on the nameplate attached to the

back of the facsimile machine as an ID code. Then press the Enter key.

The ID setting utility will transmit the ID code data from your PC to the facsimile machine

and then it will terminate.

The facsimile machine will automatically return to the standby mode.

(2) To check whether the entered character string (ID code) is correct, make the machine enter the

maintenance mode (refer to Chapter 5, Section 5.1) and then press the 1 key twice.

The facsimile machine will print out a Configuration List. At the right top of the list, "SER.#:

BROXXXXXXXXX" is printed.

(3) Check that the character string entered in step (2) is printed in "XXXXXXXXX."

If it is OK, press the 9 key twice to exit from the maintenance mode.

If something other than that is printed in XXXXXXXXX, check the connection between the

PC and facsimile machine and go back to step (1).

2-3

CHAPTER

THEORY OF OPERATION

3

CHAPTER 3 THEORY OF OPERATION

CONTENTS

3.1 OVERVIEW ......................................................................................................................3-1

3.2 MECHANISMS.................................................................................................................3-2

3.2.1 Scanner Mechanism ............................................................................................3-3

3.2.1.1 Document feeding and ejecting mechanism................................................3-3

3.2.1.2 Scanner........................................................................................................3-3

3.2.2 Laser Printing Mechanism....................................................................................3-4

3.2.2.1 Paper pulling-in, registration, feeding, and ejecting mechanism..................3-4

3.2.2.2 Print process mechanism.............................................................................3-6

3.2.2.3 Heat-fixing mechanism ................................................................................3-7

3.2.3 Sensors and Actuators.........................................................................................3-8

3.3 CONTROL ELECTRONICS...........................................................................................3-10

3.3.1 Configuration......................................................................................................3-10

3.1 OVERVIEW

3-1

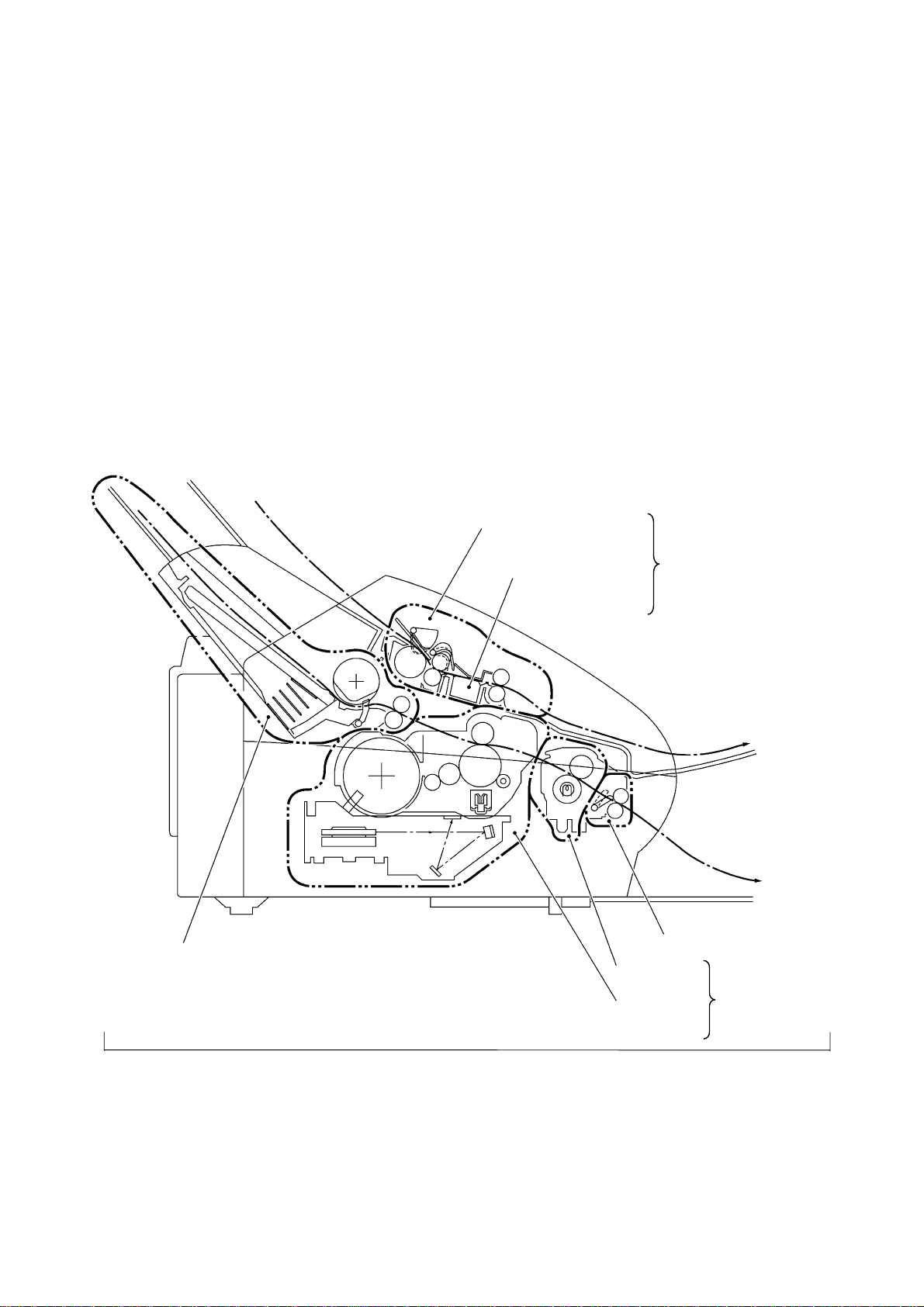

3.2 MECHANISMS

m

The facsimile machine is classified into the following mechanisms:

SCANNER MECHANISM - Document feeding and ejecting mechanism

LASER PRINTING MECHANISM - Paper pulling-in, registration, feeding, and ejecting

SENSORS AND ACTUATORS

- Document scanning mechanism

mechanisms

- Print process mechanism (consisting of charging,

exposing, developing, transferring, and erasing

processes)

