B&R Industrial Automation MAPPC2200-ENG User Manual

Panel PC 2200

built-in devices

User's manual

Version: 1.05 (December 2018)

Model no.: MAPPC2200-ENG

Translation of the original documentation

All values in this manual are current as of its creation. We reserve the right to change the contents of this manual

without notice. B&R Industrial Automation GmbH is not liable for technical or editorial errors and defects in this

manual. In addition, B&R Industrial Automation GmbH assumes no liability for damages that are directly or indirectly

attributable to the delivery, performance or use of this material. We point out that the software and hardware

designations and brand names of the respective companies used in this document are subject to general trademark,

brand or patent protection.

Table of contents

1 General information.................................................................................................. 7

1.1 Manual history.................................................................................................................................................7

1.2 Safety guidelines.............................................................................................................................................8

1.2.1 Intended use..............................................................................................................................................8

1.2.2 Protection against electrostatic discharge.................................................................................................8

1.2.2.1 Packaging.............................................................................................................................................8

1.2.2.2 Regulations for proper ESD handling.................................................................................................. 8

1.2.3 Regulations and measures........................................................................................................................8

1.2.4 Transport and storage............................................................................................................................... 9

1.2.5 Installation.................................................................................................................................................. 9

1.2.6 Operation................................................................................................................................................... 9

1.2.6.1 Protection against contact with electrical parts................................................................................... 9

1.2.6.2 Ambient conditions - Dust, moisture, aggressive gases......................................................................9

1.2.6.3 Programs, viruses and malicious programs...................................................................................... 10

1.2.7 Environmentally friendly disposal............................................................................................................ 10

1.2.7.1 Separation of materials......................................................................................................................10

1.2.8 Security concept...................................................................................................................................... 10

1.2.9 Third-party updates................................................................................................................................. 10

1.2.10 Administrator accounts.......................................................................................................................... 10

1.3 Organization of notices................................................................................................................................. 11

1.4 Guidelines......................................................................................................................................................11

1.5 Overview........................................................................................................................................................12

2 Technical data......................................................................................................... 14

2.1 Introduction....................................................................................................................................................14

2.1.1 Information about this user's manual...................................................................................................... 14

2.1.2 Description of individual modules............................................................................................................14

2.1.2.1 AP9x3 panels.....................................................................................................................................14

2.1.2.2 AP1000 panels...................................................................................................................................14

2.1.2.3 System units.......................................................................................................................................15

2.1.3 Design/Configuration............................................................................................................................... 16

2.1.3.1 Configuration...................................................................................................................................... 16

2.2 Complete system.......................................................................................................................................... 18

2.2.1 Mechanical properties..............................................................................................................................18

2.2.1.1 Dimensions.........................................................................................................................................18

2.2.1.2 Installation diagrams.......................................................................................................................... 21

2.2.1.3 Spacing for air circulation.................................................................................................................. 24

2.2.1.4 Mounting orientations......................................................................................................................... 25

2.2.1.5 Weight specifications......................................................................................................................... 26

2.2.2 Environmental properties.........................................................................................................................27

2.2.2.1 Temperature specifications................................................................................................................ 27

2.2.2.2 Relative humidity................................................................................................................................34

2.2.2.3 Vibration............................................................................................................................................. 35

2.2.2.4 Shock..................................................................................................................................................35

2.2.2.5 Degree of protection.......................................................................................................................... 35

2.2.3 Electrical properties................................................................................................................................. 36

2.2.3.1 +24 VDC power supply......................................................................................................................36

2.2.3.2 Power calculation...............................................................................................................................37

2.2.3.3 Block diagrams...................................................................................................................................39

2.2.4 Product information................................................................................................................................. 42

2.2.4.1 Identification....................................................................................................................................... 42

2.2.5 Device interfaces and slots..................................................................................................................... 43

2.2.5.1 Device interfaces - Overview.............................................................................................................43

2.2.5.2 +24 VDC power supply......................................................................................................................44

2.2.5.3 Ethernet 1 interface (ETH1)...............................................................................................................45

2.2.5.4 Ethernet 2 interface (ETH2)...............................................................................................................45

2.2.5.5 USB interfaces................................................................................................................................... 46

2 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

Table of contents

2.2.5.6 CFast slot........................................................................................................................................... 47

2.2.5.7 Power button...................................................................................................................................... 48

2.2.5.8 Reset button.......................................................................................................................................48

2.2.5.9 LED status indicators.........................................................................................................................49

2.2.5.10 Battery compartment........................................................................................................................ 50

2.2.5.11 IF option slot.................................................................................................................................... 51

2.2.5.12 Trusted Platform Module (TPM)...................................................................................................... 52

2.2.6 Features of AP1000 panels.................................................................................................................... 53

2.2.6.1 Slide-in labels.....................................................................................................................................53

2.2.6.2 Key and LED configuration................................................................................................................54

2.2.6.3 USB interface..................................................................................................................................... 58

2.2.7 Installation compatibility...........................................................................................................................59

2.2.7.1 Compatibility overview....................................................................................................................... 59

2.2.7.2 Compatibility details........................................................................................................................... 60

2.3 Individual components.................................................................................................................................. 69

2.3.1 AP9x3 panels.......................................................................................................................................... 69

2.3.1.1 5AP923.1215-00.................................................................................................................................69

2.3.1.2 5AP923.1505-00.................................................................................................................................71

2.3.1.3 5AP923.1906-00.................................................................................................................................74

2.3.1.4 5AP933.156B-00................................................................................................................................ 77

2.3.1.5 5AP933.185B-00................................................................................................................................ 80

2.3.1.6 5AP933.215C-00................................................................................................................................ 83

2.3.1.7 5AP933.240C-00................................................................................................................................ 86

2.3.2 AP1000 panels........................................................................................................................................ 89

2.3.2.1 5AP1120.0573-000.............................................................................................................................89

2.3.2.2 5AP1151.0573-000.............................................................................................................................92

2.3.2.3 5AP1120.0702-000.............................................................................................................................95

2.3.2.4 5AP1130.0702-000.............................................................................................................................97

2.3.2.5 5AP1120.101E-000............................................................................................................................ 99

2.3.2.6 5AP1130.101E-000.......................................................................................................................... 101

2.3.2.7 5AP1120.1043-000...........................................................................................................................103

2.3.2.8 5AP1180.1043-000...........................................................................................................................106

2.3.2.9 5AP1181.1043-000...........................................................................................................................109

2.3.2.10 5AP1182.1043-000.........................................................................................................................112

2.3.2.11 5AP1120.1214-000.........................................................................................................................115

2.3.2.12 5AP1120.121E-000........................................................................................................................ 118

2.3.2.13 5AP1130.121E-000........................................................................................................................ 120

2.3.2.14 5AP1120.1505-000.........................................................................................................................122

2.3.2.15 5AP1180.1505-000.........................................................................................................................125

2.3.2.16 5AP1181.1505-000.........................................................................................................................128

2.3.2.17 5AP1120.156B-000........................................................................................................................ 131

2.3.2.18 5AP1130.156C-000........................................................................................................................ 133

2.3.2.19 5AP1130.185C-000........................................................................................................................ 136

2.3.2.20 5AP1120.1906-000.........................................................................................................................138

2.3.3 System units.......................................................................................................................................... 141

2.3.3.1 5PPC2200.ALxx-000........................................................................................................................ 141

2.3.4 CFast cards........................................................................................................................................... 144

2.3.4.1 General information..........................................................................................................................144

2.3.4.2 Basic information..............................................................................................................................144

2.3.4.3 5CFAST.xxxx-00............................................................................................................................... 146

2.3.4.4 5CFAST.xxxx-10............................................................................................................................... 150

2.3.5 Interface options.................................................................................................................................... 153

2.3.5.1 5ACCIF01.FPCC-000.......................................................................................................................153

2.3.5.2 5ACCIF01.FPCS-000....................................................................................................................... 161

2.3.5.3 5ACCIF01.FPLK-000........................................................................................................................168

2.3.5.4 5ACCIF01.FPLS-000........................................................................................................................173

2.3.5.5 5ACCIF01.FPLS-001........................................................................................................................178

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 3

Table of contents

2.3.5.6 5ACCIF01.FPSC-000....................................................................................................................... 183

2.3.5.7 5ACCIF01.FPSC-001....................................................................................................................... 190

2.3.5.8 5ACCIF01.FSS0-000........................................................................................................................197

2.3.5.9 5ACCIF01.ICAN-000........................................................................................................................ 202

2.3.5.10 5ACCIF03.CETH-000.....................................................................................................................205

2.3.6 Battery compartment............................................................................................................................. 207

2.3.6.1 5ACCBT01.0000-001....................................................................................................................... 207

3 Commissioning......................................................................................................208

3.1 Installation................................................................................................................................................... 208

3.1.1 Important information for installation/commissioning............................................................................ 208

3.1.2 Installing a Panel PC with an AP9x3 panel.......................................................................................... 210

3.1.3 Installing the Automation Panel 1000 with retaining clips.....................................................................212

3.1.4 Installing the Automation Panel 1000 with clamping blocks................................................................. 214

3.1.5 Installation information for separate shipments.....................................................................................216

3.1.6 Replacing the system unit.....................................................................................................................216

3.2 Connecting to the power grid..................................................................................................................... 217

3.2.1 Installing the DC power cable............................................................................................................... 217

3.2.1.1 Wiring............................................................................................................................................... 217

3.2.2 Connecting the power supply to a B&R device.................................................................................... 218

3.2.3 Functional ground grounding concept...................................................................................................219

3.3 Connecting cables.......................................................................................................................................220

3.4 Switching on the device for the first time................................................................................................... 221

3.4.1 General information before switching on the device.............................................................................221

3.4.2 Switching on the device........................................................................................................................ 221

3.5 General instructions for the temperature test procedure............................................................................ 222

3.5.1 Procedure.............................................................................................................................................. 222

3.5.2 Evaluating temperatures in Windows operating systems......................................................................222

3.5.2.1 Evaluating with the B&R Control Center......................................................................................... 222

3.5.2.2 Evaluation with BurnInTest from PassMark.....................................................................................223

3.5.3 Evaluating temperatures in non-Windows operating systems.............................................................. 225

3.5.4 Evaluating the measurement results..................................................................................................... 225

3.6 Touch screen calibration............................................................................................................................. 226

3.6.1 Single-touch (analog resistive).............................................................................................................. 226

3.6.1.1 Windows 10 IoT Enterprise 2016 LTSB.......................................................................................... 226

3.6.2 Multi-touch (projected capacitive - PCT)...............................................................................................226

3.6.2.1 Windows 10 IoT Enterprise 2016 LTSB.......................................................................................... 226

3.7 Adjusting the display brightness................................................................................................................. 227

3.8 Known problems / Characteristics.............................................................................................................. 228

4 Software................................................................................................................. 229

4.1 UEFI BIOS options..................................................................................................................................... 229

4.1.1 General information............................................................................................................................... 229

4.1.1.1 Adaptation for touch operation........................................................................................................ 229

4.1.1.2 Overview of BIOS description..........................................................................................................229

4.1.2 UEFI BIOS setup and start procedure.................................................................................................. 231

4.1.3 Boot menu............................................................................................................................................. 232

4.1.4 Boot manager........................................................................................................................................ 233

4.1.5 Device manager.................................................................................................................................... 234

4.1.6 Setup utility............................................................................................................................................ 235

4.1.6.1 Main..................................................................................................................................................236

4.1.6.2 Advanced..........................................................................................................................................237

4.1.6.3 Security.............................................................................................................................................247

4.1.6.4 Power............................................................................................................................................... 248

4.1.6.5 Boot.................................................................................................................................................. 250

4.1.6.6 Exit....................................................................................................................................................253

4.2 Upgrade information....................................................................................................................................254

4 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

Table of contents

4.2.1 UEFI BIOS upgrade.............................................................................................................................. 254

4.2.1.1 UEFI BIOS - What do I need to know?...........................................................................................254

4.2.1.2 Procedure in the EFI shell............................................................................................................... 255

4.2.2 Firmware upgrade - Panel PC 2200..................................................................................................... 255

4.2.2.1 Procedure in Windows (B&R Control Center)................................................................................. 255

4.2.2.2 Procedure in the EFI shell............................................................................................................... 256

4.2.2.3 Automatic firmware update.............................................................................................................. 257

4.3 Multi-touch drivers.......................................................................................................................................257

4.4 Windows 10 IoT Enterprise 2016 LTSB..................................................................................................... 259

4.4.1 General information............................................................................................................................... 259

4.4.2 Order data............................................................................................................................................. 259

4.4.3 Overview................................................................................................................................................ 259

4.4.4 Features................................................................................................................................................. 259

4.4.5 Installation.............................................................................................................................................. 259

4.4.6 Drivers....................................................................................................................................................260

4.4.7 Activation............................................................................................................................................... 260

4.4.8 Characteristics, limitations..................................................................................................................... 260

4.4.9 Supported display resolutions............................................................................................................... 261

4.5 B&R Linux 9 (GNU/Linux)...........................................................................................................................262

4.5.1 General information............................................................................................................................... 262

4.5.2 Order data............................................................................................................................................. 262

4.5.3 Overview................................................................................................................................................ 262

4.5.4 Features................................................................................................................................................. 262

4.5.5 Installation.............................................................................................................................................. 262

