Page 1

®

SilkWorm

Hardware Reference Manual

2400

Publication Number 53-0001533-01

Page 2

Copyright

1998, 1999, Brocade Communications Systems, Incorporated.

ALL RIGHTS RESERVED. 53-0001533-01

BROCADE

registered trademarks of Brocade Communications Systems, Inc., in the United States and/or in other

countries.

All other brands, products, or service names are o r may be trademar ks or service marks of, and are used

to identify, products or services of their respective owners.

Notice: This document is for infor matio nal purposes only and does not set forth any warrant y , express

or implied, concerning any equipment, equipment feature, or service offered . BROCADE reserves the

right to make changes to this docu ment at any time, without notice, and assumes no respon sibility for

its use.

Export of technical data contained in this document may r equire an export license from the United States

Government.

Brocade Communications Systems, Incorporated

®

, SilkWorm®2400/2800, Fabric OSTMand the BROCADE logo are trademarks or

Page 3

Note Regarding Applicability of the Brocade®

SilkWorm®2400 Hardware Reference Manual

to Hewlett-Packard

Please be aware that the following updates apply to the SilkWorm 2400 Hardware Reference

Manual for Hewlett-Packard.

• Model numbers and part numbers are not applicable.

• Optional licensing information is not applicable.

• Notices, TOC, and Preface are applicable.

• Chapter 1 (Introduction) is applicable.

• Chapter 2 (Installation) is applicable, except for the following, which are not applicable:

- Option of one power supply

- Additional racking information available from Hewlett-Packard

• Chapter 3 (Diagnostics) is applicable.

• Appendix A (Specifications) is applicable. However, Table A should state that the operating

temperature is 10o to 30o, not 0o to 40o.

• Appendix B (Switch Support) is not applicable. Refer to your Hewlett-Packard support

contract for support information.

• Appendix C (Error Messages) is applicable.

A5625-96002

Copyright © 1999, 2000

Printed in USA 05/00

A5625-90902

Page 4

Page 5

NOTICES

FCC Warning (USA only)

This equipment has been tested and complies with the limits for a Class A computing device pursuant

to Part 15 of the FCC Rules. These limits are design ed to provide reason able protection against harmfu l

interference when equipment is operated in a commercial environment. This equi pment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operating this equipment in a

residential area is likely to cause harmful interference in which case the user is responsible for repairs.

VCCI Statement

This is a Class A product based on the standard of the Voluntary Control Council For Interference by

Information Technolog y Equipment (VC CI). If this equipment i s used in a domestic envi ronment, radio

disturbance may arise. When such trouble occurs, the user may be required to take corrective actions.

(Japanese Text)

CE Statement

The standards compliance label on the SilkWorm 2400 Fibre Channel Switch contains the CE mark

which indicates that this system conforms to the p rov isions of the following European Council

Directives, laws, and standards:

• Electro Magnetic Compatibility (EMC) Directive 89/336/EEC and the C omplementary

Directives 92/31/EEC and 93/68/EEC:

- EN550022, Class A; Emissions Industrial Environment

- EN 50082-2 Immunity Industrial Environment

- EN61000-4-2 Electro Static Discharge

- EN61000-4-3 Radiated RF

- EN61000-4-4 Electrical Fast Transients

- EN61000-4-5 Surge

- EN61000-4-6 Conducted RF

- EN61000-4-11 Line Interruption

• Low Voltage Directive (LVD) 73/23/EEC and the Complementary Directive 93/68/EEC:

- EN 60950:92 A1:93 & A2:93 & A3:95 & A4:96 & A11:97

- EN60825-1:199/A11, -2

Canadian Requirements

This class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numerique de la classe A respecte toutee les exigences du Regiements sur le material

brouilleur du Canada.

Laser Compliance

This equipment contains class 1 laser products, and it complies with FDA radiation Performance

Standards, 21 CFR Subchapter J.

Page 6

Page 7

CONTENTS 0

Preface

Chapter 1: Introduction

Switch Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manageability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Fabric Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

GBICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SWL Fiber-Optic GBIC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

LWL Fiber-Optic GBIC Module. . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Passive Copper GBIC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2: Installation

Unpacking the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Site Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Rackmount Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Installing Slide Assembly (Optional) . . . . . . . . . . . . . . . . . . . . . . 2-4

Standalone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Fiber Channel Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Serial Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Serial Cabling and Emissions Requirements. . . . . . . . . . . . . . . . . 2-8

Setting IP Address using the Serial Port . . . . . . . . . . . . . . . . . . . . 2-9

Resetting Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Verifying Power-On Self-Test (POST) . . . . . . . . . . . . . . . . . . . . . . 2-10

Chapter 3: Diagnostics

Diagnostic Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Verifying Power-On Self-Test (POST) . . . . . . . . . . . . . . . . . . . . . . . 3-2

Removing Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Diagnostic Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Status and Activity Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Front Panel LED Port Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Initialization Steps Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Appendix A: Specifications

General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

SilkWorm® 2400 Hardware Reference Manual vii

Page 8

Fabric Management Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Safety Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Optical Port Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Copper GBIC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Rack Mount Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Table Top Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Appendix B: Switch Support

Support Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Appendix C: Error Messages

Chapter Index

viii

Page 9

PREFACE

The SilkWorm® 2400 Hardware Reference Manual describes how to use and maintain

the SilkWorm

Audience

The audience for this manual includes:

■ Field Technicians

How this Manual is Organized

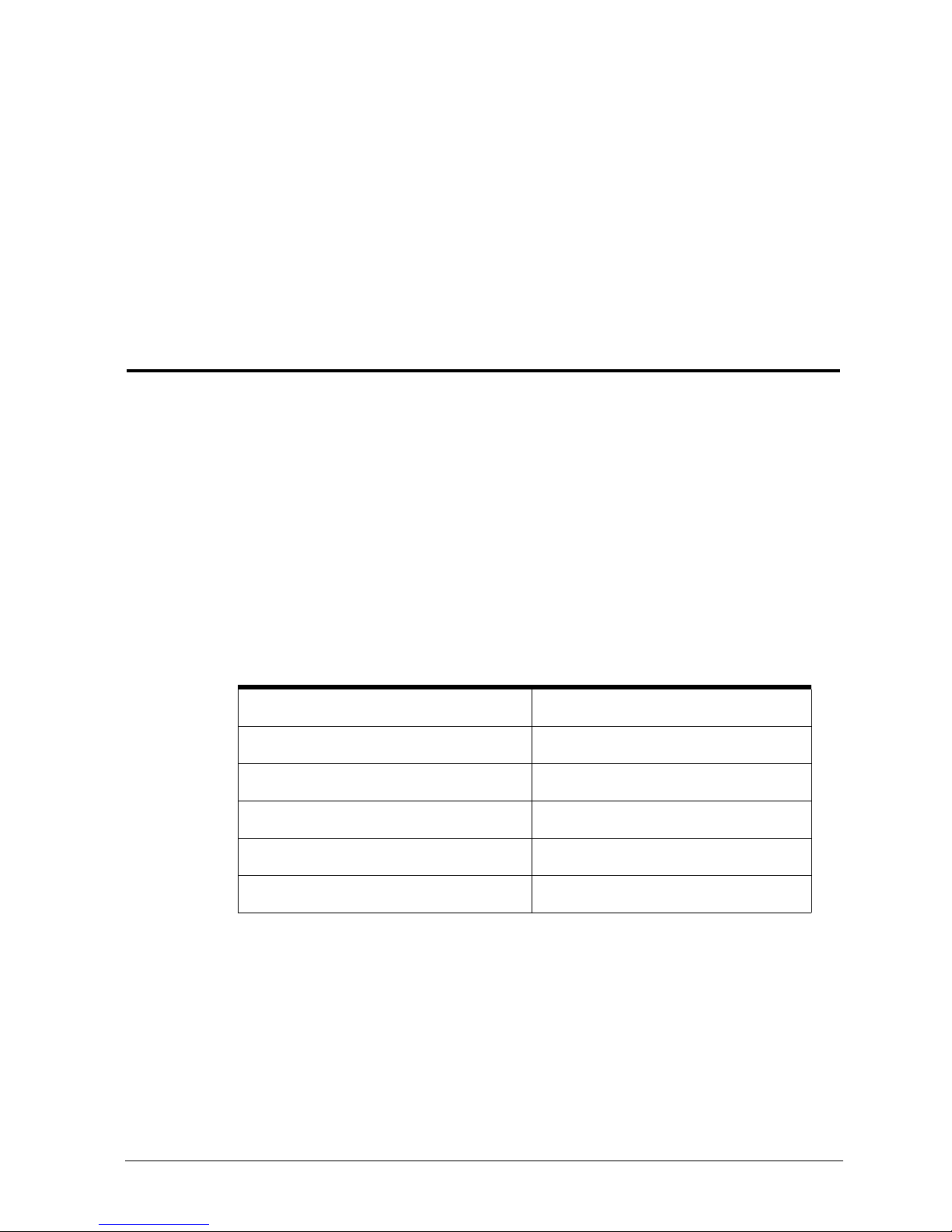

The following table describes how the manual is organized.

2400 Switch.

FOR INFORMATION ON SEE

Switch features and system components Chapter 1,

Installing and setting up the switch Chapter 2,

Diagnostics Chapter 3,

Technical specifications Appendix A,

Customer support Appendix B,

SilkWorm 2400 Hardware Reference Manual ix

Introduction

Installation

Diagnostics

Specifications

Switch Support

Page 10

Preface

Related Publications

Other publications that may provide related information include:

■ Fabric OS Version 2.0 Manual, Part Number: 53-000 1555- 01

■ Fibre Channel Standards

For detailed information on the Fibre Channel standards, see the Fibre Channel

Association web site:

http://www.fibrechannel.com

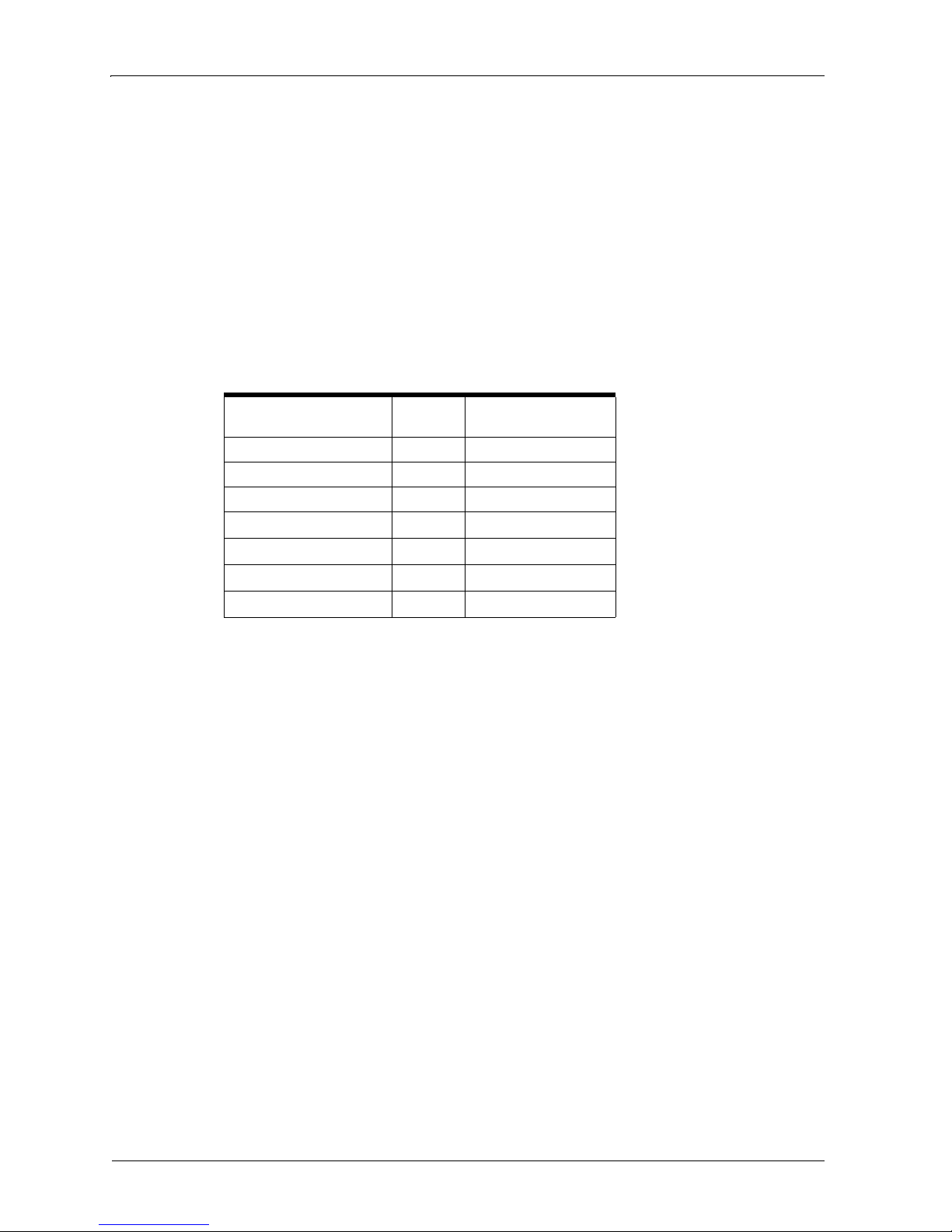

Revision Histo r y

FABRIC OPERATING

S

YSTEM VERSION

2.o

2.0

2.0

2.0

2.0

2.0

2.0

DATE DOCUMENT

11/98

1/99

2/99

3/99

4/99

4/99

7/99

First Draft

Second Draft

Beta Draft

Beta 3 Draft

Final Draft

Released

Channel Update

x

Page 11

1

INTRODUCTION 1:

Port 0

Figure 1-1 Front Panel

SilkWorm 2400 is an 8-port Fibre Channel Gig abit Switch that consist s of a motherboard

with connectors for s upporting up to 8 ports, a nd fabric operating sys tem for building and

managing a Fabric. A Fabric is an active, intelligent, interconnect scheme for Fibre

Channel server and storag e nodes. Figure 1-1 shows the front vie w of the SilkWorm 2400

switch. Ports are numbered sequentially starting with zero for the left most port. The

switch face plate includes a silk screen imprint of the port number. Up to two power

supplies are suppor ted, t hese are s hown to the left a nd ri ght of the s witch por ts i n Figure

1-1. This chapter disc usses:

■ Features

■ System Components

WARNING SilkWorm 2400 contains two power supplies. To remove all power from the

system, disconnect both power supply cords.

Port 7

Power Supply #1Power Supply #2

SilkWorm 2400 Hardware Reference Manual 1-1

Page 12

Chapter 1 Introduction

Switch Features

The switch is a high-perfo rmance Fibre Channel Gigabit Switch with the follow ing

features:

■ Simple – Easy setup and con figurat ion. After Po wer-On Se lf-Test (POST), you

need only add th e switc h’s Internet Prot ocol (IP) ad dres s. Th e rema inde r of the

switch’s setup is autom ated .

■ Intelligent – The fabric operating system allows discovery of all connected

devices and determines optimum data paths without intervention, supporting up

to 239 interco nne ct ed sw itc he s.

■ Flexible – GBIC modules support fiber and copper transmission media. The

switch’s modular constructio n g ives the swit ch a r ange of fle xi bility in creat in g,

upgrading, maintaining, and configuring a Fabric.

■ Reliable – Hig hly in tegrat ed, re liab le, multif unct ion (AS IC) dev ices a re used

throughout the sw itch.

■ High performance – Low-latency, high-performance design requires no CPU data

path interactio n resulti ng in a worst ca se dat a transfe r late ncy o f less than two

microseconds from any port to any port at peak Fibre Channel bandwidth of 100

MB/sec. The latency may differ when the destination or device is a loop.

■ Automated congestion management – Virtual channels lets the swit ch use

sophisticated co nges tion ma nage ment te chniqu es th at are per form ed

automatically by the swit ch.

■ Cascading – You can casc ade swi tches for large Fab ric sup port. Up to 239

switches can be in terco nnecte d for a la rge Fabric w ith h undred s of Fabr ic

connections.

■ Compatibility – SilkWorm

2400 has been designed to inter-operate with the

SilkWorm 1000 series switches using a compatibility mode.

■ Universal – Switch po rts are d esigned t o support F, FL and E-p ort modes of ope ration

with the software selecting the optimum mode of operation.

Performance

A minimum aggregate r outin g cap acity o f 4,00 0,000 f rames/ sec is s pecif ied for Clas s 2,

Class 3, and Class F frames. Non-bl ocki ng t hroughput of up to 8 x 100MBytes/s ec (0.8

GBytes/sec) is provided.

A maximum switch late ncy of l ess than t wo micro seconds is specifi ed for Cl ass 2, Cl ass

3, and Class F frames when the output port is free.

Manageability

The unit may be managed in-band (using Fibre Channel protocol) or out-of-band via

connecting to the 10/100BaseT Ethernet port. Management interfaces include Telnet,

SNMP, SCSI Enclosure Services (SES), or a Web Tool.

1-2

Page 13

System Components

The motherboard is enclosed in an air-cool ed chassi s which ma y be eithe r mounted in a

standard rack or used as a standalone unit. The chassis includes one or two power

supplies, a fan tray , an RJ-45 Ethernet co nnection for switch se t up and management, and

a serial port. The serial port is used for recovering factory settings only and initial

configuration of the IP address for the switch if default address is not known.

Fabric Operating System

The fabric operating system is tuned for each installation. The system provides a large

number of commands and libraries to manage real time tasks.

GBICs

The switch accommodates up to eight GBIC modules. All interfaces have status lights

visible from the front panel giving a quick, visual check of the GBIC’s status and

activity.

System Components

GBIC modules supported are the ShortWave Length (SWL) and LongWave Length

(LWL) fiber-optics, and Copper (Cu) versions.