- Heat-fixing mechanism

Document feeding and

ejecting mechanism

Document scanning

mechanism

SCANNER

MECHANISM

Paper pulling-in and

registration mechanism

LASER PRINTING MECHANISM

3-2

Paper ejecting mechanis

Heat-fixing

mechanism

Print process

mechanism

With paper feeding

mechanism

3.2.1 Scanner Mechanism

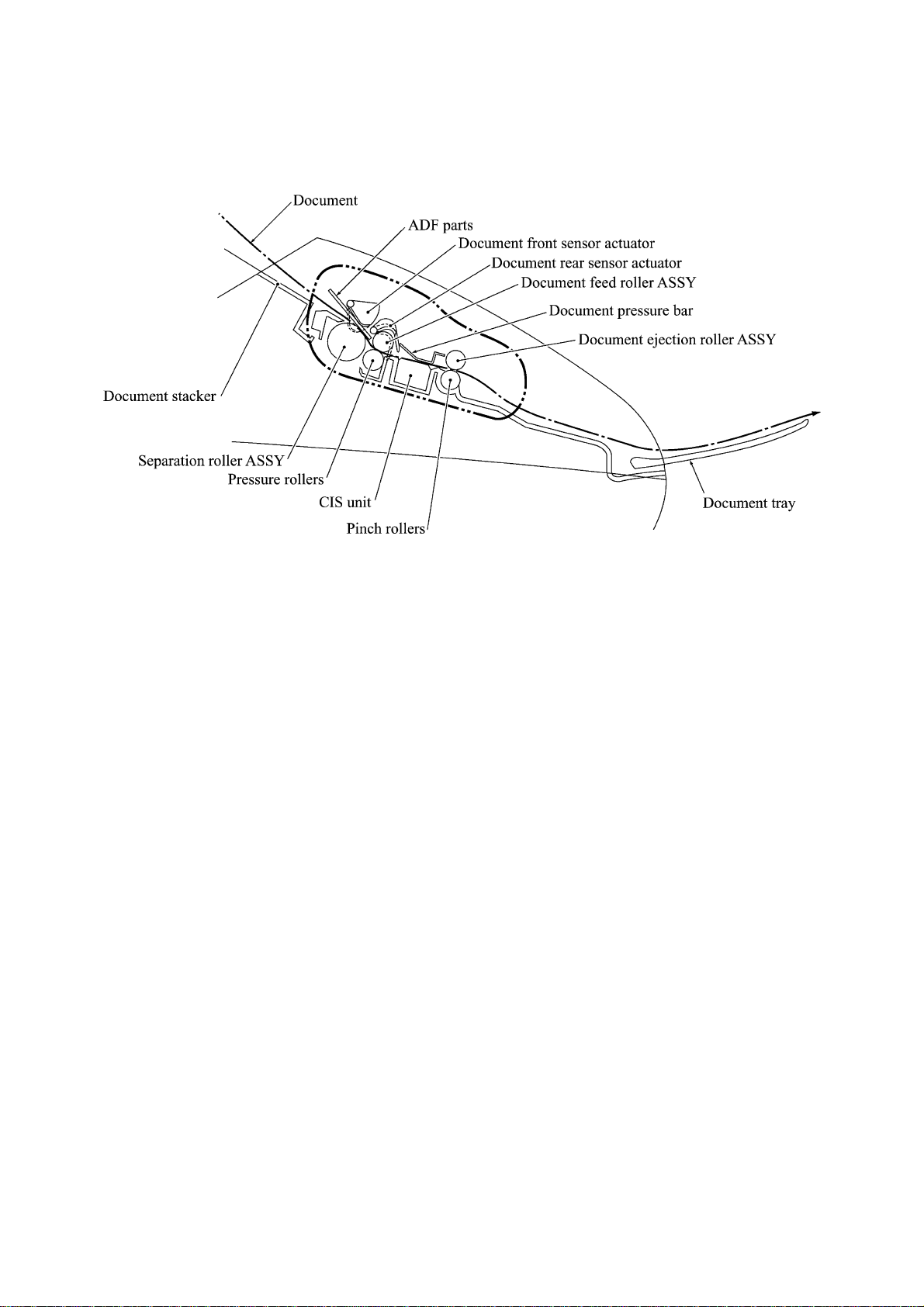

3.2.1.1 Document feeding and ejecting mechanism

This mechanism consists of the document stacker, automatic document feeder (ADF), document

ejection roller ASSY, and document sensors. (For details about the sensors, refer to Subsection

3.2.3.)

If you set documents on the document stacker with their faces down and start the scanning

operation, then the scanner motor rotates so that the ADF (which consists of the separation roller

and ADF parts) feeds those documents into the machine, starting from the bottom sheet (first page)

to the top (last page), page by page. Each document advances with the document feed roller ASSY

to the scanner, and then it is fed out of the machine with the document ejection roller ASSY.

3.2.1.2 Scanner

The scanner uses a contact image sensor (CIS) unit which consists of an LED array illuminating

documents, a self-focus lens array collecting the reflected light, a CIS PCB carrying out

photoelectric conversion to output picture element data, and a cover glass on which a document

advances. When the document passes between the document pressure bar and the cover glass, it is

scanned.

