BriskHeat B2237683 User Manual

Silicone Rubber Drum and Pail Heaters

English

TABLE OF CONTENTS

Introduction .............................................................................................................................................. 2

Applications ............................................................................................................................................. 2

Approvals ................................................................................................................................................. 2

Important Safety Instructions.................................................................................................................... 3

Heater Characteristics / Specifications ..................................................................................................... 4

Installation Instructions ............................................................................................................................. 5

Connecting Heater to Power .................................................................................................................... 6

Operation ................................................................................................................................................. 7

Emergency Procedures ............................................................................................................................ 9

Maintenance Instructions ....................................................................................................................... 10

Troubleshooting Guide ........................................................................................................................... 11

Warranty Information.............................................................................................................................. 12

INTRODUCTION

Thank you for purchasing a BriskHeat® Silicone Rubber Drum / Pail Heater. Your heater is designed to

provide a long and efficient service life with function, reliability, and safety in mind. For additional

information concerning this, or other BriskHeat

representative or contact us directly toll free at 1-800-848-7673 (U.S./Canada) or 614-294-3376.

®

products, please contact your local BriskHeat®

APPLICATIONS

Intended Applications:

• Freeze protection

• Viscosity control

• Product heating

• For use on cylindrical vessels

Prohibited Applications:

• Immersion

• Exposed to weather

• Hazardous locations (Except DHCX and

DHNX series)

Silicone Rubber

Drum and Pail Heaters

DHCH, DHCS, DHLS, DHCX, DHNH, DHNS, DHNX,

DPCH, DPCS, DPNS, ECONO and Custom Series

Instruction Manual

Language Page

English .................................................................................................................................................. 1

Spanish (Español) ............................................................................................................................... 13

French (Français) ................................................................................................................................ 25

German (Deutsch) .............................................................................................................................. 37

Italian (Italiano) ................................................................................................................................... 49

You must read and understand this manual before installing,

operating, or servicing this product. Failure to understand these

instructions could result in an accident causing serious injury or

death.

Keep these instructions for future reference.

APPROVALS

2014 / 35 / EU (Low voltage directive)

IEC 60519-1:2015, 60519-2:2006

2011 / 65 / EU (RoHS 2 directive)

Approvals valid only when installed in accordance with all applicable instructions, codes, and

regulations.

© BriskHeat® Corporation. All rights reserved.

DHCH, DHCS, DHNH, DHNS, DPCH, DPCS, DPNH, DPNS,

DHLS, ECONO and custom series.

DHCX and DHNX series.

DHCH, DHCS, DPCH, DPCS and DHLS series.

2

Silicone Rubber Drum and Pail Heaters

Silicone Rubber Drum and Pail Heaters

IMPORTANT SAFETY INSTRUCTIONS

Immediate hazards which WILL result in severe personal injury or

SAFETY ALERT SYMBOL

The symbol above is used to call your attention to instructions

concerning your personal safety. It points out important safety

precautions. It means “ATTENTION! Become Alert! Your

Personal Safety is involved!” Read the message that follows

and be alert to the possibility of personal injury or death.

A person who has not read and understood all operating

Instructions is not qualified to operate this product.

• Do not immerse heater in liquid.

• Keep volatile or combustible material away from heater

when in use.

• Use heater only in approved locations.

• Keep sharp metal objects away from heater.

• All DHCX and DHNX heaters have T ratings described

in Article 501 of the NEC code. The heaters should not

be used in an area with a lower T rating than the

heater.

• Do not modify this product. Modification will void

warranty.

Failure to observe these warnings may result in electric shock,

risk of fire, and personal injury.

End-User Must Comply to the Following:

• Only qualified personnel are allowed to connect

electrical wiring.

• Disconnect all supply power at the source before

making any power connections.

• All electrical wiring must follow local electrical codes.

• The person who performs the final installation / wiring

must be qualified for this work.

• The end-user is responsible for providing a suitable

disconnecting device.

• The end-user is responsible for providing suitable

electrical protection device. It is highly recommended

that a ground fault circuit breaker is used.

• DHCX and DHNX series: A NRTL (National

Recognized Testing Laboratory) listed temperature

controller must be used to control the surface

temperature of the heaters. The controller must be

approved for the area where it is located.

• DHCX and DHNX series: Heaters provide surface

heating, Consult proper authorities for information for

safe heating of materials/contents of any vessel

heated by DHCX and DHNX heaters.

Failure to observe these warnings may result in personal injury

or damage to the heater.

DANGER

DANGER

WARNING

Hazards or unsafe practices that COULD result in severe personal

Hazards or unsafe practices that COULD result in minor personal

• Never handle the heater while it is in operation; Always

• Inspect heater before use (see page 10).

• Never operate a heater without a temperature control

• Do not wrap the heater over itself.

• If spillage of foreign matter onto heater occurs,

• Never operate a heater without an appropriate heat

• Do not operate heater above rated temperature value.

• Fasten heater to device using approved methods only.

• Do not repair damaged or faulty heaters.

• Do not crush or apply severe physical stress on heater

• Disconnect heater when not in use.

• Use specified sized heater with same sized drum. Do

• DHCX series: Never allow the full weight of the thermal

• DHNX series: The metal enclosure must not support

Failure to observe these warnings may result in personal injury

or damage to the heater.

DANGER

death.

WARNING

injury or death.

CAUTION

injury or property damage.

