Page 1

OWNER’S GUIDE

PHOENIX MANUFACTURING, INC.

USE AND CARE MANUAL

WINDOW COOLER MODELS

For Customer Assistance

CALL 1-800-325-6952

DO NOT RETURN TO PLACE OF PURCHASE!

Congratulations: You have purchased a product of superior performance and design,

Safety

Installation

Start-up

Operation

Maintenance

Troubleshooting

which will give the best service when properly installed, operated and maintained.

This guide will provide you with information needed to mount, operate, inspect, maintain,

and troubleshoot your Brisa window evaporative air cooler.

The first section, Installation and Start-Up, gives details for installation. The second

section, Maintenance, contains operational and maintenance instructions, while

Troubleshooting includes information on commonly encountered problems.

INSTALLER: Please deliver this guide to owner.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING.

BW3501 / BW3501MX

BW4002 / BW4002MX

BW4502 / BW4502MX

BW5002 / BW5002MX

Read all instructions carefully before installation.

This cooler must be connected to 120 Volt AC, 60 Hz (cycle)

power only. NOTE: Improper voltage will void the pump and/or

motor warranties and may cause serious personal injury or

property damage.

This cooler must be plugged into a GFCI protected receptacle,

which has been properly installed in accordance with all local

and national codes. If you are not sure that the receptacle is

GFCI protected, consult with a qualified electrician.

This cooler is equipped with a power cord having an equipment

grounding conductor and grounding plug. Do not attempt to

defeat this safety device by removing the grounding pin.

Use of an extension cord is not recommended.

Do not operate if plug or cord is damaged in any way. If the unit

is damaged or malfunctions, do not continue to operate it.

Always disconnect electrical power to unit before attempting to

work on or service your cooler.

Some models may have a restricting orifice in the pump water

tube to assure proper water flow rate to the pad. Do not remove

this restrictor!

Remove the plug from the electrical receptacle by pulling on

the plug and not the cord.

Do not operate this blower (fan) motor with any solid-state

speed control device.

Do not operate this unit with pad frame(s) and/or air outlet grille

removed, this may cause the fan motor to overload and

damage the motor.

NOTE:

Do not locate unit near exhaust or vent pipes as odors or fumes

may be drawn into cooler.

Use of anode devices, chemical additives or treatments in this

cooler will void the warranty.

Your warranty does not cover shipping damage. Report all

shipping damage at once to dealer or carrier making the delivery.

For future reference, record the model and serial numbers, date

and place of purchase of your evaporative cooler here:

Model #

Serial #

Date of Purchase:

Place of Purchase:

1-999-2431 Date: 01/13

Page 2

INTRODUCTION

Your Brisa evaporative air cooler was thoroughly tested and inspected

before leaving the factory. This manual is your guide to proper

installation procedures along with information about reasonable care

and maintenance that will ensure safe, economical and trouble free

cooling. Failure to follow these instructions may damage your cooler,

impair its operation, create the potential for serious personal injury

and/or void the warranty.

Read it carefully.

A Note About Air Exhausting / Maximum Cooling

Since coolers function best when there are plenty of openings for the

air to exhaust, you can leave doors or windows open so your house

can breathe.

keep insects, dust, dirt, etc out of the cooled space, the house should

be maintained at a slightly positive air pressure (that is, there should

be slightly more air going into the house than is leaving). This is

controlled by how much the windows or doors are opened.

How much should you open your windows or doors? You should

adjust your openings until the air pressure inside the house is

nearly balanced with the air outside. A good method to determine

when the air is reasonably balanced is to place a tissue paper

against the screen in the window or door farthest from the cooler

and adjust the other openings in the house until the tissue paper

stays lightly on the screen. You can adjust different windows in the

house to direct the most airflow to the areas that are occupied

during different times of the day or night (example: living room

windows during the daytime, bedroom windows at night.)

HINT: To avoid a rush of warm air when starting the cooler be sure to

turn on the pump for a few minutes to completely wet out the pads

before starting the blower.

