Brother BES-111AF Instruction Manual

BES-111AF

BROTHER

EMBROIDERY

SYSTEM

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

COMPACT MONOGRAMMING MACHINE

INSTRUCTION MANUAL

Thank you very much for buying a BROTHER sewing machine. Before using your new machine,

jury

please read the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of

moving parts such as the needle and thread take-up lever, and consequently there is always a danger

of injury that can be caused by these parts. Follow the instructions from training personnel and

instructions regarding safe and correct operation before operating the machine so that you will know

how to use the machine correctly.

SAFETY INSTRUCTIONS

1. Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are

provided in order to ensure safe operation of this machine and to prevent accidents and injury to

yourself or other people. The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

--------- This symbol (∆) indicates something that you should be careful of. The picture inside the

triangle indicates the nature of the caution that must be taken.

(For example, the symbol at left means "beware of injury".)

--------- This symbol ( ) indicates something that you must not do.

--------- This symbol ( ) indicates something that you must do. The picture inside the circle

indicates the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

The instructions which follow this term indicate situations where failure to

follow the instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to

follow the instructions could cause in

damage to equipment and surroundings.

when usingthe machine or physical

BES-111AF

i

2. Notes on safety

g

y

g

y

DANGER

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the

wall outlet before opening the face plate of the control box. Touching areas where high voltages are

present can result in severe injury.

CAUTION

Environmental requirements

Use the sewing machine in an area which is

free from sources of strong electrical noise

such as high-frequency welders.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage

should be within ±10% of the rated voltage for

the machine.

e fluctuations which aregreater this ma

Volta

cause problems with correct operation.

The power supply capacity should be greater

than the requirements for the sewing

machine's electrical consumption.

Insufficient power supply capacity may cause

problems with correct operation.

The ambient temperature should be within the

range of 5°C to 35°C during use.

Temperatures which are lower or higher than

this may cause problems with correct

operation.

Installation

The relative humidity should be within the

range of 45% to 85% during use, and no

dew formation should occur in any

devices.

Excessively dry or humid environments

and dew formation may cause problems

with correct operation.

Avoid exposure to direct sunlight during

use.

Exposure to direct sunlight may cause

problems with correct operation.

In the event of an electrical storm, turn off

the power and disconnect the power cord

from the wall outlet.

Lightning may cause problems with

correct operation.

Machine installation should onlybe carried out

by a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may

need to be done.

The sewing machine weighs more than about

. The installation should be carried out b

30 k

two or more people.

Do not connect the power cord until

installation is complete, otherwise the machine

may operate if the foot switch is depressed by

mistake, which could result in injury.

Be sure to connect the ground. If the ground

connection is not secure, you run the risk of

receiving a serious electric shock.

BES-111AF

ii

Be sure to wear protective goggles and

gloves when handling the lubricating oil

and grease, so that they do not get into

your eyes or onto your skin, otherwise

inflammation can result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they

can cause vomiting and diarrhea.

Keep the oil out of the reach of children.

Avoid settingup the sewingmachine near

sources of strong electrical noise such as

high-frequency welding equipment.

If this precaution is not taken, incorrect

machine operation may result.

CAUTION

y

y

g

y

g

y

Sewing

This sewing machine should only be used

by operators who have receives the

necessary training in safe use beforehand.

The sewing machine should not be used

for any applications other than sewing.

Be sure to wear protective goggles when

using the machine.

If goggles are not worn, there is the danger

that if a needle breaks, parts of the broken

needle ma

result.

Attach all safety devices before using the

sewing machine. If the machine is used

without these devices attached, injury may

result.

Do not touch any of the moving parts or

press any objects against the machine

while sewin

injury or damage to the machine.

enteryour eyes and injuryma

,asthismayresult in personal

Cleaning

Turn off the power switch at the following

times, otherwise the machine may operate if

the foot switch is depressed by mistake,

which could result in injury.

- When threading the needle

- When replacing the bobbin and

needle

- When not using the machine and

when leaving the machine unattended

If an error occurs in machine operation, or if

abnormal noises or smells are noticed,

immediately turn off the power switch. Then

contact your nearest Brother dealer or a

qualified technician.

If the machine develops a problem, contact

your nearest Brother dealer or a qualified

technician.

Turn off the power switch before starting

cleaningwork, otherwise the machine

an

may operate if the foot switch is

depressed by mistake, which could result

in injury.

Maintenance and inspection

Maintenance and inspection of the sewing

machine should only be carried out by a

qualified technician.

Ask your Brother dealer or a qualified

electrician to carry out any maintenance

and inspection of the electrical system.

Turn off the power switch and disconnect

the power cord from the wall outlet at the

followin

operate if the foot switch is depressed by

mistake, which could result in injury.

times, otherwise the machine ma

- When carrying out inspection,

adjustment and maintenance

- When replacing consumable parts

such as the rotary hook and knife

Be sure to wear protective goggles and

gloves when handling the lubricating oil

and grease, so that they do not get into

your eyes or onto your skin, otherwise

inflammation can result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they

can cause vomiting and diarrhea.

Keep the oil out of the reach of children.

If the power switch needs to be left on when

carrying out some adjustment, be extremely

careful to observe safety precautions.

Use only the proper replacement parts as

specified by Brother.

If anysafetydevices have been removed, be

absolutely sure to re-install them to their

original positions and check that they

operate correctly before using the machine.

Any problems in machine operation which

result from unauthorized modifications to the

machine will not be covered by the warranty.

BES-111AF

iii

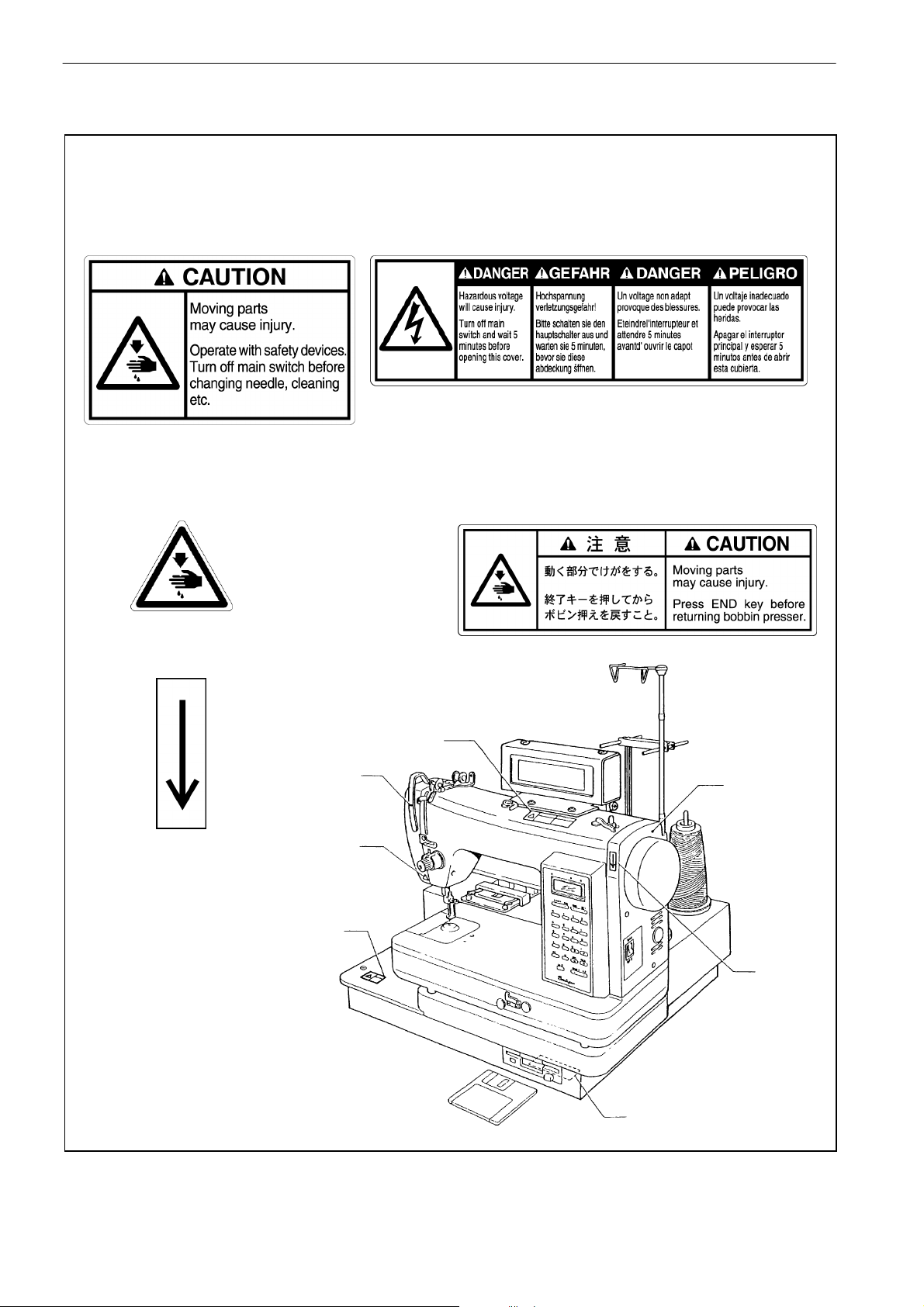

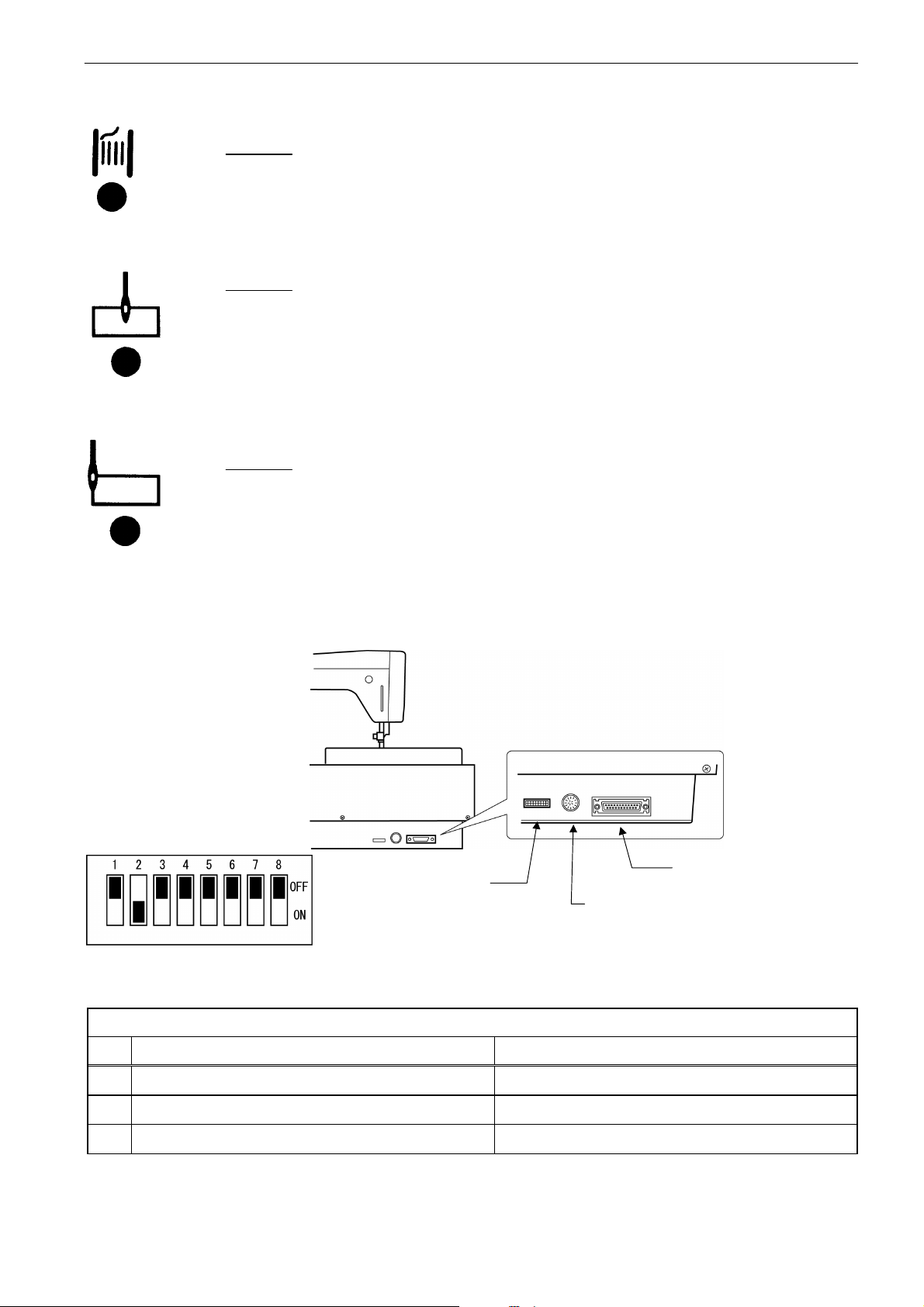

3. Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels

have been removed or are difficult to read, please contact your nearest Brother dealer.

1

2

Safety devices: Thread take-up cover, Belt cover, etc.

3

Never touch or push the

needle bar during

operation as it may result

in injuries or damage to

the sewing machine.

