Bronpi Julieta, Montserrat, Elisa, Eva, Coral Installation Instructions And User Manual

...Page 1

MOD. JULIETA

“TECNOLOGÍA OASYS (Optimum Air System)”.

Please read attentively these instructions before installation, use and maintenance.

The instructions guide is an integral part of the product.

INSTALLATION INSTRUCTIONS AND USER GUIDE

Page 2

1 GENERAL WARNINGS ............................................................................................................................................................. 4

2 FUELS ........................................................................................................................................................................................... 4

3 SAFETY DEVICES ....................................................................................................................................................................... 4

4 TECHNICAL FEATURES ............................................................................................................................................................ 6

5 INSTALLATION REQUIREMENTS ........................................................................................................................................... 6

5.2 Timber beams protection ............................................................................................................................................................7

5.3 The chimney ....................................................................................................................................................................................8

5.4 Chimney cowl............................................................................................................................................................................... 10

5.5 Connection to chimney / Combustion air (air intake) ................................................................................................... 10

5.6 Outside air intake ........................................................................................................................................................................ 11

6 STARTING UP ........................................................................................................................................................................... 12

7 USUAL OPERATION ............................................................................................................................................................... 12

8 MAINTENANCE AND CARE .................................................................................................................................................. 13

8.1 Burn pot cleaning ....................................................................................................................................................................... 13

8.2 Scrapers using (ONLY FOR 10 KW MODELS) ................................................................................................................... 13

8.3 Ash pan cleaning (ONLY FOR 10 KW MODELS) ............................................................................................................. 13

8.4 Ash pan and burn pot door joints ........................................................................................................................................ 13

8.5 Chimney cleaning ....................................................................................................................................................................... 13

8.6 Glass cleaning .............................................................................................................................................................................. 13

8.7 Exterior cleaning ......................................................................................................................................................................... 13

8.8 Seasonal shutdowns .................................................................................................................................................................. 14

9 DISPLAY OPERATION ............................................................................................................................................................. 15

9.1 Display general information.................................................................................................................................................... 15

9.2 Display keys running.................................................................................................................................................................. 16

9.3 Remote control general information ................................................................................................................................... 16

9.4 Menu option ................................................................................................................................................................................. 17

9.4.1 User menu ..................................................................................................................................................................... 17

9.4.2 Menu 1. ........................................................................................................................................................................... 17

9.4.3 Menu 2. Clock ............................................................................................................................................................... 18

9.4.4 Menú 3. Programme Adjustment ......................................................................................................................... 18

9.4.5 Menu 4. Language selection .................................................................................................................................. 26

9.4.6 Menu 5. Stand-by mode ........................................................................................................................................... 26

9.4.7 Menu 6- Sonorous mode .......................................................................................................................................... 26

9.4.8 Menu 7. Initial charge ................................................................................................................................................ 26

9.4.9 Menu 8- Stove stage ................................................................................................................................................... 27

9.5 User mode ..................................................................................................................................................................................... 28

9.5.1 Starting up stove ......................................................................................................................................................... 29

9.5.2 Operation stove ........................................................................................................................................................... 29

9.5.3 Consigned ambiance temperature changing .................................................................................................. 30

9.5.4 User fixed temperature reached by the ambiance temperature… ............................................................ 30

9.5.5 Burn pot automatic cleaning .................................................................................................................................. 31

9.5.6 Shutdown stove........................................................................................................................................................... 31

9.5.7 Shutted off stove ......................................................................................................................................................... 31

9.5.8 Re-starting up stove .................................................................................................................................................... 32

Page 3

9.6 What happens if…? ..................................................................................................................................................................... 32

9.6.1 Pellet fuel do not light ............................................................................................................................................... 32

9.6.2 Electrical supply failure (Back out). ....................................................................................................................... 32

9.7 Alarms ............................................................................................................................................................................................. 33

9.7.1 Alarm smokes temperature probe ........................................................................................................................ 33

9.7.2 Alarm smoke excess temperature ......................................................................................................................... 33

9.7.3 Alarm starting up failure ........................................................................................................................................... 33

9.7.4 Alarm shutdown during work phase .................................................................................................................. 34

9.7.5 Alarm damaged extraction smokes fan .............................................................................................................. 34

10 GENERAL MEASURES ............................................................................................................................................................. 36

Page 4

1 GENERAL WARNINGS

The heater installation has to be carried out in accordance with the local and national regulations, including

all regulations referred to national or European standards.

All heaters produced in our company are made controlling all the pieces and trying to protect both the user

and the fitter, to avoid possible accidents. We also recommend to the authorized technical fitters, to pay

special attention on electrical connections every time they carry out an operation, especially at the bare part of

cables, which should never be out of the connections box so that dangerous contacts are avoided.

The installation must be executed by authorized personnel, whose will have to supply the buyer an

installation conformity declaration, to assume full responsibility for the definitive installation and keep the

product in working order. Bronpi Calefacción S.L. will not assume any responsibility in case of absence of

fulfilment such precautions.

The manufacturer will be exempted of any responsibility opposite to damages caused to third due to incorrect

installation or bad use of the device.

To guarantee an accurate operation of the appliance the components should only be replaced for original

spares by an authorized technician.

The maintenance of the device must be carried out at least once a year, by the Authorized Technical Service.

For a major safety it is necessary to bear in mind:

Don’t touch the heater being barefooted or with humid parts of the body.

The door of the unit must be closed during the operation.

It is prohibited to modify the safety devices or regulations of the unit without the authorization

of the manufacturer.

Avoid the direct contact with the parts of the appliance that tend to reach high temperatures

during the operation.

2 FUELS

WARNING!!!

USING A BAD QUALITY PELLET FUEL OR ANY OTHER MATERIAL DAMAGES THE OPERATION OF THE

HEATER AND COULD DETERMINE THE EXPIRATION OF THE WARRANTY IN ADDITION TO EXEMPTING

RESPONSIBILITIES FROM THE MANUFACTURER.

Pellet fuel used has to be in accordance with the characteristics described in the norms:

Ö-Norm M 7135

DIN plus 51731

UNI CEN/TS 14961

Bronpi Calefacción recommends using pellet fuel 6 mm in diameter.

• PELLET FUEL STORAGE

To avoid combustion problems it is necessary to preserve the pellet fuel on a dry environment.

• PELLET FUEL SUPPLY

For supplying the heater, you have to open the hopper lid at the top of the appliance pouring directly into it

the pellet fuel, taking care not overfilling the hopper.

3 SAFETY DEVICES

• TURNING ON FAILURE

If during the ignition stage the flame does not take place, the appliance will show in the display “no ACC”. If

you try to light the machine again, in the display you will read “ATTE“which means “wait“.

This function serves to remember that, before carrying an ignition out, it is necessary to verify that the burn

pot is completely clear and clean.

• BREAKDOWN ON THE WARM AIR DISTRIBUTION FAN

In case that ventilation stops for any reason, the heater stops automatically, avoiding the overheating (not

included on hydro models).

Page 5

• BREAKDOWN ON THE SMOKE VACUUM CLEANER

If the extractor stops, the electronic card blocks automatically the pellet fuel supply.

