Briggs & Stratton PRO3600 Operator's Manual

Not for

Reproduction

PRO3600

Pressure Washer

Operator’s Manual

Manual No. 80019847 Rev -

Not for

Reproduction

Thank you for purchasing this quality-built Briggs & Stratton® pressure washer. We are pleased that you’ve

placed your condence in the Briggs & Stratton brand. When operated and maintained according to the

instructions in this manual, your Briggs & Stratton pressure washer will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with pressure

washers and how to avoid them. Because Briggs & Stratton does not necessarily know all the applications this

pressure washer could be used for, it is important that you read and understand these instructions thoroughly

before attempting to start or operate this equipment. Save these original instructions for future reference.

This pressure washer requires nal assembly before use. Refer to the Assembly section of this manual for

instructions on nal assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to nd Briggs & Stratton support and service for your pressure washer. There are

thousands of Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also

contact Briggs & Stratton Customer Service by phone at 1800-356-632 (AUS) or 0800-484-282 (NZ), or on the

Internet at BRIGGSandSTRATTON.com.au.

Pressure Washer Engine

Model Number _____________________ Model Number ______________________

Revision __________________________ Type Number _______________________

Serial Number ______________________ Code Number _______________________

Date Purchased ___________________

Table of Contents

Operator Safety....................... 3

Assembly............................ 6

Features and Controls ................ 10

Operation........................... 11

Maintenance ........................ 16

Troubleshooting ..................... 22

Warranty ........................... 23

Product Specications ................ 24

Common Service Parts ............... 24

Copyright © 2016. Briggs & Stratton Power Products Group, LLC

Milwaukee, WI, USA. All rights reserved.

BRIGGS & STRATTON POWER PRODUCTS is a registered

trademark of Briggs & Stratton Corporation

Milwaukee, WI, USA

2 BRIGGSandSTRATTON.com.au

Not for

Reproduction

Operator Safety

Equipment Description

Read this manual carefully and become

familiar with your pressure washer. Know

its applications, its limitations, and any

hazards involved.

This pressure washer operates at a maximum of

3,600 PSI (248 BAR or 24.8 MPa) at a ow rate of up

to 9.5 liters (2.5 gallons) per minute. This high quality

residential system features 30.5 cm (12 in.) wheels,

triplex pump with stainless steel pistons, automatic

cool down system, detergent siphoning system, quick

connect spray tips, heavy duty 10.7 m (35 ft.) hose,

and more.

This machine is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge.

Every eort has been made to ensure that information

in this manual is accurate and current. However, we

reserve the right to change, alter, or otherwise improve

the product and this document at any time without prior

notice.

Important Safety Information

Safety Symbols and Meanings

Read Manual

Non-Potable

Water

Fire

Moving

Parts

Slippery

Surface

Explosion

Flying

Objects

Toxic Fumes

Fall

Kickback

Chemical

Electrical Shock

Fluid Injection

Projectile

Hot Surface

Burn

Never spray

yourself, others,

animals, power

sources, or the

unit itself.

The safety alert symbol indicates a potential

personal injury hazard. A signal word (DANGER,

WARNING, or CAUTION) is used with the alert symbol

to designate a degree or level of hazard seriousness. A

safety symbol may be used to represent the type of

hazard. The signal word NOTICE is used to address

practices not related to personal injury.

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE indicates information considered important,

but not hazard-related.

WARNING POISONOUS GAS HAZARD.

Engine exhaust contains carbon monoxide,

a poisonous gas that could kill you in

minutes. You CANNOT smell it, see it, or

taste it. Even if you do not smell exhaust fumes, you

could still be exposed to carbon monoxide gas.

Some chemicals or detergents could be harmful if

inhaled or ingested, resulting in death, serious

injury, nausea, fainting or poisoning.

• Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or

plug-in carbon monoxide alarms with battery back-up

according to the manufacturer’s instructions. Smoke

alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages,

basements, crawlspaces, sheds, or other partially-

enclosed spaces even if using fans or opening doors

and windows for ventilation. Carbon monoxide can

quickly build up in these spaces and can linger for hours,

even after this product has shut o.