3-3

3.2.2 Laser Printing Mechanism

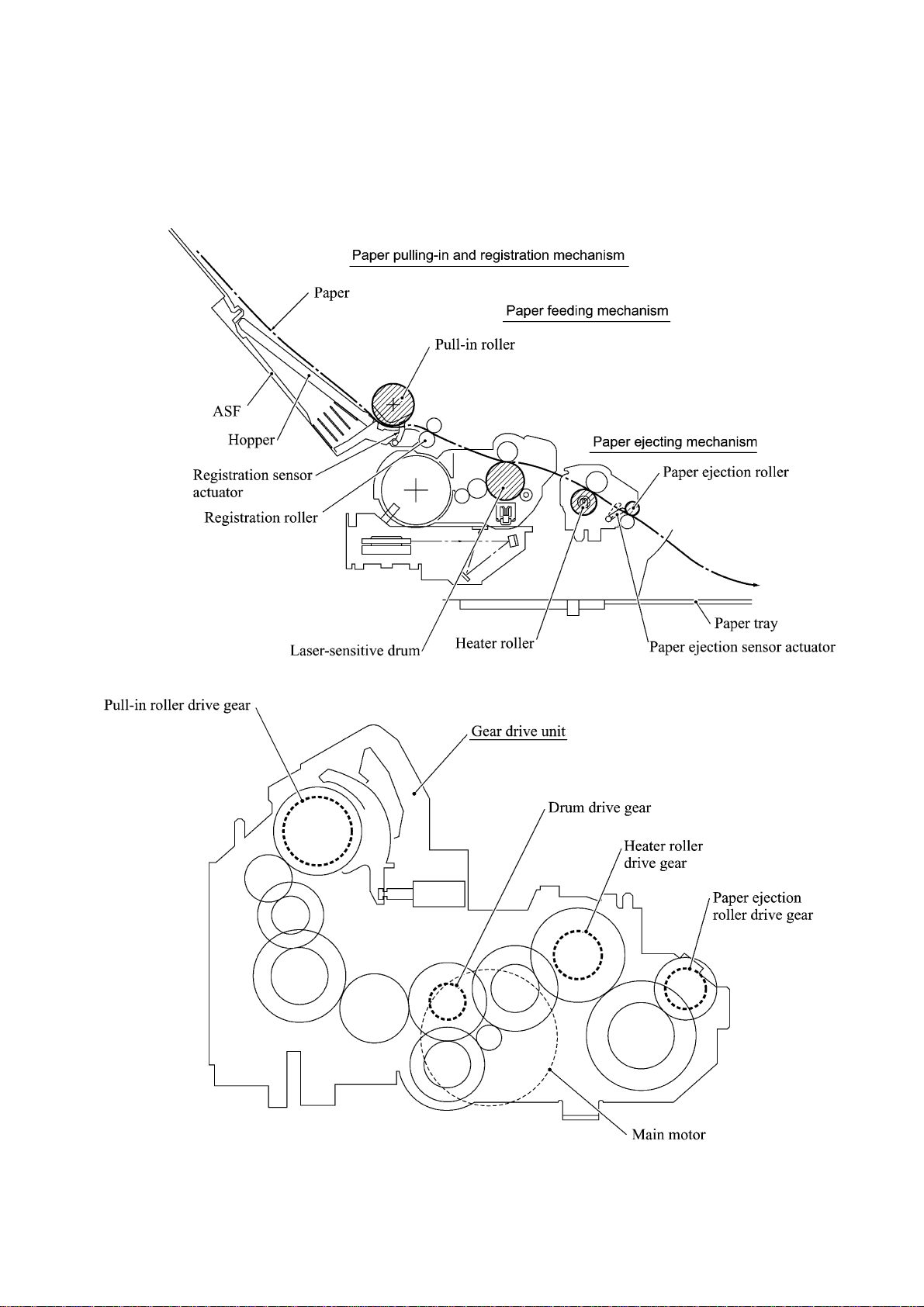

3.2.2.1 Paper pulling-in, registration, feeding, and ejecting mechanism

3-4

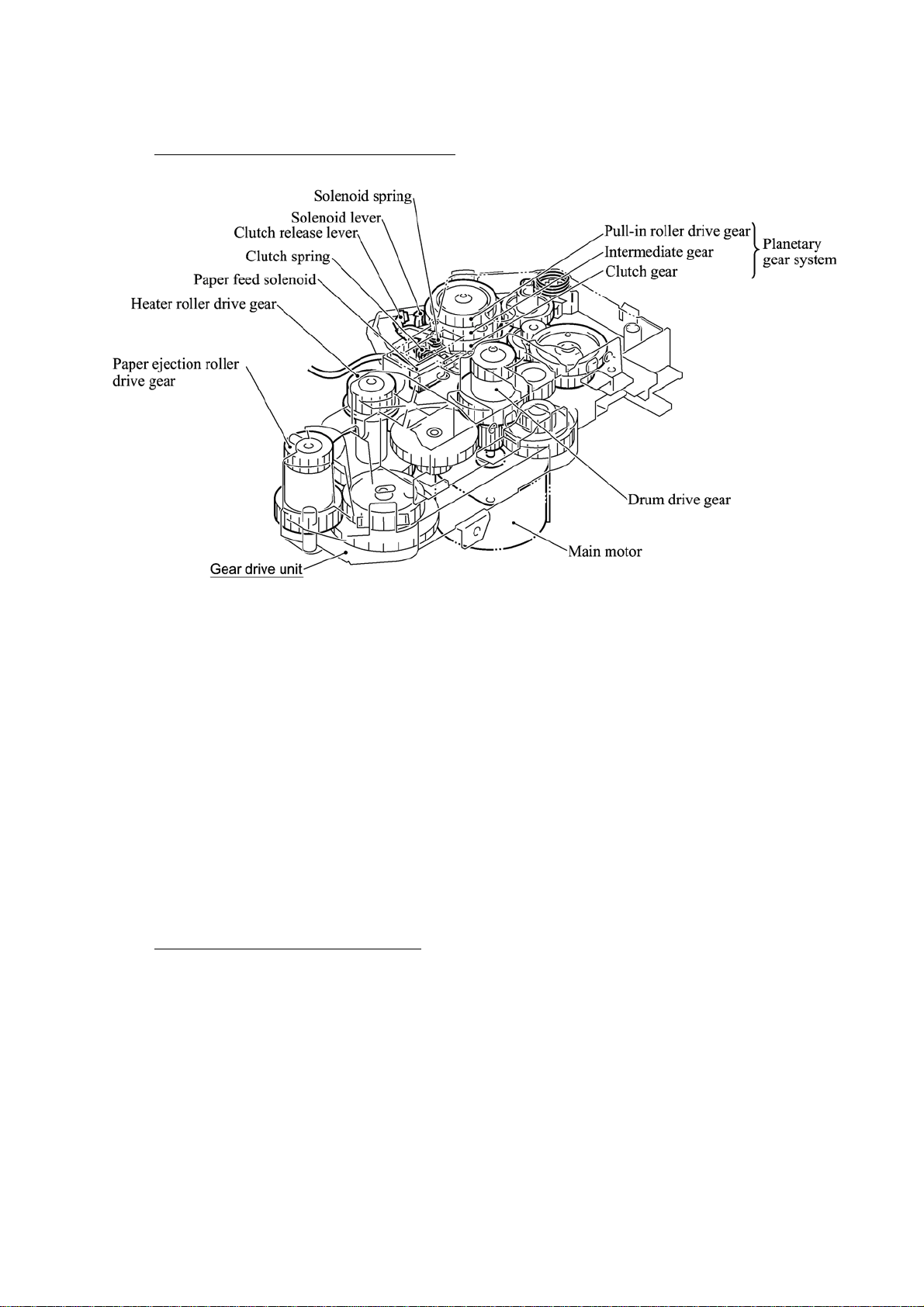

Paper pulling-in and registration mechanism

The paper pulling-in and registration mechanism consists of the pull-in roller gear (incorporated in

the auto sheet feeder ASF), planetary gear system, paper feed solenoid, solenoid lever, clutch

release lever, and registration sensor. (For the details about the sensor, refer to Subsection 3.2.3.)

