Brizo Charlotte T60085, Charlotte T60285, Charlotte T60485 Installation Instructions And Owner's Manual

Page 1

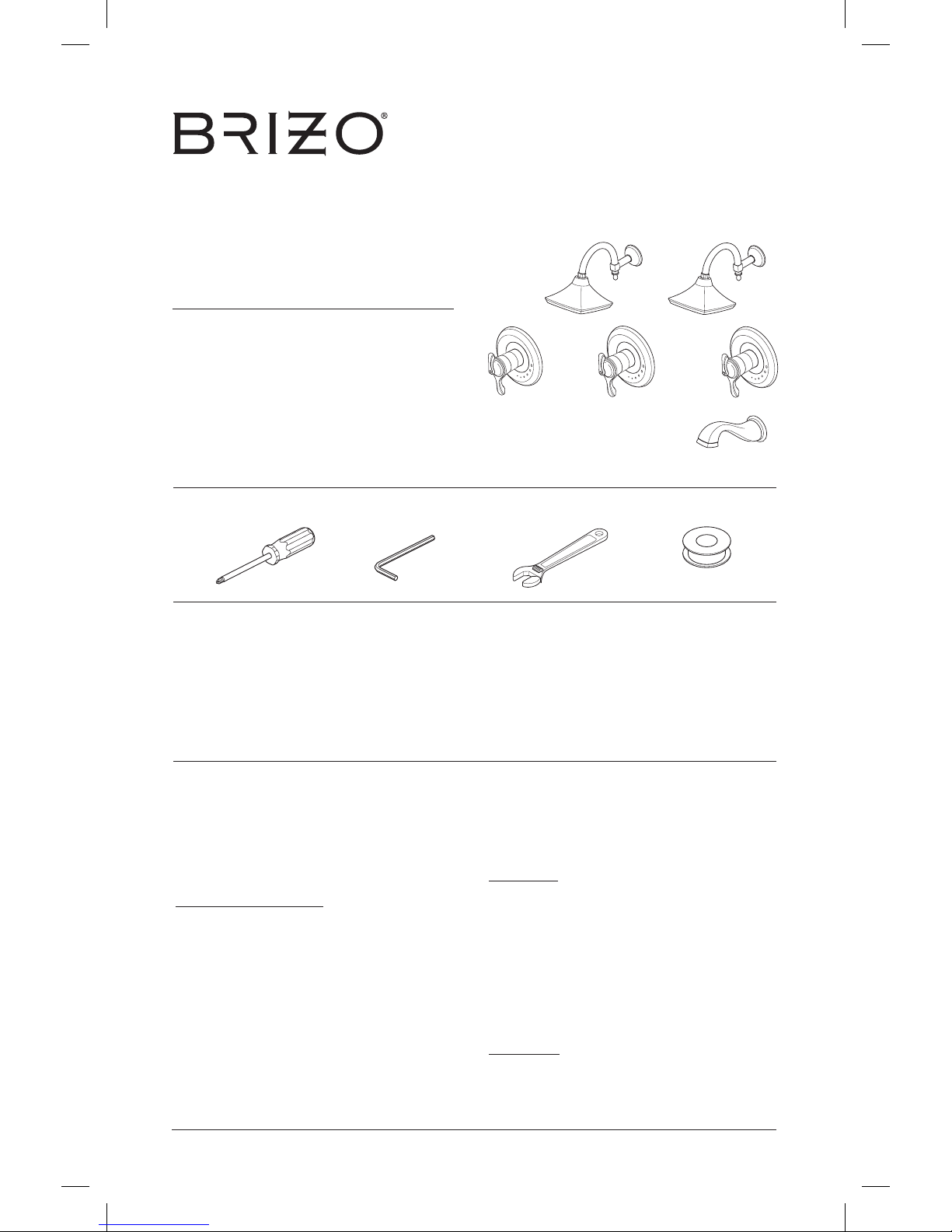

MultiChoice® Valve Trim

Installation Instructions

Owners Manual

Charlotte™

Write purchased model number here.

ASME A112.18.1 / CSA B125.1

ASSE 1016 TYPE T

Table of Contents:

Warranty ............................................................................. Page 2

Installation Instructions ....................................................... Pages 3 - 6

Maintenance ....................................................................... Page 6

Replacement Parts ............................................................. Page 7

1

You May Need

3/4/13

75651 Rev. A

THIS VALVE MEETS OR EXCEEDS THE

FOLLOWING STANDARDS:

ASME A112.18.1/CSA B125.1 and ASSE 1016.

CAUTION: This system/device must be set by the

installer to ensure safe, maximum temperature.

Any change in the setting may raise the discharge

temperature above the limit considered safe and

may lead to hot water burns.

NOTICE TO INSTALLER: CAUTION!–As the

installer of this valve, it is your responsibility

to properly INSTALL and ADJUST this valve

per the instructions given. This valve does

not automatically adjust for inlet temperature

changes, therefore, someone must make the

necessary temperature knob adjustments at

the time of installation and further adjustments

may be necessary due to seasonal water

temperature change. YOU MUST inform the

owner/user of this requirement by following the

instructions. If you or the owner/user are unsure

how to properly make these adjustments, please

refer to page 6 and if still uncertain, call us at

1-877-345-BRIZO (2749).

After installation and adjustment, you must affix

your name, company name and the date you

adjusted the temperature knob to the caution label

provided and apply or attach the label to the back

side of the closest cabinet door and the warning

label to the water heater. Leave this Instruction

Sheet for the owner’s/user’s reference.

WARNING: This thermostatic bath valve is

designed to minimize the effects of outlet water

temperature changes due to inlet pressure and

temperature changes, commonly caused by

dishwashers, washing machines, toilets and

the like. It may not provide protection from hot

water burns when there is a failure of other

temperature controlling devices elsewhere

in the plumbing system, if the temperature

knob is not properly set or if the hot water

temperature is changed after the settings

are made or if the water inlet changes due to

seasonal changes.

WARNING: Do not install a shut-off device on

either outlet of this valve. When this type of

device shuts off the water flow, it can defeat

the ability of the valve to balance the hot and

cold water pressures.

For easy installation of your Brizo® faucet

you will need:

• To READ ALL the instructions completely

before beginning.

• To READ ALL warnings,care, and

maintenance information.

T60085

T60285 T60485

Page 2

www.brizo.com

2

All parts and finishes of the Brizo® faucet are

warranted to the original consumer purchaser to

be free from defects in material & workmanship

for as long as the original consumer purchaser

owns their home. Delta Faucet Company

recommends using a professional plumber for

all installation & repair.