CAUTION

disconnect the heater from the power source and allow

to cool prior to handling.

device.

disconnect from power source and clean after heater is

allowed to cool.

sink (device being heated is considered a heat sink).

or cord assembly.

not use for other applications.

bulb controller to hang from the heater.

more than 10lbs (4.5kg).

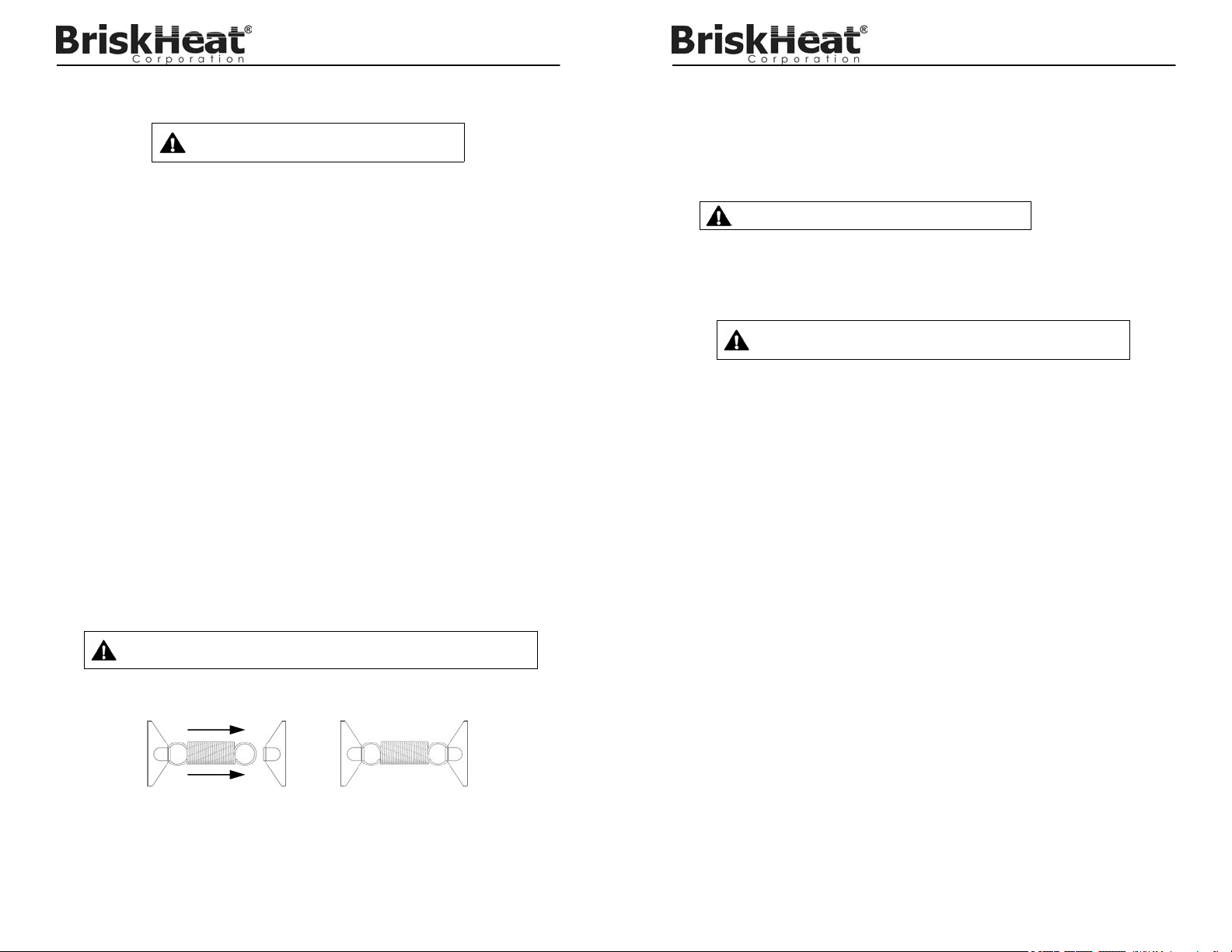

HEATER CHARACTERISTICS / SPECIFICATIONS

Part Series DHCH DHCS DHLS DHCX DHNH DHNS DHNX DPCH DPCS DPNS DPNH ECONO

Band Width 4" 4" 4" 8" 4" 4" 8" 4" 4" 4" 4” 3.6"

Layers of

Silicone

Max Power

Density

(W/in²)

Min Exposure

Temperature

Max Exposure

Temperature

Max Humidity 95% 95% 95% 95% 95% 95% 95% 95% 95% 95% 95% 95%

Ingress

Protection

Grounded

Heating

Element

Moisture and

Chemical

Resistant

Suitable for

Metal

Container

Suitable for

Plastic

Container

Suitable for

Hazardous

Locations*

Adjustable

Thermostat

Controller

Built-in High

Limit Safety

Thermostat

* Refer to product label for approved hazardous locations

3 2 2 4 3 2 4 3 2 2 3 2

4.5 4.5 4.5 2.5 4.5 4.5 2.5 1.2 1.2 1.2 1.2 4.5

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

450°F

450°F

450°F

400°F

450°F

450°F

400°F

450°F

(232°C)

(232°C)

(232°C)

(204°C)

(232°C)

(232°C)

(204°C)

IP54 IP54 IP54 IP56 IP56 IP56 IP56 IP54 IP54 IP56 IP56 IP54

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓

✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓

(232°C)

450°F

(232°C)

(-51°C)

450°F

(232°C)

-60°F

(-51°C)

450°F

(232°C)

(-51°C)

(232°C)

-60°F

450°F

© BriskHeat® Corporation. All rights reserved.