If your installation requires installing less than eight GBIC modules, the unused port

positions are protected by a metal, spring-loaded door.

SWL Fiber-Optic GBIC Module

The SWL fiber-optic GBIC module, with SC connector color-coded black, is based on

short wavelength lasers supporting 1.0625 Gbps link speeds. This GBIC module

supports 50-micron multi-mode fiber optic cables, with cables up to 500 meters in

length.The GBIC module is shipped with a protective plug in place and should remain in

place if no fiber optic cable is connected to the port. Figure 1-2 shows a GBIC module.

Figure 1-2 Short wavelength Laser (SWL) fiber optic GBIC module

The SWL GBIC module uses a Class 1 laser, which complies with the 21 CFR, subpart

(J) as of the date of manufacture.

SilkWorm 2400 Hardware Reference Manual 1-3

Page 14

Chapter 1 Introduction

LWL Fiber-Optic GBIC Module

The LWL fiber-optic GBIC module, with SC connector color-coded blue, is based on

long wavelength 1300 nm lasers support ing 1.0625 Gbps link spe eds. This GBIC module

supports 9-micron single-mode fiber. Cables up to 10 kilometers in length with a

maximum of five splices can be used. The GBIC module is shipped with a protective

plug in place and should remain in place if no fiber optic cable is connected to the port.

Figure 1-3 shows a GBIC module.

Figure 1-3 Long Wavelength Laser (LWL) fiber optic GBIC module

Passive Copper GBIC Module

The Copper (CU) GBIC module is based on the High-Speed Serial Data Connection

(HSSDC) interface standards. The GBIC provides a female HSSDC connector. Copper

cables up to 13 meters have currently been qualified, thereby supporting ANSI X3.230

FC-PH intra-cabinet requirements. Standard cables with HSSDC-to-DB9 male

connectors are also compatible. Figure 1-4 shows a passive copper GBIC.

Figure 1-4 Copper GBIC module

1-4

Page 15

2

INSTALLATION 2:

This chapter covers th e following:

■ Unpacking the sw itch

■ Selecting a location and mountin g method

■ Setting up connecti ons

SilkWorm 2400 Hardware Reference Manual 2-1

Page 16

Chapter 2 Installation

Unpacking the Switch

While unpacking the switch, check to make sure the following items are included:

■ Switch unit

■ Requested GBIC modules

■ Accessory kit containing the following:

■ Power cord, if ordered

■ Manuals, if ordered

■ Optional Software Feature Guides, if a feature(s) is ordered

■ Rubber mounting feet

Save packing materials in case you need to return the switch. Refer to Appendix B,

Switch Support for information on contacting Brocade.

Cooling Requirements

Cooling air is drawn into the chassis by six fans mounted near the rear of the chassis,

venting exhausted air through the front of the switch.

NOTE: Do not block the front or rear air vents. The switch must have

free access to ambient air for cooling.

2-2

Page 17

Unpacking the Switch

Power Requirements

Switch power connection is via two switche d connector s on the front pan el, as sho wn in

Figure 2-1. The switch power requirements are:

■ Properly wired, earth -groun ded ou tlet

■ Input voltage: 85 - 265 VAC

■ Total power: Up to 110 watts (depen ding on conf igurat ion, s ee App endix A,

Specification s)

■ Input line frequency: Nominally 47 to 63 Hz

The switch has an autoranging po wer supply that automatically accepts volta ges and line

frequencies within its ranges. A green power on indicator light is located above the

power switch in the power supply module.

NOTE: The SilkWorm

®

2400 is available in two models. The 2401

includes one power supply uni t and the 24 02 includes t wo power sup ply

units.

Power Supply 2

Figure 2-1 Model 2402 with Two Power Supplies

NOTE: The sw itch meets IE C 801- 5 surge voltag e requirements,

Power Supply 1

however, ther e is no ot her provis ion for surge pr otection buil t into the

switch’s power supplies. An installation should include normal

provisions to assure clean power.

Site Location

The switch should be installed in a secure or limited access site to control unauthorized

access to the switch’s cabling and power connections.

SilkWorm 2400 Hardware Reference Manual 2-3

Page 18

Chapter 2 Installation

Installation Considerations

The switch has optional mounting hardware to mount the switch in a standard 19-inch

rack.

Rackmount Safety Guidelines

In a rackmount installation, follow these safety guidelines:

■ When installi n g a switch in a clos ed or multi-rack assembly, make certain the air

■ Ensure that there is sufficient air flow availab le to th e switc h.

■ Verify that the switch installation, both with the slides closed and fully extended,

■ Verify the supply circuit, line fusi ng, and wire size ar e adequ ate. Re fer to the

■ Verify that all equipment installed in the rack has a reliable ground connection.

temperature, measured at the rack front, does not exceed 40° C during operation.

does not unbalance the rack or exceed the rack’s mechanical limits.

switch’s nameplate for its power requi rements.

Do not rely on connection to a branch circuit, such as power strips.

■ Route and support th e power cor d to ensure that the swit ch moves f reely on it s slides

without crimping or damaging the power cord or interfering with other equipment and

cabling installed in the rack.

Installing Slide Assembly (Optional)

Before starting switch slide installation and the switch rack installation, locate the rackmount slides and the mounting brackets package, then proceed:

To install slide assembly

1 Disassembl e the sli des by fully ext ending the s lide, pres sing the re lease, the n pulling

the slide apart.

2 Mount the sli de moving portion to each switch side as shown in Fi gure 2-2, using the

supplied slide screws.

3 Open the rack mounting package, and secure the four rack mounting attachments to

the stationary slide portion as shown in Figure 2-2.

4 Mount the two brackets using two screws (of the four provided) for each handle.

2-4

Page 19

Unpacking the Switch

Brackets are provided as part of the s li de kit . Th e br ac kets are used to secur e the swi tc h

to the rack. As shown in Figure 2-2, the two holes located towards the front of the switch

are used with the brackets. All the other holes are used for slide mounting.

Use brackets to attach switch to the rack here

Figure 2-2 Mounting the switch

1 Mount both stationary slide portions to the front and rear rack rails.

2 Engage the slide mounte d on the switc h with the sta tionary sli de portion mounted on

the rack, and press toward the rear until the latches engage.

