Page 1

ALLURE TM WS1 SERIES

NuTone ° .o .ooo

ALLU E'" Page l

WSl ES

Patent No.:

A GE HOO oso,,0, s

FOR DOMESTIC COOKING ONLY

CAUTION

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR iNJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer, ifyou have

questions, contact the manufacturer at the address or telephone number

listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and

lock the service disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting means cannot

be locked, securely fasten a prominent warning device, such as a tag, to

the service panel.

3. installation work and electrical wiring must be done by a qualified

person(s) inaccordance with all applicable codes and standards, includ-

ing fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases

through the flue (chimney) of fuel burning equipment to prevent backdraft-

ing. Follow the heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire Protection As-

sociation (NFPA), and the American Society of Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring

and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use this range hood

with an additional speed control device.

Z Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. Use with approved cord-connection kit only.

10.This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low

or medium settings.

2. Always tu rn hood O N when cooking at high heat or when cooking flaming

foods.

3. Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for the size of

the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS INTHE EVENT OFA

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray,

then turn off the burner. BE CAREFUL TO PREVENT BURNS. if the

flames do not go out immediately, EVACUATE AND CALL THE FiRE

DEPARTMENT.

2. NEVER PiCK UPA FLAMING PAN --You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam

explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know

how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on "Kitchen Fire Safety Tips" published by NFPA.

1. For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced impellers,

keep drywall spray, construction dust, etc. off power unit.

3. For best capture of cooking impurities, your range hood should be

mounted so that the top of the hood is 24-30" above the cooking surface.

4. Please read specification label on product for further information and

requirements.

Installer: Leave this manual with

the homeowner.

Homeowner: Operating and

Cleaning information on page 5.

If hood is to be installed Non-Ducted:

Purchase a set of (2) non-ducted filters from your

local distributor or retailer and attach them to the

aluminum mesh filters.

TABLE OF CONTENTS

This manual isdivided into sections as follows:

"PREPARE HOOD LOCATION"

Run ductwork from roof or wall cap, and electrical wiring from service

panel - to installation location

"PREPARE THE HOOD"

Get your hood ready for installation

"CONNECT WIRING"

Make electrical wiring connections to hood

"INSTALL HOOD"

Secure hood to cabinet and ductwork -install bulbs and filters

"OPERATION"

How to use the hood controls

"CLEANING"

Keep your hood in top working condition

"SERVICE PARTS"

Part numbers and exploded view of hood components

"WARRANTY"

One-year limited warranty and how to contact us

Page 2

ALLURE TM WS1 SERIES

NuTone ° .o .ooo

Page 2

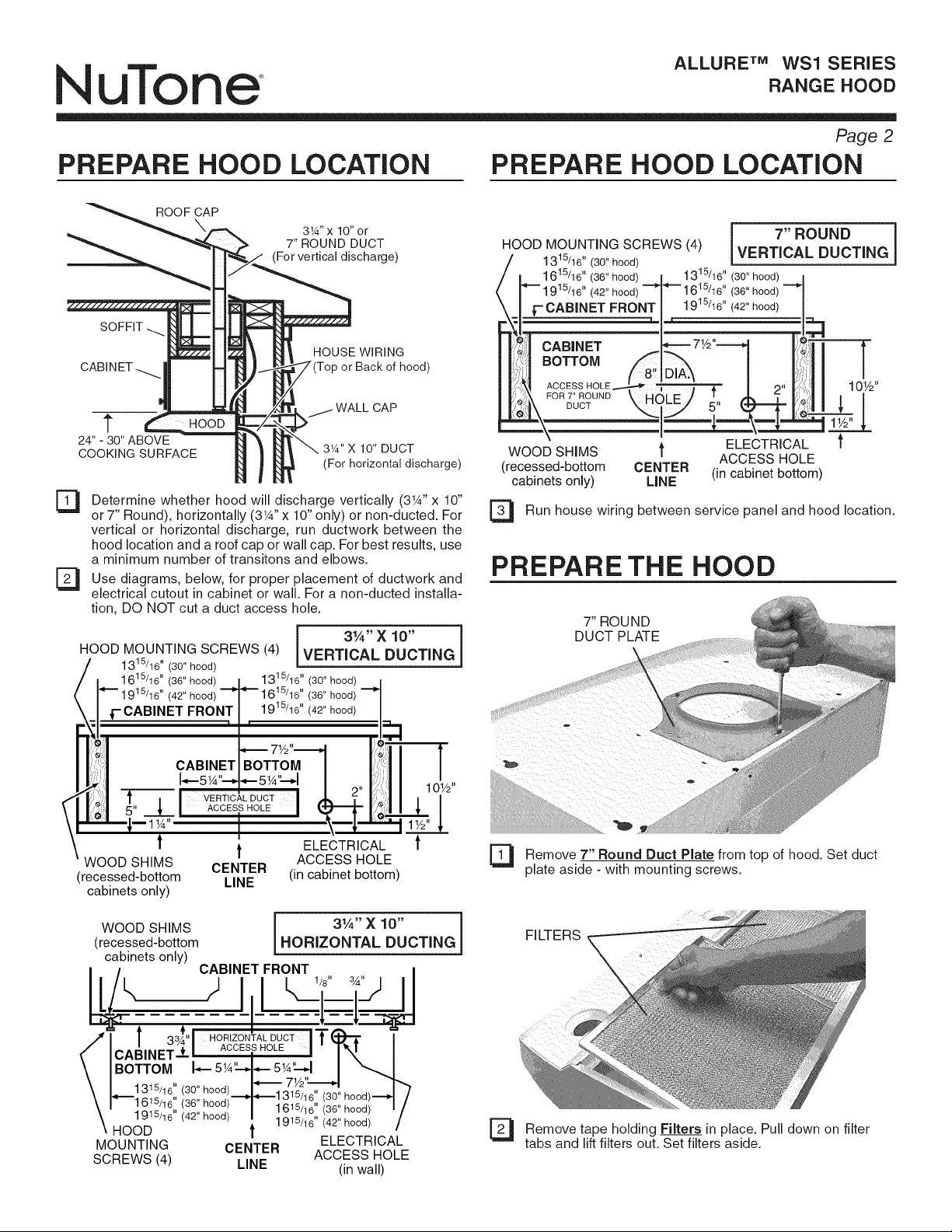

PREPARE HOOD LOCATION PREPARE HOOD LOCATION

ROOF CAP

SOFFIT

CABINET..._

31A"x 10" or

7" ROUND DUCT

(For vertical discharge)

HOUSE WIRING

or Back of hood)

HOOD MOUNTING SCREWS (4)

1315/16" (30" hood)

1615/16" (36" hood) / 1 315/16" (30" hood)

1915/16" (42" hood) --_ 1615/16 '' (36" hood)

CABINET _ 7W'_

oo,,oo / ,,

ACCESS HOLE_ _ _ 2

FOR 7" ROUND \ i_h¢'_|{::: / T ,_

i 7" ROUND

VERTICAL DUCTING i

t

24" - 30" ABOVE

COOKINGSURFACE

Determine whether hood will discharge vertically (31A'' x 10"

E]

or 7" Round), horizontally (3W' x 10" only) or non-ducted. For

vertical or horizontal discharge, run ductwork between the

hood location and a roof cap or wall cap. For best results, use

a minimum number of transitons and elbows.

