Page 1

53-1002483-03

®

21 November 2012

Brocade BigIron RX Series

Hardware Installation Guide

Supporting Multi-Service IronWare v02.9.00a

Page 2

Copyright © 2011-2012 Brocade Communications Systems, Inc. All Rights Reserved.

Brocade, Brocade Assurance, the B-wing symbol, BigIron, DCX, Fabric OS, FastIron, MLX, NetIron, SAN Health, ServerIron, TurboIron, VCS, and VDX

are registered trademarks, and AnyIO, Brocade One, CloudPlex, Effortless Networking, ICX, NET Health, OpenScript, and The Effortless Network

are trademarks of Brocade Communications Systems, Inc., in the United States and/or in other countries. Other brands, products, or service

names mentioned may be trademarks of their respective owners.

Notice: This document is for informational purposes only and does not set forth any warranty, expressed or implied, concerning any equipment,

equipment feature, or service offered or to be offered by Brocade. Brocade reserves the right to make changes to this document at any time,

without notice, and assumes no responsibility for its use. This informational document describes features that may not be currently available.

Contact a Brocade sales office for information on feature and product availability. Export of technical data contained in this document may

require an export license from the United States government.

The authors and Brocade Communications Systems, Inc. shall have no liability or responsibility to any person or entity with respect to any loss,

cost, liability, or damages arising from the information contained in this book or the computer programs that accompany it.

The product described by this document may contain “open source” software covered by the GNU General Public License or other open source

license agreements. To find out which open source software is included in Brocade products, view the licensing terms applicable to the open

source software, and obtain a copy of the programming source code, please visit

http://www.brocade.com/support/oscd.

Brocade Communications Systems, Incorporated

Corporate and Latin American Headquarters

Brocade Communications Systems, Inc.

130 Holger Way

San Jose, CA 95134

Tel: 1-408-333-8000

Fax: 1-408-333-8101

E-mail: info@brocade.com

European Headquarters

Brocade Communications Switzerland Sàrl

Centre Swissair

Tour B - 4ème étage

29, Route de l'Aéroport

Case Postale 105

CH-1215 Genève 15

Switzerland

Tel: +41 22 799 5640

Fax: +41 22 799 5641

E-mail: emea-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems China HK, Ltd.

No. 1 Guanghua Road

Chao Yang District

Units 2718 and 2818

Beijing 100020, China

Tel: +8610 6588 8888

Fax: +8610 6588 9999

E-mail: china-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems Co., Ltd. (Shenzhen WFOE)

Citic Plaza

No. 233 Tian He Road North

Unit 1308 – 13th Floor

Guangzhou, China

Tel: +8620 3891 2000

Fax: +8620 3891 2111

E-mail: china-info@brocade.com

Document History

Title Publication number Summary of changes Date

Brocade BigIron RX Series Hardware

Installation Guide

Brocade BigIron RX Series Hardware

Installation Guide

Brocade BigIron RX Series Hardware

Installation Guide

Brocade BigIron RX Series Hardware

Installation Guide

Brocade BigIron RX Series Hardware

Installation Guide

53-1002252-01 Release 02.8.00 May 2011

53-1002252-02 Updated to include the

BSMI statement (Taiwan).

53-1002483-01 Release 02.9.00 May 2012

53-1002483-02 Updated the mini-TOCs. June 2012

53-1002483-03 Fixed documentation

defects.

September 2011

November 2012

Page 3

Contents

About This Document

Supported hardware and software . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Document conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Text formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Notes, cautions, and danger notices . . . . . . . . . . . . . . . . . . . . . . x

Trademark references. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Getting technical help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Document feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Chapter 1 Product Overview

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hardware features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Management modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Interface modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4-port 10 Gigabit Ethernet module. . . . . . . . . . . . . . . . . . . . . . . . 9

16-port 10 Gigabit Ethernet oversubscribed module . . . . . . . .11

Gigabit Ethernet interface module (SFP) . . . . . . . . . . . . . . . . . .12

48-port 1 Gigabit Ethernet interface module

(Mini RJ 21 Copper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Switch fabric module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Power supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Cooling system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Rack mount kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Supported software features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Chapter 2 Installing the BigIron RX Series Switch

Installation precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

General precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Power precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Brocade BigIron RX Series Hardware Installation Guide iii

53-1002483-03

Page 4

Installing a BigIron RX-4 switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Preparing the installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unpacking a BigIron RX-4 switch . . . . . . . . . . . . . . . . . . . . . . . .25

Chassis lifting guidelines for BigIron RX-4 switches . . . . . . . . . 25

Installing a BigIron RX-4 chassis in a rack . . . . . . . . . . . . . . . . .25

Installing BigIron RX-4 modules . . . . . . . . . . . . . . . . . . . . . . . . .28

Installing power supplies in a BigIron RX-4 chassis . . . . . . . . .30

Connecting AC power to a BigIron RX-4 chassis . . . . . . . . . . . .31

Connecting DC power to a BigIron RX-4 chassis . . . . . . . . . . . .32

Final steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Installing a BigIron RX-8 switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Preparing the installation site. . . . . . . . . . . . . . . . . . . . . . . . . . .34

Unpacking a BigIron RX-8 switch . . . . . . . . . . . . . . . . . . . . . . . .34

Chassis lifting guidelines for BigIron RX-8 switches . . . . . . . . . 35

Installing the BigIron RX-8 chassis in a rack . . . . . . . . . . . . . . .35

Installing BigIron RX-8 modules . . . . . . . . . . . . . . . . . . . . . . . . .38

Installing power supplies in the BigIron RX-8 chassis . . . . . . . .40

Connecting AC power to a BigIron RX-8 chassis . . . . . . . . . . . . 41

Connecting DC power to a BigIron RX-8 chassis . . . . . . . . . . . .42

Final steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Installing a BigIron RX-16 switch . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Preparing the installation site. . . . . . . . . . . . . . . . . . . . . . . . . . .43

Unpacking a BigIron RX-16 switch . . . . . . . . . . . . . . . . . . . . . . .43

Chassis lifting guidelines for BigIron RX-16 switches . . . . . . . .44

Installing a BigIron RX-16 chassis in a rack . . . . . . . . . . . . . . . .45

Installing BigIron RX-16 modules . . . . . . . . . . . . . . . . . . . . . . . .48

Installing power supplies in a BigIron RX-16 chassis . . . . . . . .50

Connecting AC power to a BigIron RX-16 chassis . . . . . . . . . . . 51

Connecting DC power to a BigIron RX-16 chassis . . . . . . . . . . .52

Final steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Attaching a management station. . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Attaching a PC or terminal to the Console port

or Ethernet port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Attaching the management module’s Ethernet Port

to a network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Powering-on the power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Verifying proper operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Observing the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Displaying the module status . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 3 Connecting a BigIron RX Series Switch to a Network Device

Assigning passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Configuring IP addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Support of sub-net masks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Assigning an IP address to a management interface . . . . . . . .69

Assigning an IP address to an interface, virtual Interface,

or loopback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Enabling and disabling the interfaces . . . . . . . . . . . . . . . . . . . .70

iv Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 5

Understanding how the management port functions. . . . . . . . . . . . 71

Connecting a BigIron RX Series switch. . . . . . . . . . . . . . . . . . . . . . . 71

4-port 10 Gigabit Ethernet module. . . . . . . . . . . . . . . . . . . . . . .72

16-port 10 Gigabit Ethernet module . . . . . . . . . . . . . . . . . . . . .72

Installing a fiber optic module . . . . . . . . . . . . . . . . . . . . . . . . . .72

Cabling a fiber optic module . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Enhanced Digital Optical Monitoring . . . . . . . . . . . . . . . . . . . . .73

Cleaning fiber optic modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Troubleshooting network connections . . . . . . . . . . . . . . . . . . . .75

Testing network connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Pinging an IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Tracing a route . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Using virtual cable testing to diagnose a cable . . . . . . . . . . . . .77

Chapter 4 Managing the BigIron RX Series Chassis and Modules

Managing the BigIron RX Series chassis. . . . . . . . . . . . . . . . . . . . . .79

Displaying chassis status and temperature readings . . . . . . . . 79

Displaying the Syslog configuration and static and

dynamic buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Managing the cooling system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Configuring the cooling system. . . . . . . . . . . . . . . . . . . . . . . . . .83

Manually setting the fan speed . . . . . . . . . . . . . . . . . . . . . . . . .87

Monitoring the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . .87

Managing the interface modules. . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Configuring interface module boot parameters. . . . . . . . . . . . .89

Synchronizing the interface module’s IronWare images

between management and interface modules . . . . . . . . . . . . .89

Specifying an immediate boot. . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Changing priority of chassis slots for interface modules . . . . .95

Disabling and reenabling power to the interface modules . . . .95

Disabling and reenabling power to the switch

fabric modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Enabling and disabling management module CPU

usage calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Displaying management module CPU usage . . . . . . . . . . . . . . . . . . 97

Removing MAC address entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Chapter 5 Maintaining a BigIron RX Series Switch

Replacing a management module. . . . . . . . . . . . . . . . . . . . . . . . . . .99

Removing a management module . . . . . . . . . . . . . . . . . . . . . .100

Installing a new management module. . . . . . . . . . . . . . . . . . .101

Monitoring the status of an I2C failure

on a management module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Modification to show chassis command outputs . . . . . . . . . .104

Replacing an interface module . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Removing an interface module. . . . . . . . . . . . . . . . . . . . . . . . .105

Installing a new interface module. . . . . . . . . . . . . . . . . . . . . . .106

Brocade BigIron RX Series Hardware Installation Guide v

53-1002483-03

Page 6

Replacing a switch fabric module . . . . . . . . . . . . . . . . . . . . . . . . . .109

Removing a switch fabric module. . . . . . . . . . . . . . . . . . . . . . .109

Installing a new switch fabric module . . . . . . . . . . . . . . . . . . .110

Replacing a fiber-optic transceiver . . . . . . . . . . . . . . . . . . . . . . . . .110

Removing a fiber-optic transceiver . . . . . . . . . . . . . . . . . . . . . .111

Installing a new fiber-optic transceiver. . . . . . . . . . . . . . . . . . .111

Cabling a fiber-optic transceiver . . . . . . . . . . . . . . . . . . . . . . . .112

Replacing a power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Determining which power supply failed . . . . . . . . . . . . . . . . . .112

Replacing a power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Replacing cooling system components . . . . . . . . . . . . . . . . . . . . . .114

Replacing fan assemblies in the BigIron RX-16. . . . . . . . . . . .114

Replacing the fan assembly in the BigIron RX-4

and BigIron RX-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Replacing the air filters in a BigIron RX Series switch. . . . . . .119

Chapter 6 Upgrading Software Images and Configuration Files

Software images required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Software image naming conventions . . . . . . . . . . . . . . . . . . . . . . .123

Displaying flash memory and version information . . . . . . . . . . . . .124

Displaying flash information . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Displaying version information . . . . . . . . . . . . . . . . . . . . . . . . .128

Upgrading the BigIron RX Series software. . . . . . . . . . . . . . . . . . . .130

Changes to software images starting with version 02.5.00 . .130

Command change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Using unified software images to upgrade images . . . . . . . . . . . .133

Unified software image upgrade to upgrade release

02.6.00 and later. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Unified software image upgrade to upgrade

release 02.2.01 to 02.5.00 . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Upgrading images independently . . . . . . . . . . . . . . . . . . . . . . . . . .135

Upgrading software releases prior to release 02.2.01 . . . . . .135

Basic tasks in the software upgrade process . . . . . . . . . . . . .136

Upgrading the management module monitor and boot images136

Upgrading the IronWare image on a management module . .137

Upgrading the monitor and boot images on interface modules137

Upgrading the interface module’s IronWare image. . . . . . . . .138

Rebooting the management module . . . . . . . . . . . . . . . . . . . .139

Upgrading the MBRIDGE FPGA on the management

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Hitless Layer 2 OS upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . .141

vi Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 7

Loading and saving configuration files . . . . . . . . . . . . . . . . . . . . . .145

Replacing the startup configuration with the running

configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Replacing the running configuration with the startup

configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Logging changes to the startup-config file. . . . . . . . . . . . . . . .146

Copying a configuration file to or from a TFTP server . . . . . . . 147

Making local copies of the startup configuration file . . . . . . .147

Dynamic configuration loading. . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Loading the configuration information into the

running-config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Using SNMP to save and load configuration information. . . . . . . .150

Erasing image and configuration files . . . . . . . . . . . . . . . . . . . . . . .151

File synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

File synchronization between the active and standby

management modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

File synchronization between the management and

interface modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Scheduling a system reload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Reloading at a specific time . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Reloading after a specific amount of time . . . . . . . . . . . . . . . .155

