®

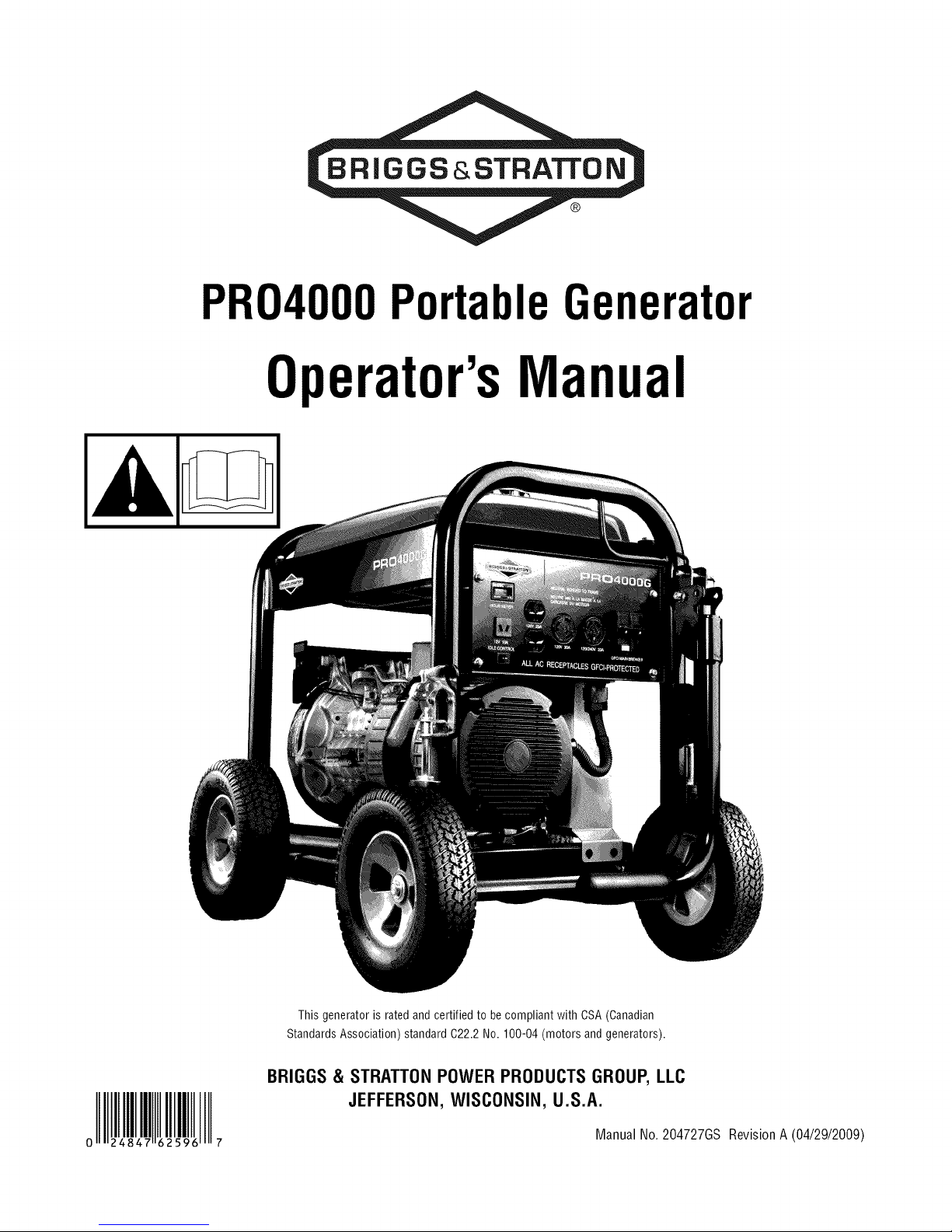

PRO4000PortableGenerator

Operator'sManual

This generator is rated and certified to becompliant with CSA (Canadian

Standards Association) standard 022.2 No. 100-04 (motors and generators).

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WISCONSIN, U.S.A.

Manual No. 204727GS

RevisionA (04/29/2009)

Thankyou for purchasing this quality-built Briggs & Stratton generator.We are pleasedthat you've placedyour confidencein

the Briggs& Stratton brand. When operated and maintained according to the instructions in this manual,your Briggs &

Stratton generatorwill provide many years of dependableservice.

Thismanualcontainssafety information to makeyou aware of the hazardsand risks associatedwith generators and how to

avoid them. This generatoris designed and intendedonly for supplying electrical powerfor operating compatibleelectrical

lighting, appliances,tools and motor loads, and is not intendedfor anyother purpose. It is important that you readand

understand these instructions thoroughly before attempting to start or operatethis equipment. Save these instructionsfor

future reference.

Thisgenerator requiresfinal assemblybeforeuse. Referto the Assemb/ysection of this manualfor instructions on final

assembly procedures. Follow the instructions completely.

Whereto FindUs

You never have to look far to find Briggs & Stratton support and service for your generator. Consultyour Yellow Pages.There

are over 30,000 Briggs & Stratton authorized service dealersworldwide who provide quality service. You canalso contact

Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Generator

Model Number

Revision

Serial Number

Engine

Model Number

Type Number

Code Number

DatePurchased

Briggs & Stratton PowerProducts Group, LLC

900 North Parkway

Jefferson, WI 53549

III

III

III III III

Copyright © 2009. All rights reserved.Nopart of this material

may be reproducedor transmitted in anyform by any means

without the expresswritten permission of Briggs & Stratton

Power Products Group, LLC.

2 BRIGGSandSTRATTON.COIVl

Tableof Contents

Operator Safety ................................. 4

Equipment Description......................................... 4

Important Safety Information.................................... 4

Assembly ..................................... 7

UnpackGenerator ............................................ 7

Shipment Contents ........................................... 7

Install Wheel Kit.............................................. 7

Add Engine Oil............................................... 8

Add Fuel.................................................... 8

System Ground .............................................. 9

Connectingto aBuilding's Electrical System........................ 9

GeneratorLocation ........................................... 9

FeaturesandControls............................ 10

Cord Sets and Receptacles.................................... 11

Ground Fault Protection....................................... 12

Operation .................................... 13

Starting the Engine .......................................... 13

ConnectingElectrical Loads.................................... 13

Stopping the Engine.......................................... 14

OperatingAutomatic Idle Control................................ 14

Oil PressureShutdown ....................................... 14

Charginga Battery........................................... 14

ColdWeatherOperation....................................... 15

Don't OverloadGenerator ..................................... 16

Maintenance .................................. 17

MaintenanceSchedule........................................ 17

GeneratorMaintenance....................................... 17

FuelValveMaintenance....................................... 18

Engine Maintenance.......................................... 18

Storage ................................................... 21

Troubleshooting ................................ 22

Schematic ................................................. 23

Wiring Diagram ............................................. 24

Warranties .................................... 25

Emissions Control System Warranty ............................. 25

GeneratorOwnerWarranty .................................... 27

Specifications ................................. 28

Product Specifications........................................ 28

Common Service Parts ....................................... 28

Frangais Espa_ol

OperatorSafety

Equipment Description

Readthis manual carefully and becomefamiliar

...... with your generator. Knowits applications, its

limitationsand any hazardsinvolved.

Thegeneratoris anengine-driven, revolvingfield, alternating

current (AC) generator. It was designedto supply electrical

power for operatingcompatible electricallighting, appliances,

tools and motor loads.Thegenerator's revolving field is

driven at about3,600 rpm by a single-cylinderengine.

This generator incorporates GFCI(Ground Fault Circuit

Interrupter) outlet protection andhas its neutral bonded to

ground to comply to OSHAinspections on job sites. This

generatorwill not function when connectedto a 2 pole

transfer switch sincethe home or building main breaker box

also has a neutral bondedto ground. When both the

generator andthe home or building breakerbox contains a

neutral bonded to ground, the generatorsGFCIwill open and

no outlets will function.

_i, WARNING Removingthe neutral bond could resultin

_1_ death, bodily injury and/or propertydamage.

m,

• DONOTremovetheneutralbond.

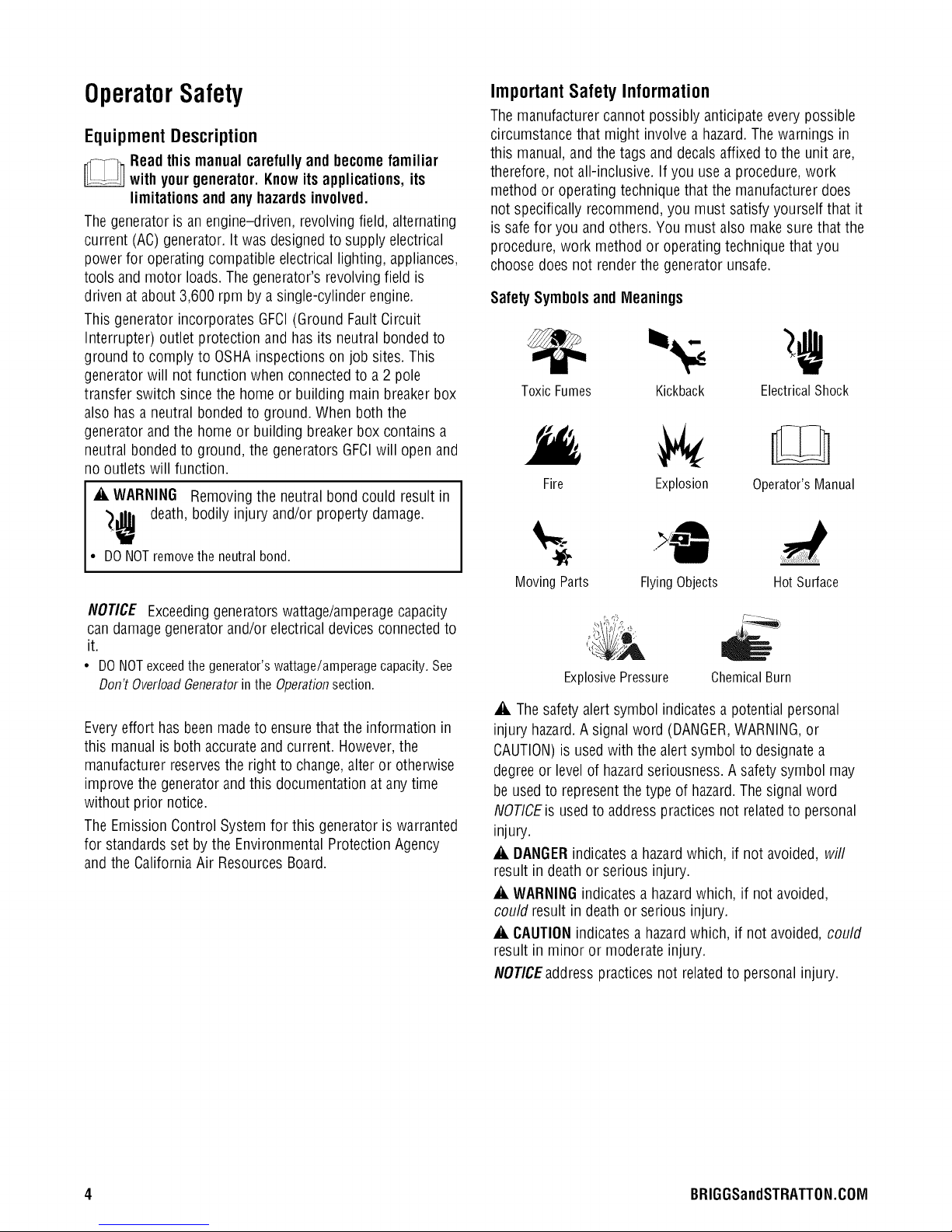

Important Safety Information

Themanufacturer cannot possibly anticipateevery possible

circumstance that might involve a hazard.Thewarnings in

this manual, and the tags and decals affixedto the unit are,

therefore, not all-inclusive. Ifyou usea procedure,work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safe for you andothers. You must also makesure that the

procedure, work method or operating technique that you

choose does not renderthe generator unsafe.

SafetySymbolsand Mleanings

Toxic Fumes Kickback ElectricalShock

Fire Explosion Operator'sManual

Moving Parts FlyingObjects Hot Surface

NOTICE Exceedinggeneratorswattage/amperagecapacity

candamagegenerator and/or electrical devices connectedto

it.

• DONOTexceedthegenerator'swattage/amperagecapacity.See

Don'tOverloadGeneratorinthe Operationsection.

Everyeffort hasbeen madeto ensurethat the information in

this manual is both accurateand current. However,the

manufacturer reservesthe right to change,alter or otherwise

improve the generator and this documentation at anytime

without prior notice.

The EmissionControl System for this generator is warranted

for standardsset by the Environmental Protection Agency

and the California Air ResourcesBoard.

,lib

ExplosivePressure

,A Thesafety alert symbol indicates a potential personal

injury hazard.A signal word (DANGER,WARNING,or

CAUTION)is usedwith the alert symbol to designatea

degreeor levelof hazardseriousness.A safety symbol may

be usedto representthe type of hazard.Thesignal word

NOTICEis usedto address practicesnot relatedto personal

injury.

_i, DANGER indicates a hazardwhich, if not avoided, will

result in deathor serious injury.

_i, WARNINGindicates a hazardwhich, if not avoided,

could result indeath or serious injury.

_i, CAUTIONindicates ahazardwhich, if not avoided, could

result in minor or moderate injury.

NOTICEaddress practices not related to personal injury.

ChemicalBurn

4 BRIGGSandSTRATTON.COIVl

Using a generator indoors CAN KiLL YOU iN MINUTES,

Generator exhaust contains carbon monoxide, This is

a poison you cannot see or smell,

A

_i, WARNING Starter cord kickback (rapid retraction) can

result in bodily injury. Kickback will pull hand

_ and arm toward engine faster than you can let

go.

Broken bones, fractures, bruises, or sprains could result.

• When starting engine, pull cord slowly until resistanceisfelt

andthen pull rapidlyto avoid kickback.

• NEVERstart or stop enginewith electricaldevices plugged in

andturned on.

V V

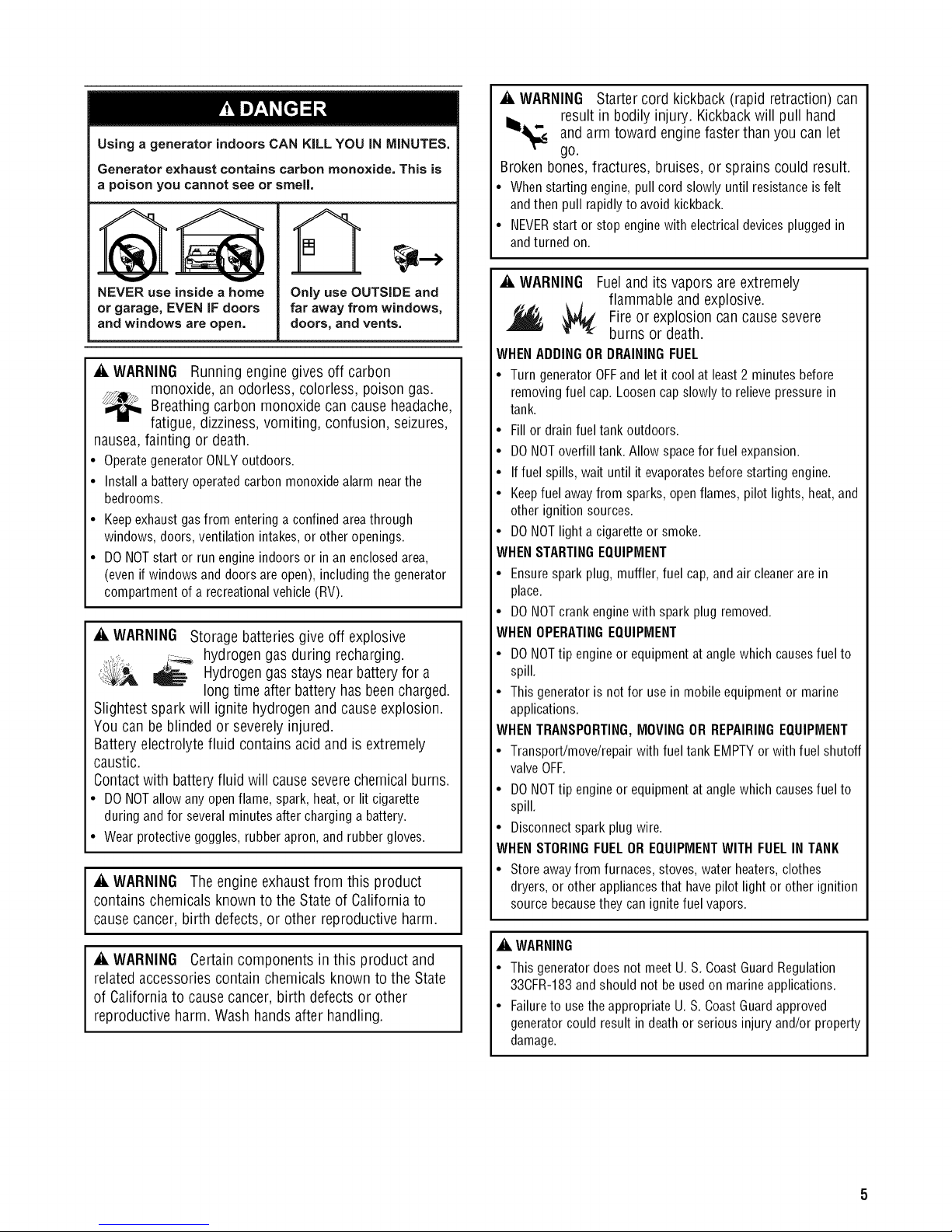

NEVER use inside a home

or garage, EVEN iF doors

and windows are open,

_i, WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

• Operategenerator ONLYoutdoors.

• Install a battery operatedcarbon monoxidealarm nearthe

bedrooms.

