Page 1

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODEL: FAX1170/1270/1570MC

FAX1010/1020/1030

MFC1770/1870MC/1970MC

Page 2

© Copyright Brother 1997

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

Page 3

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation, and maintenance of the Brother facsimile equipment. It includes information required for

field troubleshooting and repair—disassembly, reassembly, and adjustment—so that service

personnel will be able to understand equipment function, to rapidly repair the equipment and

order any necessary spare parts.

To perform appropriate maintenance so that the facsimile equipment is always in best condition

for the customer, the service personnel must adequately understand and apply this manual.

This manual is made up of six chapters and appendices.

CHAPTER I. GENERAL DESCRIPTION

CHAPTER II. INSTALLATION

CHAPTER III. THEORY OF OPERATION

CHAPTER IV. DISASSEMBL Y/REASSEMBLY AND LUBRICATION

CHAPTER V. MAINTENANCE MODE

CHAPTER VI. ERROR INDICATION AND TROUBLESHOOTING

APPENDICES Circuit Diagrams

This manual describes the model and its versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

Page 4

CHAPTER I.

GENERAL DESCRIPTION

Page 5

CONTENTS

1. EQUIPMENT OUTLINE ................................................................................. I-1

1.1 External Appearance and Weight........................................................... I-1

1.2 Components............................................................................................ I-1

2. SPECIFICATIONS .......................................................................................... I-2

Page 6

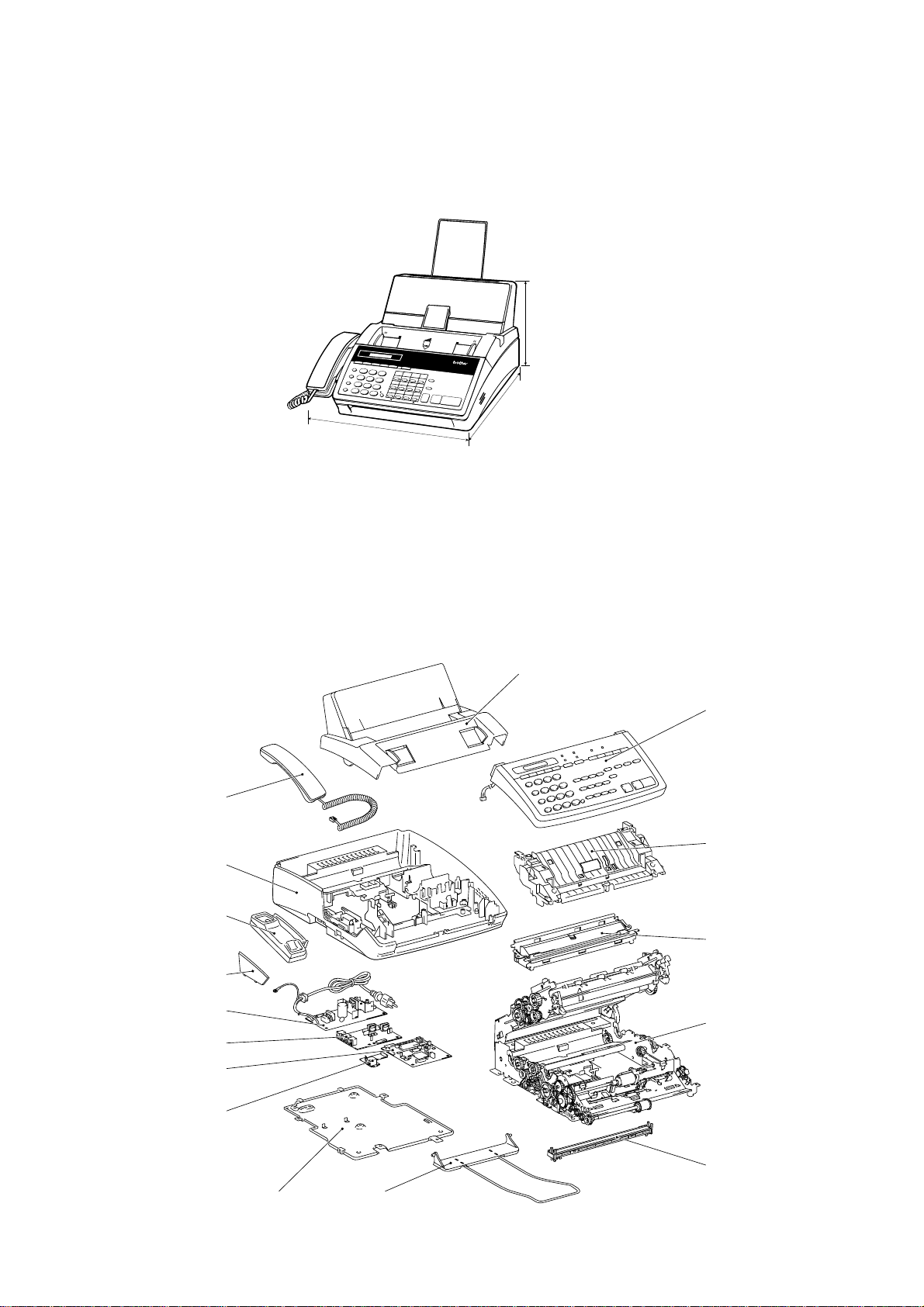

1. EQUIPMENT OUTLINE

1.1 External Appearance and Weight

The figure below shows the equipment appearance and approximate dimensions.

(Unit: mm)

Weight: Machine proper FAX1010: Approx. 5.0 kg (excluding a ribbon cartridge)

In package FAX1010: Approx. 8.7 kg

1.2 Components

The equipment consists of the following major components:

8.5"

A4

Function

Tel/Index

Resolution

Super

Mode

O. Scan

Hook

Hold

Redial/Pause

PRS

7

Speed Dial

*

Help

ABC

DEF

1

2

01

02

3

GHI

4

8

0

03

JKL

5

TUV

#

04

13

MNO

14

15

16

6

05

06

07

WXYZ

08

17

18

9

19

20

09

10

11

Copy

Shift

12

21

22

23

24

Set

Clear

A4

8.5"

IntelliFAX -1270

PLAIN PAPER FACSIMILE

Sort

Enlarge/

Reduce

Stop

Start

213 (H)

385 (D)

* 317 mm for FAX1010 which has

385.5 (W)*

no handset mount

Other models: Approx. 5.2 kg (excluding a ribbon cartridge)

Other models: Approx. 8.9 kg

Recording paper cover ASSY

Control panel

ASSY

Handset

(Not provided on

the FAX1010)

Main cover

Handset mount

(Not provided on

the FAX1010)

Side cover

(Provided only on

the FAX1010)

Power supply PCB

NCU PCB

Main PCB

Modular PCB

Bottom plate

Inner cover

Recording head

ASSY

Main frame

CIS unit

Document

ejection tray

I – 1

Page 7

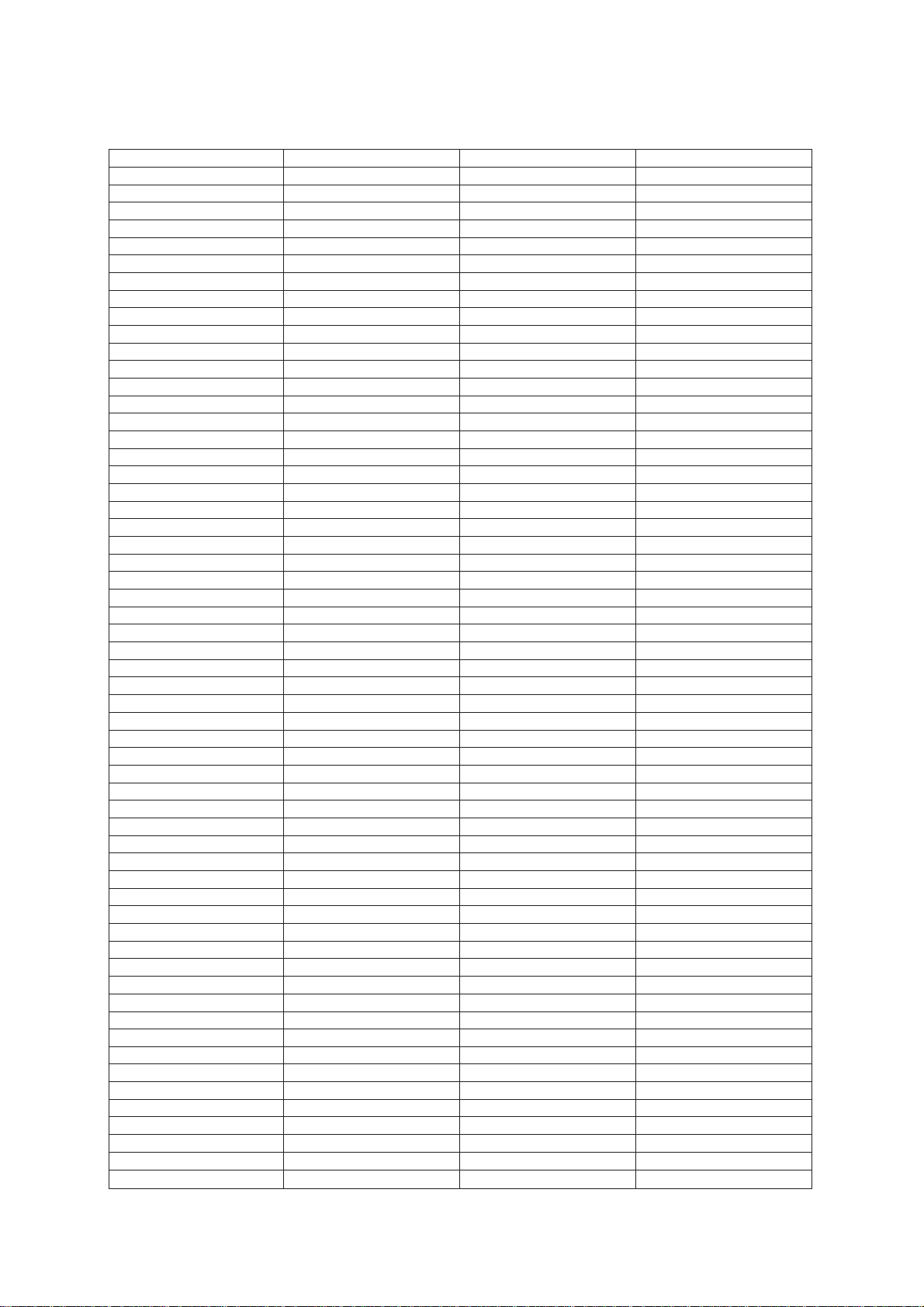

2. SPECIFICATIONS

Model FAX1170 FAX1270 FAX1570MC

Color Gray (1395) White (1397) White (1397)

Modem Speed 9600 bps 9600 bps 14400 bps

CCITT Group G3 G3 G3

Coding Method MH MH MH

Transmission Speed 15 sec. 15 sec. 9 sec.

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

ADF Capacity (pages) 20 20 20

Recording Paper Loadable 200 sheets 200 sheets 200 sheets

Paper Size Letter/Legal/A4 Letter/Legal/A4 Letter/Legal/A4

Ribbon Life (Letter-size print) 450 pages 450 pages 450 pages

Handset Yes Yes Yes

LCD Size 16 x 1 16 x 1 16 x 1

On-screen Programming Yes Yes Yes

Gray Scale 64 by Dithered 64 by Dithered 64 by E/D

Smoothing Yes Yes Yes

One-touch Dial 12 x 2 12 x 2 12 x 2

Speed Dial 26 36 100

Telephone Index Yes Yes Yes

Multi-resolution Transmission

FAX/TEL Switch Yes Yes Yes

Distinctive Ringing Yes Yes Yes

Next Fax-reservation Yes Yes Yes

Help Yes Yes Yes

TAD Interface Yes Yes Yes

Coverpage Yes, Super Yes, Super Yes, Super

Polling Type Sim/Del/Seq Sim/Del/Seq Sim/Del/Seq

Receive Password (password plus)

Delayed Transmission 3, timers 3, timers 3, timers

Call Reservation Yes Yes Yes

Call-back Message Yes Yes Yes

Speaker Phone Monitor Monitor Yes, Full-duplex

Activity Report Yes Yes Yes

Transmission Verification Report

Page Memory 512 KB (20 pages) 512 KB (20 pages) 1 MB (50 pages)

Out-of-paper Reception Yes Yes Yes

Quick Scan Yes Yes Yes

Super Quick Scan No No No

Broadcasting Yes Yes Yes

ECM Yes Yes Yes

Multi-transmission Yes Yes Yes

Multi-copying w/Sorting Yes Yes Yes

Enlargement/Reduction Ratio Yes (50-150%) Yes (50-150%) Yes (50-150%)

TAD Type No No DSP

OGM No No Yes

ICM Recording Time No No Yes, 30 min.

FAX Forwarding/Paging No Yes Yes

FAX Retrieval No Yes Yes

PCI (Missing link) Ready Ready Ready

Message Center No No Yes

Caller ID Yes Yes Yes

Fax-/Voice-on-demand No No Voice-on-demand

Mail Box No No Yes

Remote Control Yes Yes Yes

Toll Saver No No Yes

Memo/2-Way Recording No No Yes

Auto Reduction Yes Yes Yes

Confidential Mailbox No No No

Optional Memory No No No

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

I – 2

Page 8

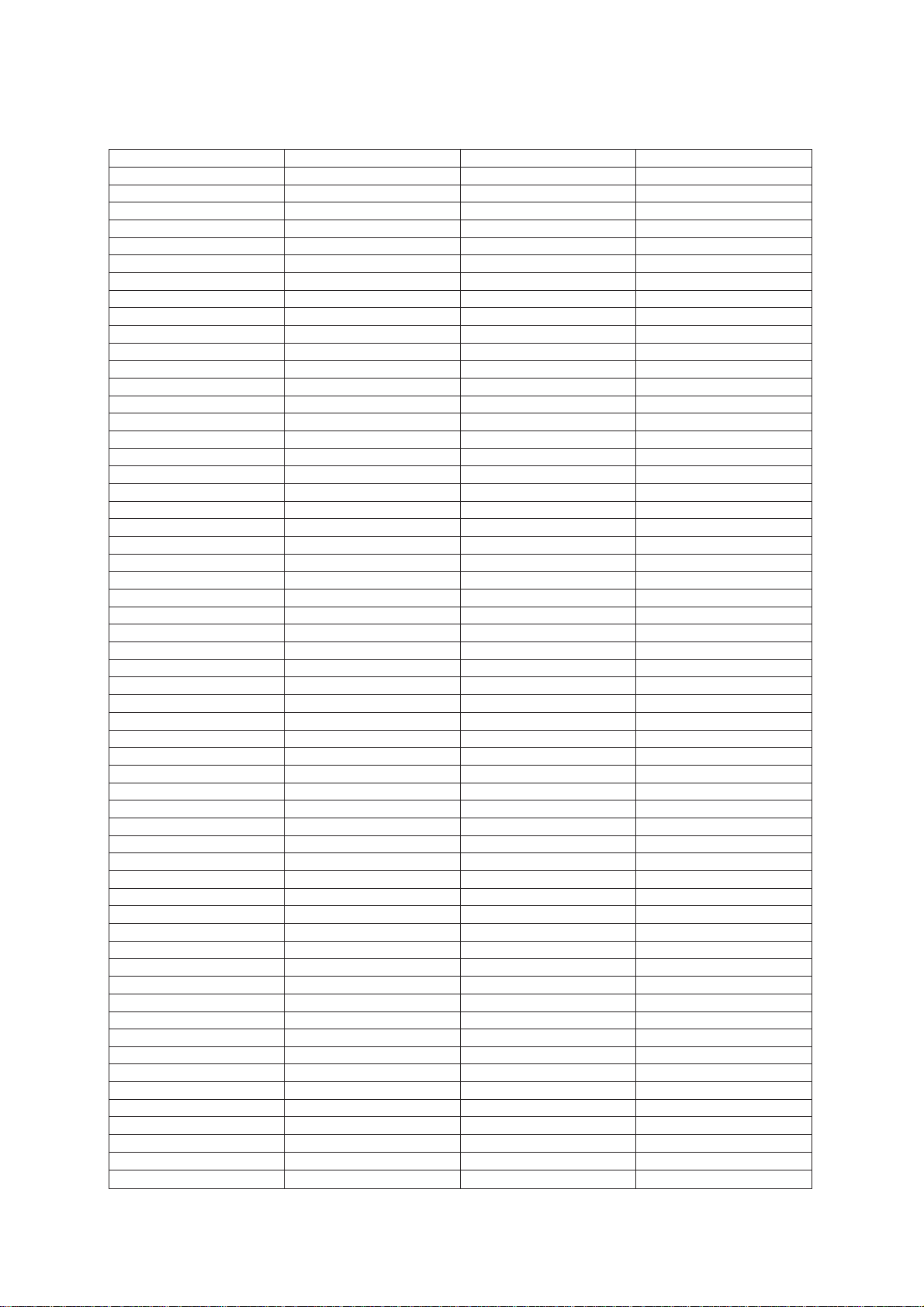

Model FAX1010 FAX1020 FAX1030

Color White (1138) White (1138) White (1138)

Modem Speed 9600 bps 9600 bps 14400 bps

CCITT Group G3 G3 G3

Coding Method MH MH MH

Transmission Speed 15 sec. 15 sec. 10 sec.