Displaying the amount of time remaining before a

scheduled reload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Canceling a scheduled reload. . . . . . . . . . . . . . . . . . . . . . . . . .155

Diagnostic error codes and remedies for TFTP transfers. . . . . . . .156

Chapter 7 Hardware Specifications

Hardware specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Physical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Storage environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Safety agency approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Electromagnetic approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Port specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Console port pin assignments . . . . . . . . . . . . . . . . . . . . . . . . .160

Management port pin assignments . . . . . . . . . . . . . . . . . . . . .161

Appendix A Regulatory Statements

U.S.A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Industry Canada statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Europe and Australia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Japan Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Brocade BigIron RX Series Hardware Installation Guide vii

53-1002483-03

Page 8

Korea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Class A statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Russia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Taiwan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

BSMI Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Appendix B Caution and Danger Notices

Caution statements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Danger notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Appendix C Software Specifications

IEEE compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

RFC support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

General protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

BGP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

OSPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

RIP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

IP Multicast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Internet drafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Appendix D Using Brocade Structured Cabling Components

Cable cinch overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

mRJ21 procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Cable cinch with two mRJ21 cables . . . . . . . . . . . . . . . . . . . . .186

Cable cinch with three mRJ21 cables . . . . . . . . . . . . . . . . . . .187

Cable cinch with four mRJ21 cables. . . . . . . . . . . . . . . . . . . . .187

Cable cinch with five mRJ21 cables . . . . . . . . . . . . . . . . . . . . .187

Cable cinch with six mRJ21 cables. . . . . . . . . . . . . . . . . . . . . .188

Cable cinch with seven mRJ21 cables . . . . . . . . . . . . . . . . . . .188

Cable cinch with eight mRJ21 cables. . . . . . . . . . . . . . . . . . . .189

RJ45 procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Cable cinch with one group of RJ45 cables . . . . . . . . . . . . . . .190

Cable cinch with two groups of RJ45 cables . . . . . . . . . . . . . .190

Cable cinch with three groups of RJ45 cables. . . . . . . . . . . . .191

Cable cinch with four groups of RJ45 cables. . . . . . . . . . . . . .191

Cable cinch with five groups of RJ45 cables . . . . . . . . . . . . . .192

Cable cinch with six groups of RJ45 cables . . . . . . . . . . . . . . .192

Cable cinch with seven groups of RJ45 cables . . . . . . . . . . . .193

Cable cinch with eight groups of RJ45 cables . . . . . . . . . . . . .193

viii Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 9

About This Document

In this chapter

•Supported hardware and software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

•Document conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

•Trademark references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

•Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

•Getting technical help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

•Document feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Supported hardware and software

Although many different software and hardware configurations are tested and supported by

Brocade Communications Systems, Inc., documenting all possible configurations and scenarios is

beyond the scope of this document.

This guide describes the Multi-Service Ironware 02.9.00 release.

The following hardware platforms are discussed in this guide:

• BigIron RX-4

• BigIron RX-8

• BigIron RX-16

Document conventions

This section describes text formatting conventions and important notice formats used in this

document.

Text formatting

The narrative-text formatting conventions that are used are as follows:

Brocade BigIron RX Series Hardware Installation Guide ix

53-1002483-03

Page 10

NOTE

ATTENTION

CAUTION

DANGER

bold text Identifies command names

Identifies the names of user-manipulated GUI elements

Identifies keywords

Identifies text to enter at the GUI or CLI

italic text Provides emphasis

Identifies variables

Identifies document titles

code text Identifies CLI output

Notes, cautions, and danger notices

The following notices and statements are used in this manual. They are listed below in order of

increasing severity of potential hazards.

A note provides a tip, guidance or advice, emphasizes important information, or provides a reference

to related information.

An Attention statement indicates potential damage to hardware or data.

A Caution statement alerts you to situations that can be potentially hazardous to you or cause

damage to hardware, firmware, software, or data.

A Danger statement indicates conditions or situations that can be potentially lethal or extremely

hazardous to you. Safety labels are also attached directly to products to warn of these conditions

or situations.

Trademark references

This document may contain references to the trademarks of the following corporations. These

trademarks are the properties of their respective companies and corporations.

These references are made for informational purposes only.

Corporation Referenced trademarks and products

Phillips Screw Company, Inc Phillips

x Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 11

Related publications

The following Brocade documents supplement the information in this guide and can be located at

http://www.brocade.com/ethernetproducts:

• BigIron RX Series Configuration Guide

• Ironware MIB Reference

Getting technical help

To contact Technical Suppor t, go to http://www.brocade.com/services-support/index.page for the

latest e-mail and telephone contact information.

Document feedback

Quality is our first concern at Brocade and we have made every effort to ensure the accuracy and

completeness of this document. However, if you find an error or an omission, or you think that a

topic needs further development, we want to hear from you. Forward your feedback to:

documentation@brocade.com

Provide the title and version number of the document and as much detail as possible about your

comment, including the topic heading and page number and your suggestions for improvement.

Brocade BigIron RX Series Hardware Installation Guide xi

53-1002483-03

Page 12

xii Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 13

Chapter

Product Overview

In this chapter

•Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

•Hardware features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

•Supported software features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Product overview

The BigIron RX Series switch provides high-performance L2/3 switching for the Enterprise, large

data centers, and grid computing topologies.

The BigIron RX Series switch provides the following benefits:

• 240 Gbps full-duplex capacity per full slot and over 1.92 Terabit switching capacity for

wire-speed, non-blocking switching and routing of up to 1.14 Bpps throughput capacity.

• Non-blocking 10 GbE and 1 GbE port density of up to 64 non-blocking 10 Gigabit Ethernet or

384 Gigabit Ethernet ports within a 16-slot chassis and up to 192 10 Gigabit Ethernet or 1,152

Gigabit Ethernet ports in a standard 7-foot Telco rack.

• Ultra-low latency routing of up to 512,000 IPv4 routes in hardware.

• Support for a comprehensive set of standards-based routing protocols including RIP, IS-IS,

BGP4, and OSFP.

• Foundry Direct Routing (FDR) with rule-based ACLs provide wire-speed forwarding, filtering and

accelerated convergence.

• End-to-end QoS delivery with Advanced Bandwidth Management (ABM) features.

• The High availability (redundancy) of the following BigIron RX Series critical components are:

- Redundant management modules with Hitless Management Failover (HMF)

- Redundant switch fabric elements

- Redundant fans

- Interface modules with hot-pleadable optics

- Hot-swappable power supplies

• 80 Gbps of cross-module link aggregation based on 802.3ad for reliant bandwidth scalability

between any two BigIron RX Series 10 Gigabit Ethernet switches.

• Built-in sFlow™ technology (RFC 3176) delivers scalable network monitoring, accounting and

billing at 10 Gbps speed using Layer 2-7 per-port information, offering detailed capacity

planning and security analysis solutions.

• A management (10/100/1000BaseTX Ethernet) port that can provide connectivity to your

existing management network.

1

Brocade BigIron RX Series Hardware Installation Guide 1

53-1002483-03

Page 14

Hardware features

7

6

5

1324

8910

1

Hardware features

The BigIron RX Series switches are composed of the following major hardware components:

• Chassis

• Management modules

• Interface modules

• Switch fabric module

• Power supplies

• Cooling system, which is composed of temperature sensors, fans, and fan control modules

• Rack mount kit

The following sections provide more information about these components.

Chassis

The BigIron RX Series chassis consists of the following four chassis:

• BigIron RX-4: Provides 4 interface slots

• BigIron RX-8: Provides 8 interface slots

• BigIron RX-16: Provides 16 interface slots

The following figures illustrate the BigIron RX Series chassis:

