Page 1

en

Not for Reproduction

Operator’s Manual

es

Manual del Operario

fr

Manuel de l’opérateur

Model 90000

Snow Seriest

Briggs & Stratton is a registered trademark

of Briggs & Stratton Corporation

English

en

E 2009 Briggs & Stratton Corporation,

Milwaukee, WI, USA. All rights reserved.

Español Français

es fr

Form No. 277614TRI

Revision: B

Page 2

1

Not for Reproduction

C

B

F

C

B

A

XXXXXX

D

G

K

I

J

H

F

L

E

G

D

2

A

E

F

B

4

A

B

C

3

A

C

B

C

D

5

A

D

B

C

E

2

BRIGGSandSTRATTON.COM

Page 3

6

Not for Reproduction

8 9

7

G

F

A

B

A

B

A

A

3

Page 4

General Information

Not for Reproduction

For replacement parts or technical assistance, record below the engine model, type, and

code numbers along with the date of purchase. These numbers are located on your

engine (see the Features and Controls page).

Date of purchase:

MM/DD/YYYY

Engine model:

Model: Code:Type:

Engine Power Rating Information

The gross power rating for individual gas engine models is labeled in accordance with

SAE (Society of Automotive Engineers) code J1940 (Small Engine Power & Torque

Rating Procedure), and rating performance has been obtained and corrected in

accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060

RPM; horsepower values are derived at 3600 RPM. Actual gross engine power will be

lower and is affected by, among other things, ambient operating conditions and

engine-to-engine variability. Given both the wide array of products on which engines are

placed and the variety of environmental issues applicable to operating the equipment,

the gas engine will not develop the rated gross power when used in a given piece of

power equipment (actual “on-site” or net power). This difference is due to a variety of

factors including, but not limited to, accessories (air cleaner, exhaust, charging, cooling,

carburetor, fuel pump, etc.), application limitations, ambient operating conditions

(temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing

and capacity limitations, Briggs & Stratton may substitute an engine of higher rated

power for this Series engine.

Operator Safety

SAFETY AND CONTROL SYMBOLS

Fire

Fast

Choke

Hazardous

Chemical

The safety alert symbol is used to identify safety information about hazards that can

result in personal injury. A signal word (DANGER, WARNING, or CAUTION) is used with the

alert symbol to indicate the likelihood and the potential severity of injury. In addition, a hazard

symbol may be used to represent the type of hazard.

Moving Parts

Stop

On Off

Read Manual

Oil

Explosion

Fuel Shutoff

Hot Surface

Toxic Fumes

Shock

Kickback

Frostbite

Slow

Fuel

Wear Eye

Protection

WARNING

The engine exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

WARNING

Briggs & Stratton does not approve or authorize the use of these engines on 3-wheel

All Terrain Vehicles (ATVs), motor bikes, fun/recreational go-karts, aircraft products,

or vehicles intended for use in competitive events. Use of these engines in such

applications could result in property damage, serious injury (including paralysis), or

even death.

NOTICE: This engine was shipped from Briggs & Stratton without oil. Before you start

the engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be covered

under warranty.

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

• Turn engine off and let engine cool at least 2 minutes before removing the fuel

cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the gasoline, do not fill above

the bottom of the fuel tank neck.

• Keep gasoline away from sparks, open flames, pilot lights, heat, and other

ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks.

Replace if necessary

• If fuel spills, wait until it evaporates before starting engine.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in

place and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN/RUN position, move throttle

(if equipped) to FAST position and crank until engine starts.

When Operating Equipment

• Do not tip engine or equipment at angle which causes gasoline to spill.

• Do not choke the carburetor to stop engine.

• Never start or run the engine with the air cleaner assembly (if equipped) or the

air filter (if equipped) removed.

When Changing Oil

• If you drain the oil from the top oil fill tube, the fuel tank must be empty or fuel

can leak out and result in a fire or explosion.

When Transporting Equipment

• Transport with fuel tank EMPTY or with fuel shut-off valve OFF.

When Storing Gasoline Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have

pilot light or other ignition source because they can ignite gasoline vapors.

DANGER indicates a hazard which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazard which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazard which, if not avoided, could result in minor or

moderate injury.

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area, do not start engine.

• Do not use pressurized starting fluids because vapors are flammable.

NOTICE indicates a situation that could result in damage to the product.

WARNING

Engines give off carbon monoxide, an odorless, colorless, poison gas.

WARNING

Certain components in this product and its related accessories contain chemicals

known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling.

4 BRIGGSandSTRATTON.COM

Breathing carbon monoxide can cause nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area, even if doors or windows are open.

Page 5

WARNING

Not for Reproduction

Rapid retraction of starter cord (kickback) will pull hand and arm

toward engine faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.

• Remove all external equipment/engine loads before starting engine.

• Direct-coupled equipment components such as, but not limited to, blades,

impellers, pulleys, sprockets, etc., must be securely attached.

WARNING

Rotating parts can contact or entangle hands, feet, hair, clothing, or

accessories.

Traumatic amputation or severe laceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling drawstrings or items that could

become caught.

WARNING

Running engines produce heat. Engine parts, especially muffler,

become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• It is a violation of California Public Resource Code, Section 4442, to use or

operate the engine on any forest-covered, brush-covered, or grass-covered land

unless the exhaust system is equipped with a spark arrester, as defined in

Section 4442, maintained in effective working order. Other states or federal

jurisdictions may have similar laws. Contact the original equipment

manufacturer, retailer, or dealer to obtain a spark arrester designed for the

exhaust system installed on this engine.

WARNING

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic

amputation, or laceration.

Fire hazard

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Disconnect battery at negative terminal (only engines with electric start.)

• Use only correct tools.

• Do not tamper with governor spring, links or other parts to increase engine

speed.

• Replacement parts must be the same and installed in the same position as the

original parts.

• Do not strike the flywheel with a hammer or hard object because the flywheel

may later shatter during operation.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

en

5

Page 6

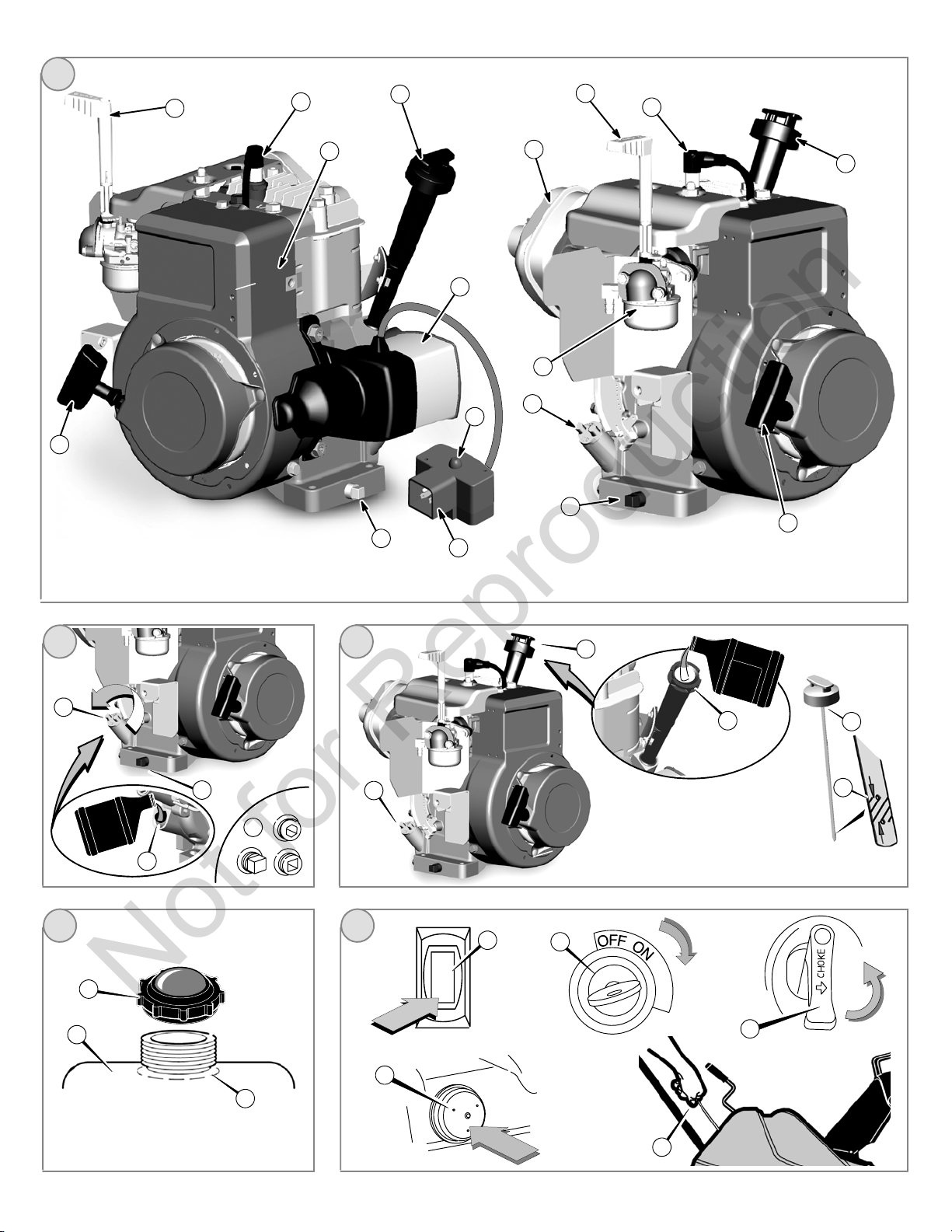

Features and Controls

Not for Reproduction

Compare the illustration

various features and controls.

