Broan XB110H Installation Manual

READ AND SAVE THESE INSTRUCTIONS

Installer: leave this guide with homeowner.

Register your product online at www.broan.com/register.

XB110H

X1 | Single-Speed

Ventilation Fan

with Humidity Sensor

INSTALLATION GUIDE

Easy installation in both

new construction and retrofit

© 2017 Broan

Table of Contents

Warnings and Cautions 2

Typical Installation 2

New Construction Installation 3

Retrofit Installation 7

Operation 12

Cleaning and Maintenance 12

Troubleshooting 12

Service Parts 13

Warranty 13

Page 2

XB110H Installation Guide

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Use only ON/OFF switch, mechanical timer or relay-switched

control.

8. Acceptable for use over a tub or shower when connected to

a GFCI (Ground Fault Circuit Interrupter) - protected branch

circuit.

9. This unit must be grounded.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. This product is designed for installation in flat ceilings. Sensor

will not function reliably if product is not installed in flat ceiling.

DO NOT MOUNT THIS PRODUCT IN A WALL.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

4. Please read specification label on product for further

information and requirements.

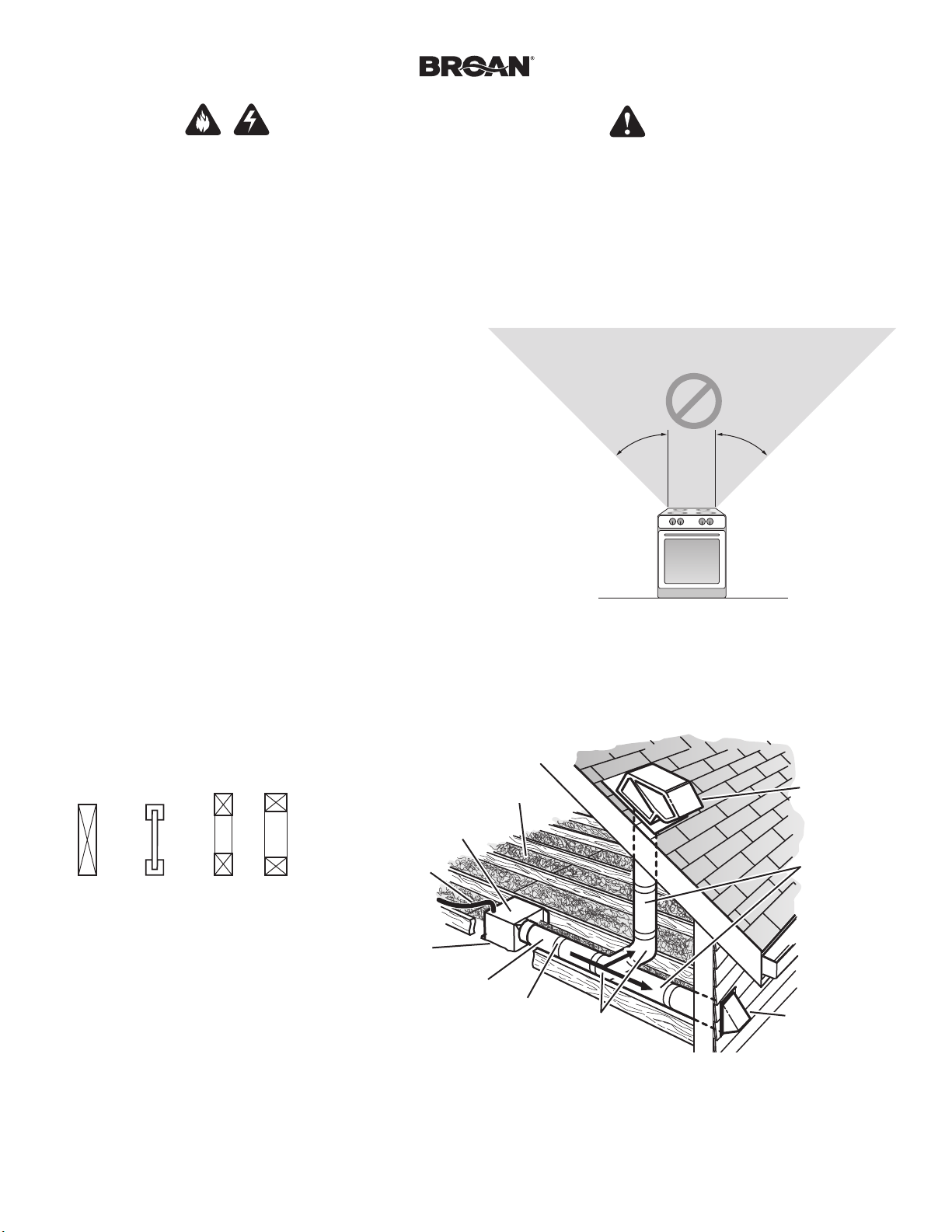

NOT FOR USE IN A COOKING AREA

Do not install above or inside this area

45° 45°

Cooking

Equipment

Floor

Typical Installation

• Installation is the same for:

Joists I-Joists Trusses

• Fits in 2" x 8" ceiling construction.

