Page 1

BRIGGS & STRATTON CORPORATION

Milwaukee, WI 53201

Part No. 190275-5/03 Printed in U.S.A.

Look for these other repair manuals from the

Briggs & Stratton Power Products line:

B3277GS Pressure Washer Familiarization

& Troubleshooting Guide

86262 Generator Familiarization &

Troubleshooting Guide

275110 Outboard Motor Repair Manual

Quality Starts With A

Master Service Technician

®

TM

Visit us at:

www.briggsandstratton.com

www.generac-portables.com

www.briggspowerproducts.com

Familiarization & Troubleshooting Guide

HAND-HELD GENERATOR

For Briggs & Stratton Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Page 2

FOREWORD

This guide has been written and published by Briggs & Stratton Corporation to aid our dealers’ mechanics and

company service personnel when servicing the products described herein.

It is assumed that these personnel are familiar with the servicing procedures for these products, or like or similar

products, manufactured by Briggs & Stratton Corporation. It is also assumed that they have been trained in the

recommended servicing procedures for these products, which includes the use of mechanics’ hand tools and any

special tools that might be required.

Proper service and repair is important to the safe, economical and reliable operation of all engine driven systems.

The troubleshooting, testing,service and repair procedures described in this guide are effective methods of

performing such operations.

We could not possibly know of and advise the service trade of all conceivable procedures or methods by which a

service might be performed, nor of any possible hazards and/or results of each procedure or method.We have not

undertaken any such wide evaluation.Therefore, anyone who uses a procedure or method not described by the

manufacturer must first satisfy himself that neither his safety,nor the safety of the product, will be endangered by

the service or operating procedure selected.

All information, illustrations,and specifications contained in this guide are based on the latest production

information available at the time of publication. However, Briggs & Stratton Corporation reserves the right to

change, alter, or otherwise improve the product at any time without prior notice.

Some components or assemblies of the product described in this guide may not be considered repairable.

Disassembly,repair and reassembly of such components may not be included in this guide.

Copyright © 2003 Briggs & Stratton Corporation

All rights reserved.

No part of this material may be reproduced or transmitted, in any form or by any means, electronic or

mechanical, including photocopying, recording or by any information storage and retrieval system, without prior

permission in writing from Briggs & Stratton Corporation.

Page 3

Hand-Held Series Generator

Familiarization & Troubleshooting Guide

Electronic Version #190275 03/03

Please click the “Bookmarks” tab at left to enable the

search and navigational features of this document.

®

Page 4

FORWARD

This guide has been written and published by Briggs & Stratton Corporation to aid our dealers' mechanics and

company service personnel when servicing the products described herein.

It is assumed that these personnel are familiar with the servicing procedures for these products, or like or similar

products, manufactured by Briggs & Stratton Power Products Group®. It is also assumed that they have been

trained in the recommended servicing procedures for these products, which includes the use of mechanics hand

tools and any special tools that might be required.

Proper service and repair is important to the safe, economical and reliable operation of all engine driven systems.

The troubleshooting, testing, service and repair procedures described in this guide are effective methods of

performing such operations.

We could not possibly know of and advise the service trade of all conceivable procedures or methods by which a

service might be performed, nor of any possible hazards and/or results of each procedure or method. We have

not undertaken any such wide evaluation. Therefore, anyone who uses a procedure or method not described by

the manufacturer must first satisfy himself that neither his safety, nor the safety of the product, will be

endangered by the service or operating procedure selected.

All information, illustrations, and specifications contained in this guide are based on the latest production

information available at the time of publication. However, Briggs & Stratton Corporation reserves the right to

change, alter, or otherwise improve the product at any time without prior notice.

Some components or assemblies of the product described in this guide may not be considered repairable.

Disassembly, repair and reassembly of such components may not be included in this guide.

Service and repair instructions for the engines used to power these products are not covered in this guide.

Engine service and repair instructions are furnished by the engine manufacturer.

Copyright © 2003 Briggs & Stratton Corporation

All rights reserved.

No part of this material may be reproduced or transmitted, in any form or by any means, electronic or

mechanical, including photocopying, recording or by any information storage and retrieval system, without prior

permission in writing from Briggs & Stratton Corporation.