5

4 Direction of operation

Thread take-up

cover

3

1

5

Belt cover

4

2

H0527

BES-111AF

iv

CONTENTS

1. An Introduction of Sewing Machine...............................................................................................1

1-1. Specifications.................................................................................................................................................... 1

2. Preparation of Sewing Machine ....................................................................................................2

2-1. Part names ....................................................................................................................................................... 2

2-2. Threading the needle thread.............................................................................................................................. 4

2-3. Winding the bobbin thread ................................................................................................................................. 5

2-4. Correctly wound bobbin..................................................................................................................................... 6

2-5. Replacing the bobbin......................................................................................................................................... 6

2-6. Replacing the needle......................................................................................................................................... 7

2-7. Installing the embroidery hoop ........................................................................................................................... 7

2-8. Adjusting the presser foot height........................................................................................................................8

2-9. Drawing out the bobbin thread ...........................................................................................................................8

2-10. Thread tension.................................................................................................................................................. 9

2-11. Replacing the lamp.......................................................................................................................................... 10

2-12. Cleaning ......................................................................................................................................................... 11

2-13. Lubrication ...................................................................................................................................................... 12

3. Sewing Preparation ....................................................................................................................13

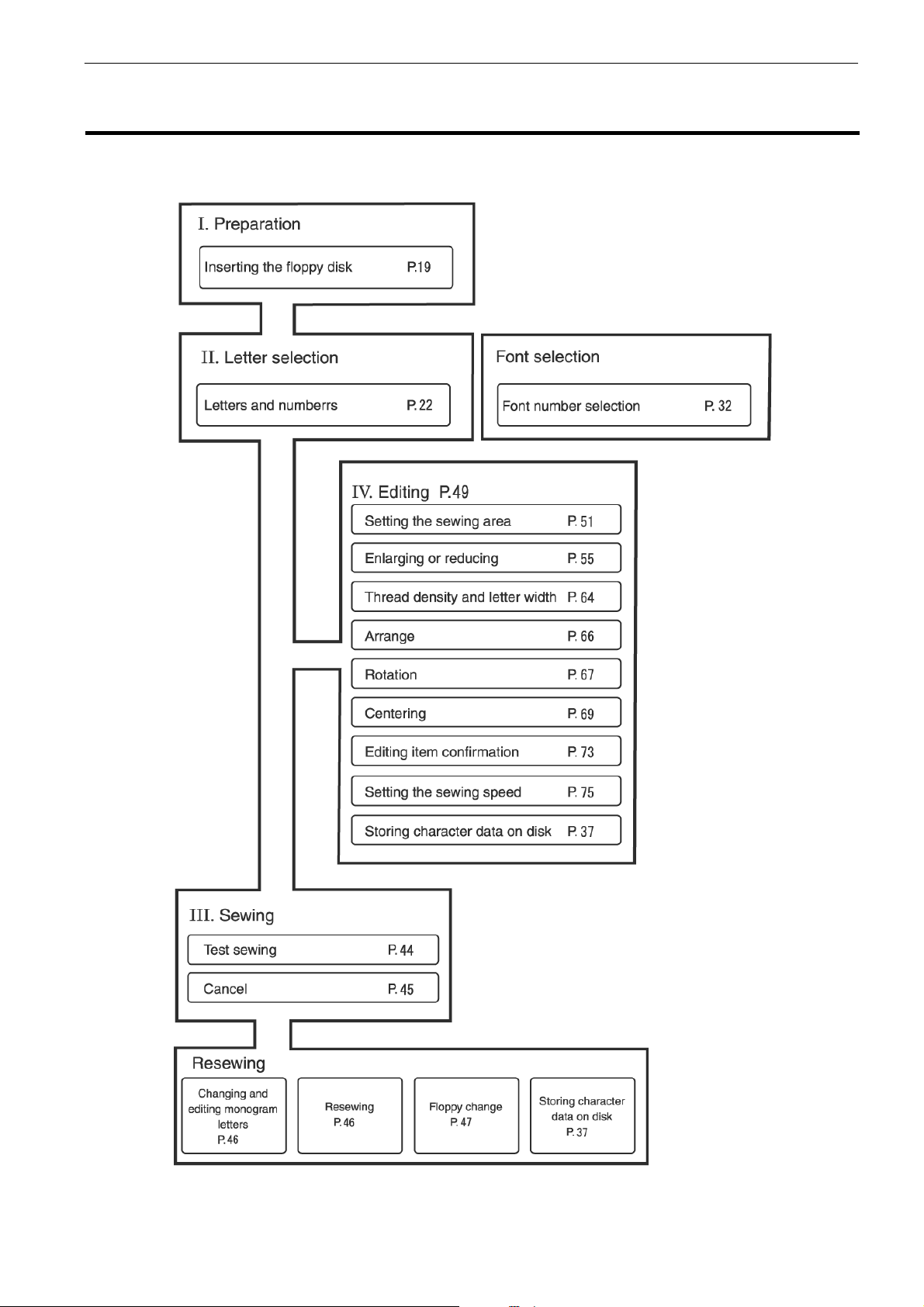

3-1. Flow chart....................................................................................................................................................... 13

3-2. Operation panel part names and functions ....................................................................................................... 14

3-3. DIP switch function.......................................................................................................................................... 17

3-4. Floppy disk ..................................................................................................................................................... 18

3-5. Connecting a keyboard and entering characters............................................................................................... 20

4. Sewing Procedure ......................................................................................................................22

4-1. Alphanumerics (upper and lower case letters, numbers)................................................................................... 22

4-1-1. If "Area over" is displayed .....................................................................................................................23

4-1-2. If "Short of area" is displayed ................................................................................................................ 24

4-1-3. Correcting a letter................................................................................................................................. 25

4-2. Setting the letter spacing ................................................................................................................................. 26

4-2-1. Space and sewing position ...................................................................................................................30

4-3. Pause............................................................................................................................................................. 31

4-4. Carriage return ................................................................................................................................................ 31

4-5. Selecting fonts for letters and numbers ............................................................................................................32

4-5-1. To embroider the letters ........................................................................................................................33

4-5-2. Letter monogram specifications (optional) .............................................................................................34

4-6. How to install Tajima floppy disk....................................................................................................................... 36

4-7. Storing character data on disk (creating a storage disk).................................................................................... 37

4-8. Reading character data ...................................................................................................................................39

5. Sewing Function .........................................................................................................................42

5-1. Sewing............................................................................................................................................................ 42

5-2. Test sewing..................................................................................................................................................... 44

5-3. To change the sewing start position after test sewing........................................................................................ 45

5-4. Cancel ............................................................................................................................................................ 45

5-4-1. Changing and editing monogram letters ................................................................................................ 46

5-4-2. Resewing ............................................................................................................................................. 46

5-4-3. Replacing the floppy disk.......................................................................................................................... 47

5-4-4. Environment settings ............................................................................................................................ 48

BES-111AF

6. Editing........................................................................................................................................ 49

6-1. Editing letters and numbers..............................................................................................................................49

6-2. Edit item selection ...........................................................................................................................................50

6-3. Setting the sewing area ...................................................................................................................................51

6-3-1. Setting sewing area for hoop number 02................................................................................................51

6-3-2. Setting sewing area for hoop number ....................................................................................................52

6-3-3. Setting the monogram area...................................................................................................................53

6-4. Enlarging or reducing.......................................................................................................................................55

6-4-1. Setting the size ratio altogether .............................................................................................................55

6-4-2. Setting the size ratio individual (1) .........................................................................................................57

6-4-2. Setting the size ratio individual (2) .........................................................................................................59

6-4-3. Automatic calculation ............................................................................................................................61

6-4-4. Designate dimensions...........................................................................................................................62

6-5. Thread density and letter width ........................................................................................................................64

6-5-1. Thread density......................................................................................................................................64

6-5-2. Letter width...........................................................................................................................................65

6-6. Arrange ...........................................................................................................................................................66

6-7. Rotation ..........................................................................................................................................................67

6-7-1. If lateral alignment is selected ...............................................................................................................67

6-7-2. If Vertical alignment is selected..............................................................................................................68

6-8. Centering ........................................................................................................................................................69

6-8-1. With centering.......................................................................................................................................70

6-8-2. Without centering..................................................................................................................................71

6-8-3. Setting the needle start position and sewing position..............................................................................72

6-9. Editing item confirmation..................................................................................................................................73

6-10. Setting the sewing speed.................................................................................................................................75

6-11. Stop position change function ..........................................................................................................................76

7. Optional Parts ............................................................................................................................ 77

7-1. Sub table.........................................................................................................................................................77

7-2. Spring .............................................................................................................................................................77

8. Trouble Shooting........................................................................................................................ 78

9. Error Messages .......................................................................................................................... 80

10. X-Y Feed Adjustment ................................................................................................................. 81

10-1. Removing the X-Y feed unit .............................................................................................................................81

10-2. Adjusting the wire in the X direction..................................................................................................................82

10-3. Adjusting the wire in the Y direction..................................................................................................................82

11. Adjusting the upper thread breakage detector............................................................................ 83

11-1. Checking the upper thread breakage detector operation ...................................................................................83

11-2. Cleaning the upper thread breakage detector ...................................................................................................83

12. Character Code List ................................................................................................................... 84

13. Floppy Disk Input Contents List ................................................................................................. 85

BES-111AF

1. An Introduction of Sewing Machine

- Interactive operation makes monogramming names easier than ever for beginners.

- Designed to be compact. Minimal installation space is required.

- Company names, club or team names, and other letters sewn can be stored on floppy disk for later

use.

- Twenty-eight styles of lettering are available.

- Letter size, thread density and letter width, letter alignment, and sewing area can be easily set, and

letters can be individually added or deleted for easier editing of the monogram.

- Optional disks of pattern designs (for sports, animals, flowers, Zodiac signs, design frames) are also

available.

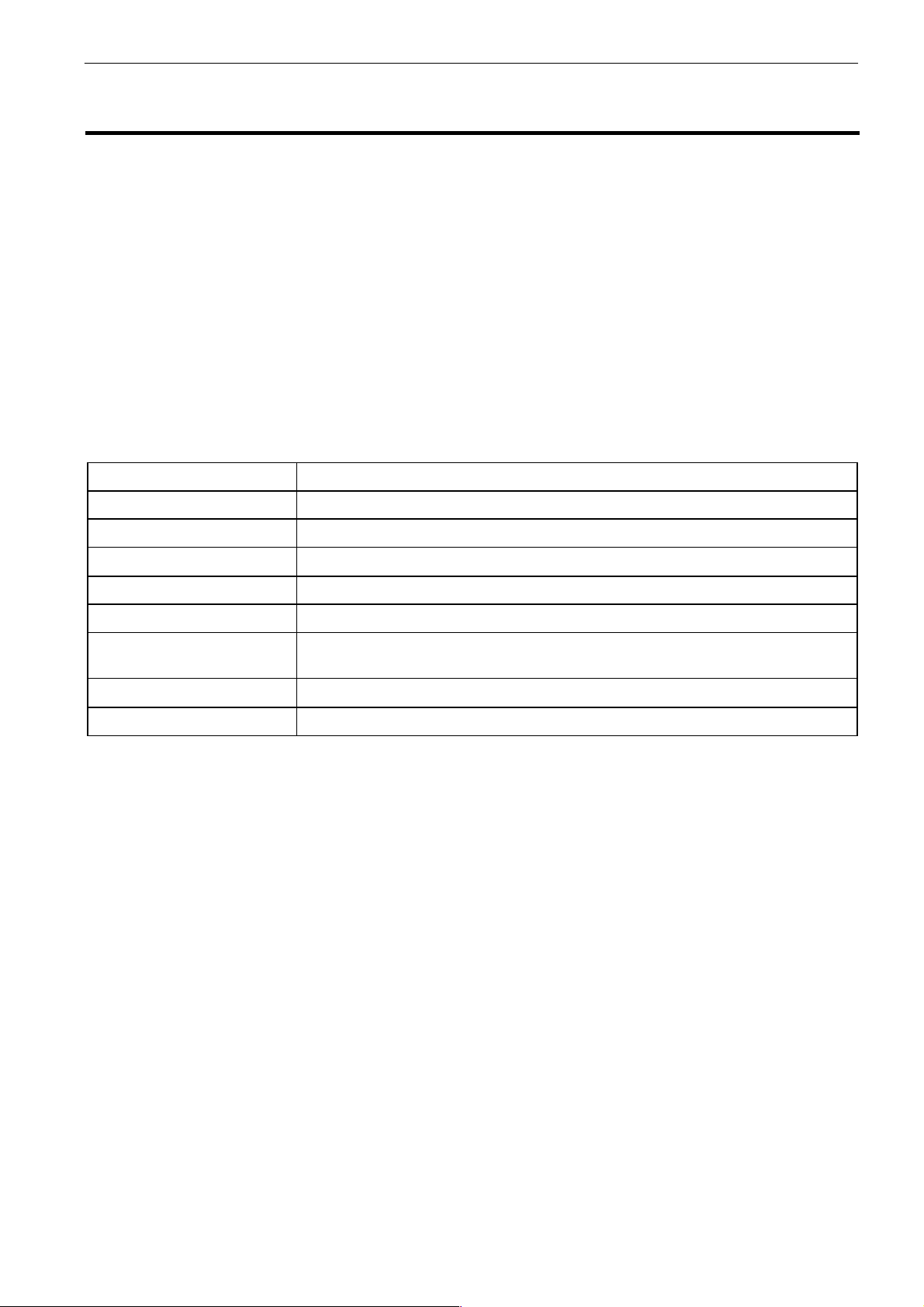

1-1. Specifications

Sewing machine model BES-111AF

Application Monogramming on suits, shirts, sportswear, handkerchiefs, other articles

Maximum sewing speed 1000 rpm

Sewing area

Stitch length 0.1 - 12.7 mm

Storage medium 3.5 floppy disk

Power

source/consumption

Dimensions

Weight 30 kg

120 mm × 100 mm

Single phase, 120, 220, 240V 50/60Hz 200VA

400 mm (D) × 540 mm (W) × 470 mm (H)

