Brocade Communications Systems FastIron SuperX, FastIron SX 1600, FSX 1600, FastIron SX 1600 Acoustic Noise-Reduced, FSX 1600-ANR Hardware Installation Manual

...Page 1

53-1001723-02

®

18 March 10

Brocade FastIron X Series

Chassis

Hardware Installation Guide

Supporting Release 07.0.01b

Page 2

Copyright © 2010 Brocade Communications Systems, Inc. All Rights Reserved.

Brocade, the B-wing symbol, BigIron, DCX, Fabric OS, FastIron, IronPoint, IronShield, IronView, IronWare, JetCore, NetIron,

SecureIron, ServerIron, StorageX, and TurboIron are registered trademarks, and DCFM, Extraordinary Networks, and SAN Health

are trademarks of Brocade Communications Systems, Inc., in the United States and/or in other countries. All other brands,

products, or service names are or may be trademarks or service marks of, and are used to identify, products or services of their

respective owners.

Notice: This document is for informational purposes only and does not set forth any warranty, expressed or implied, concerning

any equipment, equipment feature, or service offered or to be offered by Brocade. Brocade reserves the right to make changes to

this document at any time, without notice, and assumes no responsibility for its use. This informational document describes

features that may not be currently available. Contact a Brocade sales office for information on feature and product availability.

Export of technical data contained in this document may require an export license from the United States government.

The authors and Brocade Communications Systems, Inc. shall have no liability or responsibility to any person or entity with

respect to any loss, cost, liability, or damages arising from the information contained in this book or the computer programs that

accompany it.

The product described by this document may contain “open source” software covered by the GNU General Public License or other

open source license agreements. To find-out which open source software is included in Brocade products, view the licensing

terms applicable to the open source software, and obtain a copy of the programming source code, please visit

http://www.brocade.com/support/oscd.

Brocade Communications Systems, Incorporated

Corporate and Latin American Headquarters

Brocade Communications Systems, Inc.

1745 Technology Drive

San Jose, CA 95110

Tel: 1-408-333-8000

Fax: 1-408-333-8101

E-mail: info@brocade.com

European Headquarters

Brocade Communications Switzerland Sàrl

Centre Swissair

Tour B - 4ème étage

29, Route de l'Aéroport

Case Postale 105

CH-1215 Genève 15

Switzerland

Tel: +41 22 799 5640

Fax: +41 22 799 5641

E-mail: emea-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems China HK, Ltd.

No. 1 Guanghua Road

Chao Yang District

Units 2718 and 2818

Beijing 100020, China

Tel: +8610 6588 8888

Fax: +8610 6588 9999

E-mail: china-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems Co., Ltd. (Shenzhen WFOE)

Citic Plaza

No. 233 Tian He Road North

Unit 1308 – 13th Floor

Guangzhou, China

Tel: +8620 3891 2000

Fax: +8620 3891 2111

E-mail: china-info@brocade.com

Document History

Title Publication number Summary of changes Date

Brocade FastIron X Series Chassis

Hardware Installation Guide supporting

release 07.0.01b

Brocade FastIron X Series Chassis

Hardware Installation Guide supporting

release 07.0.01a

53-1001723-02 Updated release version Mar 2010

53-1001723-01 New document Feb 2010

Page 3

Contents

About This Document

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Supported hardware and software . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Document conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Text formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Command syntax conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Notes, cautions, and danger notices . . . . . . . . . . . . . . . . . . . . . . x

Notice to the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Getting technical help or reporting errors . . . . . . . . . . . . . . . . . . . . . . xi

Web access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

E-mail access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Telephone access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Chapter 1 Product Overview

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Hardware benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

POE port density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Supported configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Software features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

POE applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Support for IPv6 modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IPv6 hardware support guidelines . . . . . . . . . . . . . . . . . . . . . . . .3

Hardware features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FSX chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FSX 800 chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FSX 1600 chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

FSX 1600-ANR chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Management modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Switch fabric modules (FSX 800 and FSX 1600 only) . . . . . . .22

Interface modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Network interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Power supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cooling system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Built-in mounting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Layer 3 routing protocol table sizes. . . . . . . . . . . . . . . . . . . . . . . . . .39

Brocade FastIron X Series Chassis Hardware Installation Guide iii

53-1001723-02

Page 4

Chapter 2 Installing the Chassis

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Summary of installation tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Unpacking a system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Installation precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

General precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Lifting precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Power precautions and warnings . . . . . . . . . . . . . . . . . . . . . . . .44

Preparing the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Cabling infrastructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removing extra shipment screws (FSX and FSX 800 only) . . . . . . . 47

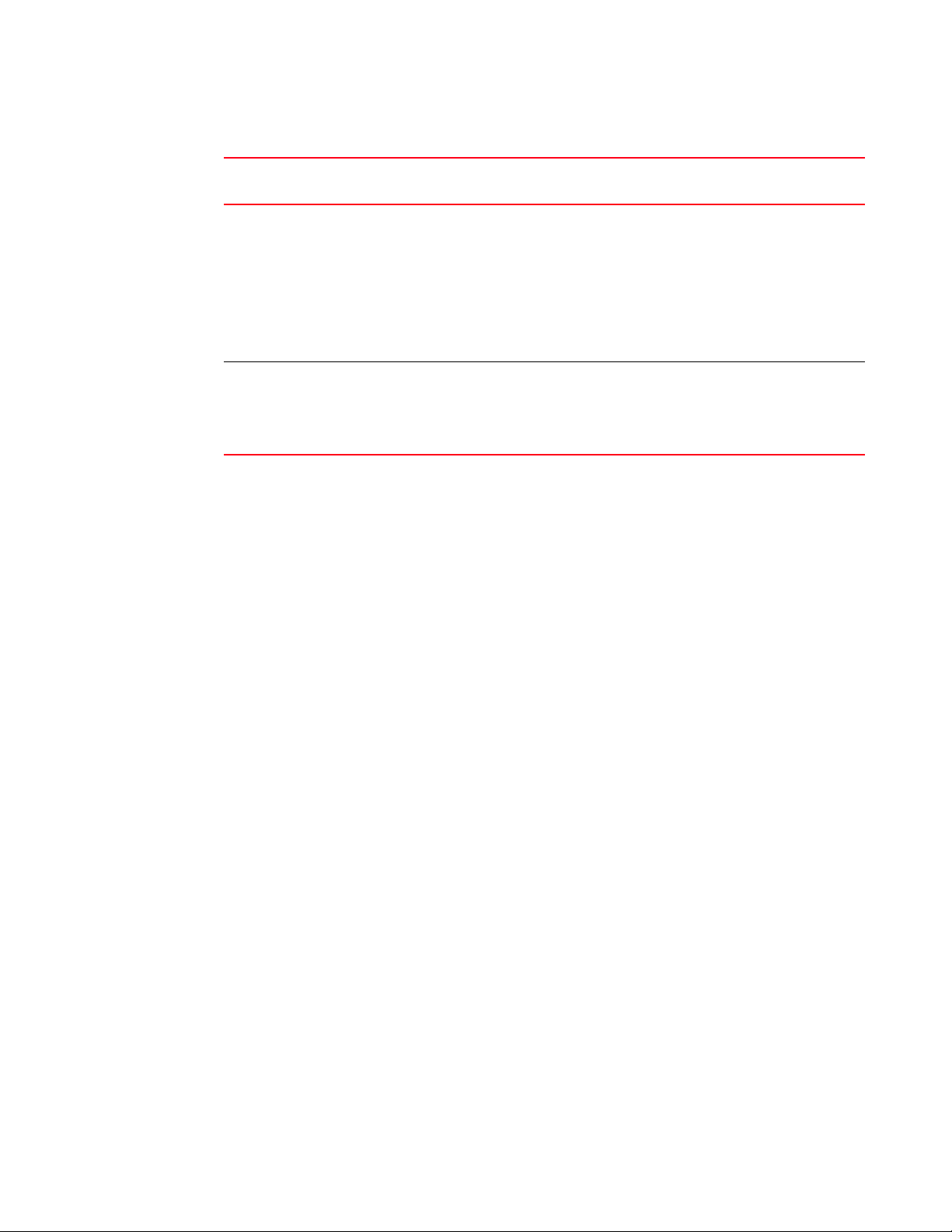

Installing a chassis in a rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Installing mounting brackets on the FSX 1600 chassis . . . . . .50

Removing the slot panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Installing the management and interface modules . . . . . . . . . . . . .51

Attaching a management station. . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Attaching a PC or terminal to the console port or 10/100/1000

copper port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Attaching a switch to an Ethernet port. . . . . . . . . . . . . . . . . . . .57

Powering on the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Connecting AC power to the chassis. . . . . . . . . . . . . . . . . . . . . .58

Connecting DC power to the chassis . . . . . . . . . . . . . . . . . . . . .60

Verifying proper operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Observing the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Displaying the module status . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Chapter 3 Connecting Network Devices and Checking Connectivity

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Assigning permanent passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Recovering from a lost password . . . . . . . . . . . . . . . . . . . . . . . .70

Configuring IP addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

IPv4 devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

IPv6 devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Connecting network devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Cable specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Connecting to Ethernet or fast Ethernet hubs . . . . . . . . . . . . . .76

Connecting to workstations, servers, or routers . . . . . . . . . . . .78

Connecting a network device to a fiber port on the Brocade device

78

Automatic MDI or MDIX detection. . . . . . . . . . . . . . . . . . . . . . . .80

Using a CX4 transceiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Testing network connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Observing LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

iv Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 5

Troubleshooting network connections. . . . . . . . . . . . . . . . . . . . . . . .82

Support for digital optical monitoring. . . . . . . . . . . . . . . . . . . . .83

Chapter 4 Managing the Chassis and Modules

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Displaying chassis status and temperature readings . . . . . . . . . . .85

Managing the cooling system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Configuring the cooling system. . . . . . . . . . . . . . . . . . . . . . . . . .90

Monitoring the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . .96

Displaying the Syslog configuration and static and dynamic buffers98

Syslog messages for PCI (hardware) errors. . . . . . . . . . . . . . . . . . . .99

Managing the switch fabric modules (FSX 800 and FSX 1600 only)99

Displaying management module CPU usage . . . . . . . . . . . . . . . . .100

Removing MAC address entries . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Chapter 5 Using a Redundant Management Module

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

How Management module redundancy works . . . . . . . . . . . . . . . .103

Management module redundancy overview . . . . . . . . . . . . . .103

Management module switchover . . . . . . . . . . . . . . . . . . . . . . .104

Switchover implications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Management module redundancy configuration . . . . . . . . . . . . . .106

Changing the default active chassis slot . . . . . . . . . . . . . . . . .106

Managing management module redundancy. . . . . . . . . . . . . . . . .107

File synchronization between the active and standby management

modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Manually switching over to the standby management module108

Rebooting the active and standby management modules . . .109

Hitless management support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

What happens during a Hitless OS upgrade and Hitless switchover

110

How a Hitless OS upgrade and Hitless switchover impacts system

functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Syslog message for Hitless OS upgrade and Hitless switchover111

Layer 2 Hitless switchover. . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Monitoring management module redundancy . . . . . . . . . . . . . . . .114

Determining management module status . . . . . . . . . . . . . . . .114

Displaying temperature information . . . . . . . . . . . . . . . . . . . . .115

Displaying switchover information . . . . . . . . . . . . . . . . . . . . . .116

Chapter 6 Maintaining the Hardware

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Hardware maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . .117

Cleaning the fiber optic connectors. . . . . . . . . . . . . . . . . . . . . . . . .117

Brocade FastIron X Series Chassis Hardware Installation Guide v

53-1001723-02

Page 6

Replacing a management module. . . . . . . . . . . . . . . . . . . . . . . . . .118

Installation precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Removing a management module . . . . . . . . . . . . . . . . . . . . . .118

Installing a new management module. . . . . . . . . . . . . . . . . . .119

Replacing a switch fabric module (FSX 800 and FSX 1600 only) .121

Removing a switch fabric module. . . . . . . . . . . . . . . . . . . . . . .122

Installing a new switch fabric module . . . . . . . . . . . . . . . . . . .122

Replacing an interface module . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Before removing an interface module . . . . . . . . . . . . . . . . . . .125

Removing an interface module . . . . . . . . . . . . . . . . . . . . . . . . .126

Installing a new interface module. . . . . . . . . . . . . . . . . . . . . . .126

Configuring a LAN or WAN Phy interface module . . . . . . . . . .129

Disabling and re-enabling an interface module. . . . . . . . . . . .130

Installing or replacing a POE daughter card . . . . . . . . . . . . . . . . . .131

Replacing a copper or fiber optic module . . . . . . . . . . . . . . . . . . . .134

Removing a copper or fiber optic module . . . . . . . . . . . . . . . .134

Installing a new copper or fiber optic module . . . . . . . . . . . . .135

Cabling a fiber optic module . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Installing or replacing a power supply . . . . . . . . . . . . . . . . . . . . . . .136

