Page 1

Workshop manual

Rider 11, Rider 13,

Rider 11 Bio, Rider 13 Bio,

Rider 16

English

Page 2

Svenska – 31

Page 3

Workshop manual

Rider 11, Rider 13

Rider 11 Bio, Rider 13 Bio

Rider 16

Contents

Safety regulations ............................................... 2

General instructions ......................................... 2

Special instructions .......................................... 2

Special tools ........................................................3

Technical data ..................................................... 4

Tightening moments.........................................4

Play .................................................................. 4

Mowing deck .................................................... 5

Control points ................................................... 5

Delivery and dealer service ................................ 7

Maintenance schedule ..................................... 9

Delivery measures ............................................ 10

To our dealer .................................................. 10

Packaging and unpacking .............................. 10

Parts enclosed in packaging .......................... 10

Battery ............................................................ 11

Steering wheel ............................................... 12

Tow plate ........................................................ 12

Oil levels ........................................................ 12

Wheels ........................................................... 13

Checking and adjusting of the mowing

deck’s ground pressure and parallelism ........ 13

Test running ................................................... 14

Speed regulator ............................................. 15

Administration ................................................ 15

Design and function.......................................... 16

General .......................................................... 16

Serial number ................................................. 17

Engine ............................................................ 18

Steering .......................................................... 19

Driving ............................................................ 20

Mowing deck .................................................. 20

Reparation instructions .................................... 23

Removing engine ........................................... 23

Replacing engine ........................................... 25

Fuel tank ........................................................ 27

Changing engine oil ....................................... 28

Checking and adjusting steering wires .......... 28

Replacing steering wires ................................ 29

Removal/installation of steering axle ............. 29

Removal/installation of wire wheel ................. 30

Checking and adjusting brake wire ................ 31

Checking and adjusting gear control .............. 32

Checking and adjusting freewheel clutch ....... 32

Checking and adjusting throttle control .......... 33

Replacing articulated steering bearing ........... 33

Removal of swing axle ................................... 35

Replacing bushings ........................................ 35

Installation of swing axle ................................ 36

Removal/installation of gear box .................... 37

Removal/installation of hydrostatic

transmission ................................................... 37

Replacing hydrostat. trans. axle seals ........... 38

Input axle .................................................. 38

Outgoing axles ..........................................39

Replacing hydrostatic transmission wire ........ 40

Bleeding hydrostatic transmission oil system 44

Adjustment of transmission neutral position .. 44

Transmission maintenance ............................ 45

Oil change ................................................. 45

Removal of belt .............................................. 46

Checking and adjusting cutting unit ground

pressure ......................................................... 47

Checking and adjusting parallelism of the

mowing deck .................................................. 47

Adjusting cutting height area .......................... 49

Adjusting cutting height .................................. 49

Removing the cutting unit .............................. 50

To leave the service position .......................... 51

Dismantling the cutting unit ............................ 52

Replacing cutting unit belts ............................ 53

Replacing belt on BioClip 103 and

Combi 103................................................. 53

Replacing belt on BioClip 90 ..................... 54

Belt replacement on mowing deck with

side- or rear discharge BioClip 112 and

Combi 112 ................................................. 54

Replacing breakpin ........................................ 55

Removal of blades with bearings ................... 55

Grinding and balancing of blades .................. 57

Electrical system ............................................... 58

Circuit diagram Rider 11 ................................ 58

Circuit diagram Rider 13 and Rider 13 Bio .... 59

Circuit diagram Rider 16 ................................ 60

Inspection of safety system ............................ 61

Troubleshooting chart

English – 1

Page 4

Safety regulations

General instructions

The workshop handbook is written for personnel who

are assumed to have general ride-on mower reparation and service know-how.

The workshop where the ride-on mower is repaired

should be equipped with safety devices in

accordance with local regulations.

No-one should attempt to repair the ride-on mower

without having first read and understood the contents

of this handbook.

The machine is tested and approved only with the

equipment originally provided or recommended by

the manufacturer.

The below-mentioned boxes are included in this

workshop handbook, as is appropriate.

WARNING!

The warning box indicates a

risk of injury to persons if the

instructions are not followed.

Special instructions

The fuel used in the ride-on mower has the

following hazardous characteristics:

• Toxic fluid and fumes

• Can cause eye and skin complaints

• Can cause breathing difficulties

• Highly flammable

When using compressed air, do not direct the

compressed air stream towards your, or anybody

else's, body. Air can be forced into the blood

stream, thereby constituting a danger to life .

Use eye protection when working with tensioned

springs.

Use hearing protectors when test driving.

After test driving, do not touch the silencer before it

has cooled down. Risk of burn injuries. This

especially applies if the ride-on mower is equipped

with a catalytic converter. If consumed, the lining on

and in the catalytic converter element is dangerous

to health. Use protective gloves when working with

the catalytic converter/silencer.

IMPORTANT INFORMATION

This box indicates a risk of damage to the

material if the instructions are not

followed.

The blades are sharp and can cause cutting

injuries. Always use protective gloves when you are

handling the blades.

Use protective glasses when working with the

mowing deck. If the belt's tension spring comes off

and flies upwards, this can cause injury to persons.

Use eye protection when working with the battery

with the plugs removed. Be extra careful when

handling battery acid. Spilling acid on the skin can

cause severe burn injuries. If acid is spilt on the

skin, rinse immediately with water. If acid gets into

the eyes, this can cause blindness, contact a

doctor.

Be careful with the maintenance of the battery.

Explosive gas is formed in the battery. Never

handle the battery when smoking or in the vicinity of

naked flames or sparks. Otherwise, the battery can

explode and cause severe injuries.

IMPORTANT INFORMATION

Waste oil and old filters shall be handled

as hazardous waste.

2 – English

Page 5

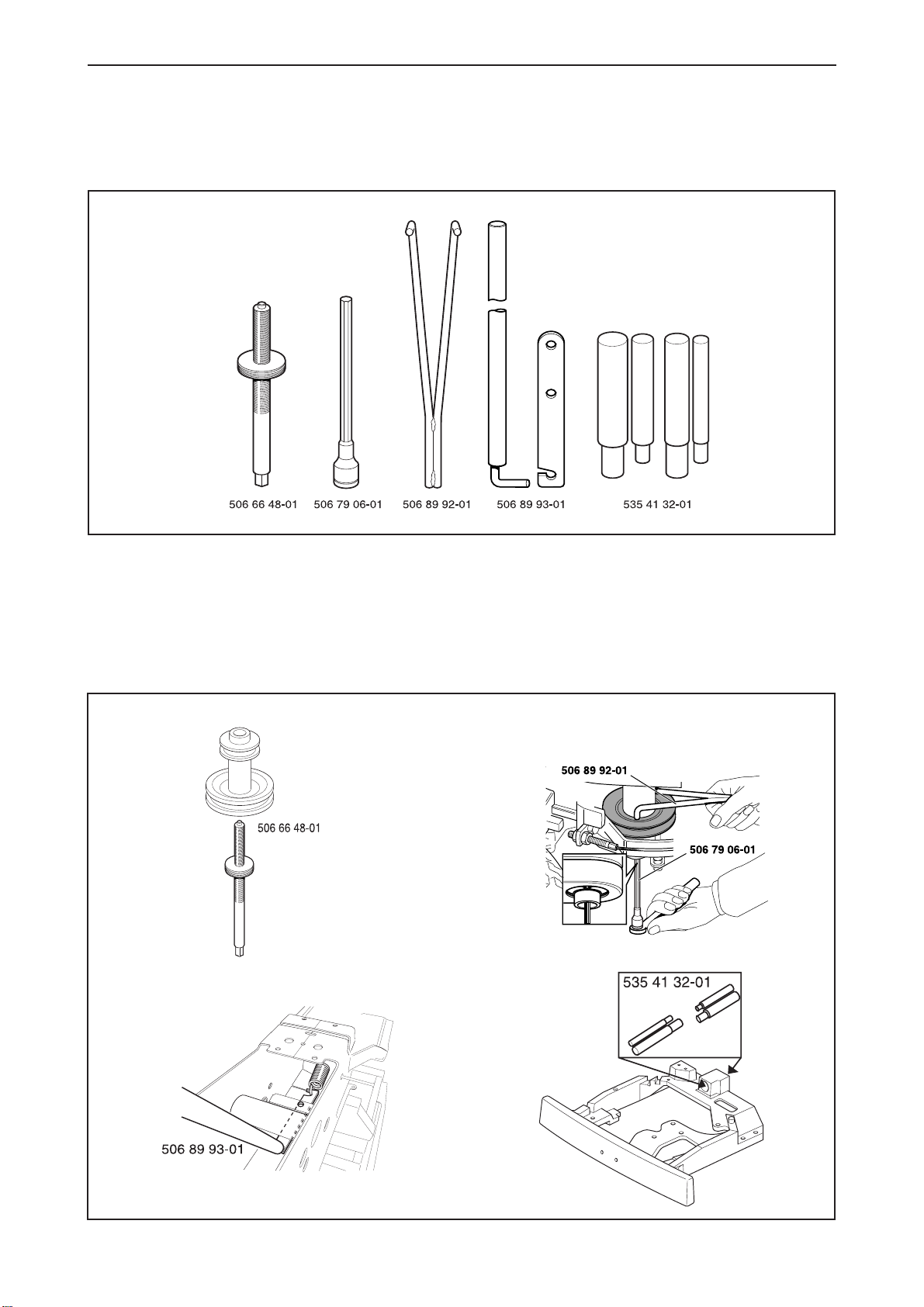

Special tools

The following special tools are used when working on the ride-on mower.

Special tools for the engine and transmission are specified in resp. Workshop Manuals.

506 66 48-01 Puller for engine pulley.

506 79 06-01 Ball-ended Allen key 3/8" to unscrew the engine pulley socket head cap screw (Briggs &

Stratton).

506 89 92-01 Counter-hold for engine belt pulley.

506 89 93-01 Tool for the articulation spring.

535 41 32-01 Set of drifts for bushings on the swing axle.