If the main motor rotates clockwise, the rotation is transmitted to the intermediate gear of the

planetary gear system. As the intermediate gear rotates, the pull-in roller drive gear also rotates

since the clutch gear is locked by the solenoid lever and the clutch release lever. Accordingly, the

pull-in roller in the ASF rotates to pull in paper into the machine, a sheet at a time.

If the paper feed solenoid is retracted and the clutch release lever is operated according to the cam

profile of the pull-in roller drive gear so as to release the clutch gear, the clutch gear rotates and

the pull-in roller drive gear does not rotate. This way, the clutch gear switches the transmission of

the motor rotation to the pull-in roller drive gear on and off.

The solenoid on/off timing and the clutch release lever timing allow this mechanism to pull in a

sheet and register it against the registration roller.

Paper feeding and ejecting mechanism

If the main motor rotates clockwise, the rotation is transmitted via the gear train to the drum drive

gear, heater roller drive gear, and paper ejection roller drive gear.

After the paper passes through the heat-fixing process, it will be ejected onto the paper tray.

If the leading edge of the paper pushes up the actuator of the paper ejection sensor, the

photosensor becomes opened, signaling the start of paper ejection. If the trailing edge has passed

through the sensor actuator, the sensor becomes closed, signaling the completion of paper ejection.

Then, the main motor stops rotation.

3-5

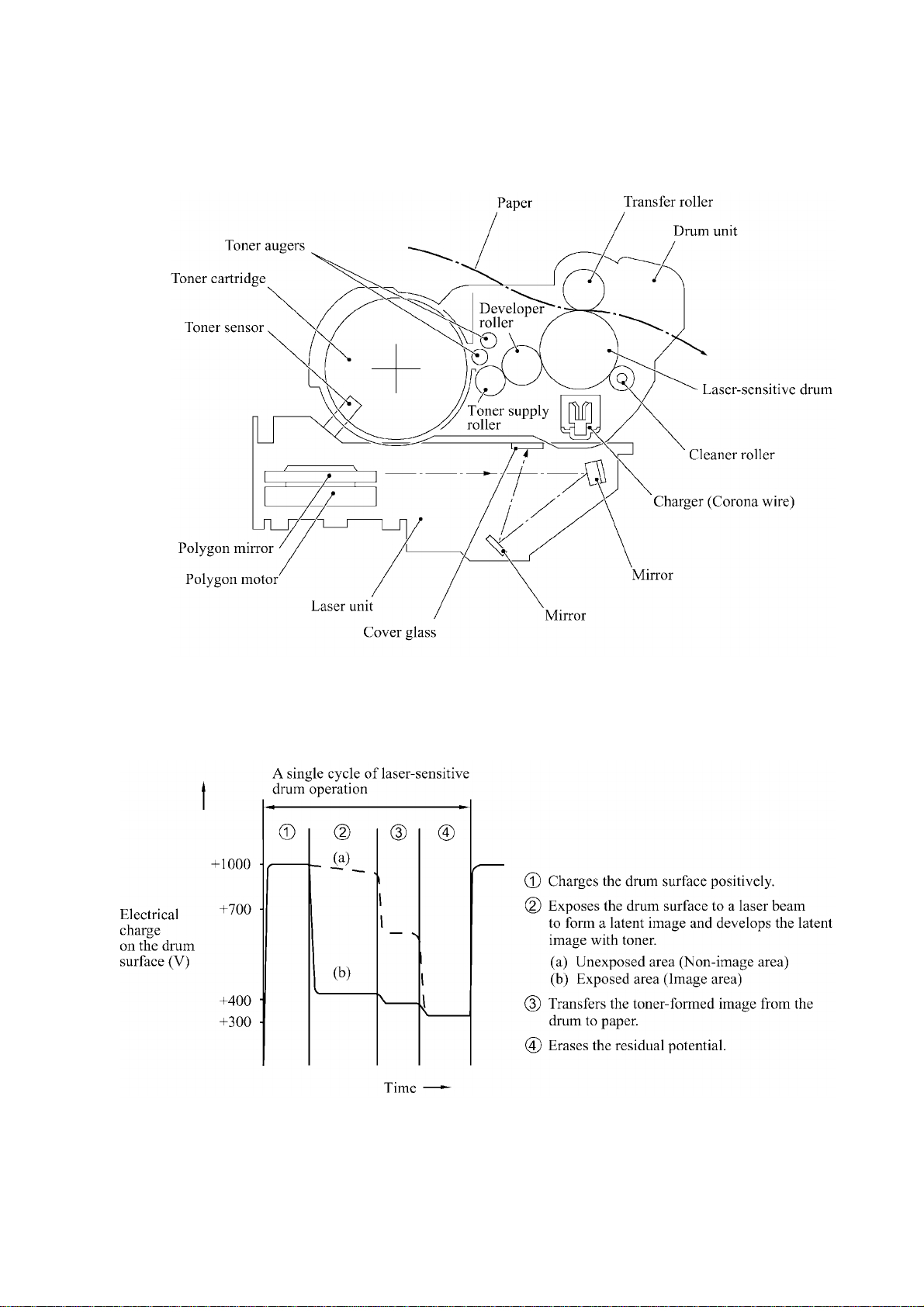

3.2.2.2 Print process mechanism

The print process unit works with laser beam, electrical charges, and toner. The graph below

shows the transition of electrical charge on the surface of the laser-sensitive drum through the five

processes: charging, exposing, developing, transferring, and erasing processes.

