COPYBOARD

SERVICE MANUAL

MODEL: CP1800/CP2000/CB200

© Copyright Brother 2000

All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation,

and maintenance of the Brother copyboard. It includes information required for field

troubleshooting and repair--disassembly, reassembly, and lubrication--so that service personnel

will be able to understand machine function, to rapidly repair the machine and order any necessary

spare parts.

To perform appropriate maintenance so that the machine is always in best condition for the

customer, the service personnel must adequately understand and apply this manual.

This manual is made up of five chapters and appendix.

CHAPTER I. GENERAL DESCRIPTION

CHAPTER II. THEORY OF OPERATION

CHAPTER III. DISASSEMBLY/REASSEMBLY AND LUBRICATION

CHAPTER IV. MAINTENANCE MODE

CHAPTER V. ERROR INDICATION AND TROUBLESHOOTING

Appendix. Circuit Diagrams

This manual describes the models and their versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

CHAPTER I.

GENERAL DESCRIPTION

CHAPTER I. GENERAL DESCRIPTION

CONTENTS

1.1 MACHINE OUTLINE............................................................................................. I-1

1.1.1 External Appearance and Weight.............................................................. I-1

1.1.2 Components............................................................................................. I-1

1.2 SPECIFICATIONS................................................................................................ I-2

1.1 MACHINE OUTLINE

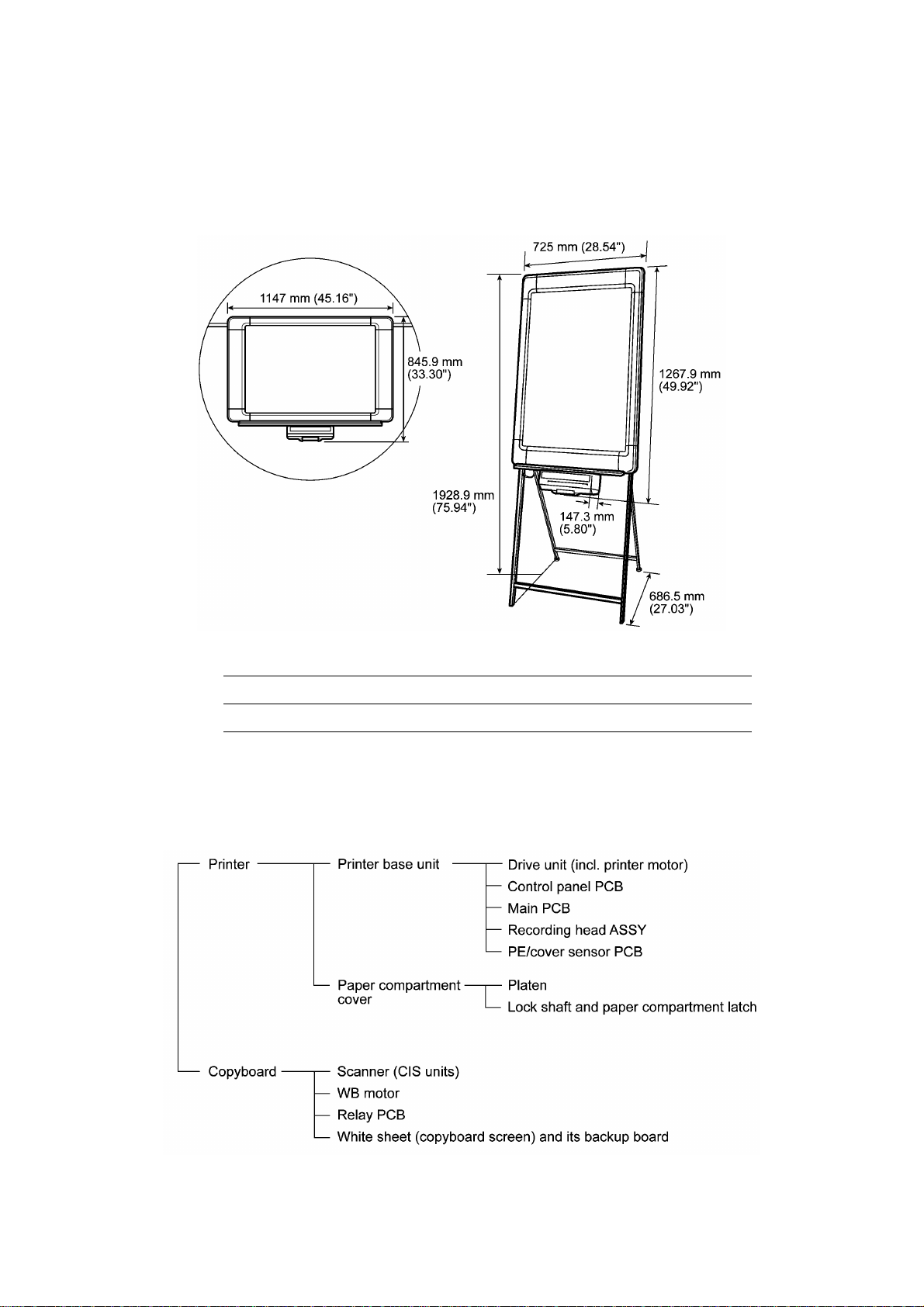

1.1.1 External Appearance and Weight

The figure below shows the machine appearance and approximate dimensions.

Weight: Machine proper 14.5 kg (32.0 lbs.) 11.8 kg (26.0 lbs.)

1.1.2 Components

The machine consists of the following major components:

CP2000/CB200 CP1800

In package 23.0 kg (50.7 lbs.) 19.5 kg (43.0 lbs.)

I - 1

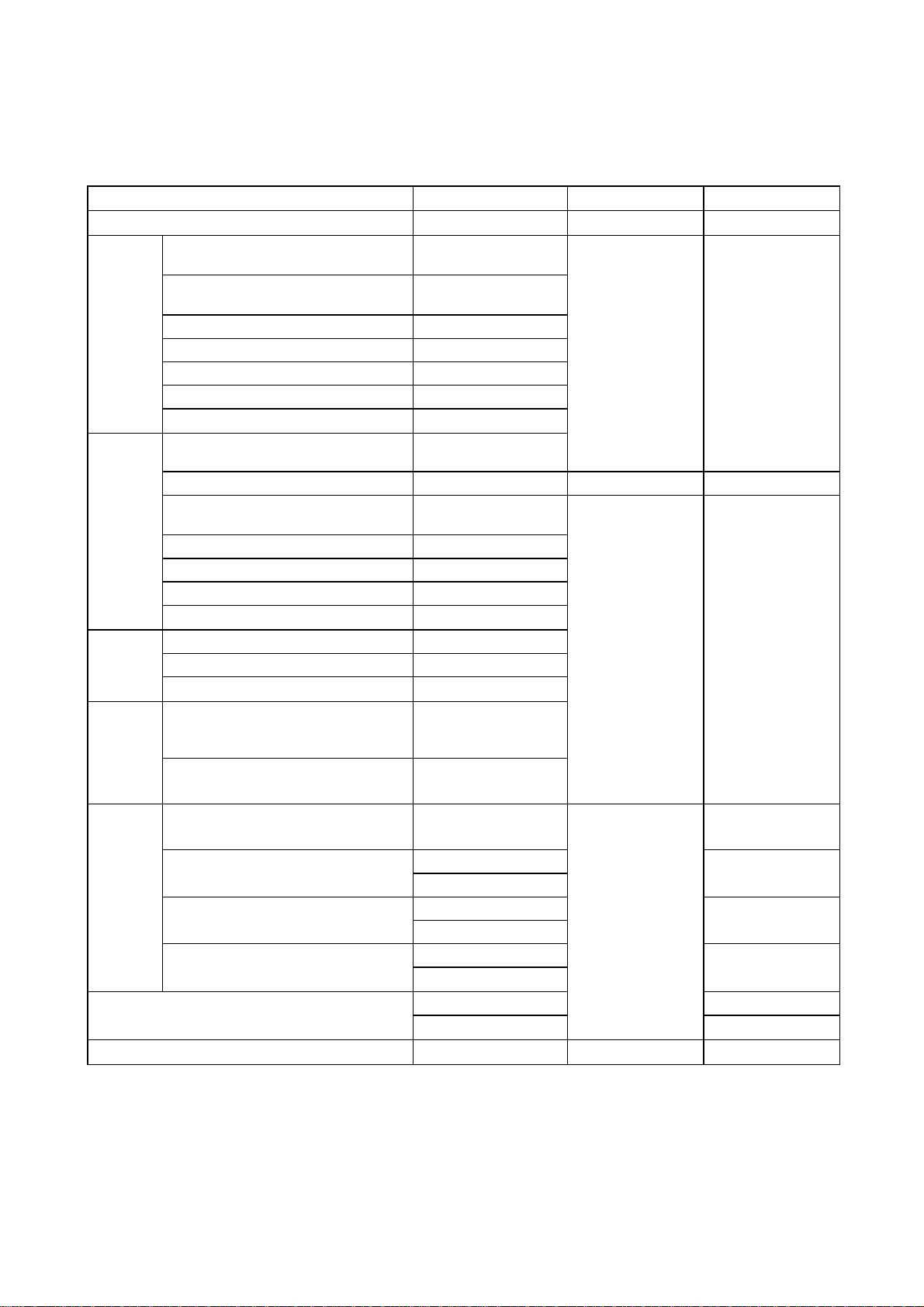

1.2 SPECIFICATIONS

Model CP2000 CB200 CP1800

MACHINE SPECIFICATIONS

INPUT

OUTPU

T

USE

POWER

SIZE

Screen Size (H) x (W) 35.43 x 23.62 inches

900 x 600 mm

Effective Scanning Area (H) x (W) 34.57 x 23.39 inches

878 x 594 mm

Ratio of Scanning Area 96.60%

Scanning Method CIS Same as left. Same as left.