English – 3

Page 6

Technical data

Dimensions: Rider 11 Rider 13

Length 2 090 mm/6,85 ft 2 000 mm/6,56 ft

Width 880 mm/2,89 ft 900 mm/2,95 ft

Height (over steering wheel) 1 070 mm/3,52 ft 1 060 m/3,48 ft

Weight 197 kg/433 lb 190 kg/419 lb

Track front 720 mm/2,36 ft 625 mm/2,05 ft

Track rear 620 mm/2,04 ft 625 mm/2,05 ft

Wheel base 860 mm/2,81 ft 860 mm/2,81 ft

Tyre size 16 x 6.50 x 8 16 x 6.50 x 8

Air pressure 60 kPa/8,5 PSI 60 kPa/8,5 PSI

Max. gradient 15° 15°

Engine: Rider 11 Rider 13

Manufacture Briggs & Stratton Briggs & Stratton

Model 28N707 286707

Power 7,7/10,5 kW/hp 9,2/12,5 kW/hp

Displacement 362 cm

Fuel min. 85 octane unleaded min. 85 octane unleaded

Tank capacity 7 litres/7,4 USqt 7 litres/7,4 USqt

Oil SAE 30 or SAE 10W/30 SAE 30 or SAE 10W/30

class SF-CC class SF-CC

Oil capacity 1,4 litres/1,5 USqt 1,4 litres/1,5 USqt

3

465 cm

3

Gearbox: Rider 11 Rider 13

Manufacture Peerless MST 205 Tuff Torq K46

Oil SAE 10W/30 class SF-CC

Oil capacity 2,2 litres/2,35 USqt

Gears, forwards 5

Gears, reverse 1

Electrical system Rider 11 Rider 13

Type 12 V, negative earth 12 V, negative earth

Battery 12 V, 24 Ah 12 V, 24 Ah

Main fuse Flat pin yoke 15 A Flat pin yoke 15 A

Spark plug Champion CJ8 or J8 Champion CJ8 or J8

Spark plug gap 0,75 mm/0,030" 0,75 mm/0,030"

Tightening moments

Carrier steering 5–10 Nm 3,5-7 lbft

Pulley steering wire 20–30 Nm 14-21 lbft

Belt wheel 35–40 Nm 25-28 lbft

Blades 45–50 Nm 32-36 lbft

Blade bearings 20–25 Nm 14-18 lbft

Belt tensioner wheel 15–25 Nm 10-18 lbft

Holder screws, engine 20–25 Nm 14-18 lbft

Holder screws, gear box 20–25 Nm 14-18 lbft

Engine pulley 70–80 Nm 50-56 lbft

Play

Clutch wire R 11: 8–10 mm

(5/16" - 3/8")

Brake control lever against stop

bolt R 11: 0–1 mm

(0 - 0.040")

Brake control lever R 11: 7–9 mm

(1/4" - 3/8")

Brake wires R13, R16: 1 mm

(0.040")

Wires, hydrostatic transmission

pedals R13, R16: 0 mm

4 – English

Page 7

Dimensions: Rider 16

Length 2 000 mm/6,56 ft

Width 900 mm/2,95 ft

Height (over steering wheel) 1 060 mm/3,48 ft

Weight 208 kg/459 lb

Track front 625 mm/2,05 ft

Track rear 625 mm/2,05 ft

Wheel base 860 mm/2,81 ft

Tyre size 16 x 6.50 x 8

Air pressure 60 kPa/8,5 PSI

Max. gradient 15°

Engine: Rider 16

Manufacture Briggs & Stratton

Model - 2002 28N707

Model 2003 - 282H070110E1

Power 11,4/15,5 kW/hp

Displacement 465 cm3/28,42 cu inch

Fuel min 85 octane unleaded

Tank capacity 7 litres/7,4 USqt

Oil mineral-2002 SAE 30 or 10W/30 class CD-CF

Oil synthetic 2003 - SAE 5W/30 or 10W/30 class SJ-CF

Oil mineral 2003 - or SAE 30 class SF-CC

Oil capacity 1,4 litres/1,5 USqt

Technical data

Gearbox: Rider 16

Manufacture Tuff Torq K 46

Oil SAE 10W/30 class SF-CC

Oil capacity 2,2 litres/2,35 USqt

Electrical system Rider 16

Type 12 V, negative earth

Battery 12 V, 24 Ah

Main fuse Flat pin yoke 15 A

Spark plug - 2002 Champion CJ8 or J8

Spark plug 2003 - Champion QC12YC

Spark plug gap 0,75 mm/0,030"

Mowing deck: Rear ejector 85 Rear ejector 97 Side ejector 97 Bio 90 Bio 103

Cutting width 850 mm 970 mm 970 mm 900 mm 1 030 mm

Cutting height 40-90 mm 40-90 mm 40-80 mm 45-95 mm 45-95 mm

Blade length 304 mm 350 mm 350 mm 480 mm 410 mm

Noise level 100 dB(A) 100 dB(A) 100 dB(A) 100 dB(A) 100 dB(A)

Weight 29,0 kg 48,0 kg 45,0 kg 39,0 kg 47,0 kg

Overall width 950 mm 1 075 mm 1 300 mm 1 000 mm 1 115 mm

Mowing deck: BioClip 112 Combi 103 Combi 112

Cutting width 1 200 mm 1 030 mm 1 220 mm

Cutting height 40-90 mm 45-95 mm 40-90 mm

Blade length 420 mm 410 mm 420 mm

Noise level 100 dB(A) 100 dB(A) 100 dB(A)

Weight 50,0 kg 47,0 kg 52,0 kg

Overall width 1 230 mm 1 115 mm 1 230 mm

English – 5

Page 8

Technical data

Control points

Mowing deck parallelism with cutting height in pos. 1: ± 2 mm ± 0,079"

Cutting height control in pos. 1: Rider 11 = 37 ± 2 mm 1,46" ± 0,079"

Bio = 45 ± 2 mm 1,77" ± 0,079"

Other = 40 ± 2 mm 1,57" ± 0,079"

Synchronous transmission belt tension Bio 103 version 1,

Combi 103: Automatic adjustment

Synchronous transmission belt tension Bio 103 version 2 at

10 N force, impression: 7 mm 1/4"

Synchronous transmission belt tension Bio 90 at 7 N force,

impression: 8 mm 5/16"

Dist. between support plate and drive belt: 3–6 mm 1/8" - 1/4"

Distance belt tensioner control lever

and belt guide, disengaged unit: 17 ± 5 mm 7/16" ± 3/16"

6 – English

Page 9

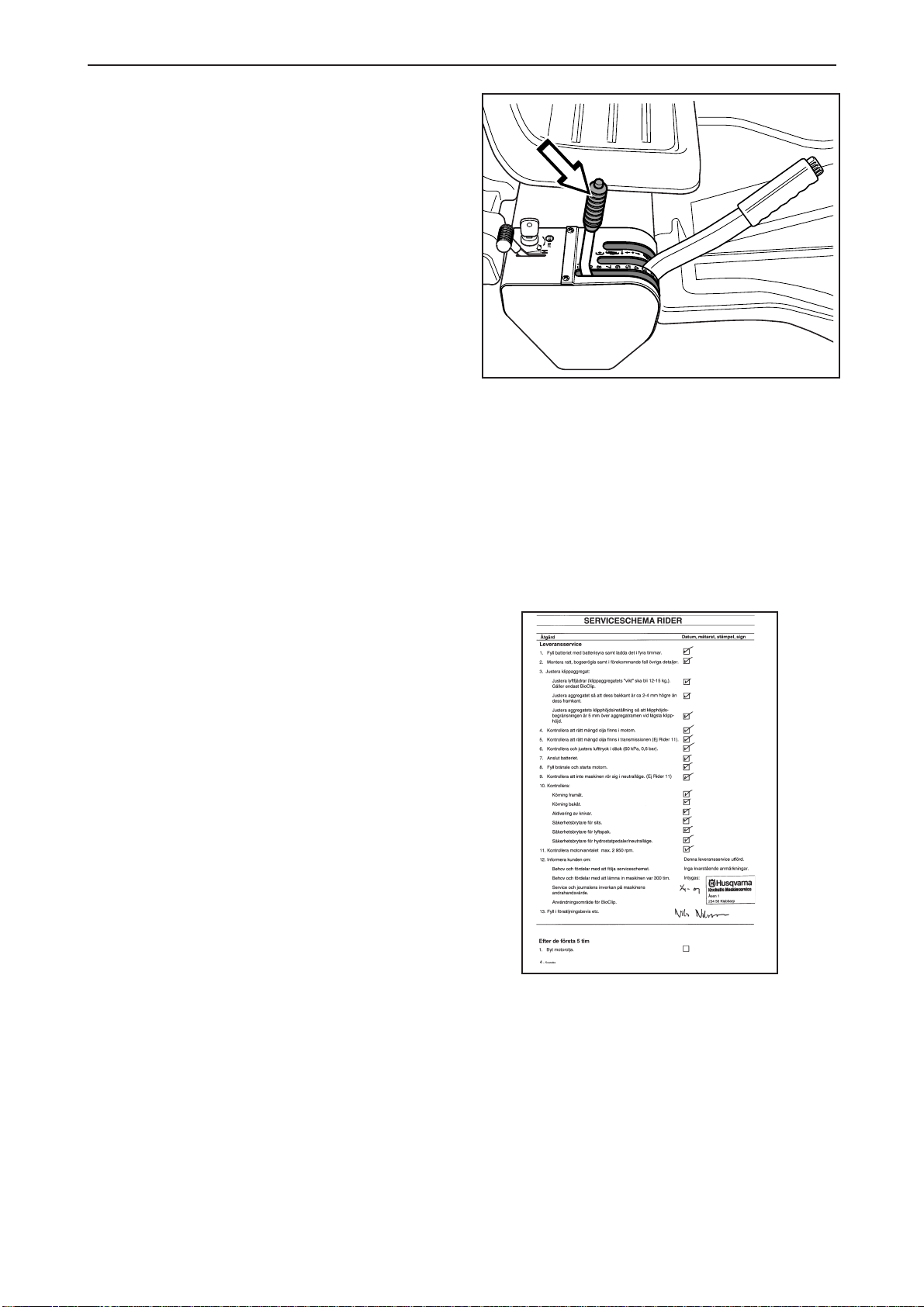

Delivery and dealer service

Pre-delivery service

1. Top up battery with acid and recharge for four hours.

2. Fit the steering wheel, tow plate, and where appropriate other parts.

3. Adjust cutting unit:

Adjust lift springs (effective weight of cutting unit should be

12–15 kg (26,5-33 lb), or set to maximum lift if brush is to be fitted). (Only applies to BioClip and

Combi.)

Adjust cutting unit so that rear edge is about 2–4 mm (1/8") higher than front edge.

Adjust cutting unit height setting so that cutting height limit is 5 mm (3/16") above the frame of the unit

at the lowest cutting height.

4. Check that engine has correct amount of oil.

5. Check that the right amount of oil is in the transmission. (Not Rider 11)

6. Check and adjust tyre pressure (60 kPa/0,6 bar/8,5 PSI).

7. Connect battery.

8. Fill with fuel and start engine.

9. Check that machine does not move in neutral. (Not Rider 11)

10. Check:

Forward drive.

Reverse drive.

Operation of blades.

Seat safety switch.

Lift lever safety switch.

11. Check engine revs 2 900 - 3 100 rpm.

Rider 16, 2003- model, 2 800-3 000 rpm.

12. Tell customer about:

Need and benefits of following the service schedule.

Need and benefits of having machine serviced every 300 hours.

The effects of maintenance on the machine’s second-hand value.

Applications for BioClip and Combi.

13. Complete proof of sale, etc.

After first 5 hours

1. Change engine oil.

English – 7

Page 10

Delivery and dealer service

Dealer service

25 hours service

1. Change the engine oil on the side-valve engine

(With high load and temperature on the

overhead-valve engine).

2. Clean/replace the airfilter’s pre-filter or oil-foam

element, if fitted. (More frequent intervals in

dusty operating conditions.)

3. Clean/replace the air filter’s filter cartridge (25

hours, 100 hours if pre-filter is fitted).

(More frequent intervals in dusty operating

conditions.)

4. Check the tyre pressures.

5. Check the mower deck (visual inspection)

6. Lubricate the belt tensioner.

7. Lubricate joints and axles.

8. Adjust the brake (Rider 11).

9. Check the V-belts.

100 hours service

1. Carry out 25 hours service as above.

2. Carry out 50 hours service as above.

3. Replace the pre-filter and filter cartridge in the

air filter.

4. Replace the fuel filter in the pipe.

5. Clean/replace the spark plug.

300 hours service

1. Inspect the machine. Reach agreement with the

customer about which additional work should be

carried out.