Determining which power supply failed . . . . . . . . . . . . . . . . . .136

Removing an AC power supply . . . . . . . . . . . . . . . . . . . . . . . . .137

Removing a DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . .139

Installing a new power supply. . . . . . . . . . . . . . . . . . . . . . . . . .141

Connecting AC power to the chassis. . . . . . . . . . . . . . . . . . . . .145

Connecting DC power to the chassis . . . . . . . . . . . . . . . . . . . . 147

Verifying proper operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Displaying the status of the power supplies . . . . . . . . . . . . . .151

Replacing the FSX and FSX 800 fan tray. . . . . . . . . . . . . . . . . . . . .151

Replacing the FSX 1600 fan assemblies . . . . . . . . . . . . . . . . . . . .154

Replacing the FSX 1600-ANR fan assemblies . . . . . . . . . . . . . . . .155

Replacing the air filter in the FastIron SX-1600 . . . . . . . . . . . . . . .157

Upgrading the device to run Layer 3 software . . . . . . . . . . . . . . . .158

Chapter 7 Hardware Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Chassis specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Physical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . .159

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Regulatory compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Maximum power consumption . . . . . . . . . . . . . . . . . . . . . . . . .164

Power source interruptions . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Pinouts and signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Cable specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

vi Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 7

Power supply specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Physical dimensions and weight. . . . . . . . . . . . . . . . . . . . . . . .170

Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . .170

Electrical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Input connector and plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Regulatory compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Safety warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Appendix A Layer 3 Upgrade Procedures

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Upgrade kit contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Installation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Detailed procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Hardware installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Software installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Appendix B Regulatory Statements

U.S.A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Industry Canada statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Europe and Australia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Japan VCCI statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Japan Denan power cord statement . . . . . . . . . . . . . . . . . . . . . . . .190

Korea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Russia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Appendix C Caution and Danger Notices

Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Dangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Brocade FastIron X Series Chassis Hardware Installation Guide vii

53-1001723-02

Page 8

viii Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 9

About This Document

NOTE

Audience

This document is designed for system administrators with a working knowledge of Layer 2 and

Layer 3 switching and routing.

If you are using a Brocade Layer 3 Switch, you should be familiar with the following protocols if

applicable to your network – IP, RIP, OSPF, BGP, IGMP, PIM, DVMRP, and VRRP.

Supported hardware and software

The following hardware platforms are supported by this release of this guide:

• FastIron SuperX® (FSX)

• FastIron SX 800® (FSX 800)

• FastIron SX 1600® (FSX 1600)

• FastIron SX 1600-ANR® (FSX 1600-ANR) Layer 2 or Layer 3 switches

This document describes software release 07.0.01b only. Refer to earlier releases of this guide for

information about software releases prior to 07.0.01b.

Document conventions

This section describes text formatting conventions and important notice formats used in this

document.

Brocade FastIron X Series Chassis Hardware Installation Guide ix

53-1001723-02

Page 10

Text formatting

NOTE

The following narrative-text formatting conventions are used in this guide.

bold text Identifies command names

Identifies the names of user-manipulated GUI elements

Identifies keywords

Identifies text to enter at the GUI or CLI

italic text Provides emphasis

Identifies variables

Identifies document titles

code text Identifies CLI output

For readability, command names in the narrative portions of this guide are presented in bold: for

example, show version.

Command syntax conventions

The following conventions for command syntax are used in this guide.

command and

parameters

[ ] Optional parameter.

variable Variables are printed in italics enclosed in angled brackets < >.

... Repeat the previous element, for example “member[;member...]”

| Choose from one of the parameters.

Commands and parameters are printed in bold.

Notes, cautions, and danger notices

The following notices and statements are used in this manual. They are listed below in order of

increasing severity of potential hazards.

A note provides a tip, guidance or advice, emphasizes important information, or provides a reference

to related information.

x Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 11

CAUTION

A Caution statement alerts you to situations that can be potentially hazardous to you or cause

DANGER

NOTE

damage to hardware, firmware, software, or data.

A Danger statement indicates conditions or situations that can be potentially lethal or extremely

hazardous to you. Safety labels are also attached directly to products to warn of these conditions

or situations.

Notice to the reader

This document may contain references to the trademarks of the following corporations. These

trademarks are the properties of their respective companies and corporations.

These references are made for informational purposes only.

Corporation Referenced Trademarks and Products

Phillips Screw Company Inc. Phillips

Related publications

The following Brocade documents supplement the information in this guide.

• FastIron Configuration Guide

• Brocade FastIron Compact Switch Hardware Installation Guide

• IronWare MIB Reference

For the latest edition of this document, which contains the most up-to-date information, refer to

Product Manuals at kp.foundrynet.com.

Getting technical help or reporting errors

Brocade is committed to ensuring that your investment in our products remains cost-effective. If

you need assistance, or find errors in the manuals, contact Brocade using one of the following

options.

Brocade FastIron X Series Chassis Hardware Installation Guide xi

53-1001723-02

Page 12

Web access

Go to myBrocade.com, click the Product Documentation tab, then click on the link to the

Knowledge Portal (KP) to obtain more information about a product, or to report documentation

errors. To report errors, click on Cases > Create a New Ticket in the KP. Make sure you specify the

document title in the ticket description.

E-mail access

Send an e-mail to IPsupport@brocade.com

Telephone access

United States and Canada: 800-752-8061

International: +800-AT FIBREE (+800 28 34 27 33)

Refer to the Services & Support page on www.brocade.com for additional toll-free numbers that

may be available within your country.

Areas unable to access 800 numbers: +1-408-333-6061

xii Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 13

Chapter

NOTE

Product Overview

Product overview

This chapter contains an overview of the following FastIron X Series® Layer 2 or Layer 3 switches:

• FastIron SuperX (FSX)

• FastIron SX 800 (FSX 800)

• FastIron SX 1600 (FSX 1600)

• FastIron SX 1600 Acoustic Noise-Reduced (FSX 1600-ANR)

Except for the ANR kit and fan modules in the FSX 1600-ANR chassis, the FSX 1600 and FSX

1600-ANR are similar devices and use the same switch fabric, management and interface modules,

and power supplies. Therefore, the FSX 1600 and FSX 1600-ANR are collectively referred to as the

FSX 1600 chassis throughout this manual, except where explicitly noted.

Designed for medium to large enterprise backbones, the FastIron X Series chassis devices are

modular switches that provide the enterprise network with a complete end-to-end Enterprise LAN

solution, ranging from the wiring closet to the LAN backbone.

1

Hardware benefits

The FastIron X Series chassis devices provide the following benefits:

• The FSX management module is non-blocking, with a built-in switch fabric module and twelve

combination Gigabit Ethernet (GbE) copper or fiber ports that provide connectivity to your

existing management network.

• The FSX 800 and FSX 1600 management modules have a console port and a 10/100/1000

port that provide connectivity to your existing management network. The management

modules optionally support 2-port 10-GbE ports or 8-port GbE fiber and copper ports.

• The FSX 800 and FSX 1600 management modules are interchangeable between devices.

However, you cannot mix IPv4 and IPv6 modules together in the same chassis.

• Optional dual management modules on the FSX 800 and FSX 1600 provide 100% redundancy.

• The crossbar (xbar) architecture enables the management module to switch 30 Gigabits per

second between each interface module and within the management module.

• The interface modules and power supplies are interchangeable among all FastIron X Series

chassis devices. However, you cannot mix IPv4 and IPv6 modules together in the same

chassis.

• The FSX 800 and FSX 1600 management, switch fabric, and interface modules are hot

swappable, which means you can remove and replace them while the chassis is powered on

and running.

• All FastIron X Series chassis devices have a passive backplane.

Brocade FastIron X Series Chassis Hardware Installation Guide 1

53-1001723-02

Page 14

Product overview

1

• Completely separate data and control planes, which results in uncompromised switching

performance, increased reliability of both planes, and increased security of the control plane in

the event of a Denial of Service (DoS) attack on the data plane.

• Distributed data and control planes, which results in uncompromised wire-speed performance

for the data plane and faster and more efficient performance of management functions for the

control plane.

POE port density

Tab le 1 shows the maximum POE port density for the FastIron X Series chassis devices.

TABLE 1 Maximum number of POE class 3 (15.4W) ports per power supply

Power Supply Number of Power

Supplies

FSX FSX 800 FSX 1600

SX-ACPWR-POE and

SX-DCPWR-POE

SX-ACPWR-POE and

SX-DCPWR-POE

SX-ACPWR-POE and

SX-DCPWR-POE

SX-ACPWR-POE and

SX-DCPWR-POE

SX-ACPWR2500-POE 1 140 140 140

SX-ACPWR2500-POE 2 280

SX-ACPWR2500-POE 3 N/A N/A 420

SX-ACPWR2500-POE 4 N/A N/A 560

1. The FSX and FSX 800 support a maximum of 192 POE ports. The FSX 1600 supports a maximum of 384 POE

ports.

1707070

2 140 140 140

3 N/A N/A 210

4 N/A N/A 280

1

280

1

280

1

1

Supported configurations

Premium FastIron X Series chassis devices support Layer 2 switching and full Layer 3 multiprotocol

routing. Standard devices support Layer 2 and base Layer 3 switching. All standard FastIron X

Series chassis devices can be upgraded to full Layer 3 multiprotocol routing, at which time they are

considered to be premium devices.

Depending on the type of management module installed in the device, IPv6 premium devices

support either IPv4 multiprotocol routing and IPv6 host and management features, or IPv6 and

IPv4 multiprotocol routing and IPv6 host and management features. For more information, refer to

“FSX management modules” on page 14 and “FSX 800 and FSX 1600 management modules” on

page 18.

All FastIron X Series chassis devices optionally support Power over Ethernet (POE), providing the

means for integrating data, voice, and video over existing Ethernet cables.

Tab le 3 lists the configurations supported on the FastIron X Series chassis devices.

2 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 15

TABLE 3 FastIron product family support configurations

Device Standard Premium (PREM) Power over Ethernet

FSX Yes Yes Yes

FSX 800 Yes Yes Yes

FSX 1600 Yes Yes Yes

Software features

Software features differ depending on the software version that is loaded on the device and the

type of management module that is installed in the chassis. Refer to the FastIron Configuration

Guide for a complete list of software features supported on your device.

POE applications

Brocade’s FastIron X Series chassis devices with POE provide Power over Ethernet, compliant with

the standards described in the IEEE 802.3af specification for delivering in-line power. The 802.3af

specification defines the standard for delivering power over existing network cabling infrastructure,

enabling multicast-enabled full streaming audio and video applications for converged services,

such as, Voice over IP (VoIP), WLAN access points, IP surveillance cameras, and other IP technology

devices.

Software features

(POE)

1

POE technology eliminates the need for an electrical outlet and dedicated UPS near IP powered

devices. With power sourcing devices, such as Brocade’s FastIron X Series chassis devices with

POE, power is consolidated and centralized in the wiring closets, improving the reliability and

resiliency of the network. Because POE can provide power over Ethernet cable, power is

continuous, even in the event of a power failure.

For POE port density, refer to “POE port density” on page 2.

For more information about POE and how to configure it, refer to the FastIron Configuration Guide.

Support for IPv6 modules

The FastIron X Series chassis devices support IPv6 management and interface modules.

For details about IPv6 modules, refer to the following sections in this chapter:

• “IPv6 hardware support guidelines”

• “FSX management modules” on page 14

• “FSX 800 and FSX 1600 management modules” on page 18

• “Interface modules” on page 23

IPv6 hardware support guidelines

Note the following guidelines and restrictions with IPv6 Management and Interface modules:

Brocade FastIron X Series Chassis Hardware Installation Guide 3

53-1001723-02

Page 16

Hardware features

1

• You cannot mix IPv4 and IPv6 modules together in the same FastIron chassis.

• If you install dual IPv6 management modules, the modules must be identical. For example, you

cannot install one 2-port management module and one 8-port management module together

in the same chassis. The modules must be of like-kind.

Hardware features

The FastIron X Series chassis devices are composed of the following major hardware components:

• Chassis

• Management module

• The FSX management module has a built-in switch fabric module.

• The FSX 800 and FSX 1600 optionally support dual management modules which provide

• Separate switch fabric modules (FSX 800 and FSX 1600 only)

• Interface modules

• Power supplies

• The fan tray in the FSX and FSX 800 is composed of six fans and a fan control module.

• The FSX 1600 has an air filter in the bottom front of the chassis and two fan trays at the rear of

the chassis.

• Built-in mounting brackets

The following sections provide more information about these components.

100% redundancy.

For details about physical dimensions, power supply specifications, and pinouts, refer to Chapter 7,

“Hardware Specifications”.

