Broil King 9202-54 Owner's Manual

PLEASE RECORD YOUR MODEL NUMBER,

HERE.

This information can be found on the silver and black OMC

caution sticker inside the lid of your stove.

Number

Number

/

/

DD

MM

YYYY

OWNER’S MANUAL

FOR USE WITH L.P. (LIQUID PETROLEUM) GAS

IN CANADA, PROPANE GAS

ANSI Z21.72-2016 / CSA 11.2-2016

BROIL KING MODEL #: 9202-54

CONTENTS

SAFETY ................................................................................ 2

INSTALLATION ............................................................ 2

L.P. GAS CYLINDER – 1Lb ................................................. 3

L.P. GAS CYLINDER – 20Lb ............................................... 4

OPD EQUIPPED CYLINDER ............................................... 5

HOSE AND REGULATOR ................................................... 5

LEAK TESTING ................................................................... 6

VENTURI TUBES ................................................................. 7

LIGHTING ............................................................................. 8

TRANSPORTING ................................................................. 9

MAINTENANCE ................................................................... 10

TROUBLESHOOTING ......................................................... 11

WARRANTY ......................................................................... 12

GUIDE DU PROPRIÉTAIRE DE BARBECUE AU

MANUAL DEL USUARIO DE PARRILLA A GAS ............... 25

READ ALL INSTRUCTIONS CAREFULLY BEFORE OPERATING YOUR GAS

RETAIN THESE INSTRUCTIONS FOR FUTURE

FOR ASSEMBLY INSTRUCTION, PLEASE SEE YOUR ASSEMBLY MANUAL.

VISIT www.omcbbq.com TO VIEW OUR ASSEMBLY

1-800-265-2150

info@omcbbq.com

GAZ

...... 13

WARNING

FIRE OR EXPLOSION HAZARD

IF YOU SMELL GAS:

1. DO NOT ATTEMPT TO LIGHT THE

APPLIANCE

2. EXTINGUISH ANY OPEN FLAME

3. DISCONNECT FROM FUEL SUPPLY

4. EVACUATE IMMEDIATELY

5. ALLOW GAS TO DISSIPATE 5 MINUTES

BEFORE RELIGHTING THE APPLIANCE

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN FIRE OR EXPLOSION,

WHICH COULD CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

SERIAL NUMBER AND DATE OF PURCHASE

Model

Serial

Date of Purchase

OR

-

-

REFERENCE.

STOVE.

VIDEOS

10095-05LP REV A 01/17

SAFETY INSTALLATION

FOR YOUR SAFETY

this or any other appliance.

DANGER

CARBON MONOXIDE HAZARD

HOME.

Your new OMC gas stove is a safe, convenient appliance

when assembled and used properly. As with all gas-fired

products, however, certain safeguards must be observed.

Failure to follow these safeguards may result in

serious injury or damage. If you have questions

concerning assembly or operation, consult your dealer,

gas appliance specialist, Gas Company or our direct

customer service line at 1-800-265-2150.

info@omcbbq.com

CAUTION

• FOR OUTDOOR USE ONLY.

• IF STORED INDOORS, DETACH AND LEAVE

CYLINDER OUTDOORS.

• THIS APPLIANCE MUST NOT BE OPERATED

UNATTENDED.

• SPECIAL CARE MUST BE TAKEN TO KEEP SMALL

CHILDREN AWAY FROM HEATED SURFACES.

Use caution when handling or transporting this

product. Metal edges can be hazardous. Use

appropriate gloves when lifting or handling. Before

lifting, remove side shelves, grids and grates.

PROPOSITION 65 WARNING

Handling the brass material on this product exposes you to

lead, a chemical known to the state of California to cause

cancer, birth defects or other reproductive harm. WASH

YOUR HANDS AFTER HANDLING THIS PRODUCT.

WARNING

Fuels used in gas or oil-fired appliances, and the produc ts

of combustion of such fuels, contain chemicals known

to the State of California to cause cancer, birth

defects or other reproductive harm. “This warning is

issued pursuant to California Health and Safety Code Sec.

25249.6”

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

THIS APPLIANCE CAN

PRODUCE CARBON MONOXIDE

WHICH HAS NO ODOR.

USING IT IN AN ENCLOSED

SPACE CAN KILL YOU.

NEVER USE THIS APPLIANCE IN

AN ENCLOSED SPACE SUCH

AS A CAMPER, TENT, CAR OR

1. In the U.S.A., this appliance must be installed in

accordance with the local code and the rele va nt nati on al

code:

ANSI Z223.1/NFPA 54 - Latest Edition National Fuel

Gas Code and Latest Local Codes where Applicable

2. In Canada, this appliance must be installed in

accordance with the local code and the relevant CSA

standards:

CSA-B149.1 Natural Gas and Propane installation

Code

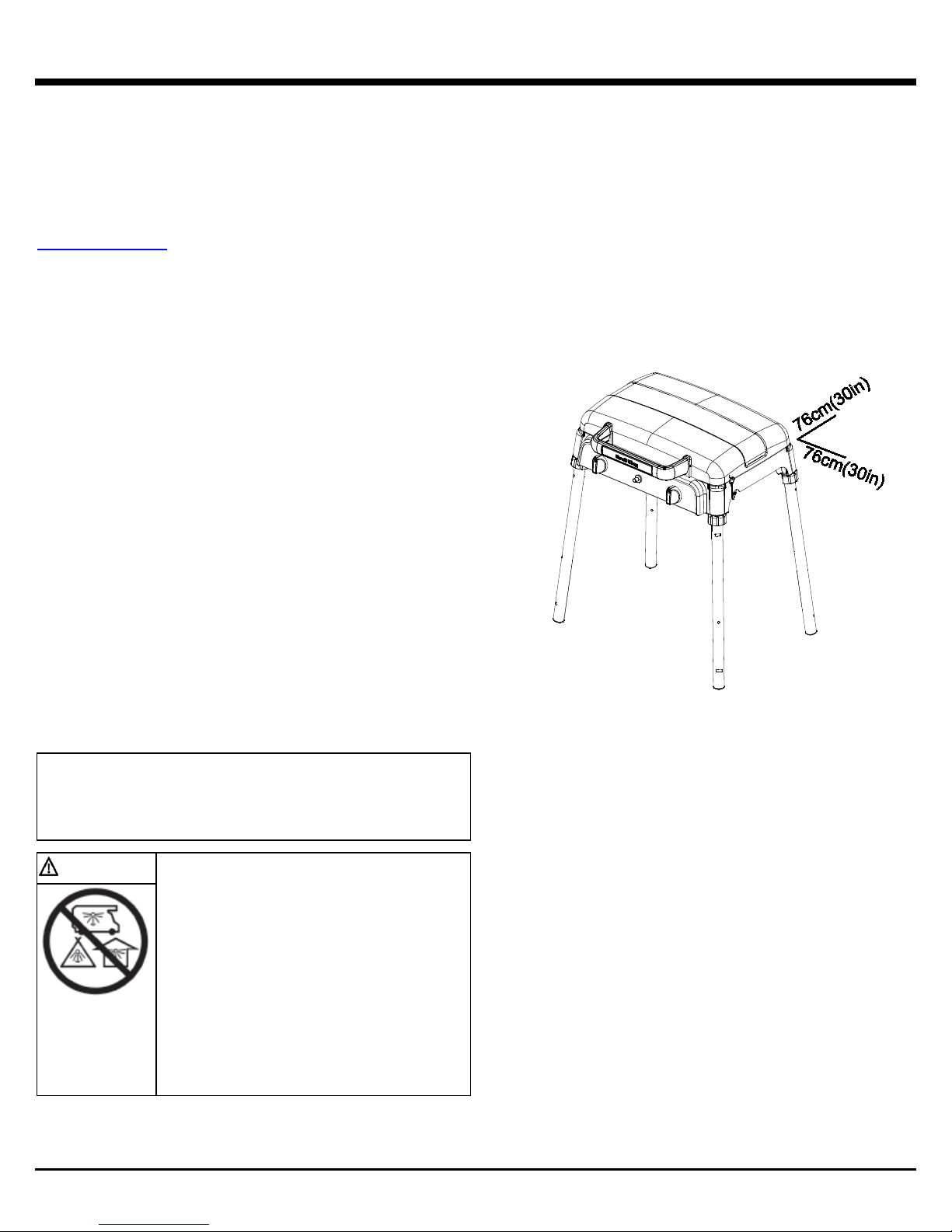

3. The appliance must be located away from combustible

surfaces by at least 76cm / 30” from each side, and

76cm / 30” from the rear.

4. Do not operate this appliance under any overhead

roof construction or foliage.

5. This appliance is for OUTDOOR USE ONLY, DO

NOT operate in garage, shed, balcony or other such

enclosed areas.

6. DO NOT restrict the flow of air to the

appliance.

7. Keep the area surrounding the appliance free

of combustible materials, gasoline, and all flammable

liquids and vapors.

8. This appliance is not intended to be installed in, or

on, recreational vehicles and/or boats.

9. Do not move the appliance while in use.

10. Do not use on tables exceeding 30 in. (76cm) in height

LP GAS CYLINDER PLACEMENT

The instructions below apply to LP models only. LP gas

cylinders must be installed according to assembly

instructions using retainer provided. Do not store a spare

cylinder under or near this appliance. All cylinders used

must be compatible with supplied means of cylinder

retention.

2

LP GAS CYLINDER – 1Lb

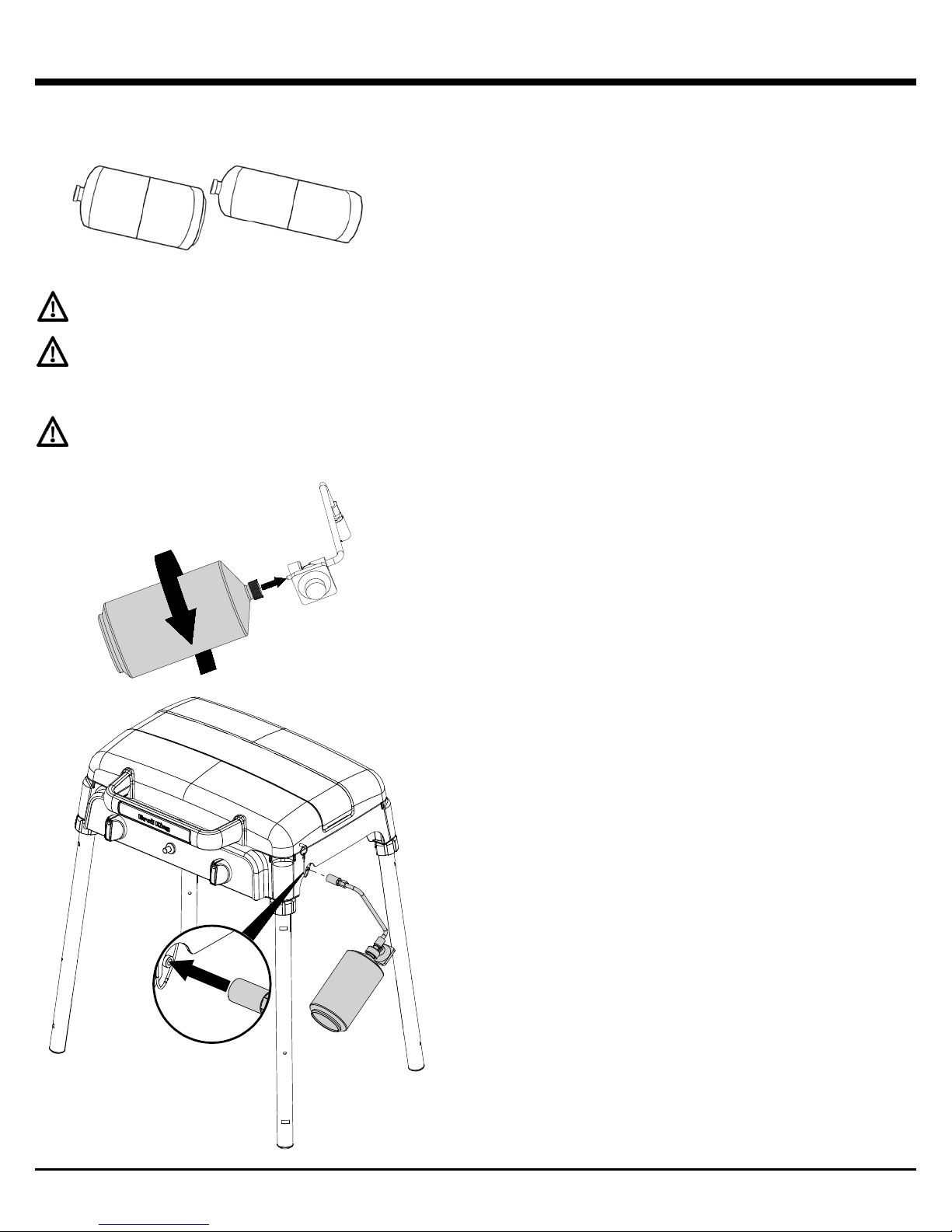

Use propane cylinders with a capacity of 14.1 oz or 16.4 oz.

You can find these tanks in the camping, hardware or

plumbing section of the store you are shopping at.

16.4oz (1.02 lbs.) 14.1oz (0.88 lbs.)

CAUTION: Use cylinders that are marked “propane

fuel” only.

NOTE: Your stove is equipped with a cylinder

supply system designed for vapor withdrawal.

While holding the regulator with one hand, pus h propane

cylinder into regulator and turn clockwise until tight.

WARNING: Do not use a wrench to tighten the

connection. Using a wrench could damage the

regulator coupling and could cause a leak.

SPECIFICATION

1. All LP gas cylinders used with this appliance must

be constructed and marked in accordance with the

Specifications for LP Gas Cylinders of the U.S.

Department of Transportation (D.O.T.) or the National

Standard of Canada, CAN/CSA-B339, Cylinders,

Spheres and Tubes for Transportation of Dangerous

Goods ; and Commission, as applicable.

2. The LP gas cylinder used for this appliance must not have

a capacity larger than 16.4 oz. (.5 kg). Approximately 8”

(20cm) high 3.9” (10cm) diameter.

3. The cylinder must be installed as per assembly

instructions.

STORAGE

1. Store the LP gas cylinder outdoors in a well-ventilated

place.

2. Do not store the LP gas cylinder in direct sunlight, near a

source of heat or combustion.

3. If you intend to store the stove indoors, disconnect and

remove the LP gas cylinder first. Disconnected cylinders

must have a dust cap installed and must not be stored in

a building, garage or any enclosed area.