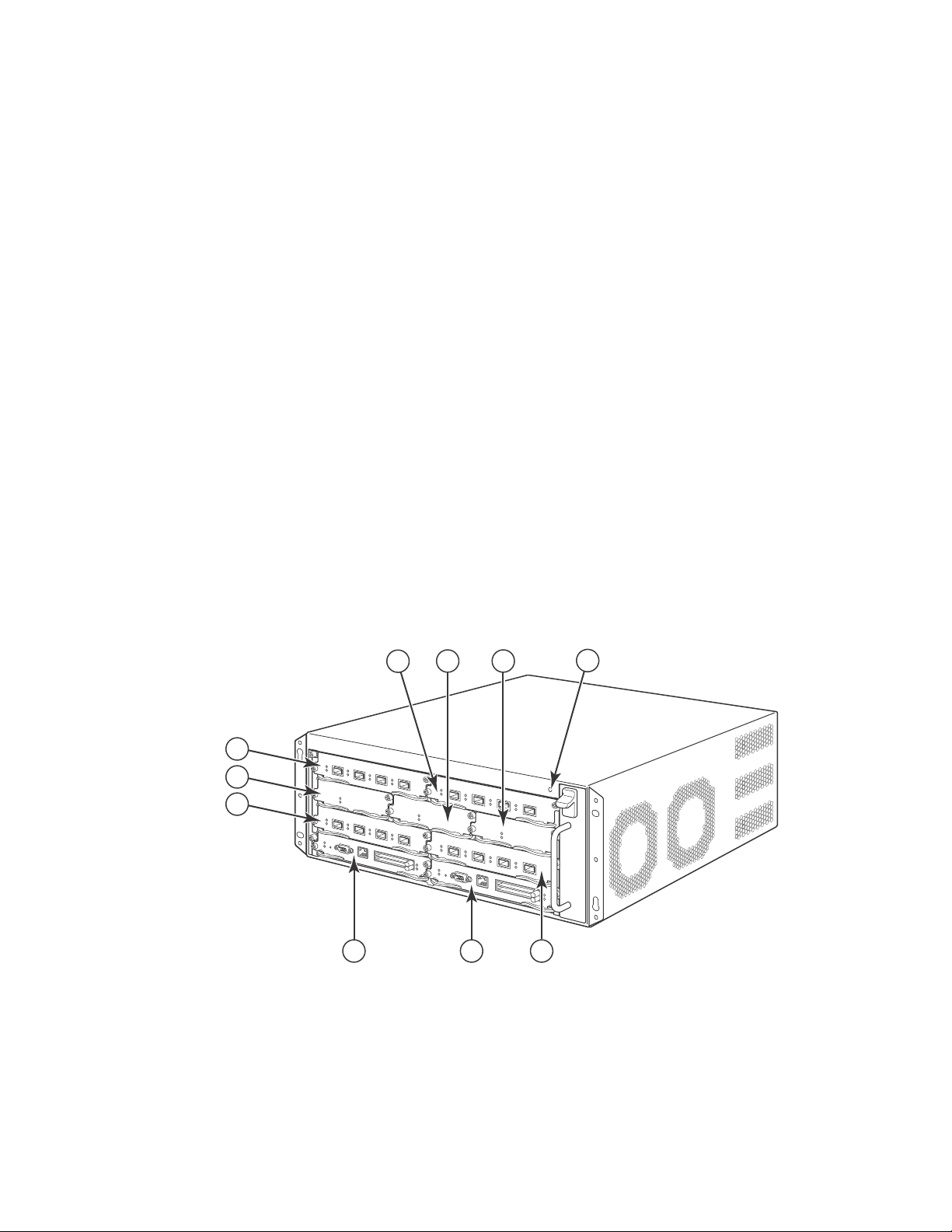

FIGURE 1 BigIron RX-4 chassis

1 Interface slot 2 6 Switch fabric slot 1

2 Switch fabric slot 2 7 Interface slot 3

3 Switch fabric slot 3 8 Management slot 1

4 ESD connector 9 Management slot 2

5 Interface slot 1 10 Interface slot 4

2 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 15

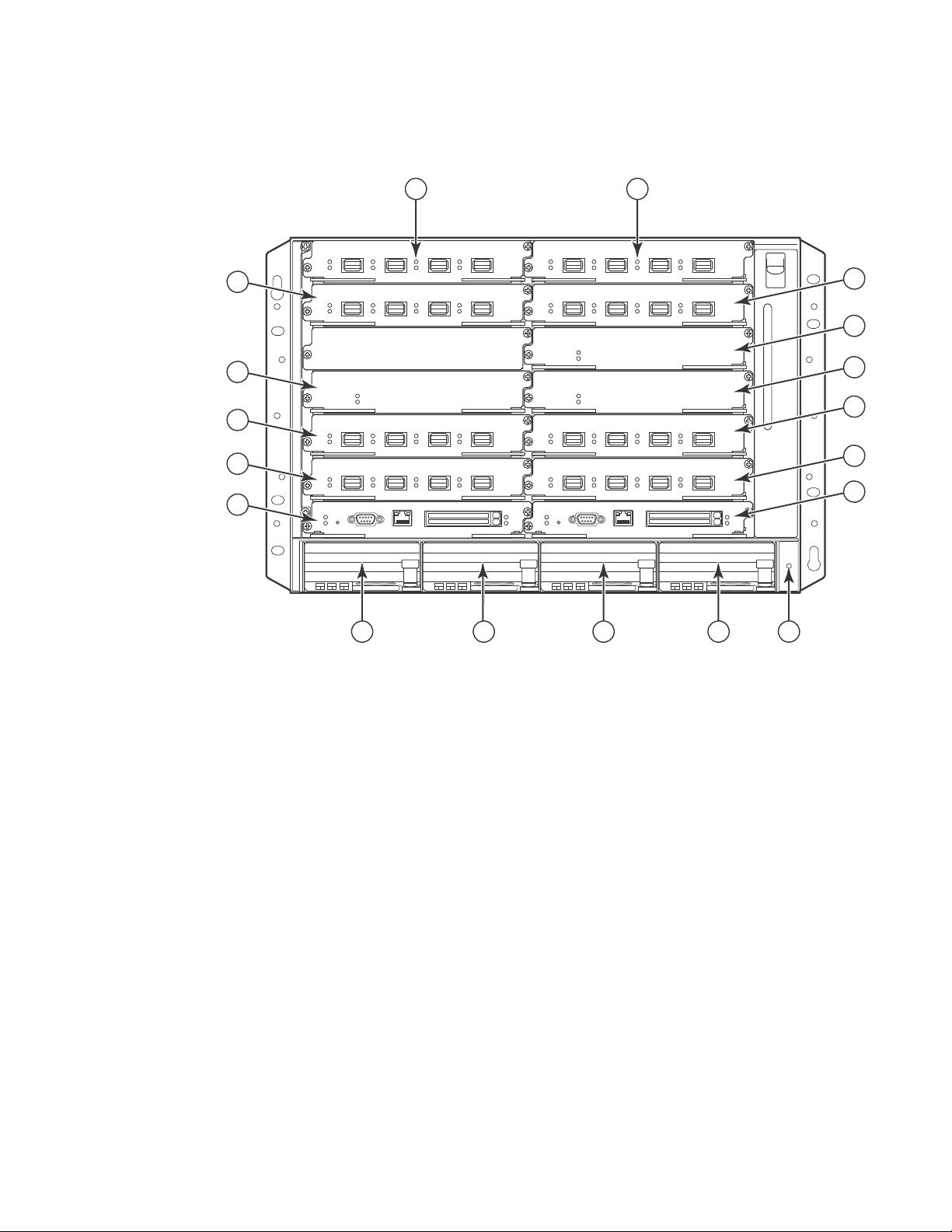

FIGURE 2 BigIron RX-8 chassis

8

10

12

6

9

7

5

4

3

14 15

11

16 17

1 2

13

18

Hardware features

1

1 Interface slot 1 10 Interface slot 7

2 Interface slot 2 11 Interface slot 8

3 Interface slot 3 12 Management slot 1

4 Interface slot 4 13 Management slot 2

5 Switch fabric slot 1 14 Power supply slot 1

6 Switch fabric slot 2 15 Power supply slot 2

7 Switch fabric slot 3 16 Power supply slot 3

8 Interface slot 5 17 Power supply slot 4

9 Interface slot 6 18 ESD connector

Brocade BigIron RX Series Hardware Installation Guide 3

53-1002483-03

Page 16

Hardware features

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

91011

1

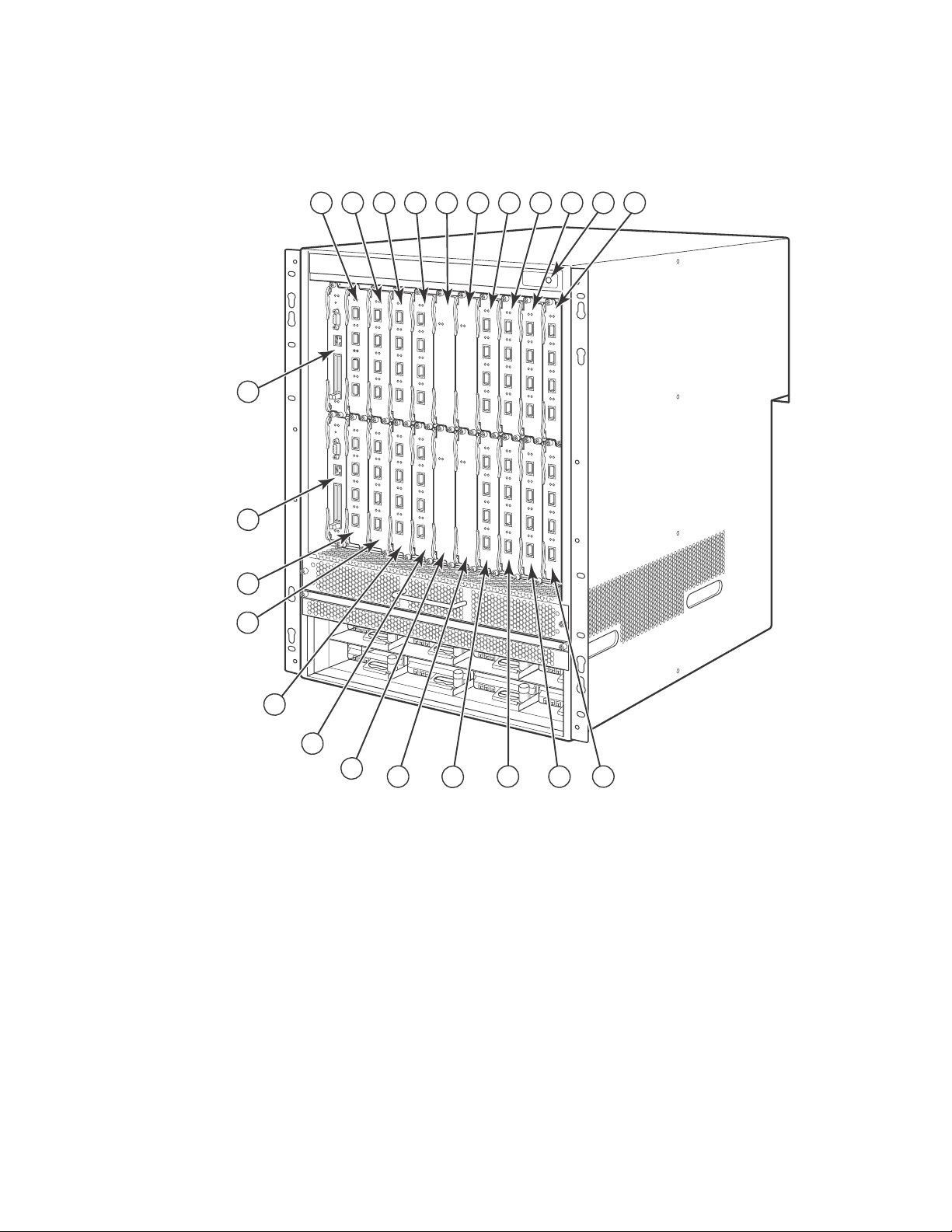

FIGURE 3 BigIron RX-16 chassis

1 Interface slot 1 10 Interface slot 10 19 Switch fabric slot 3

2 Interface slot 2 11 Interface slot 11 20 Switch fabric slot 4

3 Interface slot 3 12 Interface slot 12 21 Management slot 1

4 Interface slot 4 13 Interface slot 13 22 Management slot 2

5 Interface slot 5 14 Interface slot 14 23 ESD connector

6 Interface slot 6 15 Interface slot 15

7 Interface slot 7 16 Interface slot 16

8 Interface slot 8 17 Switch fabric slot 1

9 Interface slot 9 18 Switch fabric slot 2

4 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 17

Hardware features

1 Interface slot 1 19 Interface slot 19 37 Switch fabric slot 5

2 Interface slot 2 20 Interface slot 20 38 Switch fabric slot 6

3 Interface slot 3 21 Interface slot 21 39 Switch fabric slot 7

4 Interface slot 4 22 Interface slot 22 40 Switch fabric slot 8

5 Interface slot 5 23 Interface slot 23 41 Management slot 1

6 Interface slot 6 24 Interface slot 24 42 Management slot 2

7 Interface slot 7 25 Interface slot 25 43 Captive screws

8 Interface slot 8 26 Interface slot 26 44 ESD strap connector

9 Interface slot 9 27 Interface slot 27 45 Power supply 1

10 Interface slot 10 28 Interface slot 28 46 Power supply 2

11 Interface slot 11 29 Interface slot 29 47 Power supply 3

12 Interface slot 12 30 Interface slot 30 48 Power supply 4

13 Interface slot 13 31 Interface slot 31 49 Power supply 5

14 Interface slot 14 32 Interface slot 32 50 Power supply 6

15 Interface slot 15 33 Switch fabric slot 1 51 Power supply 7

16 Interface slot 16 34 Switch fabric slot 2 52 Power supply 8

17 Interface slot 17 35 Switch fabric slot 3

18 Interface slot 18 36 Switch fabric slot 4

1

BigIron RX-4

Upon shipment from the factory, the following components are installed in the BigIron RX-4 chassis

as described:

• Two switch fabric modules.

• A slot blank in each interface module slot. The slot blank covers a slot that does not currently

have a module installed in it, ensuring proper airflow within the chassis.

• A fan tray assembly, which is located in the front right side of the chassis. For more information

about the fans, refer to “Cooling system” on page 17.

• One power supply (AC or DC).

In the slots of the chassis you can install the following:

• Up to two management modules (one active and one redundant).

• Up to three switch fabric modules.

• Up to four interface modules.

• Up to three power supplies (AC or DC).

Before installing any modules or power supplies, you must remove the slot blank or blank power

supply faceplate, respectively.

Brocade BigIron RX Series Hardware Installation Guide 5

53-1002483-03

Page 18

Hardware features

CAUTION

1

BigIron RX-8

Upon shipment from the factory, the following components are installed in the BigIron RX-8 chassis

as described:

• Two switch fabric modules.

• A slot blank in each interface module slot. The slot blank covers a slot that does not currently

have a module installed in it, ensuring proper airflow within the chassis.

• A fan tray assembly, which is located in the front right side of the chassis. For more information

about the fans, refer to “Cooling system” on page 17.

• Two power supplies (AC or DC).

In the slots of the chassis you can install the following:

• Up to two management modules (one active and one redundant).

• Up to three switch fabric modules.

• Up to eight interface modules.

• Up to four power supplies (AC or DC).

Before installing any modules or power supplies, you must remove the slot blank or blank power

supply faceplate, respectively.

BigIron RX-16

Upon shipment from the factory, the following components are installed in the BigIron RX-16

chassis as described:

• Three switch fabric modules.

• A slot blank in each interface module slot. The slot blank covers a slot that does not currently

have a module installed in it, ensuring proper airflow within the chassis.

• A fan tray assembly located in the front right side of the chassis. and two fan assemblies

located at the rear of the chassis. For more information about the fans, refer to “Cooling

system” on page 17.

• Four power supplies.

In the slots of the chassis you can install the following:

• Up to two management modules (one active and one redundant).

• Up to four switch fabric modules.

• Up to sixteen interface modules.

• Up to eight power supplies (AC or DC).

Before installing any modules or power supplies, you must remove the slot blank or blank power

supply faceplate, respectively (BigIron RX-4, -8, and 16).

If you do not install a module in a slot, you must keep the slot blank in place. If you run the

chassis with an uncovered slot, the system may overheat.

6 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 19

Hardware features

DANGER

NOTE

Pwr

Active

10/100/1000

Port 1

Port 2

Console

RX-BI-MR

1

Figure 1, Figure 2, and Figure 3show the BigIron RX Series chassis and the slots into which you

install the various modules. You must install the primary power supplies and the redundant power

supplies as described in the figures.

Figure 1, Figure 2, and Figure 3 also show an electrostatic discharge (ESD) connector, into which

you can plug an ESD wrist strap to ground yourself while handling and installing modules.

For safety reasons, the ESD wrist strap should contain a 1 meg ohm series resistor.

The BigIron RX-16 chassis versions also include a grounding lug connector, located on the rear

panel (left side). The BigIron RX-4 and BigIron RX-8 have two threaded holes on the right side of the

chassis to accommodate the addition of a ground lug connector.

Management modules

The management module controls the BigIron RX Series hardware components, runs the

networking protocols, and provides the Real Time Operating System (RTOS).

Each BigIron RX Series chassis requires one management module and can accept a second one for

redundancy. A redundant management module works along with the active management module.

If the active module becomes unavailable, the redundant management module automatically

takes over the system operation, minimizing system downtime.

You can install management modules in dedicated slots marked M1 and M2. By default, the

system considers the module installed in the slot marked M1 to be the active management

module.