4.5.6 Drivers....................................................................................................................................................263

4.6 B&R Automation Device Interface (ADI) Control Center............................................................................ 264

4.6.1 Functions............................................................................................................................................... 264

4.6.2 Installation.............................................................................................................................................. 265

4.7 B&R Automation Device Interface (ADI) Development Kit......................................................................... 266

4.8 B&R Automation Device Interface (ADI) .NET SDK...................................................................................267

4.9 B&R Key Editor........................................................................................................................................... 268

4.10 B&R KCF Editor........................................................................................................................................ 269

4.11 HMI Service Center...................................................................................................................................270

4.11.1 5SWUTI.0001-000................................................................................................................................270

4.11.1.1 General information........................................................................................................................ 270

4.11.1.2 Order data...................................................................................................................................... 270

5 Standards and certifications................................................................................271

5.1 Directives and declarations.........................................................................................................................271

5.1.1 CE marking............................................................................................................................................271

5.1.2 EMC Directive........................................................................................................................................271

5.2 Certifications................................................................................................................................................272

5.2.1 UL certification.......................................................................................................................................272

5.2.2 EAC........................................................................................................................................................272

5.2.3 KC.......................................................................................................................................................... 272

5.2.4 RCM....................................................................................................................................................... 273

6 Accessories........................................................................................................... 274

6.1 General accessories................................................................................................................................... 274

6.1.1 Accessories - Order data...................................................................................................................... 274

6.2 Power supply connectors............................................................................................................................275

6.2.1 0TB103.9x..............................................................................................................................................275

6.2.1.1 General information..........................................................................................................................275

6.2.1.2 Order data........................................................................................................................................ 275

6.2.1.3 Technical data..................................................................................................................................275

6.3 Terminal block for IF options...................................................................................................................... 276

6.3.1 0TB1210.3100....................................................................................................................................... 276

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 5

Table of contents

6.3.1.1 General information..........................................................................................................................276

6.3.1.2 Order data........................................................................................................................................ 276

6.3.1.3 Technical data..................................................................................................................................276

6.4 USB flash drives......................................................................................................................................... 277

6.4.1 5MMUSB.xxxx-01.................................................................................................................................. 277

6.4.1.1 General information..........................................................................................................................277

6.4.1.2 Order data........................................................................................................................................ 277

6.4.1.3 Technical data..................................................................................................................................277

6.4.1.4 Temperature/Humidity diagram........................................................................................................279

6.4.2 5MMUSB.032G-02.................................................................................................................................280

6.4.2.1 General information..........................................................................................................................280

6.4.2.2 Order data........................................................................................................................................ 280

6.4.2.3 Technical data..................................................................................................................................280

6.4.2.4 Temperature/Humidity diagram........................................................................................................281

6.5 Replacement parts...................................................................................................................................... 282

6.5.1 Replacement parts - Order data........................................................................................................... 282

6.5.1.1 5ACCRPC2.0003-000 - Technical data...........................................................................................282

7 Servicing/Maintenance..........................................................................................283

7.1 Cleaning...................................................................................................................................................... 283

7.2 User tips for increasing the service life of the display................................................................................284

7.2.1 Backlight................................................................................................................................................ 284

7.2.1.1 How can the service life of backlights be extended?...................................................................... 284

7.2.2 Image persistence................................................................................................................................. 284

7.2.2.1 What causes image persistence?....................................................................................................284

7.2.2.2 How can image persistence be reduced?....................................................................................... 284

7.3 Pixel errors.................................................................................................................................................. 284

7.4 Replacing CFast cards............................................................................................................................... 285

7.5 Changing the battery.................................................................................................................................. 286

7.6 Repairs/Complaints and replacement parts................................................................................................287

Appendix A .............................................................................................................. 288

A.1 MTCX.......................................................................................................................................................... 288

A.2 Abbreviations.............................................................................................................................................. 289

A.3 Viewing angles............................................................................................................................................289

A.4 Chemical resistance................................................................................................................................... 290

A.4.1 Autotex panel overlay (polyester)......................................................................................................... 292

A.4.2 Aluminum panel overlay........................................................................................................................293

A.4.3 Coated aluminum front..........................................................................................................................293

A.4.4 Touch screen......................................................................................................................................... 294

A.5 Touch screen.............................................................................................................................................. 295

A.5.1 5-wire AMT touch screen (single-touch)...............................................................................................295

A.5.1.1 Technical data................................................................................................................................. 295

A.5.1.2 Temperature/Humidity diagram....................................................................................................... 295

A.5.2 3M touch screen (multi-touch generation 2).........................................................................................296

A.5.2.1 General information......................................................................................................................... 296

A.5.2.2 Technical data................................................................................................................................. 296

A.5.2.3 Temperature/Humidity diagram....................................................................................................... 296

A.5.3 3M touch screen (multi-touch generation 3).........................................................................................297

A.5.3.1 General information......................................................................................................................... 297

A.5.3.2 Technical data................................................................................................................................. 297

A.5.3.3 Temperature/Humidity diagram....................................................................................................... 298

6 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

General information

1 General information

Information:

This document is not intended for end customers! The safety guidelines required for end customers

must be incorporated into the operating instructions for end customers in the respective national language by the machine manufacturer or system provider.

1.1 Manual history

Version Date Change

1.00 November 2018

1.05 December 2018 Updated document.

•

First version

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 7

General information

1.2 Safety guidelines

1.2.1 Intended use

Programmable logic controllers, operating and monitoring devices (such as industrial PCs, Power Panels, Mobile

Panels, etc.) as well as the uninterruptible power supply from B&R have been designed, developed and manufactured for normal use in industry. They have not been designed, developed and manufactured for use that involves

fatal risks or hazards that could result in death, injury, serious physical harm or other loss without the assurance of

exceptionally stringent safety precautions. In particular, this includes the use of these systems to monitor nuclear

reactions in nuclear power plants, flight control systems, air traffic control, the control of mass transport vehicles,

medical life support systems and the control of weapon systems.

1.2.2 Protection against electrostatic discharge

Electrical assemblies that can be damaged by electrostatic discharge (ESD) must be handled accordingly.

1.2.2.1 Packaging

•

Electrical assemblies with housing

... Do not require special ESD packaging but must be handled properly (see "Electrical assemblies with

housing").

•

Electrical assemblies without housing

... Are protected by ESD-suitable packaging.

1.2.2.2 Regulations for proper ESD handling

Electrical assemblies with housing

•

Do not touch the connector contacts of connected cables.

•

Do not touch the contact tips on circuit boards.

Electrical assemblies without housing

The following applies in addition to "Electrical assemblies with housing":

•

All persons handling electrical assemblies and devices in which electrical assemblies are installed must

be grounded.

•

Assemblies are only permitted to touched on the narrow sides or front plate.

•

Always place assemblies on suitable surfaces (ESD packaging, conductive foam, etc.). Metallic surfaces

are not suitable surfaces!

•

Assemblies must not be subjected to electrostatic discharges (e.g. due to charged plastics).

•

A minimum distance of 10 cm from monitors or television sets must be maintained.

•

Measuring instruments and devices must be grounded.

•

Test probes of floating potential measuring instruments must be discharged briefly on suitable grounded

surfaces before measurement.

Individual components

•

ESD protective measures for individual components are implemented throughout B&R (conductive floors,

shoes, wrist straps, etc.).

•

The increased ESD protective measures for individual components are not required for handling B&R

products at customer locations.

1.2.3 Regulations and measures

Electronic devices are generally not failsafe. If the programmable logic controller, operating or control device or

uninterruptible power supply fails, the user is responsible for ensuring that connected devices, such as motors,

are brought to a safe state.

8 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

General information

When using programmable logic controllers as well as when using operating and monitoring devices as control

systems in conjunction with a Soft PLC (e.g. B&R Automation Runtime or similar product) or Slot PLC (e.g. B&R

LS251 or similar product), the safety measures that apply to industrial controllers (protection by protective equipment such as emergency stops, etc.) must be observed in accordance with applicable national and international

regulations. This also applies to all other connected devices, such as drives.

All work such as installation, commissioning and servicing are only permitted to be carried out by qualified personnel. Qualified personnel are persons who are familiar with the transport, installation, assembly, commissioning and

operation of the product and have the appropriate qualifications for their job (e.g. IEC 60364). National accident

prevention regulations must be observed.

The safety guidelines, information about connection conditions (nameplate and documentation) and limit values

specified in the technical data must be read carefully before installation and commissioning and must be strictly

observed.

1.2.4 Transport and storage

During transport and storage, devices must be protected against undue stress (mechanical stress, temperature,

humidity, aggressive atmosphere).

1.2.5 Installation

•

The devices are not ready for use and must be installed and wired according to the requirements of this

documentation in order to comply with EMC limit values.

•

Installation must be carried out according to the documentation using suitable equipment and tools.

•

Devices are only permitted to be installed by qualified personnel when the power is switched off. The control

cabinet must first be disconnected from the power supply and secured against being switched on again.

•

General safety regulations and national accident prevention regulations must be observed.

•

The electrical installation must be carried out in accordance with relevant regulations (e.g. wire cross section, fuse protection, protective ground connection).

1.2.6 Operation

1.2.6.1 Protection against contact with electrical parts

In order to operate programmable logic controllers, operating and monitoring devices and the uninterruptible power

supply, it is necessary for certain components to carry dangerous voltages over 42 VDC. Touching one of these

components can result in a life-threatening electric shock. There is a risk of death, serious injury or damage to

property.

Before switching on the programmable logic controllers, operating and monitoring devices and uninterruptible power supply, it must be ensured that the housing is properly connected to ground potential (PE rail). The ground

connection must also be made if the operating and monitoring device and uninterruptible power supply are only

connected for testing purposes or only operated for a short time!

Before switching on, live parts must be safely covered. All covers must be kept closed during operation.

1.2.6.2 Ambient conditions - Dust, moisture, aggressive gases

The use of operating and monitoring devices (e.g. industrial PCs, Power Panels, Mobile Panels, etc.) and uninterruptible power supplies in dusty environments must be avoided. This can otherwise lead to dust deposits that affect

the functionality of the device, especially in systems with active cooling (fans), which may no longer guarantee

sufficient cooling.

The presence of aggressive gases in the environment can also result in malfunctions. In combination with high

temperature and relative humidity, aggressive gases – for example with sulfur, nitrogen and chlorine components

– trigger chemical processes that can very quickly impair or damage electronic components. Blackened copper

surfaces and cable ends in existing installations are indicators of aggressive gases.

When operated in rooms with dust and condensation that can endanger functionality, operating and monitoring

devices such as Automation Panels or Power Panels are protected on the front against the ingress of dust and

moisture when installed correctly (e.g. cutout installation). The back of all devices must be protected against the

ingress of dust and moisture, however, or the dust deposits must be removed at suitable intervals.

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 9

General information

1.2.6.3 Programs, viruses and malicious programs

Any data exchange or installation of software using data storage media (e.g. floppy disk, CD-ROM, USB flash

drive, etc.) or via networks or the Internet poses a potential threat to the system. It is the user's own responsibility to

avert these dangers and to take appropriate measures such as virus protection programs, firewalls, etc. to protect

against them and to use only software from trustworthy sources.

1.2.7 Environmentally friendly disposal

All programmable logic controllers, operating and monitoring devices and uninterruptible power supplies from B&R

are designed to have as little impact on the environment as possible.

1.2.7.1 Separation of materials

To ensure that devices can be recycled in an environmentally friendly manner, it is necessary to separate out the

different materials.

Component Disposal

Programmable logic controllers

Operating and monitoring devices

Uninterruptible power supply

Batteries and accumulators

Cables

Cardboard/Paper packaging Paper/Cardboard recycling

Plastic packaging material Plastics recycling

Table 1: Environmentally friendly disposal

Electronics recycling

Disposal must be carried out in accordance with applicable legal regulations.

1.2.8 Security concept

To secure plants, systems, machines and networks against cyber threats, it is required to implement (and continuously maintain) a holistic security concept that is state of the art. B&R products and solutions are only one component of such a concept.

The user is responsible for preventing unauthorized access to plants, systems, machines and networks. Systems,

machines and components should only be connected to the corporate network or Internet if and only to the extent

necessary and if appropriate protective measures (e.g. use of firewalls and network segmentation) have been

taken.

B&R products and solutions are constantly being further developed to make them even more secure. B&R expressly

recommends that updates be performed as soon as the corresponding updates are available and that only current

product versions be used. Using outdated or no longer supported versions can increase the risk of cyber threats.

1.2.9 Third-party updates

This product includes third-party software (drivers, etc.). B&R only assumes warrants for updates/patches to thirdparty software if they have been officially released by B&R. Otherwise, updates/patches are performed at your

own risk.

1.2.10 Administrator accounts

A user with administrator rights has extensive options for accessing and manipulating the system.

Therefore, make sure that administrator accounts are adequately secured in order to prevent unauthorized

changes. To do this, use secure passwords and a standard user account for regular operation. Additional measures

such as the use of security policies must be applied as needed.

10 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

General information

1.3 Organization of notices

Safety notices

Contain only information that warns of dangerous functions or situations.

Signal word Description

Danger! Failure to observe these safety guidelines and notices will result in death, severe injury or substantial damage to property.

Warning! Failure to observe these safety guidelines and notices can result in death, severe injury or substantial damage to property.