3

© BriskHeat® Corporation. All rights reserved.

4

Silicone Rubber Drum and Pail Heaters

Silicone Rubber Drum and Pail Heaters

INSTALLATION INSTRUCTIONS

Failure to follow these instructions could result in

property damage, personal injury, or death.

Requirements:

• Electrical terminations must be completed by qualified persons.

• No special tools or protective equipment is needed to handle this product (specific applications or

surfaces may require protective equipment).

• Installation temperature range: -60°F (-51°C) to 131°F (55°C).

• Clearance of 3" (7.5cm) required around vessel during installation.

• Voltage and frequency must be within +/- 10% of the value specified on the product label.

Surface Preparation:

Always install your heater on a clean even surface for optimum performance and longevity. Debris and

residue on the surface can not only damage your heater but may also reduce the effectiveness of the

heater by reducing the heat transfer between the surface and the heater.

• Remove or avoid contact with sharp edges including rough corners, weld spatter, exposed bolts,

etc.

• Remove or avoid contact with rust, stickers, or other coverings.

• Remove oil, moisture, gel and other liquids.

Instructions:

1. Inspect heater prior to each installation (see inspection procedure).

2. Inspect vessel to be heated for any sharp edges, rust, oil, etc.

3. Ensure that there is no combustible material within 12" (30cm) of the surface to be heated.

4. Select a suitable location to install the heater. The heater should be located below the lowest

expected content level (typically the bottom 1/3) of the vessel.

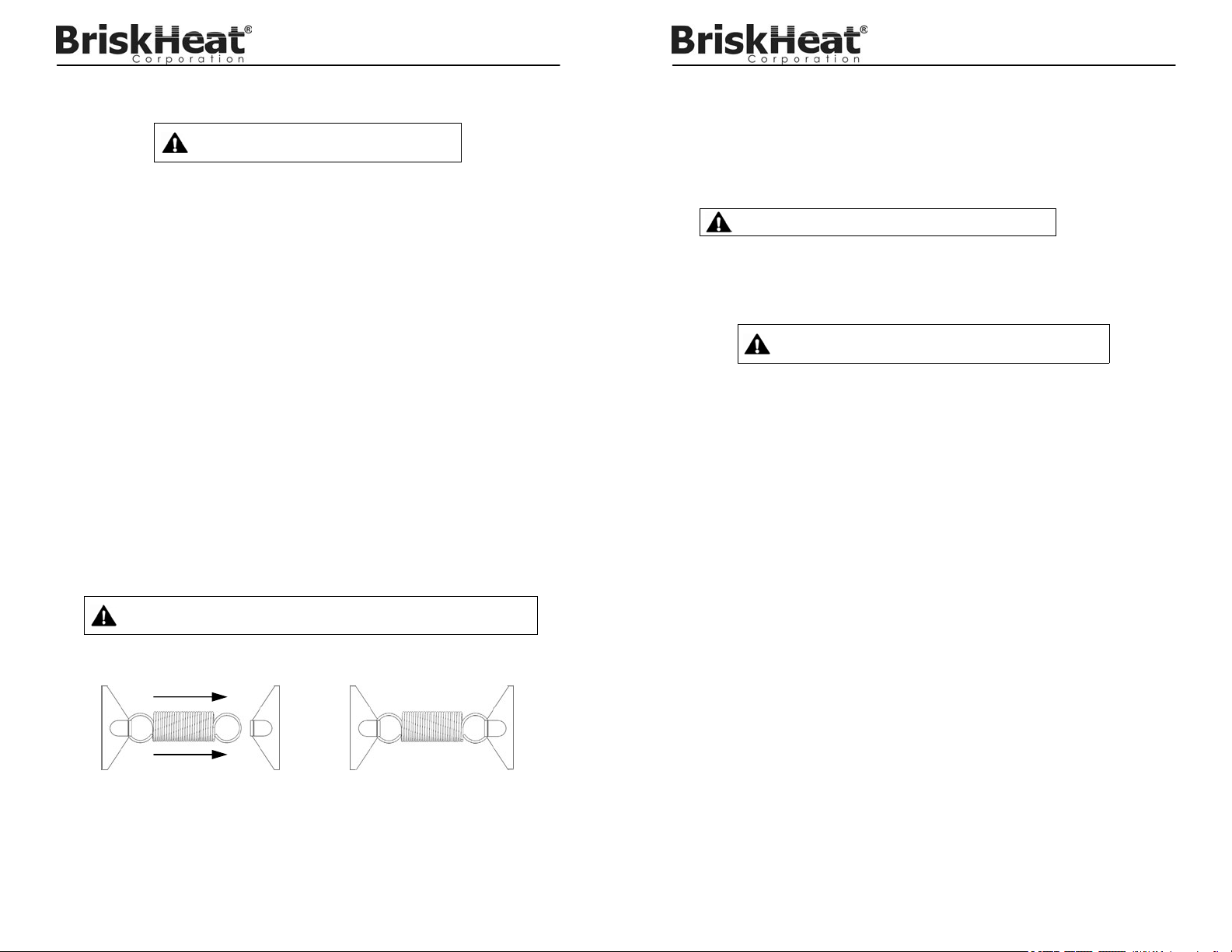

Do not overlap the heater on itself or another heater. Do not twist the heater or cover

any protrusions that may cause an air gap beneath the heater.