4. Keep out of the reach of children.

5. When the LP gas cylinder is connected to the gas stove,

the gas stove and LP gas cylinder must be stored outside

in a well-ventilated place.

OPERATION

1. Never connect your gas stove to an LP gas cylinder

without the regulator provided, and NEVER TO AN

UNREGULATED LP GAS SUPPLY. The regulator

supplied with the barbecue must be used.

2. Always leak test the LP gas cylinder to regulator

connection when connecting the LP gas cylinder to the

appliance. See “Leak Testing.”

3. Do not operate appliance if the smell of LP gas is

present. Extinguish all flame and determine source of LP

gas before proceeding. Do not ignite the appliance until

the LP gas leak has been found and sealed.

4. Always shut off LP gas cylinder valve when the appliance

is not in use.

3

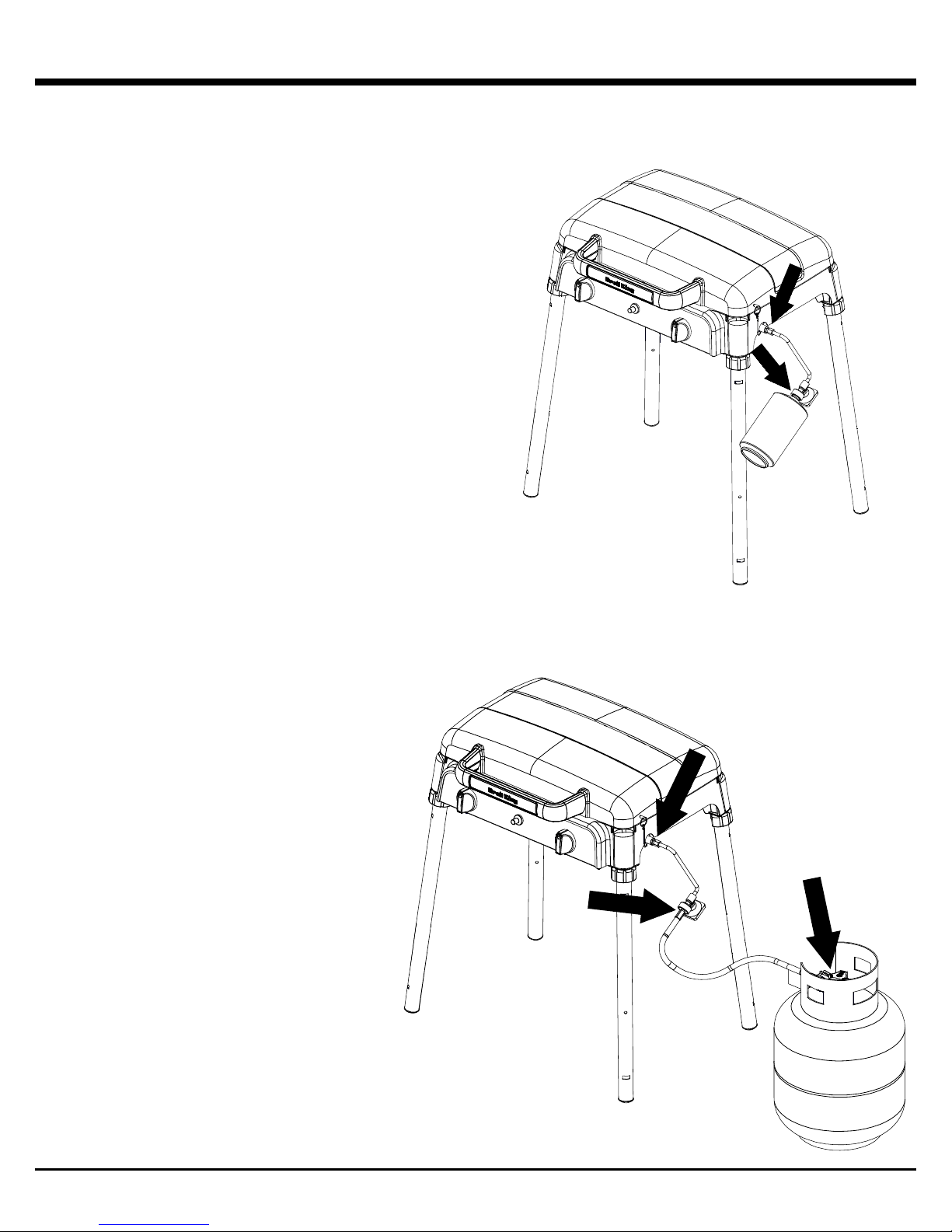

LP GAS CYLINDER – 20Lb

QCC®-1 QUICK CLOSING COUPLING

1. All OMC models are designed to be used with an LP gas

cylinder equipped with the QCC®-1 Quick Closing

Coupling system.

2. The QCC®-1 system incorporates safety features required

by the American National Standards Institute (ANSI) and

the Canadian Standards Steering Committee.

• Gas will not flow until a positive connection has been

made.

• A thermal element will shut off the flow of gas between 240°

and 300° F.

• When activated, a Flow Limiting Device will limit the flow of

gas to 10 cubic feet / hour.

3. The LP Gas Cylinder is not included with the Gas

Stove. Be sure to purchase one with the QCC® valve.

This valve is recognized by the external threads on the

inlet port of the valve. QCC® equipped cylinders are

available from your Gas Stove Dealer.

NOTE: Any attempt to connect the regulator, by use of

adapters or any other means, to any other valve could

result in damage, fire or injury and may negate the

important safety features in the QCC®-1 system.

SPECIFICATION

1. All LP gas cylinders used with this appliance must

be constructed and marked in accordance with the

Specifications for LP Gas Cylinders of the U.S.

Department of Transportation (D.O.T.) or the National

Standard of Canada, CAN/CSA-B339, Cylinders,

Spheres and Tubes for Transportation of Dangerous

Goods ; and Commission, as applicable

2. The LP gas cylinder used for this appliance must not

have a capacity exceeding 20 lb. (9 kg).

• Approximately 18” (46cm) high and 12” (31cm)

Diameter.

3. All LP gas cylinders used with this appliance should be

inspected at every filling and re qualified by a licensed

service outlet at the expiry date (10 years), in accordance

with the DOT (USA) and Canadian Transport

Commission (Canada) codes for LP Gas Cylinders.

4. All LP gas cylinders used with this appliance must be

provided with a shutoff valve terminating in a cylinder

valve outlet No. 510, specified in the Standard for

Compressed Gas Cylinder Valve Outlet and Inlet

Connection (USA) ANSI/CGA-V-1-1977 (Canada) CSA

B96.

5. The cylinder supply system must be arranged for vapor

withdrawal.

6. The cylinder must include a collar to protect the cylinder

valve.

7. The cylinder must be installed as per assembly

instructions.

8. Never fill the cylinder beyond 80% full. A fire causing

death or serious injury may occur.

9. The cylinder valve must include a safety relief device

having direct communication with the vapor space of the

cylinder.

HANDLING

1. Government regulations prohibit shipping full LP gas

cylinders. You must take your new cylinder to a LP gas

dealer for filling

2. A filled LP gas cylinder is under ver y high pres sur e.

Always handle carefully and transport in the upright

position. Protect the valve from accidental damage.

