Page 1

sv

en

Not for

Reproduction

Operator’s Manual

da

de

el

es

fi

fr

it

nl

no

pt

Betjeningsvejledning

Bedienungsanleitung

Εγχειρίδιο χρήσης

Manual del operario

Käyttöohjekirja

Manuel d’utilisation

Manuale per l’operatore

Gebruikershandleiding

Brukerens veiledning

Manual do Operador

Handbok

Copyright © 2017 Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

80026888WST

Revision A

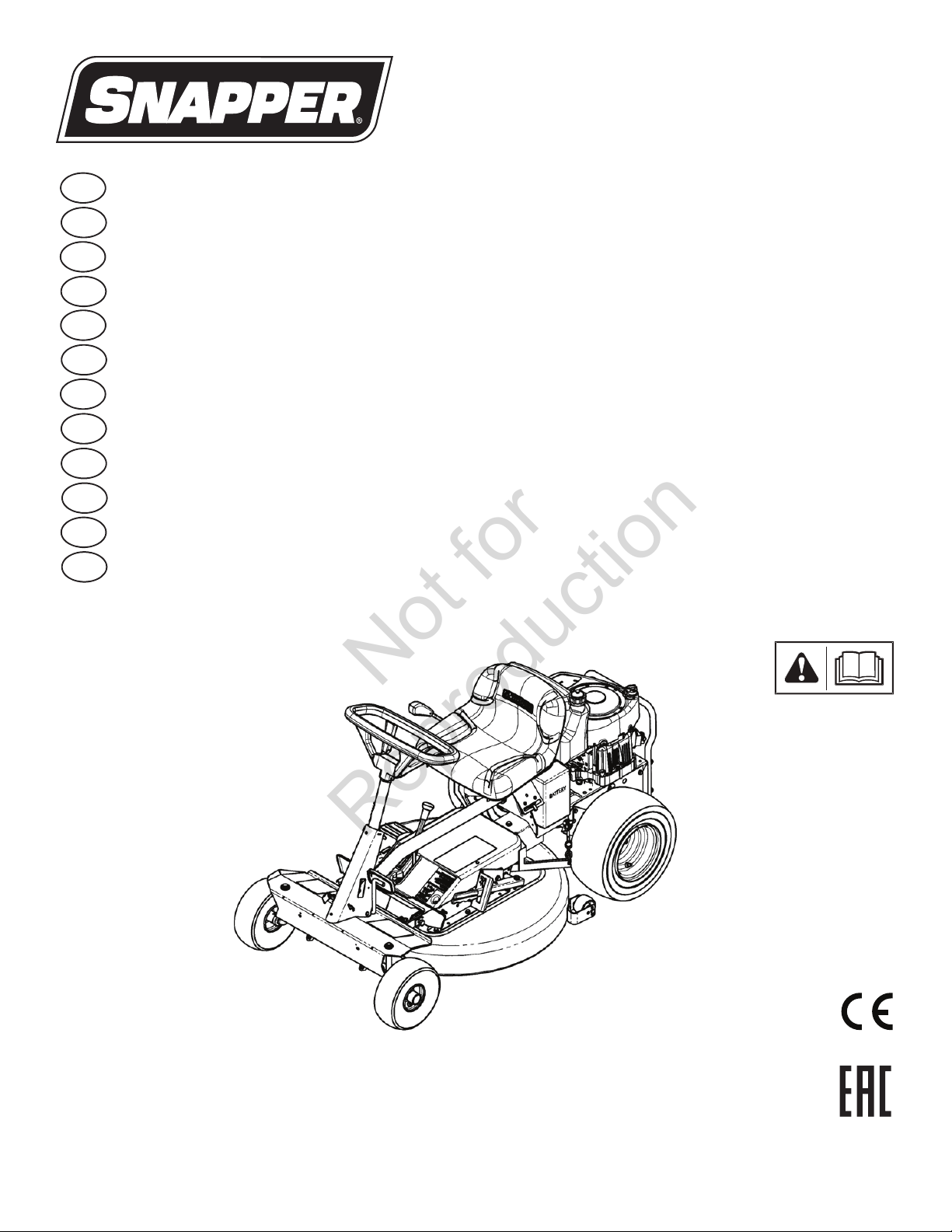

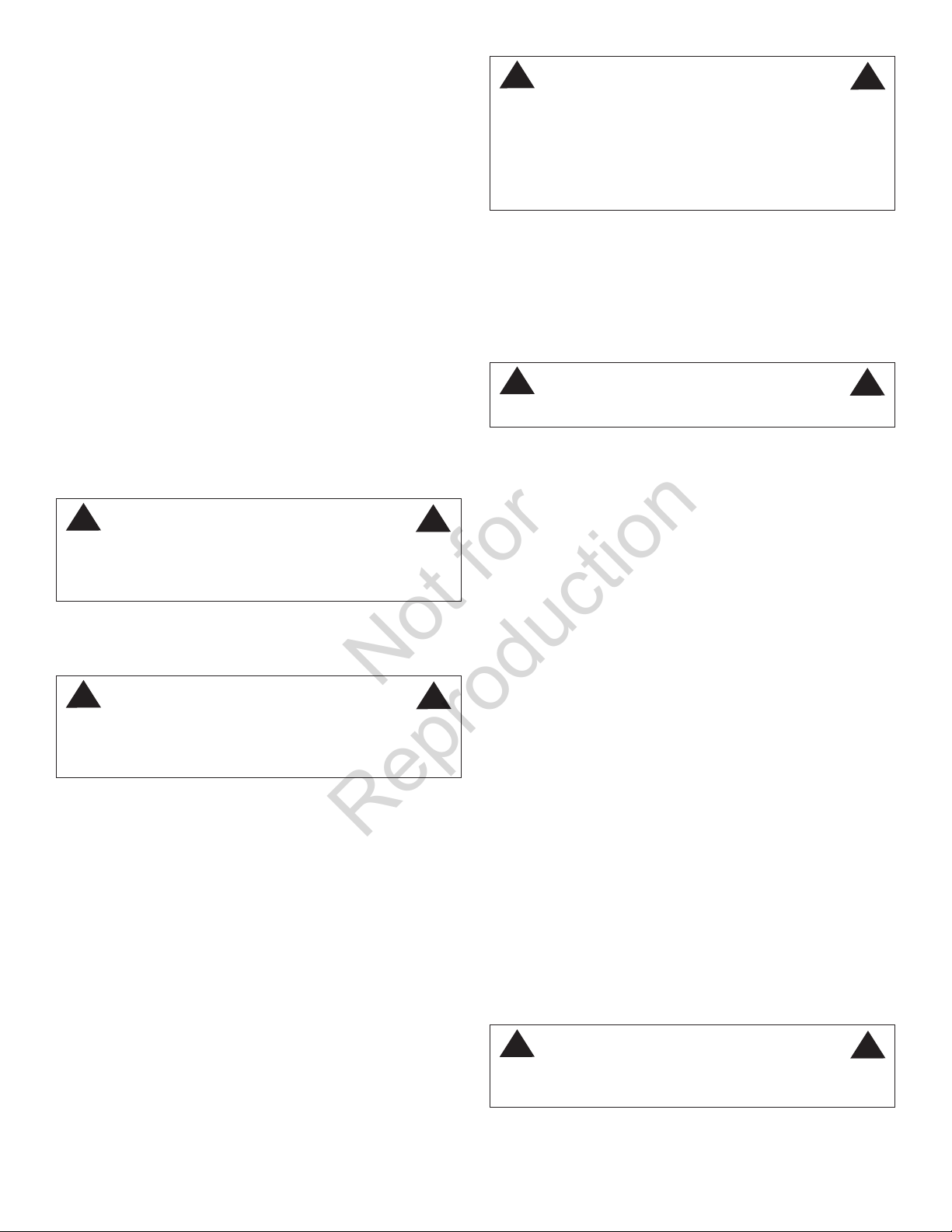

Page 2

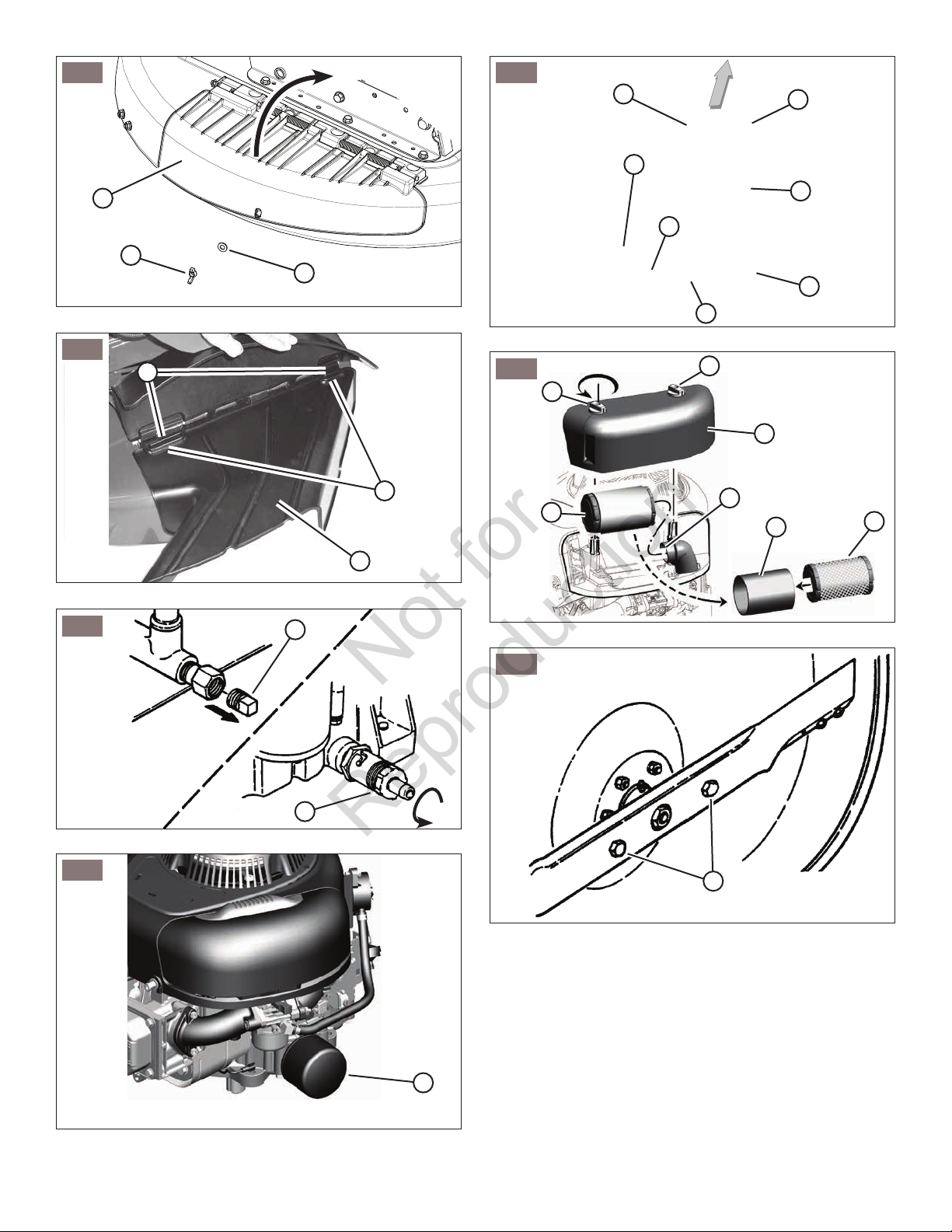

1

Not for

Reproduction

A

M

L

K

J

I

H

B

C

2

G

F

C

B

A

A

D

E

32

C

A

B

www.snapper.com2

Page 3

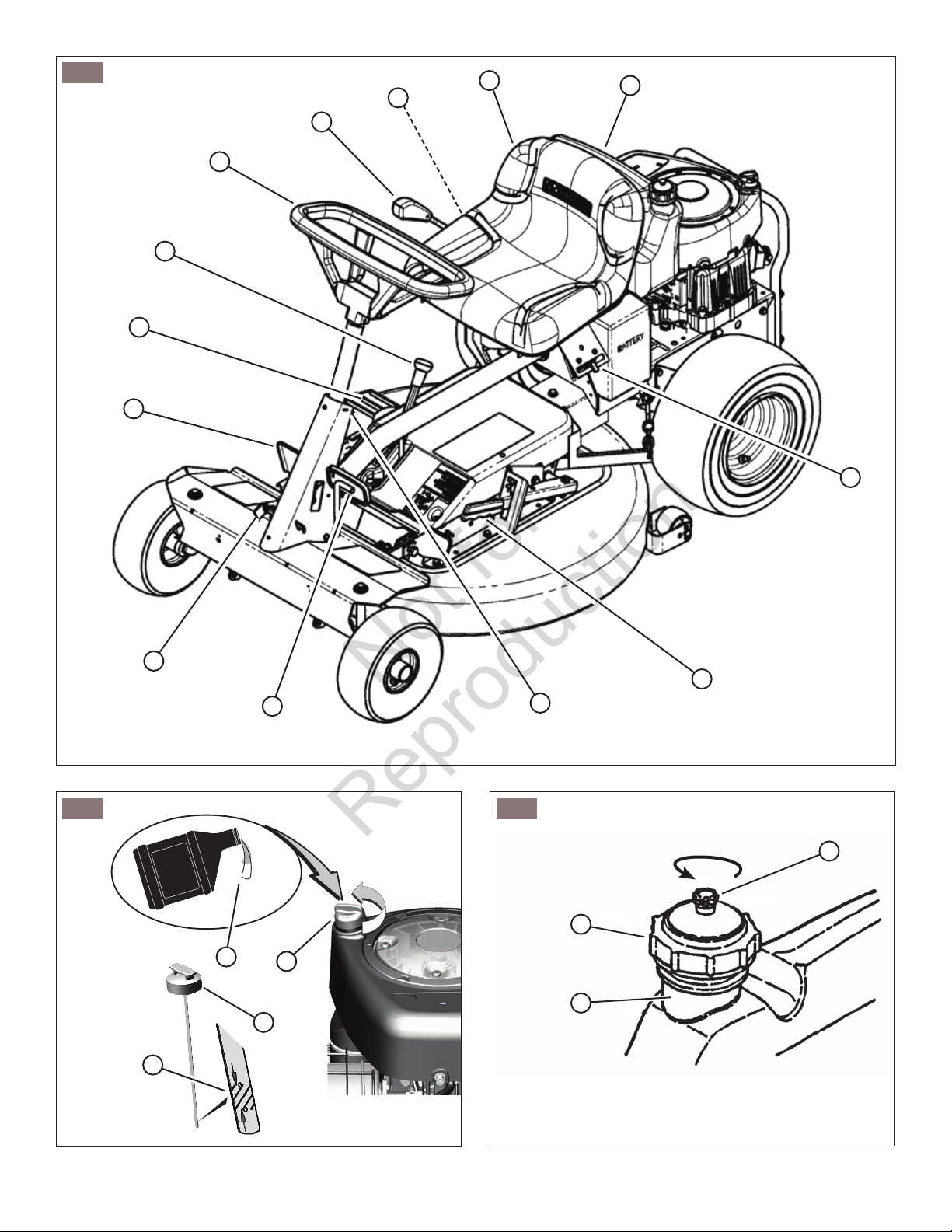

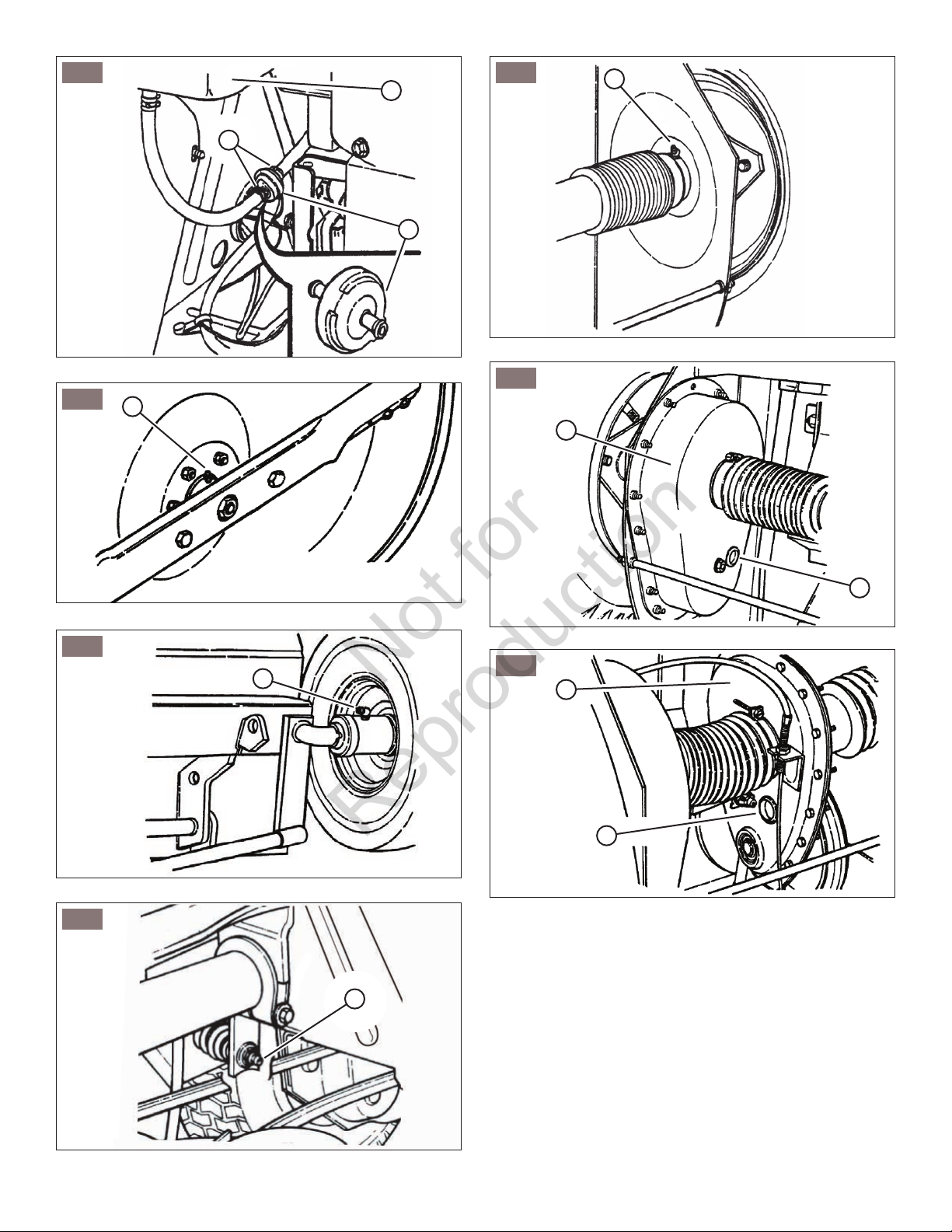