Number of Screens 2 (Endless)

Number of Screens for Copy 2

Writing Dry-erase markers

Printing Method Thermal

Copy Size Letter Letter/A4 Letter

Copy Speed Monochrome: 18 sec

R&B: N/A

Continuous Copy 1 sheet

Paper Therma PLUS, 30 m

Anti-Curl System (ACS) Yes

Print Density 8 dots/mm

Easel Stand Portrait Same as left. Same as left.

Wall Mount Portrait/landscape

Partition Hanger Portrait/landscape

Power Source AC adapter supplied,

100 to 240 VAC,

50/60 Hz

Power Consumption Standby 5W

Operating 30W

Size (H x W x D) In package inch 54.5 x 33.6 x 11.0 49.9 x 38.3 x 10.0

mm 1383 x 852 x 280 1267 x 973 x 255

Use with easel stand inch 75.9 x 28.5 x 27.0

mm 1929 x 725 x 687

Use without easel stand inch 49.9 x 28.5 x 5.8

(Portrait) mm 1268 x 725 x 147 Same as left.

Use without easel stand inch 33.3 x 45.2 x 5.8

(Landscape) mm 846 x 1147 x 147

Weight Net 14.5 kg (32.0 lbs) 11.8 kg (26.0 lbs)

Gross 23 kg (50.7 lbs) 19.5 kg (43.0 lbs)

PC I/F Yes Yes for Canada Option

N/A

N/A

Same as left.

I - 2

CHAPTER II.

THEORY OF OPERATION

CHAPTER II. THEORY OF OPERATION

CONTENTS

2.1 OVERVIEW........................................................................................................... II-1

2.2 MECHANISMS...................................................................................................... II-2

2.2.1 Scanner mechanism.................................................................................... II-2

2.2.2 Thermal printing mechanism....................................................................... II-4

2.2.3 Sensors....................................................................................................... II-5