Input/Output Width A4/A4 A4/A4 A4/A4

ADF Capacity (pages) 20 20 20

Recording Paper Loadable 200 sheets 200 sheets 200 sheets

Paper Size Letter/Legal/A4 Letter/Legal/A4 Letter/Legal/A4

Ribbon Life (A4-size print) 420 pages 420 pages 420 pages

Handset No Yes Yes

LCD Size 16 x 1 16 x 1 16 x 1

On-screen Programming Yes Yes Yes

Gray Scale 64 by Dithered 64 by Dithered 64 by E/D

Smoothing Yes Yes Yes

One-touch Dial 12 x 2 12 x 2 12 x 2

Speed Dial 36 36 100

Telephone Index Yes (Not Super) Yes (Not Super) Yes (Not Super)

Multi-resolution Transmission

FAX/TEL Switch Yes Yes Yes

Distinctive Ringing Yes Yes Yes

Next Fax-reservation Yes Yes Yes

Help Yes, Simple Yes, Simple Yes, Simple

TAD Interface Yes Yes Yes

Coverpage Yes, Super Yes, Super Yes, Super

Polling Type Std/Sec/Del/Seq Std/Sec/Del/Seq Std/Sec/Del/Seq

Receive Password (password plus)

Delayed Transmission 3, timers 3, timers 3, timers

Call Reservation Yes Yes Yes

Call-back Message Yes Yes Yes

Speaker Phone Monitor Monitor Yes, Full-duplex

Activity Report Yes Yes Yes

Transmission Verification Report

Page Memory 512 KB (20 pages) 512 KB (20 pages) 1 MB (50 pages)

Out-of-paper Reception Yes (20 pages) Yes (20 pages) Yes (50 pages)

Quick Scan Yes (18 pages) Yes (18 pages) Yes (18 pages)

Super Quick Scan No No No

Broadcasting Yes, 60 locations Yes, 60 locations Yes, 124 locations

ECM Yes Yes Yes

Multi-transmission Yes Yes Yes

Multi-copying w/Sorting Yes Yes Yes

Enlargement/Reduction Ratio Yes (50-150%) Yes (50-150%) Yes (50-150%)

TAD Type No No DSP

OGM No No Yes

ICM Recording Time No No Yes, 30 min.

FAX Forwarding/Paging Yes/No Yes/No Yes

FAX Retrieval Yes Yes Yes

PCI (Missing link) Ready Ready Ready

Message Center No No Yes

Caller ID

Fax-/Voice-on-demand No No Voice-on-demand

Mail Box No No Yes, 5

Remote Control Yes Yes Yes

Toll Saver No No Yes

Memo/2-Way Recording No No Yes

Auto Reduction Yes Yes Yes

Confidential Mailbox No No No

Optional Memory No No No

UK, Sw., Holland (Ready for France) UK, Sw., Holland (Ready for France) UK, Sw., Holland (Ready for France)

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

I – 3

Page 9

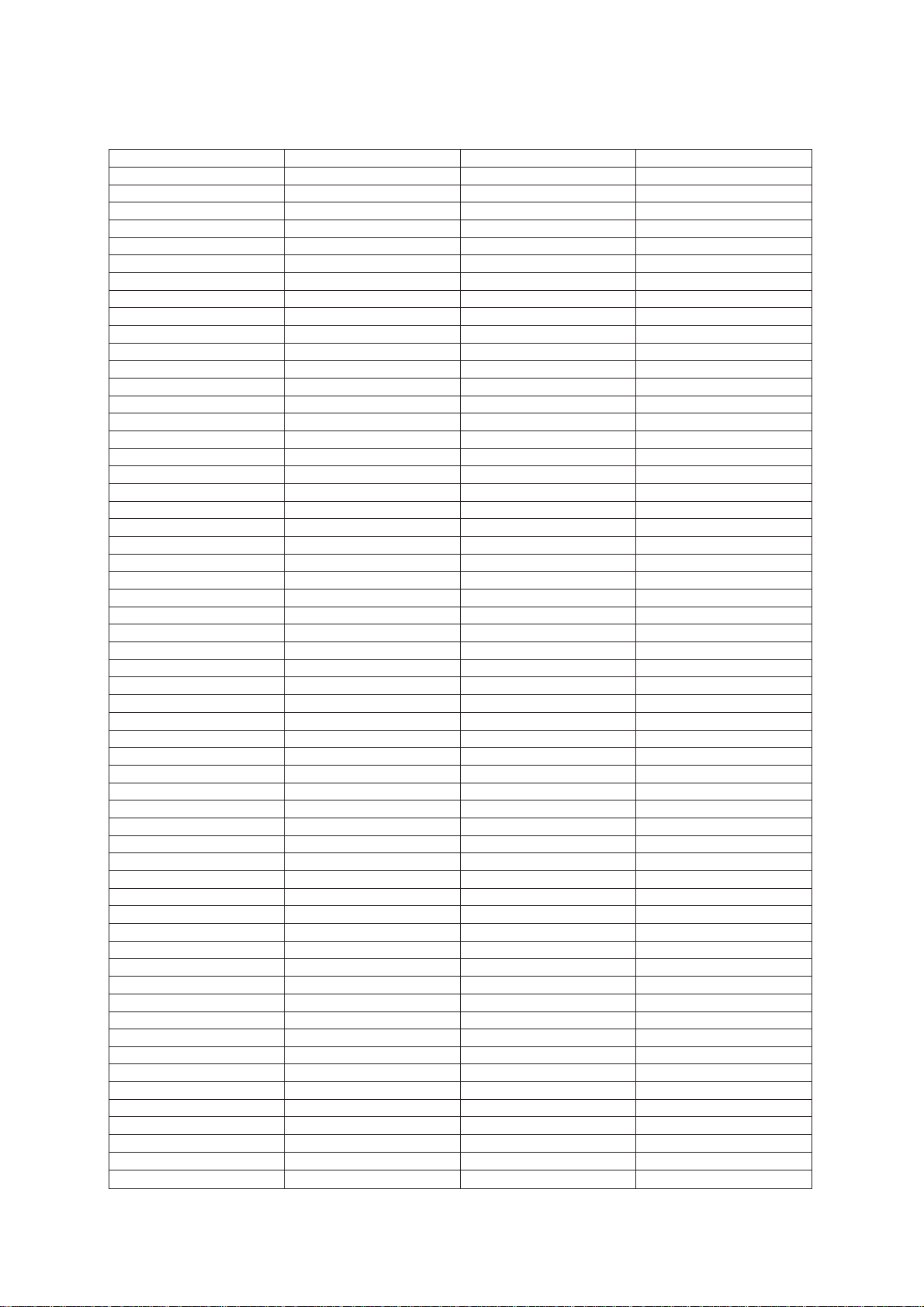

Model MFC1770 MFC1870MC MFC1970MC

Color White (1138) White (1138) White (1138)

Modem Speed 9600 bps 14400 bps 14400 bps

CCITT Group G3 G3 G3

Coding Method MH MH MH

Transmission Speed 15 sec. 9 sec. 9 sec.

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

ADF Capacity (pages) 20 20 20

Recording Paper Loadable 200 sheets 200 sheets 200 sheets

Paper Size Letter/Legal/A4 Letter/Legal/A4 Letter/Legal/A4

Ribbon Life (Letter-size print) 450 pages 450 pages 450 pages

Handset Yes Yes Yes

LCD Size 16 x 1 16 x 1 16 x 1

On-screen Programming Yes Yes Yes

Gray Scale 64 by Dithered 64 by Dithered 64 by E/D

Smoothing Yes Yes Yes

One-touch Dial 12 x 2 12 x 2 12 x 2

Speed Dial 36 36 100

Telephone Index Yes Yes Yes

Multi-resolution Transmission

FAX/TEL Switch Yes Yes Yes

Distinctive Ringing Yes Yes Yes

Next Fax-reservation Yes Yes Yes

Help Yes Yes Yes

TAD Interface Yes Yes Yes

Coverpage Yes, Super Yes, Super Yes, Super

Polling Type Sim/Del/Seq Sim/Del/Seq Sim/Del/Seq

Receive Password (password plus)

Delayed Transmission 3, timers 3, timers 3, timers

Call Reservation Yes Yes Yes

Call-back Message Yes Yes Yes

Speaker Phone Monitor Yes, Full-duplex Yes, Full-duplex

Activity Report Yes Yes Yes

Transmission Verification Report

Page Memory 512 KB (20 pages) 512 KB (20 pages) 1 MB (50 pages)

Out-of-paper Reception Yes Yes Yes

Quick Scan Yes Yes Yes

Super Quick Scan No No No

Broadcasting Yes Yes Yes

ECM Yes Yes Yes

Multi-transmission Yes Yes Yes

Multi-copying w/Sorting Yes Yes Yes

Enlargement/Reduction Ratio Yes (50-150%) Yes (50-150%) Yes (50-150%)

TAD Type No DSP DSP

OGM No Y es Yes

ICM Recording Time No Yes, 15 min. Yes, 30 min.

FAX Forwarding/Paging Yes Yes Yes

FAX Retrieval Yes Yes Yes

PCI (Missing link) Included (MFL3) Included (MFL3) Included (MFL3)

Message Center No Yes Yes

Caller ID Yes Yes Yes

Fax-/Voice-on-demand No Voice-on-demand Voice-on-demand

Mail Box No Yes Yes

Remote Control Yes Yes Yes

Toll Saver No Yes Yes

Memo/2-Way Recording No Yes Yes

Auto Reduction Yes Yes Yes

Confidential Mailbox No No No

Optional Memory No No No

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

I – 4

Page 10

CHAPTER II.

INSTALLATION

Page 11

CHAPTER III.

THEORY OF OPERATION

Page 12

CONTENTS

1. OVERVIEW..................................................................................................... III-1

1.1 Functional Block Diagram ...................................................................... III-1

2. MECHANISMS................................................................................................ III-2

2.1 Transmitting Mechanism (Feeding and scanning documents) ............... III-2

2.1.1 Automatic document feeder (ADF).................................................. III-2

2.1.2 Scanner ........................................................................................... III-3

2.2 Receiving Mechanism (Feeding paper and printing data)...................... III-4

2.3 Power Transmission Mechanism ........................................................... III-5

2.3.1 Structure of the gear train ............................................................... III-5

2.3.2 Description of planetary gear system.............................................. III-6

2.3.3 Power transmission for four operation modes................................. III-7

[ 1 ] Scanning mode (Solenoid: OFF, Motor rotation : Reverse)...................... III-8

[ 2 ] Paper feeding/ejection mode (Solenoid: ON, Motor rotation : Reverse) III-9

[ 3 ] Recording mode (Solenoid: OFF, Motor rotation : Forward) .................... III-10

[ 4 ] Copying mode (Solenoid: ON, Motor rotation : Forward) ......................... III-12

2.3.4 Power transmission route ............................................................... III-14

2.4 Sensors and Actuators........................................................................... III-16

3. CONTROL ELECTRONICS........................................................................... III-19

3.1 Configuration........................................................................................... III-19

3.2 Main PCB................................................................................................ III-20

3.3 NCU PCB................................................................................................ III-27

3.4 Control Panel PCB................................................................................. III-29

3.5 Power Supply PCB ................................................................................ III-30

Page 13

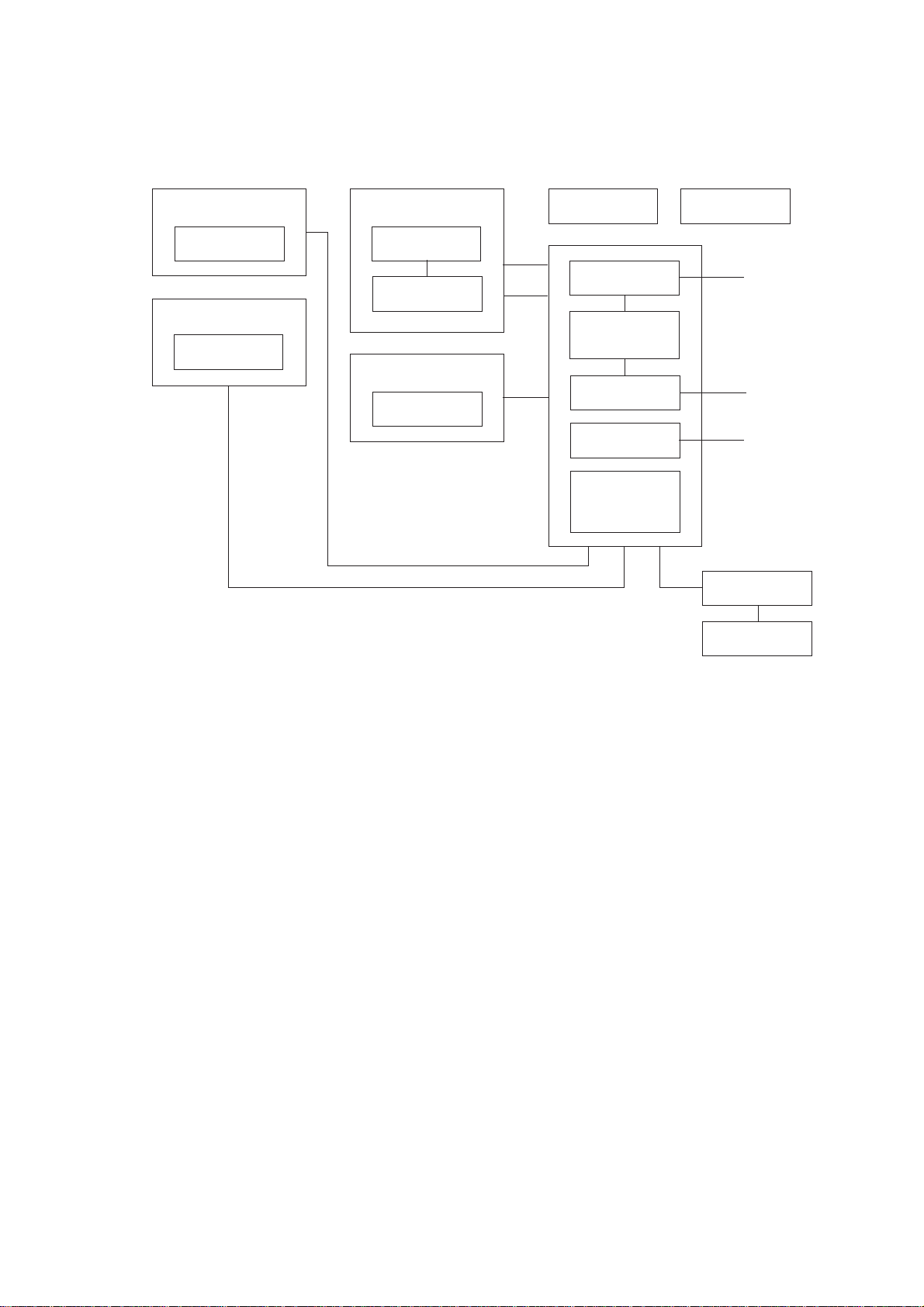

1. OVERVIEW

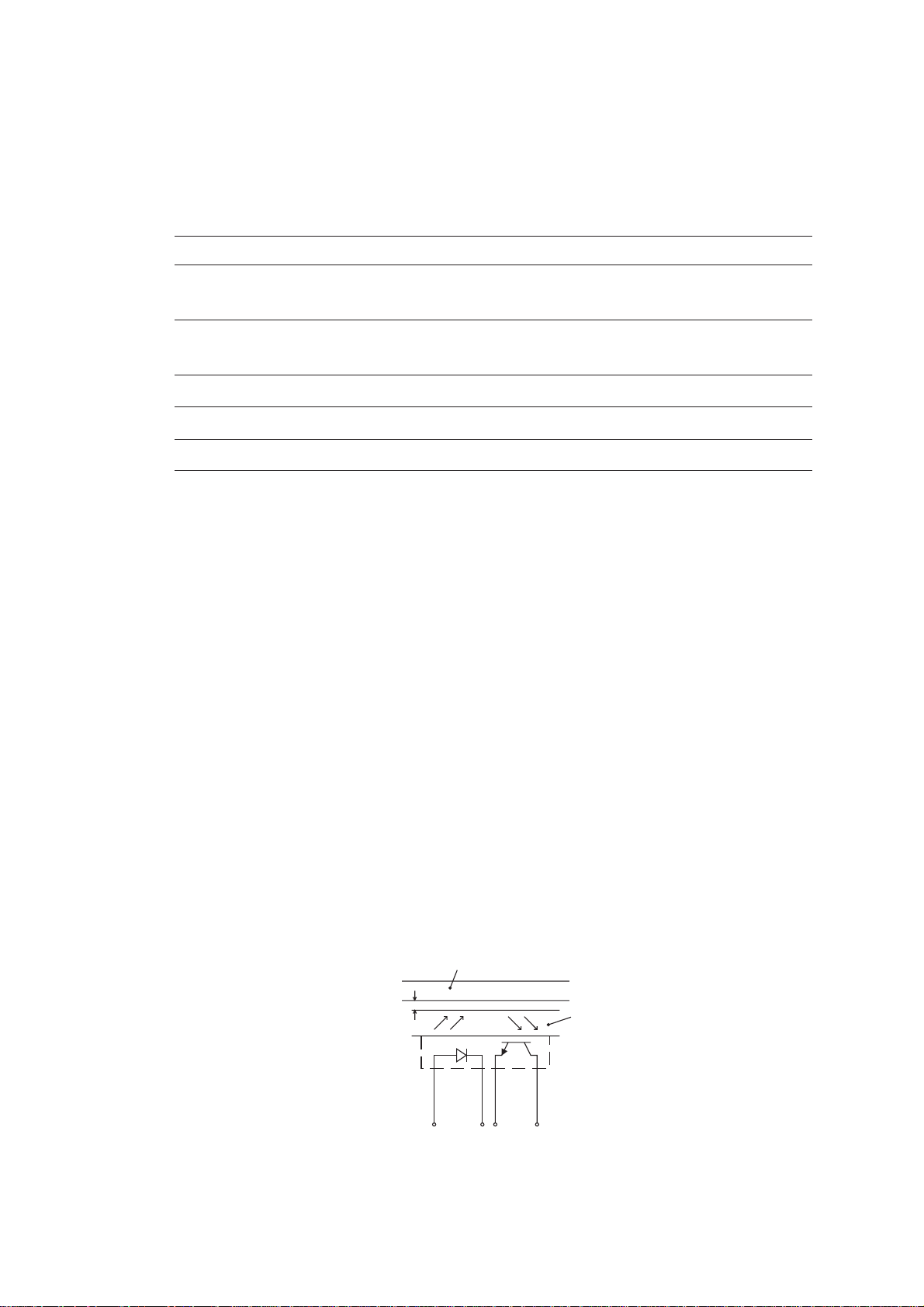

1.1 Functional Block Diagram

Control Panel

LCD

Scanner

CIS unit

Recorder

Recording head

Ribbon sensor

Main frame

Motor

Document

ejection tray

Modular PCB

(Cover sensor)