Caution! Failure to observe these safety guidelines and notices can result in minor injury or damage to property.

Notice! Failure to observe these safety guidelines and notices can result damage to property.

Table 2: Organization of safety notices

General notices

Contain useful information for users and instructions for avoiding malfunctions.

Signal word Description

Information: Useful information, application tips and instructions for avoiding malfunctions.

Table 3: Organization of general notices

1.4 Guidelines

European dimension standards apply to all dimension diagrams.

All dimensions in mm.

Unless otherwise specified, the following general tolerances apply:

Nominal dimension range General tolerance per

Up to 6 mm ±0.1 mm

Over 6 to 30 mm ±0.2 mm

Over 30 to 120 mm ±0.3 mm

Over 120 to 400 mm ±0.5 mm

Over 400 to 1000 mm ±0.8 mm

Table 4: Nominal dimension ranges

DIN ISO 2768 medium

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 11

General information

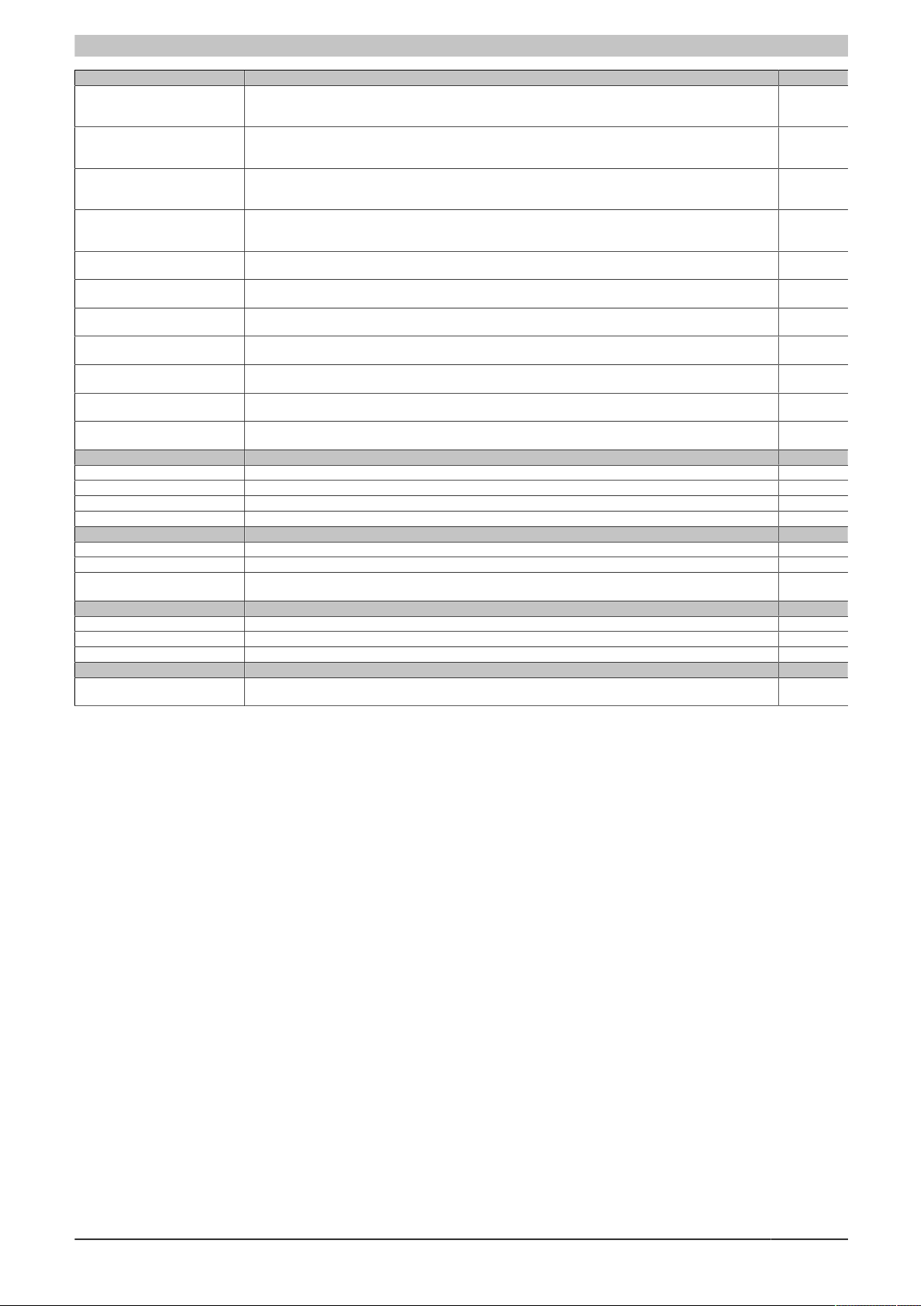

1.5 Overview

Model number Short description Page

5ACCBT01.0000-001 Battery compartment - Dark gray - Includes battery - For APC2200/PPC2200 207

5SWUTI.0001-000 HMI Service Center USB flash drive - Hardware diagnostic software - For APC810/PPC800 - For APC910/

5SWLIN.0745-MUL B&R Linux 9 - 64-bit - Multilingual - PPC2200 - Installation (without Recovery DVD) - Only available with a

5CFAST.016G-00 CFast 16 GB SLC 146

5CFAST.032G-00 CFast 32 GB SLC 146

5CFAST.032G-10 CFast 32 GB MLC 150

5CFAST.064G-10 CFast 64 GB MLC 150

5CFAST.128G-10 CFast 128 GB MLC 150

5CFAST.2048-00 CFast 2 GB SLC 146

5CFAST.256G-10 CFast 256 GB MLC 150

5CFAST.4096-00 CFast 4 GB SLC 146

5CFAST.8192-00 CFast 8 GB SLC 146

5ACCIF01.FPCC-000 Interface card - 2x CAN interfaces - 1x X2X Link interface - 1x POWERLINK interface - 512 kB nvSRAM - For

5ACCIF01.FPCS-000 Interface card - 1x RS485 interface - 1x CAN interface - 1x POWERLINK interface - 32 kB FRAM - For APC2100/

5ACCIF01.FPLK-000 Interface card - 1x POWERLINK interface - Integrated 2-port hub - 512 kB nvSRAM - For APC2100/PPC2100/

5ACCIF01.FPLS-000 Interface card - 1x RS232 interface - 1x POWERLINK interface - 32 kB FRAM - For APC2100/PPC2100/

5ACCIF01.FPLS-001 Interface card - 1x RS232 interface - 1x POWERLINK interface - 512 kB nvSRAM - For APC2100/PPC2100/

5ACCIF01.FPSC-000 Interface card - 1x RS232 interface - 1x CAN interface - 1x POWERLINK interface - 32 kB FRAM - For APC2100/

5ACCIF01.FPSC-001 Interface card - 1x RS232 interface - 1x CAN interface - 1x X2X Link Interface - 1x POWERLINK interface - 512

5ACCIF01.FSS0-000 Interface card - 2x RS422/RS485 interface - For APC2100/PPC2100/APC2200/PPC2200 - Only available with

5ACCIF01.ICAN-000 Interface card - 1x CAN interface - For APC2100/PPC2100/APC2200/PPC2200 - Only available with a new

5ACCIF03.CETH-000 Interface card - 2x ETH 10/100/1000 interface - For APC2200/PPC2200 - Only available with a new device 205

5AP1120.0573-000 Automation Panel 5.7" VGA TFT - 640 x 480 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

5AP1120.0702-000 Automation Panel 7" WVGA TFT - 800 x 480 pixels (16:10) - Single-touch (analog resistive) - Control cabinet

5AP1120.101E-000 Automation Panel 10.1" WXGA TFT - 1280 x 800 pixels (16:10) - Single-touch (analog resistive) - Control cabinet

5AP1120.1043-000 Automation Panel 10.4" VGA TFT - 640 x 480 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

5AP1120.1214-000 Automation Panel 12.1" SVGA TFT - 800 x 600 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

5AP1120.121E-000 Automation Panel 12.1" WXGA TFT - 1280 x 800 pixels (16:10) - Single-touch (analog resistive) - Control cabinet

5AP1120.1505-000 Automation Panel 15.0" XGA TFT - 1024 x 768 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

5AP1120.156B-000 Automation Panel 15.6" HD TFT - 1366 x 768 pixels (16:9) - Single-touch (analog resistive) - Control cabinet

5AP1120.1906-000 Automation Panel 19.0" SXGA TFT - 1280 x 1024 pixels (5:4) - Single-touch (analog resistive) - Control cabinet

5AP1130.0702-000 Automation Panel 7.0" WVGA TFT - 800 x 480 pixels (16:10) - Multi-touch (projected capacitive) - Control cabinet

5AP1130.101E-000 Automation Panel 10.1" WXGA TFT - 1280 x 800 pixels (16:10) - Multi-touch (projected capacitive) - Control

5AP1130.121E-000 Automation Panel 12.1" WXGA TFT - 1280 x 800 pixels (16:10) - Multi-touch (projected capacitive) - Control

5AP1130.156C-000 Automation Panel 15.6" Full HD TFT - 1920 x 1080 pixels (16:9) - Multi-touch (projected capacitive) - Control

5AP1130.185C-000 Automation Panel 18.5" Full HD TFT - 1920 x 1080 pixels (16:9) - Multi-touch (projected capacitive) - Control

5AP1151.0573-000 Automation Panel 5.7" VGA TFT - 640 x 480 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

5AP1180.1043-000 Automation Panel 10.4" VGA TFT - 640 x 480 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

Accessories

270

PPC900 - For APC2100/PPC2100 - For APC2200/PPC2200 - For APC3100/PPC3100 - For APC51x/PP500 For Automation Panel 800/900 - For Automation Panel 1000/5000

B&R Linux 9

262

new device

CFast cards

Interface options

153

APC2100/PPC2100/APC2200/PPC2200 - Only available with a new device

161

PPC2100/APC2200/PPC2200 - Only available with a new device

168

APC2200/PPC2200 - Only available with a new device

173

APC2200/PPC2200 - Only available with a new device

178

APC2200/PPC2200 - Only available with a new device

183

PPC2100/APC2200/PPC2200 - Only available with a new device

190

kB nvSRAM - For APC2100/PPC2100/APC2200/PPC2200 - Only available with a new device

197

a new device

202

device

Panels

89

installation - Landscape format - For PPC2100 / PPC2200 / link modules - Compatible with 5PP520.0573-00

95

installation - Landscape format - For PPC2100 / PPC2200 / link modules - Compatible with 5PP520.0702-00

99

installation - Landscape format - For PPC2100 / PPC3100 / PPC2200 / link modules

103

installation - Landscape format - Front USB - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules Compatible with 5PP520.1043-00

115

installation - Landscape format - Front USB - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules Compatible with 5PP520.1214-00

118

installation - Landscape format - For PPC2100 / PPC3100 / PPC2200 / link modules

122

installation - Landscape format - Front USB - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules Compatible with 5PP520.1505-00, 5AP920.1505-01, 5PC720.1505-xx, 5PC820.1505-00

131

installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

138

installation - Landscape format - Front USB - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules Compatible with 5AP920.1906-01, 5PC720.1906-00, 5PC820.1906-00

97

installation - Landscape format - For PPC2100 / PPC2200 / link modules - Compatible with 5PP520.0702-00

101

cabinet installation - Landscape format - For PPC2100 / PPC3100 / PPC2200 / link modules

120

cabinet installation - Landscape format - For PPC2100 / PPC3100 / PPC2200 / link modules

133

cabinet installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

136

cabinet installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

92

installation - Portrait format - 22 function keys and 20 system keys - For PPC2100 / PPC2200 / link modules

- Compatible with 5PP551.0573-00

106

installation - Landscape format - Front USB - 22 function keys - For PPC900/PPC2100/PPC3100/PPC2200 For link modules - Compatible with 5PP580.1043-00, 5AP980.1043-01

12 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

General information

Model number Short description Page

5AP1180.1505-000 Automation Panel 15.0" XGA TFT - 1024 x 768 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

installation - Landscape format - Front USB - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules Compatible with 5PP580.1505-00, 5AP980.1505-01

5AP1181.1043-000 Automation Panel 10.4" VGA TFT - 640 x 480 pixels (4:3) - Single-touch (analog resistive) - Control cabinet in-

stallation - Portrait format - Front USB - 38 function keys and 20 system keys - For PPC900/PPC2100/PPC3100/

PPC2200 - For link modules - Compatible with 5PP581.1043-00, 5AP981.1043-01, 5PC781.1043-00

5AP1181.1505-000 Automation Panel 15" XGA TFT - 1024 x 768 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

installation - Landscape format - Front USB - 32 function keys and 92 system keys - For PPC900/PPC2100/

PPC3100/PPC2200 - For link modules - Compatible with 5PP581.1505-000

5AP1182.1043-000 Automation Panel 10.4" VGA TFT - 640 x 480 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

installation - Landscape format - Front USB - 44 function keys and 20 system keys - For PPC900/PPC2100/

PPC3100/PPC2200 - For link modules - Compatible with 5PP582.1043-00, 5AP982.1043-01, 5PC782.1043-00

5AP923.1215-00 Automation Panel 12.1" XGA TFT - 1024 x 768 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