Page 5

1

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

TABLE OF CONTENTS

Tabe of Contents

1

2

3

4

5

INTRODUCTION

1

DISASSEMBLY

2

ASSEMBLY

4

APPENDIX

5

TROUBLESHOOTING

3

In The Interest of Safety 4

Safety Alert Symbols 4

Safety Practices 5

Generator Description 8

Generator Components 9

Serial Number Locations 10

Generator Specifications 10

Wiring Diagram 11

Output Power (AC) 11

Output Power (DC) 11

Fuel System Components 12

Fuel Group 12

General Service Information 12

Work Area 12

Hand Tools 12

Special Tools 12

Under-Voltage (DC) 22

Check (DC) Circuit Breaker 23

Check Bridge Diode 23

Check 12VDC Coil 23

Over-Voltage (AC) 24

Check Capacitor 24

Under-Voltage (AC) 26

Check Receptacle Wiring 27

Check (AC) Circuit Breaker 27

Check Stator Power Winding 28

Check Excitation Winding 28

Check Rotor Winding 29

Engine Switch 29

Pilot Lamp 30

Mounting The Rotor & Stator 33

Installing The Muffler Heat Shield 34

Connecting The Wiring Harness 35

Mount The Rear Case Half 36

Mount The Fuel Tank 37

Mount The Front Case Half 37

Resistance Values 43

Torque Specifications 43

Fasteners and Locations 44

General Disassembly Considerations 15

Case Separation 15

Access To Generator Components 17

Rotor / Stator Removal 18

Page 6

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

2

Table of Contents

1

2

3

4

5

Page 7

3

Section 1 • Introduction

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

INTRODUCTION

1

Page 8

INTRODUCTION

4

Introduction • Section 1

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

1

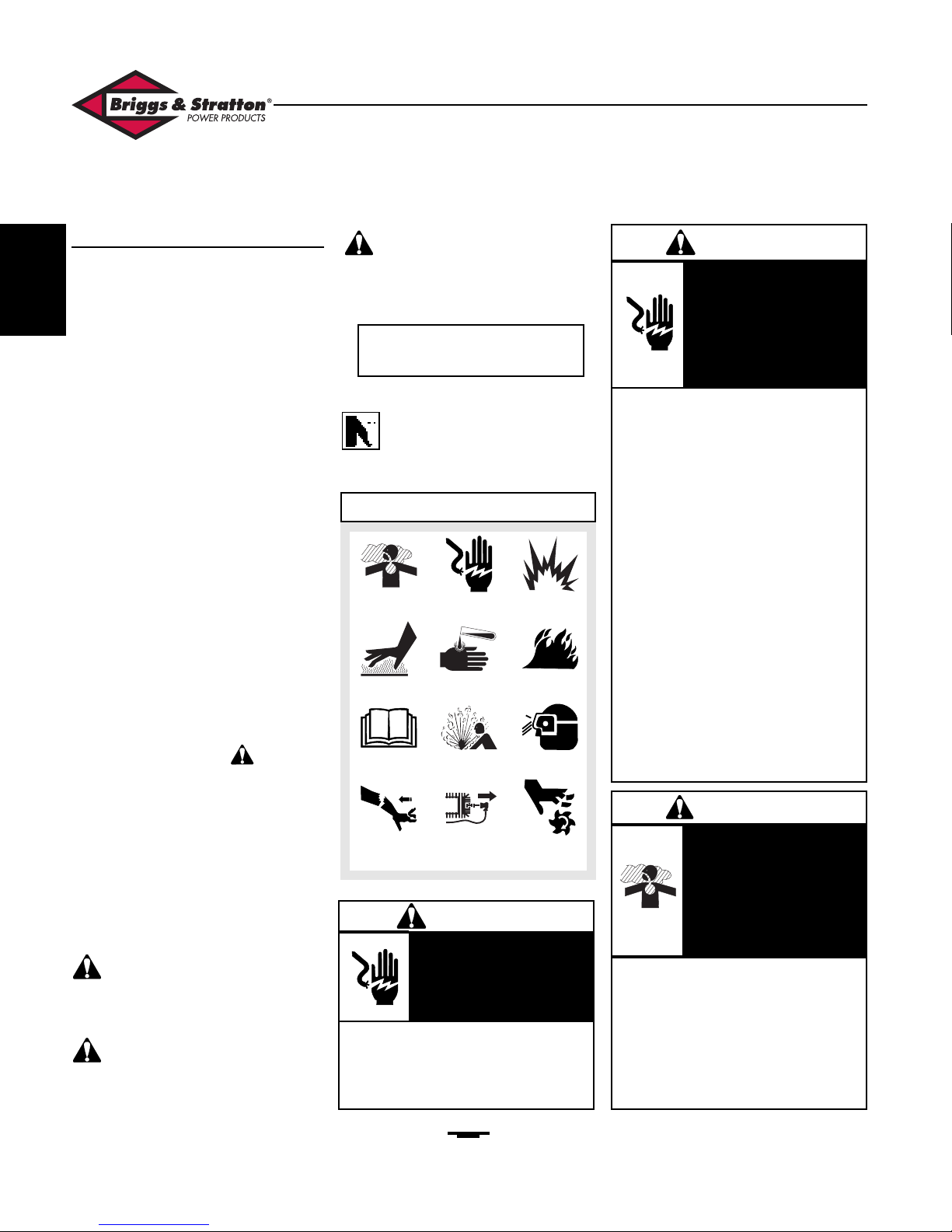

In the Interest of Safety

This manual outlines the construction,

function and servicing procedures of

the Briggs & Stratton Power Products®

“Hand-Held” generator series. It is

structured for use by trained

technicians that are working in a

properly equipped shop. Familiarity

with the proper method of using tools,

measuring equipment and workshop

procedures are essential to performing

successful maintenance and repair on

this equipment.

Ensure that all specified tools and/or

equipment are available before

attempting to service this equipment.

For a detailed discussion of the

fundamental principles involved with

the physics of electrical power

generation, refer to the "Familiarization

and Troubleshooting Guide

(Publication #86262 Revision 3 or

later)". This manual is available

through your Briggs & Stratton Central

Distributor.

Safety Alert Symbols

NOTE: This notation is used to

inform you of a method, reference

or procedure that could assist with

specific operations or decisions.

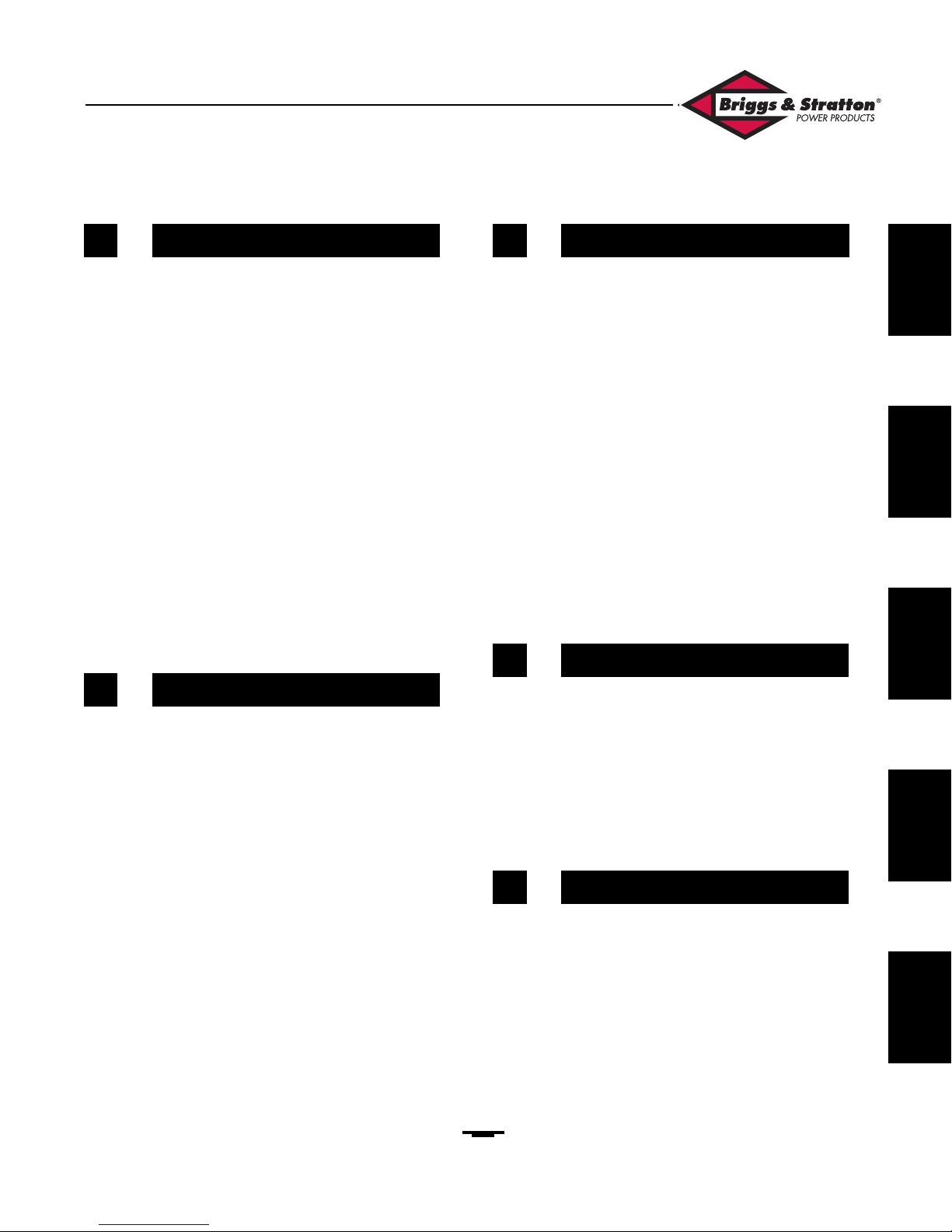

HAZARD SYMBOLS AND MEANINGS

Toxic Fumes

Electrocution

Hot Surface

Chemical Burns

Explosive Pressure

Kick Back

Entanglement

Disconnect

Spark Plug

Fire

Read

Goggles

Explosion

• Operate generator ONLY outdoors.

• Keep at least 2 feet of clearance on all

sides of generator for adequate

ventilation.

• Do not operate generator inside any

building or enclosure, including the

generator compartment of a

recreational vehicle (RV).

Running generator gives off

carbon monoxide, an

odorless, colorless, poison

gas.

Breathing carbon monoxide

will cause nausea, fainting or

death.

The safety alert symbol ( ) is used

to identify safety information about

hazards that can result in personal

injury. A signal word (DANGER,

WARNING, CAUTION) is used

with the alert symbol to indicate the

potential severity of injury. In addition,

a hazard symbol may be used to

represent the type of hazard.

DANGER: Indicates a hazard

which, if not avoided will result

in death or serious injury.

WARNING: Indicates a hazard

which, if not avoided could

result in death or serious

injury.

CAUTION: Indicates a hazard

which, if not avoided might

result in death or serious

injury.

CAUTION: When used without the

alert symbol, indicates a situation that

could result in damage to equipment.

DANGER

• When using generator for backup

power, notify utility company. Use

approved transfer equipment to isolate

generator from electric utility.

• Use a ground circuit fault interrupter

(GFCI) in any damp or highly

conductive area, such as metal decking

or steel work.

• Do not touch bare wires or

receptacles.

• Do not use generator with electrical

cords which are worn, frayed, bare or

otherwise damaged.

• Do not operate generator in the rain.

• Do not handle generator or electrical

cords while standing in water, while

barefoot, or while hands or feet are

wet.