El Use for of ductwork and

diagrams, below, placement

electrical cutout in cabinet or wall. For a non-ducted installa-

tion, DO NOT cut a duct access hole.

proper

HOODMOUNTINGSCREWS(4) VERTICAL DUCTING

1315/16" (30" hood)

1615/16" (36" hood) 1315/16" (30" hood)

1915/16" (42" hood) "--_ _-" 1615/16" (36" hood)

f- CABINET FRONT 1915/16" (42"hood)

) 1 ii I

!I CABINET BOTTOM

I 4--5 W'---D*-- 51A'_--_

1 1

i,:1 _ VERTICAL DUCT t 2"

.!_1 5" __._L ACCESS HOLE

WOOD SHIMS

(recessed-bottom

cabinets only)

t t ELECTRICAL t

CENTER (in cabinet bottom)

LINE

3W' X 10" DUCT

(For horizontal discharge)

31A"X 10"

ACCESS HOLE

°acT

WOOD SHIMS

(recessed-bottom

cabinets only)

Run house wiring between service panel and hood location.

PREPARE THE HOOD

7" ROUND

DUCT PLATE

El Remove 7" Round Duct Plate from of hood. Set duct

plate aside - with mounting screws.

f ELECTRICAL f

CENTER (in cabinet bottom)

LINE

ACCESS HOLE

top

WOOD SHIMS J 31,4" X 10" i

(recessed-bottom HORIZONTAL DUCTING

cabinets only)

CABINET FRONT

I 1/8. 3_ H

HOR_ZO.TALOUCTT_ I

CABINET- ACCESS HOLE -- I _ I I

OTTO..

15 .... 7_5"

13 /16 (3o hood) ,,

............. _315/1_' hood) ---_'" 7

]b15/16,, !rib" nooa,! I 1615/16"(36,, hood i I /

] t9 /16 [#Z" nooa) I 4 nl <, . ....... : /

HOOD _ /_ _/16 _4z nooa) /

MOUNTING

SCREWS (4)

CENTER ACCESS HOLE

LINE (in wall)

ELECTRICAL

FILTERS

Remove Filters in Pull down filter

tabs and lift filters out. Set filters aside.

tape holding place.

on

Page 3

ALLURE TM WS1 SERIES

NuTone ° .o .ooo

Page 3

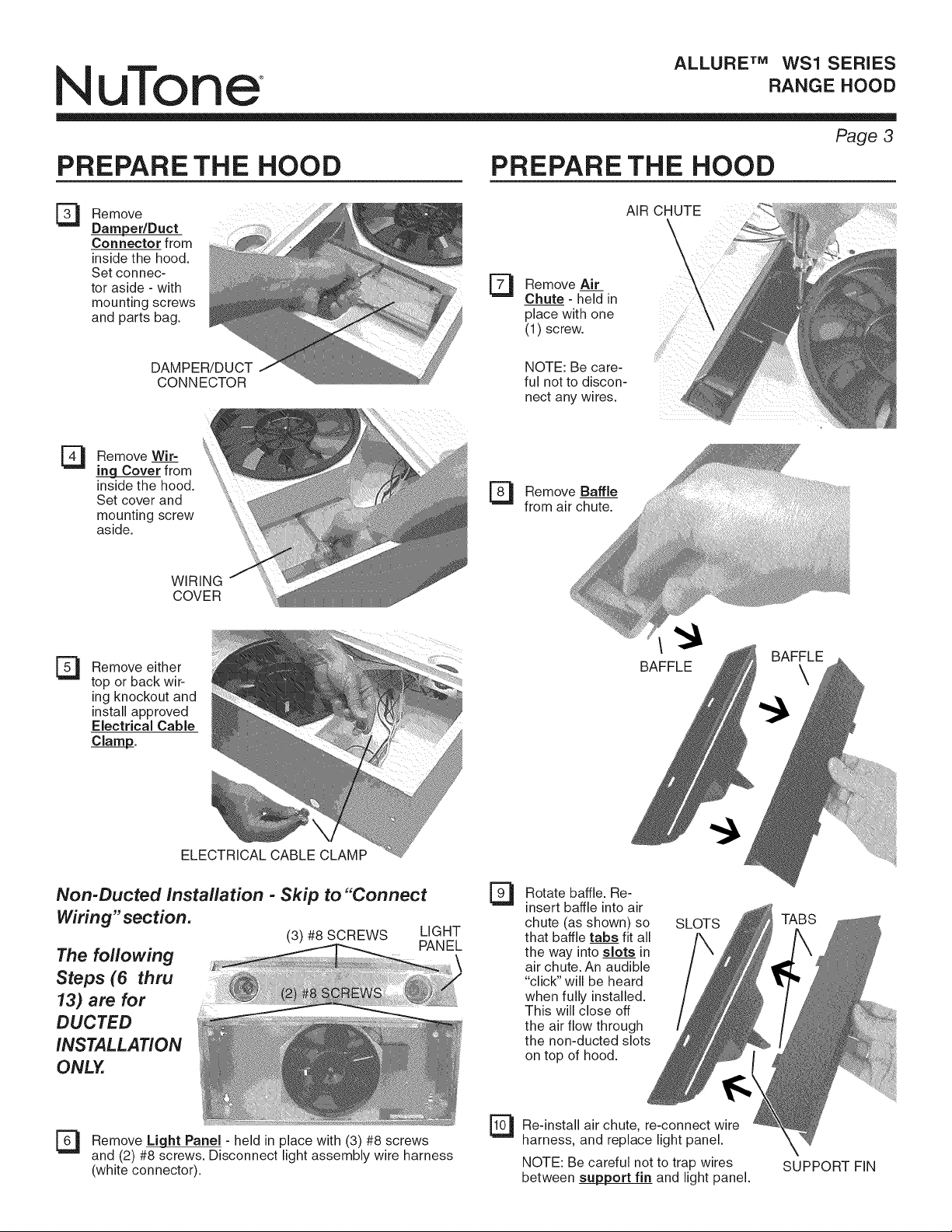

PREPARE THE HOOD PREPARE THE HOOD

El Remove AIR CHUTE

Damper/Duct

Connector from

inside the hood.

Set connec-

tor aside - with

mounting screws

and parts bag.

Remove Air

53

Chute- held in

place with one

(1) screw.

Remove Wir=

El

inside the hood.

Set cover and

mounting screw

aside.

Remove either

top or back wir-

ing knockout and

install approved

Electrical Cable

Clamp_.

DAMPER/DUCT

CONNECTOR

Cover from

WIRING

COVER

NOTE: Be care-

ful not to discon-

nect any wires.

El Remove Baffle

from air chute.

BAFFLE

BAFFLE

\

ELECTRICAL CABLE CLAMP

Non-Ducted installation - Skip to "Connect

Wiring"section.

