Brocade Communications Systems FWS648G-POE, FWS624G-POE, FWS624-POE, FWS648G, FWS624G Hardware Installation Manual

...Page 1

®

DRAFT: BROCADE CONFIDENTIAL

53-1002188-01

18 February 2011

Brocade FastIron WS

Hardware Installation Guide

Supporting Release 07.2.02

Page 2

DRAFT: BROCADE CONFIDENTIAL

Copyright © 2011 Brocade Communications Systems, Inc. All Rights Reserved.

Brocade, the B-wing symbol, BigIron, DCX, Fabric OS, FastIron, IronPoint, IronShield, IronView, IronWare, JetCore, NetIron,

SecureIron, ServerIron, StorageX, and TurboIron are registered trademarks, and DCFM, Extraordinary Networks, and SAN Health

are trademarks of Brocade Communications Systems, Inc., in the United States and/or in other countries. All other brands,

products, or service names are or may be trademarks or service marks of, and are used to identify, products or services of their

respective owners.

Notice: This document is for informational purposes only and does not set forth any warranty, expressed or implied, concerning

any equipment, equipment feature, or service offered or to be offered by Brocade. Brocade reserves the right to make changes to

this document at any time, without notice, and assumes no responsibility for its use. This informational document describes

features that may not be currently available. Contact a Brocade sales office for information on feature and product availability.

Export of technical data contained in this document may require an export license from the United States government.

The authors and Brocade Communications Systems, Inc. shall have no liability or responsibility to any person or entity with

respect to any loss, cost, liability, or damages arising from the information contained in this book or the computer programs that

accompany it.

The product described by this document may contain “open source” software covered by the GNU General Public License or other

open source license agreements. To find-out which open source software is included in Brocade products, view the licensing

terms applicable to the open source software, and obtain a copy of the programming source code, please visit

http://www.brocade.com/support/oscd.

Brocade Communications Systems, Incorporated

Corporate and Latin American Headquarters

Brocade Communications Systems, Inc.

130 Holger Way,

San Jose, CA 95134

Tel: 1-408-333-8000

Fax: 1-408-333-8101

E-mail: info@brocade.com

European Headquarters

Brocade Communications Switzerland Sàrl

Centre Swissair

Tour B - 4ème étage

29, Route de l'Aéroport

Case Postale 105

CH-1215 Genève 15

Switzerland

Tel: +41 22 799 5640

Fax: +41 22 799 5641

E-mail: emea-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems China HK, Ltd.

No. 1 Guanghua Road

Chao Yang District

Units 2718 and 2818

Beijing 100020, China

Tel: +8610 6588 8888

Fax: +8610 6588 9999

E-mail: china-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems Co., Ltd. (Shenzhen WFOE)

Citic Plaza

No. 233 Tian He Road North

Unit 1308 – 13th Floor

Guangzhou, China

Tel: +8620 3891 2000

Fax: +8620 3891 2111

E-mail: china-info@brocade.com

Document History

Title Publication number Summary of changes Date

Brocade FastIron WS Hardware

Installation Guide

53-1002188-01 New document February 2011

Page 3

Contents

DRAFT: BROCADE CONFIDENTIAL

About This Document

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Supported hardware and software . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Document conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Text formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Command syntax conventions . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Notes, cautions, and danger notices . . . . . . . . . . . . . . . . . . . . .viii

Notice to the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Getting technical help or reporting errors . . . . . . . . . . . . . . . . . . . . . . ix

Web access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

E-mail and telephone access . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1 Product Overview

Hardware features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FWS624, FWS648, FWS624G, FWS648G . . . . . . . . . . . . . . . . . . 1

FWS624-POE, FWS648-POE, FWS624G-POE, FWS648G-POE . . 2

Control features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 Installing FWS624 and FWS648 Models

Unpacking the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Package contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Summary of installation tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Lifting precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Preparing the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cabling infrastructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Installing the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Desktop installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Rack mount installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Brocade FastIron WS Hardware Installation Guide iii

53-1002188-01

Page 4

DRAFT: BROCADE CONFIDENTIAL

Installing a redundant power supply . . . . . . . . . . . . . . . . . . . . . . . . .15

RPS2-EIF Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . . 15

RPS12 external redundant power supply. . . . . . . . . . . . . . . . . . 17

Selecting a redundant power supply installation site . . . . . . . .20

Equipment checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Mounting a redundant power supply in a rack . . . . . . . . . . . . .21

Connecting devices to the redundant power supply . . . . . . . . .23

Port pin-out diagram for the RPS2-EIF power supply . . . . . . . . 24

Port pin-out diagram for the RPS12 power supply . . . . . . . . . .25

Activating power to the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Verifying proper operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Attaching a PC or terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3 Connecting Network Devices and Checking Connectivity

Assigning permanent passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Recovering from a lost password . . . . . . . . . . . . . . . . . . . . . . . .30

Configuring IP addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Devices running layer 2 software . . . . . . . . . . . . . . . . . . . . . . . .31

Devices running layer 3 software . . . . . . . . . . . . . . . . . . . . . . . .32

Connecting network devices . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Cable specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Connecting to Ethernet or Fast Ethernet Hubs . . . . . . . . . . . . .34

Connecting to workstations, servers, or routers . . . . . . . . . . . .35

Connecting a network device to a fiber port . . . . . . . . . . . . . . .35

Testing connectivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Pinging an IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Observing LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Tracing a route . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Troubleshooting network connections. . . . . . . . . . . . . . . . . . . . . . . .39

Using Virtual Cable Testing to diagnose a cable . . . . . . . . . . . .39

Digital Optical Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Chapter 4 Managing the FastIron WS Hardware

Managing FastIron WS temperature settings . . . . . . . . . . . . . . . . . .41

Removing MAC address entries . . . . . . . . . . . . . . . . . . . . . . . . .44

Displaying CPU usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Hardware maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . .45

iv Brocade FastIron WS Hardware Installation Guide

Replacing a fiber optic module . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Removing a fiber optic module. . . . . . . . . . . . . . . . . . . . . . . . . .45

Installing a new fiber optic module. . . . . . . . . . . . . . . . . . . . . . .46

Cabling a fiber optic module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Cleaning the fiber-optic connectors. . . . . . . . . . . . . . . . . . . . . . . . . .46

53-1002188-01

Page 5

DRAFT: BROCADE CONFIDENTIAL

Chapter 5 Hardware Specifications

Hardware specifications for FastIron WS models . . . . . . . . . . . . . . .47

Physical dimensions and weight. . . . . . . . . . . . . . . . . . . . . . . . . 47

Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Cooling system and fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Pinouts and signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Cable specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

AC power supply specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 51

Power specifications for POE. . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Chapter 6 Troubleshooting

Diagnosing switch indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Power and cooling problems. . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

In-band access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Appendix A Regulatory Statements

USA (FCC CFR 47 part 15 warning) . . . . . . . . . . . . . . . . . . . . . . . . . .55

Industry Canada statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Europe and Australia (CISPR 22 class A warning) . . . . . . . . . . . . . .55

Japan (VCCI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Japan power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Korea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Russia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Regulatory compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Appendix B Caution and Danger Notices

Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Brocade FastIron WS Hardware Installation Guide v

53-1002188-01

Page 6

DRAFT: BROCADE CONFIDENTIAL

vi Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 7

DRAFT: BROCADE CONFIDENTIAL

About This Document

Audience

This document is designed for system administrators with a working knowledge of Layer 2 and

Layer 3 switching and routing.

If you are using a Brocade Layer 3 Switch, you should be familiar with the following protocols if

applicable to your network – IP, RIP, OSPF, BGP, ISIS, IGMP, PIM, and VRRP.

Supported hardware and software

This guide supports FastIron WS devices running software release 07.2.00.

Document conventions

This section describes text formatting conventions and important notice formats used in this

document.

Text formatting

The narrative-text formatting conventions that are used are as follows:

bold text Identifies command names

italic text Provides emphasis

code text Identifies CLI output

Identifies the names of user-manipulated GUI elements

Identifies keywords

Identifies text to enter at the GUI or CLI

Identifies variables

Identifies document titles

For readability, command names in the narrative portions of this guide are presented in bold: for

example, show version.

.

Command syntax conventions

Command syntax in this manual follows these conventions:

Brocade FastIron WS Hardware Installation Guide vii

53-1002188-01

Page 8

DRAFT: BROCADE CONFIDENTIAL

NOTE

CAUTION

DANGER

command and

parameters

[ ] Optional parameter.

variable Variables are printed in italics enclosed in angled brackets < >.

... Repeat the previous element, for example “member[;member...]”

| Choose from one of the parameters.

Commands and parameters are printed in bold.

Notes, cautions, and danger notices

The following notices and statements are used in this manual. They are listed below in order of

increasing severity of potential hazards.

A note provides a tip, guidance or advice, emphasizes important information, or provides a reference

to related information.

A Caution statement alerts you to situations that can be potentially hazardous to you or cause

damage to hardware, firmware, software, or data.

A Danger statement indicates conditions or situations that can be potentially lethal or extremely

hazardous to you. Safety labels are also attached directly to products to warn of these conditions

or situations.

Notice to the reader

This document may contain references to the trademarks of the following corporations. These

trademarks are the properties of their respective companies and corporations.

These references are made for informational purposes only.

Corporation Referenced trademarks and products

Phillips Screw Company, Inc. Phillips

Related publications

The following Brocade documents supplement the information in this guide:

viii Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 9

DRAFT: BROCADE CONFIDENTIAL

NOTE

• FastIron Configuration Guide

• IronWare MIB Reference

For the latest edition of these documents, which contain the most up-to-date information, refer to

Product Manuals at kp.foundrynet.com.

Getting technical help or reporting errors

Brocade is committed to ensuring that your investment in our products remains cost-effective. If

you need assistance or find errors in the manuals, contact Brocade using one of the following

options.

Web access

The Knowledge Portal (KP) contains the latest version of this guide and other user guides for the

product. You can also report errors on the KP.

Log in to my.Brocade.com, click the Product Documentation tab, then click on the link to the

Knowledge Portal (KP). Then click on Cases > Create a New Ticket to report an error. Make sure you

specify the document title in the ticket description.

E-mail and telephone access

Go to http://www.brocade.com/services-support/index.page for the latest e-mail and telephone

contact information.

Brocade FastIron WS Hardware Installation Guide ix

53-1002188-01

Page 10

DRAFT: BROCADE CONFIDENTIAL

x Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 11

DRAFT: BROCADE CONFIDENTIAL

Chapter

Product Overview

Hardware features

This chapter contains an overview of the FastIron WS Switch.

The FastIron WS Series includes the following models:

• FWS624

• FWS648

• FWS624G

• FWS648G

• FWS624-POE

• FWS648-POE

• FWS624G-POE

• FWS648G-POE

These models support an optional external redundant AC power supply that can power up to four

units.