• Infinitely adjust the fan position

between joists from 14" to 24"

on center.

The ducting from this fan to the outside of the building has a strong effect on the air flow, noise and energy use of the fan. Use the shortest, straighest duct routing possible for best performance, and avoid

installing the fan with smaller ducts than recommended. Insulation around the ducts can reduce energy loss and inhibit mold growth. Fans installed with existing ducts may not achieve their rated airflow.

6-inch round rigid metal duct is recommended for best performance.

HOUSING

POWER

CABLE*

Seal gaps

around

Housing.

*Purchase

separately.

INSULATION*

(Place around and

over Fan Housing.)

FAN

ROUND

DUCT*

Seal duct

joints with

tape.

OR

ROUND

ELBOWS*

ROOF CAP*

(with built-in

damper)

Keep duct

runs short.

WALL CAP*

(with built-in

damper)

Page 3

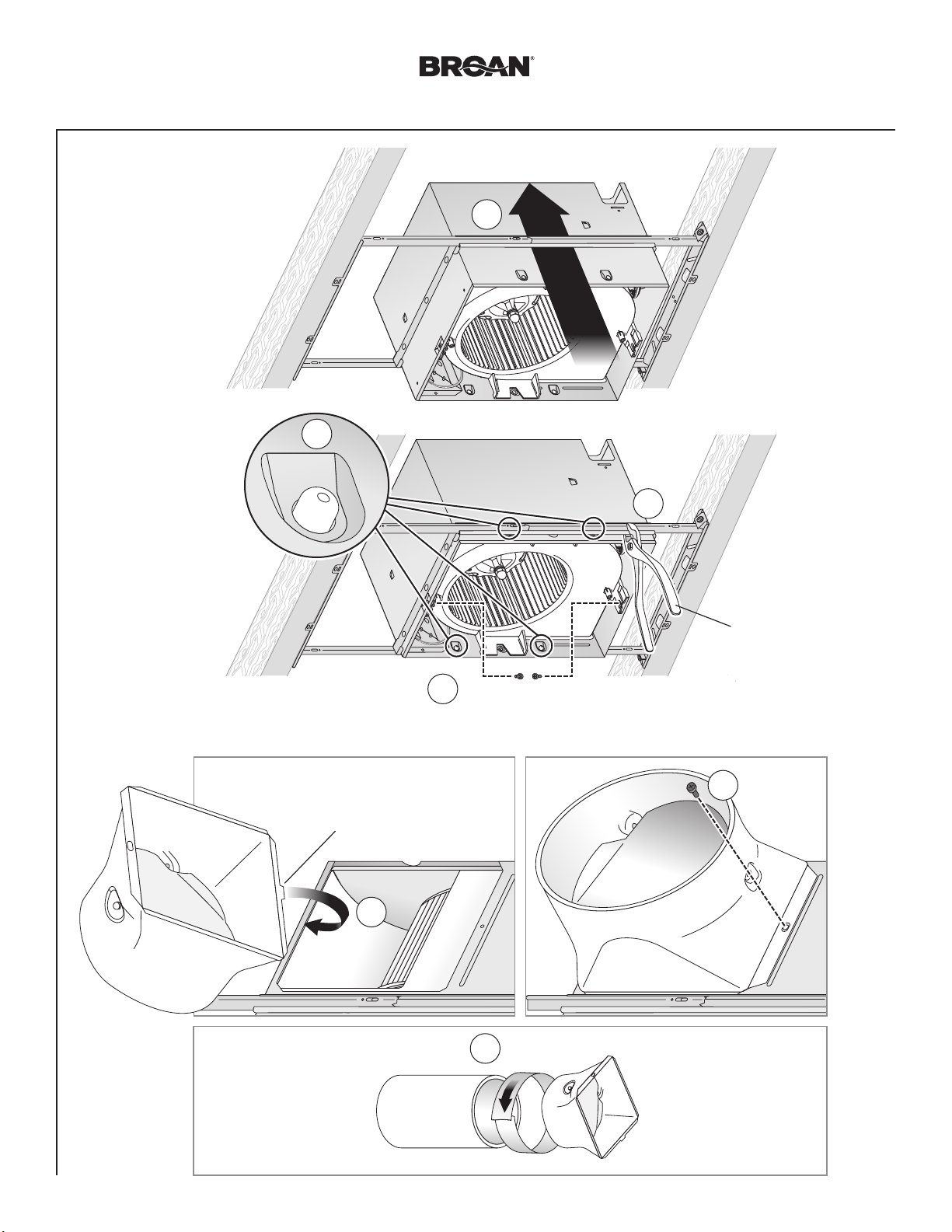

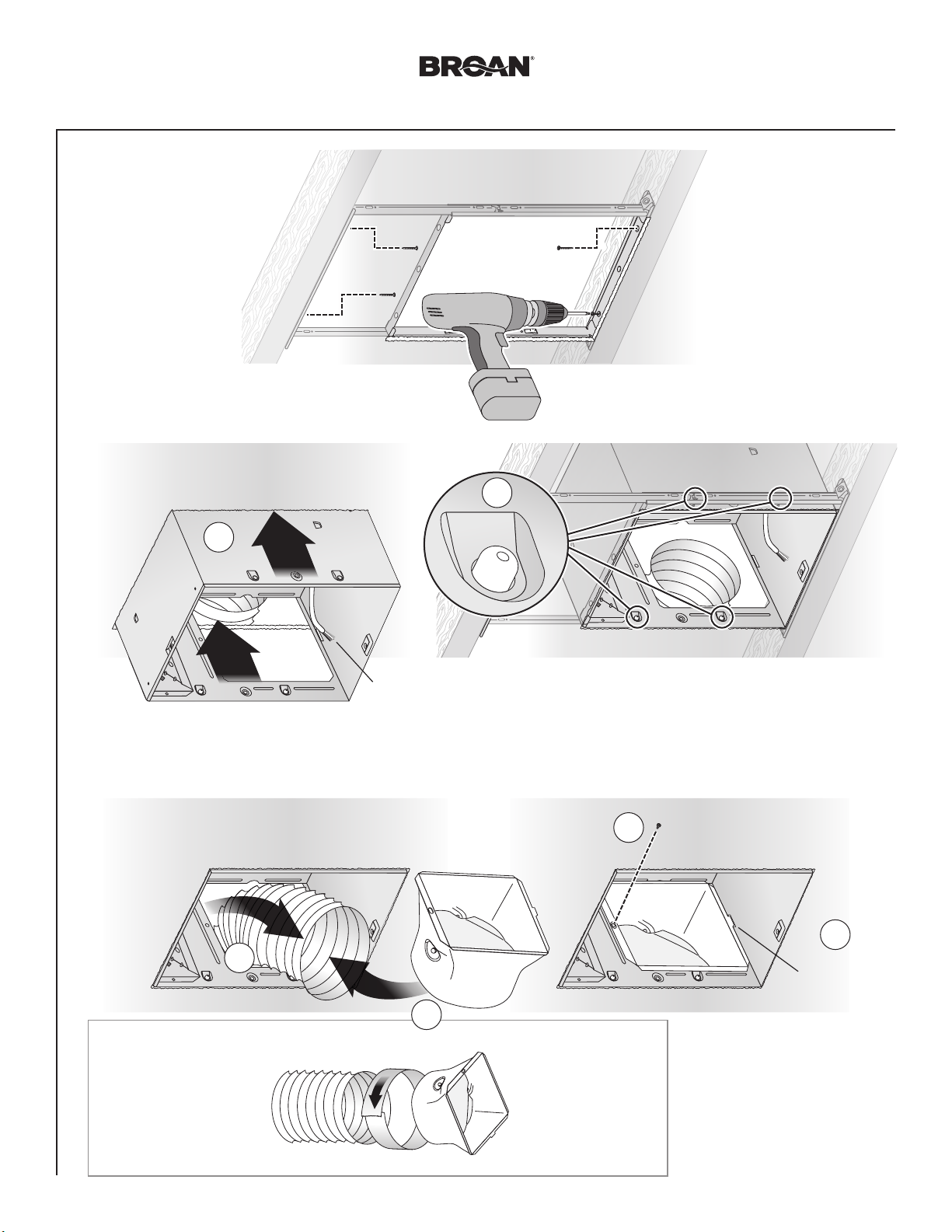

New Construction Installation

XB110H Installation Guide

Tools needed

• Power screwdriver with a Phillips bit

• Phillips screwdriver

• Flathead screwdriver

• Pliers

• Wire insulation stripper

• Wire cutter

Remove Packaging

1

Parts Bag holds

Knockout Plate

and six (6)

screws

Materials needed

• 6" round metal ducting recommended for best performance.

Use of other ducting is acceptable but may impact performance.

• Roof cap or wall cap (built-in damper recommended)

• Tape to seal duct connections

• Electrical wiring and supplies per local code requirements

Punch out Mask from

packaging. See Step 6.

Remove

Instruction

Sheet

Install

2

Mounting

Frame

2

1

4

3

Page 4

New Construction Installation

Snap-in and

3

Secure Housing

2

snap!

XB110H Installation Guide

1

4

Attach Duct Connector and Ducting

4

Top and bottom flanges

go outside Housing

Insert tab into slot

inside Housing

1

Screws from Parts Bag

3

Position Housing

between joists and

crimp channel on both

sides of Mounting Frame

to lock Housing in place.

Do not crimp Housing.

Screw from

2

Parts Bag

6" Ducting

3

Tape

Page 5

New Construction Installation

Connect Wires and Install Knockout Plate

5

• Run 120VAC electrical wiring to the installation location.