4

Not for

Reproduction

8

5

A

B

9

A

B

A

A

6

7

A

B

10

11

A

A

A

B

3

Page 4

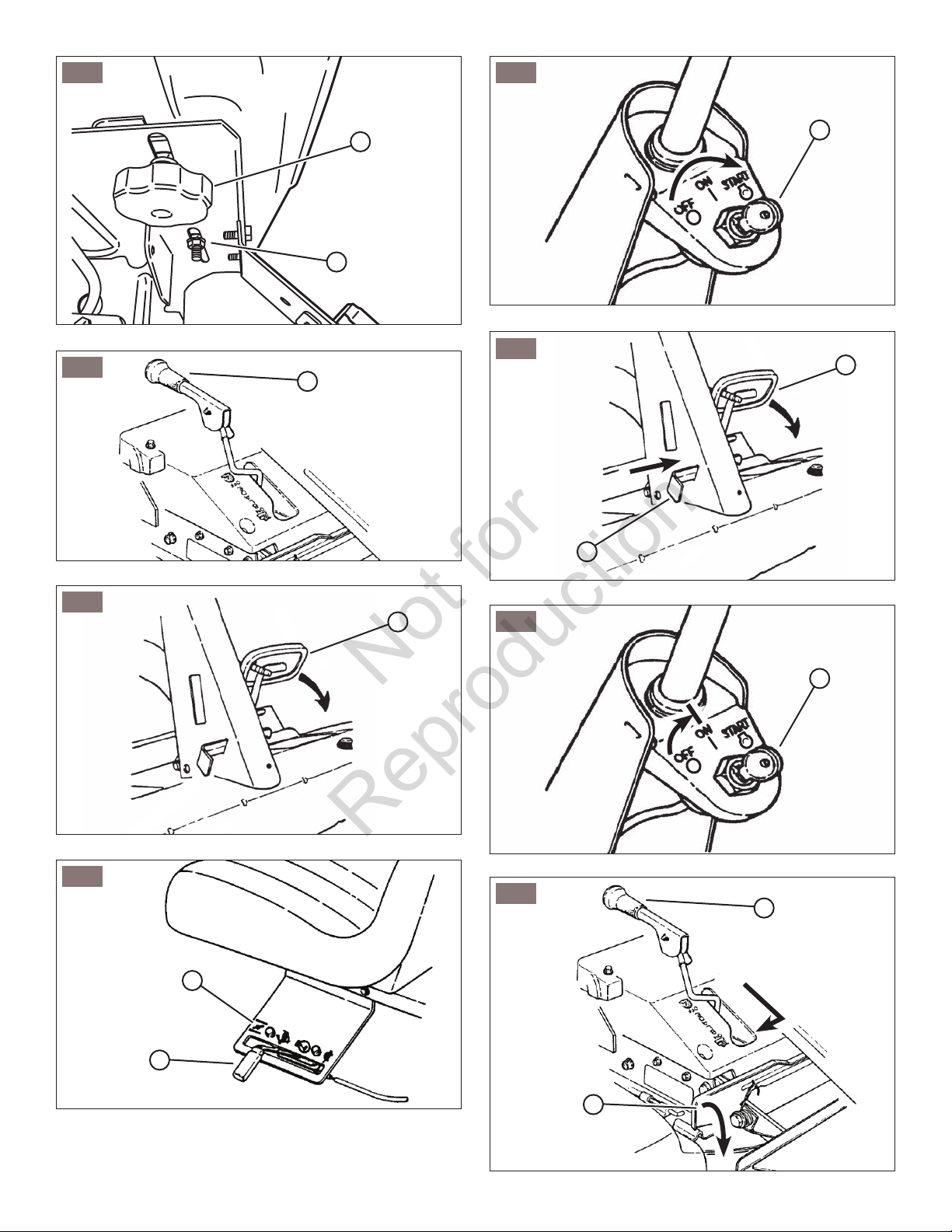

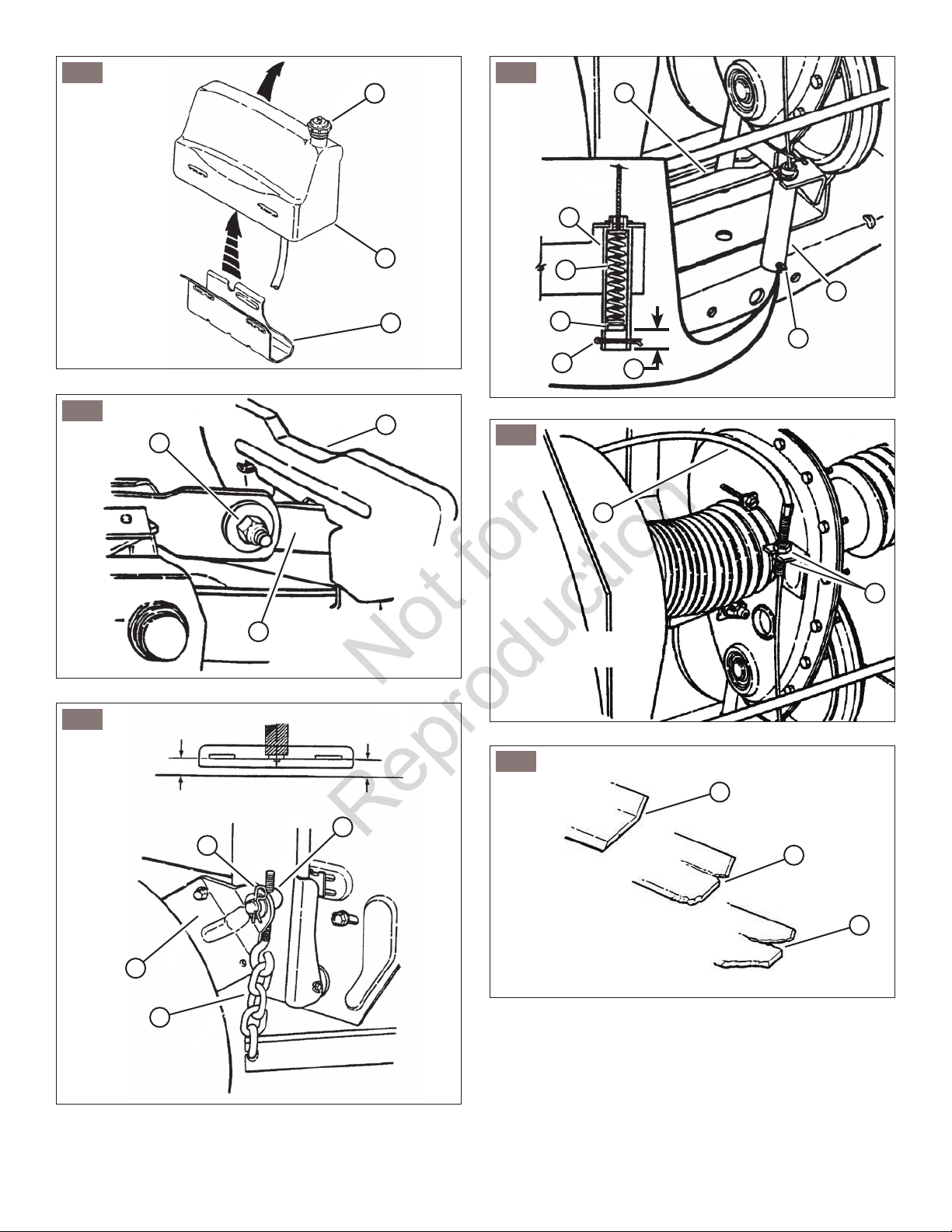

12

Not for

Reproduction

15

A

B

A

13

14

B

A

B

16

B

A

17

A

A

www.snapper.com4

Page 5

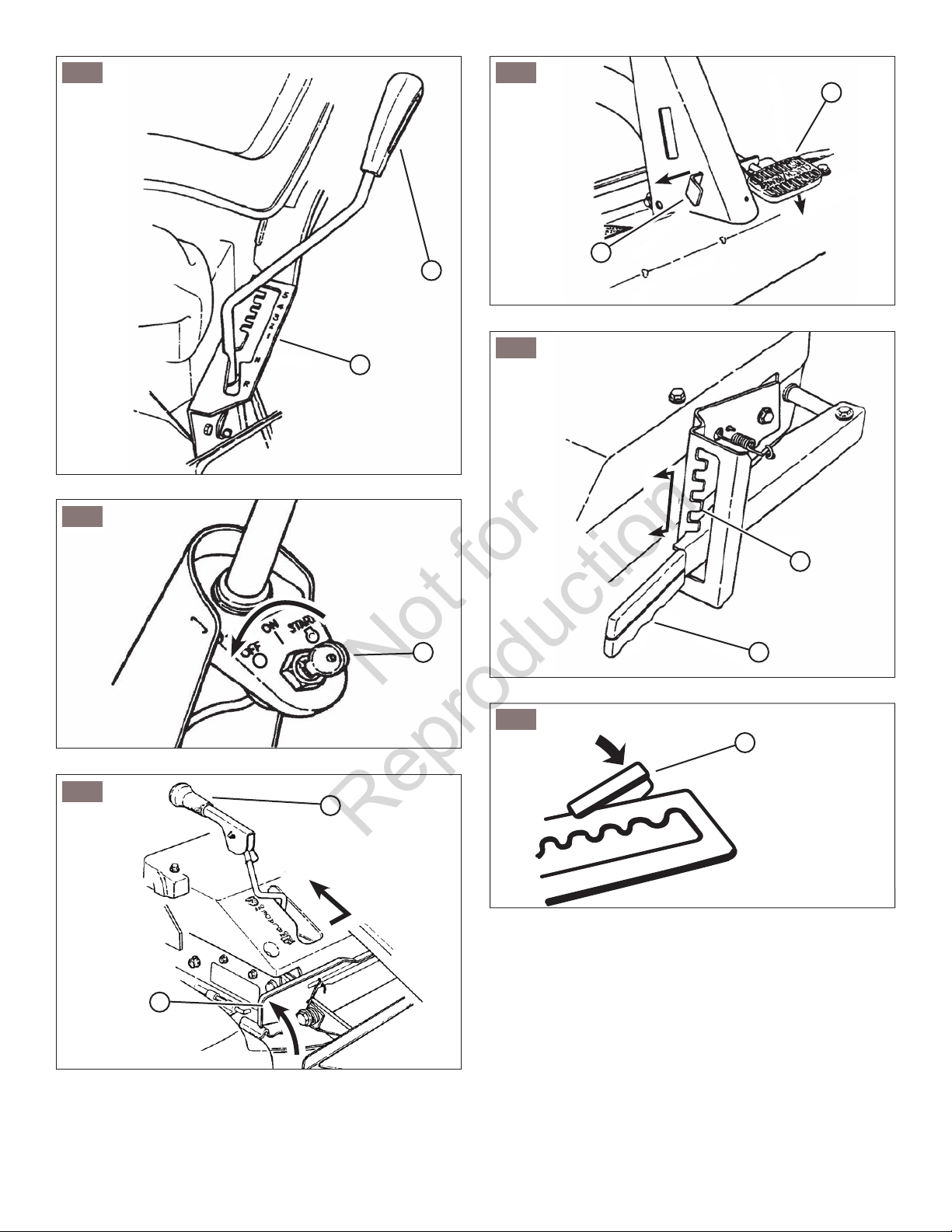

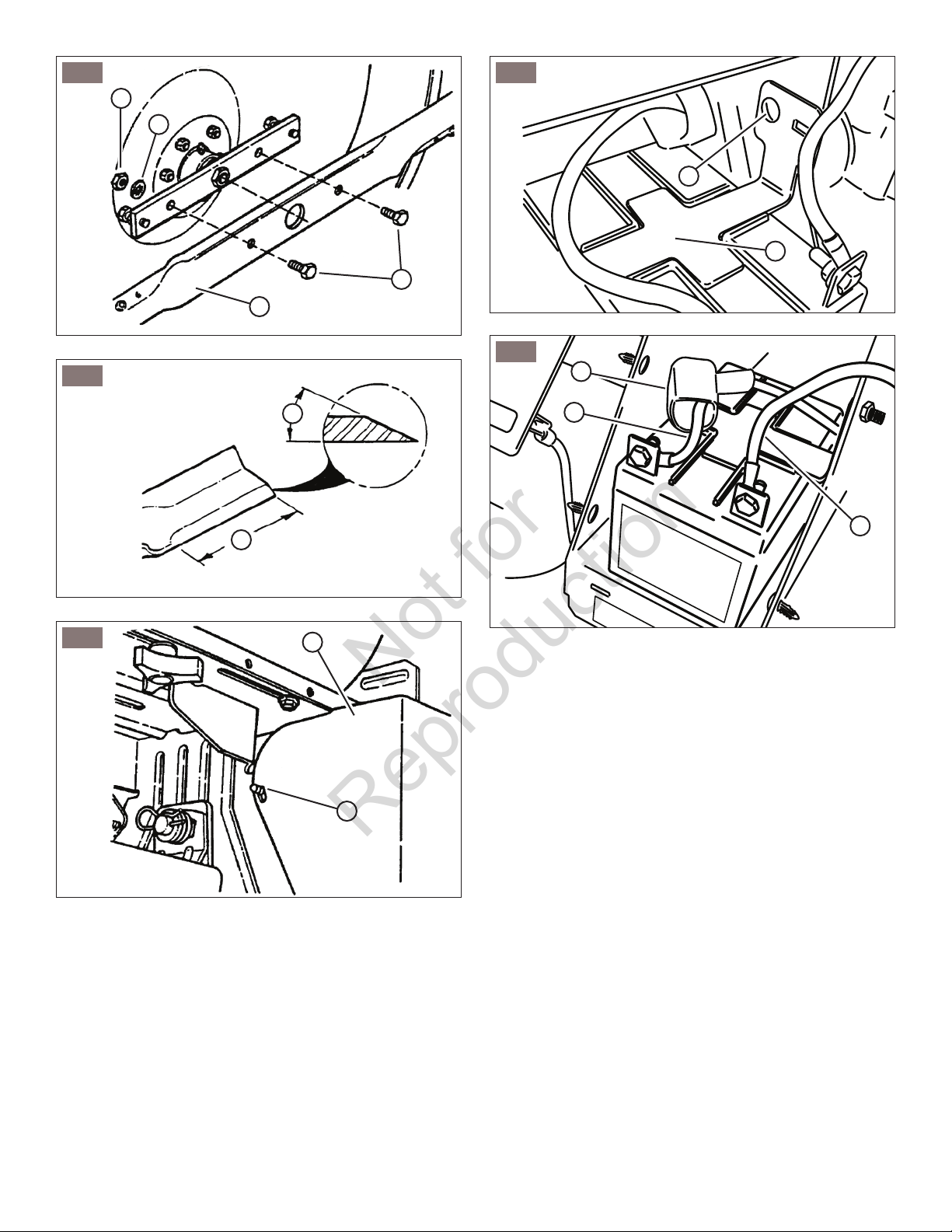

18

Not for

Reproduction

2322

A

E

B

19

20

C

G

A

B

C

C

B

A

A

23

A

C

A

D

F

D

B

E

C

21

24

B

A

A

5

Page 6

25

Not for

Reproduction

26

29

C

B

A

30

A

B

A

27

28

A

A

A

31

B

A

www.snapper.com6

Page 7

32

Not for

Reproduction

35

C

C

E

33

A

B

B

A

C

36

E

C

B

D

D

A

A

B

34

X

C

D

A

X-1/8”