1

The following sections describe the physical characteristics of the FastIron WS models. For more

details about physical dimensions, power supply specifications, and pinouts, refer to Chapter 5,

“Hardware Specifications”.

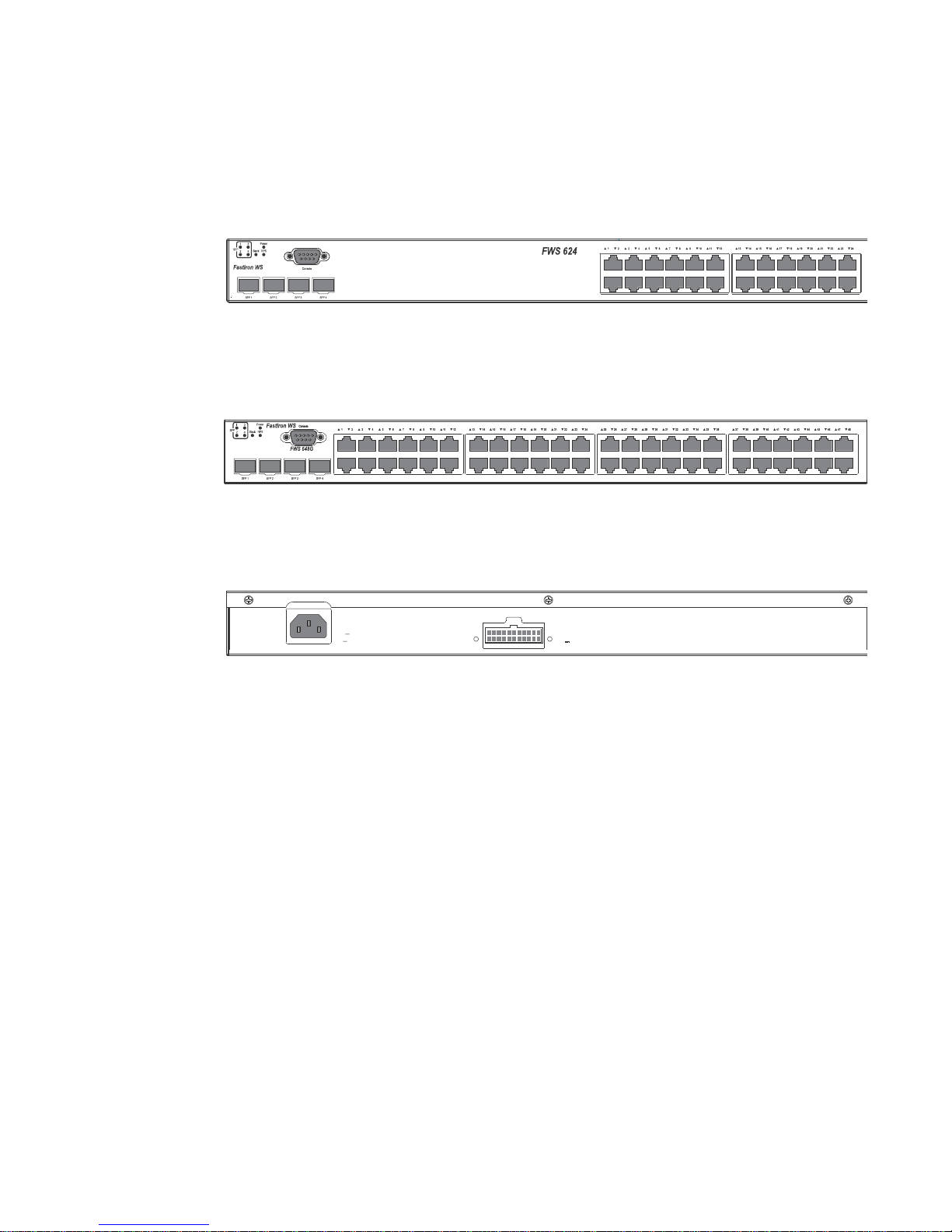

FWS624, FWS648, FWS624G, FWS648G

FastIron WS devices provide high 10/100 Mbps port density and Gigabit Ethernet uplinks in a

compact form factor:

• FastIron WS624 includes 20 x 10/100 Mbps ports plus 4 Combo 10/100/1000 Mbps copper

(RJ45) or 100/1000 Ethernet Fiber (SFP) ports.

• FastIron WS648 includes 44 x 10/100 Mbps ports plus 4 Combo 10/100/1000 Mbps copper

(RJ45) or 100/1000 Ethernet Fiber (SFP) ports.

• FastIron WS624G includes 20 x 10/100/1000 Mbps ports plus 4 Combo 10/100/1000 Mbps

copper (RJ45) or 100/1000 Ethernet Fiber (SFP) ports.

• FastIron WS648G includes 44 x 10/100/1000 Mbps ports plus 4 Combo 10/100/1000 Mbps

copper (RJ45) or 100/1000 Ethernet Fiber (SFP) ports.

Brocade FastIron WS Hardware Installation Guide 1

53-1002188-01

Page 12

Hardware features

100 240V~

50 60Hz, 2A

12V ,10A

1

DRAFT: BROCADE CONFIDENTIAL

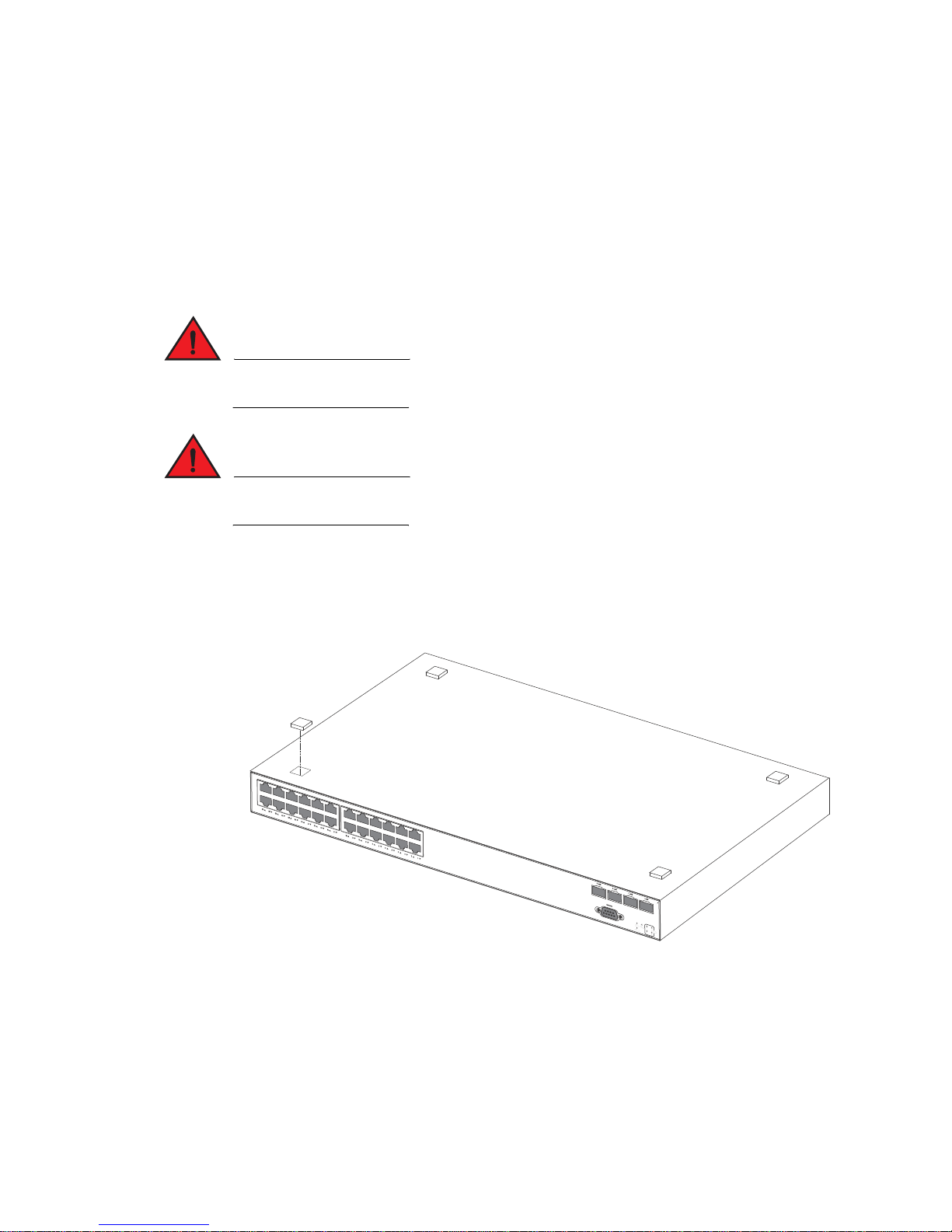

The following figures show the front and rear panels of the FastIron WS models.

