Broseley Ignite 5, Q5, Ignite 6, Q6, Ignite 7 Installation & Operating Instructions Manual

...

Mar 14/GB Issue 3 1

Installation & Operating

Instructions

Covering Models:

Ignite 5, 6 & 7

Desire 5, 6 & 7

(Q5, Q6 & Q7)

Standard & Log Store Multifuel Stoves

Tested to EN 13240

These appliances must be installed and commissioned by a HETAS registered engineer

Mar 14/GB Issue 3 2

Contents

Introduction 3

Packing List 3

Health & Safety 4

Specifications 5

Dimensions 6

Hearth Requirements & Clearances 9

Chimney Requirements 10

Combustion Air Requirements 11

Assembly 12

Stove Operation

Controls Layout 14

Controls Explained 15

Air wash System 15

Ash Pan 15

Recommended Fuels 16

Lighting the Stove

Kindling Stage 17

Burning Wood & Burning Coal 18

Warning Notes 19

Maintenance

Door Adjustment 20

Ash Removal 20

Cleaning the Stove 20

Glass Cleaning 20

Chimney Sweeping 20

Chimney Fires 20

Stove Servicing 20

Trouble-shooting 22

Commissioning Form 23

Spare Parts 24

Annual Service Record 25

Warranty 26

Mar 14/GB Issue 3 3

Introduction

Thank you for choosing one of our multifuel stoves.

The term multifuel refers to the fact that the appliance is capable of burning either wood

logs or coal (that is suitable for closed appliances). Both of these fuels have very

different air requirements in order for them to burn correctly, therefore the air controls

need to be operated differently depending on the fuel being burned (see section “Stove

Operation”).

See the section “Lighting the Stove” for further details. After reading this document, if

there is anything you are unsure about, please contact your dealer or our Technical

Support Department.

These instructions cover the basic principles to ensure the satisfactory installation of the

stove, although detail may need slight modification to suit particular local site conditions.

In all cases the installation must comply with current Building Regulations, Local

Authority Byelaws and other specifications or regulations as they affect the installation

of the stove.

It should be noted that the Building Regulations requirements may be met by adopting

the relevant recommendations given in British Standards BS 8303 and BS EN 15287-1

2007 + A1 2010 as an alternative means to achieve an equivalent level of performance

to that obtained following the guidance given in Approved Document J.

Please note that it is a requirement under the Broseley Fires warranty system that

the installation of the stove is carried out by a Competent Person registered with

a Government approved Competent Persons Scheme. HETAS Ltd operate such a

Scheme and a listing of their Registered Competent Persons can be found on

their website at www.hetas.co.uk.

Packing List

1x Steel Body stove 2x Steel side firebricks

1x Multifunction Tool 1x Steel rear firebrick

1x Instruction booklet 1x Steel baffle

1x Heat Proof Gloves Set 1x Cast iron grate

1x Spigot (flue collar) 1x Steel Ash pan

All parts will be inside the main stove body upon delivery. The spigot will generally be

bolted to the outside of the stove body.

Mar 14/GB Issue 3 4

Health & Safety

Special care must be taken when installing the stove such that the requirements of the

Health and Safety at Work Act are met.

Installation

This appliance MUST be installed and commissioned by a HETAS registered installer in

England and Wales and a fully qualified Heating Engineer in Scotland and Ireland.

Handling

Adequate facilities must be available for loading, unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should not be allowed to come into contact

with the skin. In case of contact, wash immediately with plenty of water.

Asbestos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the

course of installation then please seek specialist guidance and use appropriate

protective equipment.

Metal Parts

When installing or servicing this stove care should be taken to avoid the possibility of

personal injury.

CO Alarms

Building regulations require that whenever a new or replacement fixed solid fuel or

wood/biomass appliance is installed in a dwelling an audible carbon monoxide alarm

must be fitted in the same room as the appliance. Further guidance on the installation of

the carbon monoxide alarm is available in BS EN 50292:2002 and from the alarm

manufacturer’s instructions. Provision of an alarm must not be considered a substitute

for either installing the appliance correctly or ensuring regular servicing and

maintenance of the appliance and chimney system.

Fire Guards

When using the stove in situations where children, aged and/or infirm persons are

present a fireguard must be used to prevent accidental contact with the stove. The

fireguard should be manufactured in accordance with BS 6539.

Aerosol Sprays

Do not use an aerosol spray on or near the stove when it is alight.

Operating Tool & Gloves

Always use the operating tool and glove provided when handling parts likely to be hot

when the stove is in use.