A. Engine Identification

Model Type Code

B. Spark Plug

C. Choke Control

D. Starter Cord Handle

E. Oil Fill Cap

F. Dipstick/Oil Fill

G. Oil Drain Plug

H. Muffler

Muffler Guard (optional)

Muffler Deflector

I. Push Button Electric Start

J. Power Cord Receptacle

K. Electric Starter

L. Carburetor

1

with your engine to familiarize yourself with the location of

Operation

Oil capacity (see the Specifications section)

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty Certified oils for best

performance. Other high-quality detergent oils are acceptable if classified for service SF,

SG, SH, SJ or higher. Do not use special additives.

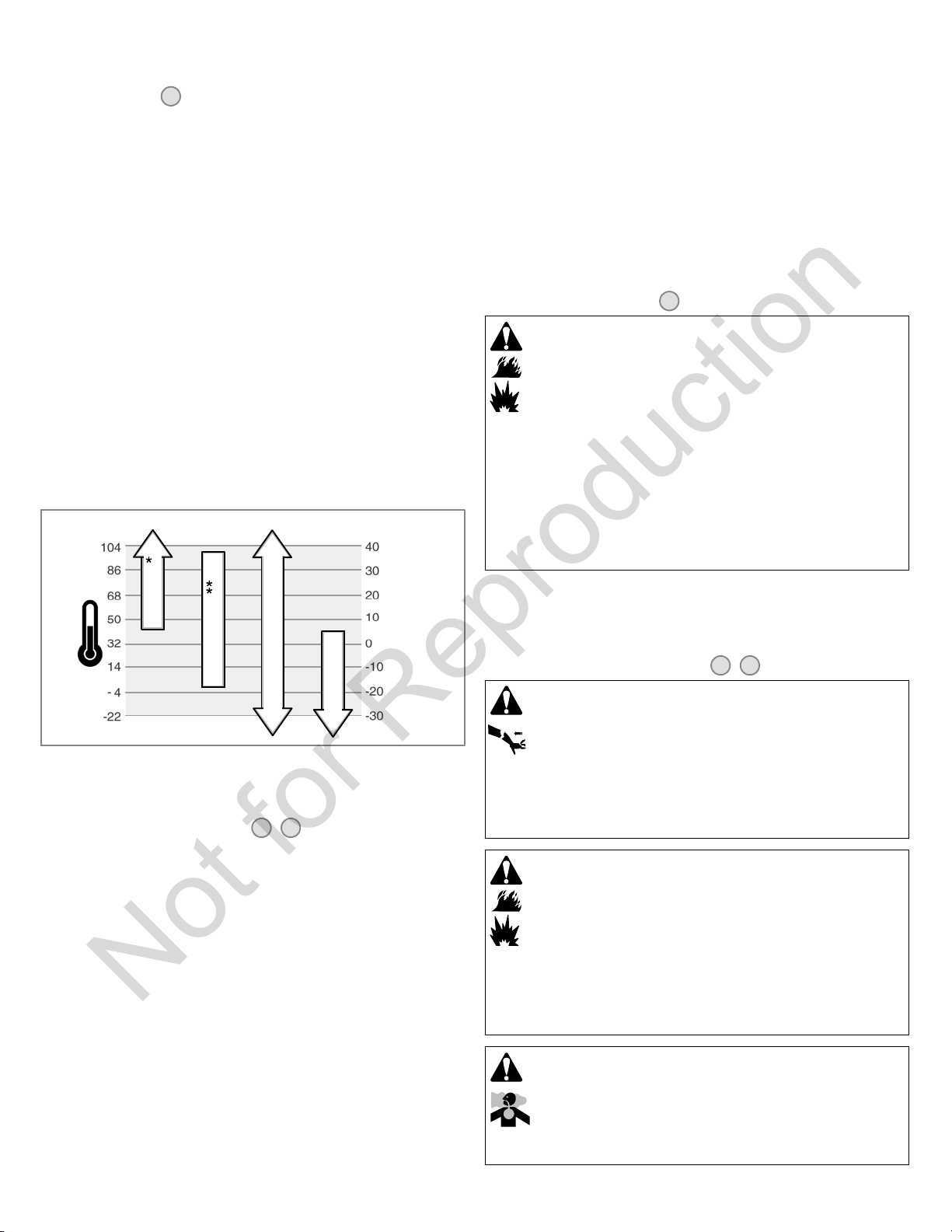

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart to

select the best viscosity for the outdoor temperature range expected.

°F °C

SAE 30

10W-30

Synthetic 5W-30

5W-30

CAUTION: Do not use unapproved gasolines, such as E85. Do not mix oil in gasoline or

modify the engine to run on alternate fuels. This will damage the engine components and

void the engine warranty.

To protect the fuel system from gum formati on, mix a fuel stabilizer into the fuel. See

Storage. All fuel is not the same. If starting or performance problems occur, change fuel

providers or change brands. This engine is certified to operate on gasoline. The

emissions control system for this engine is EM (Engine Modifications).

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON)

gasoline is acceptable. To remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause decreased performance,

increased fuel consumption, and increased emissions. See a Briggs & Stratton

Authorized Dealer for high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

How To Add Fuel - Figure

4

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

• Turn engine off and let engine cool at least 2 minutes before removing the fuel

cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the gasoline, do not fill above

the bottom of the fuel tank neck.

• Keep gasoline away from sparks, open flames, pilot lights, heat, and other

ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks.

Replace if necessary

• If fuel spills, wait until it evaporates before starting engine.

1. Clean the fuel cap area of dirt and debris. Remove the fuel cap (A) (Figure 4).

2. Fill the fuel tank (B) with gasoline. To allow for expansion of the gasoline, do not fill

above the bottom of the fuel tank neck (C).

3. Reinstall the fuel cap.

How To Start The Engine - Figure

5 6

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm

toward engine faster than you can let go.

* Below 40°F(4°C) the use of SAE 30 will result in hard starting.

** Above 80°F(27°C) the use of 10W-30 may cause increased oil consumption. Check

oil level more frequently.

How To Check/Add Oil - Figure

Before adding or checking the oil

• Place engine level.

• Clean the oil fill area of any debris.

Models with oil fill cap (Figure 2)

1. Remove the oil fill cap (A).

2. To add oil, pour the oil slowly into the engine oil fill (B). Fill to point of overflowing.

3. Replace and tighten the oil fill cap.

Models with extended dipstick (Figure 3)

1. Remove the dipstick (C) and wipe with a clean cloth.

2. Insert and tighten the dipstick.

3. Remove the dipstick and check the oil level. It should be at the top of the full indicator

(D) on the dipstick.

4. To add oil, pour the oil slowly into the engine oil fill (B). Do not overfill. After adding

oil, wait one minute and then recheck the oil level.

5. Replace and tighten the dipstick.

2 3

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.

• Remove all external equipment/engine loads before starting engine.

• Direct-coupled equipment components such as, but not limited to, blades,

impellers, pulleys, sprockets, etc., must be securely attached.

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in

place and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN/RUN position, move throttle

(if equipped) to FAST position and crank until engine starts.

WARNING

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High altitude use, see below.

• Gasoline with up to 10% ethanol (gasohol) or up to 15% MTBE (methyl tertiary

butyl ether) is acceptable.

6 BRIGGSandSTRATTON.COM

Engines give off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area, even if doors or windows are open.

Page 7

WARNING

Not for Reproduction

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic

amputation, or laceration.

Fire hazard

Maintenance

Use only original equipment replacement parts. Other parts may not perform as

well, may damage the unit, and may result in injury. In addition, use of other parts

may void your warranty.

We recommend that you see any Briggs & Stratton Authorized Dealer for all

maintenance and service of the engine and engine parts.

NOTICE: All the components used to build this engine must remain in place for proper

operation.