BES-111AF

1

2. Preparation of Sewing Machine

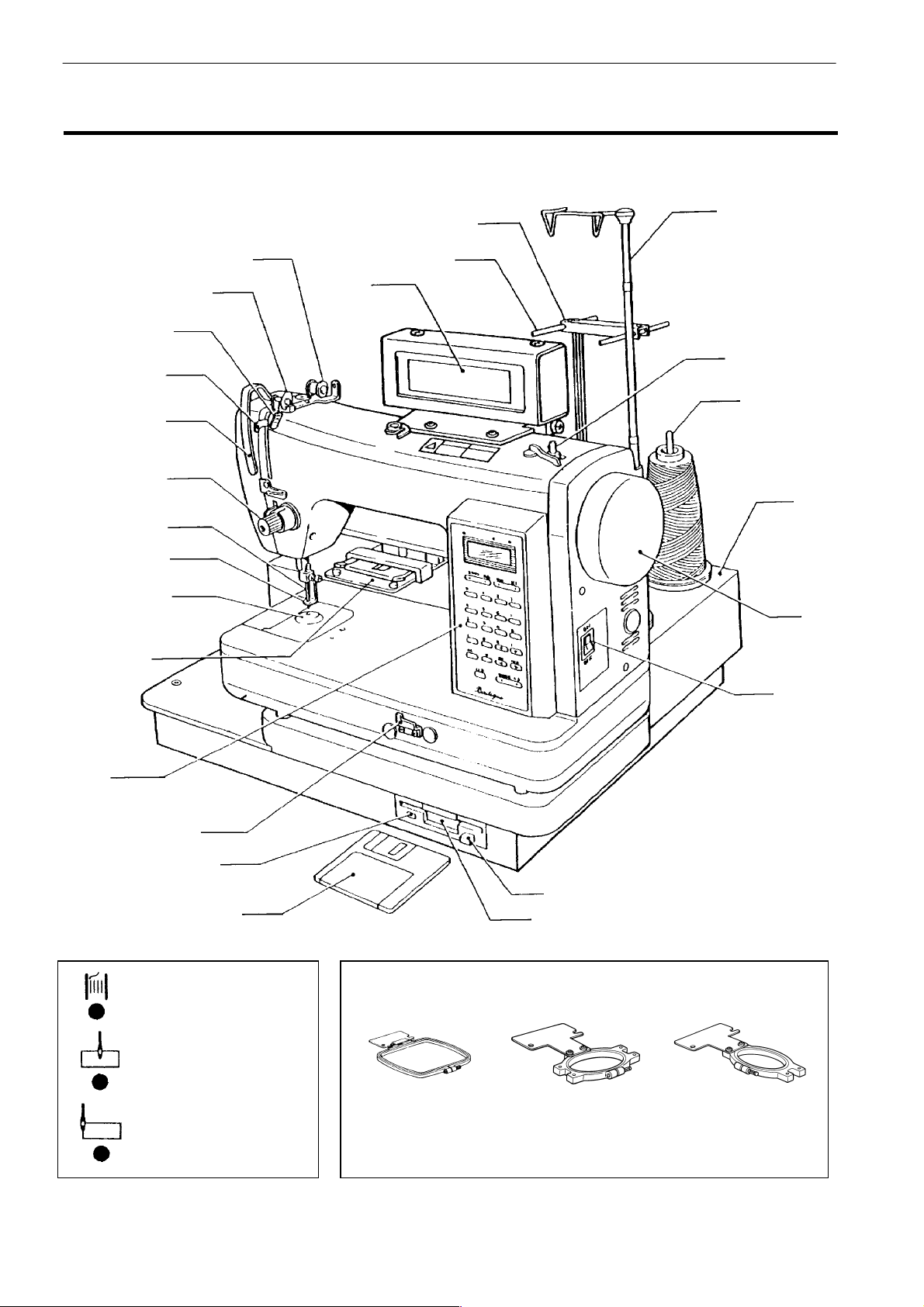

2-1. Part names

Needle thread

breakage detector

Thread retainer

Thread take-up

Thread take-up

cover

Needle thread

tension control

Needle

Work clamp

Needle & Slide

plate assy

Embroidery hoop

bracket

Pretension

Thread guide joint

Thread guide

Display

Spool stand

Bobbin thread

winder

Thread guide

Spool stud

Pulley

Power switch

Operation

panel

Guide pin support F

Floppy disk drive

indicator

H0242

Floppy disk

*Bobbin winding complete

indicator illuminates to

show that bobbin winding

is complete.

*Centering indicator

When lights, centering is

selected.

When lights, centering is

cancelled.

Floppy disk drive

Standard embroidery hoops

H0243

Standard

120 × 100 mm area

Lateral patterns

66 × 32 mm area

Eject button

H0528

H0244 H0245

Vertical patterns

36 × 64 mm area

BES-111AF

2

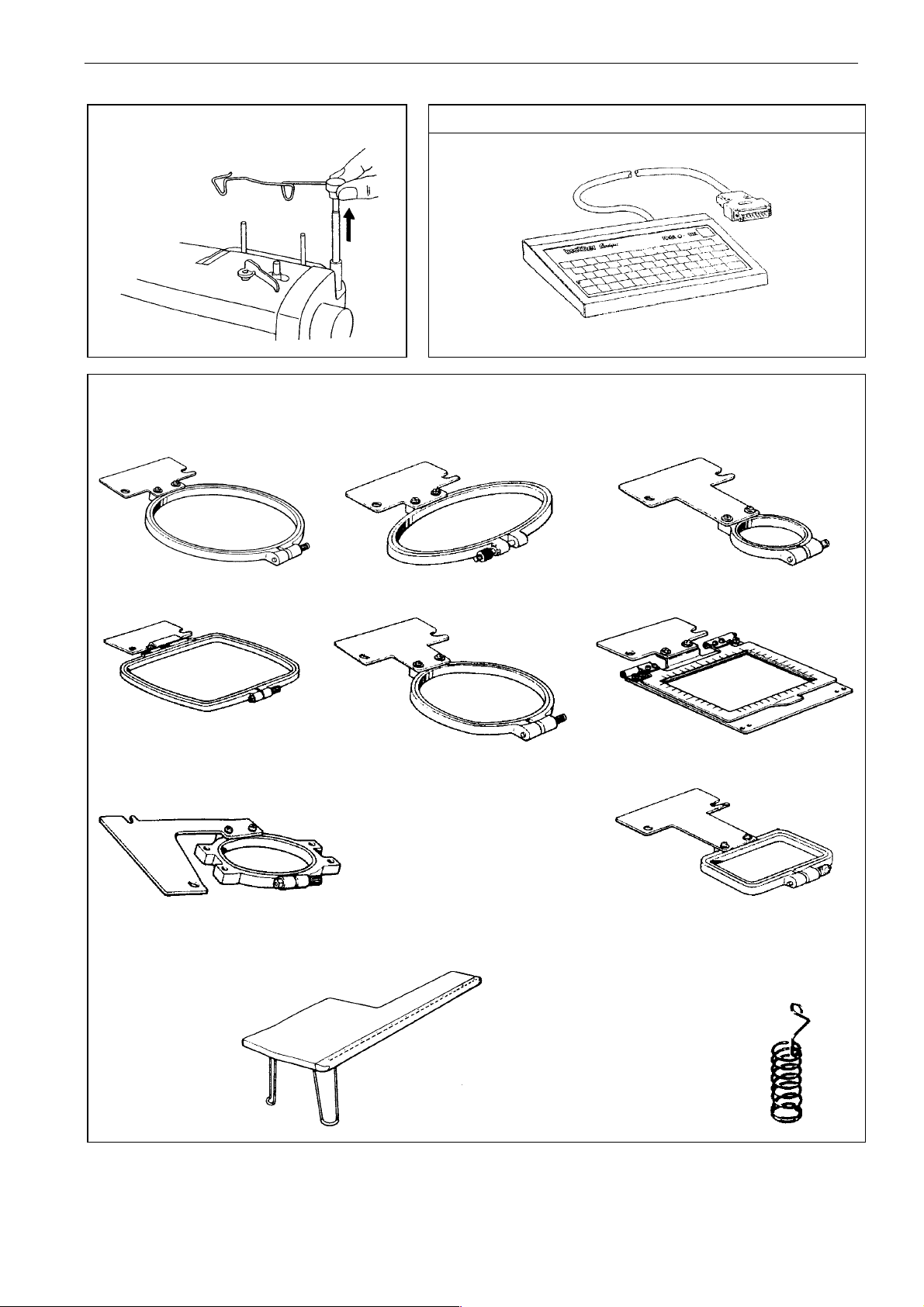

Thread guide installation Keyboard

H0246

Optional accessories (sold separately)

Embroidery hoops

Using the most suitable hoop size for the job at hand providers better results.

H0529

H0403

112×112 area

H0249

Offset type 150×100 mm area

Portable table

H0255

112×52 area

80×80 area

Vertical patterns

36×64 mm area

H0250

H0252

H0251

34×34 area

H0253

120×100 area (for leather)