Mar 14/GB Issue 3 5

Specifications

In the UK these stoves have been approved by HETAS Ltd as intermittent heating

appliances for burning coal suitable for a closed appliance and wood logs only.

Ignite & Desire 5

(Q5)

Ignite & Desire 6

(Q6)

Ignite & Desire 7

(Q7)

Nominal Heat Output (Wood) kW 5 6 7.3

Nominal Heat Output (Ancit) kW 4.9 6 7.4

Efficiency (Wood) % 82.9 79.4 79.4

Efficiency (Ancit) % 81.1 81.1 83.4

Weight Kg

Ignite 5 71

Ignite 5 LS 85

Desire 5 68

Desire 5 LS 82

Ignite 6 78

Ignite 6 LS 93

Desire 6 74

Desire 6 LS 90

Ignite 7 84

Ignite 7 LS 101

Desire 7 80

Desire 7 LS 97

Flue Diameter mm 125 125 125

Flue Diameter Inches 5 5 5

Flue Draft Min Pa 12 12 12

Flue Draft Max Pa 18 18 18

Flue Temp (Wood) °C 239 290 290

Flue Temp (Ancit) °C 210 237 237

CO Emission (@ 13% O2 Wood) % 0.46 0.46 0.29

CO Emission (@ 13% O2 Ancit) % 0.54 0.54 0.4

Flue Mass Flow (Wood) g/s 3.2 5.2 5.2

Flue Mass Flow (Ancit) g/s 3.6 4.7 4.7

European standards need to be complied to when installing this appliance.

