Page 1

INTERNAL

!

BLOWER

For use with compatible BEST

See hood manual for suitability.

MODEL iQ12

®

range hoods.

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock service disconnecting means to prevent power

from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by qualified

personnel in accordance with all applicable codes and standards, including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting.Follow the heating equipment

manufacturer’s guidelines and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this range hood with any additional solid-state

speed control device.

8. To reduce the risk of fire, use only steel ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate for the

size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSON(S) IN THE

EVENT OF A RANGE TOP GREASE FIRE,OBSERVE THE

FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO PREVENT

BURNS. IF THE FLAMES DO NOT GO OUT IMMEDIATELY,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN – You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels – This

could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you know

how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

3. This blower has a thermal overload which will automatically

shut off the motor if it becomes overheated.The motor will

restart when it cools down.If the motor continues to shut off

and restart, have the hood serviced.

4. Please read specification label on product for further information and requirements.

5. To reduce the risk of fire and to properly exhaust air on a ducted

installation, be sure to duct air outside – Do not exhaust air

into spaces within walls or ceiling or into attics, crawl spaces,

or garage.

INSTALLER:

Save this manual for Electrical Inspector

and Homeowner to use.

Page 2

MODEL iQ12

Page 2

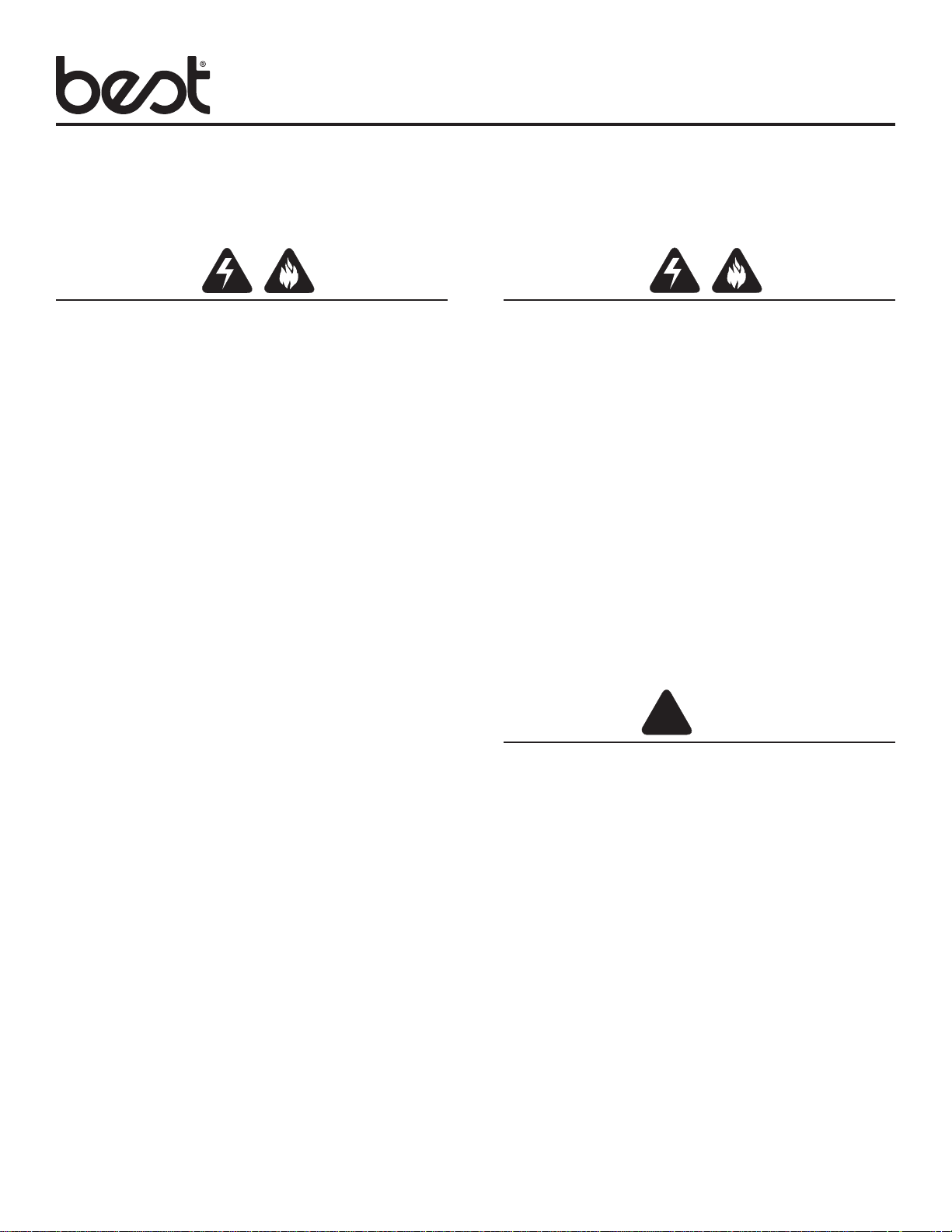

Wall & Roof Caps,

Exterior Blowers

Elbows

Ductwork

In-Line

Damper

MODEL 437

(High capacity roof cap)

MODEL 418

(10” round adjustable elbow)

MODEL 410

(10” round duct—2 ft. sections)

MODEL 421

(10” round In-Line Damper - included)

MODEL 441

(10’’ Round wall cap)

Blower

System

OPTIONAL

DECORATIVE

FLUE

IP29M

SERIES HOOD

(Canopy with

blower controls

& lighting.)

MODEL iQ12

BLOWER/ROUGH-IN KIT

(1200 cfm interior blower

& rough-in plate)

OPTIONAL

DECORATIVE FLUE

WP28M, WP29M

SERIES HOODS

(Canopy with

blower controls

& lighting.