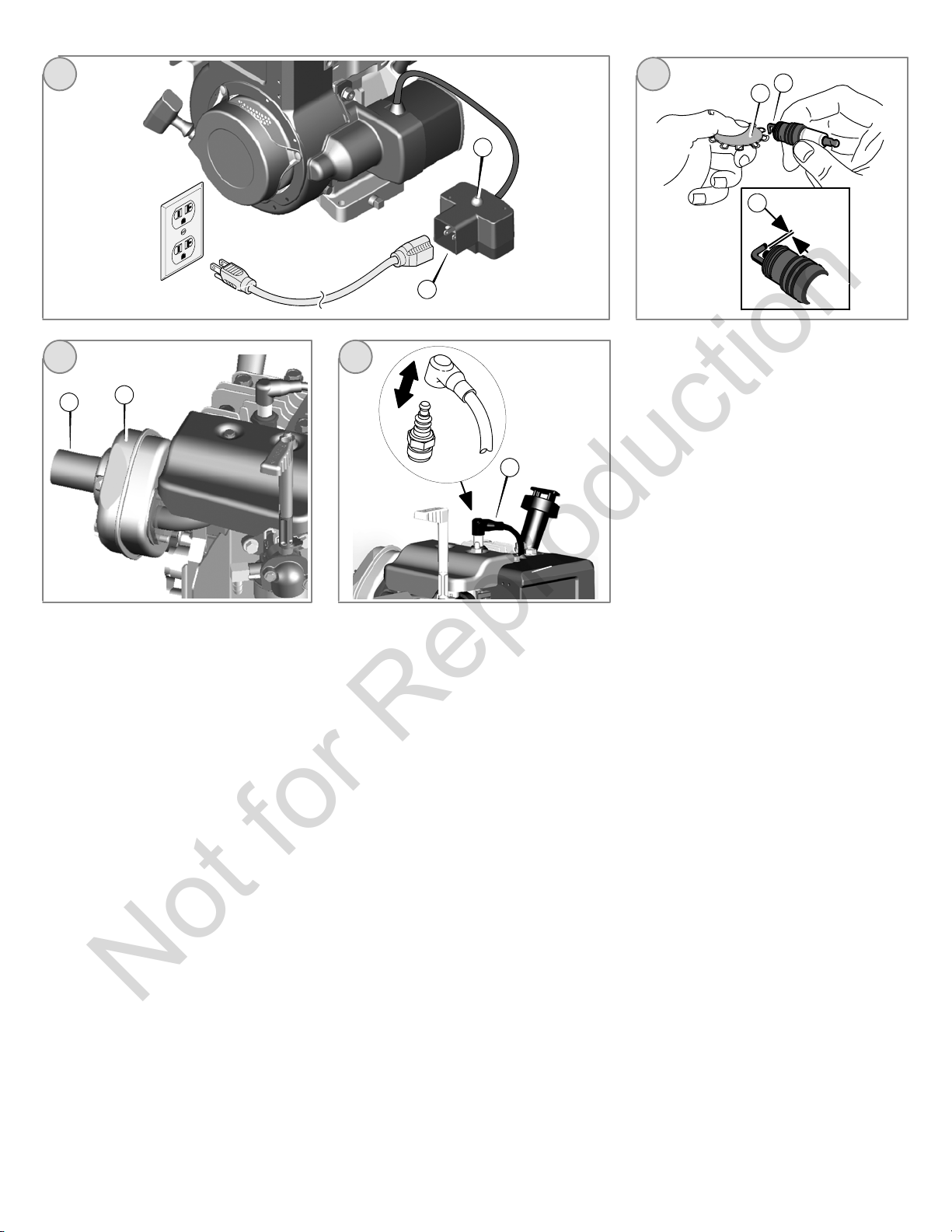

• Usea3-wireextensioncord.

• First attach extension cord to electric starter connector and then into a wall

receptacle. If additional extension cord is required, use a 3-wire.

• If the supply cord is damaged, it must be replaced by the manufacturer or its

service agent or a similarly qualified person in order to avoid a hazard.

NOTICE: This engine was shipped from Briggs & Stratton without oil. Before you start

the engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be covered

under warranty.

Note: Some engines and equipment have remote controls. See the equipment manual

for location and operation of remote controls.

1. Check the oil level. See the How To Check/Add Oil section.

2. Make sure equipment drive controls, if equipped, are disengaged.

3. Turn the fuel shut-off valve, if equipped, to the on position.

4. Turn on the equipment switch (either a rocker (A)orakey(B) switch). See Figure 5.

5. Turn the choke control (C) to the choke

Note: Choke is usually unnecessary when restarting a warm engine.

6. Push the primer (D)twotimes.

Note: Priming is usually unnecessary when restarting a warm engine.

7. Rewind Start: Firmly hold the starter cord handle (E). Pull the starter cord handle

slowly until resistance is felt, then pull rapidly.

Note: If the engine does not start after repeated attempts, go to

BRIGGSandSTRATTON.COM or call 1-800-233-3723 (in USA).

position.

Emissions Control

Maintenance, replacement, or repair of the emissions control devices and systems

may be performed by any non-road engine repair establishment or individual.

However, to obtain “no charge” emissions control service, the work must be performed

by a factory authorized dealer. See the Emissions Warranty.

WARNING

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic

amputation, or laceration.

Fire hazard

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Use only correct tools.

• Do not tamper with governor spring, links or other parts to increase engine

speed.

• Replacement parts must be the same and installed in the same position as the

original parts.

• Do not strike the flywheel with a hammer or hard object because the flywheel

may later shatter during operation.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

WARNING: Rapid retraction of the starter cord (kickback) will pull your

hand and arm toward the engine faster than you can let go. Broken bones, fractures,

bruises or sprains could result. When starting engine, pull the starter cord slowly until

resistance is felt and then pull rapidly to avoid kickback.

8. Electric Start: First connect the extension cord to the power cord receptacle (F,

Figure 6) and then into a wall receptacle. If an additional extension cord is required,

make sure it is a 3-wire.

WARNING: If the extension cord is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualified person in order to avoid a

hazard.

9. Electric Start: Depress the push button (G). After the engine starts, first disconnect

the extension cord from the wall receptacle and then from the power cord receptacle

(F).

Note: If the engine does not start after repeated attempts, go to

BRIGGSandSTRATTON.COM or call 1-800-233-3723 (in USA).

NOTICE: To extend the life of the starter, use short starting cycles (five seconds

maximum). Wait one minute between starting cycles.

10. Allow the engine to warm up for several minutes. Then, slowly move the choke

control to the run

position.

Maintenance Chart

First 5 Hours

• Change oil

Every8HoursorDaily

• Check engine oil level

Every 50 Hours or Annually

• Change engine oil

• Check muffler and muffler guard

Annually

• Replace spark plug

• Replace fuel filter (if equipped)

• Check valve clearance **

** Not required unless engine performance problems are noted.

Carburetor Adjustment

Never make adjustments to the carburetor. The carburetor was set at the factory to

How To Stop The Engine - Figure

5

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Do not choke the carburetor to stop engine.

1. Turn off the equipment switch (either a rocker (A)orakey(B) switch). See Figure 5.

2. After the engine stops, turn the fuel shut-off valve, if equipped, to the closed position.

en

operate efficiently under most conditions. However, if adjustments are required, see any

Briggs & Stratton Authorized Dealer for service.

NOTICE: The manufacturer of the equipment on which this engine is installed specifies

the top speed at which the engine will be operated. Do not exceed this speed.

How To Replace The Spark Plug - Figure

Check the gap (A, Figure 7) with a wire gauge (B). If necessary, reset the gap. Install

and tighten the spark plug to the recommended torque. For gap setting or torque, see the

Specifications section.

Note: In some areas, local law requires using a resistor spark plug to suppress ignition

signals. If this engine was originally equipped with a resistor spark plug, use the same

type for replacement.

7

7

Page 8

Inspect Muffler And Spark Arrester - Figure

Not for Reproduction

8

WARNING

Running engines produce heat. Engine parts, especially muffler,

become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• It is a violation of California Public Resource Code, Section 4442, to use or

operate the engine on any forest-covered, brush-covered, or grass-covered land

unless the exhaust system is equipped with a spark arrester, as defined in

Section 4442, maintained in effective working order. Other states or federal

jurisdictions may have similar laws. Contact the original equipment

manufacturer, retailer, or dealer to obtain a spark arrester designed for the

exhaust system installed on this engine.

Inspect the muffler (A, Figure 8) f or cracks, corrosion, or other damage. Remove the

muffler deflector (B), if equipped, and inspect for damage or carbon blockage. If

replacement parts are required, make sure to use only original equipment replacement

parts.

WARNING: Replacement parts must be the same and installed in the

same position as the original parts or fire could result.

Storage

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Storing Gasoline Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have

pilot lights or other ignition sources because they can ignite gasoline vapors.

Fuel System

Fuel can become stale when stored over 30 days. Stale fuel causes acid and gum

deposits to form in the fuel system or on essential carburetor parts. To keep fuel fresh,

use Briggs & Stratton FRESH START

drip concentrate cartridge.

There is no need to drain gasoline from the engine if a fuel stabilizer is added according

to instructions. Run the engine for 2 minutes to circulate the stabilizer throughout the fuel

system. The engine and fuel can then be stored up to 24 months.

If gasoline in the engine has not been treated with a fuel stabilizer, it must be drained into

an approved container. Run the engine until it stops from lack of fuel. The use of a fuel

stabilizer in the storage container is recommended to maintain freshness.

Engine Oil

While the engine is still warm, change the engine oil.

®

fuel stabilizer, available as a liquid additive or a

Troubleshooting

Need Assistance? Go to BRIGGSandSTRATTON.COM or call 1-800-233-3723.

Air F ilter

This engine is not equipped with an air filter. DO NOT use this engine for anything

other than snow removal.

Specifications

Engine Specifications

How To Change The Oil - Figure

Used oil is a hazardous waste product and must be disposed of properly. Do not discard

with household waste. Check with your local authorities, service center, or dealer for safe

disposal/recycling facilities.