B

37

A

B

C

7

Page 8

38

Not for

Reproduction

39

41

D

C

A

B

B

A

42

B

40

B

A

A

B

A

C

Page 9

Thank You for purchasing this quality-built Snapper®

Not for

Reproduction

product. We’re pleased that you placed your confidence

in the Snapper brand. When operated and maintained

according to the instructions in this manual, your Snapper

product will provide many years of dependable service.

Products Covered by this Manual

2691382-00

2691383-00

This manual contains safety information to make you

aware of the hazards and risks associated with the

machine and how to avoid them. This machine is designed

and intended only for finish cutting of established lawns

and is not intended for any other purpose. It is important

that you read and understand these instructions thoroughly

before attempting to start or operate this equipment. Save

these original instructions for future reference.

The Illustrated Parts List for this machine can be downloaded from www.snapper.com. Please provide model

and serial number when ordering replacement parts.

Date of Purchase________________________________

Retailer________________________________________

Retailer’s Phone Number__________________________

Equipment

Model Number____________________________

Serial Number____________________________

Table of Contents

Operator Safety .......................................................... 10

Features and Controls ............................................... 15

Operation ....................................................................15

Maintenance ...............................................................18

Safety Interlock Systems Check .............................. 21

Troubleshooting ......................................................... 26

Warranty ......................................................................28

Specifications ............................................................. 30

Engine

Model__________________________________

Type___________________________________

Code___________________________________

en

9

Page 10

Operator Safety

Not for

Reproduction

WARNING: This powerful cutting machine is capable of amputating hands and feet and can throw objects

!

that can cause injury and damage! Failure to comply with the following SAFETY instructions could result

in serious injury or death to the operator or other persons. The owner of the machine must understand

these instructions and must allow only persons who understand these instructions to operate machine.

Each person operating the machine must be of sound mind and body and must not be under the influence

of any substance, which might impair vision, dexterity or judgment.

WARNING

POISONOUS GAS HAZARD. Engine exhaust contains carbon

monoxide, a poisonous gas that could kill you in minutes. You

CANNOT see it, smell it, or taste it. Even if you do not smell exhaust

fumes, you could still be exposed to carbon monoxide gas. If you

start to feel sick, dizzy, or weak while using this product, shut it

off and get to fresh air RIGHT AWAY. See a doctor. You may have

carbon monoxide poisoning.

• Operate this product ONLY outside far away from windows, doors and vents

to reduce the risk of carbon monoxide gas from accumulating and potentially

being drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide

alarms with battery back-up according to the manufacturer’s instructions.

Smoke alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces,

sheds, or other partially-enclosed spaces even if using fans or opening doors

and windows for ventilation. Carbon monoxide can quickly build up in these

spaces and can linger for hours, even after this product has shut off.

• ALWAYS place this product downwind and point the engine exhaust away

from occupied spaces.

Protection for Children

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted to

the machine and the mowing activity. Children who have

been given rides in the past may suddenly appear in the

mowing area for another ride and be run over or backed

over by the machine. Never assume that children will

remain where you last saw them.

1. KEEP children out of the mowing area and under the

watchful care of a responsible adult other than the

operator.

2. DO NOT allow children in yard when machine is operated (even with the blade OFF).

3. DO NOT allow children or others to ride on machine,

attachments or towed equipment (even with the blades

OFF). They may fall and be seriously injured.

4. DO NOT allow pre-teenage children to operate

machine.

5. ALLOW only responsible adults & teenagers with

mature judgment under close adult supervision to

operate machine.

6. DO NOT operate blades in reverse. STOP BLADES.

LOOK and SEE behind and down for children, pets

and hazards before and while backing.

7. USE EXTRA CARE when approaching blind corners,

shrubs, trees, or other objects that may obscure vision.

Protection against Tipovers

Slopes are a major factor related to loss-of-control and

tip-over accidents, which can result in severe injury or

death. All slopes require extra CAUTION. If you cannot

back up the slope or if you feel uneasy on the slope, DO

NOT mow it. Use extra care with grass catchers or other

attachments; these affect the handling and the stability of

the machine.

1. DO NOT operate machine on slopes exceeding 10

degrees (18% grade).

2. Turn blades OFF when traveling uphill. Use a slow

speed and avoid sudden or sharp turns.

3. DO NOT operate machine back and forth across face

of slopes. Operate up and down. Practice on slopes

with blades off.

4. AVOID starting, stopping or turning on slopes. If

machine stops going uphill or tires lose traction, turn

blades OFF and back slowly straight down the slope.

5. STAY ALERT for holes and other hidden hazards. Tall

grass can hide obstacles. Keep away from ditches,

washouts, culverts, fences and protruding objects.

6. KEEP A SAFE DISTANCE (at least two mower widths)

away from edge of ditches and other drop offs. The

machine could turn over if an edge caves in.

7. Always begin forward motion slowly and with caution.

8. Use weights or a weighted load carrier in accordance with instructions supplied with a grass catcher.

DO NOT operate machine on slopes exceeding 10

degrees (18% grade) when equipped with grass catcher.

9. DO NOT put your foot on the ground to try to stabilize

the machine.

10. DO NOT operate machine on wet grass. Reduced

traction could cause sliding.

11. Choose a low enough speed setting so that you will

not have to stop or shift on a slope. Tires may lose

traction on slopes even though the brakes are functioning properly.

12. DO NOT operate machine under any condition where

traction, steering or stability is doubtful.

13. Always keep the machine in gear when going down

slopes. DO NOT shift to neutral (or actuate hydro roll

release) and coast downhill.

Preparation

1. Read, understand, and follow instructions and warnings in this manual and on the machine, engine and

attachments. Know the controls and the proper use of

the machine before starting.

2. Only mature, responsible persons shall operate the

machine and only after proper instruction.

3. Data indicates that operators age 60 and above,

are involved in a large percentage of mower-related

injuries. These operators should evaluate their ability

to operate the mower safely enough to protect them-

www.snapper.com10

Page 11

selves and others from serious injury.

Not for

Reproduction

4. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved fuel

container. DO NOT remove fuel cap or add fuel with

engine running. Add fuel outdoors only with engine

stopped and cool. Clean spilled fuel from machine. DO

NOT smoke.

5. Practice operation of machine with BLADES OFF to

learn controls and develop skills.

6. Check the area to be mowed and remove all objects

such as toys, wire, rocks, limbs and other objects that

could cause injury if thrown by blade or interfere with

mowing.

7. Keep people and pets out of mowing area.

Immediately STOP blades, STOP engine, and STOP

machine if anyone enters the area.

8. Check shields, deflectors, switches, blade controls and

other safety devices frequently for proper operation

and location.

9. Make sure all safety decals are clearly legible. Replace

if damaged.

10. Protect yourself when mowing and wear safety glasses, a dust mask, long pants and substantial footwear.

11. Know how to STOP blades and engine quickly in

preparation for emergencies.

12. Use extra care when loading or unloading the

machine into a trailer or truck.

13. Check grass catcher components frequently for signs

of wear or deterioration and replace as needed to prevent injury from thrown objects going through weak or

worn spots.

Safe Handling of Gasoline

To avoid personal injury or property damage, use extreme

care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive.

1. Extinguish all cigarettes, cigars, pipes and other sources of ignition.

2. Use only an approved fuel container.

3. DO NOT remove fuel cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. DO NOT refuel the machine indoors.

5. DO NOT store the machine or fuel container inside

where there is an open flame, spark or pilot light such

as on a water heater or other appliances.

6. DO NOT fill fuel containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always place the

containers on the ground away from the vehicle before

filling.

7. Remove gas-powered equipment from the vehicle or

trailer and refuel it on the ground. If this is not possible, then refuel equipment using a portable container,

rather than a gasoline dispenser nozzle.

8. DO NOT start gas powered equipment in enclosed

vehicles or trailers.

9. Keep the nozzle in contact with the rim of the fuel tank

or container opening at all times until fueling is complete. DO NOT use a nozzle lock-open device

10. If fuel is spilled on clothing, change clothing immediately.

11. Never overfill a fuel tank. Replace fuel cap and tighten

securely.

Operation

1. Mount and dismount machine from left side. Keep

clear of discharge opening at all times.

2. Start engine from operator’s seat, if possible. Make

sure blades are OFF and parking brake is set.

3. DO NOT leave machine with engine running. STOP

engine, STOP blades, SET brake, and remove key

before leaving operators position for any reason.

4. DO NOT operate machine unless properly seated with

feet on feet rests or pedal(s).

5. STOP BLADES and ENGINE and make sure blades

have stopped before removing grass catcher or

unclogging mower to prevent loss of fingers or hand.

6. Blades must be OFF except when cutting grass. Set

blades in highest position when mowing over rough

ground.

7. Keep hands and feet away from rotating blades

underneath deck. DO NOT place foot on ground while

BLADES are ON or machine is in motion.

8. DO NOT operate machine without entire grass catcher

or guards in place and working. DO NOT point discharge at people, passing cars, windows or doors.

9. Slow down before turning.

10. Watch out for traffic when near or crossing roadways.

11. STOP engine immediately after striking an obstruction. Inspect machine and repair damage before

resuming operation.

12. Operate machine only in daylight or with good artificial

light.

13. Move joystick (if equipped) SLOWLY to maintain control during speed and directional changes.

14. Exercise CAUTION when pulling loads. Limit loads to

those you can safely control and attach loads to hitch

plate as specified with attachment instructions.

15. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control. When towing,

travel slowly and allow extra distance to stop.

16. DO NOT operate engine in enclosed areas. Engine

exhaust gases contain carbon monoxide, a deadly

poison.

17. DO NOT discharge material against a wall or obstruction. Material may ricochet back towards the operator.

18. Only use accessories approved by the manufacturer.

See manufacturer’s instructions for proper operation

and installation of accessories.

Towing

1. Tow only with a machine that has a hitch designed for

towing. DO NOT attach towed equipment except at the

hitch point.

2. Follow the manufacturer’s recommendation for weight

limits for towed equipment and towing on slopes.

3. DO NOT allow children or others on towed equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

en

11

Page 12

Maintenance

Not for

Reproduction

1. DO NOT store machine or fuel container inside where

fumes may reach an open flame, spark or pilot light

such as in a water heater, furnace, clothes dryer or

other gas appliance. Allow engine to cool before storing machine in an enclosure. Store fuel container out

of the reach of children in a well ventilated, unoccupied

building.

2. Keep engine free of grass, leaves or excess grease to

reduce fire hazard and engine overheating.

3. When draining fuel tank, drain fuel into an approved

container outdoors and away from open flame.

4. Check brakes frequently; adjust, repair or replace as

needed.

5. Keep all bolts, nuts and screws properly tight. Check

that all cotter pins are in proper position.

6. Always provide adequate ventilation when running

engine. Exhaust gases contain carbon monoxide, an

odorless and deadly poison.

7. Disconnect negative (black) cable from battery before

performing maintenance or service. Cranking engine

could cause injury.

8. DO NOT work under machine without safety blocks.

9. Service engine and make adjustments only when

engine is stopped. Remove spark plug wire(s) from

spark plug(s) and secure wire(s) away from spark

plug(s).

10. DO NOT change engine governor speed settings or

overspeed engine.

11. Lubricate machine at intervals specified in manual to

prevent controls from binding.

12. Mower blades are sharp and can cut. Wrap the blades

or wear heavy leather gloves and use CAUTION when

handling them.

13. DO NOT test for spark by grounding spark plug next

to spark plug hole; spark plug could ignite gas exiting

engine.

14. Have machine serviced by an authorized dealer at

least once a year and have the dealer install any new

safety devices.

15. Maintain or replace safety and instruction labels as

necessary.

16. Use only factory authorized replacement parts or like

parts when making repairs.

www.snapper.com12

Page 13

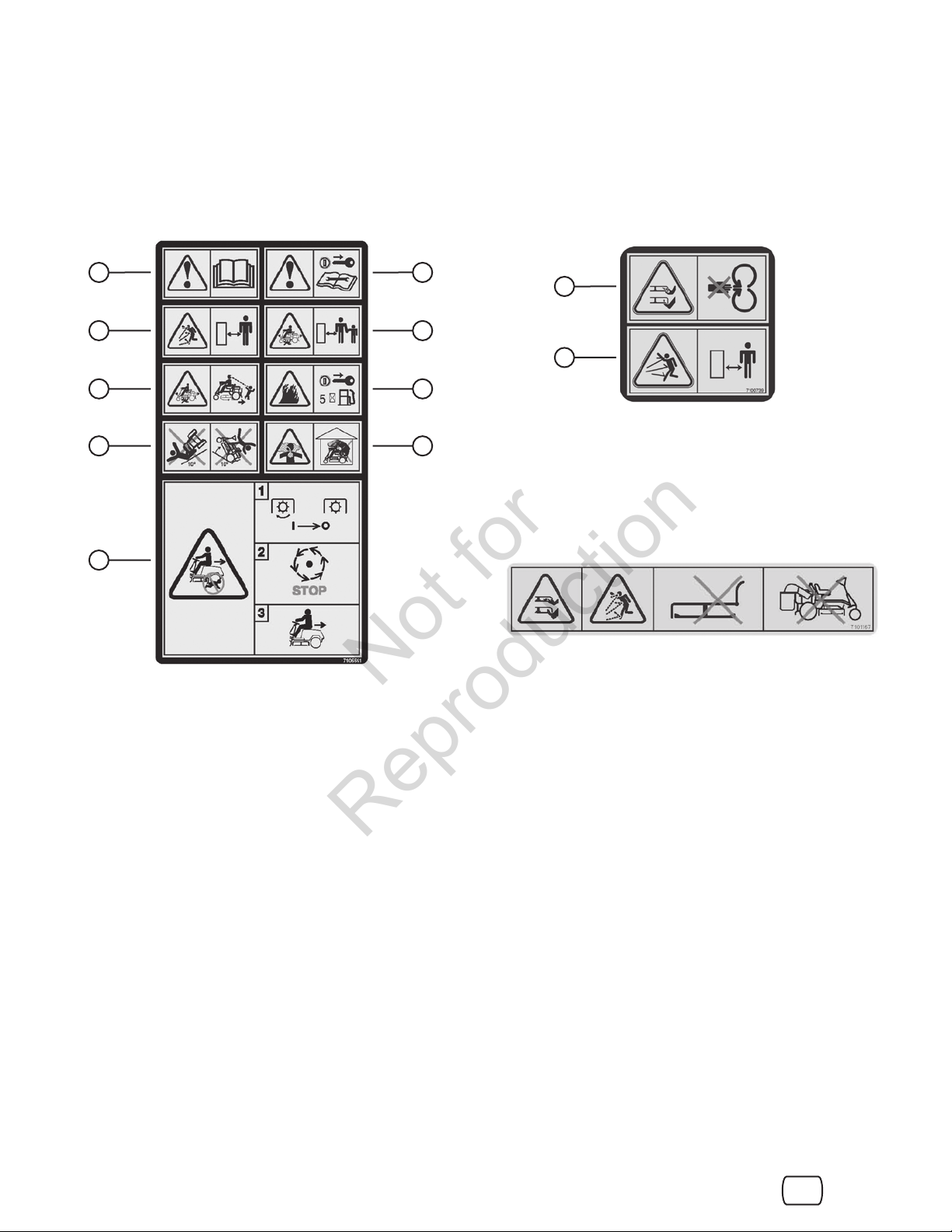

Safety and Instructional Decals

Not for

Reproduction

All DANGER, WARNING, CAUTION and instructional

messages on your rider and mower should be carefully

read and obeyed. Personal bodily injury can result when

these instructions are not followed. The information is for

your safety and it is important! The safety decals below

are on your rider and mower.