5. Wrap the heater around the vessel. Extend the spring attached to the metal tab until it hooks onto

the opposing metal tab as shown below.

Installing the Temperature Sensor (DHCX series)

1. Mount the temperature sensor as close as possible to the heater and on the outside of the drum. It

is best to mount the sensor vertically. Avoid bending or coiling the capillary tube tighter than a

1/2” (13mm) radius.

Note: The sensing point is the entire length of the sheath 10.5”(267mm). It i s impor tant that as

much of the bulb’s surface is in contact with the drum as possible.

2. Once an appropriate location has been determined, secure the sensor to the drum using aluminum

Do not immerse the sensing bulb into the contents of the drum.

or fiberglass adhesive tape.

CONNECTING HEATER TO POWER SOURCE

All electrical wiring must be completed by qualified persons and

must be in compliance with local codes and regulations.

Heater equipped with temperature controlling device:

Before connecting the heater to an electrical source, turn the adjustable dial on the heater’s control box

in the counter clockwise direction until it stops (this is the off position).

Heaters provided with a plug:

Connect the provided plug to a power supply receptacle.

Heaters provided with wire leads:

The power cable consists of three color-coded conductors: black, white and green. The black wire

should be connected to Line 1. The white wire should be connected to Line 2. The green wire

should be connected to earth ground. The power connections must be adequately rated to

electrically support the voltage and amperage of the heater. The identification label located on the

power cord displays voltage and amperage requirements.

Figure 1

6. Check for any air-gaps between the heater and the vessel.

7. Install temperature controlling device if other then adjustable thermostat (See below for DHCX).

© BriskHeat® Corporation. All rights reserved.

5

© BriskHeat® Corporation. All rights reserved.

6

Silicone Rubber Drum and Pail Heaters

Silicone Rubber Drum and Pail Heaters

OPERATION

DHCH, DHCS, DHLS, DPCH, DPCS, and ECONO series:

This product is equipped with a dial adjustable thermostat temperature controller. A maximum

temperature is identified on the label: 425°F (218°C) or 160°F (71°C). Adjust dial to desired heat output .

To increase temperature output of the heater, turn the adjustable dial in the clockwise direction. To

decrease temperature output of the heater, turn the adjustable dial in the counter clockwise direction.

Note: Ambient conditions will affect the dial’s position in which the heater begins to heat. In cooler

temperature conditions the heater will begin to heat at a lower temperature position on the dial

and in warmer temperature conditions the heater will begin to heat at a higher temperature

position on the dial.

It is recommended that a thermometer is attached to the vessel being heated. Adjust the dial until you

achieve the desired temperature.

Note: Changes in ambient conditions or in the temperature of the contents may cause the

temperature to shift over time.

For heating temperature sensitive materials that require a specific set-point or have a tight

tolerance temperature range Use of an external temperature controlling device is required. Select a

temperature controller with the accuracy necessary for the application and is approved for the location

and conditions where the drum heater is to be used. For lower temperature applications up to 212°F

(100°C) BriskHeat recommends the use of a TC4X Digital Temperature Controller. For higher

temperature applications BriskHeat recommends the use of a TTD Digital Temperature Controller.

Note: If assistance determining a proper temperature controlling device is required for your

application, please contact BriskHeat or your local distributor for application assistance and

product solutions.