2. Carry out 25 hours service as above.

3. Carry out 50 hours service as above.

4. Carry out 100 hours service as above.

5. Check the valve clearance on the engine.

10. Clean the engine’s cooling air intake.

11. Check/clean the hydrostatic transmission

gear’s cooling fins.

50 hours service

1. Carry out 25 hours service as above.

2. Change engine oil.

3. Check the oil level in the transmission.

(Rider 13, 16).

4. Check/adjust the parking brake.

(Rider 13, 16).

5. Check/adjust the throttle wire.

6. Clean the cooling fins on the engine and

transmission.

7. Check/adjust the settings on the mowing deck.

8. Inspect the flame guard/spark arrester.

(extra equipment)

At least once a season

1. Change the engine oil (25/50 hours).

2. Replace the pre-filter in the air filter.

3. Replace the filter cartridge in the air filter.

4. Check/adjust the settings on the mowing deck.

5. Adjust the parking brake.

6. Inspect the flame guard/spark arrester (extra

equipment).

7. Clean/replace the spark plug.

8. Replace the fuel filter in the pipe.

9. Clean the cooling fins on the engine and transmission.

10. Check the valve clearance on the engine.

11. 300 hours service should be carried out by an

authorised service workshop.

8 – English

Page 11

Delivery and dealer service

Maintenance schedule

The following is a list of the maintenance which should be conducted on the machine. Most of the points that

are not covered by this workshop manual are covered by the operator’s manual.

Maintenance

Page

Daily

maintenance

before

starting

Maintenance interval in

hours

25

50

100

Check the oil level in the engine 12 ●

Check the engine’s cooling air intake - ▼

Check the fuel pump’s air filter - ▼

Check the steering wires 29 ●

Check the brakes 31 ●

Check the battery 11 ●

Check the safety system 61 ●

Check the screws and nuts - ❍

Check if there is any fuel or oil leakage - ❍

Clean around the silencer

Change the engine oil side-valve engine

1)

Change the engine oil overhead-valve engine

Clean the air filter’s pre-filter

2)

28 ●

1)

28 ●

- ▼

1)

1)

1)

●

Check the mower deck 47 ●

Check the tyre pressures (60 kPa) 13 ●

Lubricate the belt tensioner

Lubricate joints and axles

3)

3)

- ▼

- ▼

Adjust the brakes, Rider 11 31 ●

Check the V-belts - ❍

Check the transmission’s cooling fins,

Rider 13 and Rider 16 - ❍

Check the transmission’s oil level,

Rider 13 and Rider 16 44 ●

Adjust the brakes, Rider 13 and Rider 16 31 ●

Check and adjust the throttle wire 26 ●

Clean the cooling fins on the engine and transmission

Replace the air filter’s pre-filter and paper filter

2)

2,4)

- ❍

- ▼

Replace the fuel filter - ▼

Replace the spark plug 8 ▼

1)

First change after 5 hours. Replace after every 25 hours with heavy loads and high temperatures. 2) Cleaning and replacing should be

carried out more frequently in dusty conditions. 3) The machine should be lubricated twice a week if used daily. 4) Carried out by

authorised service workshop.

● = Described in this Workshop Manual.

❍ = Not described in this Workshop Manual.

▼ = Described in the Operating Instructions.

WARNING!

No service procedures must be conducted on the engine or cutting unit unless:

• The engine is switched off.

• The ignition key is removed.

• The parking brake is applied.

• The cutting unit is disengaged.

• The ignition cables are removed

from the plugs.

English – 9

Page 12

Delivery measures

To our dealer

Well-performed delivery service is the first step to a

functioning aftermarket. A functioning aftermarket is

in everybody’s interest:

• The customer is satisfied with their Rider. He/she

knows where to go to get help if problems occur.

• You have a regular customer, who recommends

you and your company to other potential

customers.

• In this way we build our trademark together, and

take joint responsibility for our products and

customers.

Make sure the paper work is in good order.

Fill in the warranty and delivery documents etc. and

make sure that the customer gets the right

Operating Instructions for their machine.

Keep a customer register so that in future you can

see which machines customers have, including all

the serial numbers. This register will benefit you

when ordering spare parts and for future marketing.

In conjunction with the delivery you should also

give the customer the information required to

ensure the safe handling and care of their machine.

Pay special attention to informing the customer

about:

Packaging and unpacking

On delivery from the factory the Rider is normally

packed in special packaging. This consists of a

wooden bottom board with a top part consisting of

heavy-duty cardboard held together by plastic film.

WARNING!

Handle the transport box

carefully. Keep the goods as level

as possible. Use long forks when

lifting from the short side.

The bottom board is provided with pallet feet and

the goods can be handled with a normal fork-lift

truck from the long side. To keep the goods as level

as possible, two men should help the truck driver.

Lift the machine and drive the truck carefully.

Undo the plastic film and lift off the cardboard

sections. The Rider is placed on the bottom board,

braked and secured with wooden blocks.

Check that there is no transport damage after

removing the packaging. Report any damage to the

transport company in accordance with the standard

routines.

The packaging should not be returned.

• Safety instructions.

• Controls. Emphasise that one does not push in

the reversing lock on Rider 11 when engaging

the neutral position (start lock function).

• Checking of oil levels. Replenishing of oil, and

which type of oil is required.

• First oil change after the running-in period.

• The need for, and advantages of, following the

service schedule and regularly handing in their

Rider for service.

• Which fuel should be used.

• Mowing tips to get good results. Applications for

BioClip.

• Which accessories are available for the type of

Rider in question.

• Warranty regulations.

• Your company, and who the customer can turn to

if problems occur.

Lifting from the short side requires long pallet forks,

see diagram.

Parts enclosed in packaging, Rider

The following parts are enclosed in the transport box:

Number Part

1 Steering wheel with steering column tube

1 Socket head cap screw steering column

tube

1 Lock nut steering column tube

2 Support rollers (BioClip)

6 Battery plugs

1 Operating Instructions

1 Operating and Maintenance

Instructions Briggs & Stratton

4 Wheels (certain markets)

10 – English

Page 13

Battery

WARNING!

Measures for contact with acid

External: Rinse thoroughly with water.

Internal: Drink large quantities of water or

milk. Contact a doctor as soon as

possible.

Eyes: Rinse thoroughly with water.

Contact a doctor as soon asap.

The battery gives off explosive gas. Sparks,

naked flames and cigarettes must absolutely

not be in the near vicinity of the battery.

The battery is delivered dry-charged from the

factory. The cells are fitted with sealing film. The

battery plugs are packed in a plastic bag.

• Fill the battery cells slowly with battery acid to

the max. level mark on the battery container.

Delivery measures

• Wait 20 minutes and top up with battery acid if

necessary.

• Charge the battery with 12 V max. 6 A for 4

hours.

• Check the electrolyte level and top up if

necessary with distilled water to the top level

marks on the battery container.

Put the battery in position.

Connect the battery with the screws and nuts fitted

on the battery. Brace the screws when fitting to

avoid exposing the terminals to strain.

• Black cable is connected to -.

• Red cable is connected to +.

Make sure the cables do not rub against the

material.

Fit the cover over the battery and tighten the strap.

English – 11

Page 14

Delivery measures

Steering wheel

• Fit the steering wheel with the steering column

tube on the steering shaft.

• Screw in the socket head cap screw so that it

goes in the slot on the steering shaft. Work on

the steering wheel and tighten the socket head

cap screw so that it bottoms in the slot.

• Fit the lock nut on the socket head cap screw.

Tow plate

The tow plate is fitted the “wrong way round” at the

factory for transport reasons. Fit the tow plate on

the rear bumper as shown in the diagram.

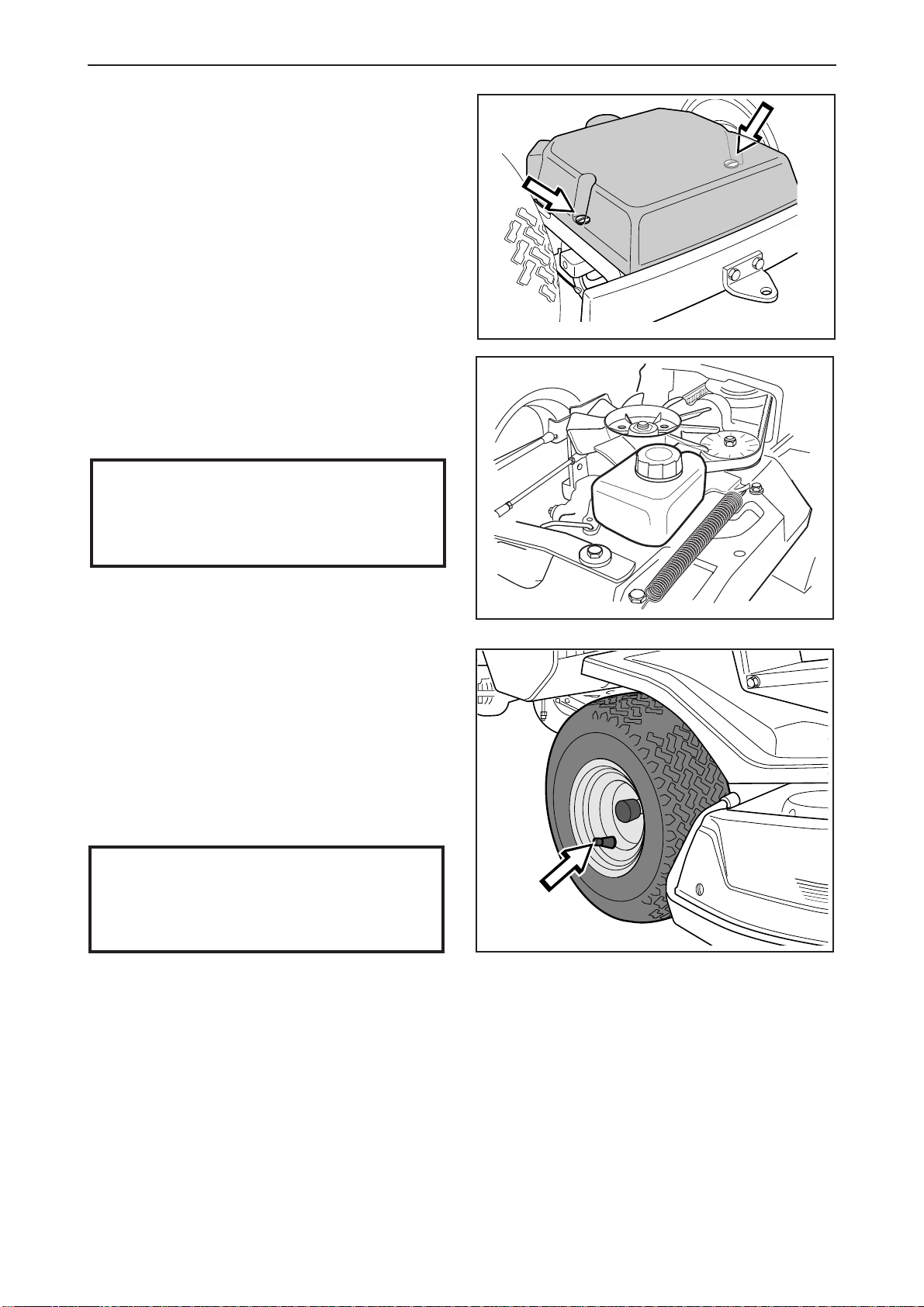

Check the oil level in the engine

Check the oil level in the engine when the Rider

stands horizontal with the engine switched off.