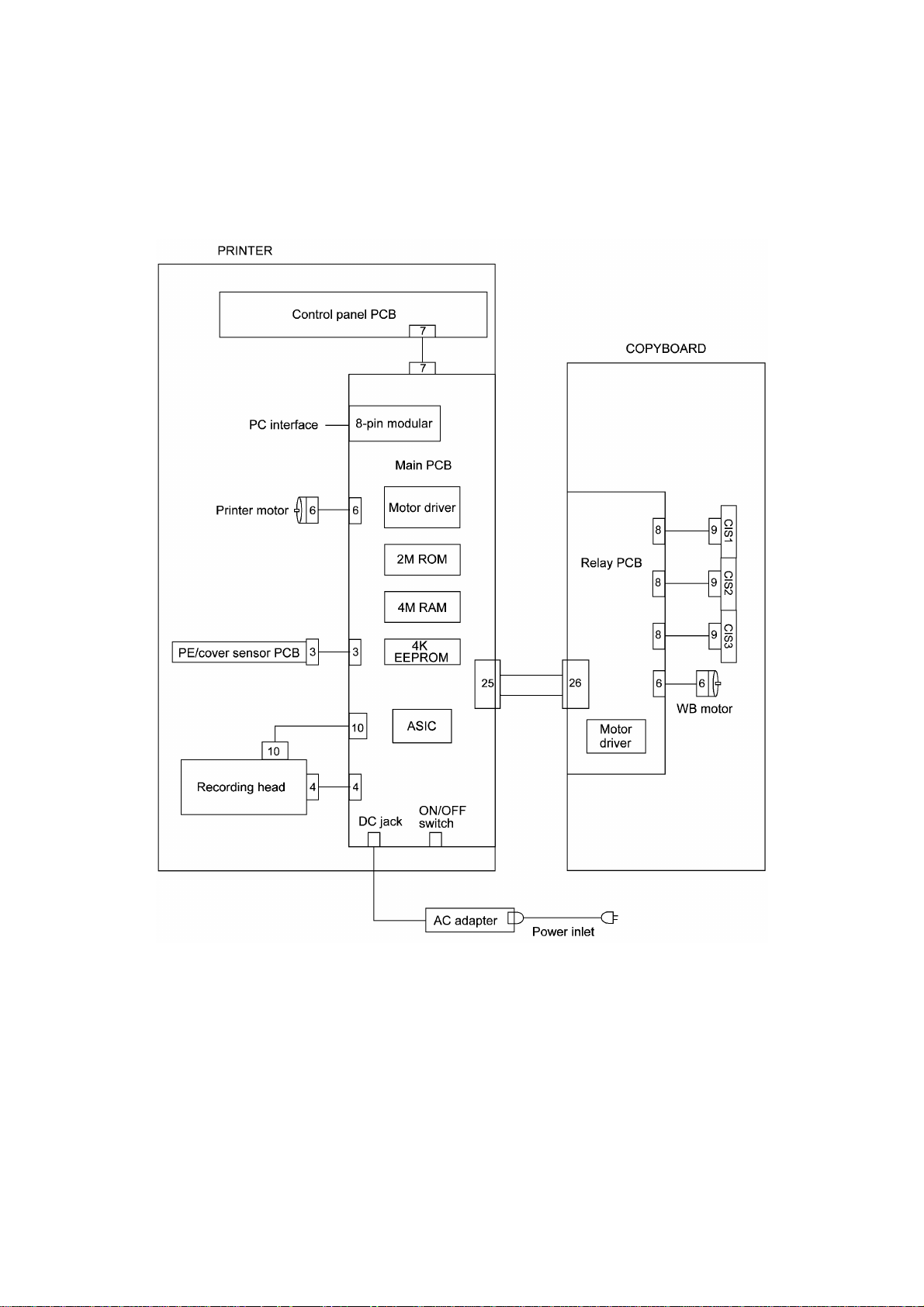

2.3 CONTROL ELECTRONICS .................................................................................. II-6

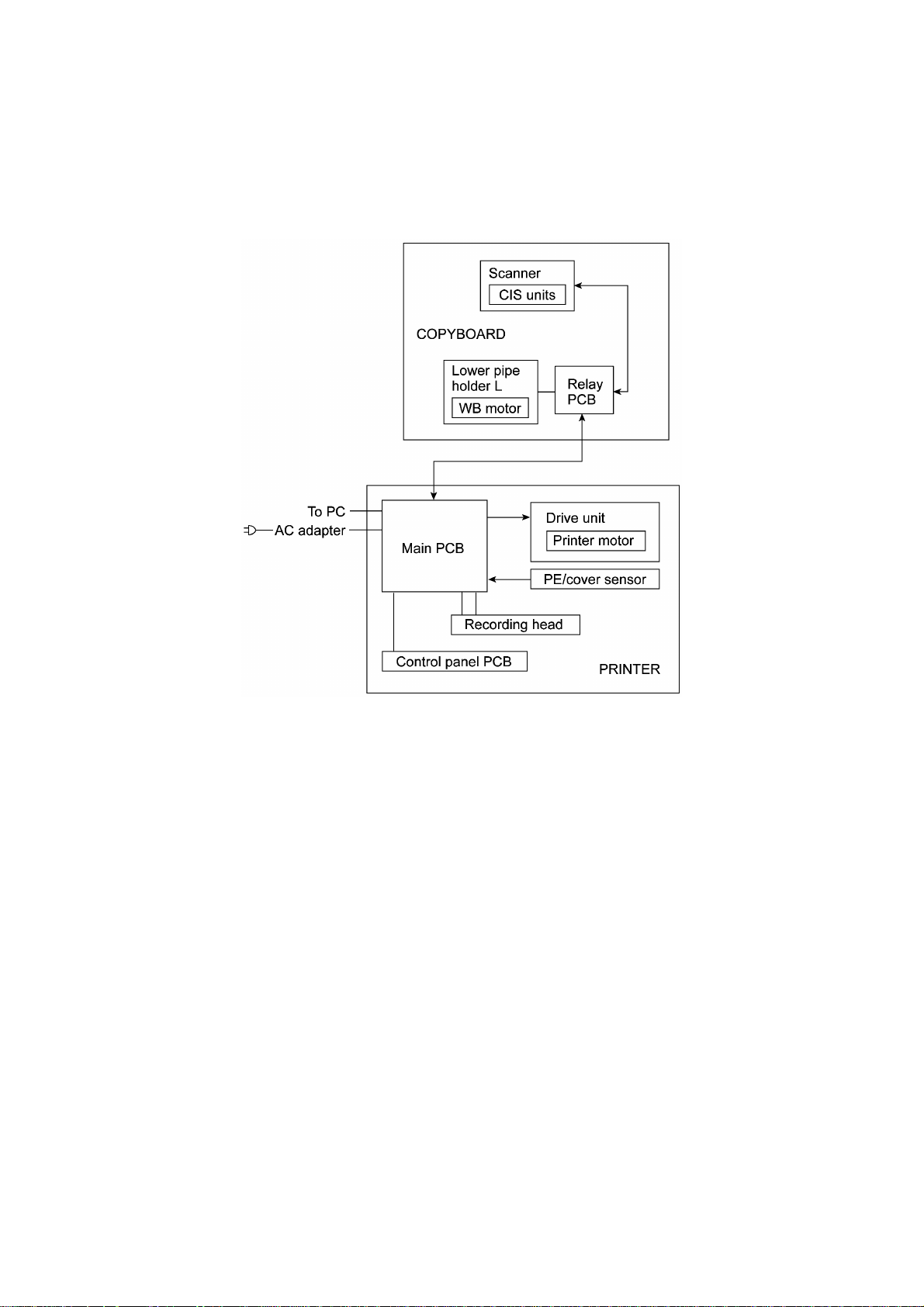

2.1 OVERVIEW

II - 1

2.2 MECHANISMS

The machine consists of the following three mechanisms and sensors:

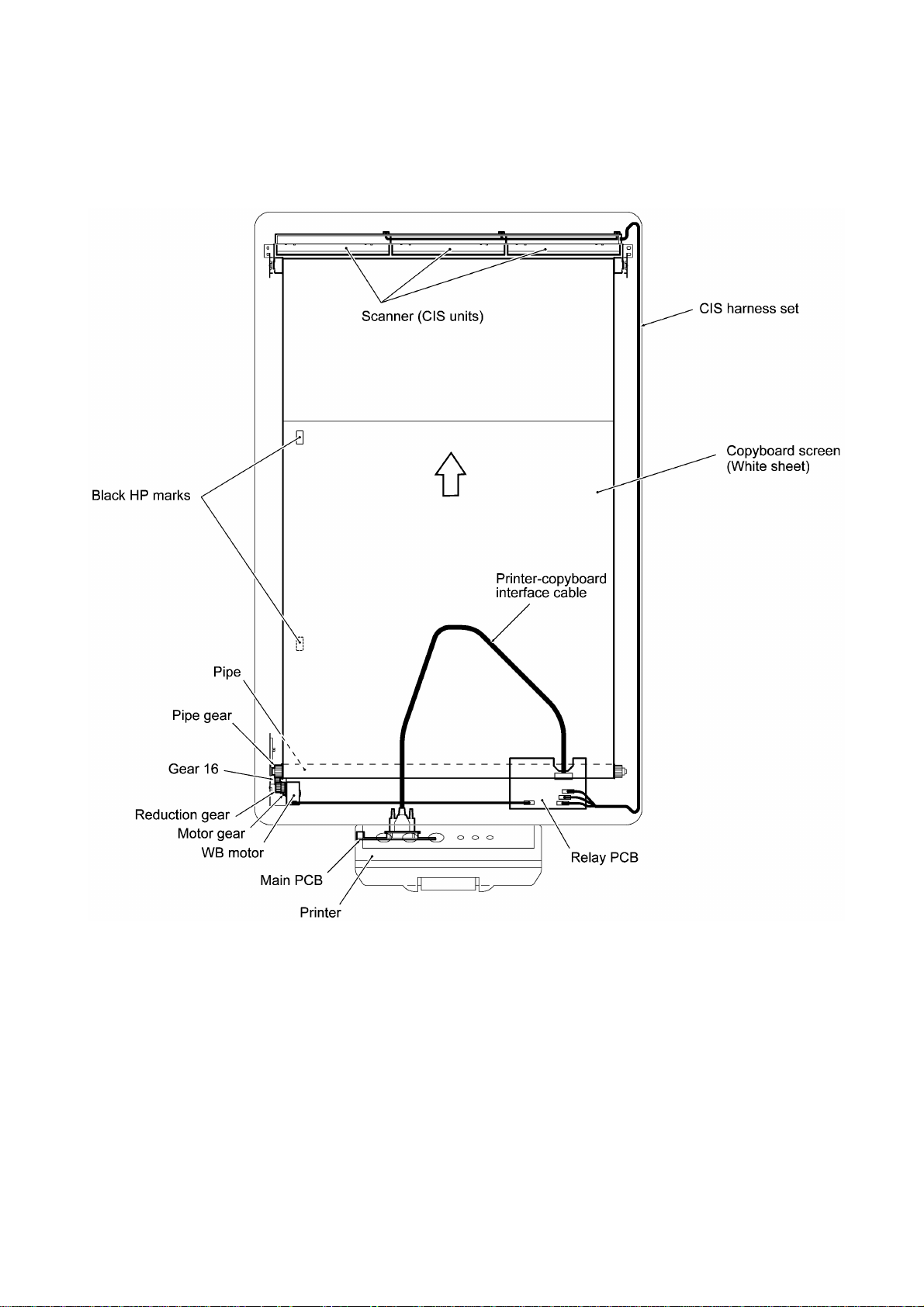

n Scanner Mechanism (Copyboard) - Scrolling the copyboard screen

n Thermal Printing Mechanism (Printer) - Printing image drawn on the copyboard screen and

n Easel Stand*

n Sensors - PE/cover sensor

2.2.1 Scanner mechanism

The scanner mechanism in the copyboard consists of a scanner, copyboard screen, WB motor,

and relay PCB, as illustrated on the next page.

The relay PCB, which is connected to the printer via the interface cable, relays power and control

signals sent from the main PCB of the printer to the WB motor and relays the scanned image with

control signals from the CIS units to the main PCB. If you press the FEED key, the WB motor

rotates to drive the screen feed pipe, scrolling up the copyboard screen.

- Scanning the copyboard screen

feeding recording paper

- Thermistor in the thermal recording head

- CIS unit which acts as a home position detector of the

copyboard screen

*Not provided for the CP1800.

The scanner uses three CIS units, each of which consists of an LED array illuminating the

copyboard screen via a glass prism bar, six lenses collecting the reflected light, and a CIS PCB

carrying out photoelectric conversion to output picture element data.

When pressing any copy-related key scrolls the copyboard screen, the CIS units scan the screen.

After a sequence of the scanning operation, the controller scrolls the screen further until the lefthand CIS unit detects either one of the two black home position (HP) marks pasted on the screen.

Home positioning of the copyboard screen is automatically performed also when you power on the

machine.

