Brizo MultiChoice T75P588, MultiChoice T75P Series, MultiChoice T75P688 Installation Instructions & Owner's Manual

Page 1

Write purchased model number here.

®

For easy installation of your Brizo

will need:

• To READ ALL the instructions completely

before beginning.

• To READ ALL warnings,care, and

maintenance information.

faucet you

Pressure Balance

MultiChoice

®

Valve with

Integrated 3 or 6 Function

Diverter Trim

Installation Instructions

Owners Manual

T75P Series

T75P588-▲

T75P688-▲

3/32”

You May Need

Table of Contents:

Warranty ............................................................................. Page 2

Installation Instructions ....................................................... Pages 3 - 7

Maintenance ....................................................................... Page 8

Replacement Parts ............................................................. Pages 10 - 11

CAUTION: This system/device must be set by the

installer to ensure safe, maximum temperature.

Any change in the setting may raise the discharge

temperature above the limit considered safe and

may lead to hot water burns.

NOTICE TO INSTALLER: CAUTION!–As the

installer of this valve, it is your responsibility

to properly INSTALL and ADJUST this valve

per the instructions given. This valve does

not automatically adjust for inlet temperature

changes, therefore, someone must make the

necessary temperature knob adjustments at

the time of installation and further adjustments

may be necessary due to seasonal water

temperature change. YOU MUST inform the

owner/user of this requirement by following the

instructions. If you or the owner/user are unsure

how to properly make these adjustments, please

refer to page 5 & 6 and if still uncertain, call us at

1-877-345-BRIZO (2749).

After installation and adjustment, you must afx

your name, company name and the date you

adjusted the temperature knob to the caution label

provided and apply or attach the label to the back

side of the closest cabinet door and the warning

label to the water heater. Leave this Instruction

Sheet for the owner’s/user’s reference.

WARNING: This thermostatic bath valve is

designed to minimize the effects of outlet water

temperature changes due to inlet pressure and

temperature changes, commonly caused by

dishwashers, washing machines, toilets and

the like. It may not provide protection from hot

water burns when there is a failure of other

temperature controlling devices elsewhere

in the plumbing system, if the temperature

knob is not properly set or if the hot water

temperature is changed after the settings

are made or if the water inlet changes due to

seasonal changes.

WARNING: Do not install a shut-off device on

either outlet of this valve. When this type of

device shuts off the water ow, it can defeat

the ability of the valve to balance the hot and

cold water pressures.

92658 Rev. A

1

02/27/17

Page 2

Parts and Finish

All parts (other than electronic parts and batteries) and finishes of this Brizo

free from defects in material and workmanship for as long as the original consumer purchaser owns the home in which the faucet was first

installed or, for commercial users, for 5 years from the date of purchase.

Electronic Parts and Batteries (if applicable)

Electronic parts (other than batteries), if any, of this Brizo

material and workmanship for 5 years from the date of purchase or, for commercial users, for one year from the date of purchase. No warranty

is provided on batteries.

Brizo Kitchen & Bath Company will replace, FREE OF CHARGE, during the applicable warranty period, any part or finish that proves defective in material and/or workmanship under normal installation, use and service. If repair or replacement is not practical, Brizo Kitchen & Bath

Company may elect to refund the purchase price in exchange for the return of the product. These are your exclusive remedies.

Brizo Kitchen & Bath Company recommends using a professional plumber for all installation and repair. We also recommend that you use only

genuine Brizo

Brizo Kitchen & Bath Company shall not be liable for any damage to the faucet resulting from misuse, abuse, neglect or improper or incorrectly

performed installation, maintenance or repair, including failure to follow the applicable care and cleaning instructions.

Replacement parts may be obtained by calling the applicable number below or by writing to:

In the United States and Mexico: In Canada:

Brizo Kitchen & Bath Company Masco Canada Limited, Plumbing Group

Product Service Technical Service Centre

55 E. 111th Street 350 South Edgeware Road

Indianapolis, IN 46280 St. Thomas, Ontario, Canada N5P 4L1

1-877-345-BRIZO (2749) 1-877-345-BRIZO (2749)

brizosupport@brizo.com customerservice@mascocanada.com

Proof of purchase (original sales receipt) from the original purchaser must be made available to Brizo Kitchen & Bath Company for all warranty

claims unless the purchaser has registered the product with Brizo Kitchen & Bath Company. This warranty applies only to Brizo

factured after January 1, 1995 and installed in the United States of America, Canada and Mexico.

BRIZO KITCHEN & BATH COMPANY SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES

(INCLUDING LABOR CHARGES) FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON THE FAUCET. Some states/provinces do

not allow the exclusion or limitation of special, incidental or consequential damages, so these limitations and exclusions may not apply to you.

This warranty gives you special legal rights. You may also have other rights which vary from state/province to state/province.

This is Brizo Kitchen & Bath Company’s exclusive written warranty and the warranty is not transferable.

If you have any questions or concerns regarding our warranty, please view our Warranty FAQs at www.Brizo.com, email us at brizosupport@brizo.com or

call us at the applicable number above.

®

replacement parts.

Limited Warranty on Brizo

®

faucet are warranted to the original consumer purchaser to be free from defects in

®

Faucets

®

faucet are warranted to the original consumer purchaser to be

®

faucets manu-

© 2017 Masco Corporation of Indiana

Cleaning and Care

Care should be given to the cleaning

of this product. Although its nish is

extremely durable, it can be damaged by

92658 Rev. A

harsh abrasives or polish. To clean, simply

wipe gently with a damp cloth and blot dry

with a soft towel.

2

Page 3

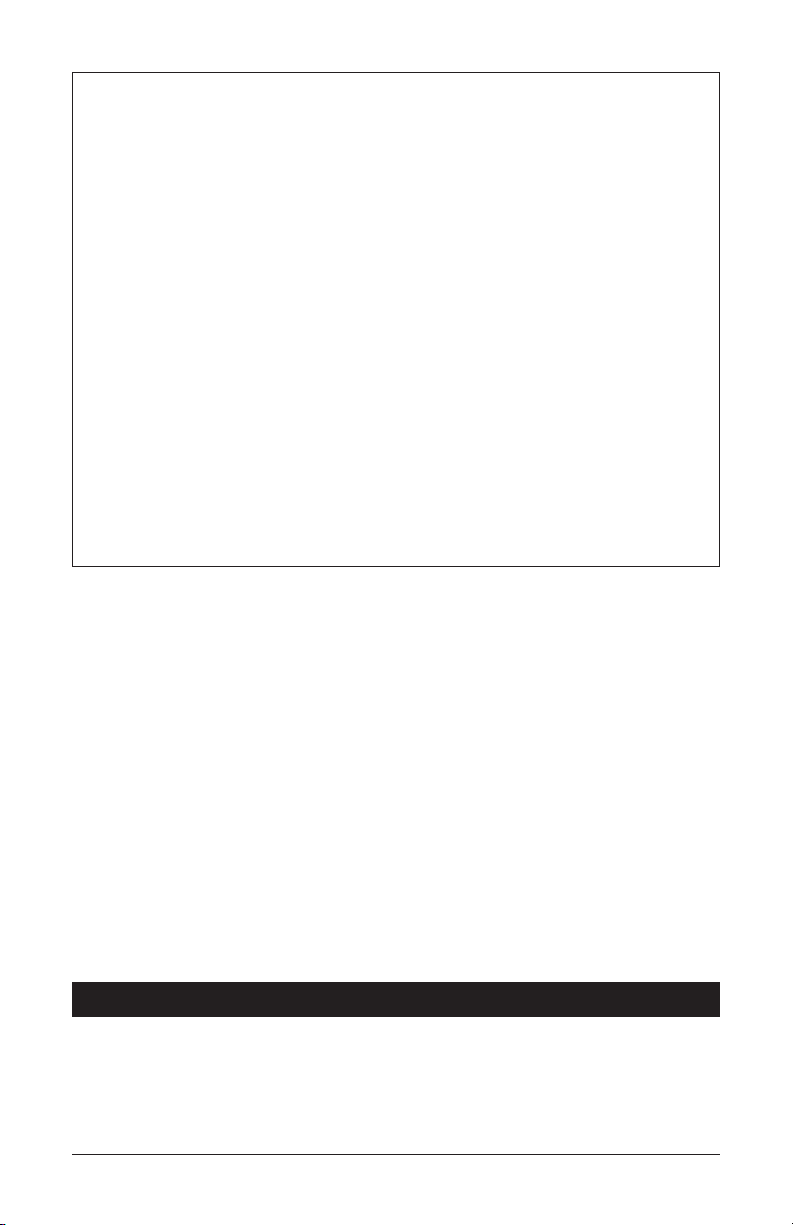

Cartridge Installation

1

T75P Series Installation

A.

4

3

2

1

2

Turn off water supplies.

bonnet nuts (2) and test caps (3) from the roughin body (4) (R75000). Place a bucket or small

container over the front of the valve body and

slowly open the water supplies to flush any

debris from the supply lines before installing the

cartridge. Turn the water supplies back off.

Remove cover (1),

Back to back Installation

Normal Installation

(changes not required)

Reverse

Installation

R75000

3

B.

3

2

4

1

4

Rotate the cartridge (1) so the words “hot side”

(2) appear on the left. Insert cartridge into valve

body as shown. Make sure the cartridge tubes

and O-rings (3) are properly seated in holes at the

base of the body. Ensure the keys on the body are

fully engaged with the slots in the body (4). A light

coating of plumbers grease applied to o-rings may

aid in assembly.

C.

4

Cold

1

3

For back to back or reverse installations (hot on

right and cold on left) insert the cartridge (1) with

the “hot side” on the right. If you are not making

a reverse or back to back installation skip this

step and continue with step 1C. Apply silicone

lube to the three o-rings shown above to make

the cartridge easier to install and remove from the

rough-in body. Install the cartridge making sure

that the keys are fully engaged with the slot in the

rough-in body (see step B). Slide o-ring (3) and

bonnet nut (4) over the cartridge and thread onto

the rough-in body. Hand tighten securely.

Hot

1

2

Thread bonnet nut (2) onto cartridge. Hand tighten

securely. Slide o-ring (1) over the cartridge and

bonnet.