• Keepexhaustgas from entering a confinedareathrough

windows, doors,ventilation intakes, or other openings.

• DO NOTstart or run engine indoors or in an enclosedarea,

(even if windows anddoors are open), including the generator

compartment of arecreational vehicle (RV).

Only use OUTSIDE and

far away from windows,

doors, and vents,

_i, WARNING Storage batteriesgive off explosive

_,il;,_ ,,-_.._.hydrogen gas during recharging.

,t_,,_._,, _ Hydrogengasstays nearbatteryfor a

long time after battery has beencharged.

Slightest spark will ignite hydrogen and cause explosion.

You can be blinded or severelyinjured.

Batteryelectrolytefluid contains acid and is extremely

caustic.

Contactwith batteryfluid will causeseverechemicalburns.

• DONOTallowanyopenflame,spark,heat,orlitcigarette

duringandfor severalminutesaftercharginga battery.

• Wearprotectivegoggles,rubberapron,andrubbergloves.

A, WARNING Theengineexhaustfrom this product

contains chemicals known to the State of Californiato

causecancer, birth defects,or other reproductive harm.

_i, WARNING Certain components in this product and

relatedaccessoriescontain chemicals known to the State

of Californiato causecancer, birth defectsor other

reproductive harm. Washhands after handling.

_i, WARNING Fuel and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe

burns or death.

WHENADDINGOR DRAININGFUEL

• Turn generator OFFand let it coolat least2 minutes before

removing fuel cap. Loosen cap slowly to relievepressure in

tank.

• Fill or drain fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• Iffuel spills,wait until it evaporatesbefore starting engine.

• Keepfuel awayfrom sparks, open flames, pilot lights, heat, and

other ignition sources.

• DONOTlight a cigaretteor smoke.

WHENSTARTINGEQUIPMENT

• Ensure spark plug, muffler, fuel cap, and air cleanerare in

place.

• DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIPMENT

• DONOTtip engine or equipmentat angle which causesfuel to

spill.

• This generator is not for use in mobile equipment or marine

applications.

WHENTRANSPORTING,MOVINGOR REPAIRINGEQUIPMENT

• Transport/move/repair with fuel tank EMPTYor with fuel shutoff

valveOFF.

• DONOTtip engine or equipmentat angle which causesfuel to

spill.

• Disconnectspark plug wire.

WHENSTORINGFUELOR EQUIPMENTWITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters,clothes

dryers, or otherappliancesthat havepilot light or other ignition

source becausethey can ignite fuel vapors.

A WARNING

• This generator does notmeet U. S. CoastGuardRegulation

33CFR-183and should not beusedon marineapplications.

• Failureto usethe appropriate U. S.CoastGuard approved

generator could result in deathor serious injury and/or property

damage.

_i, WARNING Generator produces hazardous voltage.

'),111, Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

• When using generator for backup power, notify utility company.

Use approvedtransfer equipment to isolategeneratorfrom

electric utility.

• Use a ground fault circuit interrupter (GFCI)in any damp or

highly conductivearea,such as metal decking or steel work.

• DO NOTtouch barewires or receptacles.

• DO NOTuse generator with electrical cords which areworn,

frayed, bareor otherwisedamaged.

• DO NOToperate generator in the rain or wet weather.

• DO NOThandle generator or electricalcords while standing in

water, while barefoot,or while hands or feet are wet.

• DO NOTallow unqualified personsor children to operate or

servicegenerator.

_i, WARNING Contact with muffler area can result in

serious burns.

Exhaust

combustibles, structures or damage

fuel tank causing a fire.

• DO NOTtouch hot parts andAVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keepat least5 feet (152 cm) of clearanceon all sidesof

generator including overhead.

• It is aviolation of California Public Resource Code,Section

4442, to use or operate the engineon any forest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equipped with aspark arrester, as defined in Section

4442, maintained in effective working order. Otherstates or

federal jurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a sparkarrester designed for the exhaust system

installed on this engine.

• Replacement parts must bethe same and installed inthe same

position asthe original parts.

heat/gases can ignite

_i, CAUTION Excessively high operating speeds increase

risk of injury and damage to generator.

Excessively low speeds impose a heavy load.

• DO NOTtamper with governedspeed. Generatorsupplies

correct rated frequency and voltage when running at governed

speed.

• DO NOTmodify generator in any way.

NOTICE Exceeding generators wattage/amperage capacity

can damage generator and/or electrical devices connected to

it.

• DO NOTexceedthe generator's wattage/amperage capacity. See

Don't OverloadGeneratorin the Operationsection.

• Start generator and let engine stabilize beforeconnecting

electrical loads.

• Connectelectrical loadsin OFFposition, thenturn ONfor

operation.

• Turn electrical loads OFFand disconnect from generator before

stopping generator.

NOTICE Improper treatment of generator can damage it

and shorten its life.

• Use generator only for intended uses.

• If you havequestions about intended use,ask dealeror contact

local service center.

• Operategenerator only on level surfaces.

• DO NOTexpose generator to excessivemoisture, dust, dirt, or

corrosive vapors.

• DO NOTinsert any objects through cooling slots.

• If connected devicesoverheat, turn them off and disconnect them

from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

_i, WARNING Unintentional sparking can result in fire or

_ electric shock.

WHENADJUSTINGOR MAKINGREPAIRSTO YOURGENERATOR

• Disconnectthe spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Use approved spark plug tester.

• DO NOTcheck for spark with spark plug removed.

_i, WARNING Starter and other rotating parts can

entangle hands, hair, clothing, or accessories.

• NEVERoperategeneratorwithout protective housing or covers.

• DO NOTwear looseclothing, jewelry or anythingthat may be

caught in thestarter or other rotating parts.

• Tie up long hairand removejewelry.

6 BRIGGSandSTRATTON.COIVI

Assembly

Your generator requiressome assembly and is readyfor use

after it hasbeen properly servicedwith the recommended oil

and fuel.

If you haveany problemswith the assemblyof your generator,

pleasecall the generator helplineat (800)743-4115. If calling

for assistance,pleasehavethe model,revision,andserial

numberfrom the identificationlabelavailable.SeeControls

and Featuresfor identificationlabel location.

UnpackGenerator

1. Setthe carton on a rigid, flat surface.

2. Removeeverything from carton except generator.

3. Opencarton completely by cutting each corner from

top to bottom.

4. Leavegeneratoron cartonto install wheel kit.

Install Wheel Kit

NOTICE Wheel kit is not intended for over-the-road use.

You will needthe following tools to install these

components:

• 3/8" and 13 mmwrench

• Socketwrench with a 3/8" and 13mm socket

• Pliers

• Safetyglasses

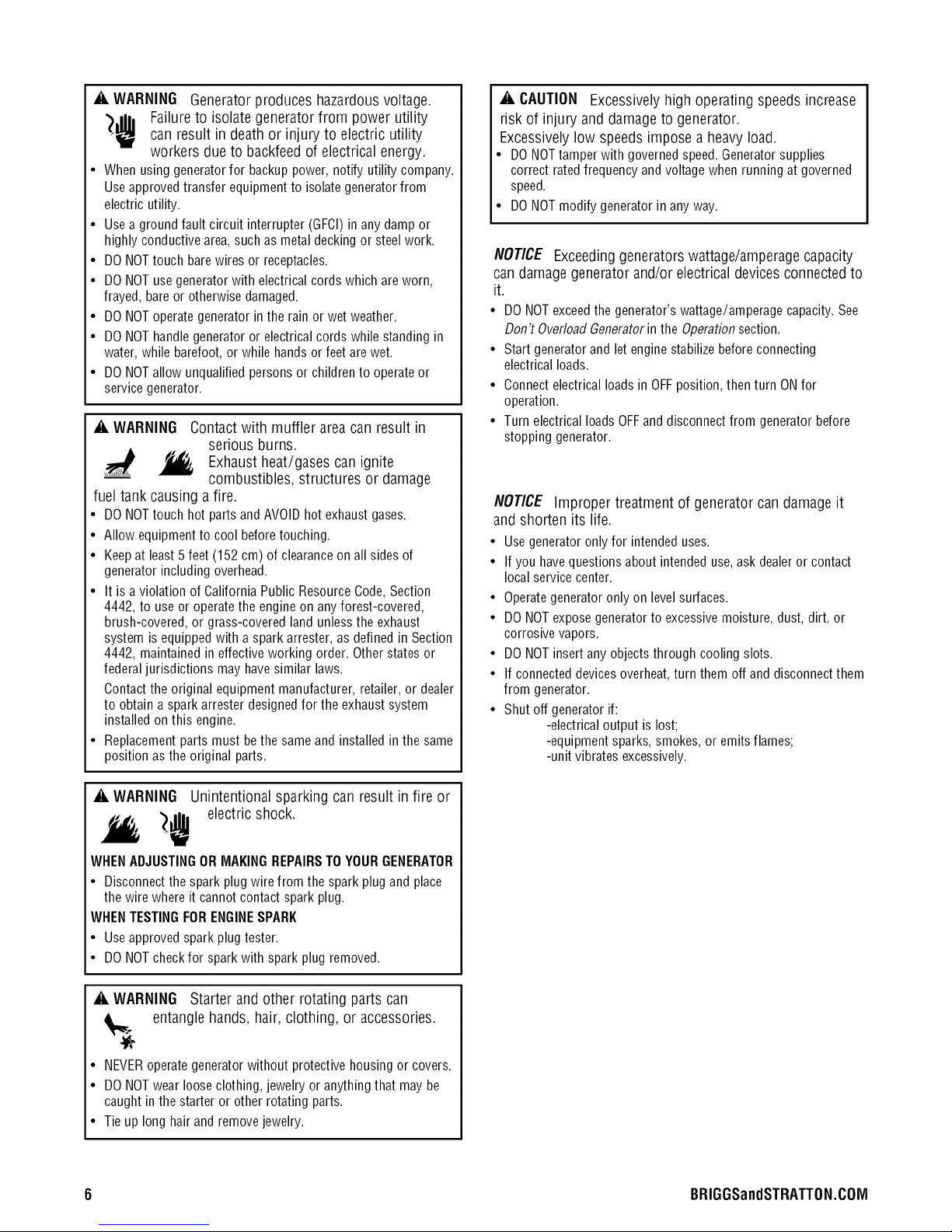

Installthewheelkit asfollows:

1. Tip generatorso that engineend is up.

2. Slide axle (A) through both mounting brackets.

3. Slide a wheel (B) over axle.

NOTICE Besure to install wheelwith raised hub inboard.

4. Placea washer (C) on axleandthen placean e-ring (D)

in axle groove.

Shipment Contents

The generatoris suppliedwith:

• Engineoil

• Operator's manual

• Batterycharge cables

• Wheelkit

• 120/240 Volt, 20 Amp locking plug

• 120Volt, 30Amp locking plug

_i, CAUTION E-rings can causeeye injury.

E-rings can spring back and become airborne

when installing or removing.

• Alwaysweareyeprotectionwheninstalling/removinge-rings.

5. Install e-ring with pliers, squeezingfrom top of e-ring

to bottom of axle.

6. Repeatsteps 3 through 5 to securesecondwheel.

7. Tip generatorso that engineside is down.

8. Attach clamps (E) to brackets (F) on both sides of

generatorwith 1/4' - 20 hexscrews (G).

9. Repeatsteps 2 through 5 to securethe third and fourth

wheels.

10.Attachhandle(H)tobracketongeneratorframeas

shown,witha50mmcapscrew(J),flatwashers(K),

nylonwashers(L),andM8locknut(M).

NOTICE DO NOTovertighten. Handlemust beable to move

up and down freely.

11. Return generator to normal operating position (resting

on wheels).

12. To apply brakes,push down firmly on handle of both

clamps until it locks in the down position andengages

the wheels.

NOTICE The generator is designedto be used on level

surfaces.

13. Loop handlepin (N) on generatorframe just above

handle bracket.

14. Raise handleand insert handlepin to movegenerator.

15. To releasebrakes,pull up on handle of both clamps

until it locks in the up position.

Add Engine Oil

1. Placegeneratoron a flat, levelsurface.

2. Cleanarea around oil fill andremoveyellow oil fill cap.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

NOTICE Improper treatment of generator can damage it

and shorten its life.

• DO NOTattempt to crank or start the engine beforeit has been

properly servicedwith the recommended oil. This may result in an

enginefailure.

_i, WARNING Fueland its vapors are extremely

flammable and explosive.

_, _ Fire or explosion can causesevere

burns or death.

WHENADDINGFUEL

• Turn generator OFFand let it cool at least2 minutes before

removing fuel cap. Loosen cap slowly to relievepressure in

tank.

• Fill fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• Iffuel spills,wait until it evaporatesbefore starting engine.

• Keepfuel awayfrom sparks, open flames, pilot lights, heat, and

other ignition sources.

• DONOTlight a cigaretteor smoke.

To protectthe fuelsystemfrom gum formation, mix ina fuel

stabilizerwhen addingfuel. SeeStorage.All fuel is not the

same.Ifyou experiencestartingor performanceproblems after

usingfuel,switch to adifferentfuel provideror changebrands.

This engineis certified to operateon gasoline.Theemission

control systemfor this engineis EM(EngineModifications).

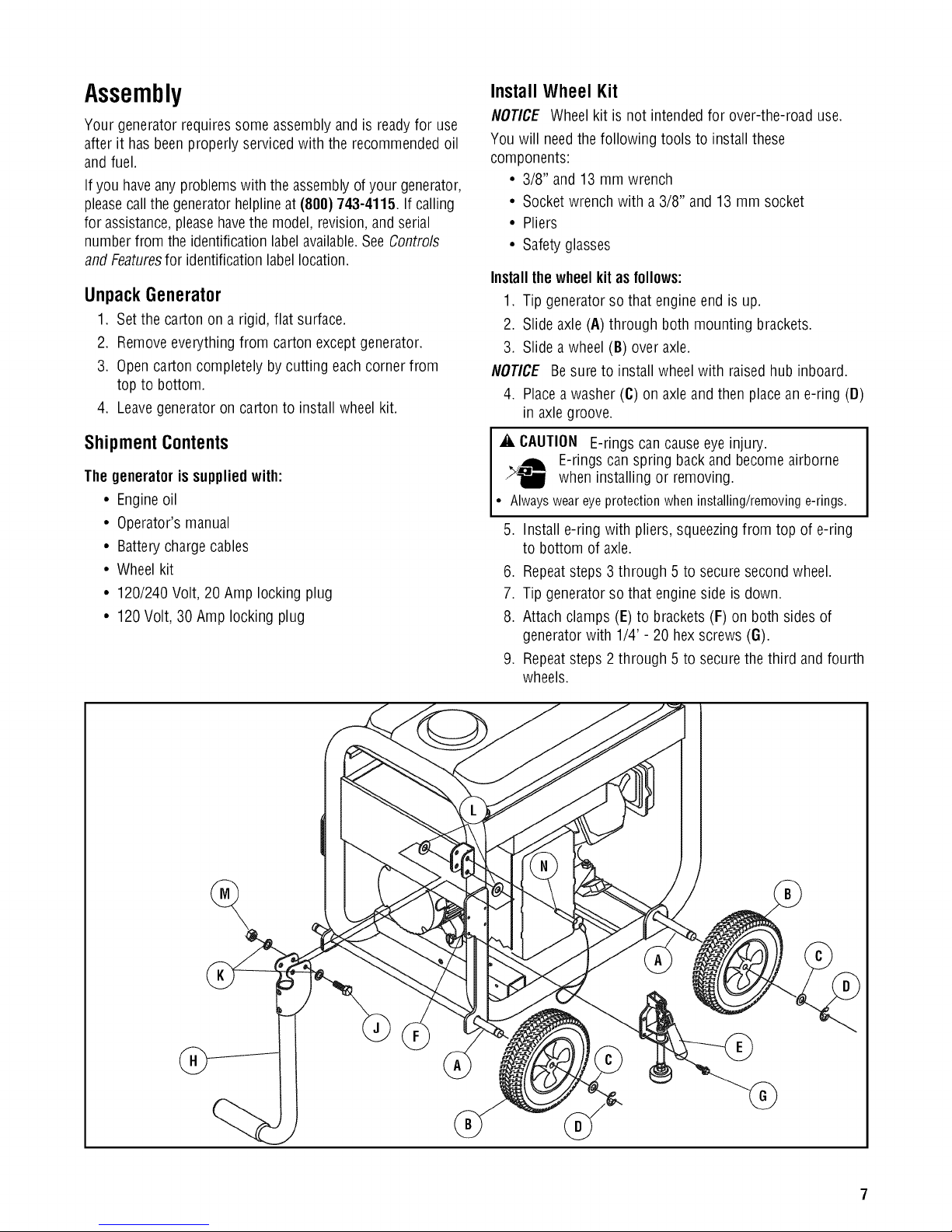

1. Cleanarea around fuel fill cap,remove cap.

2. Slowly addunleadedgasoline (A) to fuel tank (B). Be

careful not to fill abovethe baffle (C). This allows

adequatespace for fuel expansion as shown.

4. Replaceoil fill cap and fully tighten.

Add Fuel

Fuel must meet theserequirements:

• Clean,fresh, unleadedgasoline.

• A minimum of 87 octane/87AKI (91 RON).High

altitude use, seeHigh Altitude.

• Gasolinewith up to 10% ethanol (gasohol) or up to

15% MTBE(methyl tertiary butyl ether) is acceptable.

NOTICE Avoid generatordamage.

Failureto follow Operator's Manualfor fuel

recommendations voids warranty.

• DONOTuseunapprovedgasolinesuchasE85.

• DONOTmixoilin gasoline.

• DONOTmodifyengineto runonalternatefuels.

3. Install fuel capand let any spilled fuel evaporatebefore

starting engine.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remainemissions compliant, high altitude adjustment is

required.Operationwithout this adjustment will cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seea Briggs & Stratton Authorized

Dealerfor high altitude adjustment information. Operation of

the engine at altitudes below 2,500 feet (762 meters) with

the high altitude kit is not recommended.