II - 2

II - 3

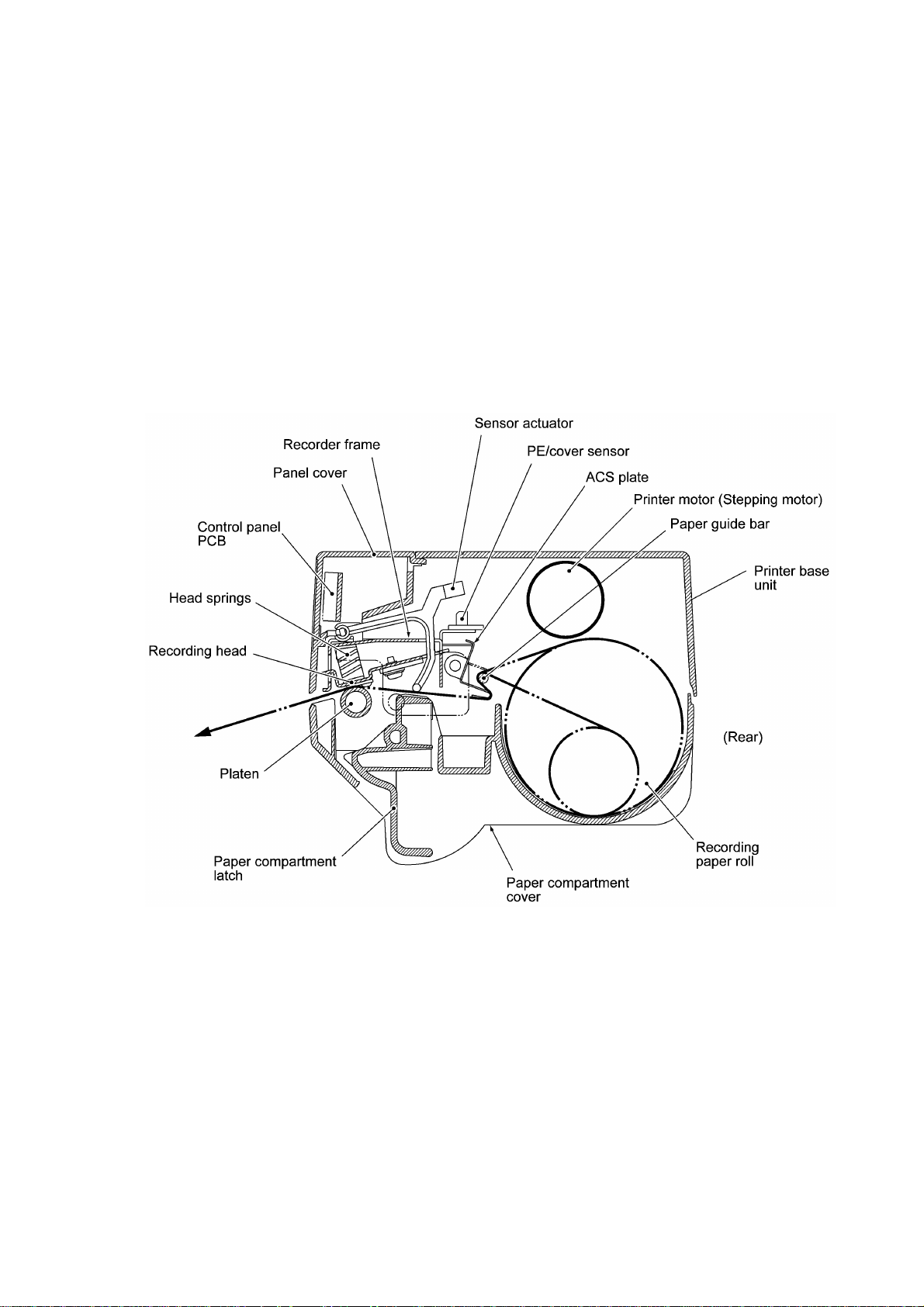

2.2.2 Thermal printing mechanism

The thermal printing mechanism in the printer consists of the thermal recording head, platen, anticurl system (ACS) plate, and paper compartment cover.

The heat-sensitive recording paper is routed between the paper guide bar and ACS plate to the

recording head which prints onto the paper pressed by the platen according to image signals

issued from the main PCB.

The ACS eliminates curl peculiar to rolled paper by curving the paper towards the opposite side of

the curl with the ACS plate.

If the printer motor (stepping motor) is driven, its rotational force is transmitted via the gear train in

the drive unit to the platen gear. The platen rotates to feed paper.

II - 4

2.2.3 Sensors

This machine has three sensors--PE/cover sensor (photosensor), thermistor in the thermal

recording head, and left-hand CIS unit acting as a home position detector of the copyboard screen.

The PE/cover sensor is located on the PE/cover sensor PCB secured to the recorder frame. It

detects whether the recording paper is present or the paper compartment cover is closed.

The thermistor in the recording head allows the controller to monitor the temperature of the head.

According to the change of the thermistor's internal resistance monitored, the controller manages

the duty cycle of the head drive current.

The left-hand CIS works as a home position detector of the copyboard screen also. If it detects

either of the two black HP marks pasted on the copyboard screen, it recognizes that the screen is

in the home position.

II - 5

2.3 CONTROL ELECTRONICS

II - 6

CHAPTER III.

DISASSEMBLY/REASSEMBLY AND

LUBRICATION

CHAPTER III. DISASSEMBLY/REASSEMBLY AND LUBRICATION

CONTENTS

3.1 DISASSEMBLY/REASSEMBLY........................................................................... III-1

n Safety Precautions.............................................................................................. III-1

n Tightening Torque List........................................................................................ III-2

n Preparation......................................................................................................... III-3

n How to Access the Object Component................................................................ III-3

n Disassembly Order Flow..................................................................................... III-4

3.1.1 Disassembly of Printer................................................................................. III-5

[ 1 ] Separating the paper compartment cover from the printer base unit ...... III-5

[ 2 ] Removing the components from the paper compartment cover ............. III-8

Removing the paper guide bar and platen ............................................. III-8

Removing the lock shaft and paper compartment latch.......................... III-9

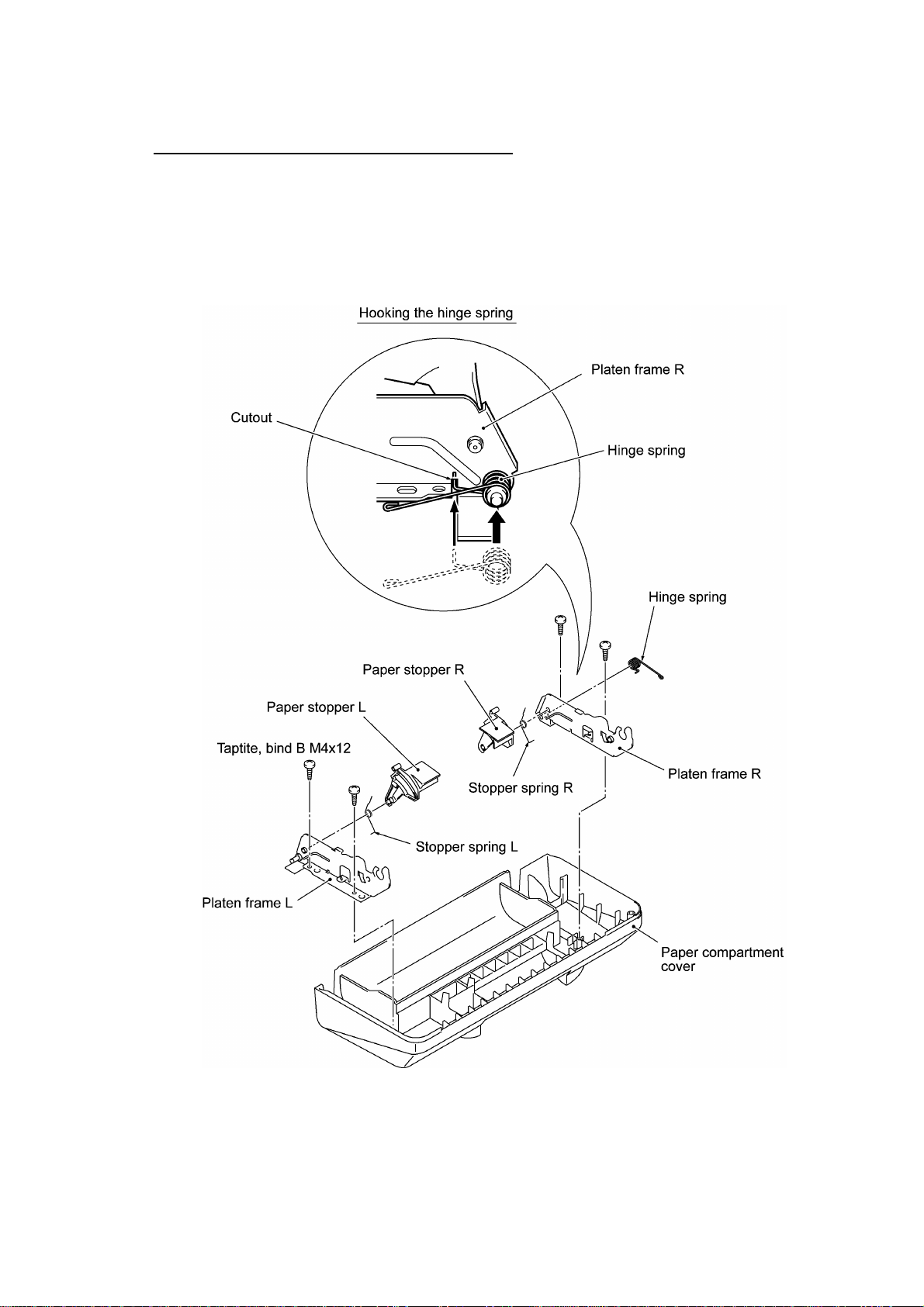

Removing the paper stoppers and platen frames................................... III-10

[ 3 ] Removing the components from the printer base unit ............................ III-12

Removing the printer support ................................................................ III-12

Removing the sub cover and control panel PCB .................................... III-13

Removing the main PCB and its bracket ............................................... III-14

Removing the drive unit and hinge plate L............................................. III-17

Removing the head protector, recording head ASSY, recorder frame,

and PE/cover sensor PCB..................................................................... III-19

Removing the films ............................................................................... III-21

3.1.2 Disassembly of Copyboard ......................................................................... III-22

[ 1 ] Removing the CIS units......................................................................... III-22

Removing the upper cover, corner covers, CIS protector, and

upper support frame.............................................................................. III-22

Removing the CIS frame and CIS units................................................. III-23

[ 2 ] Removing the relay PCB and printer-copyboard interface cable............ III-26

Removing the lower cover, corner covers, CIS protector, and

lower support frame ............................................................................... III-26

Removing the WB motor harness, relay PCB, and

printer-copyboard interface cable........................................................... III-27

i

[ 3 ] Removing the lower pipe and WB motor ............................................... III-29

Removing the lower corner plates and lower frame ............................... III-29

Removing the pipe holder stoppers, pipe spacer L, lower pipe and

its holders .............................................................................................. III-30

Removing the WB motor....................................................................... III-33

[ 4 ] Replacing the white sheet (copyboard screen) and the sheet

backup board......................................................................................... III-35

3.2 LUBRICATION ..................................................................................................... III-40

[ 1 ] Joints between the platen shaft and its bushings.................................... III-40

[ 2 ] WB motor related gears on the lower pipe holder L ............................... III-40

[ 3 ] Lower pipe holder L............................................................................... III-41

[ 4 ] Lower pipe holder R............................................................................... III-41

[ 5 ] Upper pipe shaft.................................................................................... III-42

ii

3.1 DISASSEMBLY/REASSEMBLY

nn Safety Precautions

To prevent the creation of secondary problems by mishandling, observe the following precautions

during maintenance work.