3-6

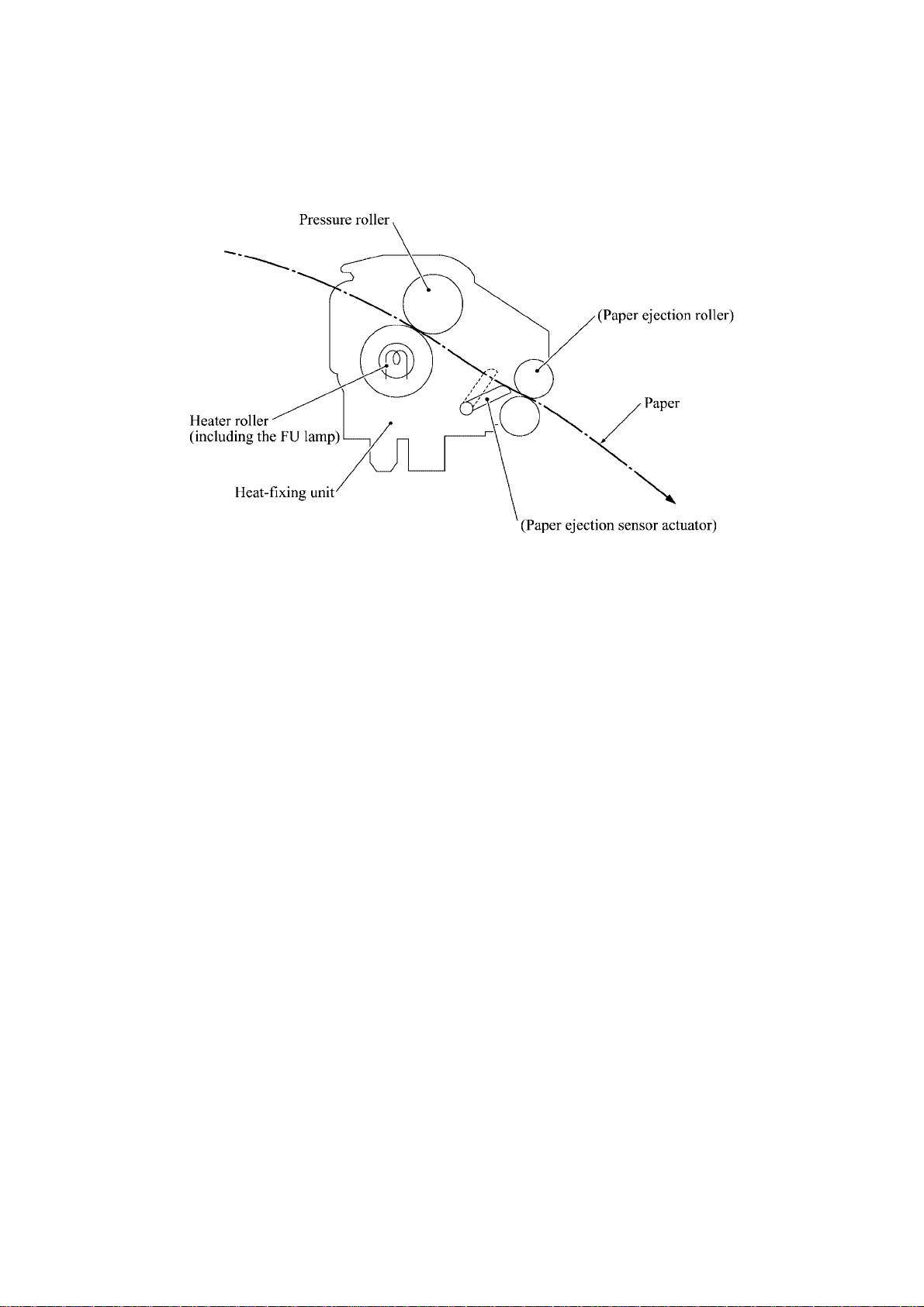

3.2.2.3 Heat-fixing mechanism

As the paper passes between the heater roller and the pressure roller in the heat-fixing unit, the

heater roller fuses the toner on the paper.