FSX chassis

The FSX chassis is 6 rack units (RUs) in height and consists of the following:

• One full slot for the management module

• Eight half slots for the interface modules

• Four slots for power supplies along the bottom of the card shelf. The power supply slots add an

additional RU to the height of the chassis.

4 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 17

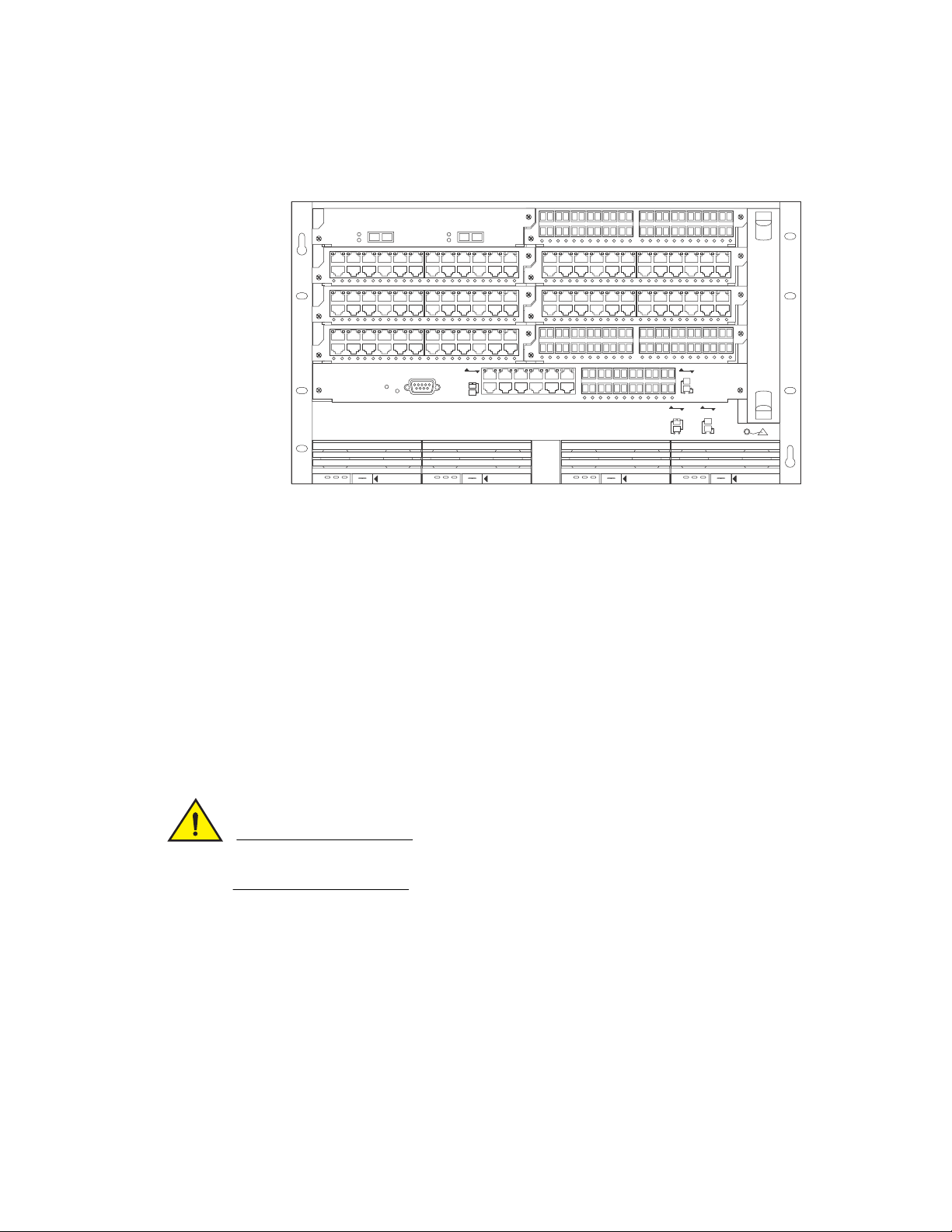

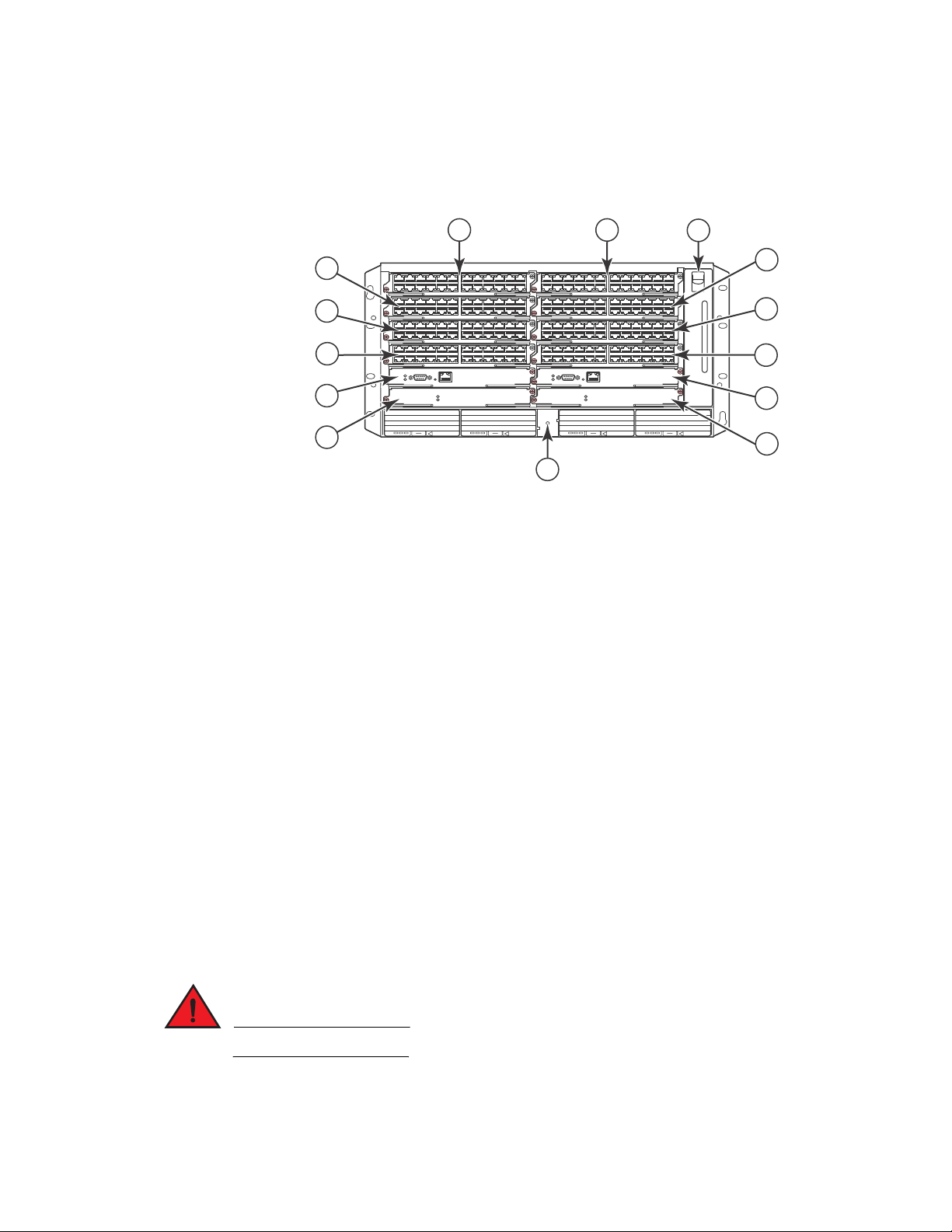

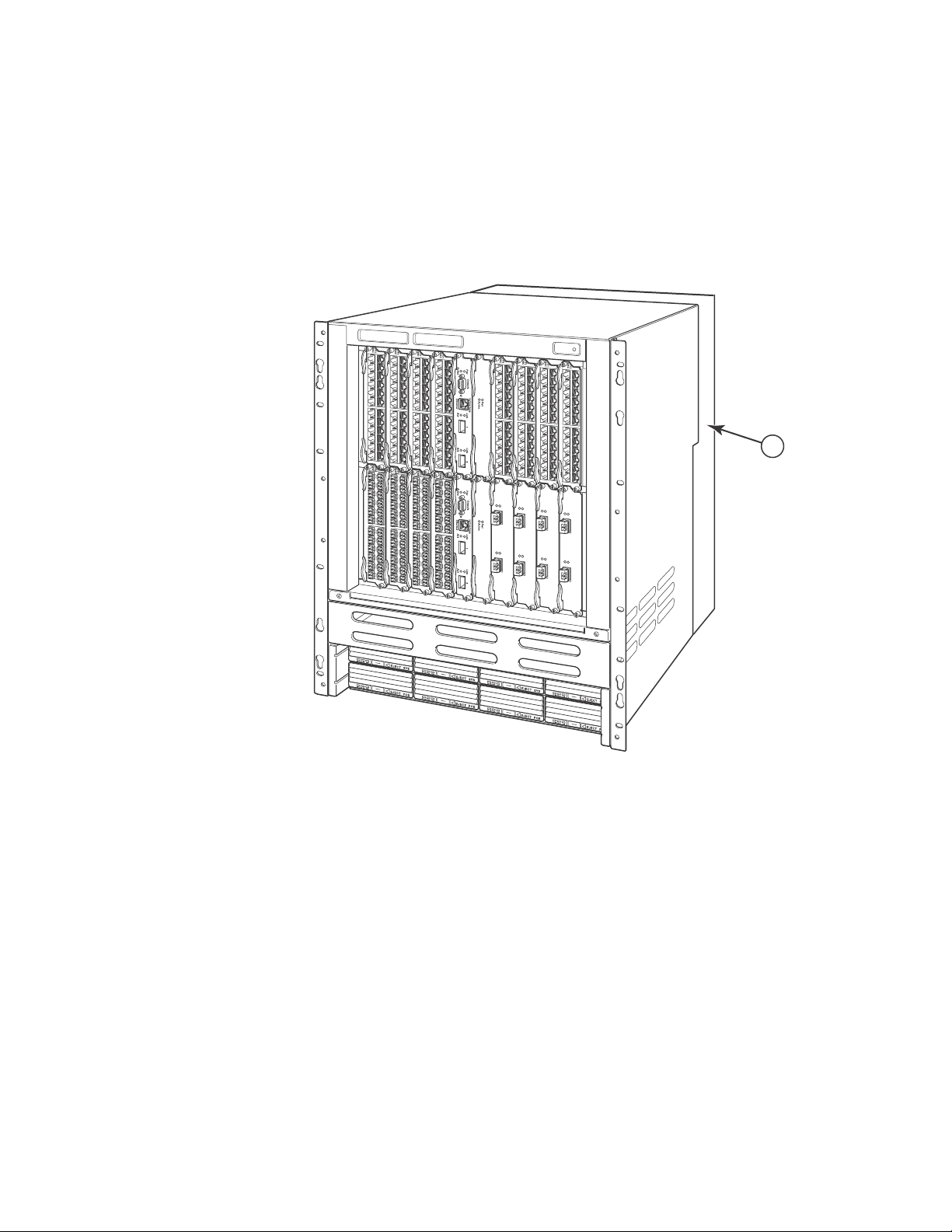

Figure 1 shows the FSX chassis.

CAUTION

DC OK ALMAC OK DC OK ALMAC OK DC OK ALMAC OK DC OK ALMAC OK

8X-12GM-4

Console

Pwr

Lnk

Odd

Even

Odd

Even

Lnk

424F

424C

42XG

424C

424C424C

424F

424C

Odd

Even

Lnk

Lnk

Odd

Even

POE

424C

424F

SYSEJECTSYSEJECTSYSEJECTSYSEJECT

Lnk

Act

Lnk

Act

12

FastIron SuperX

FIGURE 1 FSX chassis

Hardware features

1

Upon shipment from the factory, the following components are installed in the FSX chassis:

• A slot panel in each interface module slot and power supply slot that does not currently have a

module or power supply installed in it. The slot panel ensures proper airflow within the chassis.

• One or two AC or DC power supplies

• A fan tray assembly which contains the cooling system for the chassis

In the FSX slots, you can install the following:

• One management module

• Up to eight interface modules

• Up to four AC and DC power supplies: two system (12-volt) power supplies and two POE (48- or

220-volt) power supplies

Before installing any modules or power supplies, you must remove the slot panel.

If you do not install a module in a slot, you must keep the slot panel in place. If you run the

chassis with an uncovered slot, the system will overheat.