To get the maximum capacity of your cooler, and to help

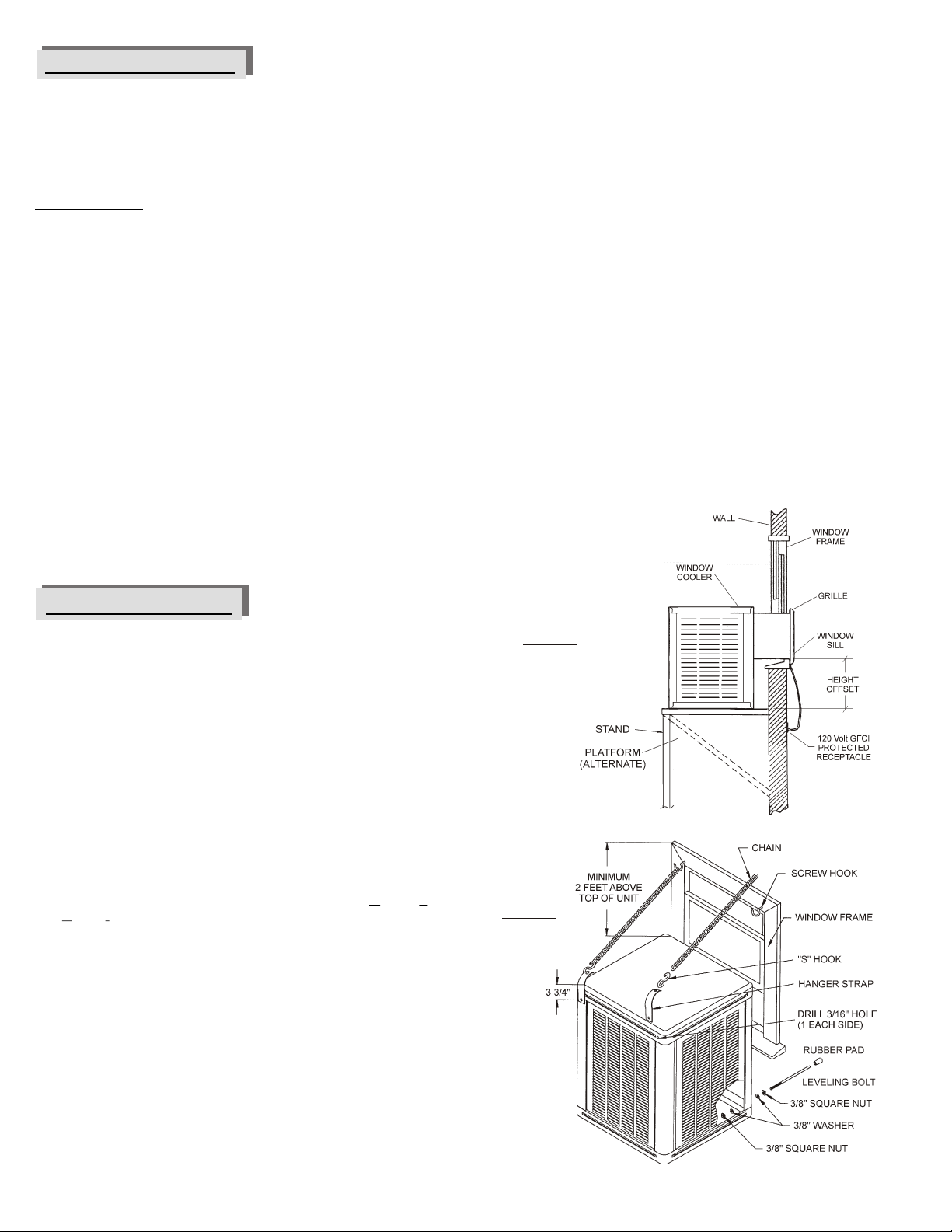

Platform or Stand Mounting

Installation normally involves locating the unit in a suitable window

and the construction of a platform or stand to support the weight of the

cooler. Since every installation is different, the exact requirements to

mount and seal a cooler against the weather will be best determined

by the location and at the time of the installation. Most installations will

require blocking of the unused portion of the window around the duct

or other modifications to the window frame may be necessary.

illustration (Fig. 1) for a typical installation. Construct a platform or

stand below the window strong enough to support the weight of the

cooler (approximately 250 pounds).

Measure and construct a level platform or stand that will allow the

bottom surface of the cooler duct to rest on the window sill. Allow

clearance for the drain/overflow standpipe connection.