5AP923.1505-00 Automation Panel 15.0" XGA TFT - 1024 x 768 pixels (4:3) - Single-touch (analog resistive) - Control cabinet

installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

5AP923.1906-00 Automation Panel 19.0" SXGA TFT - 1280 x 1024 pixels (5:4) - Single-touch (analog resistive) - Control cabinet

installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

5AP933.156B-00 Automation Panel 15.6" HD TFT - 1366 x 768 pixels (16:9) - Multi-touch (projected capacitive) - Control cabinet

installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

5AP933.185B-00 Automation Panel 18.5" HD TFT - 1366 x 768 pixels (16:9) - Multi-touch (projected capacitive) - Control cabinet

installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

5AP933.215C-00 Automation Panel 21.5" Full HD TFT - 1920 x 1080 pixels (16:9) - Multi-touch (projected capacitive) - Control

cabinet installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

5AP933.240C-00 Automation Panel 24.0" Full HD TFT - 1920 x 1080 pixels (16:9) - Multi-touch (projected capacitive) - Control

cabinet installation - Landscape format - For PPC900/PPC2100/PPC3100/PPC2200 - For link modules

System units

5PPC2200.AL02-000 PPC2200 system unit - Intel Atom E3930 1.30 GHz - Dual core - 2 GB SDRAM 141

5PPC2200.AL04-000 PPC2200 system unit - Intel Atom E3930 1.30 GHz - Dual core - 4 GB SDRAM 141

5PPC2200.AL14-000 PPC2200 system unit - Intel Atom E3940 1.60 GHz - Quad core - 4 GB SDRAM 141

5PPC2200.AL18-000 PPC2200 system unit - Intel Atom E3940 1.60 GHz - Quad core - 8 GB SDRAM 141

Terminal blocks

0TB103.9 Connector 24 VDC - 3-pin female - Screw clamp terminal block 3.31 mm² 275

0TB103.91 Connector 24 VDC - 3-pin female - Cage clamp terminal block 3.31 mm² 275

0TB1210.3100 Connector 300 VDC - 10-pin female - Cage clamp terminal block - Protected against vibration by the screw

flange

USB accessories

5MMUSB.032G-02 USB 3.0 flash drive 32 GB MLC 280

5MMUSB.2048-01 USB 2.0 flash drive 2048 MB B&R 277

5MMUSB.4096-01 USB 2.0 flash drive 4096 MB B&R 277

Windows 10 IoT Enterprise

5SWW10.0545-MUL Windows 10 IoT Enterprise 2016 LTSB - 64-bit - Entry - Multilingual - PPC2200 (UEFI boot) - Processor E3930/

E3940 - License (without Recovery DVD) - Only available with a new device

125

109

128

112

69

71

74

77

80

83

86

276

259

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 13

Technical data

2 Technical data

2.1 Introduction

2.1.1 Information about this user's manual

This user's manual contains all the necessary information for a functioning Panel PC 2200 built-in device.

2.1.2 Description of individual modules

2.1.2.1 AP9x3 panels

AP9x3 panels form the basis for the Automation Panel 9x3, Panel PC 900, Panel PC 2100, Panel PC 2200 and

Panel PC 3100 system families. They consist of a display and touch screen. Different display diagonals and touch

screen technologies are available. The panels can only be operated as a complete system in combination with

a link module (Automation Panel 9x3) or CPU board and system unit (Panel PC 900, Panel PC 2100, Panel PC

2200, Panel PC 3100). The panels are installed using retaining clips.

Single-touch panels start with model number 5AP923.xxxx-xx; multi-touch panels start with model number

5AP933.xxxx-xx.

2.1.2.2 AP1000 panels

AP1000 panels form the basis for the Automation Panel 1000, Panel PC 900, Panel PC 2100, Panel PC 2200 and

Panel PC 3100 system families. Different display diagonals and touch screen technologies as well as panels with

touch screen and keys are available. Panels can only be operated as a complete system in combination with a link

module (Automation Panel 1000) or CPU board and system unit (Panel PC 900, Panel PC 2100, Panel PC 2200,

Panel PC 3100). The panels are installed using retaining clips or clamping blocks.

14 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

Technical data

2.1.2.3 System units

System units consist of the CPU board and an aluminum housing. All interfaces and the main memory of the

PPC2200 are integrated on the system units. An interface option and CFast card can also be connected. The main

memory modules are permanently installed on the system unit and cannot be replaced.

If a system unit is installed on a panel, this results in a functional Panel PC 2200.

A system unit without a panel is not functional.

2.1.2.3.1 Features

•

Intel Atom X processor series (Apollo Lake)

•

Up to quad-core CPU performance

•

Powerful graphics (Intel HD graphics)

•

Compact dimensions

•

2x Gigabit Ethernet

•

2x USB 3.0

•

1x CFast slot

•

1x interface option slot

•

Fanless operation

•

Real time clock, RTC (battery-backed)

•

TPM 2.0 security

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 15

Technical data

2.1.3 Design/Configuration

It is possible to configure the Automation Panel 9x3, Automation Panel 1000 and Panel PC 2200 system individually

according to the operating conditions and requirements. The Automation Panel 9x3, Automation Panel 1000 or

Panel PC 2200 system is so flexible that an Automation Panel can be converted to a Panel PC or a Panel PC

to an Automation Panel.

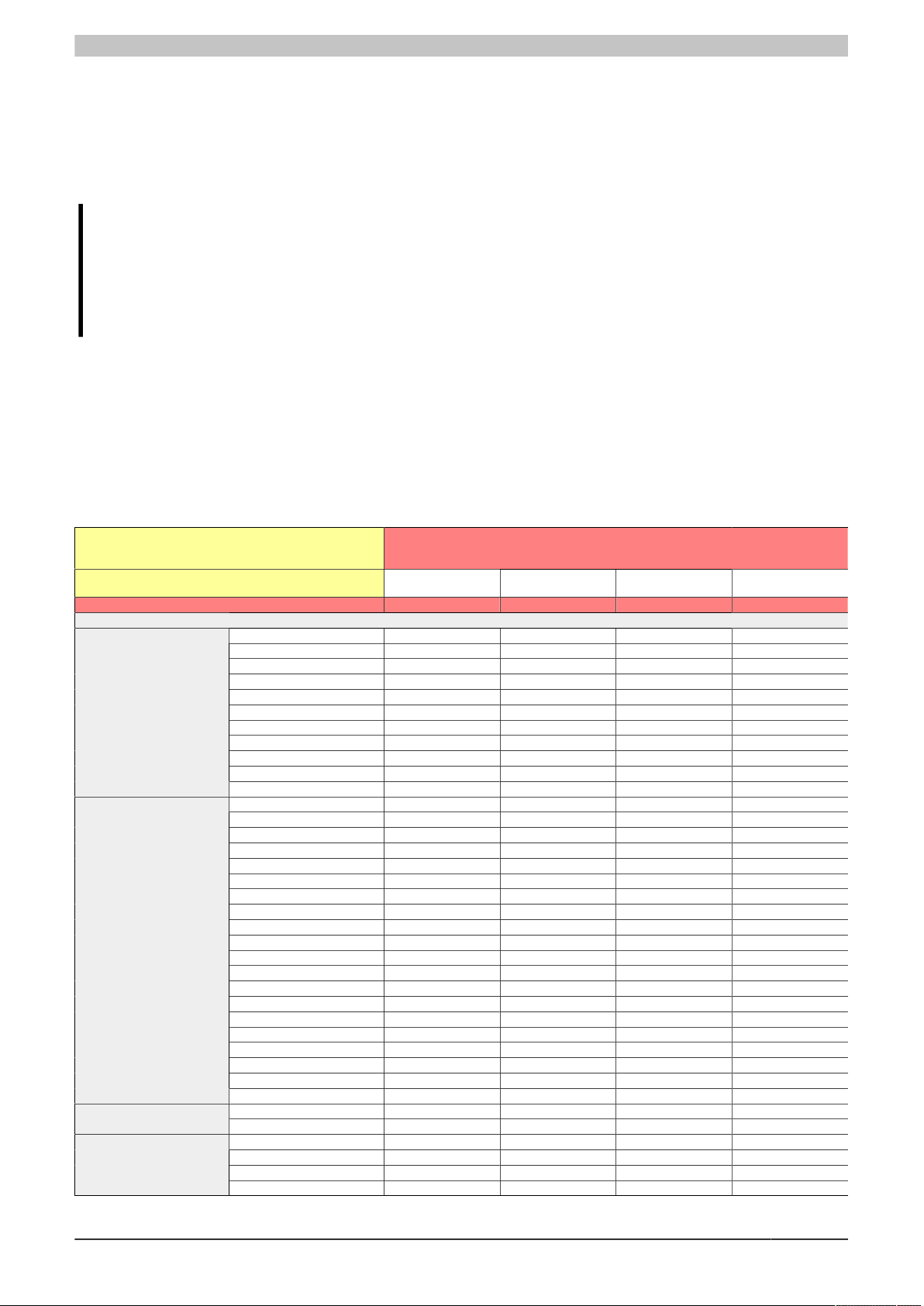

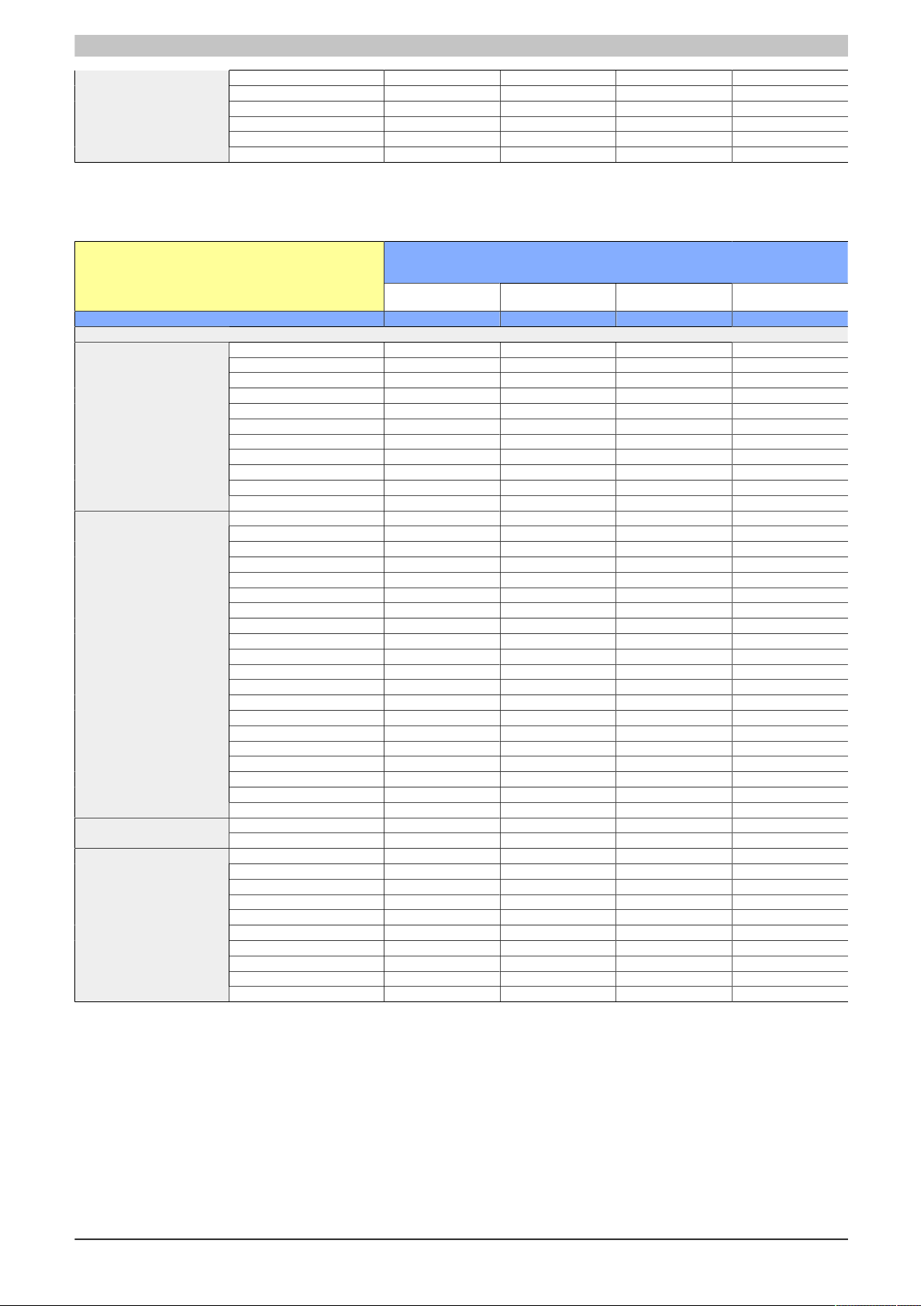

2.1.3.1 Configuration

The following individual components are mandatory for operation as a Panel PC 2200:

•

Panel

•

System unit

•

CFast card for the operating system

•

Operating system

Base system - Configuration

Panels Select 1

923 panels

5AP923.1215-00 12.1" XGA Single-touch No Landscape

5AP923.1505-00 15.0" XGA Single-touch No Landscape

5AP923.1906-00 19.0" SXGA Single-touch No Landscape

933 panels

5AP933.156B-00 15.6" HD Multi-touch No Landscape

5AP933.185B-00 18.5" HD Multi-touch No Landscape

5AP933.215C-00 21.5" FHD Multi-touch No Landscape

5AP933.240C-00 24.0" FHD Multi-touch No Landscape

1120 panels

5AP1120.0573-000 5.7" VGA Single-touch No Landscape

5AP1120.0702-000 7.0" WVGA Single-touch No Landscape

5AP1120.101E-000 10.1" WXGA Single-touch No Landscape

5AP1120.1043-000 10.4" VGA Single-touch No Landscape

5AP1120.1214-000 12.1" SVGA Single-touch No Landscape

5AP1120.121E-000 12.1" WXGA Single-touch No Landscape

5AP1120.1505-000 15.0" XGA Single-touch No Landscape

5AP1120.156B-000 15.6" HD Single-touch No Landscape

5AP1120.1906-000 19.0" SXGA Single-touch No Landscape

1130 panels

5AP1130.0702-000 7.0" WVGA Multi-touch No Landscape

5AP1130.101E-000 10.1" WXGA Multi-touch No Landscape

5AP1130.121E-000 12.1" WXGA Multi-touch No Landscape

5AP1130.156C-000 15.6" FHD Multi-touch No Landscape

5AP1130.185C-000 18.5" FHD Multi-touch No Landscape

1151 panels

5AP1151.0573-000 5.7" VGA No Yes Portrait

1180 panels

5AP1180.1043-000 10.4" VGA Single-touch Yes Landscape

5AP1180.1505-000 15.0" XGA Single-touch Yes Landscape

1181 panels

5AP1181.1043-000 10.4" VGA Single-touch Yes Portrait

5AP1181.1505-000 15.0" XGA Single-touch Yes Landscape

1182 panels

5AP1182.1043-000 10.4" VGA Single-touch Yes Landscape

System units Select 1

System unit Processor Processor -

5PPC2200.AL02-000 Intel Atom x5-E3930 1300 MHz 2 LPDDR4 SDRAM 2 GB

5PPC2200.AL04-000 Intel Atom x5-E3930 1300 MHz 2 LPDDR4 SDRAM 4 GB

5PPC2200.AL14-000 Intel Atom x5-E3940 1600 MHz 4 LPDDR4 SDRAM 4 GB

5PPC2200.AL18-000 Intel Atom x5-E3940 1600 MHz 4 LPDDR4 SDRAM 8 GB

Mass storage devices

CFast cards Select 1

5CFAST.2048-00

5CFAST.4096-00

5CFAST.8192-00

5CFAST.016G-00

5CFAST.032G-00

Interfaces

Battery compartment Selected automatically

Diagonal Resolution Touch screen Keys Format

Cores Main memory type Main memory size

Clock frequency

5CFAST.032G-10

5CFAST.064G-10

5CFAST.128G-10

5CFAST-256G-10

1)

5ACCBT01.0000-001

Table 5: PPC2200 configuration - Base system

1) The battery compartment is selected automatically.