A

C

E F

G

B

D

H

If any of these decals are lost or damaged, replace them

at once. See an authorized dealer for replacements.

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the

equipment, to follow the safety instructions necessary for

safe, effective operation.

A

B

Deck Warning - 7100739

A. Danger: Dismemberment. This mower deck can ampu-

tate limbs. Keep hands and feet away from blades.

B. Danger: Thrown Objects. This machine is capable of

throwing objects and debris. Keep bystanders away.

I

Safety Instructions - 7101166

A. Warning: Read Operator’s Manual. Read and

understand the Operator’s Manual before using this

machine.

B. Warning: Remove Key Before Servicing. Remove the

key and consult technical literature before performing

repairs or maintenance.

C. Danger: Thrown Objects. This machine is capable of

throwing objects and debris. Keep bystanders away.

D. Danger: Dismemberment. This machine can ampu-

tate limbs. Keep bystanders and children away when

engine is running.

E. Danger: Do not mow in reverse unless absolutely

necessary. Look down and behind – before and while

backing.

F. Danger: Fire Hazard. Do not add fuel while engine is

hot or running. Stop engine and allow to cool for 5 minutes prior to adding fuel.

G. Danger: Machine Rollover. Do not use this machine on

slopes greater than 10°.

H. Danger: Carbon Monoxide Poisoning. Do not operate

the engine in an unventilated area.

I. Caution: Disengage mower blades and stop forward

motion before shifting unit into reverse.

Warning - 7101167

Danger: Dismemberment and Thrown Objects Hazard.

Do not mow without discharge chute or entire grass

catcher in place.

en

13

Page 14

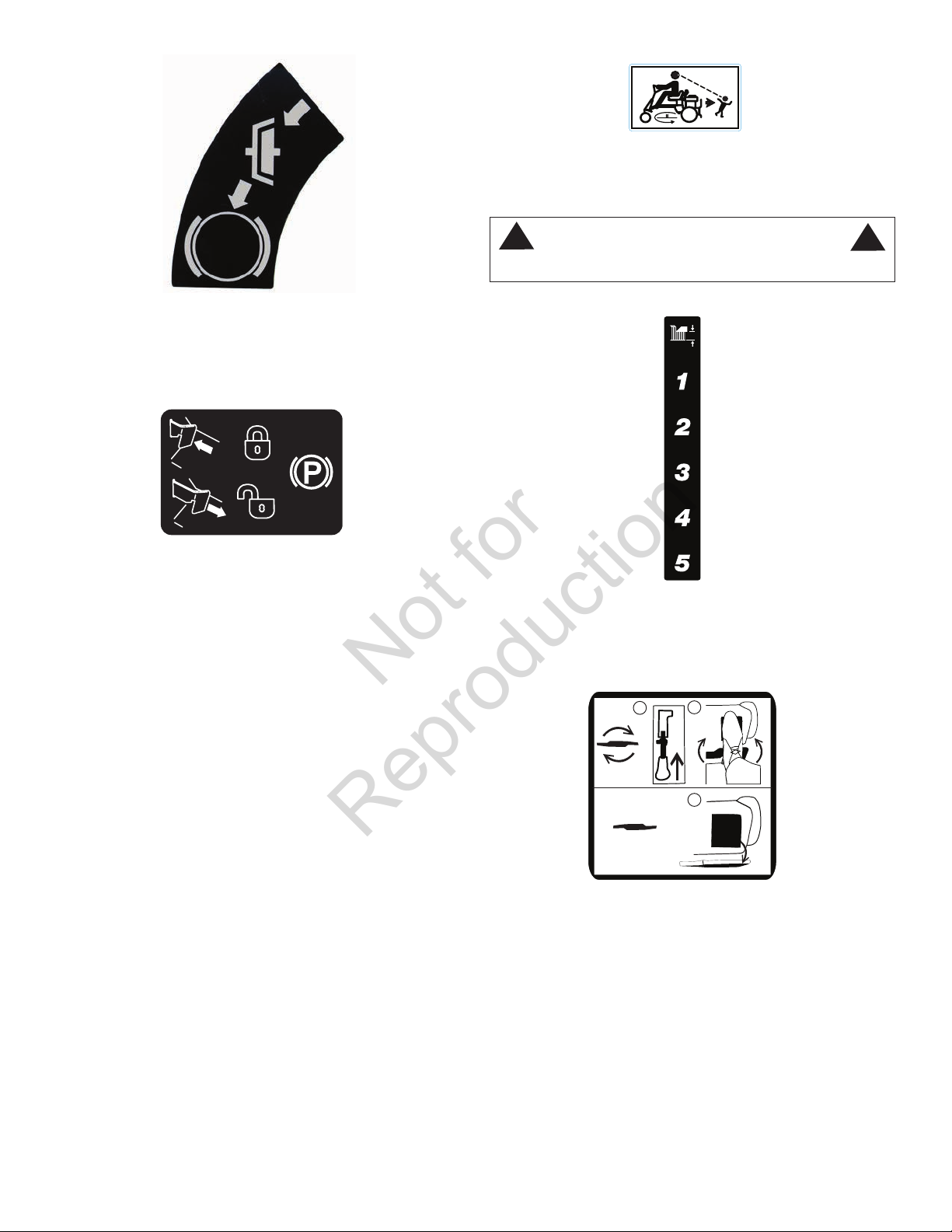

7103440

7104796

Not for

Reproduction

Reverse Lockout Override - 7104796

Identifies location of Reverse Lockout Override Lever.

Refer to “Reverse Lockout Mechanism”.

Clutch/Brake - 7028514

Shows operation of Clutch/Brake pedal. Depress

Clutch/Brake pedal to disengage clutch and apply

brake.

7103219

Park Brake - 7103219

Shows operation of park brake latch. Refer to “Setting

the Park Brake”.

!

Do not mow in reverse unless absolutely necessary.

Identifies height of cut positions. Refer to “Cutting

Height Adjustment”.

WARNING

Height of Cut - 7103440

!

1

1760758

Blade On/Blade Off - 1760758

Shows operation of mower blade. Refer to “Engaging

the Mower Blade” and “Stopping the Engine, Wheel

Drive and Mower Blade”.

2

1

www.snapper.com14

Page 15

Features and Controls

Not for

Reproduction

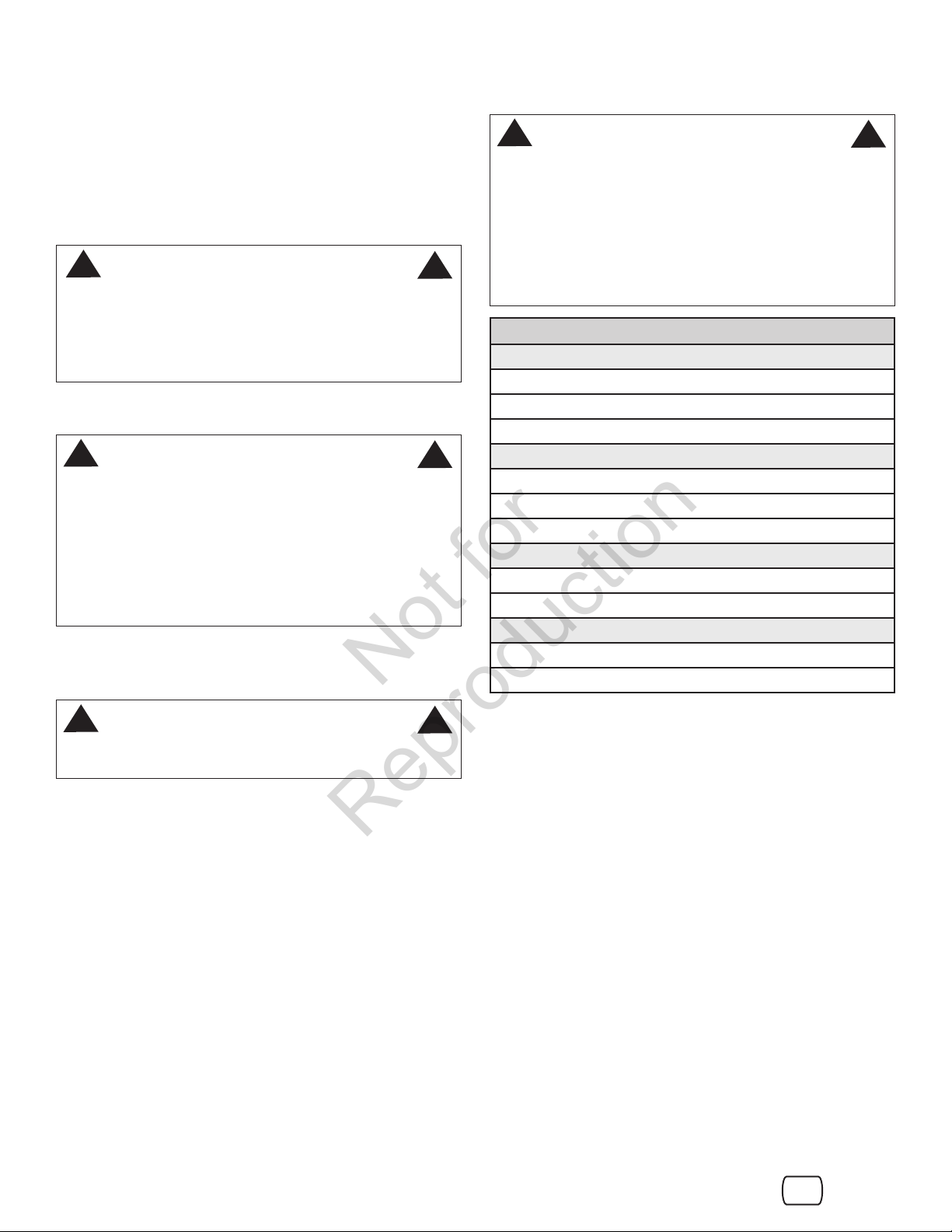

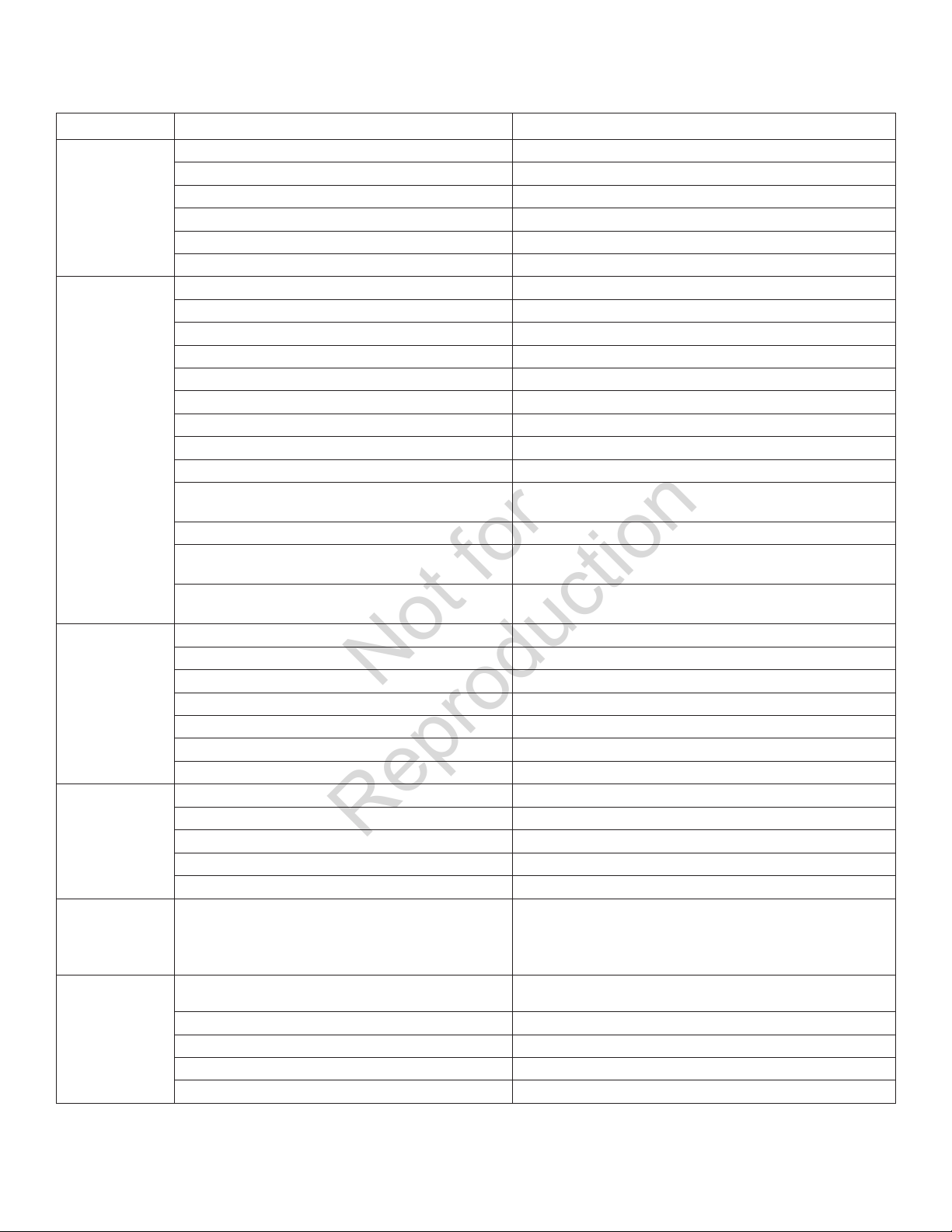

Compare Figure 1 with the table below.

NOTE: The figures and illustrations in this manual are provided for reference only and may differ from your specific

model. Contact your dealer if you have questions.