H0254

66×32 area

Spring

H0256

BES-111AF

H0257

3

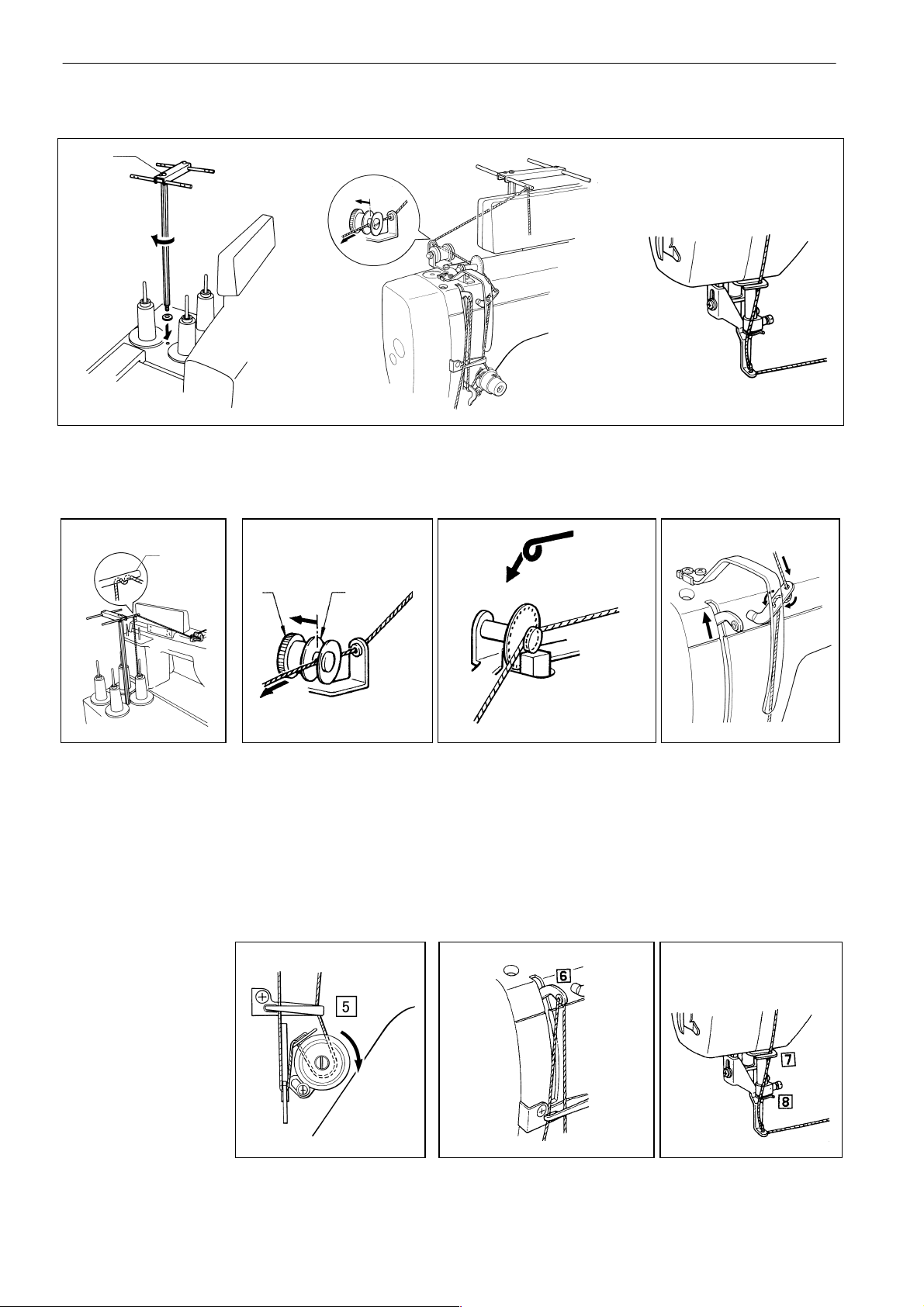

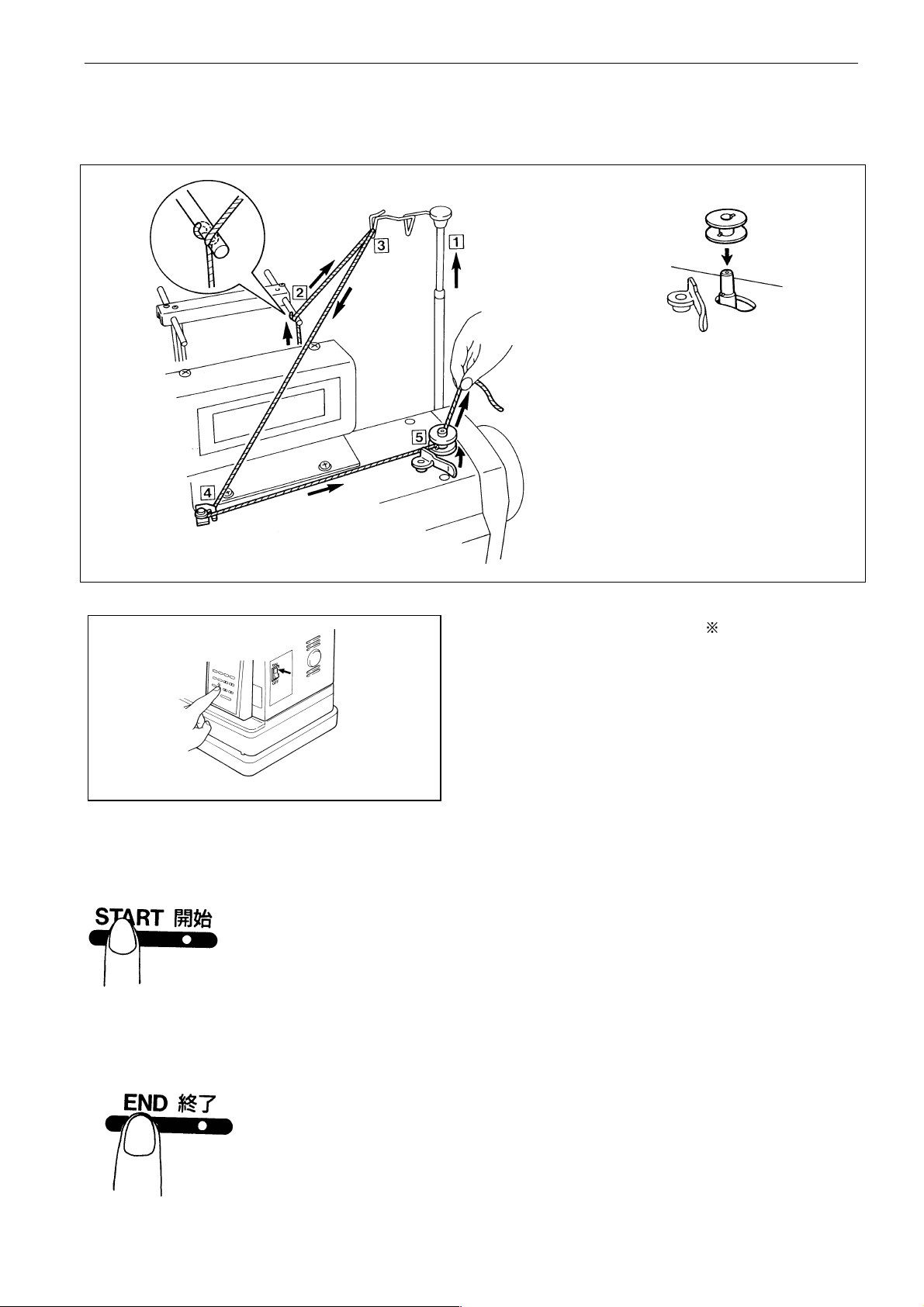

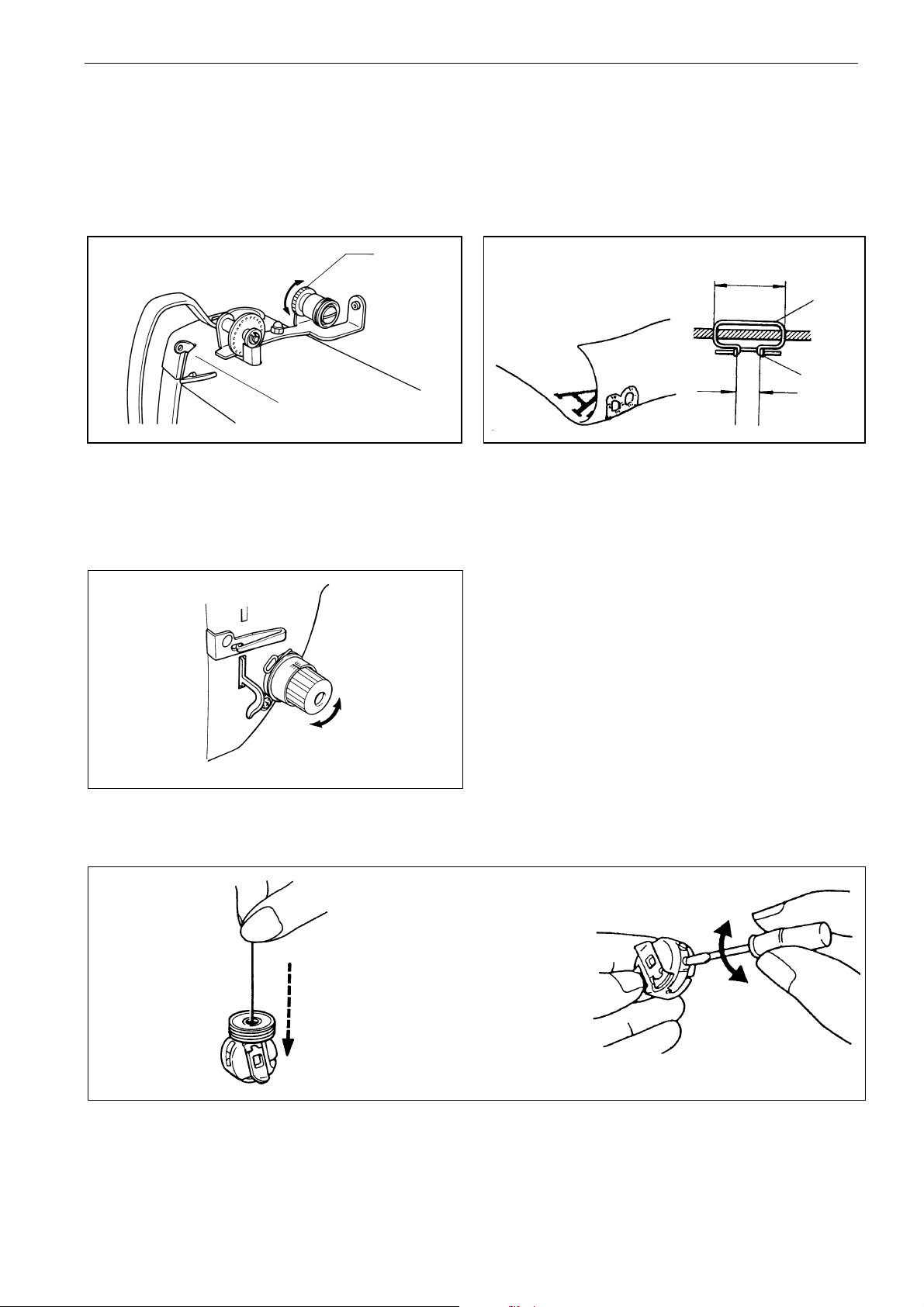

2-2. Threading the needle thread

(A)

H0258 H0259 H0260

1. Thread the thread

guide.

(1)

H0261 H0262 H0263 H0264

Pass the thread from

the outside to the

inside of the thread

guide (1).

Installing and

adjusting the thread

guide

- Screw the thread

guide support bar

in as far as it will

go.

2. Thread the

pretension.

(3)

Press the thread guide

disc (2) to open it, pass

the thread through the

hole, and adjust the thread

tension by means of the

pulley (3).

(Approx. 60 g)

0.05 - 0.1 N

(2)

5. Thread the thread

tension bracket.

3. Thread the thread guide

for the needle thread

breakage detector.

Wind the thread 2 - 3 times so

that it crosses over at the

bottom as shown in the

illustration.

6. Thread the thread takeup.

4. Thread the thread

retainer.

Turn the pulley to raise

the thread take-up lever

to its upper position.

Thread in order shown

above.

7. Thread the thread

guide and needle.

- If the thread

guide is

misaligned,

loosen the screw

(A) and turn the

thread guide until

the thread guide

hole comes to

directly above the

needle bar.

4

H0265

BES-111AF

H0266 H0267

2-3. Winding the bobbin thread

1. Set the bobbin thread

H0269

H0268

2. Turn the power switch on

Press the confirm/test <

> key, and turn the

power switch on. [Pull out upper thr. from

needle], and [Attention moving] will be

alternately displayed.

"BOBBIN THREAD WINDING START >

START END > END" will be displayed.

H0270

3. Fill the bobbin

Pass the thread through the hole in the bobbin. Hold the end of the thread and press <START>.

H0271

4. Bobbin is full

The bobbin will stop rotating when it becomes full. Press <END>, check that the sewing machine has

stopped running, and then return the bobbin presser to its original position.

(NOTE) - If the bobbin stops rotating before it becomes completely full,

press <END> to stop the sewing machine.

- If the bobbin presser is returned too quickly while the sewing

machine is running, the movement will be transmitted to the

needle bar, which might cause the needle to move.

H0272

BES-111AF

5

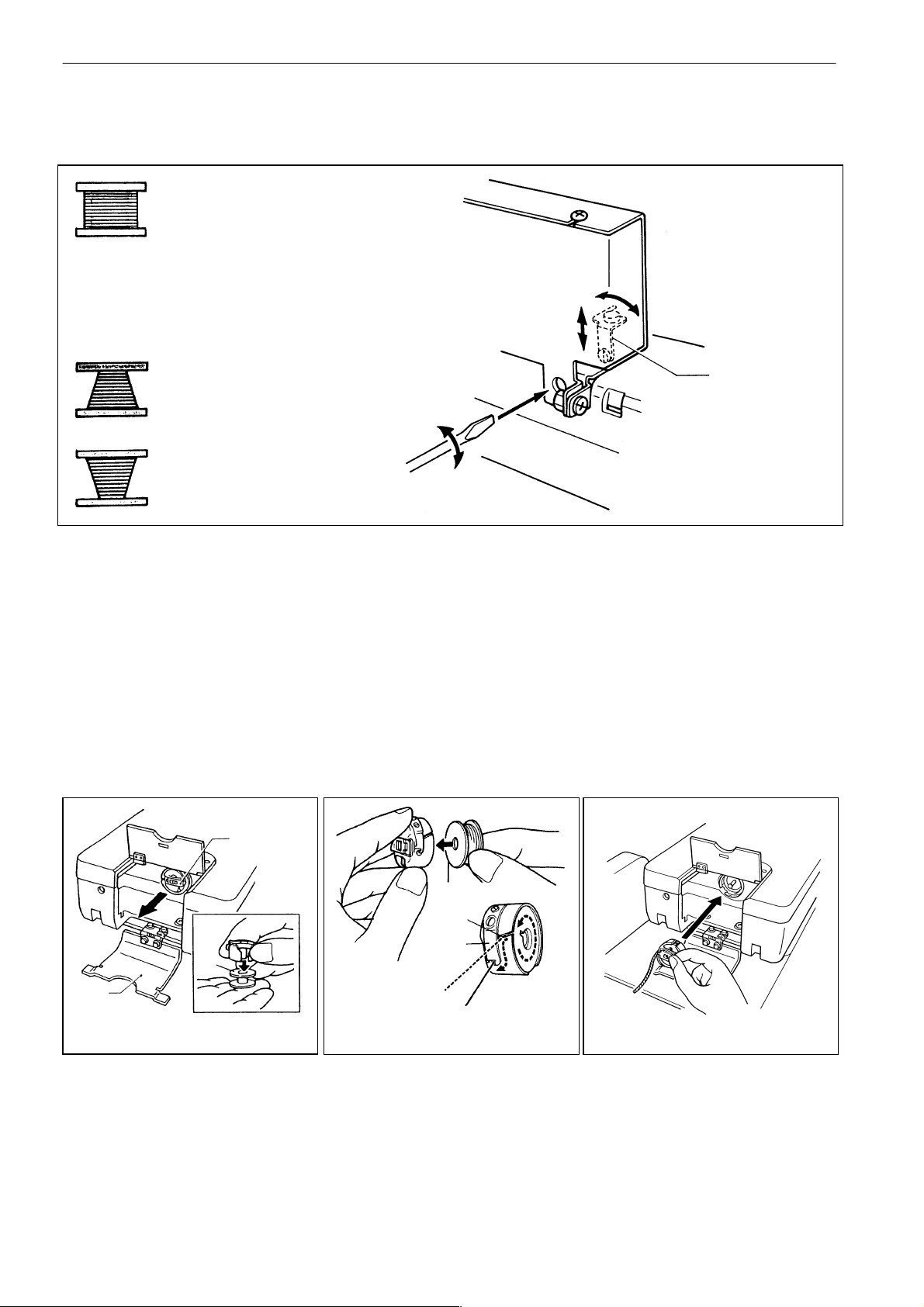

2-4. Correctly wound bobbin

If the bobbin thread is not would on the bobbin evenly, it may cause an incorrect bobbin thread tension.

Correctly wound bobbin

H0273

Loosen the screw of bobbin thread guide, and

adjust the bobbin thread tension.

Correcting bobbin winding

Raise the bobbin thread

guide.

H0274

Lower the bobbin thread

guide.

H0275

Loose

Tight

Bobbin thread

guide

H0276

The bobbin will stop rotating when it becomes full. Press <END>, check that the sewing machine has

stopped running, and then return the bobbin presser to its original position.

(MEMO) If the bobbin stops rotating before it becomes completely full, press <END> to stop the

sewing machine.

If the bobbin presser is returned too quickly while the sewing machine is running, the

movement will be transmitted to the needle bar, which might cause the needle to move.

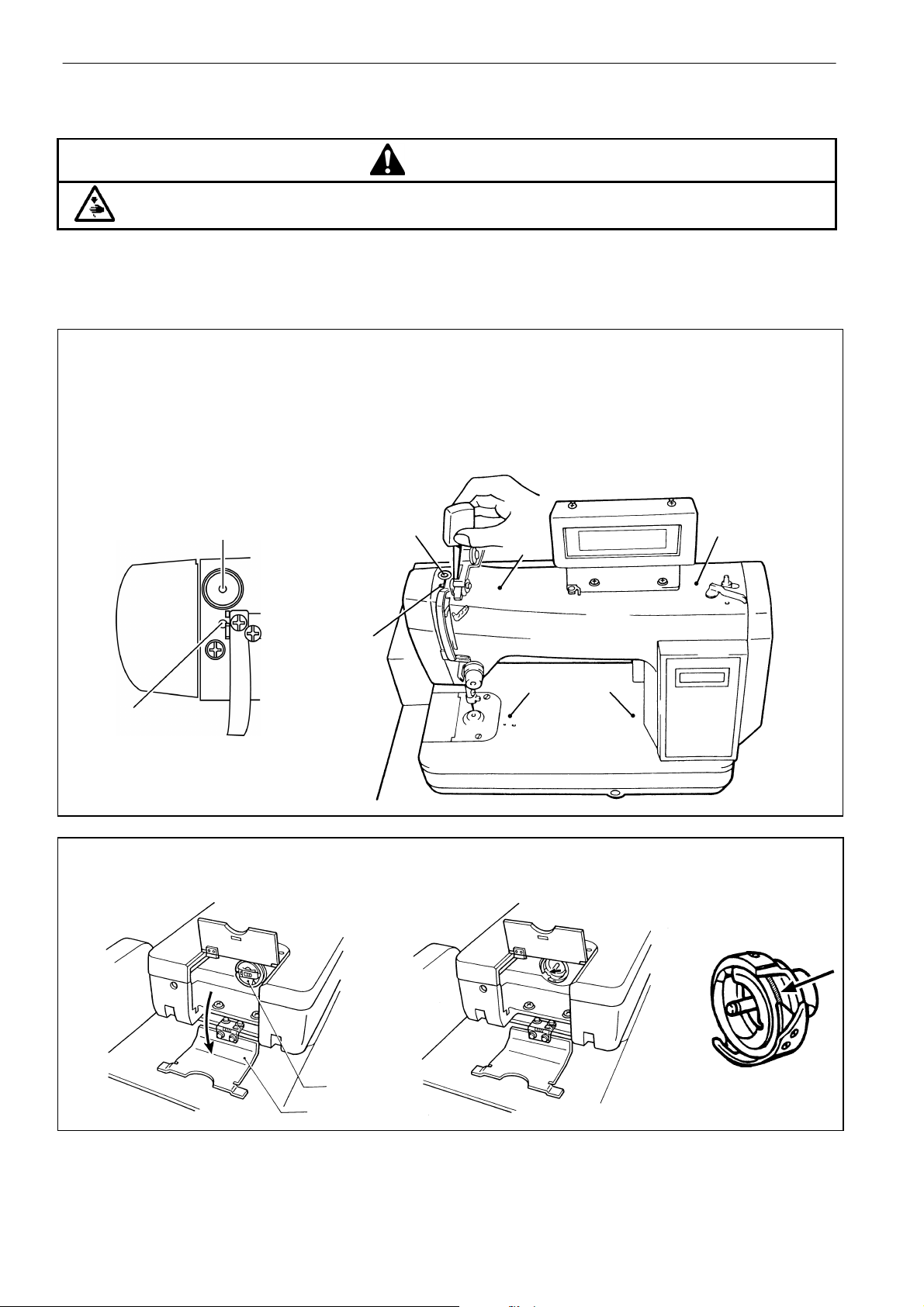

2-5. Replacing the bobbin

(NOTE) The bobbin spring may not function properly, resulting in bobbin thread breakage, if

thread ends and dust collect inside the bobbin case. Be sure to keep the bobbin case and

the shuttle body clean at all times.

