Page 1

Manual No. 206224GS Revision A (04/15/2008)

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WISCONSIN, U.S.A.

Pressure Washer

Operator’s Manual

This pressure washer is rated in accordance to the Pressure Washer Manufacture Association

(PWMA) standard PW101 (Testing and Rating Performance of Pressure Washers).

Page 2

2 BRIGGSandSTRATTON.COM

Briggs & Stratton Power Products Group, LLC

900 North Parkway

Jefferson, WI 53549

Copyright © 2008 Briggs & Stratton Power Products Group,

LLC. All rights reserved. No part of this material may be

reproduced or transmitted in any form by any means without

the express written permission of Briggs & Stratton Power

Products Group, LLC.

Thank you for purchasing this quality-built Briggs & Stratton pressure washer. We are pleased that you’ve placed your

confidence in the Briggs & Stratton brand. When operated and maintained according to the instructions in this manual, your

Briggs & Stratton pressure washer will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with pressure washers and

how to avoid them. Because Briggs & Stratton does not necessarily know all the applications this pressure washer could be

used for, it is important that you read and understand these instructions thoroughly before attempting to start or operate this

equipment. Save these instructions for future reference.

This pressure washer requires final assembly before use. Refer to the Assembly section of this manual for instructions on

final assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your pressure washer. Consult your Yellow Pages.

There are over 30,000 Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also

contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Pressure Washer

Model Number

Revision

Serial Number

Engine

Model Number

Type Number

Code Number

Date Purchased

Page 3

Table of Contents

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unpack Pressure Washer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Attach Handle and Accessory Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Add Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Add Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connect Hose and Water Supply to Pump. . . . . . . . . . . . . . . . . . . . . . . . . 10

Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Washer Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

How to Start Your Pressure Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

How to Stop Your Pressure Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How to Use Accessory Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

How to Use ProjectPro™ Nozzle System . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Applying Detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure Washer Rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning Detergent Siphoning Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Automatic Cool Down System (Thermal Relief). . . . . . . . . . . . . . . . . . . . . 16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pressure Washer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Engine Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

After Each Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Winter Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warranties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Emissions Control System Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pressure Washer Owner Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Product Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Common Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3

Français

Page 4

Operator Safety

Equipment Description

Read this manual carefully and become familiar

with your pressure washer. Know its applications,

its limitations, and any hazards involved.

This pressure washer operates at a maximum of 2,200 PSI

(151.7 BARS) and a flow rate of up to 2.2 gallons per minute

(8.3 liters per minute). This high quality residential system

features an axial cam pump with stainless steel pistons,

automatic cool down system, detergent siphoning system,

nozzle extension with quick connect fitting, a variety of quick

connect ProjectPro™ nozzles, safety goggles, heavy duty 30’

(9.1 m) hose, and more.

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the

right to change, alter, or otherwise improve the product and

this document at any time without prior notice.

The Emission Control System for this pressure washer is

warranted for standards set by the Environmental Protection

Agency and the California Air Resources Board.

Safety Rules

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION, WARNING), a pictorial and/or a safety

message to alert you to hazards. DANGER indicates a hazard

which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury. CAUTION indicates a hazard

which, if not avoided, might result in minor or moderate

injury. NOTICE, indicates a situation that could result in

equipment damage. Follow safety messages to avoid or

reduce the risk of injury or death.

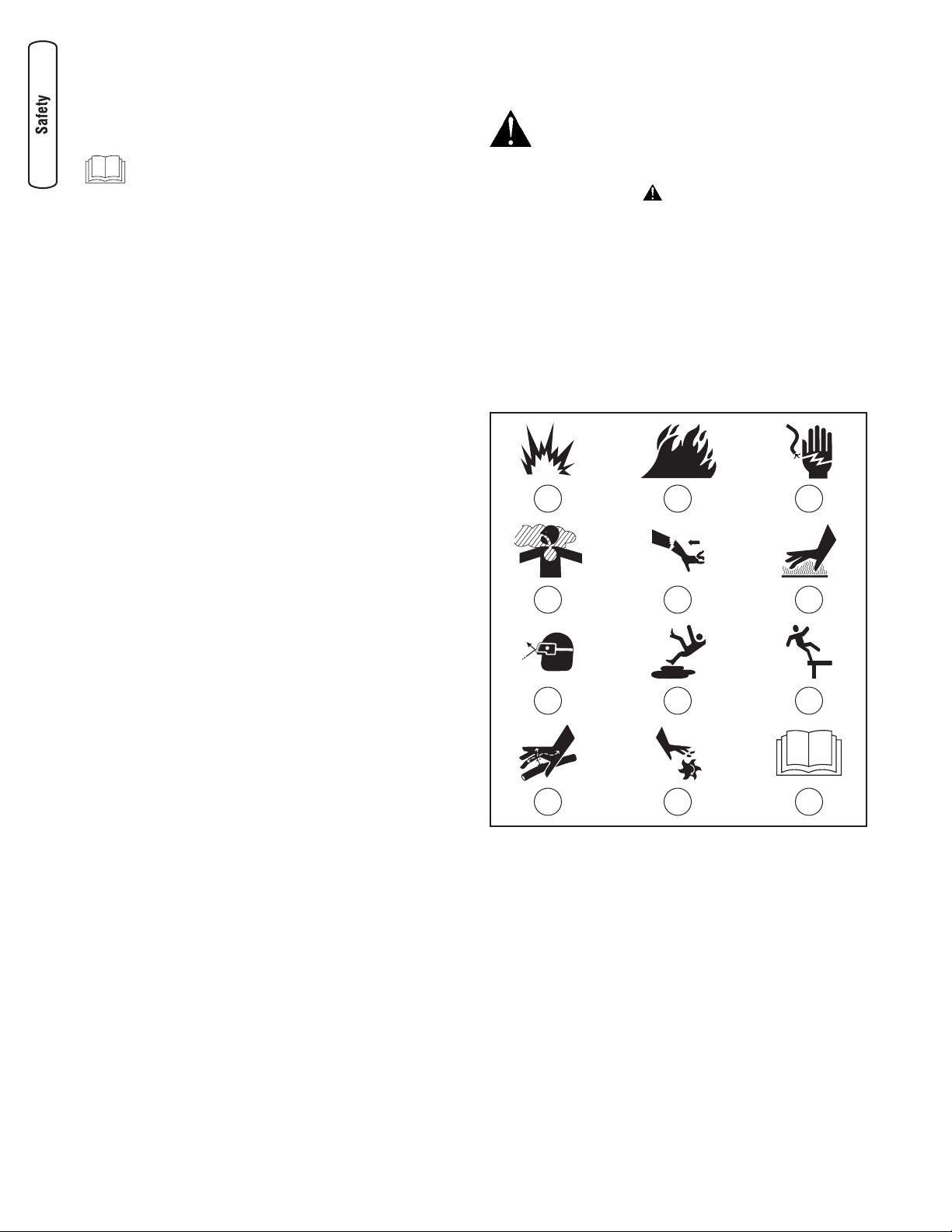

Hazard Symbols and Meanings

A - Explosion G - Flying Objects

B - Fire H - Slippery Surface

C - Electric Shock I - Fall

D - Toxic Fumes J - Fluid Injection

E - Kickback K - Moving Parts

F - Hot Surface L - Read Manual

4 BRIGGSandSTRATTON.COM

A B C

D E

G H

F

I

J K L

Page 5

5

WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

WARNING

Risk of electrocution.

Contact with power source can cause electric

shock or burn.

• NEVER spray near power source.

WARNING

Use of pressure washer can create puddles and

slippery surfaces.

Kickback from spray gun can cause you to fall.

• Operate pressure washer from a stable surface.

• The cleaning area should have adequate slopes and drainage to

reduce the possibility of a fall due to slippery surfaces.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARNING

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WHEN ADDING OR DRAINING FUEL

• Turn pressure washer OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve pressure

in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muffler, fuel cap, and air cleaner are in place.

• DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

• DO NOT tip engine or equipment at angle which causes fuel to

spill.

• DO NOT spray flammable liquids.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff valve

OFF.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes dryers,

or other appliances that have pilot light or other ignition source

because they can ignite fuel vapors.

WARNING

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting, or poisoning.

• Operate pressure washer ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes, or other openings.

• DO NOT start or run engine indoors or in an enclosed area, even

if windows and doors are open.

• Use a respirator or mask whenever there is a chance that vapors

may be inhaled.

• Read all instructions with mask so you are certain the mask will

provide the necessary protection against inhaling harmful

vapors.

WARNING

Certain components in this product and related

accessories contain chemicals known to the State of

California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

Page 6

6 BRIGGSandSTRATTON.COM

WARNING

Contact with muffler area can result in serious

burns.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (1.5 m) of clearance on all sides of pressure

washer including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

WARNING

Unintentional sparking can result in fire or

electric shock.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR PRESSURE

WASHER

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

WARNING

Starter cord kickback (rapid retraction) can result

in bodily injury. Kickback will pull hand and arm

toward engine faster than you can let go.

Broken bones, fractures, bruises, or sprains

could result.

• NEVER pull starter cord without first relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance is felt and

then pull rapidly to avoid kickback.

• After each starting attempt, where engine fails to run, always

point spray gun in safe direction, press red button and squeeze

spray gun trigger to release high pressure.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• DO NOT allow CHILDREN to operate pressure washer.

• NEVER repair high pressure hose. Replace it.

• NEVER repair leaking connections with sealant of any kind.

Replace o-ring or seal.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• ALWAYS point spray gun in safe direction, press red button and

squeeze spray gun trigger, to release high pressure, every time

you stop engine.

• NEVER aim spray gun at people, animals, or plants.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is running.

• NEVER use a spray gun which does not have a trigger lock or

trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories are

correctly attached.

Page 7

7

NOTICE

High pressure spray may damage fragile items including

glass.

• DO NOT point spray gun at glass when using red 0° nozzle.

• NEVER aim spray gun at plants.

WARNING

Risk of eye injury.

Spray can splash back or propel objects.

• Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

WARNING

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

• NEVER operate pressure washer without protective housing or

covers.

• DO NOT wear loose clothing, jewelry or anything that may be

caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

• If you have questions about intended use, ask dealer or contact

qualified service center.

• NEVER operate units with broken or missing parts, or without

protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

• DO NOT modify pressure washer in any way.

• Before starting pressure washer in cold weather, check all parts

of the equipment to be sure ice has not formed there.

• NEVER move machine by pulling on hoses. Use handle provided

on unit.

• Check fuel system for leaks or signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure

washer.

• This equipment is designed to be used with Briggs & Stratton

Power Products authorized parts ONLY. If equipment is used

with parts that DO NOT comply with minimum specifications,

user assumes all risks and liabilities.

Page 8

Assembly

Read entire operator’s manual before you attempt

to assemble or operate your new pressure washer.