Mar 14/GB Issue 3 6

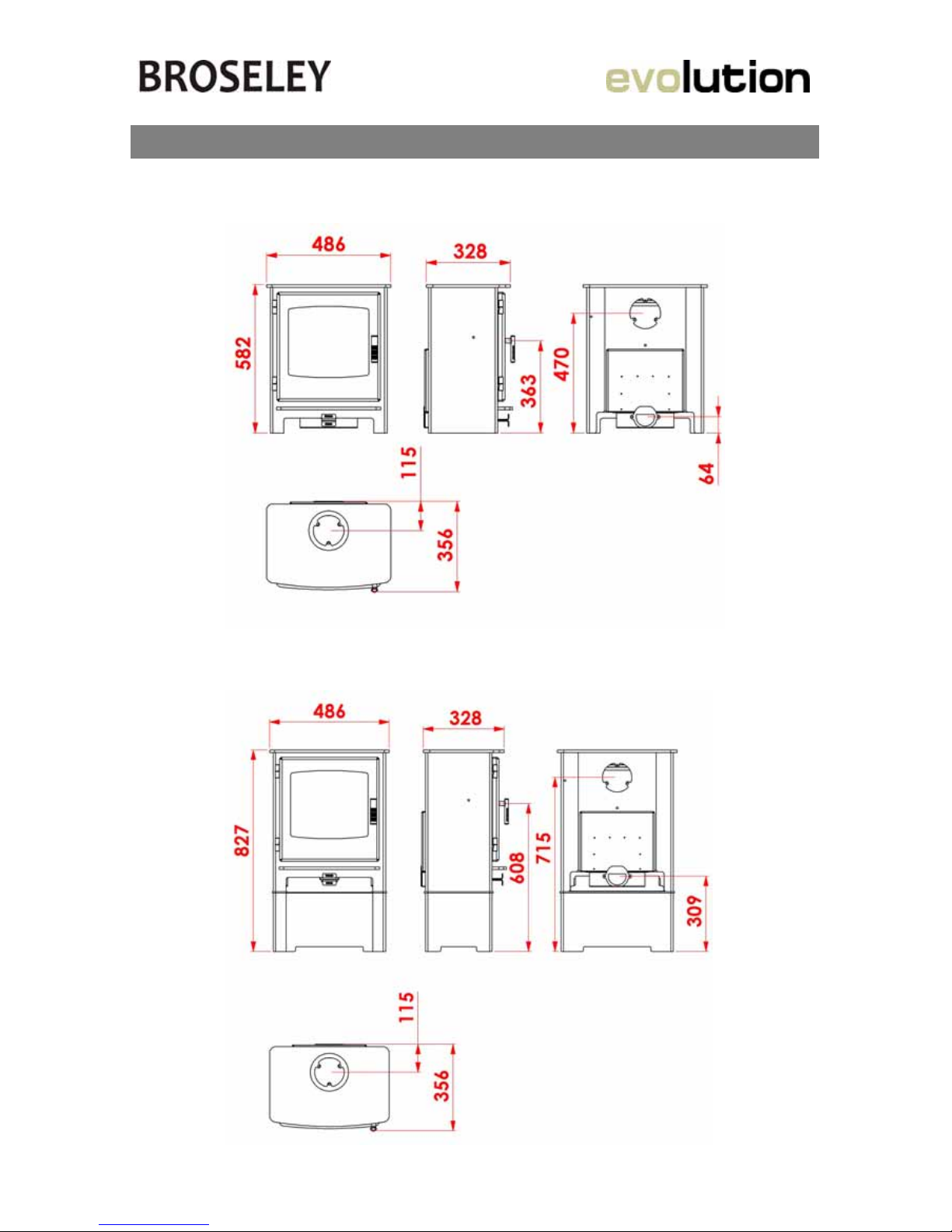

Dimensions

Ignite 5 & Desire 5 (Q5)

Ignite 5 & Desire 5 Log Store (Q5 Log Store)

Mar 14/GB Issue 3 7

Dimensions

Ignite 6 & Desire 6 (Q6)

Ignite 6 & Desire 6 Log Store (Q6 Log Store)

Mar 14/GB Issue 3 8

Dimensions

Ignite 7 & Desire 7 (Q7)

Ignite 7 & Desire 7 Log Store (Q7 Log Store)

Mar 14/GB Issue 3 9

Hearth Requirements & Clearances

The standard (without log store) appliances require a full constructional hearth

with sub-hearth as laid out in building regulations approved document J. Log

store versions are suitable for a minimum 12mm thick hearth.

Your stove must be installed on a solid, level non-combustible hearth. The hearth

protrusion in front of the stove to carpets or wooden floors must be at least 300mm. As

it is possible, that on opening the door of the stove for fuel to fall out, a fender must be

fitted if the hearth is flush with the carpet.

Clearances

The stove requires the following clearances around it to ensure the heat is released into

the room and to allow sufficient combustion air flow. A combustible material clearance is

given to prevent damage to any items that may be affected by heat.

Product Material Rear Side Hearth Above

Combustible 725mm 550mm 300mm 600mm

Ignite & Desire 5 (Q5)

Non-combustible 100mm 100mm 300mm 100mm

Combustible 725mm 550mm 300mm 600mm

Ignite & Desire 6 (Q6)

Non-combustible 100mm 100mm 300mm 100mm

Combustible 650mm 500mm 300mm 600mm

Ignite & Desire 7 (Q7)

Non-combustible 100mm 100mm 300mm 100mm

Mar 14/GB Issue 3 10

Chimney Requirements

This appliance must not be fitted into a chimney serving another heating appliance. It is

most important that there is no obstruction in the flue or chimney. Please ensure that

any existing chimney is clear of obstruction and swept clean immediately before

installation of the new stove. If the chimney has been used for an open fire it is

recommended that it be swept for a second time having been used for a month

following installation.

A flue draught minimum of 12 Pascals to a maximum 18 Pascals is required for

satisfactory appliance performance. A properly built masonry or factory constructed

chimney (with a minimum vertical height of 5 metres) should ensure a consistent

draught (draw). 45° bends can be used in the flue run (maximum of four bends) you will

need to add an extra 1 metre of vertical flue height for each bend.

The flue draught should be checked under fire at high output and if it exceeds the

recommended maximum, a draught stabiliser must be fitted so that the rate of burning

can be controlled, and to prevent over firing (See section “Warning Notes”). If you have

any doubts about the suitability of your chimney, consult your local dealer/stockist or

engineer. If your flue draft is below the minimum recommendation then it may be

necessary to increase the vertical chimney height, add additional flue insulation or

possibly add a special cowl to the top of the chimney (e.g. anti down draft cowl to

eliminate wind induced down draft).

The outlet from the chimney should be above the roof of the building in accordance with

the provisions of Building Regulations Approved Document J.

If installation is into an existing chimney then it must be sound and have no cracks or

other faults which might allow fumes into the house. Older properties, especially, may

have chimney faults or the cross section may be too large i.e. more than 230 mm x 230

mm. Remedial action should be taken, if required, seeking expert advice, if necessary. If

it is found necessary to line the chimney then a flue liner suitable for solid fuel must be

used in accordance with Building Regulations Approved Document J.