• BREAKDOWN ON THE PELLET FUEL LOADING ENGINE

If the differential engine stops, the heater keeps on working until it does not reach the minimal functioning

temperature and stops.

• ELECTRICAL CURRENT TEMPORARY FAILURE

After a brief absence of current, the heater turns on again. When electricity is missing, the heater can produce

a limited quantity of smoke inside the house during an interval from 3 until 5 minutes. THIS DOES NOT

ENDURE ANY RISK FOR THE SAFETY. That’s why Bronpi advises whenever it is possible to connect the pipe of

entry of primary air with the exterior of the housing to ensure that the heater could not detach smokes after

the above mentioned absence of current.

• ELECTRICAL PROTECTION

The heater is protected against sudden electricity oscillations by means of a general fuse placed on the back

part. (2nd 250V Slowed down). (To see photo 1).

• EXIT SMOKE PROTECTION

An electronic pressureswitch foresees to block the operation of the heater, if sudden change of pressure takes

place inside the combustion chamber (door opening, damage of engine of smokes extraction…) the heater

will go into the alarm mode. (Photo 2)

• PROTECTION BEFORE THE PELLET HIGH TEMPERATURE (80th C)

In case of overheating inside the hopper, this device blocks the appliance operation. The manual

reestablishment must be carried out by an authorized technician. (Photo 3).

The reestablishment of this safety device is not considered by the warranty, unless the assistance centre may

demonstrate the presence of a defective component.

FLOW SENSOR (Oasys Technology)

Your stove is provided with a flow sensor (Picture 4), which is placed on the primary air suction pipe; it detects

the correct circulation of the combustion air and the smokes discharge. In case of an incorrect smoke

discharge (as consequence of the incorrect entrance and exit of smokes) it sends the stove a sign of blockage.

OASYS TECHNOLOGY (Optimum Air System) obtains a constant combustion, regulating automatically the

throw according to the characteristics of the smoke pipe (curves, length, diameter etc.) and the environmental

conditions (wind, humidity, atmospheric pressure etc.). For this the installer has to introduce on the technical

menu the geographic height of the place where the stove is installed.

Picture 1 Picture 2 Picture 3 Picture 4

Page 6

4 TECHNICAL FEATURES

Features

Julieta

Weight (Kg.)

128

Height (mm)

1099

Width (mm)

528

Depth (mm)

598

Smoke discharge pipe diameter (mm)

80

Aspiration air pipe diameter (mm)

40

Volume max. warning (m3)

212

Nominal power capacity

88

Reduced power capacity

88

Global thermal power max. (Kw.)

8.5

Useful thermal power max. (Kw)

8.5

Useful thermal power min. (Kw)

3.5

Pellet consumption min. Kg/h

0.83

Pellet consumption max. Kg/h

2

Hopper capacity (Kg.)

21

Autonomy min/max (h)

25/10.5

Recommend shot to useful power max. (Pa)

~ 12

Recommend shot to useful power min. (Pa)

~ 10

Electrical consumption (W)

150-200

Electrical consumption during the ignition (W)

300

Cast iron interior

No

Automatic ignition

Si

Security pellet thermostat

Si

Remote control

SI

Weekly programmer

Si

5 INSTALLATION REQUIREMENTS

The way to install a new product is directly related to the safety and efficiency of the appliance. This is the

reason why all stoves and appliances should always be installed only by suitable trained and qualified heating

engineers. Serious damages to the appliance, as well as personal injuries, may occur if the device is installed

incorrectly.

Prior to installation, the following measures must be taken:

Check the floor is strong enough to support the weight of the unit, and if it is made of

flammable materials (wood, etc) or susceptible materials to high temperatures.

Make sure the ambience where the device will be installed has suitable ventilation (presence of

air capture).

Avoid installation in rooms with shared ventilation vents, hoods (with or without extractors),

type B gas appliances, gas bottles or other appliances which use may affect the draw to the

appliance

Page 7

Make sure the chimney and the flue system/flue liner used is accurate for the product.

Make sure each appliance has it own chimney. The same chimney can not be used for more

than one appliance.

We suggest contacting your chimney sweep to check whether chimney connexion and the combustion air

flow on the installation place.

5.1. Safety control measures

During the appliance installation, for certain risks it is necessary to bear in mind the following safety measures:

a) Keep all heat sensitive or flammable materials at least 150 cm away from the device (furniture,

curtains, clothing, etc.)

b) When the device is going to be installed on flooring that is not completely insulated, a

fireproof base (such as a suitable constructional hearth and superimposed hearth) must be

installed.

c) Do not install the device close to flammable or heat-sensitive walls.

d) The heater must only be used with the ash pan in place.

e) We recommend the installation of a carbon monoxide detector in the room where the device

is fitted.

Ash must be collected in an airtight, fireproof container.

The fire must never be lit in the presence of gases or vapours such as linoleum glue, petrol, etc. Never leave

flammable objects near the fire.

WARNING! Both the firebox and the glass become extremely hot and should never be touched directly.

If there is a fire either in the device or within the chimney then:

a) close the loading door.

b) close the air vents.

c) extinguish the fire using fire extinguishers of dioxide of carbon (CO2 powder).

d) call for the fire brigade immediately.

DO NOT TRY TO PUT THE FIRE OUT WITH WATER!!!

5.2

Timber beams protection

Given the amount of heat produced by the device, special attention must be taken to protect nearby wooden

beams. When designing the fireplace both the proximity of the beams to the exterior surfaces on the fire, and

the heat emitted from the glass door need to be taken into account. The exterior faces of combustible beams

must not be subjected to temperatures exceeding 65ºC.