Delta will replace, FREE OF CHARGE,

during the warranty period, any part or finish

that proves defective in material and/or

workmanship under normal installation, use

and service. Replacement parts may be

obtained by calling 1-877-345-BRIZO (2749)

(in the U.S. and Canada) or by writing to:

In the United States:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

In Canada:

Masco Canada Limited, Plumbing Group

350 South Edgeware Road,

St. Thomas, Ontario, Canada N5P 4L1

This warranty is extensive in that it covers

replacement of all defective parts and even finish,

but these are the only two things that are

covered. LABOR CHARGES AND/OR DAMAGE

INCURRED IN INSTALLATION, REPAIR, OR

REPLACEMENT AS WELL AS ANY OTHER

Lifetime Faucet and Finish Limited Warranty

KIND OF LOSS OR DAMAGES ARE

EXCLUDED. Proof of purchase (original sales

receipt) from the original consumer purchaser

must be made available to Delta for all warranty

claims. THIS IS THE EXCLUSIVE WARRANTY

BY DELTA FAUCET COMPANY, WHICH DOES

NOT MAKE ANY OTHER WARRANTY OF ANY

KIND, INCLUDING THE IMPLIED WARRANTY

OF MERCHANTABILITY.

This warranty excludes all industrial, commercial

& business usage, whose purchasers are hereby

extended a five year limited warranty from the

date of purchase, with all other terms of this

warranty applying except the duration of the

warranty. This warranty is applicable to Brizo®

faucets manufactured after January 1, 1995.

Some states/provinces do not allow the exclusion

or limitation of incidental or consequential

damages, so the above limitation or exclusion

may not apply to you. Any damage to this faucet

as a result of misuse, abuse, or neglect, or any

use of other than genuine Delta® replacement

parts WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and

you may also have other rights which vary from

state/province to state/province. It applies only for

Brizo® faucets installed in the United States of

America, Canada, and Mexico.

© 2013 Masco Corporation of Indiana

Cleaning and Care

Care should be given to the cleaning

of this product. Although its finish is

extremely durable, it can be damaged by

harsh abrasives or polish. To clean, simply

wipe gently with a damp cloth and blot dry

with a soft towel.

Page 3

3

B.