If there is no existing chimney then either a prefabricated block chimney in accordance

with Building Regulations Approved Document J or a twin walled insulated stainless

steel flue to BS 4543 can be used. These chimneys must be fitted in accordance with

the manufacturer’s instructions and Building Regulations.

If a flexible liner is required the liner diameter must not be less than 6” / 150mm.

Any bend in the chimney or connecting fluepipe should not exceed 45°. 90° bends are

not permitted. . For top flue installations it is possible to sweep through the appliance by

removing the internal baffle however it is recommended that you provide adequate

access (e.g. easily accessible soot door). For rear flue connection we recommend the

use of a tee section, the bottom of the tee should be capped to catch soot and debris.

Mar 14/GB Issue 3 11

Combustion Air Requirements

In order for the stove to perform efficiently and safely there should be an adequate air

supply into the room in which the stove is installed to provide combustion air. This is

particularly necessary in modern houses where drafts have been almost eliminated by

double glazing etc.

Under UK building regulations any appliance over 5kW MUST have a fixed

permanent air vent (see building regulations approved document J for further

information).

There must not be an extractor fan fitted in the same room as the stove as this can

cause the stove to emit fumes into the room. It is necessary to install a wall vent to

provide the necessary combustion air and to prevent the depletion of oxygen in the

room.

External Air Intake

It is possible to connect a direct air supply to the stove by attaching a 75mm (3 Inch)

diameter rigid or flexible pipe to the air intake shown below (rear of stove at the bottom)

using either a jubilee clip or fire cement. Please note that pipe, vents or other ducting

accessories are NOT provided.

Mar 14/GB Issue 3 12

Assembly

The diagram below shows the stove with all internals taken out. To take internals out of

the stove follow the numbered sequence backwards from 7 down to 1.

m 6 down to 1.

To refit the internals follow the numbered sequence from 1 – 7. The firebricks should be

fitted with the fibre paper on the LHS, RHS and rear components, the fibre paper should

be sandwiched between the fire brick and the main body, these are then held in position

by the retaining screws, small gaps are acceptable between the firebricks. Be careful

not to trap or squash fingers at this stage.

Mar 14/GB Issue 3 13

Assembly

It is possible to remove the stove from the store (Log store versions) this may be

necessary for transport purposes. The diagram below shows the locations of the fixings

(4x bolts labelled 1) which hold the stove to the log store.

Mar 14/GB Issue 3 14

Controls Layout

The stove is fitted with two air controls which need to be correctly operated in order to

light and maintain a fire. Both controls are situated below the ash lip of the stove (as

indicated on the diagram below) and are in the form of push/pull sliders.

Mar 14/GB Issue 3 15

Controls Explained

Primary Air Intake

The primary air intake is the bottom slider situated below the ash lip at the front of the

stove. Having the slider pushed fully inwards would indicate the intake is closed. When

the slider is fully pulled outwards the intake is completely open. This particular air intake

is adjustable throughout the area of travel in to out to control the total amount of air

required for suitable combustion.

The primary air intake is used on initial firing of the stove or when burning coal etc.

Please see the BURNING COAL for a more in depth description.

Secondary Air Intake

The secondary air intake is the top slider situated under the ash lip at the front of the

stove. Having the slider pushed fully inwards would indicate the intake is closed. When

the slider is fully pulled outwards the intake is completely open. This particular air intake

is adjustable throughout the area of travel in to out to control the total amount of air

required for suitable combustion.

The Secondary air intake is used at initial start-up and to control the burn rate of wood.

Air wash System

Air wash is a system where secondary air is drawn into the stove (by combustion)

through the air control under the ash lip and is deflected down the back face of the

glass, thus preventing the smoke coming into contact with the glass. It does not mean

that you will never have to clean the glass, but substantially lengthens the periods

between having to do so. The air-wash system works best when burning dry wood. Wet

wood will produce more deposits on the glass. Also, deposits will form on the back of

the glass when the stove is operated on low heat for extended periods (where fuel is

only just smouldering).

Ash Pan

The ash pan can be removed using the ash tool which is intended to hook the ash pan

out onto the ash lip of the stove where you can then pick it up using the glove provided.

It is recommended this is done when the stove is cold and not alight.

Mar 14/GB Issue 3 16

Recommended Fuels

This appliance has obtained approval from HETAS Ltd., for burning –

* HETAS approved coal suitable for a closed appliance.

* Split Wood logs not exceeding 35cms in length and not over 20% moisture content.

Approval does not cover the use of other fuels either alone or mixed with the suitable

fuels listed above.