INTERNAL BLOWER

RANGE HOOD SYSTEM

Page 3

INSTALLATION

MODEL iQ12

Page 3

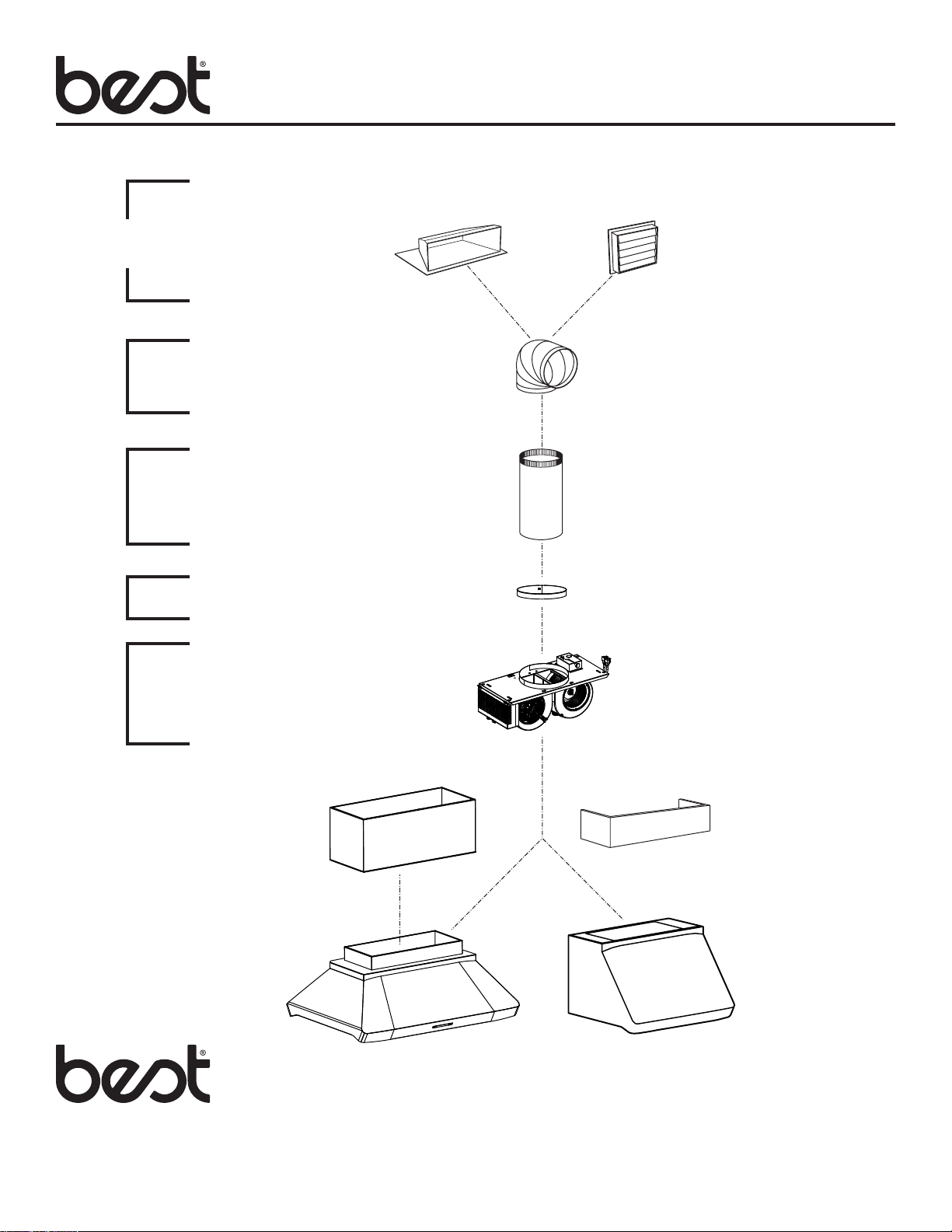

REMOVE ONE

ELECTRICAL

KNOCKOUT

1. Run power cable to installation location. Remove one knockout from rough-in plate wiring box.

VERTICAL DISCHARGE

(WP28M, WP29M, IP29M)

ROUGH-IN PLATE

GROUND WIRE

TO GROUND

SCREW

3. Remove wiring cover.

4. Connect cable to wiring box using proper connector. Connect

BLACK TO BLACK (hot), WHITE TO WHITE (neutral) and

GREEN OR BARE WIRE (ground) under second ground

screw. Replace wiring cover.

5. Run 10” round steel duct to installation location.

MODEL 421

10-IN. DAMPER

(INCLUDED)

BLACK TO BLACK

WHITE TO WHITE

HORIZONTAL DISCHARGE

(WP28M & WP29M only)

2. Attach ROUGH-IN PLATE to MOUNTING STUDS at inside,

top of hood with (4) existing #10-32 HEX NUTS.

17” MIN.

6. Install 10” damper (Model 421, included) inside the vertical

ductwork that will be attached to the rough-in plate. Do not

install in a horizontal ductwork or directly on top of the adapter

or it will not open and close properly.

Remove shipping tape if present. Secure the damper to the

duct with 3 - #8 sheet metal screws (not provided). Ensure

the damper opens and closes freely. Seal all joints with metal

foil duct tape to eliminate air leaks.

NOTE: To optimize airflow and reduce noise, position the

damper at least 17” above the top of the rough-in plate - or

as far as the duct run will allow.

Page 4

MODEL iQ12

Page 4

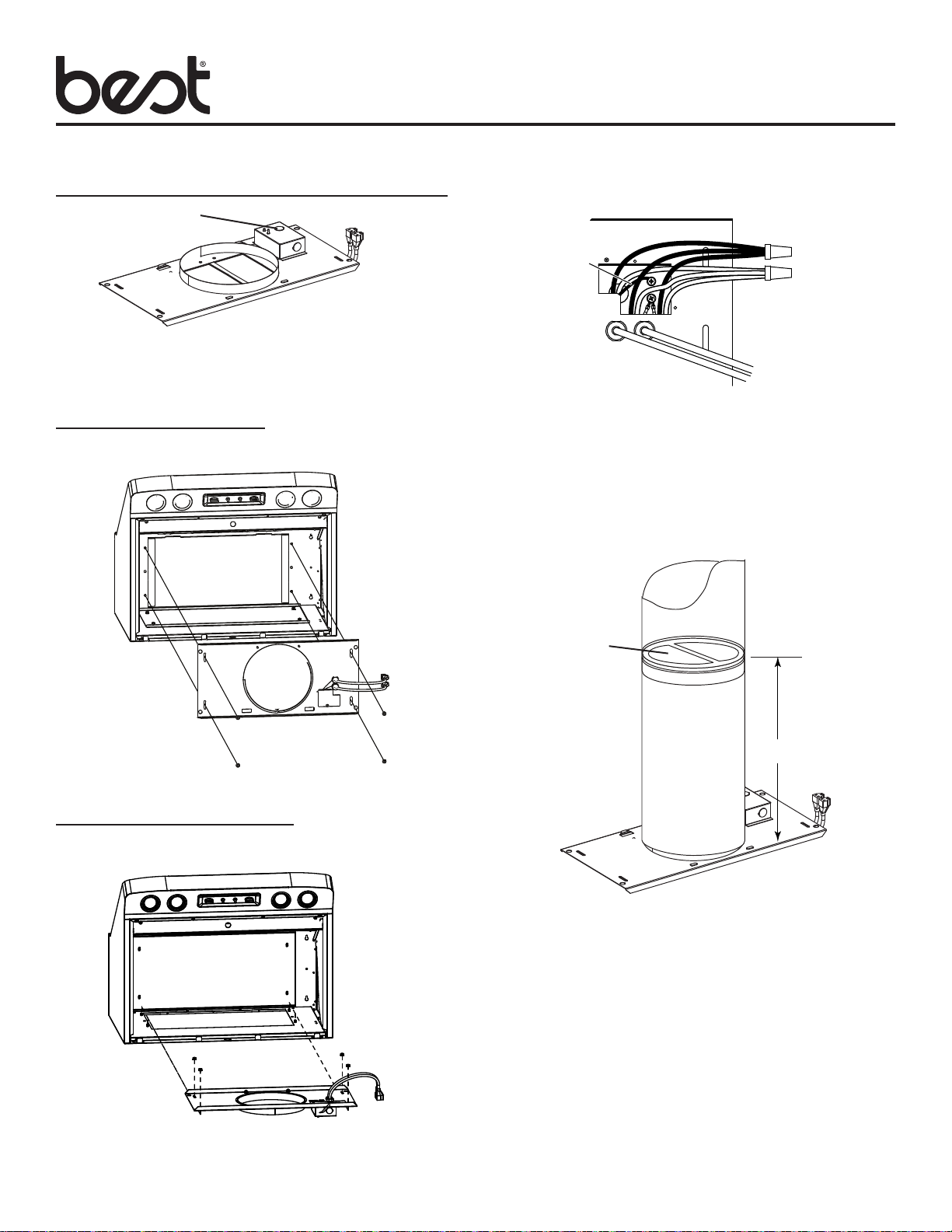

HOOD

RECEPTACLE

ROUGH-IN

PLATE

POWER

CORD

HOOD

RECEPTACLE

BLOWER

POWER

CORD

ROUGH-IN

PLATE

TABS ON

BACK EDGE

OF PLATE

SLOTS

STUDS

HEX NUTS (2)

BLOWER /

MOUNTING

PLATE

ASSEMBLY

7. Engage two TABS on BLOWER / MOUNTING PLATE ASSEMBLY into two SLOTS in ROUGH-IN PLATE. Secure

blower / mounting plate assembly to THREADED STUDS

on rough-in plate with (2) 10-24 HEX NUTS.

CALIBRATE iQ BLOWER

SYSTEM

INTERNAL BLOWER DUCTED UNITS ONLY

After the hood is installed and wired, engage the calibration

process (our Guaranteed Performance System Technology to

ensure full-rated airflow is being delivered). Prior to calibration,

ensure that all filters, light bulbs and duct system are installed.

CALIBRATION PROCESS

Hold the calibration button for 3 seconds; calibration button

will light up and stay on for up to 13 minutes. The blower will

start and begin the calibration process. When calibration is

complete, one of two things will occur:

1. The blower turns off and calibration button light stays on =

Successful calibration. Press the button to turn off the LED.

Note: The LED will also turn off if you select any blower

speed on the control.

2. The blower turns off and calibration button light blinks

continuously = Too much restriction in the ductwork is

preventing the IQ Blower System™ from achieving the rated

airflow. The blower is automatically set to maximum intensity.

NOTE: Common items that cause restrictions: restricted

damper flap (backdraft damper, wall cap, roof cap), too

many elbows, duct size less than 80% of hood outlet, poor

transition, use of flex ducting and/or crushed ducting.