FIGURE 1 FWS624, FWS624G

FIGURE 2 FWS648, FWS648G

FIGURE 3 FWS624, FWS648, FWS624G, FWS648G rear panel

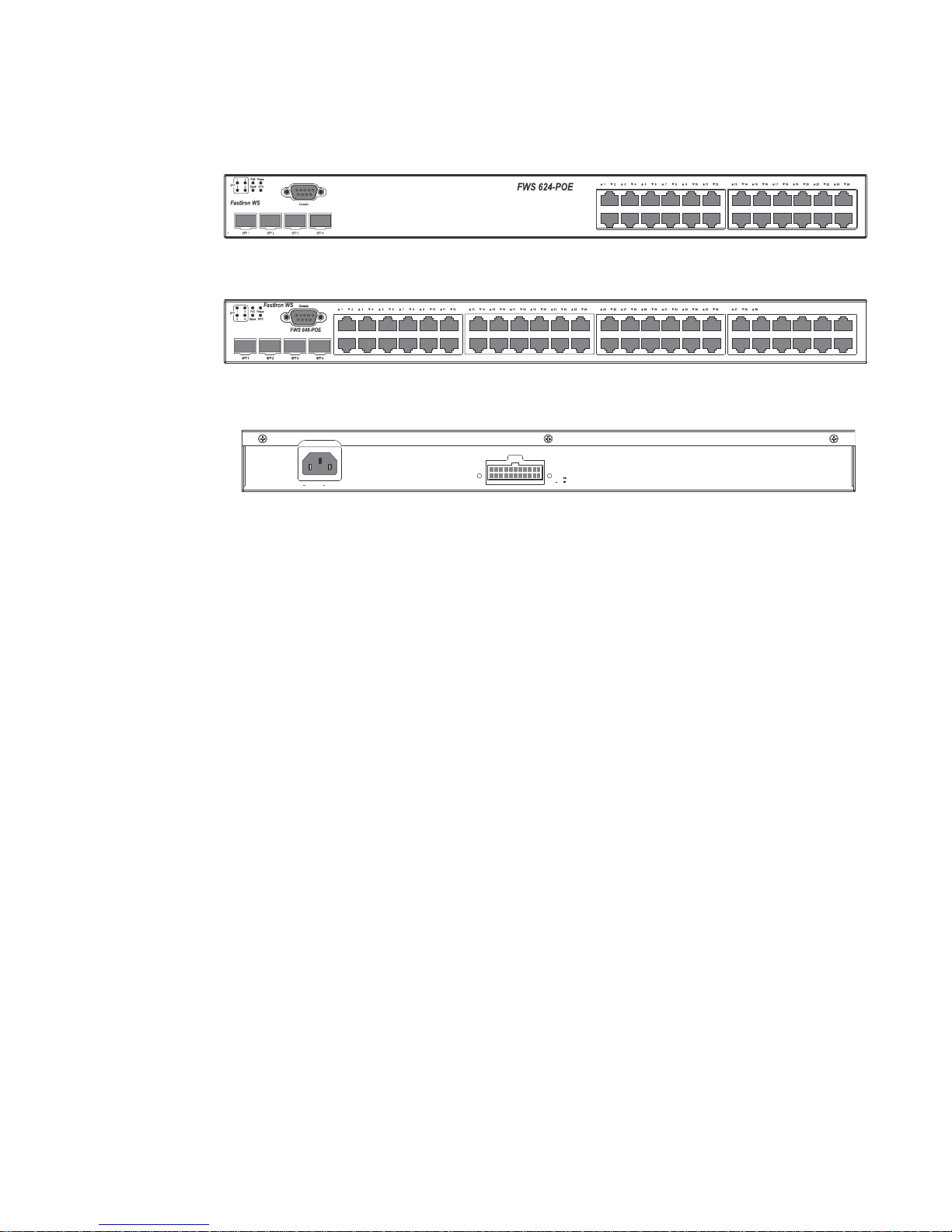

FWS624-POE, FWS648-POE, FWS624G-POE, FWS648G-POE

FastIron WS POE devices provide high 10/100 port density and Gigabit Ethernet uplinks in a

compact form factor:

• FastIron WS624-POE includes 20 x 10/100 Mbps PoE ports plus 4 Combo 10/100/1000

Mbps copper (RJ45 PoE) or 100/1000 Ethernet Fiber (SFP) ports. Unit supports 802.3af PoE.

• FastIron WS648-POE includes 44 x 10/100 Mbps PoE ports plus 4 Combo 10/100/1000

Mbps copper (RJ45 PoE) or 100/1000 Ethernet Fiber (SFP) ports. Unit supports 802.3af PoE.

• FastIron WS624G-POE includes 20 x 10/100/1000 Mbps PoE ports plus 4 Combo

10/100/1000 Mbps copper (RJ45 PoE) or 100/1000 Ethernet Fiber (SFP) ports. Unit supports

802.3af PoE.

• FastIron WS648G-POE includes 44 x 10/100/1000 Mbps PoE ports plus 4 Combo

10/100/1000 Mbps copper (RJ45 PoE) or 100/1000 Ethernet Fiber (SFP) ports. Unit supports

802.3af PoE.

The following figures show the front and rear panels of these FastIron WS models.

2 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 13

DRAFT: BROCADE CONFIDENTIAL

54V

,8.2A

+12V , 10A

100 240V~, 50 60Hz, 10A

Hardware features

FIGURE 4 FWS624-POE, FWS624G-POE

FIGURE 5 FWS648-POE, FWS648G-POE

FIGURE 6 FWS624-POE, FWS648-POE, FWS624G-POE, FWS648G-POE rear panel

1

Control features

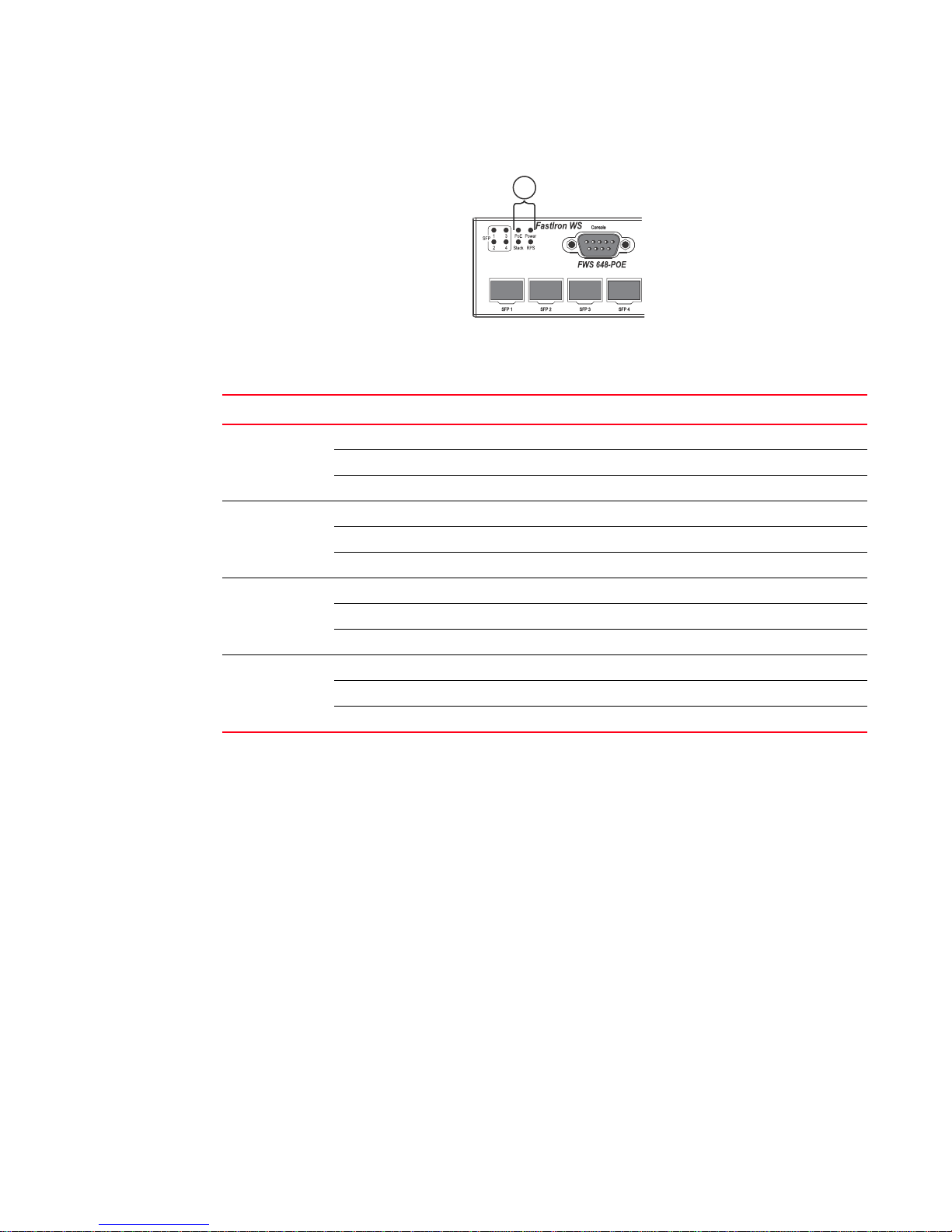

Serial management interface (console port)

The serial management interface allows you to configure and manage the device using a

third-party terminal emulation application on a directly connected PC. A straight-through EIA/TIA

DB-9 serial cable (M or F) ships with the device. The serial management interface (the console

port) is located in the left corner of the front panel.

POE applications

FWS POE devices provide Power over Ethernet (POE), compliant with the standards described in the

IEEE 802.3af specification for delivering in-line power. The 802.3af specification defines the

standard for delivering power over existing network cabling infrastructure, offering

multicast-enabled full streaming audio and video applications for converged services, such as

Voice over IP (VoIP), WLAN access points, IP surveillance cameras, and other IP technology devices.

POE technology eliminates the need for an electrical outlet and dedicated UPS near IP powered

devices. With power sourcing devices, such as the Brocade FWS624-POE and FWS648-POE, power

is consolidated and centralized in the wiring closets, improving the reliability and resiliency of the

network. Because POE can provide power over Ethernet cable, power is continuous, even in the

event of a power failure.

For more information about POE and how to configure it on FWS devices, refer to the FastIron

Configuration Guide.

FastIron WS network interfaces

FWS624 and FWS648 devices provide the following interfaces:

• 10/100 Mbpsports with RJ-45 copper connectors (Ports 5~24 or Ports 5~48)

Brocade FastIron WS Hardware Installation Guide 3

53-1002188-01

Page 14

Hardware features

1

DRAFT: BROCADE CONFIDENTIAL

• 10/100/1000 RJ-45 or 100/1000 SFP (1-GE) combo ports (Ports 1~4)

FWS624G and FWS648G devices provide the following interfaces:

• 10/100/1000 Mbps ports with RJ-45 copper connectors (Ports 5~24 or Ports 5~48)

• 10/100/1000 RJ-45 or 100/1000 SFP (1-GE) combo ports (Ports 1~4)

FastIron WS 10/100/1000 BASE-T ports

These devices contain 24/48 RJ-45 ports that operate at 10 Mbps or 100 Mbps, half or full duplex,

or at 1000 Mbps, full duplex. Because all ports support automatic MDI or MDI-X operation, you can

use straight-through cables for all network connections to PCs or servers, or to other switches or

hubs. (See “Pinouts and signalling” on page 49.) Brocade recommends using MDIX cable for

switch-to-switch connections.

Because each port supports auto-negotiation, the optimum transmission mode (half or full duplex),

and data rate (10, 100, or 1000 Mbps) can be selected automatically. If a device connected to one

of these ports does not support auto-negotiation, the communication mode of that port can be

configured manually.

Combination Ports

FWS devices contain four Small Form Factor Pluggable (SFP) combination ports (ports 1~4), that

are shared with four of the RJ45 ports In the default configuration. If an SFP transceiver is installed

in a slot and has a valid link on its port, the associated RJ45 port is disabled and cannot be used.

4 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 15

DRAFT: BROCADE CONFIDENTIAL

1

2

Hardware features

SFP network interfaces

Tab le 1 describes the network interfaces supported on the device. For network interface

specifications, refer to the table “Cable length summary table” on page 50.

TABLE 1 Supported SFP network interfaces for FWS devices

Interface Show media description

1000Base-BX-D M-GBXD

1000Base-BX-U M-GBXU

1000Base-LHA M-LHA

1000Base-LHB M-LHB

1000Base-LX M-LX

1000Base-LH M-LH

1000Base-SX M-SX

1000Base-SX2 M-SX2

1000Base-T C

100Base-BX M-FBX

100Base-FX M-FX

1310-MMF 10GbE 1310-NM

1

Port and system status LEDs

FWS devices include an LED display panel on the front panel with indicators for key system and

port indications to simplify installation and network troubleshooting. The LEDs are shown in

Figure 7 and Figure 8, and described in Table 2 and Table 3.