Although approval covers the use of the smokeless fuels listed, the claimed rated

output, has been obtained burning a single representative smokeless fuel, under

standard test conditions. However, in the home, a variety of operating conditions can

occur and the performance of the appliance may vary to some degree with these

conditions and different fuels may need to be burnt at different rates to provide the

same heat output.

The recommended fuels are Wood logs no longer than 35cms (dry, seasoned to under

20% moisture) and solid mineral fuels (e.g. Natural smokeless fuels) Larger coal

briquettes are recommended as they concentrate less heat in one spot reducing the

likelihood of damage to the grate. Ask your local fuel merchant or consult the HETAS

website for more details on these fuels.

Only authorised smokeless fuels may be used in smoke control areas.

Do NOT burn “House coal” or any other coal which are intended for use on open

fires. Suitable coal needs to be designed for use on closed appliances. Open fires send

a large amount of heat up the chimney therefore the fuel needs to burn extremely hot in

order to send heat into the room, closed appliances are highly efficient and send little

heat up the chimney therefore the fuel does not need to burn as hot. Using open fire

coal on a closed appliance will cause excessive wear on the stove and could result in

damage which will not be covered by the products warranty.

Under NO circumstances burn “petroleum coke” or any other chemically enhanced

fuel as it will burn out the internal grate and baffle plates in a very short period of time

and may damage the stove beyond repair.

Do NOT burn wet wood, This will give a poor heat output and will cause heavy

deposits of soot and tar to accumulate on the glass and throughout the stove and flue.

The coating of soot and tar in the chimney is volatile creating a high risk of chimney

fires. A growing tree contains a high percentage of water, the wood needs to be dried

out (seasoned) before it is suitable for burning (this can take several years). Wood logs

are best stored in a stack, sheltered from the weather, in a well ventilated area and

raised off the ground. This allows the air to circulate and prevents mildew.

Mar 14/GB Issue 3 17

Lighting the Stove

Curing

On initial firing you will notice a very pungent odour, this is caused through the curing of

the paint, we recommend starting with short burning sessions (with smaller quantities of

fuel) and build up gradually to allow the components of the stove to settle. Opening

doors and windows will allow the paint curing odour to dissipate and to allow ventilation

into the room. Curing times can vary but typically should take around 8-12 hours

(operation at high output) to complete.

Kindling

Stage1

With the Primary and Secondary air controls in the fully open position and the door

open, start your fire using scrunched up balls of newspaper. Form a bed on the grate

using the newspaper, then add a generous amount of dry kindling in a criss cross

pattern (as shown below).

Stage 2

Ignite the paper underneath using a match or suitable fire-lighter. Allow the paper and

kindling to burn until it reduces down into hot embers. If the fire is dying during this

stage the door can be closed but not latched leaving a small gap for extra combustion

air.

Stage 3

Add another generous load of dry kindling and allow to burn down.

It may be necessary to repeat stage 3 if the chimney is cold or if you find you have

smoke entering the room. This stage is vital for getting heat into the chimney which will

create the draw that takes the smoke away, we would expect this stage to take between

15-20 minutes.

It is critical that you do not leave the stove during the entire lighting and kindling

stage. See Burning wood and Burning Coal sections for the next steps in starting a new

fire.

Mar 14/GB Issue 3 18

Burning Wood

Once you have kindled your stove (see previous page) and your chimney (flue) is

sufficiently heated, you are now ready to start adding you logs.

Stage 4

Place 1-3 small logs onto the bed of hot embers using the gloves provided, close the

door and reduce the Primary Air Control to approximately half way. Once the logs turn

black the primary air can be fully closed.

Stage 5

Once the smaller logs have burned down you can now add 2-3 larger (or full size) logs

and close down the Secondary Air Intake as required. You can now control the burn

rate of the stove using the secondary air intake, you are looking for a controlled flame

(not smouldering in the embers or licking around the lid) this is mostly visual although a

flue pipe thermometer will help you determine correct control and is recommended for

the initial lightings.

Stage 6

Refuel as and when required (take care to open the door gradually as flames may lick

out). Open both air controls whenever refuelling. Once the wood logs turn black the

primary control can be closed fully and the fire controlled once again by the secondary

control. If you no longer want to keep the fire going simply allow it burn out.

Burning Coal

With kindling complete you are now ready to add your approved coal.