3-7

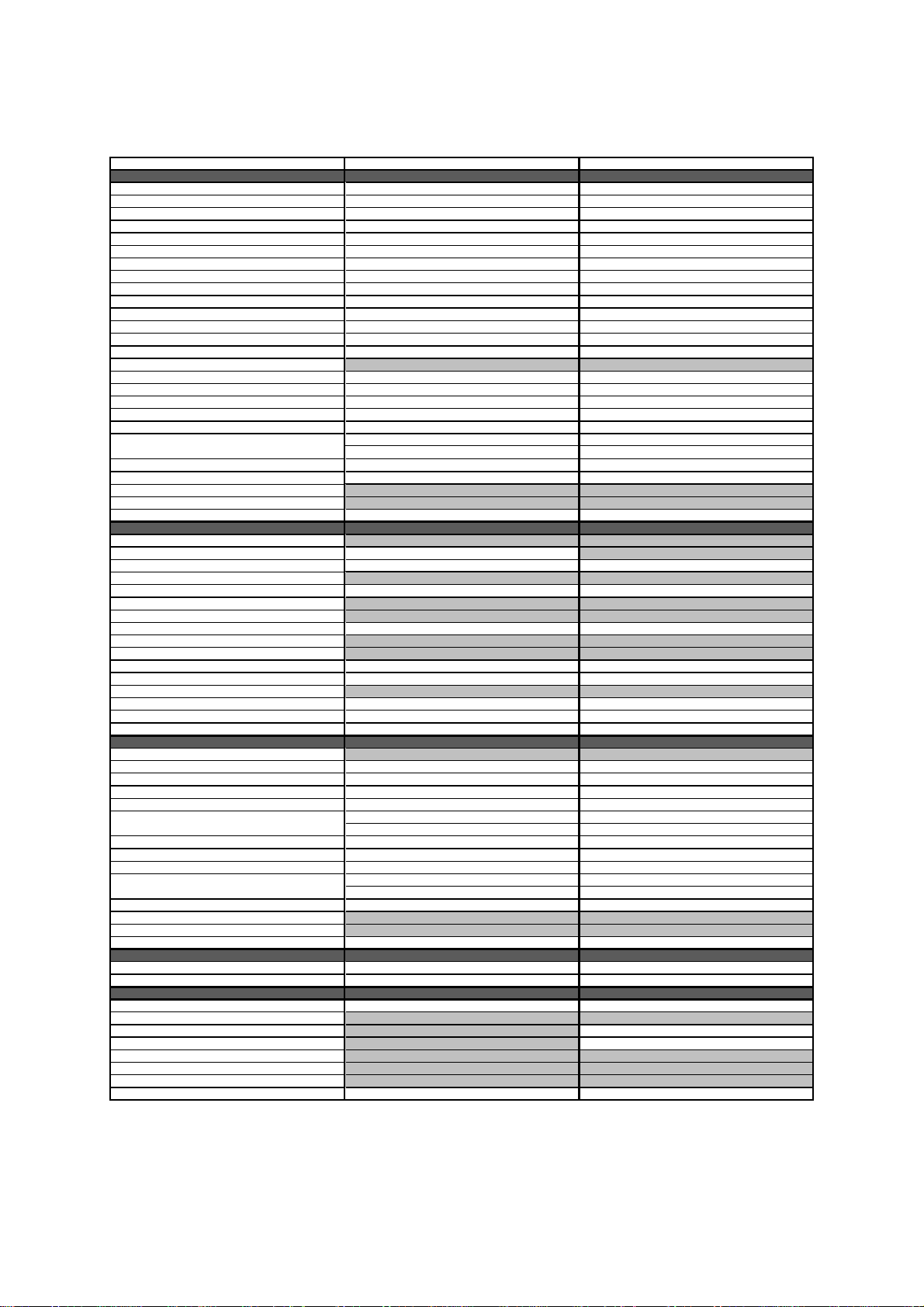

3.2.3 Sensors and Actuators

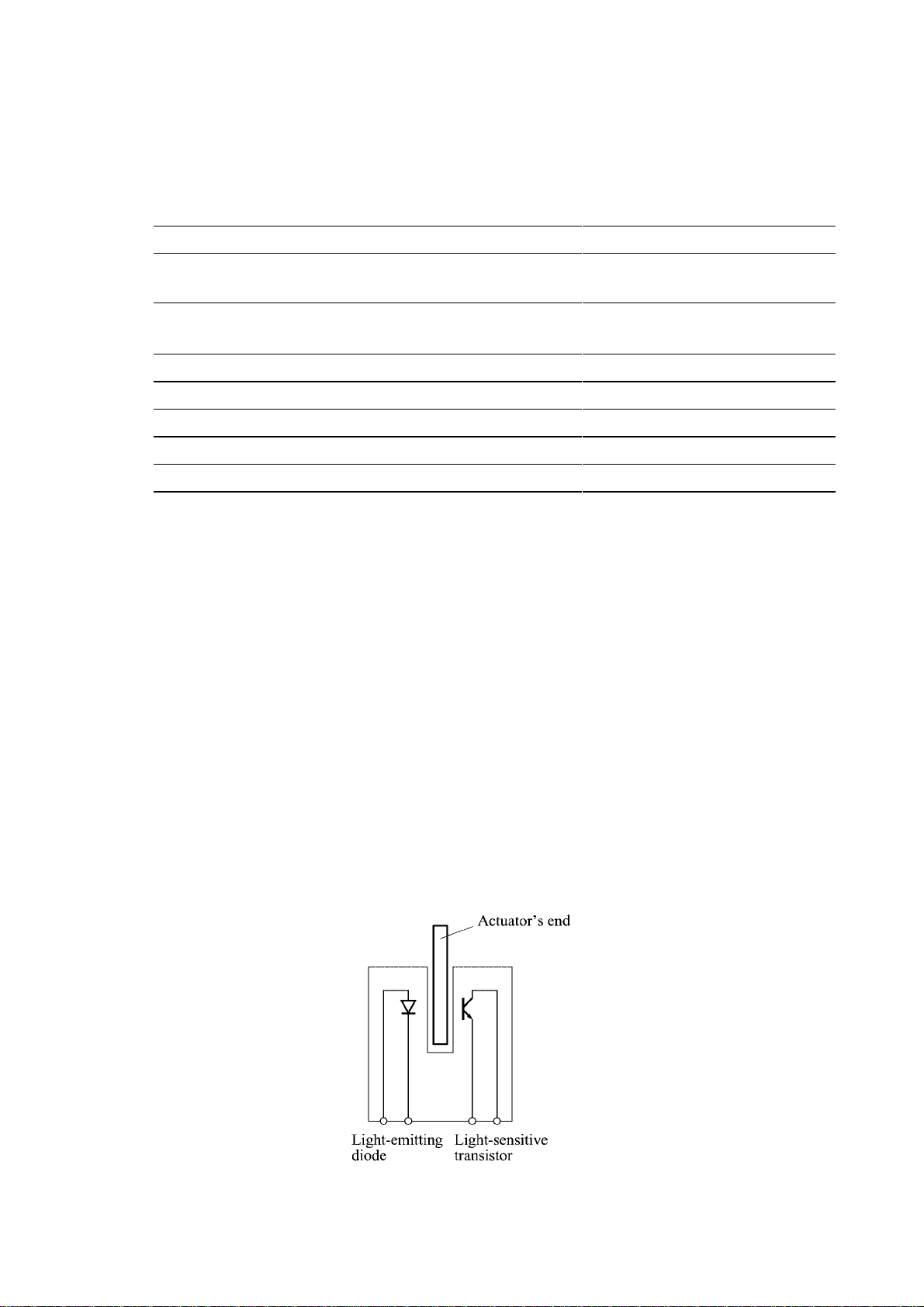

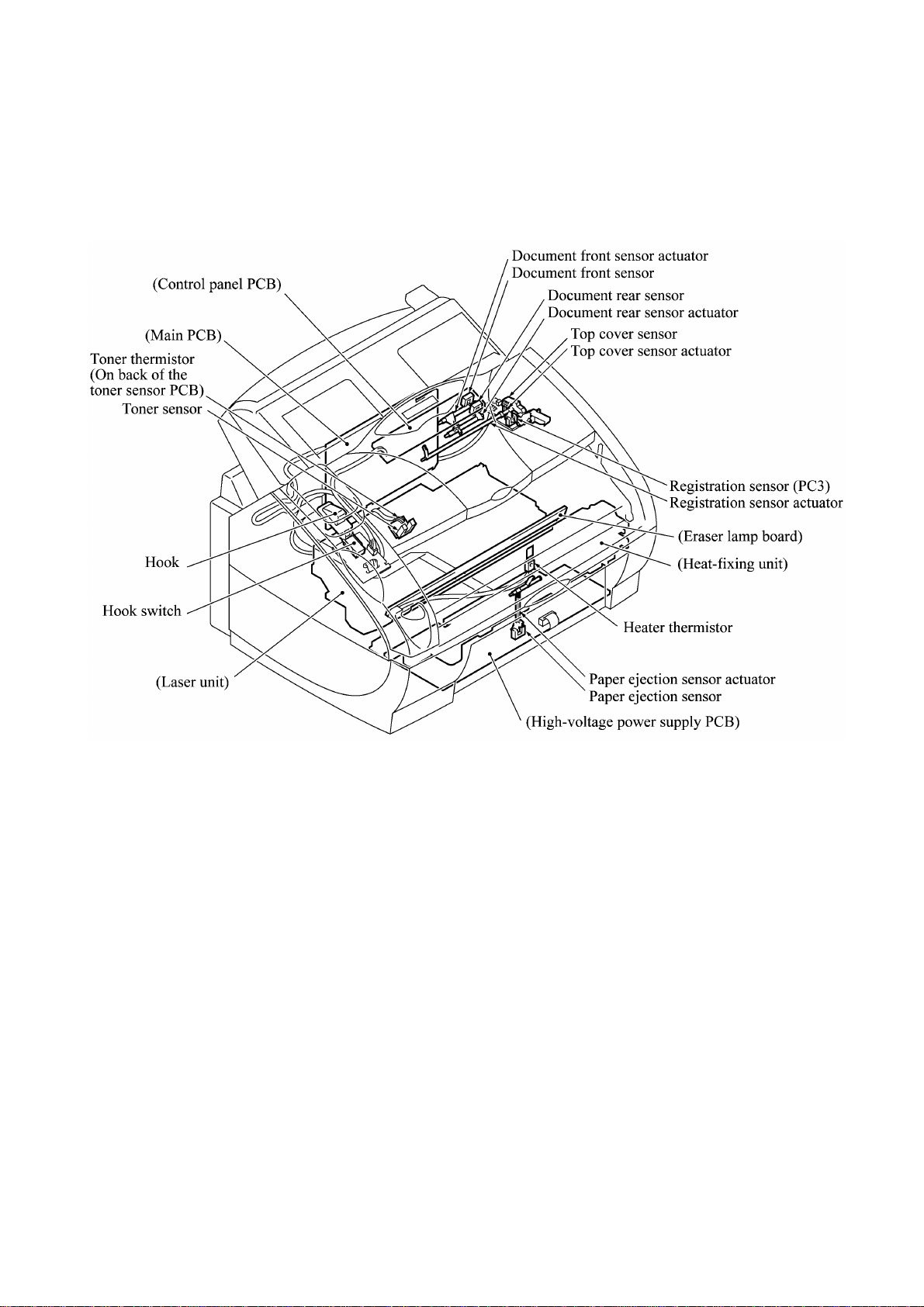

This machine has nine sensors: six photosensors, two thermistors and a mechanical switch as

described below.

Sensor name Type Located on

Document front sensor Photosensor

Document rear sensor Photosensor

Control panel PCB

Cover sensor Photosensor

Registration sensor Photosensor

Cover/registration sensor PCB

Paper ejection sensor Photosensor High-voltage power supply PCB

Toner sensor Photosensor Toner sensor PCB

Toner thermistor Thermistor Toner sensor PCB

Heater thermistor Thermistor Heat-fixing unit

Hook switch Mechanical switch Hook switch PCB*

• Document front sensor which detects the presence of documents.

• Document rear sensor which detects the leading and trailing edges of pages to tell the control

circuitry when the leading edge of a new page has reached the starting position and when the

scan for that page is over.

• Cover sensor which detects whether the top cover is closed.

• Registration sensor which detects the leading and trailing edges of paper, which allows the

controller to determine the registration timing and check paper jam.

• Paper ejection sensor which detects whether the recording paper goes out of the machine.

• Toner sensor which detects whether there is toner or a toner cartridge is loaded.

• Toner thermistor which allows the controller to monitor the ambient temperature of the toner

cartridge.

• Heater thermistor which allows the controller to monitor the temperature of the heater roller of

the fixing unit.

• Hook switch which detects whether the handset is placed on the handset mount.

These photosensors are a photointerrupter consisting of a light-emitting diode and a light-sensitive

transistor. Each of them has an actuator separately arranged as shown on the next page.