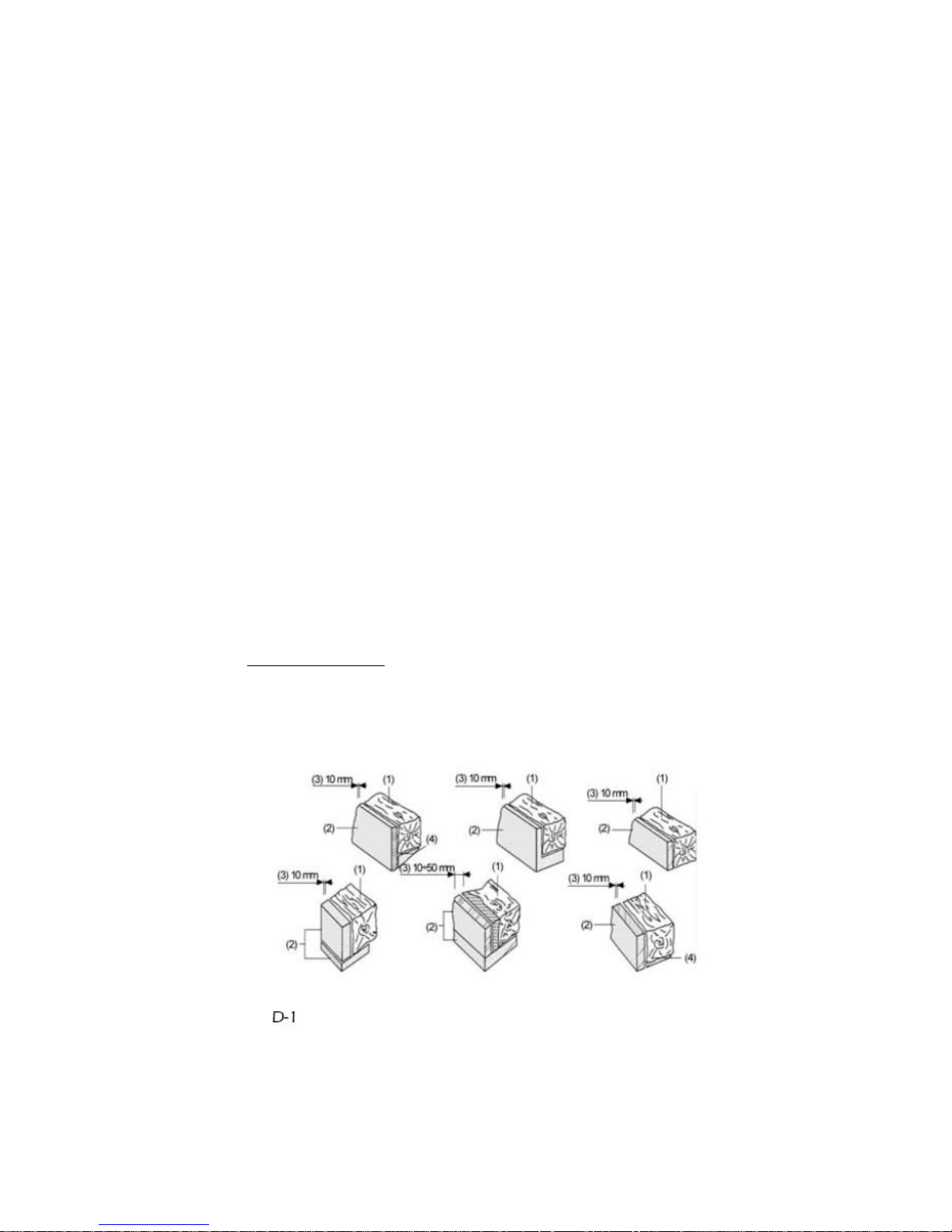

Some suggested solutions to this matter appear on the following drawing.

1-Beam;

2-Refractory Material Isolation;

3-Pothole;

4-Metallic protection;

Page 8

PLEASE NOTE:

The manufacturer admits no liability whatsoever for any malfunction in any of its products if correct

installation procedures are not followed.

5.3 The chimney

The chimney has a fundamental importance for the correct operation of the device and has two purposes:

It channels smoke and gasses harmlessly away from the room

It provides a sufficient draw to keep the fire alight.

It is essential that the chimney is correctly built and is subject to regular maintenance to keep it in good order.

(Most complaints of incorrect functioning of the device are due to an inadequate draw or other chimney

malfunction).

The correct functioning of the device requires the chimney/flue conditions:

The internal section of the chimney should preferably be circular

The entire height of the chimney must be heat insulated correctly in order to avoid problems

with smoke condensation, this is especially so in cases of external chimneys.

If metal flue pipes are fitted to form an external chimney, only twin-wall insulated flue pipes

should be used in order to avoid problems with condensation.

The chimney should have an even diameter throughout its length (i. e. no increases or

reductions in the volume of the chimney) and it should be vertical and have no bends of over

45º within it.

Any existing chimney must be swept before installation of the device.

Technical data in the flue manufacturer’s instruction manual must be complied with.

The optimum draw of a chimney should be between 10 and 14 on the Pascal scale. A lesser value (weak

draw) results in incomplete combustion which produces carbon deposits and excess smoke production. It can

also lead to smoke leaks and increases in temperature within the appliance which can (in turn) cause serious

damage to the structural components of the product.

Too much draw in the chimney can result in the fire burning too rapidly and too much heat being passed

through the tubing.

Chimneys constructed from fibrous cement, galvanised steel and chimneys with rough or porous interior

surfaces are forbidden and lead to poor functioning of the equipment. Some solutions to this problem are

suggested on the following drawing.

(1) Pavement chimney AISI 316 with double wall insulated with resistant material to 400º C. Efficiency 100 %

ideal.

(2) Traditional chimney of clay section squared in hollows. Efficiency 80% ideal.

(3) Chimney of refractory material with double insulated wall and exterior revetment of lightened concrete.

Efficiency 100% ideal.

(4) Avoid chimneys with rectangular interior section which relation is different from the drawing. Efficiency

40% mediocre.