2 3 9

Remove Oil

1. With engine off but still warm, disconnect the spark plug wire (A, Figure 9) and keep

it away from the spark plug.

2. Remove the oil drain plug ( E, Figure 2). Drain the oil into an approved receptacle.

Note: Any of the oil drain plugs (F) shown may be installed in the engine.

3. After the oil has drained, install and tighten the oil drain plug.

Add oil

• Place engine level.

• Clean the oil fill area of any debris.

• See the Specifications section for oil capacity.

Models with oil fill cap

1. Remove the oil fill cap (A, Figure 2).

2. Pour the oil slowly into the engine oil fill (B). Fill to point of overflowing.

3. Replace and tighten the oil fill cap.

Models with extended dipstick

1. Remove the dipstick (C, Figure 3) and wipe with a clean cloth.

2. Pour the oil slowly into the engine oil fill (B). Do not overfill. After adding oil, wait

one minute and then recheck the oil level.

3. Install and tighten the dipstick.

4. Remove the dipstick and check the oil level. It should be at the top of the full indicator

(D) on the dipstick.

5. Install and tighten the dipstick.

8

Model 90000

Displacement 9.02 ci (148 cc)

Bore 2.562 in (65.08 mm)

Stroke 1.750 in (44.45 mm)

Oil Capacity 18 -- 20 oz (0.54 -- 0.59 L)

Tune-up Specifications *

Model 90000

Spark Plug Gap 0.030 in (0.76 mm)

Spark Plug Torque 180 lb-in (20 Nm)

Armature Air Gap 0.006 - 0.010 in (0.15 - 0.25 mm)

Intake Valve Clearance 0.005 - 0.007 in (0.13 - 0.18 mm)

Exhaust Valve Clearance 0.007 - 0.009 in (0.18 - 0.23 mm)

* Engine power will decrease 3.5% for each 1,000 feet (300 meters) above sea level and

1% for each 10° F(5.6° C) above 77° F(25° C). The engine will operate satisfactorily at

an angle up to 15°. Refer to the equipment operator’s manual for safe allowable

operating limits on slopes.

Common Service Parts n

Service Part Part Number

Fuel Additive 5041, 5058

Resistor Spark Plug 802592

Long Life Platinum Spark Plug 5062

Spark Plug Wrench 89838, 5023

Spark Tester 19368

n We recommend that you see any Briggs & Stratton Authorized Dealer for all

maintenance and service of the engine and engine parts. Use only genuine Briggs &

Stratton parts.

BRIGGSandSTRATTON.COM

Page 9

BRIGGS & STRATTON ENGINE OWNER WARRANTY POLICY

Not for Reproduction

September 2008

LIMITED WARRANTY

Briggs & Stratton Corporation will repair or replace, free of charge, any part(s) of the engine that is defective in material or workmanship or both. Transportation charges on

product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for and is subject to the time periods and conditions

stated below. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at BRIGGSandSTRATTON.COM, or by calling

1-800-233-3723, or as listed in the ‘Yellow Pages’.

There is no other expressed warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to one year from

purchase, or to the extent permitted by law and all implied warranties are excluded. Liability for incidental or consequential damages are excluded to the extent

exclusion is permitted by law. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you sp ecific legal rights and

you may also have other rights which vary from state to state and country to country.

STANDARD WARRANTY TERMS *

Y

Brand/Product Type Consumer Use Commercial Use

Vanguardt

Extended Life Seriest; I/C®; Intekt I/C®; Intekt Pro;

Professional Seriest with Dura-Boret Cast Iron Sleeve;

850 Seriest with Dura-Boret Cast Iron Sleeve;

Snow Series MAXt with Dura-Boret Cast Iron Sleeve

All Other Briggs & Stratton Engines 2 years 90 days

* These are our standard warranty terms, but occasionally there may be additional warranty coverage that was not determined at time of publication. For a listing of

current warranty terms for your engine, go to BRIGGSandSTRATTON.COM or contact your Authorized Briggs & Stratton Service Dealer.

Y

Engines used on Home Standby Generator applications are warranted under consumer use only. This warranty does not apply to engines on equipment used f or

prime power in place of a utility. Engines used in competitive racing or on commercial or rental tracks are not warranted.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated in the table above. “Consumer

use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use f or commercial, income producing or rental purposes.

Once an engine has experienced commercial use, it shall thereafter be considered as a commercial use engine for purposes of this warranty.

No warranty registration is necessary to obtain warranty on Briggs & Stratton Products. Save your proof of purchase receipt. If you do not provide proof of the initial

purchase date at the time warranty service is requested, the manufacturing date of the product will be used to determine the warranty period.

About Your Warranty

Briggs & Stratton welcomes warranty repair and apologizes to you for being

inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most

warranty repairs are handled routinely, but sometimes requests for warranty service may

not be appropriate.

If a customer differs with the decision of the Service Dealer, an investigation will be made

to determine whether the warranty applies. Ask the Service Dealer to submit all

supporting facts to his Distributor or the Factory for review. If the Distributor or the

Factory decides that the claim is justified, the customer will be fully reimbursed for those

items that are defective. To avoid misunderstanding which might occur between the

customer and the Dealer, listed below are some of the causes of engine failure that the

warranty does not cover.

Normal wear: Engines, like all mechanical devices, need periodic parts service and

replacement to perform well. Warranty will not cover repair when normal use has

exhausted the life of a part or an engine. Warranty would not apply if engine damage

occurred because of misuse, lack of routine maintenance, shipping, handling,

warehousing or improper installation. Similarly, warranty is void if the serial number of the

engine has been removed or t he engine has been altered or modified.

Improper maintenance: The life of an engine depends upon the conditions under which

it operates, and the care it receives. Some applications, such as t illers, pumps and rotary

mowers, are very often used in dusty or dirty conditions, which can cause what appears

to be premature wear. Such wear, when caused by dirt, dust, spark plug cleaning grit, or

other abrasive material that has entered the engine because of improper maintenance, is

not covered by warranty.

This warranty covers engine related defective material and/or workmanship only

and not replacement or refund of the equipment to which the engine may be

mounted. Nor does the warranty extend to repairs required because of:

1 Problems caused by parts that are not original Briggs & Stratton parts.

2 Equipment controls or installations that prevent starting, cause unsatisfactory engine

performance, or shorten engine life. (Contact equipment manufacturer.)

3 Leaking carburetors, clogged fuel pipes, sticking valves, or other damage, caused

by using contaminated or stale fuel.

en

,

2 years 2 years

2 years 1 year

4 Parts which are scored or broken because an engine was operated with insufficient

or contaminated lubricating oil, or an incorrect grade of lubricating oil (check and

refill when necessary, and change at recommended intervals). OIL GARD may not

shut down running engine. Engine damage may occur if oil level is not properly

maintained.

5 Repair or adjustment of associated parts or assemblies such as clutches,

transmissions, remote controls, etc., which are not manufactured by Briggs &

Stratton.

6 Damage or wear to parts caused by dirt, which entered the engine because of

improper air cleaner maintenance, re-assembly, or use of a non-original air cleaner

element or cartridge. At recommended intervals, clean and/or replace the filter as

stated in the Operator’s Manual.

7 Parts damaged by over-speeding, or overheating caused by grass, debris, or dirt,

which plugs or clogs the cooling fins, or flywheel area, or damage caused by

operating the engine in a confined area without sufficient ventilation. Clean engine

debris at recommended intervals as stated in the Operator’s Manual.

8 Engine or equipment parts broken by excessive vibration caused by a loose engine

mounting, loose cutter blades, unbalanced blades or loose or unbalanced impellers,

improper attachment of equipment to engine crankshaft, over-speeding or other

abuse in operation.

9 A bent or broken crankshaft, caused by striking a solid object with the cutter blade of

a rotary lawn mower, or excessive v-belt tightness.

10 Routine tune-up or adjustment of the engine.

11 Engine or engine component failure, i.e., combustion chamber, valves, valve seats,

valve guides, or burned starter motor windings, caused by the use of alternate fuels

such as, liquified petroleum, natural gas, altered gasolines, etc.

Warranty service is available only through authorized service dealers by Briggs &

Stratton Corporation. Locate your nearest Authorized Service Dealer in our dealer

locator map on BRIGGSandSTRATTON.COM or by calling 1-800-233-3723, or as

listed in the ‘Yellow Pages’.

9

Page 10

California, U.S. EPA, and Briggs & Stratton Corporation Emissions Control Warranty Statement

Not for Reproduction

Your Warranty Rights And Obligations

November 2008

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased

to explain the emissions control system warranty on your Model Year 2008 and later

engine/equipment. In California, new small off-road engines must be designed, built, and

equipped to meet the State’s stringent anti-smog standards. B&S must warrant the

emissions control system on your engine /equipment for the periods of time listed below

provided there has been no abuse, neglect, or improper maintenance of your small

off-road engine.

Your emissions control system may include parts such as the carburetor or fuel injection

system, fuel tank, ignition system, and catalytic converter. Also included may be hoses,

belts, connectors, sensors, and other emissions-related assemblies.