8 BRIGGSandSTRATTON.COIVl

SystemGround

Thegenerator hasa system ground that connectsthe

generatorframe components to the ground terminals onthe

ACoutput receptacles.Thesystem ground is connected to

the ACneutral wire (the neutral is bonded to the generator

frame).

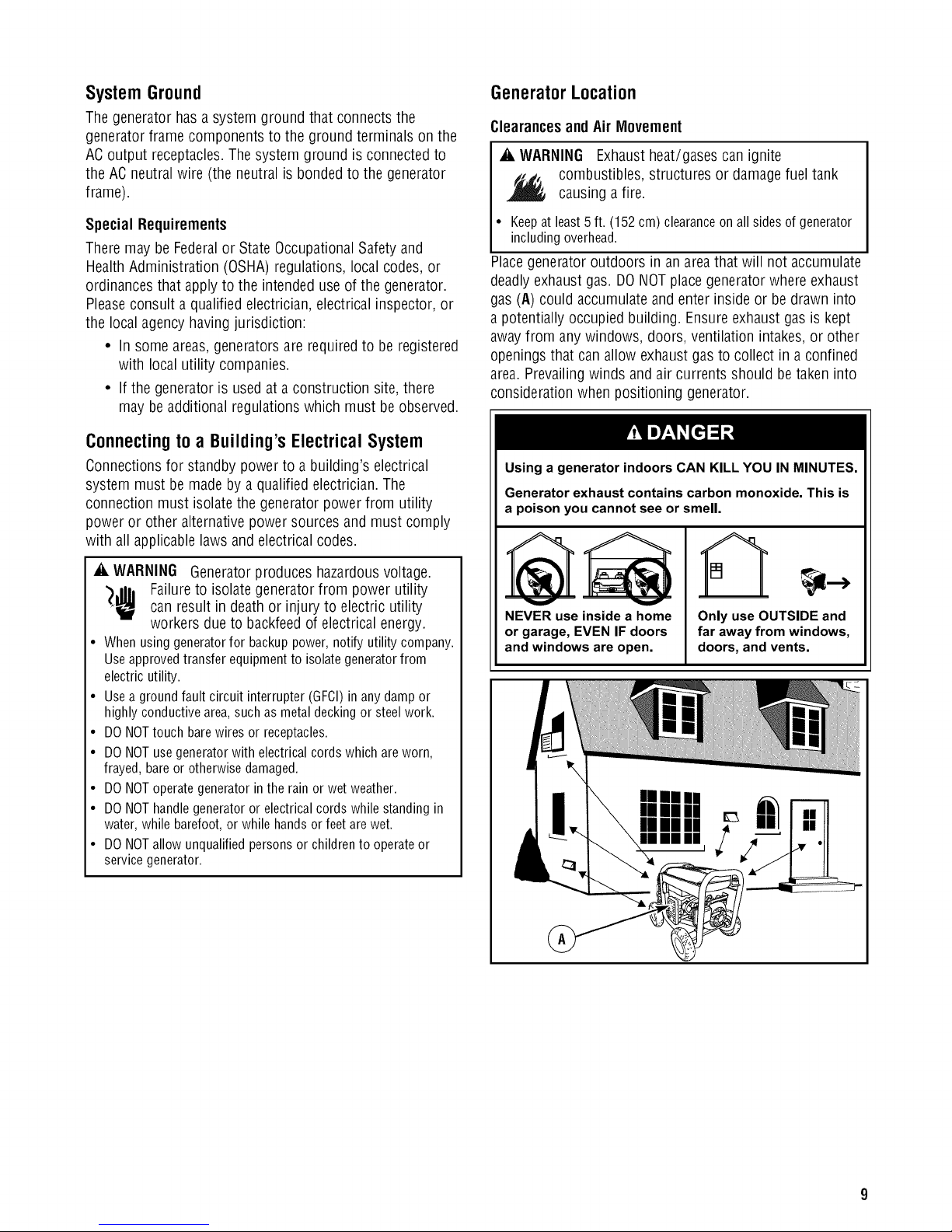

GeneratorLocation

Clearancesand Air Movement

_i, WARNING Exhaustheat/gases can ignite

combustibles, structures or damagefuel tank

causing a fire.

Special Requirements

Theremay be Federalor State OccupationalSafety and

Health Administration (OSHA)regulations, local codes, or

ordinances that applyto the intended useof the generator.

Pleaseconsult a qualified electrician, electrical inspector, or

the local agency having jurisdiction:

• In some areas,generators are requiredto be registered

with local utility companies.

• Ifthe generator is usedat a construction site, there

may be additional regulations which must be observed.

Connecting to a Building's Electrical System

Connectionsfor standby powerto a building's electrical

system must be made by a qualified electrician. The

connection must isolate the generator powerfrom utility

power or other alternativepower sources andmust comply

with all applicablelaws andelectrical codes.

A, WARNING Generatorproduces hazardousvoltage.

')Jib Failureto isolate generatorfrom power utility

can result in deathor injury to electric utility

workers due to backfeedof electrical energy.

• Whenusinggeneratorfor backuppower,notifyutilitycompany.

Useapprovedtransferequipmentto isolategeneratorfrom

electricutility.

• Useagroundfaultcircuitinterrupter(GFCI)in anydampor

highlyconductivearea,suchas metaldeckingor steelwork.

• DONOTtouchbarewiresor receptacles.

• DONOTusegeneratorwithelectricalcordswhichareworn,

frayed,bareorotherwisedamaged.

• DONOToperategeneratorintherainorwetweather.

• DONOThandlegeneratoror electricalcordswhilestandingin

water,whilebarefoot,or whilehandsorfeetarewet.

• DONOTallowunqualifiedpersonsor childrento operateor

servicegenerator.

• Keepatleast5 ft. (152cm) clearanceonall sidesof generator

includingoverhead.

Placegenerator outdoors in an areathat will not accumulate

deadlyexhaust gas. DONOTplace generatorwhere exhaust

gas (A) could accumulate and enter inside or be drawn into

a potentially occupied building. Ensureexhaustgas is kept

awayfrom any windows, doors, ventilation intakes, or other

openings that canallow exhaust gasto collect in a confined

area.Prevailingwinds and air currents should betaken into

consideration when positioning generator.

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell.

,A

B

V V

NEVER use insidea home

or garage, EVENIF doors

and windowsare open.

Only use OUTSIDE and

far away from windows,

doors, and vents.

1

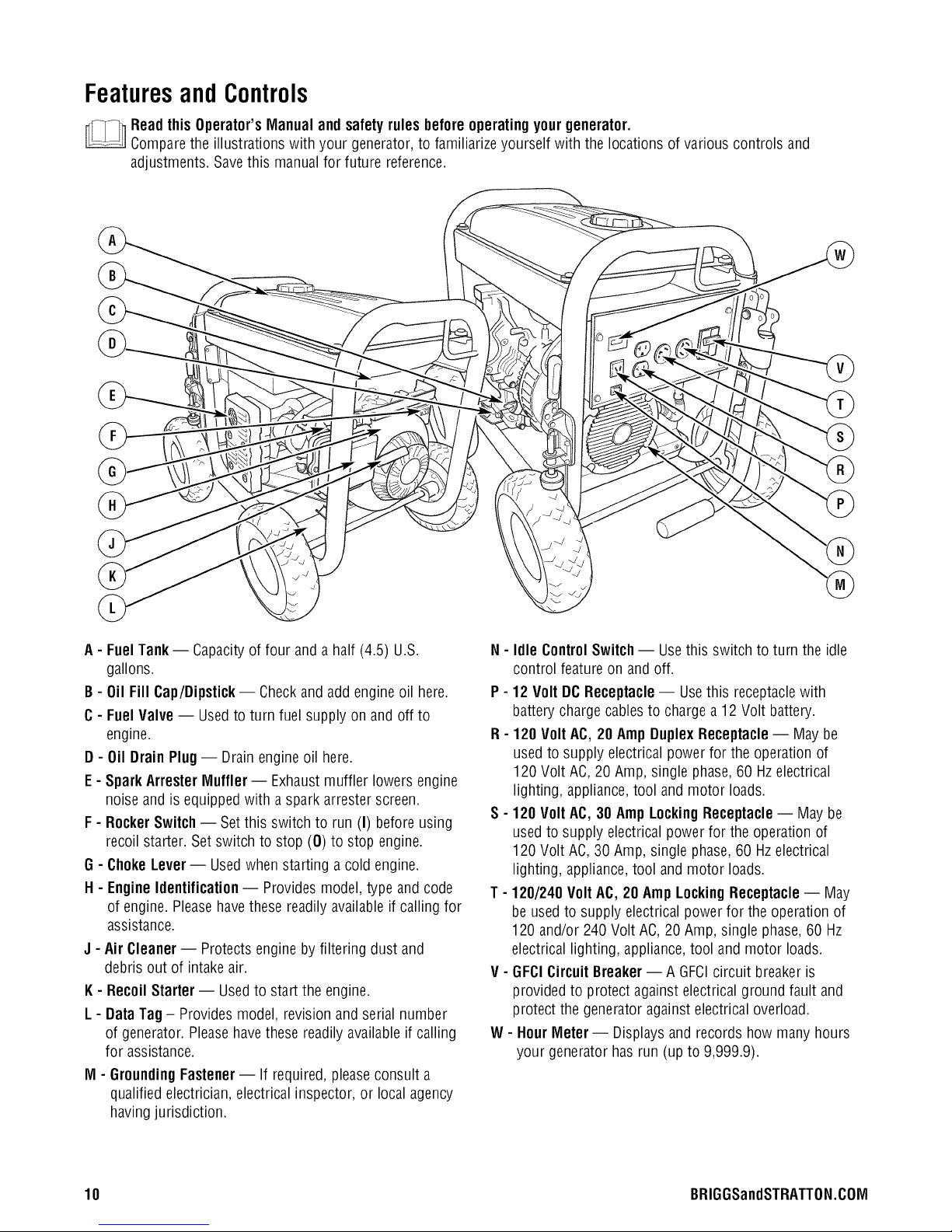

FeaturesandControls

Readthis Operator'sManualand safetyrules beforeoperatingyourgenerator.

Comparethe illustrations with your generator,to familiarize yourself with the locations of various controls and

adjustments. Savethis manual for future reference.

A- FuelTank -- Capacityof four and a half (4.5) U.S.

gallons.

B- Oil Fill Cap/Dipstick-- Checkand add engineoil here.

C- Fuel Valve-- Usedto turn fuel supply on and off to

engine.

D - Oil DrainPlug -- Drainengine oil here.

E - Spark ArrestorMuffler -- Exhaust muffler lowers engine

noise and is equipped with a spark arrestor screen.

F - Rocker Switch -- Set this switch to run (I) before using

recoil starter. Setswitch to stop (0) to stop engine.

G - ChokeLever- Usedwhen starting a cold engine.

H - Engine Identification -- Provides model, type and code

of engine. Pleasehavethesereadily availableif calling for

assistance.

J - Air Cleaner-- Protectsengine by filtering dust and

debris out of intake air.

K- Recoil Starter -- Usedto start the engine.

L - Data Tag - Provides model, revision and serial number

of generator. Pleasehavethese readilyavailableif calling

for assistance.

M - GroundingFastener-- If required, pleaseconsult a

qualified electrician, electrical inspector, or local agency

havingjurisdiction.

N - Idle ControlSwitch -- Usethis switch to turn the idle

control feature on andoff.

P - 12 Volt DC Receptacle -- Usethis receptaclewith

batterycharge cablesto chargea 12Volt battery.

R - 120Volt AC, 20 Amp DuplexReceptacle-- May be

usedto supply electrical power for the operation of

120 Volt AC,20 Amp, single phase,60 Hzelectrical

lighting, appliance,tool and motor loads.

S - 120 Volt AC,30 AmpLockingReceptacle -- May be

usedto supply electrical power for the operation of

120 Volt AC, 30 Amp, single phase, 60 Hzelectrical

lighting, appliance,tool and motor loads.

T - 120/240 Volt AC,20 AmpLockingReceptacle-- May

be usedto supply electrical power for the operation of

120 and/or 240Volt AC,20 Amp,single phase,60 I-Iz

electrical lighting, appliance,tool and motor loads.

V - GFClCircuitBreaker-- A GFCIcircuit breakeris

providedto protect against electricalground fault and

protect the generatoragainst electrical overload.

W - Hour Meter- Displays and records how many hours

your generatorhas run (up to 9,999.9).

10 BRIGGSandSTRATTON.COM

CordSetsandReceptacles

Use only high quality, well-insulated, grounded extension

cords with the generator's 120 Volt duplex receptacle.

Inspect extension cords before eachuse.

Checkthe ratings of all extensioncords beforeyou use

them. Extensioncord sets usedshould be rated for 125 Volt

ACloads at 20 Amps or greaterfor most electrical devices.

Somedevices,however, may not require this type of

extension cord. Checkthe operator's manuals of those

devicesfor the manufacturer's recommendations.

Keepextension cords asshort aspossible to minimize

voltage drop.

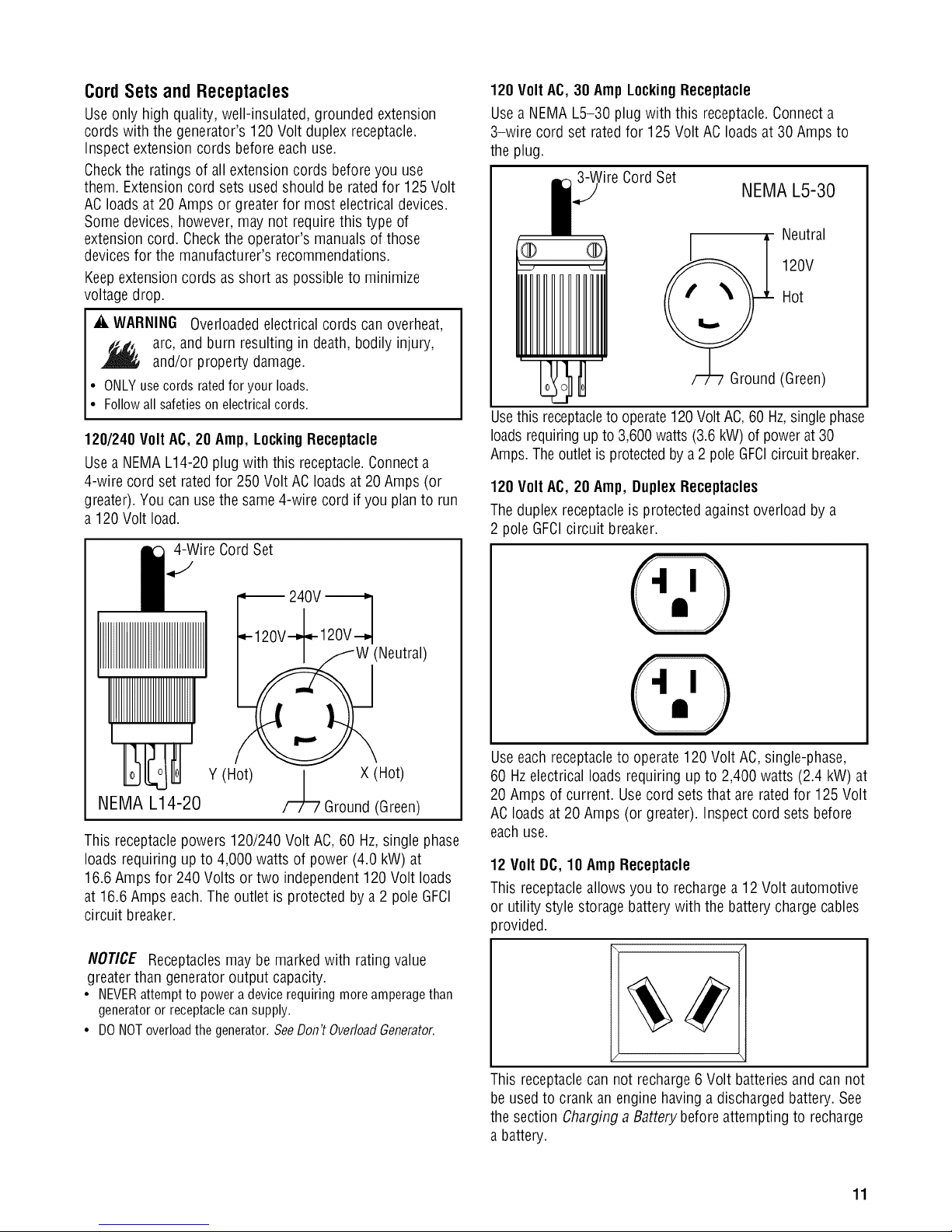

120 Volt AC, 30 Amp LockingReceptacle

Usea NEMA L5-30 plugwith this receptacle.Connecta

3-wire cord set ratedfor 125 Volt ACloads at 30 Amps to

the plug.

_'ireCord Set

NEMA L5-30

Neutral

® ®

120V

Hot

_i, WARNING Overloadedelectrical cords can overheat,

arc, and burn resulting in death, bodily injury,

and/or property damage.

• ONLYusecordsratedfor yourloads.

• Followallsafetiesonelectricalcords.

120/240 Volt AC, 20 Amp, LockingReceptacle

Use a NEMAL14-20 plugwith this receptacle.Connecta

4-wire cord set rated for 250 Volt AC loadsat 20 Amps (or

greater). You can usethe same4-wire cord if you planto run

a 120 Volt load.

I 4-Wire CordSet

(Neutral)

Y (Hot)

NEMA L14-20

This receptaclepowers 120/240 Volt AC, 60 Hz,single phase

loads requiring up to 4,000 watts of power (4.0 kW) at

16.6 Amps for 240 Volts or two independent 120 Volt loads

at 16.6 Amps each. Theoutlet is protected by a2 pole GFCI

circuit breaker.