Your pressure washer requires some assembly and is ready

for use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your pressure

washer, please call the pressure washer helpline at

(800) 743-4115. If calling for assistance, please have the

model, revision, and serial number from the identification

label available.

Unpack Pressure Washer

1. Remove the parts bag, accessories, and inserts

included with pressure washer.

2. Open carton completely by cutting each corner from

top to bottom.

3. Ensure you have all included items prior to assembly.

Items in the carton include:

• Main Unit

• Handle

• High Pressure Hose

• Spray Gun

• Nozzle Extension with Quick Connect Fitting

• Plastic Accessory Tray

• Oil Bottle

• Parts Bag (which includes the following):

• Safety Goggles

• Operator’s Manual

• Owner’s Registration Card

• Bag of 4 Multi–Colored ProjectPro™ Nozzles

• Handle/Accessory Tray Fastening Hardware Kit

(which includes):

• Carriage Bolts (2)

• Plastic Knobs (2)

• Tree Clips (4)

To prepare your pressure washer for operation, you will

need to perform these tasks:

1. Fill out and send in registration card.

2. Attach handle to main unit.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connect high pressure hose to spray gun and pump.

6. Connect water supply to pump.

7. Attach nozzle extension to spray gun.

8. Select/attach quick connect ProjectPro™ nozzle to

nozzle extension.

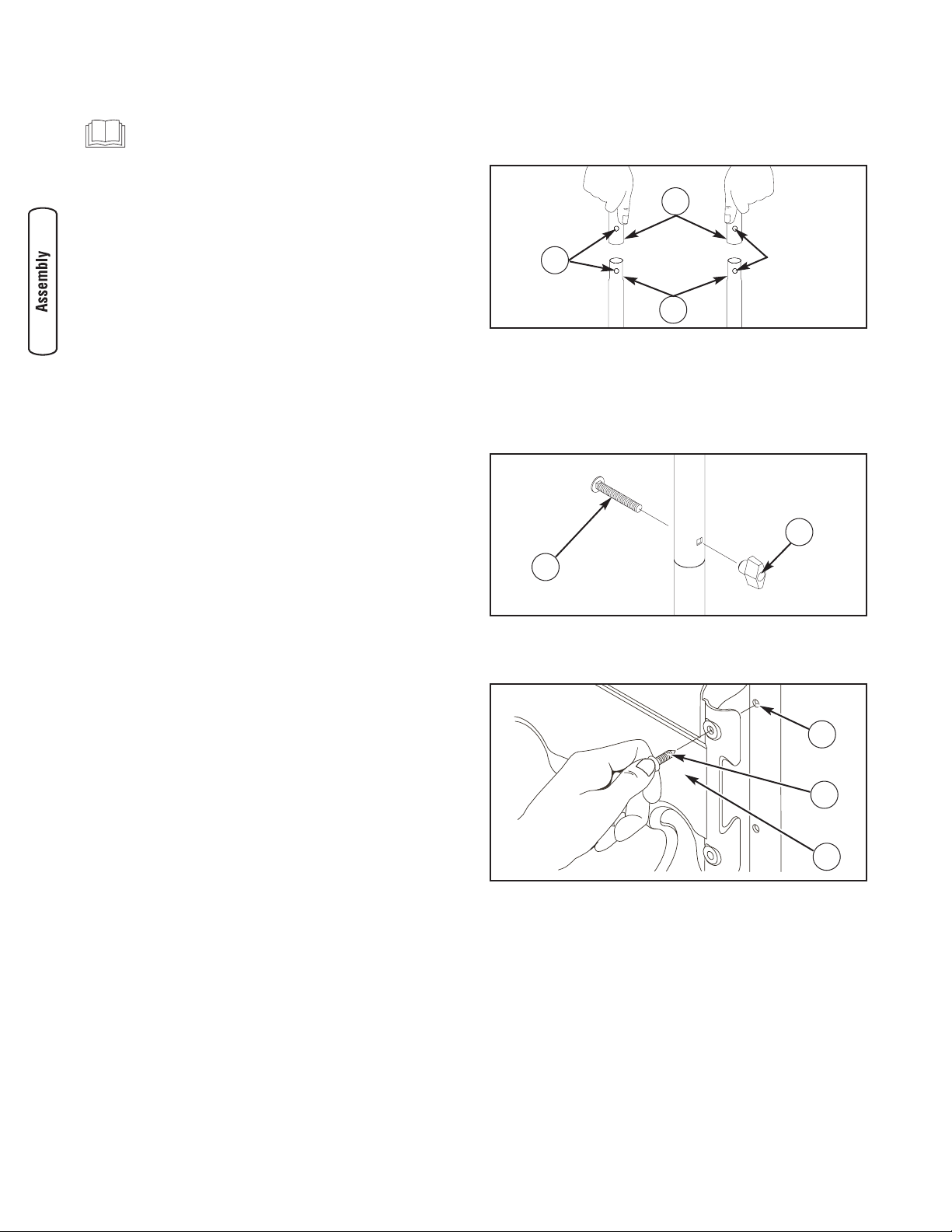

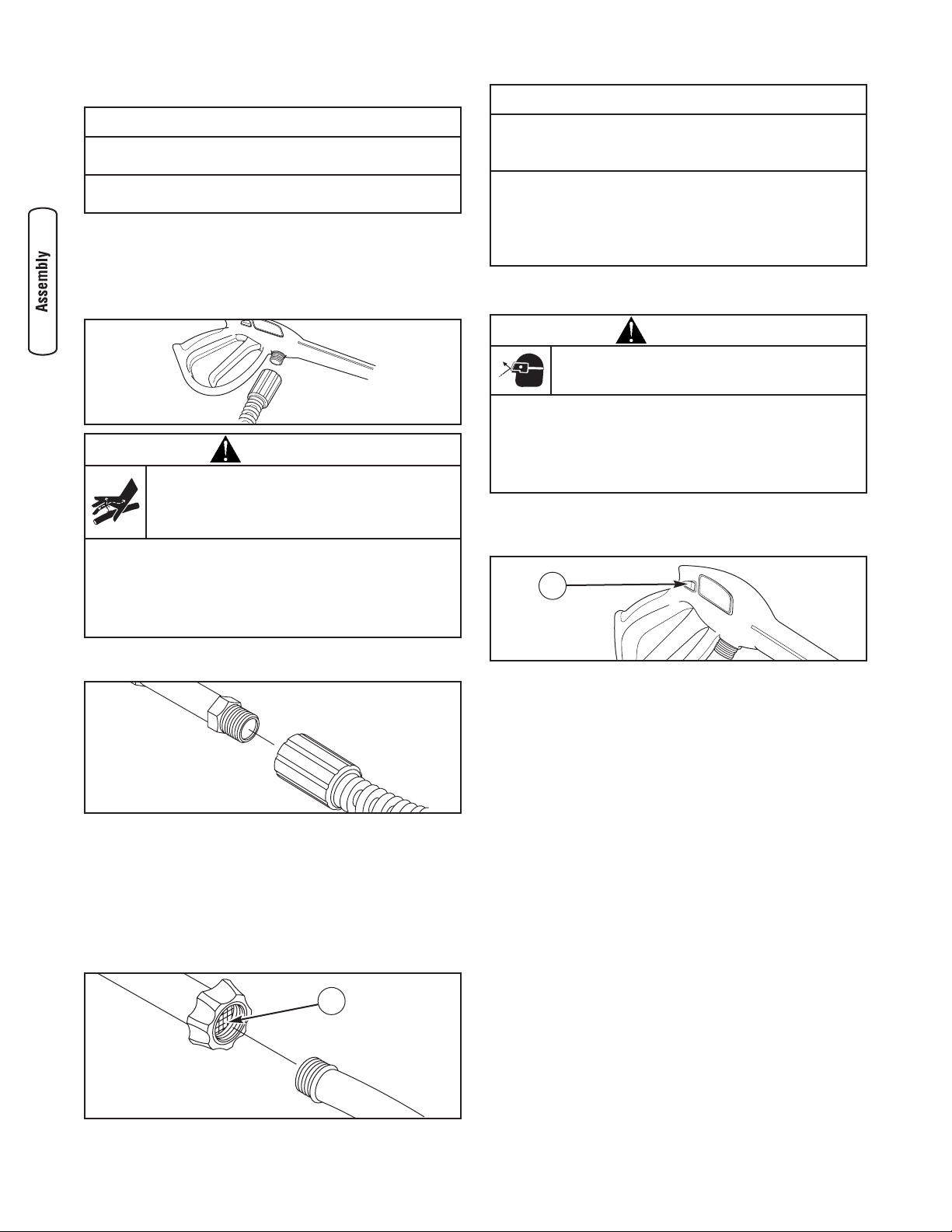

Attach Handle and Accessory Tray

1. Place handle (A) onto handle supports (B) connected to

main unit. Make sure holes (C) in handle align with

holes (C) on handle supports.

NOTE: It may be necessary to move the handle supports

from side to side in order to align the handle so it will slide

over the handle supports.

2. Insert carriage bolts (A) through holes from back of

unit and attach a plastic knob (B) from front of unit.

Tighten by hand.

3. Place accessory tray (A) over holes (C) on handle

(viewing from front of unit). Push the tree clips (B) into

the holes until they sit flat against the accessory tray.

4. Insert multi–colored ProjectPro™ nozzles and other

supplied accessories in spaces provided in accessory

tray. See How to Use Accessory Tray.