1. Remove the bobbin case. 2. Replace the bobbin. 3. Replace the bobbin case.

(2)

(3)

(1)

H0277 H0278 H0279

1. Open the needle plate side

cover (1).

2. Pull out latch (2) and remove the

bobbin case.

3. Return the latch (2) to the

original position and remove the

bobbin (3).

6

Pull out about 10 mm

of thread.

(4)

(5)

The thread should

be wrapped to the

left around the bobbin.

1. Close the bobbin case handle.

2. Pass the thread through the

notch [4] and under the tension

spring [5].

BES-111AF

1. Hold the latch (2) and insert the

bobbin case into the rotary hook

assembly.

2. Close the cover (1).

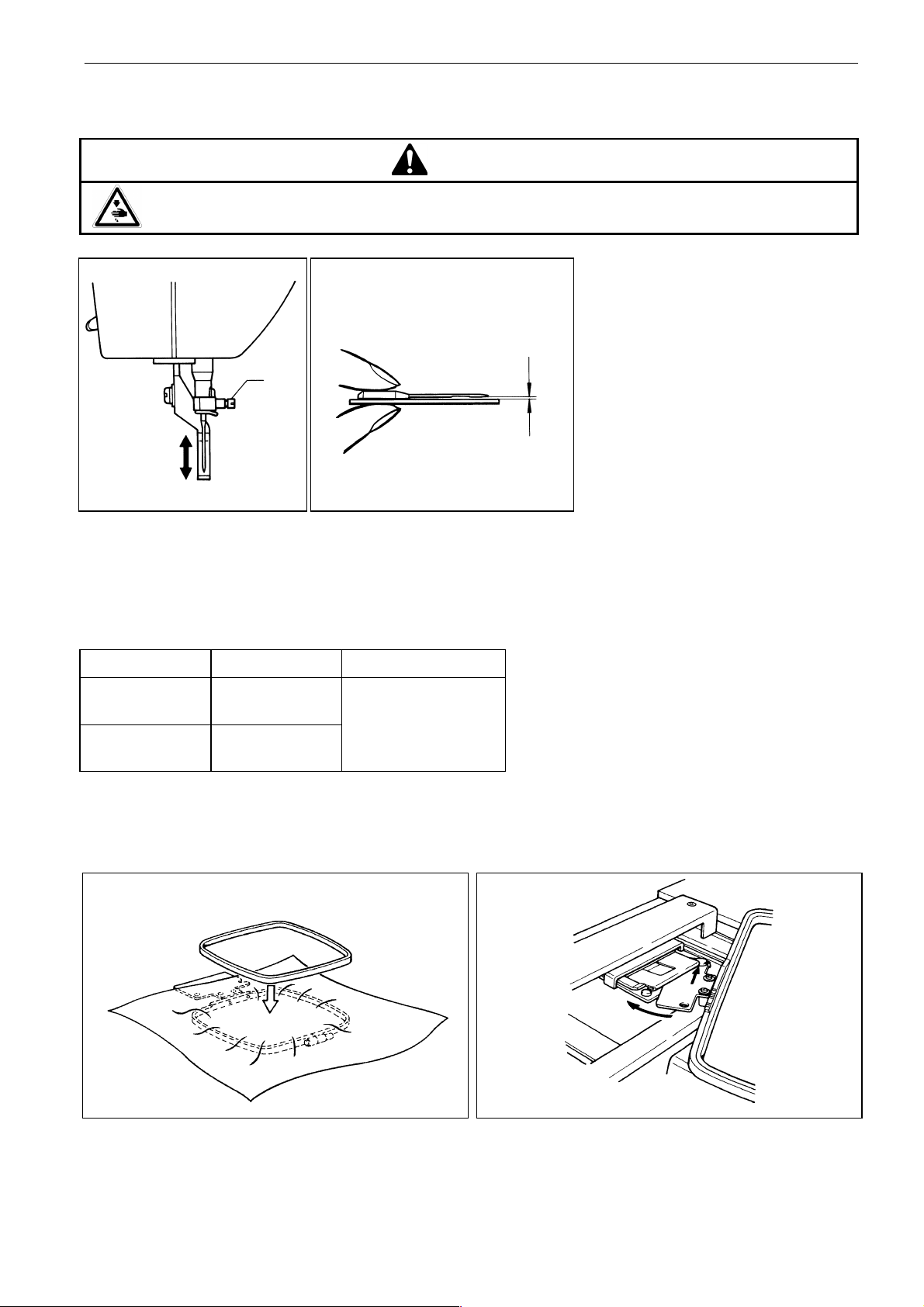

2-6. Replacing the needle

y

Turn off the power switch before startinganycleaningwork, otherwise the machine ma

operate if the start switch is pressed by mistake, which could result in injury.

CAUTION

* Checking needle is correct

Hold the needle with the flat side down.

Even, straight gap

(1)

Flat object

(needle plate, glass, etc.)

H0280

Materials and needle selection

Fabric type Needle size Embroidery thread

Denim, leather

HL × 5

#11 - #16

#75 - #150 denier

Handkerchief,

shirt, towel

HL × 5

#9 - #11

1. Loosen the screw (1), and

remove the needle.

2. Hold the needle so that the flat

side is to the right, insert until

it stops, and then tighten the

needle clamp screw (1).

* Hold the flat side of the needle

against a flat object to make

sure that the gap is even along

the length of the needle and

H0281

the needle is straight.

(NOTE) Using an incorrect needle

may cause stitches to be

skipped, thread breakage,

or damage to the material.

Check the needle

condition occasionally.

(NOTE) Better results can be obtained by

using a heavy-duty needle (#11 #14) when sewing with special

threads (gold, silver, or other

ramie yarns).

2-7. Installing the embroidery hoop

1. Fit the material into the embroidery hoop. 2. Install the embroidery hoop.

(1)

(2)

H0282 H0283

A poor fitting embroidery hoop may cause skipped

stitches, thread breakage, puckering, or other

problems.

Install the embroidery hoop firmly as shown above.

BES-111AF

7

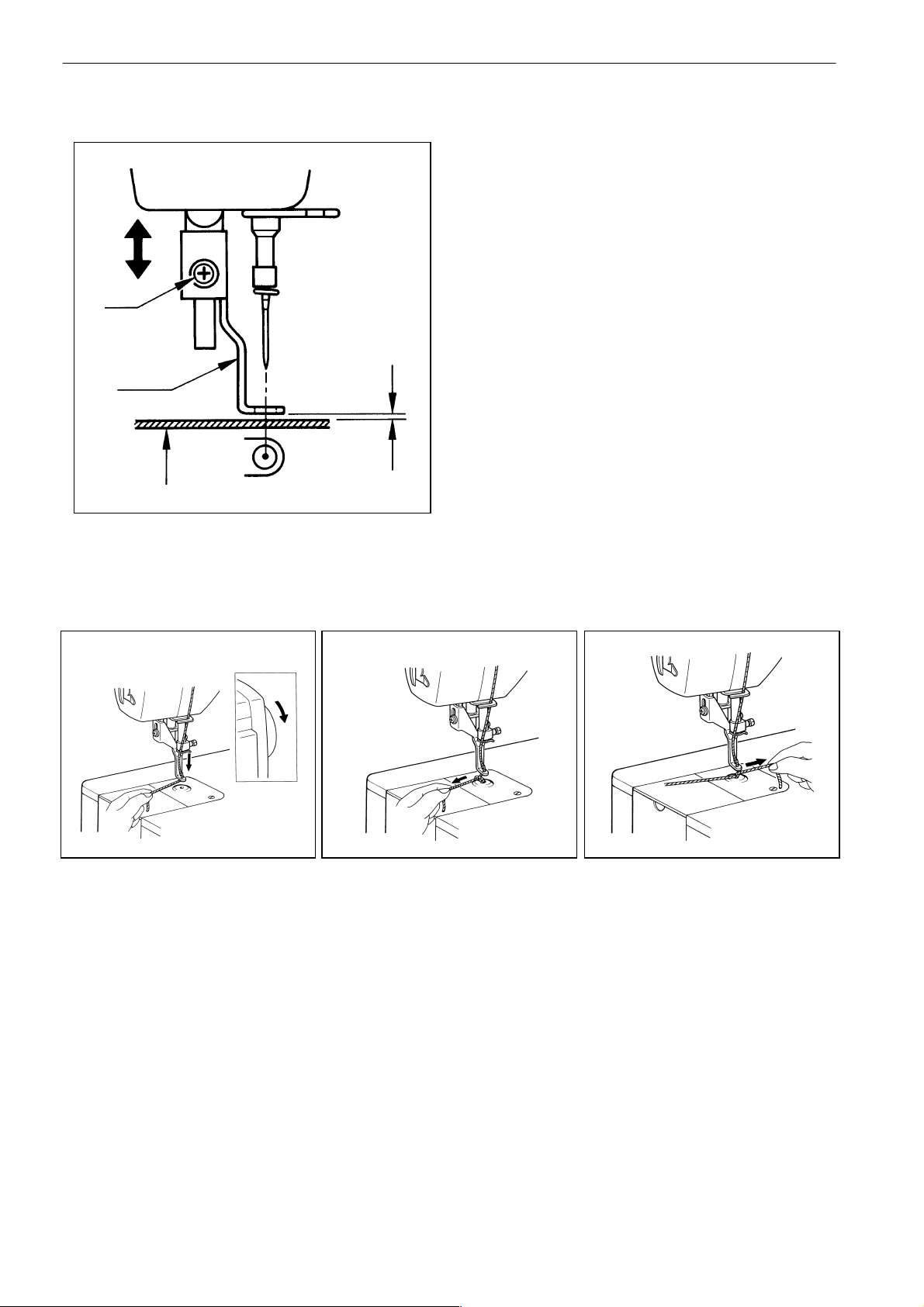

2-8. Adjusting the presser foot height

(2)

0.5 - 1mm

(1)

Turn the pulley to lower the presser foot (1) to its

lowest position. Loosen the screw (2). Adjust

the presser foot (1) by moving it up or down so

that there is a 0.5 - 1 mm clearance between the

top of the material and the bottom of the presser

foot (1).

Cloth

H0284

2-9. Drawing out the bobbin thread

1. Turn the pulley. 2. Pull the needle thread up. 3. Pull out the bobbin thread.

H0285 H0286 H0287

Hold the needle thread gently and

turn the pulley.

Pull the needle thread to draw the

bobbin thread out.

Pull both the needle and bobbin

threads out about 40 mm.

(NOTE) To pull the bobbin thread out on top of the material, press <START> when sewing, and

press any key before the embroidery hoop starts moving. The machine will stop. Pull the

bobbin thread out as described above. The machine will start sewing when <START> is

pressed.

Press any key after sewing about 5 stitches. After the machine stops, cut the bobbin

thread ends. Press <START> to continue sewing.

BES-111AF

8

2-10. Thread tension

If the thread tension is not adjusted properly, irregular stitching, material puckering, or thread breakage

may occur.

Needle thread tension

Needle thread tension dial

Low

High

Pulley

H0288 H0531 H0290

If the upper thread tension is too strong, turn

the pulley counterclockwise.

If the upper thread tension is too weak, turn the

pulley clockwise.

0.05 - 0.1 N

Low

Correct sewing tension

Upper stitch width

Needle

thread

Bobbin

thread

Lower stitch

width

Adjust the tension dial so that the needle thread

is pulled to the back of the material, and the

bottom stitch width is about 1/3 that of the upper

stitch width.

Use the thread tension dial to make fine

adjustments.

- If the needle thread tension is too high, turn

the clockwise.

- If the needle thread tension is too low, turn

the counterclockwise.

Bobbin thread tension

Correct bobbin

thread tension

0.15 - 0.2 N

High

H0291

Adjust the tension spring so that the

bobbin will not drop under its own

weight when help by the thread.

Specific tension will vary with the

thread.