Lift up the engine cover.

Loosen the dipstick and pull it out. Wipe the

dipstick and replace it.

The dipstick should be screwed fully down.

Loosen the dipstick and pull it out again. Check the

oil level.

The oil level should lie between the markings on

the dipstick. If the level is close to the “ADD” mark,

top up with oil to the “FULL” mark on the dipstick.

The oil is poured in the same hole the dipstick fits

in.

Fill the oil slowly. Tighten the dipstick correctly

before starting the engine. Start and run the engine

at idling speed for approx. 30 seconds. Turn off the

engine. Wait 30 seconds and check oil level. If

necessary fill so that the oil comes up to the

”FULL” mark on the dipstick.

Use engine oil SAE 30 or SAE 10W/30, class SFCC on all machines up to 2002 models as well as

later models of Rider 11 and 13 with side-valve

engines.

Rider 16, 2003 model

ADD

FULL

From 2003 Rider 16 models use first and foremost

synthetic engine oil class SJ-CF 5W/30 or 10W/30,

otherwise SAE30, class SF-CC.

The engine takes a total of 1.4 litres/1,5 USqt of oil.

12 – English

ADD

FULL

Page 15

RIDER 850

Checking the oil level in the

transmission

(Not Rider 11)

Remove the transmission cover. Loosen both

screws (one on each side) and lift off the

transmission cover.

Check that there is oil in the transmission’s oil tank.

Fill if necessary with engine oil SAE 10W/30 (class

SF–CC).

IMPORTANT INFORMATION

Delivery measures

Check and top up with oil after each test

drive. The oil level will drop if there are

air pockets in the transmission.

Wheels

Fit the wheels (certain markets). The tyre pressures

should be 60 kPa (0,6 kp/cm2 /8,5 PSI) on all the

wheels.

To improve the driving capacity the pressure in the

back tyres can be reduced to 40 kPa

(0,4 kp/cm2 /5,6 PSI).

Maximum permitted pressure is 100 kPa

(1,0 kp/cm2 /14 PSI).

IMPORTANT INFORMATION

Different pressures in the front tyres will

cause the blades to cut the grass at

different heights.

Checking and adjusting of the mowing

deck’s ground pressure and parallelism

Carried out after checking the tyre pressures. See

respective sections in this Workshop Manual.

English – 13

Page 16

Delivery measures

Test running

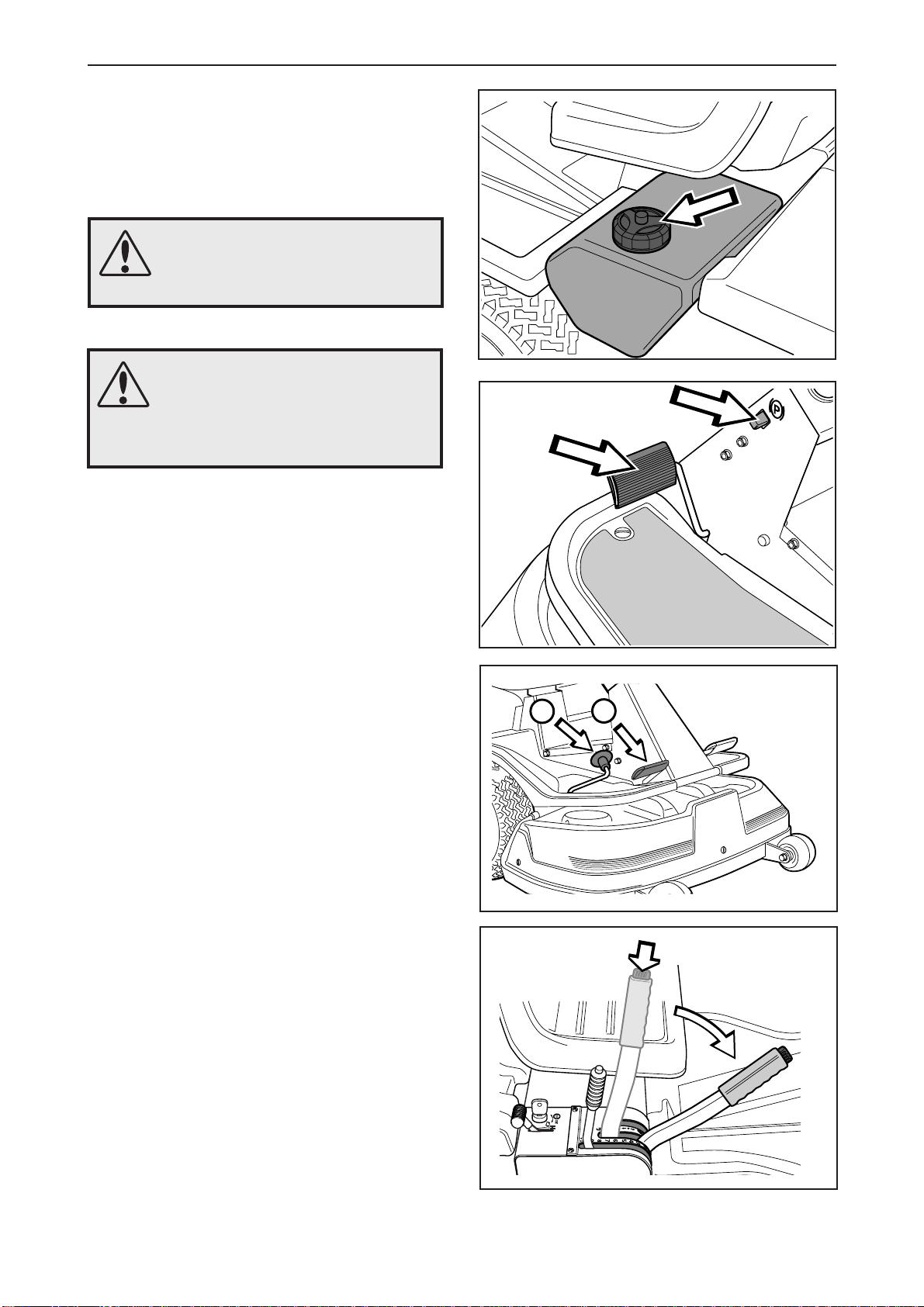

Fill up with petrol. The engine should be run on the

lowest 85 octane unleaded petrol (no oil admixture).

It can be beneficial to use environmentally adapted

alkylate petrol. Do not use petrol that contains

methanol.

WARNING!

Petrol is highly inflammable.

Observe caution and fill up with

petrol outdoors.

WARNING!

Never run the engine indoors, or

in enclosed or poorly ventilated

areas. Engine exhaust fumes

contain poisonous carbon monoxide.

Start the engine.

Check that the machine is in neutral and standing

on level ground when the parking brake is released.

(Not Rider 11)

Check the function of the parking brake.

Check driving forwards (1) and backwards (2).

Check that the starter does not function when any

of the hydrostatic transmission pedals are activated

(Rider 13, 16) or when the gear stick is not in

neutral (Rider 11).

Check that the engine stops when getting up from

the seat when any of the hydrostatic transmission

pedals are activated (Rider 13, 16) or when the

gear stick is not in neutral (Rider 11).

Check that the starter does not function when the

mowing unit is in its lower position.

2

1

14 – English

Page 17

Check the function of the mowing deck and that

there is no abnormal noise.

The mowing height can be regulated in 9 different

positions with the lever.

Deck with rear ejector, 40-90 mm,

mowing height

(1 9/16" - 3 9/16")

BioClip- and Combi- deck, 45-95 mm,

mowing height

(1 3/4" - 3 3/4")

Speed regulator

Check that the engine’s maximum speed is

regulated at:

Delivery measures

Rider 11 2 900 - 3 100 rpm

Rider 13 2 900 - 3 100 rpm

Rider 16 2 900 - 3 100 rpm

Rider 16 2003 - 2 800 - 3 000 rpm

Administration

Fill in the sales certificate and customer register

etc.

Do not forget to enter the manufacturing number on

page 3 of the operator’s manual and to verify the

delivery service in the service log.

English – 15

Page 18

RIDER

850

RIDER

850

General

Design and function

Husqvarna Riders is a series of ride-on mowers

with a large capacity. It is available in several sizes,

from the smallest Rider 11 to the largest Rider

ProFlex 21.

This manual deals with the slightly smaller

machines, the larger Pro-and ProFlex machines

can be found in a separate manual. All Riders have

articulated steering in order to easily cut around

trees and other obstacles. Moreover, they all have

front-mounted mowing decks for controlled cutting

R

R

IDER

IDER

850

850

0

0

5

5

8

8

R

R

E

E

ID

ID

R

R

and for best possible cutting results.

Husqvarna Riders can, moreover, be equipped

with various accessories such as moss rake and

dozer blade which make them flexible working

tools throughout the year.

Rider 11 and Rider 11 Bio can be delivered with a

manual gearbox, while the other models are only

available with hydrostatic transmission.

Rider 11 and Rider 13 have a mowing deck with

rear ejection. They can also be ordered with a Bio

deck, in which case they are called the Rider 11 Bio

or Rider 13 Bio.

Rider 16 is available with different mowing decks.

Bak 97 (rear ejection)

Sido 97 (side ejection)

BioClip 90

Combi 103 or Combi 112.