8 BRIGGSandSTRATTON.COM

C

A

B

A

B

A

B

C

Page 9

Add Engine Oil

1. Place pressure washer on a flat, level surface.

2. Clean area around oil fill and remove yellow oil fill

cap/dipstick.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

4. Replace oil fill cap/dipstick and fully tighten.

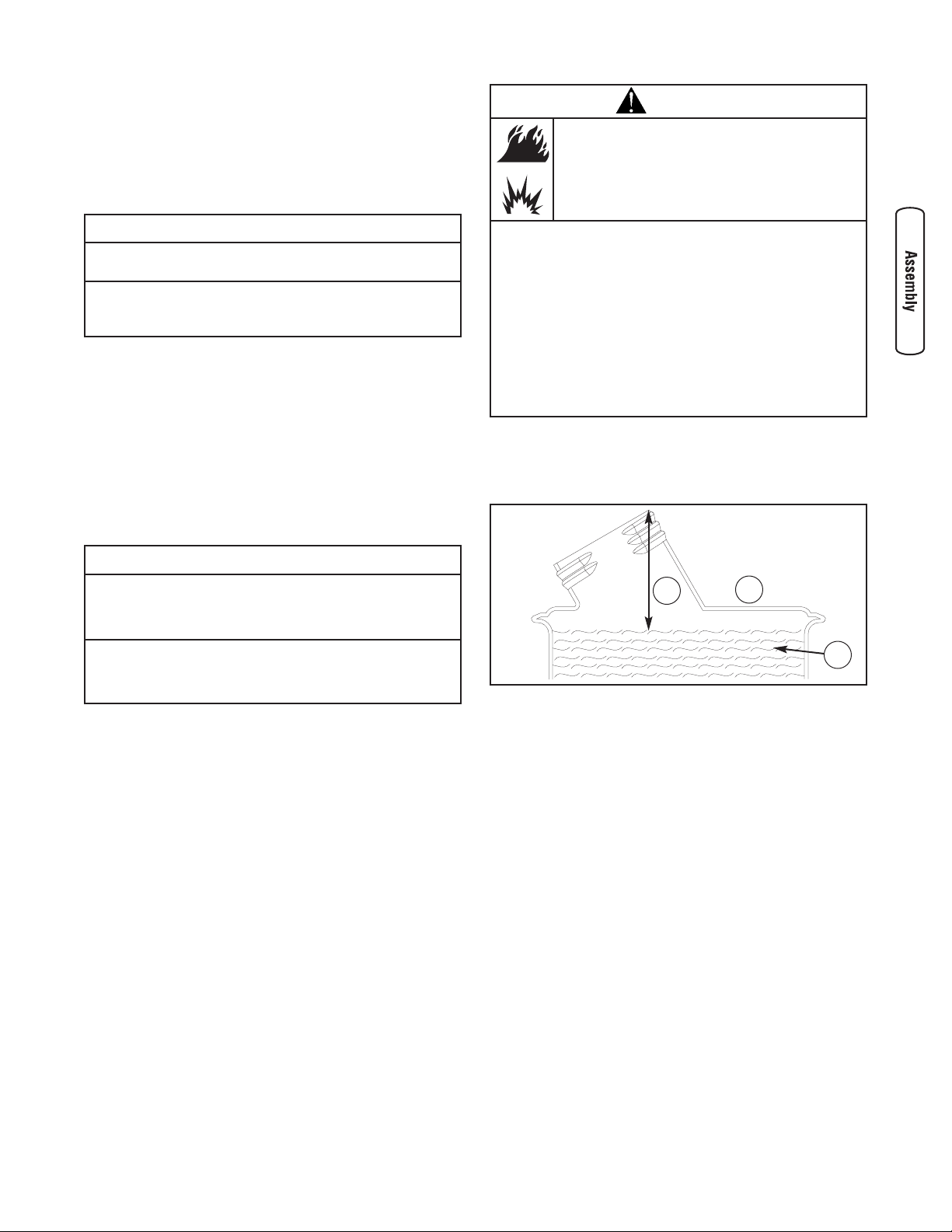

Add Fuel

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High

altitude use, see High Altitude.

• Gasoline with up to 10% ethanol (gasohol) or up to

15% MTBE (methyl tertiary butyl ether) is acceptable.

To protect the fuel system from gum formation, mix in a fuel

stabilizer when adding fuel. See Storage. All fuel is not the

same. If you experience starting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operate on gasoline. The

emission control system for this engine is EM (Engine

Modifications).

1. Clean area around fuel fill cap, remove cap.

2. Slowly add regular unleaded fuel (A) to fuel tank (B). Be

careful not to overfill. Allow about 1.5" (4 cm) (C) of

tank space for fuel expansion.

3. Install fuel cap and let any spilled fuel evaporate before

starting engine.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane / 85 AKI (89 RON) gasoline is acceptable. To

remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause

decreased performance, increased fuel consumption, and

increased emissions. See an Authorized Briggs & Stratton

dealer for high altitude adjustment information. Operation of

the engine at altitudes below 2,500 feet (762 meters) with

the high altitude kit is not recommended.

9

C

B

A

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

• DO NOT attempt to crank or start the engine before it has been

properly serviced with the recommended oil. This may result in

an engine failure.

NOTICE

Avoid pressure washer damage.

Failure to follow Operator’s Manual for fuel

recommendations voids warranty.

• DO NOT use unapproved gasoline such as E85.

• DO NOT mix oil in gasoline.

• DO NOT modify engine to run on alternate fuels.

WARNING

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WHEN ADDING FUEL

• Turn pressure washer OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve pressure

in tank.

• Fill fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

Page 10

Connect Hose and Water Supply to Pump

NOTE: Remove and discard the shipping caps from the

pump’s high pressure outlet and water inlet before attaching

hoses.

1. Uncoil high pressure hose and attach one end of hose

to base of spray gun. Tighten by hand.

2. Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

3. Run water through your garden hose for 30 seconds to

clean out any debris.

IMPORTANT: DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 100°F (38°C)).

4. Before connecting garden hose to water inlet, inspect

inlet screen (A). Clean screen if it contains debris or

have it replaced if damaged. DO NOT run pressure

washer if inlet screen is damaged.

5. Connect the garden hose (not to exceed 50 feet (15 m)

in length) to the water inlet. Tighten by hand.

6. Turn ON the water, press red button (B) on the gun and

squeeze the trigger to purge the pump system of air and

impurities.

Checklist Before Starting Engine

Review the unit’s assembly to ensure you have performed all

of the following.

1. Be sure to read the Operator Safety section and How to

Use Your Pressure Washer in Operation section before

using pressure washer.

2. Make sure handle is in place and secure.

3. Check that oil has been added to proper level in the

engine crankcase.

4. Add proper fuel to fuel tank.

5. Check for properly tightened hose connections.

6. Check to make sure there are no kinks, cuts, or damage

to high pressure hose.

7. Provide a proper water supply at an adequate flow.

10 BRIGGSandSTRATTON.COM

WARNING

Risk of eye injury.

Spray can splash back or propel objects.

• Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

NOTICE

DO NOT run the pump without the water supply connected

and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• Always be certain spray gun, nozzles and accessories are

correctly attached.

NOTICE

Damage to pump or water inlet connector will occur if a

One Way Valve (vacuum breaker or check valve) is

connected to pump.

• There MUST be at least ten feet (3M) of unrestricted garden

hose between the pressure washer inlet and any device, such as

a One Way Valve.

• Damage to equipment caused by attaching a One Way Valve to

pump will void warranty.

A

B

Page 11

11

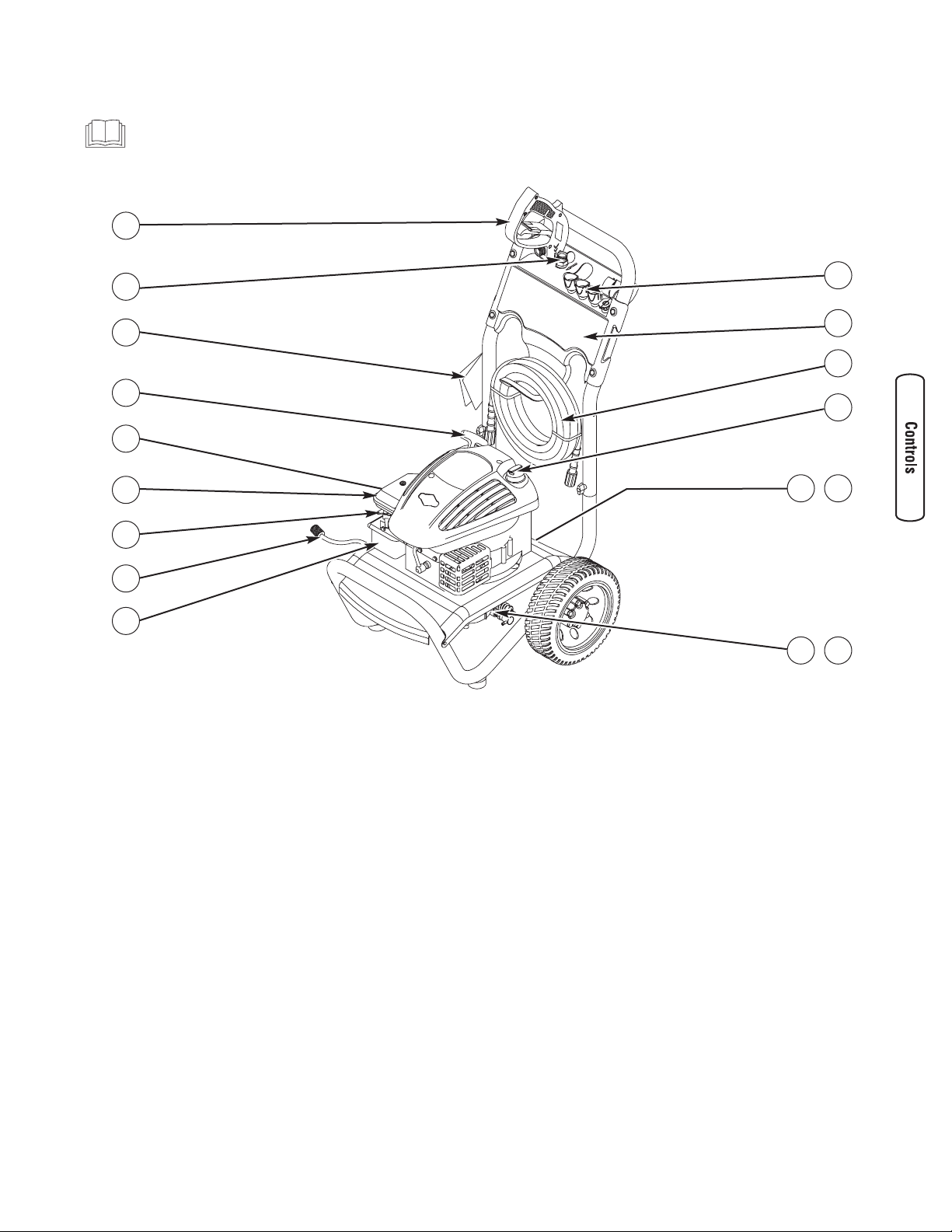

Features and Controls

Read this Operator’s Manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer, to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

A - Spray Gun — Controls the application of water onto

cleaning surface with trigger device. Includes trigger lock.

B - Nozzle Extension with Quick Connect — Allows you to

switch between four different nozzles.

C - Warning/Operating Instructions Tag — Identifies

hazards and proper procedure to start/stop pressure

washer.

D - Recoil Starter — Used for starting the engine manually.

E - Primer Bulb — Prepares a cold engine for starting.

F - Air Filter — Protects engine by filtering dust and debris

out of intake air.

G - Throttle Lever — Sets engine in starting mode for recoil

starter and stops a running engine.

H - Detergent Siphoning Tube/Filter — Use to siphon

pressure washer safe detergents into the low pressure

stream.

J- Fuel Tank — Fill tank with regular unleaded fuel. Always

leave room for fuel expansion.

K - Pump — Develops high pressure.

L - Automatic Cool Down System — Cycles water through

pump when water reaches 125°-155°F. Warm water will

discharge from pump onto ground. This system prevents

internal pump damage.