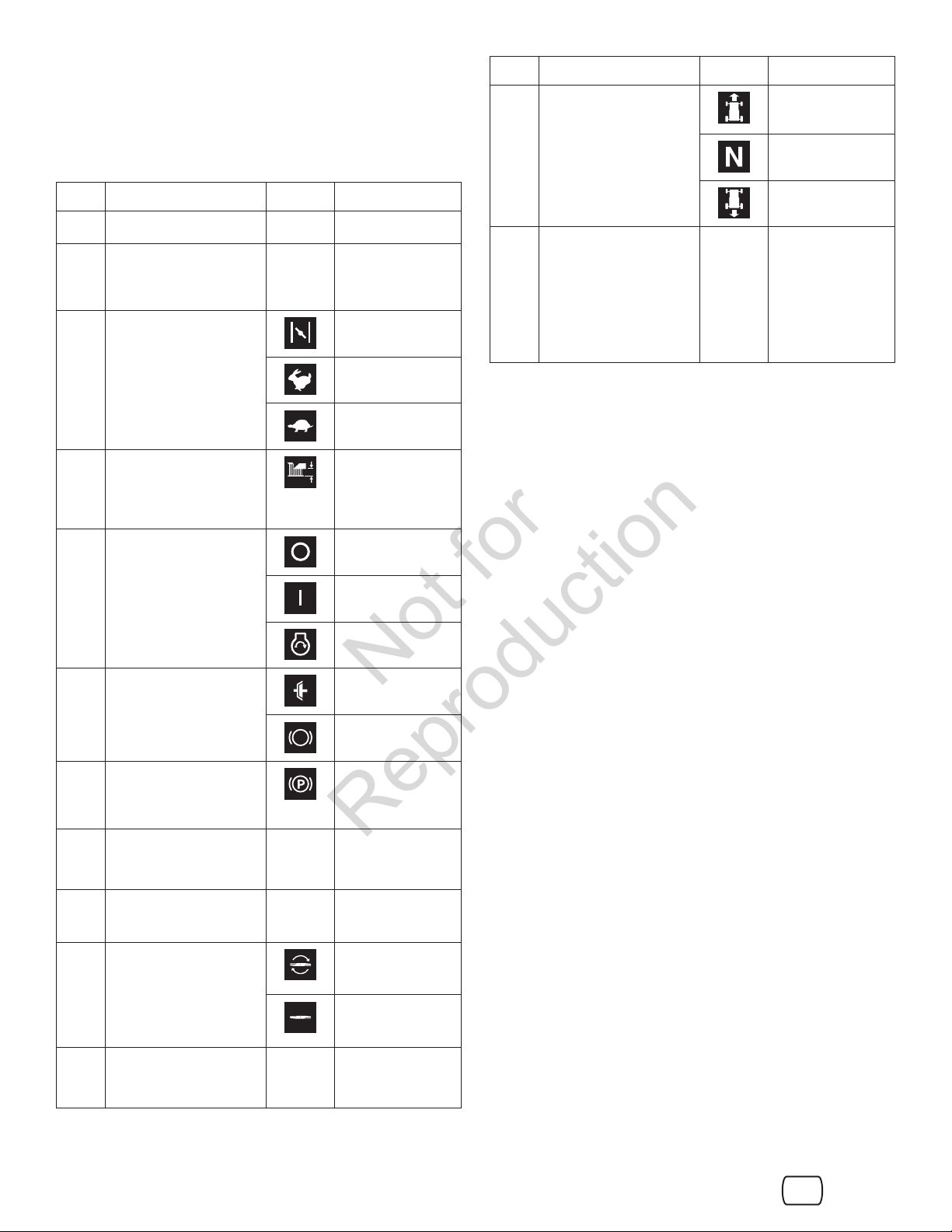

Ref. Description Icon(s) Icon Definition

L Transmission Shift

Lever - selects transmission speed and

direction

Forward ground

speed

Neutral (no

ground speed)

Ref. Description Icon(s) Icon Definition

A Operator Seat -- --

B Fuel Tank -- --

C Engine Speed

Control - controls

engine speed

D Cutting Height Adjust

Lever (hidden from

view) - adjusts cutting

height

E Ignition Switch (hid-

den from view) starts engine

F Clutch/Brake Pedal -

engages clutch and

brake

G Parking Brake Latch -

locks brake

Choke on

(closed)

Engine speed

fast

Engine speed

low

Cutting height

Engine off

Engine on (run)

Engine start

Clutch engaged

Brake on

(engaged)

Parking brake

on (engaged)

Reverse ground

speed

M Reverse Lockout

Override Lever (hidden from view) - temporarily allows mower

blade to operate

with transmission in

reverse

-- --

Operation

Before Starting

Make the following checks and perform the service

required before each start-up:

1. Check the tire pressure; add or release air as needed

to bring pressure to 15 PSI in front and 12 PSI in rear.

2. Check guards, deflectors and covers to make sure all

are in place and securely tightened.

3. Check engine oil and add oil as needed. Refer to

“How To Check/Add Oil”.

4. Adjust the seat as needed to the most comfortable

position. Refer to “Operator Seat Adjustment”.

5. Check the blade control to insure it works freely. If the

blade pedals are depressed, the blade lever can be

moved manually from “ON” to “OFF” to stop the blade.

6. Check the Reverse Lockout Mechanism. With the

blade pedals depressed, the shift lever must not go

into reverse.

7. Clean the exterior surfaces of the cutting deck and

engine of any accumulation of dirt, grass, oil, etc.

Keep the engine air intake screen and cooling fins

clear at all times.

8. Add fuel to the fuel tank. Refer to “How to Add Fuel”.

H Blade Pedal - locks

mower blade lever in

engage position

I Mulching Cover -- --

J Blade Lever - engag-

es mower blade

K Steering Wheel -

controls direction of

unit

-- --

-- --

Blade on

(engaged)

Blade off (disengaged

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SF,

SG, SH, SJ or higher. Do not use special additives.

en

15

Page 16

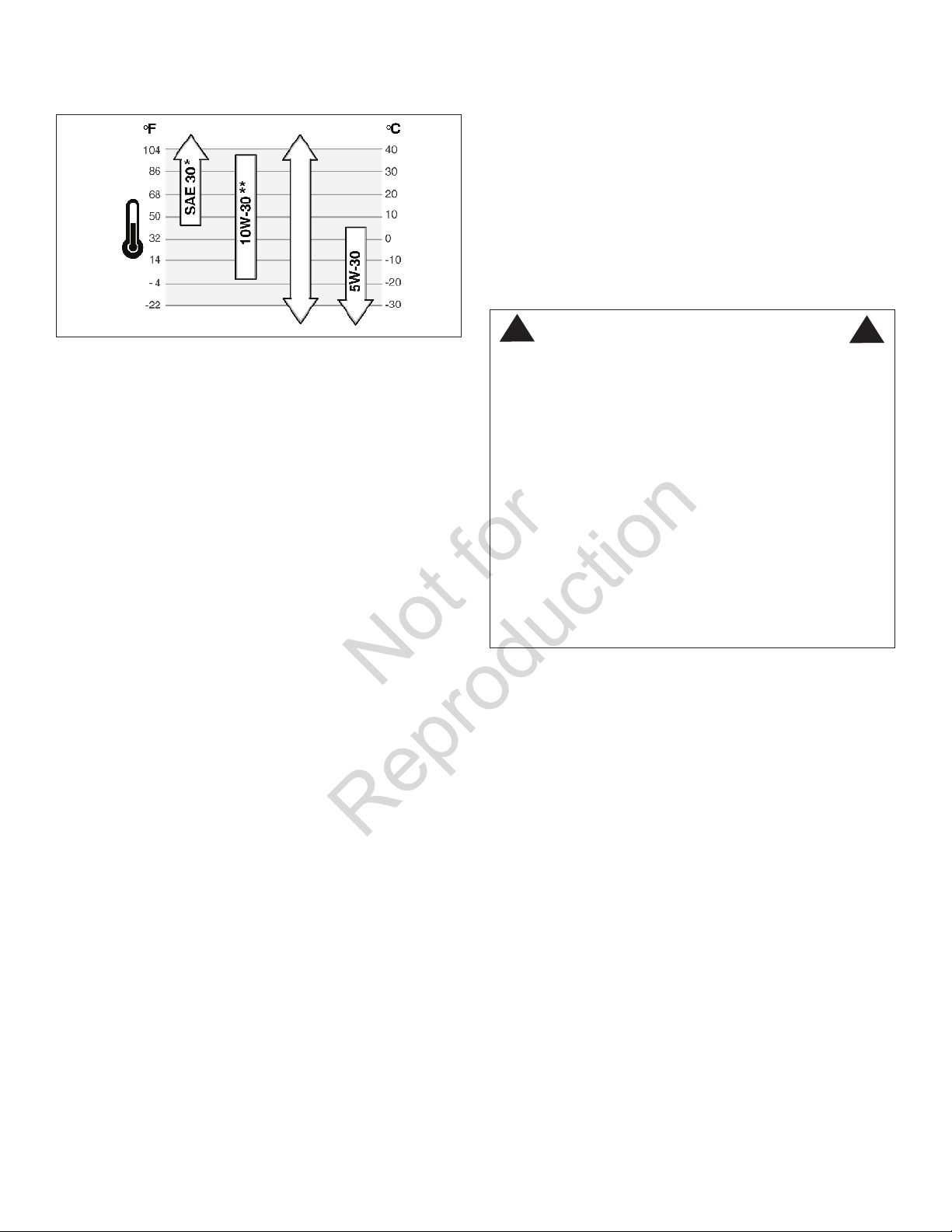

Outdoor temperatures determine the proper oil viscosity for

Not for

Reproduction

the engine. Use the chart to select the best viscosity for the

outdoor temperature range expected.

Synthetic 5W-30

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85

octane/85 AKI (89 RON) gasoline is acceptable. To remain

emissions compliant, high altitude adjustment is required.

Operation without this adjustment will cause decreased

performance, increased fuel consumption, and increased

emissions. See a Briggs & Stratton Authorized Dealer for

high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762

meters) with the high altitude kit is not recommended.

How To Add Fuel

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil con-

sumption. Check oil level more frequently.

How To Check/Add Oil

Before adding or checking the oil

• Place engine level.

• Clean the oil fill area of any debris.

1. Remove the dipstick (A, Figure 2) and wipe with a

clean cloth.

2. Insert and tighten the dipstick.

3. Remove the dipstick and check the oil level. It should

be at the top of the full indicator (B, Figure 2) on the

dipstick.

4. If low, add oil slowly into the engine oil fill (C, Figure

2). Do not overfill. After adding oil, wait one minute

and then recheck the oil level.

5. Replace and tighten the dipstick.

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High altitude use, see below.

• Gasoline with up to 10% ethanol (gasohol) is acceptable.

CAUTION: Do not use unapproved gasolines, such as E15

and E85. Do not mix oil in gasoline or modify the engine to

run on alternate fuels. This will damage the engine components and void the engine warranty.

To protect the fuel system from gum formation, mix a fuel

stabilizer into the fuel. Refer to “Storage”. All fuel is not the

same. If starting or performance problems occur, change

fuel providers or change brands. This engine is certified to

operate on gasoline. The emissions control system for this

engine is EM (Engine Modifications)

!

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

• Turn engine off and let engine cool at least 5 minutes

before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the

fuel, do not fill above the bottom of the fuel tank neck.

• Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for

cracks or leaks. Replace if necessary

• If fuel spills, wait until it evaporates before starting

engine.

1. Clean the fuel cap area of dirt and debris. Remove the

fuel cap (A, Figure 3).

2. Fill the fuel tank with fuel. To allow for expansion of the

fuel, do not fill above the bottom of the fuel tank neck

(B, Figure 3).

3. Reinstall the fuel cap. Make sure the vent (C, Figure

3) is open after refueling.

WARNING

!

Operator Seat Adjustment

1. With the engine stopped, loosen the two adjusting

knobs (A, Figure 4) and move the seat to the desired

position. After adjustment, tighten the knobs securely.

NOTE: If the seat does not move after loosening the knobs,

it may be necessary to loosen the 5/16” patch lock screws

or hex nuts (B, Figure 4) located at the rear of the seat.

www.snapper.com16

Page 17

Starting the Engine

Not for

Reproduction

WARNING

POISONOUS GAS HAZARD. Engine exhaust contains carbon

monoxide, a poisonous gas that could kill you in minutes. You

CANNOT see it, smell it, or taste it. Even if you do not smell exhaust

fumes, you could still be exposed to carbon monoxide gas. If you

start to feel sick, dizzy, or weak while using this product, shut it

off and get to fresh air RIGHT AWAY. See a doctor. You may have

carbon monoxide poisoning.

• Operate this product ONLY outside far away from windows, doors and vents

to reduce the risk of carbon monoxide gas from accumulating and potentially

being drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide

alarms with battery back-up according to the manufacturer’s instructions.

Smoke alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces,

sheds, or other partially-enclosed spaces even if using fans or opening doors

and windows for ventilation. Carbon monoxide can quickly build up in these

spaces and can linger for hours, even after this product has shut off.

• ALWAYS place this product downwind and point the engine exhaust away

from occupied spaces.

Electric Start

IMPORTANT: When the ignition key is turned to “START”,

the engine will turn over, but will not start unless the Clutch/

Brake pedal is pressed all the way down, and the Blade

Lever is in the “OFF” position. The operator should be in

the seat.

Start the engine as follows:

1. Open the vent (B, Figure 3) on the fuel filler cap (A)

by turning counterclockwise.

IMPORTANT: Failure to open the vent on the fuel filler cap

can cause the engine to stall.

2. Move the transmission shift lever to the (N) Neutral

position. Refer to “Wheel Drive”.

IMPORTANT: DO NOT start the engine with the transmission shift lever in a drive position.

!

It is possible to start the engine with the transmission

shift lever in a drive position. Follow starting instructions

carefully.

3. Make certain the Blade Lever (A, Figure 5) is in the

“OFF” position.

4. Depress the Clutch/Brake Pedal (A, Figure 6) all the

way down and hold while starting the engine.

5. Move the engine speed control (A, Figure 7) to the

choke position (B) to start a cold engine.

6. Turn the ignition key (A, Figure 8) to the “START”

position until the engine starts.

NOTE: If after 5 seconds of cranking the engine does not

start, release the key, make sure the Clutch/Brake Pedal is

fully depressed, and attempt starting again after waiting for

approximately 20 seconds.

7. After the engine starts, move the engine speed control

to the “FAST” position and allow a brief warm-up until

engine runs smooth.

8. Should the battery be too weak to start the engine,

WARNING

!

refer to “Engine (Manual Start)” to manually start the

electric start engines.

9. On Model E2813523BVE, the engine is equipped

with a fuel shut-off solenoid. If the battery is dead, the

engine can be started with the recoil back-up starter if

the engine speed control is in the choke position (HOT

engine or COLD engine).

Manual Start

IMPORTANT: When the key is turned to “ON”, and the

recoil handle is pulled, the engine will turn over, but will not

start unless the Clutch/Brake Pedal is pressed all the way

down with the Park Brake engaged, and the Blade Lever is

in the “Off” position.

Start the engine as follows:

1. Open the vent (B, Figure 3) on the fuel filler cap (A)

by turning counterclockwise.

IMPORTANT: Failure to open the vent on the fuel filler cap

can cause the engine to stall.

2. Move the transmission shift lever to the (N) Neutral

position. Refer to the section entitled “Wheel Drive”.

IMPORTANT: DO NOT start the engine with the transmission shift lever in a drive position.

!

It is possible to start the engine with the transmission

shift lever in a drive position. Follow starting instructions

carefully.

3. Make certain the Blade Lever (A, Figure 5) is in the

“OFF” position.

4. Depress the Clutch/Brake Pedal (A, Figure 9) all the

way down, move the park brake latch (B) over, and

release the clutch/brake pedal to set the park brake.

5. Move the engine speed control (A, Figure 7) to the

choke position (B) to start a cold engine.

6. Turn the key (A, Figure 10) to the “ON” position.

7. Pull the starter rope, located on the engine recoil, with

a smooth, even motion until the engine starts.

NOTE: Always guide the starter rope back into the recoil

housing. Never allow rope to snap back.

After the engine starts, move the engine speed control

to the “FAST” position.

8. Allow a brief warm-up until the engine runs smooth.

WARNING

!

Engaging the Mower Blade

!

Once blade is disengaged, it should come to a complete stop in 3 seconds or less. If the blade continues to

rotate after 3 seconds, the blade brake must be adjusted. Return machine to an authorized dealer for adjustment. DO NOT CONTINUE to operate machine until

blade brake is adjusted and functioning properly.