(3) #8 SCREWS LIGHT

The following

Steps (6 thru

13) are for

DUCTED

_!iiii;

INSTALLATION

ONLY.

El Remove L_ght Panel - held in place with (3) #8 screws

and (2) #8 screws. Disconnect light assembly wire harness

(white connector).

PANEL

Rotate baffle. Re-

insert baffle into air

chute (as shown) so

that baffle tabs fit all

the way into slots in

air chute. An audible

"click" will be heard

when fully installed.

This will close off

the air flow through

the non-ducted slots

on top of hood.

Re-install air chute, re-connect wire

harness, and replace light panel.

NOTE: Be careful not to trap wires

between _ort fin and light panel.

SLOTS

TABS

SUPPORT FIN

Page 4

ALLURE TM WSl SERIES

NuTone ° °o .ooo

Page 4

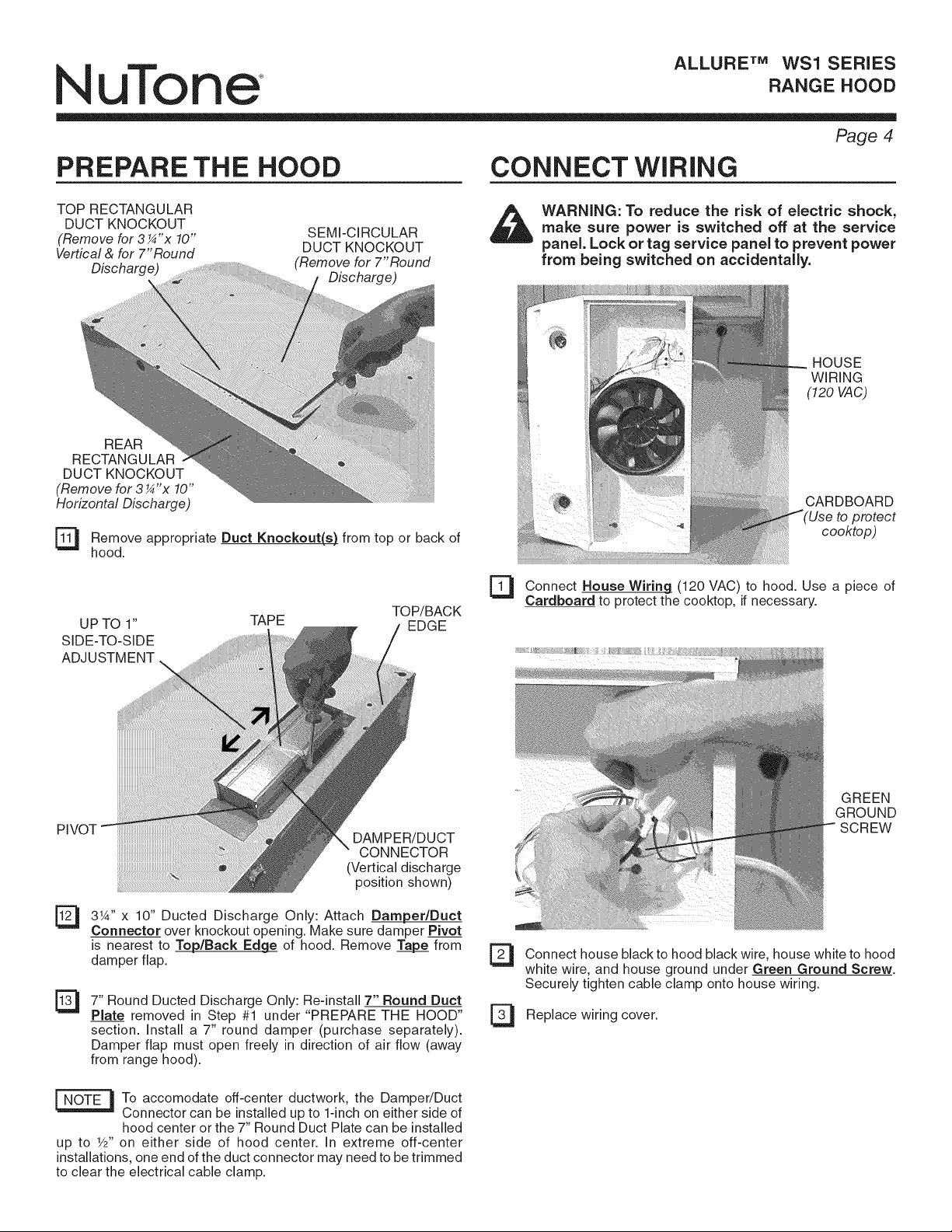

PREPARE THE HOOD CONNECT WIRING

TOP RECTANGULAR

DUCT KNOCKOUT

(Remove for 3 ¼" x 10"

Vertical & for 7"Round

Discharge)

REAR

RECTANGULAR

DUCT KNOCKOUT

(Remove for 3 ¼" x 10"

Horizontal Discharge)

El Remove Duct from back of

hood.

appropriate Knockout(_ top

SEMI-CIRCULAR

DUCT KNOCKOUT

(Remove for 7"Round

Discharge)

or

_ WARNING: To reduce the risk of electric shock,make sure power is switched off at the service

panel. Lock or tag service panel to prevent power

from being switched on accidentally.

HOUSE

WIRING

(120 VAC)

CARDBOARD

to protect

cooktop)

UPTO 1"

SIDE-TO-SIDE

ADJUSTMENT

PIVOT'

31_'' x 10" Ducted Discharge Only: Attach Damper/Duct

Connector over knockout opening. Make sure damper Pivot

is nearest to Top/Back Edg#_ of hood. Remove _ from

damper flap.

7" Round Ducted Discharge Only: Re-install 7" Round Duct

Plate removed in Step #1 under "PREPARE THE HOOD"

section. Install a 7" round damper (purchase separately).

Damper flap must open freely in direction of air flow (away

from range hood).

TAPE EDGE

DAMPER/DUCT

CONNECTOR

(Verticaldischarge

positionshown)

TOP/BACK

[_ Connect House to hood. Use of

Cardboard to protect the cooktop, if necessary.

El Connect house blackto hood black wire, house white to hood

white wire, and house ground under Green Ground Screw.

Securely tighten cable clamp onto house wiring.

El Replace wiring cover.

Wiring (120 VAC)

a

piece

GREEN

GROUND

SCREW

To accomodate off-center ductwork, the Damper/Duct

Connector can be installed up to 1-inch on either side of

hood center or the 7" Round Duct Plate can be installed

up to Y2" on either side of hood center. In extreme off-center

installations, one end of the duct connector may need to be trimmed

to clear the electrical cable clamp.

Page 5

ALLURE TM WSl SERIES

NuTone ° .o .ooo

Page 5

INSTALL HOOD NON-DUCTED FILTERS

If hood is to be installed Non-Ducted:

Purchase a set of (2) non-ducted filters from your local distributor or

retailer and attach them to the aluminum mesh filters.

(4)

MOUNTING

SCREW

(4)

El Hang hood from (4) Mounting Screws (from bag).