M - High Pressure Outlet — Connection for high pressure

hose.

N - Water Inlet — Connection for garden hose.

P - Oil Fill/Dipstick — Check and fill with oil here.

R - High Pressure Hose — Connect one end to water pump

and the other end to spray gun.

S - Accessory Tray — Provides convenient storage for

standard and optional accessories, such as brushes,

turbo wands, etc.

T - Project Pro™ Nozzles — Detergent, 0°, 15° and 40°: for

various high pressure cleaning applications.

Items Not Shown:

Identification Label (near rear of base plate) — Provides

model and serial number of pressure washer. Please have

these readily available if calling for assistance.

Safety Goggles — Always use the enclosed safety goggles

when running your pressure washer.

E

D

H

A

L

,

K

C

F

S

G

B

P

R

N

,

M

T

J

Page 12

12 BRIGGSandSTRATTON.COM

Operation

If you have any problems operating your pressure washer,

please call the pressure washer helpline at (800) 743-4115.

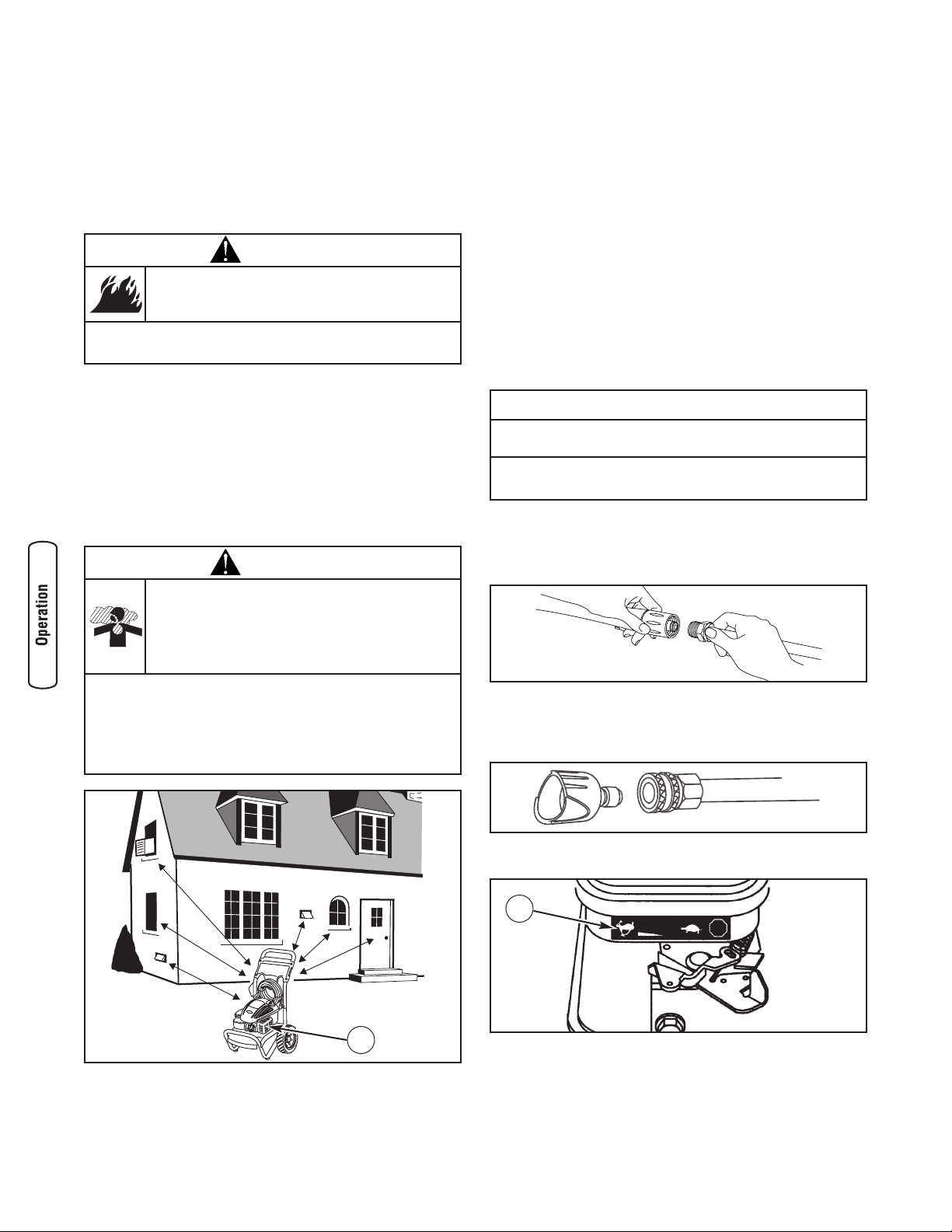

Pressure Washer Location

Clearances and Air Movement

Place pressure washer outdoors in an area that will not

accumulate deadly exhaust gas. DO NOT place pressure

washer where exhaust gas (A) could accumulate and enter

inside or be drawn into a potentially occupied building.

Ensure exhaust gas is kept away from any windows, doors,

ventilation intakes, or other openings that can allow exhaust

gas to collect in a confined area. Prevailing winds and air

currents should be taken into consideration when positioning

pressure washer.

How to Start Your Pressure Washer

To start your pressure washer for the first time, follow these

instructions step-by-step. This starting information also

applies if you have let the pressure washer sit idle for at least

a day.

1. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than

3.2 gallons (12.1 l) per minute and no less than 20 PSI

(1.38 BARS) at pressure washer end of garden hose.

DO NOT siphon supply water.

2. Check that high pressure hose is tightly connected to

spray gun and pump. See Assembly section.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure washer

pump.

5. Turn ON the water, press red button on the gun and

squeeze the trigger to purge the pump system of air and

impurities.

6. Attach nozzle extension to spray gun. Tighten by hand.

7. Choose ProjectPro™ nozzle you want to use, pull back

on collar of nozzle extension, insert nozzle and release

collar. Tug on nozzle to make sure it is securely in

place. See How to Use ProjectPro™ Nozzle System.

8. Move throttle lever to “Fast” position (B), shown as a

rabbit.

A

B

WARNING

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

• Keep at least 5 ft. (1.5 m) clearance on all sides of pressure

washer including overhead.

WARNING

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

• Operate pressure washer ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes, or other openings.

• DO NOT start or run engine indoors or in an enclosed area, even

if windows and doors are open.

NOTICE

DO NOT run the pump without the water supply connected

and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

Page 13

13

To start the engine for the very first time:

9A. Push primer bulb firmly 5 times, waiting 2 seconds

between each push.

To start engine thereafter:

9B. Press primer bulb firmly 3 times, waiting 2 seconds

between each push. For a warm engine, DO NOT press

primer bulb.

IMPORTANT: Before starting the pressure washer, be sure

you are wearing adequate safety goggles.

10. When starting engine, position yourself as

recommended below and grasp starter grip handle and

pull slowly until you feel some resistance. Then pull

rapidly to start engine.

11. Return starter grip handle slowly. DO NOT let rope

“snap back” against starter.

NOTE: Always keep the throttle lever in the “Fast” position

when operating the pressure washer.

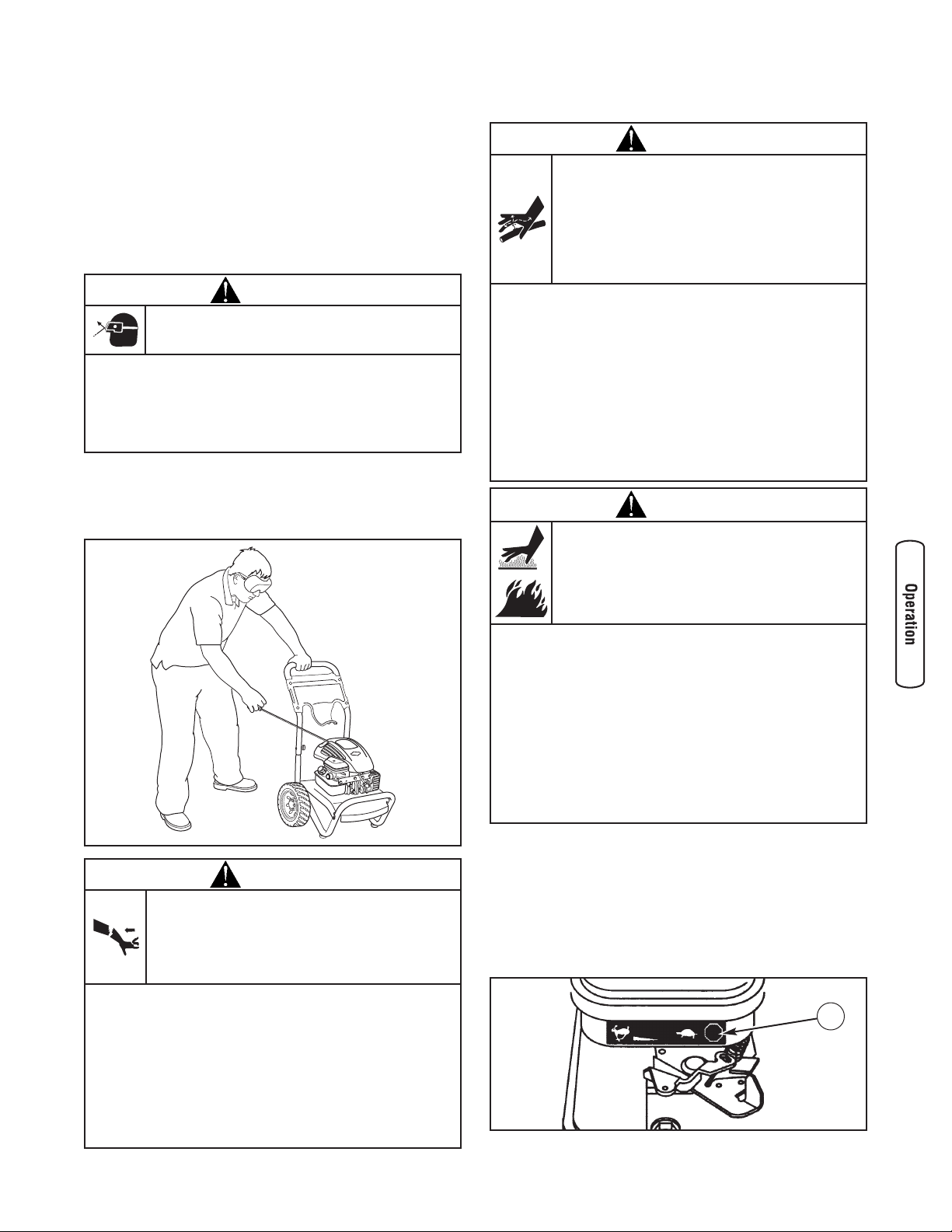

How to Stop Your Pressure Washer

1. Release spray gun trigger and let engine idle for two

minutes.