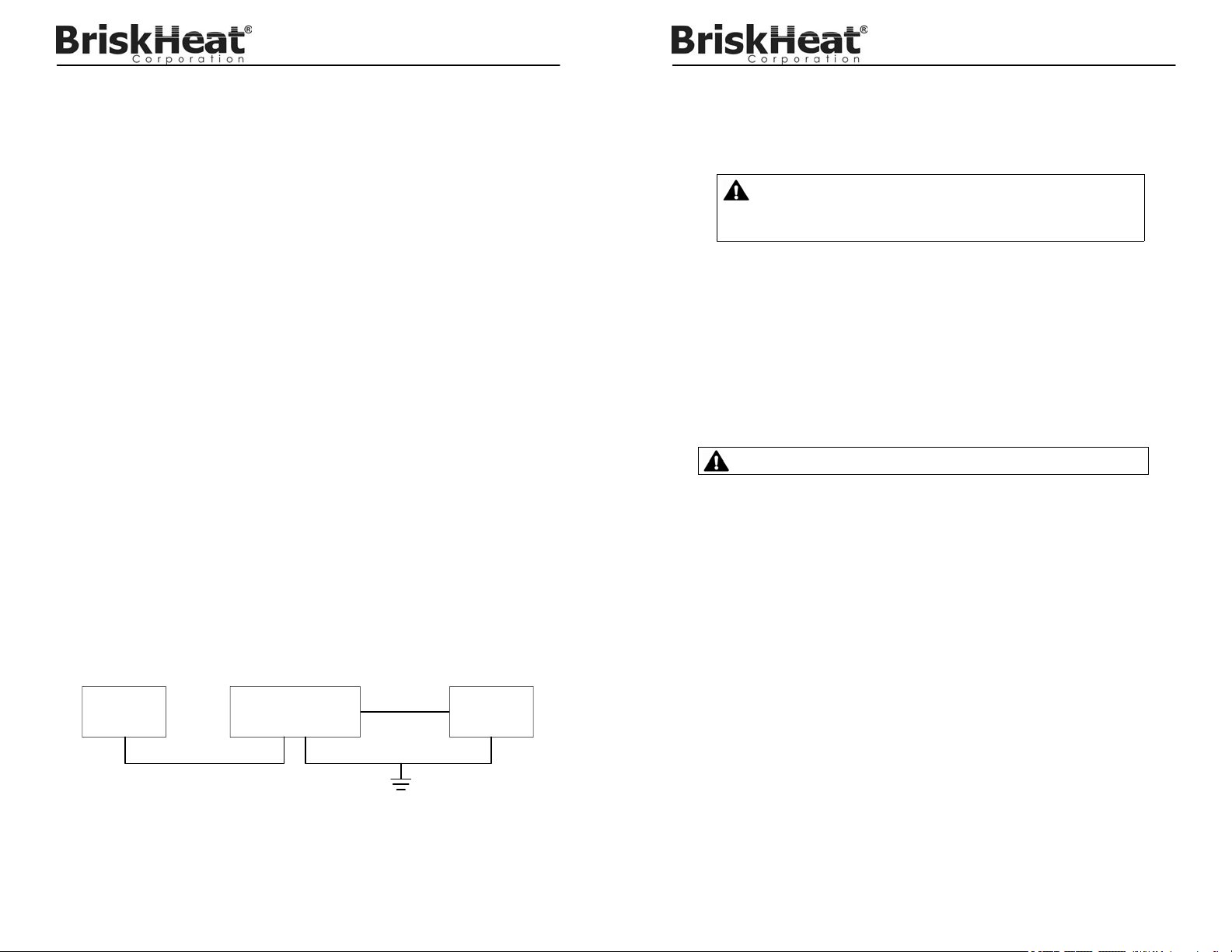

Install and connect the external temperature controlling device between the drum heater and the

electrical source as shown in Figure 2. Install the temperature controlling device in accordance with

manufacturer’s installation instructions.

Ensure a grounded connection is provided and if the temperature controlling device does not support a

grounded connection, ensure an approved earth ground source is provided.

Mount the temperature sensor between the heater’s metal tab and the outside of the container. Secure

the sensor to the container using appropriately rated aluminum or fiberglass adhesive tape.

Set the drum heater’s temperature controlling dial to the maximum temperature setting. Adjust heater

output using the external temperature controlling device.

DHCX series Remove the two screws securing the metal plate opposite the temperature sensor.

Remove the metal plate to expose the low and high limit set-point controls. Adjust the high and low

temperature set-points to an appropriate level for the application. The low temperature set-point is the

process control. The high limit set point is connected to the high temperature limit indicator light.

Replace the metal plate and secure with two screws.

Do not adjust the low set-point higher than the high limit thermostat.

Do not adjust the low set-point higher than the high temperature set-point

connected to the indicator light.

NOTE: These heaters have a built-in, high limit thermostat that will prevent it from overheating.

T-3 rated heaters: 292°F (145°C) high limit thermostat.

T-4A rated heaters: 158°F (70°C) high limit thermostat.

Drum heater operation can now be controlled using the external temperature controlling device. Follow

operating instructions for the external temperature controlling device for adjusting the specific

temperature set-point.

DHNS and DPNS series Do not operate the heater without a temperature controlling device. Failure to

use such a device may result in material damage or heater failure. If normal operating temperature

exceeds 400°F (204°C), a separate high-limit temperature cut-out sensor/controller is required to protect

the heater.

Ensure maximum intermittent exposure temperature never exceeds 450°F (232°C).

Electrical

Source

Controller Power Connection Heater Power Connection

External Temperature

Controlling Device

Figure 2

© BriskHeat® Corporation. All rights reserved.

7

Temperature

Sensor

Heater

© BriskHeat® Corporation. All rights reserved.

8

Silicone Rubber Drum and Pail Heaters

Silicone Rubber Drum and Pail Heaters

EMERGENCY PROCEDURES

Read and understand these procedures prior to using this heater.

Disconnect power to the heater in the event of an emergency.

Electric Shock:

• Do not touch the injured person while they are still in contact with the electrical current.

• Call your local emergency service if the injured person experiences: severe burns, confusion,

difficulty breathing, heart rhythm problems, cardiac arrest, muscle pain and contractions, seizures

or a loss of consciousness.

Minor Burns:

• Hold the burned area under cool running water for 10-15 minutes.

• Remove rings or other tight items from burned area.

Major Burns:

• Call your local emergency service.

• Protect the person from further harm.

• Remove rings or other tight items from burned area.

• Monitor breathing and perform CPR if necessary.

Fire:

• Call your local emergency service.

• If it is safe to do so, use a fire extinguisher to fight the fire, otherwise evacuate to a safe distance

and wait for help to arrive.

• This heater is built from material that will not support a flame but could ignite nearby combustible

material.

MAINTENANCE INSTRUCTIONS

Anyone who reads and understands these instructions is

qualified to maintain this heater.

Maintenance:

• All maintenance should be performed after heater has cooled to room temperature and with the

electricity disconnected.

• This product should be inspected prior to being installed and at least every 3 months during use.

• Dirt, oil, grease or other foreign matter can be removed with a damp rag and mild household

cleaners.

• Do not attempt to repair a damaged heater.

Inspection:

• Inspection should be performed after the heater has cooled to room temperature and with the

electricity disconnected.

• The heater should be free of any cuts, cracks, or punctures.

• The power leads should not have any visible breaks in their insulation

• The heater should be free of any build-up of dirt, oil, grease, or other foreign matter.

Storage:

• This product should be stored indoors.