16 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

Technical data

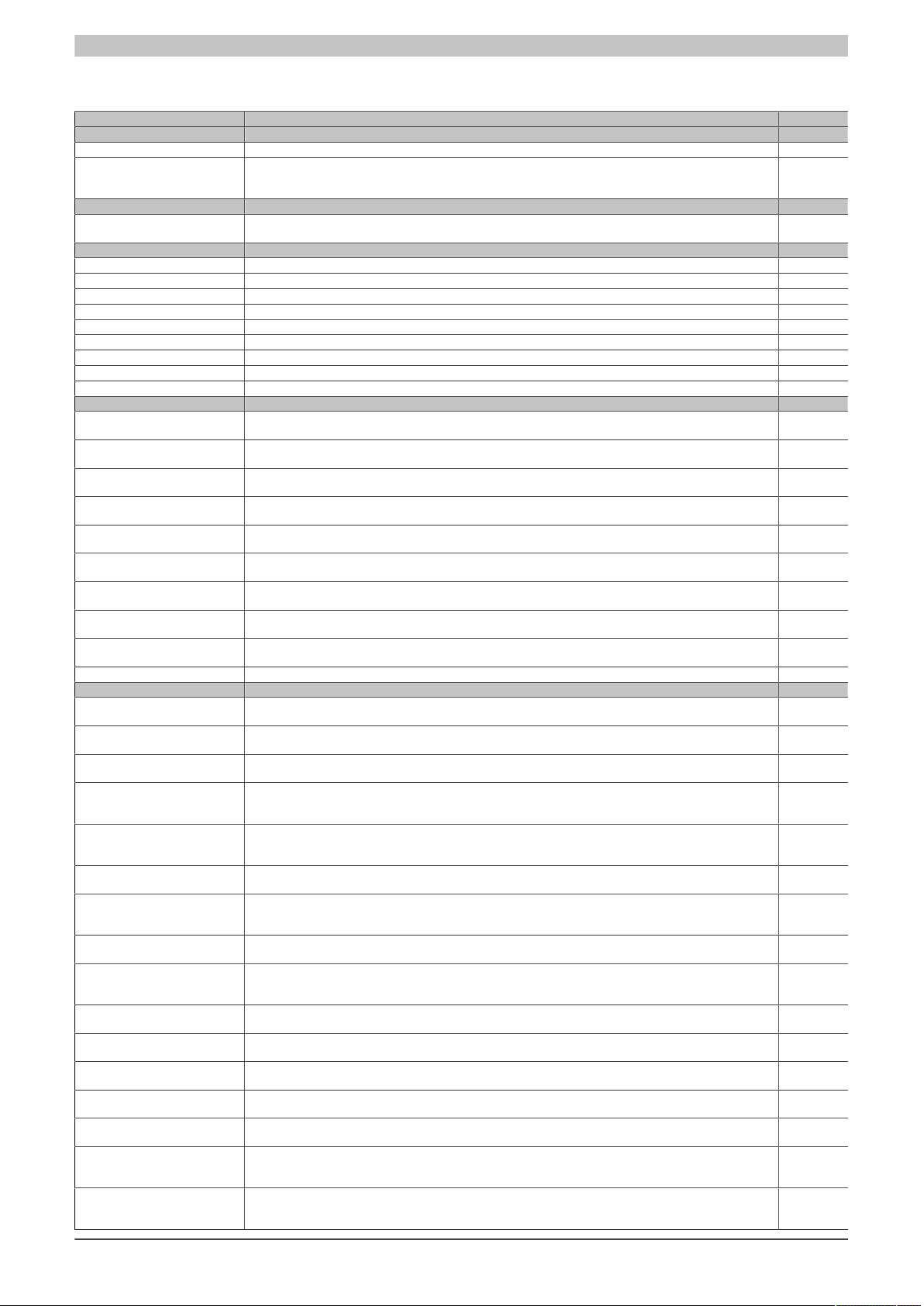

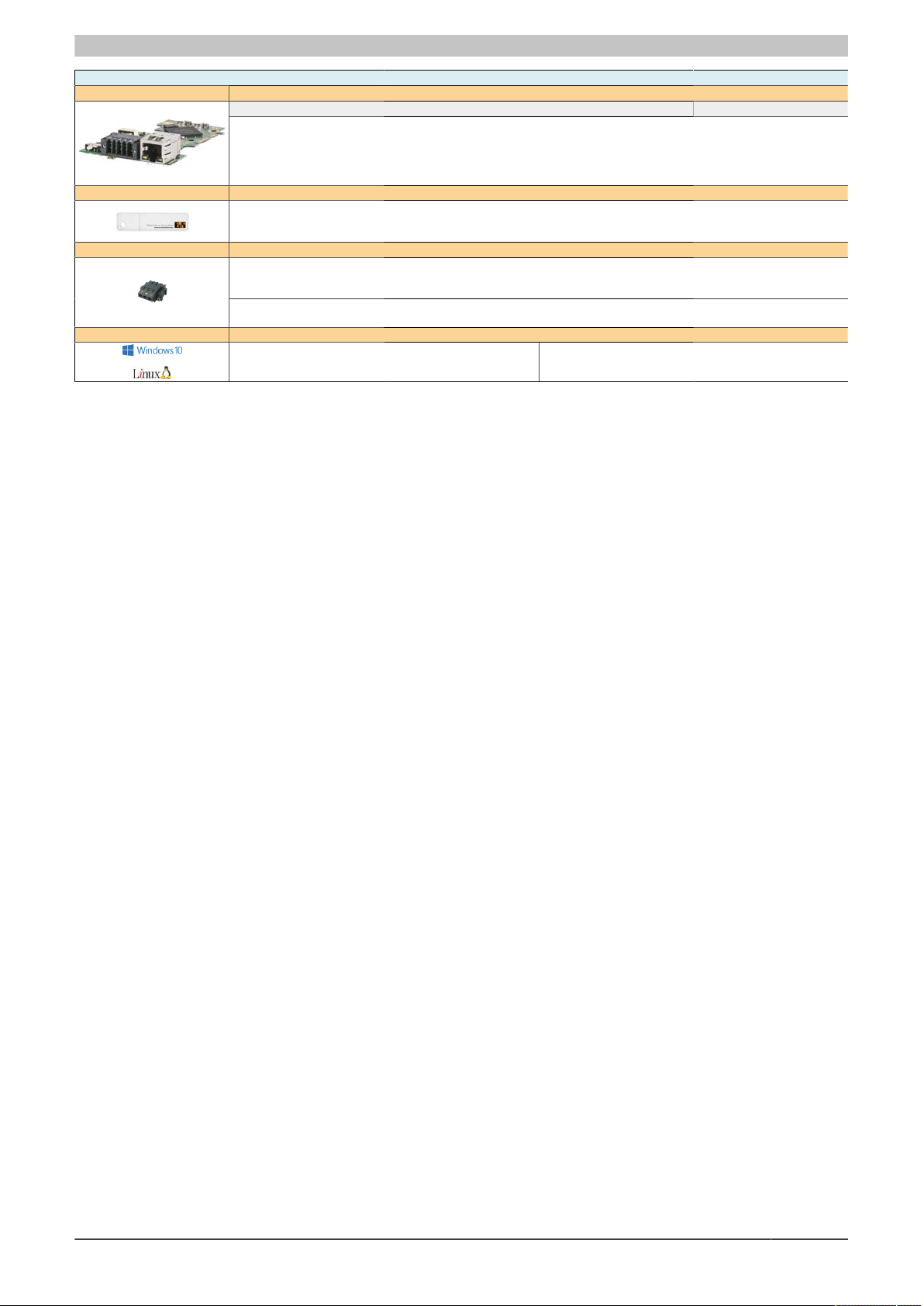

Accessories and software - Configuration

Interfaces

Accessories Optional selection

Terminal blocks Select 1

Operating systems Select 1

Interface options Optional, select 1

5ACCIF01.FPCC-000

5ACCIF01.FPLS-000

5ACCIF01.FPSC-000

5ACCIF01.FPCS-000

5ACCIF01.ICAN-000

5MMUSB.2048-01

5MMUSB.4096-01

5MMUSB.032G-02

Power supply connectors

0TB103.9

0TB103.91

Terminal block for IF option

0TB1210.3100

Windows 10

5SWW10.0545-MUL

5ACCIF01.FPLK-000

5ACCIF01.FPLS-001

5ACCIF01.FPSC-001

5ACCIF03.CETH-000

B&R Linux 9

5SWLIN.0745-MUL

Table 6: PPC2200 configuration - Accessories and software

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 17

Technical data

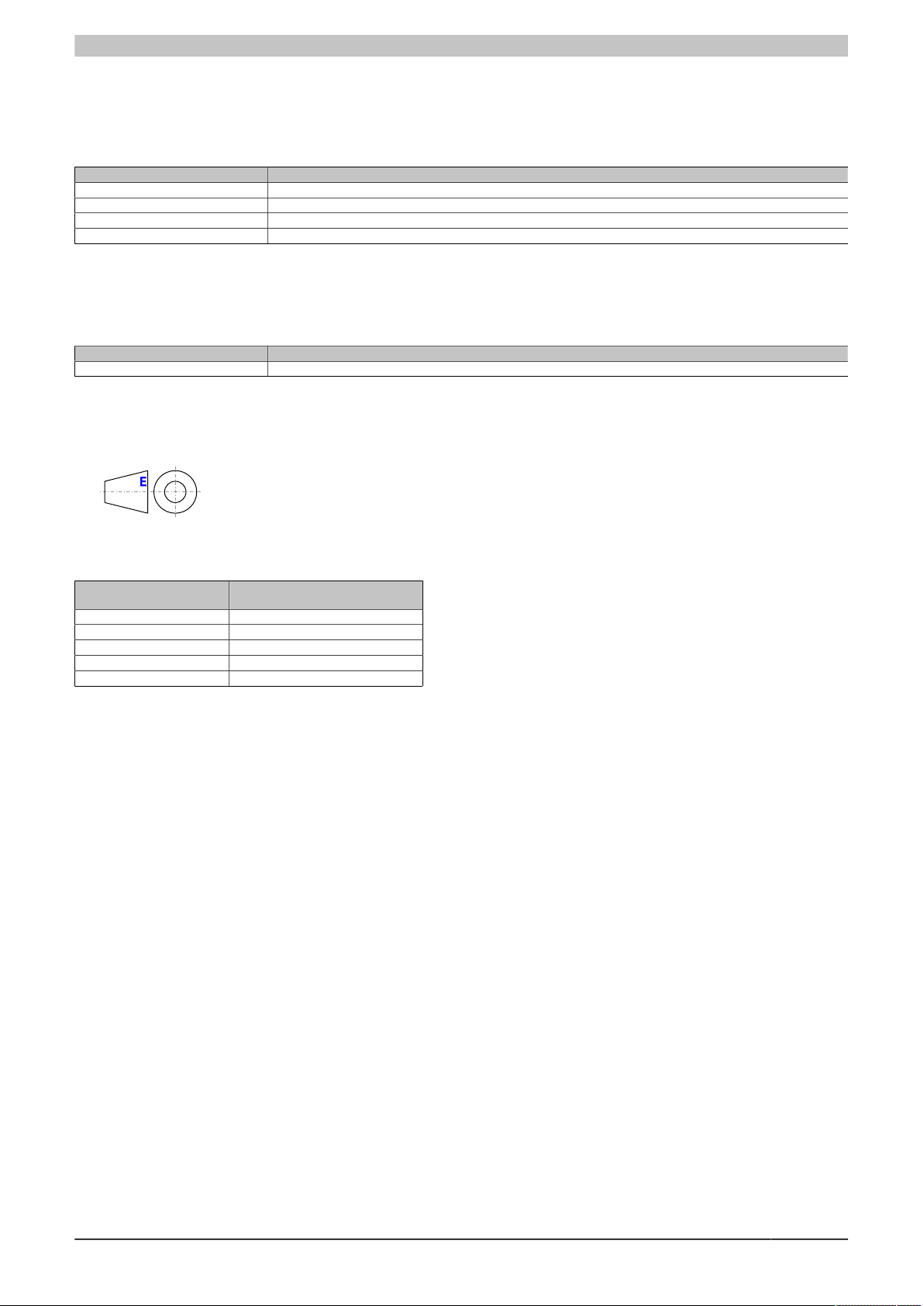

Z

C

E

D

A

B

GFX

Y

H

2.2 Complete system

2.2.1 Mechanical properties

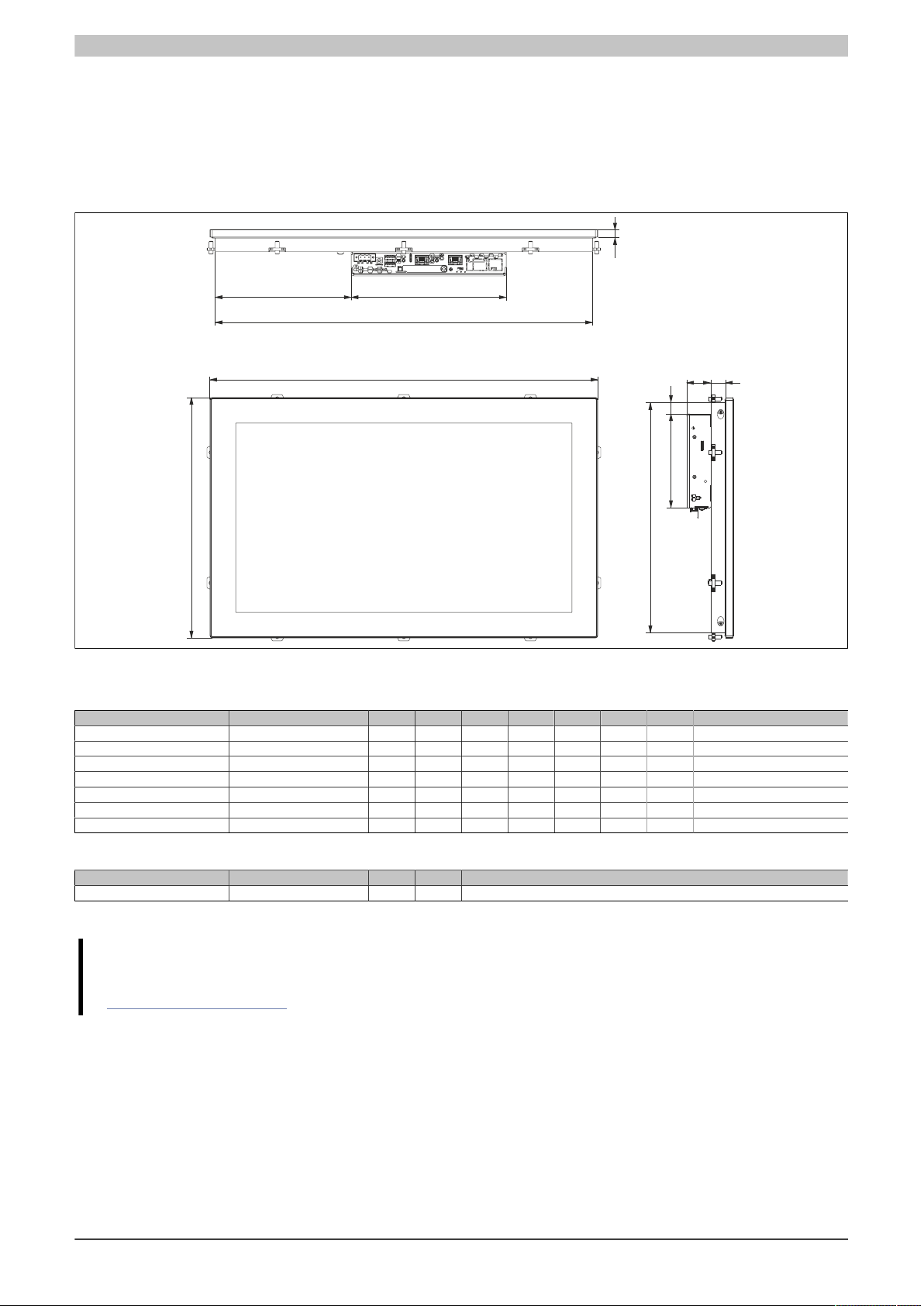

2.2.1.1 Dimensions

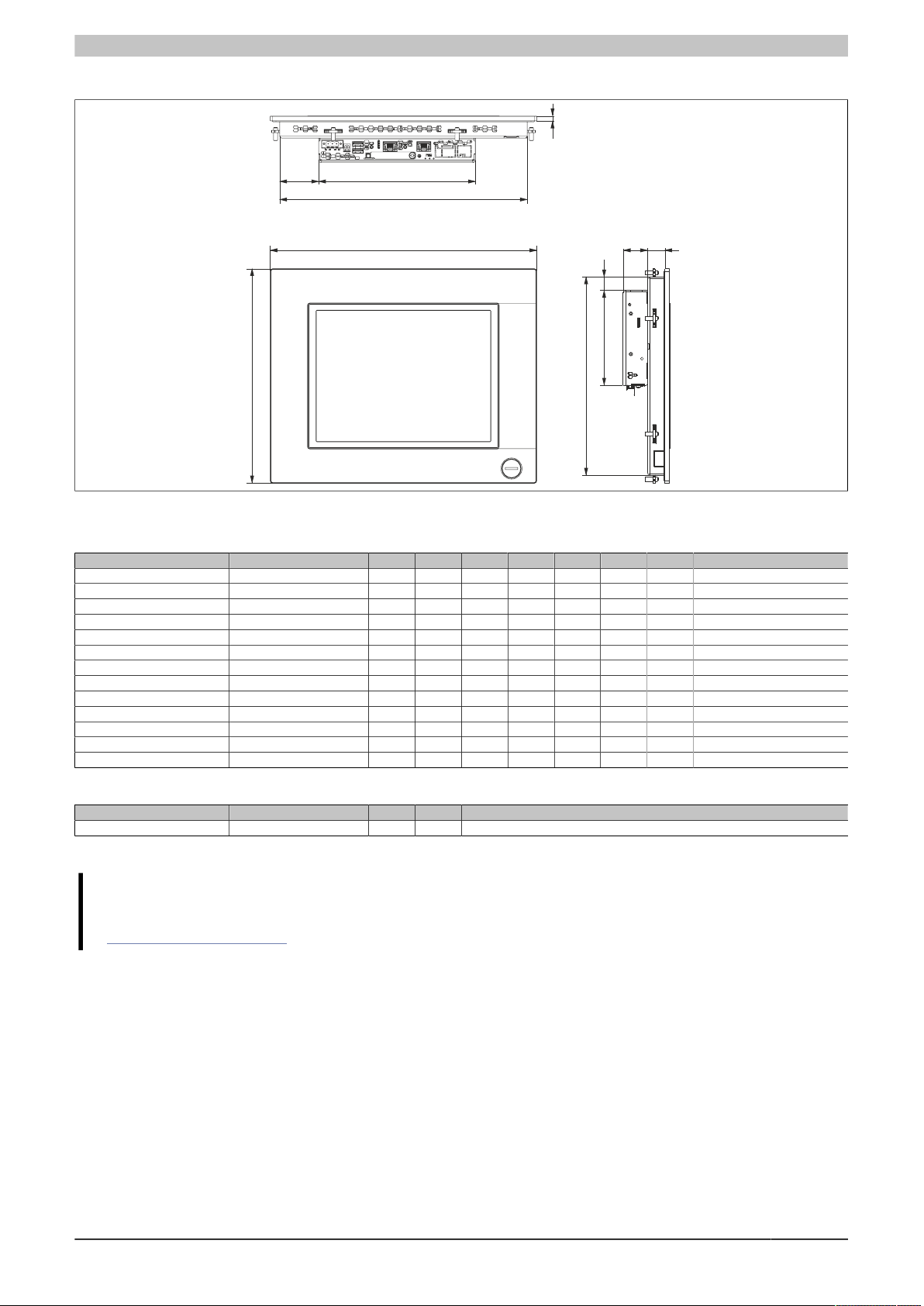

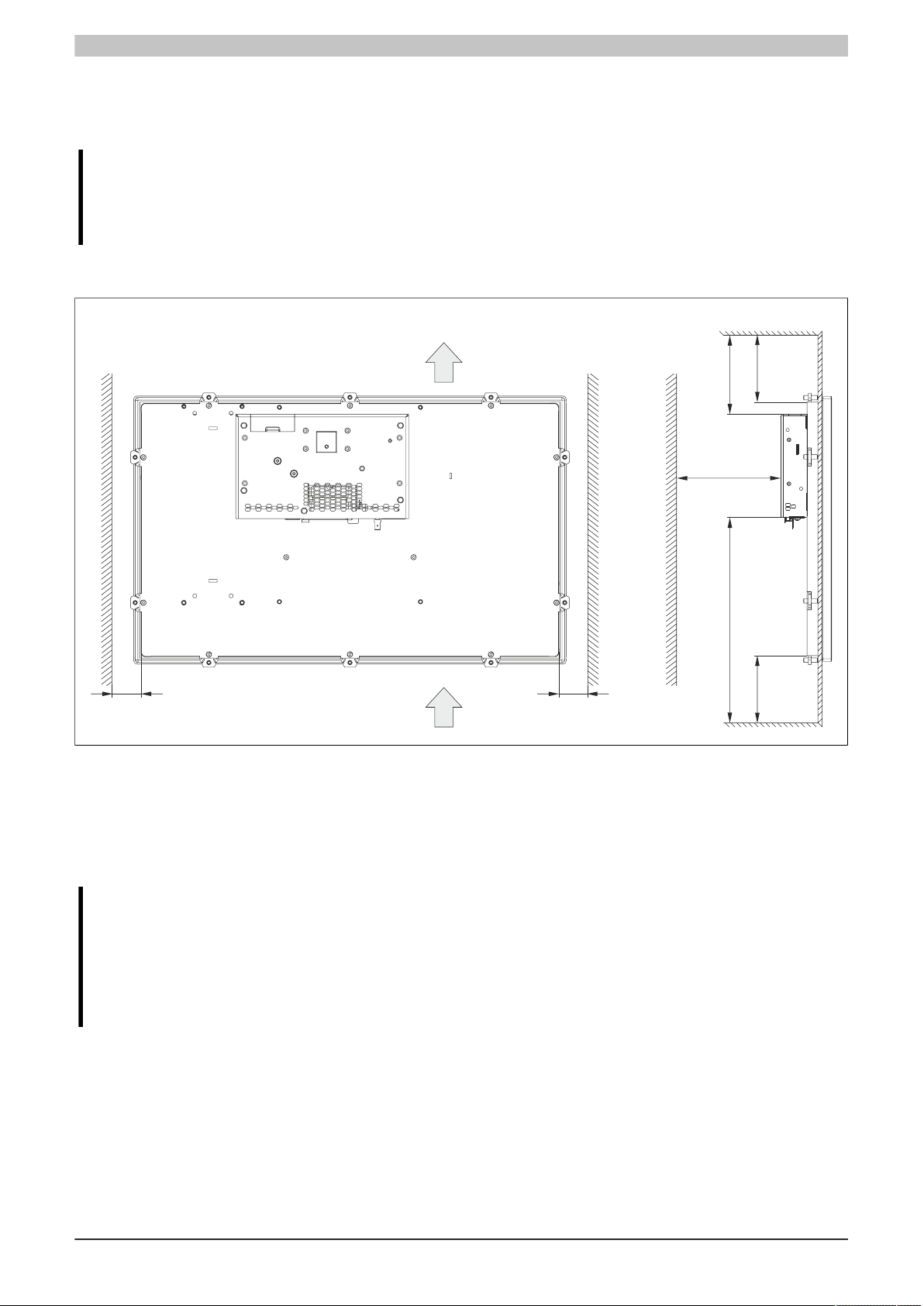

AP9x3 panels - Dimensions

Figure 1: Panel PC 2200 with AP9x3 panels - Dimensions

All dimensions in mm.