3. Do not tip the LP gas cylinder while connecting it to the

regulator. Fasten the cylinder securely during transport,

use and storage.

4. If the cylinder is tipped after it is connected to the

regulator, shut off the gas, disconnect the regulator and

have it checked before using it again.

STORAGE

1. Store the LP gas cylinder outdoors in a well-ventilated

place.

2. Do not store the LP gas cylinder in direct sunlight, near a

source of heat or combustion.

3. If you intend to store the stove indoors, disconnect and

remove the LP gas cylinder first. Disconnected cylinders

must have a dust cap installed and must not be stored in

a building, garage or any enclosed area.

4. Keep out of the reach of children.

5. When the LP gas cylinder is connected to the gas stove,

the gas stove and LP gas cylinder must be stored outside

in a well-ventilated place.

OPERATION

1. Never connect your gas stove to an LP gas cylinder

without the regulator provided, and NEVER TO AN

UNREGULATED LP GAS SUPPLY. The regulator

supplied with the stove must be used.

2. Always leak test the LP gas cylinder to regulator

connection when connecting the LP gas cylinder to the

appliance. See “Leak Testing.” (Page 6)

3. Do not operate appliance if the smell of LP gas is

present. Extinguish all flame and determine source of LP

gas before proceeding. Do not ignite the appliance until

the LP gas leak has been found and sealed.

4. Always shut off LP gas cylinder valve when the appliance

is not in use.