1

4

4

2

3

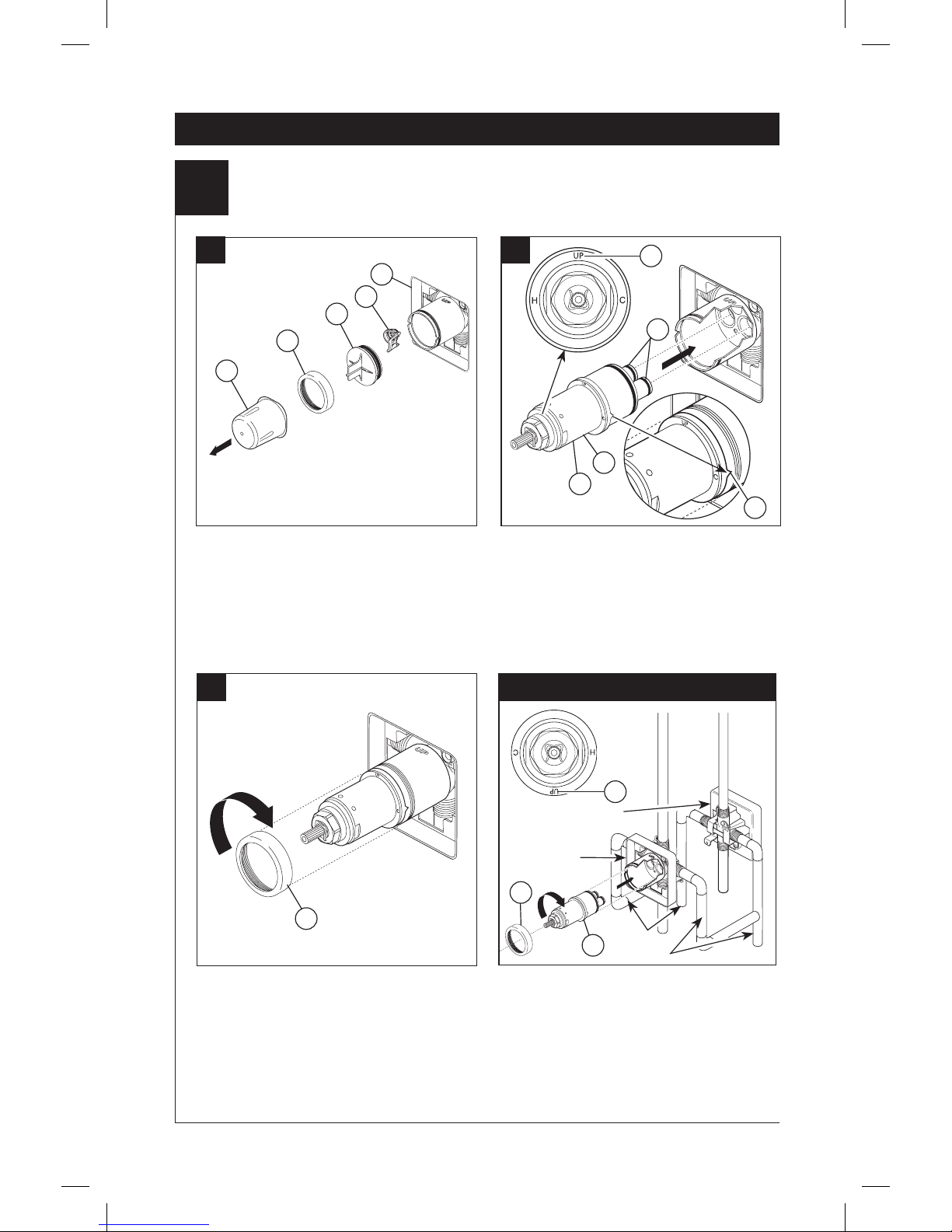

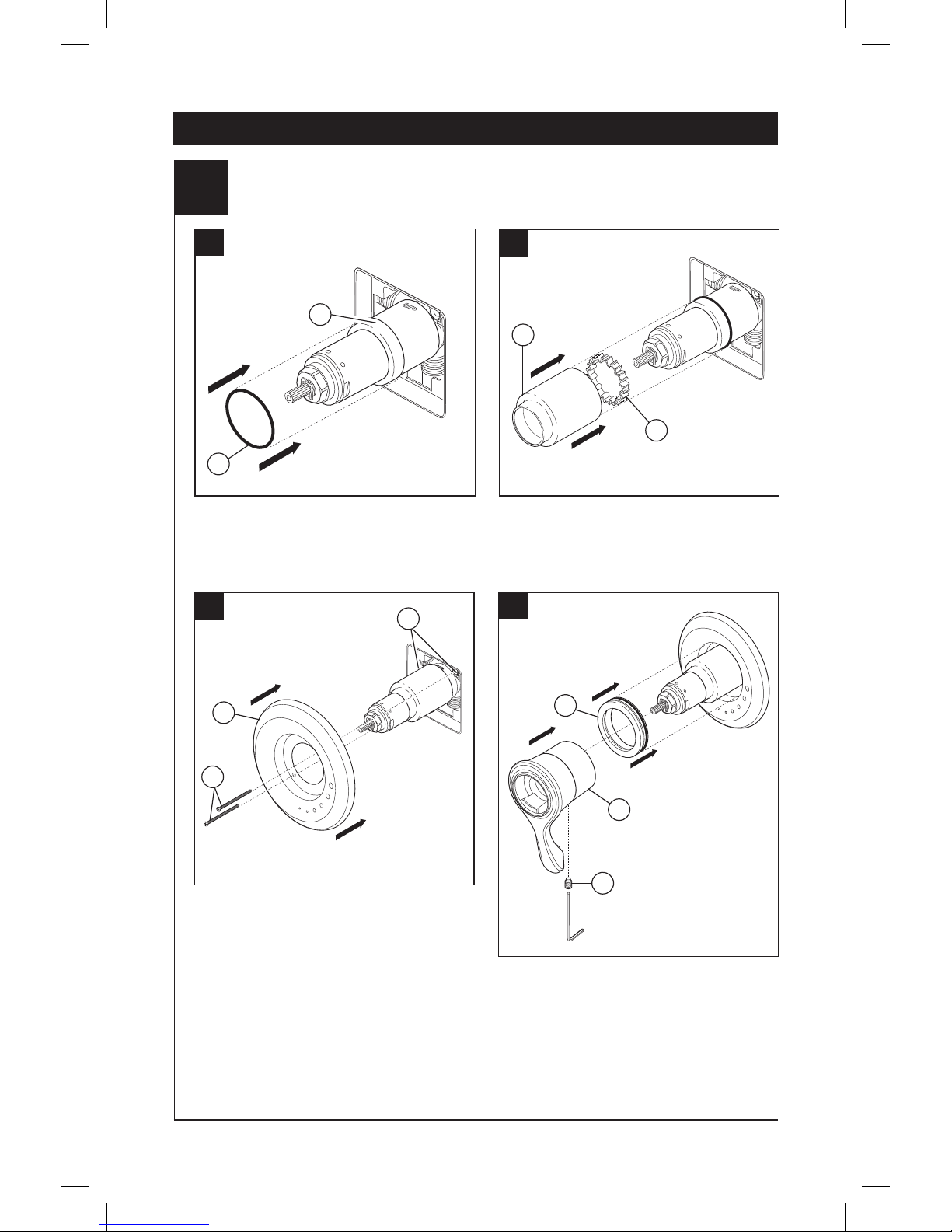

60 Series Installation

1

Cartridge Installation

A.

Turn off water supplies. Remove cover (1),

bonnet nut (2) and test cap (3) from the body. If

this is not a thin wall mounting, the entire plasterguard (4) may be removed. If screen (5) is in

place, remove before installing cartridge.

1

2

3

4

Rotate the cartridge (1) so the word “UP” (2)

appears on the top. Insert cartridge into valve

body as shown. Make sure the cartridge tubes

and O-rings (3) are properly seated in holes at

the base of the body. Ensure the keys on the

body are fully engaged with the slots in the

body (4).

For back to back or reverse installations

(hot on right and cold on left): Rotate cartridge

(1) so the word “UP” (2) appears on the bottom.

Install the cartridge making sure that the keys are

fully engaged with the slots in the brass body (see

step B). Slide bonnet nut (3) over the cartridge and

thread onto the body. Hand tighten securely.

Back to back Installation

Normal Installation

(changes not required)

Reverse

Installation

Cold

Hot

1

3

2

C.

Slide bonnet nut (1) over the cartridge and

thread onto the body. Hand tighten securely.

1

5

Page 4

4

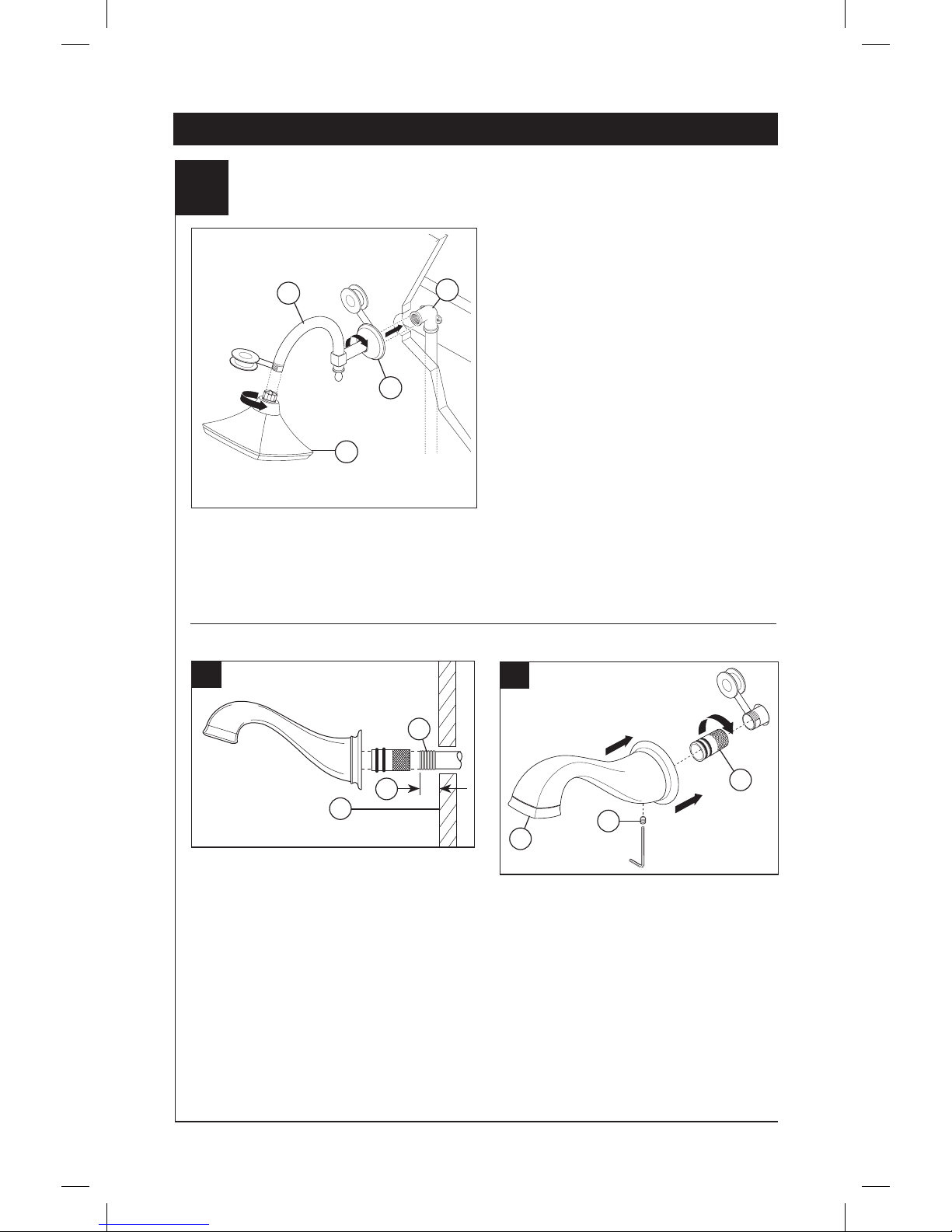

60 Series Installation

2

Showerhead and Tub Spout Installation

FOR TUB SPOUT INSTALLATION:

Install 1/2" (13 mm) threaded pipe nipple (1) to

extend past finished wall (2) per dimension (3).