(1) Turn the power off and unplug the AC cord from the power outlet before accessing parts or

units inside the machine. When disassembling the printer, unplug the AC adapter from the

left side of the printer.

(2) Be careful not to lose screws, washers, or other parts removed for parts replacement.

(3) When using soldering irons and other heat-generating tools, take care not to damage the resin

parts such as wires, PCBs, and covers.

(4) Before handling the PCBs, touch a metal portion of the machine to discharge static electricity;

otherwise, the electronic parts may be damaged due to the electricity charged in your body.

(5) When transporting PCBs, be sure to wrap them in conductive sheets such as aluminum foil.

(6) Be sure to reinsert self-tapping screws correctly, if removed.

When removing self-tapping screws from aluminum frames, aluminum material may stick to

the threads of those screws, requiring higher torque for retightening. If it happens, do not

tighten them forcedly, but use new screws and observe the specified torque values.

(7) Tighten screws to the torque values listed on the next page.

(8) When connecting or disconnecting cable connectors, hold the connector bodies not the

cables. If the connector has a lock, always slide the connector lock to unlock it.

(9) Before reassembly, apply the specified lubricant to the specified points. (Refer to Section

3.2.)

(10) After repairs, check not only the repaired portion but also that the connectors and other

related portions function properly before operation checks.

(11) After completion of repairs, always press the FEED key to scroll the copyboard screen (white

sheet) to the home position. This prevents the screen from leaving traces of being curled

along the upper and lower pipes within the scanning area.

Make sure that the copyboard screen is in the home position before storing or packing it.

III - 1

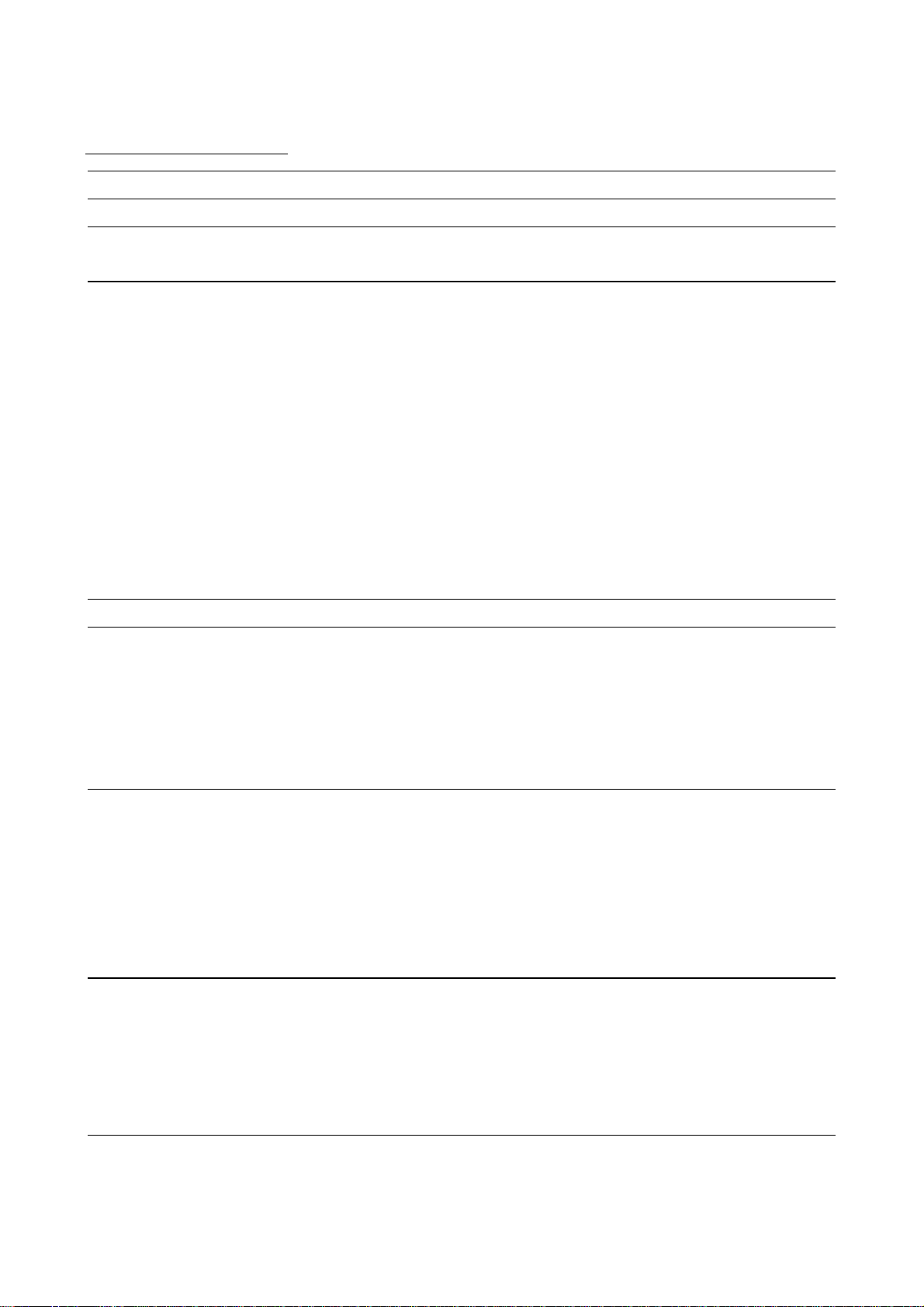

nn Tightening Torque List

Location Screw type Q'ty Tightening torque (N•m)

PRINTER

Platen stopper Taptite, pan B M4x20 1 0.69 ±0.1

Platen frames R and L Taptite, bind B M4x12 4 0.98 ±0.2

Printer support Taptite, cup S M3x6 2 0.69 ±0.1

Taptite, bind B M4x12 2 0.98 ±0.2

Sub cover Taptite, bind B M4x12 1 0.98 ±0.2

Panel cover Taptite, bind B M4x12 2 0.98 ±0.2

Control panel PCB Taptite, cup B M3x8 2 0.69 ±0.1

Main PCB Taptite, cup S M3x6 2 0.69 ±0.1

Drive unit Taptite, bind B M4x12 2 0.98 ±0.2

Printer motor cover Taptite, cup S M3x6 1 0.69 ±0.1

Printer motor Screw, pan (s/p washer) M3x6DB 1 0.69 ±0.1

Hinge plate L Taptite, bind B M4x12 2 0.98 ±0.2

Recorder frame Taptite, bind B M4x12 2 0.98 ±0.2

PE/cover sensor PCB Taptite, cup S M3x6 1 0.69 ±0.1

COPYBOARD

Upper cover Shoulder screw 3 0.78 ±0.1

Corner covers (upper) Screw, flat S M3x10 4 0.78 ±0.1

CIS protector (upper) Taptite, cup S M3x10 2 0.78 ±0.1

Upper support frame Taptite, cup S M3x10 2 0.78 ±0.1

CIS frame Taptite, cup S M3x10 4 0.78 ±0.1

CIS units Taptite, bind B M3x8 6 0.39 ±0.1

Lower cover Shoulder screw 3 0.78 ±0.1

Corner covers (lower) Screw, flat S M3x10 4 0.78 ±0.1

CIS protector (lower) Taptite, cup S M3x10 2 0.78 ±0.1

Lower support frame Taptite, cup S M3x10 2 0.78 ±0.1

PCB support Taptite, cup S M3x10 2 0.78 ±0.1

Relay PCB Taptite, cup S M3x6 2 0.78 ±0.1

Printer-copyboard interface cable Taptite, cup S M3x10 2 0.78 ±0.1

Lower corner plates R and L Taptite, cup S M3x10 4 0.78 ±0.1

Lower frame Taptite, washer S M3x10 1 0.78 ±0.1

Taptite, bind B 3x8 2 0.69 ±0.1

Pipe holder stoppers Taptite, cup S M3x8 2 0.78 ±0.1

WB motor Screw, pan (s/p washer) M3x6DB 2 0.78 ±0.1

Side covers R and L Taptite, cup S M3x10 6 0.78 ±0.1

III - 2

nn Preparation

Prior to proceeding to the disassembly procedure,

(1) Unplug

- the AC cord and AC adapter and

- the optional PC interface cable if connected. (Not shown below.)