Brocade FastIron X Series Chassis Hardware Installation Guide 5

53-1001723-02

Page 18

Hardware features

DANGER

DC OK ALMAC OK

SYSEJECT

Odd

Even

Lnk

Lnk

Odd

Even

POE

424C

424F

8X-12GM-4

Console

Pwr

Lnk

Odd

Even

Odd

Even

Lnk

7

5

3

1 2 11

4

6

8

9

10

FastIron SuperX

1

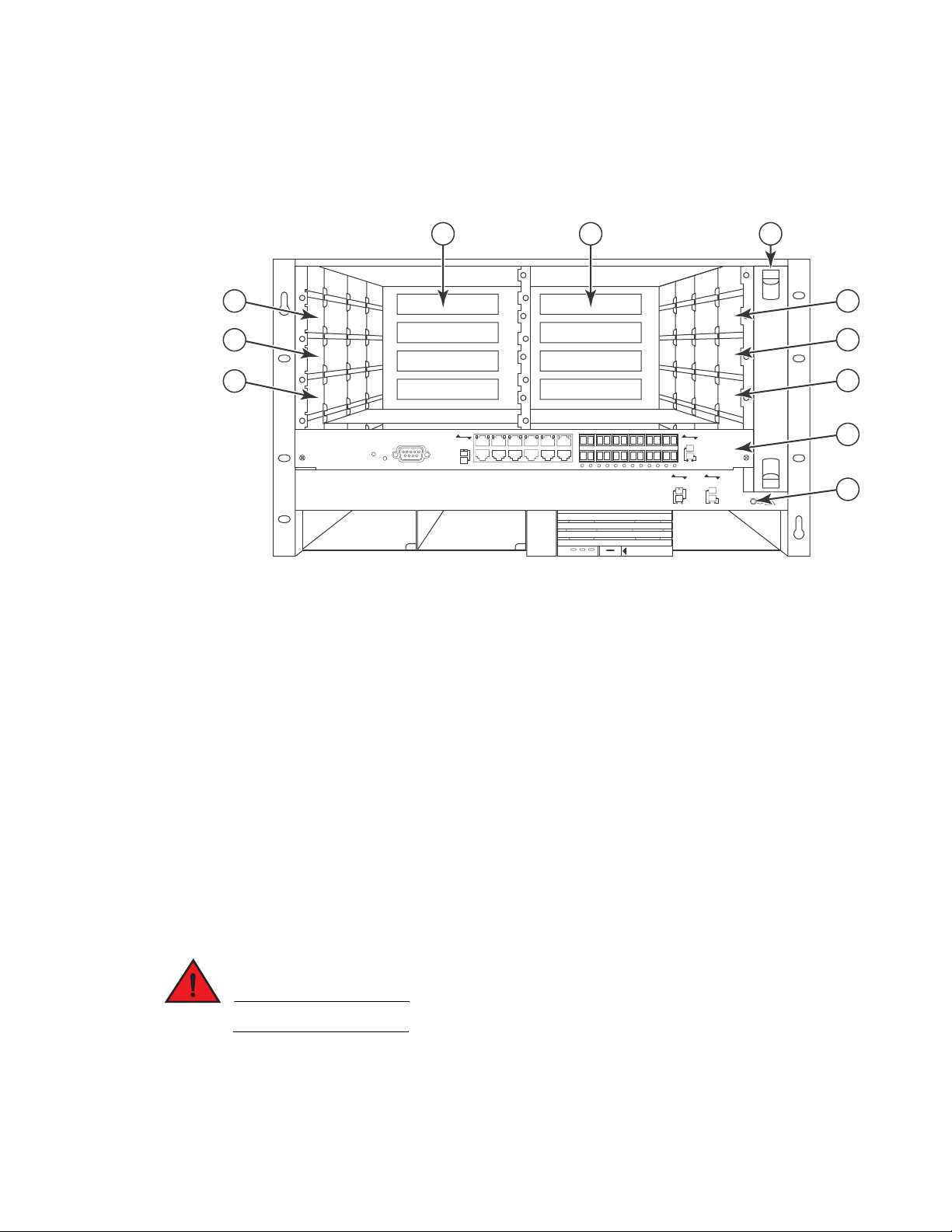

Figure 2 shows the FSX chassis and the slots into which you can install the various modules and

power supplies.

FIGURE 2 FSX chassis slots

1Slot 1

2Slot 2

3Slot 3

4Slot 4

5Slot 5

6Slot 6

7Slot 7

8Slot 8

9Slot 9

10 ESD connector

11 Fan tray

Figure 2 also shows an electrostatic discharge (ESD) connector, into which you can plug an ESD

wrist strap to ground yourself while handling and installing modules.

For safety reasons, the ESD wrist strap should contain a series 1 meg ohm resistor.

6 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 19

Hardware features

CAUTION

1

FSX 800 chassis

The FSX 800 chassis is 6 rack units in height and consists of the following:

• Two half slots for the management modules

• Two half slots for the switch fabric modules

• Eight half slots for the interface modules

• Four slots for power supplies along the bottom of the card shelf. The power supply slots add an

additional rack unit (RU) to the height of the chassis.

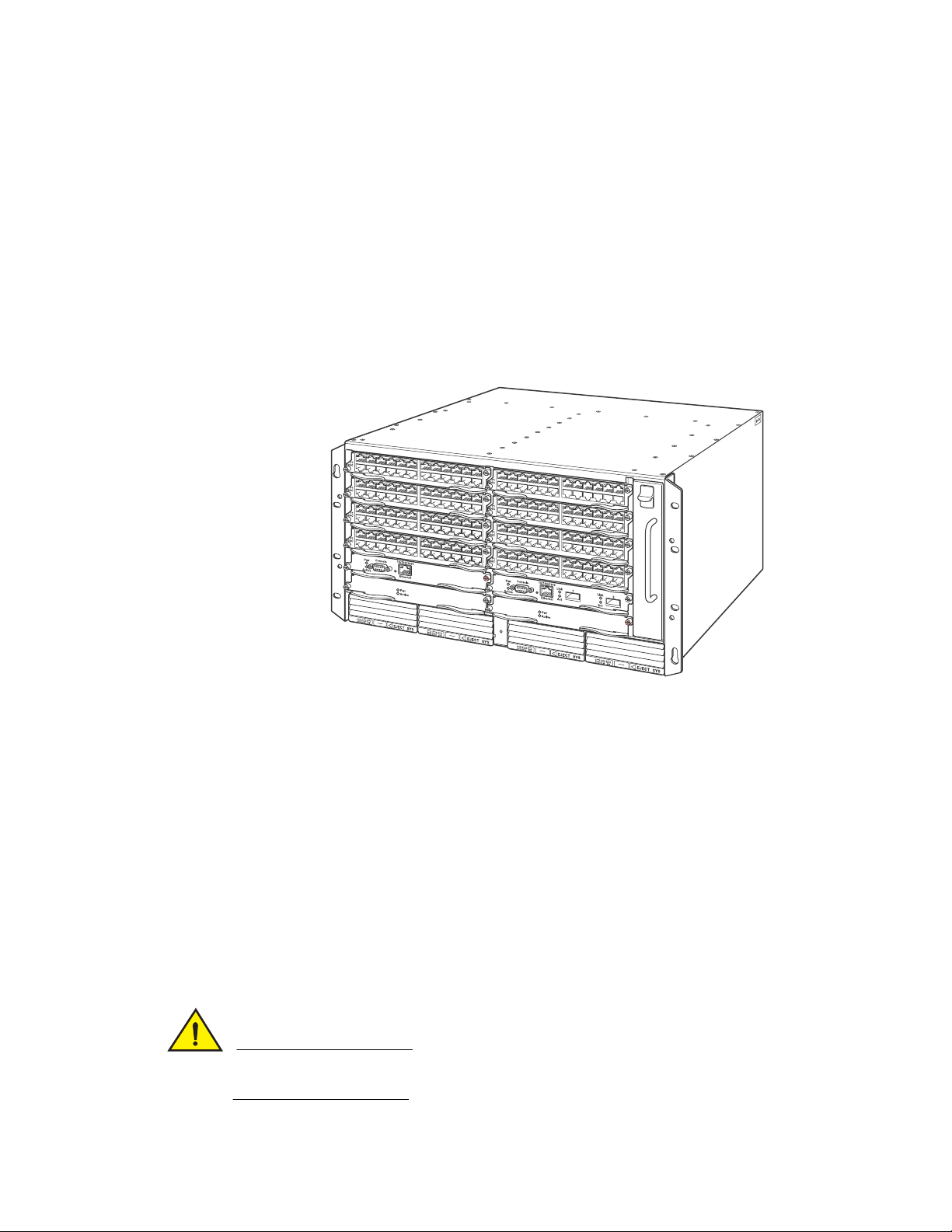

Figure 3 shows the FSX 800 chassis.

FIGURE 3 FSX 800 chassis

The FSX 800 chassis ships from the factory with the following components installed:

• Two switch fabric modules

• A slot panel in each interface module slot and power supply slot that does not currently have a

module or power supply installed in it. The slot panel ensures proper airflow within the chassis.

• One AC power supply

• A fan tray assembly which contains the cooling system for the chassis

In the FSX 800 slots, you can install the following:

• Up to two management modules

• Up to 8 interface modules

• Up to four AC and DC power supplies: two system (12-volt) power supplies and two POE (48- or

220-volt) power supplies

Before installing any modules or power supplies, you must remove the slot panel.

If you do not install a module in a slot, you must keep the slot panel in place. If you run the

chassis with an uncovered slot, the system will overheat.

Brocade FastIron X Series Chassis Hardware Installation Guide 7

53-1001723-02

Page 20

Hardware features

DANGER

1

Figure 4 shows the FSX 800 Chassis and the slots into which you can install the various modules

and power supplies.

FIGURE 4 FSX 800 chassis slots

3

5

7

9

11

1Slot 1

2Slot 2

3Slot 3

4Slot 4

5Slot 5

6Slot 6

7Slot 7

8Slot 8

9Slot 9

10 Slot 10

11 Switch Fabric Slot 1

12 Switch Fabric Slot 2

13 Fan tray

14 ESD connector

1

2

13

4

EJECT POE

F1

424C

F1

424C

F1

424C

F1

424C

10/100/1000

Console

Pwr

Active

Ethernet

Pwr

Active

AC OKDC OKALM

EJECT SYS

AC OKDC OKALM

EJECT SYS

6

8

10

F1

424C

F1

424C

F1

424C

F1

424C

AC OKDC OKALM

10/100/1000

Console

Pwr

Active

Ethernet

Pwr

Active

EJECT POE

AC OKDC OKALM

12

14

Figure 4 also shows an electrostatic discharge (ESD) connector, into which you can plug an ESD

wrist strap to ground yourself while handling and installing modules.

For safety reasons, the ESD wrist strap should contain a series 1 meg ohm resistor.

8 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 21

Hardware features

NOTE

1

FSX 1600 chassis

There are two versions of the FSX 1600 chassis:

• FSX 1600 – Part numbers for chassis and bundles begin with FI-SX-1600-xxx.

• FSX 1600 Acoustic Noise-Reduced (ANR) – An enhanced version of the FSX 1600 chassis, part

numbers for chassis and bundles begin with FI-SX-1600-ANR-xxx.

This section describes the similarities between these models. For details about how these models

differ, refer to “FSX 1600-ANR chassis” on page 12.

Except where explicitly noted throughout this manual, the FSX 1600 and FSX 1600-ANR chassis are

collectively referred to as the FSX 1600 chassis.

The FSX 1600 and FSX 1600-ANR chassis are 14 rack units in height and consist of the following:

• Two half slots for the management modules

• Two half slots for the switch fabric modules

• Sixteen half slots for the interface modules

• Eight slots for power supplies along the bottom of the card shelf

Figure 5 shows the front of the FSX 1600 chassis. The front of the FSX 1600-ANR chassis is

identical to the front of the FSX 1600 chassis.

FIGURE 5 FSX 1600 chassis front

Upon shipment from the factory, the following components are installed in the chassis:

Brocade FastIron X Series Chassis Hardware Installation Guide 9

53-1001723-02

Page 22

Hardware features

CAUTION

1

• Two switch fabric modules

• A slot panel in each interface module slot and power supply slot that does not currently have a

module or power supply installed in it. The slot panel ensures proper airflow within the chassis.

• Two AC power supplies

• A fan tray assembly which contains the cooling system for the chassis

• The FSX 1600-ANR chassis has an ANR kit attached to the rear of the chassis

In the chassis slots, you can install the following:

• Up to two management modules

• Up to 16 interface modules

• Up to eight AC or DC power supplies (four system (SYS) power supplies and four POE power

supplies)

Before installing any modules or power supplies, you must remove the slot panel.

If you do not install a module in a slot, you must keep the slot panel in place. If you run the

chassis with an uncovered slot, the system will overheat.