Page 9

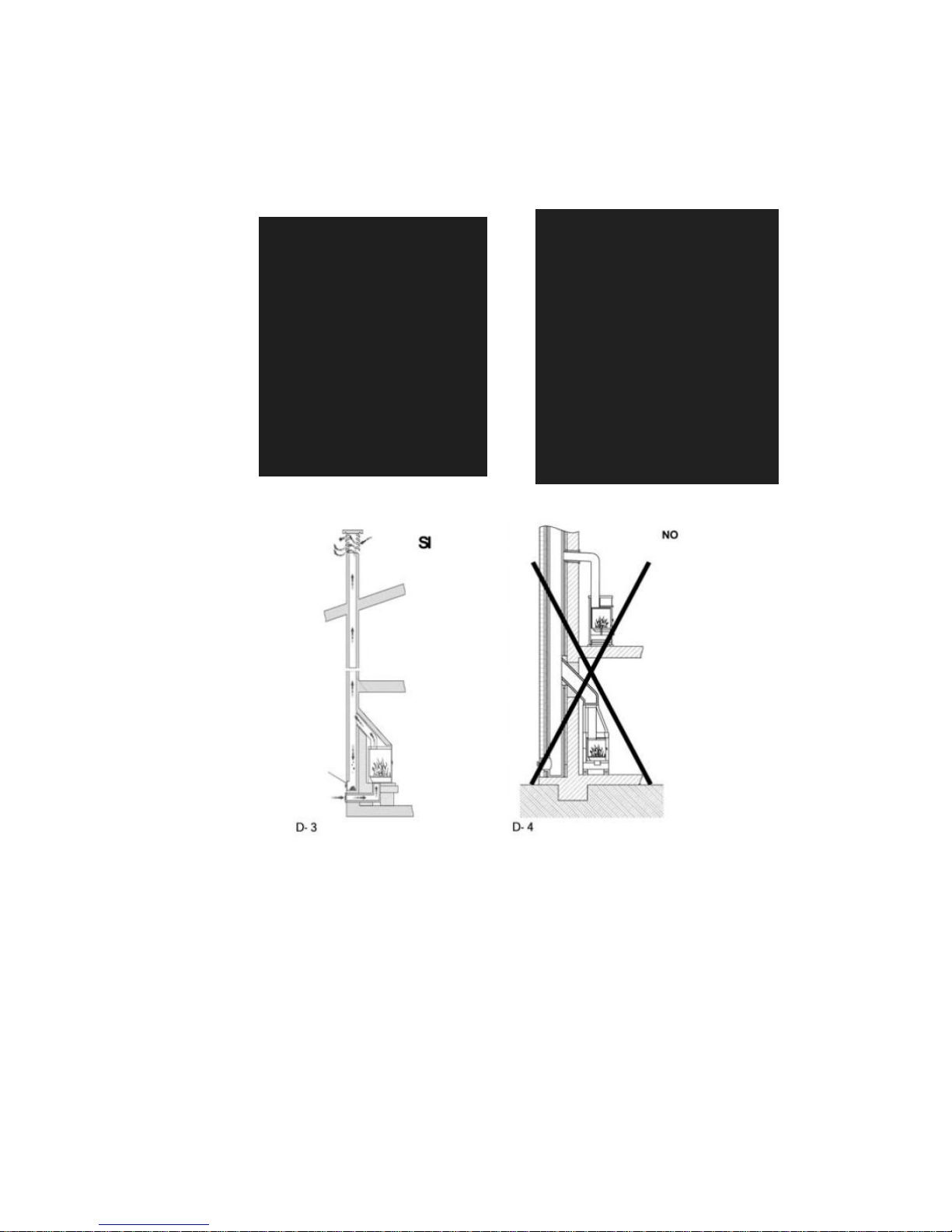

Each stove must have it own dedicated chimney to eliminate fumes and gasses. The same chimney must

never be used for more than one appliance. (See drawings D3 and D4 (Page 14). The minimum crosssectional area of the chimney must be 4 dm2 (e.g. 20 x 20 cm) for appliances having flue pipes with a

diameter less than 200 mm or 6,25 dm2 (e.g. 25 x 25 cm) for the appliances having flue pipes with a diameter

over 200 mm.

If a section of the chimney is too large to be heated adequately, this will cause problems with the appliance: to

avoid this we recommend installing a flue pipe for the entire length of the chimney.

If any section of the chimney is constructed, it will reduce the draw on the fire.

The flue pipe must be installed an adequate distance from any flammable material and have correct insulation

or a sufficient air gap. Flue pipes must never be installed inside air ventilation channels. Moveable or fixed

openings must not be made in the chimney for the connection of any other device.

See DP2, DP3 and DP4.

Page 10

(1) Axis top

(2) Roof

5.4 Chimney cowl

The pull on the flue pipe depends on the suitability of the chimney cowl. It is essential that the sectional area

of the cowl exit is at least twice (preferably 2.5 times) that of the flue pipe. The termination of the flue pipe

must always exceed the top level of the roof so that the chimney is able to discharge even in windy conditions

(DP7)

Any cowl must comply with the following conditions:

The outlet area must be at least double that of the interior section of the chimney.

It must be constructed to prevent the entry of rain, snow or foreign bodies

It must have easy access for inspection, maintenance and cleaning.

The interior section must be equal to the chimney one.

5.5 Connection to chimney / Combustion air (air intake)

The immediate connection of the device to the chimney/flue system must be made using stainless steel flue

pipe.

Flexible tubing must never be used as the joints will be subject to damage and lead to smoke leaks.

The flue pipe must be hermetically sealed to the device and have a maximum bend of 45 degrees. This will

avoid excessive condensation during lightning, prevent soot deposits and avoid impeding the release of

smoke from the fire box. If the seal is not properly connected, the stove will not function properly.

The inside diameter of the connection tube must equal the exterior diameter of the flue pipe. Flue pipes

conforming to DIN 1298 will ensure this. The pull on the chimney must be between 10 and 14 Pa.

The measuring must always be done with the device hot (nominal calorific output).

If the pull is over 15 Pa, it will be necessary to reduce it by installing an additional regulator.

Page 11

IMPORTANT!!!

Where metal flue pipes are used, it is essential that they are appropriately insulated (insulated fibre cladding)

to avoid damaging the masonry in the chimney. When the device is being installed in an existing chimney, it

must be sealed around the flue pipe exit at the bottom entrance to the chimney with a pre-formed metal plate

or other fireproof material able to withstand very high temperatures.

References

Flammable Objects

Not flammable objects

A

1500

800 B 1500

150 C 1500

400

5.6 Outside air intake

It is essential that the room in which the device is installed has sufficient fresh air intake and air circulation to

keep a good draw on the fire and to re-oxygenate the room even with the doors and windows closed.

The air inlet must be positioned so that it cannot be obstructed.

It must take fresh air directly into the room where the device is installed, be protected by grille

and have an area of at least 100 cm2.

Industrial fume exit of pre-

fabricated elements permits

excellent fume extraction.

Handmade fume exit. Correct

section of exit must be twice as

the inside section of the

chimney. Ideal 2,5 times.

Fume exit for steel chimney

with inside cone.

Page 12

Air inlets shouldn’t draw air from adjacent rooms such as garages, lavatories, boiler rooms, etc,

but should take air directly from outside the building

The stove previews the necessary air intake for the combustion on it back (40 mm diameter). It is important

not to block this air intake, and to respect the distance recommended from the walls and furnishings nearby.

It is recommended but not obligatory connecting the primary air intake of the stove to the exterior. Regarding

the material of the connection pipe, it is not necessary to be metallic, it could be made of another material

(PVC, aluminium, polyethylene, etc), note that for this line air will circulate with the outside ambiance

temperature.

6 STARTING UP

The lightning of this type of devices is completely automatic therefore you must not introduce in the burn pot

any type of material for its lightning.

During the first lightning it may happen that the device has finished the lightning cycle and does not appear

the fire. If this happens the device goes on automatically to state of alert. This is due to the fact that the feeder

of the fuel is empty and needs a time to fill. To solve this problem light again the heater again until the fire

appears.

It is prohibited the use of all the liquid, such substances like, for example, alcohol, gasoline, oil and similar. The

use of the above mentioned substances will cause the loss of the guarantee.

During its lifetime, the product will be subject to alternating cycles of heating and cooling both

on a daily basis as well as cycles of intense use or total rest depending on the season.;

Before fully settling in, the device must be subjected to several cycles of use so that the materials

and paintwork can settle in and bind flexibly;

In particular it may be noticeable on first lightning the stove that there is smell of hot metal and

fresh paint. During manufacture the paint has already been heat treated to extremely high

temperatures but before binding completely with the metal surface it needs to be run at

sustained temperatures of 200 degrees for long periods and on several occasions.

Therefore, it is important to adopt these small precautions in starting phase:

1. Keep the room well ventilated to avoid a build up of fumes.

2. For the first few lightings of the fire, take care not to overload the fire box with fuel and

preferably keep it lit for 6-10 hours continuously.

3. Repeat this procedure at least four or five times.

4. During the first few uses, nothing should be placed on the device or the paintwork, nor

should painted surfaces be touched whilst heating up.

5. Even after this initial phase of “running in” is complete, the appliance should be treated like car

engines i.e. avoid both overloading and overheating.

7 USUAL OPERATION

As well as regulating the air intake, the draw on the flue will affect the rate of combustion and the heat

output of the device. A strong pull on the chimney will need a reduction on the draw to the fire, while a weak

pull will require extra attention to the setting of the air intake controls.

Check if the draw to the fire is correct by looking at the colour of smoke being emitted. It should be

transparent. If it is white, it means that the controls have not been set correctly or the used pellet is too wet. If,

on the other hand, the smoke is black or grey, it means that the fuel is not being completely burned and the

secondary air intake must be increased.