Earlier versions even BioClip 103 or BioClip 112

16 – English

Page 19

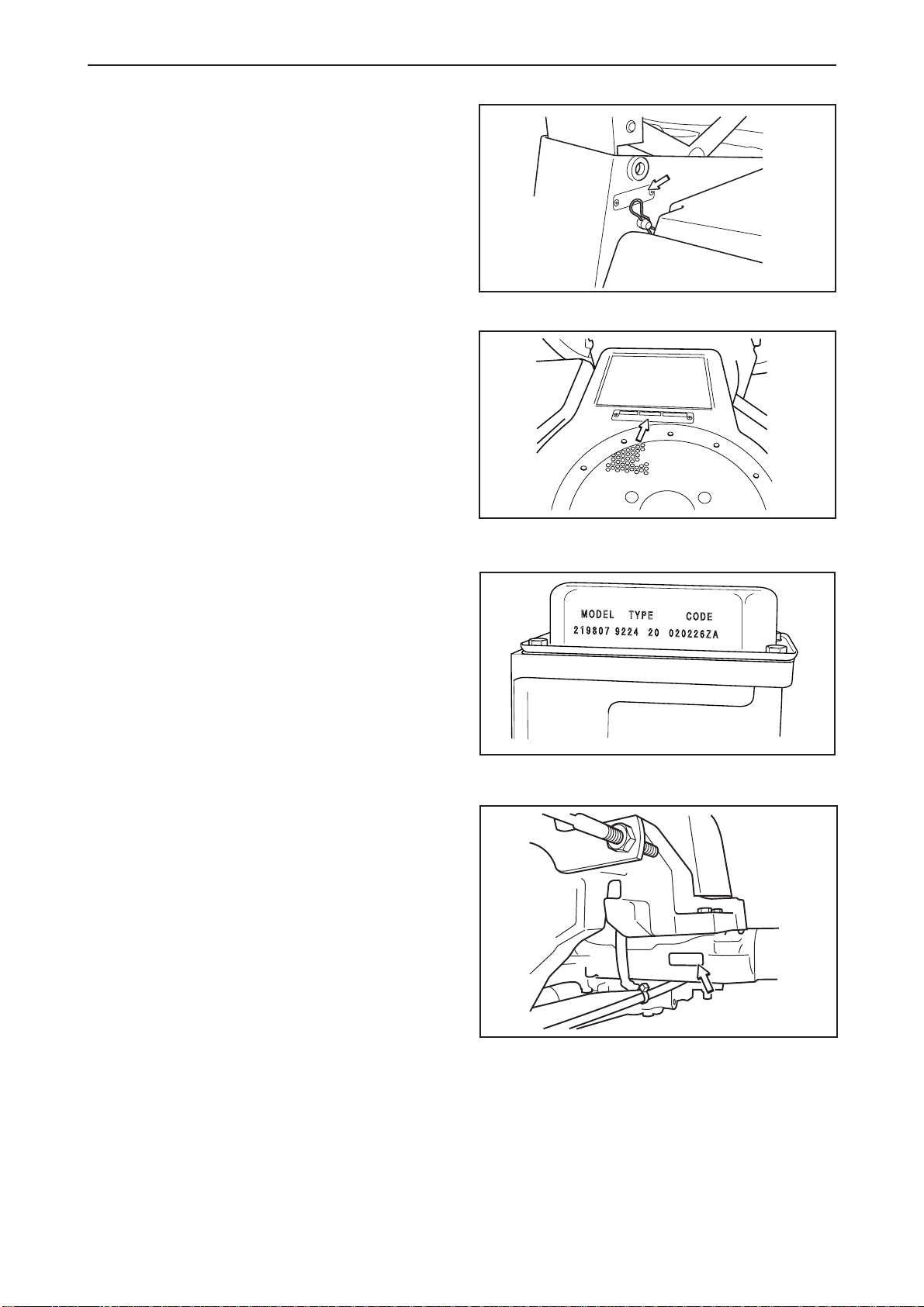

Serial number

The serial number can be found on the printed

plate attached to the front, left-hand side under the

seat. Stated on the plate, from the top are:

• The machines type designation.

• The manufacturer’s type number.

• The machine’s serial number.

State the type designation and serial number when

ordering spare parts.

On older machines the engine’s manufacturing

number is punched on a plate that is riveted to the

fan cover. On newer engines in Rider 16 the data is

punched on the cover.

The plate states:

• Model.

• Type.

• Code.

Please state these when ordering spare parts.

Design and function

The transmission’s serial number is stated on the

barcode decal located on the front of the housing

on the left-hand drive axle:

• The type designation is stated above the

barcode and starts with the letter “K”.

• The serial number is stated above the barcode

and has the prefix “s/n”.

• The manufacturer’s type number is stated under

the barcode and has the prefix “p/n”.

Older engines all versions

Newer engines Rider 16 (2003-)

State the type designation and serial number when

ordering spare parts.

English – 17

Page 20

Design and function

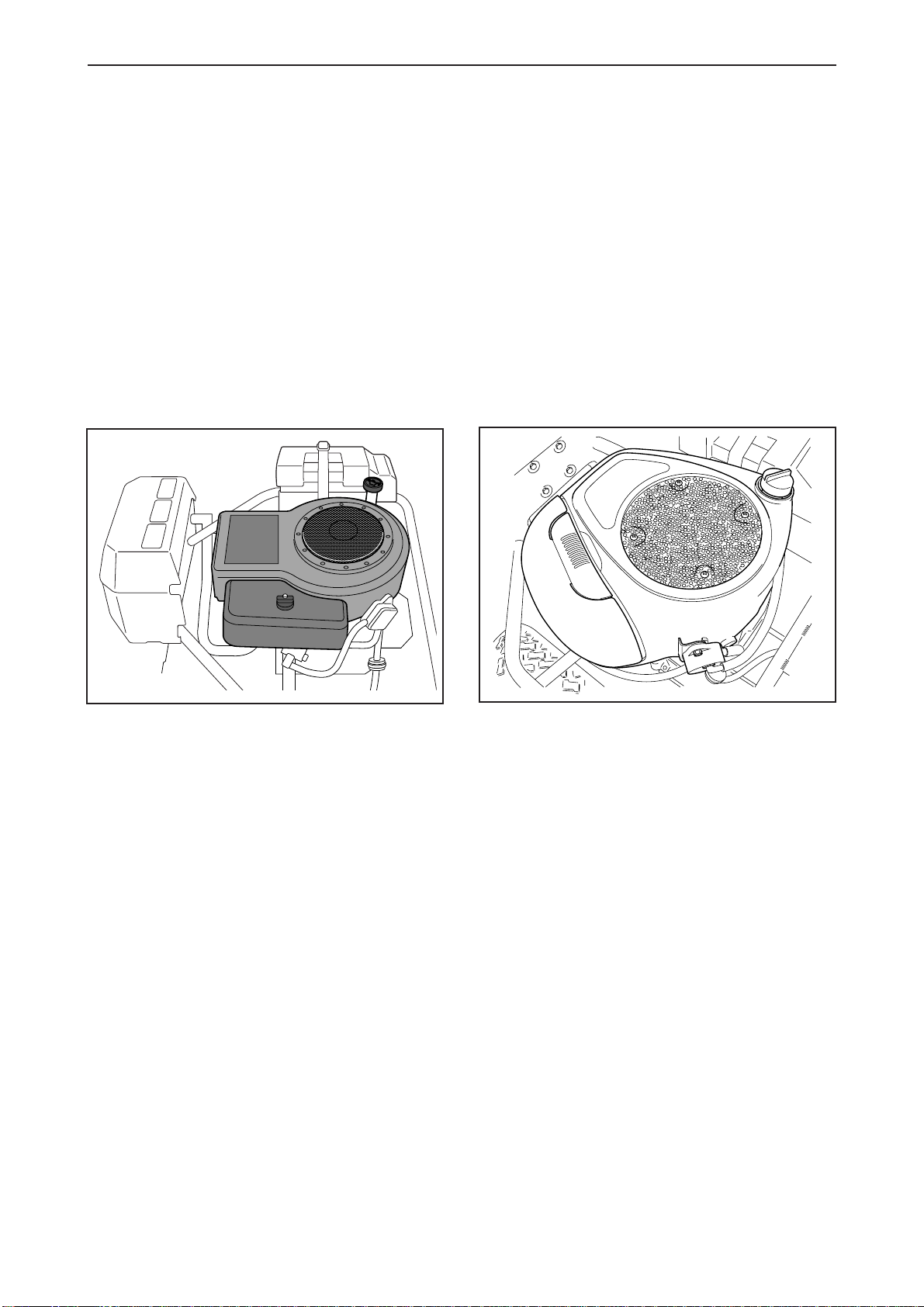

Engine

These Husqvarna Riders have single-cylinder, aircooled engines from Briggs & Stratton.

More intricate engine repairs are not described in

this workshop handbook, these can instead be

read in Briggs & Stratton's own handbooks which

contain detailed information about adjusting and

repairing the engines. The handbooks can be

ordered from an authorized service workshop.

The order numbers for the respective Rider models

are found in the table below. Please state these

when ordering manuals:

Model B & S model no.

Rider 11 28B707

Rider 13 286707

Rider 16 -2002 28N707

Rider 16 2003- 282H070110

Rider 11 and Rider 13 are fitted with a single

cylinder side-valve engine of 10.5 resp. 12.5 hp

with splash lubrication. Rider 16 is fitted with a

single cylinder overhead-valve engine of 15.5 hp. A

new overhead-valve engine with AVS (Anti Vibration System) has been introduced from 2003

models.

Side-valve engine Rider 11 and 13

It is important that only original spare parts are

used when repairing the engines. If other parts are

used, the guarantee shall no longer be valid.

Overhead-valve engine Rider 16 (2003-)

18 – English

Page 21

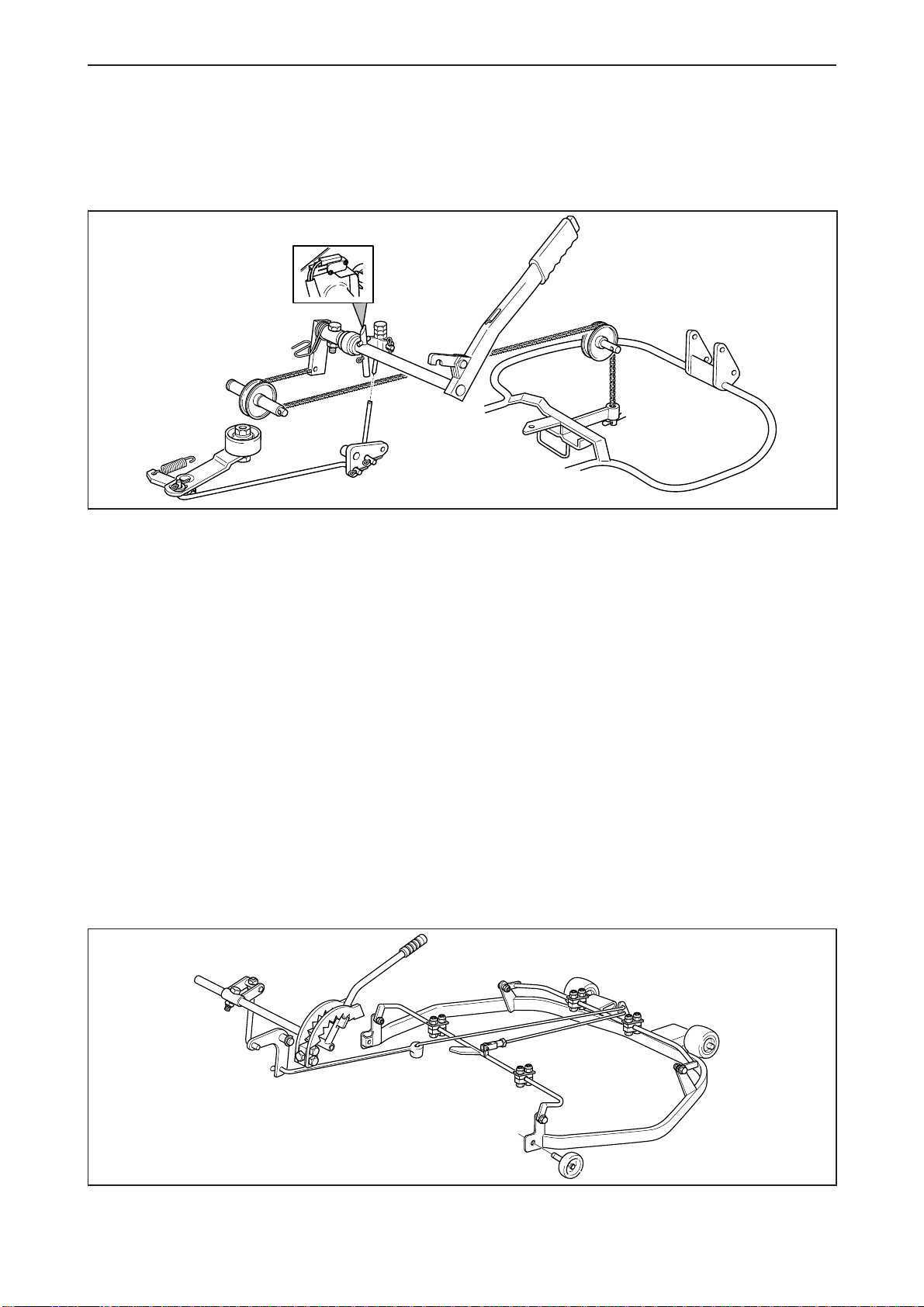

Steering

Design and function

All the ride-on mowers in the Rider series have

articulated steering. The steering force from the

steering wheel is transferred to the rear section via

wires and a chain. This ensures that the ride-on

mower is easy to manoeuvre, as well as having

high-precision steering. A Rider easily cuts around

all obstacles that may be found on the lawn.