10 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 23

Hardware features

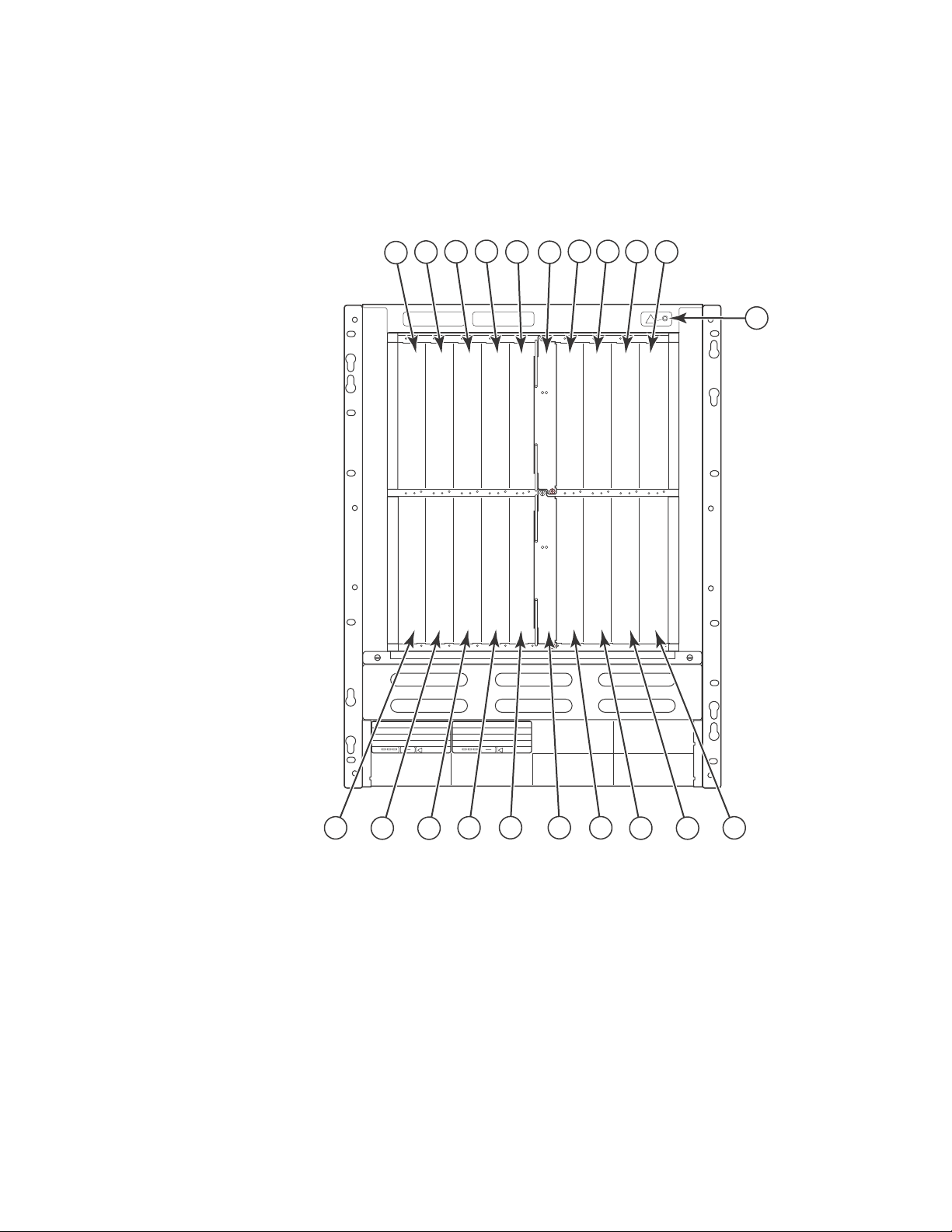

Figure 6 shows the chassis slots into which you can install the various modules and power

supplies.

FIGURE 6 FSX 1600 chassis slots

13579 1119 13 15 17

21

Active

Pwr

1

246810

1Interface slot 1

2Interface slot 2

3Interface slot 3

4Interface slot 4

5Interface slot 5

6Interface slot 6

7Interface slot 7

AC OKDC OK ALM

EJECT SYS

AC OKDC OK ALM

EJECT SYS

Active

Pwr

122014 16 18

Brocade FastIron X Series Chassis Hardware Installation Guide 11

53-1001723-02

Page 24

Hardware features

DANGER

NOTE

NOTE

NOTE

1

8Interface slot 8

9 Management slot 9

10 Management slot 10

11 Interface slot 11

12 Interface slot 12

13 Interface slot 13

14 Interface slot 14

15 Interface slot 15

16 Interface slot 16

17 Interface slot 17

18 Interface slot 18

19 Switch fabric slot 1

20 Switch fabric slot 2

21 ESD connector

Figure 6 also shows an electrostatic discharge (ESD) connector, into which you can plug an ESD

wrist strap to ground yourself while handling and installing modules.

For safety reasons, the ESD wrist strap should contain a series 1 meg ohm resistor.

FSX 1600-ANR chassis

This section describes the differences between the FSX 1600-ANR chassis and the FSX 1600

chassis. For details about the similarities, refer to “FSX 1600-ANR chassis” on page 12.

The FSX 1600 Acoustic Noise-Reduced (ANR) chassis is an enhanced version of the FSX 1600

chassis. Part numbers for the FSX 1600-ANR chassis and bundles begin with FI-SX-1600-ANR-xxx

Except where explicitly noted throughout this manual, the FSX 1600 and FSX 1600-ANR chassis are

collectively referred to as the FSX 1600 chassis.

If you want to upgrade your existing FSX 1600 to an FSX 1600-ANR chassis, you must ship it to

Brocade, where an ANR kit will be installed, then the chassis will be shipped back to you. For more

information, contact Brocade

12 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 25

Hardware features

Compared to the FSX 1600, the FSX 1600-ANR has improved, redirected airflow, better thermal

dissipation, and reduced acoustic noise. The front of the FSX 1600-ANR chassis is identical to the

FSX 1600 and both chassis use the same switch fabric, management and interface modules, and

power supplies. Figure 7 shows the front of the chassis, including a partial view of the ANR kit,

which is behind the chassis.

1

FIGURE 7 FSX 1600-ANR chassis front

1

1 ANR kit on rear of chassis

Brocade FastIron X Series Chassis Hardware Installation Guide 13

53-1001723-02

Page 26

Hardware features

1

The back of the FSX 1600-ANR chassis differs from the FSX 1600 chassis in that the FSX

1600-ANR has an extra sheet metal assembly (ANR kit) and different fan modules. The ANR kit

protrudes from the rear of the chassis, making the depth of the FSX 1600-ANR chassis four inches

longer than the FSX 1600 chassis. Figure 8 shows a side-by-side comparison of the FSX 1600 and

the FSX 1600-ANR.

FIGURE 8 Side-by-side comparison of the FSX 1600-ANR and FSX 1600 chassis

FSX 1600-ANR Chassis Rear View

The ANR chassis supports the same software release versions supported on the FSX 1600. The

display output for the CLI commands show chassis and show version identify the chassis as an

ANR chassis. Also, the SNMP object snChasType returns the chassis type ANR-Chassis. For details

about the show chassis command, refer to “Overview” on page 85. For details about the show

version command, refer to the section “Viewing System Information” in the FastIron Configuration

Guide.

FSX 1600 Chassis Rear View

Management modules

This section describes the management modules for the FastIron X Series chassis devices:

• The FSX chassis requires one management module. The management module occupies one

full slot.

• The FSX 800 and FSX 1600 chassis each require one management module and optionally

support two management modules for 100% redundancy. Each management module occupies

one half slot.

FSX management modules

The FSX management module has a built-in switch fabric module and comes with 12 combination

GbE Copper and Fiber ports.

14 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 27

Hardware features

NOTE

NOTE

NOTE

1

The FSX management module is dedicated, which means that it can be installed in the FSX chassis

only. If you attempt to install the FSX management module in the FSX 800, FSX 1600, or other

Brocade chassis, the chassis and module will not function properly.

Tab le 4 lists the management modules supported on the FSX chassis.

TABLE 4 FSX management modules

Part Number Microprocessor

Speed (MHz)

IPv4 Management Modules

SX-FI12GM-4 400 256

SX-FI12GM-4-PREM

SX-FI12GM2-4 466 512

SX-FI12GM2-4-PREM

IPv6 Management Modules

SX-FI12GM-6 400 256

SX-FI12GM-6-PREM

SX-FI12GM-6-PREM6

SX-FI12GM2-6 466 512

SX-FI12GM2-6-PREM

SX-FI12GM2-6-PREM6

MB SDRAM

The management modules with 512 MB SDRAM enable support for larger routing tables (1,000,000

BGP routes) with the full Layer 3 code.

The IPv6 management modules ending with -PREM provide additional support for full Layer 3 IPv4

routing protocols. The IPv6 management modules ending with -PREM6 provide additional support

for full Layer 3 IPv4 and IPv6 routing protocols.

The FSX management module does the following:

• Controls the FSX hardware components

• Houses and controls the switch fabric module

• Runs the networking protocols

• Provides the real time operating system

The management module is located in slot 9, just above the power supply slots (refer to Figure 2).

Brocade FastIron X Series Chassis Hardware Installation Guide 15

53-1001723-02

Page 28

Hardware features

NOTE

NOTE

1

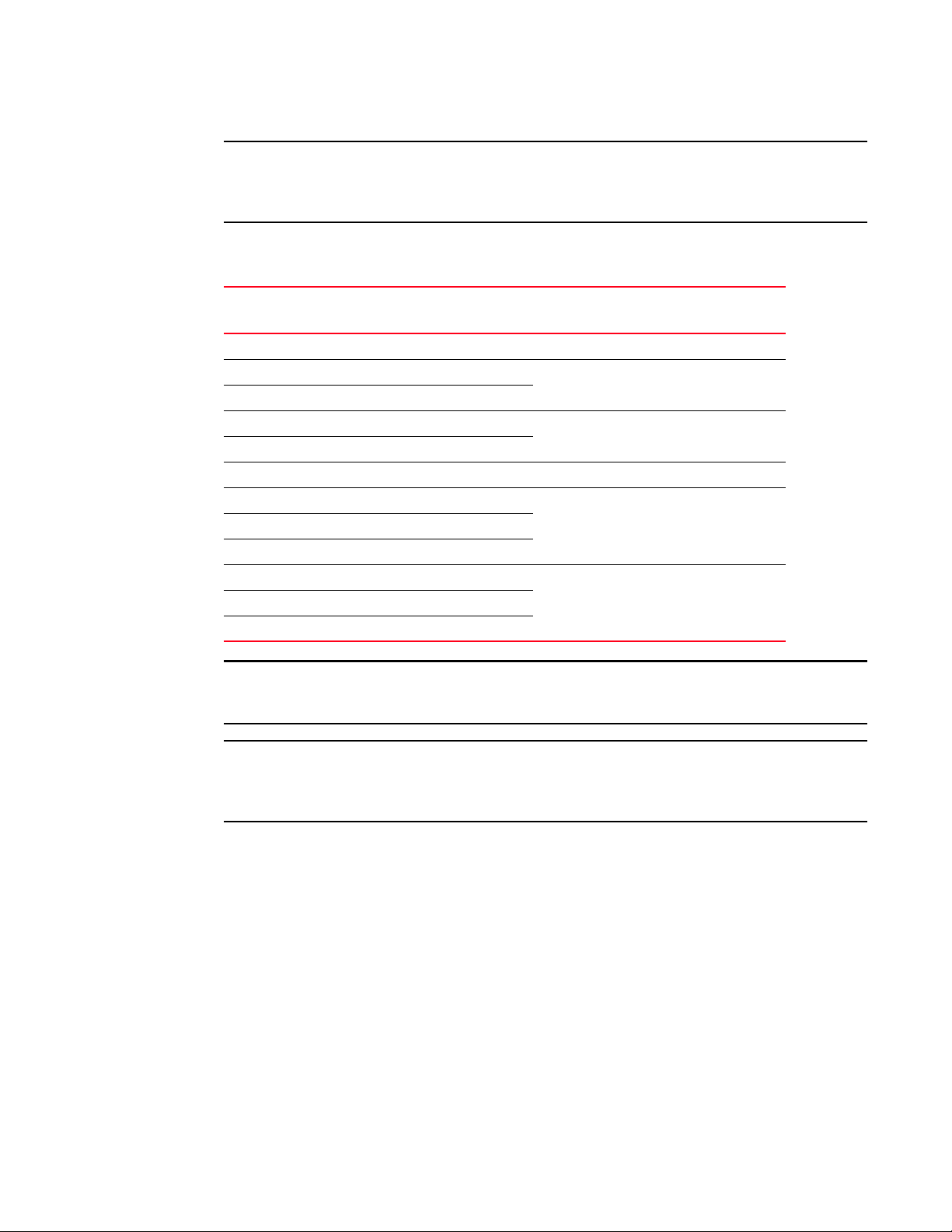

Figure 9 shows the management module’s front panel.