Slide hood towards wall until mounting screws are engaged

in narrow end of (4) Keyholes. Tighten mounting screws

securely.

_DO NOT PUSH ON FAN BLADE. the

El Connect ductwork to hood. Use Duct to make

secure and air tight.

blade may cause itto interfere with other hood parts.

Tape joints

parts

Pushing

INCANDESCENT

on

DUCT

TAPE

PAR20,

50W MAX.

HALOGEN

BULB (2)

-or-

R16,

40W MAX.

BULB (2)

OPERATION

10_ h_gh low high

fen light

Fan: The 3-position rocker switch (on the left) controls the fan. The

left position is low speed, center position is off, and right position is

high speed. An indicator light shows that the fan is on.

Light: The 3-position rocker switch (on the right) controls the lights.

The left position is low light intensity, center position is off, and right

position is high light intensity.

by NuTor_

CLEANING

_b ARNING: To reduce the risk of electric shock,

Aluminum mesh filters: Clean frequently using hot water and a

mild detergent. Filters are dishwasher safe.

Charcoal filters: Clean filter surfaces frequently with a damp cloth

and a mild detergent. DO NOT immerse filters in water or put in

dishwasher. The special "Clean Sense" feature indicates when the

filter is to be replaced. The blue and yellow strips will blend to green

when it is time to change the filter. The "Clean Sense" feature works

best when facing toward the cooking surface.

To clean hood: Remove filters. Use a damp cloth and a mild deter-

gent to wipe all grease-laden surfaces. Use care when cleaning fan

blade - it must not become bent or misaligned. DO NOT ALLOW

WATER TO ENTER MOTOR. Make sure all surfaces are completely

dry before re-installing filters and restoring power.

Motor is permanently lubricated. Do not oil or disassemble motor.

disconnect from power supply before cleaning.

Install (2) PAR20, 50 W Maximum Halogen Bulbs or (2)

R16, 40 W Maximum Incandescent Bulbs. Purchase bulbs

separately.

CAUTION: Bulbs may be hot! Refer to bulb packaging

for further information.

Replace

El filters and make fan blade turns Turn

power at service panel, and test for proper operation.

sure

freely.

on

Page 6

ALLURE TM WS1 SERIES

NuTone ° °o .ooo

Page 6

SERVICE PARTS

KEY NO. PART NO. DESCRiPTiON

1 R680508

2 R740013

3 R602017

4 R561115

R561116

R561117

R561119

5 R627518

R627519

R627520

R627533

R627579

6 R607657

7 R602534

8 R602533

9 R680504

10 *

11 R169016

12 R169002

13 R99080535

14 R401647

15 R401646

16 R531075

• * R99420635

17 99010299

99010300

99010301

18 Rl11630

19 R7201731

R7201751

R7201771

R7201732

R7201752

R7201772

R7201734

R7201754

R7201774

R720174

R720176

R720178

R7201735

R7201755

R7201775

20 R169004

• * R169010

• * Rl11626

• * 99010308

• * 99010309

• * 99010310

Order replacement parts by PART NO.- not by KEY NO.

* Standard hardware - may be purchased locally.

** Not illustrated.

7" Round Duct Plate (includes hardware)

Damper/Duct Connector (includes hardware)

Screw, #8-18 x 1A Hex* (2 in package)

Rocker Switch, Almond (2 in package)

Rocker Switch, White (2 in package)

Rocker Switch, Black (2 in package)

Rocker Switch, Biscuit (2 in package)

Nameplate, White

Nameplate, Almond

Nameplate, Stainless

Nameplate, Biscuit

Nameplate, Black

Lens

Screw, 8-18 x 3/8" (2 in package)

Ground Screw (2 req.)

Wiring Cover (includes hardware)

Rivet, Pop .125 dia.

Filter Spring Kit

Motor Mounting Screw (3 each part)

Motor (includes Motor Mounting Kit)

Air Chute Assembly

(includes Key No. 15 & hardware)

Baffle

Fan Blade (includes hairpin clip)

Hairpin Clip

Filter Kit, for 30" Hood (2 per bag)

Filter Kit, for 36" Hood (2 per bag)

Filter Kit, for 42" Hood (2 per bag)

Lamp Socket Harness

Light Panel, White, for 30" Hood

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel,

Light Panel, Biscuit, for 42" Hood

Indicator Light (includes 2 wire nuts and lens

Light Diode Assembly (includes wire nut)

Wire Harness

Non-Ducted Filter Kit, 30" (2 per bag)

Non-Ducted Filter Kit, 36" (2 per bag)

Non-Ducted Filter Kit, 42" (2 per bag)

White, for 36" Hood

White, for 42" Hood

Almond, for 30" Hood

Almond, for 36" Hood

Almond, for 42" Hood

Black, for 30" Hood

Black, for 36" Hood

Black, for 42" Hood

Stainless, for 30" Hood

Stainless, for 36" Hood

Stainless, for 42" Hood

Biscuit, for 30" Hood

Biscuit, for 36" Hood

15

13 _318

\

/

7

17 19

WARRANTY

NUTONEONEYEARLIMITEDWARRANTY

NuTonewarrants to the original consumer purchaser of its products that such

productswill befreefrom defectsin materialsorworkmanshipfor a periodof one

yearfrom the date of original purchase.THEREARENOOTHERWARRANTIES,

EXPRESSOR IMPLIED,INCLUDING,BUTNOT LIMITEDTO, IMPLIEDWAR-

RANTIESOFMERCHANTABILITYORFITNESSFORA PARTICULARPURPOSE.

Duringthis one-yearperiod, NuTonewill, atits option, repairor replace,without

charge,any product or part which is found to be defective under normal use

and service.

THISWARRANTYDOESNOTEXTENDTOFLUORESCENTLAMPSTARTERSAND

TUBES.Thiswarranty doesnot cover (a)normal maintenanceand serviceor (b)

any products or parts which havebeensubject to misuse,negligence,accident,

improper maintenanceor repair (other than by NuTone),faulty installationor

installationcontrary to recommendedinstallation instructions.

Theduration ofan impliedwarranty is limitedto the one-yearperiod asspecified

for the express warranty. Somestates do not allow limitation on how long an

impliedwarranty lasts, so theabovelimitation may notapply to you.

NUTONE'SOBLIGATIONTOREPAIRORREPLACE,ATNUTONE'SOPTION,SHALL

BETHE PURCHASER'SSOLEAND EXCLUSIVEREMEDYUNDERTHISWAR-

RANTY.NUTONESHALLNOTBE LIABLEFOR INCIDENTAL,CONSEQUENTIAL

ORSPECIALDAMAGESARISINGOUTOFORINCONNECTIONWITHPRODUCT

USEORPERFORMANCE.Some statesdo notallow the exclusionor limitation of

incidentalorconsequentialdamages,sotheabovelimitation maynot applytoyou.

This warrantygivesyou specificlegal rights,and you mayalsohaveother rights,

which vary from stateto state.Thiswarranty supersedesall prior warranties.