Connection of deck mount spouts to in–wall

valves is not recommended. Neither is the use

of hand showers connected to tub spouts in a

tub/shower push button diverter combination, or

hand showers connected in lieu of a tub spout

to a tub / shower valve.

Piping between valve body and tub spout must

be a minimum of 1/2" (13 mm) copper pipe

or 1/2" (13 mm) iron pipe in a straight drop

no less than 8" (203 mm) but no more than

18" (457 mm) long with only one iron pipe or

copper 90 degree elbow to the tub spout nipple.

1

2

3

4

1

3

(3) = 3/8

" - 1/2" (9.5 mm - 12.7 mm)

2

RP70908s

A.

B.

Install a 1/2" threaded pipe nipple to extend

beyond the finished wall 3/8" to 1/2". Apply

plumber tape to thread on pipe nipple and screw

brass adapter (1) securely onto nipple. Install set

screw on bottom of spout (2) making sure it is not

sticking through to the inside opening where it

could interfere with the assembly. Slide tub spout

over the adapter and tighten set screw, on bottom

of spout, against the adapter. Note: This spout

utilizes a pull down diverter mechanism. To

divert from spout to shower, pull down on

spout tip (3).

1

2

3

NOTE: It is suggested that you anchor your shower arm and tub spout

elbows or water lines.

FOR SHOWERHEAD INSTALLATION:

Connect top outlet (1) to shower arm (2) with

proper fittings. Apply plumber tape to pipe

threads on both ends of showerarm. To prevent

damage to finish on shower arm, insert wall end

of shower arm into shower flange (3) before

screwing arm into riser connection. Thread

showerhead (4) onto shower arm. Do not

overtighten showerhead.

Page 5

5

C.

D.

A.

B.

Slide O-ring (1) over cartridge and the bonnet

nut (2). The O-ring, which acts as a spacer to

steady the sleeve, should rest behind the

bonnet nut.

If your model requires a spacer (1), install it into

sleeve (2). Slide the sleeve over the cartridge, body

and O-ring. Ensure sleeve is properly positioned

over the front of cartridge.

Secure the escutcheon (1) to the bracket (2) with

the 2 screws provided (3). Do not overtighten

escutcheon screws.

Slide trim ring (1) over the cartridge and sleeve

and into the escutcheon. Install volume control

handle (2) with lever pointed downward to 6

o’clock position. Install set screw (3) into handle.

Push handle onto valve cartridge and tighten set

screw to secure handle.

3

Valve Trim Installation

1

2

2

1

2

2

3

60 Series Installation

1

1

3

Page 6

6

4

Installation and Adjustment of the Temperature Knob

Failure to do so may cause injury.

60 Series Installation

Adjust temperature limit stop. Turn on water

supplies; let the water run at both full hot and

full cold to ensure the water is running as hot/

cold as possible. Place a thermometer in a

plastic tumbler, and hold the tumbler in the water

stream. Place the temperature knob (1) onto the

splines (2), then rotate the temperature knob

until you achieve your maximum desired

temperature from the outlet (not more than 120°

or the lower temperature mandated by your local

plumbing code). Remove the temperature knob

and replace onto the splines (2), making sure that

the temperature knob limit stop (3) hits against

the volume handle limit stop (4) as shown.

Note: Temperature lever is intended to point

upward near 12 o’clock position. Once desired

position is acquired per instructions above, thread

screw (5) into handle (1) and secure it to valve

stem by tightening screw. Insert button (6) into

screw hole.

1

3

2

1

4

5

6

60 Series Maintenance

Faucet leaks from showerhead or tub spout:

SHUT OFF WATER SUPPLIES. Replace Cartridge

Assembly –Repair Kit RP47201.

If water does not flow:

Verify that the hot side of the cartridge is installed

on the hot water supply line. If it is not, turn off

water supplies and flip cartridge.

4

Page 7

Instrucciones para la

Instalación del Accesorio

para Válvulas MultiChoice

®

Manual para los Propietarios

Charlotte™

Escriba aquí el número del modelo comprado.

ASME A112.18.1 / CSA B125.1

ASSE 1016

Contenido:

Garantía ............................................................................. Página 2

Instrucciones de Instalación................................................ Páginas 3 - 6

Mantenimiento..................................................................... Página 6

Piezas de Repuesto............................................................ Página 7

1

Usted puede necesitar

3/4/13

75651 Rev. A

ESTA VÁLVULA CUMPLE O EXCEDE LAS

SIGUIENTES NORMAS:

ASME A112.18 1 / CSA B125.1 y ASSE 1016.

ADVERTENCIA: El instalador debe apostar

este systema/divisa para garantizar temperatura

maximo y seguro. Cualqueir cambio en el ajuste

puede subir la temperatura del agua de descarga

sobre el límite considerado seguro y puede resultar

en quemaduras de agua caliente.

AVISO PARA EL INSTALADOR: PRECAUCIÓN

– Como instalador de esta válvula, es su

responsabilidad de INSTALAR Y AJUSTAR

apropiadamente esta válvula como se describe

en las instrucciones, por lo tanto, debe

haber una persona para hacer los ajustes

necesarios del pomo para la temperatura en el

momento que se haga la instalación y pueda

necesitar ajustes adicionales por los cambios

estacionales de la temperatura del agua. USTED

DEBE informarle al dueño/usuario sobre este

requisito siguiendo las instrucciones. Si usted

o el dueño/usuario no están seguros como

hacer estos ajustes apropiadamente, por favor

refiérase al Página 6 y si todavía no está seguro,

llámenos al 1-877-345-BRIZO (2749).

Después de hacer la instalación y el ajuste,

usted puede agregarle a la etiqueta de aviso

proporcionada, su nombre, el nombre de la

compañía y la fecha cuando ajustó y el pomo para

la temperatura y aplicar o fijar la etiqueta al dorso

de la puerta del gabinete más cercano y la etiqueta

de aviso al calentador de agua. Deje la Hoja de

Instrucciones para referencia del dueño/usuario.