WARNING

en

!

17

Page 18

1. With the engine running, move the engine speed con-

Not for

Reproduction

trol to the “FAST” position.

2. Move the blade lever (A, Figure 11) forward to the

“ON” position, then press the blade pedals (B) to hold

the blade lever in the “ON” position.

Engaging the Wheel Drive

1. With the engine running, adjust the engine speed control to the “FAST” position.

2. Depress the clutch/brake pedal (A, Figure 6).

3. Place the transmission shift lever (A, Figure 12) into

the first forward speed notch (B).

4. Release the clutch/brake pedal to begin forward

motion.

5. During forward motion, the transmission shift lever

may be placed in any desired forward speed without

depressing the clutch/brake pedal.

NOTE: For best cutting results, move the transmission

shift lever into a slow forward speed and the engine speed

control to a fast position. This combination will allow the

mower blades to lift the grass while cutting smoothly and

evenly.

!

DO NOT operate blades in reverse. STOP BLADES.

LOOK and SEE behind and down for children, pets and

hazards before and while backing.

WARNING

!

Stopping the Engine,

Wheel Drive and Mower Blade

!

DO NOT leave the machine with the engine running.

STOP Blade. STOP engine. Shift to neutral and engage

park brake. Remove key.

Engine

1. Stop the engine by turning the key (A, Figure 13) to

the “OFF” position.

Wheel Drive

1. Stop motion of the Rear Engine Rider by pushing the

clutch/brake pedal (A, Figure 6) all the way down to

apply the brake.

Mower Blade

1. Stop the mower blade by releasing the blade pedals

(A, Figure 14) or moving the blade lever (B) rearward

to the “OFF” position.

WARNING

!

!

Once blade is disengaged, it should come to a complete stop in 3 seconds or less. If the blade continues to

rotate after 3 seconds, the blade brake must be adjusted. Return machine to an authorized dealer for adjustment. DO NOT CONTINUE to operate machine until

blade brake is adjusted and functioning properly.

WARNING

!

Setting the Park Brake

1. To set the park brake, depress the clutch/brake pedal

(A, Figure 9) all the way down, slide the park brake

latch (B) all the way in to the engaged position, and

release the clutch/brake pedal. A detent in the park

brake latch will keep the park brake engaged.

!

DO NOT park the machine on slopes.

2. Release the park brake by pressing down firmly on the

clutch/brake pedal (A, Figure 15). The park brake

latch (B) is spring-loaded, and will slide back to the

disengaged position unassisted.

WARNING

!

Cutting Height Adjustment

1. Adjust the cutting height by raising or lowering the

deck lift lever (A, Figure 16) into the desired height of

cut notch (B).

Reverse Lockout Mechanism

This riding mower has a Reverse Lockout Mechanism,

which prevents the mower from being shifted into reverse

with the blade running. However, if you operate your

mower near roadways or use attachments that require

quicker shifting to reverse, there is an override lever provided. This lever will allow reverse operation until the blade

pedals are released, at which time the system will return to

its Reverse Lockout mode.

This feature should never be selected unless you are

absolutely sure that no children or others are present in the

mowing area and that all children are away and supervised

by a responsible adult.

Reverse Lockout Mechanism Override

1. Stop the machine. Stop the blade.

2. Depress and hold the Override Lever (A, Figure 17).

3. Depress and hold the Blade Pedals. Release the

Override Lever.

4. Move the blade lever forward to “ON” position.

LOOK and SEE behind and down for children, pets and

hazards before and while backing.

!

WARNING

!

www.snapper.com18

Page 19

IMPORTANT: DO NOT use the Reverse Lockout

Not for

Reproduction

Mechanism Override as the normal operating mode. To

return to the Reverse Lockout Mechanism mode, release

blade pedals to turn blade off. The Override will reset to

Reverse Lockout. Check the Reverse Lockout Mechanism

frequently for proper function. With the blade pedals

depressed, the shift lever must not go into reverse. DO

NOT operate machine if Reverse Lockout Mechanism is

not functioning properly. Contact your authorized dealer for

assistance.

!

LOOK and SEE behind and down for children, pets and

hazards before and while backing.

BLADES must be turned off before backing machine.

DO NOT allow children on machine (even with blades

off) or in yard when mowing.

DANGER

!

Discharge Deflector Installation

!

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

1. Remove the nut (A, Figure 18) and washer (B) securing the bottom edge of the mulching cover (C) to the

mower deck.

WARNING

!

Maintenance

Maintenance Chart

!

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

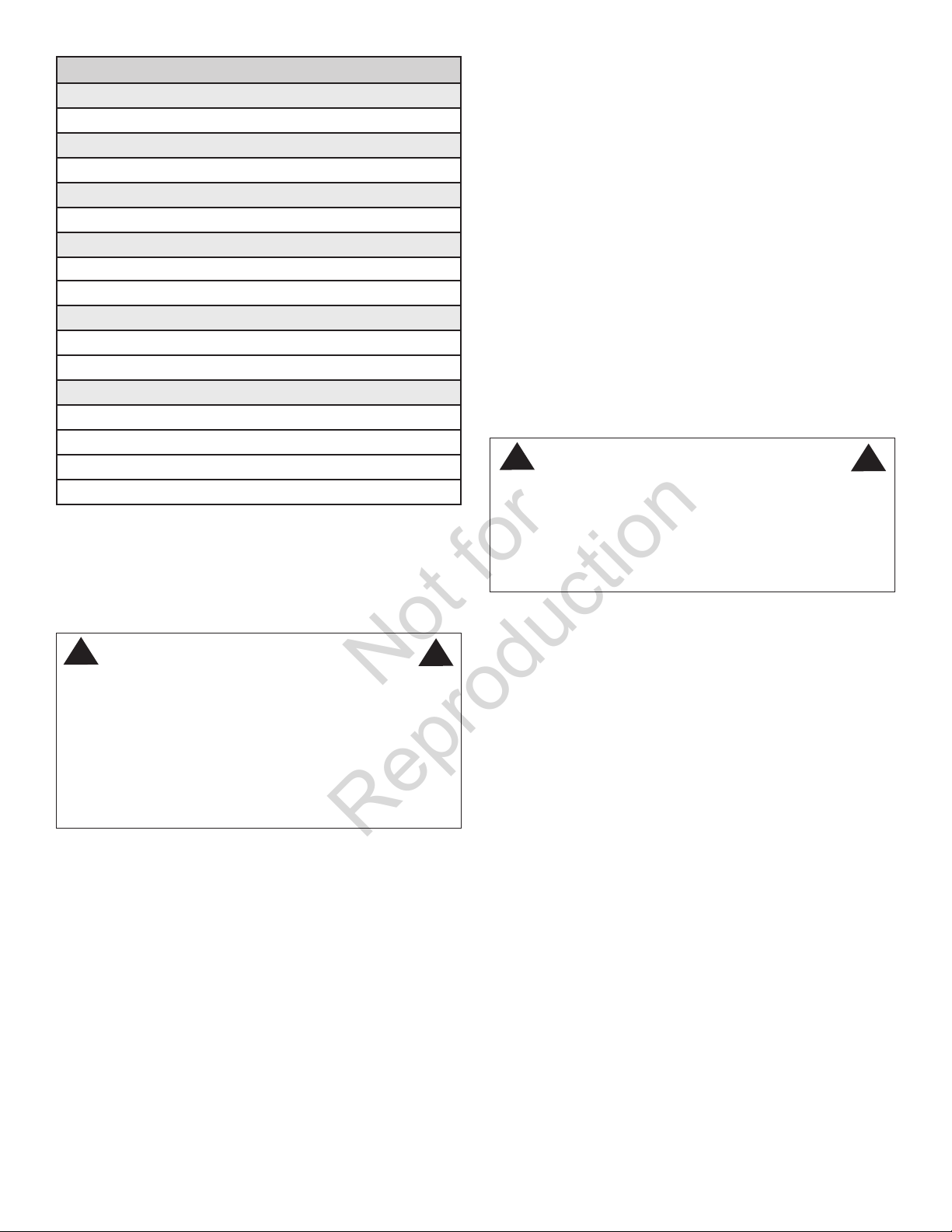

TRACTOR AND MOWER

Every 8 Hours or Daily

Check safety interlock system

Clean debris off tractor and mower deck

Clean debris from engine compartment

Every 25 Hours or Annually *

Check tire pressure

Check mower blade stopping time

Check tractor and mower for loose hardware

Every 50 Hours or Annually *

Clean battery and cables

Check tractor brakes

See Dealer Annually to

Lubricate tractor and mower

Check mower blades **

WARNING

!

!

The mulching cover must remain on the machine at all

times. Do not remove.

2. Raise the mulching cover. Replace the washer and nut

onto the retaining bolt in the deck, tightening securely.

3. Install the discharge deflector (A, Figure 19) to the

mower deck, making sure that the slots (B) in the

deflector fit over the locking tabs (C) on the mulching

cover hinge bracket.

4. Lower the mulching cover.

5. To remove the discharge deflector:

• Raise the mulching cover.

• Lift and remove the discharge deflector from the

mower deck.

• Remove the nut and washer from the retaining bolt in

the deck.

• Lower the mulching cover, securing with the washer

and nut. Tighten securely.

WARNING

!

* Whichever comes first

** Check blades more often in regions with sandy soils or

high dust conditions.

en

19

Page 20

ENGINE

Not for

Reproduction

First 5 Hours

Change engine oil

Every 8 Hours or Daily

Check engine oil level

Every 25 Hours or Annually *

Clean engine air filter and pre-cleaner **

Every 50 Hours or Annually *

Change engine oil

Replace oil filter

Annually

Replace air filter

Replace pre-cleaner

See Dealer Annually to

Inspect muffler and spark arrester

Replace spark plug

Replace fuel filter

Clean engine air cooling system

* Whichever comes first

** Clean more often in dusty conditions or when airborne

debris is present.

Change Oil Filter (if equipped)

Some models are equipped with oil filter. For replacement

intervals, see the Maintenance chart.

1. Drain the oil from the engine. Refer to “Change Engine

Oil”.

2. Remove the oil filter (A, Figure 21) and dispose of

properly.

3. Before you install the new oil filter, lightly lubricate the

oil filter gasket with fresh, clean oil.

4. Install the oil filter by hand until the gasket contacts

the oil filter adapter, then tighten the oil filter 1/2 to 3/4

turns.

5. Add oil. Refer to “How to Check/Add Oil” in the

Operation section.

6. Start and run the engine. As the engine warms up,

check for oil leaks.

7. Stop the engine and check the oil level. It should be at

the top of the full indicator on the dipstick.

Service Air Filter

!

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Never start or run the engine with the air cleaner

assembly (if equipped) or the air filter (if equipped)

removed.

WARNING

!

Engine Maintenance

!

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

WARNING

!

Change Engine Oil

Used oil is a hazardous waste product and must be disposed of properly. Do not discard with household waste.

Check with your local authorities, service center, or dealer

for safe disposal/recycling facilities.

1. Place bricks or wooden blocks under the front wheels

to lower the rear of the engine.

2. Loosen or remove the oil fill cap on the engine.

3. Place a 2 quart minimum capacity container under the

end of the oil drain (Figure 20).

4. Remove or open the oil drain plug (A or B, Figure

20), depending upon the type of oil drain plug the

engine is equipped with.

5. After all the oil has drained, replace or close the

drain plug, and wipe up any oil that may have spilled.

Dispose of used oil properly.

6. Fill the engine with new oil. Refer to “How To Check/

Add Oil” in the Operation Section.

NOTICE: Do not use pressurized air or solvents to clean

the filter. Pressurized air can damage the filter and solvents

will dissolve the filter.

The air filter system uses either a flat or a cylindrical cartridge air filter. Some models are also equipped with a precleaner that can be washed and reused.

Flat Air Filter

1. Pull up on the cover handle (A, Figure 22). Rotate the

cover handle toward the engine and then remove the

cover (B).

2. Remove the pre-cleaner (C, Figure 22), if equipped,

and the filter (D).

3. To loosen debris, gently tap the filter on a hard surface.

If the filter is excessively dirty, replace with a new filter.

4. Wash the pre-cleaner in liquid detergent and water.

Then allow it to thoroughly air dry. Do not oil the precleaner.

5. Assemble the dry pre-cleaner and the filter into the

engine base (E, Figure 22).

6. Align the tabs (F, Figure 22) on the cover with the

slots (G) in the blower housing. Rotate the cover handle back and push down to lock in place.

Cylindrical Cartridge Air Filter

1. Remove the fasteners (A, Figure 23) and the air filter

cover (B).

2. To remove the filter (C, Figure 23), lift the end of the

filter and then pull the filter off the intake (D).

3. Remove the pre-cleaner (E, Figure 23), if equipped,

from the filter.

www.snapper.com20

Page 21

4. To loosen debris, gently tap the filter on a hard surface.

Not for

Reproduction

If the filter is excessively dirty, replace with a new filter.

5. Wash the pre-cleaner in liquid detergent and water.

Then allow it to thoroughly air dry. Do not oil the precleaner.

6. Assemble the dry pre-cleaner to the filter.

7. Install the filter on the intake. Push the end of the filter

into the base as shown. Make sure filter fits securely in

the base.

8. Install air filter cover and secure with fasteners.

Rider Maintenance

!

Once blade is disengaged, it should come to a complete stop in 3 seconds or less. If the blade continues to

rotate after 3 seconds, the blade brake must be adjusted. Return machine to an authorized dealer for adjustment. DO NOT CONTINUE to operate machine until

blade brake is adjusted and functioning properly.

2. If the blade continues to rotate longer than 3 seconds

do not operate the machine. Contact your dealer for

assistance.

WARNING

!

!

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

WARNING

!

Check Mower Blade

1. Follow the WARNING statement found on this page.

2. Check the fuel level in the tank. If over 3/4 full, remove

the tank. Refer to “Removing Fuel Tank”. If 3/4 or less,

proceed to the next step.

3. Carefully stand the Rear Engine Rider on the rear bumper.

!

Remove the battery if the Rear Engine Rider will be left

standing on the rear bumper for longer than 2 hours.

Refer to “Battery Removal”. DO NOT use a cutting

blade that shows signs of excessive wear or damage

on the Rear Engine Rider. Refer to the “Mower Blade

Replacement” for proper blade inspection and service

procedures.

4. Check the torque of the blade mounting bolts (A,

Figure 24). As necessary, torque to 30 to 40 ft. lbs.

5. Check the blade for sharpness, wear and damage.

Refer to “Blade Wear Limits”.

6. Check the blade for straightness. Refer to “Adjusting

Mower Blade”.

DANGER

!

Blade Brake

Service Brake / Park Brake

1. Check the machine brake for proper function:

• Engage the park brake, and push the machine. The

rear tires should skid.

• Drive the machine forward and apply the brake.

The machine should come to a complete stop in

less than 5 ft.

2. If the brakes are not functioning properly, brake

adjustment must be completed before operating the

machine. Contact your authorized dealer.

Safety Interlock System Checks

Perform the following interlock system checks periodically during the operating season. Contact your authorized

Snapper dealer if you have questions.

!

DO NOT operate machine if any safety interlock or

safety device is not in place and functioning properly.

DO NOT attempt to defeat, modify or remove any safety

device.

Engine must not start if:

1. The Clutch/Brake Pedal is not fully depressed OR,

2. The Blade Control is in the “ON” (blades engaged)

position.

Engine should start if:

1. The Blade Control is in the “OFF” (blades disengaged)

position AND,

2. The Clutch/Brake Pedal is fully depressed.

Engine and blades must stop if:

1. The operator rises off of seat with Blade Control in

“ON” (blades engaged) position OR,

2. The operator rises off of seat with Clutch/Brake Pedal

not fully depressed.

WARNING

!

!

The following procedure requires the engine and blades

to be operated. Exercise extreme caution. Clear area of

loose parts & tools first. Only operate blades when seated

in the operator’s seat.