H0292

Increase

tension

Decrease

tension

H0293

BES-111AF

9

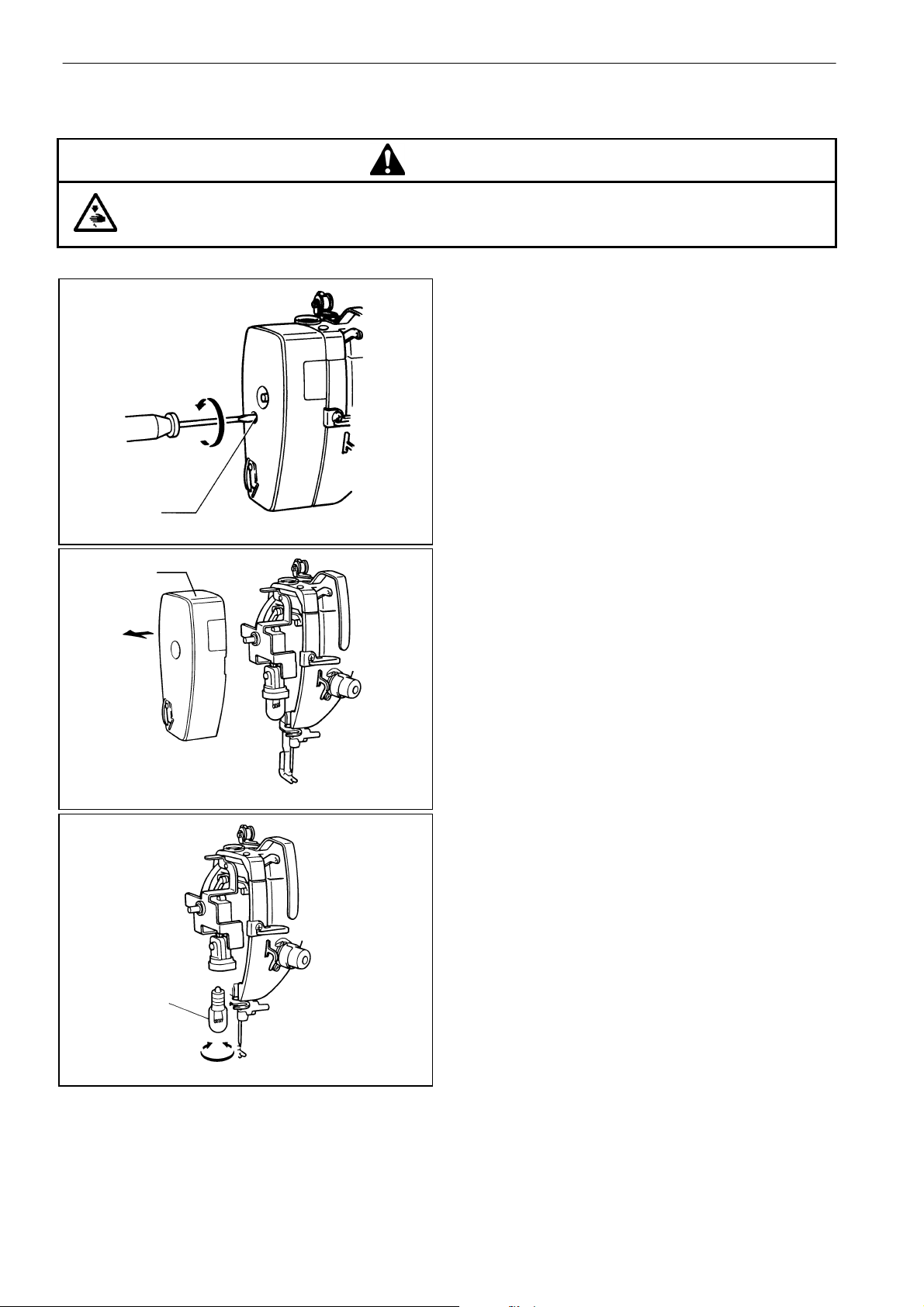

2-11. Replacing the lamp

y

Turn off the power before replacingthe lamp. Theglass part of the lamp will be not

immediatel

attempting to replace it.

after the lamp has blown, so let it stand for a while until it becomes cool before

CAUTION

1. Turn off the power switch.

2. Remove the screw (1).

(1)

(2)

H0294

3. Remove the face plate (2).

H0295

4. Unscrew and remove the lamp (3).

5. Install the new lamp.

6. Install the face plate (2) with the screw (1).

(3)

H0296

BES-111AF

10

2-12. Cleaning

A dirty or clogged machine may result in equipment failure. Be sure to keep the machine clean at all

times.

Always clean

If the machine is only slightly dirty or dusty,

wipe clean with a soft, dry cloth. If

necessary, wipe with a cloth dampened with

a neutral detergent or hot water, and then

wipe the detergent off cleanly with a cloth

dampened with hot or cold water.

Do not clean with benzene, thinner, or other

volatile solvents.

(MEMO) When cleaning the rotary hook and

its associated parts, add 1 - 2

drops of oil to the rotary hook

H0297

Avoid high temperatures

Keep the machine away from hot stoves,

irons, and similar heat sources. Store the

machine out of direct sunlight.

mechanism. After lubrication, try

sewing.

Refer to page 12 "Lubrication."

BES-111AF

11

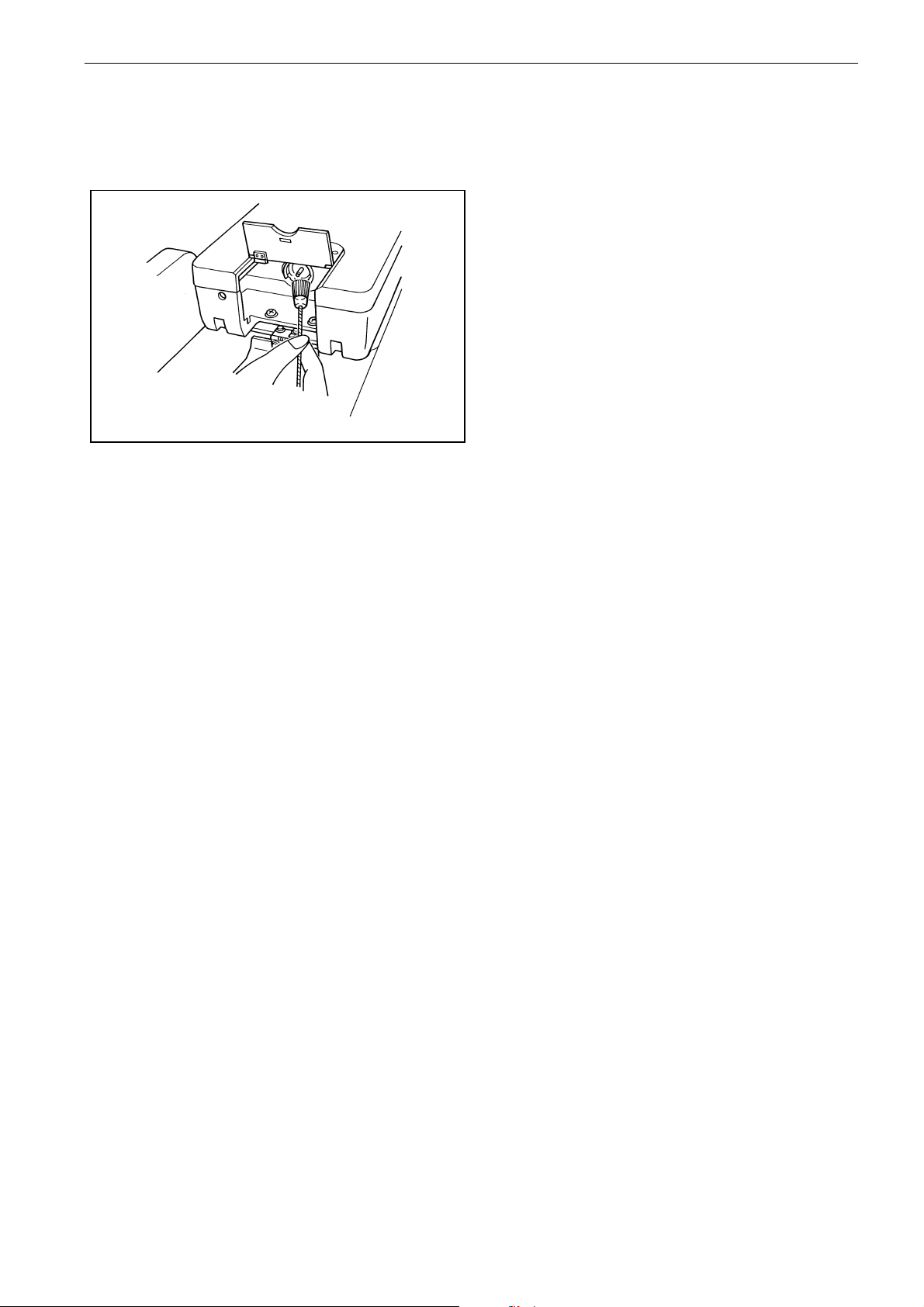

2-13. Lubrication

y

CAUTION

Turn off the power switch before startinganycleaningwork, otherwise the machine ma

operate if the start switch is pressed by mistake, which could result in injury.

(NOTE) - Be sure to use Brother-specified sewing machine oil for lubrication.

- Adding too much lubrication oil may cause the oil to get on the material; be careful not

to overfill the reservoir.

(NOTE) - Add 2-3 drops of oil at each position indicated by an arrow.

If there is oil around the lubrication position, wipe it off with a cloth.

- Lubrication is necessary at least once a month.

(If the machine is used for several hours every day, lubricate daily.)

- Lubricate the machine after using it and then be sure to run the machine without thread

or material.

(A)

(B)

(B)

H0298

1. Open the needle plate side cover (1).

2. Remove the bobbin case (2).

(A)

(C)

(E)

(F)

3. Add a drop of oil to the rotary hook.

(NOTE) DO NOT lubricate anywhere else.

(D)

H0299

(2)

(1)

H0300

BES-111AF

12

H0302

H0301

3. Sewing Preparation

3-1. Flow chart

BES-111AF

H0685

13

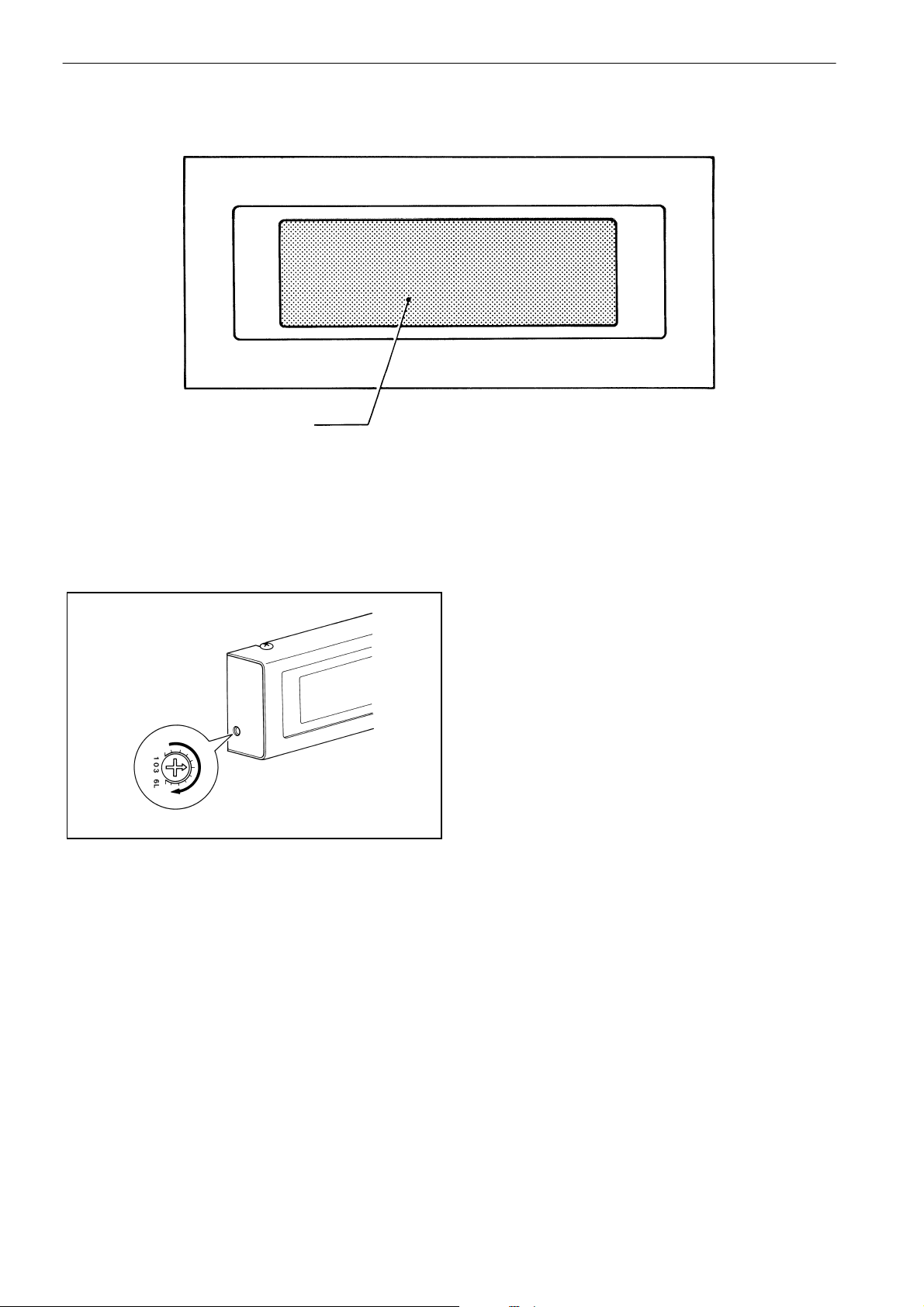

3-2. Operation panel part names and functions

Display

H0303

Display

The display shows messages, error codes, and other prompts, the selected monogram letters, editing

menus, and other items on a 30 character (8x8dots)display.

Display contrast control

Used to make it easier to read the letters on the

display.

(NOTE) Adjust the display after turning the

power switch on. [Attention moving]

will be displayed, followed by [No

Floppy Disk].