(2) SCREWS

CALIBRATION

BUTTON

ASSEMBLY

8. Install the CALIBRATION BUTTON ASSEMBLY using (2)

SCREWS (provided).

9. Plug one of the rough-in plate power cords into the control

box power cord.

10. Plug BLOWER POWER CORD and ROUGH-IN PLATE

POWER CORD into HOOD RECEPTACLES.

11. Wrap excess wires with wire ties (provided) to prevent contact

with blower wheel.

Three options are available if your hood system has too

much restriction:

1. Accept airflow as is.

a. Press the calibration button to accept airflow as is. The

IQ Blower System™ is now configured to the highest

possible performance. The blinking calibration light

goes out. Note: The LED will also turn off if you select

any blower speed on the control.

2. Correct duct restriction, clear the original calibration data,

and repeat the calibration process.

a. Correct the duct restriction.

b. Clear the original calibration data by holding calibration

button for 10 seconds. The light will blink 3 times to

confirm and the blower configuration will go back to

default settings.

c. Repeat calibration process from the beginning.

3. Clear calibration data to reset hood to default factory

setting and achieve standard high pressure blower

performance.

a. Clear calibration data and reset hood to factory default

setting by holding calibration button for 10 seconds.

The light will blink 3 times to confirm and the blower

configuration will go back to default settings.

Page 5

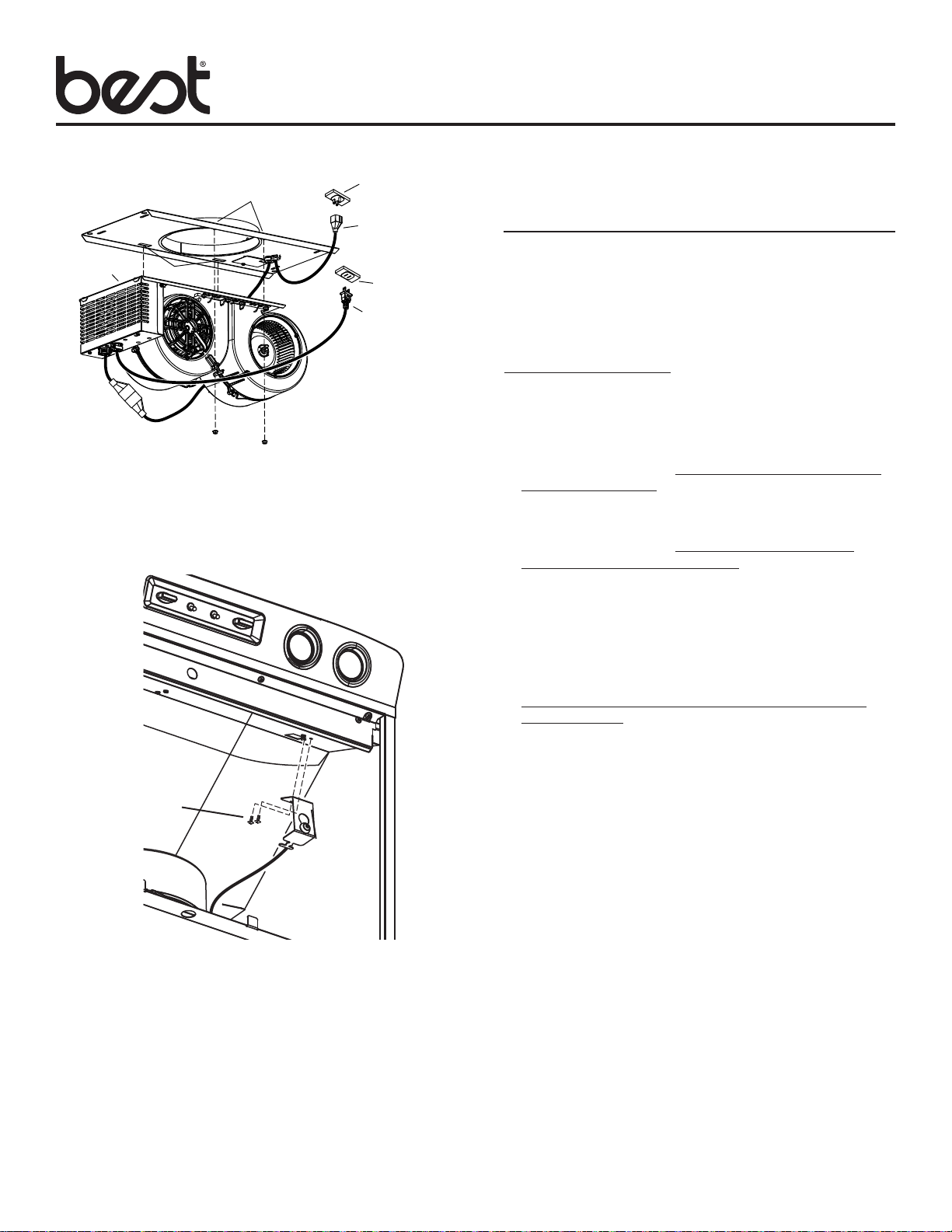

SERVICE PARTS

Model iQ12

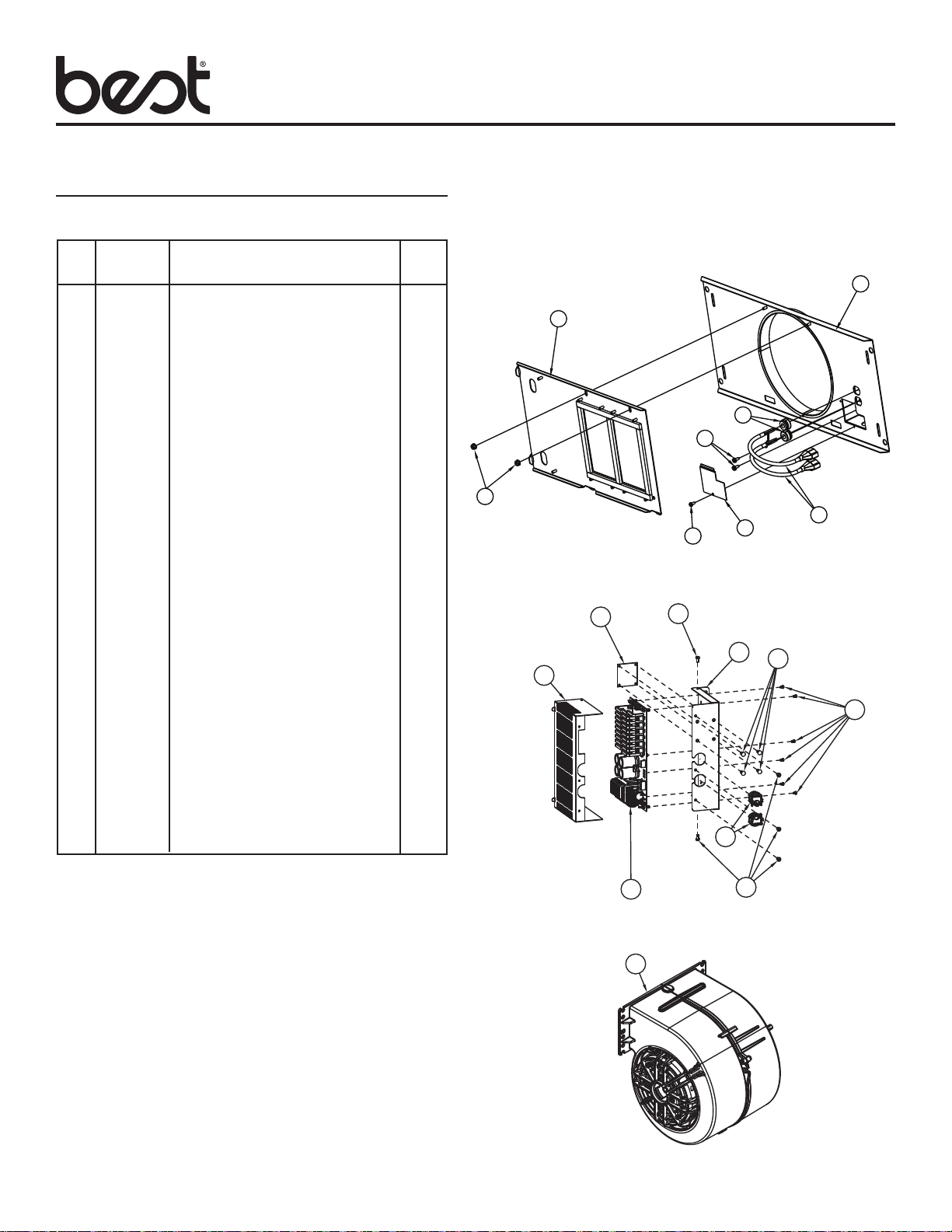

KEY PART DESCRIPTION QTY

NO. NUMBER

1 97019411 ROUGH-IN PLATE WELDMENT 1

2 98011050 MOUNTING PLATE ASSEMBLY 1

3 99440033 POWER CORD 2

4 99150471 SCREW, #10-32 X 1/2

(HEX WASHER HEAD) 2

5 99400060 STRAIN RELIEF 2

6 98003370 OUTLET BOX COVER 1

7 99170245 SCREW, #8-18X3/8” 1

8 99260488 NUT WHIZ 10-24 2

# 97019461 IQ12 ROUGH IN KIT (COMPLETE)

(INCLUDES KEYS 1-8)