• ALWAYS place this product downwind and point the

engine exhaust away from occupied spaces.

If you start to feel sick, dizzy, or weak while using this

product, get to fresh air RIGHT AWAY. See a doctor. You

may have carbon monoxide poisoning.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled when using chemicals.

• Read all instructions with mask so you are certain the

mask will provide the necessary protection against

inhaling harmful vapors when using chemicals.

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting in

death or serious injury.

• DO NOT use caustic liquid with pressure washer.

• Use ONLY pressure washer safe detergents/ soaps.

Follow all manufacturers instructions.

3

Not for

Reproduction

WARNING Exhaust heat/ gases could ignite

combustibles, structures or damage

fuel tank causing a re, resulting in

death or serious injury.

Contact with muer area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 1.5 m (5 ft.) of clearance on all sides of

pressure washer including overhead.

• Contact the original equipment manufacturer, retailer,

or dealer to obtain a spark arrester designed for the

exhaust system installed on this engine.

• Replacement parts must be the same and installed in the

same position as the original parts.

WARNING Risk of electrocution.

Contact with power source could cause

electric shock or burn resulting in death or

serious injury.

• NEVER spray near power source.

WARNING Use of pressure washer could

create puddles and slippery

surfaces causing you to fall

resulting in death or serious injury.

Kickback from spray gun (33.4 N) could cause you

to fall resulting in death or serious injury.

• Operate pressure washer from a stable surface.

• The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to slippery

surfaces.

• Be extremely careful if you must use the pressure washer

from a ladder, scaolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

WARNING Fuel and its vapors are extremely

ammable and explosive which

could cause burns, re or explosion

resulting in death or serious injury.

WHEN ADDING OR DRAINING FUEL

• Turn pressure washer engine OFF and let it cool at least

2 minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overll tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open ames, pilot lights,

heat, and other ignition sources.

• Check fuel lines, tank, cap and ttings frequently for

cracks or leaks. Replace if necessary.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muer, fuel cap, and air cleaner are in

place.

• DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

• DO NOT operate this product inside any building,

carport, porch, mobile equipment, marine applications, or

enclosure.

• DO NOT tip engine or equipment at angle which causes

fuel to spill.

• DO NOT spray ammable liquids.

WHEN TRANSPORTING, MOVING OR REPAIRING

EQUIPMENT

• Transport/move/repair with fuel tank EMPTY or with fuel

shuto valve OFF (0).

• DO NOT tip engine or equipment at angle which causes

fuel to spill.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN

TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers, or other appliances that have pilot light or other

ignition source because they could ignite fuel vapors.

WARNING Starter cord kickback (rapid

retraction) will pull hand and arm toward

engine faster than you can let go which

could cause broken bones, fractures,

bruises, or sprains resulting in serious injury.

• NEVER pull starter cord without rst relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

• After each starting attempt, where engine fails to run,

always point spray gun in safe direction, press red button

and squeeze spray gun trigger to release high pressure.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

4 BRIGGSandSTRATTON.com.au

Not for

Reproduction

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• If cut by uid, call physician immediately. DO NOT treat

as a simple cut.

• DO NOT allow CHILDREN to play with or operate

pressure washer.

• NEVER repair high pressure hose. Replace it.

• NEVER repair leaking connections with sealant of any

kind. Replace o-ring or seal.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

• NEVER aim spray gun at people, animals, or plants.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is

running.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

WARNING Risk of eye or bodily injury.

Spray could splash back or propel

objects resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with AS/NZS 1337 (ANSI Z87.1

equivalent) when using or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

• Always wear protective clothing such as a long-sleeved

shirt, long pants and close-toed shoes.

• NEVER operate pressure washer when barefoot or

wearing sandals or shorts.

CAUTION

could result in minor injury.

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other

parts to increase engine speed. Pressure washer

supplies correct rated pressure and ow when running at

governed speed.