Thanks to the articulated steering, the turning

radius is extremely small, the uncut circle when the

steering wheel is fully turned is just 20-30 cm

(8"-12")depending on which model is chosen.

Outline diagram of the articulated steering function.

Rider machines have a sliding bearing (1) on the

steering column.

English – 19

Page 22

Design and function

Driving

Rider 11 has a manual gear box with five forward

gears, neutral and one reverse gear. This gear box

is an "inline" type, which means that you can

change from neutral to fifth gear without having to

go through all the other gears.

Manual gear box on Rider 11 and Rider 11 Bio.

Rider 13 and Rider 16 are equipped with

hydrostatic transmission which provides the driver

complete control. Continuously variable speed

control, forwards and reverse, is by means of a

pedal.

Hydrostatic transmission on Rider 13 and Rider 16.

Mowing deck

The entire Rider series is equipped with frontmounted mowing decks to ensure effective cutting

even in confined areas.

Rider 11 and Rider 13 have a mowing deck with

rear ejection and a cutting width of 850 mm (34").

Rider 11 Bio and Rider 13 Bio have a Bio deck with

a cutting width of 900 mm (36").

20 – English

Rider 16 can be fitted with mowing decks with

either side or rear ejection where both have mowing

widths of 970 mm (38"), BioClip unit with mowing

width 900 mm (36") alternatively 1030 mm (41") or

Combi unit 1030 mm (41") alternatively 1120 mm

(44").

The Combi unit works as a BioClip unit when a

BioClip plug is fitted, but can be modified for rear

ejection by removing the BioClip plug.

Page 23

Design and function

Removing the BioClip plug

BioClip 900 mm (36")

Mowing deck with rear ejection, 850 mm (34").

Mowing deck with side ejection, 970 mm (38").

BioClip 1030 mm (41")

90°

Combi 1030 mm (41").

Mowing deck with rear ejection, 970 mm (38").

90°

Combi 1120 mm (44").

English – 21

Page 24

Design and function

The mowing deck is raised and lowered using the

mechanical lifting lever, which actuates a shaft that

rotates.

When the shaft rotates, the chain that is secured in

an arm on the inner end of the shaft raises or

lowers the tool frame.

The attachment’s lifting device

When lowering the unit, the two connecting rods,

via the three-point link, will alter the belt adjuster so

that the drive belt is tensioned and the blades begin

to rotate.

When the attachment is raised the microswitch in

the safety circuit is actuated.

The mowing deck is rear suspended with the lug on

the rear transverse axle in a U-bracket on the tool

frame. The front of the tool frame is linked to a

bracket on the attachment. The front rollers are

supported against the ground, for example, when

turning when the attachment tends to lean. The

rollers on the rear section of the protective frame

are used when removing and fitting the mowing

deck or moving it to the service position.

Otherwise, when dismantling, the rear of the

attachment would fall directly to the ground when

the lug on the rear axle releases its grip.

The mowing height is adjusted using the lever,

which has a catch for the different mowing height

positions. The setting for the mowing height range

is located on the same axle, see ”Adjustment of the

mowing height range”. Two connecting rods via a

toggle joint actuate the protective frame around the

mowing deck and raise or lower the mowing deck’s

cover within the mowing height range.

There are two struts on the top of the cutting unit

cover. The upper one is coupled between the

horizontal connecting rod and the tongue of the

forward perpendicular shaft on the top of the

mowing deck cover. When the shaft is rotated, it will

raise or lower the cutting unit cover in relation to the

protective frame. The lower strut (parallel strut) is

connected between the front and rear transverse

axles, so that even the rear axle rotates in the same

way as the front axle. There is an adjuster on the

parallel strut to adjust the mowing deck cover’s

parallelism with the ground. See ”Checking and

adjusting the mowing deck’s the parallelism”.

Mowing height manoeuvring

22 – English

Page 25

Reparation instructions

Removing engine

The figures under ”Dismantling” show Rider 11, 13

and Rider 16 in older designs (R16 up to the 2002

model), for a more recent Rider 16 design (2003-)

see ”Assembling the engine”. The text applies to all

versions.

1

3

Mark up and remove the engine's electrical

connections.

Newer engines, pull the connector apart.

IMPORTANT INFORMATION

Hold the bolts so that the poles are not

put under strain.

Remove the battery's fixing belt. Remove the safety

guard and remove the cable connections. Then, lift

out the battery.

2

4

Remove the clamp holding the throttle and choke

wire. Unhook the wire at its at its attachment.

Remove the cable which leads from the starter

relay to the start motor.

English – 23

Page 26

Reparation instructions

5

Remove the fuel line hose clamp from the fuel

pump and pull the fuel line downwards.

Tie the hose higher than the fuel tank level.

6

8

Insert tool no. 506 79 06-01 into the centre of the

engine pulley. Unscrew and remove the socket

head cap screw which holds the pulley and the

engine axle together. Use tool no. 506 89 92-01 as

a holder-on. Remove the pulley from the engine

axle.

Release the exhaust pipe clamps, and then remove

the exhaust pipe.

7

9

Remove the engine attachments, two on each side

of the engine, and remove the engine from the

mower.

Watch where the battery’s negative cable is

connected. Disconnect it from the engine if

necessary.

Lift the engine out of the mower, take care of the

key and spacer tube, located on the engine shaft.

Clamp together the wire holder under the engine

pulley with a pair of flat pliers and pull the wire

holder downwards.

24 – English

Page 27

Reparation instructions

Replacing engine

The figures under ”Assembling” show the newer

Rider 16 model (2003-). For

older designs (R16 up to the 2002 model), and

Rider 11 and 13 see ”Dismantling

the engine”. The text applies to all versions.

IMPORTANT INFORMATION

2

Position the pulley with tool no. 506 79 06-01 and

tighten it with moment (70-80 Nm/50-56 lbft). Use

tool no. 506 89 92-01 as a holder-on.

3

When installing the engine, it is important

that the pulley groove (1) is in a position

so the outgoing axle key (2) fits into the

groove (see diagram). Also check that

both spacing collars (3) and the key (2)

are firmly attached on the engine axle.

Grease the engine axle.

1

Position the wires in the wire holder, clamp the

holder together and, from below, lead it up through

the centre of the belt tensioner until it hooks over

the tensioner's upper edge.

4

Lower the engine and tighten the engine

attachments (two on each side of the engine) with

moment (20-25 Nm/14-18 lbft).

Hook on the throttle wire at the carburettor and fit

the wire clamp without tightening it.

English – 25

Page 28

Reparation instructions

5

Push the throttle control to full choke position. Pull

the wire’s outer casing as far to the right as

possible and tighten the clamping screw. Pull back

the throttle control to the full throttle position and

check that the choke is no longer actuated.

7

Press the fuel line securely on the fuel pump and fit

the hose clamp.

Choke not actuated.

6

8

Attach the engine's electrical connections.

Fit the exhaust pipe and tighten the retaining

screws and clamps.

26 – English

Page 29

Reparation instructions

9

Tightly screw the cable from the start motor to the

starter relay.

10

Fuel tank

Removal

WARNING!

Petrol is highly flammable and

environmentally hazardous.

Exercise caution to avoid fire and

spillage.

1. Place an appropriate container to catch the

petrol. The tank holds approx. 7 litres / 7.4

USqt.

2. Empty the petrol tank by removing the hose

from the connector under the tank.

If you do not wish to empty the tank, you can

pinch the hose with lockable welding pliers and

then remove the hose and hose clamp from the

fuel filter’s lower connector. You must then be

sure to keep the hose opening higher than the

fuel level in the tank.

3. Remove the three screws that fix the tank to the

bracket. Lower the tank and pull out the hose

through the frame of the machine (if it has been

loosened by the fuel filter).

Lift the battery into place and fasten the cable

connections and safety guard. Tighten the catching

belt.

Fitting

1. It is easier to work if you empty the tank before

fitting. Pull the tube into place, pull it under the

corner of the crank house, and attach it to the

fuel filter with the hose clamp. Make sure that

the hose cannot be chafed or rubbed.

2. Position the tank in the bracket, and secure with

the bolts.

3. Fit the fuel hose and the hose clamp to the

connector under the tank as required. Fill with

petrol and check that there are no leaks.

English – 27

Page 30

Reparation instructions

Changing the oil

The engine oil should be replaced after the first five

hours of running time, see service chart. Thereafter

it should be replaced every 50 hours of running

time (25 hours in harsh operating conditions).

WARNING!

Engine oil can be very hot if it is

drained off directly after the

engine is stopped. Therefore

allow the engine to cool down

first.

IMPORTANT INFORMATION

Spent engine oil is hazardous to health

and must not be poured out on the ground or in the nature, but should be

handed in to a designated place for

recycling.

Avoid skin contact and wash any spillage

with soap and water.

Checking and adjusting steering wires

1

Remove the frame plate by releasing the screws

(two on either side).

2

Drain plug on Rider 16

Tip! When draining the engine oil use a folded

piece of cardboard to funnel the oil into the container.

Place a container under the drain plug on the left

side of the engine.

Remove the dipstick and drain plug. Let the oil

drain into the container.

Refit the drain plug and tighten it.

Fill with oil up to the “FULL” mark on the dipstick.

Pour the oil into the same hole the dipstick goes in.

Filling procedure, see ”Delivery measures\Checking

the engine’s oil level”. Use engine oil as set out in

the ”Specifications” chapter.

Run the engine until warm, then check that there

are no oil leaks from the drain plug.

Ensure that the cables are properly situated under

the steering cable pulleys in the frame tunnel.

The tension is checked by squeezing together the

wires (as shown in the diagram). Without having to

apply too much force, the wires should be able to

be squeezed to half the distance between them.

Change the cable if it has a damaged strand

causing loose threads to protrude.

3

Hold the wire so it does not twist.

Stretch the wires by tightening the adjuster nuts

(one wire on each side of the ride-on mower). Do

not overtension them, they should only be tightened up to the steering rim. Stretch both wires

equally so that the steering wheel position is not

changed.

Check the wire tension as set out in point 2 after

you have made the adjustment.

28 – English

Page 31

Reparation instructions

Replacing steering wires

1. Release the steering wires' rear attachment (1).

2. Remove the frame plate.

3. Release the steering wires' front attachment (2)

at the steering transmission chain (6) and pull

the steering wires out throught the frame.

Note. If the old wires are still complete, the new

wires can be attached to the old ones when

they are pulled out through the frame, the new

wires will then come automatically into place.

4. Ensure that the steering wheel is in the centre

position when the rear wheels are centred. Reset the chain on the steering column’s sprocket

or adjust the rear fixture (1) for the steering

cables as needed.

Hold the cables with, for example, a wrench

when mounting so that they do not twist.

Attach the new wires. Once the new wires are

in place, check the wire tension (see “Checking

and adjusting steering wires”).