(2) Remove the tray and recording paper.

(3) CP2000/CB200: Take down the assembly of the copyboard and printer from the easel stand.

(4) Disconnect the printer-copyboard interface cable from the printer and then remove the four

decorative screws to separate the printer from the copyboard.

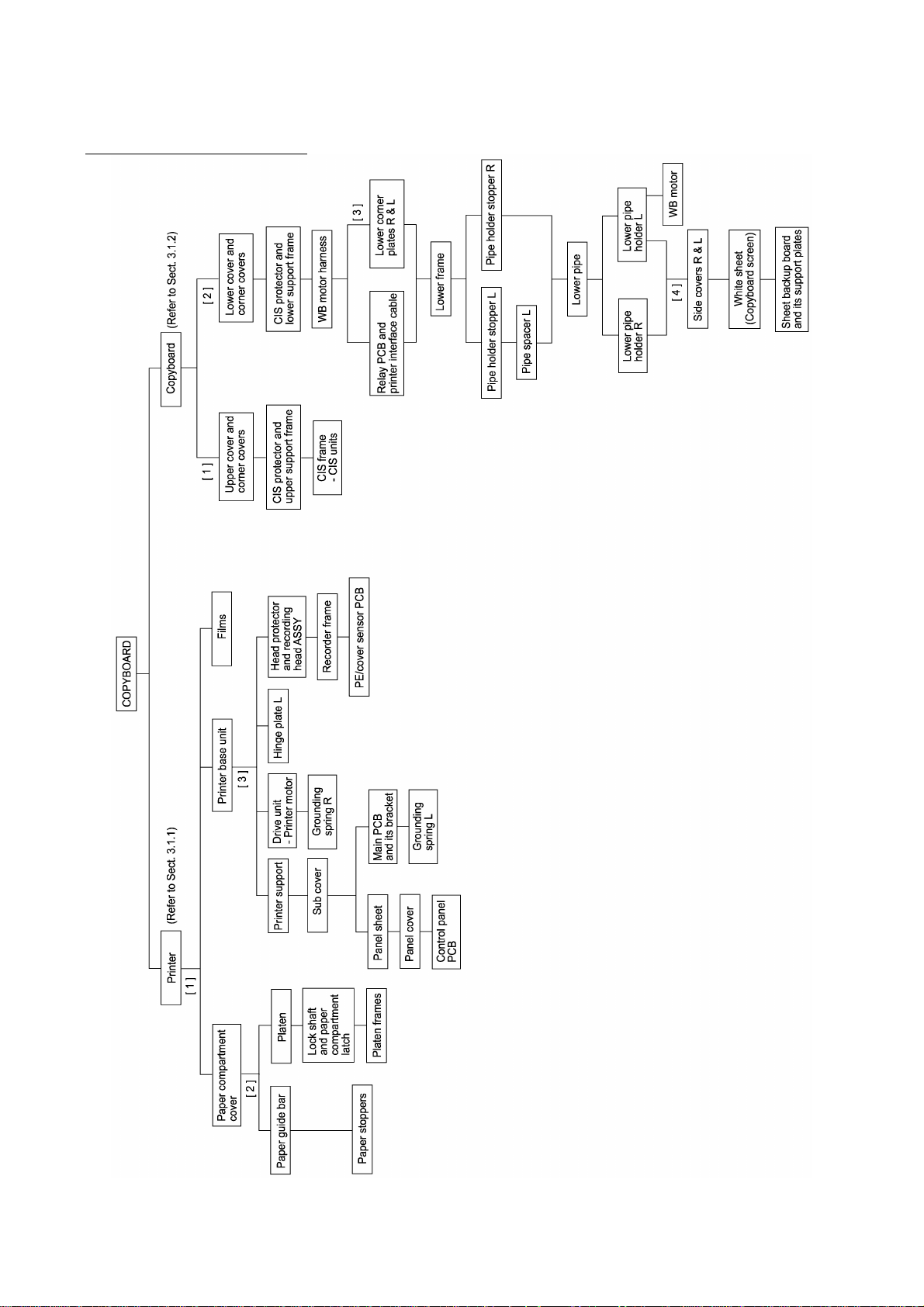

nn How to Access the Object Component

• On the next page is a disassembly order flow which helps you access the object components.

To remove the main PCB, for example, first find it on the flow. You need to remove the printer,

printer base unit, printer support, and sub cover so as to access the main PCB.

• Unless otherwise specified, the disassembled parts or components should be reassembled in

the reverse order of removal.

III - 3

nn Disassembly Order Flow

III - 4

3.1.1 Disassembly of Printer

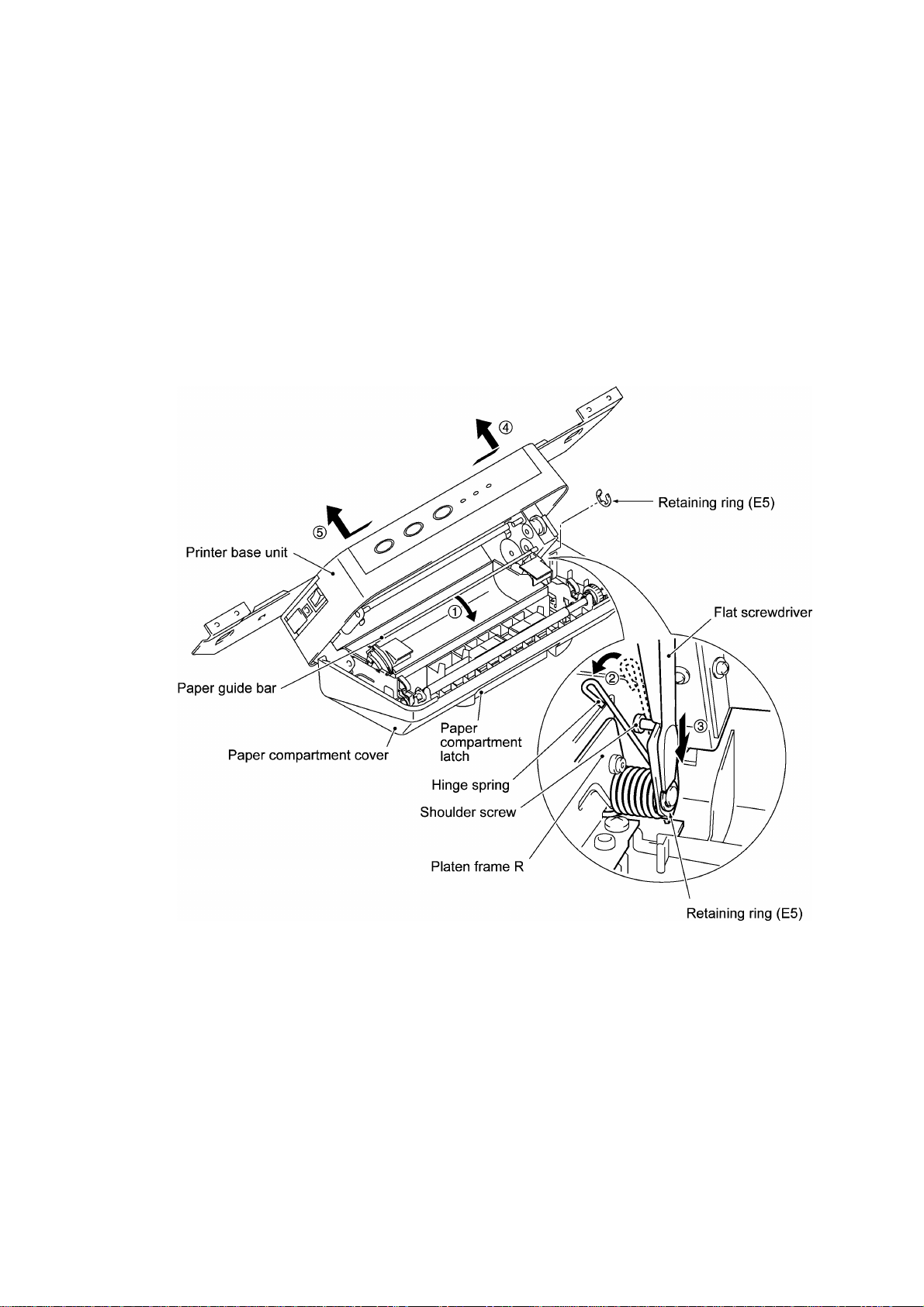

[ 1 ] Separating the paper compartment cover from the printer base unit

(1) Open the paper compartment cover by pulling up its latch.