To qualify for warranty service, you must (a) notify NuToneat the address or

telephonenumber below, (b) givethe model number andpart identificationand

(c) describethe natureof anydefectin the product orpart.At thetime of request-

ing warrantyservice,you mustpresent evidenceof theoriginal purchasedate.

NuTone,inc., 4820RedBankRoad,Cincinnati,OH45227 (1-800-543-8687)

626976D

Page 7

A

ACTO

CAIVlPANA EXTRACTORA

P4gina 7

SE

E ;1

ALLU

PARA COCINAR

ETIVl Patent No.:

DOIVlESTICO SOLAlVlENTE.

ADVERTENCIA

PARA REDUCIR EL RJESGO DE INCENDIO, CHOQUE ELECTRICO, O LESION

A PERSONAS, PROCURE LO SIGUIENTE:

1. Utilice esta unidad s61o en la manera prescrita por el fabricante. Si tiene usted

alguna pregunta, comuniquese con el fabricante a la direcci6n o el telefono

indicados en la garantia.

2. Antes de efectuar algun servicio o limpieza, se debe desconectar la corriente

electrica en el armario de circuitos y asegurarlo con Ilave para evitar que la

corriente sea conectada accidentalmente. Cuando no se puedan inmovilizar

los medios de desconexi6n de servicio, pegue con seguridad un dispositivo

de advertencia prominente, tal como una etiqueta, en el tablero de servicio.

3. Todo trabajo de instalaci6n y cableado electrico debe ser realizado por per-

sonal calificado y de acuerdo con todos los c6digos y normas pertinentes,

incluyendo los c6digos y normas relacionados con construcci6n clasificada

para incendio.

4. Aire suficiente es necesario para facilitar la combusti6n adecuada y la salida

apropiada de gases por la chimenea de la unidad y para evitar corrientes de

aire invertidas. Siga las instrucciones y medidas de seguridad del fabricante

del equipo y de las sociedades profesionales de equipos de calentadores y

los reglamentos de seguridad locales.

5. A cortar o perforar la pared o el techo, no dare el cableado electrico u otros

servicios publicos ocultos a la vista.

6. Para reducir el riesgo de incendio o de descarga electrica, no utilice este

ventilador con ningun dispositivo de una control de velocidad de estado s61ido

adicional.

7. Los abanicos con ducto deberAn siempre tener una salida hacia el exterior.

8. Para reducir el riesgo de incendio, use s61o ductos de metal.

9. Uso con el kit aprobado della conexi6n de la cuerda solamente.

10. Esta unidad se debe instalar con tierra efectiva.

PARA REDUCIR EL RIESGO DE UN INCENDIO POR GRASA EN EN LA

ESTUFA:

1. Nunca deje sin atender las unidades de superficie cuando tengan ajustes altos.

Los reboses pueden provocar humo y derrames grasosos que se pueden

incendiar. Caliente lentamente el aceite en un ajuste bajo o medio.

2. Siempre ENCIENDA la campana cuando cocine con alta temperatura o

cuando cocine alimentos que se puedan incendiar.

3. Limpie con frecuencia los ventiladores. No debe permitir que la grasa se

acumule en el ventilador ni en el filtro.

4. Utilice un sarten de tamado adecuado. Siempre utilice el utensilio adecuado

al tamado del elemento de superficie.

PARA REDUCIR EL RIESGO DE LESION A PERSONAS RESULTADO DE UN

INCENDIO DEBIDOA GRASAACUMULADA EN LAS HORNILLAS, PROCURE

LO SIGUIENTE:*

1. AHOGUE LAS LLAMAS con una tapa ajustada o charola de metal, despues

apague la hornilla. TENGA CUIDADOA FIN DE EVITAR QUEMADURAS. Si

las llamas no se apagan de inmediato, EVACUE Y AVISE A LOS BOMBEROS.

2. NO LEVANTE NUNCA UNA SARTEN QUE ESTE EN LLAMAS - Usted se

podrA quemar.

3. NO UTILICE AGUA, incluyendo toallas de cocina mojadas - puede resultar

una explosi6n de vapor violenta.

4. Utilice un extinguidor SOLAMENTE si:

A. Usted sabe que tiene un extinguidor de clas ABC y Io sabe utilizar.

B. El incendio es pequedo y contenido dentro del Area donde se inici6.

C. Los bomberos hart sido avisados.

D. Usted puede combatir el incendio con una salida a su espalda.

* Basado en las recomendaciones para "Seguridad en la Cocina" publicadas

por la NFPA de los EEUU.

US D450, 829 S

PRECAUCION

1. Solamente para uso general de ventilaci6n. No utilice para descargar mate-

riales o vapores riesgosos o explosivos.

2. Para evitar dados al motor y evitar que las navajas del abanico emitan mucho

ruido o esten fuera de balance, mantenga el motor libre de pelusa, polvo, etc.

3. Para obtener mejores resultados en la captura de los vapores de la estufa,

el parte superior del extractor debe montarse a entre 45.7 a 60.9 cm sobre

las hornillas de la estufa.

4. Por favor lea la etiqueta con las especificaciones del equipo para otros req-

uisitos y mayor informaci6n.

A la persona que realiza la instalaci6n" Deje

este manual con el dueSo de la casa.

AI due5o de la casa: Las instrucciones de

operaci6n y limpieza se encuentran en la

p gina 11.

campana

Si la se va a instalar en un sistema sin conductos:

Compre un juego de (2) filtros para sistemas sin con-

ductos en la tienda distribuidora o minorista de su Iocali-

dad y m6ntelos en los filtros de malla de aluminio.

CONTENIDO

Este manual se divide en las siguientes secciones:

"PREPARACION DEL LUGAR DONDE SE VA A INSTALAR LA CAM-

PANA"

Tienda de los conductos desde el techo o la tapa de pared, y haga la con-

exi6n electrica desde el panel de servicio hasta el sitio de la instalaci6n.

"PREPARAClON DE LA CAMPANA"

Prepare la campana para su instalaci6n

"CONEXION ELECTRICA"

Haga las conexiones electricas hacia la campana

"INSTALAClON DE LA CAMPANA"

Asegure la campana en el gabinete yen el sistema de conductos. Instale

focos y filtros.

"OPERAClON"

C6mo usar los controles de la campana

"LIMPIEZA"

Mantenga su campana en condiciones 6ptimas de funcionamiento

"PIEZAS DE REPUESTO"

Numero de las piezas y vista ampliada de los componentes de la campana

"GARANTJA"

Garantia limitada de un ado y c6mo comunicarse con nosotros

Page 8

NuTone

CAIVlPANA EXTRACTORA

PREPARACION DEL LUGAR DONDE

SE VA A INSTALAR LA CAMPANA

TAPADETECHO

t CONDUCTO DE

De 45.7 cm a 60.9 cm 8.3 cm x 25.4 cm

SOBRE LA SUPERFICIE (para descarga

PARA COCINAR horizontal)

Determine sJla descarga de la campana va a ser vertical [conducto

53

de 8.3 cm x 25.4 cm (3 ¼"x 10") o conducto redondo de 17.8 cm

(7")], horizontal [s61o conducto de 8.3 cm x 25.4 cm (3 X"x 10")] o

si es un sistema sin conductos. En el caso de descarga vertical u

horizontal, tienda los conductos entre el iugar donde va a instalar

la campana y la tapa de techo o la tapa de pared. Para obtener

los mejores resultados, utilice el nOmero minimo de transiciones

y codos.