Page 13

8 MAINTENANCE AND CARE

The maintenance operations guarantee that the product works correctly during long time. If you don’t do it, it

can damage the device.

8.1 Burn pot cleaning

The cleaning of the burn pot must be carried out every day.

Extract the burn pot and to unblock the orifices with corresponding poker, which is given

together with the heater.

Use a vacuum cleaner to eliminate the ash of the burn pot

Vacuum the ash deposited in the accommodation of the burn pot.

8.2 Scrapers using (ONLY FOR 10 KW MODELS)

The cleaning of fire box allows guaranteeing that thermal efficiency is constant during long time. This type of

maintenance must be carried out at least once a day. To carry out it is enough to use the corresponding

scrapers, which are in the top part of the heater, realizing a lower movement up to down and vice versa

repeatedly.

8.3 Ash pan cleaning (ONLY FOR 10 KW MODELS)

The ash pan must be emptied when it is necessary. The heater can’t be lightening without the ash pan inside.

8.4 Ash pan and burn pot door joints

The joints guarantee the airtightness of the heater and consequently the good functioning of the device.

It is necessary to control them periodically: if they are worn out or damaged they will have to be replaced

immediately.

These operations can only be carried out by an authorized technician.

For the correct functioning of the heater, an authorized technical service must proceed to its maintenance at

least once a year.

If the power wire is damaged, it has to be replaced by service of technical assistance or, in any case, by a

qualified technician, avoiding useless risks.

8.5 Chimney cleaning

During normal use, the device will not suffer any damage. When pellet is burnt slowly, tar and gasses are

emitted which (when combined with normal humidity) lead to creation of soot. An excessive build -up of soot

in the chimney can cause problems with the smoke discharge and a risk of fire.

Cleaning should be undertaken by a professional chimney-sweep and should be carried out when the device

is cold. It is advisable to check out the condition of the device at the same time and keep a note of dates on

which this work has been carried out

8.6 Glass cleaning

IMPORTANT:

The glass must only be cleaned when it is completely cold to avoid the possibility of shattering .Commercial

product may be used or alternatively clean it with moistened newspaper which has been dabbed in the

ashes. Abrasive cleaners should not be used to remove deposits from the glass.

GLASS BREAKAGE: The vitroceramic glass is resistant to temperatures up to 750 degrees and will not be

affected by rapid changes in temperature. It will only be damaged by mechanical shock, e.g. slamming the fire

door shut. For this reason, it is not included as a replacement part under the guarantee.

8.7 Exterior cleaning

Do not clean the exterior of the stove with water or abrasive products as they could damage the surface. Use

a duster or a moist cloth.

Page 14

8.8 Seasonal shutdowns

After cleaning the stove, the chimney and the flue pipe and completely removing any ash and residues, close

the doors and the air adjustments. The chimney must be cleaned at least once a year. Check the joints of the

device which, if damaged, will adversely affect its functioning and must be replaced. If the stove is installed in

a damp environment, put absorbent salts inside it. The interior cast iron will stay looking bright if it is wiped

with a little of vaseline.

At least once a year it is suitable to check and to clean the records of existing ashes in the low part of the

heater.

Your stove is provided by a preventive maintenance warning, established for after the 1.200 first hours of

operation, which will remember you the need of cleaning the records of your stove. To carry out these tasks,

you will have to contact your certified installer.

This message is not an alarm, but a remembering or advice, and it will let you use your stove successfully

meanwhile this message is shown on the display.

Bear in mind that your stove may need a cleaning process before the first 1200 operation established hours or

even after, this will always depend on the quality of the fuel used, the installation made for the smokes exit

and the correct regulation of the stove adapted to the installation.

CLEANING TASKS

Daily

Weekly

Monthly

Amually

Tecnician

User

Extract the burn pot from the compartment and make free its holes

using supplied poker. Extract the ash using vacuum cleaner

*

*

Pick up the ash deposited in the compartment of the burn pot

* * Use scrapers realizing a lower movement up to down several times

* * Empty the ash pan or pick up the ash when it is necessary

* * Pick up the bottom of pellet container always when it is necessary

*

*

Clean the inside of the firebox picking up the walls with adequated

vacuum cleaner

*

*

Cleaning of the fume extracting engine, complete firebox, pellet

container, complete substitution of joints and new siliconing where it is

necessary, fume pipes, entries…

*

Revision of all electronic components (electronic board, display...)

*

Revision of all electric components (tangential turbine, resistance, fume

extracting engine, circulating bomb...)

*

Page 15

VALUE

CLOCK

RESISTENCE

WORM SCREW

SMOKE ASPITATOR

INTERCHANGER

WITHOUT USE

ALARM

9 DISPLAY OPERATION

9.1 Display general information

The display shows information about the appliance operation. When you access to the menu different types

of screen can be obtained and fit the available configuration according to the access level.

Depending on the operating way, the visualization can take different meanings depending on the position on

the screen.

In the figure 14 appears an example of the heater turned on or off.

Figure14.

On the 15 picture you will see how messages are shown during the phase of programming or configuration

the operating parameters. I. e.:

1.

The screen zone “Value” shows the value introduced.

2.

The screen zone “Menu Level” shows the current menu level.

See menu chapter.

Figure15.

On the 16 picture all symbols significance are shown at the left part of the screen. The screen illumination En

la

figura 16

aparece el significado de los símbolos que hay en la izquierda de la pantalla. The screen lighting

on the “stage” paragraph indicates the corresponding device activation in accordance with the list as follows.

Figure 16.

AMBIANCE TEMPERATURE

DIALOGUE

14:24

21 ºC

OFF

P-2

POWER

STAGE

6 1 3

DIALOGUE

VALUE

08:10

MENU LEVEL

M-3-3-01

STAGE

START

PROG - 1

2 4 5

Page 16

9.2 Display keys running

Key

Description

Mode

Operating Description

1

Rise

Temperature

PROGRAMME

Modifies/increases the selected menu value

ON/OFF

Increases the ambiance thermostat temperature value

2

Decrease

Temperature

PROGRAMME

Modifies/decreases the selected menu value

ON/OFF

Decreases the ambiance thermostat temperatura value

3

Menu (Set)

-

Access to MENU

MENU

Access to consecutive submenu level

PROGRAMME

Confirms the selected value and goes to the next option of menu

4

ON/OFF

Release

WORKING

Pushing for 2 seconds the heater turns on or off, if it i son or off

respectively

BLOCKAGE

Release the heater and goes to turn off state

MENU/PROGRAMME

Goes back to the previous menu level and store the modified

information

5

Decrease

Power

ON/OFF

Decreases the heater exit power value

MENU

Goes to the previous option of menu

PROGRAMME

Goes back to the previous submenu option

6

Increase

Power

ON/OFF

Increases heater exit power value

MENU

Goes to the next option of menu

PROGRAMME

Goes to the next submenu option

9.3 Remote control general information

You will find with your stove an infrared remote control to command your stove on the distance. The keys

operating is as follows:

Key

Description

Mode

Operating Description

1

Rise

Temperature

PROGRAMME

Modifies/increases the selected menu value

ON/OFF

Increases the ambiance thermostat temperature value

2

Decrease

Temperature

PROGRAMME

Modifies/decreases the selected menu value

ON/OFF

Decreases the ambiance thermostat temperature value

2 y 5

simultaneously

Menu (Set)

-

Access to MENU

MENU

Access to the consecutive submenu level

PROGRAMME

Confirms the selected value and goes to the next option of menu

1 y 6

simultaneously

ON/OFF

Release

WORKING

Pressing for 2 seconds the heater turns on or off, if it is on or off

respectively

BLOCKAGE

Release the heater and goes to turn off state

MENU/PROGRAMME

Goes back to the previous menu level and store the modified

information

5

Decrease

Power

ON/OFF

Decreases the heater exit power value

MENU

Goes to the previous option of menu

PROGRAMME

Goes back to the previous submenu option

6

Increase

Power

ON/OFF

Increases heater exit power value

MENU

Goes to the next option of menu

PROGRAMME

Goes to the next submenu option

NOTE: You can access to the menu from the control remote, but you have to be close to the display so that

you can visualize what is shown on it.

Page 17

9.4 Menu option

Pressing the nº 3 key you access to the MENU option. This option is divided into several levels and paragraph

which allow the access to the heater programming and configuration.

These menu elements which allow the access to the technical programming of the stove are protected by a

code. These parameters have to be modified only by an authorized technical service. (Any change on the

mentioned parameters may cause a malfunction of the stove and the loss of the warranty).

9.4.1 User menu

The following table describes briefly the structure of the heater menu; only the available options for the user

are specified.

The menu element 01 is not enabled for this model.

Level 1

Level 2

Level 3

Level 4

Value

01- Reg. Aux. Ventilator

No operting

02 - Adjustments clock

01- Day

Day week

02- Hour

Hour

03- Minute

Minute

04- Day

Day month

05- Month

Month

06- Year

Year

03 – Adjustment programme

Consult chapter 9.3.4 of this guide

04 – Language Selection

01 – Italian

Set 02- French

Set 03- English

Set 04- German

Set

05- Stand-by Mode

On/Off

06- Sonorous Mode

On/Off

07- Initial Charge

Set

08- Stove Stage

Informs about the stove stage

9.4.2 Menu 1.

The menu 1 of your stove has no functionality; this is why its visualization (by default) is not operative.

1 2 6

5

Page 18

9.4.3 Menu 2. Clock

It establishes the hour and the date. The card is provided with a lithium battery to allow the autonomy of the

internal clock for 3 / 5 years.

9.4.4 Menú 3. Programme Adjustment

PLEASE NOTE: Before proceeding to the stove program configuration, please check the accurate date and

hour. The stove will be programmed according to the date and hour selected and it may no satisfy your

needing.

On the following table is briefly described the menu programme structure of the stove as well as the different

available options:

Level 1

Level 2

Level 3

Value

03 – Adjustment

Programme

1- Enable crono

01- Enable crono

On/Off

2- Daily

program

01- Daily Prog.

On/Off

02- Start 1 Day

Hour

03- Stop 1 Day

Hour

04- Start 2 Day

Hour

05- Stop 2 Day

Hour

3- Weekly

Programme

01- Weekly Prog.

On/Off

02- Start Prog. 1

Hour

03- Stop Prog. 1

Hour

04- Monday Prog. 1

On/Off

05- Tuesday Prog. 1

On/Off

06- Wednesday Prog. 1

On/Off

07- Thursday Prog. 1

On/Off

08- Friday Prog. 1

On/Off

09- Saturday Prog. 1

On/Off

VALUE

06

MENU LEVEL

Menu 02

DIALOGUE

MONTH

CLOCK

Page 19

10- Sunday Prog. 1

On/Off

11- Start Prog. 2

Hour

12- Stop Prog. 2

Hour

13- Monday Prog. 2

On/Off

14- Tuesday Prog. 2

On/Off

15- Wednesday Prog. 2

On/Off

16- Thursday Prog. 2

On/Off

17- Friday Prog. 2

On/Off

18- Saturday Prog. 2

On/Off

19- Sunday Prog. 2

On/Off

20- Start Prog. 3

Hour

21- Stop Prog. 3

Hour

22- Monday Prog. 3

On/Off

23- Tuesday Prog. 3

On/Off

24- Wednesday Prog. 3

On/Off

25- Thursday Prog. 3

On/Off

26- Friday Prog. 3

On/Off

27- Saturday Prog. 3

On/Off

28- Sunday Prog. 3

On/Off

29- Start Prog. 4

Hour

30- Stop Prog. 4

Hour

31- Monday Prog. 4

On/Off

32- Tuesday Prog. 4

On/Off

33- Wednesday Prog. 4

On/Off

34- Thursday Prog. 4

On/Off

35- Friday Prog. 4

On/Off

36- Saturday Prog. 4

On/Off

37- Sunday Prog. 4

On/Off

04- Prog. Weekend

01- Prog. Week-end

On/Off

02- Start 1

Hour

03- Stop 1

Hour

04- Start 2

Hour

05- Stop 2

Hour

Page 20

For programming the stove you have to access to menu program setting by pressing just for one time the key

nº 3 “SET”, and will displace pressing the nº 5 ó nº 6 keys to the nº 3 menu, “Programme adjustment”:

You will confirm this option by pressing again the nº 3 key, “SET”, then you will indicate to the machine that

you want to access to the programme menu.

To visualize differents submenu you have to press the nº 5 and nº 6 keys.

Submenu 03-01- Enable crono

On this submenu 03-01- Enable crono you indicate the stove you are going to program it. Pressing the nº 3

key, “SET” the following screen will appear:

As shown, on the left upper part will appear the word “OFF”, it will change to “ON” pressing the number 1

and 2. With this action you indicate the stove the intention to introduce some of the three programs:

Now you will choose the programme you want to introduce: daily, weekly or week-end. From the previous

screen you select the program pressing repeatedly the keys number 5 and 6 until you arrive to the chosen

option.

MEnu 03

ADJUSTMENT

PROGRAMME

oFF

M -3 -1 - 01

HABILITE

CHRONO

on

M -3 -1 - 01

HABILITE

CHRONO

Page 21

Submenu 03-02- Daily programme

Now you will consider i.e. you want to introduce a daily program on the stove. The you will have to place the

following screen:

Pressing just one time the nº 3 key, you will access to daily submenu programme of the stove, showing the

following screen:

You have to change the option “oFF” to “on” pressing the keys nº 1 or nº 2; you will confirm then the chosen

option.

Finally you will select the horary in which you want the stove remaining turned on. You have for it two

different starting hours and other two stopping hours: STAR 1 and STOP 1, STAR 2 and STOP 2.