Main PCB

(Document front

and rear sensors)

NCU PCB

Power supply

PCB

Sensor PCB

(Paper-edge

sensor and paper

ejection sensor)

Ribbon cartridge

To PC

Line

AC

Handset

Hook switch

sensor

III – 1

Page 14

2. MECHANISMS

The equipment is classified into the following mechanisms:

■ Transmitting Mechanism Feeding and scanning documents

■ Receiving Mechanism Feeding paper and printing data

■ Power Transmission Mechanism Switching the power transmission route

■ Sensors and Actuators

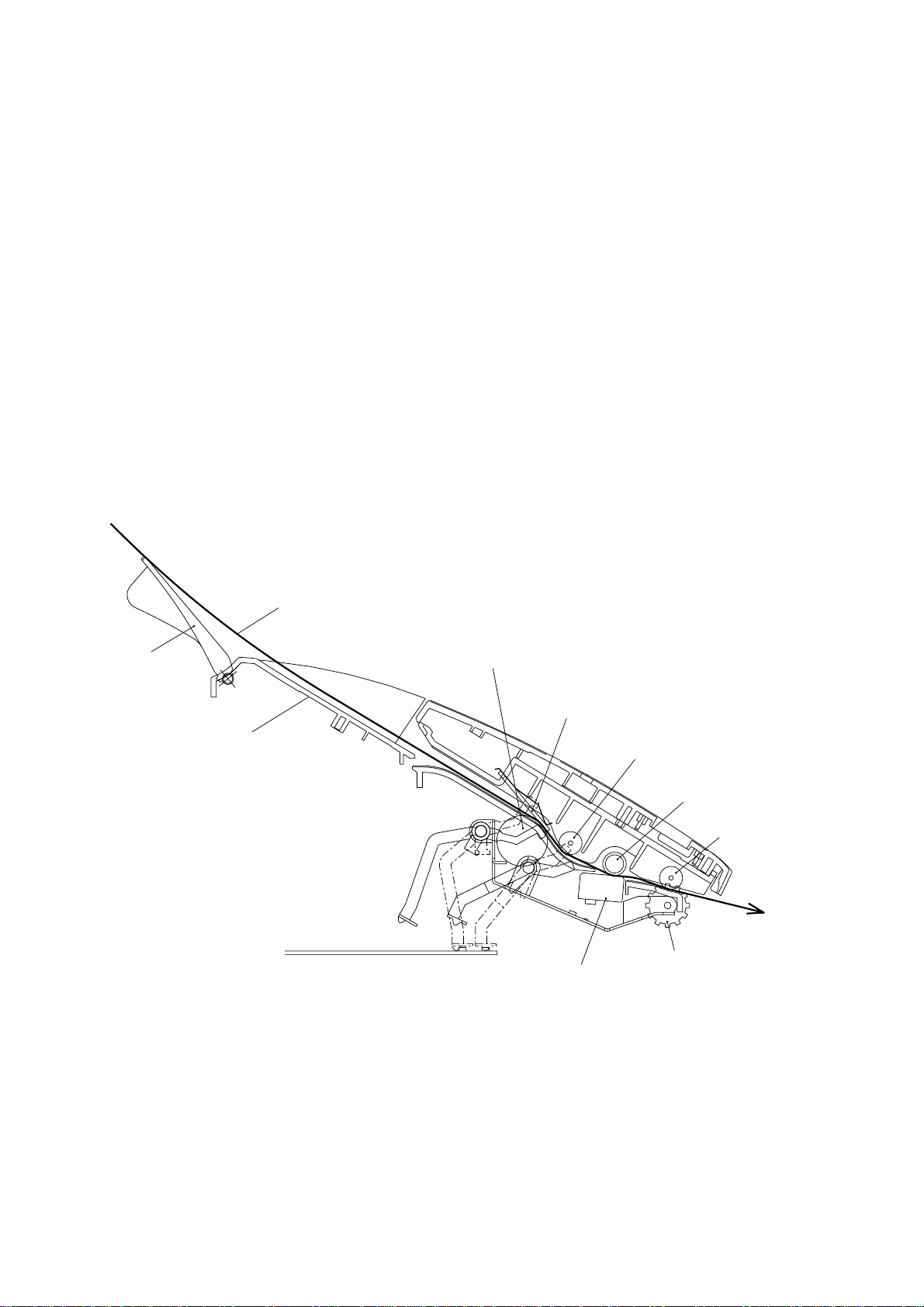

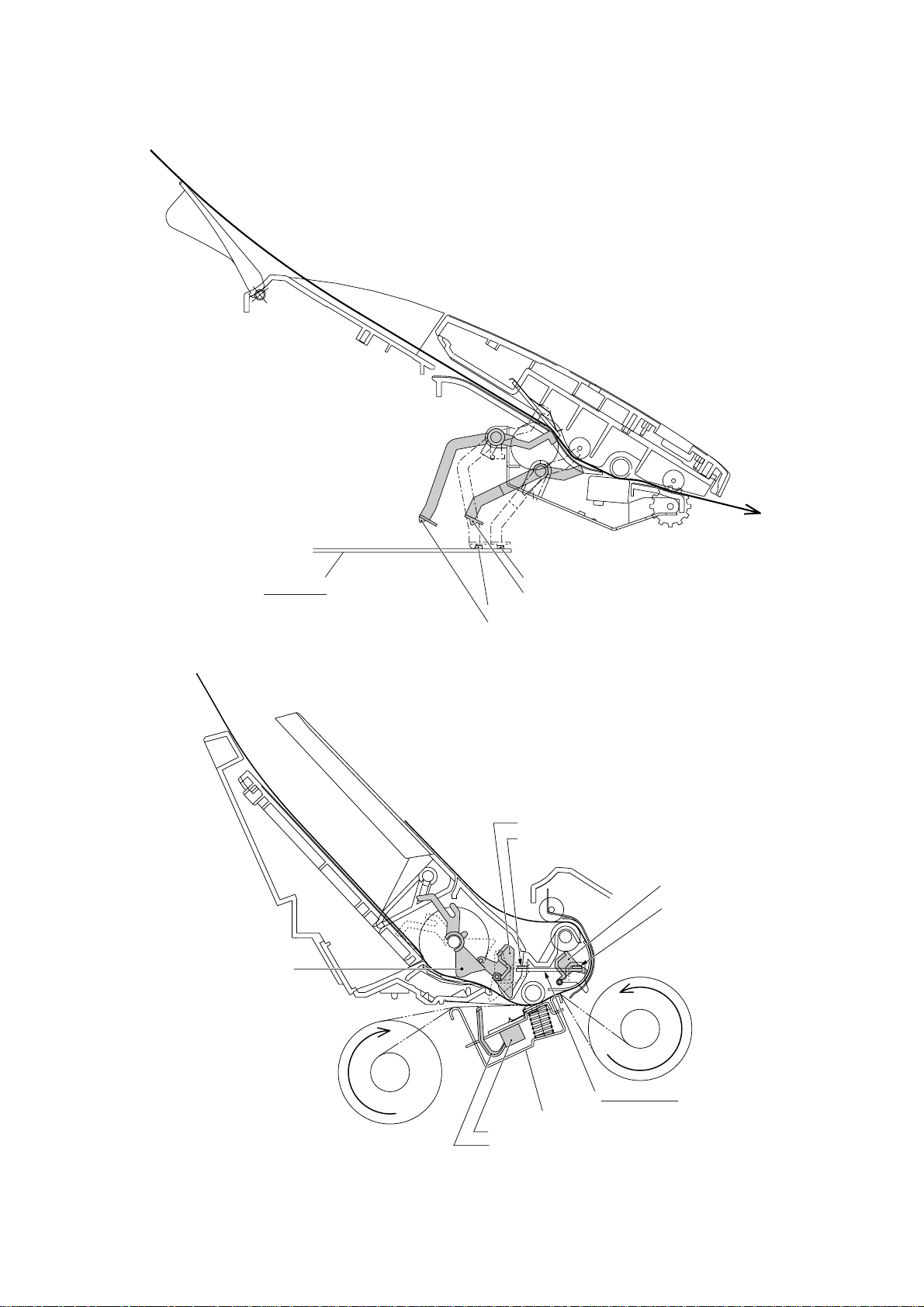

2.1 Transmitting Mechanism (Feeding and scanning documents)

The transmitting mechanism consists of the document stacker, automatic document feeder

(ADF), document feeding related rollers, scanner, and document sensors. (For details about

the sensors, refer to Section 2.4.)

For the drive power source, refer to Section 2.3.

Document

support

Document

stacker

Document

Separation roller

ADF parts

Scanner

(CIS unit)

Pressure roller,

rear

White pressure

roller

Pressure roller,

front

(Front)

Document

ejection roller

2.1.1 Automatic document feeder (ADF)

If the operator sets documents on the stacker and starts the transmitting operation, the ADF

(consisting of the separation roller and ADF parts) feeds those documents into the equipment, starting from the bottom sheet to the top, page by page. Each document advances to

the scanner, and then it is fed with the white pressure roller and document ejection roller.

III – 2

Page 15

2.1.2 Scanner

The scanner uses a contact image sensor (CIS) unit which consists of an LED array illuminating documents, a self-focus lens array collecting the reflected light, a CIS PCB carrying

out photoelectric conversion to output picture element data, and a cover glass on which a

document advances. When the document passes between the white pressure roller and the

cover glass, it is scanned.

III – 3

Page 16

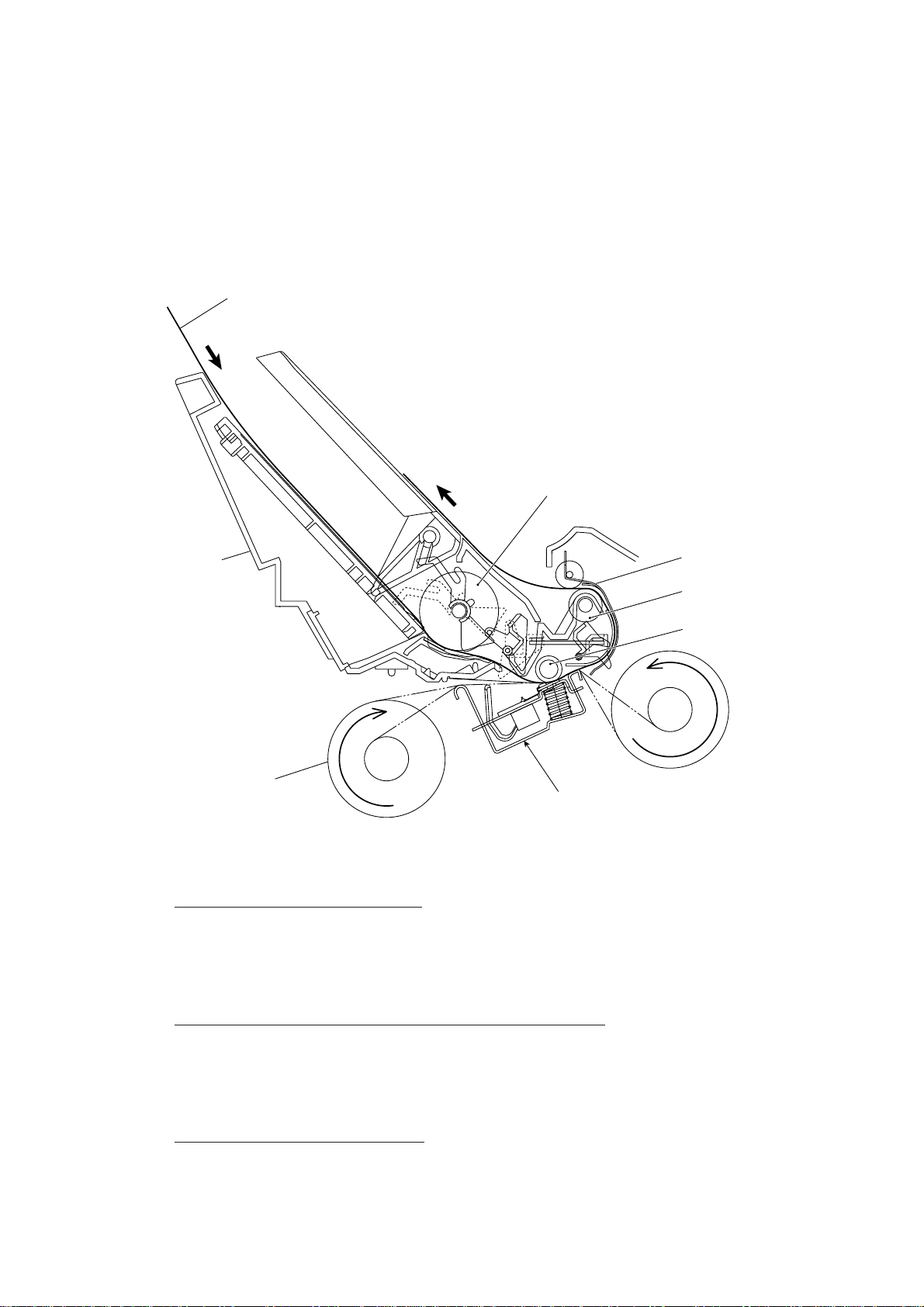

2.2 Receiving Mechanism (Feeding paper and printing data)

The receiving mechanism consists of the recording paper cover ASSY, paper feed roller

ASSY, platen, thermal recording head, paper ejection roller, and sensors. (For details about

the sensors, refer to Section 2.4.)

Paper

Paper feed roller ASSY

Recording

paper cover

ASSY

Thermal ink ribbon

Recording head

Chute ASSY

Paper ejection roller

Platen

STEP 1: In the paper feeding mode

If the equipment receives data, the control electronics activates the solenoid and rotates the

motor counterclockwise to drive the paper feed roller (and paper ejection roller). This pulls in

a sheet of paper and feeds it until its leading edge reaches the point just before the printing

position.

(Front)

STEP 2: In the recording (platen drive & ribbon take-up) mode

The control electronics deactivates the solenoid and rotates the motor clockwise to drive the

platen gear and the ribbon take-up gear as well as the paper ejection roller. This feeds the

paper up to the printing position where the thermal recording head prints, as well as feeding

the thermal ink ribbon.

STEP 3: In the paper ejecting mode

The same operation as for STEP 1 takes place so as to eject the paper.

III – 4

Page 17

2.3 Power Transmission Mechanism

The equipment has a single drive motor whose power transmission route can be switched by

the planetary gear systems and the solenoid. This switching allows the equipment to function in four operation modes (scanning, paper feeding/ejecting, recording, and copying

modes). For the details about the planetary gear systems, refer to Subsection 2.3.2.

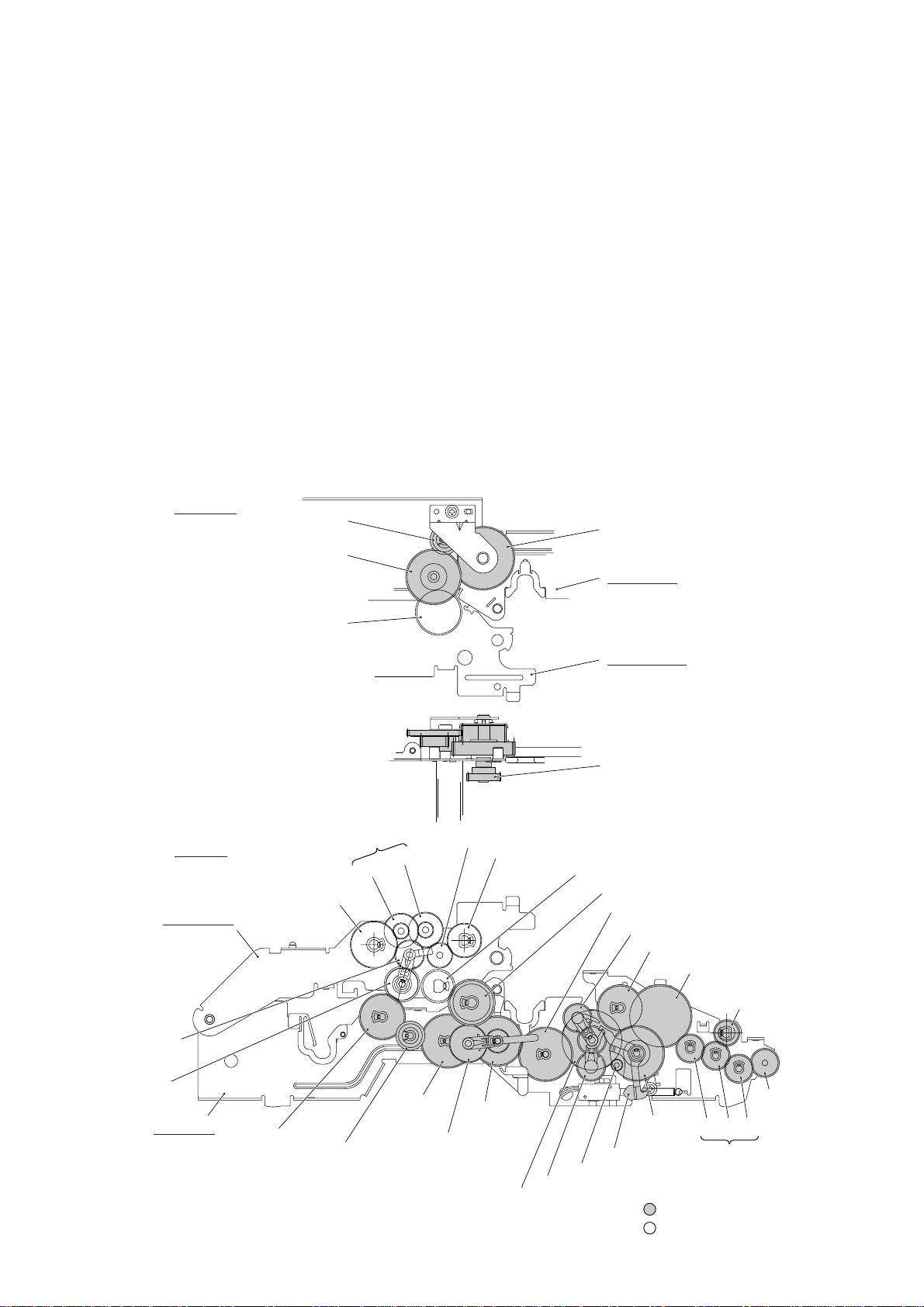

2.3.1 Structure of the gear train

At the left side of the equipment, the rotational torque of the motor on the main frame is

transmitted to the gears on the main frame and then to the gears on the platen frame. These

gears drive the document feeding/ejecting related rollers, paper feeding/ejecting related rollers, and the platen.