• Use proper UL-approved connectors to secure wiring to the Knockout Plate provided in Parts Bag.

• Connect wires as shown in wiring diagram.

Attach cable clamp to Knockout

1

Plate. Knockout Plate mounts to

outside of Housing and may be

oriented as desired.

Connect wires

2

XB110H Installation Guide

3

4

Screw from

Parts Bag

BLK

120 VAC

LINE IN

WHT

GRD

BLACK

WHITE

SENSOR

CONTROL

SWITCH*

purchase separately

*

STANDARD OR MULTI-

FUNCTION WALL SWITCHES

SENSOR/

CONTROL

MANUAL

ON

SWITCH*

MANUAL-ON

RED

BROWN

SWITCH BOX

120 VAC

LINE IN

14/3

(IF ALL

WALL SWITCH

OPTIONS

ARE USED)

RED

BLK

WHT

GRD

ORANGE

GROUND

(green or bare)

KNOCKOUT

PLATE

BLK

ORG

BRN

RECEPTACLES

RED

FAN

BLK

SENSOR/

CONTROL

WHT

• See OPERATION section on page 12

for details.

• SENSOR/CONTROL switch turns

humidity control on for automatic

operation and off for fan cleaning and

maintenance purposes.

• MANUAL-ON switch directly turns fan

on/off.

• MANUAL-ON switch is not required to

manually turn fan on (see page 10).

• SENSOR/CONTROL switch may be

located where it is not easily accessed

for everyday usage; it may need to

be labeled and located where it can’t

be turned on without being seen from

fan to comply with local and national

codes.

Page 6

New Construction Installation

Insert Mask and

6

Finish Ceiling

• Install ceiling material.

• Cut out around Housing.

CAUTION

IN ORDER TO PREVENT MOTOR/CONTROL DAMAGE:

If the blower was unplugged, power must be

disconnected (see page 2, WARNING item 2)

before inserting motor plugs into control assembly.

XB110H Installation Guide

Mask protects unit

during construction.

Remove before

installing Grille.

Install Grille

7

Plug in

Sensor

See Page 12 for Operations, Cleaning and Maintenance, and Troubleshooting.