3 Press the switch until the brackets are firmly seated on the rack front supports.

4 Secure th e swi tc h to the rack using the provided screws and nuts as shown in Figure

2-2.

5 Connect the switch to power. This completes the switch rack installation.

SilkWorm 2400 Hardware Reference Manual 2-5

Page 20

Chapter 2 Installation

Standalone

The switch is shipped in its st andal one conf igura tion. Adh esive r ubber f eet a re suppl ied

if the switch is surface mounted. Rubber feet installation is required for proper or safe

switch operation.

To install the adhesive rubber feet:

1 Clean the four depressions at each corner of the chassis bottom so that they are free

2 Remove the rubber feet from the sheet and place one in each depression.

3 Firmly press the rubber feet in place.

Fiber Channel Cable Connections

All network cable conne ctions a re to the switch’s fr ont panel . All recommen ded cablin g

supports the switch’s 1.0625-Gbps transfer rate, as shown in Table 2-1.

Table 2-1 Cabling Connections

of dust.

C

ABLE TYPE CABLE SPECIFICATION MAXIMUM

RUN LENGTH

SWL Fiber

a

Optic

LWL Fiber

a

Optic

Copper • Impedance controlled for

a. Recommend using a low EMI optical cable design.

• Duplex SC plug

connectors

• Multimode fiber

•50 µm core diameter

• 125 µm c ladding diameter

duplex cable

• Duplex SC plug

connectors

• Single mode fiber

•9 µm core diameter

• 125 µm c ladding diameter

duplex cable

150 ohm differential

systems

• Low skew, shielded quad,

150 ohm cable

• Polarized interface

• HSSDC receptacle

•500

meters

• 1641 feet

•10

Kilometers

• 84480 feet

•13 meters

• 42 feet

GBIC MODULE

OPTICAL

WAVELENGTH

780-860 µm

without open

fiber control

(non-OFC)

1270-1350 µm

without open

fiber control

(non-OFC)

NA

NOTE: The switch is not designed to interoperate with devices using

an Open Fibre Control optical interface.

2-6

Page 21

Unpacking the Switch

Fiber cable connectio ns are made to the swi tch’s front panel u sing standard dual SC plug

connectors as shown in Figure 2-3.

Figure 2-3 Dual SC fiber optic plug connector

The connectors are keyed and must be inserted into the GBIC module’s connector in

proper alignment. In most cases, one of the tw o connector plugs is a different color t o aid

in proper connector alignment.

NOTE: Remove the protective plug from the GBIC. Do not force the

fiber optic plug into the GBIC module as you may damage the

connector, the GBIC module, or both. Make certain the fiber surface

is clean, free of dust or debris, before inserting the connector into

GBIC module.

Copper cables use a High Speed Serial Data Connection (HSSDC) connector.

Serial Port Connection

The switch includes a serial port used to set the IP address when setting up or

reinitializing a switch. It is not us ed during nor mal operation. The setting s are as f ollows:

■ 8-bit

■ No parity

■ One stop bit

■ 9600 baud

SilkWorm 2400 Hardware Reference Manual 2-7

Page 22

Chapter 2 Installation

Figure 2-4 Connections

NOTE: The serial port and Telnet connection are mutually exclusive

and there can be only one serial port session active at a time. Telnet

takes priori ty, s o th e se ri al po rt is t er m inat ed wh en a Te ln et

connection is made. Th e serial connectio n is restored after the Tel ne t

session is completed but re-logging in is required. A password is

required to login to the serial port session as password checking is

skipped only at in it ia l pow e r on.

CAUTION The serial port is intended for initial configuration of the IP address or

Serial PortEthernet Port

disaster recovery only and not for regular maintenance.

Serial Cabling and Emissions Requirements

The switch uses a standard se rial cable with a male 9- pin D-Subminiature connec tor (but

only pins 2, 3 an d 5 are requir ed/supported; i f 7 is used, t his signal must a lways be driven

high, with the following pinouts:

Table 2-2 Cabling Pinouts

PIN S

1

2 TxData Transmit Data

3 RxData Receive Data

4

5 GND Logic Ground

6

7 CTS Clear to Send

8

9

IGNAL DESCRIPTION

NOTE: For dust and ESD protection, the switch includes a cover for

the serial port. When not in use, the serial port should be covered.

2-8

Page 23

Unpacking the Switch

Setting IP Address using the Serial Port

There is a label on the f ront panel of th e s witch with I P ADDRESS an d spac e to i nclude

the IP address when it is configured. This label facilitates identification of the physical

switch in main tenance mode.

The serial port is initially logged on as an “Admin” user.

To set IP Address using the Serial Port

1 Connect the serial port to a workstation using a standard serial cable with a DB9

connector.

2 Establish a connection to the shell.

The prompt is displayed as

For example: sw4:admin>

3 Enter the data to the ipAddrSet command (Fibre Channel IP address and subnet

mask and Ethernet IP address, subnet mask, and gateway address).

4 Copy the IP Address to the label provided for future reference.

switchName:userName>

Resetting Factory Defaults

In the event that a user changes a password and forgets it, the password can be

reinitialized.

To reset factory defaults

1 Connect t he s er ial po rt to a PC/ w orks ta ti on u si ng a sta nda rd serial cable with a DB9

connector.

2 Establish a connection to the shell.

The prompt is displayed as

For example: sw4:admin>

3 Enter the configDefault command. See the Fabric OS Manual for more

information.

switchName:userName>

Ethernet Connection

Connecting an existing Et hernet 10/100Ba seT LAN to the switch vi a the fr ont pan el RJ45 connector gives access to the switch’s internal SNMP agent and also allows remote

Telnet and Web access for remote monitoring and testing.

NOTE: The connection is only for Telnet, SNMP agent and the Web-

based Server access. No Fabric connection is used via this connection.

SilkWorm 2400 Hardware Reference Manual 2-9

Page 24

Chapter 2 Installation

Verifying Power-On Self-Test (POST)

The following table lists the diagnostic tests automatically run during POST.