FIGURE 9 FSX management module front panel

8X-12GM-4

Odd

Pwr

Console

Even

Lnk

Odd

Even

Lnk

1 2

1 10/100/1000 Ethernet copper

2 Gigabit Ethernet fiber

The front panel includes the following control features:

• A Console port

• 12 combination GbE Copper and Fiber ports

• 25 LEDs – One LED for power, 12 LEDs for the copper ports, and 12 LEDs for the fiber ports

• A recessed reset button

Gigabit Ethernet ports on the FSX management module

The FSX management module’s front panel includes 12 combination copper and fiber Gigabit

Ethernet ports.

• RJ-45 copper interfaces for 1000Base-T, Cat5 copper cabling – The copper ports support

automatic MDI or MDIX detection, and use auto-sensing and auto-negotiating to determine the

speed (10, 100, or 1000 Mbps) and duplex mode (full-duplex or half-duplex) of the port at the

other end of the link, and adjust the port accordingly. Note that ports operating at 1000 Mbps

operate in the full-duplex mode only and cannot be modified.

• Mini-GBIC slots for the types of fiber cabling listed in Table 32 on page 168.

The Management Module does not support copper mini-GBICs.

Some older SFP modules (mini-GBICs for Gigabit Ethernet ports) have latching mechanisms which

are larger than the newer parts. These latches could interfere with one another when inserted side

by side into a module. Avoid using these mini-GBICs side by side in the same module. These older

modules are identified by the number PL-XPL-00-S13-22 or PL-XPL-00-L13-23 above the Serial

Number. All newer mini-GBICs do not have this limitation.

The Gigabit Ethernet fiber ports operate at a fixed speed of 1000 Mbps (they do not support 10

Mbps or 100 Mbps connections), and use auto-negotiation to automatically configure the highest

performance mode of inter-operation with the connected device.

One port out of each pair of copper and fiber ports can be active at a time. For example, you can

use either copper port 2 or fiber port 2, but not both at the same time. You can use a combination

of fiber and copper ports or all copper or all fiber ports, as needed.

16 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 29

Hardware features

NOTE

1

If you attach both the copper and fiber connectors for a port to the network, the fiber connector

takes precedence over the copper connector. These ports support true media automatic detection,

meaning the device selects the fiber or copper connector based on link availability. If a fiber link

cannot be established, the device selects the copper media.

Typical uses of these ports include but are not limited to the following:

• Connecting a PC through which you can access the system directly or through a Telnet

connection and configure, monitor, and manage the FSX system.

• Connecting a Gigabit Ethernet switch, which will provide connectivity to your existing

management network. You can then access the FSX system and configure, monitor, and

manage the system from a management station.

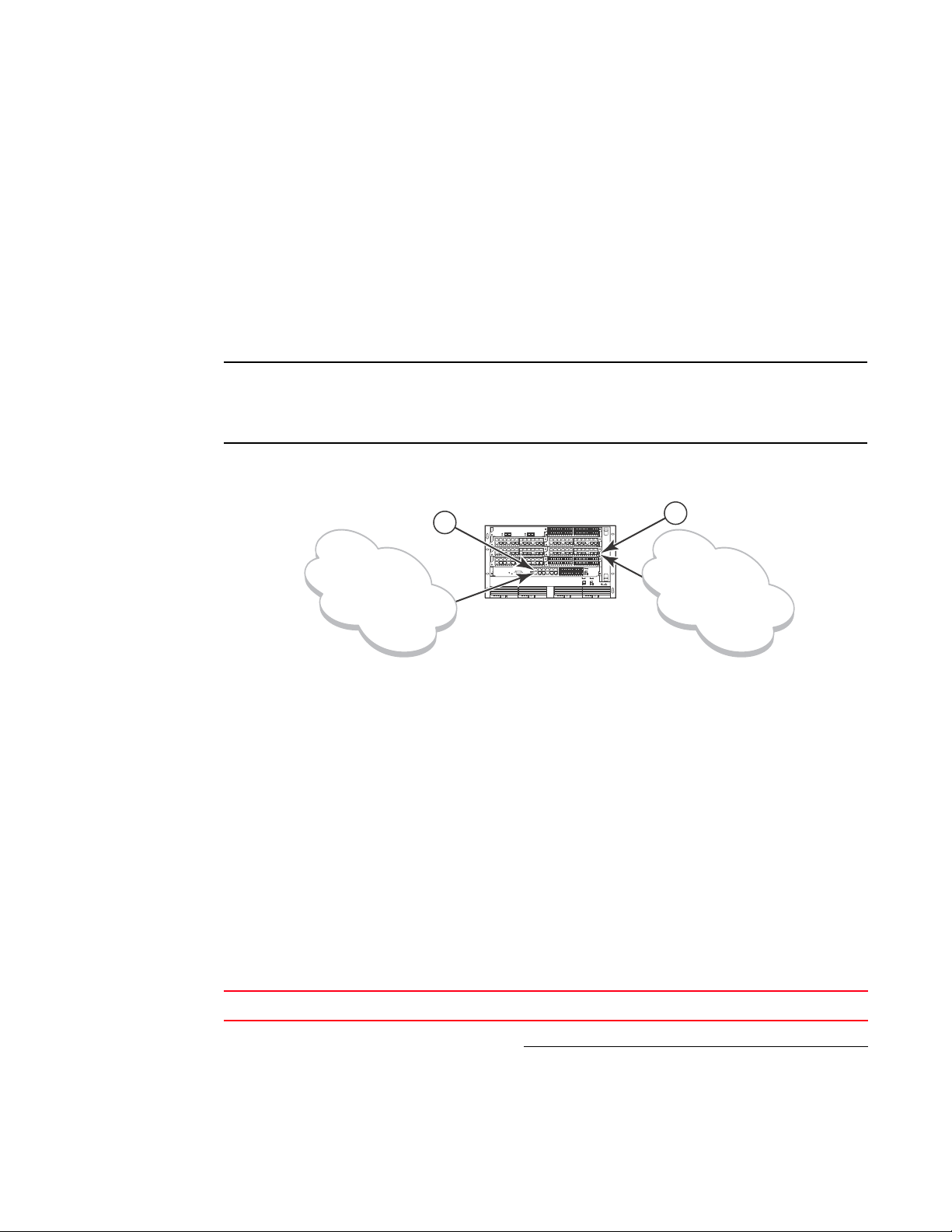

The existing management networks into which you can connect the Gigabit Ethernet ports must be

separate and isolated from the network over which user packets are switched and routed as shown

in Figure 10.

FIGURE 10 Separate management and switching or routing networks

Management

Network

1 Management port

2Interface port

FastIron Super X

1

d

FastIron SuperX

SYSEJECTSYSEJECTSYSEJECTSYSEJECT

2

t

Switching and

Routing Network

LEDs on the FSX management module

The FSX management module provides status information using the LEDs listed in Table 5. The

location of the LEDs is as follows:

• The fiber connectors use the LEDs located beneath the mini-GBIC slots.

• The copper connectors use square LEDs located in the upper right and left corners of the

upper Gigabit copper connectors. The LED on the left side is for the upper copper connector.

The LED on the right side is for the lower copper connector.

Tab le 5 describes the LEDs on the FSX management module.

TABLE 5 FSX management module LEDs

LED Description and Position State Meaning

Pwr Round LED located to the left

of the console port

Brocade FastIron X Series Chassis Hardware Installation Guide 17

53-1001723-02

On (Green) The module is receiving power.

Off The module is not receiving power.

Page 30

Hardware features

NOTE

NOTE

NOTE

1

TABLE 5 FSX management module LEDs (Continued)

LED Description and Position State Meaning

10/100/1000

Mbps Copper

Ports (

1000 Mbps Fiber

Ports

Square LED located on upper

left corner of upper copper

connector for upper copper

connector

Square LED located on upper

right corner of upper copper

connector for lower copper

connector

Round LED located beneath

the fiber connectors

On (Green) A link is established with the remote

port.

Blinking The port is transmitting and receiving

traffic.

Off A link is not established with the

remote port.

On (Green) A link is established with the remote

port.

Blinking The port is transmitting and receiving

packets.

Off A link is not established with the

remote port.

Built-in switch fabric module

The switch fabric module switches user packets from one interface module installed in the chassis

to another. On the FSX, the switch fabric module is built into the management module.

Console port

The Console port on the management module is a standard DB-9 serial connector through which

you can attach a PC or terminal to configure the system using the command line interface (CLI).

The Console port interfaces the control plane only and not the data plane.

Reset button

The reset button on the management module allows you to restart the system. The reset button is

recessed to prevent it from being pushed accidentally.

The reset button is located next to the console port on the management module.

FSX 800 and FSX 1600 management modules

The management modules for the FSX 800 and FSX 1600 are interchangeable between devices.

Standard management modules provide Layer 2 and base Layer 3 functionality only. Premium

management modules support full Layer 3 functionality.

The FSX 800 and FSX 1600 management modules are dedicated, which means that you must

install them in the FSX 800 or FSX 1600 chassis only. If you attempt to install these management

modules in the FSX or other Brocade chassis, the chassis and modules will not function properly.

You cannot intermix different management modules in the same FSX 800 or FSX 1600 chassis. The

management modules must be of like-kind.

You cannot intermix IPv6 and IPv4 modules in the same FSX 800 or FSX 1600 chassis.

18 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 31

Hardware features

NOTE

NOTE

Tab le 6 lists the management modules for the FSX 800 and FSX 1600.

TABLE 6 FSX 800 and FSX 1600 management modules

Part Number Description Microprocessor

Speed (MHz)

IPv4 Management Modules

SX-FIZMR no ports 667 512

SX-FIZMR-PREM

SX-FI2XGMR4 two 10-GbE ports 667 512

SX-FI2XGMR4-PREM

SX-FI8GMR4 eight GbE ports (four

SX-FI8GMR4-PREM

IPv6 Management Modules

SX-FIZMR-6-PREM no ports 667 512

SX-FIZMR-6-PREM6

SX-FI2XGMR6 two 10-GbE ports 667 512

SX-FI2XGMR6-PREM

SX-FI2XGMR6-PREM6

SX-FI8GMR6 eight GbE ports (four

SX-FI8GMR6-PREM

SX-FI8GMR6-PREM6

copper and four fiber

copper and four fiber)

667 512

667 512

1

MB SDRAM

512 MB SDRAM enables support for large routing tables (1,000,000 BGP routes) with the full Layer

3 code.

The IPv6 management modules ending with -PREM provide additional support for full Layer 3 IPv4

routing protocols. The IPv6 management modules ending with -PREM6 provide additional support

for full Layer 3 IPv4 and IPv6 routing protocols.

The FSX 800 and FSX 1600 management modules perform the following tasks:

• Control the hardware components

• Control the separate switch fabric modules

• Run the networking protocols

• Provide the real time operating system

FSX 800 management modules are located in slots 9 and 10, just above the switch module slots

(refer to Figure 4).

FSX 1600 management modules are located in slots 9 and 10 along the center of the chassis

(refer to Figure 6).

Brocade FastIron X Series Chassis Hardware Installation Guide 19

53-1001723-02

Page 32

Hardware features

Pwr

Console

12

Ethernet

10/100/1000

Active

Link

Act

Link

Act

Console

Pwr

Active

Ethernet

10/100/1000

1 2 3 4

5 6 7 8

1

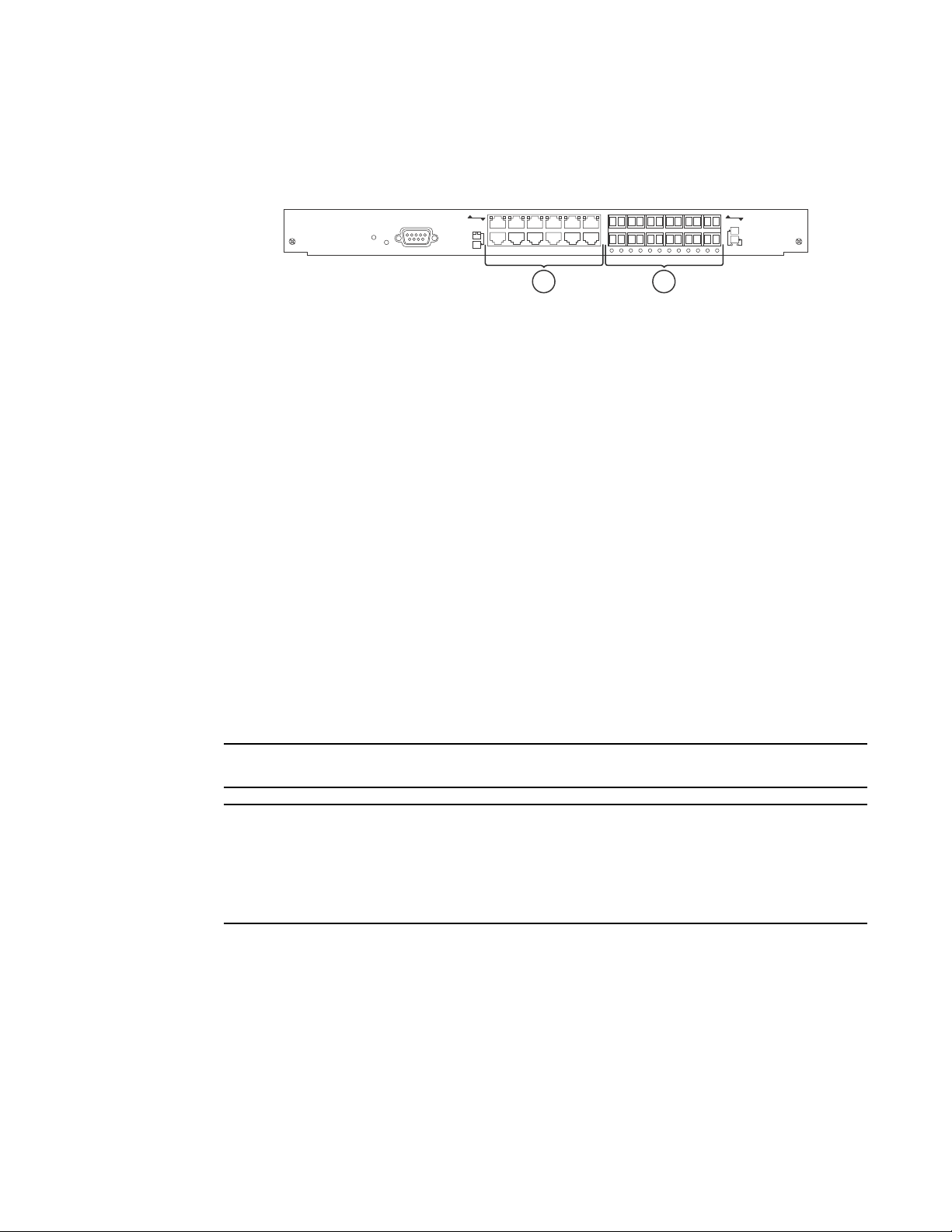

Figure 11 shows the front panel of the IPv4 and IPv6 management modules with no ports.