BigIron RX-4, The BigIron RX Series management module is dedicated, which means that you must

install it in the BigIron RX Series chassis only. If you attempt to install the BigIron RX Series

management module in another Brocade chassis or a management module intended for another

Brocade chassis in the BigIron RX Series chassis, the chassis and module will not function properly..

A management module is hot swappable, which allows you to remove and replace it without

powering down the system.

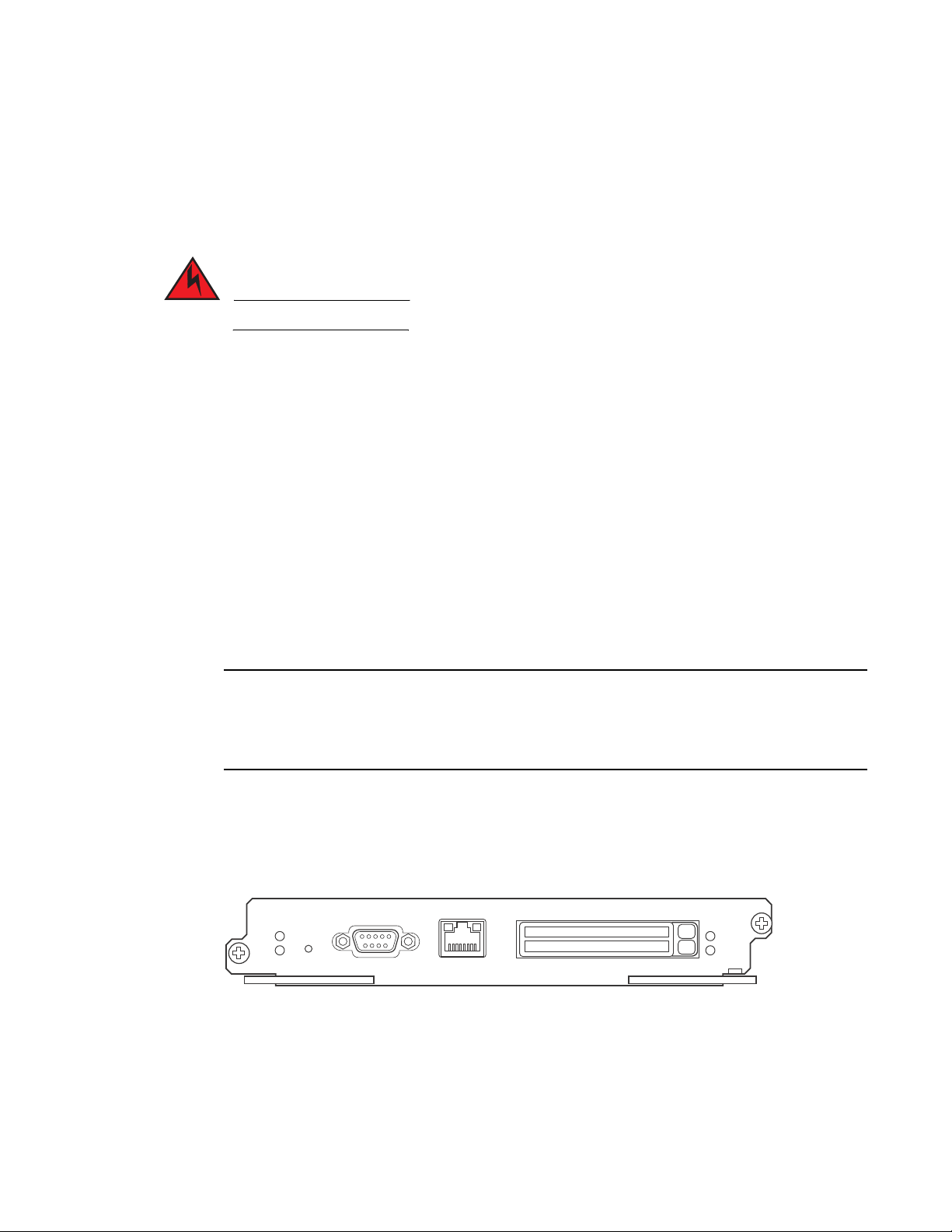

Figure 4 shows the management module’s front panel.

FIGURE 4 Management module front panel

The front panel includes the following control features:

• Two PCMCIA slots

• A Console port

• A 10/100/1000 Ethernet port

• Six LEDs

Brocade BigIron RX Series Hardware Installation Guide 7

53-1002483-03

Page 20

Hardware features

NOTE

1

PCMCIA slots

The PCMCIA slots support a flash PC card. The flash PC card provides storage space in addition to

the system’s flash memory. A flash PC card can store system files, including boot images, startup

configuration files, running configuration files, and so on. As a result, you can perform system

management tasks, such as copying files between flash PC cards, copying files between a flash PC

card and flash memory, and so on.

Console port

The Console port is a standard DB-9 serial connector through which you can attach a PC or

terminal to configure the BigIron RX Series system using the command line interface (CLI).

This port interfaces the control plane only and not the data plane.

10/100/1000 Ethernet port

The front panel includes a 10BaseT/100BaseTX/1000BaseTX auto-sensing, auto-negotiating

Ethernet port. This port has an RJ-45 unshielded twisted pair (UTP) connector.

Typical uses of this port include but are not limited to the following:

• Connecting a PC through which you can access the system through a Telnet or SSHv2

connection and configure, monitor, and manage the BigIron RX Series system.

• Connecting to the 10BaseT/100BaseTX/1000BaseTX port of a switch or router, for

connectivity to your existing management network. You can then access the BigIron RX Series

system and configure, monitor, and manage the system from a management station.

The existing management network into which you can connect the 10/100/1000 Ethernet port

must be separate and isolated from the network over which user packets are switched and routed.

This port interfaces the control plane only and not the data plane.

LEDs

Tab le 1 describes the LEDs on the management module’s front panel.

TABLE 1 Management module LEDs

LED Position State Meaning

Port 1

and

Port 2

Active Lower Left On The module is functioning as the active management

Pwr Upper Left On The module is receiving power.

Each adjacent to

the PCMCIA slot

that is

represents

On or blinking You have inserted a PCMCIA flash card in a slot or initiated

a task related to the file management system on a flash

card. As a result, the software is currently accessing the

flash card.

Off The software is not currently accessing a PCMCIA flash card

inserted in a slot.

module.

Off The module is functioning as the redundant management

module.

Off The module is not receiving power.

8 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 21

NOTE

TABLE 1 Management module LEDs (Continued)

LED Position State Meaning

Hardware features

1

10/100/100

0 Ethernet

Port

10/100/100

0 Ethernet

Port

Above and right

of RJ-45

connector

Above and left of

RJ-45 connector

On (Green) A link is established with the remote port.

Off A link is not established with the remote port.

On or blinking

(Yellow)

Off for an

extended period

The port is transmitting and receiving packets.

The port is not transmitting or receiving packets.

Interface modules

You can install up to 16 BigIron RX Series interface modules in the BigIron RX Series chassis as

described:

• BigIron RX-4: Supports up to 4 interface modules

• BigIron RX-8: Supports up to 8 interface modules

• BigIron RX-16: Supports up to 16 interface modules

A BigIron RX Series interface module is dedicated, which means that you must install it in the BigIron

RX Series chassis only. If you attempt to install a BigIron RX Series interface module in another

Brocade chassis or an interface module intended for another Brocade chassis in the BigIron RX

Series chassis, the module will not boot up to become active. Interface modules can be shared

between BigIron RX-4, BigIron RX-8, and BigIron RX-16.

The interface modules are hot swappable, which means you can remove and replace them without

powering down the system.

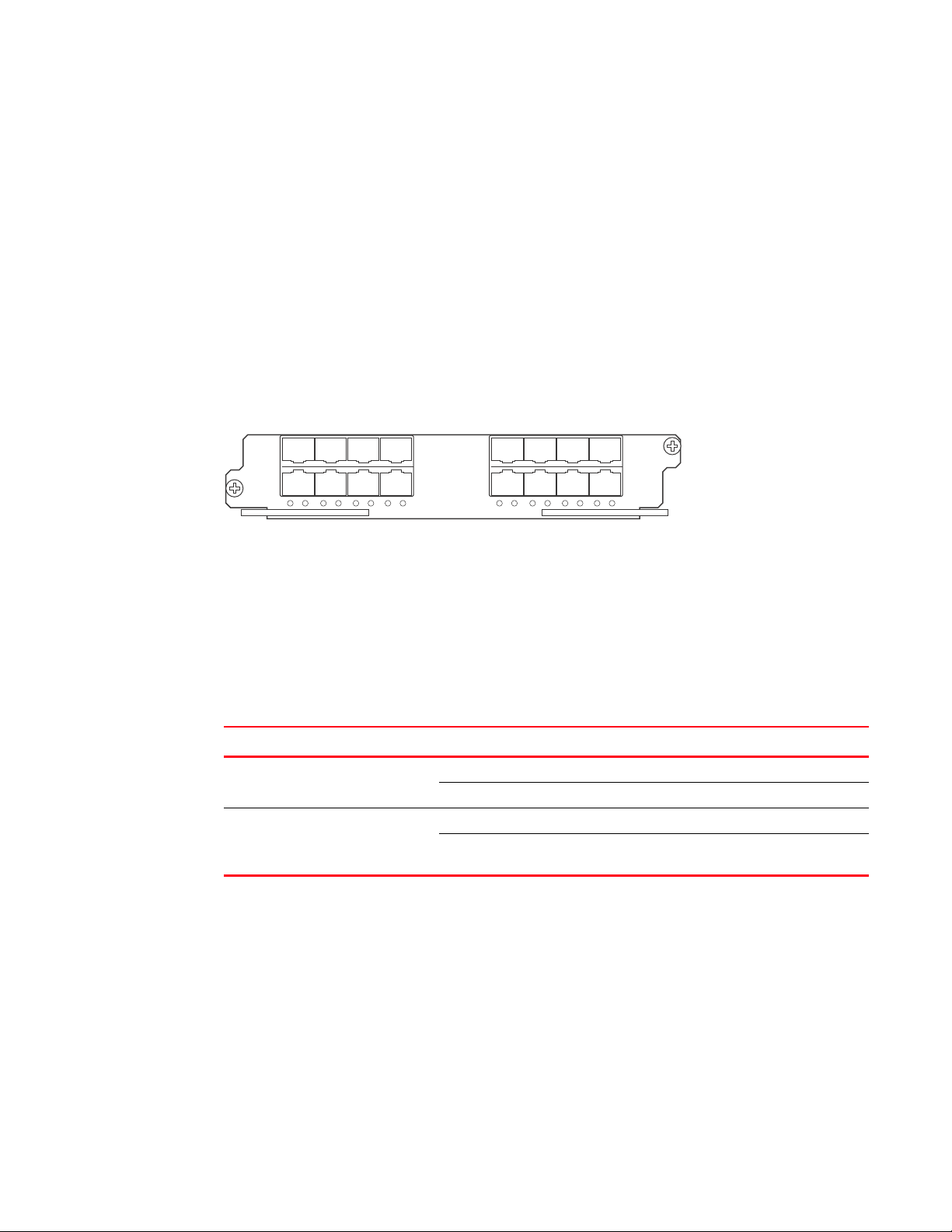

4-port 10 Gigabit Ethernet module

Figure 5 shows the 4-port 10 Gigabit Ethernet module’s front panel with XFP modules installed.

FIGURE 5 4-port 10 Gigabit Ethernet module front panel

The front panel includes the following control features:

• Four LEDs

• Four 10 Gigabit Ethernet XFP slots

LEDs

The module’s front panel includes two LEDs that indicate the status of each port.

Tab le 2 describes the LEDs on the 10 Gigabit Ethernet module’s front panel.

Brocade BigIron RX Series Hardware Installation Guide 9

53-1002483-03

Page 22

Hardware features

1

TABLE 2 10 Gigabit Ethernet module LEDs

LED Position State Meaning

Link Left of each

Ethernet port

Active Left of each

Ethernet port

On A link is established with the remote port.

Off A link is not established with the remote port.

On or blinking The port is transmitting and receiving packets.

Off for an extended

period

The port is not transmitting or receiving

packets.

A two 10-Gigabit Ethernet module contains two physical ports, through which you can connect your

BigIron RX Series switch to other network devices at a speed of 10 Gigabits.

Into a physical port, you must insert a fiber-optic module provided by Brocade. The XFP-compliant

fiber-optic modules provide an optical transceiver or physical medium dependent (PMD) interface

for single mode fiber that can be used with the LAN physical layer (PHY).