Table 2-3 POST Tests

TEST BRIEF DESCRIPTION

Memory Test Checks CPU RAM memory.

Port Register Test Checks the ASIC registers & SRAMs.

Central Memory Test Checks the motherboard SRAMs.

Port Loopback Test Checks all of the switch’s hardware:

POST behaves differently depending on the boot method. A power cycle (power off &

power on) is consid ered a cold boot. All other boots fro m a powered-on stat e (per reboot,

panic, etc.) are considered warm boots.

POST execution per cold boot executes the long version of Memory Test. POST

execution per warm boot executes a shorter version of Memory Test. Boot time with

POST varies depending on the boot method.

frames transmitted, are looped back, and received

As the POST successfully perf orms each of the t ests, a message, “

Passed,” is displayed

via the Telne t.

After the switch compl et es the POST, the por t module returns to a st eady state from the

flashing states shown during the tests.

If a yellow port mod ule light is d isplayed or i s slowly flash ing, this ind icates that t he port

is in a failed state and diagnostic output should be examined to determine the source of

failure.[ See Table 3-2 for other light indications.]

If error conditions are encountered, they can be displayed via Telnet after the switch

completes the POST.

2-10

Page 25

3

DIAGNOSTICS 3:

This chapter discusse s trouble shooting, a nd diagnost ic testing. I t includes t hese secti ons:

■ Diagnostic Overview

■ Diagnostic Command Summary

■ Status and Act ivi ty Ind ic ators

SilkWorm 2400 Hardware Reference Manual 3-1

Page 26

Chapter 3 Diagnostics

Diagnostic Overview

The switch is designed for maintenance free op eration. When the re is a suspected fai lure,

the switch has self diagnostic capabilities to aid in isolating any equipment or Fabric

failures.

The switch supports Power-On Self-Tests (POSTs) and diagnostic tests. The diagnostic

tests determine the switch’s status and isolates problems and are run via telnet

commands. For more information on diagnostic testing commands and procedures, see

the Fabric Operating System Version 2.0 Manual.

Verifying Power-On Self-Test (POST)

When powering on a switch, the switch conducts a series of diagnostic tests including:

■ Dynamic RAM Test

■ Port Register Test

■ Central Memory Test

■ CMI Connector Test

■ CAM Test

■ Port Loop Back Test

Should the switch f ail to complete POST succe ssf ul ly, the green power LED wi ll be set

to blink. This is an indication of a fault in one of the initial stages of POST and indicates

that the CPU is not able to bring up the operating environment. Should this condition

occur, the switch should be returned for repair.

If a serial link is connected to the SilkWorm 2400 switch on initial power up, the switch

type will be printed t o the terminal scree n, followed by the mess age ‘Starting RAM te st’.

On completion of the RAM test, the OS is loaded into CPU memory and the operating

environment is then booted. (A RAM test failure will result in the power LED to blink).

If the switch c an compl etel y boot th e oper ating sy stem, bu t o ther error s are en counte red

during POST, these errors will be logged in the system error log. A Telnet session or

serial link connec ti on t o the switch will enabl e vi ewing of the error log. [S ee t he Fabric

OS Reference Manual diagnosti c and telne t commands for a descr iptio n of the errSh ow

command and details on running diagnostics.]

Removing Power

NOTE: Error messages are stored in RAM and are lost when power is

removed from th e sw itc h. A c cess th e e rror m essa g e l og to vi ew a nd

note any erro r me ss age s b e fore re mov in g pow er from t he sw it ch.

3-2

Page 27

Diagnostic Commands

The following tests are available from the switch’s Telnet connection:

■ Switch Offline (switchDisable)

■ Memory Test (ramTest)

■ Port Register Test (portRegTest)

■ Central Memory Test (centralMemoryTest)

■ CMI Conn Test (cmiTest)

■ CAM Test (camTest)

■ Port Loopback Test (portLoopbackTest)

■ Cross Port Test (crossPortTest)

■ Spin Silk Test (spinSilk)

■ SRAM Data Retenti on Test (sramRetentionTest)

■ CMem Data Retention Test (cmemRetentionTest)

Diagnostic Commands

■ Switch Online (switchEnable)

Table 3-1 Offline and Online Test

FFLINE TESTS OFFLINE & ONLINE TESTS

O

portRegTest ramTest

centralMemoryTest crossPortTest

cmiTest

sramRetentionTest

cmemRetentionTest

camTest

portLoopbackTest

spinSilk

See the Fabric Operating System Reference Manual for the usage of these test

diagnostics.

SilkWorm 2400 Hardware Reference Manual 3-3

Page 28

Chapter 3 Diagnostics

Status and Activity Indicators

Front Panel LED Port Indicators

The color and flash speed of each port’s LED, as described in Table 3-2, indicates the

individual port’s status.

Table 3-2 Front Panel LED Status Indicators

RONT PANEL LEDS DEFINITION

F

No light showing No light or signal carrier (no module, no cable) for media interface

Steady yellow Receiving light or signal carrier, but not yet online

Slow* yellow Disabled (result of diagnostics or portDisable command). Flashes

Fast* yellow Error, fault with port. Flashes every 1/2 second.

Steady green Online (connected with device over cable)

Slow green Online, but segmented (loopback cable or incompatible switch) flash

Fast green Internal loopback (diagnostic). Flashes every 1/2 second.

Flickering green Online and frames flowing through port.

* Slow -- 2 second interval, Fast - 1/2 secon d interval

LEDs

every 2 seconds.

every 2 seconds.

Each switch port includes an LED indicator. A port with no GBIC installed that if

functioning properly will have no light showing on the LED. If a problem has been

detected with the port, the LED i ndicators above wi ll provide so me indication o f the type

of problem. Faults and problems are depicted with a yellow port indicator.

When a GBIC is installed and a cable is connected to a properly functioning Fibre

Channel device, the LED indica tor will be steady green. If a slow green fla sh is observed

it indicates t he port is seeing light but cannot make a proper fab ric connection. Thi s could

indicate a loopback cable is installed, the fabric is segmented (a E port connection to

another switch cannot be completed and the switches cannot form a fabric), or the

SilkWorm h as been connected to an incompatible switch.