I.e:

Starting up 09:00 hours / Shutting down 14:30 hours

Starting up 20:30 hours / Shutting down 23:00 hours

M -3 -2

DAY

PROGRAMME

oFF

M -3 -2 - 01

DAILY

PROGRAMME

on

M -3 -2 - 01

DAILY

PROGRAMME

Page 22

From the previous screen, pressing the nº 6 key will appear:

Pressing the nº 1 and nº 2 keys, you modify the value “oFF” and fix the first hour starting:

You will proceed equally to fix the first hour stopping:

oFF

M -3 -2 - 02

START 1

DAY

09:00

M -3 -2 - 02

START 1

DAY

oFF

M -3 -2 - 03

STOP 1

DAY

14:30

M -3 -2 - 03

STOP 1

DAY

Page 23

You will have to precede the same way as explained to introduce the second hour starting and stopping:

Now the daily programme of the stove is carried out with two starting hours and two stopping hours. In case

you need to program just one starting hour and one stopping hour, the option STAR 2 must indicate “oFF” as

well as the STOP 2 option must indicate “oFF”.

It is also possible to programme one starting hour START 1: 08:00 hours and a manual shutting down STOP 2 :

“oFF”. Or a manual starting START 1: “oFF”, and a stopping hour STOP 1: 22:00 hours.

Submenu 03-03- Weekly Programme

NOTE: Carrying out a carefully programme should avoid the operating hours superposition and/or inactivate

the same day on different programs.

For a weekly programming of the stove, you have to consider that 4 different starting hours and 4 different

stopping hours are available, then you will have to assign for each day of the week the activating or not of the

stove and to determinate a time interval. You will start from the following screen:

20:30

M -3 -2 - 04

START 2

DAY

23:00

M -3 -2 - 05

STOP 2

DAY

M -3 - 3

PROGRAMME

WEEK

Page 24

You will accede to the weekly programme submenu pressing the nº 3 key. The following screen will be

shown:

Change the option “oFF” to “on” pressing the keys nº 1 or nº 2, you will confirm the stove that daily

programme has been chosen:

Finally we will choose the horary; four different hours of starting and stopping are available:

- PROGRAM 1: STAR 1 and STOP 1

- PROGRAM 2: STAR 2 and STOP 2

- PROGRAM 3: STAR 3 and STOP 3

- PROGRAM 4: STAR 4 and STOP 4.

oFF

M -3 -3 - 01

PROGRAMME

WEEK

on

M -3 -3 - 01

PROGRAMME

WEEK

12:00

M -3 -3 - 02

START

PROG - 1

Page 25

After that, select the activation or deactivation of every program according to the day of the week, i.e.:

Program 1: Monday (on), Tuesday (on), Wednesday (oFF), Thursday (oFF), Friday (on), Saturday (on) and

Sunday (oFF).

Program 2: Monday (oFF), Tuesday (oFF), Wednesday (on), Thursday (oFF), Friday (oFF), Saturday (on) and

Sunday (on).

Program 3: Monday (oFF), Tuesday (on), Wednesday (on), Thursday (on), Friday (on), Saturday (on) and

Sunday (oFF).

Program 4: Monday (on), Tuesday (on), Wednesday (oFF), Thursday (oFF), Friday (oF), Saturday (oFF) and

Sunday (on).

Thanks to this kind of programming you will be able to combine 4 different horary along the days of the week

as your desire; be always care not to superimpose the horary.

Submenu 03-04- Programme Week-end

As on the daily program, this programming has two independent starting and stopping available hours, but

this time is only for Saturday and Sunday. To configure it you will start from the following screen:

To confirm the access to this programme, press the nº 3 key “SET”; the following screen will appear:

on

M -3 -3 - 04

MONDAY

PROG - 1

M -3 - 4

PROGRAMME

WEEK-END

oFF

M -3 -4 - 01

PROGRAMME

WEEK-END

Page 26

Modify the value “oFF” and select “on”:

Finally to complete the programming you have to introduce the starting and stopping hours as desired.

As mentioned, in case you need to program just one starting and stopping hour, the option STAR 2 has to

indicate “oFF” and the option STOP 2, “oFF” too.

It is also possible to program one starting hour START 1: 08:00 hours and a manual shutting down STOP 2:

“oFF”. Or a manual starting START 1: “oFF” and a stopping hour STOP 1: 22:00 hour.

9.4.5 Menu 4. Language selection

This option allows selecting the dialogue language between those available.

9.4.6 Menu 5. Stand-by mode

If you activate this option, the stove will shut down when it reaches the consigned temperature + a 4º C

differential previously introduced into the display. When the room temperature falls below the consigned

temperature – a 4º C differential, the stove carries out again an automatic starting cycle.

In case this function remains deactivated, and also from factory comes in mode “off”, when the stove reaches

the consigned temperature, it will always remain on “modulation working”, being able to overcome the

dependence, the value of the established consigned temperature.

9.4.7 Menu 6- Sonorous mode

When this mode is activated, the stove emit a sound if any anomaly is detected, getting into the alarm stage.

9.4.8 Menu 7. Initial charge

Con la estufa apagada y fría podemos efectuar una precarga de pellet durante un tiempo máximo de 90”.

Para iniciar la carga pulse la tecla 1 y para interrumpirla pulse la tecla 4.

MENU LEVEL

Menu 04

DIALOGUE

SPA

on

M -3 -4 - 01

PROGRAMME

WEEK-END

Page 27

9.4.9 Menu 8- Stove stage

It visualizes the current stage of the stove and informs about the connected devices stage.

22º C

DIALOGUE

INITIAL

CHARGE

TIME

AMBIANCE TEMPERATURE

76”

1

4

ALARM RETARD

RAL. 20

STAGE 4

TIME 1

REMAINING TIME

10”

82 ‘

OPERATIVE STAGE

STAGE

INTERCHANGER 2,3 SPEED

V1 - 2 V3 - 3

STAGE 4

SMOKE TEMPERATURE

117 ºC

1100

STAGE

SMOKE AHS VACUUM SPEED

OPERATIVE STAGE

Page 28

9.5 User mode

Now it is described the usual operation of the display installed into an air stove with reference to the available

options.

Before the ignition, the stove display remains as per it is shown on the following picture. Fig. 17

Fig. 17

CURRENT ALARM

ASPIRATION

FAILURE

STAGE

DIALOGUE

SHUT DOWN

HOUR

AMBIANCE TEMPERATURE

14:24

21 ºC

POWER

P - 2

CARGA

SINFÍN SPEED

POWER

1.5”

P - 5

DIALOGUE

Page 29

9.5.1 Starting up stove

To start up the stove, please press the nº 4 key for a few seconds. The starting up message will appear on the

display screen as shown in picture nº 18.de

estufa puls

18

Fig. 18

This starting phase has 20 minutes as maximum duration, if passed this time a visible flame has not appeared,

automatically the stove will come into the alarm stage. The screen will show the message “

Starting Failure”.

9.5.2 Operation stove

Once the smoke consigned temperature is reached, the warm air fan starts operating. The auxiliary fans (in

case the stove has it) will start operating only if they are enable.

When the starting phase is finished, the stove come into the

“Working”

mode, which represents the usual

operation mode.