Position the cooler so that the duct rests on the window sill and the

grille flanges are inside the window frame. DO NOT drive nails or

screws through bottom pan into mounting surface, this will

void the warranty.

Lower the window to rest on the top of the duct (vertically hung

windows) or slide window closed against side of duct (horizontal

slider windows). Block any remaining unused portion of the

window opening with a suitable blocking material (Plexiglas, solid

plastic sheet, solid wood panel, etc.). It will be necessary to seal

any joints around the duct to prevent entry of rain, dust/dirt,

insects, etc. Any good quality caulking or foam tape will work.

See

INSTALLATION

Carefully read the contents of this manual and review the

drawings of the cooler to familiarize yourself with the various

parts before beginning the installation process.

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

Even while routinely inspecting or servicing the inside, the cooler can

be accidentally started. Keep people and pets away from the cooler

and electrical supply when you are working on it. Before opening,

servicing or cleaning the unit, unplug the unit from the wall receptacle

and take steps to ensure that the cord cannot be plugged back in and

the cooler turned on accidentally. Do not plug power cord into the wall

receptacle until installation or service work is complete.

Before attempting to install the cooler, confirm that the following

preparations have been made:

This cooler must be plugged into a 120 volt GFCI (Ground Fault

Circuit Interrupter) protected receptacle. If you are not sure that

the receptacle is GFCI protected, consult with a qualified

electrician. This receptacle should be located within 5 feet of the

window opening (cooler power cord is 6 feet long. Use of

extension cords is not recommended).

Install cooler in a window where only fresh outside air can enter.

Avoid installing the cooler in an area where the free air

movement around and into the cooler is restricted or locations

where obnoxious odors or fumes may be drawn into cooler from

vent pipes, kitchen exhausts, etc.

Verify that the supporting surface is strong enough to bear the

weight of the cooler when in use. This unit will weigh

approximately 250 pounds when operating at full capacity.

Verify that the supporting surface is level in all directions.

Figure 1

Figure 2

2 Brisa Evaporative Window Cooler Use and Care Manual

Page 3

Mounting Using Chain Kit

An alternate installation method involves locating the unit in a suitable

window and using the included chain mounting kit to support the

weight of the cooler. As with platform or stand mounting, every

installation will be different. The exact requirements to mount and seal

a cooler against the weather will be best determined by the location

and at the time of the installation. Most installations will require

blocking of the unused portion of the window around the duct, or other

modifications to the window frame may be necessary.

illustration (Fig. 2) for a typical installation. Remember, the framing

around the window must be strong enough to support the weight of the

cooler (approximately 250 pounds).

Chain Kit contains:

2 - Screw Hooks 2 - “S” Hooks

2 - Leg Leveling Bolts 2 - Rubber Pads

4 - 3/8” Square Nuts 4 - 3/8” Washers

2 - Hanger Straps 2 - #10-24 x 1/2” long Bolts

2 - #10-24 Nuts 2 - 5 ‘ Long Chain

Install chain kit as follows:

Attach screw hooks to outside window frame approximately two

feet above top of cooler. Be sure hooks are inserted to full depth in

window framing for maximum strength.

Attach chain to each hook.

Attach hanging straps to top of rear corner support legs in the 3/16”

diameter holes using the #10-24 bolts and nuts provided. Install

“S” hooks in straps.

Place leg leveling bolts through 7/16” diameter holes in bottom of

front corner support legs. Use nut and washer on outside of

cabinet and install rubber pads on outside ends of leveling bolts.

Place second nut and washer on leveling bolts inside cabinet.

Position the cooler so that the duct rests on the window sill and the

grille flanges are inside the window frame, allowing the “Z” shaped

bracket, located under the grille, to rest on the window sill and butt

against inside of window sill flange. Connect “S” hooks and screw

hooks to chain links that bring the cooler closest to a level position.

Use leg leveling bolts to brace the cooler away from the wall.

Adjust bolts and chain to level cooler. NOTE: Cooler may need to

be re-leveled to compensate for the added weight of water.

Tighten nuts on leveling bolts inside cabinet.

Lower the window to rest on the top of the duct (vertically hung

windows) or slide window closed against side of duct (horizontal

slider windows). Block any remaining unused portion of the

window opening with a suitable blocking material (Plexiglas, solid

plastic sheet, solid wood panel, etc.). It will be necessary to seal

any joints around the duct to prevent entry of rain, dust/dirt,

insects, etc. Any good quality caulking or foam tape will work.