• Do not allow unqualified persons or

children to operate or service

generator.

Generator produces

powerful voltage.

Failure to isolate generator

from power utility can result

in death or injury to electric

utility workers due to

backfeed of electrical energy.

DANGER

• National electric code requires

generator to be properly grounded to

an approved earth ground. Call an

electrician for local grounding

requirements.

Failure to properly ground

generator can result in

electrocution, especially if the

generator is equipped with a

wheel kit.

DANGER

Page 9

5

Introduction • Section 1

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Safety Practices

• Generator exhaust gases contain

DEADLY carbon monoxide gas.

This dangerous gas, if breathed

in sufficient concentrations, can

cause unconsciousness or even

death. Operate and service this

equipment only in the open air

where adequate ventilation is

available.

• These generators were designed

and manufactured for

recreational applications. Do not

attempt to modify the unit or

use it for any application it was

not designed for. If you have any

questions about your generator's

application, ask your dealer or

consult the factory.

• The manufacturer could not

possibly anticipate every

circumstance that might involve a

hazard. For that reason, warnings

in manuals and warnings on tags

or decals affixed to the units are

not all-inclusive. If you intend to

handle, operate or service a unit

with a procedure or method not

specifically recommended by the

manufacturer, make sure that

such a procedure or method will

not render the equipment unsafe

or pose a threat to you and

others.

• Read these procedures carefully

and become familiar with your

generator set. Know its

applications, its limitations and

any hazards involved.

• Do not allow any open flame, spark,

heat, or lit cigarette around battery

during, and for several minutes after

charging.

• Wear protective goggles, rubber

apron, and rubber gloves.

Storage batteries give off

explosive hydrogen gas

during recharging.

Hydrogen gas stays around

battery for a long time after

battery has been charged.

Slightest spark will ignite

hydrogen and cause

explosion.

You can be blinded or

severely injured.

Battery electrolyte fluid

contains acid and is

extremely caustic.

Contact with battery fluid

will cause severe chemical

burns.

DANGER

• Do not touch hot surfaces.

• Allow equipment to cool before

touching.

Running engines produce

heat. Temperature of muffler

and nearby areas can reach

or exceed 150°F (65°C).

Severe burns can occur on

contact.

DANGER

• This generator does not meet U.S.

Coast Guard Regulation 33CFR-183 and

should not be used on marine

applications.

• Failure to use the appropriate U.S.

Coast Guard approved generator could

result in bodily injury and/or property

damage.

WARNING

WHEN ADDING FUEL

• Turn generator OFF and let it cool at

least 2 minutes before removing gas

cap. Loosen cap slowly to relieve

pressure in tank.

• Fill fuel tank outdoors.

• Do not overfill tank. Allow space for

fuel expansion.

• Keep all fuel away from sparks, open

flames, pilot lights, heat, and other

ignition sources.

• Do not light a cigarette or smoke.

WHEN OPERATING EQUIPMENT

• Do not tip engine or equipment at

angle which causes fuel to spill.

WHEN TRANSPORTING OR

REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY

or with fuel shutoff valve OFF.

• Disconnect spark plug wire.

• Do Not operate generator in a moving

vehicle or watercraft, because motion

can cause fuel to spill.

WHEN STORING FUEL OR

EQUIPMENT WITH FUEL IN

TANK

• Store away from furnaces, stoves,

water heaters, clothes dryer or other

appliances that have pilot light or other

ignition source because they can ignite

fuel vapors.

Fuel and its vapors are

extremely flammable and

explosive.

Fire or explosion can cause

severe burns or death.

WARNING

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

WARNING

Page 10

6

• Hand-held generators produce a very powerful

voltage that can cause an extremely dangerous

electrical shock. Avoid contact with bare wires,

terminals, etc. Never permit an untrained person to

service or assist with the procedures discussed in this

guide.

• Never handle any kind of electrical cord or device

while standing in water, while barefoot, or while

hands or feet are wet.

• Do not use worn, bare, frayed or otherwise damaged

electrical cord sets with any generator set. Using a

defective cord may result in an electrical shock or

damage to the test equipment and/or the unit.

• Gasoline is highly flammable and its vapors are

EXPLOSIVE. Do not permit smoking, open flames,

sparks or heat in the vicinity while handling gasoline.

Avoid spilling gasoline on a hot engine. Comply with

all laws regulating storage and handling of gasoline.

• Do not overfill the fuel tank. Always allow room for fuel

expansion. If the tanks are over-filled, fuel can overflow on

`to a hot engine and cause FIRE or EXPLOSION.

• These units require an adequate flow of cooling air for their

continued proper operation. Never operate or service any

unit while inside any enclosure where the free flow of

cooling air into and out of the unit might be obstructed.

Without sufficient cooling airflow, the units quickly

overheat, damaging the generator and/or nearby property.

• Never start or stop a unit with electrical loads connected

to receptacles and with the connected loads turned ON.

Start the engine and let it stabilize before connecting any

electrical loads. Turn OFF and disconnect all electrical

loads before shutting down any generator.

• This entire book is filled with important safety information

- please read it carefully.