ADVERTENCIA: Esta válvula termostática está

diseñada para minimizar los efectos de los

cambios de temperatura de agua por causa

de los cambios de presión y de temperatura

en el agua de entrada, comúnmente causados

por lavadoras de platos, lavadoras de ropa,

inodoros, y otros aparatos por el estilo. Puede

no proporcionar protección de quemaduras

de agua caliente cuando hay alguna falla de

otros aparatos para el control de temperatura

en otro sitio en el sistema de plomería. También

no proporcionará protección si el pomo para el

ajuste de la temperatura no está apropiadamente

fijo o si cambia la temperatura del agua caliente

después de hacer los ajustes o si los cambios

del agua de entrada son por los cambios

estacionales.

ADVERTENCIA: No instale un aparato de corte

o cierre en cualquiera de las tomas de esta

válvula. Cuando este tipo de aparato cierra el

flujo de agua, puede hacer fallar la habilidad de

la válvula de balancear las presiones del agua

caliente y fría.

Para instalación fácil de su llave Brizo®

usted necesitará:

• LEER TODAS las instrucciones completamente

antes de empezar

• LEER TODOS los avisos, cuidados,

e información de mantenimiento.

T60085 T60285 T60485

Page 8

www.brizo.com

2

Todas las piezas y acabados de la llave Brizo®

están garantizados al consumidor comprador

original, de estar libres de defectos de material y

fabricación, por el tiempo que el consumidor

comprador original sea dueño de su casa. Delta

Faucet Company recomienda que use un

plomero profesional para todas las instalaciones

y reparaciones.

Delta reemplazará, LIBRE DE CARGO, durante el

período de garantía, cualquier pieza o

acabado que pruebe tener defectos de material y/

o fabricación bajo instalación normal, uso y

servicio. Piezas de repuesto pueden ser obtenidas

llamando al 1-877-345-BRIZO (2749) (en los

Estados Unidos y Canada) o escribiendo a:

En los Estados Unidos:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

En Canada:

Masco Canada Limited, Plumbing Group

350 South Edgeware Road,

St. Thomas, Ontario, Canada N5P 4L1

Esta garantía es extensiva en lo que cubre el

reemplazamiento de todas las piezas

defectuosas y hasta el acabado, pero éstas son

las únicas dos cosas que están cubiertas.

CARGOS DE LABOR Y/O DAÑOS INCURRIDOS

EN LA INSTALACIÓN, REPARACIÓN, O

REEMPLAZAMIENTO COMO TAMBIÉN

CUALQUIER OTRO TIPO DE PÉRDIDA O

GarantÍa Limitada De Por Vida de la Llave y su Acabado

DAÑOS ESTÁN EXCLUÍDOS. Prueba de compra

(recibo original de venta) del comprador

consumidor original debe de ser disponible a

Delta para todos los reclamos. ESTA ES LA

GARANTÍA EXCLUSIVA DE DELTA FAUCET

COMPANY, QUE NO HACE CUALQUIER OTRA

GARANTÍA DE CUALQUIER TIPO,

INCLUYENDO LA GARANTÍA IMPLÍCITA DE

COMERCIALIZACIÓN.

Esta garantía excluye todo uso industrial,

comercial y de negocio, a cuyos compradores se

les da una garantía limitada extendida de cinco

años desde la fecha de compra, con todos los

otros términos de esta garantía aplicados,

excepto el de duración de ésta. Esta garantía es

aplicable a las llaves de Brizo® fabricadas

después de Enero 1, 1995.

Algunos estados/provincias no permiten la

exclusión o limitación de daños incidentales o

consecuentes, de manera que la limitación o

exclusión arriba escrita puede no aplicarle a

usted. Cualquier daño a esta llave, resultado del

mal uso, abuso, o descuido, o cualquier otro uso

de piezas de repuesto que no sean genuinas de

Delta® ANULARÁN LA GARANTÍA.

Esta garantía le da derechos legales específicos,

y usted puede, también tener otros

derechos que varían de estado/provincia a

estado/provincia. Es aplicable sólo a las llaves

Brizo® instaladas en los Estados Unidos de

America, Canada y Mexico.

© 2013 Masco Corporación de Indiana

Limpieza y Cuidado de su Llave

Tenga cuidado al ir a limpiar este producto.

Aunque su acabado es sumamente

durable, puede ser afectado por agentes de

limpieza o para pulir abrasivos. Para limpiar

su llave, simplemente frótela con un

trapo húmedo y luego séquela con una

toalla suave.

Page 9

3

B.

1

4

4

2

3

Instalación de la Serie 60

1

Instalación del Cartucho

A.

Cierre los suministros de agua. Quite la cubi-

erta (1), la tuerca tapa (2) y la tapa de prueba (3).

Si no es para instalar en pared delgada, puede

quitar el protector (4) de yeso completo. Si la

pantalla (5) está en lugar, quite antes de instalar

el cartucho.

1

2

3

4

Gire el cartucho (1) de manera que la palabra “UP”

(2) aparezca encima. Introduzca el cartucho en el

cuerpo de la válvula como se muestra. Asegúrese

que los tubos del cartucho y los aros O (3) estén

debidamente sentados en los agujeros en la base

del cuerpo. Asegúrese que los dentados estén

completamente encajados en las muescas del

cuerpo (4).

En las instalaciones dorso con dorso (el agua

caliente en la derecha y la fría en la izquierda):

Gire el cartucho (1) así que la palabra “UP”

de (2) aparece en el fondo. Instale el cartucho

asegurándose que los dentados estén

completamente enganchados en las muescas en

el cuerpo de bronce (vea la página B). Deslice la

tuerca tapa (3) sobre el cartucho y enrosque en el

cuerpo de la válvula. Apriete a mano bien.

Instalación de Espalda a Espalda

Instalación Normal

(No serequerá cambios)

Instalación

Invertido

Fría

Caliente

1

3

2

C.

Deslice la tuerca tapa (1) sobre el

cartucho y enrosque en el cuerpo de la válvula.

Apriete a mano bien.

1

5

Page 10

4

Instalación de la Serie 60

2

Instalación de la Cabeza de la Regadera y el Surtidor de la Bañera

PARA LA INSTALACIÓN DE REGADERA:

Conecte la salida superior (1) al brazo de la regadera o ducha (2) con los accesorios apropiados.

Aplique cinta para plomero a las roscas en ambos

extremos del brazo de la regadera. Para prevenir

daño al acabado del brazo de la regadera, inserte el

extremo que va hacia la pared, en la brida de la regadera (3) antes de atornillar el brazo en la conexión

vertical. Atornille la cabeza de la regadera (4) en el

brazo de esta. No la apriete demasiado.

PARA LA INSTALACIÓN DEL

SURTIDOR DE LA BAÑERA:

Instale una entrerrosca de tubo de 1/2” (13 mm) (1)

de manera que sobresalga la pared acabada (2)

como en la dimensión (3).