F7L7 X (Hot)

Ground (Green)

II11111111111

(Green)

Usethis receptacleto operate120 VoltAC,60 Hz,singlephase

loadsrequiringup to 3,600watts (3.6kW)of powerat30

Amps.Theoutlet is protectedby a 2 pole GFCIcircuit breaker.

120 Volt AC, 20 Amp, DuplexReceptacles

Theduplex receptacleis protected against overload by a

2 pole GFCIcircuit breaker.

Useeachreceptacleto operate 120 Volt AC, single-phase,

60 Hz electricalloads requiring upto 2,400 watts (2.4 kW) at

20 Amps of current. Usecord sets that are ratedfor 125 Volt

ACloads at 20 Amps (or greater). Inspect cord sets before

eachuse.

12 Volt DC,10 AmpReceptacle

This receptacleallows you to rechargea 12 Volt automotive

or utility style storagebatterywith the battery charge cables

provided.

NOTICE Receptacles may be marked with rating value

greater than generator output capacity.

• NEVERattempt to power adevice requiring moreamperagethan

generator or receptacle can supply.

• DONOToverloadthe generator. SeeDon't OverloadGenerator.

This receptaclecan not recharge6 Volt batteriesand can not

be usedto crank anengine having adischarged battery. See

the section Charginga Batterybefore attempting to recharge

a battery.

11

Ground Fault Protection

This unit is equippedwith a Ground Fault Circuit Interrupter

(GFCI).This device meets applicablefederal, stateand local

codes.

The GFCIprotects against electrical shockthat may be

caused if your body becomes a pathwhich electricity travels

to reachground. This could happenif you touch a"Live"

applianceor wire, or aretouching plumbing or other

materials that connectto the ground.

When protected by a GFCI,one may still feel a shock, but the

GFCIshould cut current off quickly enough so that aperson

in normal healthshould not suffer anyserious electrical

injury.

_k WARNING Generator produces hazardous

_ voltage/current.

• TheGFCIwill not protect you againstthe following situations:

-Line-to-line shocks;

-Current overloadsor line-to-line short circuits.

• Thefuse or circuit breakeratthe control panel must provide

such protection.

DuringGeneratorUse

If circuit breakertrips during use,it usually indicates faulty

electrical equipment or cords. However,test the circuit

breakeras follows;

1. Disconnect loads, reset and test circuit breakeras

described earlier. Let generator runwithout any loads

for 1 minute.

_k CAUTION If circuit breaker trips in the 1 minute

period:

• DONOTusegenerator.

• Calla Briggs& StrattonPowerProductsservicecenter.

,

If circuit breakertests correctly, the electrical

equipment or extension cords may befaulty. Replace

faulty electrical equipment andcords beforefurther

use.

A. CAUTION If circuit breaker tests correctly:

• Havequalified personnel checkall electricalequipment and

cords for any defects.

• Replaceelectricalequipment and cords or taketo a qualified

repair center.

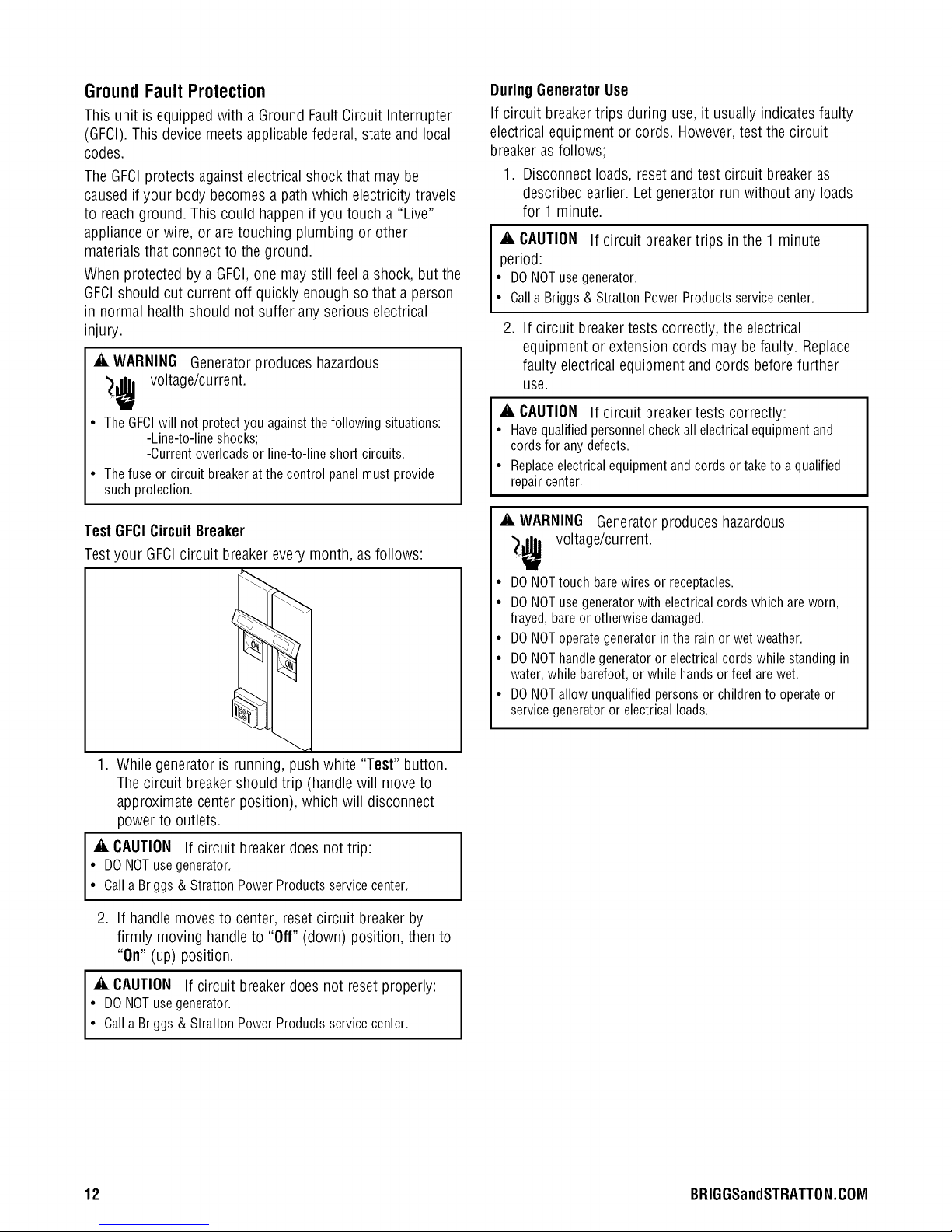

TestGFCICircuit Breaker

Testyour GFCIcircuit breaker every month, as follows:

1. While generator is running, push white "Test" button.

Thecircuit breakershould trip (handle will move to

approximate center position), which will disconnect

power to outlets.

_k CAUTION If circuit breaker does not trip:

• DONOTusegenerator.

• Calla Briggs& StrattonPowerProductsservicecenter.

2. If handlemoves to center, resetcircuit breakerby

firmly moving handleto "Off" (down) position, then to

"On" (up) position.

_k WARNING Generator produces hazardous

_1_ voltage/current.

• DO NOTtouch barewires or receptacles.

• DO NOTuse generator with electrical cords which areworn,

frayed,bare or otherwisedamaged.

• DO NOToperate generator in the rain or wet weather.

• DO NOThandle generator or electricalcords while standing in

water, while barefoot,or while hands or feet arewet.

• DO NOTallow unqualified personsor children to operate or

servicegenerator or electrical loads.

_k CAUTION If circuit breaker does not reset properly:

• DO NOTuse generator.

• Calla Briggs & Stratton Power Productsservice center.

12 BRIGGSandSTRATTON.COIVI

Operation

Starting the Engine

Disconnect all electrical loads from the generator. Usethe

following start instructions:

1. Make sure unit is on a level surface.

NOTICE Failureto start and operatethe unit on a level

surfacewill causethe unit not to start or shut down during

operation.

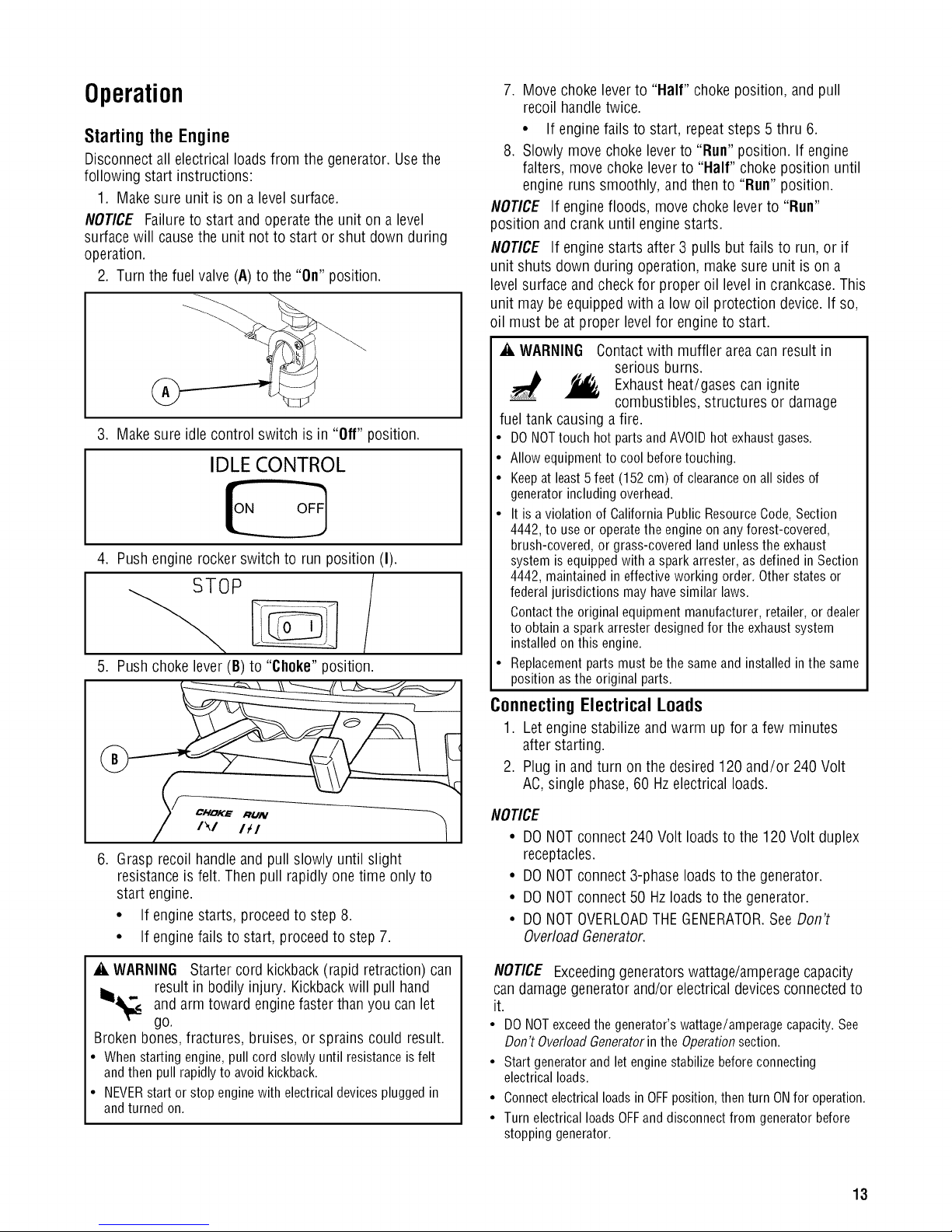

2. Turn thefuel valve (A) to the "On" position.

3. Make sure idle control switch is in "Off" position.

IDLE CONTROL

4. Push engine rocker switch to run position(I).

5. Push choke lever (B)to "Choke" position.

7. Move choke leverto "Half" choke position, and pull

recoil handletwice.

• If engine fails to start, repeatsteps 5 thru 6.

8. Slowly movechoke leverto "Run" position. If engine

falters, move choke lever to "Half" choke position until

engine runs smoothly, and then to "Run" position.

NOTICE If engine floods, move choke lever to "Run"

position and crank until enginestarts.

NOTICE If engine starts after 3 pulls but fails to run, or if

unit shuts down during operation, makesure unit is on a

level surfaceand check for proper oil level in crankcase.This

unit may be equipped with a low oil protection device. If so,

oil must beat proper levelfor engine to start.

_i, WARNING Contact with muffler area can result in

serious burns.

Exhaust heat/gases can ignite

combustibles, structures or damage

fuel tank causing a fire.

• DO NOTtouch hot parts andAVOIDhot exhaust gases.

• Allow equipmentto cool beforetouching.

• Keepat least5 feet (152 cm) of clearanceon all sides of

generator including overhead.

• It is aviolation of California Public Resource Code,Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust

system is equipped with aspark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federaljurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain aspark arrester designed for the exhaust system

installed on this engine.

• Replacement parts must bethe same and installed inthe same

position asthe original parts.

._Z Ikl Itl

6. Grasp recoil handleand pull slowly until slight

resistance is felt. Then pull rapidly one time only to

start engine.

• If engine starts, proceedto step 8.

• If engine fails to start, proceedto step 7.

_i, WARNING Starter cord kickback (rapid retraction)can

result in bodily injury. Kickbackwill pull hand

llii_ - andarm toward enginefasterthan you can let

T-"

go.

Broken bones,fractures, bruises, or sprains could result.

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpullrapidlytoavoidkickback.

• NEVERstartor stopenginewith electricaldevicespluggedin

andturnedon.

Connecting Electrical Loads

1. Let engine stabilize and warm up for a few minutes

after starting.

2. Plug inand turn on the desired 120 and/or 240 Volt

!

AC,single phase,60 Hzelectrical loads.

NOtiCE

• DONOTconnect 240 Volt loads to the 120 Volt duplex

receptacles.

• DONOTconnect 3-phaseloads to the generator.

• DONOTconnect 50 Hzloadsto the generator.

• DONOTOVERLOADTHEGENERATOR.SeeDon't

OverloadGenerator.

NOTICE Exceeding generators wattage/amperage capacity

can damage generator and/or electrical devices connected to

it.

• DO NOTexceedthe generator's wattage/amperage capacity. See

Don't OverloadGeneratorin the Operationsection.

• Start generator and let engine stabilize beforeconnecting

electrical loads.

• Connectelectrical loads in OFFposition, thenturn ONfor operation.

• Turn electrical loads OFFand disconnect from generator before

stopping generator.

13

Stoppingthe Engine

1. Turn OFFand unplug all electrical loads from generator

panel receptacles.NEVERstart or stop enginewith

electrical devicesplugged in and turned ON.

2. Move idle control switch to "Off" position.

3. Let engine run at no-loadfor severalminutes to

stabilize internaltemperatures of engineand generator.

4. Push engine rocker switch to stop position (0).

_i, WARNING Backfire,fire or engine damagecould

occur.

_i, WARNING Storage batteriesgive off explosive

,- hydrogen gasduring recharging.

_'_ Hydrogen gas stays near battery for a

long time after battery has beencharged.

Slightest spark will ignite hydrogen and cause explosion.

You can be blinded or severelyinjured.

Batteryelectrolytefluid contains acid and is extremely

caustic.

Contactwith batteryfluid will causeseverechemical burns.

• DONOTallowanyopenflame,spark,heat,orlitcigarette

duringandfor severalminutesaftercharginga battery.

• Wearprotectivegoggles,rubberapron,andrubbergloves.

• DONOTstop engine bymoving chokecontrol to "Choke"

position (]",l ).

5. Move fuel valve to "Off" position.

Operating Automatic Idle Control

This feature is designedto greatly improve fuel economy.

When this switchis turned ON,the enginewill only run at

its normal high governedengine speed when electrical loads

are connected.When electrical loads are removed,the

engine will run at a reducedspeed.

With the switchoff, the enginewill run at the normal high

engine speed.Alwayshave the switchoff whenstartingand

stoppingthe engine.

Oil Pressure Shutdown

If engine oil pressuredrops below a preset level,an oil

switch will stop the engine. Checkoil levelwith dipstick.

If oil level isbetweenADDand FULLmark on dipstick:

1. DONOTtry to restart the engine.

2. Contact a Briggs & Stratton Authorized Dealer.

3. DONOToperate engine until oil pressureis corrected.

To recharge12 Volt batteries, proceed asfollows:

1. Checkfluid levelin all battery cells. If necessary,add

ONLYdistilled water to cover separators in battery

cells. DONOTusetapwater.

2. If batteryis equippedwith vent caps, make sure they

are installed and aretight.

3. If necessary,clean batteryterminals.

_i, WARNING Battery posts, terminals and related

accessoriescontain leadand leadcompounds - chemicals

known to the State of Californiato cause cancerand

reproductiveharm. Wash handsafter handling.