1

2

3

Page 7

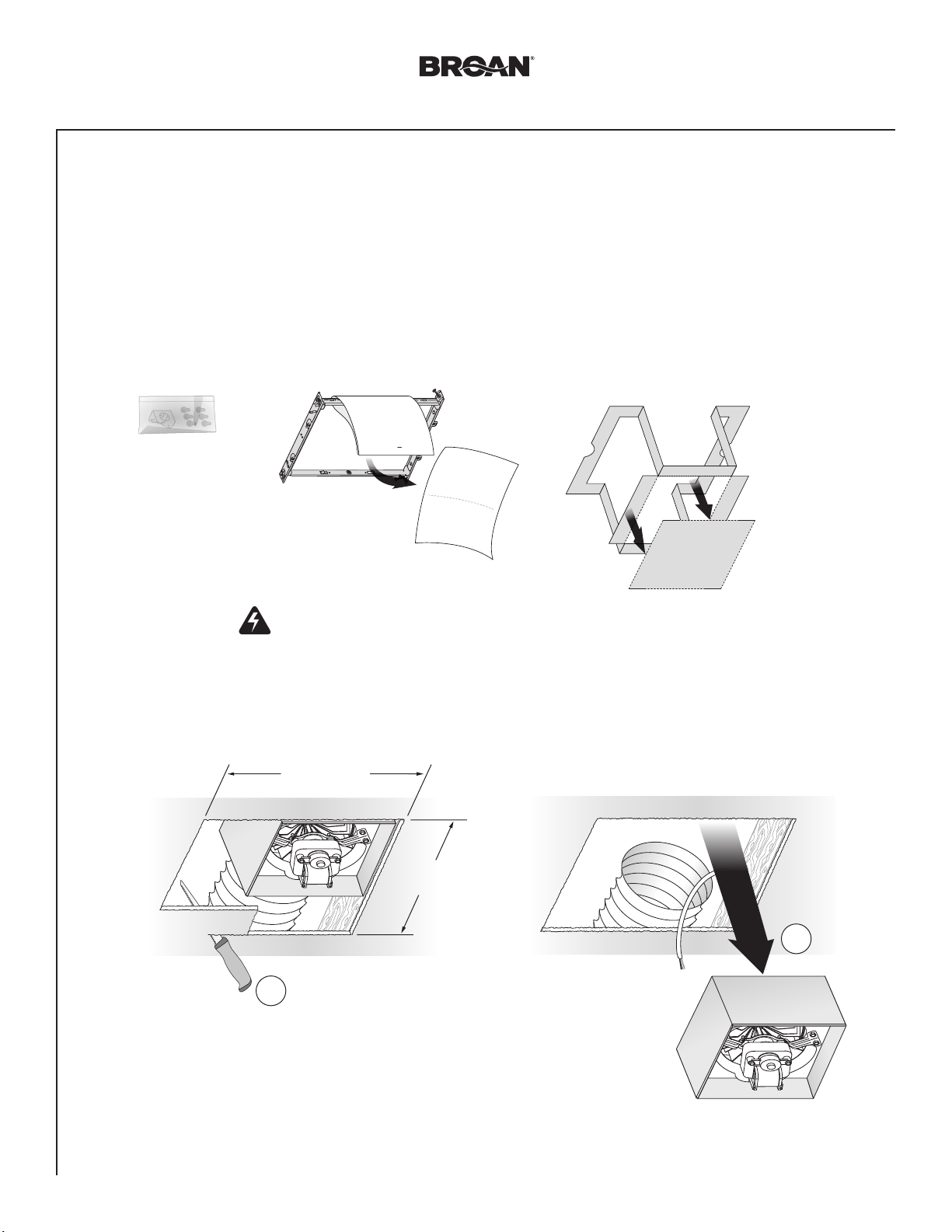

Retrofit Installation

XB110H Installation Guide

Tools needed

• Power screwdriver with a Phillips bit

• Phillips screwdriver

• Flathead screwdriver

• Pliers

• Wire insulation stripper

• Wire cutter

• Ruler

• Pencil

• Drywall saw

• Claw hammer or pry bar

• Utility knife

Materials needed

• Tape to seal duct connections

• Existing rigid duct will require the

addition of a short length of flexible duct

• Electrical wiring and supplies per

local code requirements

Remove Packaging

1

Parts Bag holds

Knockout Plate

and six (6)

screws

Remove

Instruction

Sheet

Punch out Mask from

packaging. See Step 12.

Switch Off Power

2

WARNING

Before removing existing fan, switch power off at service panel and lock the service disconnecting

means to prevent power from being switched on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

Enlarge Ceiling Opening and Remove Existing Fan

3

12" (30.5 cm)

1

11" (27.9 cm)

parallel with joists

Existing ductwork and

wiring left in place

Examine Wiring

4

Examine the existing wiring to make sure it is not damaged. If any damage is found,

DO NOT CONTINUE INSTALLATION of this product. Contact a qualified person(s) for repair.