3

92658 Rev. A

Page 4

T75P Series Installation

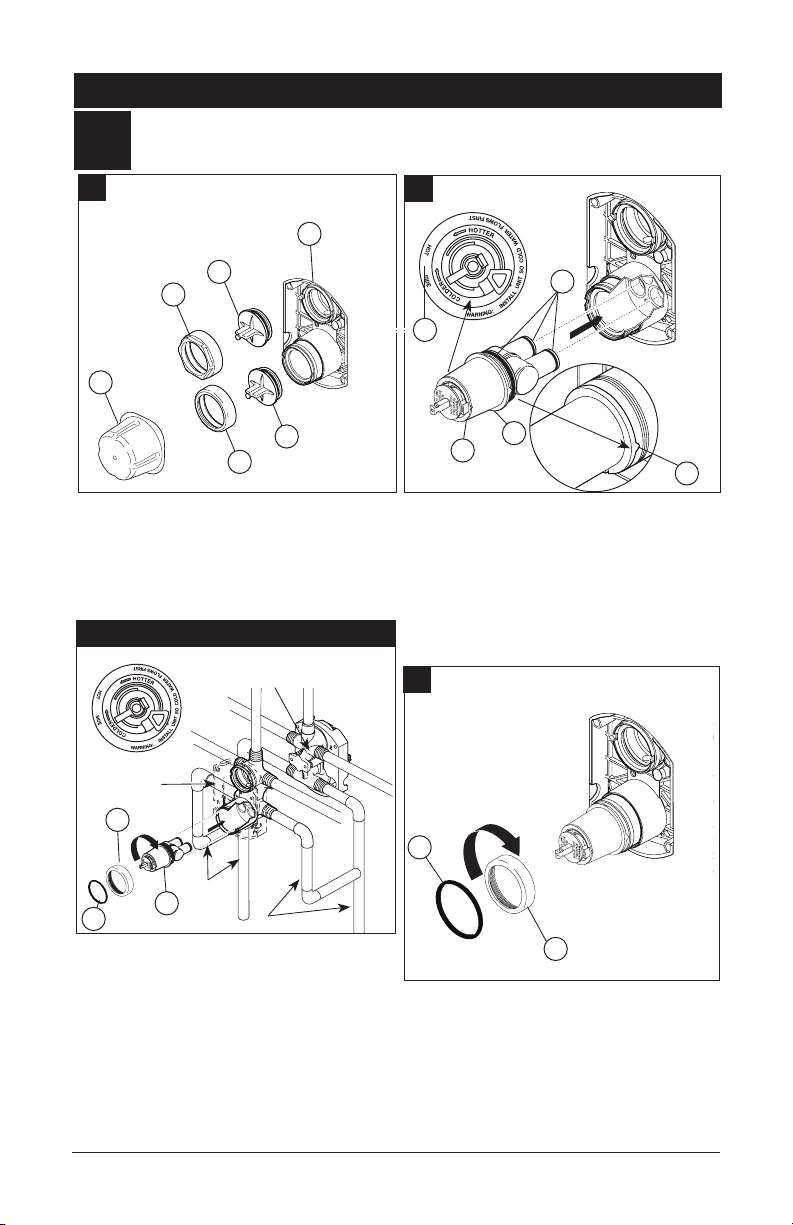

Diverter Cartridge Installation

2

A.

5

2

1

4

3

B.

2

5

FOR DIVERTER CARTRIDGE INSTALLATION:

Apply silicone lube to the o-ring (2) to make

the diverter sleeve (3) easier to install diverter

cartridge. Rotate the diverter cartridge (1) so

the pin is at the bottom for proper installation.

Apply silicone lube to the o-rings (4) to make

the diverter sleeve (3) easier to install diverter

cartridge. Align diverter sleeve so that the

notches are in the same position as the notches

on rough-in body (5).

1

Slip-On Installation

Slide bonnet nut (1) over diverter sleeve (2) and

thread into rough-in body.

Hand tighten securely.

92658 Rev. A

4

Page 5

A.

T75P Series Installation

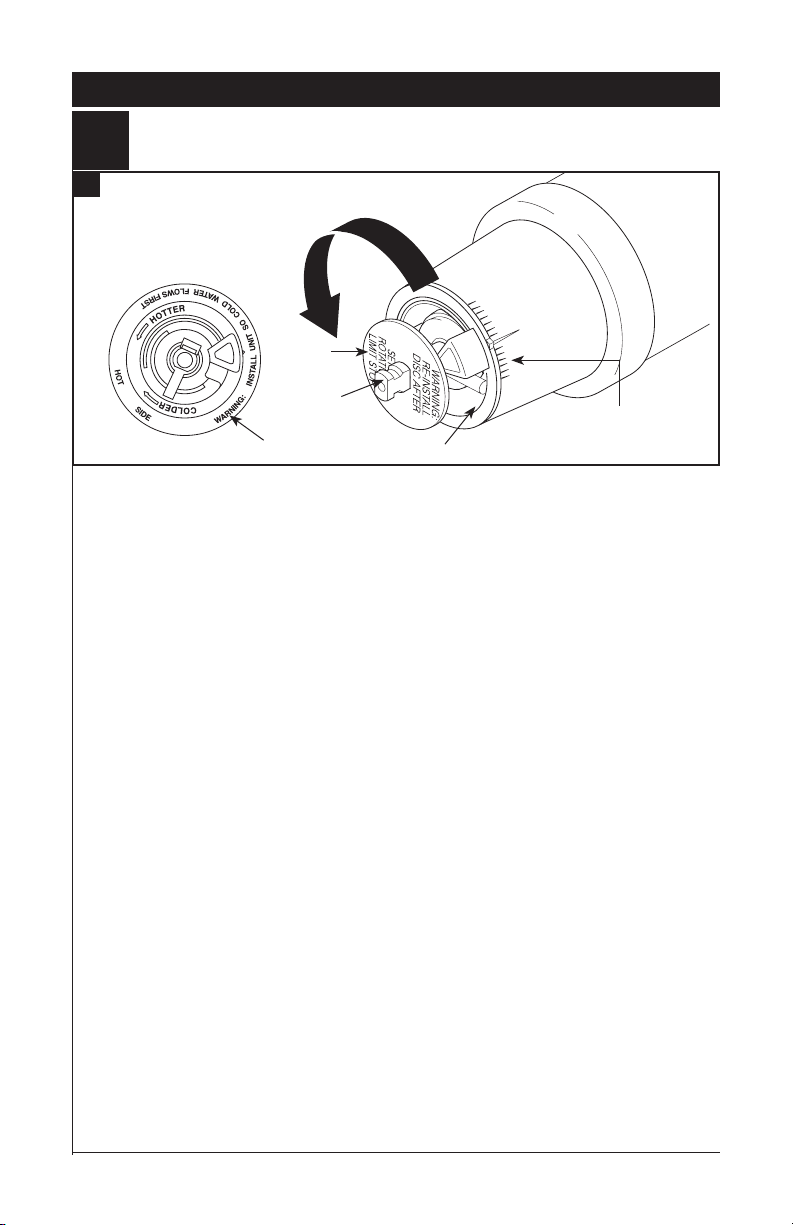

Adjusting the Rotational Limit Stop – Identify RLS type from

pages 5-6.

3

Hotter

Disc

Stem

RLS with removable disc

IMPORTANT:

The Rotational Limit Stop is used to limit the

amount of hot water available such that, if

set properly, the user will not be scalded if

the handle accidentally is rotated all the way

to “hot” when a person is showering or lling

a tub. The rst position allows the LEAST

amount of hot water to mix with the cold water

in the system. In the rst position the water

will be the coldest possible when the handle

is turned all the way to hot. As you move the

Rotational Limit Stop counterclockwise, you

progressively add more and more hot water in

the mix. The last position to the left will result

in the greatest amount of hot water to the mix,

and the greatest risk of scald injury if someone

accidentally turns the valve handle all the way

to the hot side while showering or lling a tub.

WARNING: In some instances, setting the

Rotational Limit Stop in the hottest position

(full counterclockwise) could result in

scald injury. It is necessary to adjust the

Rotational Limit Stop so that the water

coming out of the valve will not scald the

user when the handle of the valve is rotated

to the hot side.

• According to the majority of industry

standards, the maximum allowable temperature

of the water exiting the valve is 120°F (Your

local plumbing codes may require a water

temperature less than 120°F).

• The Rotational Limit Stop may need to

be readjusted seasonally if the inlet water

temperature changes. For example, during the

winter, the cold water temperature is colder

than it is during the summer which could

1st Position

result in varying outlet temperatures. A water

temperature for a comfortable bath or shower

is typically between 90°F - 110°F.

• Run the water so that the cold water is as

cold as it will get and hot water is as hot

as it will get. Place the handle on the stem

(see page 7, step 4D) and rotate the handle

counterclockwise until the handle stops.

• Place a thermometer in a plastic tumbler

and hold in the water stream. If the water

temperature is above 120°F, the Rotational

Limit Stop must be repositioned clockwise to

decrease valve outlet water temperature to be

less than 120°F or to meet the requirements

of your local plumbing codes.

• To adjust the temperature of the water

coming out of the valve, pull the disc back

to a position where it is possible to remove

the Rotational Limit Stop and readjust the

teeth engagement position to the desired

temperature. Clockwise will decrease the

outlet temperature, counterclockwise will

increase the outlet temperature. Temperature

change per tooth (notch) could be 4° - 16°F

based on inlet water conditions. Repeat as

necessary.

Push disc until fully seated.

WARNING: Failure to re-install Disc after

setting Rotational Limit Stop could result

in scald injury.

• MAKE SURE COLD WATER FLOWS FROM

THE VALVE FIRST. MAKE SURE WATER

FLOWING FROM THE VALVE

AT THE HOTTEST FLOW POSSIBLE

DOES NOT EXCEED 120°F OR THE

MAXIMUM ALLOWED BY YOUR LOCAL

PLUMBING CODE.

5

92658 Rev. A

Page 6

T75P Series Installation

B.

1

MÁS CALIENTE

PLUS CHAUD

Hotter

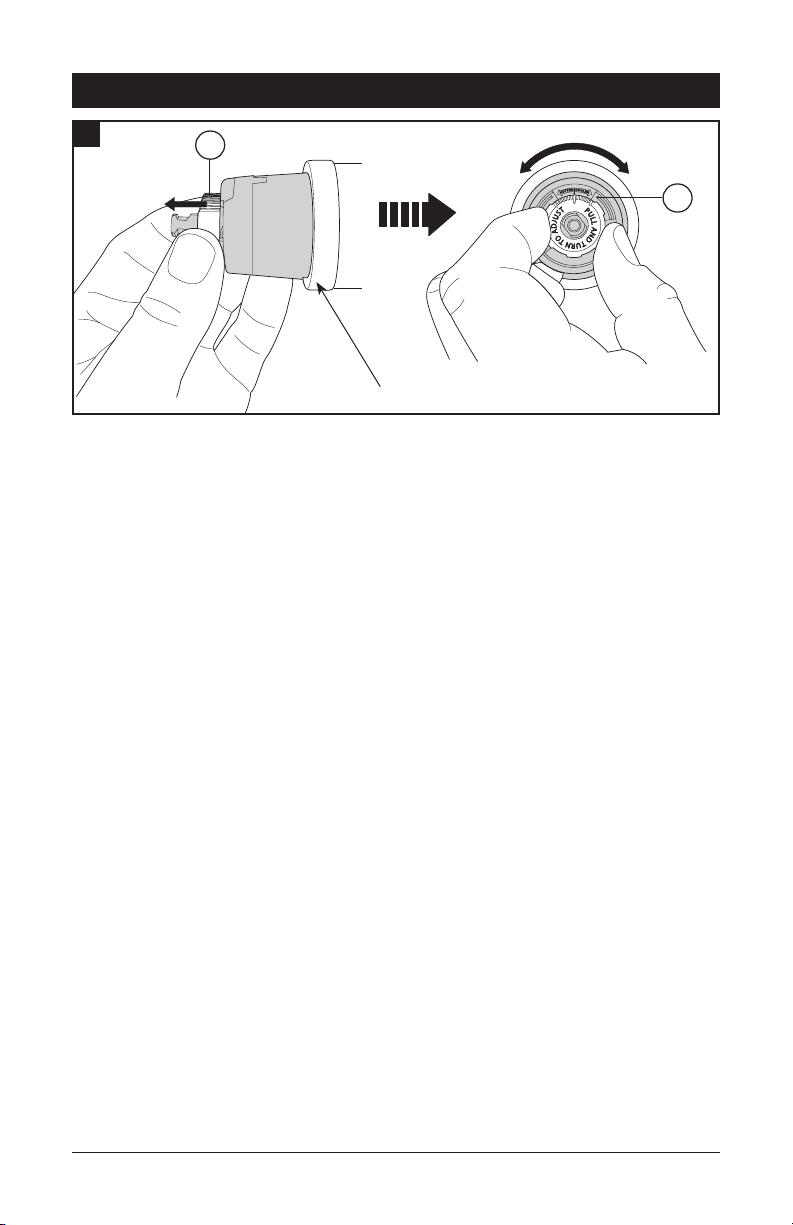

RLS with pull/turn adjustment

ADJUSTING THE ROTATIONAL LIMIT STOP

IMPORTANT: The Rotational Limit Stop

is used to limit the amount of hot water

available such that, if set properly, a scald injury

is less likely to occur if the handle accidentally

is rotated all the way to “hot” when a person

is showering or lling a tub. The rst position

allows the LEAST amount of hot water to

mix with the cold water in the system. In the

rst position the water will be the coldest

possib le when the handle is turned all the way

to hot. As you move the Rotational Limit Stop

counterclockwise, you progressively add more

and more hot water in the mix. The last position

to the left will result in the greatest amount of

hot water to the mix, and the greatest risk of

scald injury if someone accidentally turns the

valve handle all the way to the hot side while

showering or lling a tub.