The following optic modules versions are available from Brocade:

• Short wavelength (86 – 300 meters) – Brocade part number 10G-XFP-SR

• Long wavelength (10 kilometers) – Brocade part number 10G-XFP-LR

• Extra long wavelength (40 kilometers) – Brocade part number 10G-XFP-E=The front panel

includes the following control features:

• Eight LEDs

• Four 10 Gigabit Ethernet XFP slots

LEDs

The module’s front panel includes two LEDs that indicate the status of each port.

Tab le 3 describes the LEDs on the 10 Gigabit Ethernet module’s front panel.

TABLE 3 10 Gigabit Ethernet module LEDs

LED Position State Meaning

Link Left of each

Ethernet port

Active Left of each

Ethernet port

On A link is established with the remote port.

Off A link is not established with the remote port.

On or blinking The port is transmitting and receiving packets.

Off for an extended

period

The port is not transmitting or receiving

packets.

10 Gigabit Ethernet ports

A 10 Gigabit Ethernet module contain four physical ports, through which you can connect your

BigIron RX Series switch to other network devices at a speed of 10 Gigabits.

Into a physical port, you must insert a fiber optic module provided by Brocade. The XFP-compliant

fiber optic modules provide an optical transceiver or physical medium dependent (PMD) interface

for single mode fiber that can be used with the LAN physical layer (PHY).

10 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 23

Hardware features

The following optic modules versions are available from Brocade:

1

• Short wavelength (86 – 300 meters) – Brocade part number 10G-XFP-SR

• Long wavelength (10 kilometers) – Brocade part number 10G-XFP-LR

• Extra long wavelength (40 kilometers) – Brocade part number 10G-XFP-ER

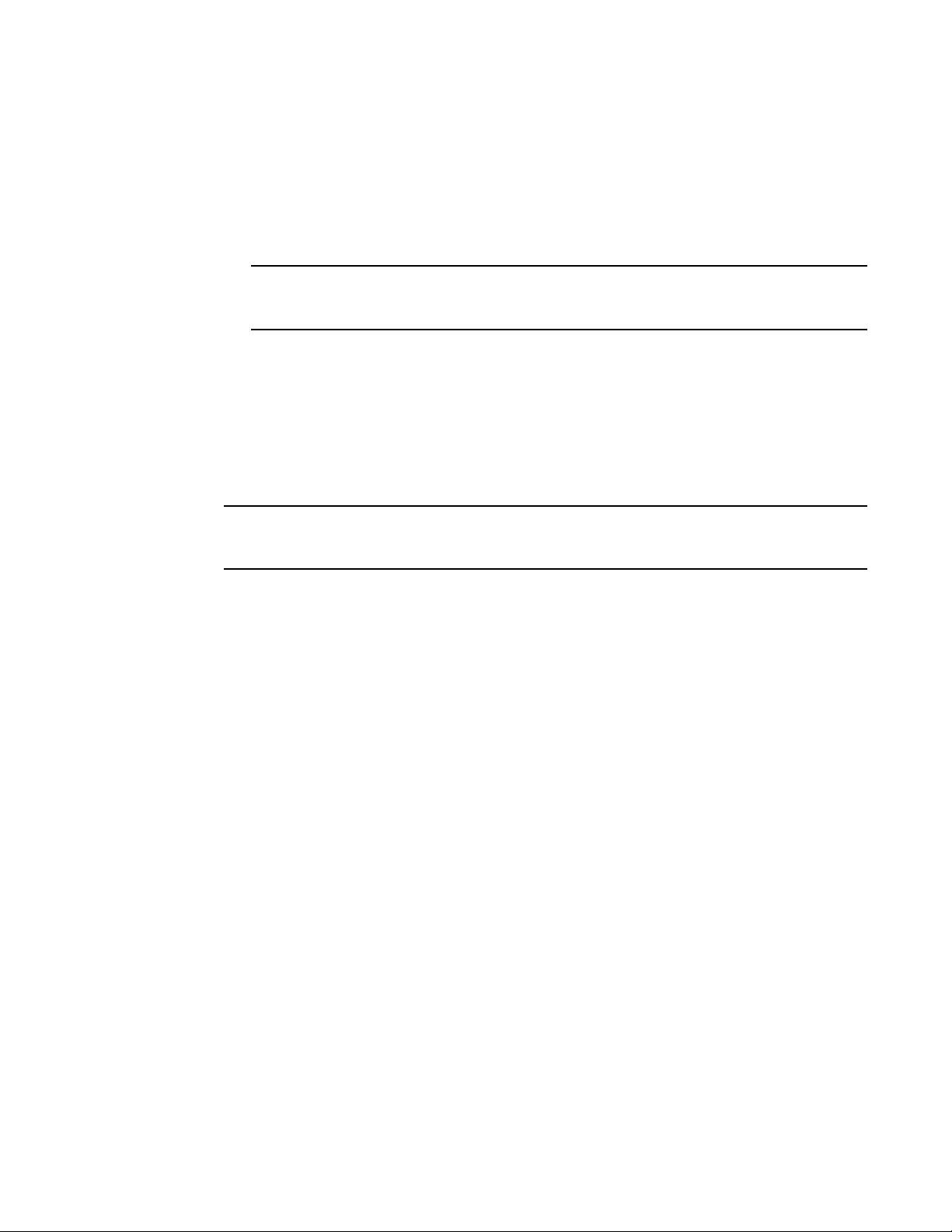

16-port 10 Gigabit Ethernet oversubscribed module

The 16 x 10GE oversubscribed module for the BigIron RX plugs into any port slot of the switch and

is compatible with all previous generations of card on that switch. It provides interfaces to 16 X

10GE ports.

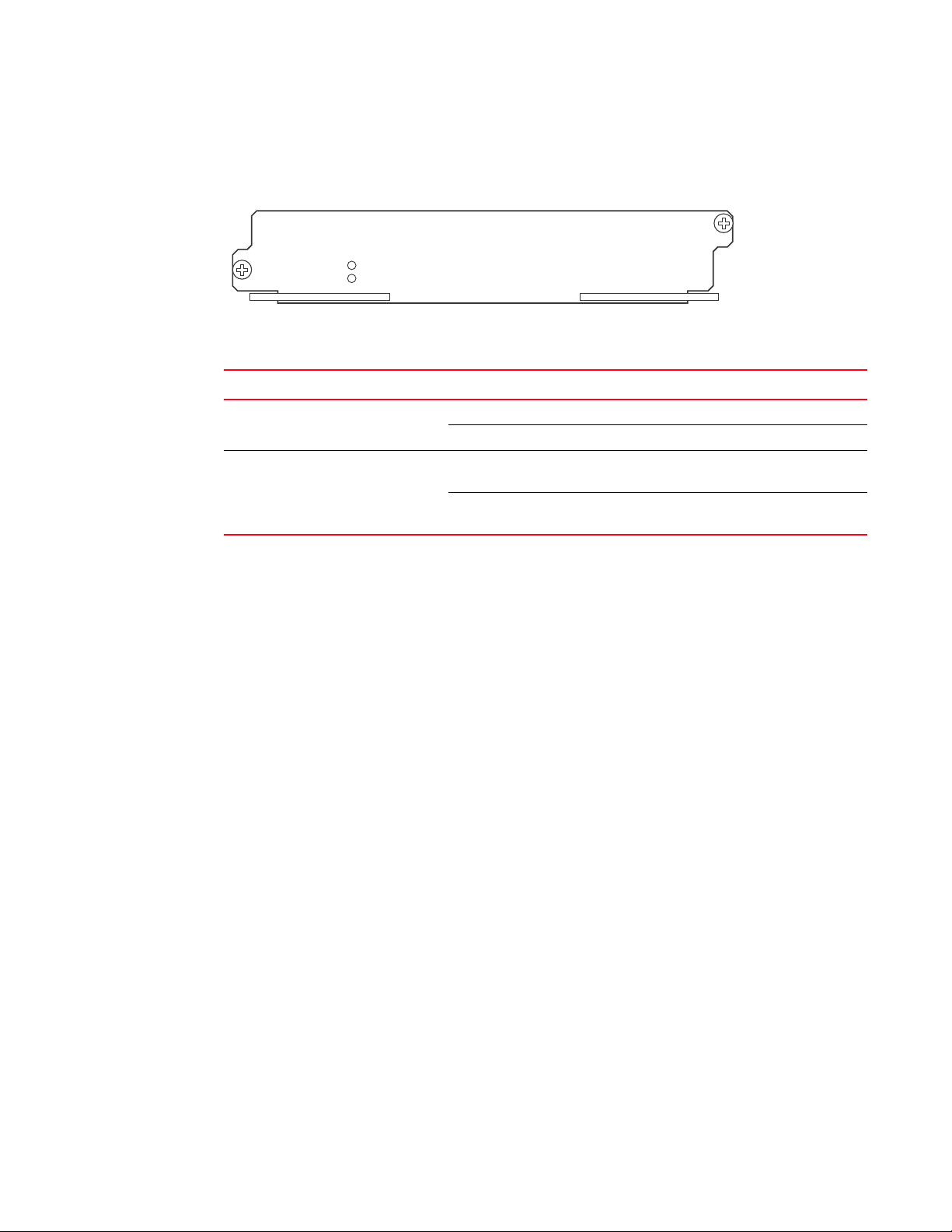

Figure 6 shows the 16-port 10 Gigabit Ethernet module’s front panel.

FIGURE 6 16-port 10 Gigabit Ethernet module front panel

The front panel includes the following control features:

• 16 LEDs

• 16 x 10 Gigabit Ethernet XFP slots

LEDs

The module’s front panel includes 16 LEDs that indicate the status of each port.

Tab le 4 describes the LEDs on the 10 Gigabit Ethernet module’s front panel.

TABLE 4 10 Gigabit Ethernet module LEDs

LED Position State Meaning

Link Below each

Ethernet port

Active Below each

Ethernet port

The following optic modules versions are available from Brocade:

On A link is established with the remote port.

Off A link is not established with the remote port.

On or blinking The port is transmitting and receiving packets.

Off for an extended period The port is not transmitting or receiving

packets.

• Short wavelength (86 – 300 meters) – Brocade part number 10G-XFP-SR

• Long wavelength (10 kilometers) – Brocade part number 10G-XFP-LR

• Extra long wavelength (40 kilometers) – Brocade part number 10G-XFP-E=The front panel

includes the following control features:

• 16 LEDs

• 16 x 10 Gigabit Ethernet XFP slots.

Brocade BigIron RX Series Hardware Installation Guide 11

53-1002483-03

Page 24

Hardware features

NOTE

NOTE

1

High speed fans requirements

• TheBigIron RX 16 requires upgrading of the rear fan modules to NI-X-16-FAN-EXH-A modules. If

the BigIron RX switch is not upgraded to support NI-X-16-FAN-EXH-A modules when 16x10G

modules are in the BigIron RX system, then the syslog message such as the following will be

displayed: SYSLOG: Mar 26 14:19:53:<12>R1, 16x10G modules in slots 10,11,13,16 must

not be running without high speed fans.

NI-X-16-FAN-EXH-A module is not shipped by default with the BigIron RX Switch. Please contact

Brocade for purchasing this module.

• When installing 16x10G modules in the BigIron RX Switch, the operating temperature must not

exceed 30C.

To display NI-X-16-FAN-EXH-A modules in an BigIron RX Switch, enter the show chassis command.

The show chassis command displays firmware Revision A (Rev A) for NI-X-16-FAN-EXH-A modules.

Rev A indicates that the BigIron RX Switch contains the required rear fan modules to support the

16X10G modules. The rpm value threshold’s (LOW/MED/MED-HI/HI) are also displayed for rear fan

modules.

If the BigIron RX Switch does not contain NI-X-16-FAN-EXH-A modules, the show chassis command

will not display Rev A for rear fan modules.

Hardware limitations

• Mirror (analyzer) ports cannot be assigned to the 16x10 card. You can monitor traffic on

16x10 ports.

• Brocade currently only supports "strict" and "destination-weighted" scheduling schemes (qos

scheduler). Refer to the Configuring QoS chapter in the BigIron RX Series Configuration Guide

for more informaton.

10 Gigabit Ethernet ports

A 16 x 10 Gigabit Ethernet module contain 16 physical ports, through which you can connect the

BigIron RX Series switch to other network devices at a speed of 10 Gigabits.

You must insert a fiber optic module provided by Brocade into a physical port. The XFP-compliant

fiber optic modules provide an optical transceiver or physical medium dependent (PMD) interface

for single mode fiber that can be used with the LAN physical layer (PHY).

The following optic modules versions are available from Brocade:

• Short wavelength (86 – 300 meters) – Brocade part number 10G-XFP-SR

• Long wavelength (10 kilometers) – Brocade part number 10G-XFP-LR

• Extra long wavelength (40 kilometers) – Brocade part number 10G-XFP-ER

Gigabit Ethernet interface module (SFP)

The 24-port 1 Gigabit Ethernet mini-GBIC (or SFP) is auto-sensing, auto-negotiating Ethernet port

and will select the FE or GE mode of operation based on the link signal received.