Disposal:

• This product does not contain any hazardous substances and may be discarded with domestic

waste.

© BriskHeat® Corporation. All rights reserved.

9

© BriskHeat® Corporation. All rights reserved.

10

Silicone Rubber Drum and Pail Heaters

Silicone Rubber Drum and Pail Heaters

TROUBLESHOOTING GUIDE

Please read this guide prior to contacting BriskHeat®. This guide is designed to answer the most

commonly asked questions. If you need additional assistance, please contact your local distributor/

representative or contact BriskHeat at 1-800-848-7673 (Toll free US / Canada) or 614-294-3376

(Worldwide), or by email at bhtsales1@briskheat.com.

PROBLEM SOLUTION(S)

Does not heat Verify heater is connected to proper voltage. The identification label located

on the power cord displays the heater’s voltage requirement.

Using an ohm meter, check to see if there is a resistance

reading (not an open circuit) in the heater.

If external temperature controlling device is installed, ensure the heaters

control dial is in the maximum heating position.

Circuit breaker is

tripping

Validate that the circuit breaker is capable of handling the amp requirement

of heater. The identification label located on the power cord displays the

heater’s amperage requirement.

Examine heater and cord for any damage.

Does not fit Confirm that the heater provided was designed to fit around your specified

drum.

If the heater was designed for the specified drum, please call

1-800-848-7673 or 614-294-3376 for further assistance.

WARRANTY INFORMATION

BriskHeat warrants to the original purchaser of this product for the period of eighteen (18) months from

date of shipment or twelve (12) months from date of installation, whichever comes first. BriskHeat’s

obligation and the exclusive remedy under this warranty shall be limited to the repair or replacement, at

BriskHeat’s option, of any parts of the product which may prove defective under prescribed use and

service following BriskHeat’s examination, is determined by BriskHeat to be defective. The complete

details of the warranty can be found online at www.briskheat.com or by contacting us at 1-800-848-7673

(toll free, U.S. / Canada) or 1-614-294-3376 (Worldwide).

© BriskHeat® Corporation. All rights reserved.

11

Corporate Headquarters:

4800 Hilton Corporate Dr.

Columbus, OH 43232, U.S.A.

Email: bhtsales1@briskheat.com

© BriskHeat® Corporation. All rights reserved.

Toll Free: 800-848-7673

Phone: 614-294-3376

Fax: 614-294-3807

12

Europe:

P.O. Box 420124

44275 Dortmund, Germany

PN:11663 Rev D APR 2017

Calentadores de caucho de silicona

para bidones y cubetas

Spanish (Español)

ÍNDICE

Introducción .......................................................................................................................................... 14

Aplicaciones .......................................................................................................................................... 14

Aprobaciones ........................................................................................................................................ 14

Instrucciones importantes de seguridad ................................................................................................ 15

Características y especificaciones de los calentadores ......................................................................... 16

Instrucciones de instalación .................................................................................................................. 17

Conexión del calentador a la fuente de alimentación ............................................................................ 18

Operación ............................................................................................................................................. 19

Procedimientos de emergencia ............................................................................................................. 21

Instrucciones de mantenimiento ............................................................................................................ 22

Guía de localización de fallas ................................................................................................................ 23

Información de garantía ........................................................................................................................ 24

INTRODUCCIÓN

Le agradecemos su compra de un calentador de caucho de silicona para bidones y cubetas BriskHeat®.

Su calentador está diseñado para proporcionar una larga y eficiente vida de servicio, con aspectos

como funcionamiento, fiabilidad y seguridad en mente. Para obtener información adicional con relación

a este u otros productos BriskHeat

directamente con nosotros llamando a la línea gratuita 1-800-848-7673 (EE. UU./Canadá) o al

614-294-3376.

®

, póngase en contacto con su representante local de BriskHeat® o

APLICACIONES

Aplicaciones previstas:

• Protección contra la congelación

• Control de viscosidad

• Calentamiento de productos

• Para utilizar en receptáculos cilíndricos

Aplicaciones prohibidas:

• Inmersión

• Exposición a la intemperie

• Ubicaciones peligrosas (excepto las series

DHCX y DHNX)

Calentadores de caucho de

silicona para bidones y cubetas

Series DHCH, DHCS, DHLS, DHCX, DHNH, DHNS,

DHNX, DPCH, DPCS, DPNS, ECONO y especiales

Manual de instrucción

Es necesario que lea y comprenda este manual antes de

instalar, operar o prestar servicio a este producto. Si no se

comprenden estas instrucciones podría producirse un

accidente que cause lesiones graves o la muerte.

Conserve estas instrucciones para consultas en el futuro.

13

APROBACIONES

2014 / 35 / EU (Directiva de baja tensión)

IEC 60519-1:2015, 60519-2:2006

2011 / 65 / EU (Directiva RoHS 2)

Las aprobaciones son válidas solamente cuando se instala conforme a todas las instrucciones,

normativa y regulaciones pertinentes.

© BriskHeat® Corporation. Todos los derechos reservados.

Series DHCH, DHCS, DHNH, DHNS, DPCH, DPCS,

DPNH, DPNS, DHLS, ECONO y especiales.

Series DHCX y DHNX.

Series DHCH, DHCS, DPCH, DPCS y DHLS.