FIGURE 7 Port status LEDs

1 Port status LEDs 2 Port status LEDs

TABLE 2 Port status LEDs

LED Status Status

Link or

Activity or Speed

(1-24/48)

SFP(1-4)

On or Flashing Amber Port has a valid link at 10 or 100 Mbps. Flashing indicates activity.

On or Flashing Green Port has a valid link at 1000 Mbps. Flashing indicates activity.

Off The link is down.

Brocade FastIron WS Hardware Installation Guide 5

53-1002188-01

Page 16

Hardware features

2

1

DRAFT: BROCADE CONFIDENTIAL

FIGURE 8 System status LEDs

2System status LEDs

TABLE 3 System status LEDs

LED Condition Status

Power Green Internal power is operating normally.

Amber Internal power supply fault.

Off Power off or failure.

Stack Off System stand alone

Green System in stacking master mode

Amber System in stacking slave mode

RPS Green Redundant power supply is providing power.

Amber Primary power supply is active, RPS is on standby.

Off Redundant power supply is off or not plugged in.

POE Green POE module is operating normally.

Amber POE module fault.

Off POE module not present.

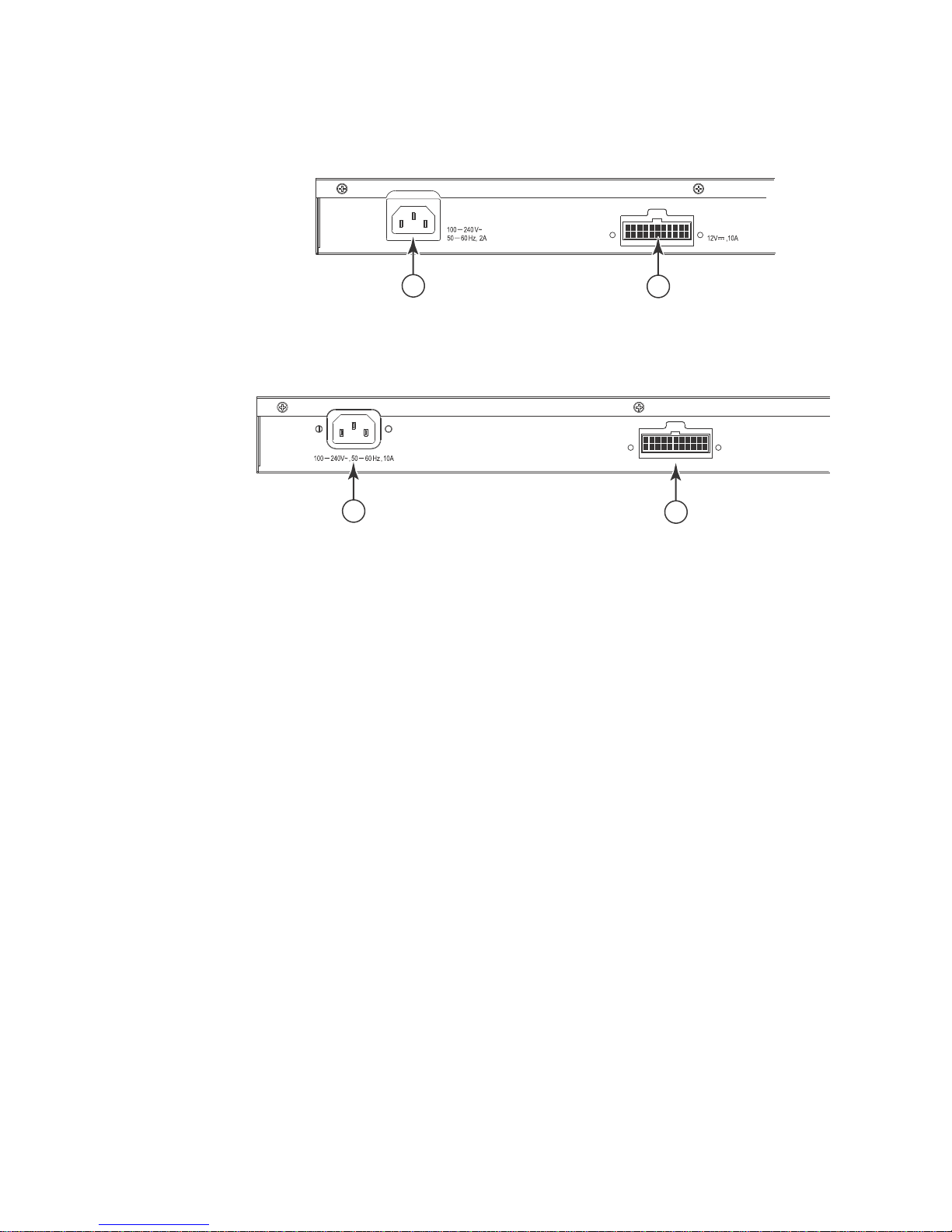

Power supplies

Optional redundant power supply

FWS devices support an optional redundant power supply (RPS), that can provide power to the

switch in the event the internal power supply fails.

Power supply receptacles

There are two power receptacles on the rear panel of each switch. The standard power receptacle

is for the AC power cord. The receptacle labeled “RPS” is for the optional redundant power supply

cord.

6 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 17

DRAFT: BROCADE CONFIDENTIAL

1

2

1

2

FIGURE 9 Power supply receptacles

1 Power socket 2 Redundant power socket

FIGURE 10 Power supply receptacles (POE Models)

Hardware features

1

1 Power socket 2 Redundant power socket

Brocade FastIron WS Hardware Installation Guide 7

53-1002188-01

Page 18

Hardware features

1

DRAFT: BROCADE CONFIDENTIAL

8 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 19

DRAFT: BROCADE CONFIDENTIAL

NOTE

NOTE

Chapter

Installing FWS624 and FWS648 Models

Unpacking the device

The procedures in this manual are intended for qualified service personnel.

Before beginning the installation, refer to the precautions in “Power precautions” on page 11. This

chapter describes how to physically install the FastIron WS.

Information about configuring IP addresses and connecting network devices is located in Chapter

3, “Connecting Network Devices and Checking Connectivity”.

The FastIron WS systems ship with all of the following items. Please review the list below and verify

the contents of your shipping container. If any items are missing, please contact the place of

purchase.

2

Package contents

The package contents of device are listed below:

• Brocade FastIron WS

• 115V AC power cable (for AC sourced devices)

• Rack mount brackets

• Warranty card

• A straight-through EIA/TIA DB-9 serial cable (F or F). The serial cable can be ordered separately

from Brocade Communications Systems Inc.. If you prefer to build your own cable, refer to the

pinout information in “Attaching a PC or terminal” on page 27.

General requirements

To manage the system, you need the following items for serial connection to the device:

• A management station, such as a PC running a terminal emulation application.

You use the serial connection to perform basic configuration tasks, including assigning an IP

address and network mask to the system. This information is required to manage the system using

the Web Management Interface or IronView Network Manager or using the CLI through Telnet.

Summary of installation tasks

Follow the steps listed below to install your FastIron WS. Details for each of these steps are

provided in this chapter and in the following chapter.

Brocade FastIron WS Hardware Installation Guide 9

53-1002188-01

Page 20

Installation precautions

DANGER

2

DRAFT: BROCADE CONFIDENTIAL

TABLE 4 Summary of installation tasks

Task

number

Task Where to find more information

1 Ensure that the physical environment that will host the

device has the proper cabling and ventilation.

2 Install any required optional modules into the device. “Activating power to the device” on page 26

3 Install the Brocade device on a desktop, in an

equipment rack.

4 Once the device is physically installed, plug the device

into a nearby power source that adheres to the

regulatory requirements outlined in this manual.

5 Verify that the system LEDs are registering the proper

LED state after power-on of the system.

6 Attach a terminal or PC to the Brocade device. This will

enable you to configure the device through the

Command Line Interface (CLI).

7 No default password is assigned to the CLI. For

additional access security, assign a password.

8 Before attaching equipment to the device, you need to

configure an interface IP address to the subnet on

which it will be located. Initial IP address configuration

is performed using the CLI with a direct serial

connection. Subsequent IP address configuration can

be performed using the Web management interface.

9 Once you power on the device and assign IP

addresses, the system is ready to accept network

equipment.

10 Test IP connectivity to other devices by pinging them

and tracing routes.

11 Continue configuring the device using the CLI or the

Web management interface. You also can use IronView

Network Manager to manage the device. Refer to the

IronView Network Management User’s Guide for

information.

12 Secure access to the device. FastIron Configuration Guide

“Preparing the installation site” on page 12

“Installing the device” on page 13

“Activating power to the device” on page 26

“Verifying proper operation” on page 27

“Attaching a PC or terminal” on page 27

“Assigning permanent passwords” on

page 29

“Configuring IP addresses” on page 30

“Devices running layer 3 software” on

page 32

“Testing connectivity” on page 37

FastIron Configuration Guide

Installation precautions

Follow these precautions when installing a Brocade device.

General precautions

All fiber-optic interfaces use Class 1 lasers.

10 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 21

DRAFT: BROCADE CONFIDENTIAL

CAUTION

CAUTION

CAUTION

DANGER

DANGER

CAUTION

CAUTION

Installation precautions

Do not install the device in an environment where the operating ambient temperature might

exceed 40o C (104o F).

Make sure the air flow around the front and sides of the device is not restricted.

Never leave tools inside the device.

Lifting precautions

2

Make sure the rack or cabinet housing the device is adequately secured to prevent it from

becoming unstable or falling over.

Mount the devices you install in a rack or cabinet as low as possible. Place the heaviest device at

the bottom and progressively place lighter devices above.

Power precautions

Use a separate branch circuit for each AC power cord, which provides redundancy in case one of

the circuits fails.

To avoid high voltage shock, do not open the device while the power is on.

Brocade FastIron WS Hardware Installation Guide 11

53-1002188-01

Page 22

Preparing the installation site

CAUTION

DANGER

DANGER

2

Ensure that the device does not overload the power circuits, wiring, and over-current protection.

To determine the possibility of overloading the supply circuits, add the ampere (amp) ratings of all

devices installed on the same circuit as the device. Compare this total with the rating limit for the

circuit. The maximum ampere ratings are usually printed on the devices near the input power

connectors.

Disconnect the power cord from all power sources to completely remove power from the device.

If the installation requires a different power cord than the one supplied with the device, make

sure you use a power cord displaying the mark of the safety agency that defines the regulations

for power cords in your country. The mark is your assurance that the power cord can be used

safely with the device.