Fig. 19

DIALOGUE

START

HOUR

AMBIANCE TEMPERATURE

14:35

21 ºC

POWER

P - 2

4

DIALOGUE

WORKING

HOUR

AMBIANCE TEMPERATURE

15:18

21 ºC

POWER

P - 3

Page 30

9.5.3 Consigned ambiance temperature changing

For modifying the consigned ambiance temperature, please press the nº 2 key to accede to the ambience

temperature set and then keys 1 and 2 for rising or decreasing respectively the temperature. The display

shows the current ambiance temperature.

Fig. 20

Fig. 20

9.5.4 User fixed temperature reached by the ambiance temperature…

When the ambience temperature reaches the value fixed by the user, or the smoke temperature reaches a too

high level, the stove will come into operating in the minimal power. See picture 21.

Figura 21

If the “

Stand-by mode”

is activated, when the ambience temperature reaches the temperature fixed by the

user, the stove shuts down automatically and come into the stand-by mode until the ambience temperature

decreases below the fixed temperature. Then the stove will start up again automatically.

DIALOGUE

SET TEMP.

AMBIANCE

IMPOSED VALUE

28 ºC

1 2 DIALOGUE

WORKING

MODULATION

HOUR

AMBIENCE TEMPERATURE

16:40

27 ºC

POWER

P - 2

Page 31

9.5.5 Burn pot automatic cleaning

During the usual operation of the stove, automatic cleanings take place on the burn pot every 90 minutes.

This cleaning takes 2 minutes and cleans the pellet remains which are deposited on the burn pot to keep the

stove in working order.

9.5.6 Shutdown stove

For shutting down the stove you just have to press the key nº 4 for a few seconds. Once the stove is turned

off, the stove starts the final cleaning phase, in which the pellet feeder stops and the smoke extractor is

operating with the maximum speed. This cleaning phase will do not finish until the stove reaches the accurate

cooling temperature.

9.5.7 Shutted off stove

In the picture 22 is shown the information on the screen when the stove is shutted down.

Fig.22

DIALOGUE

CLEANING

BURN POT

HOUR

AMBIENCE TEMPERATURE

16:40

22 ºC

POWER

P - 2

DIALOGUE

HOUR

AMBIENCE TEMPERATURE

POWER

FINAL

CLEANING

21:10

23 ºC

P - 3

DIALOGUE

HOUR

AMBIENCE TEMPERATURE

POWER

SHUT DOWN

21:10

22 ºC

P - 1

Page 32

9.5.8 Re-starting up stove

Once the stove is turned off, it will not be able to start it up again until a safety time has passed and the stove

is cool enough. If you try to start up the stove, on the screen will appear a message as shown on the picture nº

23

Fig. 23

9.6 What happens if…?

9.6.1 Pellet fuel do not light

In case of starting up failure, a message will appear on the display screen as shown on the picture

24.

Fig.24

To deactivate the alarm press the key nº 4 and the stove will come into the normally.

9.6.2 Electrical supply failure (Back out).

If a power outage takes place, when it is back again the stove will come into the

Final Cleaning

phase, until

the temperature of the stove reaches the accurate cooling temperature. Once this phase is finished, the stove

will remain shut down until the user starts it up again.

DIALOGUE

WAITING

COOLING

STARTING UP

FAILURE

FINAL

CLEANING

Page 33

9.7 Alarms

In case of any anomaly appears while operating, the electronic system of the stove will come in to show the

irregularities produced during the different operating modes, always depending on the type of anomaly.

Each alarm situation causes an automatic blockage on the stove. Pressing over the key nº 4 you will release

the stove. Once it reaches the accurate cooling temperature, the user will be able to start it up again.

9.7.1 Alarm smokes temperature probe

This alarm appears when the probe which detects the exit smoke temperature is broken or disconnected.

During this alarm phase, the stove will execute the shutting down procedure.

9.7.2 Alarm smoke excess temperature

It happens when the probe detects a smoke temperature over 250º C. Then on the display screen is shown

the following message.

Picture 25.

Fig. 25

During this alarm phase, the stove will execute the shutting down procedure.

9.7.3 Alarm starting up failure

It happens when the starting up phase is not properly executed. On the display screen a message like in the

nº

26 Picture

will be shown, and the shutting down procedure immediately activated.

Fig. 26

ALARM

PROBE

ALARM

TEMP. SMOKE

STARTING UP

FAILURE

Page 34

9.7.4 Alarm shutdown during work phase

If the flame gets shut down along the working phase, and the smoke temperature decrease below the

established minimal, an alarm as shown in the nº 27 Picture will happen, and the shutting down procedure

will immediately be activated.

Fig. 27

9.7.5 Alarm damaged extraction smokes fan

It happens when the smoke extraction fan is broken down. If this takes place, the stove shuts down and an

alarm advice appears on the display screen as in the nº 28 Picture.

Fig. 28

ALARM

NO FIRE

ASPIRATION

FAILURE

Page 35

ALARM

CODE

DESCRIPTION

PROBLEM

PROBABLY SOLUTION

AL1

BACK OUT

THE STOVE IS TEMPORALY

WITHOUT ELECTRICAL

CURRENT

Press the key nº 4 for some seconds and let

finish the final cleaning. The stove will come

back to the shut down mode.

AL2

SMOKE PROBE

PROBLEM ON THE SMOKE

PROBE

Check the probe connexion or replace it.

AL3

SMOKE TEMP.

SMOKE TEMPERATURE IS

ABOVE 270º C

Regulate the pellet fall and/or extractor

speed. Verify the kind of fuel used.

AL4

BROKEN

DOWN

EXTRACTOR

PROBLEM ON THE SMOKE

EXTRACTOR

Check the extractor electrical connexion or

replace it.

AL5

STARTING UP

FAILURE

THE PELLET FUEL DOES NOT

FALL AND BURN UP

Check the gearmotor operation and the

resistor. Check a probably blockage on the

worm screw. Check there are pellet on the

hopper.

AL6

NO PELLET

THERE IS NO PELLET ON THE

HOPPER OR DO NOT FALL

INTO THE BURNER POT

Fill the hopper. Check the worm screw

operation. Check the pellet length and if it is

caked. Clean the back of the hopper.

AL7

THERMAL

ALARM

THE PELLET SAFETY

THERMOSTAT HAS GONE

OFF

Rearm manually the thermostat. Check the

reason why the excess temperature has

caused the overheating (pellet fall, chimney

excess, type of fuel, tangential turbine

operation).

AL8

DEPRESSION

THE COMBUSTION CHAMBER

IS ON DEPRESSION

Verify the combustion chamber is hermetic:

check the locks, hermetic joints…etc. Check

the accurate gas expulsion installation

(excess of horizontal flights, elbows…etc).

Probably pellet blockage.

AL 9

LACK OF FLOW

Lack of primary air flow or

inadequate installation

Check the primary air entrance. Installation verifying

(excess horizontal section, curves, dirt, etc)

AL

DIRTY FLOWMETER

Flowmeter sensor is dirty

Clean the flow sensor to take reading correctly.

AL

FLOWMETER

FAILURE

Flow sensor is broken

Replace the flow sensor

AL b

WORM SCREW

FAILURE

Worm screw turns constantly

Verify the electric conection of the worm screw

Page 36

10 GENERAL MEASURES

Page 37

Please, do not hesitate

to contact your dealer for further information.

Loading...

Loading...