2. Move throttle to SLOW position, then STOP position (A).

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• DO NOT allow CHILDREN to operate pressure washer.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• NEVER aim spray gun at people, animals, or plants.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is running.

• NEVER use a spray gun which does not have a trigger lock or

trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories are

correctly attached.

WARNING

Contact with muffler area can result in serious

burns.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (1.5 m) of clearance on all sides of pressure

washer including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

A

WARNING

Risk of eye injury.

Spray can splash back or propel objects.

• Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

WARNING

Starter cord kickback (rapid retraction) can result

in bodily injury. Kickback will pull hand and arm

toward engine faster than you can let go.

Broken bones, fractures, bruises, or sprains

could result.

• NEVER pull starter cord without first relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance is felt and

then pull rapidly to avoid kickback.

• After each starting attempt, where engine fails to run, always

point spray gun in safe direction, press red button and squeeze

spray gun trigger to release high pressure.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

Page 14

14 BRIGGSandSTRATTON.COM

3. ALWAYS point gun in a safe direction and press red

button and squeeze spray gun trigger to release

retained high water pressure.

IMPORTANT: Spray gun traps high water pressure, even

when engine is stopped and water is disconnected.

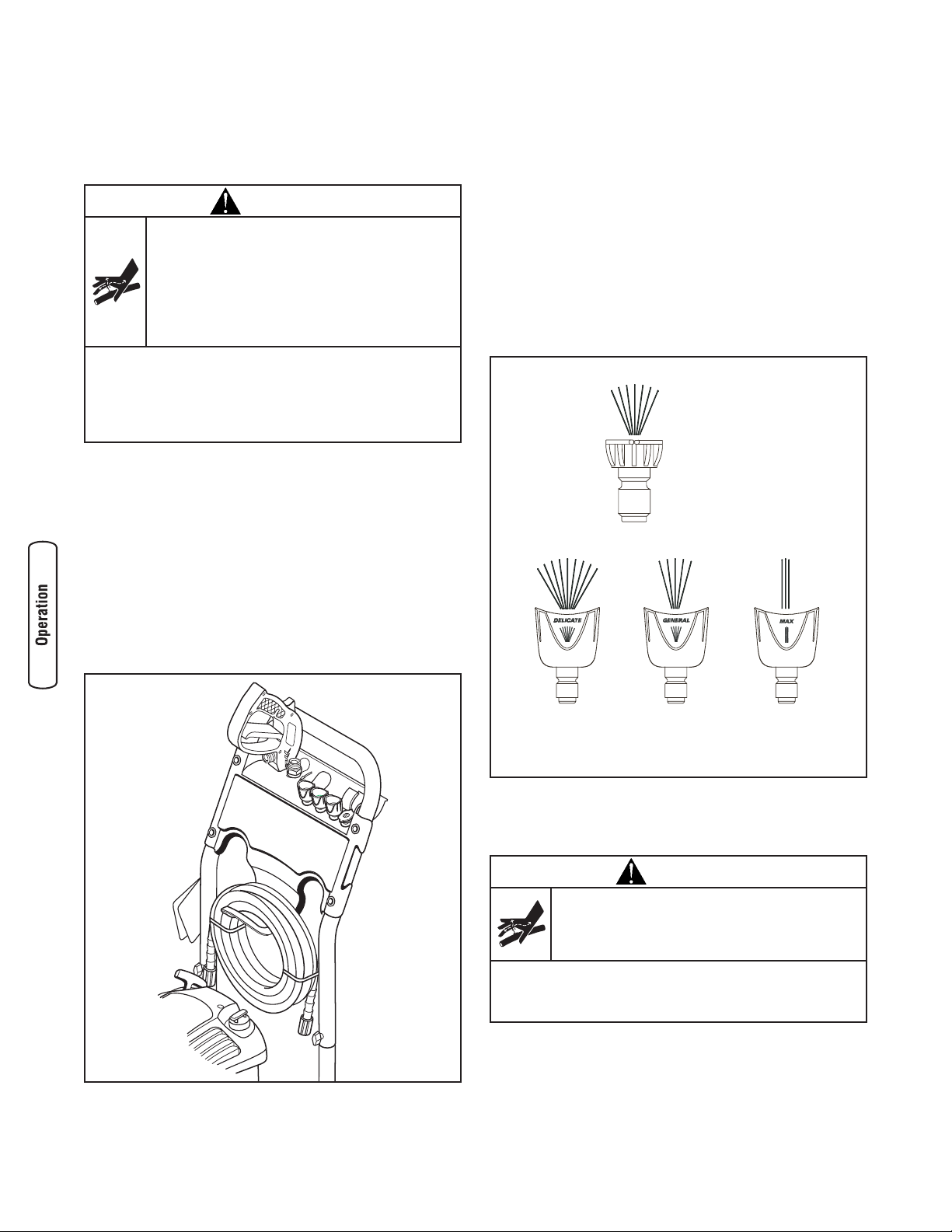

How to Use Accessory Tray

The unit is equipped with an accessory tray with places to

store your spray gun, nozzle extension and ProjectPro™

nozzles. There is also a hook at the front of the accessory tray

to hold your high pressure hose.

NOTE: The extra hole in the tray is for storing a utility brush.

The extra clip in the tray is for storing a turbo nozzle. The

brush and turbo nozzle are NOT included with your pressure

washer. You can buy these items as optional accessories.

1. Place nozzle extension through hole on accessory tray

as shown.

2. Place spray gun through hole on accessory tray on

right side of unit as shown.

3. Hang high pressure hose on hook attached to

accessory tray on front of tray as shown.

4. Insert multi–colored ProjectPro™ nozzles in spaces

provided in accessory tray.

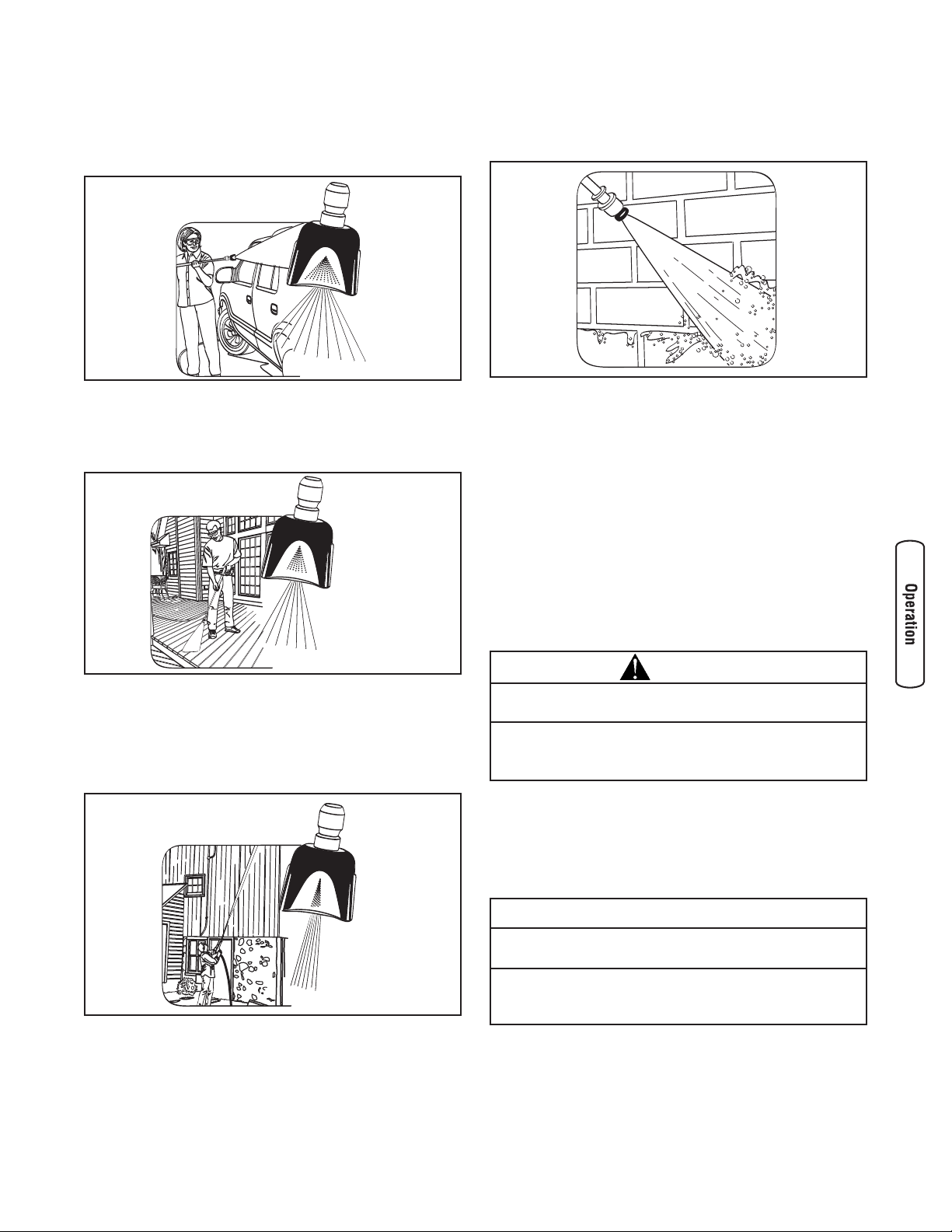

How to Use ProjectPro™ Nozzle System

The quick–connect on the nozzle extension allows you to

switch between four different ProjectPro™ system nozzles.

ProjectPro™ nozzles can be changed while pressure washer

is running once spray gun trigger lock is engaged. The

ProjectPro™ nozzles vary the pressure and spray pattern as

shown.

Follow these instructions to change ProjectPro™ nozzles:

1. Pull back collar on quick–connect and pull current

ProjectPro™ nozzles off. Store ProjectPro™ nozzles in

holder provided on the accessory tray.

Delicate

40° Yellow

1650 PSI

2.2 GPM

General

15° Orange

1950 PSI

2.1 GPM

Max

0° Red

2200 PSI

1.9 GPM

Black

Use to apply

detergent

Low Pressure

High Pressure

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

• NEVER exchange nozzles without the trigger locked on the spray

gun.

• DO NOT twist nozzles while spraying.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• After each starting attempt, where engine fails to run, always

point spray gun in safe direction, press red button and squeeze

spray gun trigger to release high pressure.