Introduction • Section 1

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Page 11

7

Section 1 • Introduction

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

1

Page 12

8

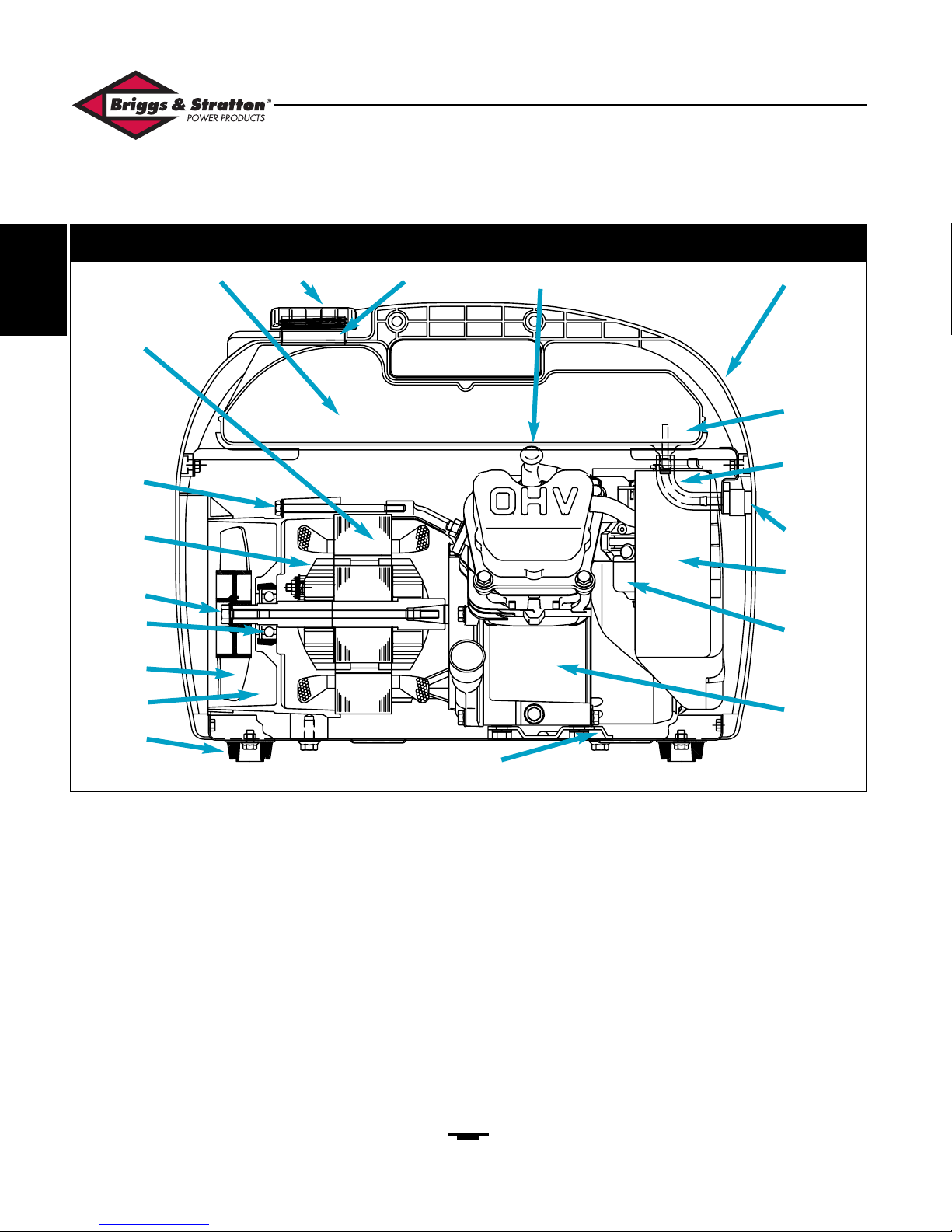

Item Nomenclature

1. Vibration Mount

2. Bearing Carrier

3. Cooling Fan

4. Rotor Bearing

5. Rotor Bolt (M6-160)

6. Rotor Assembly

7. Stator Bolt (M6-90)

8. Stator Assembly

9. Fuel Tank

10. Fuel Cap

Item Nomenclature

11. Fuel Inlet Filter

12. Spark Plug

13. Generator Case Half

14. Fuel Filter

15. Fuel Hose

16. Fuel Valve

17. Air Cleaner

18. Carburetor

19. Engine

20. Engine Base

GENERATOR DESCRIPTION

Introduction • Section 1

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 1 — Internal Components

1

7

12 13

14

15

16

17

18

19

20

11

10

9

8

6

5

4

3

2

1

Page 13

9

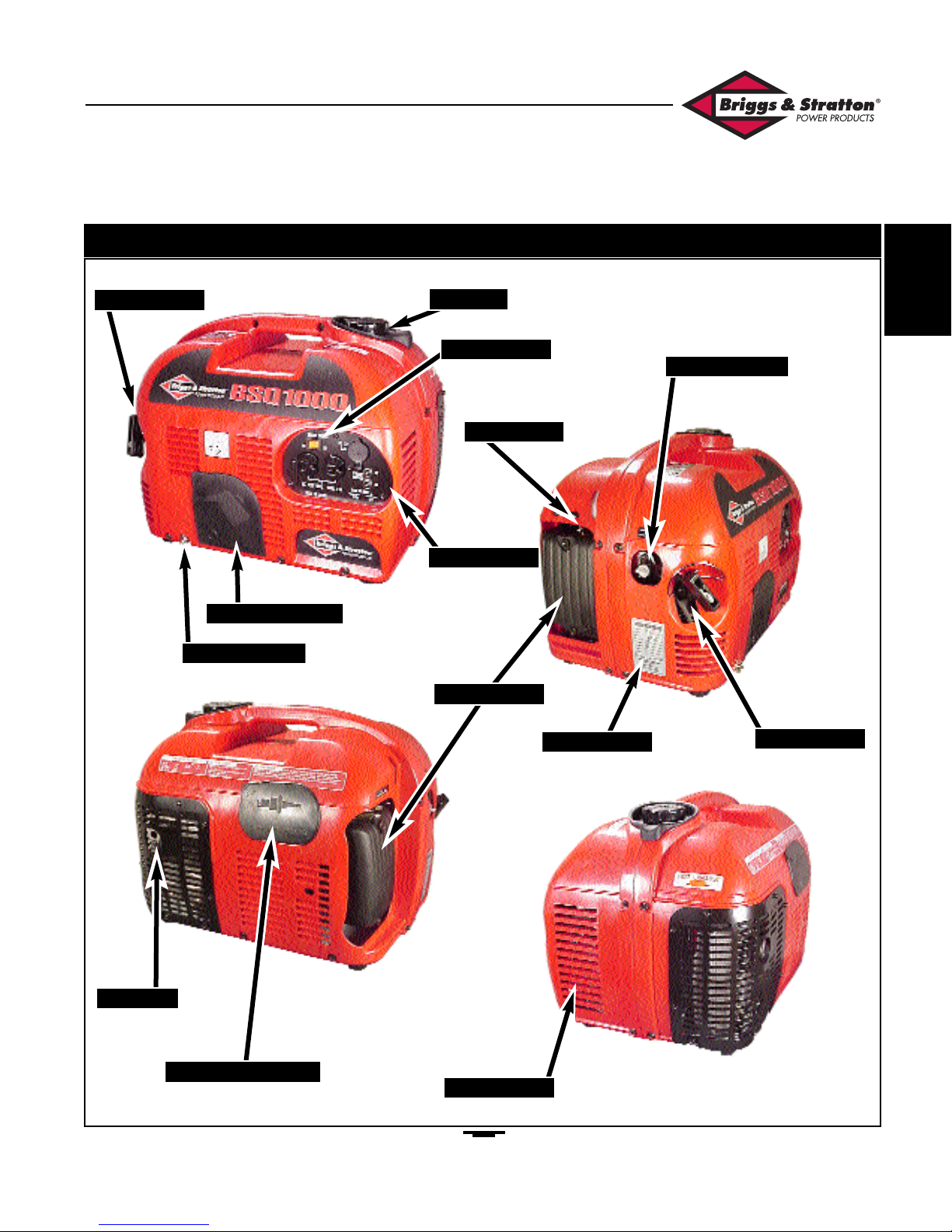

GENERATOR COMPONENTS

Section 1 • Introduction

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 2 — External Components

Control Panel

Oil Service Cover

Grounding Lug

Muffler

Spark Plug Access

Recoil Starter

Recoil Starter

Engine Switch

Air Cleaner

Data Plate

Cooling Fan

Choke Lever

Fuel Shut-Off

Fuel Cap

1

Page 14

10

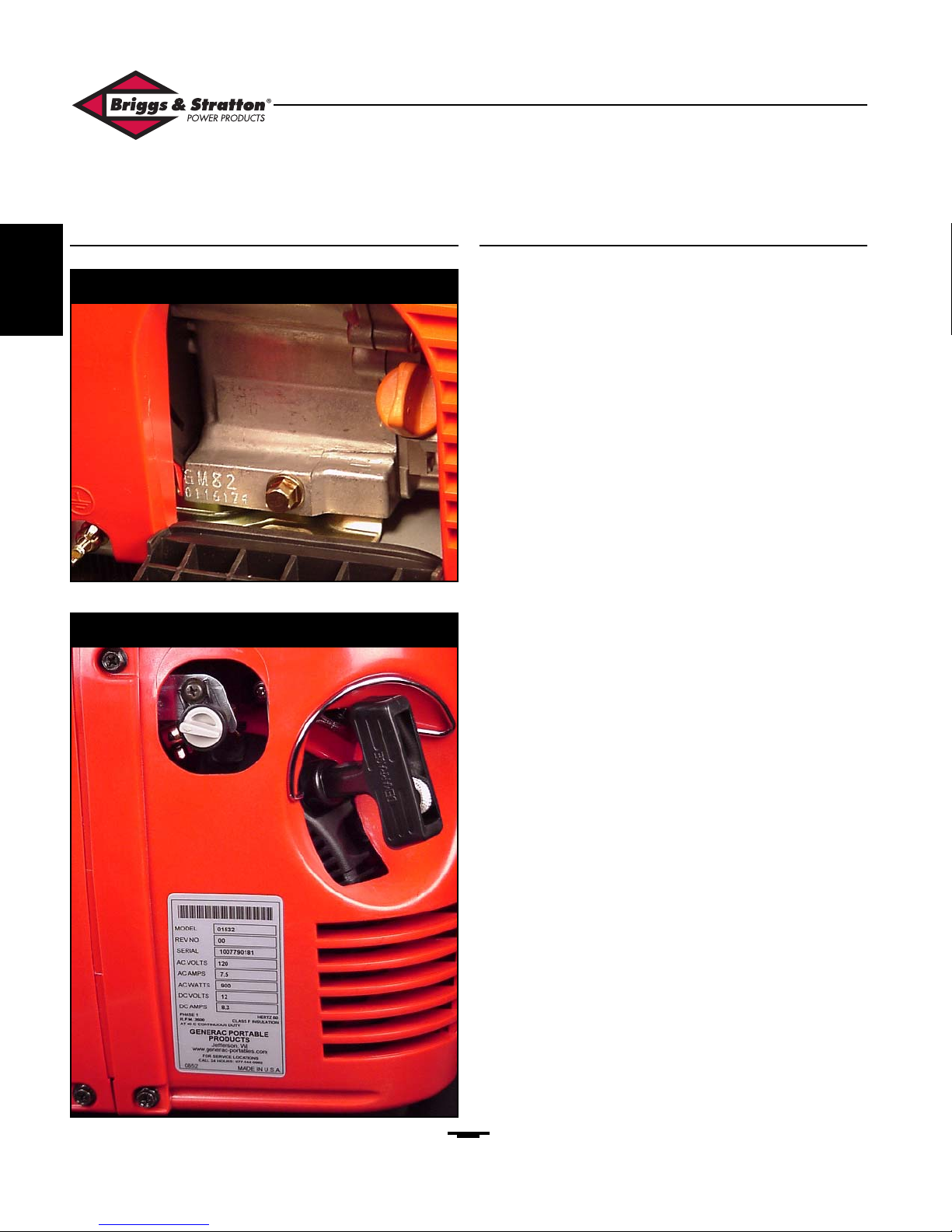

Serial Number Locations Generator Specifications

Engine:

Name: GM82 or Vanguard

Type: Air Cooled, Four

Cycle Gasoline

Engine

Displacement: 80 cubic centimeters

Max. Power: 1.8KW @ 4000RPM

Rated (AC) Power: 1.3KW @ 3000RPM

Oil Capacity: 0.4 Liter

Starting System: Recoil Starter

Oil Alert System: Yes

Generator: N. American Europe

(AC) Frequency: 60Hz

Phase: Single Single

(AC) Rated Voltage: 120 VAC 230VAC

(AC) Rated Current:: 7.5 Amps 3.2 Amps

(AC) Rated Output: 900 VA 750 VA

(AC) Maximum Output: 1000 VA 900 VA

(DC) Output: 12 VDC 12VDC

@ 8.3 Amps @ 8.3 Amps

Voltage Regulator: Condenser Condenser