If the platen gear ("a" in the figure below) on the left end of the platen shaft rotates, the gear

33RB ("b") on the right end also rotates. This way, the rotational torque is transmitted to the

gears on the right side of the equipment.

At the right side of the equipment, the rotational torque is further transmitted via the friction

torque transmission ASSY to the ribbon drive gear ("e") which drives the ribbon take-up gear

in the ribbon cartridge.

Right side

d (Gear 18)

c (Gear 20/40)

b (Gear 33RB)

Left side

T (Paper feed roller gear, Gear 55)

Platen frame

(Gears 18/41)

e (Gear 46 of Friction torque

transmission ASSY)

Main frame

Platen frame

e (Ribbon drive gear, Gear 24)

W (Clutch gear ASSY)

V

U

X (Paper ejection roller gear, Gear 40)

a (Platen gear, Gear 23)

Z (Gear 33/45)

M (Gear 39)

C (Planet gear 20B of Arm B ASSY)

D (Gear 33)

F (Separation roller gear)

I (White pressure

roller gear)

S (Planet gear

34 of Arm P

ASSY)

R (Sun gear

39/24)

Main frame

Q (Gear 33)

P (Gear 18)

O (Gear 39)

Y (Planet gear 44 of

Arm C ASSY)

B (Sun gear 20/90)

Gear Train

III – 5

N (Sun gear

36/27)

E (Gear

20/40)

Clutch lever

A (Motor gear)

L (Planet gear 20A of Arm A ASSY)

G H J

: Gears on the main frame

: Gears on the platen frame

(Front)

K (Document

ejection roller

gear)

(Gears 14/20)

Page 18

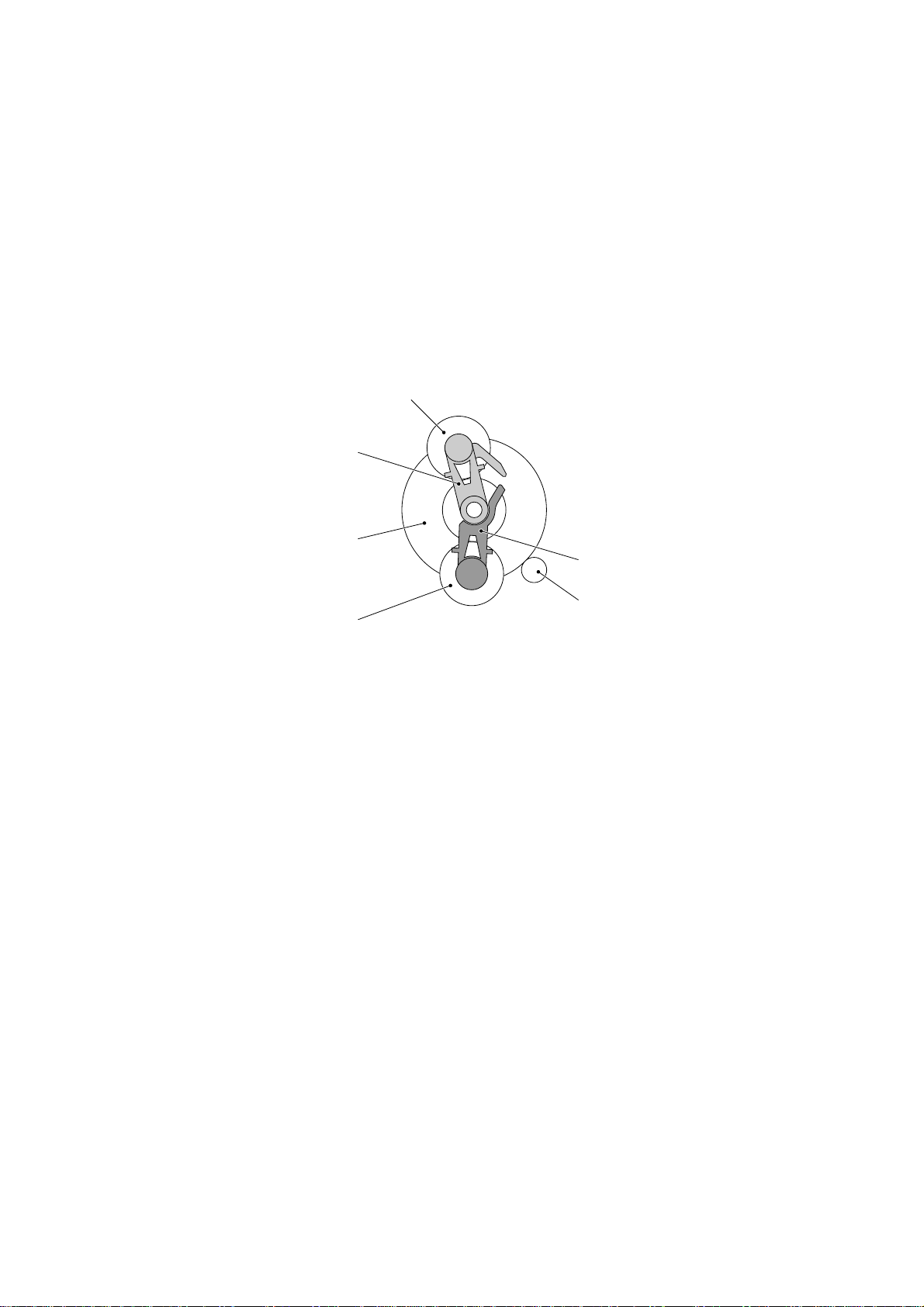

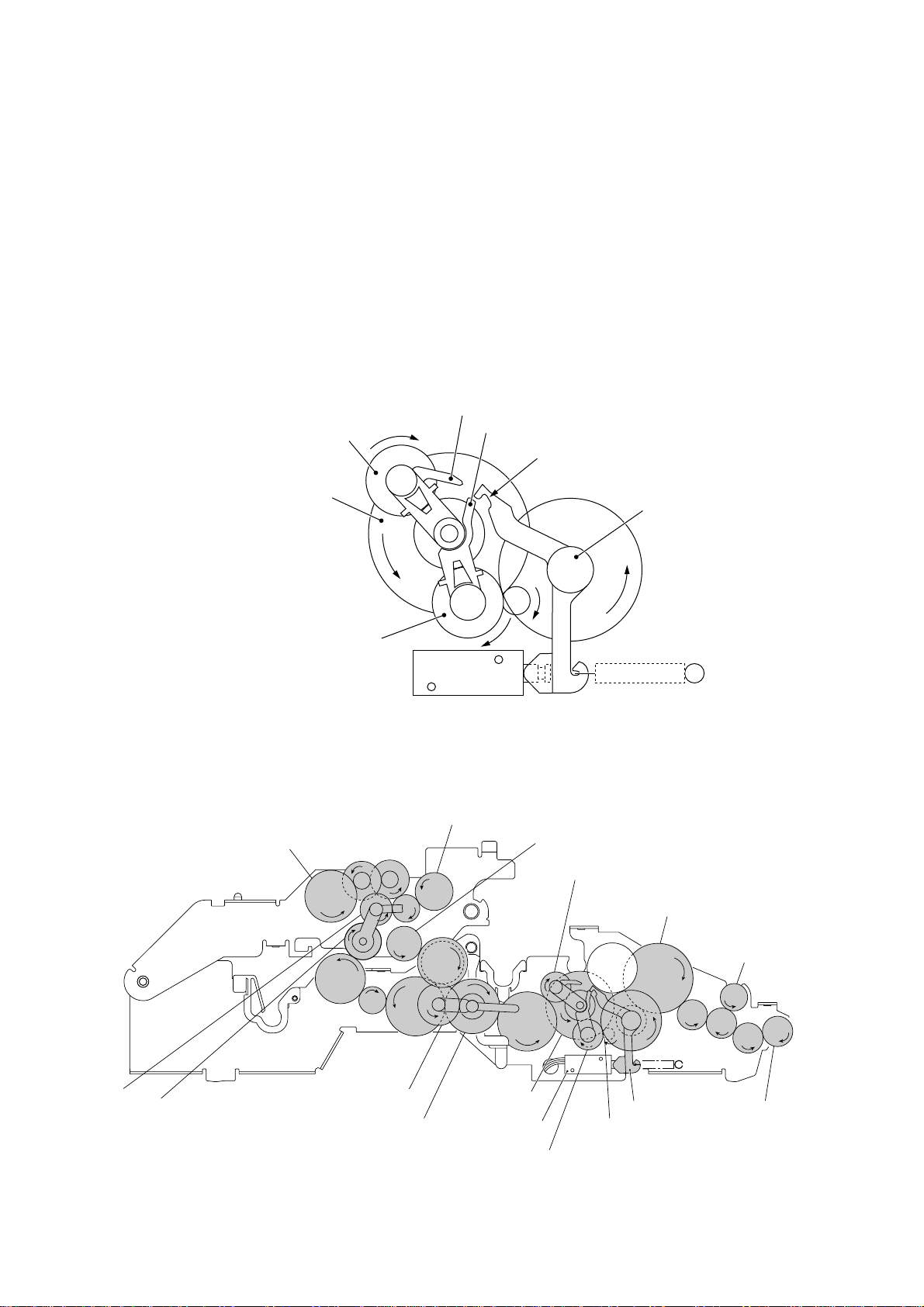

2.3.2 Description of planetary gear system

The equipment uses the following three planetary gear systems:

- Sun gear 20/90 ("B" in the figure given on the previous page) and its planet gears

- Sun gear 36/27 ("N") and its planet gear

- Sun gear 39/24 ("R") and its planet gear

This section describes the planetary gear system of the sun gear 20/90 ("B"). It consists of

the sun gear 20/90, two planet gears 20, arm A, and arm B, as shown below.

Planet gear 20B

Arm B

Sun gear 20/90

Planet gear 20A

Arm A

Motor gear

Planetary Gear System

If the motor rotates, the sun gear 20/90 rotates so that the rotational torque is transmitted to

the engagement between the sun gear and the planet gears 20. Since the arms and planet

gears are so designed that the moment of the arms is less than that of the planet gears, the

arms turn around the center shaft in the same direction as the sun gear 20/90.

If the planet gear(s) becomes engaged with any other gear so that the arm cannot turn furthermore, the rotational torque of the sun gear 20/90 is transmitted to that planet gear. Accordingly, the planet gear starts rotation in the opposite direction of the sun gear 20/90.

III – 6

Page 19

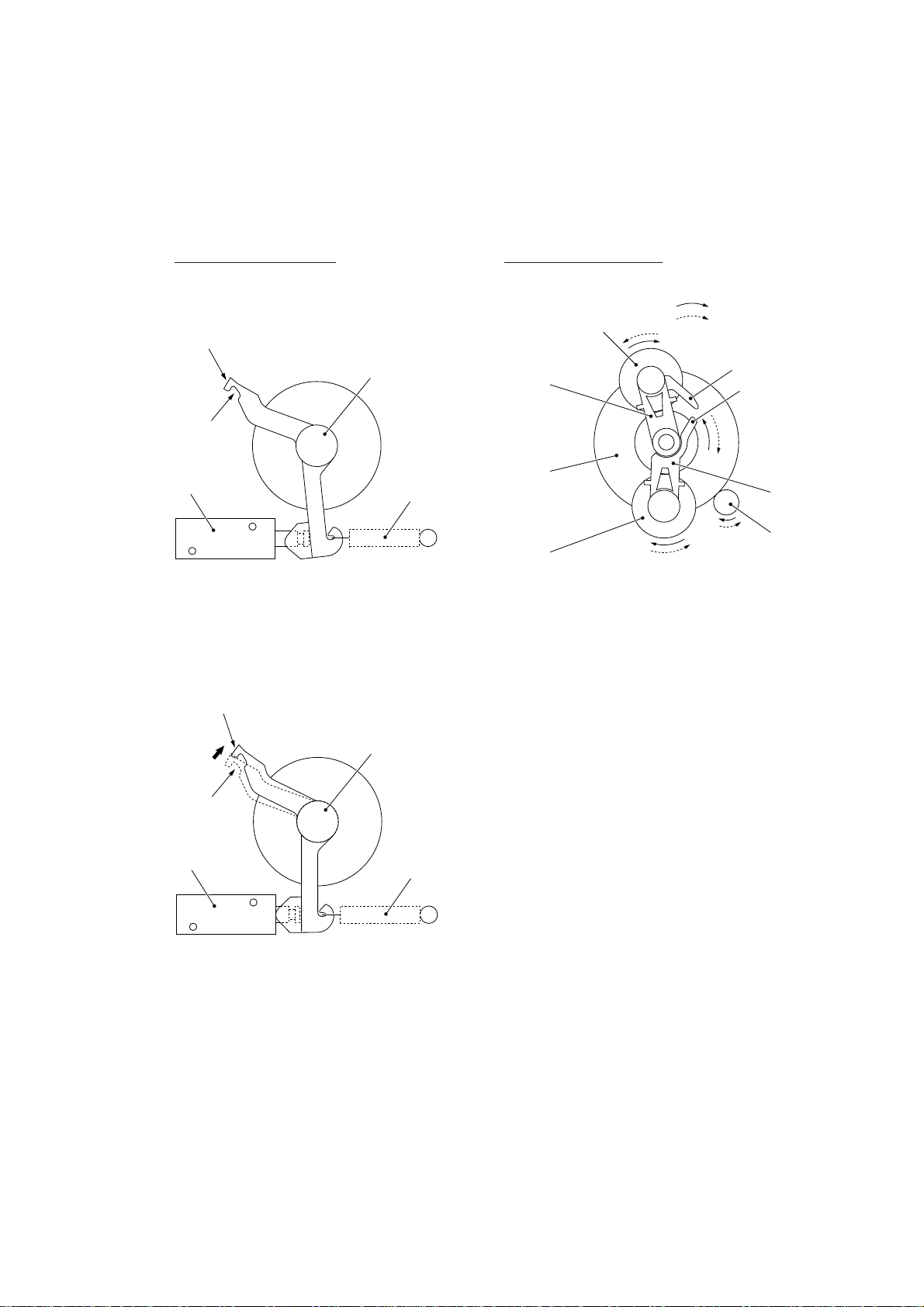

2.3.3 Power transmission for four operation modes

Depending upon the solenoid ON/OFF state and the motor rotation direction, the planetary

gear train switches the power transmission route for the four operation modes.

Solenoid ON/OFF state Motor rotation direction

Solenoid: OFF

Section y (to block the

stoppper of arm B)

Cutout x (engaged

with the stopper of

arm A)

Solenoid

Solenoid: ON

Section y (to block the

stoppper of arm B)

Clutch lever

Spring

Planet gear 20B

Arm B

Sun gear

20/90

Planet gear

20A

Forward

Reverse

Stopper of

arm B

Stopper

of arm A

Arm A

Motor

gear

Cutout x (engaged

with the stopper of

arm A)

Solenoid

Clutch lever

Spring

III – 7

Page 20

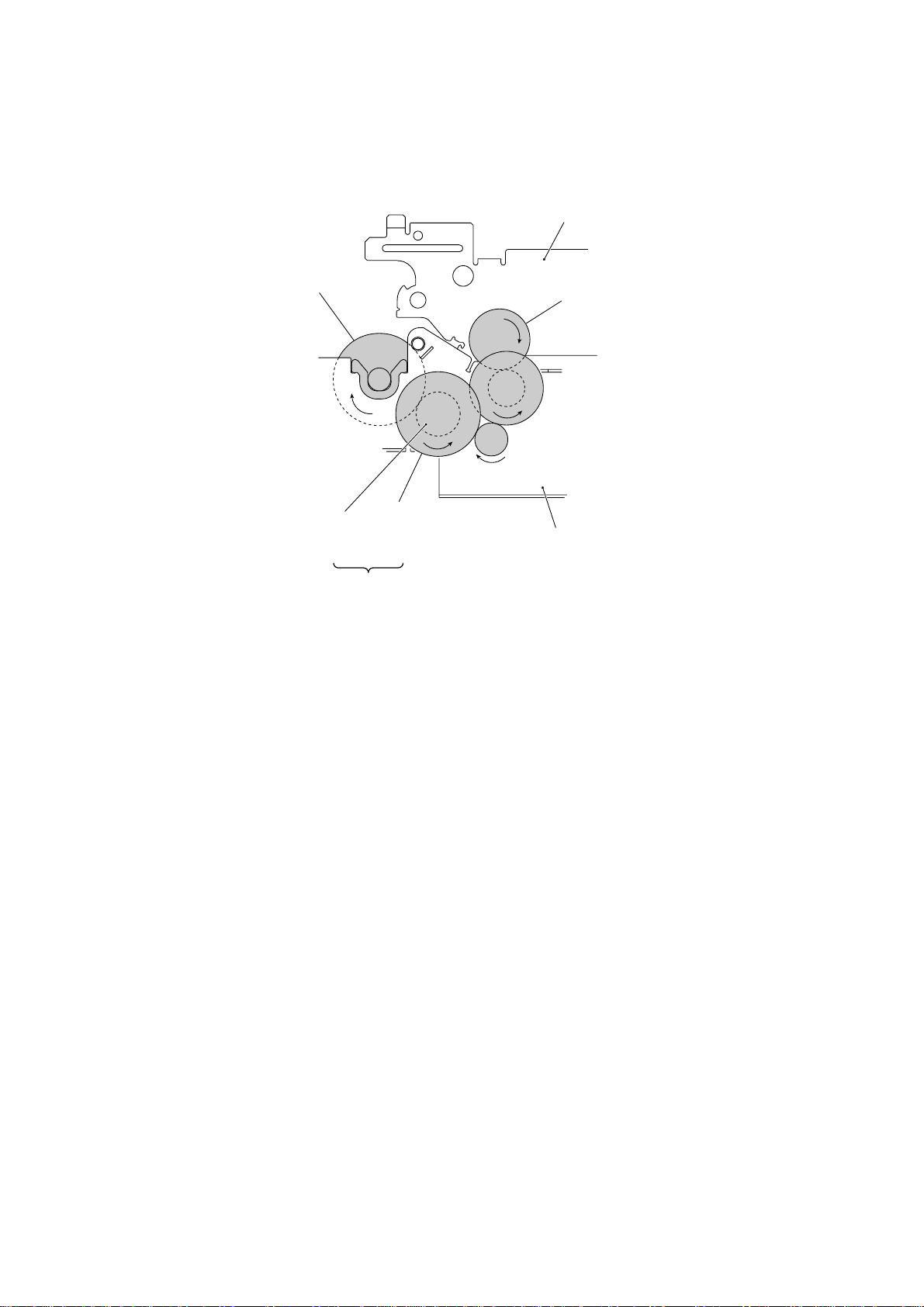

[ 1 ] Scanning mode (Solenoid: OFF, Motor rotation: Reverse)

In the scanning mode, the control electronics deactivates the solenoid. When the motor rotates in the reverse direction, the clutch lever turns counterclockwise with the spring so that

its cutout x becomes engaged with the stopper of arm A. Once arm A is locked, the planet

gear 20A ("L") will not be engaged with any other gear but simply idle.