9 PCB ENCLOSURE RIGHT 1

10 PCB ENCLOSURE LEFT 1

11 SCREW, #8-18X3/8” 5

# 97019457 PCB ENCLOSURE KIT

(INCLUDES KEYS 9-11)

12 SCREW, 3MM X 6MM PH

W/LOCK WASHER 6

13 IQ12 PCB BOARD 1

# 97019472 IQ12 PCB BOARD KIT 1

(INCLUDES KEYS 12 AND 13)

14 PCB TRIAC BOARD 1

15 STANDOFF 4

# 97019471 PCB, TRIAC BOARD KIT 1

(INCLUDES KEYS 14 AND 15)

16 99400088 STRAIN RELIEF 2

17 97018985 BLDC BLOWER 2

+ 99271491 WIRE HARNESS,VARIABLE SPEED 1

+ 99271503 WIRE HARNESS,CALIBRATION

BUTTON 1

+ 99271498 WIRE HARNESS, POWER DUAL

IQ BOARD 1

+ 99271471 WIRE HARNESS

FOR SERVICE BLOWERS 1

+ 99260488 NUT WHIZ 10-24 10

+ 99580015 10-INCH ROUND DAMPER 1

+ NOT SHOWN

# NOT SHOWN ASSEMBLED

* STANDARD HARDWARE. MAY BE PURCHASED LOCALLY.

MODEL iQ12

Page 5

1

2

5

4

8

7

14

9

13

11

6

10

16

11

3

15

12

17

Page 6

VENTILATEUR

!

INTERNE

Pour utilisation avec les hottes de cuisine BEST

Voir dans le manuel de la hotte si le modèle convient.

MODÈLE iQ12

Page 6

®

compatibles.

AVERTISSEMENT

AFIN DE DIMINUER LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION OU DE BLESSURES, SUIVEZ CES

DIRECTIVES :

1. N’utilisez cet appareil que de la manière prévue par le fabricant.

Si vous avez des questions, communiquez avec le fabricant à

l’adresse ou au numéro de téléphone indiqués dans la garantie.

2. Avant de procéder à la réparation ou à l’entretien de l’appareil,

coupez l’alimentation du panneau électrique et verrouillez le

dispositif de sectionnement de manière à empêcher que le

courant ne soit accidentellement rétabli. S’il est impossible

de verrouiller l’interrupteur principal, fixez solidement un

message d’avertissement, par exemple une étiquette, sur le

panneauélectrique.

3. L’installation et les branchements électriques doivent être

effectués par un personnel compétent, conformément aux

normes et aux codes en vigueur, y compris les normes et les

codes du bâtiment relatifs à la résistance au feu.

4. Pour éviter les refoulements, l’apport d’air doit être suffisant

pour brûler les gaz produits par les appareils à combustion et

les évacuer dans le conduit de fumée (cheminée). Respectez

les directives du fabricant de l’appareil de chauffage et

les normes de sécurité, notamment celles publiées par la

National Fire Protection Association (NFPA), l’American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE) et les codes des autorités locales.

5. Veillez à ne pas endommager le câblage électrique ou d’autres

équipements non apparents lors de la découpe ou du perçage

du mur ou du plafond.

6. Les ventilateurs canalisés doivent toujours rejeter l’air

àl’extérieur.

7. N’utilisez pas de commande de régime à semi-conducteurs

conjointement avec cet appareil.

8. Pour réduire les risques d’incendie, utilisez seulement des

conduits en acier.

9. Cet appareil doit être relié à une mise à la terre.

POUR RÉDUIRE LES RISQUES D’INCENDIE CAUSÉS PAR

DE LA GRAISSE SUR LE PLAN DE CUISSON :

a) Ne laissez jamais les éléments de surface allumés à haute

température sans surveillance. Les débordements peuvent

causer de la fumée et occasionner des écoulements de graisse

inflammables. L’huile doit être chauffée graduellement à basse

ou à moyenne température.

b) Mettez toujours la hotte en MARCHE lors de la cuisson à haute

température ou lors de la cuisson d’aliments à flamber.

c) Nettoyez souvent les ventilateurs. Ne laissez pas la graisse

s’accumuler sur le ventilateur ou les filtres.

d) Utilisez des casseroles de dimension appropriée. Utilisez

toujours une batterie de cuisine adaptée à la dimension de la

surface chauffante.

AVERTISSEMENT

OBSERVEZ LES CONSIGNES SUIVANTES AFIN DE RÉDUIRE

LES RISQUES DE BLESSURES CORPORELLES EN CAS

D’INCENDIE CAUSÉ PAR DE LA GRAISSE SUR LE PLAN

DE CUISSON :*

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle

étanche, d’une tôle à biscuits ou d’un plateau en métal

puis éteignez le brûleur. FAITES ATTENTION DE NE PAS

VOUS BRÛLER. SI LES FLAMMES NE S’ÉTEIGNENT PAS

IMMÉDIATEMENT, QUITTEZ LES LIEUX ET APPELEZ LE

SERVICE DESINCENDIES.

2. NE SOULEVEZ JAMAIS UNE CASSEROLE EN FLAMMES –

vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni de linges ou de serviettes mouillés

– une violente explosion de vapeur pourrait survenir.

4. Utilisez un extincteur SEULEMENT si :

A. Vous savez qu’il est de classe ABC et vous connaissez déjà

son mode de fonctionnement.

B. L’incendie n’est pas très important et ne se propage pas.

C. Vous avez déjà téléphoné au service des incendies.

D. Vous pouvez combattre l’incendie en faisant dos à une sortie.

* Conseils tirés de la publication de la NFPA « Kitchen Fire

Safety Tips ».

ATTENTION

1. Pour ventilation générale uniquement. N’utilisez pas cet appareil

pour évacuer des matières ou des vapeurs dangereuses ou

explosives.

2. Pour éviter d’endommager les roulements du moteur, de

déséquilibrer les pales ou de les rendre bruyantes, débarrassez

l’appareil de la poussière de plâtre, de construction, etc.

3. Le moteur du ventilateur est muni d’un dispositif de protection

contre les surcharges électriques qui le met automatiquement

hors fonction en cas de surchauffe. Il se remet en marche

lorsqu’il a refroidi. Faites réparer la hotte si le moteur continue

à fonctionner par intermittence.

4. Veuillez lire l’étiquette de spécifications du produit pour obtenir

plus de renseignements, notamment sur les exigences.

5. Pour réduire les risques d’incendie et obtenir une évacuation

adéquate de l’air dans le cas d’une installation canalisée,

acheminez les conduits jusqu’à l’air libre – n’évacuez pas l’air

dans des interstices entre les murs ou le plafond, ni dans un

grenier, un vide sanitaire ou un garage.

INSTALLATEUR :

Conservez ce manuel pour l’inspecteur

enélectricité et le propriétaire.