Rated Power Factor: 1.0 1.0

Rated: Continuous Continuous

Other:

Fuel Capacity: 4.5 Liter / 1.18 Gal 4.5 Liter / 1.18 Gal.

Continuous Operation: 6.4 Hours 6.4 Hours

Noise Level: 63 DBA 63 DBA

@ 7 Meters @ 7 Meters

Dimensions: Length: 465mm 465mm

Width: 343mm 343mm

Height: 371mm 371mm

Dry Weight: 55 lbs. / 25 Kg 55lbs. / 25 Kg

Introduction • Section 1

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 3 — Engine Serial Number Location

Figure 4 — Generator Serial Number Location

1

Page 15

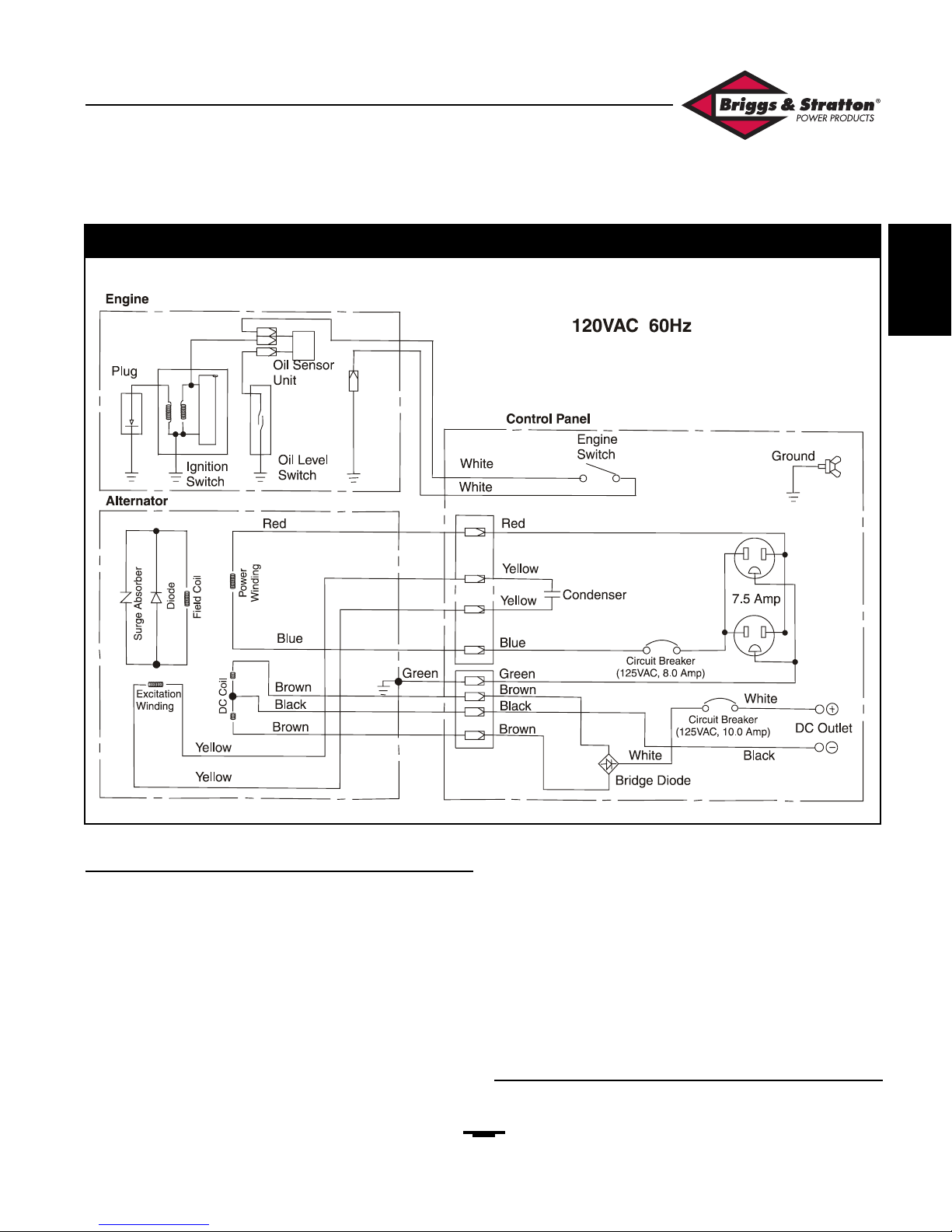

11

Output Power (AC)

The residual magnetism of the rotor induces an (AC)

voltage in the power and excitation windings when the rotor

is turned by hand (when recoil starter is pulled). The (AC)

voltage of the excitation winding builds in the condenser

until it discharges. This "capacitive discharge" then

strengthens the magnetic field in the excitation winding. As

the rotor windings "cut" this strengthened magnetic field, a

higher (AC) voltage is induced in the rotor winding. The

diode in the rotor rectifies the induced rotor (AC) to (DC).

The intensified magnetic field of the rotor "cuts" across both

the power and excitation windings. When the engine starts

and spins the rotor, residual magnetism is overcome and this

cycle continues to increase the (AC) output voltage of the

power and excitation windings until magnetic saturation and

condenser capacity is balanced. This is the calculated "Rated

Output" of the generator.

When an external load is plugged into an output receptacle,

the increased current flow intensifies the magnetic field of

the power winding. As the magnetic field of the rotor "cuts"

across the intensified field of the power winding, an

additional voltage is induced into the rotor field winding.

This increases the output of the power winding to

compensate for the voltage drop of the load.