DRAFT: BROCADE CONFIDENTIAL

Preparing the installation site

Cabling infrastructure

Ensure that the proper cabling is installed at the site. Refer to Chapter 5, “Hardware Specifications”

or www.brocade.com for a summary of supported cabling types and their specifications.

Installation location

Before installing the device, plan its location and orientation relative to other devices and

equipment. Devices can be mounted in a standard 19-inch equipment rack or on a flat surface. Be

sure to follow the guidelines below when choosing a location.

The site should:

• Maintain temperatures within 0 to 40 °C (32 to 104 °F) and humidity levels within 5% to 95%,

non-condensing.

• Allow a minimum of 3in. of space between the sides and the back of the device and walls or

other obstructions for proper air flow.

• Allow at least 3in. of space at the front and back of the device for the twisted-pair, fiber-optic,

and power cabling.

• Be accessible for installing, cabling and maintaining the devices.

• Allow the status LEDs to be clearly visible.

• Allow for twisted-pair cable to be always routed away from power lines, fluorescent lighting

fixtures and other sources of electrical interference, such as radios and transmitters.

12 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 23

DRAFT: BROCADE CONFIDENTIAL

DANGER

DANGER

Preparing the installation site

2

• Allow for the device to be connected to a separate grounded power outlet that provides 110 to

240 VAC, 50 to 60 Hz, is within 2 m (6.6 feet) of each device and is powered from an

independent circuit breaker. As with any equipment, a filter or surge suppressor is

recommended.

Installing the device

You can install Brocade systems on a desktop or in an equipment rack.

Make sure the rack or cabinet housing the device is adequately secured to prevent it from

becoming unstable or falling over.

Mount the devices you install in a rack or cabinet as low as possible. Place the heaviest device at

the bottom and progressively place lighter devices above.

Desktop installation

FIGURE 11 Attaching the adhesive feet

1. Attach the four adhesive feet to the bottom of the first device.

2. Set the device on a flat desktop, table, or shelf near an AC power source. Make sure that

adequate ventilation is provided for the system. A 3-inch clearance is recommended on each

side.

3. If you are installing a single device only, go to “Activating power to the device” on page 26.

4. If you are installing multiple devices, attach the adhesive feet to each one. Place each device

squarely on top of the one below, in any order.

Brocade FastIron WS Hardware Installation Guide 13

53-1002188-01

Page 24

Preparing the installation site

NOTE

2

5. If you are also installing an redundant power supply, place it close to the device.

Rack mount installation

You need a #2 Phillips screwdriver for installation.

Before mounting the device in a rack, consider the following factors:

• Temp eratu re: Since the temperature within a rack assembly may be higher than the ambient

• Mechanical loading: Do not place any equipment on top of a rack-mounted device.

• Circuit overloading: Be sure that the supply circuit to the rack assembly is not overloaded.

• Grounding: Rack-mounted equipment should be properly grounded. Particular attention should

To mount devices in rack follow the steps given below.

DRAFT: BROCADE CONFIDENTIAL

room temperature, check that the rack-environment temperature is within the specified

operating temperature range. (Refer to “Operating environment” on page 47.)

be given to supply connections other than direct connections to the mains.

1. Remove the rack mount kit from the shipping carton. The kit contains two L-shaped mounting

brackets and mounting screws.

2. Attach the mounting brackets to the sides of the device as illustrated in Figure 12.

FIGURE 12 Attaching the brackets

3. Attach the device in the rack as illustrated in Figure 13.

14 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 25

DRAFT: BROCADE CONFIDENTIAL

Installing a redundant power supply

FIGURE 13 Installing the device in a rack

4. If you are installing a single device, proceed to “Activating power to the device” on page 26.

2

5. If you are installing multiple devices, mount them in the rack, one below the other, in any order.

6. If you are also installing an redundant power supply, mount it in the rack below the other

devices.

Installing a redundant power supply

RPS2-EIF Redundant Power Supply

The Brocade External Redundant Power Supply (RPS2-EIF) can supply a maximum of 150 Watts of

output power per port, a total of 600 Watts of backup power to four FastIron WS devices in the

event of an AC loss or failure of an internal power supply.

The system operates as a backup to the internal power supply for a device. If an internal power

supply fails, the redundant power supply will support the device without affecting network

operation.

The following devices are supported by the FastIron RPS2-EIF:

• FastIron WS FWS624

• FastIron WS FWS648

Features and benefits

The RPS2-EIF power supply provides the following features and benefits:

• Supports four FastIron WS devices with 12V DC output

• Status LEDs located on the front panel

• AC line cord can draw power from a different supply circuit

• DC line cord provides backup power to the attached device

Brocade FastIron WS Hardware Installation Guide 15

53-1002188-01

Page 26

Installing a redundant power supply

Link

Activity

12

3

4

FanThermal Power

100-240V,50-60Hz 10A

RPS 1

RPS 2RPS 3RPS 4

4

3

2

1

5

2

• Thermal overload protection prevents the redundant power supply from overheating if a

thermal overload occurs.

• Over-voltage protection shuts down an output channel if voltage exceeds a preset threshold.

• Over-current protection shuts down the power supply if output load exceeds a preset threshold.

• Short-circuit protection prevents damage to the power supply due to a short circuit on any

output channel.

• Operates under a no-load condition.

Front and rear panels

Four power indicators and one fan indicator are located on the front panel of the power supply. The

AC supply and DC backup receptacles are located on the rear panel of the power supply.

FIGURE 14 Front and rear panels

DRAFT: BROCADE CONFIDENTIAL

1 Redundant power sockets 4-3 4 Power socket

2 Fans 5 Port and system status indicators

3 Redundant power sockets 2-1

Package contents

The RPS2-EIF power supply shipping package contains:

• Redundant power supply (RPS2-EIF)

• One AC supply power cord — US, Continental Europe or UK

• Four DC backup power cords with IEC connectors on both ends (length 152 cm each)

• Rack Mounting Kit containing brackets and screws

• Adhesive feet

• User agreement envelope

• Registration card

LEDs

The RPS2-EIF LEDs are described in Figure 15, Table 5 and Table 6.

16 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 27

DRAFT: BROCADE CONFIDENTIAL

21

Installing a redundant power supply

FIGURE 15 RPS2-EIF LEDs

1 Port indicators 2 System indicators

TABLE 5 Port status LEDs - RPS2-EIF

LED (1~4) Condition Status

Link Off The port does not have a valid connection to a device.

On Yellow The port has a valid connection to a device.

Flashing Yellow There has been an internal power failure.

Activity Off The port is not providing power to the connected device.

Flashing Green The port has been shut down due to one of the following conditions:

• The device has detected an over-current condition.

• One or more of the fans have failed.

On Green The port is providing power to a connected device.

2

TABLE 6 System status LEDs - RPS2-EIF

LED Condition Status

Power On Green AC power is being supplied to the power supply.

Off No AC power is being supplied to the power supply.

Fan On Green The fans are functioning normally.

Flashing Yellow One or more of the fans is not operating properly.

Off The fans are not receiveing power.

Thermal On Green The temperature of the unit is within an acceptable range.

Flashing Yellow The temperature is close to exceeding acceptable levels.

Off The thermal detector has failed, or the unit is powered off.

RPS12 external redundant power supply

The external redundant power supply (RPS12) can supply backup power to one of four connected

devices in the event of an AC loss or failure of an internal power supply. The system supplies the

failed device with up to 120 W for primary 12 VDC power, and up to 780 W of -54 VDC PoE power

(for PoE devices connected to the failed device).

The RPS12 monitors the power status for all attached devices and provides power to first device

with a detected power failure. The RPS12 supports the full load of the device without affecting

network operation. When the RPS12 is supplying power to a device, it cannot provide power to

other connected devices.

Brocade FastIron WS Hardware Installation Guide 17

53-1002188-01

Page 28

Installing a redundant power supply

Status

Power

Fa

n

Activity

Link

1234

1

2

3

4

2

When a device fails, the RPS12 sends status information to the other connected devices, which

then communicate the status of the RPS12 to network management software.

The following devices are supported by the FastIron RPS12:

• FastIron WS FWS624-POE

• FastIron WS FWS648-POE

• FastIron WS FWS624G-POE

• FastIron WS FWS648G-POE

Features and benefits

• Supports up to four connections to FastIron WS PoE devices

• Can supply one out of four connected device with 12V DC primary power and -54V DC PoE

power

• Status LEDs located on the front panel

• AC line cord draws power from a different supply circuit

• DC line cord provides backup power to the attached device

• Thermal overload protection prevents the RPS12 from overheating if a thermal overload

occurs.

• Over-voltage protection shuts down an output channel if the voltage exceeds a preset

threshold.

• Over-current protection shuts down the RPS12 if output load exceeds a preset threshold.

• Short-circuit protection prevents damage to the RPS12 due to a short circuit on any output

channel.

• The power supply will operate under a no-load condition.

• Supports hot connection of FastIron WS PoE devices

DRAFT: BROCADE CONFIDENTIAL

Front and rear panels

Four power indicators and one fan indicator are located on the front panel. The AC supply and DC

backup receptacles are located on the rear panel.

FIGURE 16 Front and Rear Panels

18 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 29

DRAFT: BROCADE CONFIDENTIAL

Status

P

ower

Fa

n

Activity

Link

1234

21

Installing a redundant power supply

1 Power socket 2 Redundant power sockets 4-3

3 Redundant power sockets 2-1 4 Power system status indicator

Package contents

• Redundant power supply (RPS12)

• One AC supply power cord — US, Continental Europe or UK

• One DC power cord with IEC connectors on both ends (length 152 cm each)

• Rack Mounting Kit containing brackets and screws

• Adhesive feet

• User agreement envelope

• Registration card

LEDs

Figure 17, Table 6, and Table 7 describe the functions of the RPS12 LEDs.

FIGURE 17 FastIron RPS12 LEDs

2

1 Port indicators 2 System indicators

TABLE 7 Port Status LEDs - RPS12

LED (1~4) Condition Status

Link Off The port does not have a valid connection to a device.

Activity Off The port may be connected to a device, but is not delivering power to

Brocade FastIron WS Hardware Installation Guide 19

53-1002188-01

On Yellow The port has a valid connection to a device

the device.

On Green The port is providing power to a connected device.

Page 30

Installing a redundant power supply

DANGER

CAUTION

2

TABLE 8 System Status LEDs - RPS12

LED Condition Status

Power On Green AC power is being supplied to the power supply.

Status On Green The power supply is operating normally.

Fan On Green The cooling fan is operating normally.

Selecting a redundant power supply installation site

RPS2-EIF and RPS12 power supplies can be mounted in a standard 19-inch equipment rack or on

a flat surface. Be sure to follow these guidelines when choosing a location.

DRAFT: BROCADE CONFIDENTIAL

Off No AC power is being supplied to the power supply.