See

Install Overflow Standpipe / Drain Line

Install overflow drain bushing in bottom of cooler as follows:

Slide rubber washer over drain bushing.

Push drain bushing through bottom of

cooler, assemble and tighten lock nut.

Screw plastic overflow standpipe into

the drain bushing and tighten snugly

(hand tight) to prevent leakage.

Connect a suitable drain line (copper /

PVC / garden hose) to drain bushing.

Never drain water onto a roof; mineral

build-up or damage to roof may occur.

NOTE: Drain water in accordance with local plumbing codes.

Install Bleed-off

To minimize mineral scale “buildup”use the included bleed-off

assembly. Remove the cap from

the bleed-off tee; insert the black

tubing and route the tubing

through standpipe opening into

the drain line To prevent

siphoning of the water, make sure

h

t at the bleed-off tee is above the

water level.

.

Connect Water Supply

CAUTION: All plumbing installations must comply with

local building and safety codes, and must be performed by

qualified personnel only.

NOTE: Coolers should not be connected to “soft” water systems. Soft

water will accelerate corrosion and decrease the effective life of pads

and cooler cabinet. Connect water line as follows:

A water supply valve should be installed at a convenient location

to allow the water supply to be turned on and off for servicing or

winterizing. Minimum 1/4“ diameter tubing should be used to

provide water to the cooler. Larger tubing is recommended if the

distance from the valve to the cooler is greater than 100 feet, then

reduced to 1/4” at the unit.

Install float valve in the bracket provided.

Connect tubing from water supply to float valve. Place

compression nut and ferrule over end of tubing, insert tube into

float valve then tighten compression nut to secure.

Belt Tension Adjustment

CAUTION: Disconnect all electrical power to the cooler

and insure that belt is not rotating before adjusting belt

tension.

Correct belt tension and alignment is

important, proper setup reduces power

consumption and prolongs life of belt and

motor. Check belt tension by squeezing belt.

Proper tension will allow deflection of ½ to ¾

inch. To increase or decrease belt tension,

loosen bolt in slot of motor support bracket.

Adjust belt to proper tension and retighten bolt.

CAUTION: Never operate unit with

pad frame(s) and/or air outlet grille

removed. This will result in an

overloaded condition and may

damage the motor.

Figure 3

OPERATION

Controls

The rocker control switches are used to select the operating mode of

the cooler. These switches control fan speed (High/Off/Low) and the

cooling (pump) operation (On/Off).

Brisa Evaporative Window Cooler - Use and Care Manual 3

Page 4

GENERAL INSPECTION

MAINTENANCE SCHEDULE

Initial Start-up or Annual Inspection

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

Before start-up of the cooler for the first time, or at the beginning of

each cooling season, make sure that all required connections,

adjustments, etc. have been made. Verify that:

P Cooler mounting is level; window and duct are sealed.

P Power supply cord is correctly routed, safe and secure.

P Motor, pump, drain, bleed-off, float valve, air outlet grille etc.

are correctly installed and fully functional.

P Water line securely connected, turned on, no leaks noted.

P Float adjusted for proper water level.

P Pump impeller turns free and smooth. If in doubt, remove

impeller cover (see “Cleaning Pump”) and check rotation.

P Blower wheel, shaft, pulley and motor sheave bolts / set

screws are tight.

P Motor sheave / Blower pulley alignment okay; belt correctly

tensioned, blower wheel turns freely.

Start-up Check List

CAUTION: Never operate cooler with pad frame(s)

and/or air outlet grille removed. This will result in an

overloaded condition and may damage the motor.

To verify and check out the cooler installation on initial or annual startup, the following procedure should be followed.

P Open building exhaust / relief vents (windows, doors, etc.)

P Plug supply cord into wall receptacle. Switch cooler “ON”.

P Verify that pump starts and pads are evenly wet.

P Observe that motor starts and runs.

In case of trouble on any of these steps, refer to the Troubleshooting

Chart on

Cabinet Inspection Checklist

After initial start-up and for a few weeks afterwards, check for and/or

observe the following: Refer to the Troubleshooting Chart on f

necessary.

P Leaks from water lines, pad frames, cabinet, etc.