Stage 4

Using the gloves and provided ash tool, rake the hot embers evenly over the grate and

add a small amount of coal. Close the door and allow the coal to ignite then close the

Secondary Air approximately half way. (The primary air control should be left fully open)

Stage 5

When the small load of coal has burned down add a larger load and allow time for the

coal to fully ignite, leave the Primary air intake fully open. The coal should be spread

evenly over the grate. You will now control the burn rate of the stove using the Primary

air intake. The Secondary air intake should now be fully closed. you are looking for a

controlled flame (not smouldering in the embers or licking around the lid) this is mostly

visual although a flue pipe thermometer will help you determine correct control and is

recommended for the initial lightings.

Stage 6

Add coal as and when required. Ensure that you use the ash tool when refuelling coal to

poke through any ash and debris so that it falls into the ash pan underneath, this is

critical as coal requires a flow of air from underneath the grate.

Mar 14/GB Issue 3 19

Warning Notes

Over-Firing

It is extremely important that you do NOT leave both of the air controls in the fully open

position for extended periods or run the appliance with the door open. Leaving the air

controls fully open (or running with the doors open) will lead to “over-firing”. Over-firing

is caused when too much heat is generated within the fire chamber, this will lead to

warping, buckling and general damage to the stove and its internal components. Overfiring can also be caused by an excessive flue draft.

PLEASE NOTE ANY DAMAGE TO THE APPLIANCE CAUSED THROUGH OVERFIRING WILL NOT BE COVERED BY THE WARRANTY.

We highly recommenced the use of a flue pipe thermometer so that you can monitor

how much heat you are sending up the chimney, this will both enable efficient operation

of your stove and also give a good indication if you are over-firing the appliance.

Fumes

Properly installed, operated and maintained, this appliance will not emit fumes into the

dwelling. Occasional fumes may occur whilst de-ashing and re-fuelling. However,

persistent fume emission is potentially dangerous and must not be tolerated. If fume

emission does persist, the following immediate actions should be taken:-

a. Open doors and windows to ventilate the room

b. Let the fire go out or eject and safely dispose of fuel from the appliance

c. Check for flue or chimney blockage and clean if required

d. Do not attempt to relight the fire until the cause of the fume emission has been

identified and corrected. If necessary seek expert advice

Mar 14/GB Issue 3 20

Maintenance

Door adjustment

In the case of the door rope not providing an adequate seal to the room, products of

combustion may enter the room (see warning notes), to ensure an adequate seal the

door may need to be periodically adjusted as the rope seal wears with use.

Hinge Adjustment (seal on Left hand side is not compressed):

• Ensure that the stove is cold

before proceeding

• Remove the door by lifting the

door off the hinges

• Loosen the Hinge Locking nut

inside the stove

• Rotate the hinge by 1 turn

(clockwise to tighten seal,

anticlockwise to loosen seal) on

both the top and bottom hinge,

this ensures that the door seal will

compress or loosen evenly

• Re fit the door back onto the

hinges and tighten the locking nut

inside the stove

• Check the seal provides an

adequate seal.

Door Latch adjustment (seal on Right hand side is not compressed):

• Ensure that the stove is cold

before proceeding

• Adjustment can be made with the

door on the stove

• Slacken Locking nut 1

• Adjust Locking nut 2 to required

depth

• Re tighten locking nut 1 to

complete adjustment

• Check the seal provides an

adequate seal

• Locking Nut 3 is factory set to the

correct handle shaft depth, this

Locking nut should only be

adjusted to take up slack in the

handle and not for door seal

adjustment.

Mar 14/GB Issue 3 21

Maintenance

Ash Removal

The ash pans can be removed by using the ash tool to hook it forward so that you can

grasp the pan using the gloves provided. We would recommend emptying the ash into a

metal bucket for transportation.

You should only empty the ash when the appliance and ashes are completely cool and

can be disposed of in your normal household refuse.

Cleaning the Stove

We recommend only doing this when the stove is cold using a soft brush to clean any of

the stove surfaces, this is normally sufficient to remove dust, ash and debris. For

stubborn marks you can use a damp lint free cloth, ensure that all surfaces are dried off

immediately. We do not recommend using any kind of chemicals or abrasive materials.

It is possible to touch up the paint using the original metallic black stove paint, however

this new paint will then need to cure.

Glass Cleaning

A damp lint free cloth is normally sufficient, however for stubborn build ups we would

recommend using a very fine wire wool.

Chimney Sweeping

It is essential that your chimney (flue) is swept at least once a year by a registered

professional chimney sweep. Sweeping removes particles that could otherwise fuel a

chimney fire, it should also highlight any potential issues such as leaks and damage to

the flue.