Output Power (DC)

(AC) voltages that are induced into the 12VAC winding are

rectified to (DC) by a "full-wave" bridge rectifier.

GENERATOR SYSTEMS

Section 1 • Introduction

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 5 — Generator Wiring Diagram

1

Page 16

12

Fuel System Components

Fuel Group:

The components that make up the Fuel group include the

items listed in Figure 6.

The items listed in Figure 7 are part of the fuel cap and are

not replaceable. If damage occurs to the fuel cap, its repair is

limited to replacement.

GENERAL SERVICE INFORMATION

Work Area

Good lighting and an elevated table will help you gain access

to all of the mounting hardware and accessories of the handheld generator. Certainly, larger is better but a good

minimum sized table would be 20in. by 30in. If casters are

applied to the legs of the table, be sure they are secure and

sturdy enough to support not only the generator but also

the work being performed.

Hand Tools

A minimum collection of standard mechanic's hand tools

should include:

· 3/8" drive socket set (SAE)

· 3/8" drive socket set (Metric)

· A 3/8" drive ratchet

· Short, medium and long 3/8" drive extensions

· A large (heavy) "soft" mallet

· A common screwdriver (medium length)

· A Phillips screwdriver (medium length)

· A Phillips screwdriver (short- "stubby")

· A large (heavy duty) screwdriver suitable for mild prying

Special Tools

Electronic Measuring Equipment:

The measuring equipment used in troubleshooting should be

of industrial quality and have the sensitivity to measure

electronic values to the third decimal. Its accuracy should be

within acceptable tolerances should have the ability to

measure capacitance.

Introduction • Section 1

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 6 — Fuel Systems Components

Shut-Off Valve

Fuel Hose

Fuel Cap Assembly

Fuel Strainer

Spill Well

Tank

Mounting Brackets

Tank Sump Filter

Figure 7 — Fuel Cap Assembly

1

Page 17

13

Section 2 • Disassembly

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

DISASSEMBLY

2

Page 18

14

Disassembly • Section 2

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

2

Page 19

15

General Disassembly Considerations

Always inspect the external condition of the plastic

components before disassembling the unit. Look for cracks

and broken plastic and be sure to note these conditions as

existing before maintenance is undertaken.

Hand-held generators are built to close tolerances. The

fasteners used to hold the plastic shrouds and covers are

special machine screws that have a "pilot" collar

incorporated into the grip area of the screw (Figure 8).

NOTE: When assembling plastic components, be

sure the "collar" of the screw fits into the opening of

the shroud or cover. Pinching the plastic under the

collar will break the plastic at the mounting locations.

The length of these fasteners is critical to the proper

assembly of the unit. When disassembling the generator, it is

recommended that the location and length of each fastener

be noted.

When troubleshooting becomes necessary, access to various

components, systems and structural members is required.

Regardless of the ultimate reason, a clear understanding of

the unit's disassembly will save time and effort.

NOTE: Do not attempt to remove the protective

grill that surrounds the exhaust muffler. The fasteners

that hold it in place are secured with plain nuts and

lock-washers. If you attempt to remove the grill, it

will be necessary to disassemble the case halves in

order to reinstall it properly.

Case Separation

• Remove the cover to the air cleaner.

• Set the air filter and support grill aside.

• Remove the two mounting nuts that hold the air filter

assembly to the carburetor (Figure 48, Pg. 34).

• Remove the two screws that hold the handle of the

unit together (Figure 9).

At this point, position the unit so you are facing the muffler

side of the generator.

• Remove only those fasteners that hold the rear case

half. That is:

• Those screws around the lower base of the rear

of the generator.

• The upper screws that secure the rear case-half

on the right and left side of the generator.

• Grasp the rear case half and gently separate it from the

generator unit.

Section 2 • Disassembly

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 8 — Screws with ”Pilot Collar”

Pilot Collars

Figure 9 — Remove Screws In Handle

2

Page 20

16

• Remove the screw that is next to the fuel shut-off valve

and retain the mounting bracket that supports the fuel

tank (Figure 10).

• Slide the fuel tank out of its cradle and remove the fuel

supply hose from the bottom of the tank (Figure 11).

Disassembly • Section 2

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 10 — Mounting Bracket Screw

Figure 11 — Remove Fuel Supply Hose

Hose to Tank

2

Page 21

17

NOTE: At this point, you have visual access to

many of the mechanical and electronic components of

the generator (Figure 12).

Many individual electronic components are supported by

clips and brackets that are molded parts of the front case

half. This disassembly procedure assumes you are seeking

access to the engine and generator for overhaul purposes

and the components that are held by the case will be left in

their mountings.

• Position the unit so you are facing the front of the

generator.

• Remove the screws around the base.

• Separate the electrical connectors at locations shown in

Figures 13A and 13B.

• Set the front case-half aside.

ACCESS TO GENERATOR COMPONENTS

Section 2 • Disassembly

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 12 — Access To Generator Components

Figure 13 — Generator Components

A

B

Harness Connectors

2

Page 22

18

This provides sufficient access to the generator unit for

troubleshooting, component replacement and overhaul

(Figure 14).

A view of the electrical components that are mounted on

the inside of the front case-half is provided in Figure 15.

Rotor / Stator Removal

•• Step 1:

• For easier access, position the unit as shown in

figure 16.

•• Step 2:

Remove the cooling fan as shown. (Figure 17).

NOTE: Mark the face of the fan to ensure proper

reassembly.

Disassembly • Section 2

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 14 — Generator Unit Exposed

Figure 15 — Electrical Components Mounted On Case

Figure 16 — Position For Rotor Removal / Inspection

Figure 17 — Remove Cooling Fan

2

Page 23

19

•• Step 3:

• Remove the heat shield mounting screws (Figure 18A).

•• Step 4:

• Remove the rear bearing carrier mount bolts

(Figure 18B).

•• Step 5:

• Remove the three through-bolts (Figure 19).

•• Step 6:

• Remove the rear bearing carrier and the stator

together (Figure 20).

Disassembly • Section 2

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Figure 18 — Hardware (Heat Shield / Stator Housing)

Figure 19 — Remove Stator Through-Bolts

A

B

Figure 20 — Remove Stator Housing & Stator

2

Page 24

20

Disassembly • Section 2

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

2

Page 25

21

Section 3 • Troubleshooting

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

TROUBLESHOOTING

3

Page 26

22

Troubleshooting • Section 3

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Under Voltage (DC)

Refer to Figure 21 ("Under Voltage (DC)" Flow Chart)

above for the sequential steps involved with this procedure.

To separate the case halves, see page 13.

Test A: - Check Engine RPM

(See Appendix)

Test B: - Check Receptacle Wiring

(Page 25)

Figure 21 —

Under-Voltage (DC)

Troubleshooting Flow Chart

Test A

Check Engine RPM

See Appendix

OK?

Repair/Replace

See B&S #272147

NO

DC

OK?

YES

YES

NO

Test B

Check

Receptacle

Wiring

OK

?

Repair/Replace

See Page 25

NO

DC

OK?

YES

YES

NO

Test C

Check DC

Circuit

Breaker

OK?

Repair/Replace

See Page 21

NO

DC

OK?

YES

YES

NO

Test D

Check Bridge

Diode

OK?

Repair/Replace

See Page 21

NO

DC

OK?

YES

YES

NO

Test E

Check 12VDC

Coil

OK?

Repair/Replace

See Page 21

NO

DC

OK?

YES

YES

NO

Test F

Check Rotor

Winding

OK

?

Repair/Replace

See Page 27

NO

DC

OK?

YES

YES

NO

END

3

Page 27

23

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Section 3 • Troubleshooting

Test C: - Check (DC) Circuit Breaker

•• Step 1:

• Remove the three screws that secure the control panel

to the face of the generator unit.

•• Step 2:

• Remove both the terminals at the back of the circuit

breaker (Figure 22A).