2

Page 8

Retrofit Installation

Remove Blower Assembly

5

XB110H Installation Guide

2

Both sides

Remove Wiring Panel

6

Set aside

screw

1

1

3

Set aside

Wiring Panel

2

3

Set aside

Blower

Assembly

Insert

7

Mounting

Frame

4

3

1

Remove screws from

Mounting Frame

and set aside

5

2

Bend up

four tabs

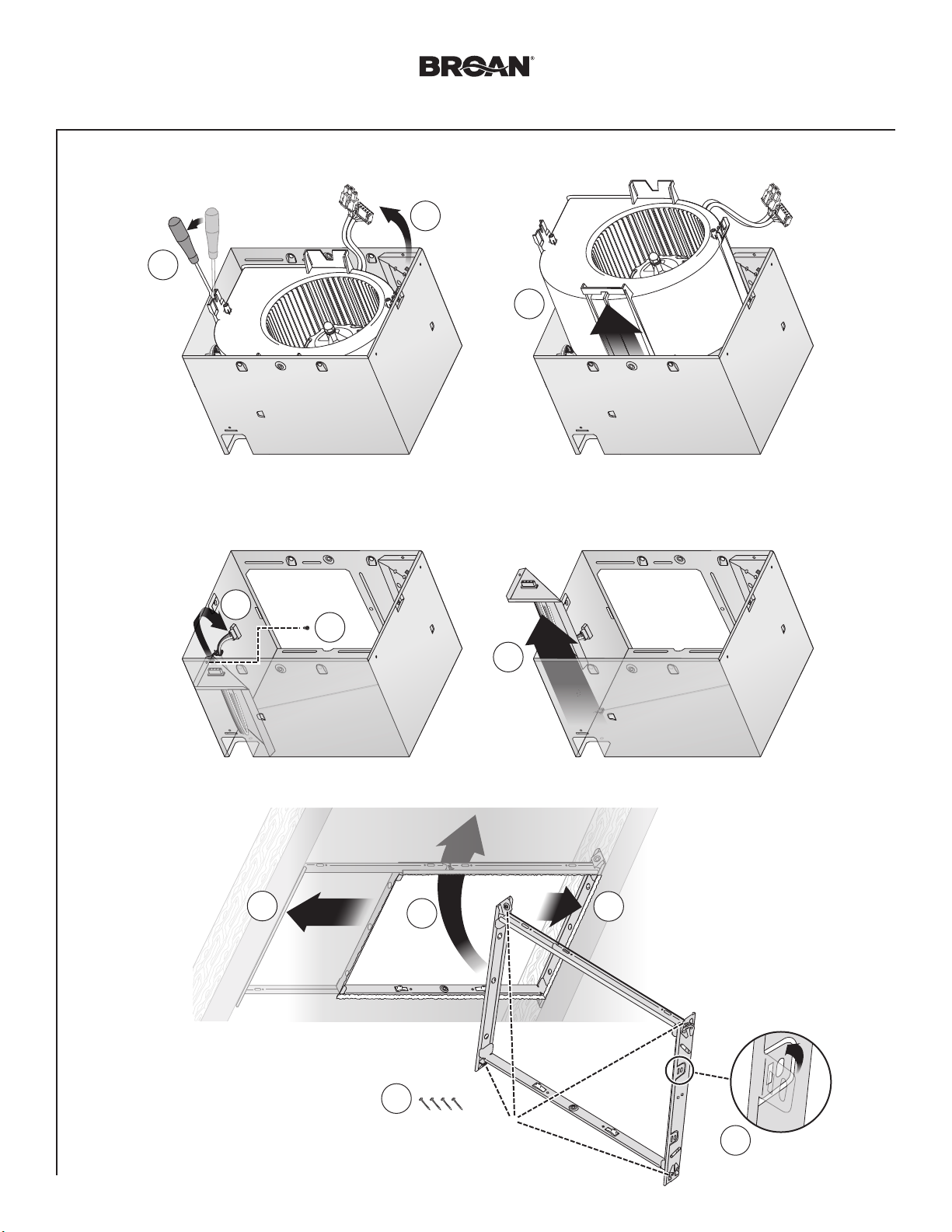

Page 9

Retrofit Installation

Secure

8

Mounting

Frame

Snap-in Housing

9

XB110H Installation Guide

Screws set

aside

in Step 7

2

10

Pull existing

ductwork

into Housing

1

Pull existing wiring into

Housing as it is inserted

into Mounting Frame

snap!

Attach Ducting and Duct Connector

1

4

Screw from

Parts Bag

3

Insert tab into

slot inside

Housing

6" Ducting

2

Tape

Page 10

Retrofit Installation

Install Knockout Plate, Connect Wires and Reinstall Wiring Panel

11

Screw from

Parts Bag

• Use proper UL-approved connectors to secure wiring to the Knockout Plate provided in Parts Bag.

• Connect wires as shown in wiring diagram.

Attach cable clamp to Knockout

1

Plate. Knockout Plate mounts to

inside of Housing and may be

oriented as

2

XB110H Installation Guide

desired.

Screw set

aside in

Step 6

5

6

4

Connect

3

wires

• See OPERATION section on page

12 for details.

• SENSOR/CONTROL switch allows

humidity control to be turned on for

automatic operation and off for fan

cleaning and maintenance purposes.

• Toggle mode can be used to manually

turn fan on.

• SENSOR/CONTROL switch may be

located where it is not easily accessed

for everyday usage; it may need to be

labeled and located where it can’t be

turned on without being seen from

fan to comply with local and national

codes.

120 VAC

LINE IN

SENSOR/

CONTROL

BLK

WHT

GRD

BLACK

WHITE

SENSOR

CONTROL*

purchase separately

*

BLK

WHT

GRD

BROWN

SWITCH BOX

120 VAC

LINE IN

14/2

ORANGERED

GROUND

(green or bare)