When frame traffic is being transferred on a port, the LED flickers fast green showing

the port is active and transferring data.

3-4

Page 29

Status and Activity Indicators

Initialization Steps Summary

At power-on or reset, the following steps are executed:

1 Preliminary POST diagnostics

2 VxWorks operating s ystem initia lization

3 Hardware initiali zation (resets, internal addresses assigned to ASICs, serial po rt

initialized, front panel initialized)

4 Full POST

5 Universal Port configuration.

6 Link initialization; receiver/transmitter negotiation to bring connected ports online

7 Fabric analysis; the switch checks for ports connected to other Fabric elements. If

there are other Fabric elements connected, it identifies the master switch.

8 Address assignment; after the master switch is identified, port addresses may be

assigned. Each switch tries to keep the same addresses that were previously used.

These are stored in the switch’s configuration flash PROM.

9 Routing table constru ction; af ter addresses are assigne d, the unicast routing tabl es are

constructed.

10 Enable normal port operation.

SilkWorm 2400 Hardware Reference Manual 3-5

Page 30

Chapter 3 Diagnostics

3-6

Page 31

A

SPECIFICATIONS A:

General Specifications

Table A-1 shows the switch specifications.

Table A-1 Switch Specifications

PECIFICATIONS DESCRIPTION

S

ANSI Fibre Channel protocol Fibre Channel ANSI Standard (FC-PH)

Fabric Initialization Complies with FC-SW 3.2

IP Over Fibre Channel (FC-IP) Complies with 2.3 of the FCA profile

System architecture Nonblocking shared-memory switch

System processor Superscalar 33-Mhz Intel i960RP

Number of Fibre Cha nnel Ports 8 port s

Fibre Channel port speed 1.0625 Gbps full duplex

Modes of operation Fibre Channel Class-2 service and Fibre Channel Class-3

Aggregate switch I/O

bandwidth

Frame buffers 16 buffers per port at 2112 bytes per frame

Fabric latency <2 microseconds with no contention

Data transmission range Up to 500 m (1,625 ft.) for short-wavelength optical link

Chassis types Back-to-front airflow (power supply out front)

SilkWorm 2400 Hardware Reference Manual A-1

connectionless service

8 Gbps, full duplex

Up to 10 kilometers (84,480 ft.) for long-w avel ength opt ical link

Page 32

Appendix

Fabric Management Specifications

Table A-2 shows Fabric management specifications:

Table A-2 Fabric Management Specifications

TANDARD FEATURES DESCRIPTION

S

Fabric management Simple Name Server, Alias Server, SNMP, Telnet, World Wide

User interface RJ45 front panel connector for 10/100Base-T Ethernet or in-

Serial port Local front panel RS-232 port for recovering factory settings

Web

band

Safety Specifications

Table A-3 shows Fabric management specifications:

Table A-3

OUNTRY SAFETY EMC

C

Canada CSA 22.2 No. 950 Third

United States UL 1950 Third Edition FCC Part 15 Class A

Japan EN60950+A1+A2+A3+A4+

International EN60950+A1+A2+A3+A4+

Safety Specifications

Edition

A11

A11

CSA C108.8 Class A

VCCI Class A

EN55022 Level A/

CISPR22 Class A

United Kingdom/

Ireland

France EN60950+A1+A2+A3+A4+

Germany EN60950+A1+A2+A3+A4+

Austria EN60950+A1+A2+A3+A4+

Spain/Portugal/Italy EN60950+A1+A2+A3+A4+

Sweden EN60950+A1+A2+A3+A4+

Norway EN60950+A1+A2+A3+A4+

A-2

EN60950+A1+A2+A3+A4+

A1 1;73/2 3/EEC

A11;73/23/EEC

A11;73/23/EEC

A11;73/23/EEC

A11;73/23/EEC

A11;73/23/EEC

A11

EN55022 Level A;

89/336/EEC

EN55022 Level A;

89/336/EEC

EN55022 Level A;

89/336/EEC

EN55022 Level A;

89/336/EEC

EN55022 Level A;

89/336/EEC

EN55022 Level A;

89/336/EEC

Page 33

Optical Port Specifications

Table A-3

OUNTRY SAFETY EMC

C

Finland EN60950+A1+A2+A3+A4+

Denmark EN60950+A1+A2+A3+A4+

Australia AS/NZS 3548:1995 Class A

New Zealand AS/NZS 3548:1995 Class A

Safety Specifications(Continued)

A1 1;73/23/EEC

A11;73/23/EEC

Optical Port Specifications

Fibre Channel interfaces of a SilkWorm 2400 system equipped with an optical port

interface uses a sho rtwave (78 0 to 850 nm.) or long wav elength (1270 to 1350 n m) laser

transmitter. The laser c omplies wi th 21 CFR( J) Clas s 1 la ser saf ety req uirements . It us es

Non-Open F ibre Contr ol (OFC) Optical GBICs in the switch circuit. Safe Class 1

operation is guaranteed by limiting optical power emitted by the port, thereby

eliminating the need for physical shutters. The optical GBIC uses the duplex-SC

connector scheme.

EN55022 Level A;

89/336/EEC

EN55022 Level A;

89/336/EEC

Copper GBIC Module

The Copper (CU) GBIC module is based on the High-Speed Serial Data Connection

(HSSDC) interface standards. The GBIC provides a female HSSDC connector. Copper

cables up to 13 meters have currently been qualified, thereby supporting ANSI X3.230

FC-PH intra-cabinet requirements. Standard cables with HSSDC-to-DB9 male

connectors are also available.