Page 7

MODÈLE iQ12

Page 7

Capuchon mural et de toit,

ventilateurs extérieurs

Coudes

Conduit

Clapet sur

conduit

Système de

ventilateur

MODÈLE 437

(capuchon de toit –

grande capacité)

MODÈLE 418

(coude rond ajustable

de 25 cm [10 po])

MODÈLE 410

(conduit rond de 25 cm [10 po]

– 2 sections de 61 cm [2 pi])

MODÈLE 421

(clapet sur conduit rond

de 25 cm [10 po] - inclus)

MODÈLE 441

(capuchon mural rond

de 25 cm [10 po])

ENSEMBLE DE

RACCORDEMENT

DE VENTILATEUR

MODÈLE iQ12

(ventilateur intérieur

de 1200 pi

de raccordement)

3

/min. et plaque

CONDUIT

DÉCORATIF

EN OPTION

HOTTE DE SÉRIE

IP29M

(capot avec

commandes de

ventilation et

d'éclairage).

SYSTÈME DE HOTTE

ÀVENTILATEUR INTERNE

CONDUIT DÉCORATIF

EN OPTION

HOTTE DE SÉRIE

WP28M et WP29M

(capot avec commandes

de ventilation et

d'éclairage).

Page 8

INSTALLATION

RETIREZ UNE RONDELLE

DÉTACHABLE POUR LE

CÂBLE ÉLECTRIQUE.

1. Acheminez un câble à trois fils jusqu’au lieu d’installation.

Retirez une rondelle détachable de la plaque du boîtier

deconnexion.

ÉVACUATION VERTICALE

(WP28M, WP29M, IP29M)

MODÈLE iQ12

Page 8

PLAQUE DE RACCORDEMENT

FIL DE TERRE

SUR LA VIS DE

MISE À LA TERRE

3. Retirez le couvercle du boîtier de câblage.

4. Fixez le câble d’alimentation au boîtier de câblage à l’aide

du connecteur approprié. Branchez les fils NOIRS ensemble

(tension), les fils BLANCS ensemble (neutre) et placez le fil

VERT ou le fil DÉNUDÉ (terre) sous la deuxième vis de mise

à la terre. Replacez le couvercle du boîtier de câblage.

5. Acheminez les conduits ronds en acier de 25 cm (10 po) vers

le lieu d’installation.

NOIR AVEC NOIR

BLANC AVEC BLANC

ÉVACUATION HORIZONTALE

(WP28M et WP29M seulement)

CLAPET DE

25 CM (10 PO)

MODÈLE 421

(INCLUS)

MIN. 43 CM

(17 PO)

6. Installez le clapet de 25 cm (10 po) (modèle 421, inclus)

à l’intérieur du conduit vertical qui sera fixé à la plaque de

raccordement. N’installez pas le clapet dans un conduit

horizontal ni directement sur l’adaptateur car il ne pourra

pas ouvrir ni fermer correctement.

Enlevez le ruban adhésif d’emballage (s’il y a lieu). Fixez le

clapet au conduit à l’aide de 3 vis à tôle n° 8 (non comprises).

Assurez-vous que le clapet s’ouvre et se ferme librement.

Scellez tous les joints avec du ruban à conduit pour éviter

les fuites d’air.

2. Fixez la PLAQUE DE RACCORDEMENT aux GOUJONS

DE MONTAGE à l’intérieur de la hotte, en haut, à l’aide des

(4) ÉCROUS HEXAGONAUX no° 10-32 existants.

REMARQUE : Pour optimiser l’écoulement de l’air et réduire

le bruit, positionnez le clapet à au moins 43 cm ( 17 po)

au-dessus de la plaque de raccordement ou aussi loin que

le conduit le permet.

Page 9

MODÈLE iQ12

Page 9

PRISE DE

PLAQUE DE

RACCORDEMENT

ERGOTS À

L’ARRIÈRE DE

LA PLAQUE

FENTES

ÉCROUS

HEXAGONAUX (2)

GOUJONS

COURANT

DE LA HOTTE

CORDON

ÉLECTRIQUE DE

LA PLAQUE DE

RACCORDEMENT

PRISE DE

COURANT

DE LA HOTTE

CORDON

ÉLECTRIQUE DU

VENTILATEUR

ENSEMBLE DE

VENTILATEUR /

PLAQUE DE

MONTAGE

7. Engagez deux ERGOTS de l’ensemble VENTILATEUR /

PLAQUE DE MONTAGE dans les FENTES de la PLAQUE

DE RACCORDEMENT. Fixez l’ensemble ventilateur / plaque

de montage sur les GOUJONS FILETÉS de la plaque de

raccordement avec (2) ÉCROUS HEXAGONAUX 10-24.

CALIBRAGE DU

VENTILATEUR iQ

VENTILATEUR INTERNE AVEC CONDUITS SEULEMENT

Une fois la hotte installée et connectée, enclenchez le

processus de calibrage (notre Technologie de performance

garantie s’assure que le débit d’air optimal seraémis). Avant

le calibrage, assurez-vous que les filtres, les ampoules

d’éclairage et les conduits sont installés.

CALIBRAGE

Maintenez le bouton de calibrage pendant 3 secondes; le

bouton s’allumera durant jusqu’à 13 minutes. Le ventilateur se

met en marche et le calibrage commence. Une fois le calibrage

terminé, il y a deuxpossibilités :

A. Le ventilateur s’arrête et la lumière du bouton de calibrage

reste allumée = Calibrage réussi. Appuyez sur le bouton

pour éteindre la DEL. Remarque : La DEL s’éteindra aussi si

vous sélectionnez n’importe quelle vitesse de ventilateur à

l’aide de la commande.

B. Le ventilateur s’arrête et la lumière du bouton de calibrage

clignote continuellement =Trop de restriction dans le

conduit empêchant le ventilateur IQ

d’air nominal. Leventilateur se règle automatiquement à

l’intensité maximale.

REMARQUE : Les causes les plus courantes de restriction

sont : un clapetcoincé (clapetantirefoulement, capuchon

mural, capuchon de toit), untrop grand nombre decoudes, un

conduit dont la dimension est 80 % inférieure à la sortie de la

hotte, unemauvaise transition, l’utilisation de conduit flexible

et/ou un conduit écrasé.

MC

d’atteindre le débit

(2) VIS

ENSEMBLE DE

BOUTON DE

CALIBRAGE

8. Installez l’ENSEMBLE DE BOUTON DE CALIBRAGE à l’aide

des (2) VIS (fournies).

9. Branchez l’un des cordons électriques de la plaque de

raccordement dans le cordon du boîtier de commande.

10. Branchez le CORDON ÉLECTRIQUE DU VENTILATEUR et

de la PLAQUE DE RACCORDEMENT dans les PRISES À

L’INTÉRIEUR DE LA HOTTE.

11. Groupez l’excédent de fil avec les attaches (fournies) pour

l’empêcher de toucher à la roue à ailettes.

Trois options s’offrent à vous si le débit de votre hotte est

soumis à une restriction trop importante :

1. Accepter le débit tel quel.

a. Appuyez sur le bouton de calibrage pour accepter le

débit d’air tel quel. Le ventilateur IQMC est maintenant

configuré au meilleur rendement possible. Le témoin

de calibrage clignotant s’éteint. Remarque : La DEL

s’éteindra aussi si vous sélectionnez n’importe quelle

vitesse de ventilateur à l’aide de la commande.

2. Corriger la restriction, effacer les données du calibrage

original et recommencer le calibrage.

a. Corrigez la restriction dans le conduit.

b. Effacez les données du calibrage original en maintenant

le bouton de calibrage pendant 10 secondes. Le témoin

clignotera 3 fois pour confirmer et le ventilateur retournera

aux paramètres par défaut.

c. Recommencez le calibrage depuis le début.

3. Effacer les données de calibrage pour rétablir les

paramètres par défaut de la hotte et obtenir le rendement

standard à haute pression du ventilateur.

a. Effacez les données de calibrage pour rétablir les

paramètres par défaut de la hotte en maintenant le bouton

de calibrage pendant 10 secondes. Le témoin clignotera

3 fois pour confirmer et le ventilateur retournera aux

paramètres par défaut.