1. Check the blade brake for proper function. The blade

should stop rotating in 3 seconds or less after moving

the blade control lever to the “OFF” position or after

releasing the blade pedals.

WARNING

!

Reverse Lockout Mechanism

Check the function of the Reverse Lockout Mechanism

with the engine off.

1. Depress and hold the blade pedals.

2. Depress and hold the clutch/brake pedal.

3. With Steps 1 and 2 performed, the shift lever must not

go into reverse.

en

21

Page 22

!

Not for

Reproduction

DO NOT operate machine if Reverse Lockout

Mechanism is not functioning properly. Contact your

dealer immediately for assistance.

WARNING

!

Battery Maintenance

Perform battery maintenance as required. Refer to

“Battery”.

Mower Deck Levelness

Check the mower deck for proper level. Adjust as

required. Refer to “Mower Deck Adjustment – Levelness”.

Clean Mower Deck

!

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

1. Check the fuel level in the tank. If over 3/4 full, remove

the tank. Refer to “Removing Fuel Tank”. If 3/4 or less,

proceed to the next step.

2. Carefully stand the Rear Engine Rider on the rear bumper.

3. Clean the underside of the mower deck, removing all

accumulation of grass clippings and debris.

4. Clean the top of the deck, removing all grass clippings

and debris.

WARNING

!

Fuel Filter

IMPORTANT: Service the fuel filter on a COLD ENGINE

ONLY!

IMPORTANT: To stop the flow of fuel, the fuel tank (C,

Figure 25) may be removed from the bracket and set on

the floor so the fuel level will be below the filter. Refer to

“Removing Fuel Tank”.

1. Remove the hose clamps (B, Figure 25) from the fuel

filter (A).

2. Remove the fuel lines from filter. Discard the filter.

3. Install a new fuel filter.

4. Reinstall the fuel tank into the bracket (if removed).

5. Carefully reinstall the fuel clamps.

6. Check the fuel system for leaks.

Lubrication – Grease Fittings

The following components on the Rear Engine Rider are

equipped with grease fittings and require periodic lubrication. Apply General Purpose grease (NLGI No.2) with a

grease gun.

1. Mower Blade Spindle

1. Follow the WARNING statement found on this page.

2. Check the fuel level in tank. If over 3/4 full, remove the

tank. Refer to “Removing Fuel Tank”. If 3/4 or less, proceed to the next step.

3. Carefully stand the Rear Engine Rider on the rear bumper.

4. Lubricate the spindle grease fitting (A, Figure 26) with

three shots of general purpose grease from a grease

gun.

NOTE: Some models are equipped with sealed spindle

bearings, which do not require lubrication.

IMPORTANT: If the Rear Engine Rider will be on its rear

bumper for longer than two hours, remove the battery.

Refer to “Battery Removal”.

2. Front Wheel Bearing

Lubricate the front wheel grease fittings (A, Figure 27)

with five shots of general purpose grease, from a grease

gun.

3. Shift Lever

Lubricate the shift lever grease fitting (A, Figure 28) with

two shots of general purpose grease from a grease gun.

4. Rear Axle Bearing

1. The grease fitting (A, Figure 29) on the left rear axle

bearing requires three shots of general purpose grease

from grease gun.

2. The right rear axle bearing is lubricated by the

differential lubricant and requires no grease.

Lubrication - Mower Deck Linkage

Lubricate all mower deck linkage pivot points with a light

coat of motor oil.

Lubrication - Differential / Chain Case

1. Stand the rear engine rider on its rear bumper and

check the fill/level plug (A, Figure 30) on the differential (B) for cracks and wear. Replace the fill/level plug if

signs of wear are visible.

IMPORTANT: If the Rear Engine Rider will be on its rear

bumper for longer than two hours, remove the battery.

Refer to “Battery Removal”.

2. To check lubricant, remove the fill/level plug and visually inspect for lubricant on the internal parts of the

differential. If no lubricant is visible on the internal parts

of the differential, add transmission grease as needed.

IMPORTANT: Overfilling of the differential with lubricant

will cause lubricant to leak onto drive components of the

Rear Engine Rider.

3. Check the fill/level plug (A, Figure 31) on the chain

case (B) for damage. If signs of wear or cracks are visible, replace with a new plug.

4. To check lubricant in the chain case, remove the fill/

level plug and look for lubricant on the internal components of the chain case. If no lubricant is visible, add

transmission grease as needed.

www.snapper.com22

Page 23

Miscellaneous Items

Not for

Reproduction

In addition to regular maintenance, the following

components of the Rear Engine Rider should be carefully

inspected regularly for wear or damage.

1. All bushings and pivot areas.

2. Check both front wheel king pins.

3. Transmission shift lever and detent.

4. Clutch disc.

5. Clutch yoke.

6. Mower deck linkage and pivot areas.

Replace worn or damaged parts. Use only factory authorized replacement parts or like parts when making repairs.

Removing the Fuel Tank

NOTE: Before removing the fuel tank from the rear engine

rider, move the rider outdoors where fumes can easily dissipate.

1. From the left side of the machine, pull the fuel tank (A,

Figure 32) straight up and away from the fuel tank

bracket (B).

2. Holding the fuel tank, remove the fuel filler cap (C,

Figure 32) and pour any remaining fuel into an

approved container.

Storage

Note: If desired, the Rear Engine Rider can be stored on

the rear bumper.

1. Thoroughly clean the Rear Engine Rider by removing

all grass clippings and debris.

2. Perform maintenance and lubrication as required.

3. Drain the fuel from the fuel tank (unless using a fuel

stabilizer - Refer to “Fuel System”).

4. Start the engine and allow it to run until the engine runs

out of fuel. This allows the carburetor and fuel system

to remain clean during storage.

5. Remove the battery. Refer to “Battery Storage”.

6. Close the vent on the fuel filler cap.

7. If desired, carefully stand the Rear Engine Rider on its

rear bumper in the desired location for storage.

Fuel System

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel

system or on essential carburetor parts. To keep fuel

fresh, use Briggs & Stratton® Advanced Formula Fuel

Treatment & Stabilizer, available wherever Briggs &

Stratton genuine service parts are sold.

For engines equipped with a FRESH START® fuel cap,

use Briggs & Stratton FRESH START® available in a

drip concentrate cartridge.

There is no need to drain gasoline from the engine if a

fuel stabilizer is added according to instructions. Run the

engine for 2 minutes to circulate the stabilizer throughout

the fuel system before storage.

If gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container.

Run the engine until it stops from lack of fuel. The use of a

fuel stabilizer in the storage container is recommended to

maintain freshness.

Engine Adjustments and Repairs

Engine adjustments and/or repairs should be performed by

an authorized dealer.

Mower Deck and Component Adjustments

!

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

The following mower deck and component adjustments

and repairs can be made by the owner. However, if there

is difficulty in achieving these adjustments and repairs, it

is recommended that these repairs be made by an authorized dealer.

WARNING

!

Mower Deck Adjustment (Side-To-Side

Levelness)

Before making deck leveling adjustments, check the tire

pressure. Front tires 15 PSI, rear tires 12 PSI. If tires are

properly inflated and mowing is still uneven, adjust side-toside deck levelness.

1. Place the Rider on a smooth level surface.

2. Turn the engine off and remove the key. Remove the

spark plug wire from the spark plug and secure the

wire away from the plug.

3. Place a piece of angle iron, pipe, or similar object

under the rear center of the deck.

4. Remove the rear hanger chains (A, Figure 34) and

allow rear center of the deck to rest on the angle iron.

5. Measure the distance from the blade tips to the floor.

If the measurement is within 1/8” from side-to-side, the

deck attitude is satisfactory. If difference from side-toside is greater than 1/8”, continue with adjustment.

6. Loosen the hardware (A, Figure 33) that retains the

left side of the blade pedal (B).

7. Move the lift arm (C, Figure 33) up or down as

required until the blade tips are within 1/8” of each

other.

8. Tighten the hardware loosened in Step 6. Recheck

both sides of the deck for correct levelness.

9. Readjust the rear hanger chain pivots (B, Figure 34)

to align with the holes in the support brackets (D).

10.Remove the angle iron, pipe, or similar object, and proceed to check front to rear levelness.

en

23

Page 24

Mower Deck Adjustment (Front-to-Rear

Not for

Reproduction

Levelness)

With the Rear Engine Rider on a smooth, level surface,

rotate the blade until the blade tips are at the front and rear

of the deck. Measure the distance from the blade tips to

the floor (Figure 34). The distance should be the same, or

the rear 1/8” to 1/4” lower than the front. If the rear blade

tip is higher than the front, or is more than 1/4” lower than

the front, proceed with adjustment.

1. Remove the rear hanger chains (A, Figure 34).

2. Turn each hanger pivot (B, Figure 34) the same num-

ber of rotations on the eye-bolt to raise or lower the

rear of the deck.

3. Reinstall the rear hanger chains and measure the

blade tips again.

4. Repeat Steps 1 through 3 until proper levelness is

obtained.

Rear Engine Rider Drive Components

!

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

Service Brake / Park Brake Adjustment

Test the wheel brake on a dry concrete surface. When

properly adjusted, the Rear Engine Rider will stop within 5

feet from fastest speed. If stopping distance is more than 5

feet, the wheel brake should be adjusted as follows:

1. Follow the WARNING statement found on this page.

2. Check the fuel level in tank. If over 3/4 full, remove

tank. Refer to “Removing The Fuel Tank”. If 3/4 or

less, proceed to the next step.

3. Carefully stand the Rear Engine Rider on its rear bumper.

4. Depress the clutch/brake pedal (A, Figure 9) all the

way down. Move and hold the park brake lever (B) in

the “ON” position and release the clutch/brake pedal to

set the park brake.

5. Measure the distance (A, Figure 35) between the

end of the clutch/brake cable (B) and the bottom of

the housing (C). The measurement should be no less

than 1/2” and no greater than 3/4”.

NOTE: The cotter pin, brake spring, and clutch yoke (D, E,

and F, Figure 33) are noted for reference purposes only.

6. If the measurement is less than 1/2” or greater than

3/4”, loosen the two jam-nuts (A, Figure 36). Hold the

clutch/brake cable (B) to the chain case bracket.

7. Adjust the cable up or down using the jam-nuts to

obtain a distance of 1/2” to 3/4” between the end of the

clutch/brake cable (adjustment shown in inset of Figure

WARNING

!

37) and the bottom of the housing.

8. After adjustment is complete, securely tighten the

cable jam-nuts.

9. Retest the wheel brake.

Mower Blade Replacement

!

Wear heavy leather gloves when handling or working

around cutting blades. Blades are extremely sharp and

can cause severe injury. DO NOT use a cutting blade

that shows signs of excessive wear or damage.

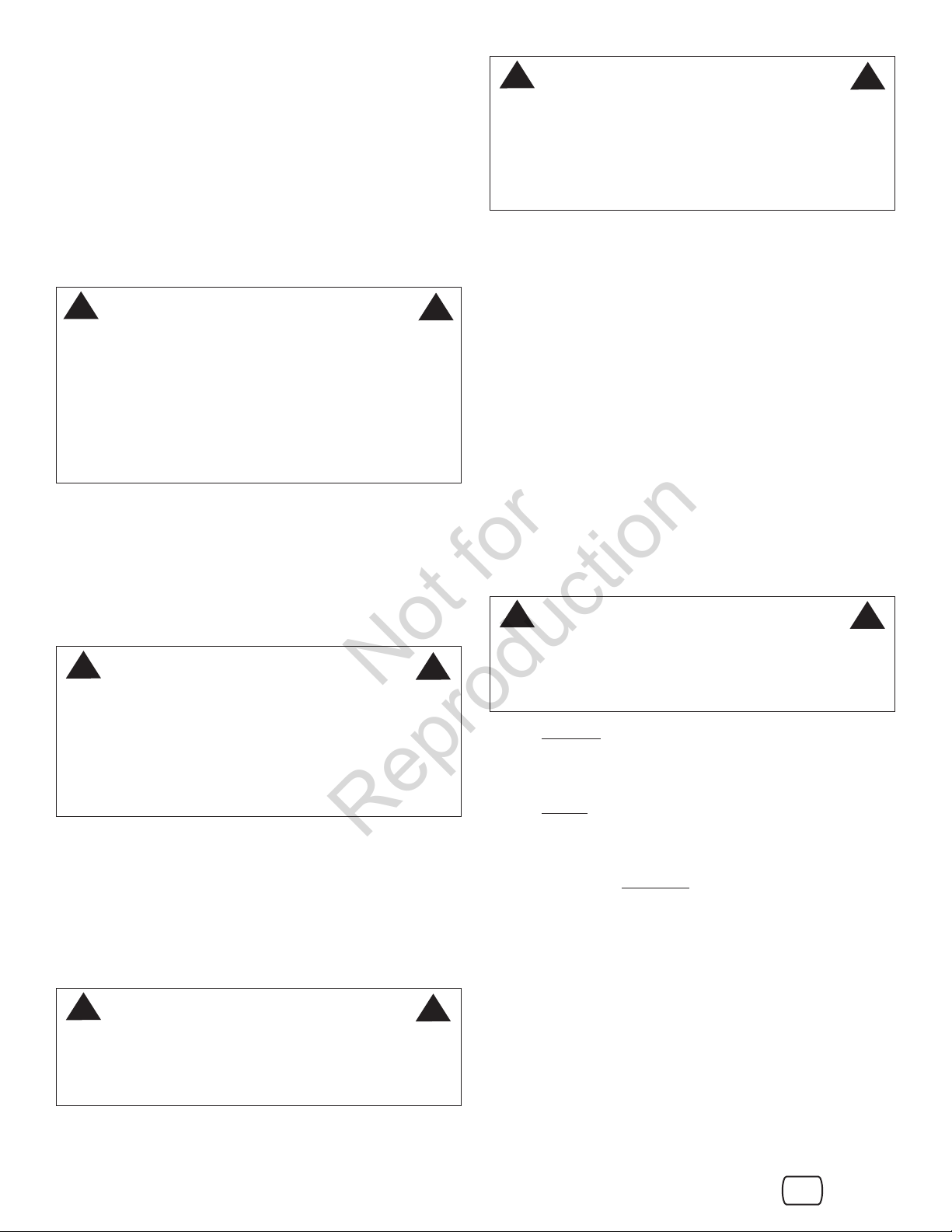

Blade Wear Limits

1. Inspect the blade frequently for signs of excessive

wear or damage (Figure 37):

(A) New blade;

(B) Wear limit (notch starts);

(C) Dangerous condition - do not use on mower!

Replace with new blade.

Blade Sharpening

1. Follow the WARNING statements found on this page.

2. Check the fuel level in the tank. If over 3/4 full, remove

the tank. Refer to “Removing The Fuel Tank”. If 3/4 or

less, proceed to the next step.

3. Carefully stand the Rear Engine Rider on its rear

bumper.

4. Remove the bolts (B, Figure 38), washers (C) and

nuts (D) securing the mower blade (A) to the spindle.

5. Inspect the condition of the blade (Figure 37).

6. If the blade is in good condition, sharpen at 22 to 28

degrees (B, Figure 39). DO NOT sharpen beyond

existing cutting edge (A).

7. Check blade balance after sharpening. If necessary,

correct blade balance by grinding the heavy end of the

blade.

8. Reinstall the blade. Torque the blade mounting bolts to

the recommended range of 30 to 40 ft. lbs.

WARNING

!

Battery

Battery Removal

1. Carefully pull each side of the battery cover (A, Figure

40) away from the ratchet fasteners (B) and remove

the cover.

2. Remove the hardware (A, Figure 41) securing the battery holddown bracket (B), and remove the bracket.

3. Disconnect the BLACK (Negative) cable (C, Figure

42) from the negative battery terminal. Retain the

mounting hardware.

!

Always disconnect the BLACK negative (-) battery cable

first.

4. Disconnect the RED (Positive) cable (A, Figure 42)

from the positive battery terminal. Retain the mounting

hardware.

WARNING

!

www.snapper.com24

Page 25

5. Remove the battery from the battery compartment.

Not for

Reproduction

Battery Installation

1. Slide the battery into the battery compartment.

2. Connect the RED positive (+) cable (A, Figure 42)

to the positive terminal (+) on the battery with the

removed hardware.