• DO NOT modify pressure washer in any way.

NOTICE High pressure spray could damage fragile

items including glass.

• DO NOT point spray gun at glass when using red (0°) spray

tip.

• NEVER aim spray gun at plants.

Excessively high operating speeds

WARNING Unintentional sparking could cause

re or electric shock resulting in

death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

WARNING Starter and other rotating parts

could entangle hands, hair, clothing, or

accessories resulting in serious injury.

• NEVER operate pressure washer without protective

housing or covers.

• DO NOT wear loose clothing, jewelry or anything that

could be caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

• If you have questions about intended use, ask dealer or

contact qualied service center.

• NEVER operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

• DO NOT modify pressure washer in any way.

• Before starting pressure washer in cold weather, check all

parts of the equipment to be sure ice has not formed there.

• NEVER move machine by pulling on hoses. Use handle

provided on unit.

5

Not for

Reproduction

Assembly

Read entire operator’s manual before you

attempt to assemble or operate your new

pressure washer.

Your pressure washer requires some assembly and is

ready for use after it has been properly serviced with

the recommended oil and fuel.

If you have any problems with the assembly of your

pressure washer, please call the pressure washer

helpline at 1800-356-632 (AUS) or 0800-484-282

(NZ). If calling for assistance, please have the model,

revision, and serial number from the identication label

available.

Unpack Pressure Washer

1. Remove the parts bag, accessories, and inserts

included with pressure washer.

2. Open carton completely by cutting each corner

from top to bottom.

3. Ensure you have all included items prior to

assembly.

Items in the carton include:

• Main Unit

• Handle

• High Pressure Hose

• Spray Gun

• Nozzle Extension with Quick Connect Fitting

• Parts Bag (which includes the following):

• Operator’s Manual

• Ba g containing 5 Multi–Colored Spray Tips

• Garden Hose Adapter

• Hardware Kit (which includes):

• Carriage Bolts (4)

• Plastic Knobs for Handle (2)

• Metal Spring Clips (2)

• Plastic Knobs (2)

To prepare your pressure washer for operation,

you will need to perform these tasks:

1. Attach handle to main unit.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connect high pressure hose to spray gun and

pump.

6. Connect water supply to pump.

7. Attach nozzle extension to spray gun.

8. Select/attach quick connect spray tip to nozzle

extension.