12 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 25

Hardware features

NOTE

NOTE

1

The device will be FE or GE capable, but will only display that is GE to indicate the maximum speed

capability of the module.

The actual speed will be displayed once the link is seen and the port auto-senses the speed of the

SFP.

You can issue the show media command to display the type of optic installed and determine the

speed the port will run at when the link is received.

Figure 7 shows the 24-port 1 Gigabit Ethernet mini-GBIC (or SFP) module’s front panel.

1

FIGURE 7 24-port 1 Gigabit Ethernet SFP module front panel

1Port status LEDs

The front panel includes the following control features:

• LEDs

• 24 1-Gigabit Ethernet mini-GBIC (SFP) ports

TABLE 5 Gigabit Ethernet module LEDs

Position State Meaning

Below each Ethernet

port

(left-side LED

supports port in top

row while right-side

LED supports port in

bottom row)

On or blinking The port is transmitting and receiving packets.

Off for an extended period The port is not transmitting or receiving packets.

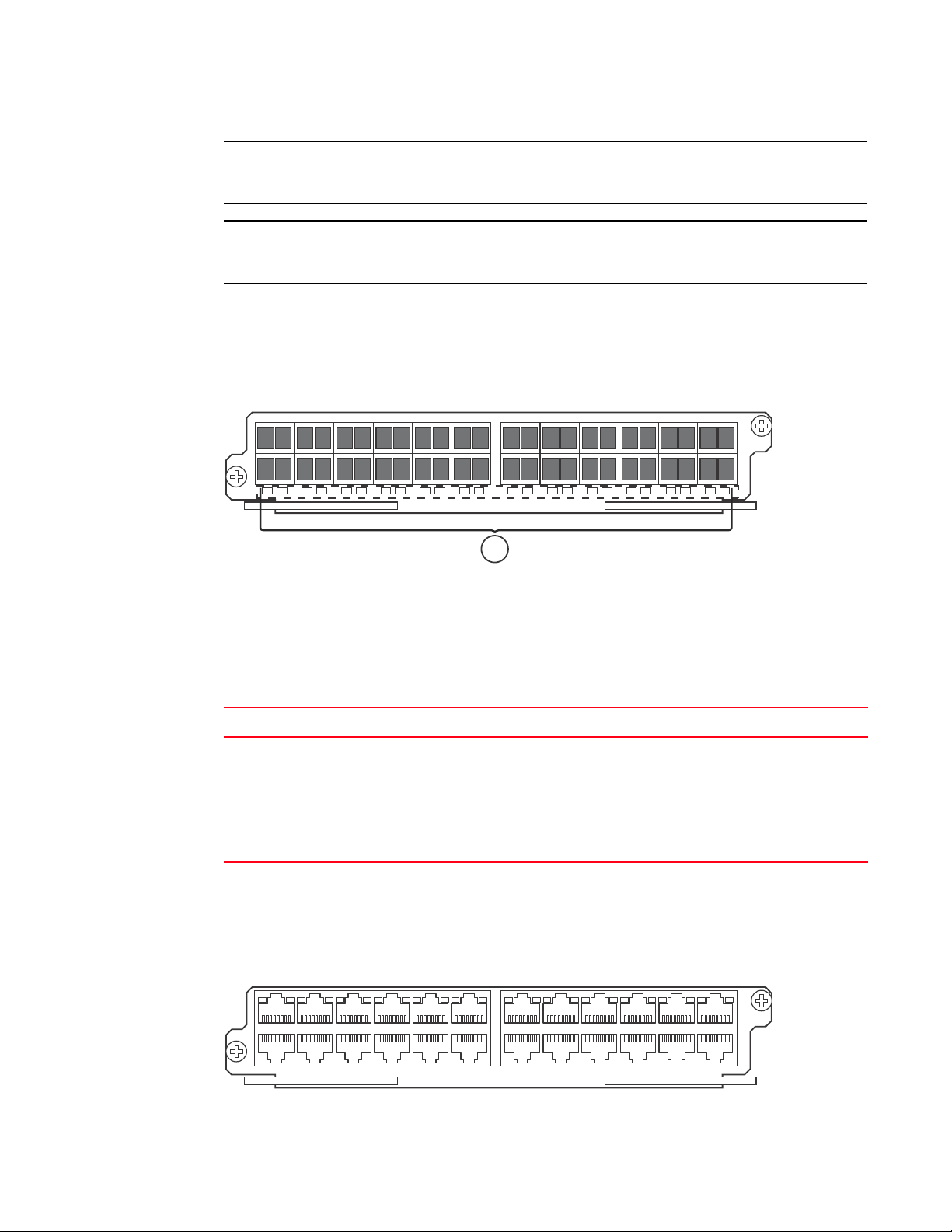

Gigabit Ethernet interface module (RJ-45)

Figure 8 shows the 24-port 1 Gigabit Ethernet module’s front panel.

FIGURE 8 24-port 1 Gigabit Ethernet module front panel

The front panel includes the following control features:

Brocade BigIron RX Series Hardware Installation Guide 13

53-1002483-03

Page 26

Hardware features

1

6

7

12

13

18

19

24

25

30

31

36

37

42

43

48

1 2 3 4 5 6 7 8

1

• LEDs

• 24 1-Gigabit Ethernet ports

TABLE 6 Gigabit Ethernet module LEDs

LED Position State Meaning

Link Left of each

Ethernet port

Active Left of each

Ethernet port

On A link is established with the remote port.

Off A link is not established with the remote port.

On or blinking The port is transmitting and receiving packets.

Off for an extended

period

The port is not transmitting or receiving

packets.

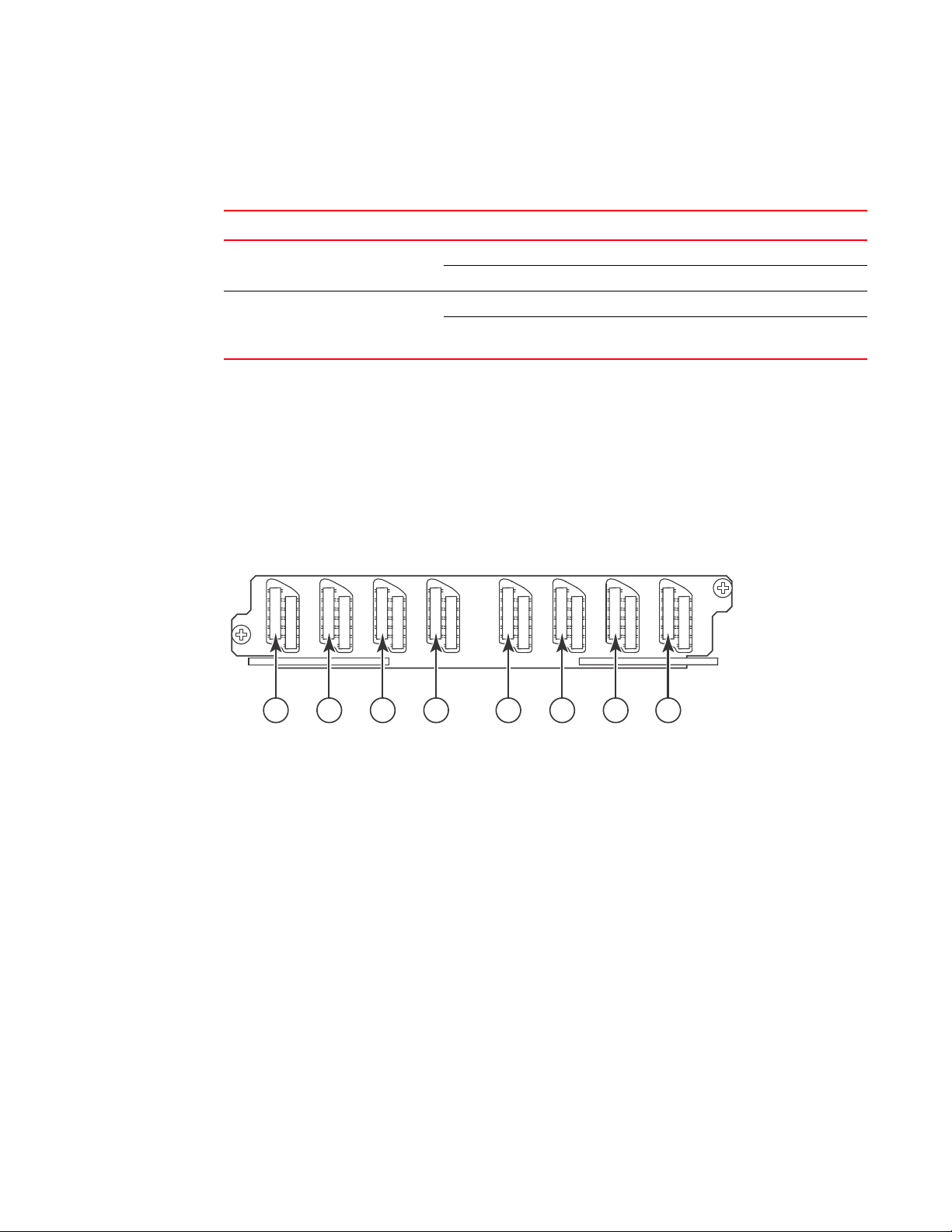

48-port 1 Gigabit Ethernet interface module (Mini RJ 21 Copper)

The interface modules are hot swappable, which means you can remove and replace them without

powering down the system.

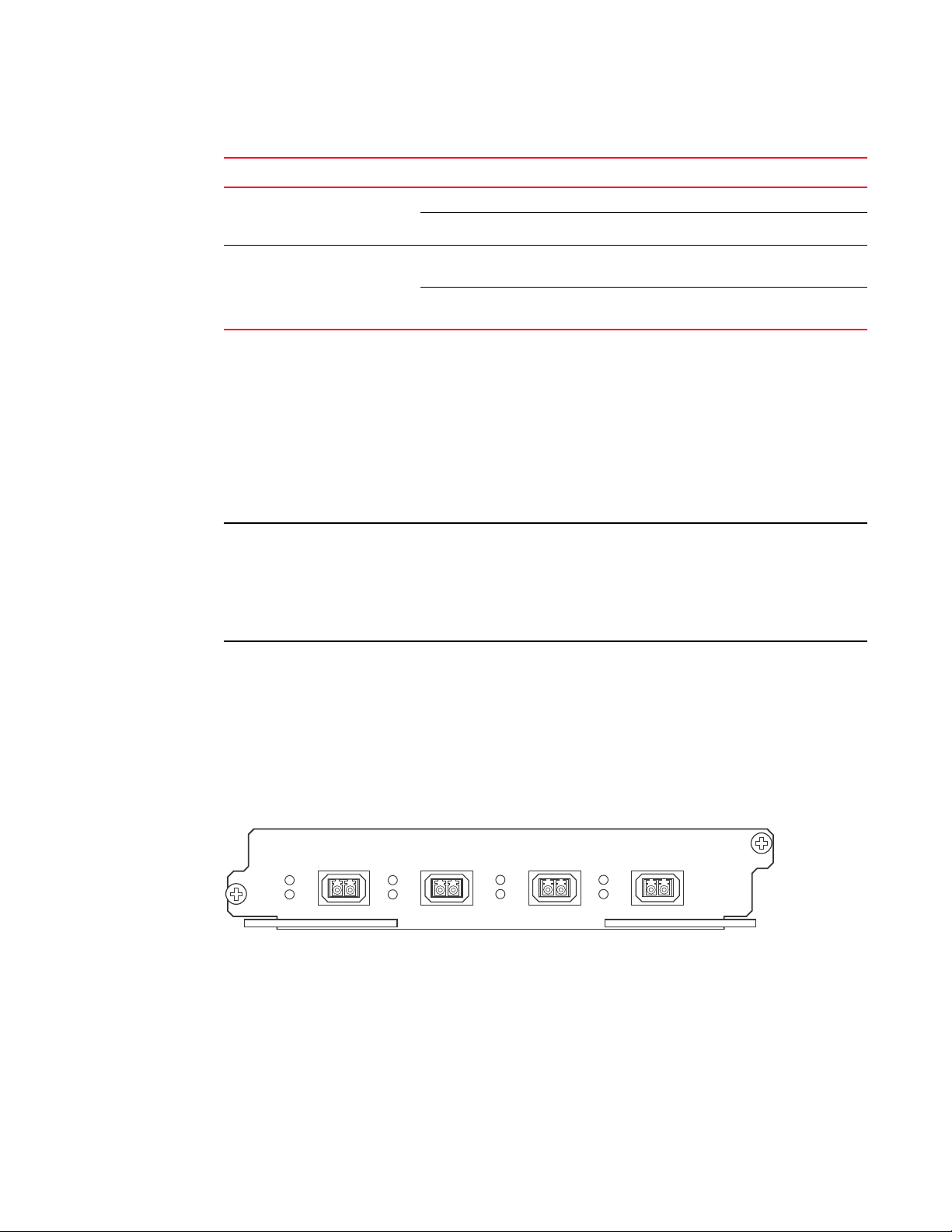

Figure 9 shows the 48-port GoC interface module’s front panel.