Where a warrantable condition exists, B&S will repair your engine/equipment at no cost

to you including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage:

Small off-road engines are warranted for two years. If any emissions-related part on your

engine/equipment is defective, the part will be repaired or replaced by B&S.

Owner’s Warranty Responsibilities:

• As the small engine/equipment owner, you are responsible for the performance of

the required maintenance listed in your owner’s manual. B&S recommends that you

retain all receipts covering maintenance on your engine/equipment, but B&S cannot

deny warranty solely for the lack of receipts or your failure t o ensure the performance

of all scheduled maintenance.

• As the engine/equipment owner, you should however be aware that B&S may deny

you warranty coverage if your engine/equipment or a part has failed due to abuse,

neglect, improper maintenance, or unapproved modifications.

• You are responsible for presenting your engine/equipment to a B&S distribution

center, servicing dealer, or other equivalent entity, as applicable, as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount of

time, not to exceed 30 days. If you have any questions regarding your warranty

rights and responsibilities, you should contact B&S at (414) 259-5262.

Briggs & Stratton Emissions Control Warranty Provisions

The following are specific provisions relative to your Emissions Control Warranty Coverage. It is in addition to the B&S engine warranty for non-regulated engines found in the

Operator’s Manual.

1. Warranted Emissions Parts

Coverage under this warranty extends only to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the engine

purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel pump

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and switches

2. Length of Coverage

• Connectors and assemblies

For a period of two years from date of original purchase, B&S warrants to the original

purchaser and each subsequent purchaser that the engine is designed, built, and

equipped so as to conform with all applicable regulations adopted by the Air

Resources Board; that it is free from defects in material and workmanship that could

cause the failure of a warranted part; and that it is identical in all material respects to

the engine described in the manufacturer’s application for certification. The warranty

period begins on the date the engine is originally purchased.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as required

maintenance in the owner’s manual supplied, is warranted for t he warranty

period stated above. If any such part fails during the period of warranty

coverage, the part will be repaired or replaced by B&S at no charge to the

owner. Any such part repaired or replaced under the warranty will be warranted

for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection in the owner’s

manual supplied, is warranted for the warranty period stated above. Any such

part repaired or replaced under warranty will be warranted for the remaining

warranty period.

• Any warranted part that is scheduled for replacement as required maintenance

in the owner’s manual supplied, is warranted for the period of time prior to the

first scheduled replacement point for that part. If the part fails prior to the first

scheduled replacement, the part will be repaired or replaced by B&S at no

charge to the owner. Any such part repaired or replaced under warranty will be

warranted for the remainder of the period prior to the first scheduled

replacement point for the part.

• Add on or modified parts that are not exempted by the Air Resources Board

may not be used. The use of any non exempted add on or modified parts by the

owner will be grounds for disallowing a warranty claim. The manufacturer will

not be liable to warrant failures of warranted parts caused by the use of a non

exempted add on or modified part.

3. Consequential Coverage

Coverage shall extend to the failure of any engine components caused by the

failure of any warranted emissions parts.

4. Claims and Coverage Exclusions

Warranty claims shall be filed according to the provisions of the B&S engine

warranty policy. Warranty coverage does not apply to failures of emissions parts

that are not original equipment B&S parts or to parts that fail due to abuse, neglect,

or improper maintenance as set forth in the B&S engine warranty policy. B&S is not

liable for warranty coverage of failures of emissions parts caused by the use of

add-on or modified parts.

Look For Relevant Emissions Durability Period and Air Index Information

On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Emissions

Standard must display information regarding the Emissions Durability Period and the Air

Index. Briggs & Stratton makes this information available to the consumer on our

emissions labels. The engine emissions label will indicate certification information.

The Emissions Durability Period describes the number of hours of actual running time

for which the engine is certified to be emissions compliant, assuming proper

maintenance in accordance with the Operating & Maintenance Instructions. The

following categories are used:

Moderate:

Engine is certified to be emissions compliant for 125 hours of actual engine running time.

Intermediate:

Engine is certified to be emissions compliant for 250 hours of actual engine running time.

Extended:

Engine is certified to be emissions compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year.

Therefore, the Emissions Durability Period of an engine with an intermediate rating

would equate to 10 to 12 years.

10 BRIGGSandSTRATTON.COM

Briggs & Stratton engines are certified to meet the United States Environmental

Protection Agency (USEPA) Phase 2 emissions standards. For Phase 2 certified

engines, the Emissions Compliance Period referred to on the Emissions Compliance

label indicates the number of operating hours for which the engine has been shown to

meet Federal emissions requirements.

For engines less than 225 cc displacement.

Category C = 125 hours , Category B = 250 hours , Category A = 500 hours

For engines of 225 cc or more displacement.

Category C = 250 hours , Category B = 500 hours , Category A = 1000 hours

Page 11

Información General

Not for Reproduction

Para conseguir repuestos o asistencia técnica registre los números de modelo, tipo y

código de su motor junto con la fecha de compra. Estos números los encuentra

localizados en su motor (consulte la página de Características y Controles).

Fecha de compra:

MES/DIA/AÑO

Modelo del motor:

Modelo:

Información de Clasificación de Potencia d el Motor

La clasificación de potencia para un modelo de motor a gas en particular se designa de

acuerdo al código J1940 de SAE (Sociedad de Ingenieros Automotrices) (Procedimiento

de Clasificación de Potencia & Torque del Motor Pequeño), y la clasificación de

desempeño ha sido obtenida y corregida de acuerdo con el código J1995 de SAE

(Revisión 2002-05). Los valores de torque se obtienen a 3060 RPM; los valores de

potencia se obtienen a 3600 RPM. La potencia bruta actual del motor será inferior y está

afectada, entre otras cosas, por las condiciones ambientales operativas y la variabilidad

de motor a motor. Dado ambos un amplio conjunto de productos en los cuales son

puestos nuestros motores, y la variedad de emisiones ambientales aplicables al operar

el equipo, el motor a gas no desarrollará la potencia nominal cuando sea usado en una

parte del equipo acoplado (potencia real “en el-sitio”). Esta diferencia se debe a una

variedad de factores que incluyen, pero sin limitarse a, accesorios (filtro de aire, sistema

de escape, sistema de carga, sistema de enfriamiento, carburador, bomba de

combustible, etc.) limitaciones de la aplicación, condiciones ambientales de operación

(temperatura, humedad, altitud), y la variabilidad de motor a motor. Debido a las

limitaciones, Briggs & Stratton puede sustituir un motor con clasificación de potencia

más alta por esta serie de motor.

Tipo:

Código:

Seguridad del Operario

SÍMBOLOS DE SEGURIDAD Y C ONTROL

Fuego

Fast

Estrangulador

Químico

Peligroso

El símbolo de aviso de seguridad se utiliza para identificar la información de

seguridad relacionada con los peligros que pueden ocasionar lesiones personales. Se

señaliza con una palabra (PELIGRO, ADVERTENCIA o PRECAUCIÓN) con el símbolo de

aviso para indicar la probabilidad de una lesión y su gravedad potencial. Además, un

símbolo de peligro puede ser utilizado para representar el tipo de peligro.

Parar

On Off

Lea el

Manual

Aceite

Explosión

Válvula de Paso

de Combustible

Superficie

Caliente

PELIGRO indica un peligro que si no es evitado, ocasionará la muerte o

heridas graves.

ADVERTENCIA indica un peligro que si no es evitado, podría ocasionar la

muerte o heridas graves.

Gases TóxicosPartes en Movimiento

Descarga Eléctrica

Contragolpe

Congelado

Slow

Combustible

Protección

Para los Ojos

ADVERTENCIA

La descarga de escape que expele este motor por este producto contiene químicos

conocidos para el Estado de California que pueden ocasionar cáncer, defectos de

nacimiento u otros daños que pueden ser perjudiciales para la reproducción.

ADVERTENCIA

Briggs & Stratton no aprueba ni autoriza el uso de estos motores en Vehículos Todo

Terreno de 3-ruedas (ATVs), bicicletas motorizadas, karts para diversión/recreo,

productos para aviación o vehículos para uso en eventos competitivos. El uso de

estos motores en tales aplicaciones podría ocasionar daños a la propiedad, lesiones

graves (incluyendo parálisis), o incluso la muerte.

NOTIFICACIÓN: Este motor fue despachado de Briggs & Stratton sin aceite. Antes de

darle arranque al motor, asegúrese de agregar aceite de acuerdo con las instrucciones

de este manual. Si da arranque al motor sin que éste tenga aceite, se dañará hasta tal

punto que no podrá ser reparado y no será cubierto por la garantía.

ADVERTENCIA

La gasolina y sus vapores son extremadamente inflamables y

explosivos.

Un incendio o una explosión pueden causar graves quemaduras o la

muerte.

Cuando Aprovisione con Combustible

• Apague el motor y deje q ue el motor se enfríe por lo menos 2 minutos antes

de remover la tapa de combustible.

• Llene el tanque de combustible en exteriores o en un área bien ventilada.

• No llene demasiado el tanque de combustible. Para permitir la expansion de

la gasolina, no llene arriba de la parte inferior del cuello del tanque de

combustible.

• Mantenga la gasolina y sus vapores a distancia de chispas, llamas abiertas,

testigos piloto, calor, o de cualquier otra fuente de encendido.