WARNING: In some instances, setting the

Rotational Limit Stop in the hottest position

(full counterclockwise) could result in scald

injury. It is necessary to adjust the Rotational

Limit Stop so that the water coming out of

the valve will not scald the user when the

handle of the valve is rotated to the hot side.

• According to the majority of industry standards,

the maximum allowable temperature of the

water exiting the valve is 120°F (Your local

plumbing codes may require a water

temperature less than 120°F).

• The Rotational Limit Stop may need to be

re-adjusted seasonally if the inlet water

temperature changes. For example, during the

winter, the cold water temperature is colder

than it is during the summer which could

result in varying outlet temperatures. A water

temperature for a comfortable bath or shower

is typically between 90°F - 110°F.

• Run the water so that the cold water is as

cold as it will get and hot water is as hot as

it will get. Place the handle on the stem (see

page 9, step 4F) and rotate the handle counterclockwise until the handle stops.

• Place a thermometer in a plastic tumbler

and hold in the water stream. If the water

temperature is above 120°F, the Rotational

Limit Stop must be repositioned clockwise to

decrease valve outlet water temperature to be

less than 120°F or to meet the requirements of

your local plumbing codes.

• To adjust the temperature of the water coming

out of the valve, pull the white Rotational

Limit Stop (1) outward and rotate. Clockwise

rotation will decrease the outlet temperature,

counterclockwise rotation will increase the

outlet temperature. Temperature change per

tooth (notch) could be 4° - 16°F based on inlet

water conditions. Repeat as necessary. When

finished, make sure that the Rotational Limit

Stop is fully retracted into the seated position.

WARNING: Do not take the Rotational Limit

Stop apart.

• MAKE SURE COLD WATER FLOWS FROM

THE VALVE FIRST. MAKE SURE WATER

FLOWING FROM THE VALVE AT THE

HOTTEST FLOW POSSIBLE DOES NOT

EXCEED 120°F OR THE MAXIMUM ALLOWED

BY YOUR LOCAL PLUMBING CODE.

HOTTER

COLDER

MÁS FRÍA

PLUS FROID

1

92658 Rev. A

6

Page 7

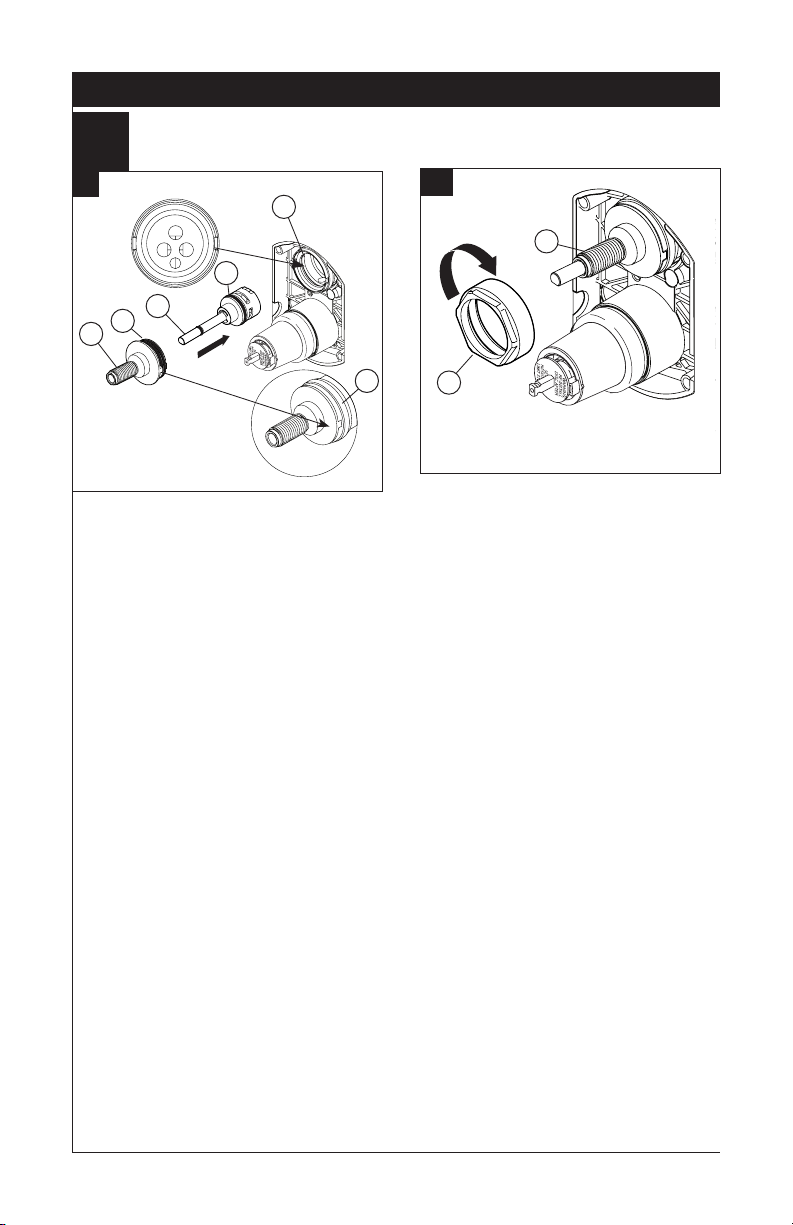

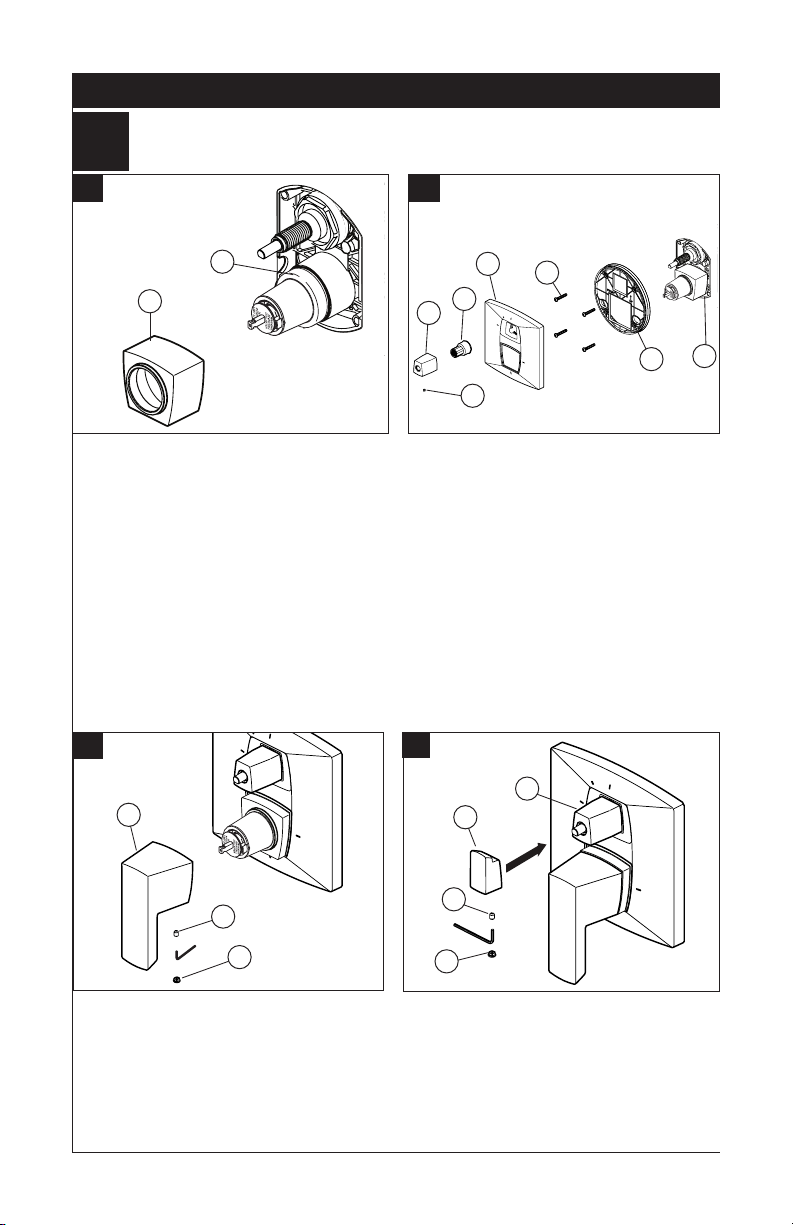

Trim Installation

4

T75P Series Installation

A.

2

1

Trim Sleeve Installation

Slide trim sleeve (1) over cartridge, bonnet (2),

and O-ring. Ensure sleeve is properly positioned

over the cartridge. O-ring will help keep trim

sleeve securely in position.

C.

B.

5

4

6

7

3

2

8

Escutcheon Installation

Secure backplate (2) to rough-in body (3) using 4

screws (4) provided. Ensure backplate is oriented

front side forward.

oriented front side forward and markings are

. If mounting to an uneven surface, apply

visible

appropriate sealant around the backplate to

supplement rubber seal. Align holes in escutcheon

(5) with cartridges and slide escutcheon (5) onto

backplate. Secure escutcheon by threading trim

nut (6) onto diverter sleeve. Do not overtighten.

Slide diverter trim sleeve (7) over trim nut and

secure into position with set screw (8).

thick wall installation, an optional extension

kit is available to accommodate up to 1" of

additional wall thickness. Order RP91024 &

RP92548.

Note: Be sure backplate is

For

D.

9

10

11

Valve Handle Installation

Slide handle (9) over cartridge, aligning at

surfaces inside handle with at surfaces on

side of cartridge. Handle lever should point

downward (6 o'clock) in the off position. Secure

handle with set screw (10) and press button (11)

cover into hole.

2

1

3

4

Diverter Handle Installation

Insert diverter handle (1) onto trim sleeve (2).

Using a allen wrench, insert set screw (3) into

handle (1). Applying pressure, insert set screw

cover (4) until properly seated.

7

92658 Rev. A

Page 8

Potential scald or thermal shock injury could result due to cross ow if outlet at

the shower is blocked or restricted (e.g., pause control on showerhead). Be sure

5

to point showerhead away from you when re-starting ow or install inlet check

valves on both supply lines to prevent possible injury.

T75P Series Maintenance

Faucet leaks from tub spout/showerhead:

SHUT OFF WATER SUPPLIES.

Replace seats and springs–Repair

Kit RP4993. Check condition of lower O-rings

and replace if necessary RP14414. See

Helpful Hints 1, 2, & 3.

If leak persists:

SHUT OFF WATER SUPPLIES.

Replace valve cartridge RP46074.

See Helpful Hints 1, 2, 3 & 5.

Unable to maintain constant

water temperature:

Replace valve cartridge RP46074 or follow

instructions in Helpful Hints 1, 2, 4 & 5.

Helpful Hints:

1. Before removing valve cartridge assembly

for any maintenance, be sure to note the

position of the rotational limit stop on the cap.