Page 15

15

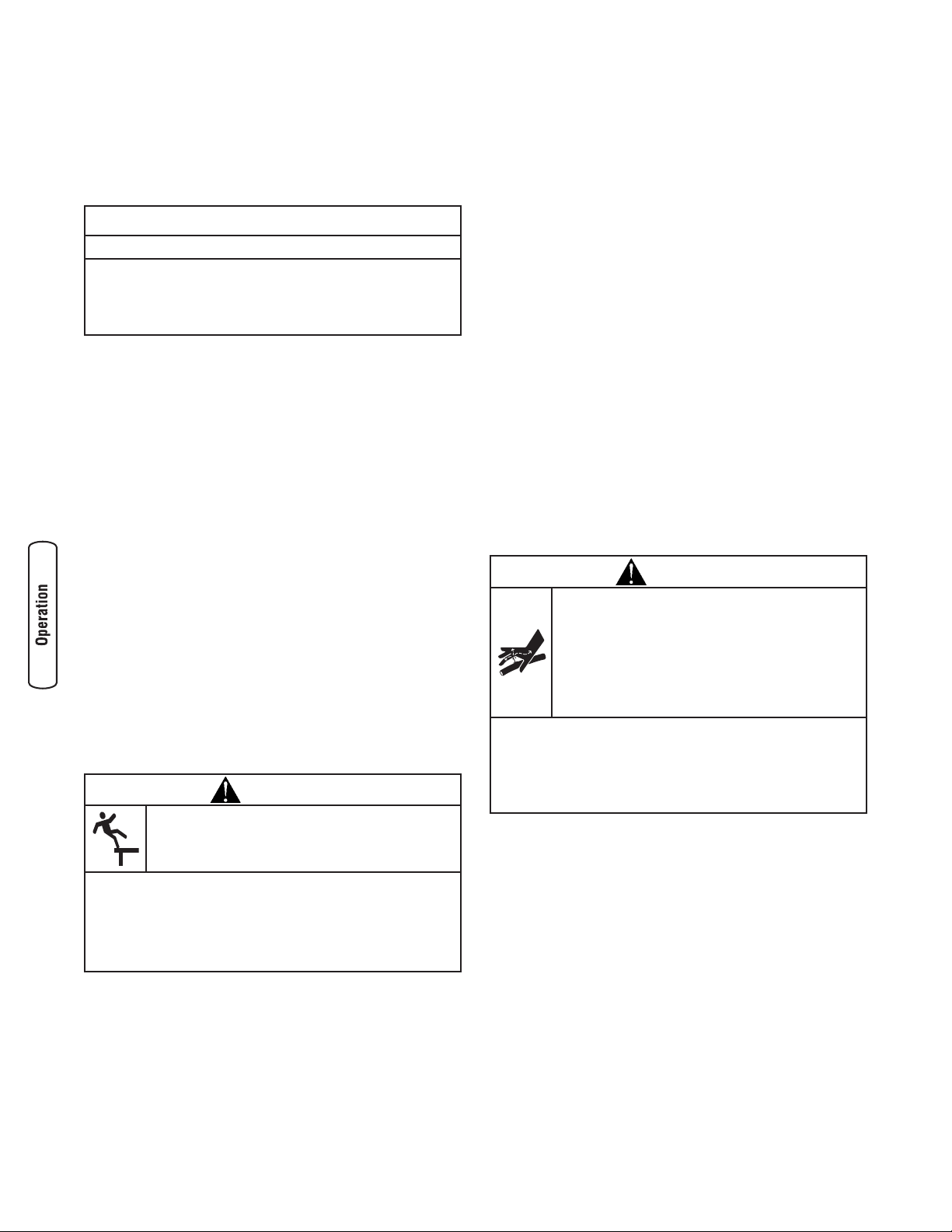

2. Select desired ProjectPro™ nozzle:

• For delicate rinse (lower pressure and higher flow),

for gentle cleaning of cars/trucks, boats, RV’s, patio

furniture, lawn equipment, etc., select yellow

Delicate ProjectPro™ nozzle.

• For general rinsing (medium pressure and medium

flow), ideal for most all purpose cleaning such as

home siding, brick patios, wood decks, driveways

and sidewalks, garage floors, etc., select orange

General ProjectPro™ nozzle.

• For maximum rinsing (higher pressure and lower

flow), for stubborn or hard to reach surface such as

second story surfaces, paint removal, oil stains,

rust removal or other stubborn substances (tar,

gum, grease, wax, etc.), select red Max

ProjectPro™ nozzle.

• To apply detergent, applies project specific cleaners

to help break down stubborn dirt and grime on a

variety of surfaces, select black ProjectPro™

cleaning detergent nozzle.

3. Pull back on collar, insert new ProjectPro™ nozzle and

release collar. Tug on ProjectPro™ nozzle to make sure

it is securely in place.

Usage Tips

• For most effective cleaning, keep spray tip from 8 to

24 inches (20 to 61 cm) away from cleaning surface.

• If you get spray tip too close, especially using a high

pressure spray tip, you may damage surface being

cleaned.

• DO NOT get closer than 6 inches (15 cm) when

cleaning tires.

Applying Detergent

To apply detergent, follow these steps:

1. Review use of ProjectPro™ nozzles.

2. Prepare detergent solution as required by job.

3. Place small filter end of detergent siphoning tube into

detergent container.

NOTE: Make sure the filter is fully submerged in detergent

while applying detergent.

CAUTION

Chemicals can cause bodily injury, and/or property

damage.

• NEVER use caustic liquid with pressure washer.

• Use ONLY pressure washer safe detergents/soaps. Follow all

manufacturers instructions.

NOTICE

Contact with the hot muffler can damage detergent

siphoning tube.

• When inserting the filter into a detergent solution bottle, route

the tube so as to keep it from inadvertently contacting the hot

muffler.

Page 16

16 BRIGGSandSTRATTON.COM

4. Make sure black detergent nozzle is installed.

NOTE: Detergent cannot be applied with the high pressure

ProjectPro™ nozzle (Orange, Yellow or Red).

5. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray

gun and pump. Turn on water.

6. Start engine following instructions How to Start Your

Pressure Washer.

7. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward, using

long, even, overlapping strokes.

8. Allow detergent to "soak in" for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent

surface from drying. DO NOT allow detergent to dry on

(prevents streaking).

IMPORTANT: You must flush the detergent siphoning

system after each use by placing the filter into a bucket of

clean water, then run the pressure washer in low pressure

for 1-2 minutes.

Pressure Washer Rinsing

For Rinsing:

1. Remove black detergent nozzle from nozzle extension.

2. Select and install desired high pressure nozzle following

instructions How to Use ProjectPro™ Nozzle System.

3. Keep the spray gun a safe distance from the area you

plan to spray.

4. Apply a high pressure spray to a small area, then check

the surface for damage. If no damage is found, it is

okay to continue cleaning.

5. Start at the top of the area to be rinsed, working down

with same overlapping strokes as you used for washing

and applying detergent.

Cleaning Detergent Siphoning Tube

If you used the detergent siphoning tube, you must flush it

with clean water before stopping the engine.

1. Place detergent siphoning tube/filter in a bucket full of

clean water.

2. Remove high pressure nozzle from nozzle extension.

3. Select and install black detergent nozzle following

instructions How to Use ProjectPro™ Nozzle System.

4. Flush for 1-2 minutes.

5. Shut off engine following instructions How to Stop

Pressure Washer and turn off water supply.

6. ALWAYS point gun in a safe direction and press red

button and squeeze spray gun trigger to release

retained high water pressure.

IMPORTANT: Spray gun traps high water pressure, even

when engine is stopped and water is disconnected.

Automatic Cool Down System (Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach temperatures above

125°F. The system engages to cool the pump by discharging

the warm water onto the ground.

WARNING

Kickback from spray gun can cause you to fall.

• Operate pressure washer from a stable surface.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

NOTICE

You must attach all hoses before you start the engine.

• Starting the engine without all the hoses connected and without

the water turned ON will damage the pump.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• After each starting attempt, where engine fails to run, always

point spray gun in safe direction, press red button and squeeze

spray gun trigger to release high pressure.

Page 17

17

Maintenance

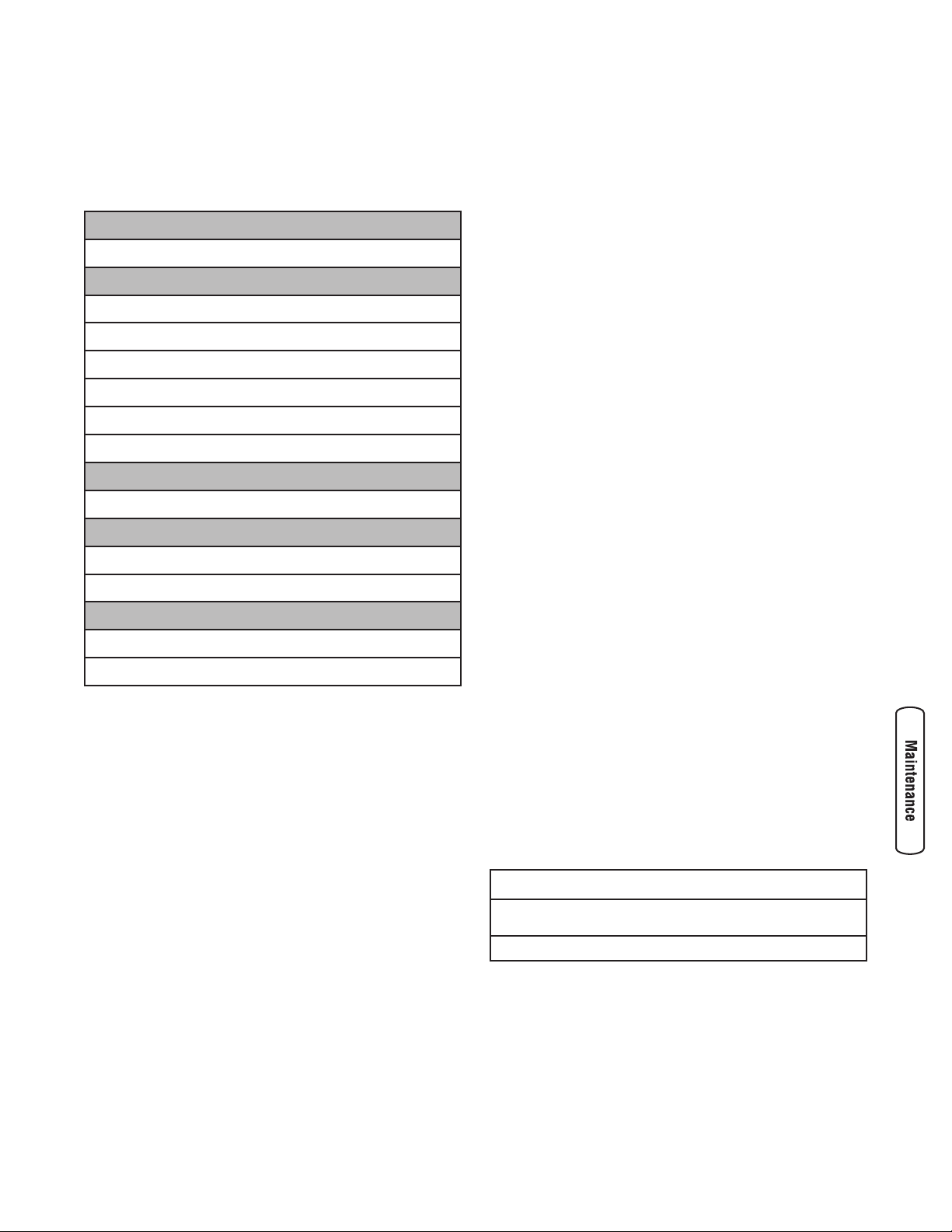

Maintenance Schedule

Follow the hourly or calendar intervals, whichever occurs

first. More frequent service is required when operating in

adverse conditions noted below.