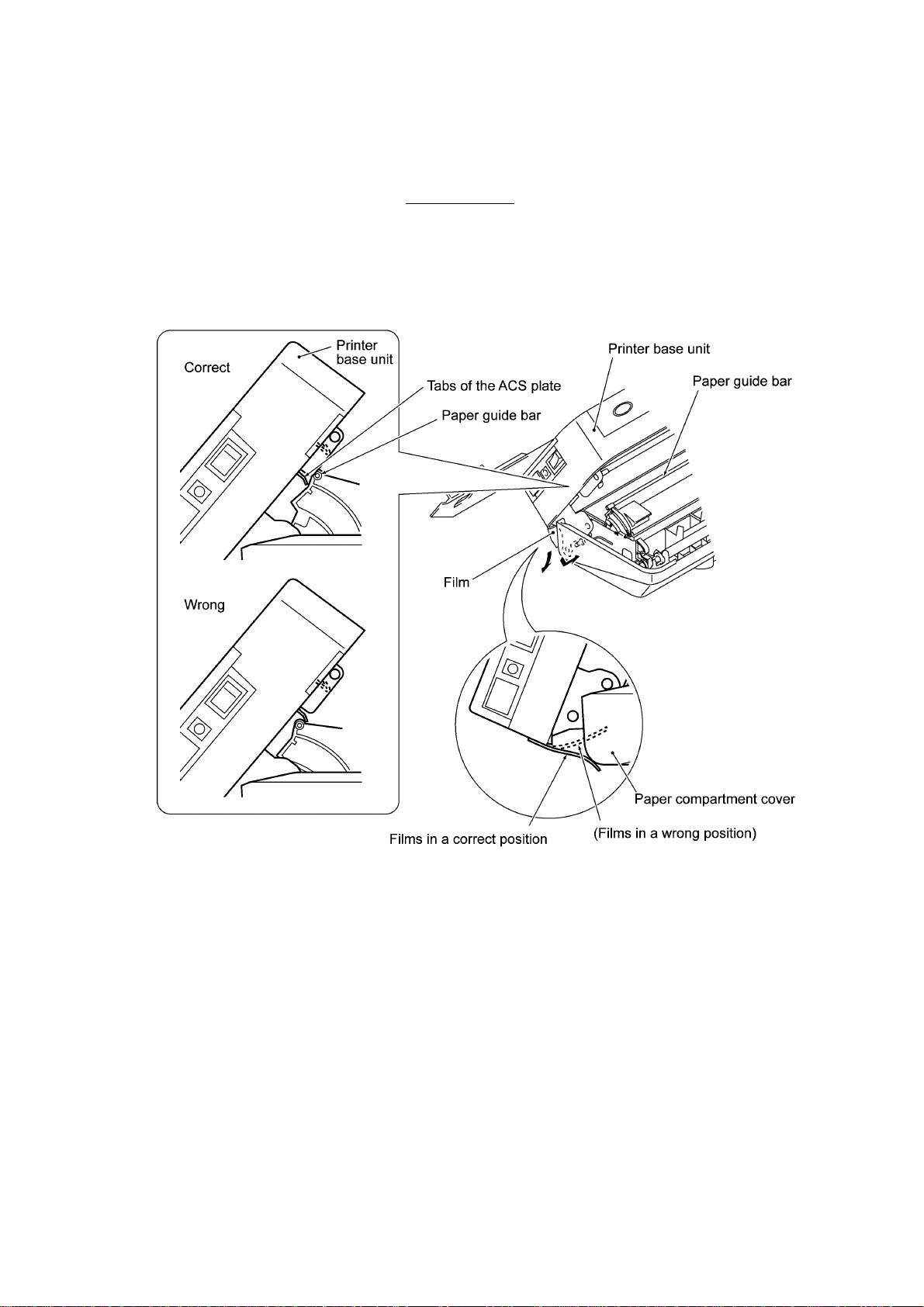

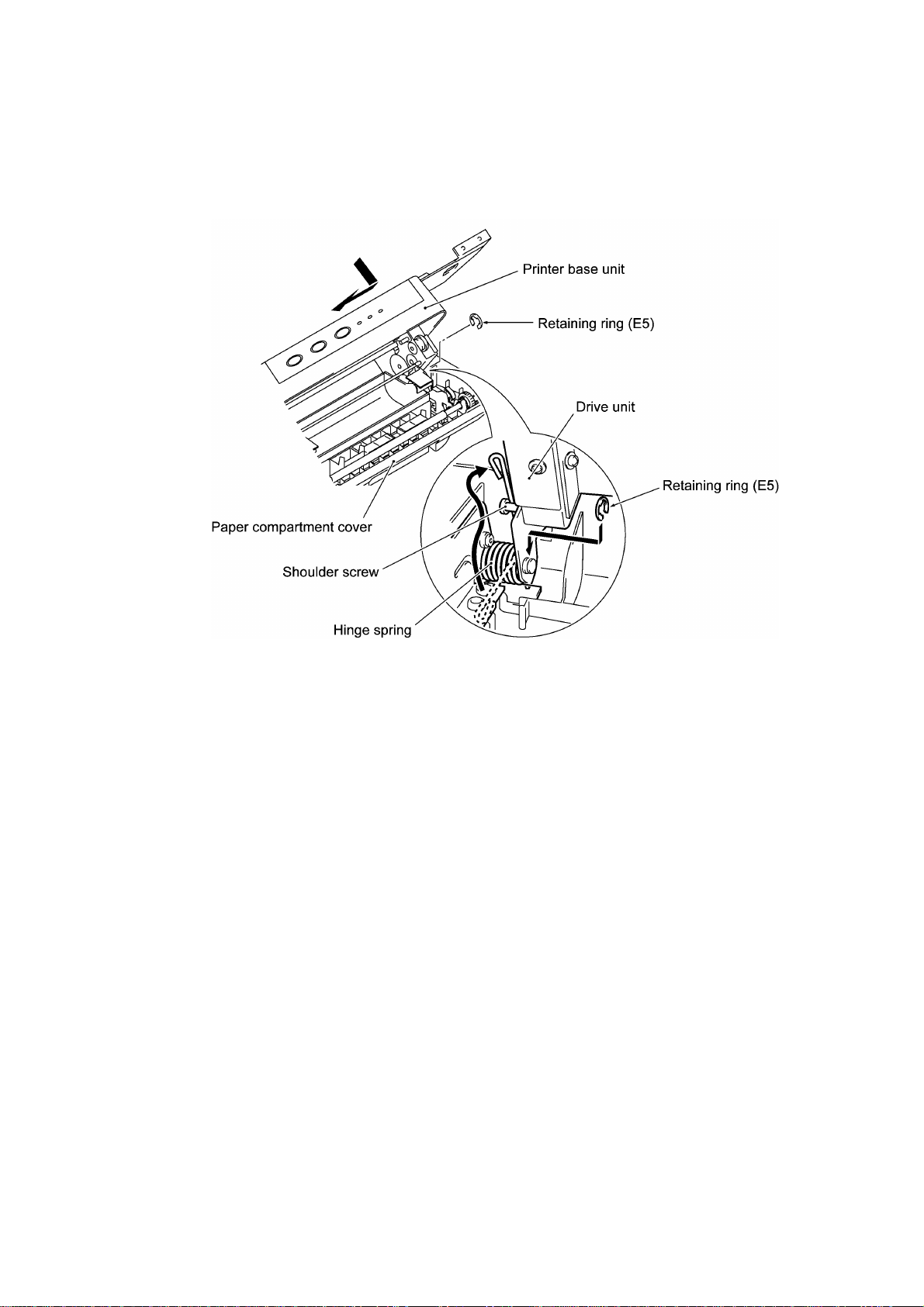

(2) Pull the paper guide bar in the direction of arrow • and unhook the hinge spring from the

shoulder screw (arrow ‚).

(3) Remove the retaining ring (E5) (arrow ƒ) from the shaft of the platen frame R.

(4) Shift the printer base unit in the direction of arrows „ and … to release it from the shafts of

the platen frame R and L, respectively.

III - 5

nn Reassembling notes

When reinstalling the printer base unit to the paper compartment cover:

1) Hold the printer base unit at a right angle from the paper compartment cover and fit it

over the shafts of the platen frames L and R.

When doing this, take care not to bring the paper guide bar inside the tabs of the ACS

plate or not to bring the films inside the paper compartment cover.

III - 6

2) Set the retaining ring (E5) onto the shaft of the platen frame R.

3) Hook the hinge spring onto the shoulder screw.

III - 7

[ 2 ] Removing the components from the paper compartment cover

Removing the paper guide bar and platen

(1) If the printer base unit has not been removed, open the paper compartment cover by pulling

up its latch.