FIGURE 11 FSX 800 and FSX 1600 management module with no ports

Pwr

Active

Console

10/100/1000

Ethernet

Figure 12 shows the front panel of the IPv4 and IPv6 management modules with two 10-GbE ports.

FIGURE 12 FSX 800 and FSX 1600 management module with two 10-GbE ports

Figure 13 shows the front panel of the IPv4 and IPv6 management modules with eight GbE ports.

FIGURE 13 FSX 800 and FSX 1600 IPv4 and IPv6 8-port management module

The front panel on the management modules include the following control features:

• A Console port and 10/100/1000 RJ-45 copper port allow you to access the system’s CLI

directly from a PC or terminal or through a Telnet connection to the PC or terminal.

• Depending on the type of management modules installed in the device, the management

modules have the following ports:

• no 10-GbE fiber ports

• two 10-GbE fiber ports

• eight GbE copper and fiber ports (four copper and four fiber)

• LEDs for power and active or standby status

• Four LEDs for the two 10-GbE fiber ports (2-port 10-GbE modules only)

• A recessed reset button

10/100/1000 GbE Copper Port on the FSX 800 and FSX 1600 management modules

The 10/100/1000 RJ-45 copper port on the management module enables you to attach a PC or

terminal. From this Ethernet port, you can access the system’s CLI or Web Management Interface

directly from the PC or terminal or through a Telnet connection to the PC or terminal.

10-GbE Ports on the FSX 800 and FSX 1600 2-port 10-GbE management modules

The FSX 800 and FSX 1600 2-port 10-GbE management modules come with two 10-GbE fiber

ports through which you can connect your device to other network devices at a speed of 10

Gigabits per second.

20 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 33

Hardware features

NOTE

NOTE

1

The 10-GbE ports have optical interfaces with LC connectors for 10-Gigabit Small Form Factor

Pluggable (XFP) MSA-compliant transceivers. The transceivers support the fiber optic cabling for

LAN PHY listed in Tab le 32 on page 168.

Gigabit Ethernet Ports on the FSX 800 and FSX 1600 8-port management modules

The FSX 800 and FSX 1600 8-port management modules come with eight copper and fiber Gigabit

Ethernet ports (four copper and four fiber), through which you can connect your device to other

network devices at a speed of 1 Gigabit per second. These ports are not combo ports and can be

used simultaneously. The following list describes the copper and fiber ports.

• The copper ports have RJ-45 copper interfaces for 1000Base-T, Cat5 copper cabling – The

copper ports support automatic MDI or MDIX detection, and use auto-sensing and

auto-negotiating to determine the speed (10, 100, or 1000 Mbps) and duplex mode

(full-duplex or half-duplex) of the port at the other end of the link, and adjust the port

accordingly. Ports operating at 1000 Mbps operate in the full-duplex mode only and cannot be

modified.

• The fiber ports have mini-GBIC slots for the types of fiber cabling listed in Table 32 on

page 168.

The Management Module does not support copper mini-GBICs.

Some older SFP modules (mini-GBICs for Gigabit Ethernet ports) have latching mechanisms which

are larger than the newer parts. These latches could interfere with one another when inserted side

by side into a module. Avoid using these mini-GBICs side by side in the same module. These older

modules are identified by the number PL-XPL-00-S13-22 or PL-XPL-00-L13-23 above the Serial

Number. All newer mini-GBICs do not have this limitation.

The Gigabit Ethernet fiber ports operate at a fixed speed of 1000 Mbps (they do not support 10

Mbps or 100 Mbps connections), and use auto-negotiation to automatically configure the highest

performance mode of inter-operation with the connected device.

LEDs on the FSX 800 and FSX 1600 management modules

The management modules provide status information using the LEDs listed in Table 7.

TABLE 7 FSX 800 and FSX 1600 management module LEDs

LED Description and Position State Meaning

Pwr Round LED located to the left of the

console port

Active Round LED located to the left of the

console port

10/100/1000 Copper Port LEDs

Lnk Left-most LED above the port On The port is connected.

On (Green) The module is receiving power.

Off The module is not receiving power.

On (Green) The module is the active management

module.

Off The module is not the active management

module.

Off No port connection exists.

Brocade FastIron X Series Chassis Hardware Installation Guide 21

53-1001723-02

Page 34

Hardware features

Pwr

Active

1

TABLE 7 FSX 800 and FSX 1600 management module LEDs (Continued)

LED Description and Position State Meaning

Act Right-most LED above the port. On or Blinking The port is transmitting and receiving

traffic.

Off The port is not transmitting or receiving

traffic.

1000 Mbps Fiber Port LEDs

Lnk or Act Round LED located beneath the

fiber connectors

10-GbE Port LEDs

Lnk Top-most LED to the left of the port. On Fiber port is connected.

Act Bottom-most LED to the left of the

port.

On (Green) A link is established with the remote port.

Blinking The port is transmitting and receiving

packets.

Off A link is not established with the remote

port.

Off No fiber port connection exists.

On or Blinking The port is transmitting and receiving

traffic.

Off The port is not transmitting or receiving

traffic.

Console port

The Console port on the management module is a standard DB-9 serial connector through which

you can attach a PC or terminal to configure the system using the command line interface (CLI).

The Console port interfaces the control plane only and not the data plane.

Reset button

The reset button on the management module allows you to restart the system. The reset button is

recessed to prevent it from being pushed accidentally.

The reset button is located next to the console port on the management module.

Switch fabric modules (

FSX 800

and

FSX 1600

only)

The switch fabric modules switch user packets from one interface module installed in the chassis

to another. Unlike the FSX, which has a switch fabric module built into the management module,

the switch fabric modules in the FSX 800 and FSX 1600 chassis are separate from the

management modules and are physically located next to the management modules.

Figure 14 shows the FSX 800 and FSX 1600 switch fabric module.

FIGURE 14 FSX 800 and FSX 1600 switch fabric module

22 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 35

Hardware features

NOTE

1

LEDs on the switch fabric module

The front panel provides status information using the LEDs listed in Table 8.

TABLE 8 Switch fabric module LEDs

LED Description and Position State Meaning

Pwr Top-most LED On (Green) The module is receiving power.

Off The module is not receiving power.

Active Bottom-most LED On (Green) The module is functioning properly.

Off The module is not functioning properly.

Interface modules

This section describes the Interface modules for the FastIron X Series chassis devices:

• In the FSX chassis, you can install up to eight Interface modules in the slots shown in Figure 2

on page 6.

• In the FSX 800 chassis, you can install up to eight Interface modules in the slots shown in

Figure 4 on page 8.

• In the FSX 1600 chassis, you can install up to 16 interface modules in the slots shown in

Figure 6 on page 11.

You cannot mix IPv4 and IPv6 modules together in the same chassis.

Tab le 9 lists the supported Interface modules for each FastIron X Series chassis type.

TABLE 9 Interface modules

Interface Module Part Number FSX

IPv4 Interface Modules

24-port Gigabit Ethernet Fiber (1000

Mbps only)

24-port Gigabit Ethernet copper

without POE

24-port Gigabit Ethernet copper with

POE

24-port 100/1000 Hybrid Fiber SX-FI424HF X X X

2-port 10-Gigabit Ethernet LAN

module

2-port 10-Gigabit Ethernet LAN or

WAN module

IPv6 Interface Modules

24-port Gigabit Ethernet copper

without POE

24-port Gigabit Ethernet copper with

POE

SX-FI424FXXX

SX-FI424CXXX

SX-FI424PXXX

SX-FI42XG X X X

SX-FI42XGW X X X

SX-FI624CXXX

SX-FI624PXXX

FSX 800 FSX 1600

Brocade FastIron X Series Chassis Hardware Installation Guide 23

53-1001723-02

Page 36

Hardware features

CAUTION

CAUTION

NOTE

1

TABLE 9 Interface modules (Continued)

Interface Module Part Number FSX

24-port 100/1000 Hybrid Fiber SX-FI624HF X X X

2-port 10-Gigabit Ethernet LAN

module

SX-FI62XG X X X

FSX 800 FSX 1600

Hot swap support

• The interface modules are hot swappable, which means you can remove and replace them

without powering down the system; however, you must issue the disable module command

before you remove the modules from the chassis.

• Issuing the disable module command before removing the module is not required on the FSX

800 and FSX 1600 chassis. This is referred to as “Enhanced Hot Swap”.

It is recommended that modules be disabled through the CLI before removal from the chassis. If

the operator wishes to remove the module without first disabling the module, the Enhanced Hot

Swap capability in software Release 03.2.00 and later supports this procedure for the FastIron

SX 800 and FastIron SX 1600 chassis. Enhanced Hot Swap (that is, no CLI disable) should be

performed during a maintenance window. On rare occasions, an Enhanced Hot Swap may result

in a software reload of the system. The likelihood of this event is very low.

It is important to wait a minimum of 10 seconds between the removal and insertion of a line

module. Re-insertion of a line module less than 10 seconds after the removal of a line module

may result in the line module not being properly recognized.

Refer to “Replacing an interface module” on page 124 for instructions.

24-port Gigabit Ethernet copper interface module

The 24-port Gigabit Ethernet Copper interface module has 24 10/100/1000 ports with RJ-45

connectors for Cat5 cabling. The copper ports support automatic MDI or MDIX detection, and use

auto-sensing and auto-negotiating to determine the speed (10, 100, or 1000 Mbps) and duplex

mode (full-duplex or half-duplex) of the port at the other end of the link, and adjust the port

accordingly. Note that ports operating at 1000 Mbps operate in the full-duplex mode only and

cannot be modified.

The 24-port Gigabit Ethernet Copper Interface module supports Power over Ethernet (POE). You

can either order the interface module with POE capability, or upgrade your existing 24-port Gigabit

Ethernet Copper module by installing a POE daughter card. To run POE on your system, you must

also install at least one 48-volt power supply.

Instructions for installing a POE daughter card are provided in “Installing or replacing a POE daughter

card” on page 131.

24 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 37

Hardware features

Figure 15 shows the front panel of the IPv4 24-port Gigabit Ethernet copper module.

FIGURE 15 IPv4 24-port Gigabit Ethernet copper module front panel

1

1

424C

13

2 14 24

POE LEDs

1Port 1

2Port 2

13 Port 13

14 Port 14

24 Port 24

Figure 16 shows the front panel of the IPv6 24-port Gigabit Ethernet copper module.

FIGURE 16 IPv6 24-port Gigabit Ethernet copper module front panel

1

13

624C

2

14 24

POE LEDs

1Port 1

2Port 2

13 Port 13

14 Port 14

24 Port 24

The front panel includes the following control features:

• 24 10/100/1000 copper ports

• 24 LEDs for port status

• 24 LEDs for Power over Ethernet (POE) status

Brocade FastIron X Series Chassis Hardware Installation Guide 25

53-1001723-02

Page 38

Hardware features

NOTE

NOTE

NOTE

NOTE

1

The POE LEDs work only when POE is enabled on your device.