H0304

BES-111AF

14

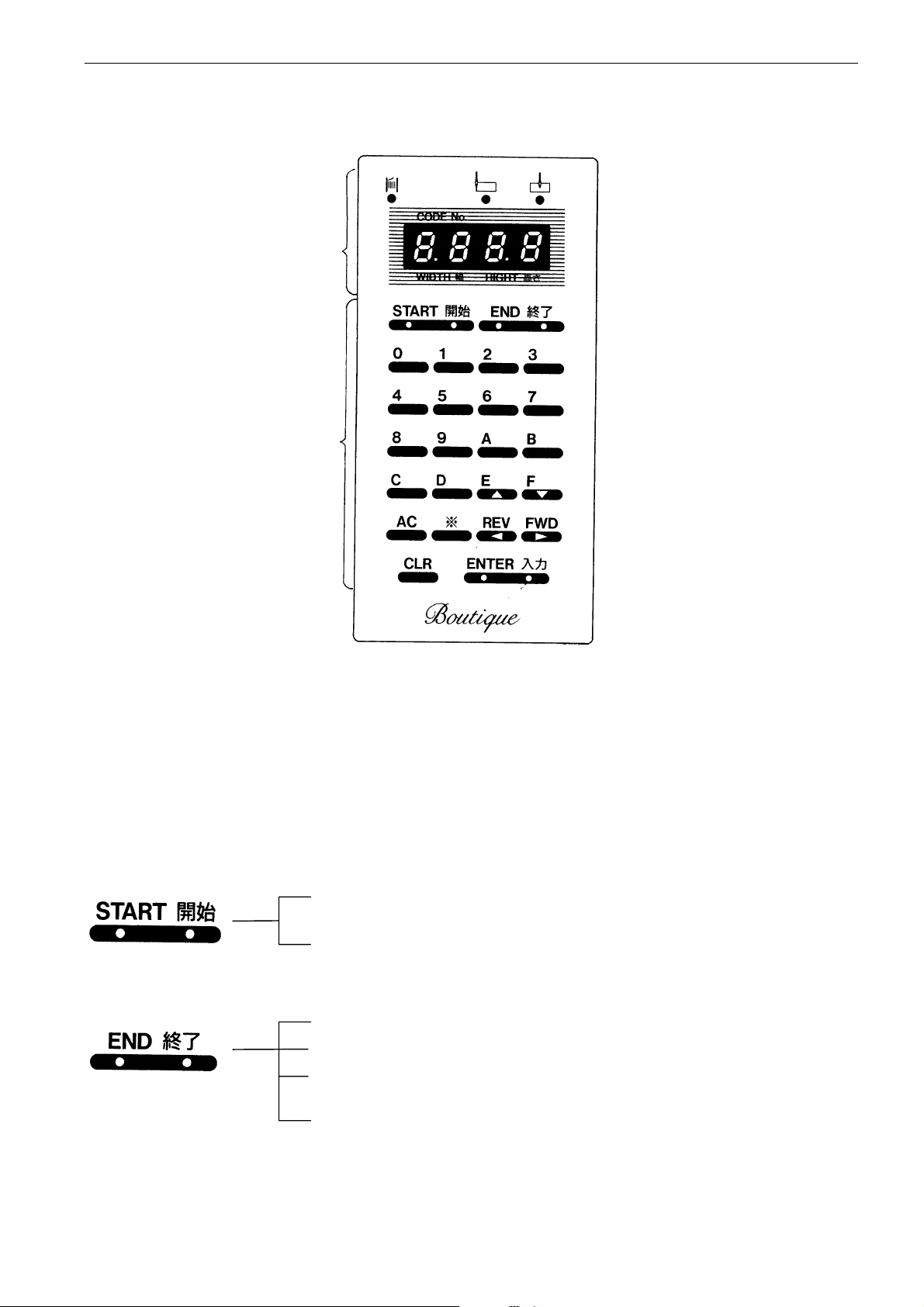

Operation panel

LED indicators

Key board

H0305

LED indicators

The text (2 letters or numbers) entered with the character code, and the enlargement/reduction size

ratio (letter width and height) are displayed.

* The letters A, E, and F will always be displayed in upper case, and B, C, and D will always be displayed in

lower case.

Keyboard

START key

Used to start sewing after selecting the monogram letters, and to select

the sewing mode.

H0306

Used for editing after setting the font number.

END key

Used to edit after selecting the letters.

Used to sew after setting the font number or editing.

H0307

Used to cancel a change in the sewing pattern, test operation, or

changes in floppy disk settings.

Used to terminate the enlargement and reduction ratio mode.

BES-111AF

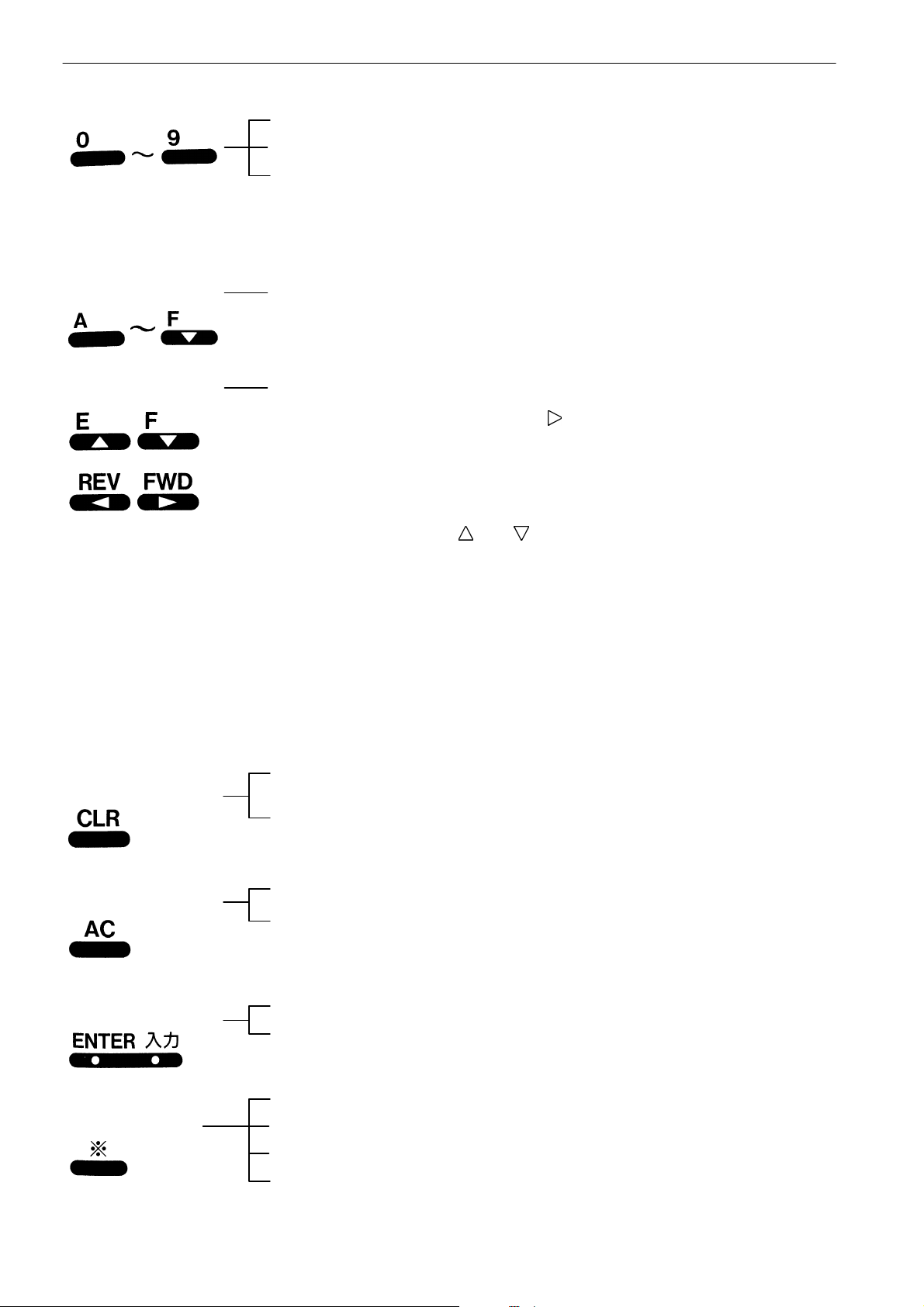

15

Number keys

H0308

Used to enter the character code.

Used to select the editing task number and to enter edit task settings.

Used to select letter enlargement or reduction (ratio and dimensions).

Numeric key "1" is used to set the sewing speed when in sewing standby

mode.

Numeric key "2" is used to wind the bobbin thread when in sewing standby

mode.

Letter keys

Jog keys

H0309

H0310

H0311

Used to enter character codes.

(E and F are also used as jog keys.)

Used to move the needle position in the direction of the arrow on thekey.

(MEMO) While pressing the FWD (

) key, turn on the power. The setting

for DIP switch No. 8 will be reversed.

REV. and FWD. are used to move the cursor position on the

display.

Also used to move the needle position one stitch at a time

forward or back when resewing after thread breakage.

(MEMO) The jog keys (

and ) are used to move the needle position at

the sewing start forward or backward by 100-stitch blocks when

restarting sewing after a thread breakage.

(MEMO) The jog keys can be used when editing with [1. Area] and

[Designate point on upper left] and [Designate point on lower

right] are alternately displayed, or when the needles start

position is set before starting to sew and [Move needle to start

point > ent] is displayed or [Move needle to start point > ent] and

[Area over] are alternately displayed, or [Move needle to start

point > ent] and [Sewing > start, Trace > *, Quit > end] are

alternately displayed.

CLR key

H0312

All clear key

H0313

ENTER/FIX key

Confirm/test key

H0315

Used to clear the letter over the cursor in the display.

Edited contents will remain unchanged.

Used to clear the LED Character code or to reset the ratio (letter width and

height) to the standard (default) value in order to re-enable entry.

Used to clear all letters on the display.

All edit contents will be automatically reset to the standard default values

when <AC> is used.

Used to reset all edited contents to the standard values.

Used to convert character codes to letters.

Used when entering area, letter size ratio, font number, thread density and

letter width, and the needle start point settings.

H0314

Used when winding the bobbin thread.

Used to confirm edit task contents.

Used when testing the sewing position of selected letters.

Used to determine why hollow letters are displayed.

BES-111AF

16

Bobbin winding complete indicator

Illuminates to show that bobbin winding is complete.

H0316

Centering indicator

This means that the needle start point is in the center of characters or

pattern.

H0317

Centering canceled indicator

This means that the needle start point is to the left of characters or pattern.

H0318

3-3. DIP switch function

H0004

(MEMO) All DIP switches are set to OFF

before delivery. (Excluding SW2)

DIP switch

Keyboard connector

(For bar code connector)

H0005

DIP switch function

SW OFF ON

1 Needle thread breakage detector activated. Needle thread breakage detector deactivated.

2 --- Keyboard activated.

8 Brother disk mode Tajima TFD mode.

BES-111AF

17

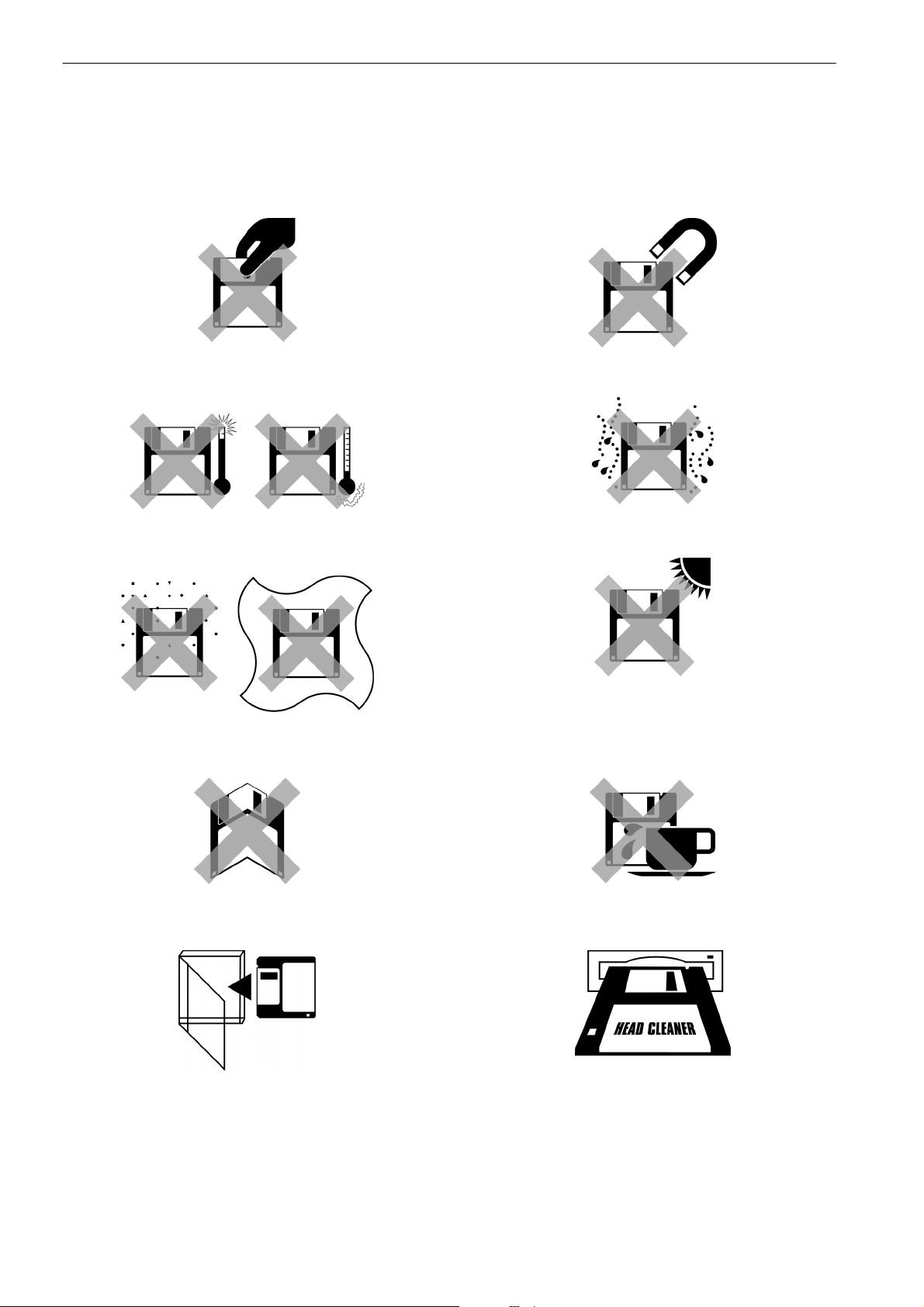

3-4. Floppy disk

y

y

y

Notes on usage

Do not carelessl

open the disk shutter and

touch the electromagnetic face.

H0319

Do not store the disk in a location that is subject

to temperature extremes.

H0321

Do not store or use the disk in a dusty location.

Do not place the disk directly on a cloth.

Keep items with a magnetic charge, such as

magnetic drivers, away from the disk.

H0320

Do not use the disk in a damp location.

H0322

Do not store the disk in direct sunlight.

H0323

Do not bend the disk or place objects on top of

it.

H0325

Protect the disk from damage and dust b

returning it to the case after use.

H0327

H0324

Do not let the disk come in contact with solvents,

beverages, or other liquids.

H0326

Use a commerciallyavailable cleaningdisk to

clean the floppy disk head regularly.

H0328

Do not remove the floppydisk when the flopp

disk access lamp is turned on.