4

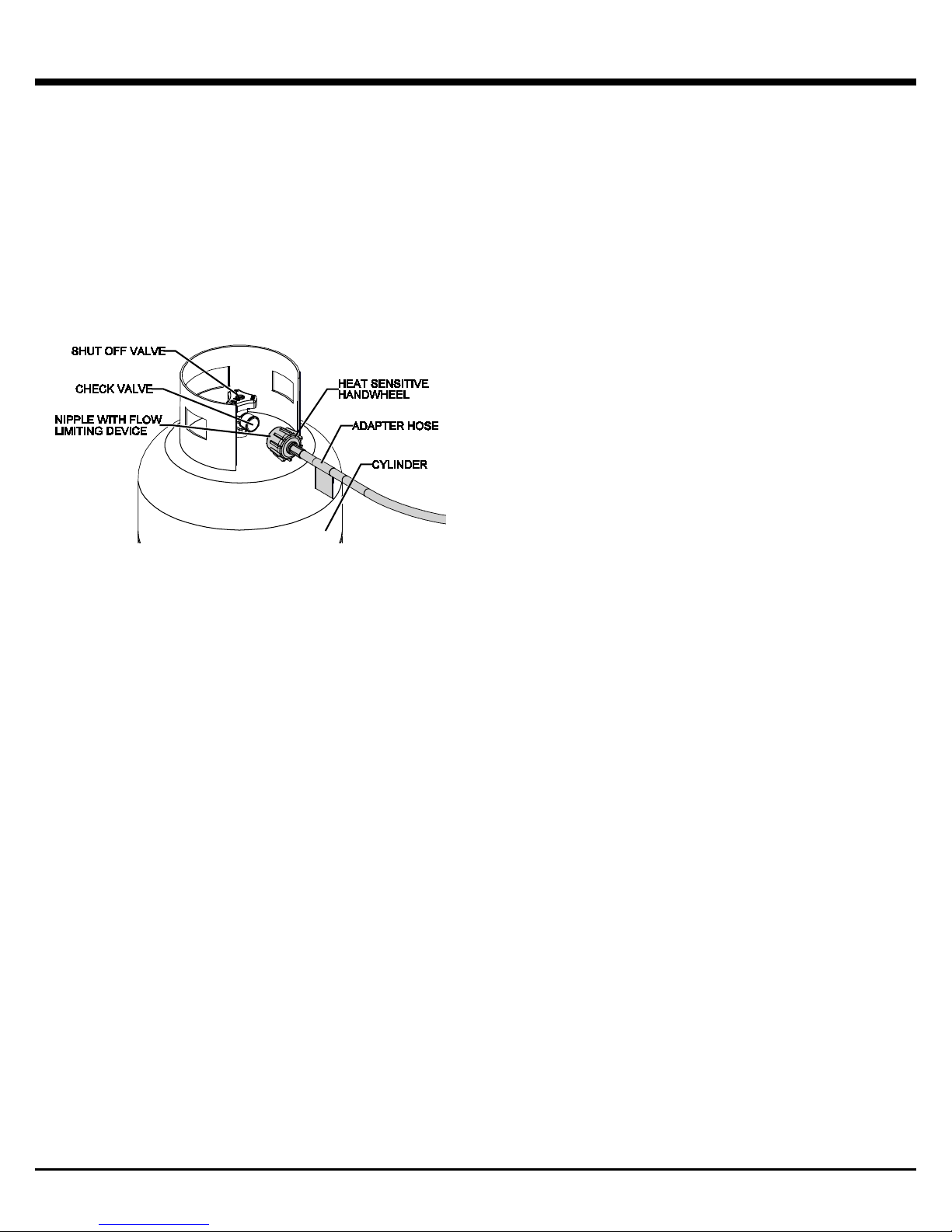

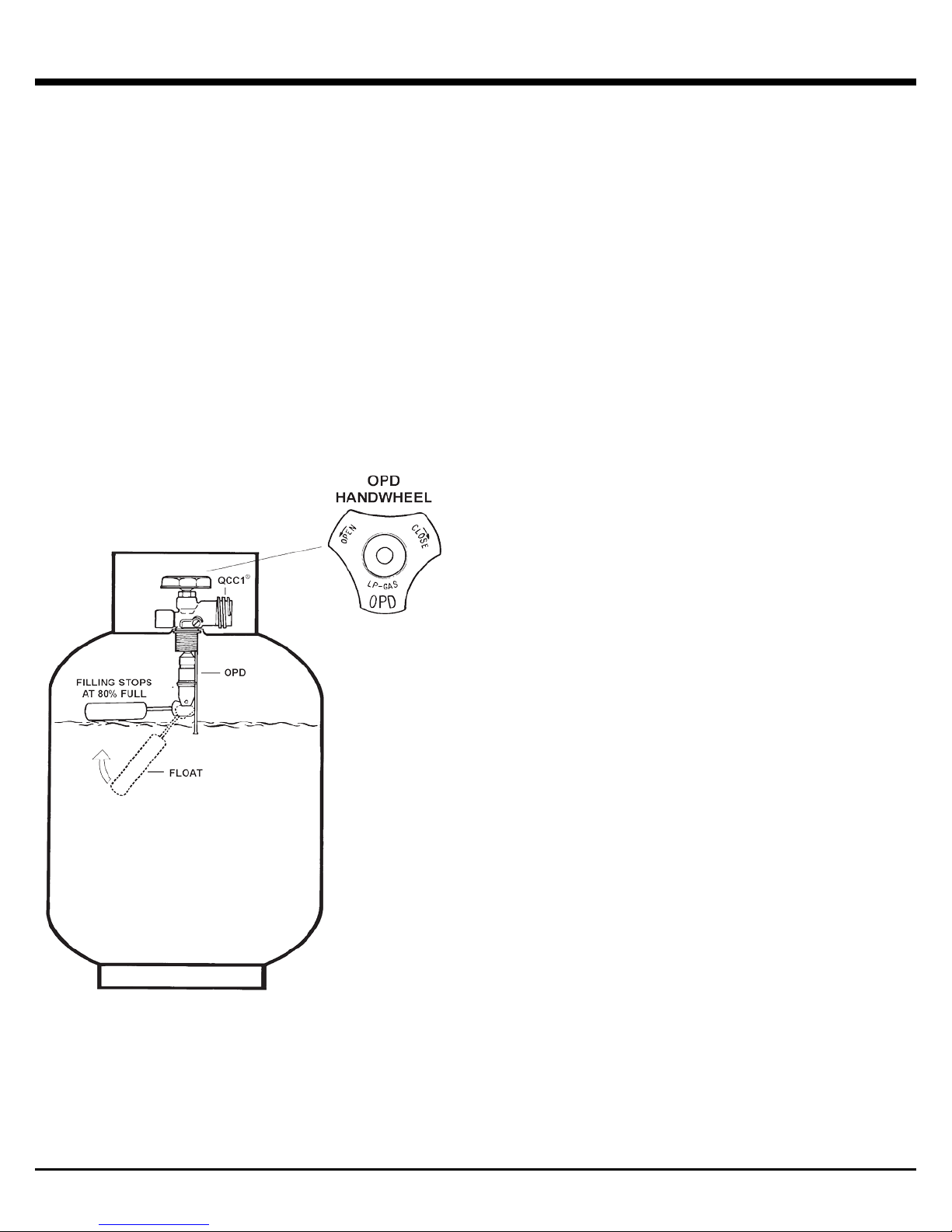

OPD EQUIPPED CYLINDER HOSE & REGULATOR

OVERFILL PREVENTION DEVICE

1. The standard for outdoor gas appliances, ANSI Z21.58/

CAN/CGA-1.6, requires that appliances be used with

cylinders equipped with an Overf ill Preve nti on Device

(OPD).

2. The OPD is designed to reduce the potential for the

overfilling of propane cylinders, thus reducing the

possibility of relief valve discharges of raw propane. The

OPD causes a slower purge/fill operation. Some

consumers have been advised by filling stations that these

cylinders are “defective.” This is not a defect. Some

propane filling stations may not be aware of this device and

its effect on the purge/fill operation.

3. New OPDs coming onto the market have technology that

allows for much greater BTU outputs which will decrease

the amount of time it takes to purge a cylinder.

IDENTIFICATION

To identify these cylinders, the OPD hand whe el has been

standardized to the shape shown.

1. All models are equipped with a hose and regulator with a

QCC®-1 Quick Closing Coupling.

2. The QCC® coupling contains a magnetic Flow Limiting

Device which will limit the flow of gas should there be a leak

between the regulator and the appliance valve. This device

will activate if the cylinder valve is opened while the

appliance valves are open. Be sure the appliance valves

are off before the cylinde r valve is opened to prevent

accidental activation.

3. The QCC® coupling incorporates a heat sens itive hand

wheel that will cause the back check module in the QCC®

cylinder valve to close when exposed to temperatures

between 240° and 300°F. Should this occur, do not attempt

to reconnect the hand wheel. Remove hose/regulator

assembly and replace with a new one.

4. The pressure regulator is set at 11 inches WC (water

column) and is for use with LP gas only. The hose and hose

couplings comply with CGA Standard CAN 1.83. No

modifications or substitutions should be attempted.

5. Protect the hose from dripping grease and do not allow the

hose to touch any hot surface, including the base casting

of the stove.

6. Inspect the seal in the QCC® cylinder valve when replacing

the LP gas cylinder or once per year whichever is more

frequent. Replace the seal if there is any indication of cracks,

creases, or abrasion.

7. Inspect the hose before each use. If the hose is cracked, cut,

abraded or damaged in any way, the appliance must not be

operated.

8. For repair or replacement of the hose/regulator assembly,

contact customer service.

CONNECTION

1. Be sure cylinder valve and applianc e valves are “OFF.”

2. Align the small end of the hose with the regulator fitting and

turn clockwise until tight.

3. Center the nipple in the cylinder valve and hold in place.

Using other hand, turn the hand wheel clockwise until there is

a positive stop. Do not use tools. Hand tighten only. When

making the connection, hold the regulator in a parallel

with the cylinder valve, so as not to cross thread the

connection.

4. Leak test connections. See “Leak Testing.” (Page 6)

5. Refer to lighting instructions. To avoid activating the Flow

Limiting Device when lighting, open cylinder valve

slowly with the appliance valves off. If the Flow Limiting

Device is accidentally activated, turn off cylinder valve and

appliance valves, wait 10 seconds to allow the device to

reset, open cylinder valve slowly, then open the appliance

valve.

DISCONNECTION

Always close LP cylinder valve and remove coupling nut before

moving cylinder from specified operation position.

5

LEAK TESTING

All factory-made connections have been rigorously tested

for gas leaks. However, shipping and handling may have

loosened a gas fitting.

AS A SAFETY PRECAUTION:

• Test all fittings for leaks before using your gas grill.

• Test the cylinder valve for leaks each time the

cylinder is filled.

• Test for leaks every time you connect a gas fitting.

• Do not smoke at any time while testing.

• Never test for leaks with a lit match or open flame.

• Test for leaks outdoors.

TO TEST FOR LEAKS:

1. Extinguish any open flame or cigarettes in the area.

2. Be sure that cylinder valve and gas grill valves are

“OFF.”

3. Connect LP gas cylinder. See “Hose and Regulator.”

4. Prepare a soap solution of one part water, one part

liquid detergent.

5. With a full gas cylinder, open cylinder slowly.

6. Brush the soap solution on each connection.

7. A leak is identified by a flow of bubbles from the area of

the leak.

8. If a leak is detected, close the gas cylinder “shut-off”

valve, tighten the connection and retest.

9. If the leak persists, contact your gas grill dealer for

assistance. Do not attempt to operate appliance if a

leak is present.