14

Calentadores de caucho de silicona

para bidones y cubetas

Calentadores de caucho de silicona

para bidones y cubetas

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

PELIGRO

SÍMBOLO DE ALERTA DE SEGURIDAD

El símbolo precedente se utiliza para llamarle la atención sobre

instrucciones concernientes a su seguridad personal. Sirve para

señalar precauciones de seguridad importantes. Significa

'¡ATENCIÓN! ¡Manténgase alerta! ¡Está en juego su

seguridad personal!' Lea el mensaje que sigue a continuación y

manténgase alerta ante la posibilidad de lesiones personales o la

muerte.

Una persona que no haya leído y comprendido las

instrucciones de operación no está calificada para operar este

producto.

• No sumerja el calentador en líquido.

• Mantenga los materiales volátiles o combustibles lejos

del calentador cuando esté en uso.

• Utilice el calentador solamente en los lugares

aprobados.

• Mantenga los objetos metálicos aguzados lejos del

calentador.

• Todos los calentadores DHCX y DHNX tienen las

especificaciones de temperatura (T ratings) descritas

en el Artículo 501 del Código Eléctrico Nacional de los

EE. UU. (NEC). No se deben utilizar los calentadores

en un área con una especificación de temperatura (T

rating) más baja que la del calentador.

• No modifique este producto. La modificación anulará

la garantía.

No respetar estas advertencias puede resultar en descarga

eléctrica, riesgo de incendio y lesiones personales.

El usuario final debe cumplir con lo siguiente:

• Solo el personal calificado está autorizado para

conectar cableado eléctrico.

• Desconecte toda la alimentación eléctrica en el origen

antes de hacer cualquier conexión eléctrica.

• Todo el cableado eléctrico debe observar los códigos

eléctricos locales.

• La persona que realice la instalación/cableado final

• debe estar calificada para este trabajo.

• El usuario final es responsable de proporcionar un

dispositivo de desconexión adecuado.

• El usuario final es responsable de proporcionar un

dispositivo de protección eléctrica adecuado. Se

recomienda muy especialmente utilizar un interruptor

automático de protección contra fallas a tierra.

• Series DHCX y DHNX: se debe utilizar un controlador

de temperatura aprobado por un NRTL (laboratorio de

pruebas reconocido en el ámbito nacional) para

controlar la temperatura de superficie de los

calentadores. El controlador debe estar aprobado para

el área en el que está ubicado.

• Series DHCX y DHNX: los calentadores proporcionan

calentamiento de superficies; para obtener información

sobre el calentamiento seguro de materiales/contenido

de cualquier receptáculo calentado por calentadores

DHCX y DHNX, consulte a las autoridades

pertinentes.

No prestar atención a estas advertencias puede resultar en

lesiones personales o daños al calentador.

PELIGRO

PELIGRO

ADVERTENCIA

© BriskHeat® Corporation. Todos los derechos reservados.

Riesgos inmediatos que CAUSARÁN lesiones personales graves

Riesgos o prácticas inseguras que PODRÍAN CAUSAR lesiones

Riesgos o prácticas inseguras que PODRÍAN CAUSAR lesiones

personales menores o daños materiales.

• No maneje nunca el calentador cuando esté en

operación; desconecte siempre el calentador de la

fuente de alimentación y espere a que se enfríe antes

de manejarlo.

• Inspeccione el calentador antes del uso (vea la página

10).

• No opere nunca un calentador sin un dispositivo de

control de temperatura.

• No envuelva el calentador sobre sí mismo.

• Si se produce un derrame de material extraño sobre el

calentador, desconéctelo de la fuente de alimentación

y límpielo después de que se haya enfriado.

• No opere nunca un calentador sin un disipador de

calor apropiado (el dispositivo que se está calentando

se considera un disipador de calor).

• No opere nunca un calentador por encima del valor de

temperatura nominal. Sujete el calentador al

dispositivo solo mediante métodos aprobados. No

repare calentadores dañados o defectuosos.

• No aplaste ni aplique presión física severa sobre el

conjunto de calentador o de cables de alimentación.

• Desconecte el calentador cuando no se esté

utilizando.

• Utilice el calentador del tamaño especificado con el

bidón del mismo tamaño. No lo utilice para ninguna

otra aplicación.

• Serie DHCX: No permita nunca que el peso completo

del controlador de ampolla térmica cuelgue del

calentador.

• Serie DHNX: la carcasa metálica no debe soportar

más de 10 lb (4.5 kg).

No prestar atención a estas advertencias puede resultar en

lesiones personales o daños al calentador.

15

o la muerte.

ADVERTENCIA

personales graves o la muerte.

PRECAUCIÓN

PRECAUCIÓN

CARACTERÍSTICAS Y ESPECIFICACIONES DE LOS CALENTADORES

Característica

Ancho de la

banda

Capas de

silicona

Densidad de

potencia máx.

(W/pulg.²)

Temperatura

de exposición

Temperatura

de exposición

Humedad

Protección

contra ingreso

Elemento

calentador

conectado

Resistente a

la humedad y

los productos

Apto para

recipientes

metálicos

Apto para

recipientes

plásticos

Apto para

ubicaciones

peligrosas*

Controlador

de termostato

ajustable

Termostato

de seguridad

de límite

superior

Para conocer las ubicaciones peligrosas aprobadas, consulte la etiqueta del producto.

*

DHCH DHCS DHLS DHCX DHNH DHNS DHNX DPCH DPCS DPNS DPNH ECONO

Serie

4" 4" 4" 8" 4" 4" 8" 4" 4" 4" 4” 3.6"

3 2 2 4 3 2 4 3 2 2 3 2

4.5 4.5 4.5 2.5 4.5 4.5 2.5 1.2 1.2 1.2 1.2 4.5

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

-60°F

min.

máx.

máx.