On Red The power supply has detected an abnormal condition.

On Red The cooling fan is not operating normally.

Do not place a redundant power supply on the floor as the case is not waterproof. It is

recommended that either of the redundant power supplies be installed in a network equipment

rack.

Remove the power cord from a power supply before you install it in or remove it from the device.

Otherwise, the power supply or the device could be damaged as a result. (The device can be

running while a power supply is being installed or removed, but the power supply itself should not

be connected to a power source.)

The installation site should meet these requirements:

• Be at the center of all the devices you want to link, and near a power outlet.

• Maintain temperatures within 0 to 40 °C (32 to 104 °F) and humidity levels within 5% to 95%,

non-condensing.

• Provide adequate space (approximately 5.08 cm (2 inches) on all sides for proper air flow.

• Be accessible for installing, cabling and maintaining the devices.

• Allow the status LEDs to be clearly visible.

• Allow for twisted-pair cable to be always routed away from power lines, fluorescent lighting

fixtures and other sources of electrical interference, such as radios and transmitters.

• Provide a separate grounded power outlet that provides 100 to 240 VAC, 50-60 Hz, is within

2.44 m (8 feet) of each device, and is powered from an independent circuit breaker.

• As with any electrical equipment, a filter or surge suppressor is recommended.

20 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 31

DRAFT: BROCADE CONFIDENTIAL

Installing a redundant power supply

2

Equipment checklist

When you unpack the RPS2-EIF or RPS12 power supply, make sure you have received all the

components. (Refer to “Package contents” on page 16.) Before beginning the installation, be sure

you have all other necessary installation equipment.

Optional rack-mounting equipment

If you plan to rack-mount a redundant power supply, have the following equipment available:

• Four mounting screws for each device you plan to install (screws are not included)

• A screwdriver (Phillips or flathead, depending on the type of screws used)

Mounting a redundant power supply in a rack

Before mounting the redundant power supply in a rack, consider the following factors:

• Temp eratu re: Since the temperature within a rack assembly may be higher than the ambient

room temperature, check that the rack-environment temperature is within the specified

operating temperature range.

• Mechanical loading: Do not place any equipment on top of a rack-mounted device.

• Circuit overloading: Be sure that the supply circuit to the rack assembly is not overloaded.

• Grounding: Rack-mounted equipment should be properly grounded. Particular attention should

be given to supply connections other than direct connections to the mains.

Follow these steps to install a redundant power supply in a rack.

1. Attach the brackets to the power supply using the screws provided in the Bracket Mounting Kit.

Refer to Figure 18.

FIGURE 18 Attaching the mounting brackets

2. Mount the power supply in the rack, using four rack-mounting screws (not provided). Refer to

Figure 19.

Brocade FastIron WS Hardware Installation Guide 21

53-1002188-01

Page 32

Installing a redundant power supply

Lin

k

Ac

ti

v

ity

12

3

4

Fa

n Thermal Power

2

FIGURE 19 Installing the redundant power supply in a rack

DRAFT: BROCADE CONFIDENTIAL

3. If installing multiple redundant power supplies, mount them in the rack one below the other, in

any order.

Desktop or shelf mounting

1. Attach the four adhesive feet to the bottom of the first redundant power supply. Refer to

Figure 20.

FIGURE 20 Attaching the adhesive feet

2. Set the power supply on a flat surface near an AC power source, making sure there are at least

5.08 cm (2 inches) of space on all sides for proper air flow.

22 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 33

DRAFT: BROCADE CONFIDENTIAL

100-240V, 50-60Hz 10A

RPS 1

Installing a redundant power supply

Connecting devices to the redundant power supply

The FastIron RPS2-EIF is supported on the following devices:

• FastIron WS624

• FastIron WS648

The FastIron RPS12 is supported on the following devices:

• FastIron FWS624-POE

• FastIron FWS648-POE

To connect devices to a redundant power supply, follow these steps.

1. Connect one end of the AC cord to the AC receptacle on the device, and the other end to a

grounded power outlet. Refer to Figure 21.

FIGURE 21 Power receptacle

2

2. Connect one end of a DC cord to the redundant power receptacle on the device and the other

end to an available receptacle on the redundant power supply.

3. Repeat step 1 and step 2 to connect up to four devices to the redundant power supply. Refer to

Figure 22.

4. Connect one end of the AC cord to the AC receptacle on the redundant power supply, and the

other end to a grounded power outlet.

5. Check the LEDs on the redundant power supply to ensure proper operation. On the RPS2-EIF

and RPS12, the Power LED should light up. If the LEDs do not light, refer to “Troubleshooting”

on page 53 for more information.

Brocade FastIron WS Hardware Installation Guide 23

53-1002188-01

Page 34

Installing a redundant power supply

NOTE

1

5

3

6

4

2

2

FIGURE 22 Connecting multiple devices to a redundant power supply.

DRAFT: BROCADE CONFIDENTIAL

1Input port 4 FWS devices

2 AC power supply no.1 5 Output port

3 Redundant power supply 6 AC power supply no.2

For International use, you may need to change the AC line cord. You must use a line cord set that

has been approved for the receptacle type in your country.

Port pin-out diagram for the RPS2-EIF power supply

Figure 23 and Table 9 describe the pin-outs for the RPS2-EIF power supply.

24 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 35

DRAFT: BROCADE CONFIDENTIAL

GND

18

29

310

411

512

613

714

N.C.

GND

12 V RPS Present

12 V Status 1

12 V Status 2

12 V Power Good

GND GND

Installing a redundant power supply

FIGURE 23 RPS2-EIF power supply port pinout diagram

N.C.

2

TABLE 9 Port pin-out diagram for the RPS2-EIF power supply

Pin Name Description

1, 7, 8, 14 GND Ground connection

2, 9 N.C. No current

3, 4, 5, 6 12 V 12 volts current

10 RPS Present Indicates that a redundant power supply is attached and

11, 12 Status 1, Status 2 Status indicator

13 Power Good Indicates that power is being supplied to the redundant

Port pin-out diagram for the RPS12 power supply

Figure 24 and Table 10 describe the pin-out diagram for the RPS12 power supply.

functioning

power supply

Brocade FastIron WS Hardware Installation Guide 25

53-1002188-01

Page 36

Activating power to the device

2

110

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

-54 V -54 V RTN

N. C.

RPS Present

Power Good

-54 V

-54 V

N. C.

N. C.

N. C.

12 V

12 V RTN

12 V

-54 V RTN

-54 V RTN

12 V RTN

RPS Type

RPS Power Good

2

FIGURE 24 Pin-out diagram for the RPS12 power supply.

DRAFT: BROCADE CONFIDENTIAL

TABLE 10 Port pin-out diagram for the RPS12 power supply

Pin Name Description

1, 2, 3 -54 V -54 volts connection

4, 5, 6, 13 N.C. No connection

7, 8 12 V 12 volts connection

9, 18 12 V RTN 12 volts return connection

Activating power to the device

10, 11, 12 -54 V RTN -54 volts return connection

14 RPS Present Indicates that a redundant power supply is attached and

15 RPS Type Indicates either load-sharing or redundant mode

16 RPS Power Good Indicates that power is being supplied to the redundant

17 Power Good Connected device internal power supply status

After you complete the physical installation, you can activate power to the device.

functioning

power supply

26 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 37

DRAFT: BROCADE CONFIDENTIAL

NOTE

NOTE

NOTE

NOTE

1. Remove the power cord from the shipping package.

2. Attach the AC power cable to the AC connector on the rear panel.

3. Insert the power cable plug into a 115V/120V outlet.

To turn the system off, simply unplug the power cord or cords.

The socket should be installed near the equipment and should be easily accessible.

If the outlet is not rated 115/120V, stop and get the appropriate cable for the outlet.

Verifying proper operation

After you have installed a redundant power supply, verify that the device is working properly by

plugging it into a power source and verifying that it passes the self test.

Verifying proper operation

2

1. Connect the power cord supplied with the device to the power connector on the power supply

on the rear of the device.

2. Insert the other end into a properly grounded electrical outlet.

FastIron devices do not have power switches. They power on when you connect a power cord to

the device and to a power source.

If your installation requires a different power cord than that supplied with the device, make

sure you use a power cord that displays the mark of the safety agency that defines the

regulations for power cords in your country. The mark is your assurance that the power cord

can be used safely with the device.

3. Verify that the LED for the power supply is green.

4. Verify proper operation by observing the LEDs.

LEDs for linked ports will come on during the boot process, then all LEDs will go off. Once the

boot sequence is complete, LEDs for linked ports will again come on.

For more details on specific LED conditions after system start-up, refer to the section, “LEDs”

on page 16.

Attaching a PC or terminal

To assign an IP address, you must have access to the text-based command line interface (CLI). The

CLI is described in detail in the FastIron Configuration Guide. You can access the CLI by attaching a

serial cable to the Console port. After you assign an IP address, you can access the system through

Telnet, the Web Management Interface, or IronView Network Manager.

Attach a management station using the serial port.

Brocade FastIron WS Hardware Installation Guide 27

53-1002188-01

Page 38

Attaching a PC or terminal

NOTE

NOTE

6 9

15

2

DRAFT: BROCADE CONFIDENTIAL

1. Connect a PC or terminal to the serial port using a straight-through cable. The serial port has a

male DB-9 connector.

You will need to run a terminal emulation program on the PC.