UtJlJcelos siguientes diagramas para colocar adecuadamente los

conductos y hacer el corte exacto para la conexi6n eiCctrica en

el gabinete o en la pared. En el caso de aquelias instalaciones

en sJstemas sin conductos, NO haga ningOn orificio de acceso

para el conducto.

iISTEMA VERTICAL DE CONDUCTOSDE 8.3 25.4 1/4" 10 i

TORNILLOS PARA EL MONTAJE DE LA CAMPANA (4)

35.4cm (campana de 762 cm) 35.4 cm (campana de 76,2 cm)

43.0cm (campana de 91.4 cm)D" 43.0 cm (campana de 91,4 cm)

cm (campana de 106.7 cm) 50.6

FRENTE DEL GABINETE

1

CONDUCTO DE

8.3 cm x 25.4 cm O

REDONDO DE 17.8 cm

• (para descarga vertical)

CABLEADO ELECTRICO

DOMCSTICO (Parte superior

TAPADEPARED

cm x cm

la campana)

(3

P4gina 8

PREPARACION DEL LUGAR DONDE

SE VA A INSTALAR LA CAMPANA

I SISTEMA VERTICAL DE CONDUCTOS 1REDONDOS DE 17.8 CM (7")

TORNILLOS PARA EL MONTAJE DE LA CAMPANA (4)

35.4cm (campana de 76.2 cm) 35.4cm (campana de 76.2 cm)

43.0 cm (campana de 91.4 cm)! 43,0 cm (campana de 91.4 cm)>

(campana de t06.7 cm)l_(),_6 cm (campana de106_7 cm)

,F"FRENTE DEL GABINETE

GABJNETE fl_ |

oR,F,c,ooE_J._/OR,F,C,O'_!

AO1_.OuPA_A_OE2_ ± 50._

REDONDODE \ DE OlA./1 2 7 cm

CUNAS DE MADERA

(s61o gabinetes de

fondo empotrado)

Haga las conexiones del cableado domCstico entre el panel de

servicio y el lugar donde va a instalar la campana.

t

LJNEA ORIFICiO DE ACCESO PARA

CENTRAL LOS CABLES ELC:CTRICOS

(en el fondo del gabinete)

PREPARACION DE LA CAMPANA

PLACA DEL CONDUCTO

REDONDO DE 17.8 CM (7")

x

19.1 cm-

FONDO DELtGABINETE

I.-13.3om-+133ore-4

DELCONDUCTOHORIZONTAL

I ORIFIClODEACOESO I

- 3.2 cm 1

CUNAS DE MADERA

(s61o gabinetes de

fondo empotrado)

_ISTEMA HORIZONTAL DE CONDUCTOS DE 8.3 ¢mx 25.4 ¢m (31/,¢, x 10"_

CUNAS DE MADERA

(s61o gabinetes de fondo empotrado)

._., FRENTE DEL GABINETE 1,9 cm I

1

t

LiNEA ORIFICIO DE ACCESO PARA

CENTRAL

LOS CABLES ELI_CTRICOS

(en el fondo del gabinete)

26.7 cm

t

k, 2=1 X_2 cmI_/ II

! T

I • .IOONOOOTOHORIZONTALII

FONDODEL=-i

I 36.4 cm (campana de 762 cm) I- 36.4 cm icamCp_n-a'de 76,2 cm) I 7

I' 43,0 cm (campana de 91,4 cm) T 43.0 cm (campana de 91,4 cm)_l /

60,6cm(campanade1067cm) I 60.6cm(campanade106,7_1)/

TORNILLOS PARA LJNEA PARALOSCABLES

EL MONTAJE DE CENTRAL ELECTRICOS(en la pared)

LA CAMPANA (4)

ORIFICIODEACCESO

El Quite la del conducto redondo de 17.8 de ia

|

I_ Quite la cinta los fiitros Tire hacia

placa

superior de la campana. Col6queia aparte, con los tornillos de

montaje.

FiLTROS

de las lengOetas del filtro y sgtquelos levantgtndolos. Coloque los

que sujeta

filtros a un lado.

en SU

lugar. abajo

cm

(7") parte

Page 9

CAMPANA EXTRACTORA

NuTone

P_gina 9

PREPARACIONDELACAMPANA PREPARACIONDELACAMPANA

[_ Quite el conector

del requlador de

tiro/conector del

interior de la cam-

pan& Ponga aparte

el conector, con los

tornillos de montaje

y la bolsa de piezas.

CONECTOR DEL REGULADOR

DE TIRO/CONDUCTO

Quite la cubierta

El

de la conexi6n

el_ctrica del

interior de la

campana. Ponga

aparte la cubierta

y los tornillos de

montaje.

CUBIERTA DE LA

NEXION ELECTRICA

[_ Quite el agujero

clego para los

cables el6ctricos,

ya sea el superior

o el posterior, e

instale una

para cable el_c-

trico aprobada.

GRAPA DEL CABLE ELECTRICO

Para instalaciones sin conducto, pase a la

secci6n "Conexi6n El_ctrica"

Los siguientes (3)#8TORNILLOS

PANEL DE

ILUMINACION

pasos (del

6 al 13) son

SOLO PARA

INSTALACI=

ONES CON

CON DUCTO.

Quite el panel de iluminaci6n - fijado con (3) #8 tornillos

El y (2) #8 tornillos. Desconecte el juego del arn6s del alam-

bre (conectador blanco).

CONDUCTO

Quite el

El PARA AIRE

ducto para aire

- fijado con un

(1) tornillo.

NOTA: Tenga

cuidado de no

desconectar

ning0n cable.

[_ uite el deflec=

tor del conducto

para aire.

Gire el deflec-

rq

tor. Vuelva

a insertar el

deflector en

el conducto

para aire de

manera (seg0n Io dem-

ostrado) que las aletas

entren totalmente en las

ranuras del conducto

para aire. Un "tecleo"

audible sera oido

cuando esta insta-

lado completamente.

Esto se cerrara del

aire atraviesa las

ranuras sin conduc-

tos encima de la

campana.

El Reinstale el

conducto para

aire, vuelva al

conectar el arn6s del alambre, y

substituya el panel de iluminaci6n.

NOTA: Tenga cuidado de que ninguno ALETA DE APOYO

de los cables quede atrapado entre la aleta de apoyo y el

panel de iluminaci6n.

con =

DEFLECTOR

DEFLECTOR

ALETAS

Page 10

NuTone

CAM PANA EXTRACTO RA

PREPARACIONDELACAMPANA

AGUJERO CIEGO SUPERIOR DEL

CONDUCTO RECTANGULAR

(Quite en el caso de descargas verti-

cales de 8.3 cm x 25.4 cm

(3 ¼"x 10") o de descargas

con conductos

redondos de

17,8 cm (7")

AGUJERO CIEGC

POSTERIOR DEL

CONDUCTO RECTAN-

GULAR

(Quite en el caso de descargas

horizontales de 8.3 cm x 25.4

cm (3 ¼"x 10")

[_ Quite a o a ujeros ciegos para

eJ u'ero los con_uctos

apropiados de la parte superior o de la parte posterior de la

campana.