6

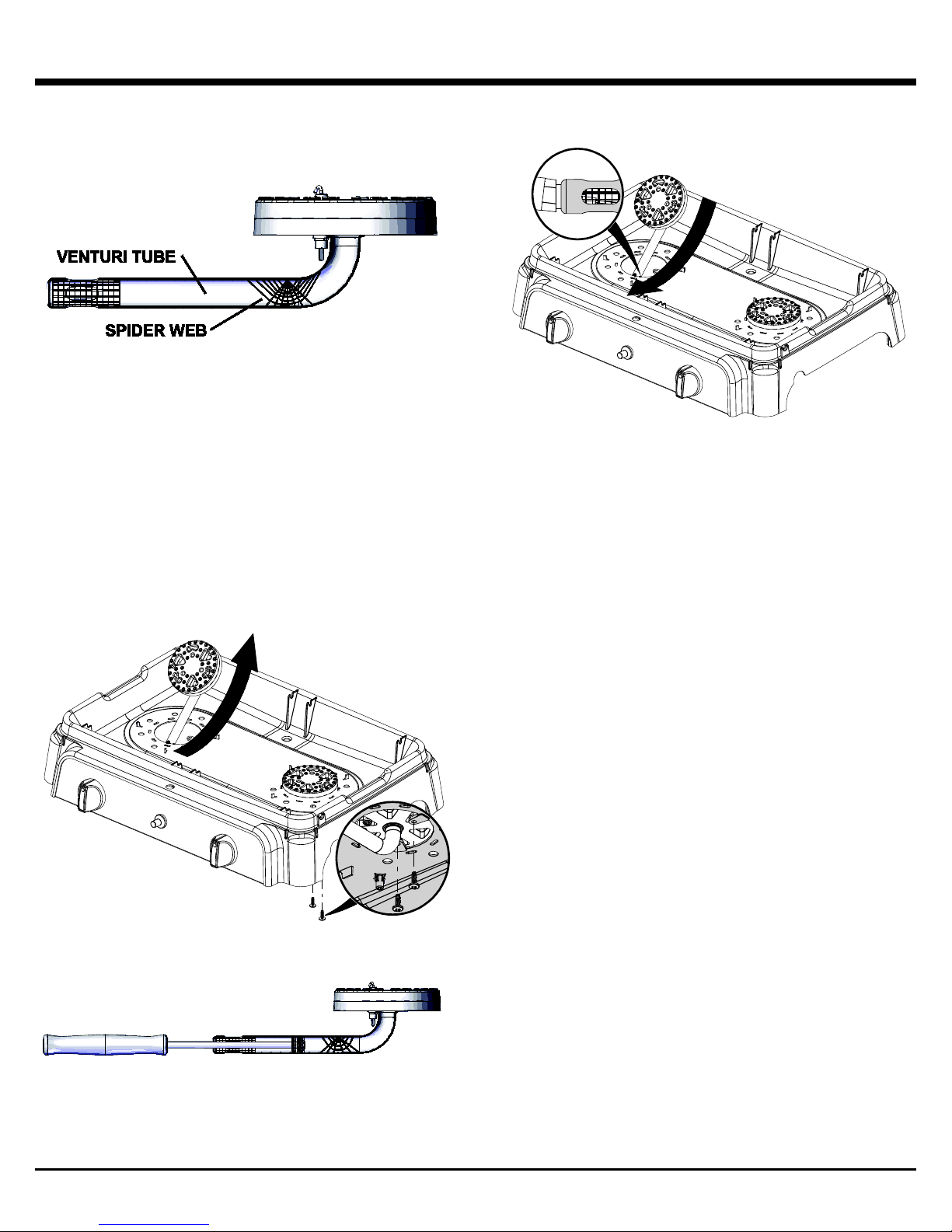

VENTURI TUBES

Always keep venturi tubes clean. Blockages in the venturi

tubes caused by spiders, insects and nests can cause a

flashback fire. In fact, although the gas stove may still

light, the backed up gas can ignite and cause a fire around

the venturi tubes at the control panel.

If a flashback fire occurs, turn off gas at the source

immediately

Inspect and clean the venturi if any of the following

symptoms occur:

1. You smell gas.

2. Your gas stove does not reach temperature.

3. Your gas stove heats unevenly.

4. The burners make popping noises.

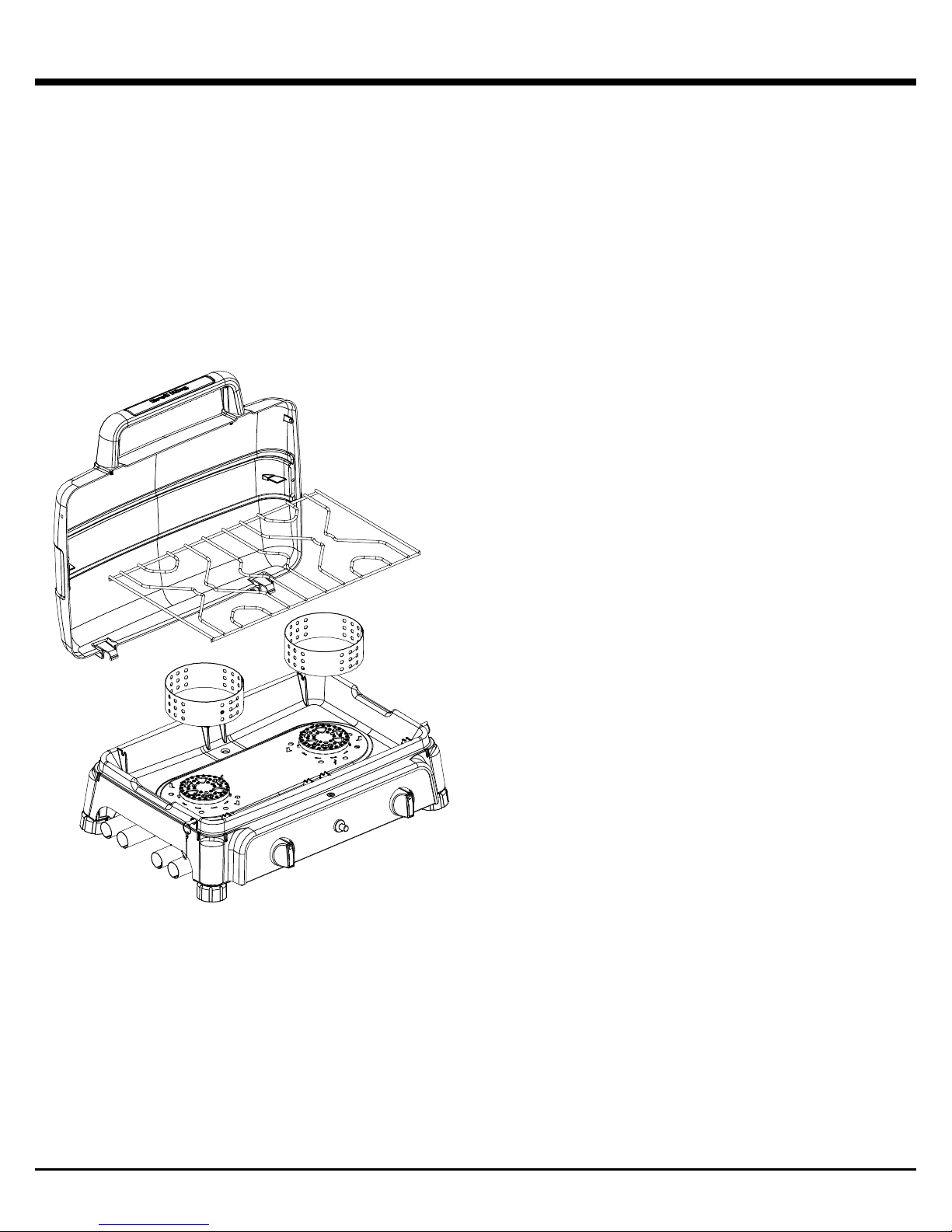

INSPECTING & CLEANING

1. Turn off gas by closing the propane cylinder valve

2. When gas stove is cool, remove the burner fasteners.

Proceed to lift the burners from the gas stove housing.

3. Clean the venturi tubes with a pipe cleaner or venturi

cleaning tool (Accessory #77310 or #18270).

4. Lower the burner into position in the gas stove

housing, making sure that the venturi tubes are

correctly aligned and fitted on the orifices.