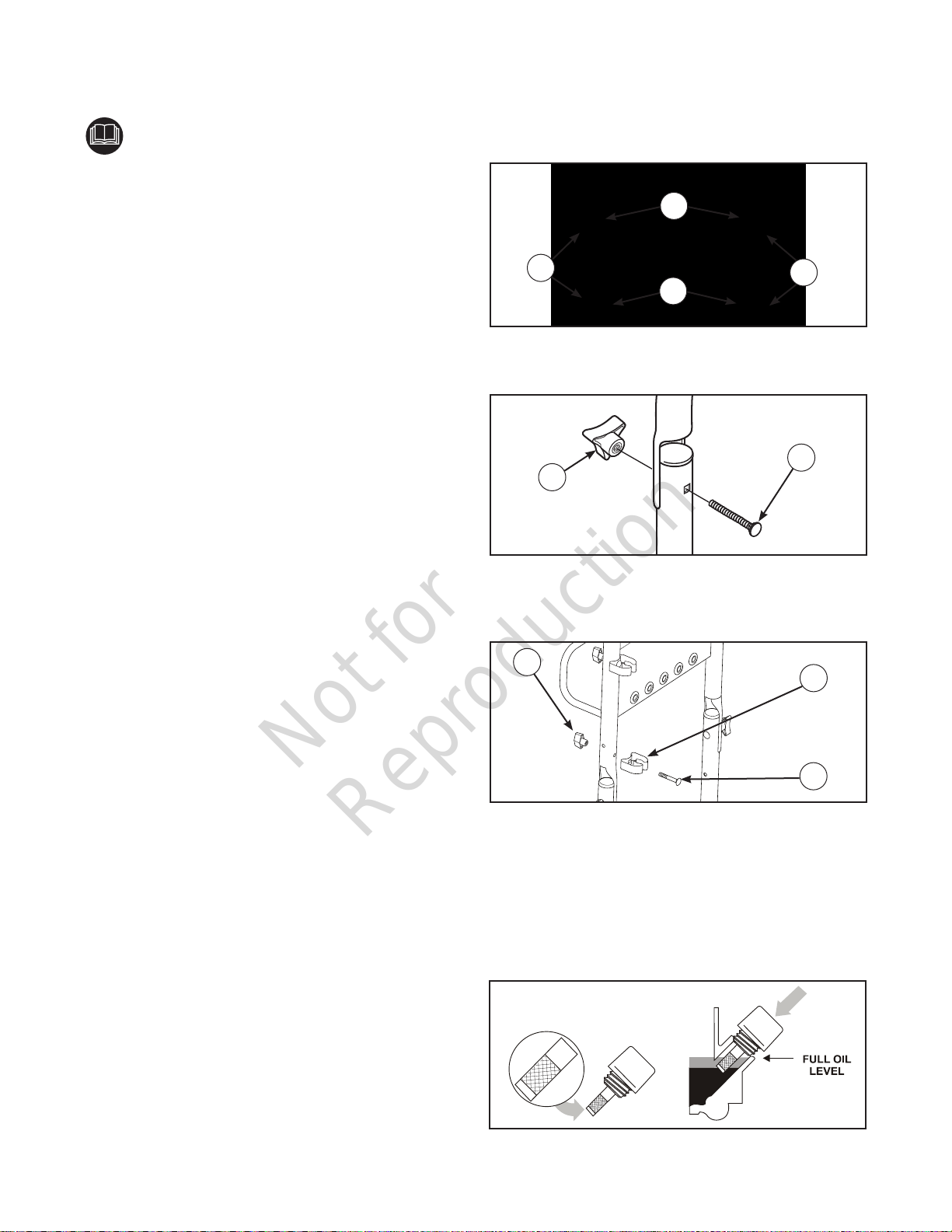

Attach Handle

1. Place handle (A) onto handle supports (B)

connected to main unit. Make sure holes (C) in

handle align with holes (C) on handle supports.

A

C

B

2. Insert handle carriage bolts (D) through holes from

inside of unit and attach a plastic knob (E) from

outside of unit. Tighten by hand.

E

3. Attach metal spring clips (F) by installing carriage

bolts (D) through holes on left side of handle

(facing front of unit). Attach plastic knobs (G) and

tighten by hand.

G

C

D

F

D

Add Engine Oil

1. Place pressure washer on a at, level surface.

2. Clean area around oil ll and remove yellow oil ll

cap/ dipstick.

3. Slowly pour engine oil into oil ll opening.

Checking oil level frequently, ll to point of

overowing.

6 BRIGGSandSTRATTON.com.au

Not for

Reproduction

NOTICE Pause to permit oil to settle. Wipe dipstick

clean each time oil level is checked. DO NOT overll.

3. Install fuel cap and let any spilled fuel evaporate

before starting engine.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

• DO NOT attempt to crank or start the engine before it has

been properly serviced with the recommended oil. This

could result in an engine failure.

5. Replace oil ll cap/ dipstick and fully tighten.

Add Fuel

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 91 RON (87 octane/87 AKI). For

high altitude use, see High Altitude.

• Gasoline with up to 10% ethanol (gasohol) is

acceptable.

WARNING Fuel and its vapors are extremely

ammable and explosive which

could cause burns, re or explosion

resulting in death or serious injury.

WHEN ADDING FUEL

• DO NOT use unapproved gasoline such as E15 and

E85.

• DO NOT mix oil in gasoline or modify engine to run on

alternate fuels.

• Turn pressure washer engine OFF and let it cool at least

2 minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

• Fill fuel tank outdoors.

• DO NOT overll tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open ames, pilot lights,

heat, and other ignition sources.