Chimney Fires

In the event of a chimney fire ensure both Primary and Secondary air controls are fully

closed and the door(s) remain closed at all times. If the chimney fire does not go out or

if there is a serious risk to people and property, call the fire brigade immediately.

Regular sweeping of the chimney will remove combustible particles and will reduce the

risk of chimney fires.

Stove Servicing

Your stove should be inspected annually to ensure all seals are present and correct and

to gauge the condition of the internal components. The service should be done by a

HETAS registered engineer who also perform a spillage test and ascertain the correct

functioning of the plumbing circuit.

Mar 14/GB Issue 3 22

Trouble-shooting

Smoke comes out of the stove when the loading door is opened.

• The chimney cavity into which the 150mm flue pipe has been installed may be

less than the minimum requirement.

• Deposits (soot or other obstructions) may have built up in the chimney and be

restricting the flow of waste products. This flow rate is known as the ‘draw’.

• Insufficient draw, this is especially common during milder weather. You will need

to prolong the kindling stage to ensure the chimney (flue) is completely hot (you

may even need to pre-heat the chimney using a method advised by the installer)

• Combustion air intake is not large enough or another appliance (e.g. Extractor

fan) is taking air away from the stove.

The Stove does not produce the expected heat into the room.

• Has the flue pipe been sealed to the chimney to prevent heat being drawn up the

chimney to waste?

• Green or wet wood is being burnt.

• The chimney has excessive draw (this is unusual). Seek installer advice with

regard to installing a Flue Draught Stabiliser.

• The stove has been recessed into the existing fireplace and a lot of heat is being

absorbed by the surrounding fireplace walls rather than being radiated into the

room. Pull the stove forward.

• For the maximum efficiency of heat transference into the room the stove should

be sited on the hearth of the fireplace rather than recessed.

The Stove burns too fast.

• Use whole logs rather than split ones.

• The wood being used may be generally too small.

• The “air-tight” seal between the fibre rope on the doors and the casting may have

been lost, adjust door handle lock nuts or hinges to reinstate this seal or replace.

• The chimney has excessive draw (seek installers advice on this point).

• The fibre rope seal between the door and the glass may be leaking. Tighten or

replace.

• The fibre rope on doors and glass has worn out. Replace.

The Stove door does not seal properly.

• Adjust the door hinges (maintenance section) to ensure a good seal on the left

hand side of the door.

• Adjust the door latch (maintenance section) to ensure a good seal on the right

hand side of the door.

• Replace door seal if the above does not provide an adequate seal.

Mar 14/GB Issue 3 23

Commissioning Form

Commissioning Statement and Check-list

Stove Purchased

From:_________________________________________________________________

Address:_______________________________________________________________

Telephone Inc area code:_________________________________________________

Installation Date:_____/_____/__________ Stove Name:________________________

1

st

year service is due 1 year from this date

Product Serial Number:________________ Invoice Number:_____________________

Stove installed by:_______________________________________________________

Address:_______________________________________________________________

Telephone Inc area code:_________________________________________________

HETAS Registration Number:______________________________________________

Check-list (please indicate Yes or No by circling or ticking appropriatley)

Is the flue system the correct length and diameter for stove: Yes No

Flue swept and checked for soundness: Yes No

Manufacturers clearances adhered: Yes No

Smoke spillage test performed on stove: Yes No

Stove controls fully explained to end user: Yes No

Correct fuels explained to end customer: Yes No

CO Alarm fitted and tested: Yes No

Instruction booklet & HETAS certificate handed to end user: Yes No

Signature:__________________________ Print Name:_________________________

Mar 14/GB Issue 3 24

Spare Parts

Steel Door Version

1: Stove Engine. 2: LHS and RHS baffle plate set, 3: Rear Baffle, 4: Top Baffle, 5: Cast

Grate, 6: Cast grate front, 7: Ash pan, 8: Latch, 9: Air box, 10: Coal Slider

11: Wood Slider, 12: Door Handle, 13: Steel Door, 14: Glass, 15: Steel door Glass

retaining bar (x2), 16: Steel door Latch shaft, 17: Steel Door Hinge

Mar 14/GB Issue 3 25

Annual Service Record

1ST YEAR SERVICE completion date:

SERVICE ENGINEER: REG. No.

COMPANY NAME: .

COMPANY ADDRESS: .

POSTCODE:

CONTACT NUMBER

2ND YEAR SERVICE completion date:

SERVICE ENGINEER: REG. No.

COMPANY NAME: .