The motor's rotational torque turns the sun gear 20/90 ("B") clockwise so that the planet gear

20B ("C") transmits the torque to the separation roller gear ("F"), white pressure roller gear

("I") and document ejection roller gear ("K") via the several gears.

C (Planet gear 20B)

B (Sun gear 20/90)

L (Planet gear 20A)

Arm A Locked by Cutout

Solenoid

xx

x of Clutch Lever

xx

B (Sun gear 20/90)

Cutout x of clutch lever

Stopper of arm A

Clutch lever

F (Separation

roller gear)

C (Planet gear 20B)

I (White pressure

roller gear)

Solenoid

Active Gears

III – 8

D

L

Clutch lever

A (Motor gear)

G

H

E

J

K (Document

ejection roller

gear)

(Front)

Page 21

[ 2 ] Paper feeding/ejecting mode (Solenoid: ON, Motor rotation: Reverse)

In the paper feeding/ejecting mode, the control electronics activates the solenoid to release

the stopper of arm A. When the motor rotates in the reverse direction, the sun gear 20/90

("B") rotates clockwise so that the planet gear 20A ("L") transmits the torque via the gear 39

("M") and other gears to the paper feed roller gear ("T") and paper ejection roller gear ("X").

Since the stopper of arm B is blocked by the section y of the clutch lever, the planet gear

20B ("C") is merely idle without engaging with any other gear.

Stopper of arm B

C (Planet gear 20B)

Section y of clutch lever

B (Sun gear 20/90)

L (Planet gear 20A)

T (Paper feed roller gear)

Stopper of arm A

Solenoid

Arm B Blocked by Section y of Clutch Lever

X (Paper ejection roller gear)

V

U

B (Sun gear 20/90)

W

Clutch lever

S (Planet

gear 34)

R (Sun gear 39/24)

Q

P

O

L (Planet gear 20A)

Active Gears

III – 9

C

N

Y

M

(Front)

Solenoid

Clutch lever

A (Motor gear)

Page 22

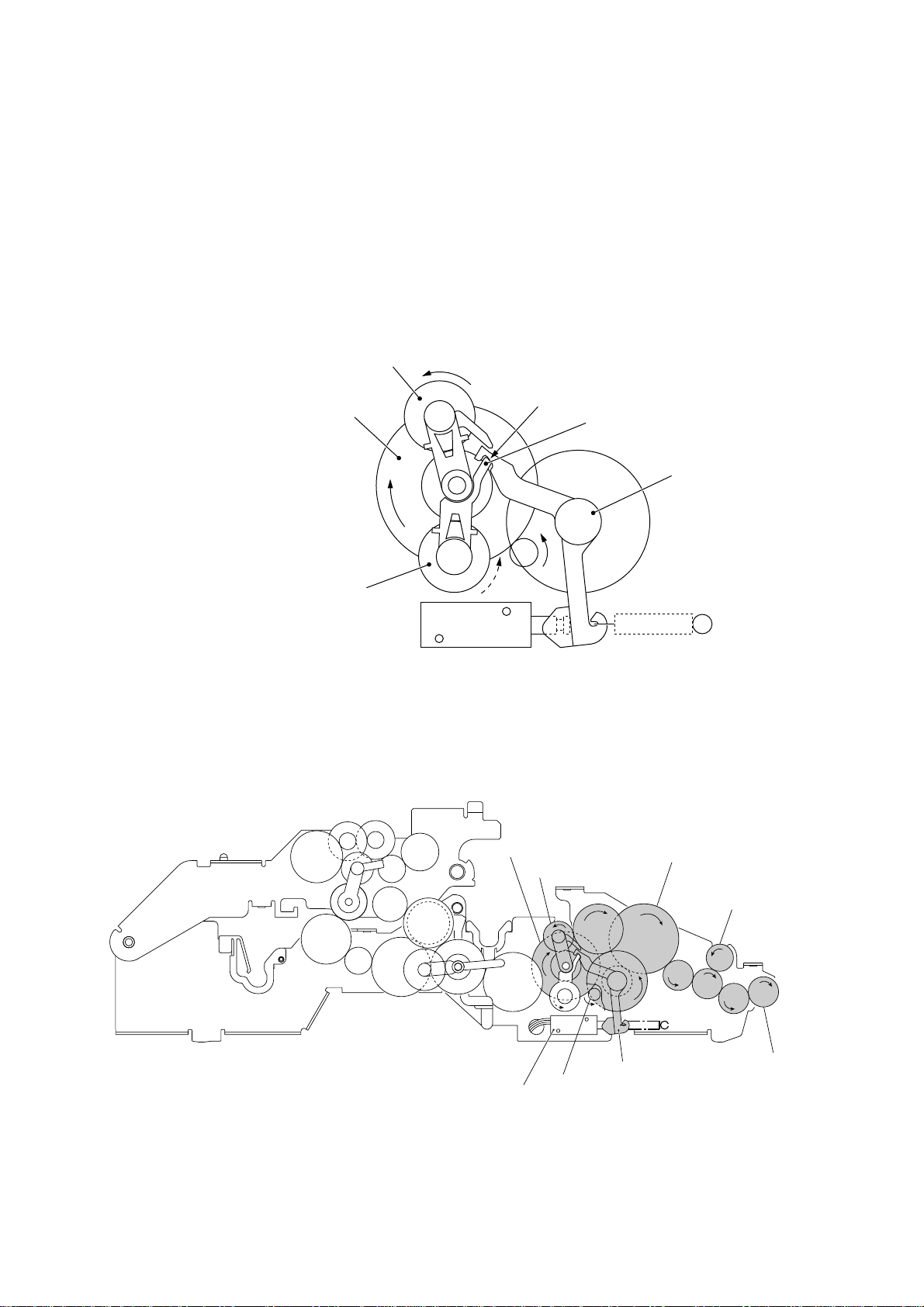

[ 3 ] Recording mode (Solenoid: OFF, Motor rotation: Forward)

In the recording mode, the control electronics deactivates the solenoid. When the motor rotates in the forward direction, the clutch lever turns counterclockwise with the spring so that

its cutout x becomes engaged with the stopper of arm A. Once arm A is locked, the planet

gear 20A ("L") will not be engaged with any other gear but simply idle.

The motor's rotational torque turns the sun gear 20/90 ("B") counterclockwise so that the

planet gear 20B ("C") transmits the torque via the gear 39 ("M") and other gears to the platen

gear ("a") as well as the paper ejection roller gear ("X").

The platen advances recording paper and its paper movement rotates the paper feed roller.

Consequently, the paper feed roller shaft rotates faster than the paper feed roller gear ("T").

If the platen gear ("a" in the figure below) on the left end of the platen shaft rotates, the gear

33RB ("b") on the right end also rotates so as to drive the friction torque transmission ASSY

and ribbon drive gear ("e") that rotates the ribbon take-up gear ("f") in the ribbon cartridge, as

shown on the next page.

C (Planet gear 20B)

B (Sun gear 20/90)

L (Planet gear 20A)

T (Paper feed roller gear)

Solenoid

Arm A Locked by Cutout

X (Paper ejection roller gear)

V

U

Cutout x of clutch lever

xx

x of Clutch Lever

xx

a (Platen gear)

C (Planet gear 20B)

Stopper of arm A

Clutch lever

S (Planet

gear 34)

R (Sun gear 39/24)

W

Z

Q

P

Y (Planet gear 44)

N (Sun gear 36/27)

Active Gears on the Left Side

O

III – 10

B (Sun gear 20/90)

M

L

(Front)

Clutch leverSolenoid

A (Motor gear)

Page 23

f (Ribbon take-up gear

in the ribbon cartridge)

Platen frame

b (Gear 33RB)

(Front)

Ribbon

drive gear

(Gear 24)

c

d

Friction torque

transmission

ASSY (Gear 46)

e

Active Gears on the Right Side

Main frame

III – 11

Page 24

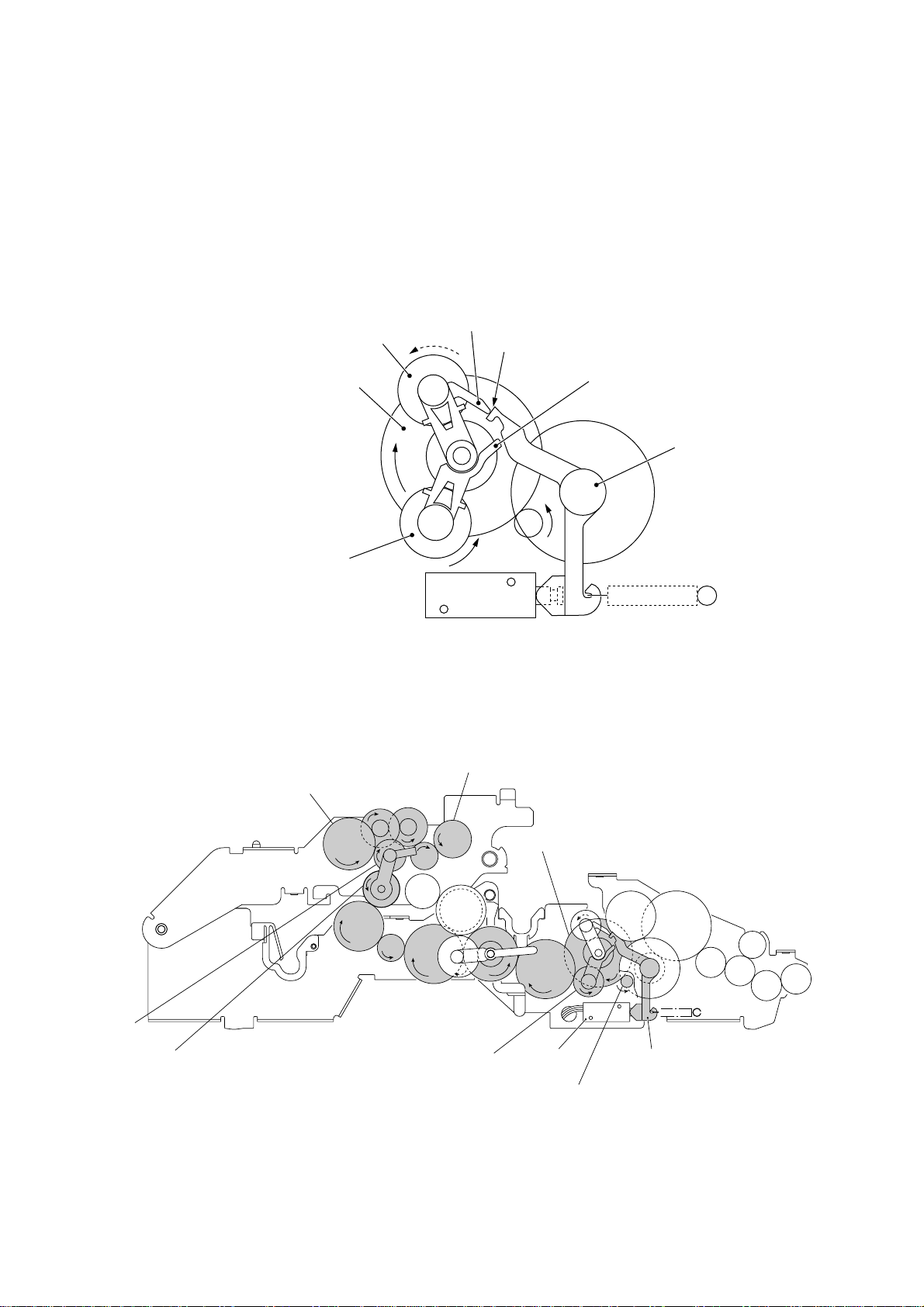

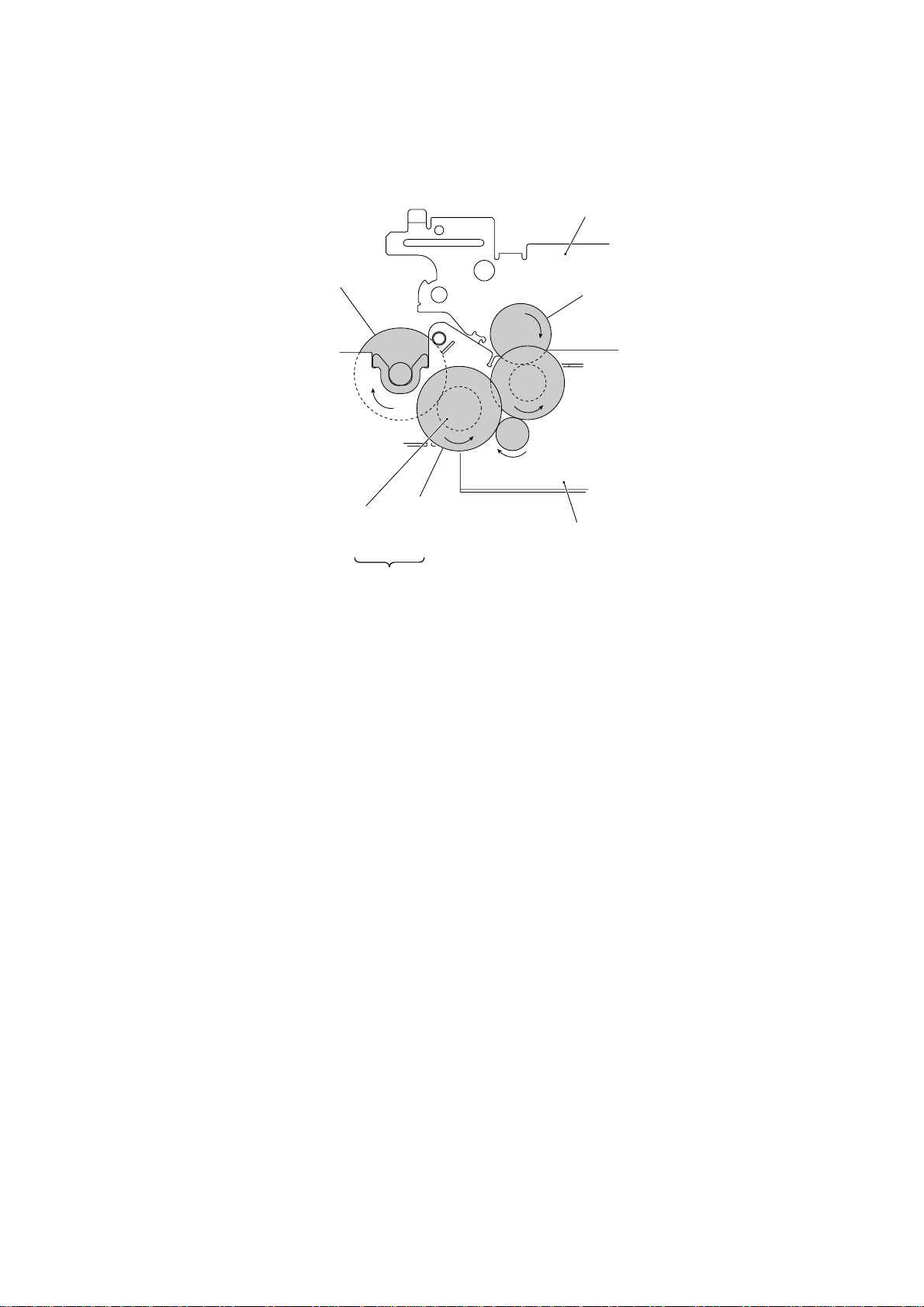

[ 4 ] Copying mode (Solenoid: ON, Motor rotation: Forward)

The control electronics activates the solenoid to release the stopper of arm A from the clutch

lever. When the motor rotates in the forward direction, the sun gear 20/90 ("B") rotates

counterclockwise so that the planet gear 20A ("L") transmits the torque to the document

scanner mechanism (e.g., the separation roller gear ("F"), white pressure roller gear ("I") and

document ejection roller gear ("K")) and the planet gear 20B ("C") transmits the torque to the

recording mechanism (e.g., the platen gear ("a"), paper feed roller gear ("T"), and paper

ejection roller gear ("X")).