2. Open the terminal emulation program and set the session parameters as follows:

• Baud: 9600 bps

• Data bits: 8

• Parity: None

• Stop bits: 1

• Flow control: None

The serial communication port acts as a management connection point for a PC or SNMP

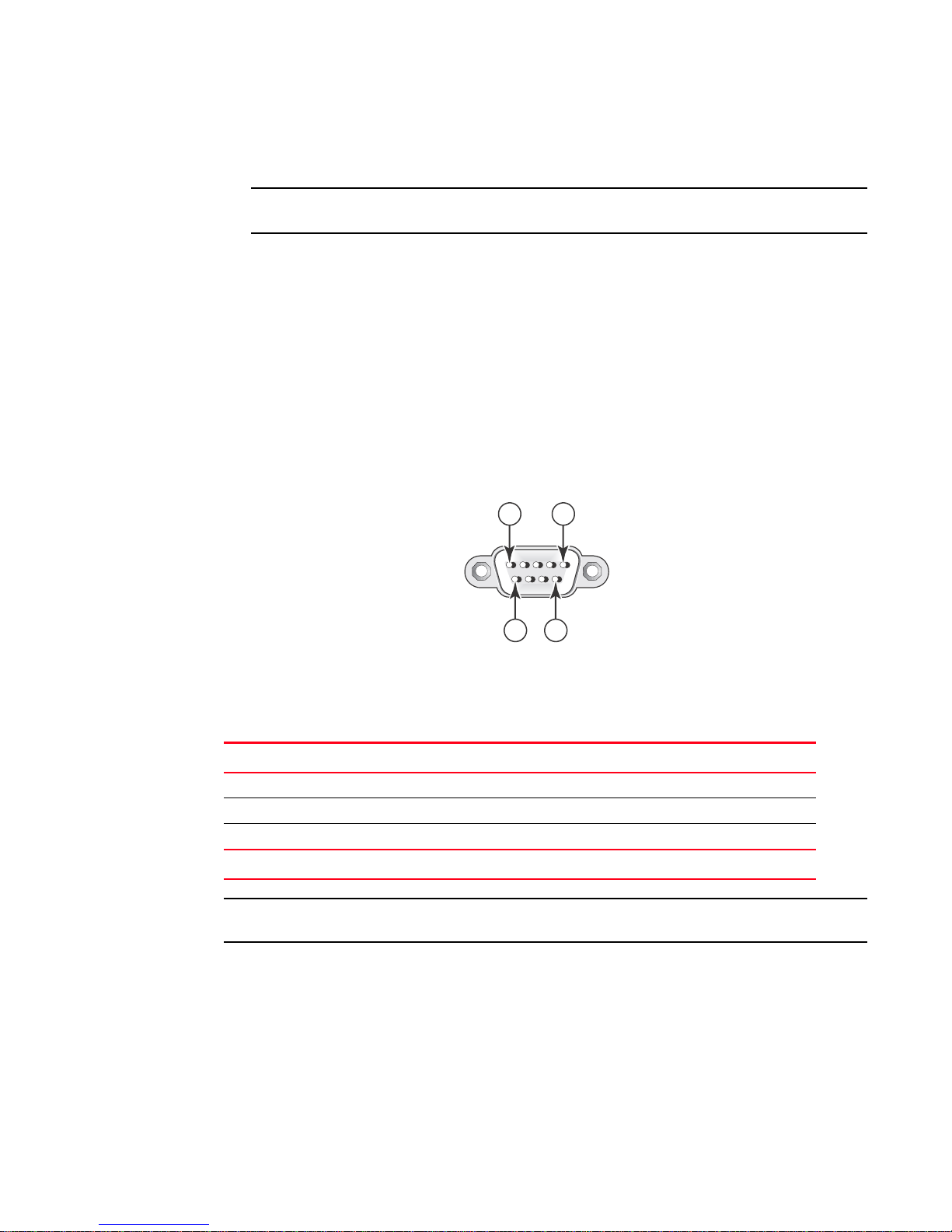

workstation. Brocade devices have a standard male DB-9 connector, shown in Figure 25.

FIGURE 25 Serial port (DB-9 DTE) pin-out

Most PC serial ports also require a cable with a female DB-9 connector. Terminal connections will

vary, requiring either a DB-9 or DB-25 connector, male or female. Serial cable options between a

Brocade device and a PC or terminal are shown in Table 11.

TABLE 11 Serial cable wiring map

9-pin serial port on device Null modem 9-pin DTE port on PC

2 TXD (transmit data) ----------------------------> 2 RXD (receive data)

3 RXD (receive data) <---------------------------- 3 TXD (transmit data)

5 SGND (signal ground) <--------------------------> 5 SGND (signal ground)

No other pins are used.

As indicated in Tab le 11 , some of the wires should not be connected.

28 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 39

DRAFT: BROCADE CONFIDENTIAL

DANGER

NOTE

NOTE

Chapter

Connecting Network Devices and Checking Connectivity

Assigning permanent passwords

This chapter provides the details for connecting network devices.

The procedures in this manual are for qualified service personnel.

By default, the CLI is not protected by passwords. To secure CLI access, Brocade strongly

recommends assigning passwords. Refer to the FastIron Configuration Guide.

You cannot assign a password using the Web Management Interface. You can assign passwords

using IronView Network Manager if an enable password for a Super User has been configured on the

device.

The CLI contains the following access levels:

3

• User EXEC – The level you enter when you first start a CLI session. At this level, you can view

some system information but you cannot configure system or port parameters.

• Privileged EXEC – This level is also called the Enable level and can be secured by a password.

You can perform tasks such as manage files on the flash module, save the system

configuration to flash, and clear caches at this level.

• CONFIG – The configuration level. This level lets you configure the system IP address and

configure switching and routing features. To access the CONFIG mode, you must already be

logged into the Privileged level of the EXEC mode.

You can set the following levels of Enable passwords:

• Super User – Allows complete read-and-write access to the system. This is generally for system

administrators and is the only password level that allows you to configure passwords.

You must set a super user password before you can set other types of passwords.

• Port Configuration – Allows read-and-write access for specific ports but not for global

(system-wide) parameters.

• Read Only – Allows access to the Privileged EXEC mode and CONFIG mode but only with read

access.

Set passwords.

1. At the opening CLI prompt, enter the following command to change to the Privileged level of the

EXEC mode.

FWSSwitch>enable

Brocade FastIron WS Hardware Installation Guide 29

53-1002188-01

Page 40

Configuring IP addresses

NOTE

NOTE

NOTE

3

DRAFT: BROCADE CONFIDENTIAL

2. Access the CONFIG level of the CLI by entering the following command.

FWSSwitch# configure terminal

FWSSwitch(config)#

3. Enter the following command to set the super-user password.

FWSSwitch(config)# enable super-user-password <text>

You must set the super-user password before you can set other types of passwords.

4. Enter the following commands to set the port configuration and read-only passwords.

FWSSwitch(config)# enable port-config-password <text>

FWSSwitch(config)# enable read-only-password <text>

If you forget your super-user password, refer to “Recovering from a lost password” on page 30.

Syntax: enable super-user-password | read-only-password | port-config-password <text>

Passwords can be up to 32 characters long.

Recovering from a lost password

By default, the CLI does not require passwords. However, if someone has configured a password for

the device but the password has been lost, you can regain super-user access to the device using

the following procedure.

Recovery from a lost password requires direct access to the serial port and a system reset.

Recover from a lost password.

1. Start a CLI session over the serial interface to the Brocade device.

2. Reboot the device.

3. While the system is booting, before the initial system prompt appears, enter b to enter the boot

monitor mode.

4. Enter no password at the prompt. (You cannot abbreviate this command.)

5. Enter boot system flash primary at the prompt. This command causes the device to bypass the

system password check.

After the console prompt reappears, assign a new password.

Configuring IP addresses

You must configure at least one IP address using the serial connection to the CLI before you can

manage the system using the other management interfaces.

Brocade devices support both classical IP network masks (Class A, B, and C subnet masks, and so

on) and Classless Interdomain Routing (CIDR) network prefix masks:

30 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 41

DRAFT: BROCADE CONFIDENTIAL

CAUTION

NOTE

Configuring IP addresses

3

• To enter a classical network mask, enter the mask in IP address format. For example, enter

“209.157.22.99 255.255.255.0” for an IP address with a Class-C subnet mask.

• To enter a prefix number for a network mask, enter a forward slash ( / ) and the number of bits

in the mask immediately after the IP address. For example, enter “209.157.22.99/24” for an

IP address that has a network mask with 24 significant (“mask”) bits.

By default, the CLI displays network masks in classical IP address format (example:

255.255.255.0). You can change the display to the prefix format. Refer to the FastIron

Configuration Guide.

Devices running layer 2 software

Configure an IP Address on a device running Layer 2 software.

1. At the opening CLI prompt, enter enable.

FWSSwitch> enable

2. Enter the following command at the Privileged EXEC level prompt (for example, FWSSwitch#),

then press Enter. This command erases the factory test configuration if still present:

FWSSwitch# erase startup-config

Use the erase startup-config command only for new systems. If you enter this command on a

system you have already configured, the command erases the configuration. If you accidentally

do erase the configuration on a configured system, enter the write memory command to save the

running configuration to the startup-config file.

3. Access the configuration level of the CLI by entering the following command.

FWSSwitch# configure terminal (Privileged EXEC Level)

FWSSwitch(config)# (Global CONFIG Level)

4. Configure the IP address and mask for the switch.

FWSSwitch(config)# ip address 192.22.3.44 255.255.255.0

5. Set a default gateway address for the switch.

FWSSwitch(config)# ip default-gateway 192.22.3.1

You do not need to assign a default gateway address for single subnet networks.

Syntax: enable [<password>]

Syntax: configure terminal

Syntax: [no] ip address <ip-addr> <ip-mask>

or

Syntax: [no] ip address <ip-addr>/<mask-bits>

Syntax: ip default-gateway <ip-addr>

Brocade FastIron WS Hardware Installation Guide 31

53-1002188-01

Page 42

Configuring IP addresses

NOTE

NOTE

NOTE

3

DRAFT: BROCADE CONFIDENTIAL

Devices running layer 3 software

Devices require a software license to be able to run Edge Layer 3 features. For details, see the

FastIron Configuration Guide.

Configuring IP addresses

You can configure an IP address on the following types of Layer 3 switch interfaces:

• Ethernet port

• Virtual routing interface (also called a Virtual Ethernet or “VE”)

• Loopback interface

By default, you can have up to 24 IP addresses on each interface, but you can increase this number

to 128 IP addresses.

Once you configure a virtual routing interface on a VLAN, you cannot configure Base Layer 3

interface parameters on individual ports in the VLAN. Instead, you must configure the parameters

on the virtual routing interface itself.

Brocade devices support both classical IP network masks (Class A, B, and C subnet masks, and so

on) and Classless Interdomain Routing (CIDR) network prefix masks:

• To enter a classical network mask, enter the mask in IP address format. For example, enter

“209.157.22.99 255.255.255.0” for an IP address with a Class-C subnet mask.

• To enter a prefix network mask, enter a forward slash ( / ) and the number of bits in the mask

immediately after the IP address. For example, enter “209.157.22.99/24” for an IP address

that has a network mask with 24 significant bits (ones).

By default, the CLI displays network masks in classical IP address format (example:

255.255.255.0). You can change the display to prefix format.

Assigning an IP address to an Ethernet port

To assign an IP address to port 0/1/1, enter the following commands.

FWSSwitch(config)# interface ethernet 0/1/1

FWSSwitch(config-if-0/1/1)# ip address 192.45.6.1 255.255.255.0

You also can enter the IP address and mask in CIDR format, as follows.

FWSSwitch(config-if-0/1/1)#ip address 192.45.6.1/24

Syntax: [no] ip address <ip-addr> <ip-mask>

or

Syntax: [no] ip address <ip-addr>/<mask-bits>

32 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 43

DRAFT: BROCADE CONFIDENTIAL

NOTE

Configuring IP addresses

3

Assigning an IP address to a loopback interface

Loopback interfaces are always up, regardless of the states of physical interfaces. You can

configure up to eight loopback interfaces.

You can add up to 24 IP addresses to each loopback interface.

To add a loopback interface, enter commands such as those shown in the following example.