P Cooler pads: even wetting, no dry streaks.

P Confirm water level depth setting is correct.

P Verify full, even flow in water distribution system.

P Blower wheel / motor rotates freely, no unusual noises.

P Belt condition / tension / alignment OK.

P Check motor mounting, cabinet hardware, set screws on

page 6.

page 6 i

pulleys, blower wheel are tight

Regular maintenance and periodic inspection is the key to long and

successful service from your Brisa cooler. The cooler should receive

major servicing at least once a year, more often if conditions require

(dusty environment, constant use, poor water quality, etc.) For

maximum cooling efficiency, long life and appearance, every two

months during operation, the cooler should be inspected and cleaned.

NOTE: Do Not Undercoat the Water Reservoir

Your cooler's water reservoir is finished with our Peblar XT®

appliance-type finish. It is so hard that asphalt-type cooler water pan

under-coatings will not stick to it. Undercoating will break free,

clogging the pump and water distribution system.

NOTE: Do not use cooler cleaners, cooler treatments, anodes or other

chemical additives in this evaporative cooler. Use of any additives or

water treatment other than the furnished bleed-off will void your

warranty and may impair the life of the cooler.

Before starting any maintenance operation, thoroughly read all

operating and maintenance instructions and observe all

cautions and warnings.

Cleaning

CAUTION: Never wash your cooler cabinet with a

garden hose; water may harm motor and pump or seep

into ductwork. Motors damaged by water are NOT covered

under warranty.

All foreign materials, mineral scale, hard water deposits, dirt, etc.

should be removed from pad frames, water pan and other

components. Your cooler's long lasting finish can be brought to likenew condition by using warm water and a soft cloth.

NOTE: Avoid using scouring pads, steel wool or wire brushes, as

these will damage the finish and encourage corrosion.

Maintenance & Inspection

IMPORTANT: Before operating cooler at the beginning

of each cooling season, turn blower wheel, cooler motor

and pump motor shafts by hand to make sure they turn

freely. Failure to do so may result in burning out motor.

Periodic inspection of your cooler will enhance the chance for long,

trouble-free service life. For maximum efficiency, every two months

during operation, or any time the cooler is opened, the cooler should

be inspected. Some suggested items to look for:

P Check for leaks from pad frames, cabinet, etc.

P Any dry spots or streaks on pads when pump is operating?

P Are bolts, nuts and set screws still snug?

P Are the bearings, etc., making any unusual noises?

P Does the blower wheel turn freely?

P Is float level set correctly?

P Is water in the bottom pan clean?

P Belt condition / tension / alignment OK?

Adjust Belt Tension

Each time you inspect your cooler, be sure to check belt tension on

motor and blower assembly. Check belt condition and replace it if

frays or cracks appear. Check alignment of blower pulley with motor

pulley (see page 3 for detailed steps).

4 Brisa Evaporative Window Cooler - Use and Care Manual

Page 5

Cleaning Water Pump & Hose

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

CAUTION: Do not allow pump to fall over and become

submerged; water will damage pump motor.

Clean water pump and hose assembly as follows:

Unplug pump cord, remove

mounting bracket screw and

remove pump from cooler. Shake

gently to remove water.

To prevent breakage, carefully

release the snap-out impeller

cover plate and remove cover

plate from the pump body.

Using a mild detergent solution and a

soft cloth, clean deposits from screen,

around impeller and cover plate. Spin

impeller to dislodge any remaining

foreign material.

Remove any foreign material in the hose adapter

(between the pump and hose), or between the hose

and the water distributor assembly.

Rinse and reinstall impeller cover plate.

Reinstall pump and reconnect pump cord.

Draining

Drain the cooler for cleaning or at the end of the season as follows:

Unplug cooler power supply cord from wall receptacle.

Turn off water supply and remove pad frames.

Connect a drain hose to the drain fitting on the bottom of the

reservoir, if not already connected to drain line.

Remove overflow standpipe from the drain fitting.

Drain and clean reservoir. Remove any remaining water with

a rag or sponge.

Touch-Up

The hardness, adhesion and smoothness of the internal and external

finish on your cooler makes it extremely unlikely that scratches or

chipping will occur. In the event that finish damage does occur, it

should be promptly repaired by the following procedures:

1. Sand the area around bare metal spots.

2. Prime and paint with a quality paint.

Do not use asphalt type cooler undercoat material in water

reservoir. Undercoat will break free, clogging the pump and

water distributor.