CINTA POSTERIOR

AJUSTE

LATERAL

HASTA DE

2.5 CM ("

PARA CONDUCTO SEMI-

AGUJERO CIEGO

CIRCULAR

(Quite en el caso de

descargas con conductos

redondos de 17,8 cm (7")

BORDE SUPERIOR/

CONEXION ELECTRICA P_gina 10

ADVERTENCIA: Para reducir el riesgo de descar-

gas el_ctricas, aseg_rese de apagar ei interruptor

de alimentaci6n el_ctrica en el panel de servicio.

Bloquee o rotule el panel de servicio para evitar

que alguien conecte accidentalmente la energia

el_ctrica.

CABLEADO

DOMESTICO

(120 VCA)

CARTON

(Para proteger

la superficie de

la estufa.)

[_ Haga la conexi6n el_ctrica del suministro dom_stico (120

VCA) en la campana. Si es necesario, use un pedazo de

cart6n _para proteger la superficie de la estufa.

3ONECTOR DEL

PIVOTE

S61o para descargas con conductos de 8.3 cm x 25.4 cm (3 1A"

x 10"): Coloque el conectador del regulador de tiro/conducto

sobre la abertura del agujero ciego.Aseg0rese de que el pivote del

regulador de tiro quede Iom&s cerca posible del borde superior/

posterior de la campana. Quite la cinta de la aleta del regulador

de tiro.

S6io para descargas con conducto redondo de 17.8 cm (7"):

El

Vuelva a instalar la piaca del conducto redondo de 17.8 cm

_que quit6 en el paso 1 de la secci6n "PREPARACI6N DE LA

CAMPANPt' Instale un regulador de tiro redondo de 7" (se compra

por separado). La aieta del regulador se debe abrir libremente

en direcci6n del flujo de aire (en sentido contrario a la campana

Para acomodar los conductos descentrados, el conector del

regulador de tiro/conducto se pueden instalar a una distancia

hasta de 2.5 cm (1") desde el centre de la campana hacia

cualquier lade o la placa del conducto redondo de 17.8 cm (7") se pueden

instalar a una distancia hasta de 1.3cm (W') desde el centre de la campana

hacia cualquier lade. En instalaciones exc_ntricas extremas, un extreme del

conector de regulador de conducto puede necesitar set cortado al clare la

REGULADOR DE

TIRO/CONDUCTO

posicidn

de descarga vertical.)

Conecte el cable negro del suministro dom6stico con el cable

negro de la campana, el cable blanco del suministro dom6stico

con el cable blanco de la campana y la conexi6n atierra del

suministro dom_stico debajo del torniilo verde de conexi6n

a tierra. Apriete fijamente una grapa para cable el6ctrico a

cableado dom6stico.

Vuelva a instalar la cubierta de la conexi6n el6ctrica.

El

TORNILL0

DE

C0NEXION

ATIERRA

Page 11

CAMPANA EXTRACTORA

NuTone

P_gina 11

INSTALACION DE LA CAMPANA FILTROS SIN CONDUCTOS

Si la campana se va a instalar en un sistema sin conductos:

Compre un juego de (2) filtros para sistemas sin

conductos en la tienda distribuidora o minorista de su

Iocalidad y sujete a los filtros de malla de alumino.

ORIFICIO

BA-

CALLAVE

(4)

OPERAClON

TORNILLO

DE

MONTAJE

(4)

low fan h_gh _ow light hfgh

Cuelgue lacampana de los (4) orificios de montaj#_ (que se

El

encuentran en la bolsa de piezas). Deslice la campana hacia

la pared hasta que los orificios de montaje queden conectados

en el extremo angosto de los (4) orificios tipo bocallave.

Apriete fijamente los tornillos de montaje.

NO EMPUJE EN LA HOJA DEL VENTILADOR.

El empujar en la aspa del ventilador puede hacerla interferir con

otras piezas de la capilla.

CINTA

PARA

CON-

DUCTOS

[_ Conecte el sistema de conductos en la Use cinta

para conductos para fijar y sellar las uniones.

campana.

FOCO DE

HALOGENO

PAR20,

50W MAX. (2)

- O -

R16, 40W MAX.

BULBOS

INCANDESCENTES

(2)

[_ Instale (2) focos de hal6geno PAR20, de 50W maximo o (2)

R16 bulbos incandescentes del mAximo de 40W. Compre

los bulbos por separado.

Ventilador: El interruptor oscilante de 3 posiciones (de la izquierda)

controla el ventilador. La posici6n hacia la izquierda es lavelocidad

baja, la posici6n central es apagado y la posici6n hacia la derecha

es la velocidad alta. Una luz indicadora se ilumina cuando el ven-

tilador esta encendido.

Luz: El interruptor oscilante de 3 posiciones (de la derecha) controla

las luces. La posici6n de la izquierda es luz de baja intensidad, la

posici6n central es apagado y la posici6n a la derecha es luz de

alta intensidad.

LIMPIEZA

_ ADVERTENCIA: Para reducir el riesgo de una

Filtros de malla de aluminio: Limpie frecuentemente los filtros

con agua caliente y un detergente suave. Los filtros se pueden

lavar en lavaplatos.

Filtros de carb6n: Limpie frecuentemente los filtros con agua ca-

liente y un detergente suave. NO sumerja los filtros en agua ni los

coloque en el lavaplatos. La caracteristica especial "Clean Sense"

(Detecci6n de limpieza) indica cuando se debe reemplazar elfiltro.

Las lineas azules y amarillas se combinaran produciendo un color

verde cuando sea el momento de cambiar el filtro. La caracteristica

"Clean Sense" funciona mejor cuando se coloca orientada hacia la

superficie para cocinar.

Para limpiar la campana: Quite los filtros. Use un paso h_medo y

un detergente suave para limpiar las superficies con grasa. Tenga

cuidado cuando limpie la hoja del ventilador. No se debe doblar ni

desalinear. NO PERMITA LA ENTRADA DEAGUA EN EL MOTOR.

AsegOrese deque todas las superficies est6n completamente secas

antes de volver a colocar los filtros y conectar la energia el6ctrica.

El motor estS.permanentemente lubricado. No lubrique ni desmonte

el motor.

descarga el_ctrica, desconecte el suministro

el_ctrico antes de limpiar la unidad.

_ PRECAUClON: iLos bulbos pueden ser calientes!

[_ Vuelva a colocar los filtros, asegOrese de la hoja de

Refiera a la empaqueta del bulbo para la informaci6n

adicional.

Y que

ventilador gira libremente. Conecte la energia en el panel de

servicio y revise el funcionamiento adecuado de lacampana.