FIGURE 9 48-port GoC interface module front panel

1 Ports 1 -6 5 Ports 25-30

2 Ports 7-12 6 Ports 31-36

3 Ports 13 -18 7 Ports 37-42

4 Ports 19 -24 8 Ports 43-48

The front panel includes eight Mini RJ-21 Connectors that support six 10/100/1000 Gigabit

Ethernet ports each. Figure 9 shows the ports that are supported per RJ-21 connector. A cable

connects from the RJ-21 connector on the interface module to a Mini RJ-21 connector on a patch

panel. At the patch panel, the ports are broken out into individual RJ-45 connectors for each port.

Cables and patch panels that support this module are available through any Tyco International

distribution partner. Information about these products is available at the following URL:

www.ampnetconnect.com/foundrynetworks

14 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 27

Hardware features

NOTE

NOTE

NOTE

High speed fans requirements

1

• TheBigIron RX 16 requires upgrading of the rear fan modules to NI-X-16-FAN-EXH-A modules. If

the BigIron RX switch is not upgraded to support NI-X-16-FAN-EXH-A modules when 48x1G

modules are in the BigIron RX system, then the syslog message such as the following will be

displayed: SYSLOG: Mar 26 14:19:53:<12>R1, 48x1G modules in slots 10,11,13,16 must not

be running without high speed fans.

NI-X-16-FAN-EXH-A module is not shipped by default with the BigIron RX Switch. Please contact

Brocade for purchasing this module.

• When installing 48x1G modules in the BigIron RX Switch, the operating temperature must not

exceed 30C.

To display NI-X-16-FAN-EXH-A modules in an BigIron RX Switch, enter the show chassis command.

The show chassis command displays firmware Revision A (Rev A) for NI-X-16-FAN-EXH-A modules.

Rev A indicates that the BigIron RX Switch contains the required rear fan modules to support the

48x1G modules. The rpm value threshold’s (LOW/MED/MED-HI/HI) are also displayed for rear fan

modules.

If the BigIron RX Switch does not contain NI-X-16-FAN-EXH-A modules, the show chassis command

will not display Rev A for rear fan modules.

Switch fabric module

The switch fabric module switches uses packets from one interface module installed in a chassis to

another. The BigIron RX Series switches can be configured with switch fabric modules as

described:

• BigIron RX-4: Accommodates three switch fabric elements with two required and one

redundant for a fully loaded system. It is shipped with two switch fabric elements. You must

purchase an additional switch fabric element if you want your BigIron RX-4 equipped for

redundancy.

• BigIron RX-8: Accommodates three switch fabric elements with two required and one

redundant for a fully loaded system. It is shipped with two switch fabric elements. You must

purchase an additional switch fabric element if you want your BigIron RX-8 equipped for

redundancy.

• BigIron RX-16: Accommodates four switch fabric elements with three required and one

redundant for a fully loaded system. It is shipped with three switch fabric elements. You must

purchase an additional switch fabric element if you want your BigIron RX-16 equipped for

redundancy.

The switch fabric elements used for the BigIron RX-4 are a different part than those used on the

BigIron RX-8, and BigIron RX-16.

The BigIron RX Series switch fabric module is dedicated, which means that it functions properly in

the BigIron RX Series chassis only. If you attempt to install a BigIron RX Series switch fabric module

in another Brocade chassis or a switch fabric module intended for another Brocade chassis in the

BigIron RX Series chassis, the chassis and switch fabric module will not function properly.

Brocade BigIron RX Series Hardware Installation Guide 15

53-1002483-03

Page 28

Hardware features

Pwr

Active

BI-SWF

1

Figure 10 shows the switch fabric module’s front panel.

FIGURE 10 Switch fabric module front panel

The front panel includes two LEDs, which Tab le 7 describes.

TABLE 7 Switch fabric module LEDs

LED Position State Meaning

Pwr Above Active LED On The module is receiving power.

Off The module is not receiving power.

Active Below Pwr LED On The chassis switch fabric is active and ready

to switch user packets.

Off for an extended

period

The chassis switch fabric is not active and

cannot switch user packets.

Power supplies

The BigIron RX Series switches support the following power supply options:

• BigIron RX-4: Accommodates three power supplies (AC or DC) with one required and two

redundant. It is shipped with one power supply. You must purchase one or two additional

power supplies if you want your BigIron RX-4 equipped for redundancy.

• BigIron RX-8: Accommodates four power supplies (AC or DC) with two required and two

redundant. Because power is supplied over a common power bus, any power supply purchased

in addition to the two required will provide backup for any supply that fails. Equipping a BigIron

RX-8 with two additional power supplies provides full redundancy for both of the required

power supplies.

• BigIron RX-16: Accommodates eight power supplies (AC or DC) with four required and four

redundant. Because power is supplied over a common power bus, any power supply purchased

in addition to the four required will provide backup for any supply that fails. Equipping a BigIron

RX-16 with four additional power supplies provides full redundancy for all of the required power

supplies.

In the BigIron RX-8, and BigIron RX-16, you install the power supplies (AC or DC) in the slots along

the bottom of the chassis. In the BigIron RX-4, the power supplies (AC or DC) are installed in slots in

the rear of the chassis.The installed power supplies provide power to all chassis components,

sharing the workload equally and reporting their status to the management module. If the

management module detects that one of these power supplies has failed or overheated, the

management module will redistribute the failed power supply’s workload to the remaining power

supplies.

16 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 29

Hardware features

DANGER

NOTE

1

Each power supply has three LEDs on its faceplate that provide status for the input power, output

power and notification of alarms sent. If the input power and output power LEDs are on (a steady

green), the power supply is providing power to the chassis components. The power supplies are hot

swappable, which means you can remove and replace them without powering down the system.

The power supplies are hot swappable, which means they can be removed and replaced while

the BigIron RX Series chassis is powered on and running. However, Brocade recommends that

you disconnect a power supply from its power source before removing and replacing it. The

BigIron RX-8, or -16 chassis can be running while a power supply is being removed and replaced,

but the power supply itself should not be connected to a power source. Otherwise, you could be

injured or the power supply or other parts of the device could be damaged. (

1

Cooling system

The cooling system of BigIron RX Series switches is configured as described:

• BigIron RX-4: Is equipped with a fan module containing two 4-speed fans.

• BigIron RX-8: Is equipped with a fan module containing four 4-speed fans.

• BigIron RX-16: Is equipped with three fan assemblies. The fan tray located in the lower front of

the chassis contains six 4-speed fans. There are two fan assemblies located in the rear of the

chassis. Each of these contain a 4-speed fan that pulls air through the chassis. The BigIron

RX-16 is equipped with eight controllers to support redundancy.

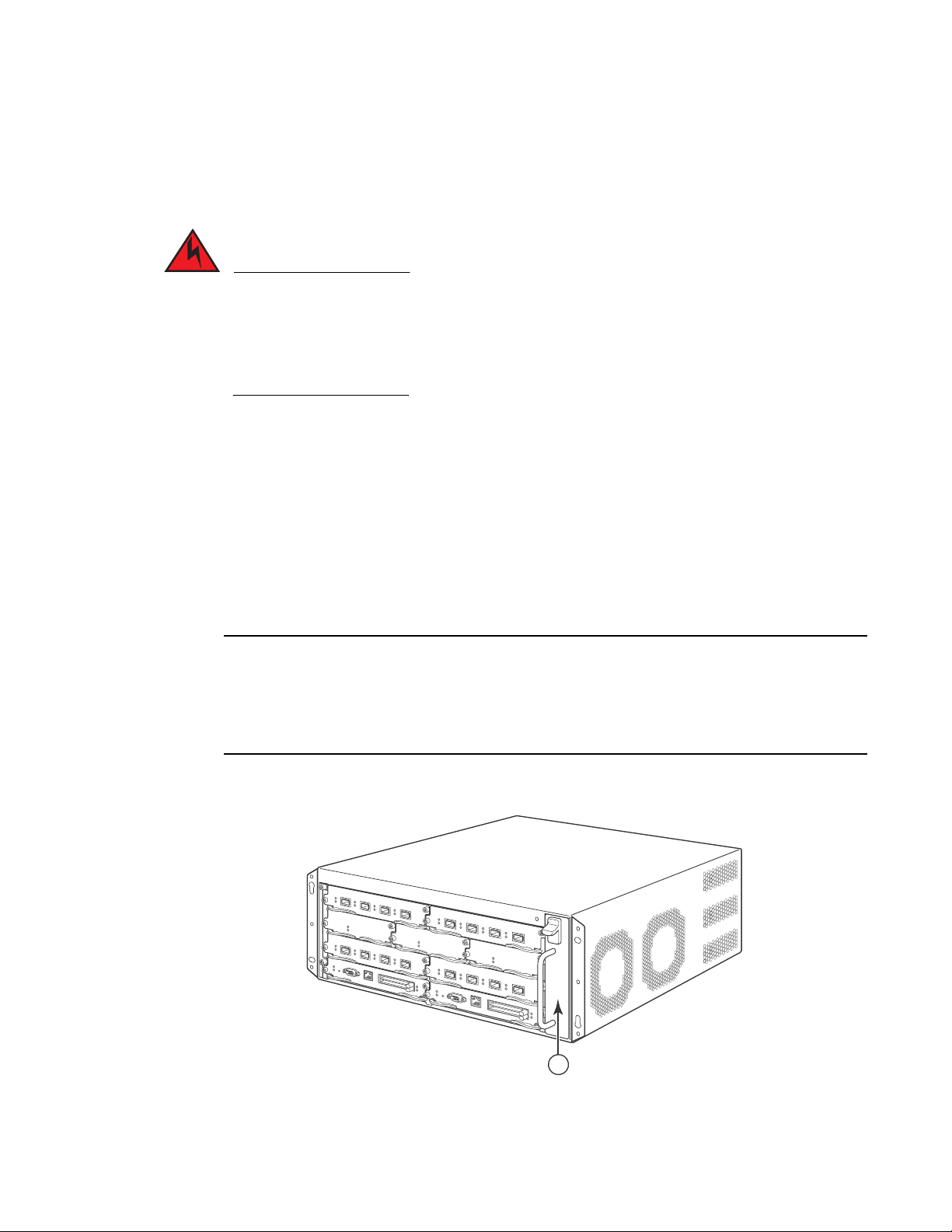

As shown in Figure 11 and Figure 12, the fans are located in the front of the BigIron RX-4 and BigIron

RX-8 chassis. Figure 13 and Figure 14 show the front and rear locations of the fans on the BigIron

RX-16. A new revision of the controller for the fan tray assemblies has been added for software

release 02.2.01 and later. There is no visible change to the fan assemblies or the procedures for

replacing the assemblies. Earlier software versions will not recognize the new controller.