5. Secure burners with burner fas teners .

7

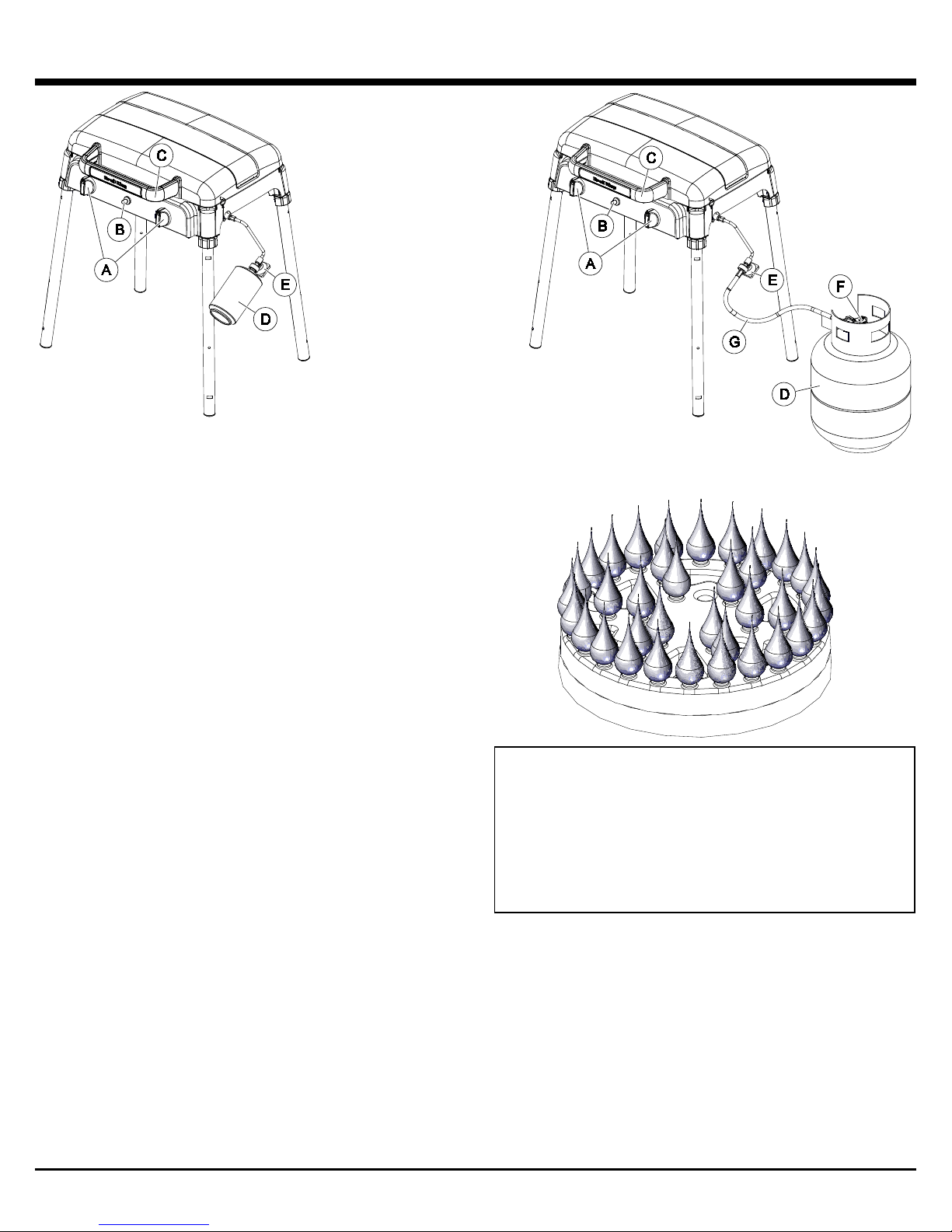

LIGHTING

A. BURNER CONTROL

B. IGNITOR

C. HANDLE

D. CYLINDER

E. REGULATOR

F. CYLINDER VALVE

G. CYLINDER ADAPTER HOSE

LIGHTING INSTRUCTIONS

1. The appliance must be assembled as per the

assembly instructions.

2. Ensure LP cylinder is full and properly connected to

the regulator.

3. Ensure there are no gas leaks in the gas supply

system. See: “Leak Testing.” (Page 6)

4. Ensure that the venturi tubes are properly located

over the gas valve orifices. See “Venturi Tubes.”

(Page 7)

5. Ensure that ignition wires are connec te d.

6. Carefully review all instructions on the information

plate attached to the gas stove.

7. WARNING: Always open lid before lighting and

do not lean over gas stove while lighting.

8. WARNING: Do not close lid when burners are lit

or hot.

9. Do not place food directly on the grid.

10. Set control knobs to “OFF” and turn on the gas supply.

LIGHTING THE BURNER:

a. Open gas stove lid and leave open.

b. Push and turn control knob to “HIGH.”

c. Push ignitor 3 or 4 times or use match to light.

d. Burner should ignite within 5 seconds; turn off gas

source immediately if ignition does not occur in this

timeframe.

CAUTION - Check your gas stove after lighting.

All burner ports should show a 2.5cm / 1” flame on “HIGH.”

If any of the following symptoms occur there is probably a

blockage in the venturi tubes. Shut off gas at once and

clean the venturi tubes. See “Venturi Tubes.” (page 7)

1. You smell gas.

2. A flashback fire occurs.

3. Your gas grill heats unevenly.

4. The burners make popping noises.

IF BURNER DOES NOT IGNITE:

1. Push and turn control knob to “OFF.” Wait 5 minutes

then try again with control knob set at “MEDIUM.”

2. If any burner will not light, see “Troubleshooting” (page

11). If problem persists, do not attempt to operate the

appliance; contact OMC, your dealer or an approved

service center.

SHUTDOWN:

1. Turn off cylinder valve.

2. Turn control knobs to “OFF.”

8

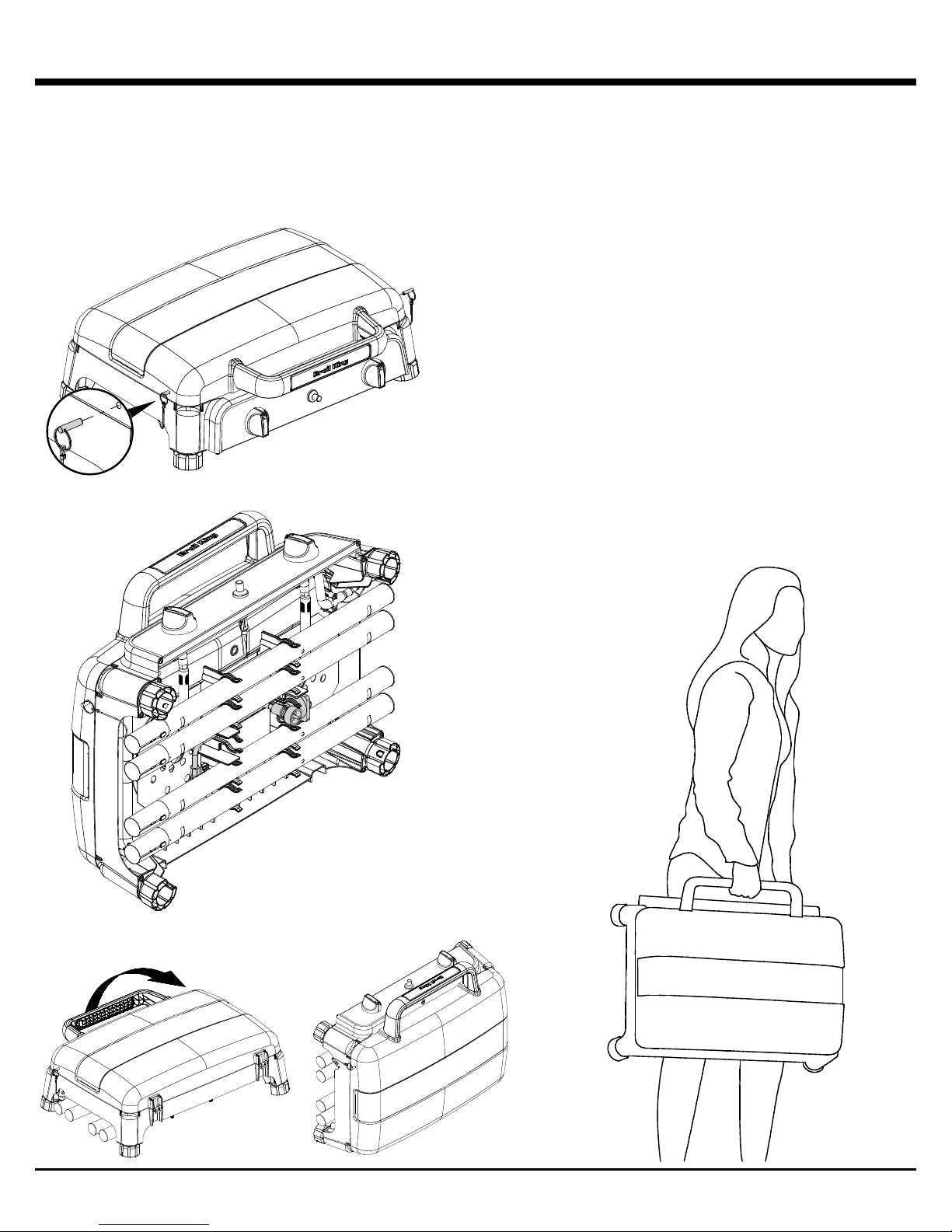

TRANSPORTING

• CAUTION HOT SURFACES

• Let the stove cool completely before cleaning,

maintenance, storage or transportation.

• Remove regulator adapter hose and propane tank

before storage or transportation.

Lock lid in closed position with locking pins.

1.

2. Ensure regulator and legs are secured into leg retainer.

3. Flip stove onto hinges to lift and carry like a suitcase.

9

MAINTENANCE

REGULAR MAINTENANCE

• CAUTION HOT SURFACES

• Let the stove cool completely before cleaning,

maintenance, storage or transportation.

TO CLEAN

1. Move stove away from flame and other ignition

sources.

2. Remove propane cylinder and regulator from stove.

3. Wipe surfaces clean with a damp soft cloth and a mild

dish detergent. DO NOT USE ABRASIVES.

4. You can disassemble some components of the stove

to assist in cleaning.

ANNUAL MAINTENANCE

The following components should be inspected and

cleaned at least once a year or after any period of storage

over 30 days to ensure optimal performance, safety and

efficiency.

BURNERS

Remove burners and inspect for cracks and deterioration.

Clean venturi tubes using a pipe cleaner or venturi brush

to eliminate any blockages. See “Venturi Tubes.” (Page 7)

While the burners are removed, clean the interior of stove

base.

HOSE

Inspect and replace if necessary.

EXTERIOR FINISH

If white oxidation spots appear, wash the outs ide of the

stove with a mild soap and water solution. Rinse the

surfaces thoroughly then wipe them with a cloth dipped in

cooking oil to restore the luster. For repair of paint

scratches and scuffs, use a good quality HIGH

temperature (600°F) spray paint for touch-up.

STAINLESS STEEL

Wash with soap and water. Use stainless steel cleaner to

polish and remove stains or marks. Weathering can cause

stainless steel to turn a tan color. This is discoloration and

is not considered a manufacturing defect.

RESIN COMPONENTS

Wash with soap and water.

REPLACEMENT PARTS

If a problem is found with the regulator, hose, burner, or

control valves, do not attempt repair. See your dealer,

approved service center, or contact the factory for repairs

or replacement parts. To ensure optimum performance,

use only original OMC replacement parts.

LEAK TEST

When reconnecting a gas cylinder on propane models, be

sure to check for leaks. See “Leak Testing.” (Page 6)

GRID

Use a light detergent and water and then rinse and dry

with paper towel; ne ver air dry grid or use a dishwasher.

10

TROUBLESHOOTING

Leak detected at cylinder,

1. Regulator fitting loose.

1. Tighten fitting and “Leak Test.” (Page 6).

Flames Beneath Control

1. Venturi blocked.

1. Remove burner and clean venturi. See “Venturi

Flickering Burner Flame or

1. Excess flow safety device has been

1. Turn LP cylinder valve off then turn all burners to

Burner Not Lighting

1. Out of LP Gas.

1. Refill LP Gas Cylinder.

Ignitor Not Working

1. Ignitor wire(s) not connected

1. Ensure main burner and side burner electrode

Decreasing Heat, “Popping

1. Out of LP Gas.

1. Refill LP Gas Cylinder.

Regulator Humming Noise

1. Cylinder valve opened too quickly.

1. Open cylinder valve slowly.

Yellow Flame

1. Some yellow flame is normal. If it is

1. Remove burner, clean venturi. See “Venturi Tubes”

If troubleshooting fails to solve any of these or any other issues, please visit www.omcbbq.com for more information including

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

SMELL OF GAS

regulator or other connection.

Panel (Flashback Fire)

Low Temperatures on HIGH

Setting

SHUT OFF LP CYLINDER VALVE AT ONCE.

DO NOT USE THE APPLIANCE UNTIL LEAK IS SEALED.

2. Gas leak in hose/regulator or control valves.

activated in connection between cylinder and

barbecue.

2. Ignitor issue.

3. Excess flow safety device has been activated.

4. Regulator is not fully connected to the cylinder

valve.

5. A leak in the system causing the excess flow

device to activate.

6. Venturi blocked or misaligned with valve

orifice.

7. Orifice(s) blocked.

8. Hose is twisted.

2. See authorized service center.

Tubes” (Page 7).

OFF position. Disconnect the regulator from the

cylinder. Wait two minutes. Re-attach regulator to

the cylinder. Open the cylinder valve slowly. Wait

one minute. Light grill as per “Lighting” (Page 8).

2. Try manually lighting burner with a match. See

“Lighting” (Page 8). If burner lights successfully, it

is an ignitor issue. See “Ignitor not Working” below

3. Follow “Flickering Flame or Low Temperatures on

HIGH setting” solution above.

4. Tighten the regulator hand wheel.

5. Leak test connections to determine loose fitting.

Tighten fitting. Leak test system.

6. Remove burner, clean venturi and realign with

valve orifice. See page 7 for assistance.

7. Remove burner, clean orifices with a pin or fine

wire. Do not drill orifices.

8. Straighten hose. Keep away from bottom casting.

2. Electrode misaligned on burner

3. Ignitor malfunction

Sound”

2. Venturi blocked.

excessive, the venturi may be blocked.

2. Burner ports blocked.

troubleshooting videos, tricks and tips or call customer service at 1-800-265-2150

wires are all connected

2. Realign electrode and clear any surrounding

debris from area

3. See “Lighting” procedure (Page 8).

2. Remove burner, clean venturi. See “Venturi Tubes”

(Page 7) for assistance.

(page 7) for assistance.

2. Remove burner & clean with soft bristle brush

(e.g. toothbrush).

11

Loading...

Loading...