COMPANY ADDRESS: .

POSTCODE:

CONTACT NUMBER

3RD YEAR SERVICE completion date:

SERVICE ENGINEER: REG. No.

COMPANY NAME: .

COMPANY ADDRESS: .

POSTCODE:

CONTACT NUMBER

4TH YEAR SERVICE completion date:

SERVICE ENGINEER: REG. No.

COMPANY NAME: .

COMPANY ADDRESS: .

POSTCODE:

CONTACT NUMBER

5TH YEAR SERVICE completion date:

SERVICE ENGINEER: REG. No.

COMPANY NAME: .

COMPANY ADDRESS: .

POSTCODE:

CONTACT NUMBER

6TH YEAR SERVICE completion date:

SERVICE ENGINEER: REG. No.

COMPANY NAME: .

COMPANY ADDRESS: .

POSTCODE:

CONTACT NUMBER

Receipts should be retained for each service beyond year six.

Mar 14/GB Issue 3 26

Warranty

This appliance must be installed and commissioned by a fully qualified, registered engineer. A “Declaration of

completion Certificate” must be obtained for the installation and retained by the end user. Failure to comply with these

requirements may void your warranty. You, as the end user, have a contract by law with the supplier / dealer from

whom you purchased the product. That dealer then has the same contract with the manufacturer or wholesaler and

these have a contract with their suppliers.

ALL CLAIMS MUST FOLLOW THIS PROCEDURE.

Thank you for choosing a Product from Broseley Fires Ltd. This warranty gives you specific legal rights. The

statutory rights of the consumer are not affected by the warranty, or the consumers’ rights against the dealer arising

from their sales / purchase contract.

The manufacturers’ warranty:

Your Product will be free from defective parts, material, and workmanship at the time of its original purchase for a

period of Five (5) years. This Warranty will become active as of one month from the date of delivery.

This warranty does not cover any failure of the unit due to normal wear and tear, misuse, abuse, accident, illegal

modification, illegal installation or repair, damage resulting from improper use or failure to maintain the product.

Variations in color and texture are a natural characteristic of heating products. Colour changes may result from

exposure to light and other elements which are a part of the aging process. These material variations and changes

are not covered by this warranty. If during the warranty period, this Product fails to operate under normal use and

service, due to defects in material and / or workmanship, Broseley Fires will either repair or replace the product.The

repaired or replaced product shall be warranted for the remaining period of the original warranty + the time taken to

days from the date of repair, whichever is longer.

Repair or replacement may involve the use of functionally equivalent reconditioned units. Repl aced parts or

components will become the property of Broseley Fires.

Should you wish to claim under the warranty, please contact the supplier / dealer from whom you purchased the

appliance. Do not claim directly to Broseley Fires, as they are unable to process any direct claim from an end user.

Product design and any specifications are subject to change without notice. This is due to our continuous product

development and improvement. The buyer will not be entitled to request free upgrades to the new design or

compensation for previously purchased products or any products on order.

• This Warranty covers all Broseley Fires costs within the Warranty period.

If the appliance remains uninstalled for a period greater than six months from date of delivery the Warranty will

become active six months from the date of original invoice to the distributor.

IN NO EVENT SHALL BROSELEY FIRES BE LIABLE FOR INCIDENTAL OR CONCEQUENTIAL DAMAGES OF ANY NATURE WHATSOEVER,

INCLUDING BUT NOT LIMITED TO LOST PROFITS OR COMMERCIAL LOSS

, TO THE FULL EXTENT THOSE DAMAGES CAN BE DISCLAIMED

BY LAW

. (if applicable)

NON - COVERAGE OF THE GUARANTEE

The consumable items within the product are not covered by the warranty, nor is the glass

If the end-user’s claim should not be covered by this guarantee, the end-user shall be liable for costs incurred by

Broseley Fires such as callout and inspection costs for examination of the product, transportation costs of the product

as well as any other relevant costs. If, after having been informed about the non-coverage of the guarantee, the enduser wants to have the repairs done, the end-user shall additionally pay for any spar e parts used and for the labour

and transportation costs incurred. If repairs are carried out under this guarantee, the remaining guarantee period for

the product shall be extended by the period of time that has elapsed since the complaint was officially logged with

Broseley Fires until the repairs have been completed

A COPY OF OUR FULL TERMS AND CONDITIONS IS AVAILABLE ON REQUEST.

** End-user means the natural or legal person who owns the product and who has not acquired it with a view to reselling or

installing it in the course of business

Loading...

Loading...