FIGURE 11 Fan component locations for the BigIron RX-4

1Fan module

Brocade BigIron RX Series Hardware Installation Guide 17

53-1002483-03

Page 30

Hardware features

1

1

1

FIGURE 12 Fan component locations for the BigIron RX-8

1Fan module

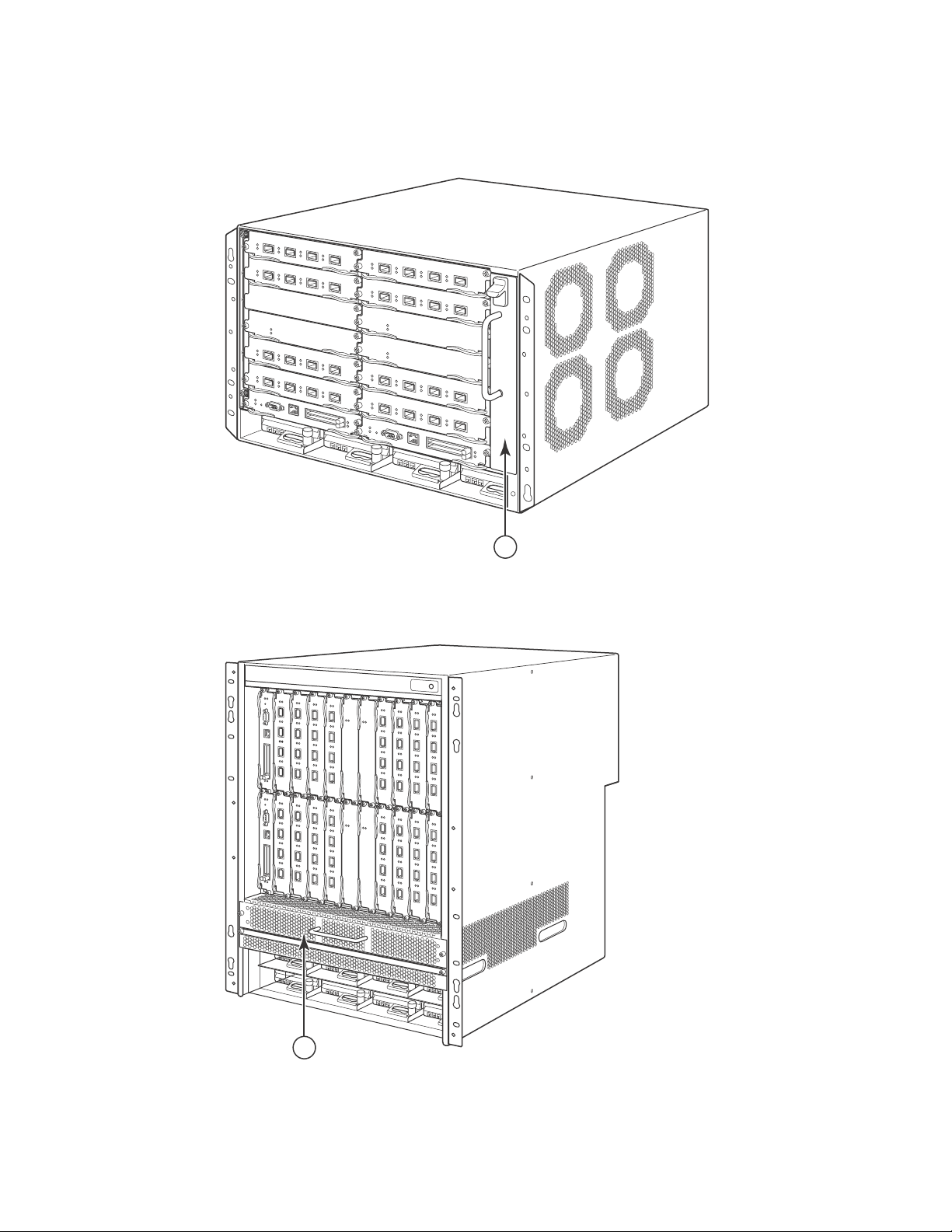

FIGURE 13 Front fan component locations for the BigIron RX-16

1 Front fan assembly

18 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 31

FIGURE 14 Rear fan component locations for the BigIron RX-16

1

Hardware features

1

1Fan modules

Upon system startup, the fans in the BigIron RX Series switches operate at high speed, then the

management module lowers the fan speed to low speed.

By default, the BigIron RX Series switch polls the temperature sensor on each module every 60

seconds to get a temperature reading. Depending on the temperature readings for the modules,

the system can do the following:

• Leave the fan speed as is

• Increase the fan speed

• Decrease the fan speed

• Shut down a module to prevent damage

If the temperature of a module exceeds specified high temperature thresholds, the system

generates a Syslog message and SNMP trap. The system can also shut the module down if the

temperature exceeds the highest threshold.

LEDs

The fan control modules include a bi-color LED, which indicates the status of the fans. Table 8

describes the LED.

Brocade BigIron RX Series Hardware Installation Guide 19

53-1002483-03

Page 32

Supported software features

CAUTION

1

TABLE 8 Fan control module LED

LED Position State Meaning

Fan control module

LED

To avoid overheating of the BigIron RX Series chassis, do not remove more than one fan at a time.

Rear of chassis Off The fans are not receiving power.

Green The fans are working and responding to

controls from the fan control module.

Amber The fans are not working and not responding

to controls from the fan control module.

Rack mount kit

The BigIron RX Series switches are shipped equipped for mounting in a standard 19-inch

(EIA310-D) rack as described:

• The BigIron RX-4 and BigIron RX-8 are equipped with built-in mounting brackets and are

shipped with mounting screws.

• The BigIron RX-16 switches ship with two L-shaped mounting brackets and mounting screws.

Alternatively, you can use a mid-mount kit (ordered separately) to center-mount the BigIron RX

chassis using two L-shaped mounting brackets. The mid-mount kit comes with instructions for

installing the mounting brackets and mounting the device in a rack.

Contact Brocade Communications Systems, Inc for information about mid-mount kits.

In a rack, you can install the following number of BigIron RX Series chassis depending on the

model:

• BigIron RX-16 – up to 3 BigIron RX-16 chassis

• BigIron RX-8 – up to 6 BigIron RX-8 chassis

• BigIron RX-4 – up to 10 BigIron RX-4 chassis

Supported software features

For a complete list of software features supported on the BigIron RX Series switch, refer to the

software release notes for this device. For information about configuring basic, non-protocol

software features supported on this device,refer to the BigIron RX Series Configuration Guide.

20 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 33

Chapter

DANGER

DANGER

DANGER

Installing the BigIron RX Series Switch

In this chapter

•Installation precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

•Installing a BigIron RX-4 switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

•Installing a BigIron RX-16 switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

•Attaching a management station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

•Powering-on the power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

•Verifying proper operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Installation precautions

This chapter contains information on how to install a BigIron RX Series switch. Before proceeding,

please read the cautions and warnings below that apply to the entire family of BigIron RX Series

switches.

2

The procedures in this manual are for qualified service personnel.

If the installation requires a different power cord than the one supplied with the device, make

sure you use a power cord displaying the mark of the safety agency that defines the regulations

for power cords in your country. The mark is your assurance that the power cord can be used

safely with the device.

Follow these precautions when installing a BigIron RX Series switch.

General precautions

All fiber-optic interfaces use Class 1 Lasers.

Brocade BigIron RX Series Hardware Installation Guide 21

53-1002483-03

Page 34

Installation precautions

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

DANGER

DANGER

DANGER

2

Do not install the device in an environment where the operating ambient temperature might

exceed 40o C (104o F).

Make sure the air flow around the front, sides, and back of the device is not restricted.

If you do not install a module in a slot, you must keep the slot blank in place. If you run the

chassis with an uncovered slot, the system may overheat.

Never leave tools inside the chassis.

Power precautions

Use a separate branch circuit for each AC power cord, which provides redundancy in case one of

the circuits fails.

Make sure to choose the appropriate circuit device, depending on the number of AC power

supplies installed in the chassis.

Disconnect the power cord from all power sources to completely remove power from the device.

Make sure that the power source circuits are properly grounded, then use the power cord

supplied with the device to connect it to the power source.

22 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 35

Installation precautions

DANGER

DANGER

DANGER

CAUTION

CAUTION

CAUTION

If the installation requires a different power cord than the one supplied with the device, make

sure you use a power cord displaying the mark of the safety agency that defines the regulations

for power cords in your country. The mark is your assurance that the power cord can be used

safely with the device.

Make sure the rack or cabinet housing the device is adequately secured to prevent it from

becoming unstable or falling over.

Mount the devices you install in a rack or cabinet as low as possible. Place the heaviest device at

the bottom and progressively place lighter devices above.

2

Ensure that the device does not overload the power circuits, wiring, and over-current protection.

To determine the possibility of overloading the supply circuits, add the ampere (amp) ratings of all

devices installed on the same circuit as the device. Compare this total with the rating limit for the

circuit. The maximum ampere ratings are usually printed on the devices near the input power

connectors.

BigIron RX-4, -8, and -16 devices with DC power sources are intended for installation in restricted

access areas only. A restricted access area is where access can be gained only by service

personnel through the use of a special tool, lock and key, or other means of security, and is

controlled by the authority responsible for the location.

For a DC system, the gauge of wire will be determined by the power source as well as the power

supply draw (refer to Table 9). Use a grounding wire of at least 6 American Wire Gauge (AWG). The

AWG wire should be attached to an agency-approved crimp connector (provided on the BigIron RX

Series chassis), crimped with the proper tool. The single crimp connector should allow for

securement to both ground screws on the enclosure. For BigIron RX-16, and -8, and -4, use a

grounding wire of at least 6 AWG. For the grounding lug, use UL-listed Panduit crimp connector,

P/N LCD6-10A, and two 10-32, PPH screws to secure the crimp connector to chassis. The

grounding position is located on the side of chassis, adjacent ground symbol.

Brocade BigIron RX Series Hardware Installation Guide 23

53-1002483-03

Page 36

Installing a BigIron RX-4 switch

CAUTION

2

TABLE 9 The American Wire Gauge (AWG) guidelines

AWG Ohms per 100 feet Maximum Amps for chassis wiring Maximum Amps for power

5 0.3133 118 47

6 0.3951 101 37

7 0.4982 89 30

8 0.6282 73 24

9 0.7921 64 19

10 0.9989 55 15

11 1.26 47 12

12 1.588 41 9.3

For the DC input circuit to the system, make sure there is a UL-Listed 30 amp circuit breaker,

minimum -48Vdc, double pole, on the input to the terminal block. The input wiring for connection

to the product should be Listed copper wire, 8 AWG, marked VW-1, and rated minimum 9o C.

transmission

Installing a BigIron RX-4 switch

This section describes the steps you will perform to install a BigIron RX-4 switch:

• “Preparing the installation site”

• “Unpacking a BigIron RX-4 switch”

• “Chassis lifting guidelines for BigIron RX-4 switches”

• “Installing a BigIron RX-4 chassis in a rack”

• “Installing BigIron RX-4 modules”

• “Installing power supplies in a BigIron RX-4 chassis”

• “Connecting AC power to a BigIron RX-4 chassis”

• “Connecting DC power to a BigIron RX-4 chassis”

• “Final steps”

Preparing the installation site

Cabling infrastructure

Ensure that the proper cabling is installed in the site.

For information on cabling, refer to “Installing power supplies in a BigIron RX-4 chassis” on

page 30, “Attaching a management station” on page 54, and “Connecting a BigIron RX Series

switch” on page 71.

24 Brocade BigIron RX Series Hardware Installation Guide

53-1002483-03

Page 37

Installing a BigIron RX-4 switch

NOTE

DANGER

2

Installation location

Before installing the switch, plan its location and orientation relative to other devices and

equipment. For cooling purposes, allow a minimum of six inches of space between the sides, front,

and the back of the chassis and walls or other obstructions. If a chassis is installed within a

perforated enclosure, the perforations must have openings on at least 60 percent of the surface.

Unpacking a BigIron RX-4 switch

The BigIron RX-4 switch ships with several items. Review the list below, and verify the contents. If

any items are missing, contact the place of purchase:

• BigIron RX-4 chassis with the appropriate number of switch fabric modules already installed in

the slot marked SF and slot blanks installed in all other module slots.

You must provide standard #12-24 pan-head screws for mounting the BigIron RX-4 chassis into a

rack.

• A 115V AC power cable for each AC power supply you purchase from Brocade.

Follow the steps given below to unpack a BigIron RX-4 chassis.

1. Move the pallet to a staging area as close to the installation site as possible.

2. Position the shipping carton with the arrows pointing up.

3. Remove the strap that secures the shipping carton to the pallet.

4. Remove the plastic cover and shipping carton.

5. Save the shipping carton, pallet, and packing materials in case you need to move or ship the

chassis at a later time.

Chassis lifting guidelines for BigIron RX-4 switches

A fully-populated BigIron RX-4, chassis is heavy. TWO OR MORE PEOPLE ARE REQUIRED WHEN

LIFTING, HANDLING, OR MOUNTING THESE DEVICES.

Before lifting or moving the switch, disconnect all external cables. For lifting and moving a BigIron

RX-4 chassis, follow the guidelines explained in this section.

Installing a BigIron RX-4 chassis in a rack

This section describes the following tasks:

• “Preparing to mount a BigIron RX-4 chassis in a rack”

• “Removing BigIron RX-4 extra shipment screws”

• “Mounting a BigIron RX-4 chassis in a rack”

• “Removing the slot blanks”

Brocade BigIron RX Series Hardware Installation Guide 25

53-1002483-03

Page 38

Installing a BigIron RX-4 switch

3

1

2

2

Preparing to mount a BigIron RX-4 chassis in a rack

Because of the weight of a fully loaded BigIron RX-4 chassis, Brocade recommends mounting a

chassis in a rack before installing the modules and AC power supplies if necessary.

In a standard 19-inch (EIA310-D) rack, you can install up to ten BigIron RX-4 chassis.

For each BigIron RX-4 chassis that you install in a rack, you must provide four standard #12-24

pan-head screws with which to mount and secure the chassis. Before performing this task, you