BES-111AF

18

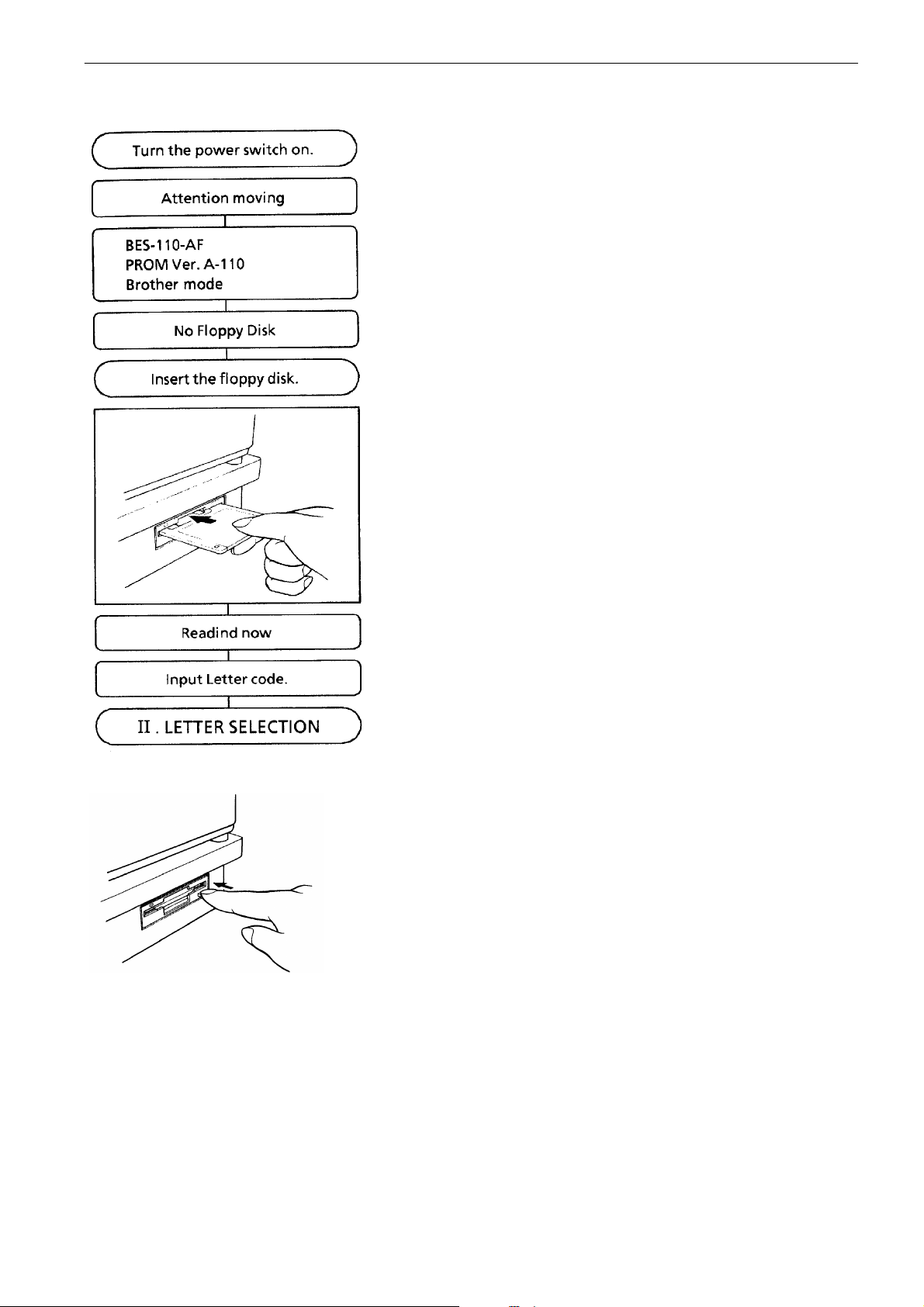

Inserting the floppy disk

1. The display will come on when the power switch is

turned on.

An alarm will beep four times, and the needle will be positioned

at the center of the embroidery hoop.

2. Insert the Alphabet floppy disk.

*1 It will not be possible to read or write to disk, and drive

or disk problems may result if the disk is not properly

inserted.

*2 Floppy disks are a magnetic storage medium. The data

on the disk can be easily damages by magnetism, and

the disks should therefore be kept away from magnets,

televisions, telephones, and other products which may

produce a magnetic field. Floppy disks should not be

brought near the slide plate since it has a magnet on its

back.

Displayed when the floppy disk drive indicator goes out.

* [Input Letter code] will be displayed if in the

default settings mode. If the letters have been

set, the entered letters will be displayed.

H0624

Removing the disk

Press the eject button. The disk will pop out, and [No Floppy

Disk] will be displayed. Do not try to eject the disk while the

floppy disk drive indicators is on.

H0330

*1 If the power switch is turned on when the needle is lowered, [Turn pulley] will be displayed and

an alarm will sound. After turning the pulley, [Press start key] and [Attention moving] will be

alternately displayed, and the alarm will continue to sound. Press <START>.

*2 If the power switch is turned on after the Alphabet disk is inserted, [Reading now] will be

displayed, followed by [Input Letter code].

*3 If the power switch is turned on after the memory disk inserted, or if the memory disk is inserted

first after the power switch is turned on, [Replace with Alphabet F. D.] will be displayed. Insert

the Alphabet disk.

BES-111AF

19

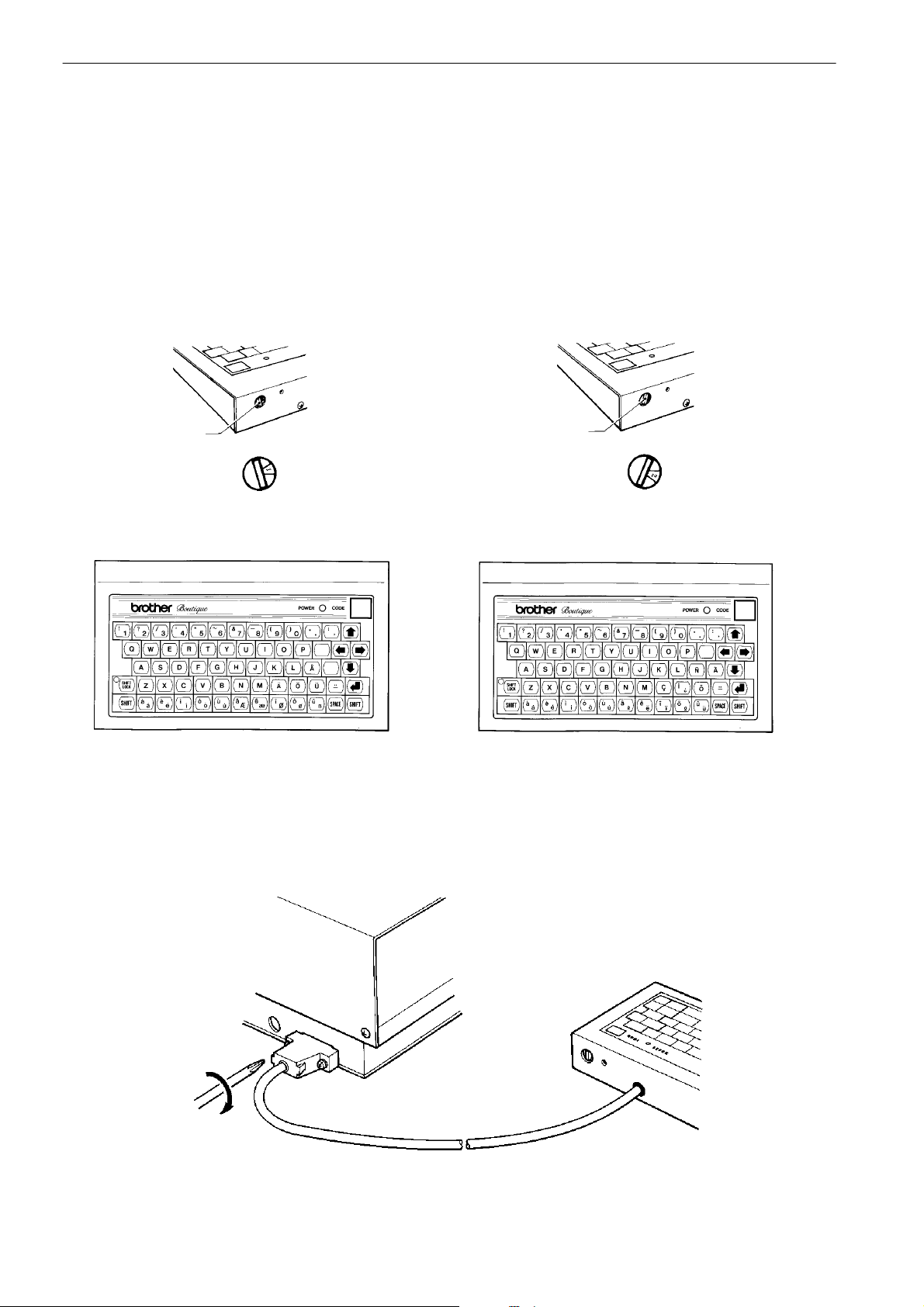

3-5. Connecting a keyboard and entering characters

Characters can be entered using a keyboard, to the sewing machine. Note that there are some keys

which are only operable on the sewing machine operating panel.

Connecting keyboard

1. Keyboard selector

Set the keyboard selector (1) to the keyboard (A or B) used.

[For German, Finnish, Norwegian, and Swedish] [For French, Spanish, and Italian]

(1)

Keyboard A Keyboard B

H0532 H0533

H0534 H0535

(1)

2. Connecting the keyboard to the machine

Turn the power switch on the sewing machine off.

(NOTE) Do not turn the power switch off until the floppy disk drive indicator goes out.

See the figures below.

Make sure that SW2 of the DIP switchpack is turned ON.

Machine

Tighten

BES-111AF

20

Keyboard

H0536

Entering letters

Letters can be entered from the keyboard to the machine only when the machine is in the character

entry mode.

Power switch ON.

See page 20. Insert the floppy disk.

Input Letter code.

Characters can now be entered using the keyboard.

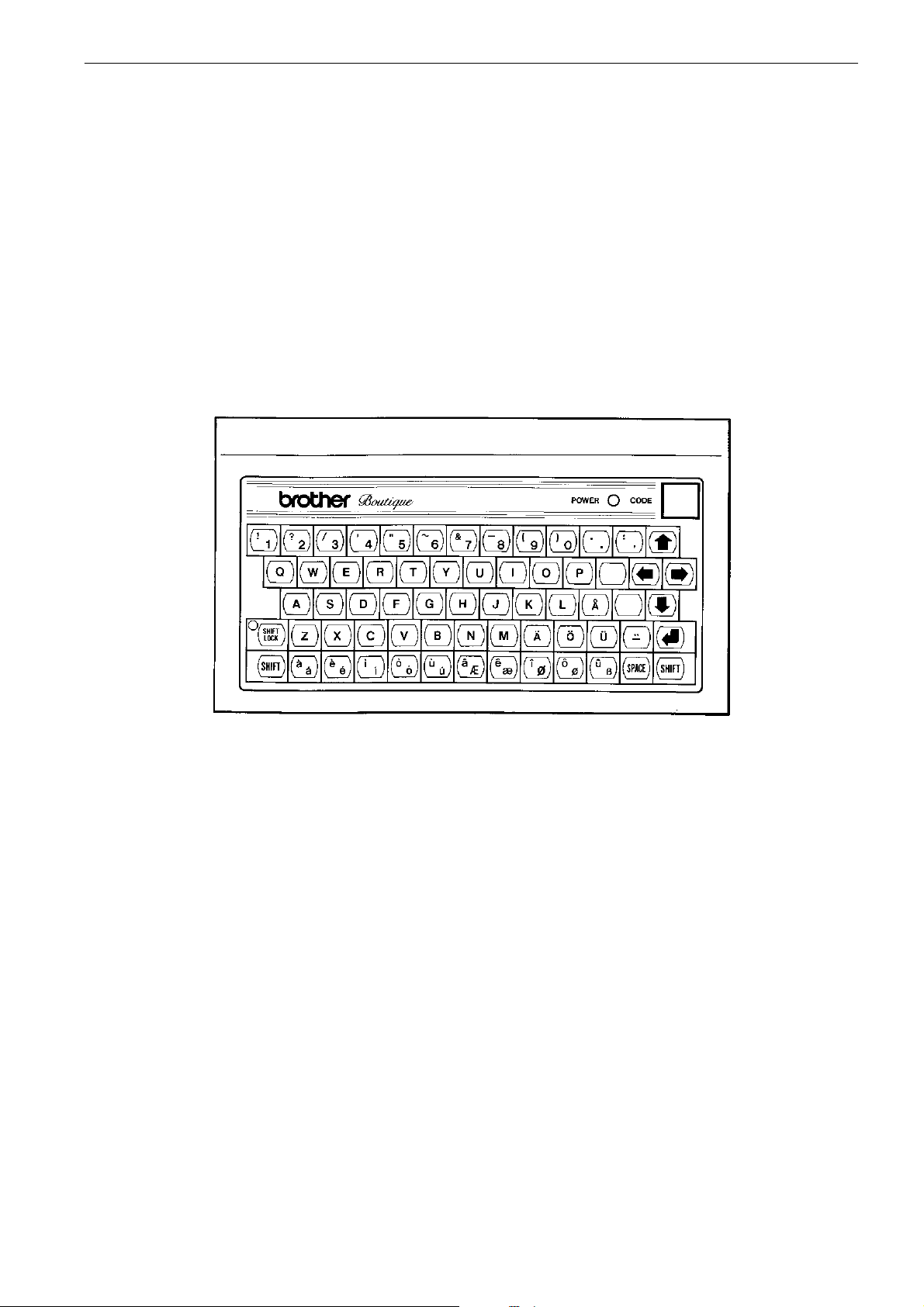

Those letters shaded in the figure below can be used.

After ending character entry from the keyboard.

After entering the letters, press <START> to proceed immediately to font selection and sewing,

or press <END> to proceed to font selection and editing.

Capitals, symbols, and other characters in the upper left corner of each key can be entered using the SHIFT key. Lower case

letters, numbers, and other characters in the lower right corner of each key can be entered normally.

H0534

(NOTE) Characters cannot be entered using the keyboard unless the is in the character entry

mode.

(NOTE) A maximum of 30 characters can be displayed.

BES-111AF

21

Loading...

Loading...