Page 10

PIÈCES DE RECHANGE

Modèle iQ12

MODÈLE iQ12

Page 10

REPÈRE N° DE

PIÈCE

1 97019411 PLAQUE DE RACCORDEMENT

2 98011050 ENSEMBLE DE PLAQUE DE

3 99440033 CORDON ÉLECTRIQUE 2

4 99150471 VIS, N° 10-32 X 1/2

5 99400060 BRIDE DE CORDON 2

6 98003370 COUVERCLE DE BOÎTIER

7 99170245 VIS, N° 8-18X3/8 PO 1

8 99260488 ÉCROU À RONDELLE 10-24 2

# 97019461 ENSEMBLE DE

9 BOÎTIER PCB DE DROITE 1

10 BOÎTIER PCB DE GAUCHE 1

11 VIS, N° 8-18X3/8 PO 5

# 97019457 ENS. DE BOÎTIER PCB

12 VIS, 3MM X 6MM PH AVEC

13 CIRCUIT PCB IQ12 1

# 97019472 ENS. DE CIRCUIT PCB IQ12

14 CIRCUIT PCB TRIAC 1

15 TAQUET 4

# 97019471 ENS. DE CIRCUIT PCB TRIAC

16 99400088 BRIDE DE CORDON 2

17 97018985 VENTILATEUR BLDC 2

+ 99271491 FAISCEAU DE CÂBLES,

+ 99271503 FAISCEAU DE CÂBLES,

+ 99271498 FAISCEAU DE CÂBLES, CIRCUIT

+ 99271471 FAISCEAU DE CÂBLES POUR

+ 99260488 ÉCROU À RONDELLE 10-24 10

+ 99580015

+ NON ILLUSTRÉ

# ILLUSTRÉ DÉMONTÉ

* MATÉRIEL STANDARD. EN VENTE DANS UNE QUINCAILLERIE

PRÈS DE CHEZ VOUS.

DESCRIPTION QTÉ

1

SOUDÉE

MONTAGE

(TÊTE HEXAGONALE

ÀRONDELLE)

ÉLECTRIQUE

RACCORDEMENT IQ12

(COMPLET)

(COMPREND PIÈCES 1-8)

(COMPREND PIÈCES 9-11)

RONDELLE DE BLOCAGE

(COMPREND 12 ET 13)

(COMPREND 14 ET 15)

RÉGIMEVARIABLE

BOUTONDE CALIBRAGE

D’ALIMENTATION IQ DOUBLE

VENTILATEURS DE SERVICE

AMORTISSEUR RONDE DE 10 PO

1

2

1

6

1

1

1

1

1

1

1

1

2

5

4

8

7

14

9

13

11

17

6

10

16

11

3

15

12

Page 11

VENTILADOR

!

INTERNO

MODELO iQ12

Página 11

Para usarse con campanas de estufa compatibles de BEST

Consulte el manual de la campana para su idoneidad.

®

.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA

ELÉCTRICA O LESIONES PERSONALES, OBSERVE

LOSIGUIENTE:

1. Use la unidad solo de la manera indicada por el fabricante. Si

tiene preguntas, comuníquese con el fabricante a la dirección

o al número telefónico que se incluye en la garantía.

2. Antes de dar servicio o limpiar la unidad, interrumpa el

suministro eléctrico en el panel de servicio y bloquee los

medios de desconexión del servicio para evitar que la

electricidad sea reanudada accidentalmente. Cuando no sea

posible bloquear los medios de desconexión del servicio, fije

firmemente una señal de advertencia (como una etiqueta) en

un lugar visible del panel de servicio.

3. Solo personal calificado debe realizar el trabajo de instalación

y el cableado eléctrico, de acuerdo con todos los códigos y las

normas correspondientes, incluidos los códigos y las normas

de construcción específicos sobre protección contra incendios.

4. Es necesario suficiente aire para que se lleve a cabo una

combustión y una extracción adecuadas de los gases a

través del tubo de humos (chimenea) del equipo quemador

de combustible, con el fin de evitar el contratiro. Siga las

directrices y las normas de seguridad del fabricante del equipo

de calefacción, como las publicadas por la Asociación Nacional

de Protección contra Incendios (National Fire Protection

Association, NFPA), y la Sociedad Americana de Ingenieros

en Calefacción, Refrigeración y Aire Acondicionado (American

Society for Heating, Refrigeration and Air Conditioning

Engineers, ASHRAE), y las autoridades de los códigos locales.

5. Al cortar o perforar a través de la pared o del cielo raso,

tenga cuidado de no dañar el cableado eléctrico ni otros

serviciosocultos.

6. Los ventiladores con conductos siempre deben ventearse

hacia el exterior.

7. No use esta campana de estufa junto con ningún dispositivo

adicional de estado sólido para el control de la velocidad.

8. Para reducir el riesgo de incendio, use solamente conductos

de acero.

9. Esta unidad debe estar conectada a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO

POR GRASA PRESENTE EN LA ESTUFA:

a) Nunca deje desatendidas las unidades de la superficie cuando

estén en ajustes altos de calor. Los alimentos en ebullición

provocan derrames grasosos y con humo que se pueden

incendiar. Caliente el aceite lentamente en ajustes de calor

bajo o medio.

b) Siempre ENCIENDA la campana cuando cocine con calor alto

o cuando cocine alimentos inflamables.

c) Limpie frecuentemente los ventiladores. No permita la

acumulación de grasa en el ventilador ni en el filtro.

d) Use una cacerola del tamaño adecuado. Siempre use utensilios

de cocina que sean apropiados para el tamaño del elemento

de la superficie.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES PERSONALES EN

EL CASO DE QUE LA GRASA DE LA ESTUFA SE INCENDIE,

SIGA LAS SIGUIENTES PRECAUCIONES*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una

charola para galletas o una bandeja de metal, y después

apague el quemador. PROCEDA CON CUIDADO PARA

EVITAR QUEMADURAS. SI LAS LLAMAS NO SE APAGAN

INMEDIATAMENTE, EVACÚE EL ÁREA Y LLAME AL

DEPARTAMENTO DE BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA, se puede

quemar.

3. NO USE AGUA ni toallas húmedas, ya que provocará una

violenta explosión de vapor.

4. Use un extintor SOLO si:

A. El extintor es clase ABC y usted sabe cómo usarlo.

B. El incendio es pequeño y está confinado al área en la que se

inició.

C. Se ha llamado al departamento de bomberos.

D. Puede combatir el incendio teniendo la espalda orientada hacia

una salida.

* Basado en “Kitchen Fire Safety Tips” (Sugerencias para la

seguridad contra incendios en la cocina) publicado por NFPA.

PRECAUCIÓN

1. Solo para usarse como medio de ventilación general. No debe

usarse para la extracción de materiales o vapores peligrosos

o explosivos.

2. Para evitar daños a los cojinetes del motor y rotores ruidosos

o desbalanceados, mantenga la unidad de potencia protegida

contra rociados de yeso, polvos de construcción, etc.

3. Este ventilador tiene una protección contra sobrecargas

térmicas que automáticamente apagará el motor en caso de

sobrecalentamiento. El motor reanudará su funcionamiento

cuando se enfríe. Si el motor continúa apagándose y

encendiéndose, solicite servicio para la campana.

4. Lea la etiqueta de especificaciones del producto para ver

información y requisitos adicionales.

5. Para reducir el riesgo de incendio y para descargar

adecuadamente el aire en una instalación con conductos,

asegúrese de dirigir el aire hacia el exterior. No descargue el

aire hacia espacios contenidos entre paredes o cielos rasos,

ni hacia áticos, sótanos bajos ni la cochera.

INSTALADOR:

Conserve este manual para que lo use

elinspector eléctrico y el propietario.

Page 12

MODELO iQ12

Página 12

Tapas de pared y techo,

ventiladores exteriores

Codos

Sistema de

tubería

Regulador

de tiro en

línea

Sistema de

ventilación

MODELO 437

(tapa de techo de alta

capacidad)

MODELO 418

(codo redondo ajustable

de 10 pulg. [25 cm])

MODELO 410

(conducto redondo de

10 pulg. [25 cm] –

secciones de 2 pies

[61 cm])

MODELO 421

(regulador redondo en

línea de 10 pulg.

[25 cm]- incluido)

MODELO 441

(tapa redonda de 10 pulg.

[25 cm] para pared)

JUEGO DE

VENTILADOR/

EMPALME

MODELO iQ12

(ventilador interno

de 1200 pcm y placa

de empalme)

TUBO DE HUMOS

DECORATIVO

OPCIONAL

CAMPANA SERIE

IP29M

(Se requiere cubierta

con controles del

ventilador e

iluminación).