No se recomienda la conexión en paredes de tubos

de salida que son para la instalación en el área

de los bordes. Tampoco se recomienda el uso de

regaderas de mano conectadas a los tubos de

salida de bañeras, en combinación bañera/regadera,

con desviador de botón a presión, o regaderas de

mano conectadas en lugar de un tubo de salida de

bañera a una válvula de bañera/regadera.

La tubería entre el cuerpo de la válvula y el tubo de

salida de la bañera debe ser de tubo de cobre de un

mínimo de 1/2” (13 mm) o tubo de hierro de 1/2” (13

mm) en caída recta no menos de 8” (203 mm) pero

no más de 18” (457 mm) de largo con sólo un codo

de 90°, de hierro o cobre, a la entrerrosca del tubo

de salida de agua.

1

3

(3) = 3/8

" - 1/2" (9.5 mm - 12.7 mm)

2

RP62605s

A.

B.

Instale una entrerrosca de 1/2" de manera que

sobresalga de 3/8" a 1/2" de la pared terminada.

Aplique cinta de plomero en el roscado de la

entrerrosca y atornille el adaptador de latón en

la entrerrosca (1). Revise la posición del tornillo

de ajuste en el fondo del surtidor (2)

asegurándose que no se está pegando a la

parte interior de la abertura donde podría

interferir con en ensamble. Deslice el surtidor de

la bañera sobre el adaptador y apriete el tornillo

de ajuste, en la parte inferior del surtidor, contra

el adaptador. Nota: Este surtidor utiliza un

mecanismo de desvío que se hala hacia

abajo. Para desviar del surtidor a la regadera,

hale la salida en el surtidor (3).

1

2

3

NOTA: Se sugiere que ancle el brazo de su regadera y los codos del

surtidor de la bañera o las líneas de agua.

1

2

3

4

Page 11

5

C.

A.

Deslice el aro O (1) sobre el cartucho y la

tuerca tapa (2). El aro O, el cual funciona como

un separador para estabilizar la manga, debe

quedar apoyado en la tuerca tapa.

Fije la roseta con orificio (1) al soporte (2)

usando los 2 tornillos suministrados (3). No

apriete demasiado los tornillos de la roseta.

3

Instalación Final

1

2

1

2

3

Instalación de la Serie 60

B.

Si su modelo requiere un separador (1), insértelo en

la manga (2). Deslice la manga sobre el cartucho, el

cuerpo de la pieza y el aro O. Asegure la cubierta de

ajuste se coloca correctamente sobre el frente del

cartucho de la ducha.

2

1

Deslice el anillo de accesorio (1) sobre el

cartucho y la manga y en la chapa de cubierta.

Instale la manija del control del volumen (2) con

la palanca apuntando hacia abajo, en la posición

de las 6 en el reloj. Instale de tornillo de ajuste (3)

en la manija. Presione la manija en el cartucho

de la válvula y apriete el tornillo de ajuste para

fijar la manija.

D.

2

1

3

Page 12

6

4

Instalación y Ajuste del Pomo de Temperatura

El no hacerlo puede causar lesión.

Instalación de la Serie 60

¡Ajuste el tope del límite de temperatura.

Abra los suministros de agua, deje correr el

agua, tanto la caliente como la fría a lo máximo,

para garantizar que el agua está saliendo lo más

caliente / fría posible. Coloque un termómetro

en un vaso plástico, y sostenga el vaso en el

chorro de agua. Coloque la perilla o control de

la temperatura (1) en las ranuras (2), luego, gire

la perilla de temperatura hasta que logre su

temperatura máxima deseada desde la toma

(no más de 120° o la temperatura más baja

autorizada por su código local de plomería).

Retire la perilla de temperatura y vuelva a

colocarla en las ranuras (2), asegurándose que la

perilla o control del tope del límite de temperatura

(3) queda situada contra la manija del control

de volumen (4), como se muestra. Nota: la

palanca de temperatura debe señalar hacia

arriba, cerca de las 12 en punto. Una vez que la

posición deseada se adquiere, como establecida

en las instrucciones arriba, atornille el tornillo (5)

en el mango (1) y fíjelo a la espiga de la válvula

apretando el tornillo. Inserte el botón (6) en el

agujero del tornillo.

Mantenimiento de la Serie 60

Si la llave de agua tiene una filtración o

escape de agua desde el surtidor o la cabeza

de la regadera:

CIERRE LOS SUMINISTROS DE AGUA. Cambie

el Ensamble del cartucho – Piezas de Repuesto

RP47201.

Si no fluye el agua:

Verifique que el lado caliente del cartucho

esté instalado en la línea de fuente de la agua

caliente. Si no es, dé vuelta apagado a los

abastecimientos de agua y mueva de un tirón

el cartucho.

1

3

2

1

4

5

6

4

Page 13

Instructions d’installation

Finition de la soupape

MultiChoice

®

Guide d’utilisation

Charlotte™

Inscrivez le numéro de modèle ici.

ASME A112.18.1 / CSA B125.1

ASSE 1016

Table des matières

Garantie ............................................................................. Page 2

Instructions d’installation .................................................... Pages 3 - 6

Maintenance ....................................................................... Page 6

Pièces de rechange ........................................................... Page 7

1

Articles dont vous pouvez avoir besoin:

3/4/13

75651 Rev. A

Ce robinet satisfait aux exigences des normes

ASME A112.18.1/CSA B125.1 et ASSE 1016 ou

les surpasse.

ATTENTION: L’installateur doit régler l’appareil

pour que la température maximale de l’eau chaude

soit sans danger. Toute modification des réglage

peut entraîner une élévation de la température à

la sorite du robinet au delà de la température sans

danger et pourrait causer un échaudage.

AVIS À L’INSTALLATEUR : ATTENTION! – En

qualité d’installateur, vous êtes tenu

d’INSTALLER et de RÉGLER ce robinet

conformément aux instructions. Ce robinet ne

s’adapte pas automatiquement aux fluctuations

de la température de l’eau d’alimentation. Par

conséquent, il faut régler le bouton de

température au moment de l’installation et il

peut être nécessaire de faire de nouveaux

réglages par la suite en raison des fluctuations

saisonnières de la température de l’eau. VOUS

DEVEZ informer le propriétaire ou l’utilisateur

de cette exigence. En cas de doute quant à la

marche à suivre pour faire ces réglages,

veuillez consulter page 6 si un doute persiste,

et si cette incertitude persiste, appelez-nous au

1-877-345-BRIZO (2749).

Après avoir terminé l’installation et le réglage, vous

devez inscrire, sur l’étiquette de mise en garde

fournie, votre nom, le nom de votre entreprise et la

date à laquelle vous avez réglé le bouton de

température, puis fixer l’étiquette à l’endos de la

porte de la coiffeuse. Vous devez également fixer

l’étiquette d’avertissement au chauffe-eau. Veuillez

laisser ce feuillet d’instructions au propriétaire

ou à l’utilisateur pour qu’il puisse le consulter

au besoin.