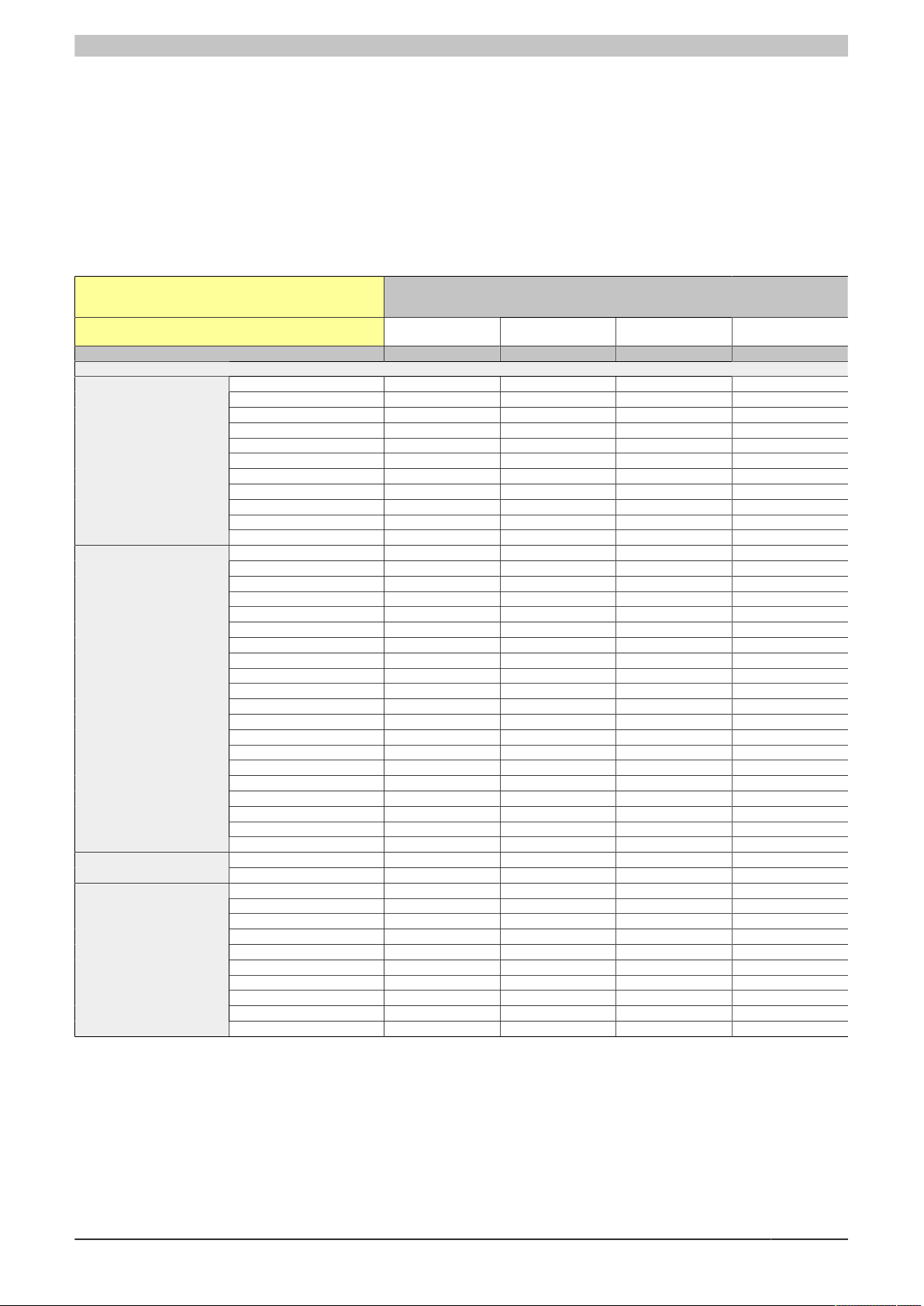

Display type Model number A B C D E F G H

12.1" single-touch 5AP923.1215-00 315 239 302 48 9 226 13.5 13.5

15.0" single-touch 5AP923.1505-00 370 288 357 84.5 9 275 14.5 13.5

19.0" single-touch 5AP923.1906-00 440 358 427 149 9 345 23 13.5

15.6" multi-touch 5AP933.156B-00 414 258.5 401 105.5 9 245.5 20 13.5

18.5" multi-touch 5AP933.185B-00 475 295 462 166.5 9 282 18 13.5

21.5" multi-touch 5AP933.215C-00 541.5 333 528.5 199.75 9 320 18 13.5

24.0" multi-touch 5AP933.240C-00 598.5 364 585.5 228.25 9 351 18 13.5

Table 7: AP9x3 panels - Dimensions

Component Model number X Y Z

System unit 5PPC2200.ALxx-000 29.7 115 190

Table 8: System units - Dimensions

Information:

2D and 3D drawings (DXF and STEP formats) can be downloaded from the B&R website

(www.br-automation.com).

18 Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation

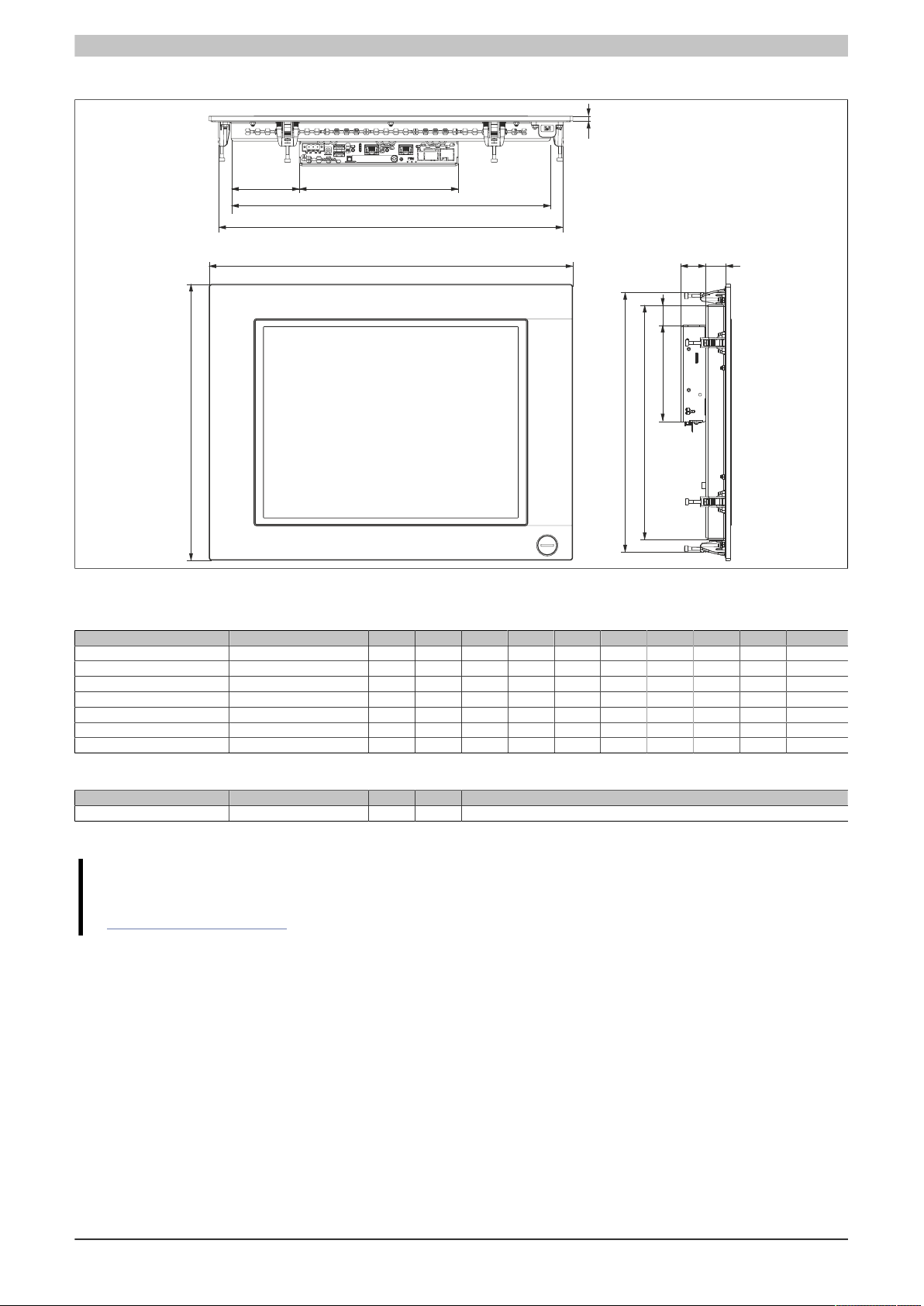

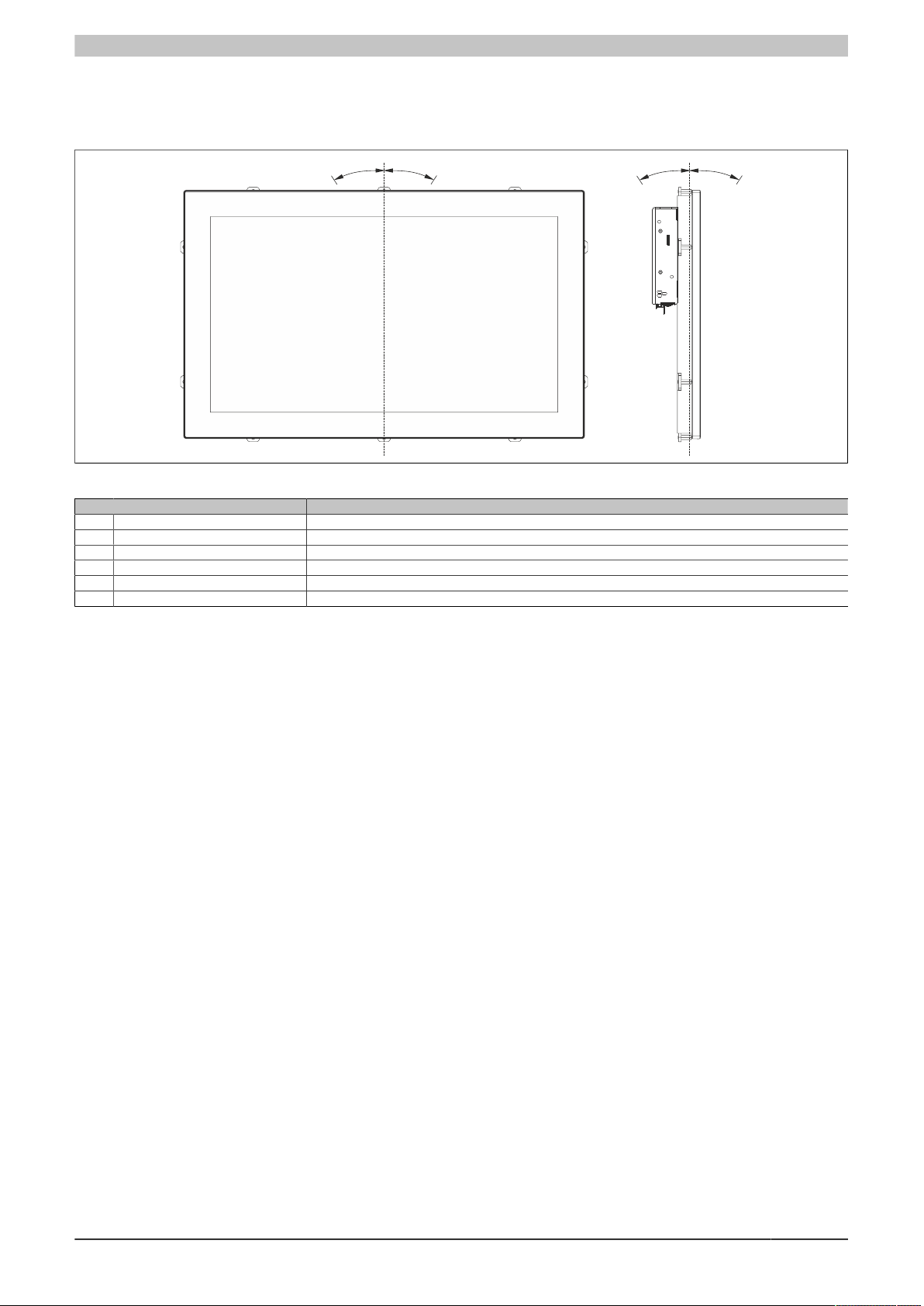

AP1000 panels with retaining clips - Dimensions

A

B

G

C

D

Z

X

H

Y

F

E

Technical data

Figure 2: Panel PC 2200 with AP1000 panels with retaining clips - Dimensions

All dimensions in mm.