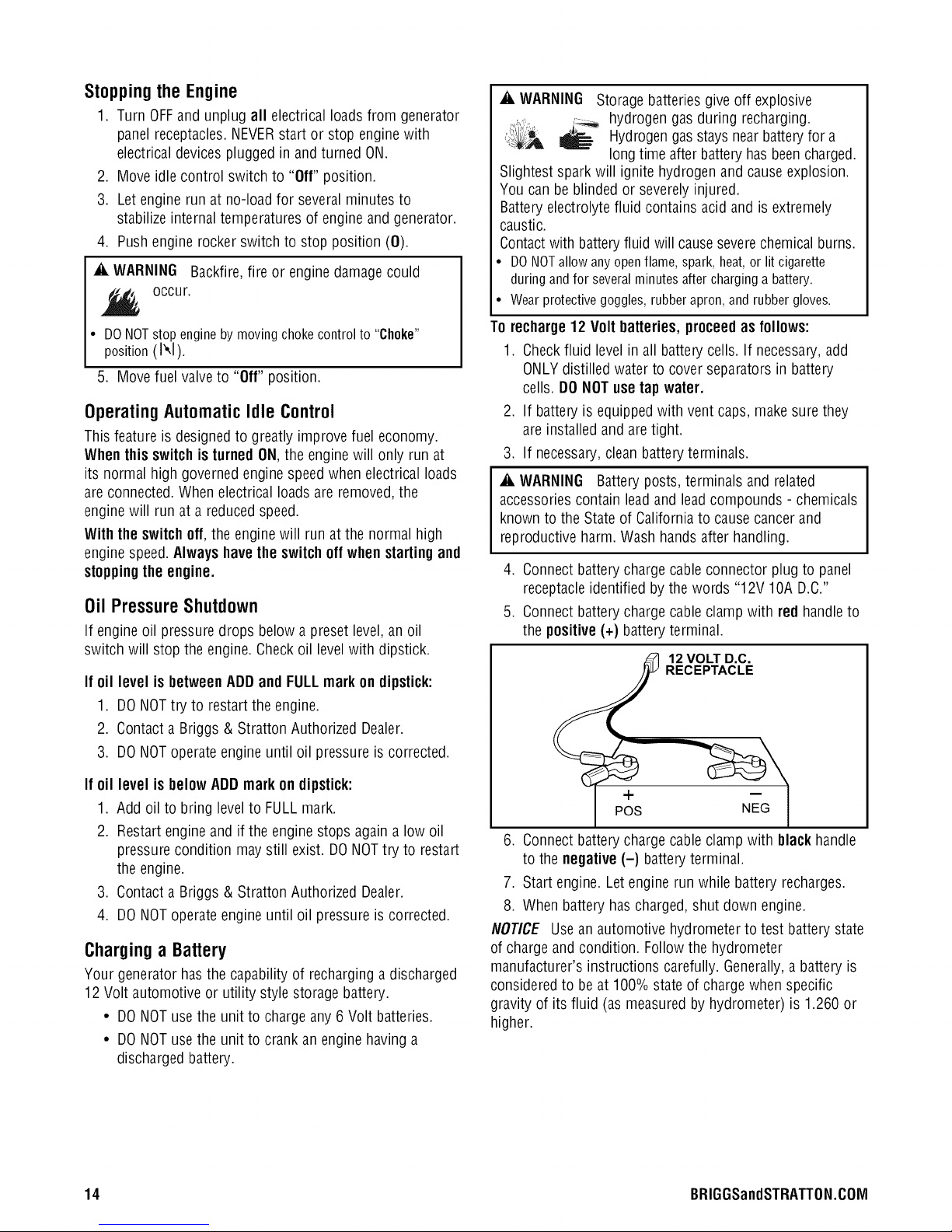

4. Connectbattery chargecable connector plug to panel

receptacleidentified by the words "12V IOA D.C."

5. Connectbattery chargecable clamp with red handleto

the positive(+) batteryterminal.

12 VOLT D.C.

RECEPTACLE

If oil level is

1.

Add oil to bring level to FULLmark.

2.

Restart engine and if the engine stops again a low oil

belowADDmark on dipstick:

pressure condition may still exist. DONOTtry to restart

the engine.

.

Contact a Briggs & Stratton Authorized Dealer.

4.

DONOToperateengine until oil pressure is corrected.

Charging a Battery

Your generator has the capability of recharging a discharged

12 Volt automotive or utility style storage battery.

• DONOTuse the unit to charge any 6 Volt batteries.

• DONOTuse the unit to crank an engine having a

discharged battery.

14 BRIGGSandSTRATTON.COIVl

+

POS NEG

6. Connectbattery chargecable clamp with blackhandle

to the negative(-) battery terminal.

7. Start engine. Let engine run while battery recharges.

8. When battery hascharged, shut down engine.

NOTICE Use an automotive hydrometerto test batterystate

of charge and condition. Follow the hydrometer

manufacturer's instructions carefully. Generally,a battery is

considered to be at 100% stateof charge when specific

gravity of its fluid (as measured by hydrometer) is 1.260 or

higher.

Cold WeatherOperation

Under certain weather conditions (temperatures below 40°F

[4°0] combined with high humidity), your generator may

experienceicing of the carburetor and/or the crankcase

breather system. To reduce this problem, you needto

perform the following:

1. Make sure generator hasclean,fresh fuel.

2. Openfuel valve(turn valve to open position).

3. Use SAE5W-30 oil.

4. Checkoil leveldaily or after every eight (8) hours of

operation.

5. Maintain generatorfollowing MaintenanceSchedulein

Maintenancesection.

6. Shelter unit from elements.

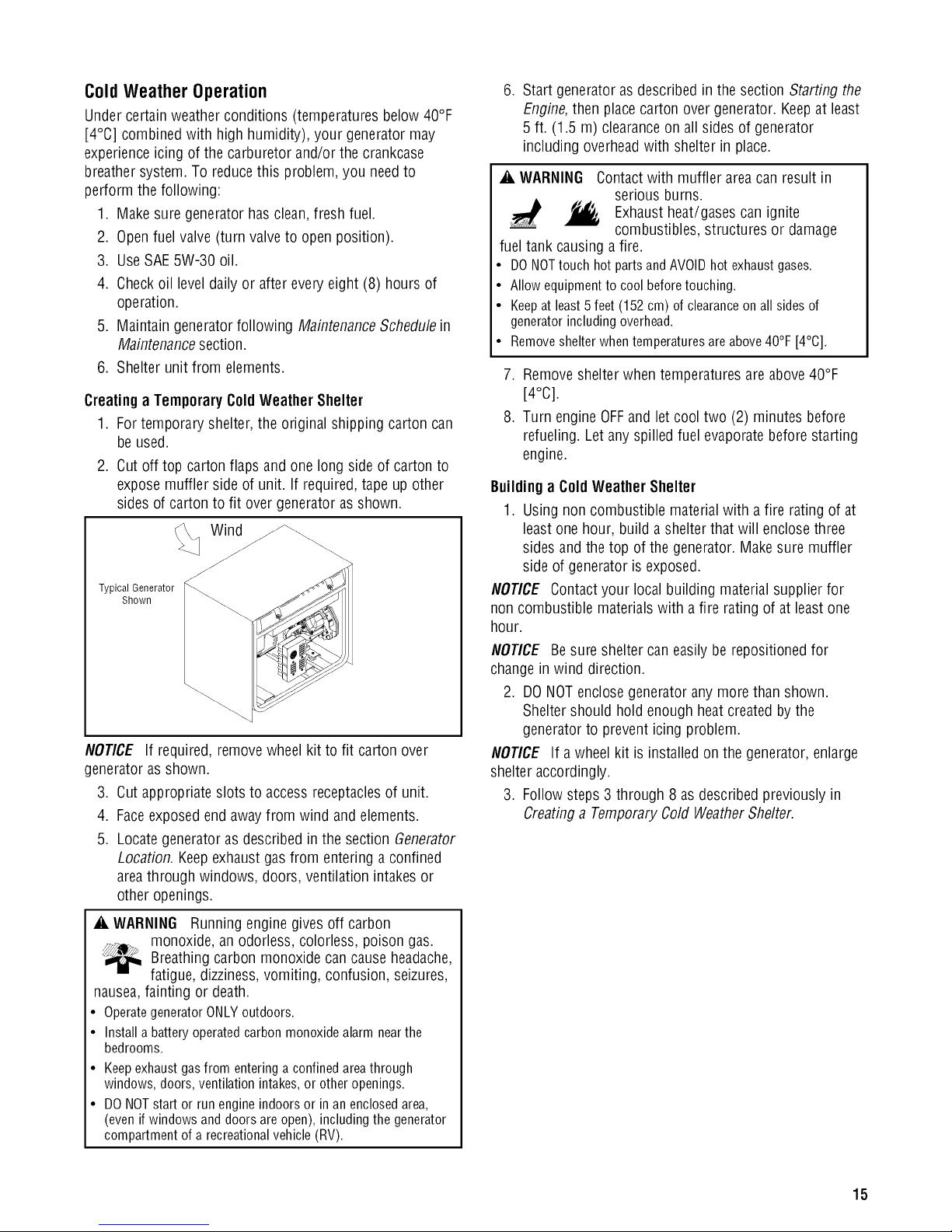

Creatinga TemporaryColdWeather Shelter

1. Fortemporary shelter,the original shipping carton can

be used.

2. Cut off top cartonflaps andone long sideof carton to

expose muffler side of unit. If required,tape up other

sides of carton to fit over generatoras shown.

Wind

Typical Generator

Shown

NOTICE If required, removewheel kit to fit carton over

generator asshown.

3. Cut appropriate slots to access receptaclesof unit.

4. Faceexposedend away from wind and elements.

5. Locate generatoras described in the section Generator

Location. Keepexhaust gasfrom entering aconfined

areathrough windows, doors, ventilation intakes or

other openings.

,

Start generator as described in the section Starting the

Engine,then placecarton over generator. Keepat least

5 ft. (1.5 m) clearanceon all sides of generator

including overheadwith shelter in place.

A WARNING Contactwith muffler area can result in

serious burns.

Exhaust

heat/gases can ignite

combustibles, structures or damage

fuel tank causinga fire.

• DONOTtouchhotpartsandAVOIDhot exhaustgases.

• Allowequipmentto coolbeforetouching.

• Keepatleast5 feet(152cm)of clearanceonall sidesof

generatorincludingoverhead.

• Removeshelterwhentemperaturesareabove40°F[4°C].

7. Removeshelter when temperatures are above 40°F

[4°C].

8. Turn engine OFFand let cool two (2) minutes before

refueling. Let anyspilled fuel evaporatebefore starting

engine.

Buildinga ColdWeather Shelter

1. Using noncombustible materialwith a fire rating of at

least one hour, build a shelter that will enclose three

sides and the top of the generator. Makesure muffler

side of generator is exposed.

NOTICE Contactyour local building materialsupplier for

non combustible materialswith a fire rating of at least one

hour.

NOTICE Besure shelter caneasily be repositioned for

changein wind direction.

2. DONOTenclose generator any more than shown.

Sheltershould hold enough heat createdby the

generatorto prevent icing problem.

NOTICE If a wheel kit is installed on the generator, enlarge

shelter accordingly.

3. Follow steps 3 through 8 asdescribed previously in

Creatinga TemporaryCold WeatherShelter.

A WARNING Runningengine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathingcarbon monoxidecancause headache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

• OperategeneratorONLYoutdoors.

• Installa batteryoperatedcarbonmonoxidealarmnearthe

bedrooms.

Keepexhaustgas from entering a confined areathrough

windows, doors,ventilation intakes, or other openings.

DO NOTstart or run engine indoors or in an enclosedarea,

(even if windows anddoors are open), including the generator

compartment of arecreational vehicle (RV).

15

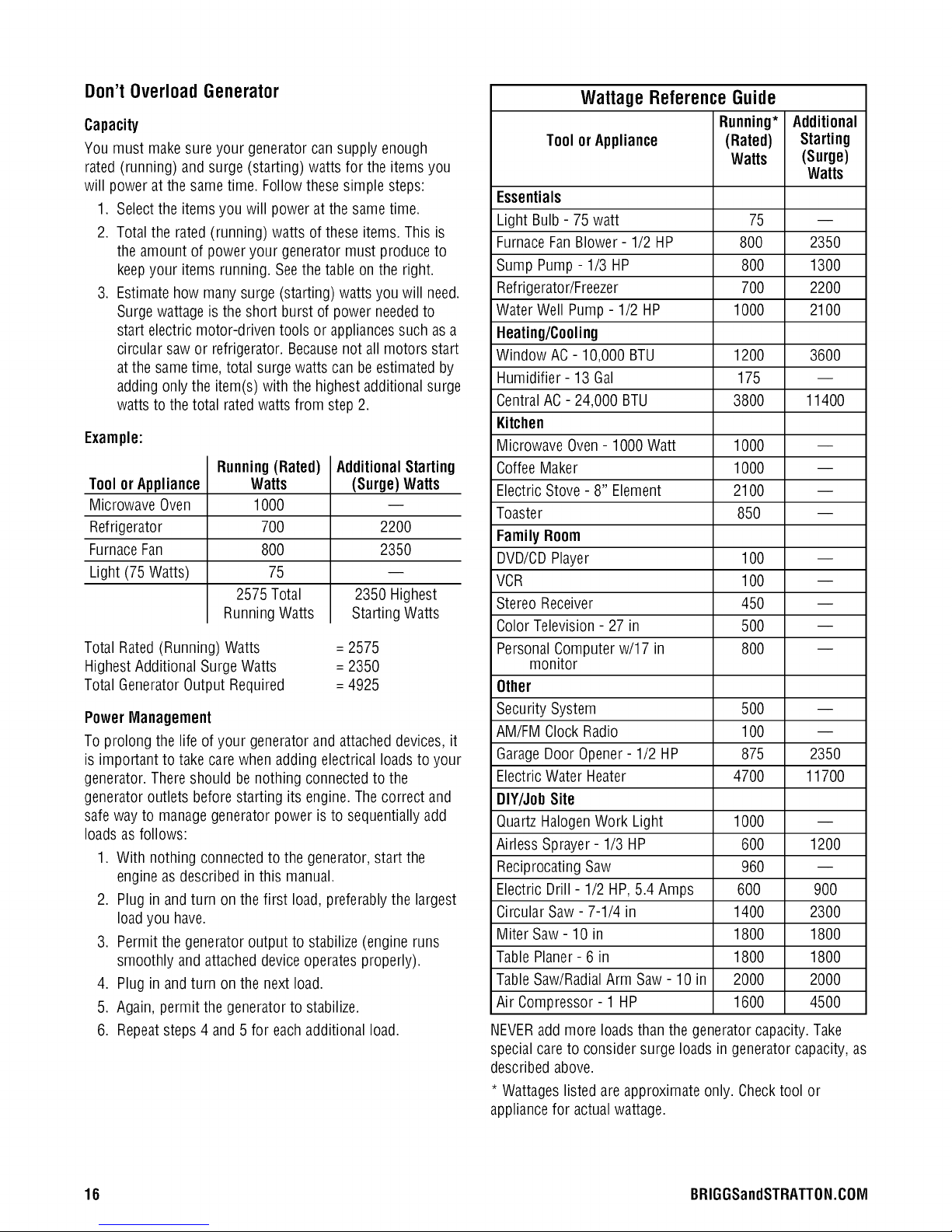

Don't Overload Generator

Capacity

You must make sureyour generator cansupply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

1. Selectthe items you will power at the same time.

2. Total the rated(running) watts of these items. This is

the amount of power your generator must produce to

keepyour items running. Seethe table on the right.

3. Estimatehow many surge (starting) watts you will need.

Surge wattageis the short burst of power neededto

start electric motor-driven tools or appliancessuch as a

circular saw or refrigerator. Becausenot all motors start

atthe sametime, total surgewatts can be estimatedby

adding only the item(s) with the highest additionalsurge

watts to the total ratedwattsfrom step2.

Example:

Running(Rated)

Toolor Appliance

Microwave Oven

Refrigerator

FurnaceFan

Light (75 Watts)

Total Rated(Running) Watts = 2575

HighestAdditional SurgeWatts = 2350

Total GeneratorOutput Required =4925

Power Mlanagement

To prolong the life of your generatorand attacheddevices, it

is important to take care when adding electrical loadsto your

generator. Thereshould be nothing connectedto the

generator outlets before starting its engine.Thecorrect and

safe way to managegeneratorpower isto sequentially add

loads asfollows:

1. With nothing connectedto the generator,start the

engine asdescribed inthis manual.

2. Plug in andturn on the first load, preferablythe largest

load you have.

3. Permit the generatoroutput to stabilize (engineruns

smoothly and attacheddeviceoperates properly).

4. Plug in andturn on the next load.

5. Again, permit the generatorto stabilize.

6. Repeatsteps 4 and 5 for eachadditional load.

Watts

1000

7OO

8OO

75

2575 Total

RunningWatts

AdditionalStarting

(Surge) Watts

2200

2350

2350 Highest

Starting Watts

WattageReferenceGuide

Running* Additional

Tool orAppliance (Rated) Starting

Watts (Surge)

Watts

Essentials

Light Bulb - 75 watt 75 --

FurnaceFanBlower- 1/2 HP 800 2350

Sump Pump- 1/3 HP 800 1300

Refrigerator/Freezer 700 2200

Water Well Pump - 1/2 HP 1000 2100

Heating/Cooling

Window AC - 10,000 BTU 1200 3600

Humidifier- 13 Gal 175 --

CentralAC- 24,000 BTU 3800 11400

Kitchen

Microwave Oven- 1000 Watt 1000 --

CoffeeMaker 1000 --

Electric Stove - 8" Element 2100 --

Toaster 850 --

Family Room

DVD/CDPlayer 100 --

VCR 100 --

Stereo Receiver 450 --

Color Television- 27 in 500 --

PersonalComputer w/17 in 800 --

monitor

Other

Security System 500 --

AM/FM Clock Radio 100 --

GarageDoor Opener- 1/2 HP 875 2350

ElectricWater Heater 4700 11700

DIY/JohSite

Quartz HalogenWork Light 1000 --

Airless Sprayer- 1/3 HP 600 1200

Reciprocating Saw 960 --

Electric Drill - 1/2 HP, 5.4 Amps 600 900

Circular Saw - 7-1/4 in 1400 2300

Miter Saw- 10 in 1800 1800

TablePlaner- 6 in 1800 1800

TableSaw/RadialArm Saw - 10 in 2000 2000

Air Compressor - 1 HP 1600 4500

NEVERadd more loads than the generator capacity.Take

special careto consider surge loads in generator capacity, as

described above.

* Wattageslisted areapproximate only. Checktool or

appliancefor actualwattage.

16 BRIGGSandSTRATTON.COIVl

Maintenance

MaintenanceSchedule

Follow the hourly or calendarintervals, whichever occurs

first. More frequent serviceis required when operating in

adverseconditions noted below.