• Compruebe con frecuencia si existen grietas o fugas en las mangueras de

combustible, el tanque, la tapa y en los accesorios. Cámbielos si es

necesario

• Si se derramó combustible, espere hasta que se haya evaporado antes de darle

arranque al motor.

Cuando le de Arranque al motor

• Asegúrese que la bujía, el mofle, la tapa de combustible y el filtro de aire (si

está equipado) estén en su lugar, y firmemente asegurados.

• No haga girar el motor si removió la bujía.

• Si el motor se inunda, ajuste el estrangulador (si está equipado) en la posición

OPEN/RUN, coloque el acelerador (si está equipado) en la posición FAST y

haga girar el motor hasta que de arranque.

Cuando Opere El Equipo

• No incline el motor ni el equipo a un ángulo que pueda ocasionar derrames de

gasolina.

• No use el estrangulador para detener el motor.

• Nunca arranque u opere el motor si removió el conjunto del filtro de aire (si está

equipado) o el filtro de aire (si está equipado).

Cuando cambie el aceite

• Si drena el aceite desde el tubo superior de llenado de aceite, el tanque de

combustible debe estar vacío o de lo contrario podría presentarse una fuga de

combustible que podría ocasionar un incendio o una explosión.

Cuando Transporte el Equipo

• Transpórtelo con el tanque de combustible VACÍO o con la válvula de paso de

combustible en la posición OFF.

Almacenamiento de la Gasolina o del Equipo con Combustible en el Tanque

• Almacene a distancia de hornos, estufas, calentadores de agua u otros

aparatos que utilicen testigos piloto u otras fuentes de encendido ya que estos

pueden encender los vapores de gasolina.

PRECAUCIÓN indica un peligro que, si no es evitado, podría ocasionar

lesiones menores o moderadas.

NOTIFICACIÓN indica una situación que podría ocasionar daños al

producto.

ADVERTENCIA

Ciertos componentes en este producto y sus accesorios relacionados contienen

químicos que el Estado de California considera que ocasionan cáncer, defectos

congénitos y otros daños en el aparato reproductivo. Lávese las manos después de

manejarlos.

es

ADVERTENCIA

Dar arranque al motor crea chispeo.

El chispeo puede encender los gases inflamables cercanos.

Podría ocurrir una explosión o un incendio.

• Si hay una fuga de gas natural o gas propano LP en el área, no le de arranque

al motor.

• No use líquidos de arranque presurizado ya que los vapores son inflamables.

11

Page 12

ADVERTENCIA

Not for Reproduction

Los motores emiten monóxido de carbono, un gas venenoso que

carece de olor y de color.

Respirar monóxido de carbono puede ocasionar náuseas, desmayos

olamuerte.

• Dele arranque al motor y opérelo en exteriores.

• No le de arranque al motor ni lo opere en un área encerrada, aun cuando las

puertas o las ventanas se encuentren abiertas.

ADVERTENCIA

La retracción rápida de la cuerda de arranque (contragolpe) le halará

la mano y el brazo hacia el motor más rápido de lo que usted la pueda

dejar ir.

Podrían ocasionarse roturas de huesos, fracturas, moretones o

torceduras.

• Cuando le de arranque al motor, hale lentamente la cuerda hasta que se sienta

resistencia y después hálela rápidamente para evitar un contragolpe.

• Remueva todas las cargas externas del equipo/motor antes de darle arranque

al motor.

• Los componentes de acople directo del equipo tal como, pero sin limitarse a,

cuchillas, impulsores, poleas, dientes de piñones, etc. se deben asegurar

firmemente.

ADVERTENCIA

Las partes rotantes pueden tener contacto o enredar las manos, los

pies, el cabello, la ropa o los accesorios.

Puede producirse una traumática amputación o una grave laceración.

• Opere el equipo con los protectores en su lugar.

• Mantenga sus manos y sus pies a distancia de las partes rotantes.

• Recójase el cabello largo y quítese las joyas.

• No use ropa floja, tiras que cuelguen ni artículos que puedan ser agarrados.

ADVERTENCIA

El funcionamiento de los motores produce calor. Las partes de los

motores, especialmente el mofle, se calientan demasiado.

Pueden ocurrir graves quemaduras a causa de su contacto.

Desechos combustibles, tal como hojas, grama, maleza, etc. pueden

alcanzar a encenderse.

• Deje que el mofle, el cilindro y las aletas del motor se enfríen antes de tocarlos.

• Remueva los desechos acumulados en el área del mofle y en el área del

cilindro.

• Usar u operar el motor en un terreno que contenga bosques, arbustos o pasto

es una violación al Código de Recursos Públicos de California, Sección 4442, a

menos que el sistema de escape esté equipado con un atrapachispas, según se

define en la Sección 4442, mantenido en excelente estado de funcionamiento.

Otros estados o jurisdicciones federales pueden tener leyes similares. Contacte

al fabricante, comerciante o distribuidor del equipo original para obtener un

atrapachispas diseñado para el sistema de escape instalado en este motor.

ADVERTENCIA

Un chispeo involuntario puede producir un incendio o una descarga

eléctrica.

Una puesta en marcha involuntaria puede ocasionar un enredo, una

amputación traumática o una laceración.

Peligro de incendio

Antes de hacer ajustes o reparaciones:

• Desconecte el cable de la bujía y mántegalo a distancia de la bujía.

• Desconecte la batería en la terminal negativa (únicamente motores con

arranque eléctrico).

• Use únicamente las herramientas correctas.

• No manipule los resortes del regulador, las varillas u otras partes para

incrementar la velocidad del motor.

• Los repuestos deben ser iguales e instalarse en la misma posición que tenían

las partes originales.

• No golpee la volante con un martillo ni con un objeto pesado ya que la volante

podría astillarse más adelante durante la operación.

Cuando compruebe chispa:

• Utilice un probador aprobado.

• No compruebe chispa si removió la bujía.

12 BRIGGSandSTRATTON.COM

Page 13

Características y Controles

Not for Reproduction

Compare la ilsutración

las diversas características y controles.

A. Identificación del motor

Modelo Tipo Código

B. Bujía

C. Control del Estrangulador

D. Manija de la Cuerda del Arrancador

E. Tapón de Llenado de Aceite

F. Varilla Indicadora de Nivel/Llenado de Aceite

G. Tapón de Drenaje de Aceite

H. Mofle

Protector del Mofle (opcional)

Deflector del Mofle

I. Arranque Eléctrico con Botón Pulsador

J. Receptáculo de cuerda de energía

K. Arranque Eléctrico

L. Carburador

1

con su motor para que se familiarice con la localización de

Operación

Capacidad de aceite (consulte la sección de Especificaciones)

Recomendaciones de Aceite

Recomendamos el uso de aceites Briggs & Stratton Warranty Certified para obtener el

mejor desempeño. Otros aceites detergentes de alta calidad son aceptables si están

clasificados para servicio SF, SG, SH, SJ o mayores. No utilice aditivos especiales.

Las temperaturas externas determinan la viscosidad adecuada del aceite para el motor.

Utilice la tabla para seleccionar la mejor viscosidad según el rango de temperatura

externa esperado.

°F °C

SAE 30

10W-30

5W-30 Sintético

* Si se utiliza SAE 30 a una temperatura inferior a los 40°F(4°C) se producirá un

arranque difícil.

** Si se utiliza 10W-30 a una temperatura superior a los 80°F(27°C) se podrá

ocasionar un mayor consumo de aceite. Verifique el nivel de aceite con mayor

frecuencia.

Cómo Comprobar/Añadir Aceite - Figura

Antes de añadir o comprobar el nivel de aceite

• Coloque el motor a nivel.

• Limpie el área de llenado de aceite de todo desecho.

Modelos con tapón de llenado de aceite (Figura 2)

1. Retire el tapón de llenado de aceite (A).

2. Para añadir aceite, vierta el aceite lentamente por dentro del tubo de llenado de

aceite (B). Llene hasta el punto de rebose.

3. Vuelva a colocar y apriete el tapón de llenado de aceite.

Modelos con varilla extendida (Figura 3).

1. Remueva la varilla indicadora de nivel de aceite (C) y límpiela con un trapo limpio.

2. Inserte y apriete la varilla indicadora de nivel de aceite.

3. Remueva la varilla indicadora de nivel de aceite y compruebe el nivel de aceite. El

aceite debe llegar arriba del indicador de (D) en la varilla indicadora de nivel de

aceite.

4. Para añadir aceite, vierta el aceite lentamente por dentro del tubo de llenado de

aceite (B). No llene excesivamente. Después de añadir aceite, espere un minuto y

vuelva a comprobar el nivel de aceite.

5. Coloque y apriete la varilla indicadora de nivel de aceite.

Recomendaciones para el Combustible

El combustible debe cumplir con estos requerimientos:

• gasolina limpia, fresca y libre de plomo.

• Un mínimo de 87 octanos/87 AKI (91 RON). Vea a continuación si se usa a alta

altitud.

• Gasolina hasta con el 10% de ethanol (gasohol) o hasta el 15% de MTBE (methyl

tertiary butyl ether), es aceptable.