3-8

Location of Sensors and Actuators

3-9

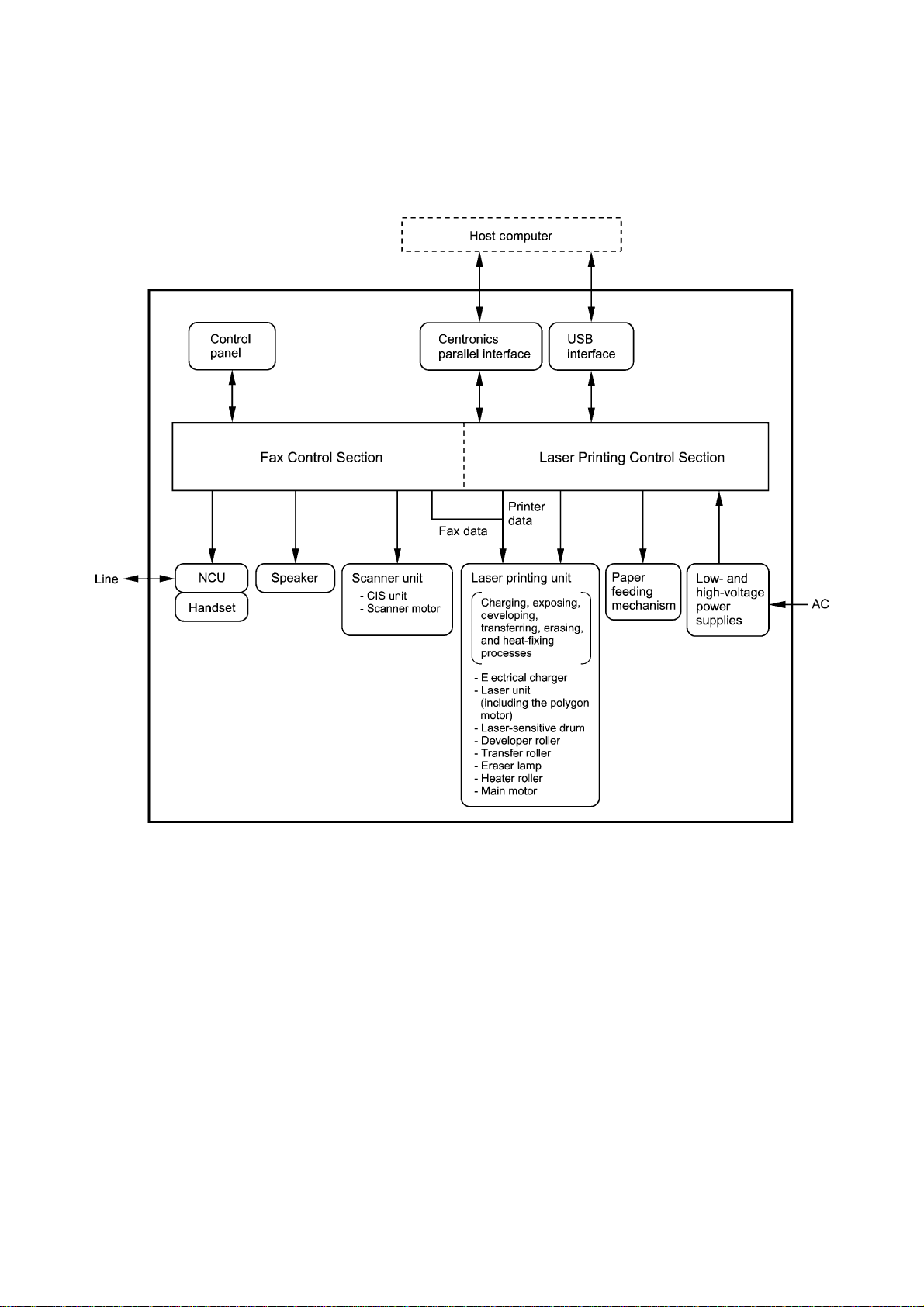

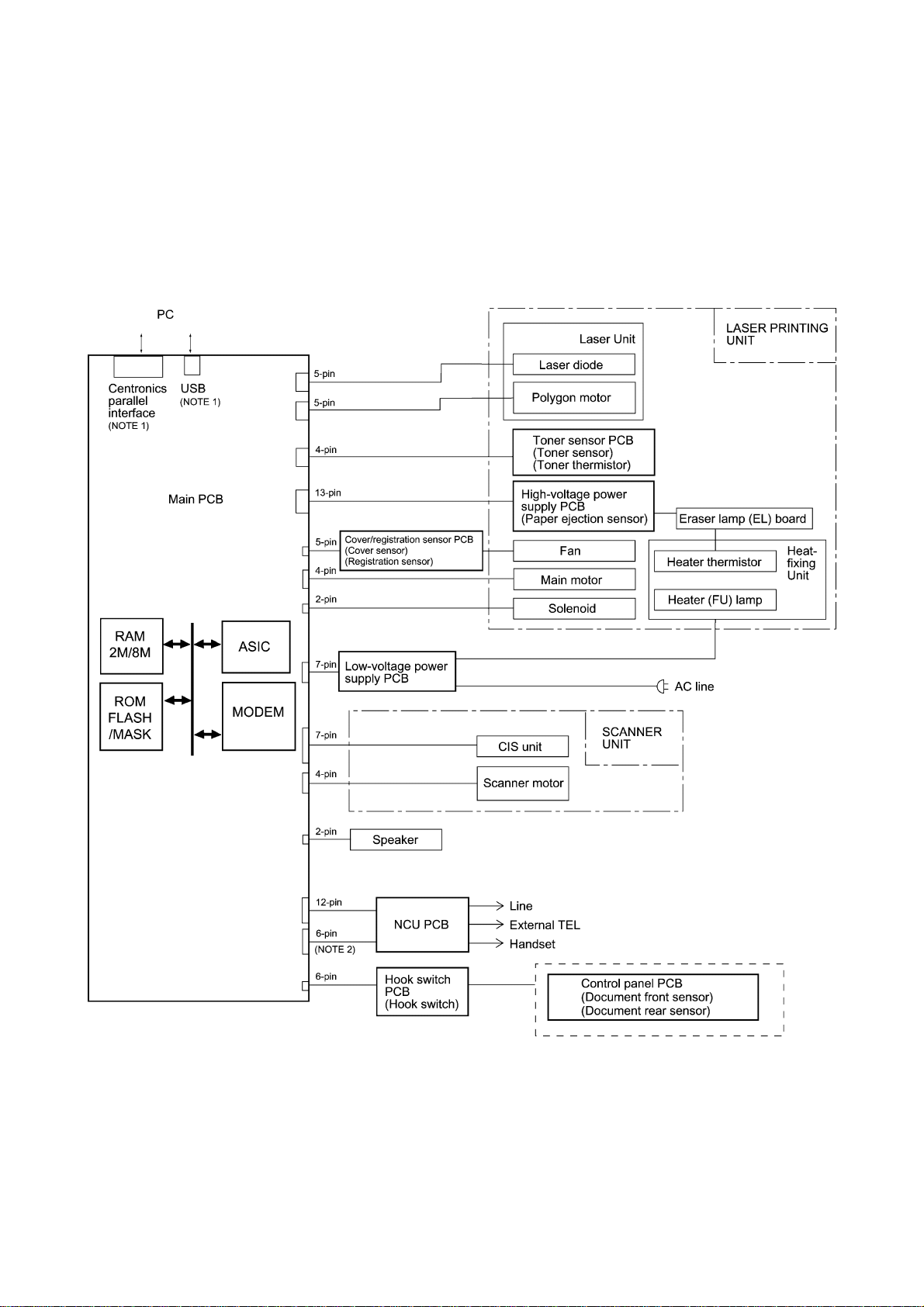

3.3 CONTROL ELECTRONICS

3.3.1 Configuration

The hardware configuration of the facsimile machine is shown below.

Configuration of Facsimile Machine

(NOTE 1) Not provided on some models.

(NOTE 2) Provided on the European, Pacific, and Asian versions.

3-10