SISTEMA DE CAMPANA DE ESTUFA

CON VENTILADOR INTERNO

TUBO DE HUMOS

DECORATIVO

OPCIONAL

CAMPANA DE LAS

SERIES WP28M Y

WP29M

(Se requiere cubierta

con controles del

ventilador e

iluminación).

Page 13

INSTALACIÓN

RETIRE UN

AGUJERO CIEGO

ELÉCTRICO

1. Haga pasar el cable eléctrico al sitio de la instalación.

Retire un agujero ciego de la caja de cableado de la caja

deempalme.

DESCARGA VERTICAL

(WP28M, WP29M, IP29M)

MODELO iQ12

Página 13

PLACA DE EMPALME

CABLE DE TIERRA

A TORNILLO DE

PUESTA A TIERRA

3. Quite la cubierta de la conexión eléctrica.

4. Conecte el cable a la caja del cableado con el conector

adecuado. Conecte NEGRO A NEGRO (vivo), BLANCO A

BLANCO (neutro) y VERDE O SIN FORRO (tierra) debajo

del segundo tornillo de puesta a tierra. Vuelva a colocar la

cubierta de la conexión eléctrica.

5. Coloque el conducto de acero redondo de 10 pulg. (25 cm)

en el sitio de la instalación.

NEGRO CON NEGRO

BLANCO CON BLANCO

DESCARGA HORIZONTAL

(Solo WP28M y WP29M)

MODELO 421,

REGULADOR

DE 10 PULG.

(25 CM) (INCLUIDO)

17 PULG.

(43 CM) MÍN.

6. Instale el regulador de 10 pulg. (25 cm) (Modelo 421, incluido)

dentro del conducto vertical que se conectará a la placa de

empalme. No instale en un conducto horizontal ni directo

sobre la parte superior del adaptador, o no se abrirá y cerrará

adecuadamente.

Retire la cinta de envío, si está presente. Asegure el

regulador al conducto con 3 tornillos de chapa metálica #8

(no incluidos). Asegúrese de que el regulador de tiro abra

y cierre libremente. Selle todas las uniones con cinta para

conductos metálica para eliminar fugas de aire.

2. Fije la PLACA DE EMPALME a los MONTANTES DE

MONTAJE de la parte superior interna de la campana con

cuatro (4) TUERCAS HEXAGONALES #10-32, incluidas.

NOTA: Para optimizar el flujo de aire y reducir el ruido,

coloque el regulador por lo menos a 17 pulg. (43 cm) por

arriba de la placa de empalme, o hasta donde lo permita el

tendido del conducto.

Page 14

MODELO iQ12

Página 14

RECEPTÁCULO

PLACA DE

EMPALME

LENGÜETAS

EN EL BORDE

POSTERIOR

DE LA PLACA

MONTANTES

RANURAS

TUERCAS

HEXAGONALES (2)

CONJUNTO

DE PLACA

DE MONTAJE/

VENTILADOR

DE LA CAMPANA

CABLE

ELÉCTRICO

DE LA PLACA

EMPALME

RECEPTÁCULO

DE LA CAMPANA

CABLE

ELÉCTRICO

DEL VENTILADOR

7. Enganche las dos LENGÜETAS del CONJUNTO DE PLACA

DE MONTAJE/VENTILADOR en las dos LENGÜETAS de la

PLACA DE EMPALME. Fije el conjunto de placa de montaje/

ventilador a los PERNOS ROSCADOS de la placa de

empalme con dos (2) TUERCAS HEXAGONALES 10-24.

CALIBRACIÓN DEL

VENTILADOR iQ

SOLO UNIDADES CON CONDUCTOS DE VENTILADOR

INTERNO

Después de instalar y cablear la campana,

active el proceso de calibración (nuestratecnología de sistema

de desempeño garantizado, para asegurar que se suministre el

flujo de aire nominaltotal). Antes de la calibración, asegúrese

de que todos los filtros, bombillas de luz y el sistema de

conductos estén instalados.

PROCESO DE CALIBRACIÓN

Sostenga el botón de calibración 3segundos; el botón se

encenderá y estará así hasta por 13 minutos. El ventilador

arrancará y comenzará el proceso de calibración. Cuando se

termine la calibración, ocurriráuna de dos cosas:

1. El ventilador se apaga y la luz del botón de calibración

permanece encendida = Calibración exitosa. Presione el

botón para apagar la luz LED. Nota: La luz LED también se

apagará si selecciona alguna velocidad del ventilador en el

control.

2. El ventilador se apaga y el botón de calibración destella

continuamente = Demasiada restricción en los conductos

impide que el ventilador IQ™ obtenga el flujo de aire

nominal. El ventilador se configura automáticamente en su

intensidad máxima.

NOTA: Elementos comunes que provocan restricciones:

el alerón del regulador está restringido (regulador

decontratiro, tapadepared, tapa de techo), demasiados

codos, tamaño de conducto menor del 80% de salida de

la campana, mala transición, uso de conductos flexibles

y/oconductosaplastados.

(2) TORNILLOS

CONJUNTO

DEL BOTÓN DE

CALIBRACIÓN

8. Instale el CONJUNTO DEL BOTÓN DE CALIBRACIÓN

condos (2) TORNILLOS (incluidos).

9. Conecte uno de los cables eléctricos de la placa de empalme

con el cable eléctrico de la caja de control.

10. Conecte el CABLE ELÉCTRICO DEL VENTILADOR y el

CABLE ELÉCTRICO DE LA PLACA DE EMPALME en

losRECEPTÁCULOS DE LA CAMPANA.

11. Envuelva el exceso de cable con amarres (incluidos) para

prevenir el contacto con el disco del ventilador.

Hay disponibles tres opciones si el sistema de campana tiene

demasiada restricción:

1. Aceptar el flujo de aire como está.

a. Presione el botón de calibración para aceptar el flujo de

aire tal cual. El ventilador IQ™ está configurado ahora

en el rendimiento más alto posible. La luz de calibración

destellante se apaga. Nota: La luz LED también se

apagará si selecciona alguna velocidad del ventilador en

el control.

2. Corrija la restricción del conducto, despeje los datos de

calibración originales y repita el proceso de calibración.

a. Corrija la restricción del conducto.

b. Despeje los datos de calibración originales manteniendo

presionado el botón de calibración durante 10 segundos.

La luz destellará 3 veces para confirmar y la configuración

del ventilador regresará a los ajustes predeterminados.

c. Repita el proceso de calibración desde el principio.

3. Despeje los datos de calibración para reiniciar la campana

a la configuración de fábrica y obtener un rendimiento

estándar de alta presión del ventilador.

a. Despeje los datos de calibración y reinicie la campana

a los ajustes predeterminados de fábrica manteniendo

presionado el botón de calibración durante 10 segundos.

La luz destellará 3 veces para confirmar y la configuración

del ventilador regresará a los ajustes predeterminados.

Page 15

PIEZAS DE SERVICIO

Modelo iQ12

MODELO iQ12

Página 15

CLAVE N.º NÚMERO

DE PIEZA

1 97019411 ESTRUCTURA SOLDADA DE LA

2 98011050 CONJUNTO DE LA PLACA

3 99440033 CABLE ELÉCTRICO 2

4 99150471 TORNILLO, 10-32 X ½

5 99400060 ALIVIO DE TENSIÓN 2

6 98003370 CUBIERTA DE LA CAJA DESALIDA 1

7 99170245 TORNILLO, #8-18X3/8 PULG. 1

8 99260488 TUERCA WHIZ DE 10-24 2

# 97019461 JUEGO DE PLACA DE EMPALME

9 CAJA PCB, DERECHA 1

10 CAJA PCB, IZQUIERDA 1

11 TORNILLO, #8-18X3/8 PULG. 5

# 97019457 JUEGO DE CAJA PCB (INCLUYE

12 TORNILLO, 3 MM X 6 MM PH CON

13 TABLERO PCB, IQ12 1

# 97019472 JUEGO DE TABLERO PCB IQ12

14 TABLERO TRIAC PCB 1

15 SEPARADOR 4

# 97019471 JUEGO DE TABLERO TRIAC PCB

16 99400088 ALIVIO DE TENSIÓN 2

17 97018985 VENTILADOR BLDC 2

+ 99271491 ARNÉS DE CABLES, VELOCIDAD

+ 99271503 ARNÉS DE CABLES, BOTÓN DE

+ 99271498 ARNÉS DE CABLES, TABLERO IQ

+ 99271471 ARNÉS DE CABLES PARA LOS

+ 99260488 TUERCA WHIZ DE 10-24 10

+ 99580015 AMORTIGUADOR REDONDO DE

DESCRIPCIÓN CANT.