•• Step 3:

• With the circuit breaker ON and your VOM set to

ohms, check for continuity at the terminals of the

circuit breaker (Figure 22B).

- Continuity = Circuit Breaker OK

- No Continuity = Defective Circuit Breaker.

Replace Circuit Breaker

Test D: - Check Bridge Diode

With the control panel still removed:

•• Step 1:

• Locate and separate the harness connector that has the

two brown wires. Push the male half of the connector

aside.

NOTE: You must follow the Diode Test

instructions that are provided with the meter you are

using.

•• Step 2:

• Using the female terminals of the brown wires and the

positive output terminal of the cigarette lighter, or the

DC receptacle, you can check continuity of the bridge

diode wiring (Figure 23).

Test E: - Check 12VDC Coil

With the control panel still removed:

•• Step 1:

• Locate and separate the harness connector that has the

two brown wires coming.from the stator.

•• Step 2:

• With your VOM set to ohms, read the coil resistance

at the terminal of the brown leads in the connector

(Figure 24).

•• Step 3:

• Compare readings with resistance values in the

apppendix.

Test F: - Check Rotor Winding

(See Test G on Page 27)

Figure 22 — Checking (DC) Circuit Breaker

Figure 23 — Checking The Bridge Diode

Yes Yes Yes

(+) ~1 ~2 (-)

~1 No No Yes

~2 No No Yes

(-) No No No

Negative Probe (-)

Positive Probe (+)

(+)

Figure 24 — Reading 12VDC Coil Resistance

A

B

Brown

3

Page 28

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

"Over Voltage" (AC)

Refer to Figure 25 ("Over Voltage (AC)" Flow Chart) above

for the sequential steps involved with this procedure. To

separate the case halves, see page 13.

Test A: - Check Engine RPM

(See Appendix)

Test B: - Check Capacitor

The capacitor can be checked without disassembling the unit

case-halves.

•• Step 1:

• Remove the three screws that secure the control panel

to the face of the generator unit (Figure 26).

•• Step 2:

• Disconnect the harness connector that has the two

yellow wires.

•• Step 3:

• Using a jumper wire, (Figure 27) short the two yellow

terminals that come from the capacitor. Then remove

the jumper wire.

24

Section 3 • Troubleshooting

Figure 25 —

Over-Voltage (AC)

Troubleshooting Flow Chart

Figure 26 — Remove Control Panel

Test A

Check Engine RPM

See Appendix

OK

?

Test B

Check

Capacitor

Repair/Replace

See Page 22

OK?

AC

OK?

AC

OK?

END

Repair/Replace

See B&S #272147

YES

YES

YES

YES

NO

NO

NO

NO

3

Page 29

25

Section 3 • Troubleshooting

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

•• Step 4:

• Refer to the owner's manual of your VOM and test the

capacitor according to the directions for your

equipment.

• Find the rating of the capacitor on its body or in the

appendix of this manual.

• Compare reading with the stated value .

Replace the capacitor if it is found to be faulty.

Figure 27 — Short the Capacitor Terminals

Figure 28 — Testing the Capcitor

Yellow

3

Page 30

26

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Troubleshooting • Section 3

Figure 29 —

Under-Voltage (AC)

Troubleshooting Flow Chart

Test A

Check Engine RPM

See Appendix

OK?

Repair/Replace

See B&S #272147

NO

AC

OK?

YES

YES

NO

Test B

Check

Receptacle

Wiring

OK?

Repair/Replace

See Page 25

NO

AC

OK?

YES

YES

NO

Test C

Check AC

Circuit

Breaker

OK?

Repair/Replace

See Page 25

NO

AC

OK?

YES

YES

NO

Test D

Check Stator

Power

Winding

OK?

Repair/Replace

See Page 26

NO

AC

OK?

YES

YES

NO

Test E

Check

Capacitor

OK?

Repair/Replace

See Page 22

NO

AC

OK?

YES

YES

NO

Test F

Check

Excitation

Winding

OK?

Repair/Replace

See Page 26

NO

AC

OK?

YES

YES

NO

Test G

Check Rotor

Winding

OK

?

Repair/Replace

See Page 27

NO

AC

OK?

YES

YES

NO

END

3

Page 31

Section 3 • Troubleshooting

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

27

Under Voltage (AC)

Refer to Figure 29 ("Under Voltage (AC)" Flow Chart) on

the preceding page for the sequential steps involved with

this procedure. To separate the case halves, see page 13.

Test A: - Check Engine RPM

(See Appendix)

Test B: - Check Receptacle Wiring

•• Step 1:

• Remove the three screws that secure the control panel

to the face of the generator unit.

•• Step 2:

• Test the receptacle for:

- Shorted contacts.

- Burned or cracked insulation material.

- Faulty terminal screws (Figure 30).

•• Step 3:

• If any faults are found,

- Replace receptacle.

Test C: - Check AC Circuit Breaker

•• Step 1:

Remove both the terminals at the back of the circuit

breaker (Figure 31A).

•• Step 2:

• With the circuit breaker CLOSED and your VOM set

to ohms, check for continuity at the terminals of the

circuit breaker (Figure 31B).

- Continuity: = Circuit Breaker - OK

- No Continuity: = Defective Circuit Breaker.

Replace Circuit Breaker

Figure 30 — AC Receptacle

Figure 31 — Checking Circuit Breaker

3

Page 32

28

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Troubleshooting • Section 3

Test D: - Check Stator Power Winding

•• Step 1:

• Disconnect the 4-pin harness connector that contains

the yellow wires.

•• Step 2:

• On the male portion of the connector, locate the pins

that connect the blue and red wires (This harness

should be coming from the generator stator assembly

see figure 32).

•• Step 3:

• With your VOM set to ohms, measure the resistance

across the blue and red wires that come from the

stator (Figure 32).

• Compare reading with the resistance values in the

appendix.

- Within tolerance: Power winding is good

- Exceeds tolerance: Replace Stator

Test E: - Check Capacitor

(Page 22)

Test F: - Check Excitation Winding

•• Step 1:

• Disconnect the harness connector that contains the

yellow wires.

•• Step 2:

• On the male portion of the connector, find the pins

that connect the two yellow wires (This harness should

be coming from the generator stator assembly see

figure 33).

•• Step 3:

• With your VOM set to ohms, measure the resistance

across the two yellow wires that come from the stator

(Figure 33).

• Compare reading with the resistance values in the

appendix.

- Within tolerance: Excitation winding is good

- Exceeds tolerance: Replace Stator

Figure 33 — Checking Excitation Winding

Figure 32 — Checking Stator Power Winding

3

Page 33

29

Section 3 • Troubleshooting

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Test G: - Check Rotor Winding

The rotor is considered a non-serviceable part because it is

a sealed unit that would require disassembly to properly

test. Therefore, it is by process of eliminating all other

possible faults that the rotor can be considered faulty.

NOTE: Piercing the red or blue wire and checking

across the terminal post of the rotor diode is not

recommended.

Before rotor replacement, follow the checklist outlined

below:

• Check Engine RPM

• Check Capacitor

• Check Output Receptacle & Wiring

• Check Circuit Breaker (AC)

• Check Circuit Breaker (DC)

• Check Stator Power Winding

• Check Excitation Winding

• Check Bridge Diode

• Check 12VDC Coil

Engine Switch

•• Step 1:

• Remove the three screws that secure the control panel

to the face of the generator unit.

•• Step 2:

• Remove the terminals from the switch.

•• Step 3:

• With your VOM set to ohms, cycle the switch to ON

and test for continuity (Figure 34).

- You should have continuity.

•• Step 4:

• Cycle the switch to OFF.

- You should not have continuity.

Figure 34 — Checking The Engine Switch

3

Page 34

30

Troubleshooting • Section 3

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Pilot Lamp

Some early units were equipped with a green pilot lamp. If

this is the case, troubleshoot the lamp using the instructions

that follow;

•• Step 1:

• Remove the three screws that secure the control panel

to the face of the generator unit.

•• Step 2:

• Remove the terminals from the lamp.