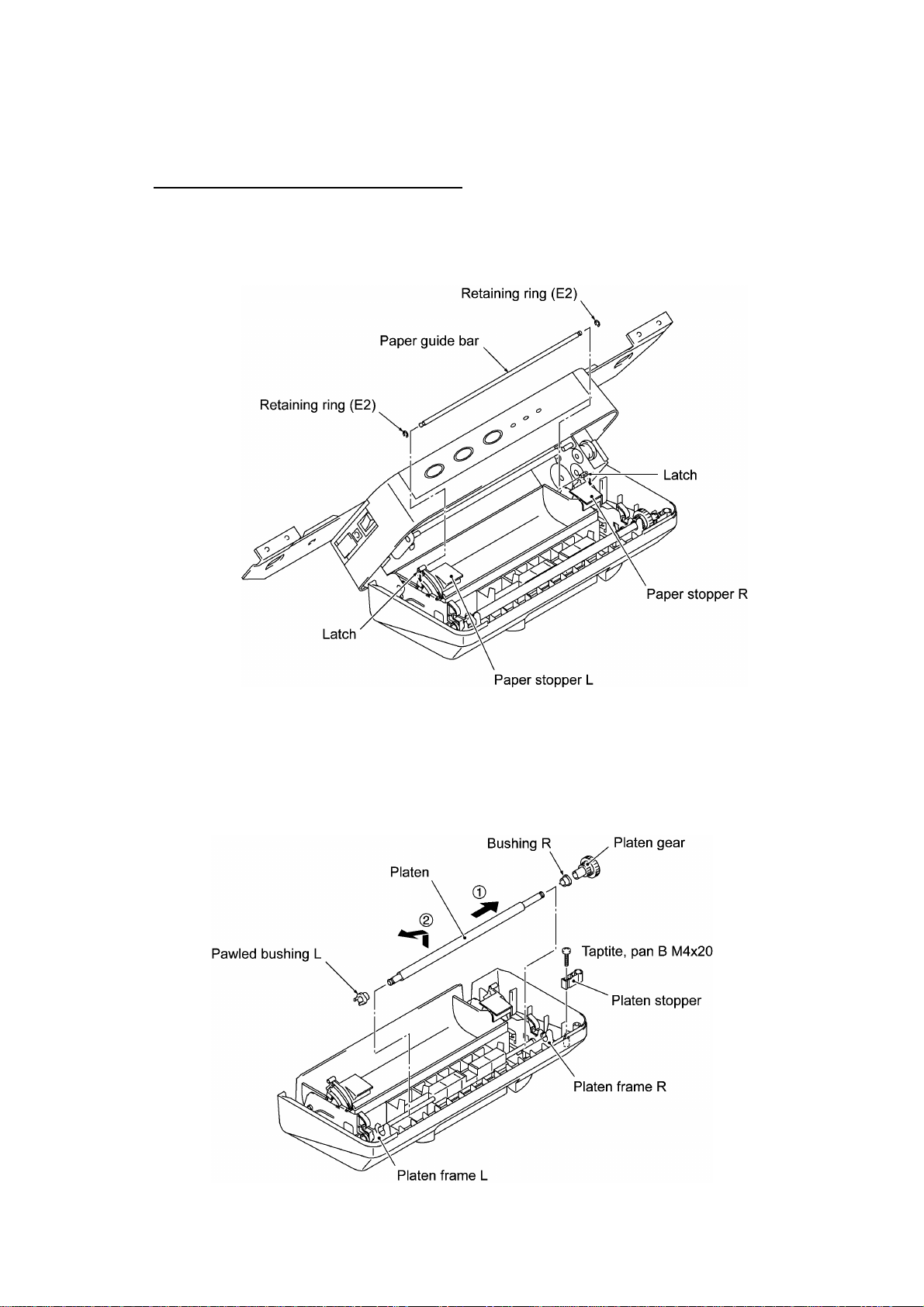

(2) Remove the retaining ring (E2) from each end of the paper guide bar, then remove the paper

guide bar from the paper stoppers R and L.

(3) Remove the platen stopper (one pan B taptite screw, M4x20).

(4) At the right end of the platen shaft, remove the platen gear by pulling its pawl outwards and

then remove the bushing R. At the left end, remove the pawled bushing L by pulling its pawls

outwards.

(5) Move the platen to the right (arrow •) to take out the left end from the platen frame L and

then take it out to the left (arrow ‚).

III - 8

Removing the lock shaft and paper compartment latch

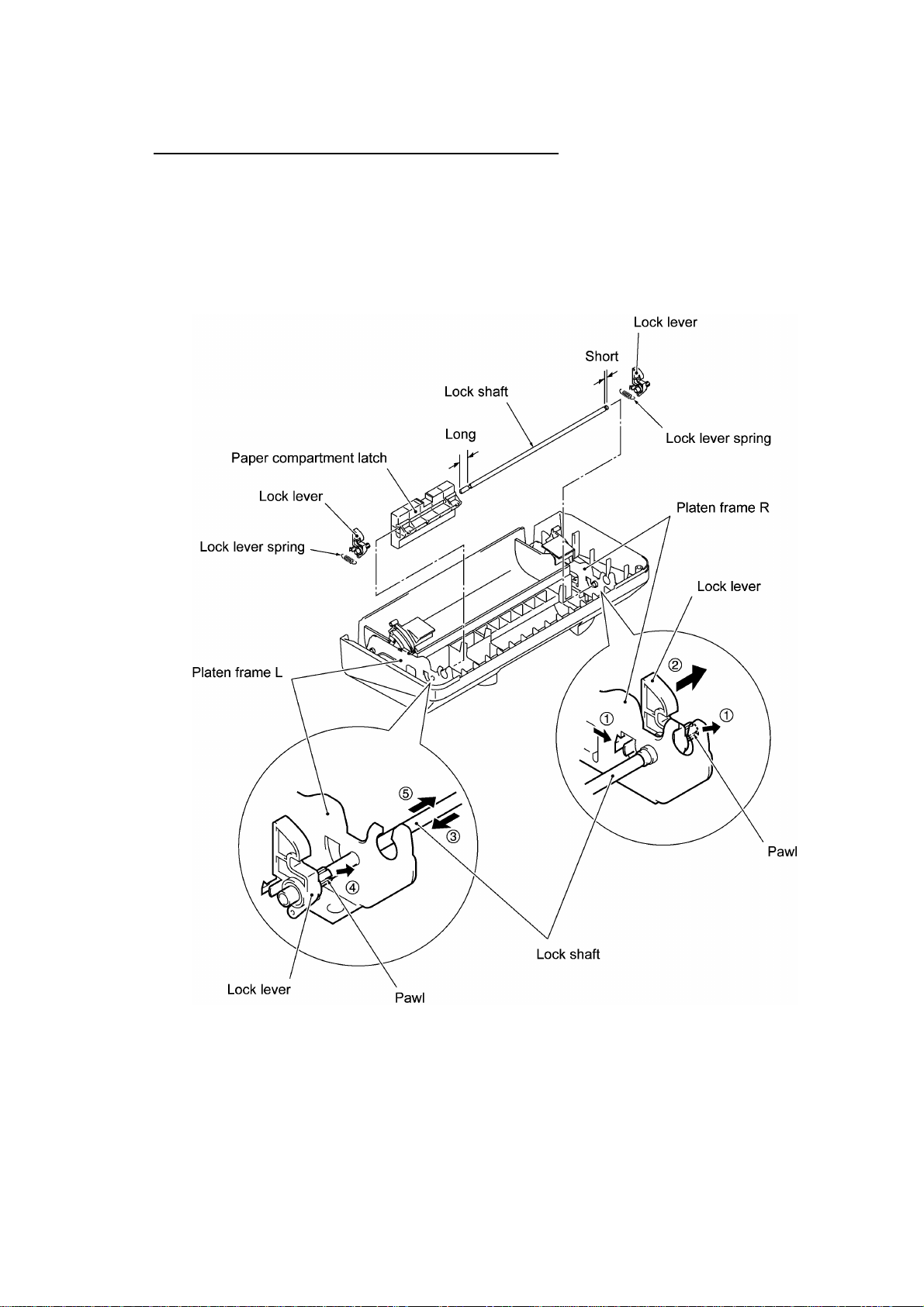

(6) At the right end of the lock shaft, remove the lock lever by unlatching the pawls in the

direction of arrows • and pulling the lock lever outwards (arrow ‚) and then unhook the lock

lever spring from the platen frame R.

(7) Move the lock lever to the left (arrow ƒ). At the left end of the lock shaft, remove the lock

lever by unlatching the pawl (arrow „) and then unhook the lock lever spring from the platen

frame L. Take out the lock shaft (arrow …).

nn Reassembling notes

• When inserting the lock shaft through the paper compartment latch, face its short end to the

right as shown above.

III - 9

Removing the paper stoppers and platen frames

(8) Remove two screws from the platen frame R and take out the platen frame R together with

the hinge spring, paper stopper R and its spring.

(9) Remove two screws from the platen frame L and take out the platen frame L together with the

paper stopper L and its spring.

III - 10