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

(-51°C)

450°F

450°F

450°F

400°F

450°F

450°F

(232°C)

(232°C)

(232°C)

(204°C)

(232°C)

95% 95% 95% 95% 95% 95% 95% 95% 95% 95% 95% 95%

IP54 IP54 IP54 IP56 IP56 IP56 IP56 IP54 IP54 IP56 IP56 IP54

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓

✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓

✓ ✓

(232°C)

400°F

(204°C)

(-51°C)

450°F

(232°C)

-60°F

(-51°C)

450°F

(232°C)

(-51°C)

(232°C)

© BriskHeat® Corporation. Todos los derechos reservados.

16

-60°F

450°F

-60°F

(-51°C)

450°F

(232°C)

-60°F

(-51°C)

450°F

(232°C)

Calentadores de caucho de silicona

para bidones y cubetas

Calentadores de caucho de silicona

para bidones y cubetas

INSTRUCCIONES DE INSTALACIÓN

Si no se siguen estas instrucciones podrían producirse

daños materiales, lesiones personales o la muerte.

Requisitos:

• Las terminaciones eléctricas deben estar a cargo de personas calificadas.

• No se necesita ninguna herramienta especial ni equipo de protección para manejar este producto

(puede haber aplicaciones o superficies específicas que requieran equipo de protección).

• Rango de temperaturas de instalación: -60°F (-51°C) a 131°F (55°C).

• Se requiere un espacio libre de 3" (7.5 cm) alrededor del receptáculo durante la instalación.

• La tensión y la frecuencia deben estar dentro de +/-10% del valor especificado en la etiqueta del

producto.

Preparación de la superficie:

Instale siempre su calentador sobre una superficie limpia y uniforme, para asegurar un desempeño y

longevidad óptimos. Los desperdicios y residuos presentes en la superficie no solo pueden dañar su

calentador sino también reducir su efectividad, al reducir la transferencia de calor entre la superficie y el

calentador.

• Elimine o evite el contacto con bordes aguzados, como ángulos rugosos, salpicaduras de

soldadura, pernos expuestos, etc.

• Elimine o evite el contacto con óxido, autoadhesivos y otras coberturas.

• Elimine el aceite, humedad, geles y otros líquidos.

Instrucciones:

1. Inspeccione el calentador antes de cada instalación (vea el procedimiento de inspección).

2. Inspeccione el receptáculo a calentar para ver si tiene bordes aguzados, oxidación, aceite, etc.

3. Asegúrese de que no haya material combustible dentro de 12" (30 cm) de la superficie a calentar.

4. Seleccione una ubicación apropiada para instalar el calentador. El calentador debe colocarse

debajo del más bajo nivel previsto de contenido del receptáculo (normalmente el tercio inferior).

Do not overlap the heater on itself or another heater. Do not twist the heater or cover

any protrusions that may cause an air gap beneath the heater.

5. Enrolle el calentador alrededor del receptáculo. Extienda el resorte fijado a la lengüeta metálica

hasta que se enganche en la lengüeta metálica opuesta, como se muestra a continuación.

Instalación del sensor de temperatura (serie DHCX)

1. Monte el sensor de temperatura tan cerca del calentador como sea posible y en la parte exterior

del bidón. Lo mejor es montar el sensor verticalmente. Evite doblar o enrollar el tubo capilar con

un radio menor de 1/2" (13 mm).

Nota: El punto sensor es la longitud completa de la funda: 10.5” (267 mm). Es importante que

esté en contacto con el bidón la mayor superficie posible de la ampolla.

No sumerja la ampolla detectora en el contenido del bidón.

2. Una vez que se haya determinado la ubicación apropiada, fije el sensor al bidón utilizando cinta

adhesiva de aluminio o fibra de vidrio.

CONEXIÓN DEL CALENTADOR A LA FUENTE DE ALIMENTACIÓN

Todo el conexionado eléctrico debe estar a cargo de personas calificadas y

debe cumplir con los códigos y reglamentaciones locales.

Calentadores equipados con un dispositivo controlador de temperatura:

Antes de conectar el calentador a una fuente de alimentación, gire el cuadrante ajustable de la caja de

control del calentador en sentido antihorario hasta que haga tope (esta es la posición Apagado (OFF)).

Calentadores provistos de un enchufe:

Conecte el enchufe provisto a un tomacorriente eléctrico.

Calentadores provistos de cables de conexión:

El cable de alimentación se compone de tres conductores con código de colores: negro, blanco y verde.

El cable negro debe conectarse a la Línea 1. El cable blanco debe conectarse a la Línea 2. El cable

verde debe conectarse a tierra. Las conexiones de alimentación deben dimensionarse de manera

adecuada con el fin de soportar eléctricamente la tensión (volts) y la corriente (amperes) del calentador.

La etiqueta de identificación ubicada en el cable de alimentación muestra los requisitos de tensión

(volts) y corriente (amperes) del calentador.

Figura 1

6. Averigüe si hay espacios de aire entre el calentador y el receptáculo.

7. Instale el dispositivo controlador de temperatura, si no es un termostato ajustable (vea abajo el

caso del DHCX).

© BriskHeat® Corporation. Todos los derechos reservados.

17

© BriskHeat® Corporation. Todos los derechos reservados.

18

Loading...

Loading...