• Check fuel lines, tank, cap and ttings frequently for

cracks or leaks. Replace if necessary.

• DO NOT light a cigarette or smoke.

To protect the fuel system from gum formation, mix

in a fuel stabilizer when adding fuel. See Storage.

All fuel is not the same. If you experience starting or

performance problems after using fuel, switch to a

dierent fuel provider or change brands. This engine is

certied to operate on gasoline. The emission control

system for this engine is EM (Engine Modications).

1. Clean area around fuel ll cap, remove cap.

2. Slowly add unleaded gasoline (A) to fuel tank (B).

Be careful not to ll above the bae (C). This allows

adequate space for fuel expansion as shown.

High Altitude

t altitudes over 1524 m (5,000 ft.), a minimum

85 octane / 85 AKI (89 RON) gasoline is acceptable.

To remain emissions compliant, high altitude

adjustment is required. Operation without this

adjustment will cause decreased performance,

increased fuel consumption, and increased emissions.

See an Authorized Briggs & Stratton dealer for high

altitude adjustment information. Operation of the

engine at altitudes below 762 m (2,500 ft.) with the

high altitude kit is not recommended.

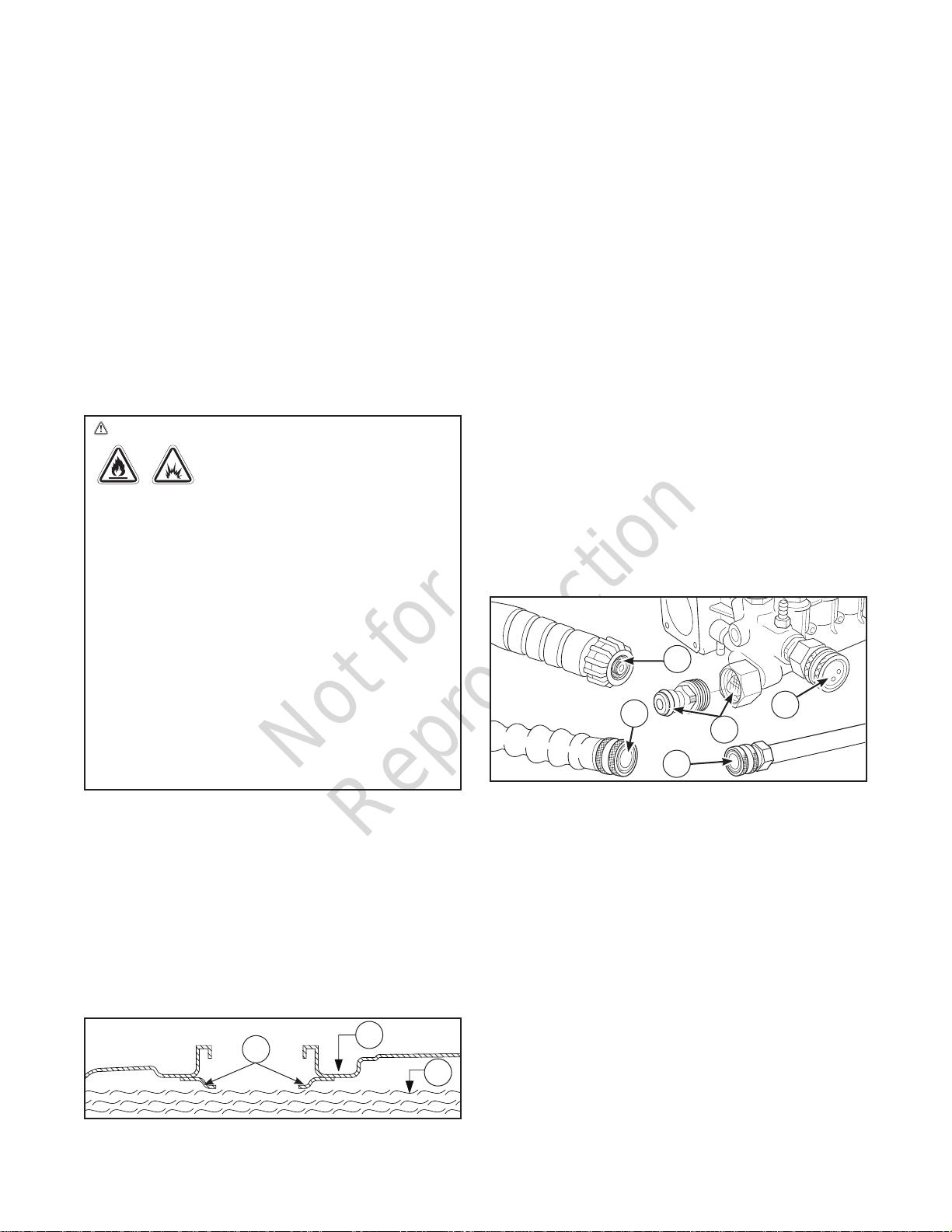

Lubricate O-Rings

Lubrication of o-rings is extremely important for

installation and operation. The use of a lubricant

(petroleum or synthetic grease) during assembly helps

seat o-rings properly and provides an improved seal. It

also helps protect the o-ring from damage by abrasion,

pinching or cutting and extends the life of the o-ring.

NOTICE ALWAYS apply a small amount of lubricant

on o-rings prior to assembling the garden hose to the

pump inlet (D), high pressure hose to pump outlet (E),

high pressure hose (F), spray gun (G), and nozzle

extension (H).

G

F

D

H

Lubricate all connections shown, following these

instructions:

1. Inspect and clean connecting surfaces prior to

lubrication and assembly.

2. Use lubricants sparingly during assembly; a light

lm is all that is required.

3. Use a small brush or cotton swab to apply grease

directly to o-rings where they are not accessible

(QC tting, M22 tting).