The valve cartridge assembly must always be

put back in the same position. BE SAFE! After

you have nished the installation, turn on

valve to make sure COLD WATER FLOWS

FIRST.

2. To remove valve cartridge from body, shut

off water supplies and remove handle and

bonnet nut. Do not pry the valve cartridge

out of the body with a screwdriver. Place

handle on stem and rotate counterclockwise

approximately 1/4 turn after the stop has

been contacted. Lift valve cartridge out of

body.

3. To remove seats and springs, remove

valve cartridge. Separate cap assembly

from the housing assembly by rotating

the cap assembly counterclockwise 90

(degrees). Separate cap and housing

assemblies. Remove seats and springs and

replace. Place the largest diameter of the

spring into the seat pocket rst and then

press the tapered end of the seal over the

spring. Reassemble valve cartridge and

replace in body following instructions given

in 1 above.

4. If the water in your area has lime,

rust, sand or other contaminants in it,

your pressure balance valve will require

periodic inspection. The frequency of the

inspection will depend on the amount of

contaminants in the water. To inspect valve

cartridge remove it and follow the steps in

note 1 above. Turn the valve to the full mix

position and shake the cartridge vigorously.

If there is a rattling sound, the unit is

functional and can be reinstalled following

instructions given in note 1 above. If

there is no rattle, replace valve cartridge

RP46074.

5. Push disc until fully seated. See page 5

for more details.

o

92658 Rev. A

8

Page 9

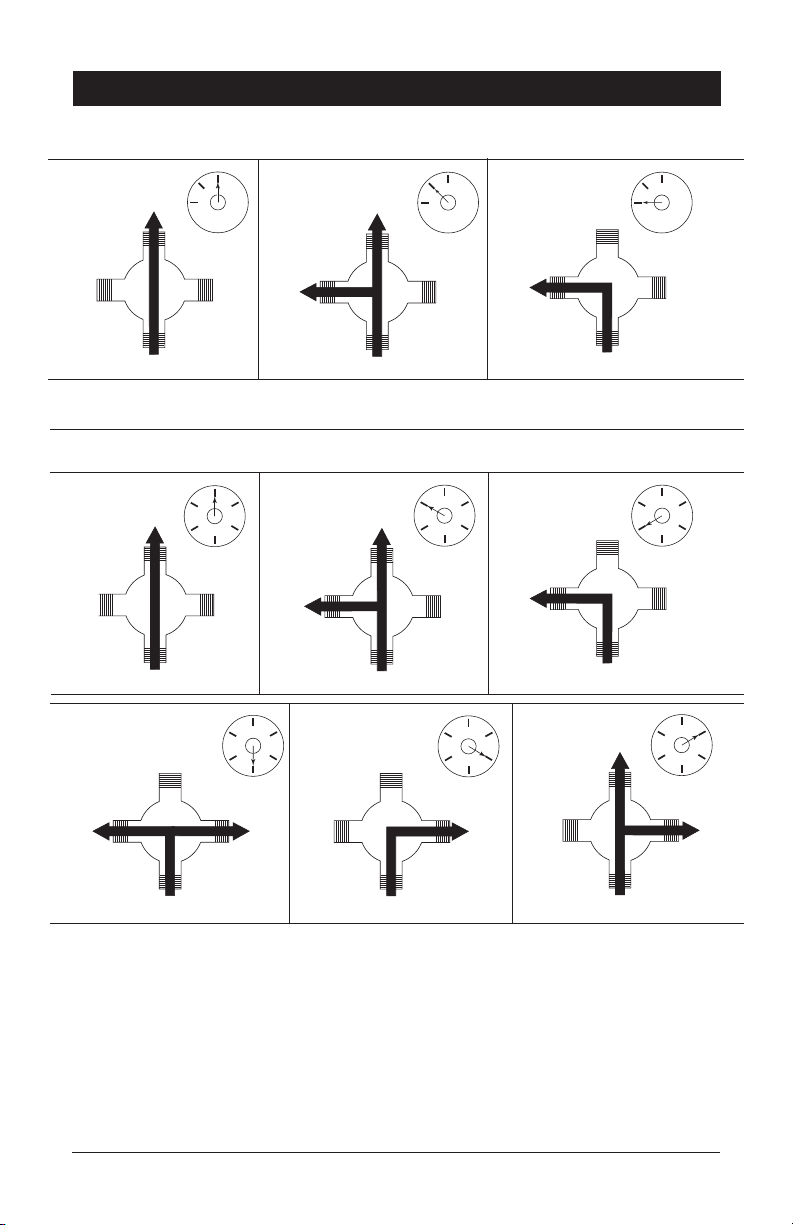

Diverter Handle Reference Sheet

Water Flow For 3 Function Diverter / Flujo de agua para Desviadores de 3 posiciones / Écoulement

de l’eau pour les inverseurs à 3 positions

1st Position

1 ª posición

1ère position

Outlet 1

Salida 1

Sortie 1

2nd Position ✱

2 ª Posición ✱

2e position ✱

Outlet 1

Salida 1

Sortie 1

3rd Position

3 ª posición

3e position

Outlet 1

Salida 1

Sortie 1

Outlet 2

Salida 2

Sortie 2

In / Entrada / Entrée

✱ Shared positions do not exist in non-shared cartridges.

✱ Los ajustes o posiciones compartidas no existen en los cartuchos no-compartidos.

✱ Comme leur nom l’indique, les cartouches sans position partagée ne comportent aucune position partagée.

Water Flow For 6 Function Diverter / Flujo de agua para Desviadores de 6 posiciones / Écoulement

de l’eau pour les inverseurs à 6 positions

1st Position

1 ª posición

1ère position

Outlet 2

Salida 2

Sortie 2

4th Position ✱✱

4 ª posición ✱✱

4e position ✱✱

Outlet 2

Salida 2

Sortie 2

Outlet 1

Salida 1

Sortie 1

In / Entrada / Entrée

Outlet 1

Salida 1

Sortie 1

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

Outlet 2

Salida 2

Sortie 2

Outlet 3

Salida 3

Sortie 3

In / Entrada / Entrée

2nd Position ✱✱

2 ª Posición ✱✱

2e position ✱✱

Outlet 2

Salida 2

Sortie 2

In / Entrada / Entrée In / Entrada / Entrée

5th Position

5 ª posición

5e position

Outlet 2

Salida 2

Sortie 2

Outlet 1

Salida 1

Sortie 1

Outlet 1

Salida 1

Sortie 1

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

Outlet 2

Salida 2

Sortie 2

3rd Position

3 ª posición

3e position

Outlet 2

Salida 2

Sortie 2

Outlet 3

Salida 3

Sortie 3

In / Entrada / Entrée

6th Position ✱✱

6 ª posición ✱✱

6e position ✱✱

Outlet 2

Salida 2

Sortie 2

Outlet 1

Salida 1

Sortie 1

Outlet 1

Salida 1

Sortie 1

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

In / Entrada / Entrée

✱✱ Shared positions do not exist in non-shared cartridges.

✱✱ Los ajustes o posiciones compartidas no existen en los cartuchos no-compartidos.

✱✱ Comme leur nom l’indique, les cartouches sans position partagée ne comportent aucune position partagée.

In / Entrada / Entrée

9

In / Entrada / Entrée

92658 Rev. A

Page 10

92658 Rev. A

Page 11

Escriba el número del modelo comprado.

Para una fácil instalación de su llave de agua/

grifo Brizo® va a necesitar:

• LEER TODAS las instrucciones completamente

antes de comenzar.

• LEER TODAS las advertencias, cuidados, e

información de mantenimiento.

Válvula de presión balanceada

MultiChoice® con con 3 o 6

funciones integradas Manga de

accesorio del desviador

Instrucciones de instalación

El manual para el propietario

Serie T75P

T75P588-▲

T75P688-▲

3/32” & 1/8”

Puede necesitar

Tabla de contenido:

Garantía ........................................................................... Página 2

Instrucciones de instalación ............................................. Páginas 3 - 7

Mantenimiento .................................................................. Página 8

Piezas de repuesto .......................................................... Páginas 10 - 11

ADVERTENCIA: Este sistema/dispositivo debe estar

congurado por el instalador para asegurar una

temperatura máxima segura. Cualquier cambio en el ajuste

puede aumentar la temperatura de descarga por encima del

límite considerado seguro y puede resultar en quemaduras

por agua caliente.

AVISO PARA EL INSTALADOR: ¡ATENCIÓN! Como el

instalador de esta válvula, es su responsabilidad de

INSTALAR y AJUSTAR correctamente esta válvula

según las instrucciones proporcionadas. Esta válvula

no se ajusta automáticamente a los cambios de

temperatura de entrada, por lo tanto, alguien debe

hacer los ajustes necesarios con la perilla de control de

temperatura en el momento de la instalación y ajustes

adicionales pueden ser necesarios debido a cambios

estacionales de la temperatura del agua. USTED DEBE

informar al propietario/ usuario de este requisito

siguiendo las instrucciones. Si usted o el dueño/

consumidor no está seguro de como hacer estos ajustes,

consulte la página 5 y 6 y si aún tiene duda, llámenos al

1-877-345-BRIZO (2749).

Después de la instalación y el ajuste, debe colocar su

nombre, nombre de la empresa y la fecha en que ajustó

la perilla de control de la temperatura a la etiqueta de

precaución proporcionada y aplique o pegue la etiqueta en

02/27/17

la parte trasera de la puerta del armario más cercano y la

etiqueta de advertencia al calentador de agua. Deje esta

hoja de instrucciones para referencia del propietario

/usuario.

ADVERTENCIA: Esta válvula termostática de baño

está diseñada para minimizar los efectos de los

cambios de temperatura del agua de salida debido

a cambios de presión y temperatura, causados

habitualmente por los lavaplatos, las lavadoras, los

inodoros y otros aparatos similares. Puede no ofrecer

protección contra las quemaduras por agua caliente

cuando hay un fallo de otros dispositivos para el

control de temperatura en otras partes del sistema de

plomería, si la perilla para el control de la temperatura

no está congurada correctamente o si se cambia

la temperatura del agua caliente después de realizar

los ajustes o si el agua admisión cambia debido a los

cambios estacionales.

ADVERTENCIA: No instale un dispositivo de cierre

en cualquiera de las tuberías de salida de agua de

esta válvula. Cuando este tipo de dispositivo cierra

el ujo del agua, pueda aminorar el propósito de la

válvula para balancear las presiones del agua caliente

y fría.

1

92658 Rev. A

Page 12

Garantía Limitada de las llaves de agua/grifos Brizo

Piezas y Acabado

Todas las piezas (menos las piezas electrónicas y las pilas) y acabados de esta llave de agua - grifo Brizo® están garantizados al consumidor

comprador original, de estar libres de defectos en materiales y mano de obra durante el tiempo que el comprador original sea dueño de la

casa en la cual la llave de agua fue instalada por primera vez o, para los usuarios comerciales, por cinco (5) años desde la fecha de

compra.

Piezas electrónicas y las baterías/pilas (si aplicable)

Las piezas electrónicas (excepto las baterías), sea el caso, de este grifo Brizo® están garantizadas al consumidor comprador original, de estar

libres de defectos en materiales y mano de obra durante 5 años desde la fecha de compra o, para los usuarios comerciales, durante un año

desde la fecha de compra. La garantía no cubre las baterías.

Brizo Kitchen & Bath Company reparará o reemplazará, SIN COSTO ALGUNO, durante el período de garantía aplicable, cualquier pieza o

acabado que presente defectos en materiales y/o mano de obra bajo instalación, uso y servicio normal. Si la reparación o sustitución no es

práctica, Brizo Kitchen & Bath Company podrá optar reintegrarle el precio de la compra a cambio de la devolución del producto. Estos son

sus únicos recursos.