Page 12

NuTone CAMPANA EXTRAOTORASERIE WSl ALLURE TM

P_gina 12

3

Y

7

626976D

PIEZAS DE SERVICIO ,

CLAVENO.

1

2

3

4

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Pidapiezasde repuestodando como referenciael N°. DEPIEZA,no el N°. DECLAVE

* Herrajeest£ndar:se puedecomprar en laferreteriade laIocalidad.

** Noilustrado.

PIEZANO.

R680508

R740013

R602017

R561115

R561116

R561117

R561119

R627518

R627519

R627520

R627533

R627579

R607657

R602534

R602533

R680504

R169016

R169002

R99080535

R401647

R401646

R531075

R99420635

R531075

99010300

99010301

Rl11630

R7201731

R7201751

R7201771

R7201732

R7201752

R7201772

R7201734

R7201754

R7201774

R720174

R720176

R720178

R7201735

R7201755

R7201775

R169004

R169010

Rl11626

99010308

99010309

99010310

Placaparaconducto redondode 17.8cm (incluyeherraje)

Conectorde reguladorde tiro/conducto (incluye herraje)

Tornillo,#8-18 x 1/4 hexagonal*(2 en el paquete)

Interruptor oscilante,color almendra(2 en el paquete)

Interruptor oscilante,color blanco(2 enel paquete)

Interruptor oscilante,color negro(2 en el paquete)

Interruptor oscilante,cer£mica(2 en el paquete)

Placadeidentificaci6n,color blanco

Placadeidentificaci6n,color almendra

Placadeidentificaci6n, inoxidable

Placadeidentificaci6n,cer£mica

Placade identificaci6n,color negro

Lentes

Tomillo, 8-18 x 3/8" (2enel paquete)

Tornillode conexi6na tierra

Cubiertaparala conexi6nel£ctrica(incluyeherraje)

Remache,.125dia.

Juegode resortede filtro

Tornillode montajedel motor (3cada pieza)

Motor (incluyejuego de montajede motor)

Juegode conducto paraaire

(incluyeclavesno. 15y herraje)

Deflector

Hojadelventilador (incluyesujetadorde horquilla)

Sujetadordehorquilla

Juegodefiltros, paracampanasde76.2 cm (2 por bolsa)

Juegodefiltros, paracampanasde91.4 cm (2 por bolsa)

Juegodefiltros, paracampanasde106.7 cm (2 por bolsa)

Cableadopreformadoparael recept£culodel foco

Paneldeiluminaci6n, blanco,para campanasde76.2 cm

Paneldeiluminaci6n, blanco,para campanasde91.4 cm

Paneldeiluminaci6n, blanco,para campanasde 106.7cm

Paneldeiluminaci6n,almendra,paracampanasde76.2 cm

Paneldeiluminaci6n,almendra,paracampanasde91.4 cm

Paneldeiluminaci6n,almendra,paracampanasde106.7cm

Paneldeiluminaci6n, negro,paracampanasde 76.2 cm

Paneldeiluminaci6n, negro,paracampanasde 91.4 cm

Paneldeiluminaci6n, negro,paracampanasde 106.7 cm

Paneldeiluminaci6n,inoxidable,paracampanasde76.2cm

Paneldeiluminaci6n,inoxidable,paracampanasde91.4cm

Paneldeiluminaci6n,inoxidable,paracampanasde106.7cm

PaneldeiluminaciCn,cer£mica,paracampanasde76.2 cm

PaneldeiluminaciCn,cer_mica,paracampanasde91.4 cm

PaneldeiluminaciCn,cer_imica,paracampanasde 106.7cm

Luzindicadora(incluye 2 tuercas dealambresy lentes)

Montajedediodo dela luz (incluyetuercadealambre)

Arn_s dealambres

Juegodefiltros parasin conductos,76.2 cm (2 por bolsa)

Juegodefiltros parasin conductos,91.4 cm (2 por bolsa)

Juegodefiltros parasin conductos, 106.7cm (2 por bolsa)

DESCRIPCION

15

/

14

17 19

GARANTIA

NuTone garantiza al consumidor comprador original de sus productos que di-

chos productos carecera.n de defectos en materiales o en mano de obra por un

3erfodo de un aflo a partir de la fecha original de compra. NO EXISTEN OTRAS

GARANTIAS, EXPLICITAS O IMPLICITAS, INCLUYEND©, PERO NO LIMITADAS

A, GARANTIAS IMPLICITAS DE COMERCIALIZACION O APTITUD PARA UN

PROPOSITO PARTICULAR.

Durante el perfodo de un aflo, y a su propio criterio, NuTone reparar_, o reemplaz-

ara, sin costo alguno cualquier producto o pieza que se encuentre defectuosa

bajo condiciones normales de servicio y uso.

ESTA GARANTIA NO SE APLICA ATUBOS Y ARRANCADORES DE LAMPARAS

FLUORESCENTES. Esta garantfa no cubre (a) mantenimiento y servicio nor-

males o (b) cualquier producto o piezas que hayan sido utilizadas de forma er-

r6nea, negligente, que hayan causado un accidente, o que hayan sido reparadas

o mantenidas inapropiadamente (pot otras compafiias que no sean NuTone),

instalaci6n defectuosa, o instalaci6n contraria alas instrucciones de instalaci6n

recomendadas.

La duraci6n de cualquier garantfa implfcita se limita a un periodo de un aflo como

se especifica en la garantfa expresa.Algunos estados no permiten limitaciones en

cuanto al tiempo de expiraci6n de una garantfa implfcita, por Ioque la limitaci6n

antes mencionada puede no aplicarse a usted.

LA OBLIGACION DE NUTONE DE REPARAR O REEMPLAZAR, SIGUIENDO

EL CRITERI© DE NUTONE, DEBERA SER EL UNICO Y EXCLUSIVO RE-

CURS© LEGAL DEL COMPRADOR BAJO ESTA GARANTIA. BROAN NO

SERA RESPONSABLE POR DAI':,IOS INCIDENTALES, CONSIGUIENTES_O

POR DAI_IOS ESPECIALES QUE SURJAN A RAIZ DEL US© O DESEMPENO

DEL PRODUCTO. Algunos estados no permiten la exclusi6n o limitaci6n de

dafios incidentales o consiguientes, por Io que la limitaci6n antes mencionada

puede no aplicarse a usted.

Esta garantfa le proporciona derechos legales especfficos, y usted puede tam-

bien tener otros derechos, los cuales varfan de estado a estado. Esta garantia

reemplaza todas las garantfas anteriores.

Para calificar en la garantia de servicio, usted debe (a) notificar a NuTone al

domicilio o numero de telefono na abajo, (b) dar el ntimero del modelo y la

identificaci6n de la pieza, y (c) describir la naturaleza de cualquier defecto en el

producto o pieza. En el momento de solicitar servicio cubierto pot la garantfa,

usted debe de presentar evidencia de la fecha original de compra.

NuTone, Inc., 4820 Red Bank Road, Cincinnati, OH 45227 (1-800-543-8687)

3

I

GARANTIA NUTONE LIMITADA POR UN ANO

Loading...

Loading...