If the platen gear ("a" in the figure below) on the left end of the platen shaft rotates, the gear

33RB ("b") on the right end also rotates so as to drive the friction torque transmission ASSY

and ribbon drive gear ("e") that rotates the ribbon take-up gear ("f") in the ribbon cartridge, as

shown on the next page.

Stopper of arm B

C (Planet gear 20B)

Stopper of arm A

Cutout x of clutch lever

B (Sun gear 20/90)

L (Planet gear 20A)

T (Paper feed roller gear)

Solenoid

Arm A Released from Coutout

X (Paper ejection roller gear)

U

V

W

a

Z

XX

X of Clutch Lever

XX

a (Platen gear)

C (Planet gear 20B)

Clutch lever

F (Separation roller gear)

I (White pressure

roller gear)

S (Planet

gear 34)

R (Sun gear 39/24)

Q

P

Y (Planet gear 44)

N (Sun gear 36/27)

Active Gears on the Left Side

O

B (Sun gear

20/90)

III – 12

M

Solenoid

L

E

Clutch lever

A (Motor gear)

L (Planet gear 20A)

G

H

J

(Front)

K (Document

ejection roller

gear)

Page 25

f (Ribbon take-up gear

in the ribbon cartridge)

Platen frame

b (Gear 33RB)

(Front)

Ribbon

drive gear

(Gear 24)

Friction torque

transmission

ASSY (Gear 46)

e

Active Gears on the Right Side

c

d

Main frame

III – 13

Page 26

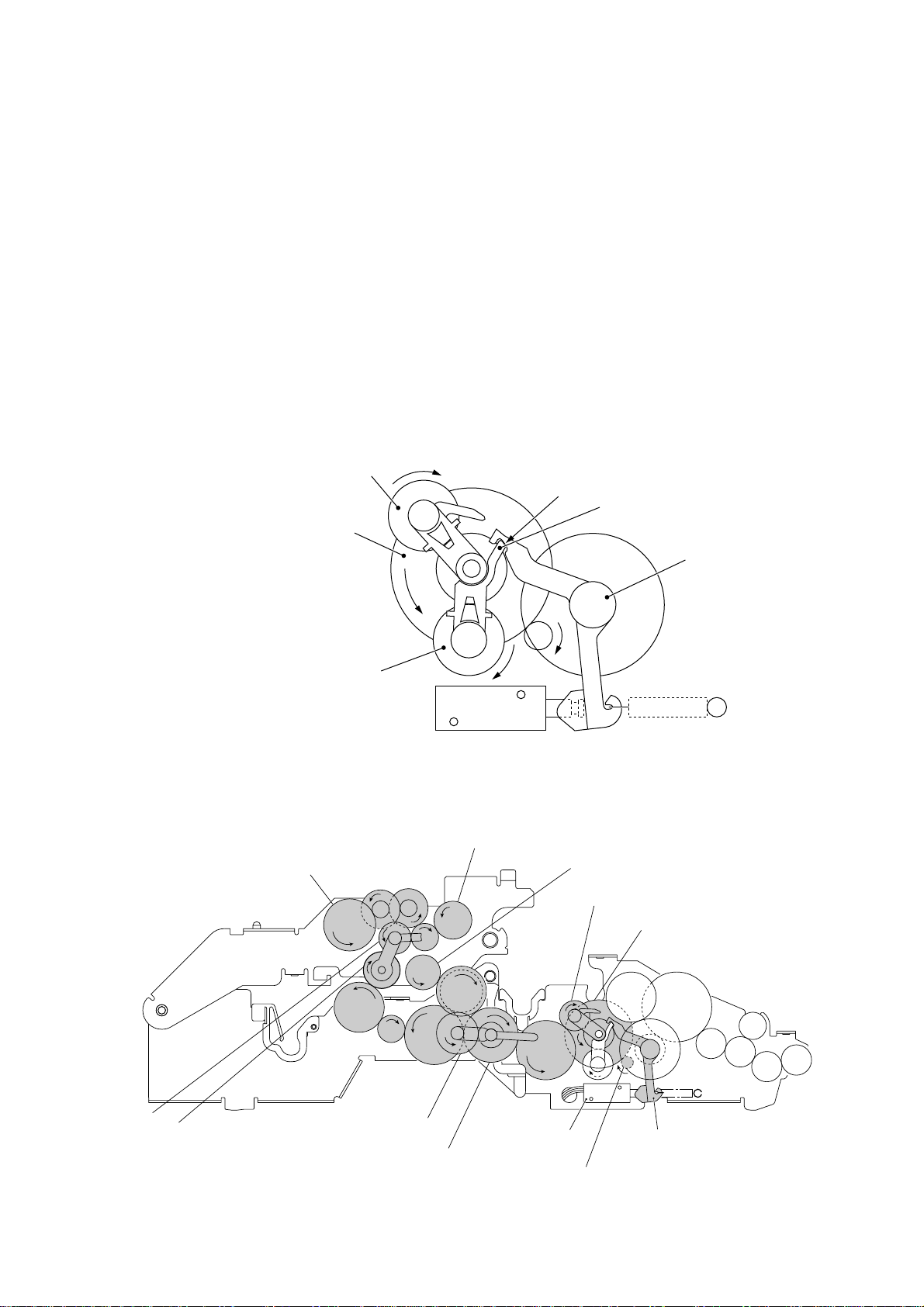

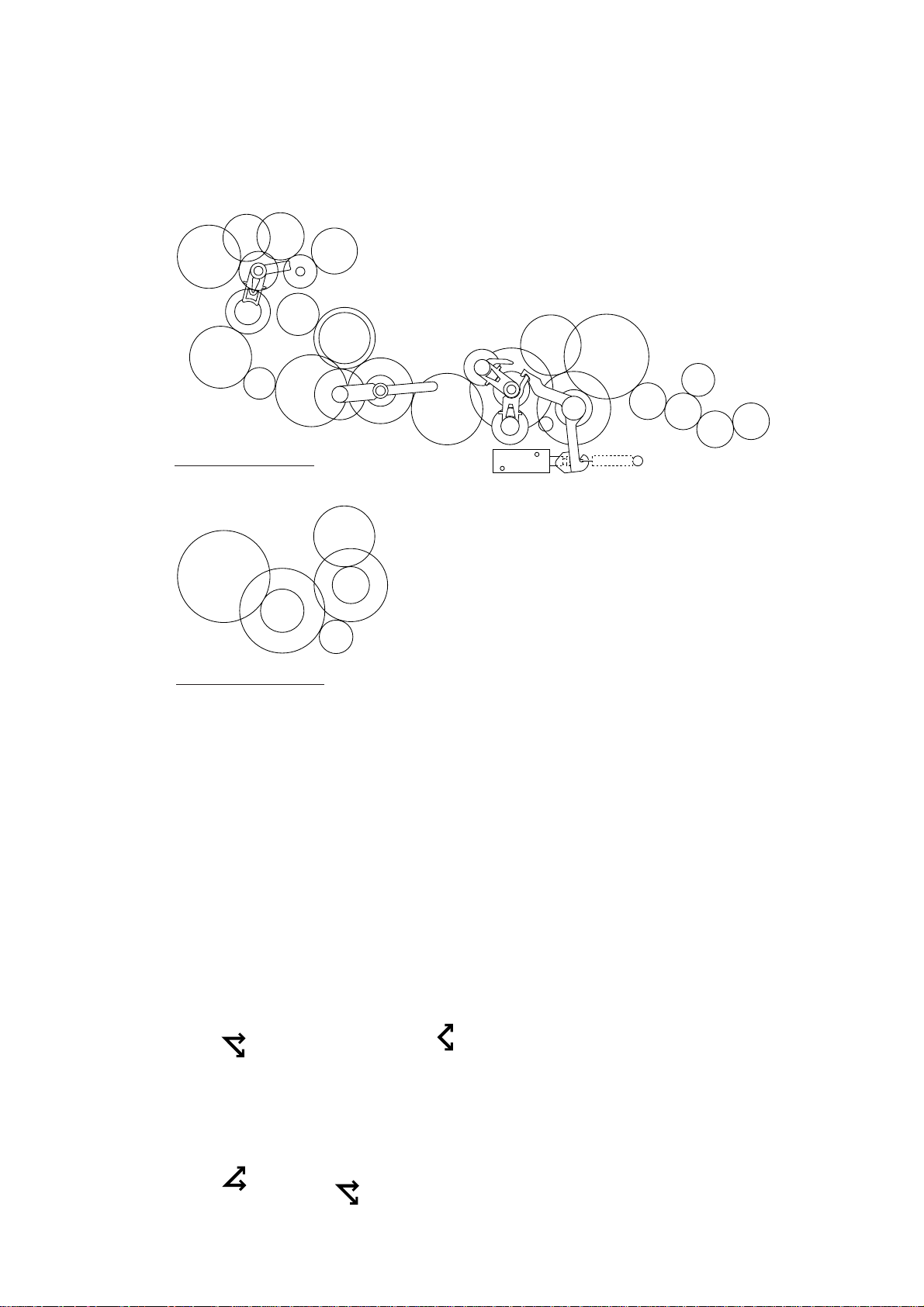

2.3.4 Power transmission route

Rotation of the motor gear is transmitted as shown below.

U

V

T

S

R

Q

P

X

W

a

Z

O

Y

Gears on the Left Side

f

D

C

N

b

c

B

M

L

A

F

I

G

H

E

K

J

e

d

Gears on the Right Side

A: Motor gear

B: Sun gear 20/90

C: Planet gear 20B

D: Gear 33

E: Gear 20/40

F: Separation roller gear

G: Gear 14/20

H: Gear 14/20

I: White pressure roller gear

J: Gear 14/20

K: Document ejection roller gear

L: Planet gear 20A

M: Gear 39

N: Sun gear 36/27

O: Gear 39

P: Gear 18

Q: Gear 33

R: Sun gear 39/24

S: Planet gear 34

T: Paper feed roller gear

U: Gear 18/41

V: Gear 18/41

W: Clutch gear

X: Paper ejection roller gear, Gear 40

Y: Planet gear 44

Z: Gear 33/45

a: Platen gear, Gear 23

b: Gear 33RB

c: Gear 20/40

d: Gear 18

e: Friction torque transmission ASSY (Gear 46)

and ribbon drive gear (Gear 24)

f: Ribbon take-up gear in the ribbon cartridge

[ 1 ] Scanning Mode (Solenoid: OFF, Motor rotation: reverse)

A ➜ BC ➜ D ➜ E ➜ F ➜ G ➜ H

(Motor)

L (Idling)

(Separation

roller)

I (White pressure roller)

J ➜ K

(Document

ejection roller)

[ 2 ] Paper Feeding/Ejecting Mode (Solenoid: ON, Motor rotation: reverse)

C (Idling)

A ➜ BL ➜ M ➜ NO ➜ P ➜ Q ➜ R ➜ S ➜ T ➜ U ➜ V ➜ W ➜ X

(Motor)

Y (Idling)

(Paper feed

roller)

III – 14

(Paper ejection

roller)

Page 27

[ 3 ] Recording Mode (Solenoid: OFF, Motor rotation: forward)

A ➜ BC ➜ M ➜ N

(Motor)

L (Idling)

Y ➜ Z ➜ a (Platen) ➜ b ➜ c ➜ d ➜ e ➜ f (Ribbon take-up gear)

O ➜ P ➜ Q ➜ R ➜ S ➜ WX (Paper ejection roller)

[ 4 ] Copying Mode (Solenoid: ON, Motor rotation: forward)

Y ➜ Z ➜ a (Platen) ➜ b ➜ c ➜ d ➜ e ➜ f (Ribbon take-up gear)

A ➜ B

(Motor)

C ➜ M ➜ N

L ➜ E ➜ F➜ G ➜ HI (White pressure roller) V ➜ U ➜ T

(Separation

roller)

O ➜ P ➜ Q ➜ R ➜ S ➜ WX (Paper ejection roller)

J ➜ K

(Document

ejection roller)

V ➜ U ➜ T

(Paper feed

roller, Idling)

(Paper feed

roller)

III – 15

Page 28

2.4 Sensors and Actuators

This equipment has four photosensors and three mechanical switches (two for the FAX1010)

as described below.

Sensor name Type Located on

Document front sensor Photosensor (PH1) Main PCB

Document rear sensor Photosensor (PH2) Main PCB

Paper ejection sensor Photosensor (PH1) Sensor PCB

Paper-edge sensor Photosensor (PH2) Sensor PCB

Cover sensor Mechanical switch (SW1) Modular PCB

Ribbon sensor Mechanical switch (SW1) Recording head

Hook switch sensor* Mechanical switch (SW1) Hook switch PCB

• Document front sensor which detects the presence of documents.

• Document rear sensor which detects the leading and trailing edges of pages to tell the

control circuitry when the leading edge of a new page has reached the starting position

and when the scan for that page is over.

• Paper ejection sensor which detects whether a paper jam has occurred.

• Paper-edge sensor which detects the leading and trailing edges of paper and the presence of paper as well as detecting whether the paper front cover is closed.

These photosensors are of a reflection type consisting of a light-emitting diode and a lightsensitive transistor. Each of them has an actuator separately arranged (see the next page),

except that the paper-edge sensor has two actuators for sensing the paper and the paper

front cover. When an actuator is not activated, its white end lies in the path of light issued

from the light-emitting diode and reflects its light so that the reflected light enters the lightsensitive transistor. If a document or paper comes in so as to activate the actuator, the

actuator's white end goes out of the light path and no reflected light enters the light-sensitive

transistor. This way, the sensor detects the presence of documents or paper.

• Cover sensor which detects whether the recording paper cover ASSY is closed.

• Ribbon sensor which detects whether the ink ribbon is loaded.

• Hook switch sensor* which detects whether the handset is placed on the handset mount.

The cover sensor has an actuator separately arranged (see page III-18). If the actuator is

activated, its lower end releases the cover sensor lever so that the sensor signals the detection.

Path of actuator's end

Approx. 0.7 mm

* Not provided on the FAX1010

Lightemitting

diode

Lightsensitive

transistor

Glass

III – 16

Page 29

(Front)

Main PCB

Front cover

sensing actuator

Document rear sensor

Document rear sensor actuator

Document front sensor

Document front sensor actuator

Paper-edge sensor actuator

Paper-edge sensor

Paper ejection sensor

actuator

Paper ejection sensor

(Front)

Recording head

Ribbon sensor

Ribbon sensor actuator

Location of Sensors and Actuators (1)

III – 17

Sensor PCB

Page 30

Cover sensor actuator

Cover sensor

Cover sensor lever

Hook switch sensor actuator**

Hook switch sensor**

Hook switch PCB**

Modular PCB

Handset mount*

Location of Sensors and Actuators (2)

* Not provided on the FAX1010

** Not provided on the FAX1010 or those versions equipped with a Binatone handset

III – 18

Page 31

3. CONTROL ELECTRONICS

3.1 Configuration

The hardware configuration of the facsimile equipment is shown below.

Line

External

telephone

Handset*

2-pin

4-pin

2-pin

NCU PCB

(Note)

(Note)

12-pin: U.S.A. versions

18-pin: European versions

Speaker

PC I/F

Motor

Modular

PCB

Solenoid

Recording head

2

*

8-pin

2-pin

6-pin

2-pin

11-pin

5-pin

Sensor

PCB

*

P2

ASIC

Main PCB

1

*

14-pin

Control

panel PCB

5-pin

7-pin

CIS unit

COG

14-pin

FPC key

2-pin

2-pin 4-pin 2-pin

*

3

Hook

*

switch

PCB

5

4-pin

4

*

Microphone

(Only on the FAX1570MC/1030/MFC1870MC/1970MC)

Power supply PCB

Ni-MH

battery

* Not provided on

the FAX1010

1

*

On the main PCB are these sensors:

• Document front sensor (PH1)

• Document rear sensor (PH2)

2

*

On the modular PCB is the cover sensor.

3

*

On the sensor PCB are these sensors:

• Paper ejection sensor (PH1)

• Paper-edge sensor (PH2)

4

*

On the hook switch PCB* is the hook switch sensor (SW1).

5

*

On the recording head is the ribbon sensor (SW1).

Configuration of Facsimile Equipment

III – 19

Page 32

3.2 Main PCB

The main PCB, which is the nucleus controlling the entire operation of the equipment, consists of a FAX engine (ASIC), memories, MODEM, motor drive circuitry, sensor detection circuitry, and analog circuits for scanning, recording, and power transmission shifting.

NCU

Power

supply

ROM

E2PROM

DRAM

FAX

engine

(ASIC)

Motor

driver

Control panel

Recording head

CIS

Motor

Speaker

Modular

PCB (for

PC I/F)

Hook

switch

sensor*

Sensors

** Not provided on the

FAX1010 or those

versions equipped

with a Binatone

handset

On the following pages, the main PCB circuit diagrams are described on the basis of the

FAX1570MC/1030/MFC1870MC/1970MC.