Blower Shaft Bearings

Blower shaft bearings need periodic lubrication. They should be

checked 20-30 days after initial start-up of operation. The oil cups on

the bearings should be filled with a good grade of SAE 20W or 30W

non-detergent oil when necessary. Under normal use, oiling is

required every three months of operation. Do Not Over- Oil.

Pump Motor Bearings

The pump motor does not require lubrication.

Changing Cooler Pads

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

Your cooler pads should be changed at least twice a year… at the

beginning of and midway through a season . However, your pads may

need to be changed more frequently, depending on local air and water

conditions. For instance, in areas where mineral content of the water

is high, deposits may build up in the cooler pads, restricting airflow.

Replace pads as follows:

Remove pad assembly from cabinet.

Remove pad retainers from frame, using caution as retainers can

spring back. Carefully remove all aspen from retainers. Remove

and discard old pads.

Using a mild detergent, wash dirt and scale from pad frames and

rinse with fresh water. Wire brushing is not recommended. If finish

is damaged or rusting is noted, repair area as noted in the “TouchUp” section.

Lay new pad in frame, starting at trough end, making sure pad is

snug against trough and outer edges with no air spaces. Pad must

completely fill frame (no gaps) or hot air may enter building.

Pad thickness should be

uniform across the frame.

Replace pad retainers and

lock under edge of frame.

Sharp points must be buried

into pad (they hold pad in

place and prevent sagging).

Pre-soak pads and check for air gaps along

edges, reinstall pad frames into unit.

Winter Shut Down:

- Always drain all of the water out of the cooler and water supply line

when not in use for prolonged periods, and particularly at the end of

the season. Keep the water line disconnected from both the cooler

and the water supply so it does not freeze.

- Disconnect power from cooler during extended periods of non-use.

Lubrication

Motor Bearings

Some motors used in Brisa coolers have ports for lubricating the

motor and are oiled at the factory. If the need for oiling is indicated, see

individual motor nameplate for specific instructions on re-lubricating

the motor. Under normal use, these motors require oiling about every

12 months of operation. Do Not Over-Oil.

REPLACEMENT PARTS

When ordering replacement parts, always refer to the serial and

model number of your cooler. Use the part numbers listed in the

accompanying parts list, as illustrated in the diagrams for your model.

Brisa Evaporative Window Cooler - Use and Care Manual 5

Page 6

TROUBLESHOOTING GUIDE: Should an obvious problem occur with your cooler consult the following table. If you

cannot correct the problem, or if it persists, contact qualified service personnel.

PROBLEM / SYMPTOM

Water draining from unit

Dry pads

Motor does not start or no air delivery

Inadequate air delivery

Motor cycles on & off

Noisy operation

Excessive humidity in house

POSSIBLE CAUSE

Float valve out of adjustment

Float movement obstructed

Float valve non-functional

Pump intake clogged

Water pump non-functional

Clogged water line

Pad trough clogged

Switch non-functional

Wiring non-functional

Water turned off to cooler

Electrical power disconnected

Belt too loose or too tight

Defective motor

Defective switch

Broken belt

Insufficient air exhaust

Belt too loose

Pads plugged

Low voltage

Excessive belt tension

Blower shaft tight or locked

Bearings dry

Pad frame(s) or air outlet grille removed

Blower rubbing on housing

Motor sheave or blower set screws loose

Inadequate exhaust

CORRECTIVE ACTION

Adjust float to 2 1/2“ water depth

Free float from obstruction

Replace float assembly

Remove obstruction

Replace water pump

Locate and free obstruction

Clear debris from trough

Replace switch

Repair or replace non-functional wiring

Turn on water supply

Check power receptacle and cord

Adjust belt tension

Replace motor

Replace switch

Replace belt

Open windows to increase air flow

Adjust belt tension or replace if needed

Replace pads

Check voltage

Adjust belt tension

Oil or replace bearings

Oil bearings

Re-install pad frame(s) or air outlet grille

Reposition wheel

Tighten set screws

Open doors and windows to increase ventilation

6 Brisa Evaporative Window Cooler - Use and Care Manual

WIRING DIAGRAM

Loading...

Loading...