Brizo Kitchen & Bath Company recomienda que use un plomero profesional para todas las instalaciones y reparación. También recomienda

que utilice sólo piezas de repuesto Brizo®.

Brizo Kitchen & Bath Company no será responsable de cualquier daño a la llave de agua/grifo resultante del uso indebido, abuso, negligencia

o uso inapropiado o instalación realizada de forma incorrecta, mantenimiento o reparación, incluyendo el no seguir las instrucciones de cuidado y limpieza aplicables.

Las piezas de repuesto se pueden obtener llamando al número que figura más abajo o escribiendo a:

En los Estados Unidos y Mexico: En Canadá:

Brizo Kitchen & Bath Company Masco Canada Limited, Plumbing Group

Product Service Technical Service Centre

55 E. 111th Street 350 South Edgeware Road

Indianapolis, IN 46280 St. Thomas, Ontario, Canada N5P 4L1

1-877-345-BRIZO (2749) 1-877-345-BRIZO (2749)

brizosupport@brizo.com customerservice@mascocanada.com

La prueba de compra (recibo original de venta) del comprador original debe ponerse a la disposición de Brizo Kitchen & Bath Company para

todos los reclamos de garantía a menos que el comprador haya registrado el producto con Brizo Kitchen & Bath Company. Esta garantía

se aplica solamente a las llaves de agua/grifos Brizo® fabricadas después de 1 de enero de 1995 e instalados en los Estados Unidos de

América, Canadá y México.

BRIZO KITCHEN & BATH COMPANY NO SERÁ RESPONSABLE POR DAÑOS ESPECIALES, INCIDENTALES O CONSECUENTES

(INCLUYENDO CARGOS DE LABOR) YA SEAN RESULTANTES DEL INCUMPLIMIENTO DE CUALQUIER GARANTÍA EXPRESA O

IMPLÍCITA DE LA LLAVE DE AGUA/GRIFO. Algunos estados/provincias no permiten la exclusión o limitación de daños especiales, incidentales o consecuentes, por lo que estas limitaciones y exclusiones pueden no aplicarle en su caso.

Esta garantía le otorga derechos legales especiales, y usted también puede tener otros derechos que varían de estado/provincia a estado/

provincia.

Esta es la garantía exclusiva por escrito de Brizo Kitchen & Bath Company’s, y la garantía no es transferible.

Si usted tiene alguna pregunta o inquietud acerca de nuestra garantía, por favor vea nuestra sección de Preguntas Frecuentes sobre la garantía www.

Brizo.com, email us at brizosupport@brizo.com.

®

Limpieza y Cuidado

Se debe tener cuidado con la limpieza

de este producto. Aunque su acabado

es extremadamente resistente, puede

92658 Rev. A

© 2017 Masco Corporación of Indiana

ser dañado por abrasivos o pulimentos

ásperos. Para limpiar, simplemente frote

con un paño húmedo y seque con una

toalla suave.

2

Page 13

Instalación del cartucho

1

Instalación de la Series T75P

A.

4

3

2

1

3

2

Cierre los suministros de agua.

tuercas tapas (2) y las tapas de prueba (3) del cuerpo de

la tubería preliminar detrás de la pared (4). Coloque una

cubeta o recipiente pequeño sobre el frente del cuerpo

de la válvula y abra lentamente los suministros de agua

para eliminar cualquier residuo de las líneas de suministro

antes

de instalar el cartucho. Cierre otra vez el agua de

suministro.

Instalación de dorso con dorso.

Instalación

inversa

Quite la tapa (1), las

Instalación normal

(no se requieren cambios)

B.

3

2

4

4

1

Gire el cartucho (1) de modo que las palabras "hot side”

lado caliente (2) aparezcan a la izquierda. Inserte en el

cuerpo de la válvula como se muestra. Asegúrese de que

los tubos del cartucho y las juntas tóricas (3) estén bien

colocadas en los oricios de la base del cuerpo. Asegúrese

de que las muescas del cuerpo estén completamente

acopladas con las ranuras del cuerpo (4). Un ligero

recubrimiento de grasa de plomero aplicado a las juntas

tóricas puede ayudar en el ensamblaje.

C.

4

Fría

1

3

Para instalaciones de dorso con dorso o inversas (caliente

a la derecha y fría a la izquierda) inserte el cartucho (1)

con el lado "caliente" en la derecha. Si no está haciendo

una instalación inversa o dorso con dorso, omita este paso

y continúe con el paso 1C. Aplique lubricante de silicona

a las tres juntas tóricas mostradas arriba para facilitar la

instalación del cartucho y retirar del cuerpo de la tubería

interna o prelimiar. Instale el cartucho asegurándose de

que las muescas estén completamente acopladas con la

ranura en el cuerpo de la tubería interna (Véase el paso

B). Deslice la junta tórica (3) y la tuerca tapa (4) sobre el

cartucho y enrosque en el cuerpo de la tubería interna o

detrás de la pared. Apriete jamente a mano.

Caliente

1

2

Enrosque la tuerca tapa (2) en el cartucho. Apriete a

mano de forma segura. Deslice la junta tórica (1) sobre el

cartucho y el casquete.

3

92658 Rev. A

Page 14

Instalación de la Series T75P

Instalación del cartucho de desvío

2

A.

5

2

1

4

3

5

PARA LA INSTALACIÓN DEL CARTUCHO DE DESVÍO:

Aplique lubricante de silicona a la junta tórica (2) para

facilitar la instalación del cartucho desviador con el

casquillo desviador (3).

Gire el cartucho desviador (1) de manera que el pasador

esté en la parte inferior para su correcta instalación.

Aplique el lubricante de silicona a las juntas tóricas (4)

para facilitar la instalación del cartucho desviador con el

casquillo desviador (3).

Alinee el casquillo desviador de manera que las muescas

están en la misma posición que las muescas en el cuerpo

de la tubería preliminar (5).

B.

2

1

Instalación deslizable

Deslice la tuerca tapa (1) sobre el casquillo desviador (2)

y enrosque en el cuerpo de la tubería preliminar.

Apriete a mano de forma segura.

92658 Rev. A

4

Page 15

A.

Instalación de la Series T75P

El ajuste del tope del límite rotacional – Identique el tipo de RLS de

las páginas 5 y 6.

3

Más caliente

Disco

Espiga

RLS (tope) con disco desmontable

IMPORTANTE:

El tope del límite rotacional se utiliza para limitar la cantidad

de agua caliente disponible de manera que si se ajusta

correctamente, el usuario no se escaldará si la manija se

gira accidentalmente hasta el lado caliente “hot” mientras

que una persona se ducha o se llena la bañera. La primera

posición permite que la cantidad MENOR de agua caliente

se mezcle con el agua fría en el sistema. En la primera

posición el agua es lo más fría posible cuando la manija se

gira completamente hacia el lado caliente.

Al mover el tope del límite rotacional en el sentido contrario

a las agujas del reloj, añade progresivamente más agua

caliente en la mezcla. La última posición a la izquierda

resultará en la mayor cantidad de agua caliente añadida

a la mezcla, y el mayor riesgo de lesión por escaldadura

si alguien accidentalmente gira la manija de la válvula

completamente hacia el lado caliente mientras se ducha o

llena la bañera.

ADVERTENCIA: En algunos casos, el ajuste del tope

del límite rotacional en la posición más caliente (en

sentido contrario a las agujas del reloj) podría provocar

lesiones resusltantes de escaldaduras. Es necesario

ajustar el tope del límite rotacional para que el agua

que sale de la válvula no escalde al usuario cuando la

manija de la válvula se gira hacia el lado caliente.

• Según la mayoría de los estándares de la industria, la

temperatura máxima permitida del agua que sale de la

válvula es 120°F (Sus códigos locales de plomería pueden

requerir una temperatura del agua menor de 120° F).

• Es posible que sea necesario reajustar el tope de límite

rotacional si cambia la temperatura del agua de entrada.

Por ejemplo, durante el invierno, la temperatura del agua

fría es más fría que durante el verano, lo que podría resultar

en temperaturas de salida variables. La temperatura del

agua para un baño o ducha cómoda es típicamente entre

90° F - 110° F.

1ra posición

• Deje que el agua fluya para que el agua fría salga tan

fría como sea posible y el agua caliente salga tan caliente

como sea posible. Coloque la manija en la espiga (vea la

página 7, paso 4D) y gire la manija en sentido contrario a

las agujas del reloj hasta que ya no se pueda girar más.

• Coloque un termómetro en un vaso plástico y

manténgalo bajo el chorro de agua. Si la temperatura

del agua es más de 120°F, el tope del límite rotacional

debe ser reposicionado en el sentido de las agujas del

reloj para disminuir la temperatura del agua de la salida

de la válvula a menos de 120°F o para cumplir con los

requisitos de los códigos locales de plomería.

• Para ajustar la temperatura del agua que sale de la

válvula, hale el disco hacia atrás a una posición en la

que sea posible retirar el tope del límite rotacional y

reajustar la posición de acoplamiento de los dentados

a la temperatura deseada. En el sentido de las agujas

del reloj disminuirá la temperatura de salida, en el

sentido contrario al de las agujas del reloj, aumentará la

temperatura del agua de salida. El cambio de temperatura

por dentado podría ser de 4° - 16° F basado en las

condiciones del agua de entrada. Repita si es necesario.

Empuje el disco hasta que quede totalmente asentado.

ADVERTENCIA: Si no vuelve a instalar el disco

después de ajustar el tope del límite rotacional, podría

producir lesiones por escaldado.

• ASEGÚRESE DE QUE EL AGUA FRÍA FLUYA

PRIMERO DE LA VÁLVULA. ASEGÚRESE DE QUE LA

TEMPERATURA DEL AGUA CALIENTE QUE FLUYE

DE LA VÁLVULA AL MÁXIMO FLUJO CALIENTE

NO EXCEDA 120°F O LA TEMERATURA MÁXIMA

PERMITIDA POR SU CÓDIGO LOCAL DE PLOMERÍA.

5

92658 Rev. A

Page 16

Instalación de la Series T75P

B.

1

MÁS CALIENTE

MÁS FRÍA

MÁS CALIENTE

A.RLS (tope) con ajuste para halar/girar

AJUSTE DEL TOPE DEL LÍMITE ROTACIONAL

IMPORTANTE: El tope del límite rotacional se utiliza

para limitar la cantidad de agua caliente disponible

de modo que, si se ajusta correctamente, es menos

probable que produzca una lesión como resultado

de escaldadura si la manija se gira accidentalmente

hacia el lado “caliente” cuando una persona se está

duchándo o llenando una bañera. La primera posición

permite que la MENOR cantidad de agua caliente se

mezcle con el agua fría en el sistema. En la primera

posición, el agua saldrá lo más fría posible cuando

la manija está completamente abierta. Al mover el

tope del límite rotacional en el sentido contrario a

las agujas del reloj, añade progresivamente más y

más agua caliente en la mezcla. La última posición a

la izquierda resultará en la mayor cantidad de agua

caliente añadida a la mezcla, y el mayor riesgo de

lesión como resultado de escaldadura si alguien

accidentalmente gira la manija de la válvula hasta el

lado caliente mientras se ducha o llena una bañera.

ADVERTENCIA: En algunos casos, el ajuste del tope

del límite rotacional en la posición más caliente

(en sentido contrario a las agujas del reloj) podría

provocar lesiones por escaldadura. Es necesario

ajustar el tope del límite rotacional para que el

agua que sale de la válvula no escalde al usuario

cuando la manija de la válvula se gira hacia el lado

caliente.