5W-30

2 3

es

NOTIFICACIÓN: No use gasolina que no haya sido aprobada, tal como E85. No mezcle

el aceite con la gasolina, ni modifique el motor para operarlo con combustibles alternos.

Esto dañará los componentes del motor e invalidará la garantía del motor.

Para proteger el sistema de combustible de la formación de depósitos de goma,

mézclele un estabilizador de combustible cuando le añada combustible. Consulte el

aparte Bodegaje. Todos los combustibles no son lo mismo. Si usted experimenta

problemas de arranque o de desempeño, después del uso del combustible, cambie de

proveedor de combustible o de marca. Este motor está certificado para operar con

gasolina. El sistema de control de emisiones para este motor es EM (Modificaciones del

Motor).

Alta Altitud

A elevaciones superiores a 5,000 feet (1.524 metros), es aceptable gasolina con un

mínimo de 85 octanos/ 85 AKI (89 RON). A fin de cumplir con las emisiones, se requiere

ajuste para gran altitud. El operar sin éste ajuste causará una disminución el

rendimiento, un aumento del consumo de combustible y un aumento en las emisiones.

Consulte con un distribuidor autorizado de Briggs & Stratton con relación al ajuste para

gran altitud.

No se recomienda operar el motor a elevaciones inferiores a 2,500 feet (762 metros) con

el juego para gran altitud.

Cómo Añadir Combustible - Figura

4

ADVERTENCIA

La gasolina y sus vapores son extremadamente inflamables y

explosivos.

Un incendio o una explosión pueden causar graves quemaduras o la

muerte.

Cuando Aprovisione con Combustible

• Apague el motor y deje q ue el motor se enfríe por lo menos 2 minutos antes

de remover la tapa de combustible.

• Llene el tanque de combustible en exteriores o en un área bien ventilada.

• No llene demasiado el tanque de combustible. Para permitir la expansion de

la gasolina, no llene arriba de la parte inferior del cuello del tanque de

combustible.

• Mantenga la gasolina y sus vapores a distancia de chispas, llamas abiertas,

testigos piloto, calor, o de cualquier otra fuente de encendido.

• Compruebe con frecuencia si existen grietas o fugas en las mangueras de

combustible, el tanque, la tapa y en los accesorios. Cámbielos si es

necesario

• Si se derramó combustible, espere hasta que se haya evaporado antes de darle

arranque al motor.

1. Limpie el área de la tapa de combustible de polvo y desechos. Retire la tapa de

combustible (A) (Figura 4).

2. Llene el tanque de combustible (B) con gasolina. A fin de permitir la expansión de la

gasolina, no llene por encima del fondo del cuello del tanque de combustible (C).

3. Vuelva a colocar la tapa de combustible.

Cómo Darle Arranque al Motor - Figura

5 6

ADVERTENCIA

La retracción rápida de la cuerda de arranque (contragolpe) le halará

la mano y el brazo hacia el motor más rápido de lo que usted la pueda

dejar ir.

Podrían ocasionarse roturas de huesos, fracturas, moretones o

torceduras.

• Cuando le de arranque al motor, hale lentamente la cuerda hasta que se sienta

resistencia y después hálela rápidamente para evitar un contragolpe.

• Remueva todas las cargas externas del equipo/motor antes de darle arranque

al motor.

• Los componentes de acople directo del equipo tal como, pero sin limitarse a,

cuchillas, impulsores, poleas, dientes de piñones, etc. se deben asegurar

firmemente.

ADVERTENCIA

La gasolina y sus vapores son extremadamente inflamables y

explosivos.

Un incendio o una explosión pueden causar graves quemaduras o la

muerte.

Cuando le de Arranque al motor

• Asegúrese que la bujía, el mofle, la tapa de combustible y el filtro de aire (si

está equipado) estén en su lugar, y firmemente asegurados.

• No haga girar el motor si removió la bujía.

• Si el motor se inunda, ajuste el estrangulador (si está equipado) en la posición

OPEN/RUN, coloque el acelerador (si está equipado) en la posición FAST y

haga girar el motor hasta que de arranque.

13

Page 14

ADVERTENCIA

Not for Reproduction

Los motores emiten monóxido de carbono, un gas venenoso que

carece de olor y de color.

Respirar monóxido de carbono puede ocasionar náuseas, desmayos

olamuerte.

• Dele arranque al motor y opérelo en exteriores.

• No le de arranque al motor ni lo opere en un área encerrada, aun cuando las

puertas o las ventanas se encuentren abiertas.

ADVERTENCIA

Un chispeo involuntario puede producir un incendio o una descarga

eléctrica.

Una puesta en marcha involuntaria puede ocasionar un enredo, una

amputación traumática o una laceración.

Peligro de incendio

• Use una cuerda de extensión de 3 cables.

• Conecte primero la cuerda de extensión al conector del arranque eléctrico y

luego a una toma de la pared. Si se requiere una cuerda de extensión adicional

utilice una cuerda de 3 cables.

• Si la cuerda de alimentación está dañada, ésta debe ser suministrada por el

fabricante o su agente de servicio o por una persona similarmente calificada

para evitar un riesgo.

NOTIFICACIÓN: Briggs & Stratton despacha este motor sin aceite. Antes de arrancar el

motor, asegúrese de añadir aceite de acuerdo con las instrucciones en este manual. Si

arranca el motor sin aceite, no será posible reparar el daño y no estará cubierto por la

garantía.

Nota: Algunos motores y equipos tienen controles remotos. Vea el manual del equipo

para la ubicación y operación de los controles remotos.

1. Verifique el nivel de aceite. Consulte la sección Cómo verificar/Agregar aceite.

2. Asegúrese de que los controles de la transmisión del equipo, si están equipados,

estén desconectados.

3. Gire la válvula de cierre de combustible, si está equipada, a la posición on.

4. Gire el suiche del equipo (ya sea un suiche de balancín (A) o de llave (B)) a la

posición on. Vea Figura 5.

5. Gire el control del estrangulador (C) a la posición choke

Nota: Generalmente el estrangulador no es necesario cuando se enciende un motor

caliente.

6. Oprima el cebador (D) dos veces.

Nota: Generalmente no es necesario utilizar el cebador cuando se le va a volver a

dar arranque a un motor ya caliente.

7. Arranque retráctil: Sostenga firmemente la manija de la cuerda de arranque (E).

Hale lentamente la manija de la cuerda de arranque hasta que se sienta resistencia,

después hálela rápidamente.

Nota: Si el motor no arranca después de varios intentos, visite

BRIGGSandSTRATTON.COM o llame al 1-800-233-3723 (en los EE.UU.).

.

Cómo Detener el Motor - Figura

5

ADVERTENCIA

La gasolina y sus vapores son extremadamente inflamables y

explosivos.

Un incendio o una explosión pueden causar graves quemaduras o la

muerte.

• No use el estrangulador para detener el motor.

1. Gire el suiche del equipo (ya sea un suiche de balancín (A) o de llave (B)) a la

posición off. Vea Figura 5.

2. Después de que el motor se detenga, gire la válvula de cierre de combustible, si

está equipada, a la posición closed.

Mantenimiento

Utilice sólo repuestos originales para los equipos. Es posible que otros repuestos

no funcionen tan bien, dañen la unidad y hasta pueden ocasionar lesiones.

Además, el uso de otros repuestos puede anular la validez de su garantía.

Recomendamos que contacte a cualquier Distribuidor Autorizado de Briggs & Stratton

para todo lo relacionado con el mantenimiento y el servicio del motor y sus partes.

NOTIFICACIÓN: Todos los componentes utilizados para fabricar este motor deben

mantenerse en su lugar para una correcta operación.

Control de Emisiones

El mantenimiento, cambio o reparación de los dispositivos y sistemas del control

de emisiones pueden ser realizados por cualquier establecimiento o persona que

repare motores todo terreno. Sin embargo, para obtener servicio de control de

emisiones “sin costo”, la labor debe ser realizada por un distribuidor autorizado por la

fábrica. Vea la Garantía de Emisiones.

ADVERTENCIA

Un chispeo involuntario puede producir un incendio o una descarga

eléctrica.

Una puesta en marcha involuntaria puede ocasionar un enredo, una

amputación traumática o una laceración.

Peligro de incendio

Antes de hacer ajustes o reparaciones:

• Desconecte el cable de la bujía y mántegalo a distancia de la bujía.

• Desconecte la batería en la terminal negativa (únicamente motores con

arranque eléctrico).

• Use únicamente las herramientas correctas.

• No manipule los resortes del regulador, las varillas u otras partes para

incrementar la velocidad del motor.

• Los repuestos deben ser iguales e instalarse en la misma posición que tenían

las partes originales.

• No golpee la volante con un martillo ni con un objeto pesado ya que la volante

podría astillarse más adelante durante la operación.

Cuando compruebe chispa:

• Utilice un probador aprobado.

• No compruebe chispa si removió la bujía.

ADVERTENCIA: La retracción rápida de la cuerda de arranque

(contragolpe) le halará la mano y el brazo hacia el motor más rápido de lo que

usted la pueda dejar ir. Podrían ocasionarse roturas de huesos, fracturas,

moretones o torceduras. Cuando le de arranque al motor, hale lentamente la

cuerda hasta que se sienta resistencia y después hálela rápidamente para evitar un

contragolpe.