Removal/installation of steering axle

1. Release the steering wires' rear attachment (1).

Remove the frame plate.

2. Remove the steering wheel and steering

column by releasing the lock nut and

unscrewing the locking screw, lift the steering

wheel and steering column upwards.

3. Remove the two steering wheel rod carriers (4).

4. Unscrew the bolt (5) from the bottom end of the

steering column.

5. Pull the steering axle (6) upwards and move the

lower part of the axle backwards to remove the

steering transmission chain (3).

6. Move the upper bearing (7) uppwards until it

goes free from the steering axle (6). If the

bearing is to be replaced, the bushing (8) must

be knocked out of the bearing.

7. Slide the bearing (9) off the bottom end.

8. Take the steering axle out (6) downwards.

9. To assemble the steering axle, the reverse

order is applied. For assembly purposes, the

two steering wheel rod carriers (4), are tightened with moment (5–10 Nm/3,5-7 lbft).

English – 29

Page 32

Reparation instructions

Removal/installation of wire wheel

1. Remove the frame plate.

2. Detach the steering wires' rear attachment (1) .

3. Remove the screw (2) and detach the wire

wheel (5).

4. Remove the bearing's circlip (3) and knock out

the bearing (4).

5. To install the wire wheel, the reverse order is

applied.

The screw (2) is to be mounted in the rear hole

on the frame. The bushing (6) is to be placed

between the frame and the cable pulley.

Ensure that the cables are properly situated

under the steering cable rollers (7) in the frame

tunnel.

Ensure that the steering wheel is in the centre

position when the rear wheels are centred. Reset the chain on the steering column’s sprocket

or adjust the rear fixture (1) for the steering

cables as needed.

Hold the cables with, for example, a wrench

when mounting so that they do not twist.

After installation, check the wire tension (see

“Checking and adjusting steering wires”).

30 – English

Page 33

Reparation instructions

Checking and adjusting brake wire

Rider 11

Check that the brake is correctly adjusted by

measuring the distance between the brake lever

and the front edge of the recess on the chassis.

The distance should be 0–1 mm/0-0,040" when the

brake is not applied.

Rider 13 and Rider 16

Check that the brake is correctly adjusted by

positioning the ride-on mower on a gentle slope and

applying the brake.

If the ride-on mower does not stand still, the brake

needs to be adjusted.

The brake is adjusted in the following way:

1. Release the lock nuts (1).

1. Remove the lock nuts (1).

2. Stretch the wire with the adjuster screw (2) so

that the distance between the brake lever and

the front edge of the recess on the chassis is 1

mm/0,040".

3. Tighten the lock nuts (1) after adjustment.

When the brake wire has been adjusted, check

that the brake lever does not have too much

movement. If the lever's free movement

exceeds 9 mm/3/8", this should be adjusted by

tightening the nut on the brake lever.

2. Stretch the wire with the adjuster screw (2) until

all the play in the wire disappears.

3. Tighten the lock nuts (1) and finally check that

the brake is correctly adjusted.

WARNING!

A badly adjusted brake can lead

to reduced braking capacity.

English – 31

Page 34

Reparation instructions

Checking and adjusting gear control

Rider 11

Check the gear control adjustment by setting the

gear change lever to the ”N” position. When the

lever (4) goes easily into the neutral position, the

control is correctly adjusted.

In other cases, the control is adjusted in the

following way:

Checking and adjusting freewheel

clutch Rider 11

1

The freewheel clutch is correctly adjusted when the

tensioning wheel's outward movement is stopped

by the belt and not by the wire.

2

1

Detach the lock nut (1) on the ball joint.

2

Press the locking spring (2) backwards so that the

spherical socket (3) can be lifted away from the pivot

on the lever (4).

3

Adjust the spherical socket (3) position on the

connecting rod (5) until the right adjustment is

obtained.

4

Lock the setting with the lock nut (1) and press the

locking spring (2) into position.

IMPORTANT INFORMATION

Check that the locking spring goes

through the hole in the spherical socket.

There should be a play (A) of 8-10 mm/5/16" - 3/8"

between the wire nipple and the lever.

3

32 – English

Adjust the freewheel clutch wire as follows:

• Pull out the rubber sleeve (1). Loosen the nut (2)

and adjust the wire using the adjuster screw (3).

• Tighten the lock nut (2) after adjustment.

Page 35

Reparation instructions

Checking and adjusting throttle control

Rider 13 and Rider 16

1. Detach the locking nut (1) on the ball joint.

2. Push the lock spring (2) forwards far enough

for the spherical socket (3) to be lifted off from

the pivot on the lever (4).

Replacing articulated steering bearing

1

• Remove the engine according to the earlier

description (see “Removing engine”).

• Block up the ride-on mower in front of the

articulated steering.

2 Rider 11

3. Press the throttle pedal to the bottom and

move the lever (4) forwards as far as it goes

using a screwdriver.

4. Adjust the position of the spherical socket (3)

on the connecting rod (5) so that it just fits over

the pivot on the lever. Fit the spherical socket

on the pivot.

5. Lock the setting with the lock nut (1) and press

the locking spring (2) into position.

IMPORTANT INFORMATION

Check that the locking spring goes

through the hole in the spherical socket.

2

5

3

1

• Release the tensioning wheel spring (1).

• Release the clutch, gear and brake wire (2, 3

and 4) and remove the wires' holder plates (5

and 6).

2 Rider 13 and Rider 16

4

• Release the tensioning wheel spring (1).

• Release the hydrostatic transmission wire (2)

from the arm (3) and the casing from the holder

(4).

• Release the cable from the neutral position

contact (5).

• Release the brake wire from the arm under the

tank and the casing’s holder from the rear frame

(6).

English – 33

Page 36

Reparation instructions

3

5

• Work off the belts from the pulley (2).

• Loosen the steering wires (1) and remove the

steering rim.

• Remove the pulley (2). Move the lower part

forwards, the upper part backwards and detach

the pulley.

4

WARNING!

The articulation spring is

strongly tensioned and can

cause injury if it flies off. Wear

safety glasses and gloves when

removing/attaching the spring.

Remove the inner circlip (1) from the lower bearing

(see diagram). The rear section is now loose and

can be moved. Then detach the outer circlip (2) and

take the bearing out downwards.

6

• Take the upper bearing out upwards, if it does

not come out easily, it should be knocked out

from below.

• Insert the new bearings and assemble the

articulated steering in the reverse removal order.

Detach the articulation spring. This spring is

heavily tensioned and should be offloaded using

tool 506 89 93-01 before the bolt for the rear

bracket is removed.

34 – English

• After re-assembly, the wire tension should be

checked (see “Checking and adjusting steering

wires”). Also check that the controls and wires

are correctly adjusted.

• Check the setting of the neutral position switch

on machines with hydrostatic transmission, see

”Electrical system\Microswitch neutral position”.

Page 37

Reparation instructions

Removal of swing axle

1

• Block-up the machine in front of the rear frame.

• Remove the transmission/gear box cover.

2 Rider 11

• Release the tensioning wheel spring (1).

• Release the hydrostatic transmission wire (2)

from the arm (3) and the casing from the holder

(4).

• Release the cable from the neutral position

contact (5).

• Release the brake wire from the arm under the

tank and the casing’s holder from the rear frame

(6).

• Remove the circlip and lift off the hydrostatic

transmission’s fan (7).

• Remove the rear belt (8).

• Remove the circlip and washer from the swing

axle and pull the rear frame backwards.

3

• Detach the tensioning wheel spring (1) and the

clutch wire (2).

• Disconnect the tensioning wheel arm (3) from

the rear frame, and detach the belt from the gear

box pulley.

• Detach the gear and brake wires (4 and 5) and

remove the wires' holding plates (6).

• Remove the circlip and washer from the swing

axlel (7) and pull the rear frame out backwards.

2 Rider 13 and 16

Remove the circlip and washer from the swing

axle's inner holder (1) and pull the swing axle out

backwards. Use a sledgehammer or puller if

needed.

If the dust protection (2) is damaged, this should be

replaced by a new one.

Replacing bushings

Once the swing axle has been removed the

bushings fitted to the rear frame must be replaced.

Dismantling is carried out using a standard drift,

see ”Special tools”.

Assembling new bushings is carried out using a

drift, see ”Special tools”. Ensure the grooves in the

bushings run horizontally. It is important that the

outer edge of the outermost bushing is flush with

the outer edge of the hole.

Lubricate the bushings with a lithium-based grease.

English – 35

Page 38

Reparation instructions

Installation of swing axle

1

• Grease half of the axle (the half that has not

been turned down) and press it from the back

into the steering spindle (see diagram).

• Attach the washer and circlip on the swing axle's

inner holder.

3 Rider 11

• Attach a washer and circlip onto the swing axle

(1).

• Firmly secure the wires' holder plates (2), as well

as the gear and brake wires (3 and 4).

• Connect the belt onto the pulley and tightly screw

the tensioning wheel arm (5) onto the rear frame.

• Attach the clutch wire (6) and the tensioning

wheel spring (7).

• Fix the dust guard (with a thin lip behind) approx.

2/3 of the way in on the axle and lubricate the

axle on both sides of the dust guard.

2

Roll the rear frame forwards and press it in on the

swing axle.

3 Rider 13 and 16

• Fit the washer and circlip on the swing axle.

• Fit the hydrostatic transmission wire and its

casing (2+4).

• Fit the cable on the neutral position contact (5).

• Fit the rear belt (8).

• Fit the brake wire on the arm under the tank and

the casing’s holder on the rear frame (6).

• Fit the tensioning wheel spring (1).

36 – English

• Fit the hydrostatic transmission’s fan and the

circlip (7).

4 . Check that wires and controls are correctly

adjusted (see Inspection and adjusting of

respective wires). Finally, fit the cover on the

transmission/gearbox.

Check the setting of the neutral position switch

on machines with hydrostatic transmission, see

”Electrical system\Microswitch neutral position”.

Page 39

Reparation instructions

Removal/installation of gear box

Rider 11

1

• Block-up the machine in front of the rear frame

and dismantle the rear wheels.

• Remove the cover from over the gear box.

2

Removing/installation of hydrostatic

transmission Rider 13 H/13 H Bio and

Rider 16 H

1

• Block-up the machine in front of the rear frame

and remove the back wheels.

• Remove the transmission cover.

2

• Release the tensioning wheel spring (1).

• Unfasten the clutch wire (2), and detach the belt

from the gear box pulley.

• Detach the gear and brake wires (3 and 4).

• Insert a garage jack under the gear box and

unscrew the gear box's five holder screws (5).

3

• Lower the garage jack and pull out the gear box.

• Installation of the gear box is carried out in the

reverse removing gear box order

• After installation, check that the clutch, brake

and gear wires are correctly adjusted (see

“Checking and adjusting brake wire”, “Checking

and adjusting gear control” and “Checking and

adjusting freewheel clutch”).

• Release the tensioning wheel spring (1).

• Remove the fan (2), it is held by a circlip.

• Work off the drive belt (3).

• Remove the oil tank (4).

• Release the brake wire spring and remove the

brake wire from the brake lever (concealed under

the oil tank).

• Release the hydrostatic transmission link (5) in

the front ball joint.

• Remove the screw (6) holding the arm.

• Remove the freewheel clutch control (7) with its

spring.

English – 37

Page 40

Reparation instructions

3

Insert a garage jack under the hydrostatic transmission and loosen its five holder screws.