• Según la mayoría de los estándares de la industria, la

temperatura máxima permisible del agua que sale de

la válvula es 120°F (Sus códigos locales de plomería

pueden requerir una temperatura del agua menor de

120°F).

• Es posible que sea necesario reajustar el tope del límite

rotacional si la la temperatura del agua de entrada

cambia. Por ejemplo, durante el invierno, la temperatura

del agua fría es más fría que durante el verano, lo que

podría resultar en temperaturas de salida variables. La

temperatura del agua para un baño o ducha cómoda es

típicamente entre 90°F - 110°F.

• Deje que el agua fluya de manera que el agua fría

esté lo más fría posible que pueda estar y la caliente lo

más caliente posible. Coloque la manija en la espiga

(consulte la página 9, paso 4F) y gire la manija en

sentido opuesto a las manijas del reloj – izquierda hasta

que la manija se detenga.

• Coloque un termómetro en un vaso plástico y

manténgalo bajo el chorro de agua. Si la temperatura

del agua es más de 120°F, el tope del límite rotacional

debe ser reposicionado en el sentido de las agujas del

reloj para disminuir la temperatura del agua de la salida

de la válvula a menos de 120°F o para cumplir con los

requisitos de los códigos lcoales de plomería.

• Para ajustar la temperatura del agua que sale de la

válvula, hale el tope del límite rotacional (1) hacia

afuera y gírela. La rotación a la derecha disminuirá

la temperatura de salida, la rotación a la izquierda

incrementará la temperatura salida. El cambio de

temperatura por dentado podría ser de 4° - 16°F

basado en las condiciones del agua de entrada. Repita

si es necesario. Cuando haya terminado, asegúrese

de que el tope del límite rotacional se haya retraído

completamente hacia la posición sentada.

ADVERTENCIA: No desarme el tope de límite de

rotación.

• ASEGÚRESE DE QUE EL AGUA FRÍA FLUYA

PRIMERO DE LA VÁLVULA. ASEGÚRESE DE QUE

EL AGUA QUE FLUYE DE LA VÁLVULA LO MÁS

CALIENTE POSIBLE NO EXCEDA 120°F NI EL MÁXIMO

PERMITIDO POR SU CÓDIGO LOCAL DE PLOMERÍA.

1

92658 Rev. A

6

Page 17

Instalación del accesorio de la válvula

4

Instalación de la Series T75P

A.

2

1

Instalación de la manga de accesorio

Deslice la manga de accesorio (1) sobre el cartucho, el

casquete (2) y la junta tórica. Asegúrese de que la manga

esté colocada correctamente sobre el cartucho. La junta

tórica ayudará a mantener la manga de ajuste en posición

ja.

C.

9

B.

5

6

7

8

Instalación de la chapa de cubierta

Fije la placa trasera (2) al cuerpo de la tubería prelimiar

(3) con los 4 tornillos (4) suministrados. Asegúrese de

que la placa trasera esté orientada hacia adelante.

Nota: Asegúrese de que la placa posterior esté

orientada con el frente hacia delante y las marcas

son visibles.

aplique sellador apropiado alrededor de la placa trasera

para complementar la junta de goma. Alinee los agujeros

en la chapa de cubierta (5) con los cartuchos y deslice

la chapa (5) en la placa trasera. Fijee la chapa de

cubierta roscando la tuerca de ajuste (6) en el manguito

del desviador. No lo apriete demasiado. Deslice el

manguito de accesorio del desviador (7) sobre la tuerca

de ajuste y asegúrelo con el tornillo de jación (8).

la instalación en paredes gruesas, se dispone de

un kit de extensión opcional para acomodar hasta

1" de grosor de pared adicional. Ordene RP91024 y

RP92548.

4

2

Si se monta en una supercie irregular,

Para

D.

2

1

3

10

11

Instalación de la manija de la válvula

Deslice la manija (9) sobre el cartucho, alineando las

supercies planas dentro de la manija con supercies

planas en el lado del cartucho. La palanca de la manija

debe apuntar hacia abajo (6 horas) en la posición

cerrada. Fije la manija con el tornillo de jación (10) y

presione la tapa del botón (11) en el oricio.

3

4

Instalación del desviador de la manija

Inserte la manija del desviador (1) sobre el casquillo del

accesorio (2).

Usando una llave allen, inserte el tornillo de jación (3) en

la manija (1).

Aplicando presión, inserte la tapa del tornillo de ajuste (4)

hasta que esté bien asentada.

7

92658 Rev. A

Page 18

Existe la posibilidad de lesión por escaldadura o de choque térmico resultante de un ujo cruzado en el

caso que la salida de la regadera/ducha está bloqueada o restringida (por ejemplo, pause el control de la

5

cabeza de la regadera/ducha). Asegúrese de apuntar la regadera/ducha alejado de usted cuando vuelva

a iniciar el ujo o instale las válvulas de retención de la entrada en ambas líneas de suministro para evitar

posibles lesiones.

Mantenimiento de la Series T75P

Si el agua se ltra por la llave de agua de la regadera:

CIERRE LOS SUMINISTROS DE AGUA

Reemplace asientos y resortes –Juego de piezas de

repuesto RP4993. Verique el estado de las juntas tóricas

inferiores y, si es necesario, reemplácelas RP14414.

Consulte Sugerencias útiles 1, 2 y 3.

Si la fuga persiste:

CIERRE LOS SUMINISTROS DE AGUA.

Reemplace el cartucho de la válvula RP46074. Consulte

Sugerencias útiles 1, 2, 3 y 5.

Incapaz de mantener constante la temperatura del agua:

Reemplace el cartucho de la válvula RP46074 o siga las

instrucciones en Consejos útiles 1, 2, 4 y 5.

Sugerencias útiles:

1. Antes de retirar el ensamble del cartucho de la válvula

para hacer cualquier mantenimiento, asegúrese de tomar

nota de la posición del tope del límite rotacional en la tapa. El

ensamble del cartucho de la válvula debe siempre colocarse

otra vez en la misma posición. ¡CUIDESE! Después de haber

terminado la instalación, abra la válvula para asegurarse de

que el AGUA FRÍA FLUYE PRIMERO.

2. Para retirar el cartucho de la válvula del cuerpo, cierre

el suministro de agua y retire la manija y la tuerca tapa.

No extraiga el cartucho de la válvula del cuerpo con un

destornillador. Coloque la manija sobre la espiga y gírela

aproximadamente 1/4 de vuelta en sentido contrario a las

agujas del reloj después de haber tropezado al tope del

límite. Levante el cartucho de la válvula hacia afuera del

cuerpo.

3. Para retirar los asientos y resortes, retire el cartucho de

la válvula. Separe el ensamble de la tapa del ensamble

(piezas) del bastidor girando el ensamble de la tapa

90º (grados) en sentido contrario a las agujas del reloj.

Separe los ensambles o piezas, de la tapa y del bastidor.

Retire los asientos y resortes y reemplácelos. Primero

coloque el diámetro más grande del resorte en el lugar

del asiento y luego presione el extremo cónico del sello

sobre el resorte. Vuelva a montar el cartucho de la válvula

y cambie el cuerpo siguiendo las instrucciones indicadas

en el punto 1.

4. Si el agua de su área tiene cal, óxido, arena u otros

contaminantes, la válvula para balancear la presión

requerirá inspección periódica. La frecuencia de la

inspección dependerá de la cantidad de contaminantes

en el agua. Para inspeccionar el cartucho de la válvula,

extráigalo y siga los pasos en la Nota 1 anterior. Gire

la válvula a la posición de mezcla completa y agite el

cartucho vigorosamente. Si hay un sonido de traqueteo,

la unidad es funcional y puede volver a instalarla

siguiendo las instrucciones dadas en la nota 1 anterior.

Si no escucha traqueteo, reemplace el cartucho de la

válvula RP46074.

5. Empuje el disco hasta que quede completamente

asentado. Para más detalles, vea la página 5.

92658 Rev. A

8

Page 19

Hoja de referencia para la manija desviadora

Water Flow For 3 Function Diverter / Flujo de agua para Desviadores de 3 posiciones / Écoulement

de l’eau pour les inverseurs à 3 positions

1st Position

1 ª posición

1ère position

Outlet 1

Salida 1

Sortie 1

2nd Position ✱

2 ª Posición ✱

2e position ✱

Outlet 1

Salida 1

Sortie 1

3rd Position

3 ª posición

3e position

Outlet 1

Salida 1

Sortie 1

Outlet 2

Salida 2

Sortie 2

In / Entrada / Entrée

✱ Shared positions do not exist in non-shared cartridges.

✱ Los ajustes o posiciones compartidas no existen en los cartuchos no-compartidos.

✱ Comme leur nom l’indique, les cartouches sans position partagée ne comportent aucune position partagée.

Water Flow For 6 Function Diverter / Flujo de agua para Desviadores de 6 posiciones / Écoulement

de l’eau pour les inverseurs à 6 positions

1st Position

1 ª posición

1ère position

Outlet 2

Salida 2

Sortie 2

4th Position ✱✱

4 ª posición ✱✱

4e position ✱✱

Outlet 2

Salida 2

Sortie 2

Outlet 1

Salida 1

Sortie 1

In / Entrada / Entrée

Outlet 1

Salida 1

Sortie 1

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

Outlet 2

Salida 2

Sortie 2

Outlet 3

Salida 3

Sortie 3

In / Entrada / Entrée

2nd Position ✱✱

2 ª Posición ✱✱

2e position ✱✱

Outlet 2

Salida 2

Sortie 2

In / Entrada / Entrée In / Entrada / Entrée

5th Position

5 ª posición

5e position

Outlet 2

Salida 2

Sortie 2

Outlet 1

Salida 1

Sortie 1

Outlet 1

Salida 1

Sortie 1

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

Outlet 2

Salida 2

Sortie 2

3rd Position

3 ª posición

3e position

Outlet 2

Salida 2

Sortie 2

Outlet 3

Salida 3

Sortie 3

In / Entrada / Entrée

6th Position ✱✱

6 ª posición ✱✱

6e position ✱✱

Outlet 2

Salida 2

Sortie 2

Outlet 1

Salida 1

Sortie 1

Outlet 1

Salida 1

Sortie 1

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

Outlet 3

Salida 3

Sortie 3

In / Entrada / Entrée

✱✱ Shared positions do not exist in non-shared cartridges.

✱✱ Los ajustes o posiciones compartidas no existen en los cartuchos no-compartidos.

✱✱ Comme leur nom l’indique, les cartouches sans position partagée ne comportent aucune position partagée.

In / Entrada / Entrée

9

In / Entrada / Entrée

92658 Rev. A

Page 20

92658 Rev. A

Page 21

Instructions d’installation des

éléments de finition de la soupape

®

MultiChoice

à pression autorégularisée avec inverseur intégré

à 3 ou 6 fonctions

Manuel d’utilisation

Série T75P

Inscrivez le numéro du modèle acheté ici

Pour installer votre robinet Brizo® facilement,

vous devez:

• LIRE TOUTES les instructions complètement

avant de débuter.

• LIRE TOUS les avertissements ainsi que toutes

les instructions de nettoyage et d’entretien.

Ce dont vous pouvez avoir besoin

Table des matières:

Garantie ........................................................................... Página 2

Instructions d’installation .................................................. Páginas 3 - 7

Maintenance ..................................................................... Página 8

.

Pièces de rechange ........................................................ Páginas 10 - 11

T75P588-▲

T75P688-▲

ATTENTION: Ce système ou cet appareil doit être réglé

par l’installateur pour que sa température maximale soit

sans danger. Tout changement du réglage peut entraîner

une hausse de température au delà de la limite considérée

sécuritaire et occasionner l’ébouillantage.