1

Clean if clogged. Replace if perforated or torn.

2

Service more often under dirty or dusty conditions.

General Recommendations

Regular maintenance will improve the performance and

extend the life of the pressure washer. See any qualified

dealer for service.

The pressure washer’s warranty does not cover items that

have been subjected to operator abuse or negligence. To

receive full value from the warranty, the operator must

maintain the pressure washer as instructed in this manual,

including proper storage as detailed in Winter Storage and

Long Term Storage.

NOTE: Should you have questions about replacing

components on your pressure washer, please call

(800) 743-4115 for assistance.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least once

each season. Follow the requirements in the Maintenance

Schedule chart above.

NOTE: Once a year you should clean or replace the spark

plug, clean or replace the air filter, and check the spray gun

and nozzle extension assembly for wear. A new spark plug

and clean air filter assure proper fuel-air mixture and help

your engine run better and last longer.

Pump Oil

DO NOT attempt any oil maintenance on this pump. The

pump is pre-lubricated and sealed from the factory, requiring

no additional maintenance for the life of the pump.

Emissions Control

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by any

non-road engine repair establishment or individual.

However, to obtain ”no charge” emissions control service,

the work must be performed by a factory authorized dealer.

See the Emissions Warranty.

Before Each Use

1. Check engine oil level.

2. Clean debris.

3. Check water inlet screen for damage.

4. Check high pressure hose for leaks.

5. Check detergent siphoning tube and filter for damage.

6. Check spray gun and nozzle extension assembly for

leaks.

7. Rinse out garden hose to flush out debris.

Pressure Washer Maintenance

Clean Debris

Daily or before use, clean accumulated debris from cleaning

system. Keep linkage, spring and controls clean. Keep area

around and behind muffler free from any combustible debris.

Inspect cooling air slots and openings on the pressure

washer. These openings must be kept clean and

unobstructed.

Pressure washer parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt, oil, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

Check and Clean Inlet Screen

Examine the screen on the pump’s water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

First 5 Hours

• Change engine oil

Every 8 Hours or Daily

• Check/clean water inlet screen

1

• Check high pressure hose

• Check detergent siphoning hose

• Check spray gun and assembly for leaks

• Clean debris

• Check engine oil level

Every 25 Hours or Yearly

• Service air cleaner

2

Every 50 Hours or Yearly

• Change engine oil

• Service spark arrester

Every 100 Hours or Yearly

• Service spark plug

• Air cooling system

2

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

• DO NOT insert any objects through cooling slots.

Page 18

18 BRIGGSandSTRATTON.COM

Check High Pressure Hose

The high pressure hose can develop leaks from wear,

kinking, or abuse. Inspect the hose each time before using it.

Check for cuts, leaks, abrasions or bulging of cover, damage

or movement of couplings. If any of these conditions exist,

replace the hose immediately.

Check Detergent Siphoning Tube

Examine the filter on the detergent tube and clean if clogged.

The tube should fit tightly on the barbed fitting. Examine the

tube for leaks or tears. Replace the filter or tube if either is

damaged.

Check Gun and Nozzle Extension

Examine the hose connection to the spray gun and make

sure it is secure. Test the trigger by pressing the red button

and making sure the trigger “springs back” into place when

you release it. You should not be able to press the trigger

without pressing the red button. Replace spray gun

immediately if it fails any of these tests.

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure. The

principal cause of excessive pump pressure is a nozzle

clogged or restricted with foreign materials, such as dirt, etc.

To correct the problem, immediately clean the nozzle

following these instructions:

1. Shut off engine and turn off water supply.

2. ALWAYS point gun in a safe direction and press red

button and squeeze spray gun trigger to release

retained high water pressure.

3. Remove nozzle from end of nozzle extension.

4. Use a small paper clip to free any foreign material

clogging or restricting nozzle (A).

5. Remove nozzle extension from spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Back flush

between 30 to 60 seconds.

7. Reinstall nozzle into nozzle extension.

8. Reconnect nozzle extension to spray gun.

9. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray

gun and pump. Turn on water.

10. Start engine following instructions How to Start Your

Pressure Washer.

11. Test pressure washer by operating with each quick

connect nozzle.

O-Ring Maintenance

Purchase an O-Ring/Maintenance Kit, model 6048, by

contacting the nearest authorized service center. It is not

included with the pressure washer. This kit includes

replacement o-rings, rubber washer and water inlet filter.

Refer to the instruction sheet provided in the kit to service

your unit’s o-rings.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST exceed maximum pressure

rating of unit.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

• NEVER repair leaking connections with sealant of any kind.

Replace o-ring or seal.

A

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• After each starting attempt, where engine fails to run, always

point spray gun in safe direction, press red button and squeeze

spray gun trigger to release high pressure.

Page 19

19

Engine Maintenance

Oil

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SF, SG,

SH, SJ or higher. DO NOT use special additives.

Outdoor temperatures determine the proper oil viscosity for

the engine. Use the chart to select the best viscosity for the

outdoor temperature range expected.

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W30 may cause increased oil

consumption. Check oil level more frequently.

NOTE: Synthetic oil meeting ILSAC GF-2, API

certification mark and API service symbol with

“SJ/CF ENERGY CONSERVING” or higher, is an

acceptable oil at all temperatures. Use of synthetic

oil does not alter required oil change intervals.

Checking Oil Level

Oil level should be checked prior to each use or at least

every 8 hours of operation. Keep oil level maintained.

1. Make sure pressure washer is on a level surface.

2. Remove oil dipstick and wipe dipstick with clean cloth.

Replace and tighten dipstick. Remove and and check oil

level.

3. Verify oil is at “Full” mark on dipstick. Replace and

tighten dipstick.

Adding Engine Oil

1. Make sure pressure washer is on a level surface.

2. Check oil level as described in Checking Oil Level.

3. If needed, slowly pour oil into oil fill opening to the

“Full” mark on dipstick. DO NOT overfill.

4. Replace and tighten dipstick.

Changing Engine Oil

Change the engine oil after the first 5 hours and every

50 hours thereafter. If you are using your pressure washer

under extremely dirty or dusty conditions, or in extremely

hot weather, change the oil more often.

KEEP OUT OF REACH OF CHILDREN. DON’T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

WARNING

Unintentional sparking can result in fire or

electric shock.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR PRESSURE

WASHER

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

NOTICE

Overfilling with oil may cause the engine to not start, or

hard starting.

• DO NOT overfill.

• If over the FULL mark on dipstick, drain oil to reduce oil level to

FULL mark on dipstick.

CAUTION

Avoid prolonged or repeated skin contact with used motor

oil.

• Used motor oil has been shown to cause skin cancer in certain

laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Page 20

20 BRIGGSandSTRATTON.COM

Change oil while engine is still warm from running, as

follows:

1. Drain fuel tank by running pressure washer until fuel

tank is empty.

2. Disconnect spark plug wire and keep it away from

spark plug.

3. Clean area around oil fill, remove oil fill cap/dipstick.

Wipe dipstick clean.

4. Tip your pressure washer to drain oil from oil fill into a

suitable container making sure you tip your unit away

from spark plug. When crankcase is empty, return

pressure washer to upright position.

5. Slowly pour recommended oil (about 20 oz. (0.6 l)) into

oil fill opening. Pause to permit oil to settle. Fill to

“Full” mark on dipstick.

6. Wipe dipstick clean each time oil level is checked. DO

NOT overfill.

7. Replace and tighten dipstick.

8. Wipe up any remaining oil.

9. Reconnect spark plug wire to spark plug.

Service Air Cleaner

Your engine will not run properly and may be damaged if

you run it with a dirty air cleaner.

Service the air cleaner once every 25 hours of operation or

once each year, whichever comes first. Service more often if

operating under dirty or dusty conditions.

To service the air cleaner, follow these steps:

1. Remove screw (A).

2. Carefully remove air cleaner assembly to prevent debris

from falling into carburetor.

3. Take air cleaner assembly apart and clean all parts.

Wash foam air cleaner (B) in liquid detergent and

water. Squeeze dry in a clean cloth.

4. SATURATE foam air cleaner in engine oil and squeeze

in a clean cloth to remove excess oil.

5. Reinstall clean or new foam air cleaner in base (C).

6. Install air cleaner securely on carburetor with screw.

Service Spark Plug

Change the spark plug every 100 hours of operation or once

each year, whichever comes first. This will help your engine

to start easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. Use the recommended

replacement plug. See Specifications.

4. Check electrode gap with wire feeler gauge and reset

spark plug gap to recommended gap if necessary (see

Specifications).

5. Install spark plug and tighten firmly.

Spark Arrester Service

Your engine is not factory-equipped with a spark arrester. In

some areas, it is illegal to operate an engine without a spark

arrester. Check local laws and regulations. A spark arrester is

available from your nearest qualified service center.The spark

arrester must be serviced every 50 hours to keep it

functioning as designed.

If the engine has been running, the muffler will be very hot.

Allow the muffler to cool before servicing spark arrester.

• Remove spark arrester screen for cleaning and

inspection.

• Replace if screen is damaged.

A

B

C

WARNING

Contact with muffler area can result in serious

burns.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (1.5 m) of clearance on all sides of pressure

washer including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Page 21

21

Air Cooling System

Over time debris may accumulate in cylinder cooling fins and

cannot be observed without partial engine disassembly. For

this reason, we recommend you have a qualified service

dealer clean the cooling system per recommended intervals

(see Maintenance Schedule in beginning of Maintenance

section). Equally important is to keep top of engine free from

debris. See Clean Debris.

After Each Use

Water should not remain in the unit for long periods of time.

Sediments or minerals can deposit on pump parts and freeze

pump action. Follow these procedures after every use:

1. Shut off engine, turn off water supply, point gun in a

safe direction, press red button and squeeze trigger to

relieve trapped pressure, and let engine cool.

2. Disconnect hose from spray gun and high pressure

outlet on pump. Drain water from hose, gun, and nozzle

extension. Use a rag to wipe off the hose.

3. Empty pump of all pumped liquids by pulling recoil

handle about six times. This should remove most liquid

in pump.