!

• Changeengine oil

• Cleandebris

• Checkengineoil level

• Service engineair cleanerpre-filter'

• Changeengine oil'

• Serviceengine air cleanerpaper filter'

• Servicefuel filter

• Servicespark plug

• Inspect muffler and spark arrester

• Cleancooling system'

1 Service more often under dirty or dusty conditions.

GeneralRecommendations

Regular maintenancewill improve the performance and

extend the life of the generator.Seeany authorizeddealer for

service.

Thegenerator's warranty does not cover items that have

been subjectedto operator abuseor negligence.To receive

full valuefrom the warranty, the operator must maintain the

generator asinstructed in this manual.

Someadjustments will needto be made periodically to

properly maintain your generator.

All service and adjustments should be made at least once

eachseason.Follow the requirementsin the Maintenance

Schedulechart above.

NOTICE Oncea year you should cleanor replacethe spark

plug and replacethe air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and help your engine run

better and last longer.

EmissionsControl

Maintenance, replacement, or repair of the emissions

controldevicesand systemsmay be performedby any

non-roadengine repair establishmentor individual.

However,to obtain "no charge" emissions control service,

the work must beperformed by a factory authorizeddealer.

Seethe Emissions Warranty.

GeneratorMaintenance

Generatormaintenanceconsists of keepingthe unit clean

and dry. Operateand store the unit in a clean dry

environment where it will not be exposedto excessive dust,

dirt, moisture, or any corrosive vapors. Coolingair slots in

the generator must not become cloggedwith snow, leaves,

or any other foreign material.

NOTICE DO NOTusewater or other liquids to clean

generator. Liquids canenter engine fuel system, causing

poor performance and/or failure to occur. In addition, if

liquid enters generator through cooling air slots, some of the

liquid will be retainedin voids and cracks of the rotor and

stator winding insulation. Liquid anddirt buildup on the

generator internalwindings will eventually decreasethe

insulation resistanceof these windings.

Cleaning

Dailyor before use, look around and underneaththe

generatorfor signs of oil or fuel leaks. Cleanaccumulated

debris from inside and outside the generator. Keepthe

linkage, spring and other engine controls clean. Keepthe

areaaround andbehind the muffler free from any

combustible debris. Inspect cooling air slots and openings

on generator. Theseopenings must be kept clean and

unobstructed.

Engine parts should be kept cleanto reducethe riskof

overheating and ignition of accumulateddebris:

• Usea damp cloth to wipe exterior surfaces clean.

NOTICE Improper treatment of generator can damage it

and shorten its life.

• DO NOTexpose generator to excessivemoisture, dust, dirt, or

corrosive vapors.

• DONOTinsert any objects through cooling slots.

• Usea soft bristle brush to loosen cakedon dirt or oil.

• Usea vacuum cleanerto pick up loose dirt and debris.

17

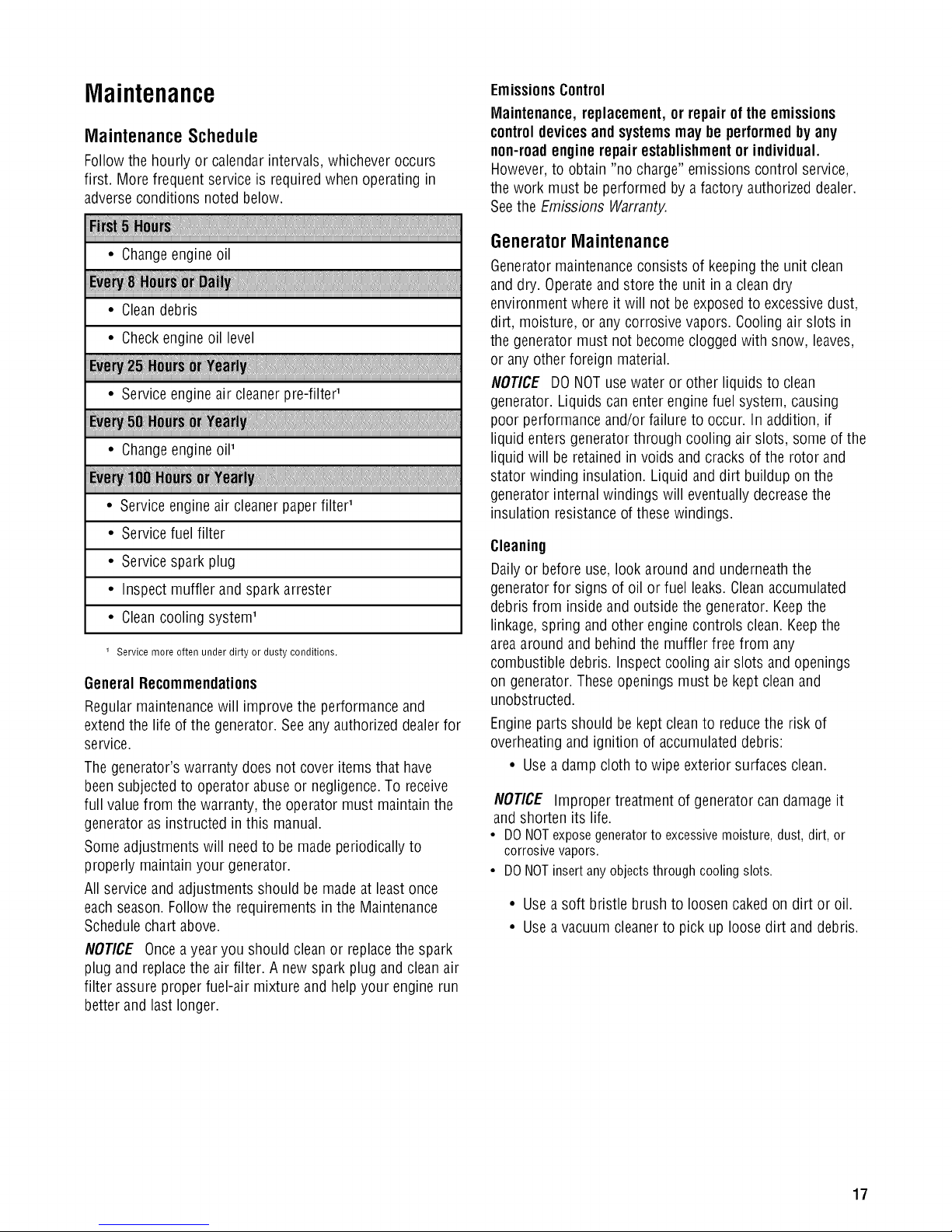

FuelValve Maintenance

Thefuel valve is equipped with a fuel sediment cup, screen,

retaining ring and o-ring that needto becleanedevery

100 hours or once a year (whichever occurs first).

1. Move fuel valve to "Off" position.

2. Removesediment cup (A) from fuel valve. Remove

o-ring (B), retaining ring (C) and screen (D) from fuel

valve.

oF oc

68 _mo >_20

104 n _, __ , !l_'X_ 40

86 _om__ _,_ o__ 30

so 10

32 o ._m -- 0

-2214-4 -- , l--___' -30-20-10

3. Wash sediment cup, o-ring, retaining ring, andscreen

in a nonflammable solvent. Drythem thoroughly.

4. Placescreen, retaining ring, and o-ring into fuel valve.

Install sedimentcup andtighten securely.

5. Move fuel valve to "On" position, and checkfor leaks.

Replaceo-ring if there is any leakage.

EngineMaintenance

_i, WARNING Unintentionalsparking can result in fire or

_ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTOYOUR

GENERATOR

• Disconnectthesparkplugwirefromthesparkplugandplace

thewirewhereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

• Useapprovedsparkplugtester.

• DONOTcheckfor sparkwith sparkplugremoved.

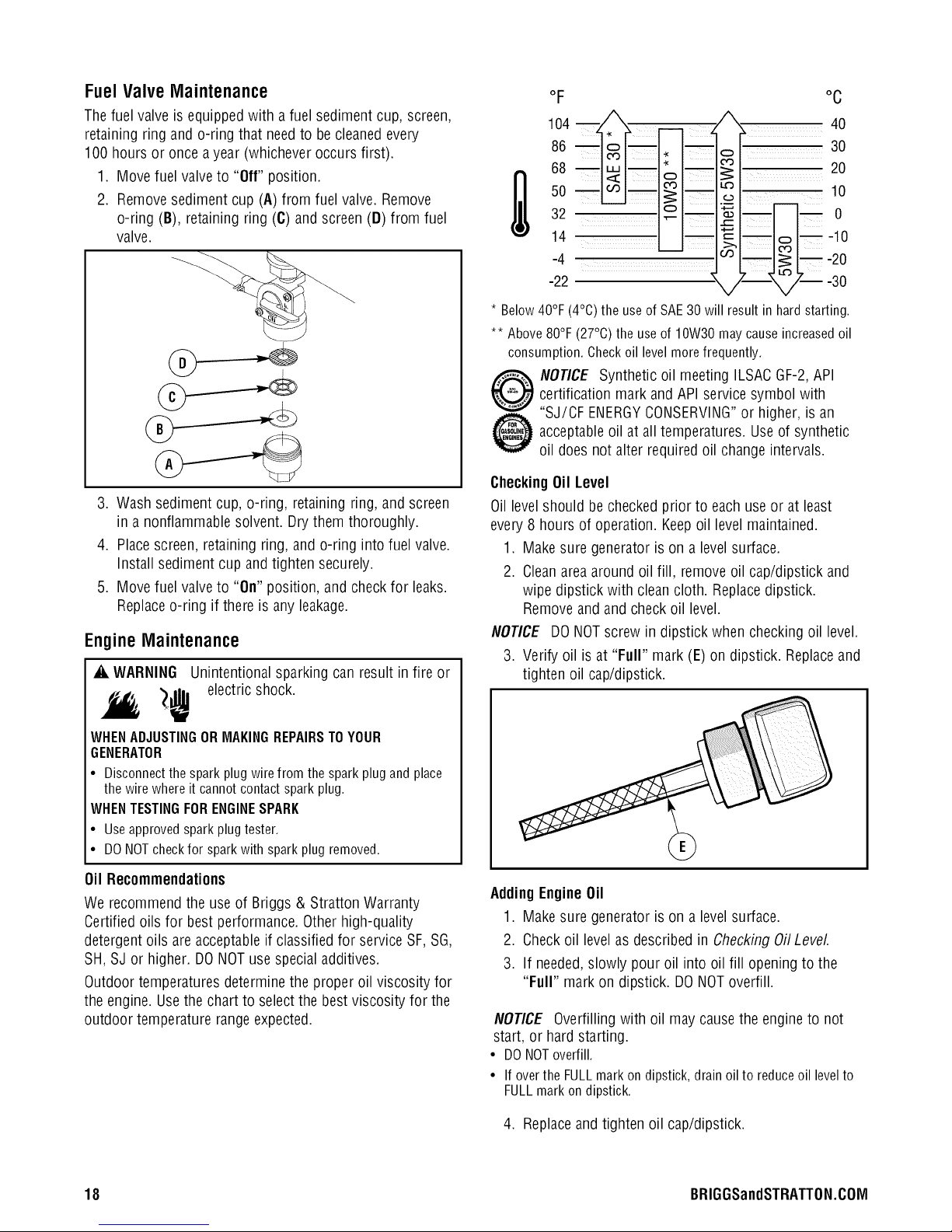

* Below 40°F

** Above 80°F (27°C) the useof 10W30 may cause increasedoil

consumption. Oheckoil levelmore frequently.

CheckingOil Level

Oil level should be checked prior to each useor at least

every 8 hours of operation. Keepoil levelmaintained.

1. Make sure generator is on a level surface.

2. Cleanarea around oil fill, removeoil cap/dipstick and

NOTICE DO NOTscrew in dipstick when checking oil level.

3. Verify oil is at "Full" mark (E) on dipstick. Replaceand

(4°C)theuseofSAE30 will resultin hardstarting.

certification mark and API servicesymbol with

NOTICE Synthetic oil meeting ILSACGF-2,API

"SJ/CF ENERGYCONSERVING"or higher, is an

acceptableoil at all temperatures. Useof synthetic

oil does not alter required oil change intervals.

wipe dipstick with cleancloth. Replacedipstick.

Removeandand check oil level.

tighten oil cap/dipstick.

Oil Recommendations

We recommendthe useof Briggs & Stratton Warranty

Certified oils for best performance.Otherhigh-quality

detergent oils are acceptableif classified for serviceSF, SG,

SH, SJ or higher. DONOTuse specialadditives.

Outdoor temperatures determine the proper oil viscosity for

the engine. Usethe chart to select the best viscosity for the

outdoor temperature rangeexpected.

18 BRIGGSandSTRATTON.COIVl

AddingEngineOil

1. Make sure generator is on a level surface.

2. Checkoil level as described in CheckingOilLevel

3. If needed,slowly pour oil into oil fill opening to the

"Full" mark on dipstick. DONOToverfill.

NOTICE Overfilling with oil may causethe engine to not

start, or hard starting.

• DONOToverfill.

• Ifoverthe FULLmarkondipstick,drainoilto reduceoil levelto

FULLmarkondipstick.

4. Replaceand tighten oil cap/dipstick.

ChangingEngineOil

If you are usingyour generator under extremely dirty or

dusty conditions, or in extremelyhot weather, changethe oil

more often.

& CAUTION Avoid prolonged or repeated skin contact

with used motor oil.

• Used motor oil has beenshown to cause skin cancer in certain

laboratory animals.

• Thoroughly wash exposed areaswith soap and water.

POLLUTE.CONSERVERESOURCES.RETURN

USEDOILTOCOLLECTIONCENTERS.

KEEPOUTOFREACHOFCHILDREN.DON'T

Changethe oil while the engineis still warm from

running,as follows:

1. Make sure unit is on a level surface.

2. Disconnectthe spark plug wire from the spark plug and

placethe wire where it cannot contact spark plug.

3. Cleanarea around oil drain plug.The oil drain plug is

located at base of engine,opposite carburetor.

4. Removeoil drain plug and drain oil completely into a

suitable container.

5. Reinstall oil drain plug andtighten securely. Remove oil

cap/dipstick.

6. Slowly pour recommendedoil (about 30 oz.) into oil fill

opening. Pauseto permit oil to settle. Fill to "Full" mark

on dipstick.

7. Wipe dipstick cleaneachtime oil levelis checked. DO

NOToverfill.

8. Reinstall oil cap/dipstick. Tighten cap securely.

9. Wipe up any spilled oil.

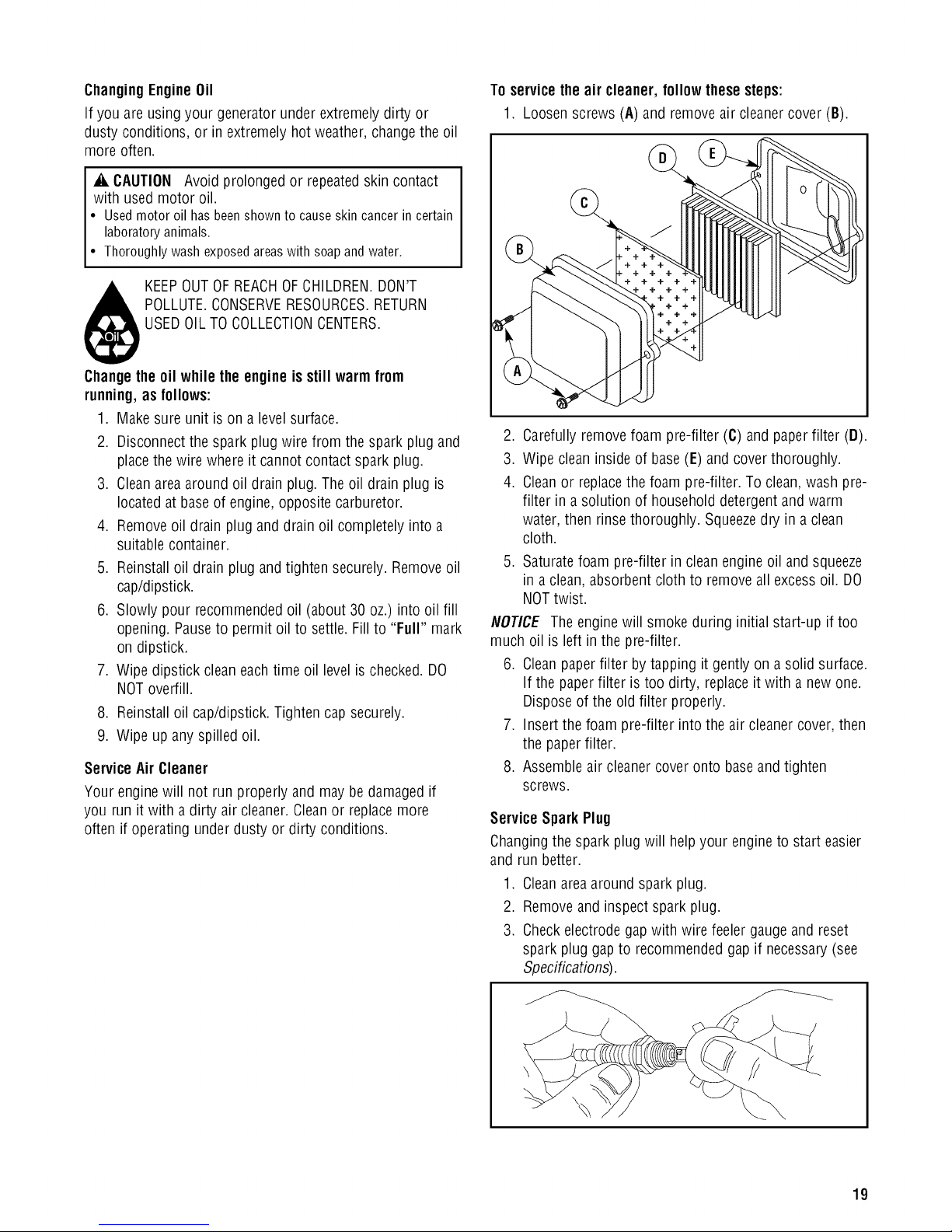

ServiceAir Cleaner

Your enginewill not run properly and may be damaged if

you run it with a dirty air cleaner.Cleanor replacemore

often if operating underdusty or dirty conditions.