AVIS À L’INSTALLATEUR: ATTENTION! - En qualité

d’installateur de cette soupape, vous avez la

responsabilité de L’INSTALLER et de la RÉGLER

correctement selon les instructions fournies. Cette

soupape ne s’adapte pas automatiquement aux

uctuations de la température de l’eau d’alimentation.

Par conséquent, il faut régler le bouton de température

maximale au moment de l’installation et il peut être

nécessaire de faire de nouveaux réglages par la

suite en raison des uctuations saisonnières de

la température de l’eau. VOUS DEVEZ informer le

propriétaire ou l’utilisateur de cette exigence. En cas de

doute quant à la marche à suivre pour faire ces réglages,

veuillez consulter la page 5 et 6 Si vous avez encore des

doutes, veuillez appeler au 1-877-345-BRIZO (2749).

Après avoir terminé l’installation et le réglage, vous devez

inscrire, sur l’étiquette de mise en garde fournie, votre nom,

le nom de votre entreprise et la date à laquelle vous avez

réglé le bouton de température maximale, puis xer

02/27/17

l’étiquette à l’endos de la porte de la coiffeuse. Vous

devez également xer l’étiquette d’avertissement au

chauffe-eau. Veuillez laisser ce feuillet d’instructions

au propriétaire ou à l’utilisateur pour qu’il puisse le

consulter au besoin.

MISE EN GARDE: Ce robinet thermostatique à

équilibrage de pression pour baignoire est conçu

pour limiter les effets des uctuations de température

de l’eau causées par les variations de la pression

d’alimentation attribuables au fonctionnement d’un

lave-vaisselle, d’une machine à laver, d’un cabinet

d’aisances ou d’un autre appareil qui consomme

de l’eau. Il peut ne pas protéger l’utilisateur contre

l’échaudage en cas de défectuosité d’un autre

dispositif de régulation de la température, de réglage

erroné du bouton de température maximale, de

modication de la température de l’eau chaude après

le réglage du bouton de température maximal ou de

uctuation saisonnière de la température de l’eau

d’alimentation.

MISE EN GARDE: N’installez pas de dispositif d’arrêt

sur une sortie quelconque de cette soupape. En

interrompant l’écoulement de l’eau, ce dispositif peut

empêcher la soupape d’équilibrer les pressions d’eau

chaude et d’eau froide.

1

92658 Rev. A

Page 22

Pièces et finis

Toutes les pièces et tous les finis de ce robinet Brizo® sont protégés contre les défectuosités du matériau et les vices de fabrication par

une garantie qui est consentie au premier acheteur et qui demeure valide tant que celui-ci demeure propriétaire de la maison dans laquelle

l’accessoire a été installé. Dans le cas d’une utilisation commerciale, la garantie est de 5 ans à compter de la date d’achat.

Composants électroniques et piles (le cas échéant)

Si ce robinet Brizo® comporte des composants électroniques, ces composants (à l’exception des piles) sont protégés contre les défectuosités

du matériau et les vices de fabrication par une garantie consentie au premier acheteur qui est d’une durée de 5 ans à compter de la date

d’achat. Dans le cas d’une utilisation commerciale, la garantie est d’un an à compter de la date d’achat. Aucune garantie ne couvre les piles.

Pendant la période de garantie applicable, Brizo Kitchen & Bath Company réparera ou remplacera GRATUITEMENT toute pièce qui présen-

tera une défectuosité de matériau et/ou un vice de fabrication pour autant que le produit ait été installé, utilisé et entretenu normalement. S’il

est impossible de réparer ou de remplacer le produit, Brizo Kitchen & Bath Company pourra rembourser le prix d’achat en échange du produit

retourné. Il s’agit de vos seuls recours.

Brizo Kitchen & Bath Company recommande de confier l’installation et la réparation à un plombier professionnel. Nous vous recommandons

également d’utiliser uniquement des pièces de rechange d’origine Brizo®.

Brizo Kitchen & Bath Company se dégage de toute responsabilité à l’égard de toute détérioration du produit résultant d’une usure raisonnable

et des dommages causés par un mauvais usage, un usage abusif, la négligence ou l’utilisation d’une méthode d’installation, de maintenance

ou de réparation incorrecte ou inadéquate, y compris les dommages résultant du non-respect des instructions de nettoyage et d’entretien

applicables.

Vous pouvez obtenir des pièces de rechange en appelant au numéro de téléphone ci-dessous ou en écrivant à:

Aux États-Unis et au Mexique: Au Canada:

Brizo Kitchen & Bath Company Masco Canada Limited, Groupe plomberie

Product Service Centre de services techniques

55 E. 111th Street 350 South Edgeware Road

Indianapolis, IN 46280 St. Thomas, Ontario, Canada N5P 4L1

1-877-345-BRIZO (2749) 1-877-345-BRIZO (2749)

brizosupport@brizo.com customerservice@mascocanada.com

La preuve d’achat (reçu original) du premier acheteur doit être présentée à Brizo Kitchen & Bath Company pour toutes les demandes en vertu

de la garantie, sauf si le produit a été enregistré auprès de Brizo Kitchen & Bath Company. La présente garantie s’applique uniquement aux

accessoires Brizo® installés aux États-Unis d’Amérique, au Canada et au Mexique.

BRIZO KITCHEN & BATH COMPANY SE DÉGAGE DE TOUTE RESPONSABILITÉ À L’ÉGARD DES DOMMAGES PARTICULIERS,

CONSÉCUTIFS ET INDIRECTS (Y COMPRIS LES FRAIS DE MAIN-D’ŒUVRE ) QUI DÉCOULENT D’UNE RUPTURE D’UNE GARANTIE

IMPLICITE OU EXPLICITE DU ROBINET. Dans les États ou les provinces où il est interdit d’exclure ou de limiter les dommages particuliers,

consécutifs ou indirects, les exclusions ou les limites susmentionnées ne s’appliquent pas. La présente garantie vous procure des droits particuliers reconnus par la loi. Vous pouvez avoir d’autres droits qui varient selon l’État ou la province.

La présente garantie écrite est la seule garantie offerte par Brizo Kitchen & Bath Company et elle n’est pas transférable.

Si vous avez des questions ou des préoccupations en ce qui concerne notre garantie, veuillez consulter la page Warranty FAQs à www.Brizo.com, nous

faire parvenir un courriel à brizosupport@brizo.com ou nous appeler au numéro applicable.

Garantie limitée sur les robinets Brizo

®

Nettoyage et entretien

Ce produit doit être nettoyé avec soin.

Bien que le ni soit extrêmement durable,

il peut être abîmé par des agents de

polissage puissants ou des nettoyants

92658 Rev. A

© 2017 Division de Masco Indiana

fortement abrasifs.

Pour le nettoyer, il suft de le frotter

doucement avec un chiffon humide, puis

de l’éponger avec une serviette douce.

2

Page 23

Installation de la cartouche

1

Instructions d’installation - série T75P

A.

4

3

2

1

3

2

Fermez les robinets d’alimentation.

(1), les écrous-chapeaux (2) et les capuchons d'essai (3)

du corps de robinetterie brute (4). Placez un seau ou un

petit contenant sur l’avant du corps de soupape et ouvrez

lentement les robinets d’arrêt pour évacuer les corps

étrangers de la tuyauterie avant d’installer la cartouche.

Fermez de nouveau les robinets d’arrêt.

Installation dos à dos

Installation normale

(aucun changement requis)

Installation

inversée

Retirez le capuchon

B.

3

2

4

1

4

Tournez la cartouche (1) de manière que l’inscription «

Hot Side » (2) se trouve du côté gauche. Introduisez la

cartouche dans le corps de soupape comme le montre la

gure. Assurez-vous que les tubes et les joints toriques de

la cartouche (3) sont bien calés dans les trous dans la base

du corps. Assurez-vous que les ergots qui se trouvent sur

le corps de soupape sont introduits à fond dans les rainures

du corps (4). Vous pouvez enduire les joints toriques d’un

peu de graisse de plomberie pour faciliter l’assemblage.

C.

4

Froid

1

3

Dans le cas d’une installation dos à dos ou inversée (eau

chaude à droite et eau froide à gauche), introduisez la

cartouche (1) de manière que l’inscription « Hot Side » se

trouve du côté droit. Si vous n’installez pas la soupape de

cette manière, passez à l’étape 1C. Ajoutez du lubriant à

base de silicone aux trois joints toriques montrés ci-dessus

pour faciliter la pose de la cartouche dans le corps de

robinetterie brute et sa dépose.

Installez la cartouche en prenant soin d’introduire les ergots

entièrement dans les rainures du corps de robinetterie

brute (reportez-vous à l’étape B). Glissez le joint torique (3)

et l'écrou-chapeau (4) sur la cartouche et vissez-le sur le

corps de robinetterie brute. Serrez-le à la main solidement.

Chaud

1

2

Vissez l'écrou-chapeau (2) sur la cartouche. Serrez à la

main solidement. Glissez le joint torique (1) sur la cartouche

et le chapeau.

3

92658 Rev. A

Page 24

Instructions d’installation - série T75P

Installation de la cartouche de l'inverseur

2

A.

5

2

1

4

3

B.

2

5

INSTALLATION DE LA CARTOUCHE DE L'INVERSEUR

Ajoutez du lubrifiant à base de silicone au joint torique

(2) pour faciliter la pose du manchon de l'inverseur (3)

et la cartouche de l’inverseur. Vous pouvez enduire les

joints toriques (4) d’un peu de graisse de plomberie

pour faciliter l’assemblage.Tournez la cartouche de

l'inverseur (1) en prenant soin de faire correspondre

l'ergot de détrompage au bas de la cartouche avec le

trou dans le corps de robinet brut.Ajoutez du lubriant à

base de silicone aux joints toriques (4) pour faciliter la

pose du manchon de l'inverseur (3) dans la cartouche de

l'inverseur. Installez le manchon de l'inverseur en prenant

soin de faire correspondre les encoches avec les rainures

dans le corps de robinetterie brute (5)

1

Installation de l’écrou-chapeau

Glissez l'écrou-chapeau (1) sur le manchon de

l'inverseur (2) et vissez-le sur le corps de robinetterie

brute.

Serrez-le à la main solidement.

92658 Rev. A

4

Page 25

A.

Instructions d’installation - série T75P

Réglage de la butée de température maximale (BTM) – Déterminer le

type de BTM en consultant les pages 5 et 6.

3

Plus chaud

Disque

Tige

BTM avec disque amovible

IMPORTANT:

La butée de température maximale sert à limiter la quantité

d’eau très chaude disponible. Ainsi, pour autant qu’elle soit

réglée correctement, la personne qui utilise la douche ou

la baignoire ne sera pas ébouillantée si elle ou quelqu’un

d’autre tourne la manette jusqu’à l’extrémité de la plage

d’eau chaude par inadvertance. La première position est

celle qui laisse passer le MOINS d’eau très chaude dans le

mélange. Si la butée de température maximale est réglée à

la première position, l’eau est aussi froide qu’elle peut l’être

lorsque vous tournez la manette jusqu’à l’extrémité de la

plage d’eau chaude. À mesure que vous déplacez la butée

de température maximale dans le sens inverse à celui des

aiguilles d’une montre, vous obtenez de plus en plus d’eau

très chaude dans le mélange. La dernière position est celle

qui laisse passer le plus d’eau très chaude dans le mélange

et celle qui présente le plus grand risque d’ébouillantage

si la personne qui utilise la douche ou la baignoire ou

quelqu’un d’autre tourne la manette jusqu’à l’extrémité de la

plage d’eau chaude par inadvertance.