SilkWorm 2400 Hardware Reference Manual A-3

Page 34

Appendix

Environmental Specifications

The SilkWorm 2400 switch’s pr imary operating environments are server rooms, network

equipment closets, and office environments. Th e acceptable environment al r ange s for a

SilkWorm switch are shown in Table A-4:

Table A-4 SilkWorm 2400 Environmental Specifications

Specification Value

Temperature (ope rati ng) 0°

Temperature (non -op erati ng ) -35°

Operating humidity 5% to 85% noncondensing @ 40°

Nonoperating humidity 95% RH noncondensing @ 40°

Operating Altitude 0 to 3 kilometers above sea level

Nonoperating Altitude 0 to 12 kilometers above sea level

Operating shock 5g, 11MS duration, half sine

Nonoperating shock 20g, 11MS duration, sq.wave

Operating vibration 5, 5-500-5Hz@1.0 octave/minute

Nonoperating vibration 10, 5-500-5Hz@1.0 octave/minute

Handling drop

C to 40 °C

C to 65 °C

C

C

Dimensions

The switch may be configured for either rack mount or tabletop use.

Rack Mount Dimensions

1U, 19-in. rack mount (EIA compliant)

H: mm (1.71 in.), W: 428.6 mm (16.88 in.), D: 450.0 mm (17.72 in.)

Table Top Dimensions

H: 43.4 mm (1.86 in.), W: 428.6 mm (16.88 in.), D: 450.0 mm (17.72 in.)

Weight

17 lbs.

A-4

Page 35

Power Supply

The SilkWorm 2400 has a universal power supply capable of functioning worldwide

without volt age jumpers or switches. The supply is autoranging in terms of

accommodating input voltages and line frequencies.

The power supply meets the following requirements:

Table A-5 Power Supply Requirements

Total power 110 watts

Input voltage 85 to 265 VAC

Input line frequency 47 to 63 Hz.

Inrush Current 10 Amps Peak, > 300 usec - hot/cold start

Harmonic Distortion Active power factor correction per IEC1000-3-2

Input Line Protection Fused in both hot & neutra l lines

Power Supply

Maximum Dime ns ions 3.5”W X 1.5”H X 11”L

Redundancy Dual Supplies - Hot Pluggable

BTU Rating 110 watts X 3.412 BTU/hr/watts = 375 BTU/hr

The power supply has a modular design that plug s directly into the enclosure throu gh the

front panel, mating to an internal blind-mate connector. It provides facilities to support

a dual redundandant power supply configuration in which the supplies are hotswappable.

An integral on/off switch, input filter and power indicator are provided in the power

supply.

SilkWorm 2400 Hardware Reference Manual A-5

Page 36

Appendix

A-6

Page 37

B

SWITCH SUPPORT B:

Support for your switch ca n be obtaine d from the supplier of your switch. Pl ease cont act

the supplier to report hardware or software problems. The supplier is also the correct

source for switch repairs or for supplying spare components.

Support Tool

Included in the switch software is a command that will provide a display of a variety of

information that is helpful in diagnosing switch related problems. This command is:

suppportShow. This comma nd can be entered into a telne t session command window and

the results should be saved and supplied to your support contact.

SilkWorm 2800 Hardware Reference Manual B-1

Page 38

Appendix

B-2

Page 39

C

ERROR MESSAGES C:

This appendix explains the error message format and possible errors.

There is one error message fo rmat for the swit ch whethe r you are gathe ring i nformat ion

from the local RS-232 serial port or using a remote Telnet session.

In all cases, the last err or encount ered is the first error displ ayed. Up to 64 mess ages are

held in a buffer. If the 64 message limit is exceeded, the messages are overwritten in a

first in, first out sequence.

errShow command displays all detected errors. The output provides additional

The

information over the front panel display. The following information is displayed in

Figure E-1:

■ There are two errors which have been detected.

■ The task ID and task name that incurre d th e er ror (task name are d is played using the

i command).

■ The error type, date and time, the error level, and description.

■ If there is more than one occurrence of an error type, the number of occurrences is

shown in brackets following the date and timestamp.

NOTE: The error counter goes to a maximum of 999.

SilkWorm 2400 Hardware Reference Man ual C-1

Page 40

Appendix

The display halt s after each e rr or i s displayed, prompt ing you to eithe r press <Enter> to

continue or type a

Q to quit. Continue pressing <Enter> until the prompt (=>) is

displayed.

switch:admin> errShow

Date & Time of

Occurences

Number of Occurences

Error 02

--------

Task ID

Task Name

0x103dc470 (tSwitch): Apr 9 10:41:06 (4)

Error SENSOR-FAILED, 3, sensor 7 (Fan 2) is below minimum

Type <CR> to continue, Q<CR> to stop:

Error Type

Error 01

-------0x103dc470 (tSwitch): Apr 9 10:40:51

Error DIAG-TIMEOUT, 1,

Port 2 receive timeout.

Error Level

Description

Err#0004

Type <CR> to continue, Q<CR> to stop:

Figure E-1 errShow Command Example

To display error messages via Telnet

1 From the prompt, enter errShow command.

2 To scroll through the error list, type <CR>

3 Scroll thr oug h er ror l og ( if no e rr ors enc ount er ed, the command returns “No Er ro r”) .

C-2

Page 41

INDEX

C

complete installation 2-1

components, system 1-3

connections

ethernet

fibre optic cable 2-6

serial port 2-7

cooling requirements 2-2

2-9

setting address

2-9

L

LEDs

flash speed and color

green 3-4

yellow 3-4

link initialization 3-5

M

managing SilkWorm

via front panel buttons

3-4

x

D

diagnostics 3-2

dimensions

rackmount

table top A-4

A-4

E

ethernet connections 2-9

F

features 1-2

fiber optic cable connections 2-6

fibre channel protocol A-1

G

GBIC module 1-3, 1-4

I

initialization 3-5

installation

attaching rubber feet

complete install 2-1

cooling requirements 2-2

power requirements 2-3

rackmount considerations 2-4

site location 2-3

unpacking the switch 2-2

introduction 1-1

ipAddrSet command

2-6

O

operating system 3-5

P

POST 3-5

power requirements 2-3

R

rackmount installation 2-4

requirements

cooling

power 2-3

2-2

S

serial port

cabling

pinouts 2-8

setting IP Address 2-9

specifications A-1

system components 1-3

2-8

V

VxWorks 3-5

SilkWorm 2400 Hardware Reference Manual Index-1

Page 42

Index

Index-2

Loading...

Loading...