•• Step 3:

• With your VOM set to ohms, check for continuity

through the lamp (Figure 35).

- No continuity: Replace lamp.

Figure 35 — Checking The Pilot Lamp

3

Page 35

31

Section 4 • Assembly

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

ASSEMBLY

4

Page 36

32

Assembly • Section 4

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

4

Page 37

33

Section 4 • Assembly

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Mounting The Rotor & Stator

Position the generator/base plate assembly as shown in

figure 36, before mounting the stator assembly.

• Mount the rotor on the tapered shaft of the engine

(Figure 37).

NOTE: The rotor is not timed in any way.

• Position the stator and the rear bearing carrier over

the rotor and align the feet with the mounting holes in

the base plate (Figure 38).

• Install the bolts but do not tighten yet.

Make sure the stator is seated in the machined lands of its

cradle as shown in figure 39A and 39B.

With the stator properly seated in the machined lands of its

cradle:

Figure 36 — Generator / Base Plate Assembly

Figure 37 — Mount The Rotor

Figure 38 — Positioning The Stator

Figure 39 — Seating The Statot Assembly

4

A

B

Page 38

34

Assembly • Section 4

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

• Install the three stator through-bolts and tighten until

the rear bearing carrier is secure (Figure 40).

• Check to make sure there are no obstructions to the

rotation of the rotor assembly.

• Torque the through bolts to 85 lbs. in.

• Torque the mounting bolts in the feet of the rear

bearing carrier to 180 lbs. in.

• Slip the rotor mount bolt through the cooling fan. Start

the bolt in the threads of the engine output shaft by

hand (Figure 41).

Before tightening the rotor mount bolt:

• Check the orientation of the fan (Figure 42).

Torque the rotor mount bolt to 100 lbs. in.

Install The Muffler Heat Shield

• Slip the heat shield between the muffler and the

generator until the mounting flanges of the rear bearing

carrier align with the mounting flange of the heat shield

(Figure 43A & 43B).

Figure 40 — Securing The Stator Assembly

Figure 41 — Installing Rotor Mount Bolt

Figure 42 — Cooling Fan Orientation

Figure 43 — Generator Heat Shield

A

B

4

Page 39

35

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

• Install the mounting screws and tighten until the heat

shield is secure.

NOTE: Make sure that the bent angles of the heat

shield are in contact with surfaces of the engine as

shown in figure 44.

Check to make sure that all the mounting hardware is tight

and secure.

Connecting The Wiring Harness

The control panel that is mounted in the front case half is

connected to the generator by means of two four-pin cable

connectors. The associated wires colors are identical.

• Match the wire colors of the two harness connectors

and seat each connector until it locks into place

(Figure 45).

• Connect one lead of the engine run switch to the

engine ground wire.

• Connect the other wire from the engine run switch to

the connector that also houses the blue wire from the

ignition coil (Figure 46).

Figure 44 — Check Heat Shield Contact And Mounting

Figure 45 — Harness Connectors

Section 4 • Assembly

Figure 46 — Ground And Run Switch

4

Page 40

36

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Mount The Rear Case Halve

• Position the unit as shown in figure 47.

• Mount the air cleaner housing to the two studs that

extend through the carburetor (Figure 48A).

• Insert the oil breather hose into the back of the air cleaner

housing (Figure 48B).

NOTE: Make sure that the steel bushings are

installed in the housing for the air cleaner

(Figure 48A).

The rear case half is mounted on the carriage first.

• Align the rear case half with the mounting holes in the

generator carriage.

• Refer to figure 49A & B and place the fasteners as shown.

The tank support brackets are shown in figure 50A & B.

• Insert the left-hand tank support bracket inside the case

stiffener and secure to the rear case half with a M5-16

screw with a medium pilot collar (Figure 50A).

• Mount the right hand bracket as shown in figure 50B.

Assembly • Section 4

Figure 47 — Unit Positioned For Closure

Figure 48 — Breather Tube & Air Filter Housing

Figure 49 — Rear Case Half Fasteners

A

B

M6-16

M6-20

M6-20

A

B

Figure 50 — Fuel Tank Support Brackets

A

B

M5-16

4

Page 41

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

37

Mount The Fuel Tank

Inspect the tank for the following items;

• Ensure that the fuel strainer is installed in the bottom of

the tank sump.

• Check that the rubber vibration seals are glued on the

seams of the fuel tank.

• Seat the tank in the area above the support brackets

(Figure 51).

• Connect the fuel supply hose to the tank as shown in

figure 52.

Mount The Front Case Half

Before mounting the front case half, ensure that the LOS

module is oriented on its mounting as shown in figure 53.

• Position the front case half close enough to the generator

unit in order to make the wiring connections to the Low

Oil Sense (LOS) module and start switch (Figure 54).

Section 4 • Assembly

Figure 51 — Mounting The Fuel Tank

Figure 52 — Connecting The Fuel Supply Hose

Figure 53 — LOS Orientation

Figure 54 — Start Switch & (LOS) Wiring

4

Page 42

38

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

• Route the starter rope through its opening in the case.

• Align the front case half with the mounting points in the

generator carriage and install the fasteners (figure 55).

With the mounting fasteners tight, connect the wiring

harness connectors through the opening of the control

panel (Figure 56).

• Match the colors of the wires.

NOTE: Match the color-coding of the wires to

make sure that you are making the proper

connections (Figure 57).

• Install the control panel face plate (Figure 58).

• Install oil service cover (Figure 59).

Assembly • Section 4

Figure 55 — Fastener Locations On Front Case Half

Figure 56 — Access To Wiring Harness

Figure 57 — Wiring Harness Connections

Figure 58 — Install Control Panel

4

Page 43

39

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

• Install air filter assembly (Figure 60).

• Install fuel spill well and fuel cap (Figure 61).

Section 4 • Assembly

Figure 59 — Install Oil Service Door

Figure 61 — Install Spill Well & Fuel Cap

Figure 60 — Install Air Filter Assembly

4

Page 44

40

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Assembly • Section 4

4

Page 45

41

Section 5 • Appendix

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

APPENDIX

5

Page 46

42

Appendix • Section 5

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

5

Page 47

43

Resistance Values

Rotors:

(60HZ) 4.06 ohm

(50HZ) 4.10 ohm

Stators:

(60HZ)

Excitation Winding 3.911 ohm

Power Winding 1.010 ohm

12VDC Winding .429 ohm

(50HZ)

Excitation Winding 4.79 ohm

Power Winding 4.33 ohm

12VDC Winding .510 ohm

Capacitors:

(60HZ) 14 µFu

(50HZ) 14 µFu

APPENDIX

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

Section 5 • Appendix

Torque Specifications

Engine:

Item Size Torque Value

(In. Lbs.)

Connecting Rod M6x30 85

Crankcase Cover M6x12 85

M8 180

Muffler M8 180

Head Bolt M8x55 220

Flywheel Nut M12 400

Spark Plug M14 180

Oil Drain Plug M10 180

Cooling Fan 5/16" 85

Pivot Bolt M8 180

General Screws M5 35

Rocker Arm Assy. M6x16 45

M8 180

CT Bolt M6 85

M8 180

Rocker Box Cover M6x12 45

Generator:

Rotor Bolt M6 100

Stator Bolt M6 85

Tapping Screw M6 45

General Screws M4 20

M5 35

M6 45

M8 180

5

Page 48

44

M6-16

M6-20

M6-20

M5-10

M5-10

M5-16

M5-16

M6-16

M6-16

M6-16

Appendix • Section 5

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

5

Figure 62 — Fastener Sizes and Locations

Page 49

45

Section 5 • Appendix

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

M6-90

M8-12

M8-12

M8

Self-Tapping Screw

M8-12

M6-160

5

Figure 63 — Fastener Sizes and Locations (Continued)

Page 50

46

Appendix • Section 5

Hand-Held Series Generators • Familiarization & Troubleshooting Guide

5

Loading...

Loading...