AVERTISSEMENT : Dans certaines circonstances,

le fait de régler la butée de température maximale à

la position la plus chaude (position extrême dans le

sens inverse à celui des aiguilles d’une montre) peut

occasionner l’ébouillantage. Il est essentiel de régler

la butée de température maximale de manière que

l’eau qui s’écoule du robinet ne puisse ébouillanter

l’utilisateur lorsque lui ou quelqu’un d’autre tourne la

manette du robinet jusqu’à l’extrémité de la plage d’eau

chaude.

• Selon la majorité des normes de l’industrie, la température

maximale de l’eau s’écoulant du robinet ne doit pas

dépasser 120 °F (49 °C) (le code de plomberie de votre

région peut exiger une température inférieure à 120 °F).

• La butée de température maximale peut devoir être réglée

de nouveau si la température de l’eau d’alimentation varie

selon les saisons. À titre d’exemple, pendant l’hiver, la

température de l’eau froide est plus basse que pendant

l’été, ce qui peut influer sur la température de l’eau à la

sortie du robinet. La température de l’eau pour un bain ou

une douche confortable se situe généralement entre 90 °F

et 110 °F (32 °C – 43 °C).

1re Position

• Laissez couler l’eau froide jusqu’à ce qu’elle soit aussi

froide que possible et faites la même chose pour l’eau

chaude. Placez la manette sur la tige (voir page 7, étape

4D) et tournez-la dans le sens inverse à celui des aiguilles

d’une montre jusqu’à ce qu’elle s’arrête.

• Placez un thermomètre dans un gobelet en plastique

et tenez le gobelet sous le jet d’eau. Si la température

de l’eau est supérieure à 120 °F (49 °C), vous devez

déplacer la butée de température maximale dans les sens

des aiguilles d’une montre pour abaisser la température

de l’eau qui s’écoule du robinet. La température doit être

inférieure à 120 °F ou elle doit satisfaire aux exigences du

code de plomberie de votre région.

• Pour régler la température de l’eau qui sort du robinet,

tirez sur le disque jusqu’à ce que vous puissiez enlever

la butée de température maximale et modifier sa position

pour obtenir la température désirée. Tournez la butée

dans le sens des aiguilles d’une montre pour diminuer

la température de l’eau à la sortie du robinet et dans

le sens inverse à celui des aiguilles d’une montre pour

accroître la température. Le changement de température

par dent (cran) est de 4 °F à 16 °F (2 °C – 9 °C) selon la

température de l’eau d’alimentation. Répétez la procédure

au besoin. Une fois que vous avez terminé, poussez le

disque jusqu’à ce qu’il soit bien calé et remettez le joint

torique en place.

AVERTISSEMENT : Le robinet pourrait causer

l’ébouillantage si le disque n’est pas remis à sa place

après que la butée de température maximale a été

réglée

• ASSUREZ-VOUS QUE DE L’EAU FROIDE S’ÉCOULE

DU ROBINET EN PREMIER. ASSUREZ-VOUS QUE

LA TEMPÉRATURE DE L’EAU LA PLUS CHAUDE

POSSIBLE QUI S’ÉCOULE DU ROBINET NE

DÉPASSE PAS 120 °F (49 °C) OU LE MAXIMUM

AUTORISÉ PAR LE CODE DE PLOMBERIE DE VOTRE

RÉGION.

5

92658 Rev. A

Page 26

Instructions d’installation - série T75P

B.

1

PLUS CHAUD

PLUS CHAUD

Molette de réglage « tirer-tourner » de la

butée de température maximale (BTM)

AJUSTEMENT DE LA BUTÉE DE TEMPÉRATURE MAXIMALE

IMPORTANT: La butée de température maximale sert

à limiter la quantité d’eau très chaude disponible.

Ainsi, pour autant qu’elle soit réglée correctement, la

personne qui utilise la douche ou la baignoire ne sera

pas ébouillantée si elle ou quelqu’un d’autre tourne la

manette jusqu’à l’extrémité de la plage d’eau chaude

par inadvertance. La première position est celle qui

laisse passer le MOINS d’eau très chaude dans le

mélange. Si la butée de température maximale est

réglée à la première position, l’eau est aussi froide

qu’elle peut l’être lorsque vous tournez la manette

jusqu’à l’extrémité de la plage d’eau chaude. À mesure

que vous déplacez la butée de température maximale

dans le sens inverse à celui des aiguilles d’une montre,

vous obtenez de plus en plus d’eau très chaude dans

le mélange. La dernière position est celle qui laisse

passer le plus d’eau très chaude dans le mélange et

celle qui présente le plus grand risque d’ébouillantage

si la personne qui utilise la douche ou la baignoire ou

quelqu’un d’autre tourne la manette jusqu’à l’extrémité

de la plage d’eau chaude par inadvertance.

AVERTISSEMENT : Dans certaines circonstances,

le fait de régler la butée de température maximale à

la position la plus chaude (position extrême dans le

sens inverse à celui des aiguilles d’une montre) peut

occasionner l’ébouillantage. Il est essentiel de régler

la butée de température maximale de manière que

l’eau qui s’écoule du robinet ne puisse ébouillanter

l’utilisateur lorsque lui ou quelqu’un d’autre tourne

la manette du robinet jusqu’à l’extrémité de la plage

d’eau chaude.

• Selon la majorité des normes de l’industrie, la

température maximale de l’eau s’écoulant du robinet ne

doit pas dépasser 120 °F (49 °C) (le code de plomberie

de votre région peut exiger une température inférieure à

120 °F).

• La butée de température maximale peut devoir

être réglée de nouveau si la température de l’eau

d’alimentation varie selon les saisons. À titre d’exemple,

pendant l’hiver, la température de l’eau froide est

plus basse que pendant l’été, ce qui peut influer sur

la température de l’eau à la sortie du robinet. La

température de l’eau pour un bain ou une douche

confortable se situe généralement entre 90 °F et 110 °F

(32 °C – 43 °C).

• Laissez couler l’eau froide jusqu’à ce qu’elle soit aussi

froide que possible et faites la même chose pour l’eau

chaude. Placez la manette sur la tige (voir page 9,

étape 4F) et tournez-la dans le sens inverse à celui des

aiguilles d’une montre jusqu’à ce qu’elle s’arrête.

• Placez un thermomètre dans un gobelet en plastique

et tenez le gobelet sous le jet d’eau. Si la température

de l’eau est supérieure à 120 °F (49 °C), vous devez

déplacer la butée de température maximale dans

les sens des aiguilles d’une montre pour abaisser

la température de l’eau qui s’écoule du robinet. La

température doit être inférieure à 120 °F ou elle doit

satisfaire aux exigences du code de plomberie de votre

région.

• Pour régler la température de l’eau qui sort du robinet,

tirez la butée de température maximale blanche (1) vers

l’extérieur. Tournez la butée dans le sens des aiguilles

d’une montre pour diminuer la température de l’eau à

la sortie du robinet et dans le sens inverse à celui des

aiguilles d’une montre pour accroitre la température. Le

changement de température par dent (cran) est de 4

°F à 16 °F (2 °C – 9 °C) selon la température de l’eau

d’alimentation. Une fois que vous avez terminé, assurezvous que la butée retourne à sa position d’origine.

AVERTISSEMENT : Ne démontez pas la butée de

température maximale.

• ASSUREZ-VOUS QUE DE L’EAU FROIDE S’ÉCOULE

DU ROBINET EN PREMIER. ASSUREZ-VOUS QUE LA

TEMPÉRATURE DE L’EAU LA PLUS CHAUDE POSSIBLE

QUI S’ÉCOULE DU ROBINET NE DÉPASSE PAS 120 °F

(49 °C) OU LE MAXIMUM AUTORISÉ PAR LE CODE DE

PLOMBERIE DE VOTRE RÉGION.

PLUS FROID

1

92658 Rev. A

6

Page 27

Instructions d’installation - série T75P

Installation des pièces de nition

4

A.

2

1

Installation du manchon de nition

Glissez le manchon de nition (1) sur la cartouche, le

chapeau (2) et le joint torique. Assurez-vous que le

manchon est positionné correctement sur la cartouche. Le

joint torique maintiendra le manchon de nition en place.

C.

9

B.

5

6

7

8

Installation de la plaque de nition

Fixez la plaque arrière (2) au corps de robinetterie (3)

à l’aide des 4 vis (4) fournies. Assurez-vous que la face

avant de la plaque arrière est orientée vers l'avant.

: Assurez-vous que la face avant de la plaque arrière

est orientée vers l'avant et que les inscriptions

sont visibles.

composé d’étanchéité autour de la plaque arrière pour

garantir l’étanchéité. Alignez les trous de la plaque

de nition (5) avec les cartouches et glissez la plaque

de nition (5) sur la plaque arrière. Fixez la plaque de

nition en vissant l’écrou de nition (6) sur le manchon

de l’inverseur. Prenez garde de trop serrer. Glisser

le manchon de nition (7) de l’inverseur sur l’écrou

de nition et xez-le avec la vis de calage (8).

une installation dans un mur épais, commandez

les trousses de rallonge facultatives RP91022

et RP92548 qui autorisent une épaisseur de mur

supplémentaire de 1 po.

4

2

Si la surface est inégale, appliquez du

Pour

D.

2

1

3

Note

10

11

Installation de la manette de la soupape

Glissez la manette (9) sur la cartouche en alignant les

surfaces planes à l’intérieur de la manette avec les

surfaces planes sur le côté de la cartouche. La manettelevier doit être orientée vers le bas (à 6 heures) en

position de fermeture. Fixez la manette avec la vis de

calage (10) et appuyez sur le capuchon (11) pour l’insérer

dans le trou.

3

4

Installation de la manette de l'inverseur

Introduisez la manette de l'inverseur (1) sur le manchon

de nition (2). Au moyen d'une clé Allen, insérez la vis de

calage (3) dans la manette (1). En exerçant une pression,

introduisez le capuchon de la vis de calage (4) jusqu'à ce

qu'il soit bien calé.

7

92658 Rev. A

Page 28

Possibilité d’ébouillantage ou de choc thermique pouvant causer des lésions en raison d’une inversion de

la circulation de l’eau si la sortie de la douche est bloquée ou restreinte (p. ex. : circulation bloquée par la

commande d’arrêt sur la pomme de douche). Avant d’ouvrir le robinet, déplacez la pomme de douche pour

5

ne pas vous faire arroser. Vous pouvez également installer des clapets de non-retour sur les deux tuyaux

d'alimentation pour éliminer les risques de blessures.

Maintenance - série T75P

Fuite du robinet par la pomme de douche :

FERMEZ LES ROBINETS D’ALIMENTATION.

Remplacez les sièges et les ressorts - trousse de

réparation RP4993. Vériez l’état des joints toriques

inférieurs et remplacez-les au besoin - pièce

RP14414.

Reportez-vous aux conseils utiles 1, 2 et 3

Si la fuite persiste :

FERMEZ LES ROBINETS D’ALIMENTATION.

Remplacez la cartouche RP46074.

Reportez-vous aux conseils utiles 1, 2, 3, 4 et 5.

Incapacité de conserver la température de l’eau

constante :

Remplacez la cartouche de soupape RP46074 ou

suivez les conseils utiles 1, 2, 3, 4 et 5.

Conseils utiles :

1. Avant d’enlever la cartouche de la soupape pour

en faire l’entretien, prenez note de la position de la

butée de température maximale sur le chapeau. La

cartouche de la soupape doit toujours être replacée

au même endroit. PENSEZ SÉCURITÉ! Après avoir

terminé l’installation, ouvrez la soupape pour vous

assurer que de L’EAU FROIDE S’ÉCOULE EN

PREMIER.

2. Pour retirer la cartouche du corps, fermez les

robinets d’alimentation et enlevez la manette ainsi