Display type Model number A B C D E F G H

5.7" single-touch 5AP1120.0573-000 212 156 196 3 5.7 140 19.5 2.5

5.7" keys 5AP1151.0573-000 212 245 196 3 5.7 229 19.5 2.5

7.0" single-touch 5AP1120.0702-000 212 156 196 3 5.7 140 19.5 2.5

7.0" multi-touch 5AP1130.0702-000 209 153 196 3 9 140 20 7.25

10.1" single-touch 5AP1120.101E-000 279 191 266 38 9 178 18 13.5

10.1" multi-touch 5AP1130.101E-000 279 191 266 38 9 178 18 13.5

10.4" single-touch 5AP1120.1043-000 323 260 300 47.2 5.7 240 21 16

10.4" single-touch with keys 5AP1180.1043-000 323 260 300 47.2 5.7 240 21 16

12.1" single-touch 5AP1120.121E-000 324 221.5 311 60.5 9 208.5 18 13.5

12.1" multi-touch 5AP1130.121E-000 324 221.5 311 60.5 9 208.5 18 13.5

15.6" single-touch 5AP1120.156B-000 414 258.5 401 105.5 9 245.5 20 13.5

15.6" multi-touch 5AP1130.156C-000 414 258.5 401 105.5 9 245.5 20 13.5

18.5" multi-touch 5AP1130.185C-000 475 295 462 166.5 9 282 18 13.5

Table 9: AP1000 panels with retaining clips - Dimensions

Component Model number X Y Z

System unit 5PPC2200.ALxx-000 29.7 115 190

Table 10: System units - Dimensions

Information:

2D and 3D drawings (DXF and STEP formats) can be downloaded from the B&R website

(www.br-automation.com).

Panel PC 2200 built-in devices User's manual V 1.05 Translation of the original documentation 19

Technical data

F

GHX

Y

I

A

B

C

D

Z

E

J

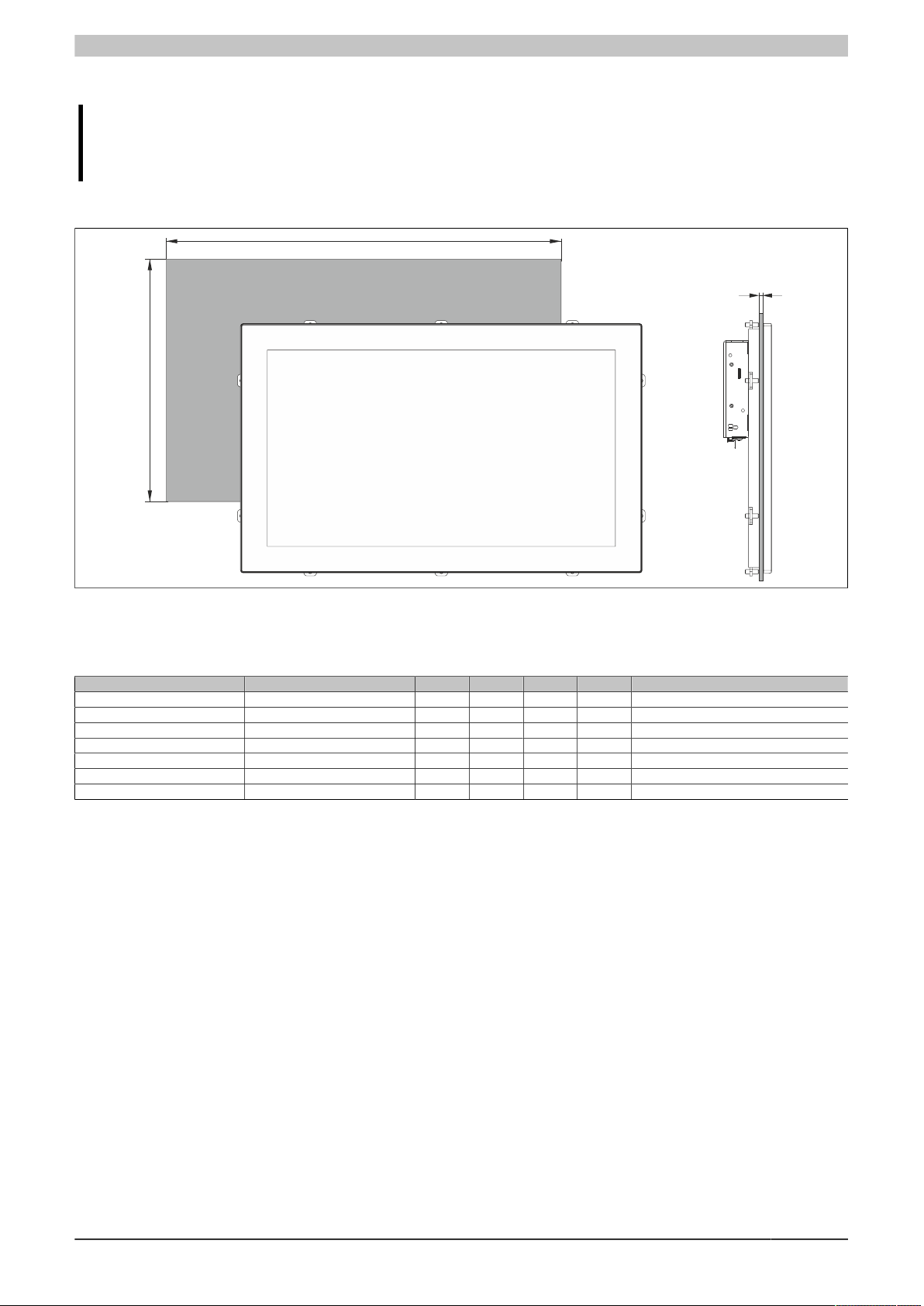

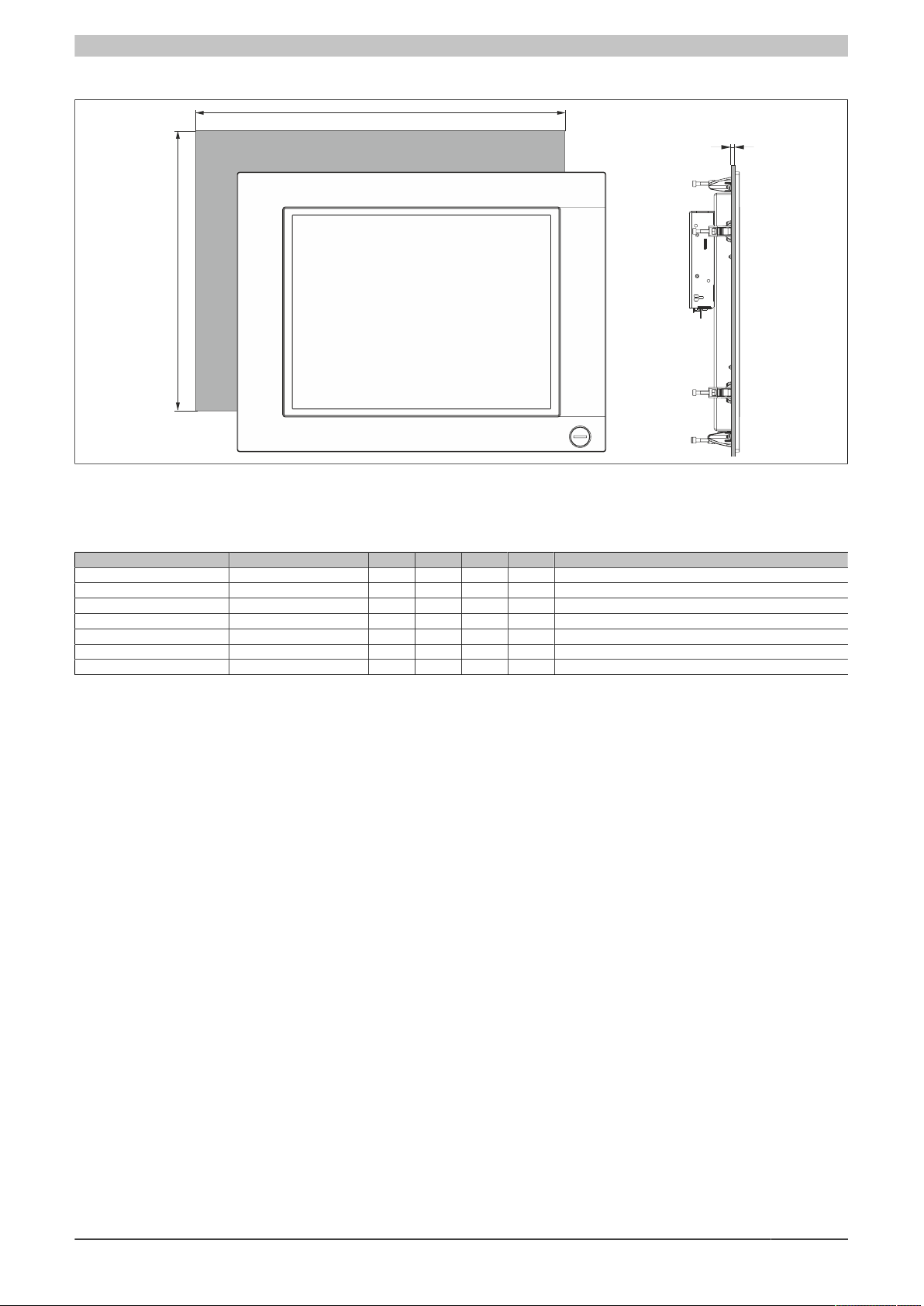

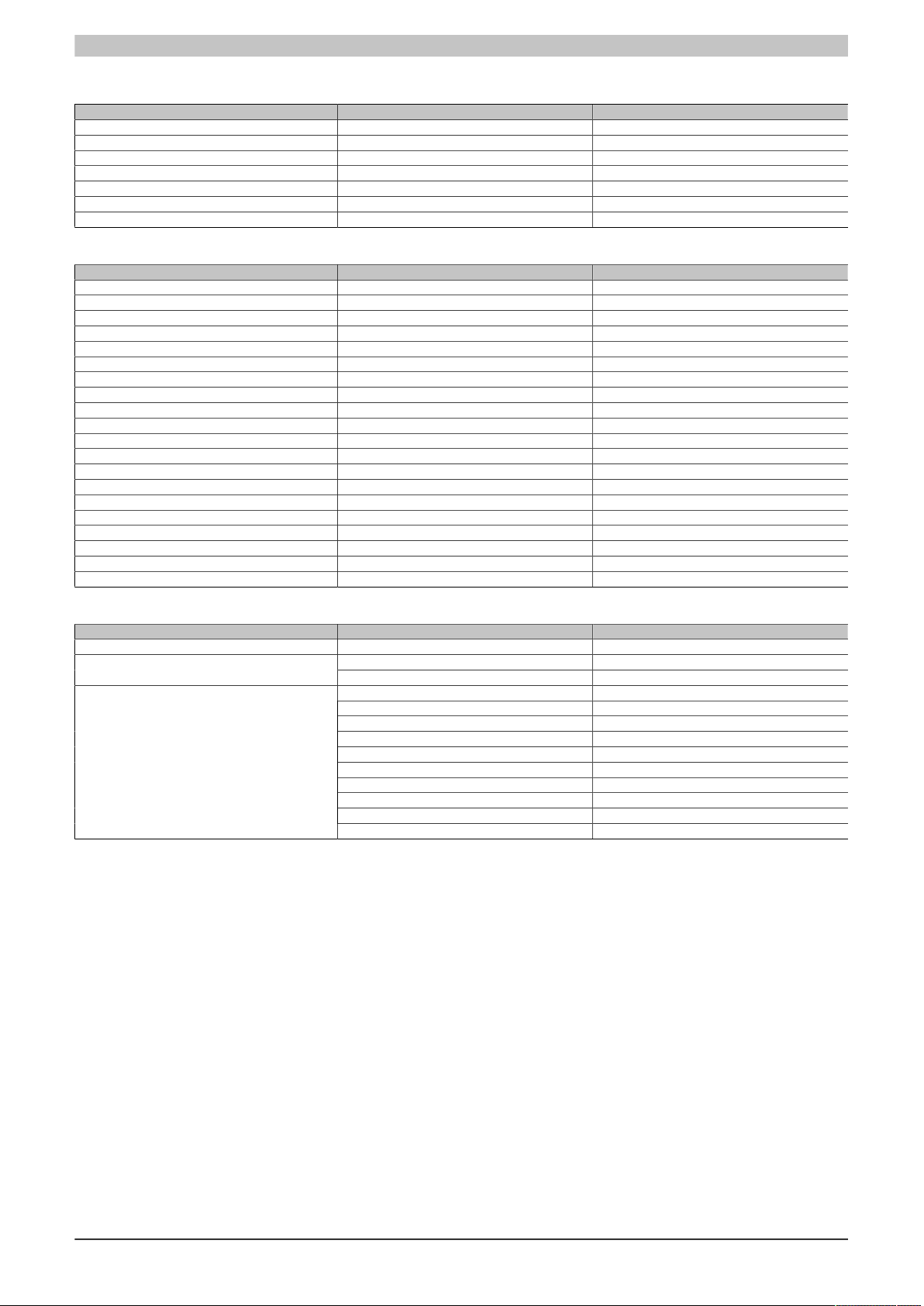

AP1000 panels with clamping blocks - Dimensions

Figure 3: Panel PC 2200 with AP1000 panels with clamping blocks - Dimensions

All dimensions in mm.