MISE EN GARDE – Ce robinet thermostatique

pour baignoire est conçu pour limiter les

effets des fluctuations de température de l’eau

causées par les variations de la pression et la

température attribuables au fonctionnement

d’un lave-vaisselle, d’une machine à laver, d’un

cabinet d’aisances ou d’un autre appareil qui

consomme de l’eau. Il peut ne pas protéger

l’utilisateur contre l’échaudage en cas de

défectuosité d’un autre dispositif de régulation

de la température, si de haute température ou

du bouton de température est mauvais, si la

température de l’eau chaude a été modifiée

après que les réglages ont été effectués ou si la

température de l’eau d’alimentation a changé en

raison du changement de saison.

MISE EN GARDE – N’installez pas de dispositif

d’arrêt sur une sortie quelconque de ce robinet.

En interrompant l’écoulement de l’eau, ce

dispositif peut empêcher le robinet d’équilibrer

les pressions d’eau chaude et d’eau froide.

Pour installer votre robinet Brizo® facilement,

vous devez:

•LIRE TOUTES les instructions avant de débuter.

•LIRE TOUS les avertissements ainsi que toutes les

instructions de nettoyage et d’entretien.

T60085 T60285 T60485

Page 14

www.brizo.com

2

Toutes les pièces et les finis du robinet Brizo®

sont protégés contre les défectuosités de

matériau et les vices de fabrication par une

garantie qui est consentie au premier acheteur

et qui demeure valide tant que celui-ci demeure

propriétaire de sa maison. Delta recommande

de faire appel à un plombier compétent pour

l'installation et la réparation du robinet.

Pendant la période de garantie, Delta remplacera

GRATUITEMENT toute pièce ou tout fini,

présentant une défectuosité de matériau ou un

vice de fabrication pour autant que l'appareil

ait été installé, utilisé et entretenu correctement.

Pour obtenir des pièces de rechange, veuillez

communiquer par téléphone au numéro

1-877-345-BRIZO (2749) (aux États-Unis ou

au Canada) et par écrit à l'une des adresses

suivantes :

Aux États-Unis

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

Au Canada

Masco Canada Limited, Plumbing Group

350 South Edgeware Road,

St. Thomas, Ontario, Canada N5P 4L1

La présente garantie s'applique au remplacement

de toutes les pièces défectueuses, y compris

le fini, et elle ne couvre que ces éléments.

LES FRAIS DE MAIN-D'OEUVRE ET (OU)

LES DOMMAGES PROVOQUÉS AU COURS

DE L'INSTALLATION, DE LA RÉPARATION

OU DU REMPLACEMENT D'UN ÉLÉMENT

AINSI QUE LES PERTES OU DOMMAGES

GARANTIE À VIE LIMITÉE DES ROBINETS ET DE LEURS FINIS

DE TOUTE AUTRE NATURE NE SONT

PAS COUVERTS PAR LA GARANTIE. Toute

réclamation en vertu de la présente garantie

doit être adressée à Delta, accompagnée de la

preuve d'achat (original de la facture) du premier

acheteur. CETTE GARANTIE EST LA SEULE

OFFERTE PAR DELTA FAUCET COMPANY OU

DELTA FAUCET CANADA, SELON LE CAS.

ELLE EXCLUT TOUTE AUTRE GARANTIE,

Y COMPRIS LA GARANTIE IMPLICITE DE

QUALITÉ MARCHANDE.

Les robinets installés dans un établissement

industriel ou commercial ou dans une place

d'affaires sont protégés par une grantie étandue

de cinq ans qui prend effet à compter de la

date d'achat. Toutes les autres conditions de

la garantie de cinq ans sont identiques à celle

de la présente garantie. La présente garantie

s'applique à tous les robinets Brizo® fabriqués

après le 1er janvier 1995.

Dans les États ou les provinces où il est interdit

d'exclure ou de limiter les responsabilités à

l'égard des dommages indirects ou fortuits, les

exclusions et les limites susmentionnées ne

s'appliquent pas. Les dommages résultant d'une

mauvaise utilisation, d'une utilisation

abusive de la négligence ou de l'utilisation de

pièces autres que des pièces d'origine Delta®

RENDENT LA GARANTIE NULLE ET SANS

EFFET.

La présente garantie vous donne des droits

précis qui peuvent varier selon votre lieu de

résidence. Elle ne s'applique qu'aux robinets

Brizo® installés aux États-Unis, au Canada et

au Mexique.

© 2012 Division de Masco Indiana

Instructions de nettoyage

Il faut le nettoyer avec soin. Même si son

fini est extrêmement durable, il peut être

abîmé par des produits fortement abrasifs ou des produits de polissage. Il faut

simplement le frotter doucement avec un

chiffon humide et le sécher à l'aide d'un

chiffon doux.

Page 15

3

B.

1

4

4

2

3

Installation – Série 60

1

Installation de la cartouche.

A.

Interrompez l’arrivée d’eau. Enlevez le

couvercle (1), l’écrou à portée sphérique (2) et

le capuchon d’essai (3) du corps. Si vous

n’installez pas l’appareil dans une paroi mince,

vous pouvez retirer le protecteur (4) complètement. Si l’écran (5) est en place, enlevez avant

d’installer la cartouche.

1

2

3

4

Tournez la cartouche (1) de sorte que le mot «

UP » (2) se trouve sur le dessus. Introduisez la

cartouche dans le corps de la soupape comme

le montre la figure. Assurez-vous que les tubes

et les joints toriques (3) sont bien calés dans les

orifices à la base du corps. Assurez-vous que les

ergots sont parfaitement engagés dans les

rainures du corps (4).

Dans le cas d’une installation dos à dos ou inversée

(eau chaude à droite et eau froide à gauche) : Tournez

la cartouche (1) de sorte que le mot « UP » (2) se

trouve sur le dessus. Installez la cartouche en vous

assurant que les ergots sont introduits entièrement

dans les rainures du corps de laiton (reportez-vous à

l’étape B). Faites glisser l’écrou à portée sphérique (3)

sur la cartouche et vissez-le sur le corps. Serrez à la

main fermement.

Installation dos à dos

Installation normale

(Non modifiée)

Installation

Inversée

Eau Froides

Eau Chaude

3

2

C.

Faites glisser l’écrou à portée sphérique (1) sur

la cartouche et vissez-le sur le corps. Serrez à

la main fermement.

1

1

5

Page 16

4

Installation – Série 60

2

Installation de la pomme de douche et du bec de baignoire

INSTALLATION DU BEC

DE BAIGNOIRE:

Installez un manchon fileté de 1/2 po (13 mm) (1).

La saillie par rapport à la surface finie du mur (2)

doit être conforme à la dimension (3).

Il est déconseillé de connecter un bec de robinet

de comptior sur une valve murale. De même il est

déconseillé d'utiliser une doche à main dans la combinaison baignoire et douche avec bouton-poussoir

inverseur.