E

B

C

TANK

FUEL

A

7

Not for

Reproduction

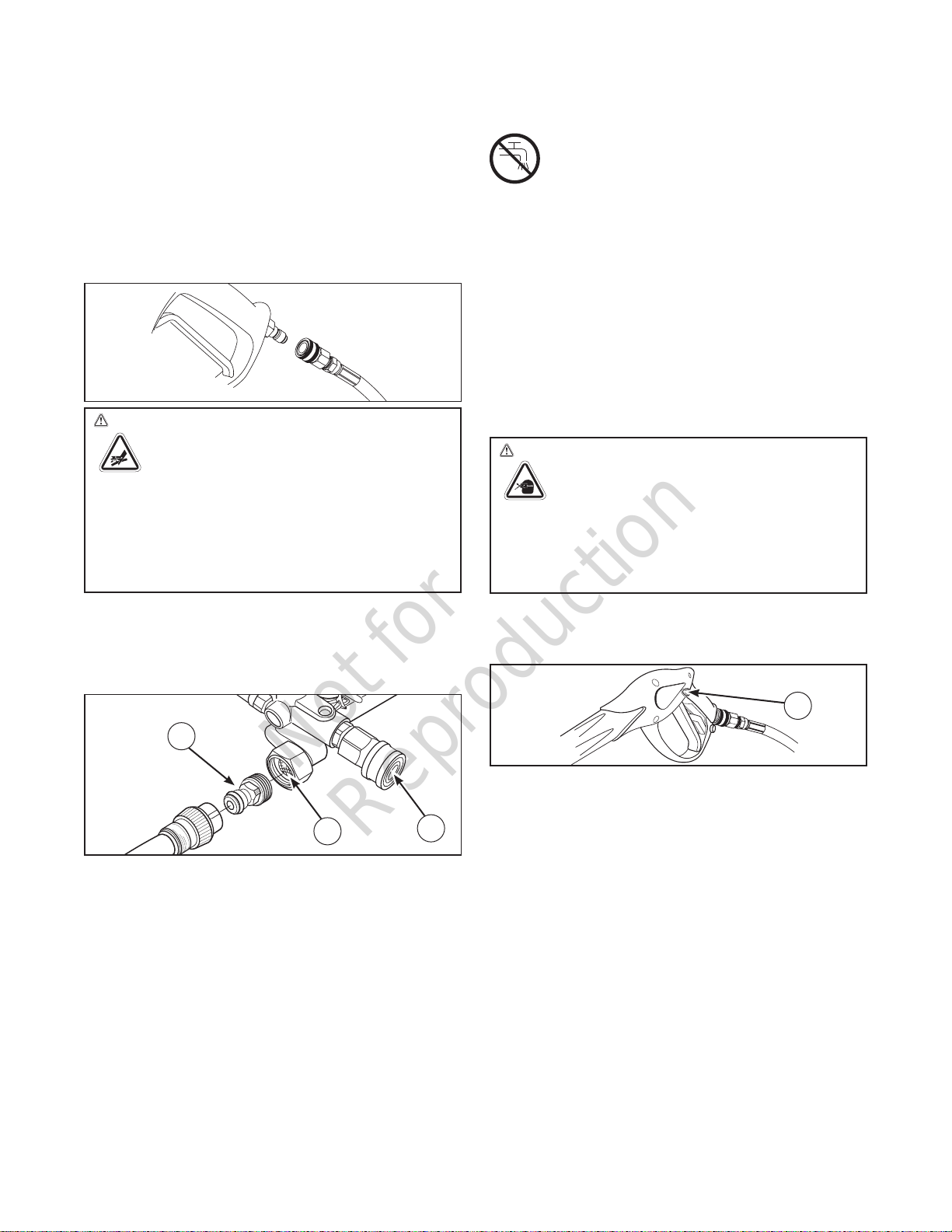

Connect Hose and Water Supply to Pump

NOTICE DO NOT run the pump without the water

supply connected and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

1. Uncoil high pressure hose and attach quick

connect end of hose to base of spray gun. Pull

down on collar of quick connect, slide onto spray

gun and let go of collar. Tug on hose to be sure of

tight connection.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

NOTICE DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 38°C (100°F)).

WARNING! Water that has owed through a

backow preventer is considered to be non-

potable.

NOTICE Using a One Way Valve (vacuum breaker

or check valve) at pump inlet could cause pump or

inlet connector damage.

• There MUST be at least 3 m (10 ft) of unrestricted garden

hose between the pressure washer inlet and any device,

such as a vacuum breaker or check valve.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

6. Connect garden hose (not to exceed 15.24 m

(50 ft) in length) to water inlet. Pull back on collar

of quick connect, slide tting onto water inlet and

let go of collar. Pull on garden hose to be sure of a

tight connection.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with AS/NZS 1337 (ANSI Z87.1

equivalent) when using or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

2. Similarly, attach other end of high pressure hose

to high pressure outlet (A) on pump. Pull down

on collar of quick connect, slide onto pump and

let go of collar. Pull on hose to be sure of tight

connection.

C

B

3. Before connecting garden hose to water inlet,

inspect inlet screen (B). Clean screen if it contains

debris or have it replaced if damaged. DO NOT

run pressure washer if inlet screen is damaged.

4. Attach garden hose adapter (C) to water inlet.

Tighten by hand.

5. Run water through your garden hose for

30 seconds to clean out any debris.

A

6. Turn ON the water, press red button (D) on the

gun and squeeze the trigger to purge the pump

system of air and impurities.

D

Checklist Before Starting Engine

Review the unit’s assembly to ensure you have

performed all of the following.

1. Make sure handle is in place and secure.

2. Check that oil has been added to proper level in

the engine crankcase.

3. Add proper fuel to fuel tank.

4. Check for properly tightened hose connections.

5. Check to make sure there are no kinks, cuts, or

damage to high pressure hose.

6. Provide a proper water supply at an adequate ow.

7. Be sure to read Operator Safety and Operation

before using pressure washer.

8 BRIGGSandSTRATTON.com.au

Loading...

Loading...