FWSSwitch(config)# exit

FWSSwitch(config)# int loopback 1

FWSSwitch(config-lbif-1)# ip address 10.0.0.1/24

Syntax: interface loopback <num>

The <num> parameter specifies the virtual interface number. You can specify from 1 to the

maximum number of virtual interfaces supported on the device. To display the maximum number

of virtual interfaces supported on the device, enter the show default values command. The

maximum is listed in the System Parameters section, in the Current column of the virtual-interface

row.

Assigning an IP address to a virtual routing interface

A virtual interface is a logical port associated with a Layer 3 Virtual LAN (VLAN) configured on a

Base Layer 3 Switch. You can configure routing parameters on the virtual interface to enable the

Layer 3 Switch to route protocol traffic from one Layer 3 VLAN to the other, without using an

external router.

This section describes how to configure an IP address on a virtual interface.

The switch uses the lowest MAC address on the device (the MAC address of port 1 or 0/1/1) as the

MAC address for all ports within all virtual interfaces you configure on the device.

To add a virtual interface to a VLAN and configure an IP address on the interface, enter commands

such as the following.

FWSSwitch(config)# vlan 2 name IP-Subnet_1.1.2.0/24

FWSSwitch(config-vlan-2)# untag 0/1/1 to 0/1/4

FWSSwitch(config-vlan-2)# router-interface ve1

FWSSwitch(config-vlan-2)# interface ve1

FWSSwitch(config-vif-1)# ip address 1.1.2.1/24

The first two commands in this example create a Layer 3 protocol-based VLAN name

“IP-Subnet_1.1.2.0/24” and add a range of untagged ports to the VLAN. The router-interface

command creates virtual interface 1 as the routing interface for the VLAN. The last two commands

change to the interface configuration level for the virtual interface and assign an IP address to the

interface.

Syntax: router-interface ve <num>

Syntax: interface ve <num>

Deleting an IP address

To delete an IP address, enter a command such as the following.

FWSSwitch(config-if-0/1/1)# no ip address 1.1.2.1

Brocade FastIron WS Hardware Installation Guide 33

53-1002188-01

Page 44

Configuring IP addresses

NOTE

Orange

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Green

Brown

Blue

White/Orange Stripe

White/Green Stripe

White/Blue Stripe

White/Brown Stripe

End BEnd A

EIA/TIA 568B RJ-45 Wiring Standard

10/100BASE-TX Crossover Cable

3

DRAFT: BROCADE CONFIDENTIAL

This command deletes IP address 1.1.2.1. You do not need to enter the subnet mask.

To delete all IP addresses from an interface, enter the following command.

FWSSwitch(config-if-0/1/1)# no ip address *

Syntax: no ip address <ip-addr> | *

Connecting network devices

Brocade devices support connections to other vendors’ routers, switches, and hubs, as well other

Brocade devices.

Connectors

Refer to “Cable length summary table” on page 50.

For port pinouts, refer to the section “Pinouts and signalling” on page 49.

Cable specifications

Refer to “Cable specifications” on page 50 for cable lengths and types.

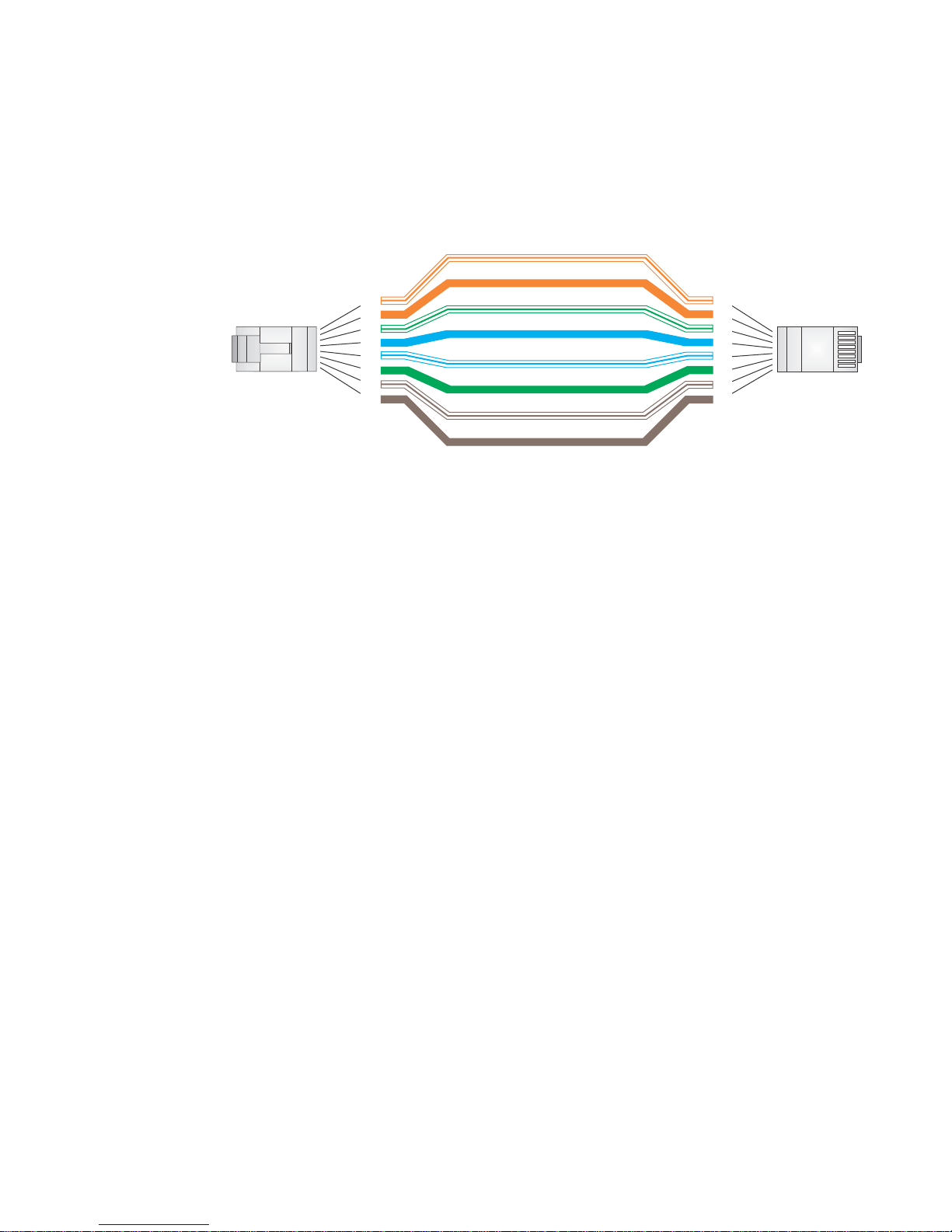

Connecting to Ethernet or Fast Ethernet Hubs

For copper connections to Ethernet hubs, a 10/100BaseTX or 1000BaseT switch, or another

Brocade device, a crossover cable is required (Figure 26 and Figure 27). If the hub is equipped with

an uplink port, it will require a straight-through cable instead of a crossover cable.

The 802.3ab standard (automatic MDI or MDIX detection) calls for automatic negotiation of the

connection between two 1000Base-T ports. Therefore, a crossover cable may not be required; a

straight-through cable may work as well. For more information about this feature, refer to the

FastIron Configuration Guide.

FIGURE 26 UTP crossover cable

34 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 45

DRAFT: BROCADE CONFIDENTIAL

Orange

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Green

Brown

Blue

White/Orange Stripe

White/Green Stripe

White/Blue Stripe

White/Brown Stripe

End BEnd A

EIA/TIA 568B RJ-45 Wiring Standard

10/100BASE-TX Straight-through Cable

Configuring IP addresses

FIGURE 27 Straight-through cable

Connecting to workstations, servers, or routers

3

Straight-through UTP cabling is required for direct UTP attachment to workstations, servers, or

routers using network interface cards (NICs).

Fiber cabling is required for direct attachment to Gigabit NICs or switches and routers through fiber

ports. Refer to “Connecting a network device to a fiber port” on page 35.

Automatic MDI or MDIX detection

All 10/100 and Gigabit Ethernet Copper ports on the Brocade FastIron WS devices support

automatic Media Dependent Interface (MDI) and Media Dependent Interface Crossover (MDIX)

detection. This feature is enabled on all 10/100 and Gigabit copper ports by default. For each port,

you can disable auto MDI or MDIX, designate the port as an MDI port, or designate the port as an

MDIX port.

For more information about this feature and how configure it, refer to the FastIron Configuration

Guide.

Connecting a network device to a fiber port

For direct attachment from the Brocade device to a Gigabit NIC, switch, or router, fiber cabling with

an LC connector is required.

To connect the Brocade device to another network device using a fiber port, you must do the

following:

• Install a fiber optic module (SFP transceiver or mini-GBIC)

• Cable the fiber optic module

The following sections provide information about performing these tasks.

Installing a fiber optic module

Brocade FastIron WS Hardware Installation Guide 35

53-1002188-01

You must install a fiber optic module (SFP) in each SFP slot you want to use.

Page 46

Configuring IP addresses

NOTE

DANGER

3

DRAFT: BROCADE CONFIDENTIAL

You can install a new fiber optic module in an SFP slot while the FastIron WS CHE1 is powered on

and running.

Before installing one of these modules into the slot, have the following on hand.

An ESD wrist strap with a plug for connection to a metal surface. For safety reasons, the ESD wrist

strap should contain a series 1 megohm resistor.

All fiber optic interfaces use Class 1 lasers.

Install a fiber optic module.

1. Put on the ESD wrist strap and ground yourself by attaching the clip end to a metal surface

(such as an equipment rack) to act as ground.

2. Remove the new module from its protective packaging.

3. Gently insert the fiber optic module into the slot until the module clicks into place. The module

is keyed to prevent incorrect insertion.

FIGURE 28 Installing a fiber optic module

Cabling a fiber optic module

Cable a fiber optic module.

1. Remove the protective covering from the fiber-optic port connectors and store the covering for

future use.

2. Before cabling a fiber optic module, Brocade strongly recommends cleaning the cable

connectors and the port connectors. For more information, refer to “Cleaning the fiber-optic

connectors” on page 37.

3. Gently insert the cable connectors (a tab on each connector should face upward) into the port

connectors until the tabs lock into place.

4. Observe the link and active LEDs to determine if the network connections are functioning

properly. For more information about the LED indicators, refer to Tab le 12 on page 38.

36 Brocade FastIron WS Hardware Installation Guide

53-1002188-01

Page 47

DRAFT: BROCADE CONFIDENTIAL

NOTE

Cleaning the fiber-optic connectors

To avoid problems with the connection between the fiber optic module (SFP (mini-GBIC)) and the

fiber cable connectors, Brocade strongly recommends cleaning both connectors each time you