4. Store unit in a clean, dry area.

5. If storing for more than 30 days, see Long Term

Storage on next page.

Keep areas within heavy line clear of debris.

WARNING

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes dryers,

or other appliances that have pilot light or other ignition source

because they can ignite fuel vapors.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• ALWAYS point spray gun in safe direction, press red button and

squeeze spray gun trigger, to release high pressure, every time

you stop engine.

Page 22

22 BRIGGSandSTRATTON.COM

Winter Storage

To protect the unit from freezing temperatures:

1. Follow steps 1-3 in the previous section After Each Use.

2. Use pump saver, Model 6039, to treat pump. This

minimizes freeze damage and lubricates pistons and

seals.

3. If pump saver is not available, connect a 3 ft. (1 m)

section of garden hose to water inlet adapter. Pour

RV-antifreeze (antifreeze without alcohol) into hose.

Pull recoil handle twice. Disconnect 3 ft. (1 m) hose.

4. Store unit in a clean, dry area.

Long Term Storage

If you do not plan to use the pressure washer for more than

30 days, you must prepare the engine and pump for long

term storage.

Protect Fuel System

Fuel Additive:

Fuel can become stale when stored over 30 days. Stale fuel

causes acid and gum deposits to form in the fuel system or

on essential carburetor parts. To keep fuel fresh, use Briggs

& Stratton FRESH START™ fuel stabilizer, available as a

liquid additive or a drip concentrate cartridge.

There is no need to drain gasoline from the engine if a fuel

stabilizer is added according to instructions. Run the engine

for 2 minutes to circulate the stabilizer throughout the fuel

system. The engine and fuel can then be stored up to

24 months.

If gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container. Run

the engine until it stops from lack of fuel. The use of a fuel

stabilizer in the storage container is recommended to

maintain freshness.

Change Engine Oil

While engine is still warm, drain oil from crankcase. Refill

with recommended grade. See Changing Engine Oil in Engine

Maintenance.

Oil Cylinder Bore

• Remove spark plug and pour about 1/2 ounce (15 ml)

of clean engine oil into the cylinder.

• Install spark plug and pull starter handle slowly to

distribute oil.

Protecting the Pump

To protect the pump from damage caused by mineral

deposits or freezing, use PumpSaver, Model 6039, to treat

pump. This prevents freeze damage and lubricates pistons

and seals.

NOTE: PumpSaver is available as an optional accessory. It is

not included with the pressure washer. Contact the nearest

authorized service center to purchase PumpSaver.

To use PumpSaver, make sure the pressure washer is turned

off and disconnected from supply water. Read and follow all

instructions and warnings given on the PumpSaver

container.

Other Storage Tips

1. DO NOT store fuel from one season to another unless it

has been treated as described in Protect Fuel System.

2. Replace fuel container if it starts to rust. Rust and/or

dirt in fuel can cause problems if it’s used with this

unit.

3. Cover unit with a suitable protective cover that does not

retain moisture.

4. Store unit in a clean and dry area.

NOTICE

You must protect your unit from freezing temperatures.

• Failure to do so will permanently damage your pump and render

your unit inoperable.

• Freeze damage is not covered under warranty.

NOTICE

You must protect your unit from freezing temperatures.

• Failure to do so will permanently damage your pump and render

your unit inoperable.

• Freeze damage is not covered under warranty.

WARNING

Storage covers can be flammable.

• DO NOT place a storage cover over a hot pressure washer.

• Let equipment cool for a sufficient time before placing the cover

on the equipment.

Page 23

23

Troubleshooting

Problem Cause Correction

Pump has following problems: failure

to produce pressure, erratic pressure,

chattering, loss of pressure, low water

volume.

1. Low pressure nozzle installed.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5. Clogged inlet hose screen.

6. Water supply is over 100°F (38°C).

7. High pressure hose is blocked or

leaks.

8. Spray gun leaks.

9. Nozzle is obstructed.

10. Pump is faulty.

1. Replace with high pressure nozzle.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch leak.

5. Check and clean inlet hose screen.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

8. Replace spray gun.

9. Clean nozzle.

10. Contact local service facility.

Detergent fails to mix with spray.

1. Detergent siphoning tube is not

submerged.

2. Detergent siphoning tube/filter is

clogged or cracked.

3. High pressure nozzle installed.

1. Insert detergent siphoning tube into

detergent.

2. Clean or replace filter/detergent

siphoning tube.

3. Replace with low pressure nozzle.

Engine runs good at no-load but "bogs"

when load is added.

Engine speed is too slow. Move throttle control to FAST position. If

engine still "bogs down", contact local

service facility.

Engine will not start; or starts and runs

rough.

1. Low oil level.

2. Dirty air cleaner.

3. Out of fuel.

4. Stale fuel.

5. Spark plug wire not connected to

spark plug.

6. Bad spark plug.

7. Water in fuel.

8. Excessively rich fuel mixture.

1. Fill crankcase to proper level.

2. Clean or replace air cleaner.

3. Fill fuel tank.

4. Drain fuel tank; fill with fresh fuel.

5. Connect wire to spark plug.

6. Replace spark plug.

7. Drain fuel tank; fill with fresh fuel.

8. Contact local service facility.

Engine shuts down during operation.

Out of fuel. Fill fuel tank.

Engine lacks power. Dirty air filter. Replace air filter.

Page 24

24 BRIGGSandSTRATTON.COM

Warranties

Emissions Control System Warranty

Briggs & Stratton Corporation (B&S), the California Air

Resources Board (CARB) and the United States

Environmental Protection Agency (U.S. EPA)

Emissions Control System Warranty Statement (Owner’s

Defect Warranty Rights and Obligations)

California, United States and Canada Emissions Control

Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and

B&S are pleased to explain the Emissions Control System

Warranty on your small off-road engine (SORE). In

California, new small off-road engines model year 2006 and

later must be designed, built and equipped to meet the

State’s stringent anti-smog standards. Elsewhere in the

United States, new non-road, spark-ignition engines certified

for model year 1997 and later must meet similar standards

set forth by the U.S. EPA. B&S must warrant the emissions

control system on your engine for the periods of time listed

below, provided there has been no abuse, neglect or

improper maintenance of your small off-road engine.

Your emissions control system includes parts such as the

carburetor, air cleaner, ignition system, fuel line, muffler and

catalytic converter. Also included may be connectors and

other emissions related assemblies.

Where a warrantable condition exists, B&S will repair your

small off-road engine at no cost to you including diagnosis,

parts and labor.

Briggs & Stratton Emissions Control Defects Warranty

Coverage

Small off-road engines are warranted relative to emissions

control parts defects for a period of two years, subject to

provisions set forth below. If any covered part on your

engine is defective, the part will be repaired or replaced by

B&S.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for

the performance of the required maintenance listed in your

Operating and Maintenance Instructions. B&S recommends

that you retain all your receipts covering maintenance on

your small off-road engine, but B&S cannot deny warranty

solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

As the small off-road engine owner, you should however be

aware that B&S may deny you warranty coverage if your

small off-road engine or a part has failed due to abuse,

neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine

to an Authorized B&S Service Dealer as soon as a problem

exists. The undisputed warranty repairs should be completed

in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a B&S Service

Representative at (414) 259-5262.

The emissions warranty is a defects warranty. Defects are

judged on normal engine performance. The warranty is not

related to an in-use emissions test.

Briggs & Stratton Emissions Control Defects Warranty

Provisions

The following are specific provisions relative to your

Emissions Control Defects Warranty Coverage. It is in

addition to the B&S engine warranty for non-regulated

engines found in the Operator’s Manual.

1. Warranted Parts

Coverage under this warranty extends only to the parts

listed below (the emissions control systems parts) to

the extent these parts were present on the engine

purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive

valves and switches

• Connectors and assemblies

Page 25

25

2. Length of Coverage

B&S warrants to the initial owner and each subsequent

purchaser that the Warranted Parts shall be free from

defects in materials and workmanship which caused the

failure of the Warranted Parts for a period of two years

from the date the engine is delivered to a retail

purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be

performed at no charge to the owner, including

diagnostic labor which leads to the determination that a

Warranted Part is defective, if the diagnostic work is

performed at an Authorized B&S Service Dealer. For

emissions warranty service contact your nearest

Authorized B&S Service Dealer as listed in the “Yellow

Pages” under “Engines, Gasoline,” “Gasoline Engines,”

“Lawn Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the

provisions of the B&S Engine Warranty Policy.

Warranty coverage shall be excluded for failures of

Warranted Parts which are not original B&S parts or

because of abuse, neglect or improper maintenance as

set forth in the B&S Engine Warranty Policy. B&S is not

liable to cover failures of Warranted Parts caused by

the use of add-on, non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for

replacement as required maintenance or which is

scheduled only for regular inspection to the effect of

“repair or replace as necessary” shall be warranted as

to defects for the warranty period. Any Warranted Part

which is scheduled for replacement as required

maintenance shall be warranted as to defects only for

the period of time up to the first scheduled replacement

for that part. Any replacement part that is equivalent in

performance and durability may be used in the

performance of any maintenance or repairs. The owner

is responsible for the performance of all required

maintenance, as defined in the B&S Operator’s Manual.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any

engine components caused by the failure of any

Warranted Part still under warranty.

Emission Information

Engines that are certified to meet the California Air

Resources Board (CARB) Emission Standards must display

information regarding the Emissions Durability Period and

Air Index. The engine manufacturer makes this information

available to the consumer on emission labels. The engine

emission label will indicate certification information.

The Emissions Durability Period describes the number of

hours of actual running time for which the engine is certified

to be emissions compliant, assuming proper maintenance in

accordance with the Operating & Maintenance Instructions.

The following categories are used:

Moderate: Engine is certified to be emission compliant for

125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant

for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for

500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to

25 hours per year. Therefore, the Emissions Durability

Period of an engine with an intermediate rating would

equate to 10 to 12 years.

Certain engines will be certified to meet the United States

Environmental Protection Agency (USEPA) Phase 2 emission

standards. For phase 2 certified engines, the Emissions

Compliance Period referred to on the Emissions Compliance

label indicates the number of operating hours for which the

engine has been shown to meet Federal emission

requirements.

For engines less than 225 cc displacement:

Category C = 125 hours

Category B = 250 hours

Category A = 500 hours.

For engines of 225 cc or more displacement:

Category C = 250 hours

Category B = 500 hours

Category A = 1000 hours.

Page 26

26 BRIGGSandSTRATTON.COM

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC PRESSURE WASHER OWNER WARRANTY POLICY

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the pressure washer that is defective in material or

workmanship or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This

warranty is effective for the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in

our dealer locator map at BRIGGSandSTRATTON.COM.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some

states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state or country to country.

2 years

90 days

Consumer Use

Commercial Use

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated above.