4

Replacing hydrostatic transmission axle

sealing collars

Sealing collar replacement - input axle

Remove the cooling fan, it is held by a circlip. Remove the pulley from the input axle by pulling it

upwards and then removing the circlip under the

pulley.

IMPORTANT INFORMATION

The area around the sealing collar must be

absolutely clean! If the hydrostatic oil is

contaminated with dirt, this can lead to a

shorter hydrostatic transmission

operational life.

1

• Lower the garage jack and pull out the

hydrostatic transmission.

• Installation of the hydrostatic transmission is

carried out in the reverse hydrostatic transmission removing order

• After fitting the brake wire and hydrostatic

transmission wires, check that they are

correctly adjusted (see “Inspection and

adjustment of brake wire” and “Inspection and

adjustment of speed control”). Check also the

oil level in the hydrostatic transmission, and top

up if necessary. Check the setting of the

neutral position switch on machines with

hydrostatic transmission, see ”Electrical

system\Microswitch neutral position”.

• Clean the input axle and the area around the

sealing collar of all dirt and rust.

• Insert a screwdriver between the sealing collar and

the axle and bend the sealing collar out of the axle

housing with a twisting motion.

2

• Wrap insulation tape around the input axle to

protect the new sealing collar from damage to

splines and grooves.

Start by wrapping from the bottom and continue

upwards over the axle until the entire axle is

wrapped in tape.

38 – English

• Lubricate the axle and the inside of the new

sealing collar with grease so that the collar can

slide easily.

Page 41

3

• Place the sealing collar on the axle with the

smooth side upwards, and

carefully

press it

downwards.

• Use the thick end of a 1/4" extender to

carefully

knock down the sealing collar until the upside of

the collar is level with the axle housing's upper

edge.

Move the extender in a circle around the sealing

collar so that it is evenly pressed down, all the

way around.

• Remove the insulation tape from the axle and

assemble the lower circlip and the pulley with the

hexagonal hub facing upwards.

Reparation instructions

• Clean the outgoing axle and the area around the

sealing collar of all dirt and rust.

• Insert a screwdriver between the sealing collar

and the axle and bend the sealing collar out of

the axle housing with a twisting motion.

2

• Fasten the fan and the washer and assemble the

upper circlip.

• Install the hydrostatic transmission in the ride-on

mower as indicated in the previous description

(see “Removal/installation of hydrostatic transmission”).

Sealing collar replacement - outgoing axles

1

Remove the rear wheels. Remove the circlips and

pull the wheels outwards. Do not mislay the key

that sits between the hub and axle. Use removing

tool 506 57 00-01 if necessary.

Remove the spacing sleeve and washer from the

wheel axle.

• Wrap insulation tape around the outgoing axle

from the start of the key-way and outwards until

even the circlip's groove is covered with tape.

This is done to protect the new sealing collar

from damage.

• Lubricate the axle and the inside of the new

sealing collar with grease so that the collar can

slide easily.

IMPORTANT INFORMATION

Dirt must not be allowed to get into the

transmission as this can shorten its

operational life.

IMPORTANT INFORMATION

Before the sealing collar is completely

installed, check that the sealing collar's

metal spring reinforcement sits on the

side of the sealing collar which leads

inwards towards the transmission.

English – 39

Page 42

Reparation instructions

3

• Place the sealing collar on the axle, with the

metal spring inwards, and press it in

• Use the narrow end of a 1/4" extender to

carefully

reaches the bottom of the axle housing. Only

knock on the steel cover.

Move the extender in a circle around the sealing

collar so that it is pressed in evenly all the way

around and tight against the axle.

• Remove the insulation tape from the axle and

repeat, as is necessary, the entire procedure for

the second axle.

knock in the sealing collar until it

carefully

Replacing hydrostatic transmission wire

Removal of hydrostatic transmission wire

1

.

Remove the frame plate by undoing the screws

(two on each side).

2

• Replace the washer, spacing sleeve, key and

rear wheel on the axle. Fit the circlip that holds

the wheel and the plastic cover over the axle

end.

• Fill the transmission's oil container with SAE

10W30 oil until the oil level reaches the "MAX"marking.

• Bleed the transmission as directed in “Bleeding

of the hydrostatic transmission’s oil system”.

Loosen the hydrostatic transmission’s front lock nut

a 1/4 turn and remove the lock spring.

3

• Operate the ride-on mower and then check that

there is no oil leaking from the new axle sealing

collars.

• Check the oil level and top up if necessary after

test running.

40 – English

Remove the hydrostatic transmission wire’s front

clamp fixed inside the middle bracket.

Page 43

Reparation instructions

4. Remove the transmission cover. 7. Lift off the linkage and pull out the wire.

5

Follow the hydrostatic transmission wire backwards

towards the transmission and cut off the cable ties

round the wire.

6

8

Lift out the transmission wire with the linkage

attached.

9

Remove the lock spring at the transmission wire’s

rear linkage. Release the clamp holding the wire’s

casing.

Unscrew both ball joints from the hydrostatic

transmission wire.

10

Remove the entire hydrostatic transmission wire.

English – 41

Page 44

Reparation instructions

Refitting hydrostatic transmission wire

1

Screw the front ball joint onto the new transmission

wire and tighten the lock nut.

3

Press the wire casing in the front holder in the

middle bracket.

4

2

Run the wire through the mower so that it follows

the same route as the old wire.

Screw tight the hydrostatic transmission wire’s

clamp. Press the linkage in its holder and fit the

lock spring.

5

42 – English

Screw tight the linkage on the lower part of the

transmission wire. Screw 10-12 turns so that the

linkage has the correct length.

Page 45

Reparation instructions

6

Draw the transmission wire along with the other

cabling. Place the wire at the bottom in the clamp,

under the articulated steering’s bearing.

7

10

~80

Fix the hydrostatic transmission wire with a cable

ties.

11

Put the wire in position and screw tight the casing

with the rear clamp.

8. Adjust the wire as directed in “Inspection and

adjustment of speed regulator”. Connect the

rear linkage and fit the lock spring. Tighten the

rear lock nut for the linkage.

Refit the frame plate using the four screws.

9. Check the setting of the neutral position contact.

See ”Electrical system\Microswitch neutral

position”.

English – 43

Page 46

Reparation instructions

Bleeding the hydrostatic transmission

oil system

1

• Check the hydrostatic transmission oil level.

• Start the engine and set the throttle control to

idle.

2

Adjustment of transmission neutral

position

1. Bleed the hydrostatic transmission oil system.

2. Lift the back of the ride-on mower up so that the

wheels are off the ground and place blocks

under the machine.

3

• Repeat opening and closing the disengaged

clutch control whilst the front respective rear

pedals are alternately pressed down.

• When the mower starts to move set the governor

control lever to high idle.

3. Repeat quick starts and emergency stops until

the transmission responds as it should.

• Check also the oil level in the hydrostatic transmission, and top up if necessary.

• The neutral position is adjusted by turning the

hexagonal axle on the transmission (see diagram).

• Start the engine and set the throttle control to full

throttle.

• Unscrew the hexagonal axle lock nut and turn

the axle clockwise until the drive shafts start to

rotate backwards.

• Make a mark on the top of the axle.

4. Check and top up with oil if necessary after test

driving.

44 – English

Page 47

Reparation instructions

4

1 = Axle

2 = Lock nut

• Slowly turn the axle anti-clockwise until the drive

shafts stop rotating backwards and make a mark

on the transmission housing (RS).

• Slowly turn the axle anti-clockwise until the drive

shafts start to rotate forwards.

• Slowly turn the axle clockwise until the drive

shafts stop rotating forwards and make a mark

on the transmission housing (FS).

• Turn the axle clockwise 1/3 of the distance

between the marked stop points.

• Hold the axle (N=8) firmly and tighten the lock

nut (N=17).

• Check that the drive shafts do not rotate in the

neutral position by slowly transferring the

steering arm to the neutral position from the

forwards and reverse positions.

5

1 = Axle

2 = Lock nut

If the drive shafts do not rotate backwards despite

the hexagonal axle having rotated a full turn, the

neutral position is to be adjusted in the following

way:

• Slowly turn the axle anti-clockwise until the drive

shafts start to rotate forwards.

• Slowly turn the axle clockwise until the drive

shafts stop rotating forwards and make a mark on

the transmission housing (FS) and the axle.

• Turn the axle clockwise 8° from the mark on the

transmission housing.

• Hold the axle (N=8) firmly and tighten the lock nut

(N=17).

Transmission maintenance

Oil change

Most garden owners do not have tools for or

experience of changing transmission oil. The

transmission probably has a longer operational life

than other ride-on mower components, this makes

transmission oil changes less important for most

customers. However, the transmission's operational

life is increased if oil changes are made.

If the ride-on mower is used

recommended to change the oil firstly after 50

hours use and every 300 hours use thereafter.

The transmission K 46 has a capacity for 2.2 litres/

2,35 USqt (SAE10W/30 engine oil, grade SF-CC).

The oil does not need changing in a manual

gearbox.

professionally,

it is

English – 45

Page 48

Reparation instructions

Changing oil – Rider 13 and Rider 16

Empty the hydrostatic transmission with the two

plugs, width across flats 14 mm. The other screws

have smaller widths.

IMPORTANT INFORMATION

Spent engine oil is hazardous to health

and must not be poured out on the

ground or in the nature, but should be

handed in to a designated place for

recycling.

Avoid skin contact and wash any spillage

with soap and water.

Removing the belt

Rider 11, Rider 13 H, Rider 16 H och Rider 14

Pro

Starting point when Removing the belt:

• A deck is not mounted on the machine.

• The front part of the belt hangs loose.

The complete belt is removed as follows only if a

snow blade is to be fitted on the machine.

8

9

Fill up with oil in the oil tank.

Bleed the transmission as directed in “Bleeding of

the hydrostatic transmission’s oil system”. Top up

with oil after bleeding.

Test run the machine and recheck the oil level.

1. Loosen the belt guide and support pulley.

2. Loosen the belt tensioning pulley.

3. Prise the belt off the middle pulley and remove

the belt.

Reverse the above sequence to refit the belt.

46 – English

Page 49

Reparation instructions

Checking and adjusting mower deck

ground pressure

1 1

Check the tyre pressures (60 kPa/8,5 PSI).

Place a set of bathroom scales under the mower

deck's frame (front edge) so that the deck rests on

the scales.

2

Checking and adjusting mower deck

parallelism

Check the tyre pressures (60 kPa/8,5 PSI).

Place the ride-on mower on an even surface and

measure the distance between the ground and the

edge of the deck, at the front and rear of the cover.

The cutting unit should slope forwards slightly so

that the rear edge is 2-4 mm (1/8") higher than the

front edge.

Adjust the mowing deck's ground pressure with the

adjuster nuts placed behind the front wheels on

both sides of the ride-on mower. The ground

pressure should be between 12 and 15 kg/26.5-33

lbs and the springs tensioned equally.

2

Adjusting Rider 11 and Rider 13 H

2

• Remove the front cover and the right-hand

fender.

• Vertical adjustment of the mowing deck is made

with the adjuster nuts on the back edge of the liftstrut.

• Raise the mowing deck at the front edge by

shortening the lift-strut.

Lower the mowing deck at the front edge by

lengthening the lift-strut.

• Tighten the nuts against each other after the

adjustment.