!

Always connect the RED positive (+) battery cable

first.

3. Connect the black negative (-) cable (C, Figure 42)

to the negative terminal (-) on the battery with the

removed hardware.

4. Apply a small amount of grease over the terminals to

prevent corrosion.

5. Reinstall the positive terminal cover (B, Figure 42)

over the positive terminal.

6. Reinstall the battery holddown bracket (B, Figure 41),

securing with the removed hardware (A).

7. Reinstall the battery cover (A, Figure 40).

!

Always shield the positive terminal with the positive terminal cover.

WARNING

WARNING

!

!

en

25

Page 26

Troubleshooting

Not for

Reproduction

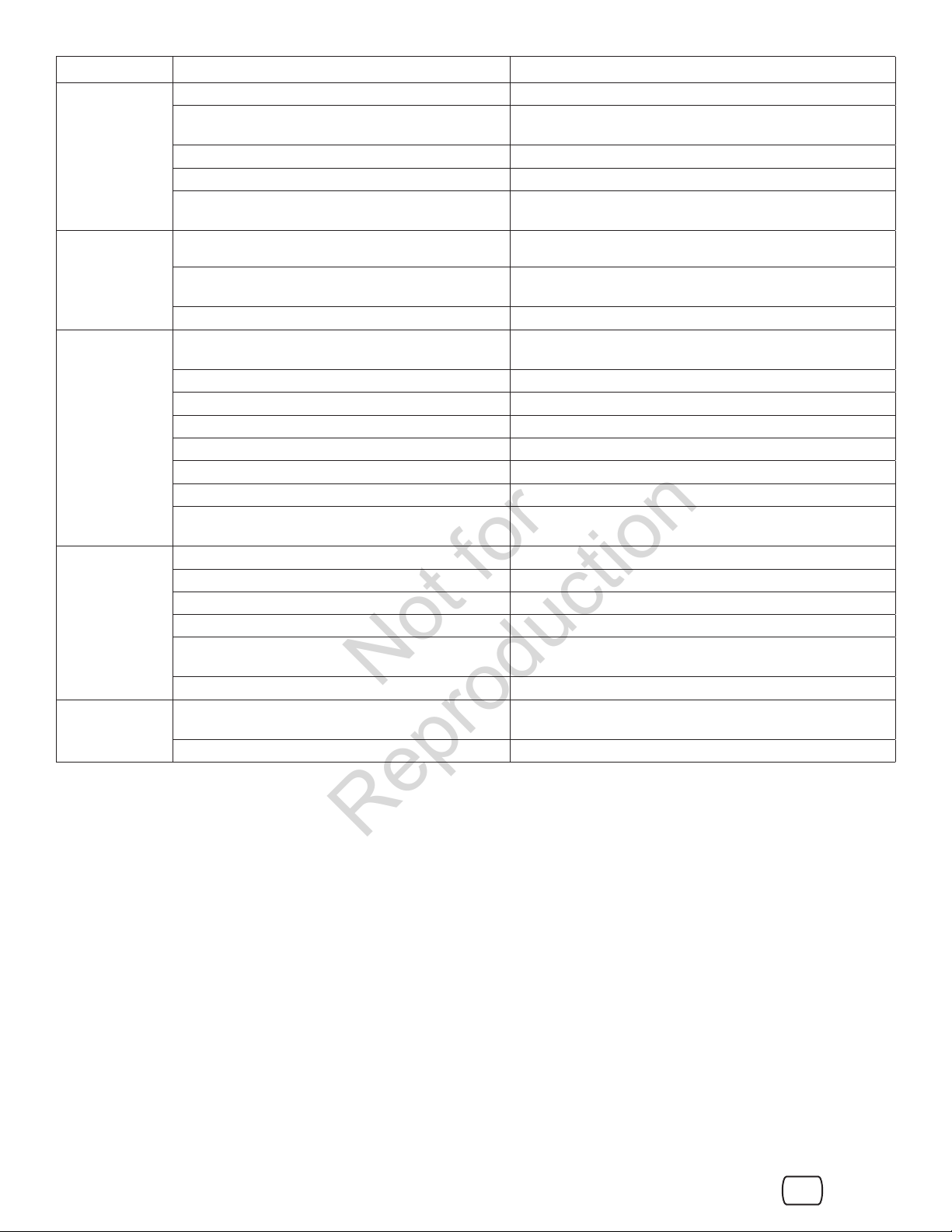

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Engine Will

Not Start

Using Recoil

Starter.

Engine Will

Not Start

Using Electric

Starter.

Engine Stalls

After Running.

Engine Loses

Power.

Engine

Backfires

When Turned

To “STOP”.

Excessive

Vibration.

1. Fuel tank empty. 1. Fill fuel tank with fresh fuel to proper level.

2. Engine needs choking. 2. Move engine speed control to CHOKE position.

3. Spark plug wire disconnected. 3. Place spark plug wire onto spark plug.

4. Faulty parking brake, blade or ignition switch. 4. Contact authorized dealer.

5. Park brake not engaged. 5. Engage park brake.

6. Ignition is in the OFF position. 6. Turn ignition switch to the RUN position.

1. Fuel tank empty. 1. Fill fuel tank with fresh fuel to proper level.

2. Engine needs choking. 2. Move engine speed control to CHOKE position.

3. Spark plug wire disconnected. 3. Place spark plug wire onto spark plug.

4. Faulty parking brake, blade or ignition switch. 4. Contact authorized dealer.

5. Park brake not engaged. 5. Engage park brake.

6. Blown Fuse. 6. Replace with new 20 AMP fuse.

7. Faulty interlock module. 7. Contact authorized dealer.

8. Ignition is in the OFF position. 8. Turn ignition switch to the START position.

9.Battery is weak or dead. 9. Charge or replace with new battery.

10. Battery cables loose, broken disconnected

or corroded.

11. Faulty electric starter or starter solenoid. 11. Contact authorized dealer.

12. Starter cable loose, broken or disconnected. 12. Connect starter cable. If broken, replace with new

13. Electrical wiring harness disconnected or

broken.

1. Operator not in seat. 1. Sit in operator’s seat.

2. Engine speed control in CHOKE position. 2. Move engine speed control to FAST position.

3. Fuel tank empty. 3. Fill fuel tank with fresh fuel to proper level.

4. Engine air pre-cleaner and or air cleaner dirty. 4. Clean free of all debris.

5. Spark plug defective or gap set improperly. 5. Service spark plug.

6. Fuel filter restricted. 6. Replace fuel filter.

7. Water, debris or stale fuel in fuel system. 7. Drain and clean fuel system.

1. Excessive load on engine. 1. Lessen load.

2. Engine air pre-cleaner or air cleaner dirty. 2. Clean or replace filters.

3. Spark plug faulty. 3. Service spark plug.

4. Water, debris or stale fuel in fuel system. 4. Drain and clean fuel system. Replace filter.

5. Debris build up on engine cooling screen. 5. Clean all debris from engine cooling screen.

1. Engine speed control set to FAST. 1. Set engine speed control to SLOW and allow engine

1. Damaged, out of balance or bent mower

blades.

2. Loose blade components. 2. Service and tighten loose parts.

3. Loose or missing air lift (if equipped). 3. Replace air lifts. Tighten to proper torque.

4. Lumpy or frayed belt. 4. Replace belt. Contact authorized dealer.

5. Bent Idler, stationary or spindle pulley. 5. Replace pulley. Contact authorized dealer.

10. Clean and connect battery cables. If broken,

replace with new battery cables.

starter cable.

13. Connect or replace with new wiring harness.

to idle. Then, turn key to “OFF”.

1. Service mower blade(s).

www.snapper.com26

Page 27

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Not for

Reproduction

Rider Will Not

Move Or Loss

of Traction.

Blade(s) Not

Cutting.

Cutting Grass

Improperly.

Poor Grass

Discharge.

Oil Leaking. 1. Leaking chain case or differential plugs. 1. Verify plugs are not cracked & are in good shape.

1. Drive disc worn or damaged. 1. Replace drive disc.

2. Rubber drive disc is not tracking properly on

drive disc.

3. Tapered axle bolt and nut missing. 3. Contact authorized dealer.

4. Axle bearing seized. 4. Contact authorized dealer.

5. Insufficient lubrication in chain case or

transmission/differential.

1. Blade engagement lever in the “OFF” position.

2. Mower belt slipping. 2. Adjust or replace mower belt. Contact authorized

3. Cutting blade is dull, worn or damaged. 3. Sharpen or replace cutting blade.

1. Uneven tire pressure. 1. Bring to proper pressure. 15 PSI (1,03 bar) front tire

2. Cutting height too low or high. 2. Adjust cutting height.

3. Engine speed too slow. 3. Move engine speed control to FAST position.

4. Forward speed too fast. 4. Move transmission shift lever to a slower speed.

5. Terraced cut, side to side. 5. Adjust side to side level.

6. Excessive deck pitch, front to rear. 6. Adjust front to rear level.

7. Cutting blade(s) dull or damaged. 7. Sharpen cutting edges or replace blade(s).

8. Mower belt slipping. 8. Adjust tension or replace mower belt. Contact

1. Engine speed too slow. 1. Move engine speed control to FAST position.

2. Forward speed too fast. 2. Move transmission shift lever to a slower speed.

3. Grass is wet. 3. Mow when grass is dry.

4. Excessively dull, worn or damaged blade(s). 4. Service mower blade.

5. Build up of grass clippings and debris under

deck.

6. Improper blade installed on deck. 6. Install proper blades.

2. Leaking engine block. 2. Contact authorized dealer.

2. Adjust rubber drive disc.

5. Contact authorized dealer.

1. Move lever to the “ON” position.

dealer.

& 12 PSI (0,83 bar) rear tire.

authorized dealer.

5. Clean the underside of deck.

Check gaskets.

en

27

Page 28

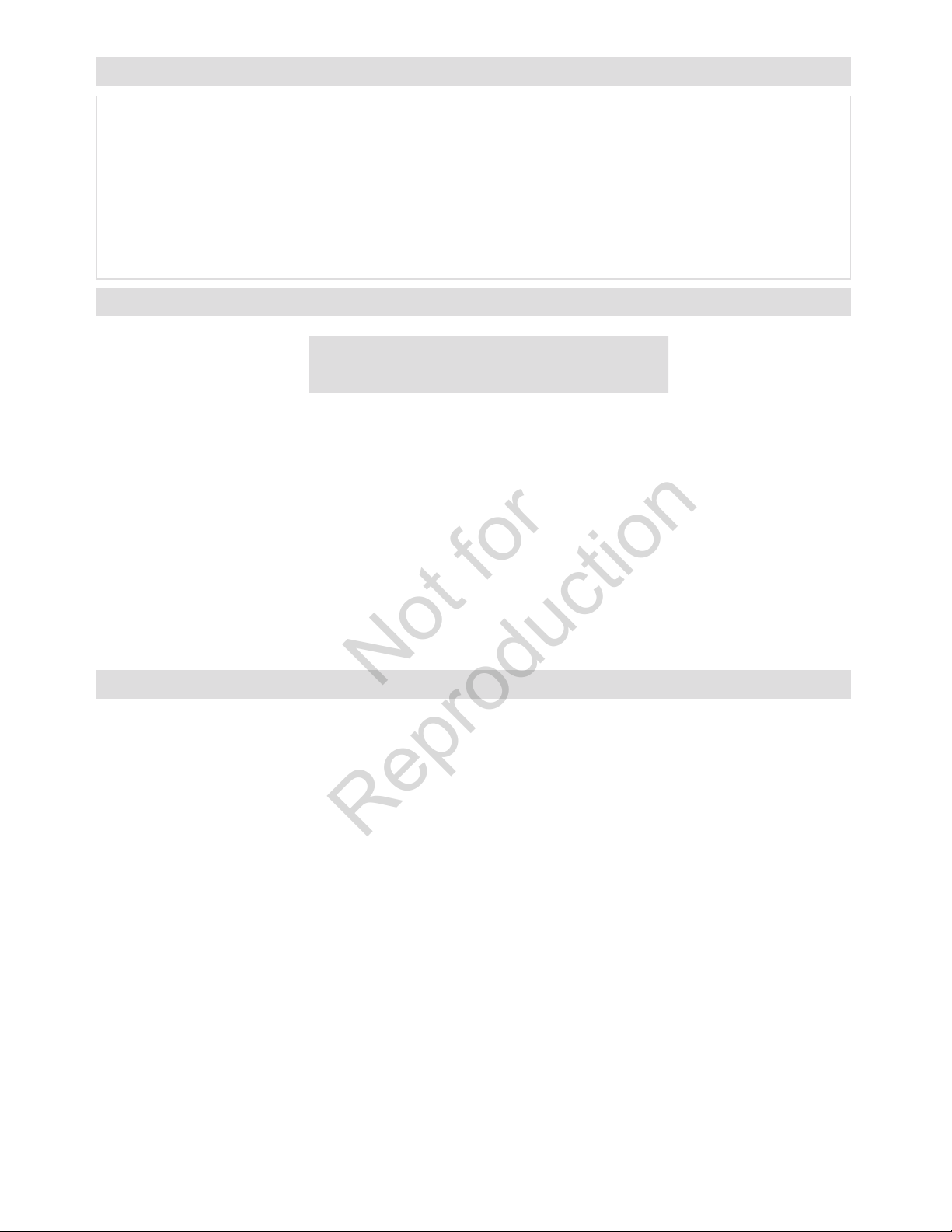

BRIGGS & STRATTON PRODUCTS WARRANTY POLICY January 2014

Not for

Reproduction

LIMITED WARRANTY

Briggs & Stratton warrants that, during the warranty period specified below, it will repair or replace, free of charge, any part that is defective in material or workmanship

or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for and is

subject to the time periods and conditions stated below. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at www.Snapper.

com. The purchaser must contact the Authorized Service Dealer, and then make the product available to the Authorized Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to the warranty

period listed below, or to the extent permitted by law. Liability for incidental or consequential damages are excluded to the extent exclusion is permitted

by l aw. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other rights which vary from state to state or country to country.**

WARRANTY PERIOD

Item Consumer Use Commercial Use

Equipment 36 months 3 months

Engine* 24 months

Battery (if equipped) 12 months 12 months

* Applies to Briggs & Stratton engines only. Warranty coverage of non-Briggs & Stratton engines is provided by that engine manufacturer. Emissions-related components

are covered by the Emissions Warranty Statement.

** In Australia - Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be

of acceptable quality and the failure does not amount to a major failure. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at

BRIGGSandSTRATTON.COM, or by calling 1300 274 447, or by emailing or writing to salesenquires@briggsandstratton.com.au, Briggs & Stratton Australia Pty Ltd, 1

Moorebank Avenue, NSW, Australia, 2170.

The warranty period begins on the date of purchase by the first retail or commercial consumer. “Consumer use” means personal residential household use by a retail

consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes. Once a product has experienced commercial use, it

shall thereafter be considered as a commercial use product for purposes of this warranty.

To ensure prompt and complete warranty coverage, register your product at the website shown above or at www.onlineproductregistration.com, or mail the completed

registration card (if provided), or call 1-800-743-4115 (in USA).

Save your proof of purchase receipt. If you do not provide proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the product

will be used to determine the warranty period. Product registration is not required to obtain warranty service on Briggs & Stratton products..

12 months

ABOUT YOUR WARRANTY

Warranty service is available only through Snapper Authorized Service Dealers. This warranty covers only defects in materials or workmanship. It does not cover damage

caused by improper use or abuse, improper maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator’s Manual. Using the product in a way not described in the Operator’s

Manual or using the product after it has been damaged will not be covered under this warranty. Warranty coverage will also not be provided if the serial number on the

product has been removed or the product has been altered or modified in any way, or if the product has evidence of abuse such as impact damage or water/chemical

corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules provided in the Operator’s Manual, and serviced or

repaired using genuine Briggs & Stratton parts or equivalent. Damage caused by lack of maintenance or use of non-original parts is not covered by warranty.