BLK

ORG

BRN

KNOCKOUT

PLATE

RED

FAN

BLK

SENSOR/

CONTROL

WHT

RECEPTACLES

Pa g e 11

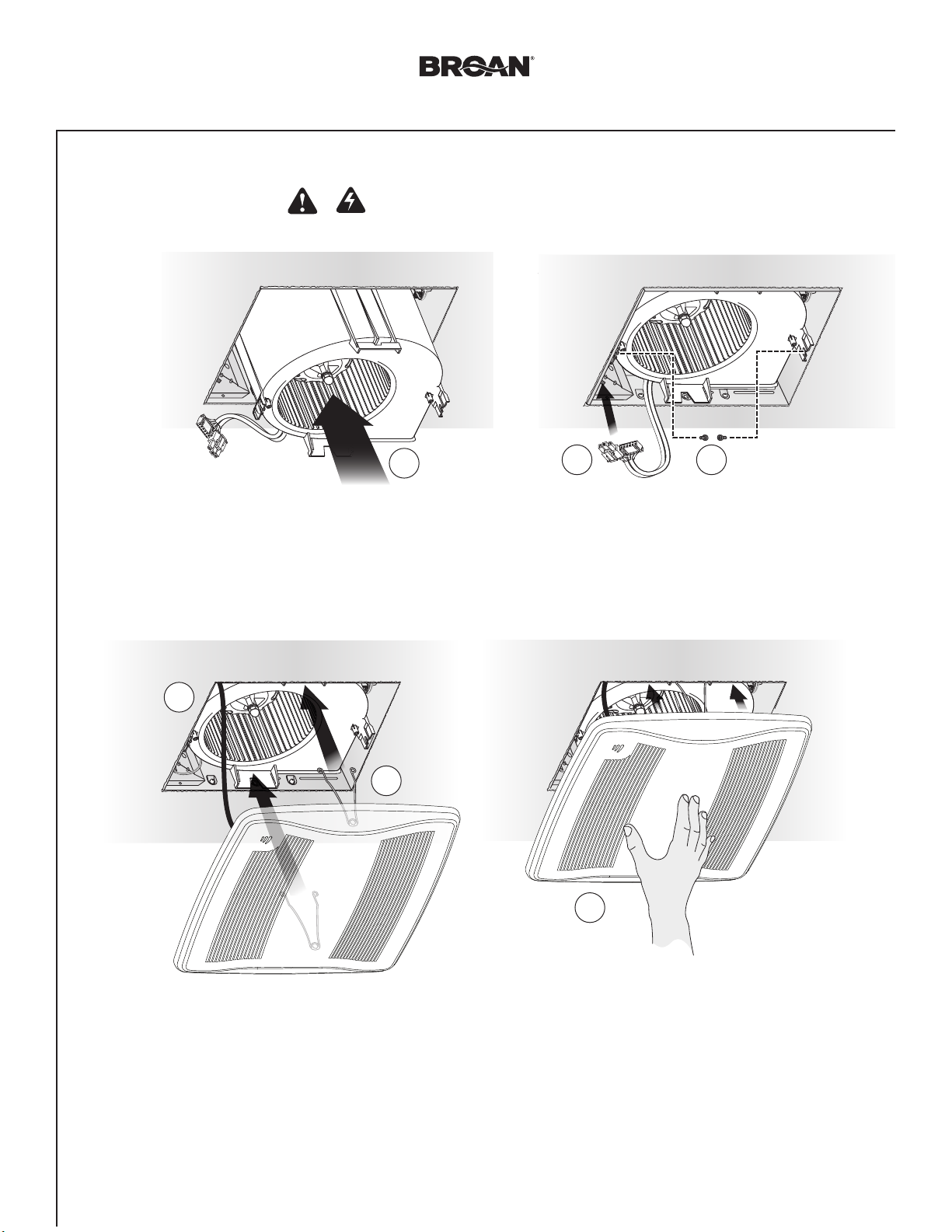

Retrofit Installation

Reinsert and Secure Blower Assembly

12

CAUTION

Power must be disconnected (see page 2, WARNING item 2) before inserting motor plugs into control assembly.

XB110H Installation Guide

IN ORDER TO PREVENT MOTOR/CONTROL DAMAGE:

13

Plug in

Sensor

Install Grille

1

1

2

2 3

Screws from Parts Bag

If ceiling repairs are needed, place Mask in

Housing after Blower Assembly is secured.

See New Construction Installation Step 6.

Remove Mask before installing Grille.

3

Page 12

XB110H Installation Guide

WARNING Before servicing or cleaning unit,

switch power off at service panel and lock the service

disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

Operation

It is normal for this ventilation fan to take approximately 5

seconds to start running after it is turned on.

Modes

(For reference, wiring diagrams are on pages 5 and 10.)

Humidity sensing:

1. Turn sensor/control wall switch on (make sure manual-

on wall switch is off if it is installed).

2. Sensor monitors humidity level for (a) moderate to rapid

rise or (b) above set-point.

3. Fan operates at certified airflow rate to reduce humidity.

4. When humidity decreases, fan enters time delay mode.

(See below.)

Manual-on (optional manual-on wall switch must be

installed):

1. Turn manual-on wall switch on (sensor/control wall

switch can be on or off).

2. Fan operates at certified airflow rate.

3. Fan turns off when manual-on wall switch is turned off.

Toggle (for manual operation when optional manual-on

wall switch is not installed or manually activated timedoff is desired):

1. Turn sensor/control wall switch on (make sure manual-

on wall switch is off if it is installed).

2. Wait at least one-second.

3. Turn switch off for less than one-second.

4. Turn switch back on.

5. Fan will operate at certified airflow rate and enter time

delay mode. (See next.)

Time Delay:

Fan continues to run until user-adjustable TIME delay has

passed, then fan turns off.