LEDs for 24-port copper module

The front panel of the 24-port Gigabit Ethernet copper module includes 24 LEDs that indicate the

status of each port, and 24 LEDs (on bottom) that indicate the status of POE.

The POE LEDs work only when POE is enabled on your device.

The copper ports provide status information using the LEDs described in Table 10.

TABLE 10 LEDs for 10/100/1000 copper ports

LED Position State Meaning

Link or Activity Square LED located on upper left

corner of upper copper connector

for upper copper connector

Square LED located on upper

right corner of upper copper

connector for lower copper

connector

POE (if

applicable)

Round LED located beneath the

copper ports

The first (left-most) LED is for port

1, the second LED is for port 2,

the third LED is for port 3, etc.

On (Green) A link is established with the remote

port.

Blinking The port is transmitting and receiving

traffic.

Off A link is not established with the

remote port.

On (Green) The port is enabled, a

power-consuming device has been

detected, and the module is supplying

power to the device.

Off The port is not providing in-line power.

24-port Gigabit Ethernet fiber interface module

The 24-port Gigabit Ethernet Fiber interface module has 24 ports with connectors for mini-GBIC

transceivers (Small Form Factor Pluggable (SFP) Multisource Agreement (MSA)-compliant

transceivers). The ports support both fiber and copper mini-GBICs in any combination.

The copper mini-GBICs are not supported on the FSX Management Module’s combination Gigabit

Ethernet Copper and Fiber ports.

The ports on the 24-port Gigabit Ethernet fiber module operate at a fixed speed of 1000 Mbps

(they do not support 10 Mbps or 100 Mbps connections). In addition, the ports operate in

full-duplex mode only, and use auto-negotiation to automatically configure the highest performance

mode of inter-operation with the connected device.

The mini-GBIC slots support the types of 1000Base fiber and copper cabling listed in “Network

interfaces” on page 30.

Some older SFP modules (mini-GBICs for Gigabit Ethernet ports) have latching mechanisms which

are larger than the newer parts. These latches could interfere with one another when inserted side

by side into a module. Avoid using these mini-GBICs side by side in the same module. These older

modules are identified by the number PL-XPL-00-S13-22 or PL-XPL-00-L13-23 above the Serial

Number. All newer mini-GBICs do not have this limitation.

26 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 39

Hardware features

424F

2

24

1

13

LEDs

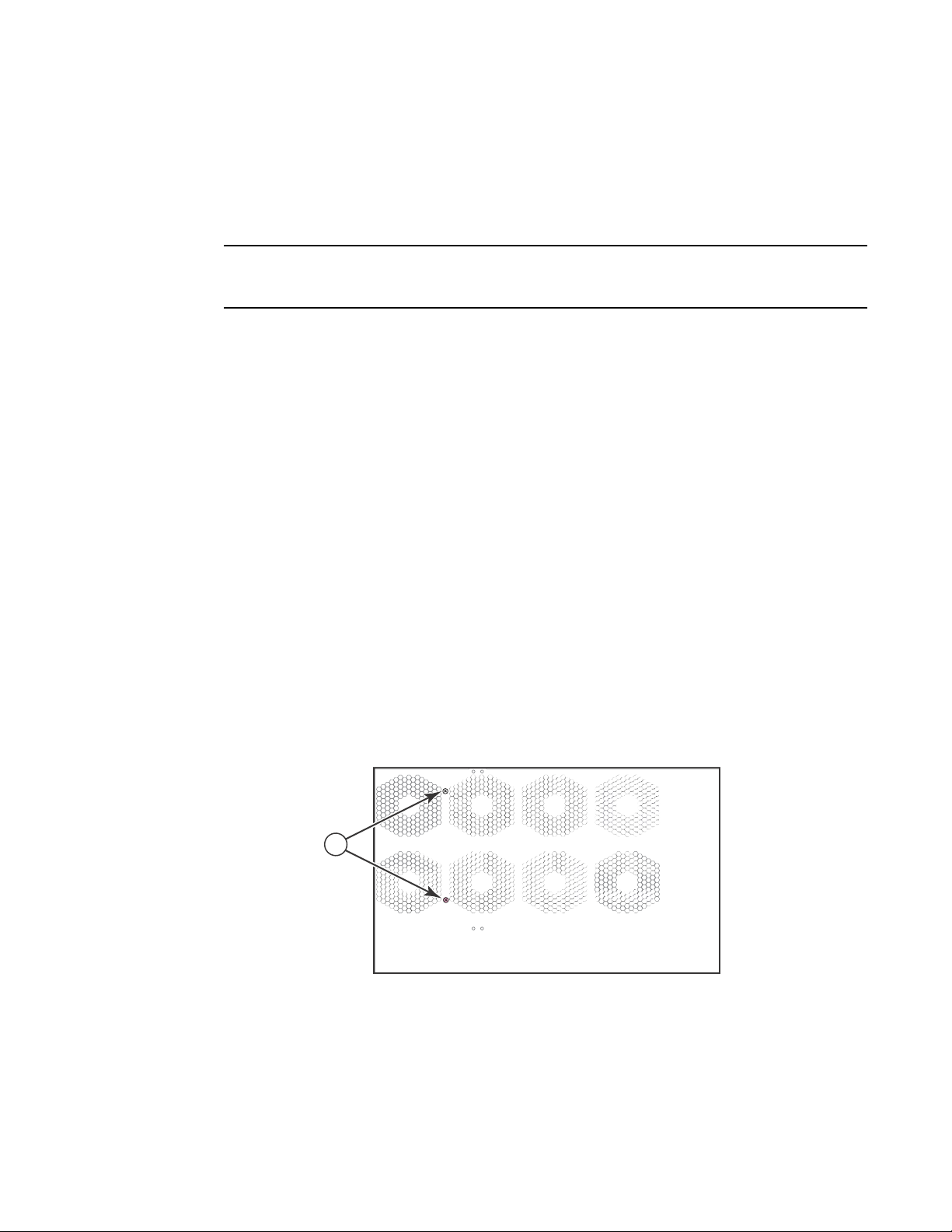

Figure 17 shows the front panel of the IPv4 24-port Gigabit Ethernet fiber module.

FIGURE 17 IPv4 24-port Gigabit Ethernet fiber module front panel

1Port 1

2Port 2

13 Port 13

1

24 Port 24

The front panel includes the following control features:

• 24 Gigabit Ethernet fiber ports

• 24 LEDs

LEDs for 24-port fiber module

The fiber module’s front panel includes 24 LEDs that indicate the status of each port. The LEDs are

located beneath the mini-GBIC slots for the ports (refer to Figure 17). The left-most LED is for Port

1, the second LED is for Port 2, and so on.

The ports provide status information using the LEDs described in Table 11.

TABLE 11 LEDs for 1000 Mbps ports on the 24-port fiber module

LED Position State Meaning

Link or Activity Round LED located

beneath the fiber

connectors

On (Green) A link is established with the remote port.

Blinking The port is transmitting and receiving packets.

Off A link is not established with the remote port.

24-port 100/1000 hybrid fiber interface module

The 100/1000 hybrid fiber module has 24 ports with connectors for mini-GBIC transceivers (also

called Small Form Factor Pluggable (SFP) Multisource Agreement (MSA)-compliant transceivers).

The ports support 100 and 1000 fiber mini-GBICs.

Brocade FastIron X Series Chassis Hardware Installation Guide 27

53-1001723-02

Page 40

Hardware features

SX

424HF

2 24

1

13

LEDs

SX

624HF

2 24

1

13

LEDs

1

Figure 18 shows the IPv4 100/1000 Hybrid Fiber interface module’s front panel.

FIGURE 18 IPv4 100/1000 hybrid fiber interface module front panel

1Port 1

2Port 2

13 Port 13

24 Port 24

Figure 19 shows the IPv6 100/1000 Hybrid Fiber interface module’s front panel.

FIGURE 19 IPv6 100/1000 hybrid fiber interface module front panel

1Port 1

2Port 2

13 Port 13

24 Port 24

The front panel includes the following control features:

• 24 Gigabit Ethernet fiber ports

• 24 LEDs

The ports on the 24-port 100/1000 Gigabit Ethernet Hybrid Fiber module operate at a fixed speed

of 100 or 1000 Mbps (they do not support 10 Mbps connections), and use auto-negotiation to

automatically configure the highest performance mode of inter-operation with the connected

device.

28 Brocade FastIron X Series Chassis Hardware Installation Guide

53-1001723-02

Page 41

Hardware features

42XG

Lnk

Act

Lnk

Act

12

62XG

Lnk

Act

Lnk

Act

12

1

The mini-GBIC slots support the 100Base and 1000Base fiber cabling listed in “Network

interfaces” on page 30.

Support for 100Base-FX on the 100/1000 interface module

The 24-port 100/1000 fiber interface module supports the following types of SFPs for 100Base-FX:

• Multimode SFP – maximum distance is 2 kilometers

• Bidirectional single mode SFP – maximum distance is 10 kilometers

• Long Reach (LR) – maximum distance is 40 kilometers

• Intermediate Reach (IR) – maximum distance is 15 kilometers

To enable support for 100BaseFX, you must enter the CLI command 100-fx at the Interface level of

the CLI. For CLI command details, refer to the section “Enabling and Disabling Support for

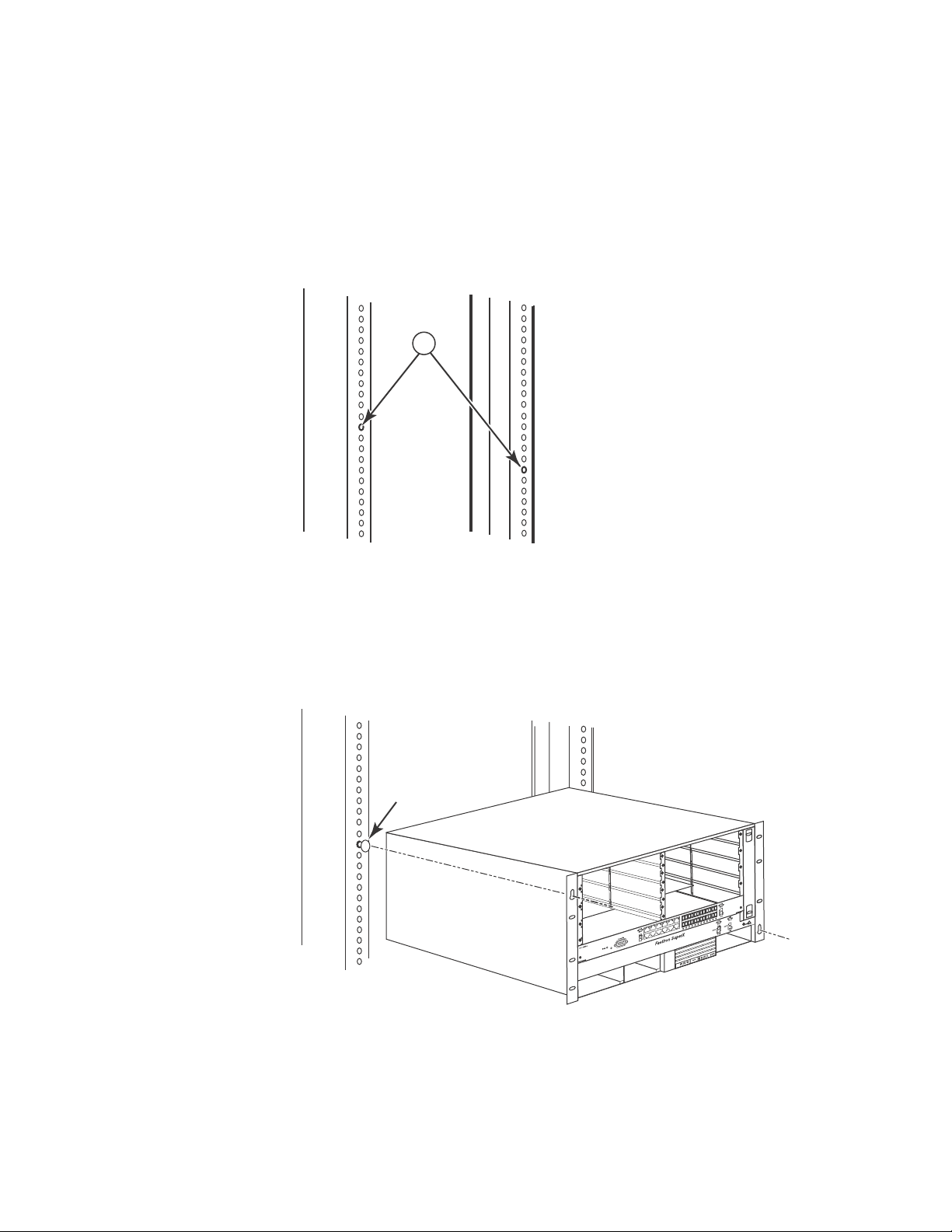

100BaseFX” in the FastIron Configuration Guide.