8. Arranque eléctrico: Primero conecte la cuerda de extensión al receptáculo de

cuerda de energía (F, Figura 6) y después en el tomacorriente de la pared. Si se

requiere una cuerda de extensión adicional, asegúrese de que sea una cuerda de 3

cables.

ADVERTENCIA: Si la cuerda de alimentación está dañada, ésta debe

ser suministrada por el fabricante o su agente de servicio o por una persona

similarmente calificada para evitar un riesgo.

9. Arranque eléctrico: Oprima el botón pulsador (G). Después de que el motor

arranque, desconecte primero la cuerda de extensión del tomacorriente de la pared

y después del receptáculo de cuerda de energía (F).

Nota: Si el motor no arranca después de varios intentos, visite

BRIGGSandSTRATTON.COM o llame al 1-800-233-3723 (en los EE.UU.).

NOTIFICACIÓN: Para extender la vida del arrancador, utilice ciclos cortos de

arranque (máximo cinco segundos). Espere un minuto entre los ciclos de arranque.

10. Permita que el motor se caliente por varios minutos. Luego mueva el control del

estrangulador, lentamente, hacia la posición run

14 BRIGGSandSTRATTON.COM

.

Cuadro de Mantenimiento

Las Primeras 5 horas

• Cambie aceite

Cada 8 Horas o Diariamente

• Compruebe el nivel de aceite del motor.

Cada 50 horas o una vez al año

• Cambie el aceite del motor

• Compruebe el mofle y el protector del mofle.

Anualmente

• Cambie la bujía

• Cambie el filtro de combustible

• Compruebe la tolerancia de la válvula **

** No se requiere a menos que se detecten problemas de rendimiento del motor.

Ajuste del Carburador

Nunca realice ajustes en el carburador. El carburador ha sido ajustado en la fábrica para

operar eficientemente bajo la mayoría de las condiciones. Sin embargo, si se requiere

que éste sea ajustado, consulte un Distribuidor de Servicio Autorizado por Briggs &

Stratton.

NOTIFICACIÓN: El fabricante del equipo en el cual es instalado el motor especifica la

velocidad máxima en la cual será operado el motor. No exceda esta velocidad.

Page 15

Cómo Cambiar la Bujía - Figura

Not for Reproduction

Compruebe el entrehierro (A, Figura 7) con un calibrador de espesor (B). Si es

necesario, reajuste el entrehierro. Instale y apriete la bujía al par de apriete

recomendado. Para el ajuste del entrehierro o el par de apriete, consulte la sección de

Especificaciones.

Nota: En algunas áreas, las leyes locales requieren el uso de una bujía con resistencia

para suprimir las señales de encendido. Si este motor vino originalmente equipado con

una bujía con resistencia, utilice el mismo tipo de bujía cuando la reemplace.

Inspección del Mofle y el Atrapachispas - Figura

7

8

ADVERTENCIA

El funcionamiento de los motores produce calor. Las partes de los

motores, especialmente el mofle, se calientan demasiado.

Pueden ocurrir graves quemaduras a causa de su contacto.

Desechos combustibles, tal como hojas, grama, maleza, etc. pueden

alcanzar a encenderse.

• Deje que el mofle, el cilindro y las aletas del motor se enfríen antes de tocarlos.

• Remueva los desechos acumulados en el área del mofle y en el área del

cilindro.

• Constituye una violación del Código de Recursos Públicos de California,

Sección 4442, el utilizar u operar el motor en terrenos cubiertos con bosques,

maleza o grama, a menos que el sistema de escape esté equipado con un

atrapachispas, tal como se define en la Sección 4442, mantenido en correcto

orden de funcionamiento. Otros estados pueden tener leyes similares. Póngase

en contacto con el fabricante, minorista o distribuidor del equipo original para

obtener un atrapachispas diseñado para el sistema de escape instalado en este

motor.

Examine el mofle (A, Figura 8) en busca de grietas, corrosión u otro tipo de daños.

Remueva el deflector del mofle (B), si está equipado, y examine en busca de daños o

bloqueos de carbón. Si se requieren repuestos, asegúrese de utilizar solamente partes

de repuesto originales para el equipo.

Bodegaje

ADVERTENCIA

La gasolina y sus vapores son extremadamente inflamables y

explosivos.

Un incendio o una explosión pueden causar graves quemaduras o la

muerte.

Almacenamiento de la Gasolina o del Equipo con Combustible en el Tanque

• Almacene a distancia de hornos, estufas, calentadores de agua u otros

aparatos que utilicen testigos piloto u otras fuentes de encendido ya que estos

pueden encender los vapores de gasolina.

Sistema de Combustible

La lata de combustible se pasa cuando es almacenada durante más de 30 días. El

combustible pasado ocasiona que se formen depósitos de goma y ácido en el sistema

de combustible o en las partes esenciales del carburador. Para mantenerlo fresco utilice

el estabilizador de combustible FRESH START

un aditivo líquido o un cartucho concentrado de goteo.

No hay necesidad de drenar gasolina del motor si se agrega un estabilizador de

combustible de acuerdo con las instrucciones. Deje correr del motor durante 2 minutos

para circular el estabilizador a través del sistema de combustible. De ese modo el motor

y el combustible pueden ser almacenados hasta por 24 meses.

Si la gasolina en el motor no ha sido tratada con un estabilizador de combustible, debe

ser drenada a un recipiente aprobado. Deje correr del motor hasta que pare por falta de

combustible. Se recomienda el uso de un estabilizador de combustible en el recipiente

de almacenamiento para mantener la frescura.

Aceite del Motor

Cambie el aceite del motor mientras que el motor se encuentre todavía caliente.

®

de Briggs & Stratton, disponible como

Detección de Fallas

¿Necesita Asistencia? Vaya a BRIGGSandSTRATTON.COM o marque el teléfono

1-800-233-3723

.

Especificaciones

ADVERTENCIA: Los repuestos deben ser iguales y ser instalados en

la misma posición que tenían las partes originales, de lo contrario puede ocurrir un

incendio.

Filtro de Aire

Este motor no viene equipado conunfiltrodeaire.NO use este motor para ninguna

otra aplicación distinta a la remoción de nieve.

Cómo Cambiar el Aceite - Figura

El aceite usado es un producto de desecho peligroso. Disponga del aceite usado

apropiadamente. No lo descarte en la basura doméstica. Verifique con sus autoridades

locales, con el centro de servicio, o con su distribuidor para obtener información acerca

de las facilidades seguras para su destrucción/reciclaje.

2 3 9

Remoción del Aceite

1. Con el motor apagado pero aún caliente, desconecte el cable de la bujía (A)y

manténgalo a distancia de la bujía (Figura 9).

2. Retire el tapón de drenaje de aceite (E, Figura 2). Drene el aceite en el recipiente

apropiado.

Nota: Cualquiera de los tapones de drenaje de aceite (F) mostrados se pueden

instalar en el motor.

3. Después de haber drenado el aceite, instale y apriete el tapón de drenaje de aceite.

Aprovisionamiento de aceite

• Coloque el motor a nivel.

• Limpie el área de llenado de aceite de todo desecho.

• Para la capacidad de aceite vea la sección Especificaciones.

Modelos con Tapón de Llenado de Aceite

1. Remueva el tapón de llenado de aceite (A, Figura 2).

2. Vierta el aceite lentamente por dentro del tubo de llenado de aceite del motor (B).

Llene hasta el punto de rebose.

3. Vuelva a colocar y apriete el tapón de llenado de aceite.

Modelos con varilla extendida.

1. Remueva la varilla indicadora de nivel de aceite (C, Figura 3) y límpiela con un trapo

limpio.

2. Vierta el aceite lentamente por dentro del tubo de llenado de aceite del motor (B).

No lo llene excesivamente.. Después de añadir aceite, espere un minuto y a

continuación vuelva a comprobar el nivel de aceite.

3. Coloque y ajuste la varilla indicadora.

4. Remueva la varilla indicadora de nivel de aceite y compruebe el nivel de aceite. El

aceite debe llegar arriba del indicador de (D) en la varilla indicadora de nivel de

aceite.

5. Coloque y ajuste la varilla indicadora.

es

Especificaciones del Motor

Modelo 90000

Desplazamiento 9,02 in3(148 cm3)

Diámetro Interno del Cilindro 2,562 in (65,08 mm)

Carrera 1,750 in (44,45 mm)

Capacidad de Aceite 18 -- 20 oz (0,54 -- 0,59 L)

Especificaciones de Aju ste *

Modelo 90000

Entrehierro de la Bujía 0,030 in (0,76 mm)

Apriete de la bujía 180 lb-in (20 Nm)

Entrehierro Inducido 0,006 - 0,010 in (0,15 - 0,25 mm)

Tolerancia de la Válvula de Admisión 0,005 - 0,007 in (0,13 - 0,18 mm)

Tolerancia de la Válvula de Escape 0,007 - 0,009 in (0,23 - 0,28 mm)

* La potencia del motor disminuirá 3,5% por cada 1.000 pies (300 metros) sobre el nivel