To servicethe air cleaner, followthese steps:

1. Loosen screws (A) and removeair cleaner cover (B).

2. Carefully removefoam pre-filter (C) andpaper filter (D).

3. Wipe cleaninside of base(E) and cover thoroughly.

4. Cleanor replacethe foam pre-filter. To clean, wash pre-

filter in a solution of householddetergent and warm

water, then rinse thoroughly. Squeezedry in aclean

cloth.

5. Saturatefoam pre-filter in cleanengine oil and squeeze

in a clean, absorbent cloth to removeall excessoil. DO

NOTtwist.

NOTICE The engine will smoke during initial start-up if too

much oil is left inthe pre-filter.

6. Cleanpaperfilter by tapping it gently ona solid surface.

If the paperfilter is too dirty, replaceit with a new one.

Disposeof the old filter properly.

7. Insert the foam pre-filter into the air cleanercover, then

the paper filter.

8. Assembleair cleaner cover onto baseand tighten

screws.

Service Spark Plug

Changingthe spark plug will helpyour engineto start easier

and run better.

1. Cleanarea around spark plug.

2. Removeand inspect spark plug.

3. Checkelectrode gapwith wire feeler gauge and reset

spark plug gap to recommended gapif necessary(see

Specifications).

19

4. Replacespark plug if electrodesare pitted, burned or

porcelain is cracked. Usethe recommended

replacementspark plug. SeeSpecifications.

5. Install spark plug andtighten firmly.

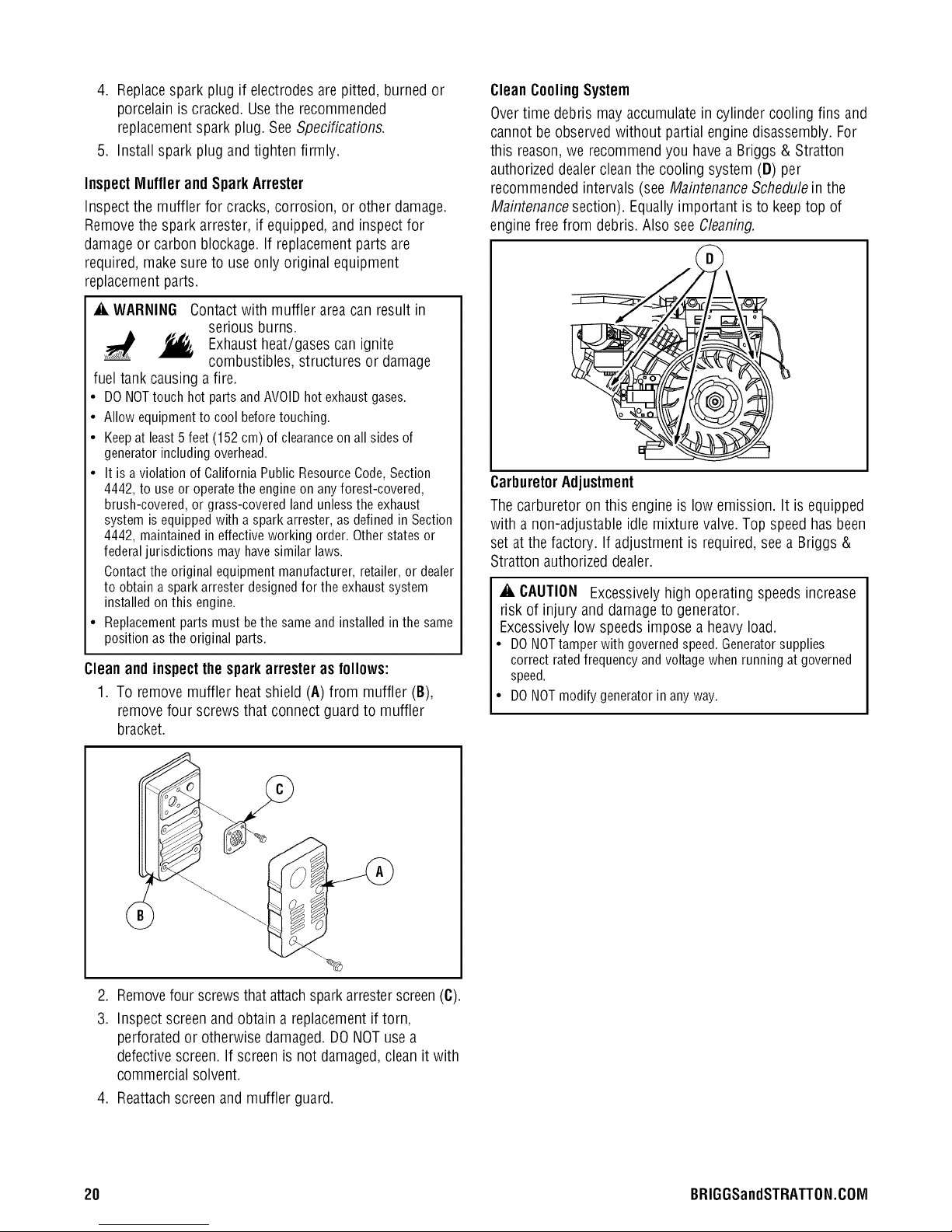

InspectMluffler and Spark Arrester

Inspect the muffler for cracks, corrosion, or other damage.

Removethe spark arrester, if equipped, and inspectfor

damageor carbon blockage. If replacementparts are

required, make sure to use only original equipment

replacementparts.

_i, WARNING Contact with muffler area can result in

serious burns.

Exhaust heat/gases can ignite

combustibles, structures or damage

fuel tank causing a fire.

• DO NOTtouch hot parts andAVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keepat least5 feet (152 cm) of clearanceon all sidesof

generator including overhead.

• It is aviolation of California Public Resource Code,Section

4442, to use or operate the engineon any forest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equipped with aspark arrester, as defined in Section

4442, maintained in effective working order. Otherstates or

federal jurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a sparkarrester designed for the exhaust system

installed on this engine.

• Replacement parts must bethe same and installed inthe same

position asthe original parts.

Cleanand inspectthesparkarresteras follows:

1. To remove muffler heatshield (A) from muffler (B),

removefour screws that connect guard to muffler

bracket.

CleanCoolingSystem

Overtime debris may accumulatein cylinder cooling fins and

cannot be observedwithout partial enginedisassembly. For

this reason,we recommendyou havea Briggs & Stratton

authorized dealerclean the cooling system (D) per

recommended intervals (seeMaintenanceScheduleinthe

Maintenancesection). Equally important is to keeptop of

engine freefrom debris. Also see Cleaning.

'\

CarburetorAdjustment

Thecarburetor on this engine is low emission. It is equipped

with a non-adjustable idle mixture valve. Top speed has been

set at the factory. If adjustment is required,see a Briggs &

Stratton authorized dealer.

_i, CAUTION Excessively high operating speeds increase

risk of injury and damage to generator.

Excessively low speeds impose a heavy load.

• DO NOTtamper with governedspeed. Generatorsupplies

correct rated frequency and voltage when running at governed

speed.

• DO NOTmodify generator in any way.

.

Removefour screwsthat attachsparkarresterscreen(C).

3.

Inspect screenand obtain areplacementif torn,

perforated or otherwise damaged. DONOTuse a

defective screen.If screenis not damaged,clean it with

commercial solvent.

4. Reattachscreen and muffler guard.

20 BRIGGSandSTRATTON.COIVl

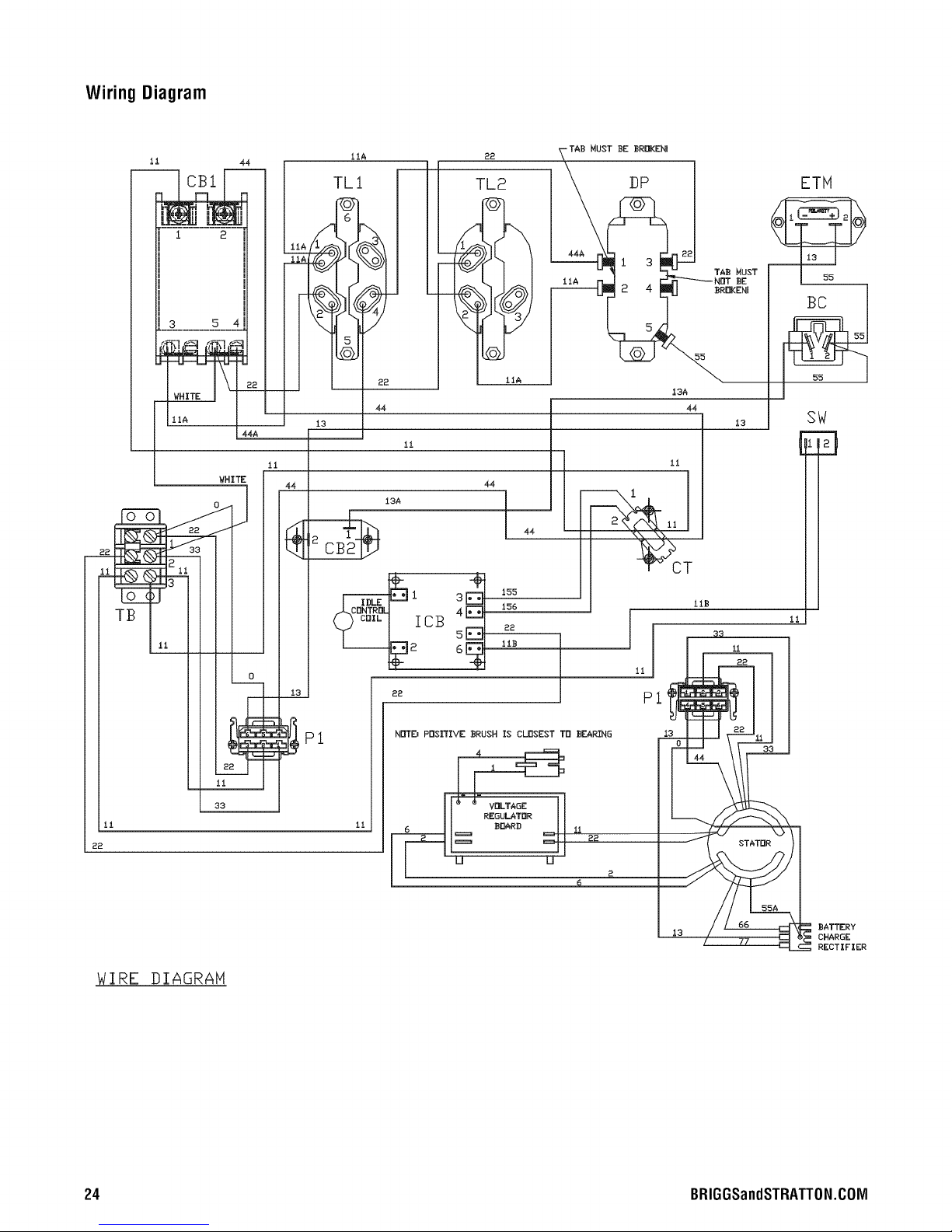

Storage

Thegenerator should be started at leastonce every seven

days and allowed to run at least 30 minutes. If this cannot be

done and you must store the unit for more than 30 days,use

the following guidelines to prepare it for storage.

GeneratorStorage

• Cleanthe generator as outlined in Cleaningin the

Maintenancesection.

• Checkthat cooling air slots and openingson generator

are open and unobstructed.

LongTerm StorageInstructions

Fuelcan becomestale when stored over 30 days.Stalefuel

causesacid and gum deposits to form in the fuel system or

on essential carburetor parts. To keepfuel fresh, use Briggs

& Stratton FRESHSTART® fuel stabilizer, availableasa

liquid additive or adrip concentratecartridge.

Thereis no needto drain gasolinefrom the engineif a fuel

stabilizer is added according to instructions. Runthe engine

for 2 minutes to circulate the stabilizerthroughout the fuel

system. The engine andfuel canthen be stored up to

24 months.

If gasoline in the engine hasnot beentreated with a fuel

stabilizer, it must bedrained into an approvedcontainer. Run

the engine until it stops from lack of fuel. The useof a fuel

stabilizer in the storage container is recommended to

maintain freshness.

ChangeEngineOil

While engine is still warm, drain oil from crankcase.Refill

with recommended grade.See Changing Engine Oil.

OtherStorageTips

1. DONOTstore fuel from one seasonto another unless it

has beentreated as described in Protect FuelSystem.

2. Replacefuel can if it starts to rust. Contaminatedfuel

will cause engine problems.

3. Cover unit with a suitable protective coverthat does not

retain moisture.

_i, WARNING Storagecovers can be flammable.

• DO NOTplace a storage cover overa hot generator.

• Let equipment coolfor a sufficient time before placing the cover

on the equipment.

4. Store generator in clean, dry area.

_i, WARNING Fueland its vapors are extremely

flammable and explosive.

_ J

_, _ Fire or explosion can causesevere

burns or death.

WHENSTORINGFUELOREQUIPMENTWITHFUELINTANK

• Store away from furnaces, stoves, water heaters,clothesdryers

or other appliances that have pilot light or other ignition source

becausethey can ignite fuel vapors.

WHENDRAININGFUEL

• Turn generator OFFand let itcool at least2 minutes before

removing fuel cap. Loosen cap slowly to relievepressure in

tank.

• Drain fuel tank outdoors.

• Keepfuel awayfrom sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOTlight a cigarette or smoke.

21

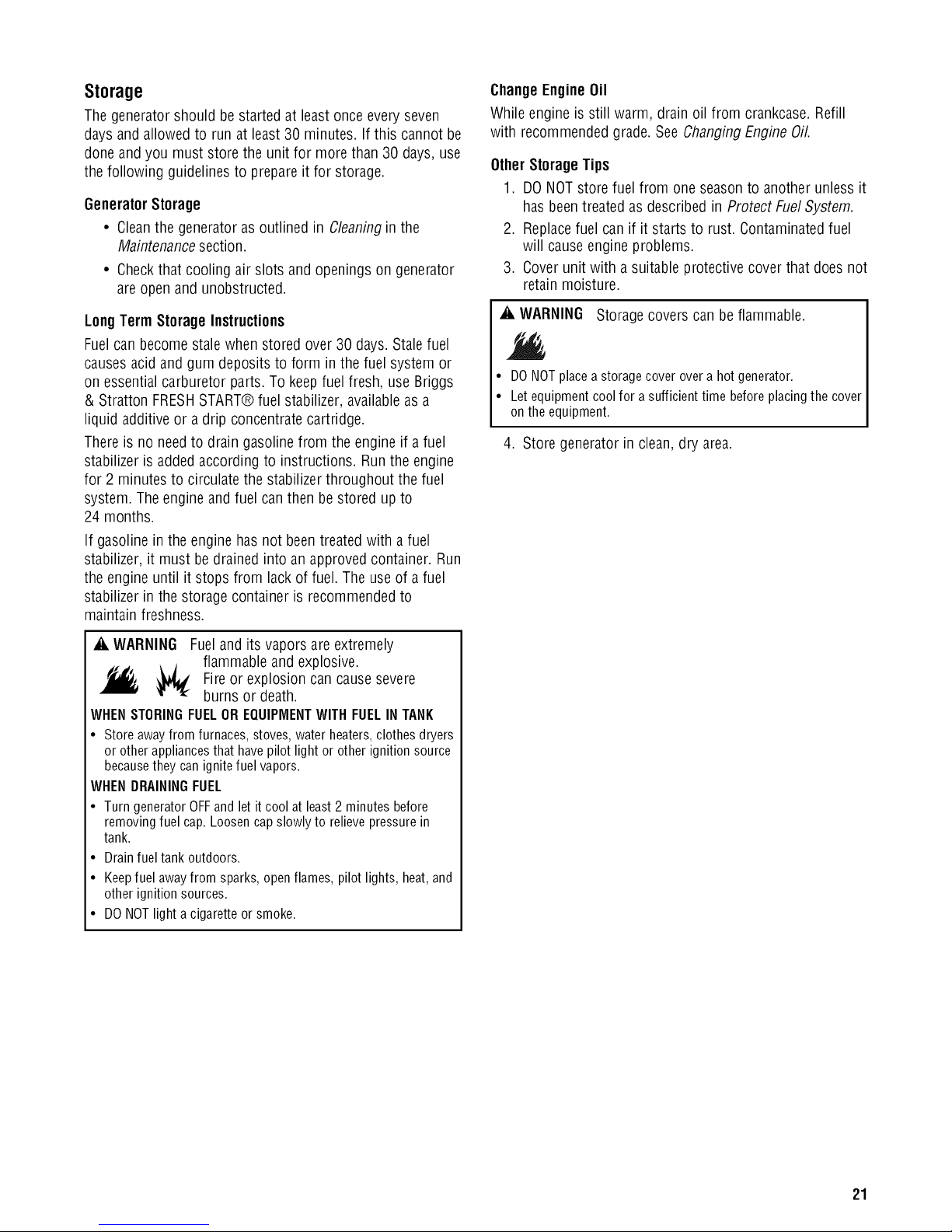

Troubleshooting

Problem

Engineisrunning,but noAC

outputis available.

Enginerunsgoodat no-load

but "bogs down"when loads

are connected.

Enginewill notstart; or starts

and runsrough.

Engineshutsdownwhen

running.

Enginelackspower.

Engine"hunts" or falters.

Cause

1. GFCIcircuit breakeris open.

2. Fault in generator.

3. Poor connection or defectivecord set.

4. Connecteddeviceis bad.

1. Short circuit in aconnectedload.

,

Enginespeed is too slow.