PLACA DE EMPALME

DEMONTAJE

(CABEZA DE ARANDELA

HEXAGONAL)

IQ12 (COMPLETO

(INCLUYE LAS CLAVES 1-8)

LAS CLAVES 9-11)

ARANDELA DE SEGURIDAD

(INCLUYE LAS CLAVES 12 Y 13)

(INCLUYE LAS CLAVES 14 Y 15)

VARIABLE

CALIBRACIÓN

DOBLE ELÉCTRICO

VENTILADORES DE SERVICIO

10 PULG.

1

1

2

8

6

1

1

1

1

1

1

1

2

5

4

16

10

6

15

11

7

14

9

13

11

1

3

12

+ NO SE MUESTRA

# NO SE MUESTRA ARMADO

* TORNILLERÍA ESTÁNDAR. SE PUEDE COMPRAR EN UNA

FERRETERÍA LOCAL.

17

Page 16

MODEL / MODÈLE / MODELO iQ12

WARRANTY / GARANTIE / GARANTÍA

ONE YEAR LIMITED WARRANTY FOR BEST PRODUCTS

Broan-NuTone LLC (Broan-NuTone) warrants to the original consumer purchaser of Best products that such products will be free from defects in materials or workmanship

for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED

WARRANTIES OR MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT BULBS, FUSE, FILTERS, DUCTS, ROOF CAPS, WALL

CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject

to misuse, negligence, accident, improper maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation

instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow limitation on how long an implied

warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER

THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH

PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number stated below, (b) give the model number and part identification and

(c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you must present evidence of the original purchase date.

In USA - BEST® Hartford, Wisconsin 800-558-1711

In Canada - BEST® Drummondville, QC 866-737-7770

www.BestRangeHoods.com

GARANTIE LIMITÉE D’UN AN DES PRODUITS BEST

Broan-NuTone LLC (Broan-NuTone) garantit à l’acheteur original que les produits Best sont libres de tout vice de matériau ou de fabrication pour une période d’un an à

compter de la date d’achat originale. CETTE GARANTIE NE COMPORTE AUCUNE AUTRE GARANTIE, EXPRESSE OU TACITE, Y COMPRIS, MAIS SANS S’Y LIMITER, LES

GARANTIES TACITES DE VALEUR MARCHANDE OU D’ADAPTATION À UN USAGE PARTICULIER.

Durant cette période d’un an, Broan-NuTone réparera ou remplacera gratuitement, à sa discrétion, tout produit ou toute pièce jugés défectueux dans des conditions

normales d’utilisation.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES HALOGÈNES OU INCANDESCENTES, FUSIBLES, FILTRES,

CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS MURAUX ET AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie ne couvre pas (a) les frais d’entretien ou de

service normaux ni (b) tout produit ou toute pièce soumis à un abus, une négligence, un accident, un entretien ou une réparation inadéquats (autres que ceux effectués

par Broan-NuTone), une mauvaise installation ou une installation contraire aux instructions recommandées.

La durée de toute garantie tacite est limitée à la période d’un an stipulée pour la garantie expresse. Certains territoires ou provinces interdisant de limiter la durée d’une

garantie tacite, la limitation ci-dessus peut ne pas s’appliquer à votre situation.

L’OBLIGATION POUR BROAN-NUTONE DE RÉPARER OU DE REMPLACER LE PRODUIT, À SA DISCRÉTION, CONSTITUE LE SEUL RECOURS DE L’ACHETEUR EN VERTU

DE LA PRÉSENTE GARANTIE. BROAN-NUTONE NE PEUT ÊTRE TENUE RESPONSABLE DES DOMMAGES INDIRECTS OU CONSÉCUTIFS NI DES DOMMAGES-INTÉRÊTS

PARTICULIERS DÉCOULANT DE L’UTILISATION OU DU RENDEMENT DU PRODUIT. Certains territoires ou provinces ne permettant pas la limitation ou l’exclusion des

dommages indirects ou consécutifs, la limitation ci-dessus peut ne pas s’appliquer à votre situation.

La présente garantie vous confère des droits spécifiques reconnus par la loi. D’autres droits pourraient également vous être accordés selon la législation locale en vigueur.

La présente garantie remplace toutes les autres garanties précédentes.

Pour vous prévaloir de cette garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou au numéro de téléphone indiqués ci-dessous, (b) donner le numéro de modèle

du produit et le numéro d’identification de la pièce et (c) décrire la nature de la défectuosité du produit ou de la pièce. Lors de votre demande de garantie, vous devez

présenter une preuve de la date d’achat originale.

Aux États-Unis – BEST® Hartford, Wisconsin 800-558-1711

Au Canada – BEST® Drummondville, QC 866-737-7770

www.BestRangeHoods.com

Page / Página 16

Broan-NuTone LLC (Broan-NuTone) garantiza al consumidor comprador original de los productos BEST que tales productos estarán libres de defectos en materiales o

mano de obra durante un período de un año a partir de la fecha de la compra original. NO EXISTEN OTRAS GARANTÍAS, EXPRESAS NI IMPLÍCITAS, INCLUIDAS (PERO

SIN LIMITARSE A) GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN O IDONEIDAD PARA UN PROPÓSITO PARTICULAR.

Durante este período de un año, Broan-NuTone, a su criterio, reparará o reemplazará sin cargo alguno cualquier pieza o producto que se encuentre defectuoso bajo

condiciones normales de uso y servicio.

LA PRESENTE GARANTÍA NO CUBRE ARRANCADORES DE LÁMPARAS FLUORESCENTES, TUBOS, BOMBILLAS DE HALÓGENO E INCANDESCENTES, FUSIBLES,

FILTROS, CONDUCTOS, TAPAS DE TECHO O DE PARED Y DEMÁS ACCESORIOS DE CANALIZACIÓN. Esta garantía no cubre (a) mantenimiento y servicio normales, ni

(b) ningún producto o piezas que se hayan sometido a uso inadecuado, negligencia, accidente, mantenimiento o reparación inadecuada (no hecha por Broan-NuTone),

instalación incorrecta o instalación en contra de las instrucciones de instalación recomendadas.

La duración de cualquier garantía implícita se limita a un período de un año, como se especifica en la garantía expresa. Algunos estados no permiten limitaciones en

cuanto al tiempo de vencimiento de una garantía implícita, por lo que la limitación antes mencionada podría no aplicarse a usted.

LA OBLIGACIÓN DE BROAN-NUTONE DE REPARAR O REEMPLAZAR, A CRITERIO DE BROAN-NUTONE, SERÁ EL ÚNICO Y EXCLUSIVO RECURSO DEL COMPRADOR

BAJO ESTA GARANTÍA. BROAN-NUTONE NO SERÁ RESPONSABLE POR DAÑOS INCIDENTALES, RESULTANTES O ESPECIALES QUE SURJAN DEL USO O DESEMPEÑO

DEL PRODUCTO O EN RELACIÓN CON EL MISMO. Algunos estados no permiten la exclusión o limitación de daños incidentales o resultantes, por lo que la limitación

antes mencionada podría no aplicarse a usted.

Esta garantía le otorga derechos legales específicos, y usted podría tener otros derechos que varían de un estado a otro. Esta garantía sustituye a todas las garantías

anteriores.

Para tener derecho al servicio de la garantía, usted debe (a) notificar a Broan-NuTone a la dirección y número de teléfono que aparecen abajo, (b) proporcionar el número

de modelo y la identificación de la pieza y (c) describir la naturaleza de cualquier defecto en el producto o pieza. En el momento de solicitar el servicio cubierto por la

garantía, debe presentar un comprobante de la fecha de compra original.

En EE. UU. – BEST® Hartford, Wisconsin 800-558-1711

En Canadá – BEST® Drummondville, QC 866-737-7770

www.BestRangeHoods.com

GARANTÍA LIMITADA DE UN AÑO PARA LOS PRODUCTOS BEST

99045166B

Loading...

Loading...