Le tuyau entre le corps du robinet et le bec de bain

doit consister en un tuyau de cuivre ou en un tuyau

de fer d’au moins 1/2 po (13 mm), long d’au moins 8

po (203 mm) et d’au plus 18 po (457 mm). Ce tuyau

doit être droit, installé à la verticale et raccordé au

manchon fileté du bec par un seul coude de 90

degrés en fer ou en cuivre.

INSTALLATION DE LA POMME DE DOUCHE :

Raccordez la sortie supérieure (1) au bras de

douche (2) à l’aide des raccords appropriés.

Appliquez du ruban de plomberie sur les filets

aux deux extrémités du bras de douche. Pour

éviter d’abîmer le fini du bras de douche,

introduisez l’extrémité du bras de douche côté

mur dans la collerette (3) avant de visser le bras

de douche dans le raccord du tuyau vertical.

Vissez la pomme de douche (4) sur le bras de

douche. Prenez garde de trop la serrer.

1

3

(3) = 3/8

po - 1/2 po (9.5 mm - 12.7 mm)

2

RP62605s

A.

B.

1

2

3

Installez un manchon fileté de 1/2 po de

manière qu’il présente une saillie de 3/8 po à 1/2

po par rapport au mur fini. Appliquez du ruban

de plomberie sur le filetage du manchon et

vissez l’adaptateur en laiton (1) solidement sur

le manchon. Vérifiez la position de la vis de

calage en-dessous du bec (2) pour vous assurer

qu’elle ne fait pas saillie suffisamment à

l’intérieur de celui-ci pour gêner sa mise en

place. Glissez le bec sur l’adaptateur et serrez la

vis de calage en dessous du bec contre

l’adaptateur. Note : Ce bec est muni d’un

mécanisme d’inverseur qui coulisse vers le

bas. Pour dévier l’eau vers la douche,

poussez le coulisseau à l’extrémité du bec

(3) vers le bas.

NOTE : Nous vous recommandons de fixer le bras de douche et les coudes

du bec de baignoire ou la tuyauterie.

1

2

3

4

Page 17

5

C.

A.

B.

Faites glisser le joint torique (1) sur la cartouche

et l’écrou à portée sphérique (2). Le joint sert

de pièce d’espacement et il stabilise le

manchon; il doit se trouver derrière l’écrou à

portée sphérique.

Si le modèle que vous installez nécessite une

pièce d’espacement (1), introduisez-la dans le

manchon (2). Faites glisser le manchon sur la

cartouche, le corps et le joint torique. Assurez la

couverture d’équilibre est correctement placé audessus de l’avant de la cartouche de douche.

Fixez la rosace (1) sur le support (2) à l’aide des

2 vis fournies (3). Prenez garde de serrer les vis

de la rosace excessivement.

3

Installation des pièces de finition

1

2

2

1

2

3

Installation – Série 60

1

Glissez l’anneau de finition (1) sur la cartouche

et le manchon, puis dans la plaque de finition.

Montez la manette de la commande de débit (2)

de manière que le levier soit orienté vers le bas,

à 18 heures. Montez la vis de calage (3) dans la

manette. Poussez la manette sur la cartouche

de la soupape et serrez la vis de calage pour

immobiliser la manette.

D.

2

1

3

Page 18

6

4

Installation et réglage du bouton de température

Il y a risque de blessure si le bouton de température n’est pas réglé.

Installation – Série 60

Réglez la butée de température maximale.

Ouvrez les robinets d’arrêt. Laissez l’eau chaude

et l’eau froide couler à fond jusqu’à ce que la température de l’eau qui s’écoule se stabilise. Placez

un thermomètre dans un gobelet et tenez le gobelet

sous le jet d’eau. Placez le bouton de température

(1) sur les cannelures (2), puis tournez le bouton

de température jusqu’à ce que l’eau soit à la

température maximale voulue (pas plus de 120° ou

température plus basse exigée par le code de plomberie local). Enlevez le bouton de température et

replacez-les sur les cannelures (2) en vous assurant

que la butée de température maximale (3) s’appuie

contre la butée de la manette de débit (4) comme le

montre la figure. Note : La manette de température

est conçue pour être orientée vers le haut à la

position 12 heures. Après avoir réglé les éléments

conformément aux instructions qui précèdent, vissez

la vis (5) dans la manette (1) et fixez la manette à

la tige de soupape en serrant la vis. Introduisez le

bouton (6) dans le trou de vis.

Maintenance – Série 60

Le robinet fuit par le bec de baignoire ou la

pomme de douche :

INTERROMPEZ L’ALIMENTATION EN EAU. Remplacez la cartouche – Kit de réparation RP47201.

Si l’eau ne coule pas :

Vérifiez que le côté chaud de la cartouche est

installé sur la canalisation d’alimentation d’eau

chaude. S’il n’est pas, arrêtez les

approvisionnements en eau et renversez l

a cartouche.

1

3

2

1

4

5

6

4

Page 19

7

T60085, T60285 & T60485 Models / Modelos / Modèles

s Specify Finish

s Especifíque el Acabado

s Précisez le Fini

RP70908s

Tub Spout/Pull-Down Diverter

Tubo de Salida para Bañera/Desviador de Halar

Bec/Avec Dérivation sur Embout

RP49349

Adapter

Adaptador

Adaptateur

RP70905s

Escutcheon

Chapetón

Rosace

RP70909s

Shower Arm & Flange

Brazo de Regadera y Pestaña

Tuyau de Pomme de Douche et Collerette

RP49090

Trim Screws

Atornillos de Franja

Vis de Finition

RP12630

Longer Screws

Tornillos Más Grandes

Vis Plus Longues

RP47201

Cartridge Assembly

Cartucho

Cartouche

RP50879s

Trim Sleeve

Manga de Franja

Manchon de Finition

RP49089s

Trim Ring

Aro de accesorio

Anneau décoratif

RP23336

O-Ring

Anillo "O"

Joint Torique

RP70906s

Handle Assembly & Set Screw

Ensamble de la Manija y Tornillo de Ajuste

Poignée et Vis de Calage

RP70907s

Temperature Knob, Screw & Button

Perilla de la Temperatura, Tornillo y Botone

Poigneé de Réglage de Température, Vis et bouton

RP70916

Set Screw & Allen Wrench

Tornillos de Ajuste y Llaves Hexagonales

Vis de calage et Clés hexagonales

Order Model 87385s

Showerhead

Cabeza de Regadera

Pomme de Douche

RP70918s

Button & O-ring

Botone y Anillo “O”

Bouton et Joint Torique

RP70917s

Spout Flange

Brida del Surtidor

Collerette du bec

RP63510

Set Screw & Allen Wrench

Tornillos de Ajuste y Llaves Hexagonales

Vis de calage et Clés hexagonales

RP74785

Available Extension Kit

Kit de Extensión disponible

Kit d’extension disponibles

Page 20

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

Loading...

Loading...