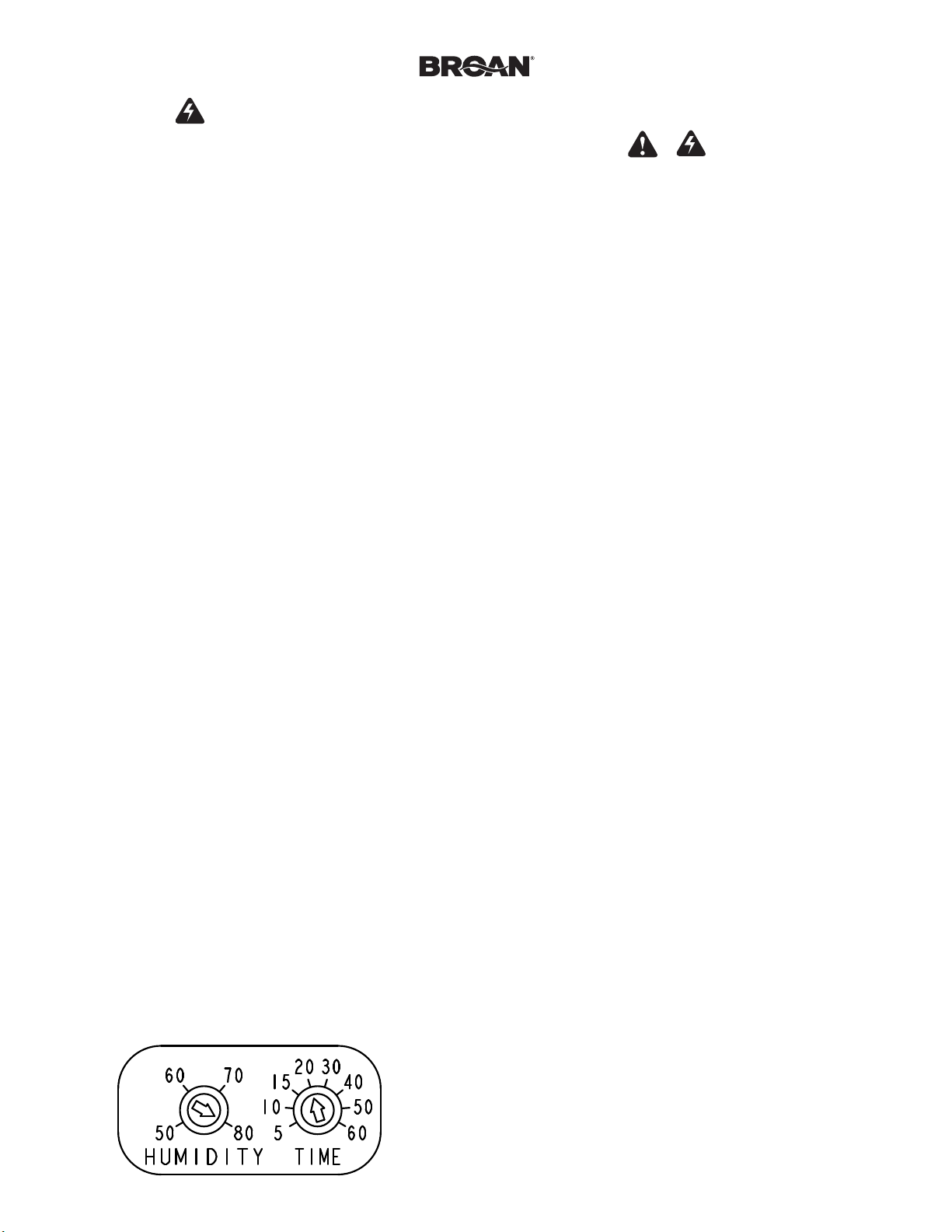

To Set User-Adjustable Humidity Sensitivity**

Using a small, flat-blade screwdriver, carefully rotate HUMIDITY adjustment until arrow points to desired humidity

level shown in percent relative humidity (%RH).

To Set User-Adjustable Time Delay**

Using a small, flat-blade screwdriver, carefully rotate TIME

adjustment until the arrow points to the desired minutes of

time delay.

** User-adjustable controls are located in corner of Fan

Housing behind Grille.

Cleaning and Maintenance

CAUTION

IN ORDER TO PREVENT MOTOR/CONTROL DAMAGE:

DO NOT remove motor plug to stop spinning motor.

Power must be disconnected (see WARNING at top left of

this page) before motor plug is removed or inserted into

control assembly.

To Clean

For quiet and efficient operation, long life and attractive

appearance, remove Grille and vacuum interior of unit with a

dusting brush attachment.

Do not use cleaning sprays, solvents or water on, or near, the

sensor.

Motor is permanently lubricated and never needs oiling. If

motor is making excessive or unusual noises, replace Control

Assembly and Motor.

Troubleshooting

Before continuing, turn off power as previously noted in

WARNING and CAUTION sections at the top of this page.

Symptom: Fan does not run.

• Check for an open fuse or circuit breaker in the building’s service panel.

• Check that the two (2) plug-in connections for the Motor and the Control are seated firmly in place.

• Check two (2) plug-in connections for Sensor and its

Control are seated firmly in place.

• Check that the Blower Wheel spins freely.

Symptom: Humidity mode does not operate fan.

• Check two (2) plug-in connections for Sensor and its

Control are seated firmly in place.

Symptom: The fan runs erratically.

• Check that the Blower Wheel is firmly attached to the

Motor shaft and both spin freely.

Symptom: The fan seems noisy.

• Check that the back draft damper in the fan’s Duct

Connector pivots freely. Screws used to attach the duct

to the Duct Connector may be preventing the damper

from opening.

• Check that the back draft damper in the wall or roof cap

pivots freely. These dampers are sometimes mistakenly

painted shut or obstructed by bird and insect debris.

Loading...

Loading...