Sensors

2

E

PROM: Electrically Erasable Programmable Read-only Memory

DRAM: Dynamic Random Access Memory

Block Diagram of Main PCB

Ni-MH battery

Microphone

III – 20

Page 33

12345678

L3 0

6

PANEL

P11

B5B-PH

WHI T E

GND FG

+5V

R8

*

5

1

3

2

4

GND

33A LI GT

42F DASNO

43D DAREC

42F DAST

E5V

E0V

E5V

R92

75F

R93

100F

R94

75F

E0V

C16

CC104

R96

75K

R95

10KF

C78

CC104

GND

7

+26V

E0V

C79

CC104

C14

C101

C50

0

C77

CC104

R7 4 70

15B PCLK

15B SDOT

R9 470

15B SDIN

C15

C13

C101

C101

+5V

#9

T7D60

R132

10K

R87 10K

17

ADPDMD

52C CLBSY

52D CLRXS

R133 10 k

32F RIBON

42F TLOF2

43B TADH

44D TXSL

45D HAFH

46E SPON

38C FRNT

37B FSEN

37B RSEN

17B CSEN

38C REAR

32E ST1

32E ST2

32E HDC

32E DIN

32E DOUT

34C E1CS

34C SMC

36C RDAT

23C MTI1

23C MTI0

32A RB

37D SEON

33B VI D

C39

CC104

MI O0 ( P WM)

18

MI O1 ( P WM)

19

MI O2 ( P WM)

20

MI O3

21

MI O4

22

MI O5

23

MI O1 1

24

MI O1 2

25

MI O1 3

205

MVDD

208

MVSS

204

MONMDCK

103

LIGT(PWM)

80

SEON(OD)

76

SEN2

77

SEN3

78

SEN4

79

SEN5

30

SEN6

31

SEN7

32

SEN8

92

ST1

91

ST2

93

HDC

94

DI N

90

DOUT

106

E1CS

107

SPSL( SMC)

102

RDAT

95

CL2

98

CL1

99

CLB

100

RB

101

DI F

104

TG

52

RDA61

56

CP1I

55

CP3I

54

CP4I

53

CPNN

50

RDA6

51

AVDD

58

AVDD

49

REFH

48

REFL

47

AGND VSS

59

AGND

AAPDMD

DPDMDT

DPDMCK

APDMCK

APDMDT

AMUTE

MEXTL

MUTE

MTXL

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

DA8

DA9

D00

D01

D02

D03

D04

D05

D06

D07

VDD

VDD

VDD

VDD

VDD

VDD

VDD

VDD

VDD

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

R59 10k

R68 10k

L5V

C70

C38

CC104

0

+5V

GND

GND

R86 *

C68

*

GND

34C,32A TG

33D CP3I

E5V

C73

C76

CC104

CC104

E0V

A

B

C

D

+5V

GND

E

F

+5V

5

Q6

RH5VA4 3

VCC

OUT

GND

GND

R70

200

16

ADMD

14

AAMD

R67

200

12

DMT

R66

300

11

DMK

R64

300

9

AMK

8

AMT

3

C5

C4

C3

C2

C1

C0

C3

2

C4

1

C5

6

C0

5

C1

4

C2

13

AMUT

7

MUT

207

L2 100

206

R117 20 0

109

DA0

R118

110

DA1

200

111

DA2

RA2

112

DA3

200

113

DA4

115

DA5

116

DA6

RA1

117

DA7

200

118

DA8

120

DA9

127

D0

128

D1

129

D2

130

D3

131

D4

133

D5

134

D6

135

D7

10

43

97

114

132

147

165

190

201

15

38

60

81

96

C43

C51

105

CC104

CC104

119

142

156

164

200

R90

1.5K

C65

CC104

C61

CC30P

TBUS 48A,58D

DABUS

26B,26E

DBUS 25E,36D

C59

CC104

RSTL 16A,47B, 14B,57E

R80 1M

XT1

CSA16 MX

GND

14A RSTL

#12 74VHCU04FS

R60 4.7K

R61

XT2

220

D57. 6 D6

C42

CC5P

C0V

C60

c63

CC104

CC104

2

1432

C71

CC102B

C66

CC104

#9

T7D60

44

143

141

R116 10 0

27B RMRD

27B ROMC

12B PCLK

+5B

12B SDOUT

12B SDIN

R88 100

14A RSTL

25C BARMRD

25C BARMWE

42F ADLC

46E VOL1

42F EAT

42B,38E CMLH

42E RDPS

43E PLS

43A TELL

17C HOOK

42F CI

42F TLOF

45E RNGO

46E VOL3

46D RNGL

42D OTO

32F LATC

33C CLMP

33C CPWM

53B CLSEL

25B EPCK

23F SOL RM3

38E PWON

34C SRAM

25B EPDO

23E MTVR

R131 10 K

L5V

+5V

L4

0

C72

CC104

GND

R114100

R79 *

R78 *

L5V

GND

L5V

P7 *

SHORT-2

GND

C0V

70

75

124

123

122

166

167

177

176

175

67

66

68

73

74

65

72

71

57

83

82

187

188

189

191

192

193

194

195

39

40

184

203

89

185

186

26

27

28

29

182

183

108

41

121

69

88

74VHCU0 4F S

5137

25D RAS

R82

0

25D CAS

C62

CC30P

R84

22K

R85 *

+5B

C67

CC104

GND

GND

8

4

C41

CC5P

GND

C69

CC104

RST

EXTL

XTL

RAS0

CAS

RMRD

RMWE

ROMC

IORD

IOWE

PCLK

SDOUT

SDIN

CK32ON

CK32

BAKCLK

BAENB

BAVDD

BAKSEL

BARMRD

BARMWE

LNCR(COMP)

SOL ( OD)

PWON

CML

DPS

PLS

TEL

HOOK

CI

TLOF

STD

RI NG

SPON

E2CS

CTXD

PO1

PO2

P03 ( OD)

RM1

RM2

RM4

PIO1

PIO2

PIO3( SRAM)

PIO4( OD)

PIO5

PIO6

EIT 1

#12

119

1

64

RSTL 14A

RTCCON

61

RVDD

RVDD

62

REXT

63

RXT

202

CRXD

199

CKS

196

TXD

197

RXD

198

CTS

84

MM1

85

MM2

86

MM3

87

MM4

45

TSTA

46

TSTB

125

IORQ

126

MREQ

140

CK16

144

CK8M

145

RD

146

WR

168

NMI

169

INT

170

BSAK

171

BSRQ

172

WAI T

173

RFSH

174

M1

136

A0

137

A1

138

A2

139

A3

148

A4

149

A5

150

A6

151

A7

152

A8

153

A9

154

A10

155

A11

157

A12

158

A13

159

A14

160

A15

161

MA1 6

162

MA1 7

163

MA1 8

178

ODPI O0

179

ODPI O1

180

ODPI O2

181

ODPI O3

42

VOL2 46E

ODPI O4

33

FDCLK

34

FDOUT

35

FDIN

36

CTSEL 53A,53B

FCS1

37

FCS2

+5V

L1

0

14

C40

CC104

LX

0

GND

R81 200

GND

CLRST

CLTXS

R91

0

CRXD

CKS

TXD

RXD

CTS

PBUS

17B

MM1

MM2

MM3

MM4

MBUS 23C

L5V

IORQ

R83 10K

MREQ

CK16

RD

WR

RBUS 3 4D

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

ABUS 26B,34D

CLCI

CLCK

CLBUS 51C

3

XT3

C-001R

C75

C74

CC10P

CC12P

GND

16B PBUS

L5V

R10

4.7K

12D CSEN

GND

R11

4.7K

15C HOOK

GND

+5B

+5V

D1

R125

*

0

A

RVDD

R127

C108

*

CC104

GND

C6

*

GND

PCI

+5V

CRXD

CKS

+5V

TXD

RXD

CTS

C17

*

GND

P15

IMSA-9110S-08L

+5V

HOOK

L5

MMZY601B

C18

CC101

GND

P14

B2B- PH

WHI T E

A

3

B

1

6

5

9

4

2

8

7

C

1

:

2

D

E

F

21 345678

Main PCB Circuit Diagram 1/5

1 FAX engine (ASIC) which integrates a CPU, digital portion of MODEM and gate array

for managing the I/Os, memories, and drivers.

2 XT1, oscillator for the CPU.

3 XT3, oscillator for the calendar clock.

4 XT2, oscillator for the MODEM.

5 Reset IC which turns on at the powering-on sequence and at any of the reset opera-

tions.

6 Connector for the control panel

7 Recording head drive voltage detector

8 Inverters

9 Connector for the modular PCB

: Connector for the hook switch PCB

A Backup circuit for the calendar clock

III – 21

Page 34

12345678

PS

+26V

4

1

1

A

2

3

P0V

P3

B4B-PH

+9V

DA1

1SS378

3

5

7

BAT

1

2

GND

P6

B2B-PH

BLACK

MOTOR

3

4

2

6

5

1

P2

B6B-PH

+5V

R130

R110

20K

0

C106

P0V

SOL

P13

B2B-PH

BLUE

CC332B

R111

*

R2

1/2W

1

Q11 *

+26V

1

D3

1SS120

2

R112

*

B

C

D

E

F

+9V

C3

C96

16V47

CC104

GND

R113

1K

C91

CC104

R1

1/2W

1

P0V

Q2

DTD113 ZK

GND

2

#3 KIA7805

IN OUT

GND

C97

C5

CC104

16V47

+5V

4

Q12 RH5RA47

IN OUT

2

7

817

13

3

5

6

9

10

12

19

24

22

21

23

4

20

11

GND

#1

MTD2003F

OUT1

OUT2

OUT3I0IN3

OUT4

NC

NC

NC

NC

NC

NC

NC

6

NC

VR

C/ R

VSA

RSA

VSB

RSB

R119

*

C4

16V47

GND

27

MM1

IN1

26

MM3

IN2

MM2

16

MM4

IN4

25

18

I1

1

VMM

14

VMM

15

VCC

28

VCC

29

GND

30

GND

MTVR 15D

SOL 1 5D

+5V

15D EPCK

15D EPDO

+5B

MBUS 16B

15A RAS

MTI 0 12 E

MTI 1 12 E

+26V

+5V

C105

C90

CC104

CC104

C1

C107

35V/220

50v

105 C

CC104

P0V

15A CAS

15B BARMWE

15B BARMRD

14D DABUS

14E DBAS

C95

CC104

R120

4.7k

8

VCC VSS

6

SCL

A0

5

SDA

A1

7

TEST A2

#4

24LC16(1870MC)

24LC32(1970MC)

C94

CC104

#7 (1970MC)

HM514400

13

VCC26VSS

4

-RAS

23

-CAS

3

-WE

22

-OE

9

DA0

DQ1

A0

10

DA1

DQ2

A1

11

DA2

DQ3

A2

12

DA3

DQ4

A3

14

DA4

A4

15

DA5

A5

16

DA6

A6

17

DA7

A7

18

DA8

A8

5

DA9

A9

8

GND+5V

R76 STD MODEL=0

D. S MODEL= *

R77 STD MODEL=*

D. S MODEL=0

14D DABUS

16D ABUS

+5V

15A ROMC

15A RMRD

A0

A1

DA9

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

DA3

DA4

DA5

DA6

DA7

DA8

4

1

2

3

#8

PD27C2001B-15

1

VPP

32

VCC

22

-CE

24

-OE

31

-PGM

12

A0

11

A1

10

A2

9

A3

8

A4

7

A5

6

A6

5

A7

27

A8

26

A9

23

A10

25

A11

4

A12

28

A13

29

A14

3

A15

2

A16

30

A17 D7

C58

CC104

9

GND+5V

16

GND

13

D0

D0

14

D1

D1

15

D2

D2

17

D3

D3

18

D4

D4

19

D5

D5

20

D6

D6

21

D7

A

B

C

GND+5B

D0

1

DA0

D1

2

DA1

D2

24

DA2

D3

25

DA3

DA4

DA5

DA6

DA7

DA8

DA9

C93

CC104

#5 (1970MC)

HM514400

13

VCC26VSS

4

-RAS

23

-CAS

3

-WE

22

-OE

9

A0

10

A1

11

A2

12

A3

14

A4

15

A5

16

A6

17

A7

18

A8

5

A9

GND+5B

D4

1

DA0

DQ1

D5

2

DA1

DQ2

D6

24

DA2

DQ3

D7

25

DA3

DQ4

DA4

DA5

DA6

DA7

DA8

DA9

C64

CC104

#6 (1870MC)

HM514800JP

1

VCC15VSS

14

VCC

8

-RAS

23

-CAS

7

-WE

22

-OE

10

A0

11

A1

12

A2

13

A3

16

A4

17

A5

18

A6

19

A7

20

A8

9

A9

A

GND+5B

28

VSS

6

NC

21

NC

D0

2

DQ1

D1

3

DQ2

D2

4

DQ3

D3

5

DQ4

D4

24

DQ5

D5

25

DQ6

D6

26

DQ7

D7

27

DQ8

D

E

:

F

21 345678

Main PCB Circuit Diagram 2/5

1 Connector for the power supply PCB which supplies 25V and 8V.

2 3-terminal regulator which eliminates unstabilized components of the +8V source to

generate stabilized +5V source.

3 Connector for the Ni-MH battery which supplies approx. 5V.

(Provided on the FAX1570MC/1030/MFC1870MC/1970MC)

4 3-terminal regulator which generates +5B source from +8V to back up the DRAM

(that stores received data).

(Provided on the FAX1570MC/1030/MFC1870MC/1970MC)

5 Connector for the motor

6 Motor driver

7 Connector for the clutch solenoid (that switches the power transmission).

8 E2PROM (32-kilobit for the FAX1570MC/1030/MFC1970MC, 16-kilobit for other mod-

els.)

9 ROM (2-megabit. Note that the qualification machines for demonstration have a 4-

megabit ROM.)

: DRAMs (1-megabyte, two 4-megabit chips) provided on the FAX1570MC/1030/

MFC1970MC.

A DRAM (512-kilobyte) provided on the MFC1870MC. The FAX1170/1270/1010/1020/

MFC1770 has its equivalent DRAM on location #7.

III – 22

Page 35

1

1

1

2

2

2

2

2

2

12345678

+5V

#10

LC82102W

42

RSTH VDD

38

RSTL

39

AIN

40

TEMP

41

ATAP

37

ADREFL

45

PORT0

44

PORT1

35

PORT2

34

PORT3

43

AVDD

36

AGND

46

AGND

31

TRIG

30

ICLK

29

IOCS

28

MCS

27

IOE

23

ME

22

RD

21

WR

25

CLKI N

32

RESET

20

A0

19

A1

18

A2

16

A3

15

A4

14

A5

13

A6

12

A7

11

A8

SD/PD7

R5V

12D FSEN

12D RSEN

4

4

-1

-2

R129

100K

Q13

KRC107S

+5V

R128

100K

C112

*

C103

C104

CC102B

CC102 B

GND

+5V

R126

PH2

100K

SG-105F308

GND

+5V

R124

PH1

100K

SG-105F308

GND

GND

6

1

4

3

2

#13

UMG5N

GND

-2

1

+5V

C99

CC104

GND

RDAT 1 2E

DBUS 1 4E

-7

3

3

-1

12E SEON

33F HRLY

42E CMLL

GND

R0V

10

24

VDD

56

VDD

9

DGND

17

DGND

26

DGND

DGND

DGND

PD6

PD5

PD4

PD3

PD2

PD1

PD0

DACK

DREQ

MTP

SAMP

CLK1

CLK2

C98

49

CC104

64

47

48

50

51

52

53

54

55

57

58

59

GND

33

62

RS

63

SH

61

60

8

D0

D0

7

D1

D1

6

D2

D2

5

D3

D3

4

D4

D4

3

D5

D5

2

D6

D6

1

D7

D7

CIS

A

1

2

3

4

5

7

P9

B7B-PH

TM

9

10

11

8

7

2

3

6

1

5

4

P5

B11B-PH

+26V

R97 470

RB 12 E

R98 270

TG 12E

R5V

C82

CC104

R0V6

C8 16V/ 10

Q10

KRC107S

R102

10K

R0V

R0V

+5V

C88

C84

C89

CC101

CC101

CC101

GND

C86

C87

C83

*

*

*

GND

C109

CC102

R101

10K

C85

CC101

R105

10K

Q1

2SD1858

R3

1W

30

Q9

2SK1399

R5V

R0V

+5V

GND

R106 10 0

R104 20 0

R103 1K

R107

33KF

R108

100KF

R109

10KF

GND

Q7

2SC3052

R5V

Q8

2SC3052

LIGT 11C

-4

1

VID 12E

-5

1

CLMP 15D

R5V

R100

2.2K

CPWM 15D

R99 22K

C80

CC104

R0V

CP3I 12F

ST2 12D

DOUT 12 E

DI N 12E

HDC 1 2D

ST1 12D

LATC 15C

HRLY 36E

RI BON 1 2D

1

-6

R5V

R123

300

R122

200

R121

0

C102

C100

CC104

*

R0V

C81

CC104C716v

10

R0V

R5V

C101

CC104

R0V

12E TG

12E SMC

12E E1CS

15D SRAM

IORQ

MREQ

RD

WR

CK16

16B RBUS

14A RSTL

A0

A1

A2

A3

A4

A5

A6

A7

A8

16D ABUS

-1

-2

-3

B

1

C

2

D

-1

-2

-3

E

-4

-3

-5

F

+26V

REAR 12D

FRNT 12D

4

PWON 15 D

CMLH 15B

3

SENSOR

P1

B5B- PH

BLACK

A

5

2

4

1

3

B

C

D

E

F

21 345678

Main PCB Circuit Diagram 3/5

1 Connector for the CIS

1-1: Power for the CIS LED array

1-2: Clock output

1-3: Trigger signal output. One shot of this signal triggers a line of scan.

1-4 LED control signal output circuit which controls the intensity of the CIS LED array.

1-5: Input of video data (VID) to the FAX engine

1-6: Clamp circuitry that gives the bias level to the amplifier of the VID input circuit according to

the CLMP and CPWM signals issued by the CPU (that monitors the current video data

input) for compensating the DC component of video signals for the next scan line.

Working with the FAX engine, this circuitry carries out the standard scanning. (This

circuitry is provided on the FAX1170/1270/1010/1020/MFC1770/1870MC.)