3.

Generatoris overloaded.

4.

Shorted generator circuit.

5.

Cloggedor dirty fuel filter.

1.

Engineswitch setto stop (0) position. 1.

2.

Fuelvalveis in "Off"position. 2.

3. Low oil level.

4. Dirty air cleaner.

5. Cloggedor dirty fuel filter.

6. Out of fuel.

7. Stalefuel.

,

Spark plug wire not connectedto spark

plug.

9. Badspark plug.

10. Water in fuel.

11. Flooded.

12. Excessivelyrich fuel mixture.

13. Intakevalvestuck open or closed.

14. Engine has lost compression.

1. Out of fuel.

2. Cloggedor dirty fuel filter.

3. Low oil level.

1. Loadis too high.

2. Dirty air filter.

3. Cloggedor dirty fuel filter.

1. Carburetoris runningtoo rich or too lean.

2. Cloggedor dirty fuel filter.

Correction

1. Resetcircuit breaker.

2. Contact Briggs & Stratton authorized

dealer.

3. Checkand repair.

4. Connectanotherdevice that is in good

condition.

1. Disconnectshorted electrical load.

.

Contact Briggs & Stratton authorized

dealer.

3.

SeeDon't OverloadGenerator.

4.

Contact Briggs & Stratton authorized

dealer.

5.

Cleanor replacefuel filter.

Setswitch to run (I) position.

Turnfuel valveto "On"position.

3. Fillcrankcaseto proper levelor place

generatoron level surface.

4. Cleanor replaceair cleaner.

5. Cleanor replacefuel filter.

6. Fillfuel tank.

7. Drainfuel tank and carburetor; fill with

fresh fuel.

8. Connectwire to spark plug.

9. Replacespark plug.

10. Drainfuel tank and carburetor; fill with

fresh fuel.

11. Wait 5 minutes and re-crank engine.

12. Contact Briggs & Stratton authorized

dealer.

13. Contact Briggs & Stratton authorized

dealer.

14. Contact Briggs & Stratton authorized

dealer.

1. Fillfuel tank.

2. Cleanor replacefuel filter.

3. Fillcrankcaseto proper levelor place

generatoron level surface.

1. SeeDon't OverloadGenerator.

2. Replaceair filter.

3. Cleanor replacefuel filter.

1. Contact Briggs & Stratton authorized

dealer.

2. Cleanor replacefuel filter.

22 BRIGGSandSTRATTON.COIVl

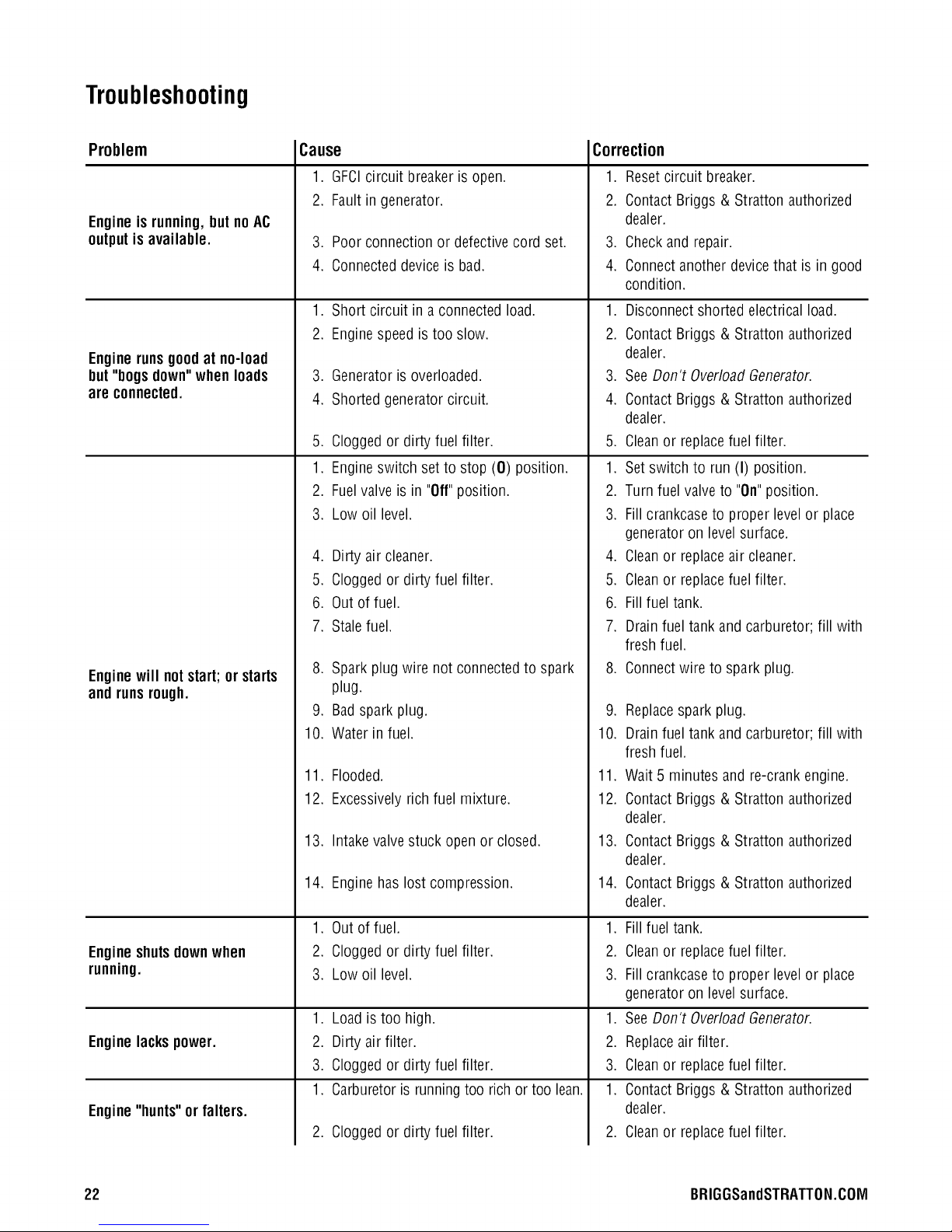

Schematic

55A

BATTERY CHARGE

PI-6 12V DC

CB2

13 _ 13A

loA

1P

IDLE CONTROL

CIRCUIT BOARD ==

IDLE

CONTROL

COIL

HQURMETER

12VDC

155

156

22

LiB oi_o_____

IDLE

CONTROL

SWITCH

11

22 J 022 VOLTAGE J

i oli i

BLA_ _ REGULATOR (_ I WH__.ITE

|

55

1

/'PI-2

_TB-3

II

I 20A

I 2P

GFCI '

m

m

i

L ....

22

11

POWER

\

\

0

PI-5

22

POWER

155

156

44

/

t PI-4

CT

.... l

I

i

I

I

i

m

i

IIA

IIA

120V

30A

WHITE_

WHITE

12o/a4ov

2oA

SCHEHATIC

23

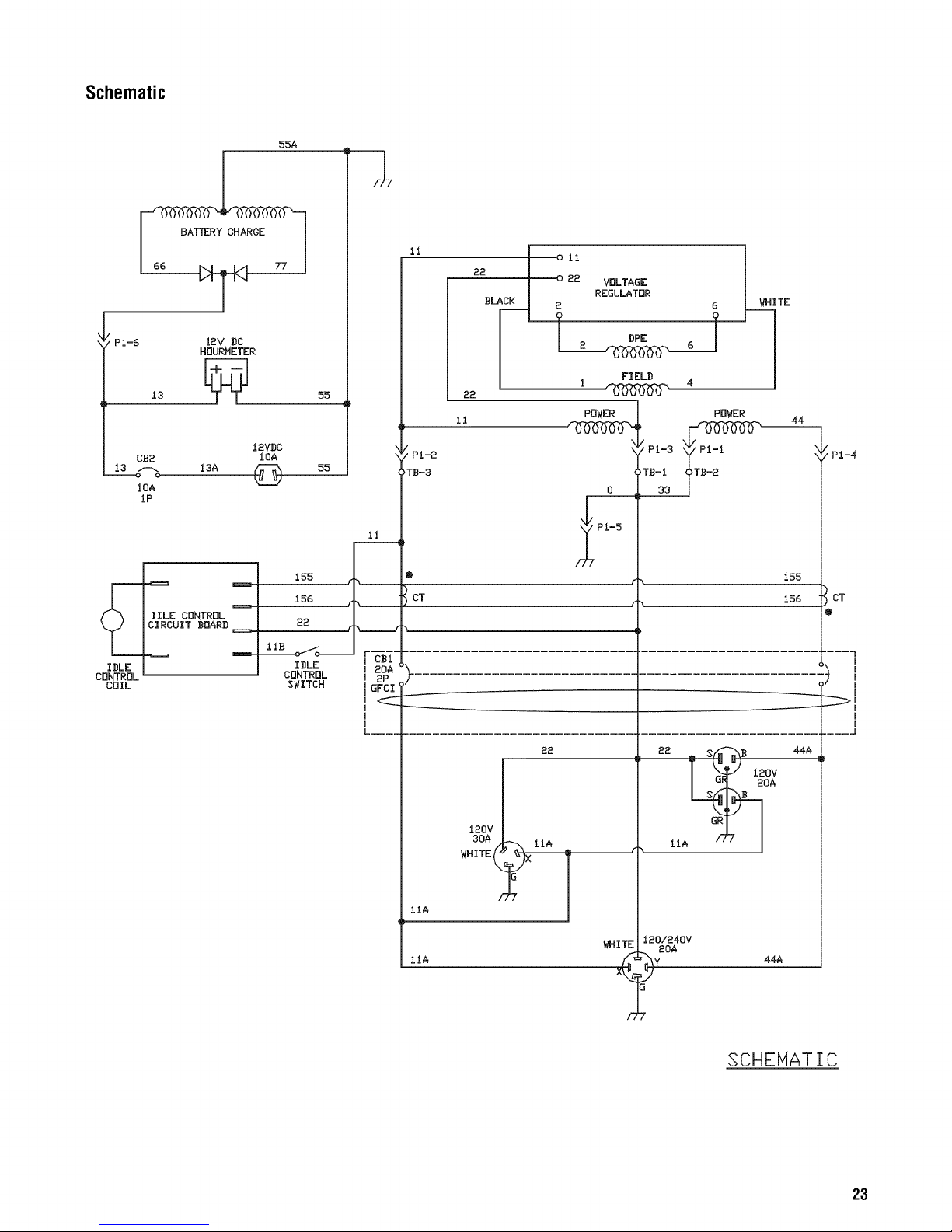

WiringDiagram

11

r..............

0

WHITE

44

IIA

TL1

22

TL2

MUST ]BE BRDKENI

DP

ETM

--i

L 55

11A

44

13

ii

ii

44

13

li

22

WIRE DIAGRAM

ii

o__

N

=r

LI

33

BATTERY

77

CHARGE

RECTIFIER

24 BRIGGSandSTRATTON.COIVl

Warranties

California,U.S. EPA,andBriggs& Stratton

CorporationEmissionsControlWarranty

Statement

YourWarranty RightsAndObligations

The CaliforniaAir ResourcesBoard,U.S. EPA,and Briggs &

Stratton (B&S) are pleasedto explainthe emissions control

system warranty on your ModelYear2008 andlater

engine/equipment. In California,new small off-road engines

must be designed, built, and equipped to meetthe State's

stringent anti-smog standards. B&Smust warrant the

emissions control system on your engine/equipmentfor the

periods of time listed below provided there has been no

abuse, neglect,or improper maintenanceof your small off-

road engine.

Your emissions control system may include partssuch as

the carburetor or fuel injection system, fuel tank, ignition

system, and catalytic converter. Also included may behoses,

belts, connectors, sensors, andother emissions-related

assemblies.Wherea warrantable condition exists, B&S will

repair your engine/equipmentat no cost to you including

diagnosis, parts, and labor.

Manufacturer'sWarrantyCoverage:

Small off-road engines arewarranted for two years. If any

emissions-related part on your engine/equipment is

defective,the part will be repaired or replacedby B&S.

Owner's WarrantyResponsibilities:

• As the small engine/equipment owner, you are

responsiblefor the performance of the required

maintenancelisted in your owner's manual. B&S

recommendsthat you retainall receipts covering

maintenanceonyour engine/equipment, but B&S

cannot deny warranty solely for the lack of receiptsor

your failure to ensurethe performanceof all scheduled

maintenance.

• As the engine/equipmentowner,you should however

be awarethat B&Smay deny you warranty coverageif

your engine/equipmentor a part hasfailed due to

abuse, neglect,improper maintenance,or unapproved

modifications.

• Youare responsiblefor presentingyour

engine/equipmentto a B&Sdistribution center,

servicing dealer,or other equivalententity, as

applicable, assoon as a problem exists. Thewarranty

repairsshould be completed in a reasonableamount of

time, not to exceed30 days. If you haveany questions

regardingyour warranty rights andresponsibilities, you

should contact B&Sat (414) 259-5262.

Briggs& Stratton EmissionsControlWarrantyProvisions

Thefollowing are specific provisions relativeto your

Emissions Control Warranty Coverage.It is in addition to the

B&S enginewarranty for non-regulatedengines found in the

Operator's Manual.

1. Warranted Emissions Parts

Coverageunder this warranty extends only to the parts

listed below (the emissions control systems parts) to

the extentthese parts were present on the engine

purchased.

a. FuelMetering System

• Cold start enrichment system (soft choke)

• Carburetorand internal parts

• Fuelpump

• Fuelline, fuel line fittings, clamps

• Fueltank, capand tether

• Carboncanister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purgeand vent line

C,

Ignition System

• Spark plug(s)

• Magnetoignition system

d,

CatalystSystem

• Catalyticconverter

• Exhaustmanifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum,temperature, position, time sensitive

valvesandswitches

• Connectorsand assemblies

,

Length of Coverage

For a period of two yearsfrom date of original

purchase, B&S warrants to the original purchaser and

eachsubsequent purchaserthat the engine is designed,

built, and equippedso as to conform with all applicable

regulations adopted by the Air Resources Board; that it

is free from defectsin materialand workmanship that

could cause the failure of a warranted part; and that it

is identical in all material respects to the engine

described in the manufacturer's application for

certification. The warranty period beginson the datethe

engine is originally purchased.

25

Thewarranty on emissions-related parts is asfollows:

• Anywarranted part that is not scheduledfor

replacementas required maintenancein the owner's

manual supplied, is warranted for the warranty period

stated above. If any such part fails during the period of

warranty coverage,the part will be repairedor replaced

by B&S at no chargeto the owner. Any such part

repairedor replacedunder the warranty will be

warranted for the remaining warranty period.

• Anywarranted part that is scheduled only for regular

inspection in the owner's manual supplied, is warranted

for the warranty period statedabove. Any such part

repairedor replacedunder warranty will be warranted

for the remaining warranty period.

• Anywarranted partthat is scheduledfor replacementas

requiredmaintenancein theowner's manualsupplied, is

warrantedfor the period of time prior to the first

scheduledreplacementpointfor that part. If the part fails

prior to thefirst scheduled replacement,the part will be

repairedor replacedby B&S at no charge to the owner.

Anysuch part repairedor replacedunderwarrantywill

be warrantedfor the remainder of the period prior to the

first scheduledreplacementpointfor the part.

• Addon or modified parts that are not exempted by the

Air Resources Board may not be used.The useof any

non exempted add on or modified parts by the owner

will be grounds for disallowing a warranty claim. The

manufacturer will not be liable to warrantfailures of

warranted parts causedbythe useof a non exempted

add on or modified part.

3. ConsequentialCoverage

Coverageshall extend to the failure of anyengine

components causedby the failure of anywarranted

emissions parts.

4. Claimsand CoverageExclusions

Warranty claims shall be filed according to the

provisions of the B&S enginewarranty policy. Warranty

coveragedoes not apply to failures of emissions parts

that are not original equipment B&S partsor to parts

that fail due to abuse, neglect, or improper maintenance

as set forth in the B&S engine warranty policy. B&Sis

not liable for warranty coverageof failures of emissions

parts causedby the useof add-on or modified parts.

LookFor RelevantEmissionsDurability Period andAir

IndexInformationOnYour EngineEmissionsLabel

Enginesthatare certified to meetthe CaliforniaAir

ResourcesBoard (CARD)Emissions Standardmust display

information regardingthe Emissions Durability Period and

the Air Index. Briggs & Stratton makesthis information

availableto the consumer on our emissions labels. The

engine emissions labelwill indicate certification information.

TheEmissionsDurabilityPerioddescribesthe number of

hours of actual runningtime for which the engine is certified

to be emissions compliant, assuming proper maintenancein

accordancewith the Operating& Maintenance Instructions.

Thefollowing categoriesare used:

Moderate:

Engine is certified to be emissions compliant for 125 hours

of actual enginerunning time.

Intermediate:

Engine is certified to be emissions compliant for 250 hours

of actual enginerunning time.

Extended:

Engine is certified to be emissions compliant for 500 hours

of actual enginerunning time.

Forexample,a typical walk-behind lawn mower is used 20 to

25 hours peryear. Therefore,the Emissions Durability

Period of anengine with an intermediate rating would

equateto 10to 12 years. Briggs & Stratton enginesare

certified to meet the United States EnvironmentalProtection

Agency (USEPA)Phase2 emissions standards.For Phase2

certified engines, the Emissions CompliancePeriod referred

to on the EmissionsCompliancelabel indicatesthe number

of operating hours for which the engine has beenshown to

meet Federalemissions requirements.

Forengines less than 225 cc displacement.

CategoryC= 125 hours

CategoryB= 250 hours

CategoryA= 500 hours

Forengines of 225 cc or more displacement.

CategoryC= 250 hours

CategoryB= 500 hours

CategoryA= 1000 hours

26 BRIGGSandSTRATTON.COM