1-7 SANYO LSI that carries out the high-quality scanning. (Provided on the FAX1570MC/1030/

MFC1970MC)

2 Connector for the thermal recording head

2-1: Power 5V for the thermal recording head

2-2: Thermister signals which are normalized by the resistor network and fed to the FAX engine

2-3: Strobe signals

2-4: Data signals

2-5: Ribbon sensor signal

3 Connector for the sensor PCB

3-1: Paper-edge sensor signal

3-2: Paper ejection sensor signal

4 Document front and rear sensor circuitry that is active only while the SEON signal is on.

4-1:PH2, document rear sensor

4-2:PH1, document front sensor

III – 23

Page 36

12345678

R26 75K

4

C25 CC221

R29 56K

6

-

7

5

+

R30

#18

4.7K

I324

AREF

C28

CC105(2125CHIP)

43

C

C9

16V10

R89

3.3K

C45

CC104

R62

100K

R36

1K

Q5 KRC1 07 S

C44

CC221

C48

CC104

AREF

R34

300

M0V

M0V

R63 1K

C46

D2

CC103B

HZS5C

M0V

-3

2

RNGL 1 5C

9

CNT

3

1

5

#19

0

4053

R32

100K

15B VOL1

-1

15E VOL2

-2

15C VOL3

-3

12D SPON

+26v

C24

50V

C11

CC104

35V10

M0V

C49

CC102B

R65

56K

:

5

#15

TC35133F

3

6

DPDMCK

TXOUT

7

DPDMDT

9

APDMCK

10

APDMDT

11

C3

12

C4

13

C5

5

MUTE

8

-PD

+5V

1

VDD

15

RXI NA

16

RXI NB

2

VBIAS

AREF

+9V

#2

NJM38 6M

3

R35

12K

M0V

GND

R134

1K

C47

CC104

4

VSS

14

VSS

MOV

C111

CC104

GND

8

C2

762

10V100

5

1

+

8

4

R115

C92

33K

CC103B

D10

1SS120

C113

( 5 mm)

16V10

GND

DMK

DMT

AMK

AMT

C3

C4

C5

MUT

RSTL 14A

TBUS 14D

GND

9

SP

P4

B2B- PH

WHI T E

A

B

C

D

1

2

E

F

R15 1.5 K

C20 CC681

R23 56K

R31 10K

13

-

14

R21 10K

12

+

#18

KI3 24

R22

1/10W

1K

M0V

CMLH 15C

M0V

11

CNT

13

1

14

C

#19

0

4053

R74

100K

53B CTSL

-2

2

D7 1SS1 20

D4 *

R13 0

R18 0

D6 1SS1 20

D5 *

C21 CC681

R24 150K

9

-

8

10

+

R16

R14

4.7K

M0V

R12 100K

C19

CC104

M0V

+5V

GND

+26V

#18

0

KI324

AREF

R19 *

R17

*

Q4 *

AREF

OTO 15C

+26V

D9

1SS120

R5 1 K

PLS 15 C

+5V

CMLL 36E

R4

R6

R37

1K

22K

22K

TLOF 15C

TLOF2 12D

CI 15C

C12

CC103B

GND

A

B

C

D

E

F

1

NCU

9

6

7

5

1

10

11

12

3

8

13

14

16

17

18

2

15

4

P10

IMSA-9110S-18L

SL

RL1

RL2

TLSL 51B,53 B

Q3

KRC107S

M0V

C110

CC104

RDPS 1 5C

EAT 15 B

ADLC 15B

DAST 1 1D

DASND 1 1C

C27 CC104

+5V

+26V

R20

*

D8

*

R25 200K

2

15

2

1

C22 CC103B

DAREC 1 1C

-1

TELL 15 C

10

CNT

2

0

CTSL 53B

C

1

#19

1

R33 1.5 K

4053

TADH 12C

10

CNT

C57

0

CC104

1512

C

#17

1

4053

C23 *

R28 43K

R71

27K

2

1

3

+

R27

#18

4.7K

KI324

AREF

6

MOV

7

TLRL 53A

CTRL 51A,53B

3

R72 1.5 K

R73 1.5 K

-1

13

1

0

55D HFRL

TXSL 1 2C

11

CNT

14

C

#17

4053

R75

1.5K

5

3

15C RNGO

HAFH 12C

9

CNT

0

412

C

#17

1

4053

-2

:

:

:

+5V

16

#19

C26

CC104

4053

678

GND

M0V

M0V

+5V

16 4

#17

C56

CC104

4053

678

M0V

#18

KI3 24

11

21 345678

Main PCB Circuit Diagram 4/5

1 Connector for the NCU

2 Analog signal selectors

2-1: Selects either input signals from the handset or those from the MODEM.

2-2: Selects either RL1 or RL2 signals inputted from the communications network.

2-3: Selects either sound signals (e.g., alarm beeps, key clicks and ringer sounds)

generated by the FAX engine or signals selected by 2-2.

3 Voice switching analog selectors

3-1: Switches between the output line and input line for monitoring. When

switched to the output line, this selector allows FAX sending operation to be

monitored; when switched to the input line, it allows received voices to be

monitored.

3-2: Selects either voice signals inputted from the communications network or re-

corded voice signals inputted from the microphone or handset through the

MODEM.

4 Amplifier circuit for signals outputted from the MODEM.

5 Analog front end IC which processes the analog I/O signals from/to the MODEM.

6 Amplifier & shaper circuit for signals inputted from the communications network.

7 Telephone circuit for transmitting signals.

8 Speaker amplifier circuit which amplifies sounds issued from the above analog signal

selector 2-3 and feeds them to the speaker.

III – 24

Page 37

9 Connector for the speaker

: Speaker volume control circuit

:-1: VOL1 OFF ON ON

:-2: VOL2 OFF OFF ON

:-3: VOL3 OFF OFF ON

Speaker volume High Medium Low (ON: Closed OFF: Opened)

III – 25

Page 38

12345678

A

B

C

R55 75K

C35 CC221

R48 56K

6

-

7

5

+

R47

#14

4.7K

BA10358F

HREF

16V10

C52

CC104

HREF

R69

C53

100K

CC221

C10

C55

CC104

M0V

M0V

C29

CC104

2

R53 *

44D HFRL

TLSL 51B, 53B

#14

BA10358F

4

+5V

C34

CC104

M0V

D

C33

CC681B

C37 681B

R57 100 K

2

1

3

+

R58

#14

4.7K

BA10358F

R54

100K

HREF

MOV

+5V

16 8

#11

4053

678

M0V

+5V

MI C

RL1

6

RL2

E

P12

B2B- PH

RED

7

1

R44

C31

R43

8.2K

CC104

10K

R45

C32

R46

8.2K

CC104

10K

MOV

F

C36

CC102B

3

#16

TC35133F

R56

56K

3

6

DPDMCK

TXOUT

7

DPDMDT

9

APDMCK

10

APDMDT

11

C3

12

C4

13

C5

5

MUTE

8

-PD

+5V

1

VDD

15

RXI NA

16

RXI NB

2

VBIAS

HREF

C54

CC104

4

VSS

14

VSS

MOV

DMK

ADMD

AMK

AAMD

C0

C1

C2

AMUT

RSTL 14A

TBUS 14D

A

B

C

D

E

F

21 345678

Main PCB Circuit Diagram 5/5

1 Connector for the microphone

2 Voice signal amplifier circuit

These are provided on the FAX1570MC/

1030/MFC1870MC/1970MC.

3 Analog portion of MODEM

III – 26

Page 39

3.3 NCU PCB

The NCU PCB switches the communications line to telephone or built-in MODEM, under the

control of the main PCB.

123

1

RA351X2

A

SBT0260X2

or

FL5R200PNX2

JW16

A

SBT0260X4

or

FL5R200PNX4

A

FG

FG

8

7

2

A

3

4

5

4

B

3

4-4PMJ

2

C

3

4

1

A

D

3. COMPONENTS IN PARENTHESIS NOT TO BE MOUNTED.

+26V

CR1

MZF-24HG

or

OUAZ-SS-124D

+

-

4

3

V1

21

TELOFF

4

3

S0V

+5V

C

B

E

S0V

SREF

S0V

+26V

6

NCUSL

TELSL

TELRL

TELOFF

+26V

+5V

S0V

RL1

PLS

CI

RL2

CML

+5V

S0V

6033B-12Z

A

B

C

P1

D

45

2

CML

S0V

FG

+5V

8

or

BA10358

4

S0V

4

S0V

3

4

S0V

5

PLS

1

2

S0V

R24

JW

6

4

5

5

1

2

9

TELRL

TELSL

RL2

REF

REF

4

CI

S0V

3

631

+26V

JW9

S0V

+5V

SREF

S0V

53

42

REF

421

:

REF

123 56

4

NCU PCB Circuit Diagram (U.S.A. versions)

1 Surge absorbers

2 Line relay (CML relay)

3 Line transformer

4 Circuit related to the line transformer

5 High-impedance transformer circuit

6 Calling signal detector

7 Loop current detector

8 Dial pulse generator

9 Telephone circuit

: Reference voltage generation circuit for the operational amplifiers in 4 and 9

A Noise filters (provided on the FAX1570MC/MFC1870MC/1970MC)

III – 27

Page 40

LINE

TAD

BI NATONE

CN3

4-4PMJ

2

A- OUT

S

E

JW8

(10)

JW11

(10)

JW9

(10)

JW10

(10)

1

2

S0V

P1

B2B- PH

CH2

E

+5V

S0V

SOV

4

7

5

TELOFF1

6

3

2

1

+

1

4

-

2

3

TELRL

+

S0V

D

G

S

+

+

+5V

C

C

C

C

DASND

-

M

E

B

M

B

M

B

M

B

-

CML

RDPS

S0V

+5V

S0V

S0V

S0V

RDPS

9

CML

+5V

S0V

TELOFF1

DAST

RDPS

EARTH

TELRL

ADLC

DASND

P2

IMSA-6033B

-18Z

8

2

RL1

6

PLS

3

17

13

20

14

19

RL2

7

1

16

5

18

4

POL

15

10

11

12

1

6

4

3

REF

136

4

REF

REF

REF

A- OUT

-

2

1

+

3

REF

S0V

+5V

S0V

+

R27

10K

+5V

S0V

S0V

414

4

1

1

33223

2

S0V

S0V

S0V

-

+

+5V

S0V

+26V

FG

III – 28

Page 41

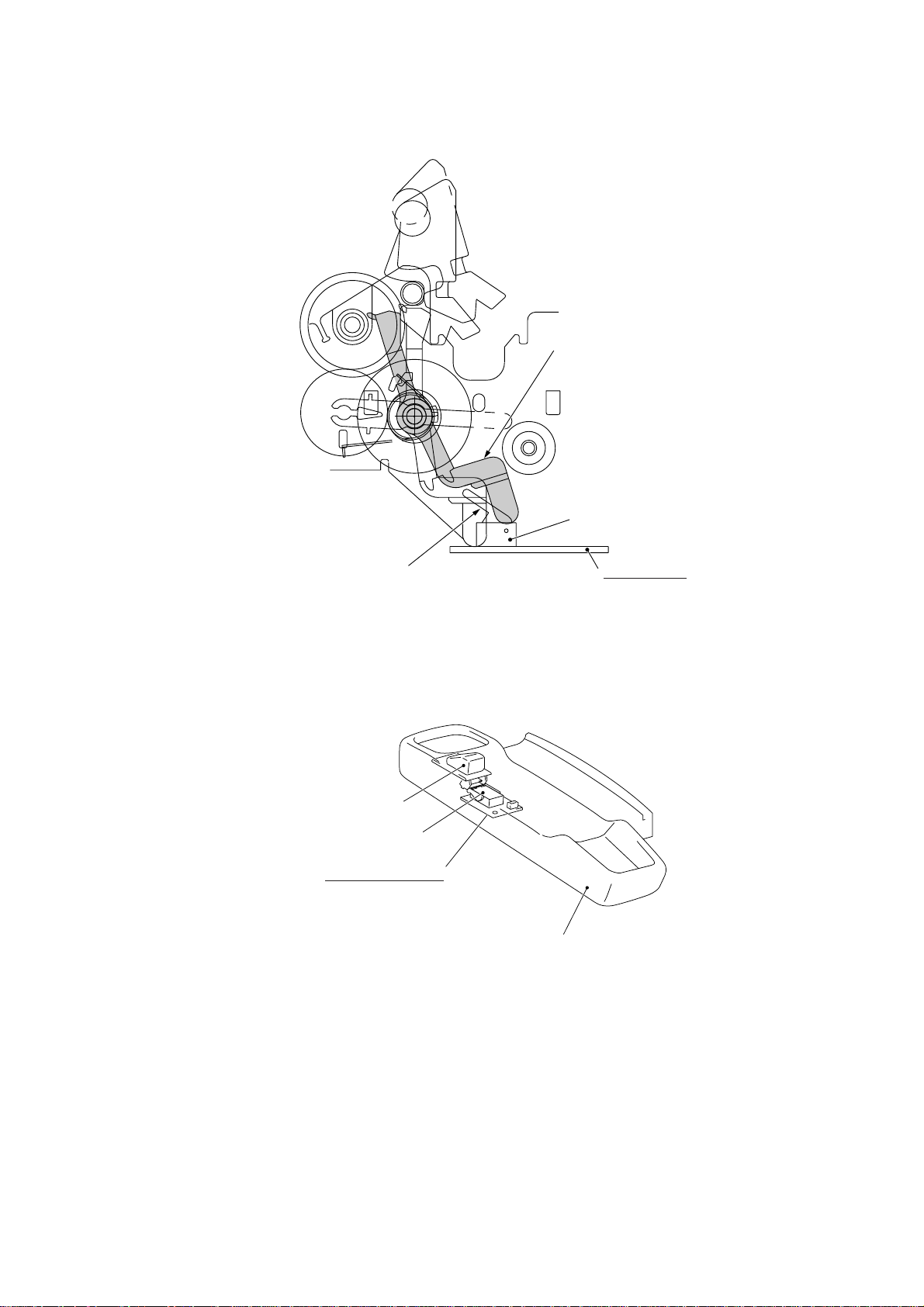

1.6 Paper Feed Roller ASSY and Paper Feed Sub Chute

(1) Remove the front cover sensing actuator from the paper feed roller shaft by pulling up

the actuator's rear edge as shown below.

Paper feed roller ASSY

(Front)

Platen frame

Front cover sensing

actuator

Pull up here

to remove.

Boss of the paperedge sensor actuator

Front cover sensing

actuator

(2) At the left end of the paper feed roller ASSY (when viewed from the rear), remove the

bushing by pulling its pawls outwards.

(3) At the right end, remove the paper feed roller gear (Gear 55) by pulling its pawl out-

wards.

Next, pull the paper feed roller shaft to the right until the left end of the shaft comes out

of the main frame and then tilt the shaft to the right so that the bushing-fixed end can

pass through the lower hole, and take it out to the left.

Paper feed roller ASSY

Bushing

Paper feed roller

gear (Gear 55)

Pawled bushing

Lower hole

(Rear)

IV – 12

Page 42

(4) At the either end of the paper feed sub chute, release the latch from the paper feed

chute with a flat screwdriver as illustrated below, and then pull up the paper feed sub

chute.

Paper feed sub chute

Slot provided

in the paper

feed chute

Platen frame

Latch

Leading-edge sensor

actuator

Sub chute

film

Latch

Paper feed

chute

(Rear)

Latch

■ Reassembling Notes

• When setting the paper feed sub chute, push the paper-edge sensor actuator into the

home position.

• Set the paper feed sub chute so that the sub chute film comes into the slot provided in the

paper feed chute.

IV – 13

Page 43

• When setting the paper feed roller ASSY at the left side of the platen frame, turn up the

planet gear 34 of the arm P ASSY so that the planet gear 34 comes above the sun gear

39/24 and becomes engaged with the paper feed roller gear (Gear 55), as illustrated below.

Clutch gear ASSY

Gears 18/41

Platen frame

Planet gear 34

Sun gear 39/24

Paper feed

roller gear

(Gear 55)

• When setting the front cover sensing actuator onto the paper feed roller shaft, make sure

that it supports the boss of the paper-edge sensor actuator as shown on the previous

page.

IV – 14

Page 44

1.7 Paper Feed Chute, Sensor PCB, and Paper-edge and Paper Ejection Sensor

Actuators

(1) Remove the two screws.

(2) Remove the sensor PCB by releasing the two latches.

(3) Disconnect the main-sensor harness from the sensor PCB.

(4) Pull up the lead wires of the main-sensor harness out of the sheath, and then take out

those wires (not the sheathed section) from the clamp of the paper feed chute.

(5) Take out the paper feed chute.

Pull up the

lead wires

out of the

sheath.

Paper feed chute

Main-sensor harness

Platen

frame

(Rear)

Sensor PCB

Clamp (on the

paper feed chute)

Platen frame

Main-sensor

harness

IV – 15

Page 45

(6) Remove the paper-edge sensor actuator by pulling the support "x" outwards.

(7) Remove the paper ejection sensor actuator by pushing the hook "y" from the rear of the

paper feed chute.

Paper ejection sensor actuator

Paper ejection sensor (PH1)

Latch

Latch

Paper ejection sensor

actuator

Paper feed

chute

Paper ejection sensor (PH1)

Sensor

PCB

Paper-edge sensor (PH2)

Paper-edge sensor

actuator

Hook "y"

Support "x"

Separator pad

(Rear)

Spring

Sensor PCB

Paper-edge sensor (PH2)

(Rear)

Main-sensor harness connector

(8) Pull up the separator pad while squeezing it to the right or left. The spring also comes

off.

■ Reassembling Notes

• Make sure that the paper ejection sensor actuator is set on the sensor PCB.

• As illustrated on the previous page, route the main-sensor harness through the cutout of

the platen frame. When routing it through the clamp of the paper feed chute, first put the

lead wires only into the clamp and then pull up the vinyl sheath.

IV – 16

Page 46

1.8 Paper Ejection Roller

(1) At the left end of the paper ejection roller (when viewed from the rear), remove the

bushing by pulling its pawls outwards.

(2) At the right end, remove the paper ejection roller gear (Gear 40) by pulling its pawl out-

wards. Next, take out the paper ejection roller together with the bushing and the curved

washer.

Pawled

bushing

Paper ejection roller

Curved washer

Bushing

Paper ejection

roller gear

(Gear 40)

Platen

frame

(Rear)

IV – 17

Page 47

1.9 Gears on the Platen Frame

Paper ejection roller gear

(Gear 40)

Gears 18/41

Clutch gear ASSY

Paper feed roller gear

Planet gear 34 of

the arm P ASSY

Sun gear 39/24

(Gears 18/41)

U

V

W (Clutch

gear ASSY)

Platen frame

X (Paper ejection roller

gear, Gear 40)

T (Paper feed roller gear, Gear 55)

Platen frame

S (Planet gear

34 of Arm P

ASSY)

R (Sun gear

39/24)

IV – 18

a (Platen gear,

Gear 23)